Ingersoll-Rand 65178X-XXX-B User Manual

OPERATOR’S MANUAL 65178X-XXX-B

INCLUDING: SERVICE KITS, TROUBLESHOOTING, PARTS LIST,

DISASSEMBLY & REASSEMBLY.

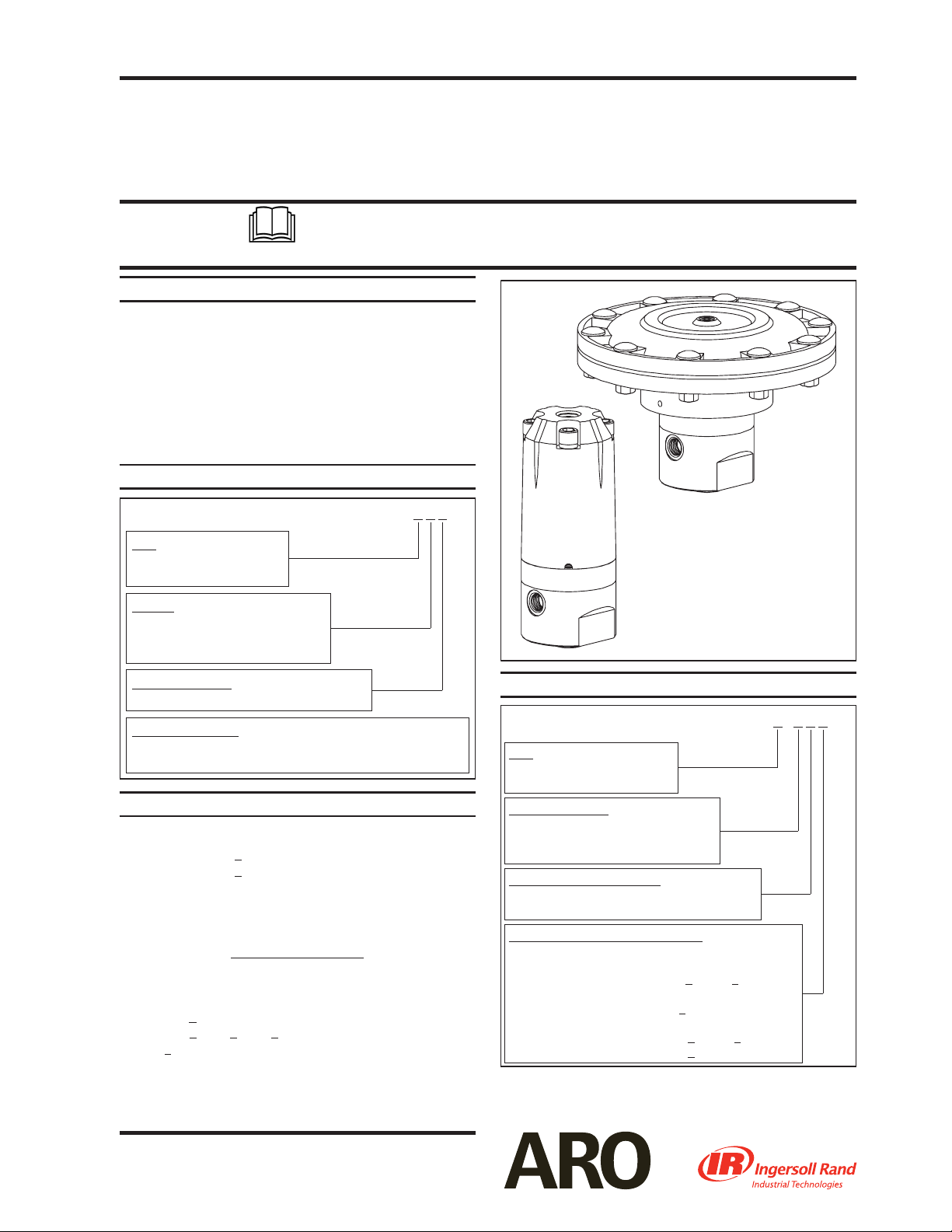

HIGH PRESSURE

MATERIAL REGULATOR

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

SERVICE KITS

Use only genuine ARO® replacement parts to assure com-

patible pressure rating and longest service life.

Order 637219-XXX-B rebuild kit (see chart below) for gen-

eral repair of the regulator. This includes a diaphragm kit

and a valve kit.

Fluid diaphragm kit 61962-1 can be ordered separately

(see page 4).

Valve kit can be ordered separately (see page 4).

