Ingersoll-Rand 65665B, 65666, 66620, 656652B, 65662 User Manual

...

OPERATOR’S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

6564X-X

6566X-X

6” AIR MOTORS

6564X-X and 66620

4” STROKE

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

THIS MANUAL COVERS THE FOLLOWING MODELS

65643 65662 65665Ć2B 66620

65645 65665ĆB 65666

SERVICE KITS

61355 for general repair of all 6" air motors.

GENERAL DESCRIPTION

The 6" air motor is a general purpose power unit and is used with many

2Ćball, 4Ćball and chop check pumps. It utilizes tie rod type construction

for easy breakdown and it connects to the various lower ends via tie rods

for easy operation. Consult pump model operator's manual for specific

instructions. It is recommended that a muffler be connected to the exĆ

haust port to reduce noise to acceptable OSHA standards.

MODEL

6566X-X

6” STROKE

66620

RELEASED: 8-28-91

REVISED: 10-11-01

(REV. K)

Filtered and oiled air will allow the air motor to operate more efficiently

and yield a longer life to operating parts and mechanisms. A filter capaĆ

ble of filtering particles larger than 50 microns should be used with an

oiler. Keep the oiler supplied with a good grade of S.A.E. no. 90W nonĆ

detergent gear oil, set at a rate not to exceed 1 or 2 drops per minute.

NOTICE

DO NOT OPERATE AIR MOTOR ABOVE RECOMMENDED

AIR PRESSURE OF 150 P.S.I. (10.3 BAR) OR 75 CYCLES PER

MINUTE.

Check model plate.

Air motor may be rated differently in the next assembly.

INGERSOLL-RAND COMPANY

P.O. BOX 151 ONE ARO CENTER BRYAN, OHIO 43506Ć0151

(419) 636-4242 FAX (419) 633-1674

2001 PRINTED IN U.S.A.

AIR MOTOR PARTS LIST

PARTS SO MARKED ARE INCLUDED IN 61355 SERVICE KIT.

REF. DESCRIPTION (SIZE IN INCHES) QTY PART NO. REF. DESCRIPTION (SIZE IN INCHES) QTY PART NO.

1 Machine Screw (#8 Ć 32 x 7/8") 4 Y136Ć90ĆS

2 Deflector 1 90409

Deflector (model 65665Ć2B) 1 90409Ć1

3 Screw (#10 Ć 24 x 1/2") 6 95956827

4 Machine Screw (#8 Ć 32 x 3/4") 8 Y19Ć89ĆS

5 Washer 8 90084

6 Machine Screw (1/4" Ć 28 x 3/4") 2 Y119Ć49ĆC

7 Lock Washer (1/4" i.d.) 2 Y14Ć416

8 Air Motor Cap 1 90078

Air Motor Cap (model 65665Ć2B) 1 90078Ć5

9 Valve Guide 1 90488

10 Gasket 1 90083Ć1

11 Valve Plate and Pin Assembly 1 65756

12 Insert Spring Assembly 1 65807

13 Valve Insert 1 99202

14 Valve Plate Gasket 1 90479

15 O" Ring (1/16" x 1Ć3/8" o.d.) 2 Y325Ć26

16 Washer 1 91344

17 O" Ring (1/16" x 7/8" o.d.) 2 Y325Ć18

18 Head Assembly 1 65890

Head Assembly (model 65665Ć2B) 1 65890Ć3

19 U" Cup (3/16" x 1Ć3/8" o.d.) 1 Y186Ć51

20 O" Ring (1/8" x 6" o.d.) 2 Y325Ć256

21 Machine Screw (#8 Ć 32 x 3/8") 4 Y136Ć85ĆS

22 Adapter 1 90111

23 Piston Assembly 1 61419

24 O" Ring (1.191" o.d.) 1 90085

25 Nut 1 90112

26 Valve Rod See chart, page 4

27 Air Cylinder See chart, page 4

28 Tube See chart, page 4

29 O" Ring See chart, page 4

30 Air Motor Base Assembly See chart, page 4

31 Valve Piston 1 92395

32 Valve Plate Gasket 1 90482

33 Valve Plate 1 90480

34 Pilot Insert 1 90487

35 Valve Guide 2 90481

36 Washer 1 90105

37 Upper Gland 1 91006

38 Seal 1 91007

39 O" Ring (.103" x 1.255" o.d.) 1 91207

40 Extension Rod 1 90080

41 Ground Lug 1 93006

42 Piston Adapter 1 92393

43 Lower Gland 1 90114

44 Washer 1 91345

45 O" Ring (1/16" x 7/16" o.d.) 1 Y325Ć11

46 Bolt See chart, page 4

47 Retaining Ring See chart, page 4

48 Guide Washer See chart, page 4

49 U" Cup See chart, page 4

50 Nut See chart, page 4

51 Washer See chart, page 4

52 Piston Rod See chart, page 4

Smart Parts", Keep these items on hand in addition to the service kits for fast repair and reduction of downtime.

