Page 1

OPERAT

OR’S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

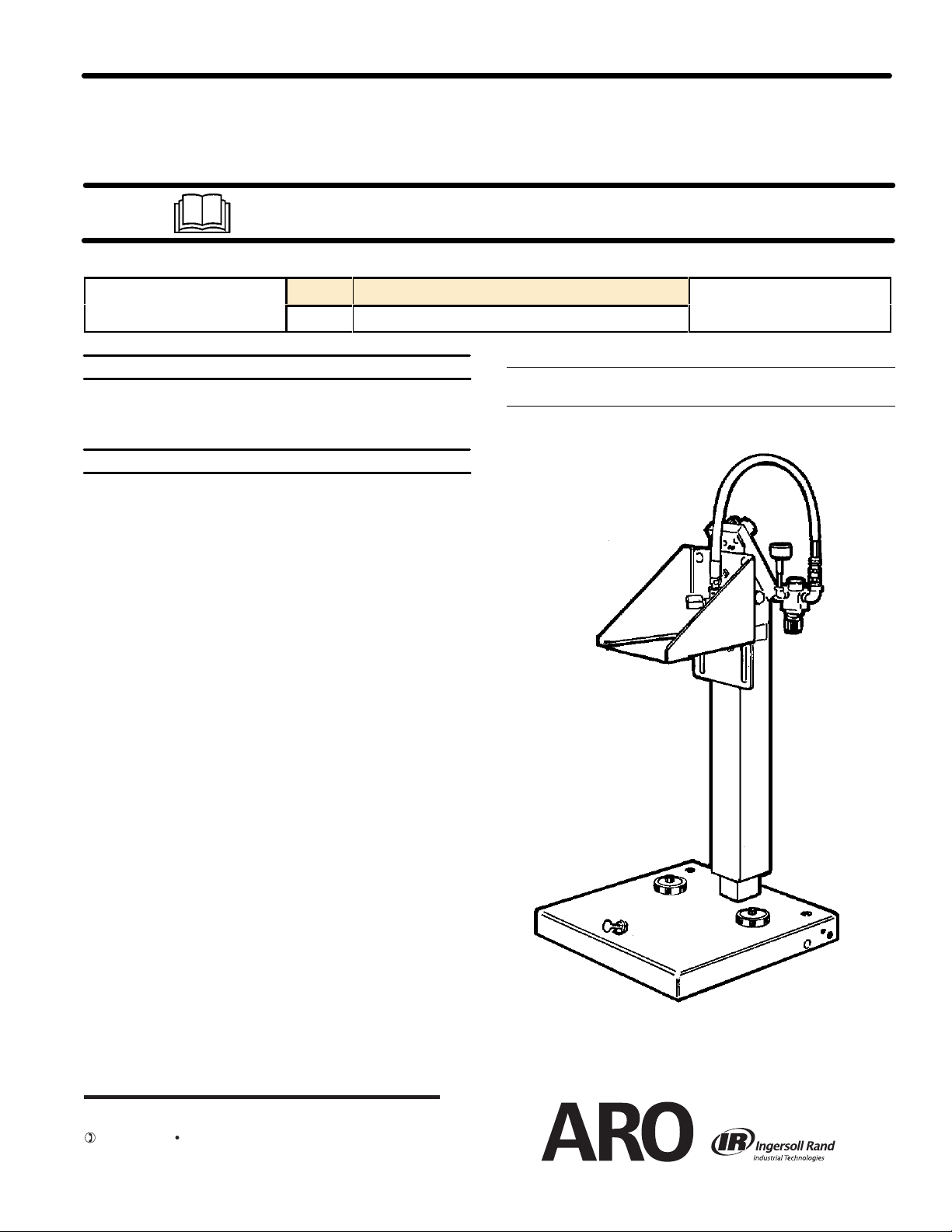

SINGLE POST LIFT/RAM

For use with 5 Gallon Drums (T apered or Straight)