REBUILD KIT DESCRIPTION CHART

637219 - X X 1 - B

RELEASED: 2-12-93

REVISED: 1-11-08

(REV. F)

Typ e

0 - Downstream

1 - Back Pressure

Ball Size

A - 0.1875”

B - 0.250”

C - 0.500”

Ball & Seat Material

1 - Tungsten Carbide

Rebuild Kit Selection

Example: Model # 651780-A3B-B

Rebuild Kit # 637219-0A1-B

SPECIFICATIONS

Model Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65178X-XXX-B

Typ e . . . . . . . . 651780-XXX-B . . . . . . . . . . . . . Downstream

651781-XXX-B . . . . . . . . . . . . . Back Pressure

Material Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . see model chart

Material Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . see model chart

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . see gure 10

PERFORMANCE DATA

Regulated Pressure Range . . . . . . . . . . . . . . . see model chart

Maximum Regulated Pressure . . . . . . . . . . . see model chart

Maximum Inlet Pressure

651780-XXA-B . . . . . . . . . . . . . . . . . . . . . . . . . . 3000 p.s.i. (206.9 bar)

651780-XXB-B, -XXC-B, -XXR-B . . . . . . . . . . . 6000 p.s.i. (413.8 bar)

651781-XXX-B . . . . . . . . . . . . . . . . . . . . . . . . . . 3000 p.s.i. (206.9 bar)

Maximum Temperature Limits . . . . . . . . 0° to 200° F (-18° to 93° C)

Figure 1

MODEL DESCRIPTION CHART

65178 X - X X X - B

Typ e

0 - Downstream

1 - Back Pressure

Port Size, (Ball Size)

A - 3/8 - 18 N.P.T.F. (0.1875”)

B - 3/8 - 18 N.P.T.F. (0.2500”)

C - 3/4 - 14 N.P.T.F. (0.500”)

Body Material, (Seat Material)

1 - Carbon Steel (Tungsten Carbide)

3 - 316 Stainless Steel (Tungsten Carbide)

Regulated / Maximum Pressure Range

A - 400 - 1250 p.s.i. (27.6 - 86.2 bar)

B - 100 - 3000 p.s.i. (6.9 - 206.9 bar) Back Pressure models

- 1000 - 3000 p.s.i. (69 - 206.9 bar) -AXB and -BXB

Downstream models

- 750 - 2500 p.s.i. (51.7 - 172.4 bar) -CXB Downstream models

C - 2000 - 5000 p.s.i. (137.9 - 344.8 bar)

R - 400 - 5000 p.s.i. (27.6 - 344.8 bar) -AXR and -BXR models

- 750 - 5000 p.s.i. (51.7 - 344.8 bar) -CXR models

INGERSOLL RAND COMPANY LTD

P.O. BOX 151 ONE ARO CENTER BRYAN, OHIO 43506-0151

(800) 276-4658 FAX (800) 266-7016

© 2008 CCN 99443798

OPERATING AND SAFETY PRECAUTIONS

EXCESSIVE AIR PRESSURE

STATIC SPARK

Read and heed all warnings, cautions and safety pre-

cautions before operation of this unit.

Be certain anyone operating this equipment or fluid

system has been trained to use it safely.

WARNING

HIGH PRESSURE DEVICE. Improper usage of

this equipment could result in serious injury. The possibility of injection into the esh is a potential hazard.

Wear approved safety glasses or face shield and other

equipment as needed to prevent injury. Never allow any part of the human body to come in front of

or in contact with the material outlet, the tip, or the

material outlet of the dispensing device. An injection

injury can be serious. If an injection accident should

occur, it is very important that you contact a quali ed

physician for immediate treatment.

WARNING

MISAPPLICATION HAZARD. Do not use the

regulator when the uid inlet pressure is too high for

the designed operating range. Excessive inlet pressure can cause a lock-out situation. Lock-out occurs

when the inlet pressure is beyond the regulator’s

spring capacity. The valve will not open. Attempts to

disassemble components while in a lock-out condition may result in injury.

WARNING

COMPONENT RUPTURE. Do not operate

regulator at an inlet pressure greater than speci ed.

To avoid possible damage or personal injury do not

operate this unit at pressure higher than the stated

operating range as it appears on the model plate.

HAZARDOUS MATERIALS

HAZARDOUS PRESSURE

WARNING

DISASSEMBLY HAZARD. Do not disassemble

this regulator when it is under pressure. Relieve pressure in the pumping system before attempting service

or disassembly procedures. Disconnect air lines and

carefully bleed pressure o the system. Be certain the

system is not maintaining pressure due to a material

restriction in the hose, line, dispensing device, or the

spray or extrusion tip. Failure to relieve pressure both

up stream and downstream may result in an injury

upon disassembly.