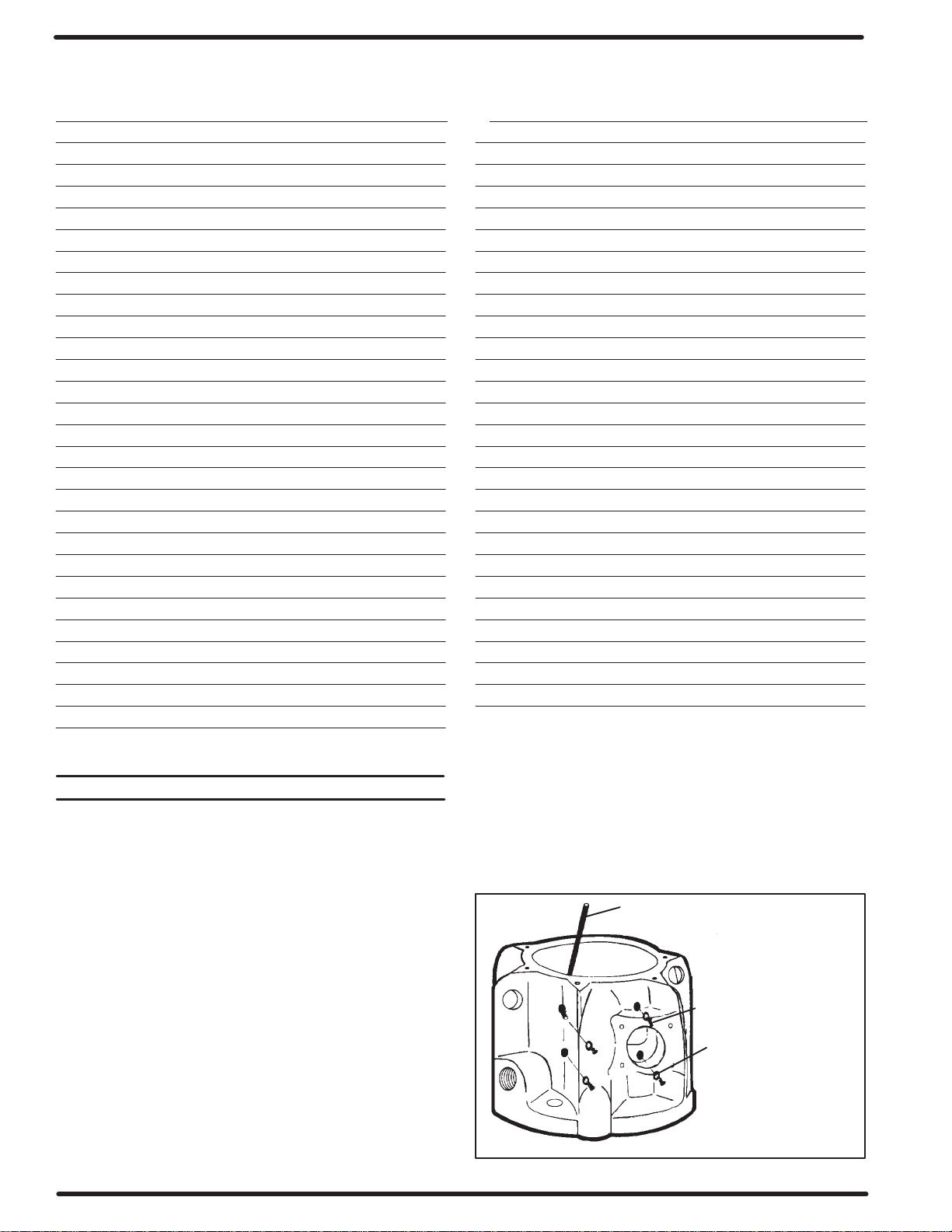

DISASSEMBLY OF AIR MOTOR

NOTE: ALL THREADS ARE RIGHT HAND.

1. Force the (23) piston assembly up by pushing the (52) piston rod toĆ

ward the top of the air motor.

2. Remove the four (1) machine screws from the (2) deflector.

3. Remove the (2) deflector.

4. Remove the six (3) screws from the (8) air motor cap.

5. Remove the (8) air motor cap and (10) gasket.

6. Loosen the eight (4) machine screws (which hold the (11) valve plate

and pin assembly, (9) valve guide, two (35) valve guides and the (33)

valve plate) until the (9 and 35) valve guides can be removed by pullĆ

11. Remove the (13) valve insert and the (34) pilot insert.

12. Remove the (32 and 14) gaskets.

13. Remove the (12) insert spring assembly.

14. Remove the two (6) machine screws and the two (7) lock washers

from the (37) upper gland (see figure 9).

15. Pull the (31) valve piston upward until the (37) upper gland has

pulled out of its chamber.

ALLEN WRENCH

(USE AN ALLEN WRENCH

TO PUSH OUT SCREWS &

WASHERS AS SHOWN.)

ing upward (see figure 9).

7. Remove the eight (4) machine screws and eight (5) washers from

4 SCREWS (8)

the 6" air motor by pressing outward with a small allen wrench (see

figures 1 and 9).