651615–X

RELEASED:

REVISED: 6–21–10

2–25–95

(REV. C)

READ THIS MANUAL CAREFULL

OPERA

THIS MANUAL COVERS THE FOLLOWING MODELS

MODEL TYPICAL PUMP APPLICATION

651615 3'' & 4-1/4'' AIR MOTORS (TIE ROD PUMPS)

TING OR SER

SERVICE KITS

Rebuild Kit for E512LM Valve - 116722

Repair Kit for 127112-000 Miniature Regulator - 104158

GENERAL

The ARO Model 651615-X Single Post Lift/Ram uses a 3-1/2'' airpowered cylinder which is welded to a heavy gauge base base. It is norĆ

mally used to raise and lower a fluid handling pump and follower in and

out of of standard 5-gallon drum or when used as a ram it can force

high viscosity flowable material into the pump inlet.

When properly secured, this unit has the ability to raise a pump to clear

a standard 5-gallon drum. The operator is then able to easily remove

the pump from a pail.

This Lift/Ram uses a hand lever 4-way control valve which controls the

air necessary to raise and lower the lift. This unit includes an auxiliary

manual air valve which is used to supply a controlled amount of air

pressure to the bottom of the follower plate. When the Control Valve is

in the ``UP'' position a small amount of air pressure applied under the

follower plate will help to raise the follower plate, pump and lift by reĆ

lieving the vacuum. See Page 3.

DESCRIPTION

Y BEFORE INST

VICING THIS EQUIPMENT

BASE DIMENSIONS: 20'' SQUARE (508 mm)

HEIGHT: LOWERED 36-3/4'' (.9m), RAISED 56-1/4'' (1.7 m)

ALLING,

.

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX (800) 892-6276

www.ingersollrandproducts.com

© 2010

651615

SINGLE POST LIFT

Page 2

OPERATING

AND SAFETY PRECAUTIONS

Z Read and heed all Warnings, Cautions, and Safety PrecauĆ

tions before operating.

Z Use only genuine ARO replacement parts to assure compatĆ

ible pressure rating and longest service life.

Shock hazard.

Striking electrical

fixtures can cause

injury.

WARNING PREVENT ELECTRIC SHOCK. Be certain the

area above the lift is clear of electrical fixtures, devices and

wiring. Examine the working area and take necessary action to asĆ

sure adequate clearance for the lift and pump assembly to raise to

the fullest limit and function properly.

Pinch hazard.

Follower can descend

quickly causing injury

WARNING PINCH HAZARD. Follower can descend quickly,

causing injury. Keep hands clear when aligning with containĆ

er. In the raising and lowering function the lift could get hung up or

the descent could be temporarily restricted. The lift could in some

Keep the area

overhead clear of

electrical devices.

Keep hands clear

when aligning with

container

.

situations drop suddenly and be hazardous. If the follower plate

does not enter the drum properly, DO NOT ATTEMPT TO REĆ

POSITION IT WITH YOUR HANDS; release the downward presĆ

sure, raise the lift, realign the drum and restart.

WARNING STAND CLEAR. When raising or lowering the lift

keep clear and operate from a safe position.

Hazardous pressure.

Can result in injury or

property damage.

Do not exceed maxi

mum inlet air pressure.

-

WARNING HAZARDOUS PRESSURE. Do not exceed maxiĆ

mum inlet air pressureof 160 psi(11 bar).Operating lift at higher

pressure may cause lift damage and/or personal injury and/or

property damage. Do not service or clean pump, hoses or dispensĆ

ing valve while the system is pressurized.

WARNING DO NOT EXCEED DRUM PRESSURE LIMITS.

Know the pressure limitations of the drum and regulate the air presĆ

sure within safe limits when supplying air follower plate.

CAUTION Be certain all operators of this equipment have

been trained for safeworking practices,understand it's limitaĆ

tions, and wear their safety goggles/equipment as required.