WARNING

BONNET REMOVAL HAZARD. Do not attempt to remove the four bonnet retaining bolts

without rst relieving the tension on the main spring.

Failure to relieve tension could result in an accident

upon disassembly.

WARNING

PREVENT FIRES. Keep solvents away from

heat, sparks or open flame. Keep containers closed

when not in use. When pumping, flushing or recirculating volatile solvents, be certain the area is adequately ventilated.

CAUTION

FLUSH SUPPLY LINE. Before installing uid

regulator blow the supply lines clear and ush to remove contaminates.

WARNING

= Hazards or unsafe practices which

could result in severe personal injury,

death or substantial property damage.

CAUTION

= Hazards or unsafe practices which

could result in minor personal injury,

product or property damage.

NOTICE

= Important installation, operation or

maintenance information.

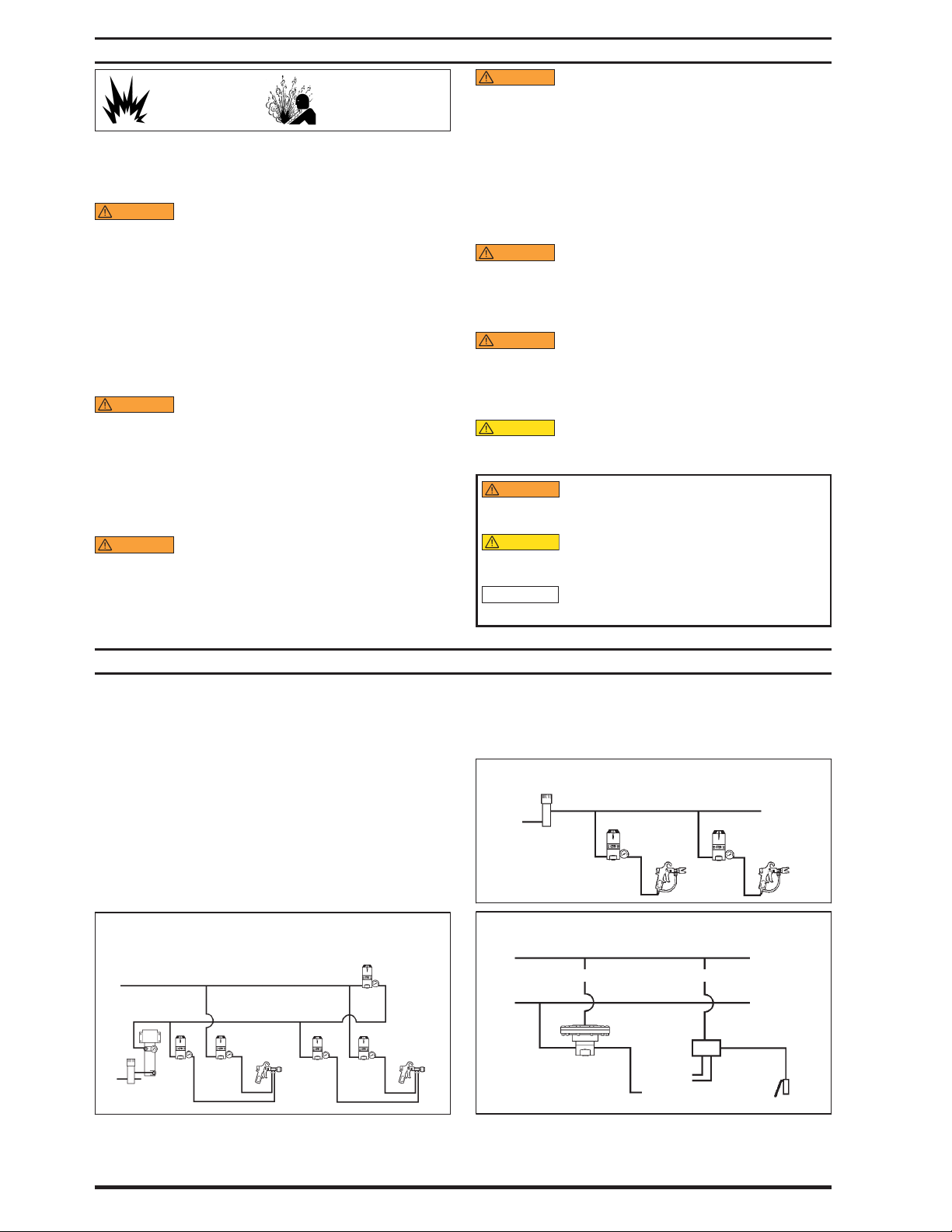

INSTALLATION

Refer to the typical installation view which best applies.