5 WASHERS (8)

8. With a screwdriver, unhook the (12) insert spring assembly from the

bottom of the (11) valve plate and pin assembly.

9. Remove the (12) insert spring assembly from the pins in the top of

the (11) valve plate and pin assembly.

10. Remove the (11) valve plate and pin assembly and (33) valve plate

by pulling upward. If they are stuck, tap the top edge lightly with a soft

FIGURE 1

(THE REMAINING FOUR

WASHERS AND SCREWS

ARE ON THE OPPOSITE

SIDE.)

face hammer or screwdriver handle (do not tap with anything metalĆ

lic).

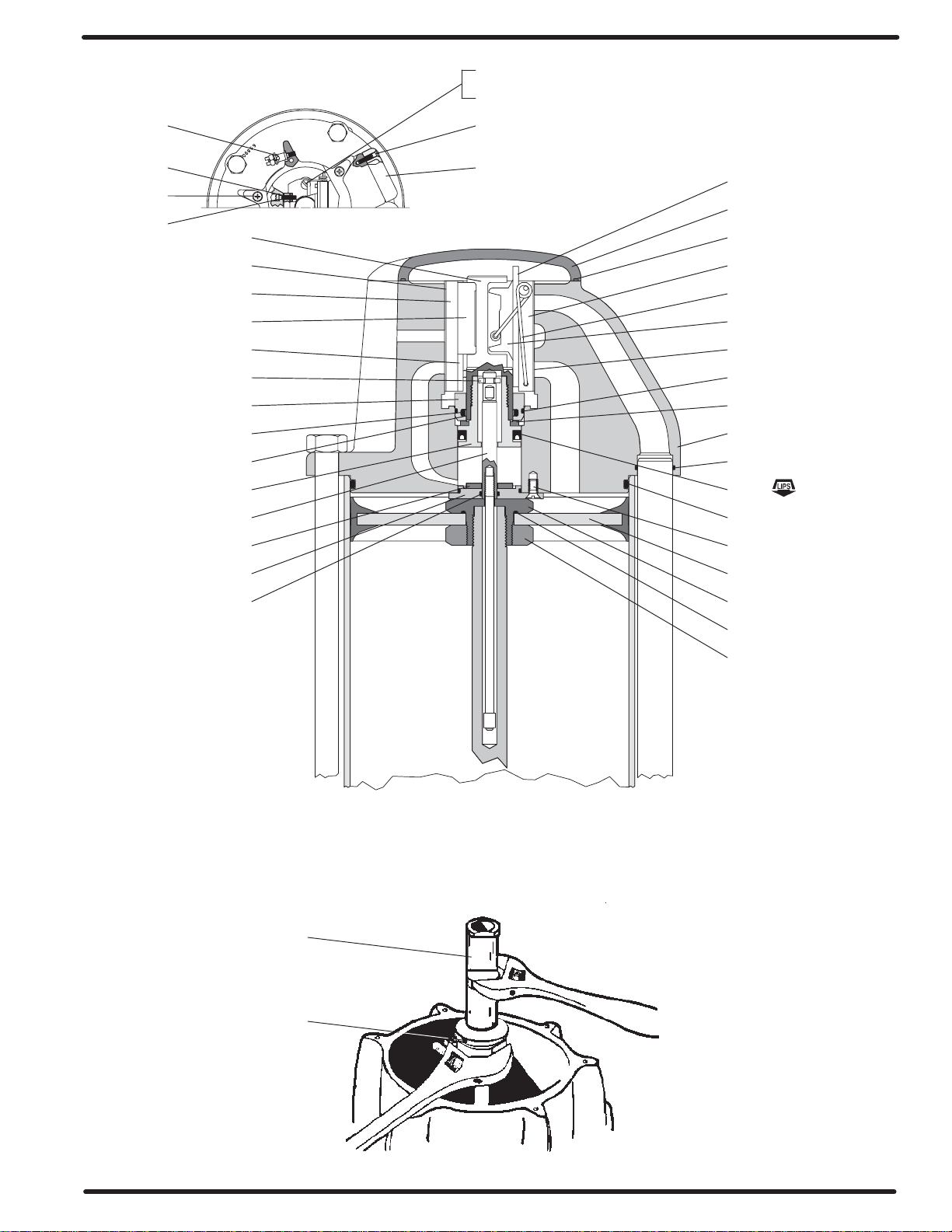

PAGE 2 OF 8 6564XĆX

41

6

PART NUMBERS LISTED BELOW AND ON PARTS

7

1

AIR MOTOR HEAD

LIST (OPPOSITE PAGE) ARE TYPICAL.

4

3

5

31

32

33

34

35

36

37

39

38

42

40

44

43

45

2

9

8

10

11

12

13

14

15

16

18

17

19

20

21

23

22

NOTE: LUBRICATE WITH PARKER

‘‘O” RING LUBE (ARO P/N 36460).

31

42

24

25

FIGURE 2

FIGURE 3

PAGE 3 OF 86564XĆX

Loading...

Loading...