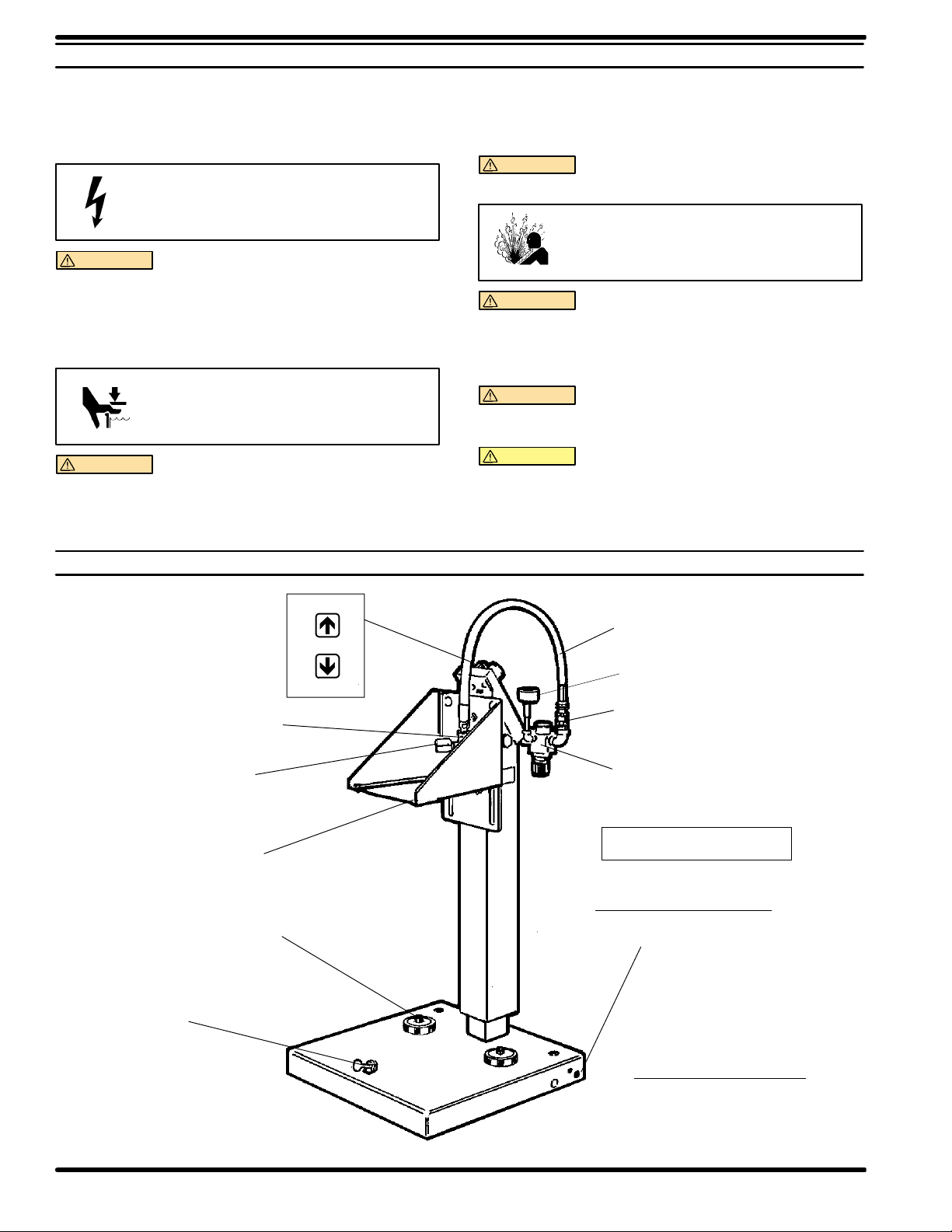

FIGURE 1

THUMB

SCREW

Y43-4-C

STREET ELBOW

Y167-5

ADAPTER

(1/4 NPT X 1/2 NPT)

MOUNTING

BRACKET

(See Page 8)

DRUM STOP

UP

NEUTRAL

DOWN

MAJOR COMPONENTS

622553-2

AIR HOSE

(1/2 NPT(M) X 1/2 NPT(M) )

GAUGE

75366

SWIVEL

PUMP AIR

MANIFOLD

Maximum Inlet Air Pressure

160 PSI (11 bar)

Optional Items Available

PORTABILITY KIT

66713 (See Page 8)

Included but not shown

Fasteners used to mount pump

to mounting plate.