Locate the regulator as close as possible to the spray gun

or dispensing device for best pressure control.

Identify the regulator INLET / OUTLET (flow direction).

The regulator is marked with an arrow on the body base

(refer to gure 10).

When flexible fluid lines are used, mount the regulator

securely using the (2) 1/4” - 20 threaded holes in the base

(see gure 10).

Flush supply line before installing regulator.

Remote models require maximum 100 p.s.i. (6.9 bar)

signal pressure. Start with a signal pressure as low as possible and adjust upward until proper ow is reached.

TYPICAL RECIRCULATING SYSTEM

Back Pressure

Regulator

Heater

Back Pressure

Regulator

Filter

Down

Stream

Regulator

Back Pressure

Regulator

Down

Stream

Regulator

Filter

TYPICAL DEAD END SYSTEM

Down

Filter

Stream

Regulator

TYPICAL REMOTE SYSTEM

(Air)

F-R-L

Remote

Regulator

(Material)

Extrusion Gun

F-R-L

Automatic

Down

Stream

Regulator

4-Way Valve

Limit Switch

Figure 2

ARO® is a registered trademark of Ingersoll Rand Company Loctite® and 242® are registered trademarks of Henkel Loctite Corporation

271™ and 680™ are trademarks of Henkel Loctite Corporation Hytrel® is a registered trademark of the DuPont Company

Page 2 of 8 65178X-XXX-B (en)

Perma-lok® is a registered trademark of National Starch and Chemical Corporation

OPERATING INSTRUCTIONS

TROUBLE SHOOTING

Refer to pages 4 and 5 for parts reference.