Four Y6-63-C Screws

Four Y13-6-C Washers

651615-XPAGE 2 OF 8

Page 3

LIFT/RAM INSTALLATION

WARNING Failure to properly install the lift assembly can

result in severe personal injury and property damage. Read

the warning on page 2.

1. Establish the desired location for the lift/ram and pay special attenĆ

tion to work area above, this area above the lift must be open, withĆ

out obstructions and safely away from any electrical devices.

2. Place the pump on the follower plate and align the pump and folĆ

lower plate on the base and assemble pump to the mounting brackĆ

et on the ram.

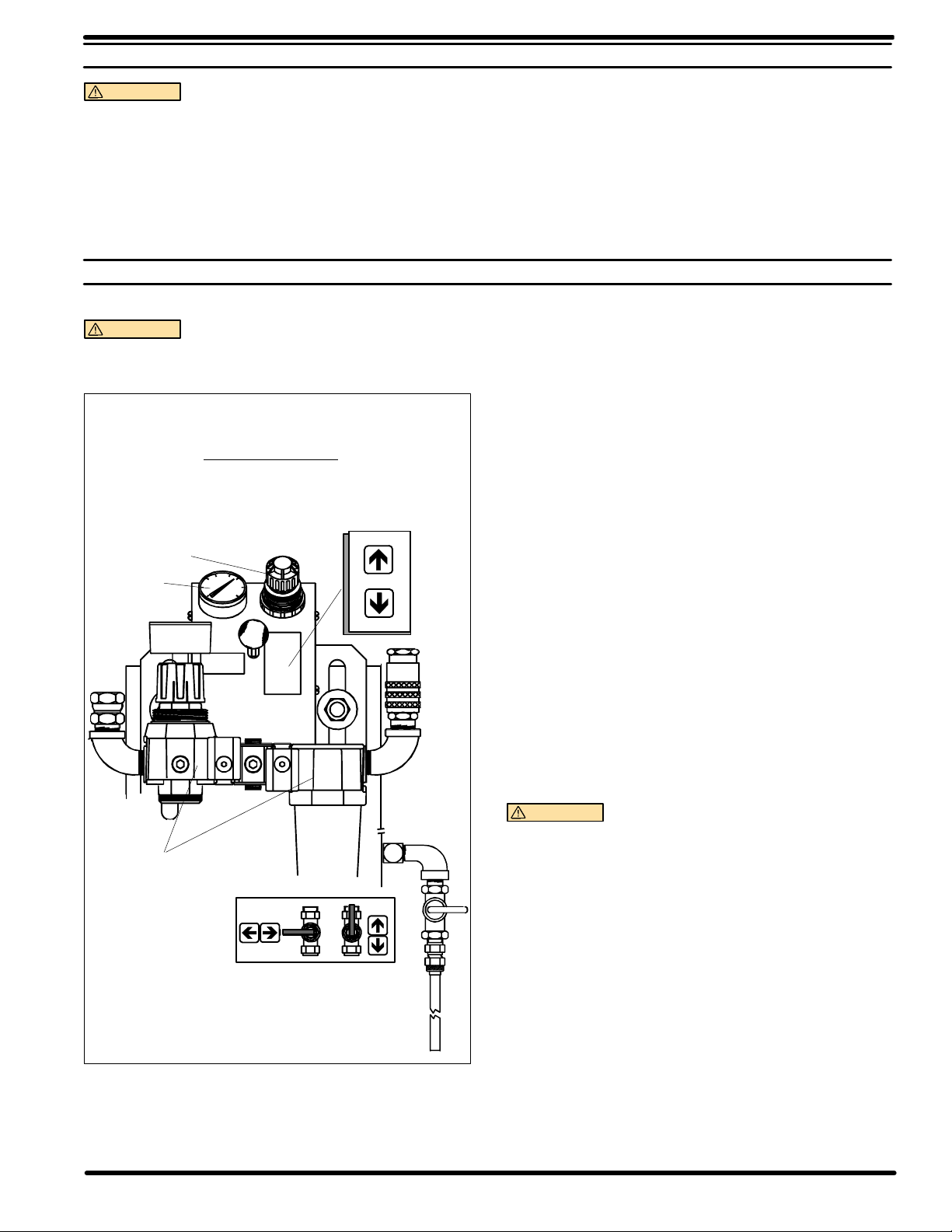

OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS / INITIAL SETUP PROCEDURE

WARNING STAND CLEAR. When raising or lowering the

lift. Read the warning on page 2.

AIR CONTROLS

CONTROL

LEVER

PRESSURE

REGULATOR

GAUGE

UP

NEUTRAL

DOWN

3. Assemble air hose to air motor inlet.

4. Install the check and follower plate air hose from the Control Valve.

5. Assemble the vent plug to the follower plate.

NOTE: The ram was tested at the factory. The unit should be generally

checked over for leakage because the fittings on the system may have

loosened in shipment.

TO RAISE LIFT, (THE FIRST TIME):

1. Take note of the pump/drum clearance above. Be certain the lift is

clear of any objects above. Also refer to OPERATING AND SAFEĆ

TY PRECAUTIONS found on page 2.

2. Connect the air supply (160 PSI MAX) to the air inlet.

3. Shift the control valve lever to the ``UP'' position.

4. Raise the lift high enough to clear the height of the drum. Stop the

lift upward travel by moving the control valve lever to the (center)