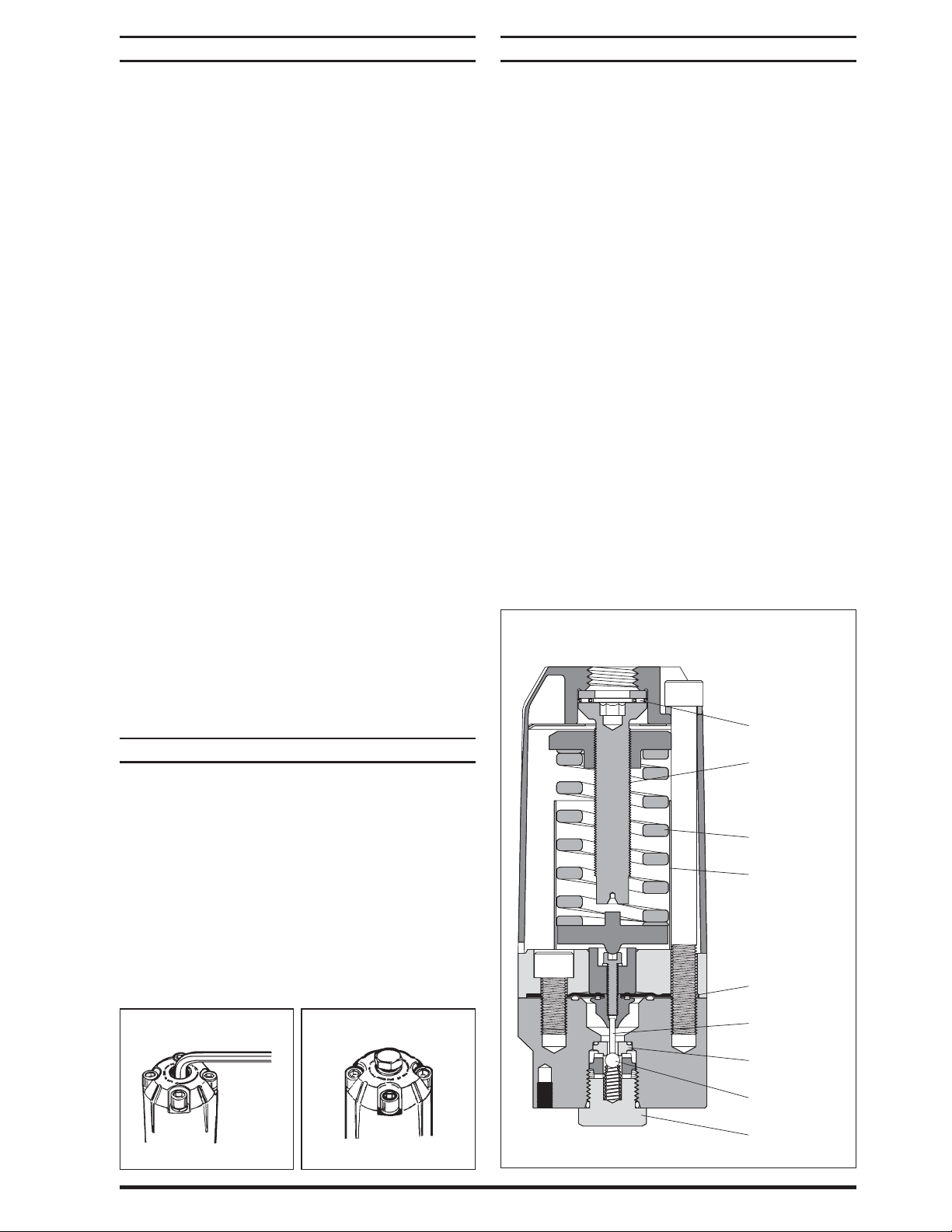

To INCREASE outlet pressure, turn the (6) adjusting screw

CLOCKWISE (see gure 3).

To DECREASE outlet pressure, turn the (6) adjusting

screw COUNTERCLOCKWISE (see gure 3).

NOTE: Part Y106-109 Allen wrench is included to make necessary pressure adjustments.

FLUSH-OUT FEATURE FOR DOWNSTREAM MODELS ONLY.

See gure 4.

Flush the regulator periodically. The interval may vary de-

pending on the amount and type of material used.

By using a wrench and “flush-out” plug (provided), the

operator is able to move the entire spindle downward

and force the ball off the seat which should purge the

regulator of particle build-up.

NOTE: The flush-out procedure temporarily overrides the

adjusted pressure. It will not, however, affect the regulator

setting when ushing operation is completed.

FLUSH-OUT PROCEDURE

Remove spray gun or dispensing device, this will allow

1.

any particles to clear from the system.

Insert (21) flush-out plug and turn clockwise until it

2.

touches the (4) washer (see view on page 5).

Turn up to two turns maximum. This will allow the ball to

3.

unseat and pass material at free ow (unregulated). DO

NOT attempt to turn further to avoid damage.

Turn the plug back to its original position.

4.

No uid pressure.

Check for damaged or worn diaphragms.

Look for possible obstruction by hardened material or

foreign matter, periodically use the regulator “Flush-out”

feature (Downstream models only). Use a uid lter upstream from the regulator.

Pressure creeps above the setting when system is

dead ended and in a static (no ow) mode.

Check for dirty seat and clean as appropriate.

Check for worn or damaged seat and replace if necessary.

Outlet pressure drops below setting.

Check pump for proper operation and check for possible

leakage problems.

Look for a clogged supply line problem, ush the supply

line.

Fluid leakage from spring housing.

Check the bonnet hold-down screws and the plate hold

down screws and re-torque as needed.

Check for damaged diaphragm, replace as needed.

Regulator will not function, even when dispensing device is opened.

Check for possible obstruction in the uid line.

Inlet pressure is too high, causing a “Lock-Out” situation.

Read “WARNING: MISAPPLICATION HAZARD” found on

page 2.

SEAT PLUG FEATURE

The (47) plug, located at the base of the regulator, can be

removed for access to the ball and seat assembly for cleaning and inspection for wear. With this feature, the regulator

does not have to be unthreaded from the pumping system.

Be certain to relieve system pressure (See “WARNING: DISASSEMBLY HAZARD”).

MAINTENANCE

Disassembly should be done on a clean work bench and

use clean cloths.

If replacement parts are necessary, refer to the parts list

and drawings on pages 4 and 5.

Upon reassembly, lubricate parts and use Loctite where

indicated. Follow the torque speci cations as shown.

Service kits are available, which include parts typically

needed for an overhaul.

Keep good records of service activity and include the

regulator in a preventive maintenance program.

Certain “Smart Parts” are indicated with a “

list, these parts should be available for fast repair and re-

duction of down time.

View of Spring

Adjustment Procedure.

View of Flush-Out Plug.

” in the parts

Typical Downstream Regulator Cross Section

View Showing Major Components.

Bearing

Adjusting Screw

Adjusting Spring

Spring Stop

to prevent compressing

spring to solid height)

Dual Diaphragm

Valve Stem

Seat

(used

Ball

Seat Plug

Figure 3 Figure 4

65178X-XXX-B (en) Page 3 of 8

Figure 5

Loading...

Loading...