``NEUTRAL'' position.

TO RAISE LIFT, (NORMAL OPERATION):

1. Adjust the Follower Plate Air Valve pressure up to approximately 8

psig. DO NO OVERPRESSURIZE THE DRUM to avoid damage.

NOTE: Air from this valve will only pass when the Control Lever is

in the ``UP'' position.

2. Shift the control valve lever to the ``UP'' position.

3. Raise the lift high enough to clear the height of the drum. Stop the

lift upward travel by moving the control valve lever to the (center)

``NEUTRAL'' position.

PUMP

FILTER-REGULATOR

OFF

FOLLOWER PLATE

AIR SUPPLY VALVE

FIGURE 2

ON

TO CHANGE DRUM:

NOTE: The Control Lever should be in the ``NEUTRAL'' position.

1. Place a new drum into position.

TO LOWER LIFT:

WARNING PINCH HAZARD. Follower can descend quickly

causing injury. Keep hands clear when aligning with containĆ

er. Read the warning on page 2.

NOTE: Be certain the Follower Plate vent plug has been removed so

that the air trapped between the follower and the material is allowed to

escape from this vent. Captured air between the follower plate and

drum will escape.

NOTE: The lift may hesitate momentarily before starting downward,

the air pressure inside the post air chamber must decrease before it will

begin to descend.

1. Shift the control valve lever to the ``DOWN'' position and proceed to

lower the pump.

2. Replace the vent plug once the material begins to ooze from the

vent opening.

651615-X

PAGE 3 OF 8

Page 4

PARTS LIST

Single Post Ram/Lift

ITEM DESCRIPTION (SIZE IN INCHES)

1 Gauge (1) 29975

2 Tube 5" (1) 44632 j

3 Tube 4.75" (4) 44632 j

4 Screw (1/4-20) (3) Y99-45-C

5 Nut (1/4-20) (3) Y12-4-C

6 Washer (1/4") (3) Y13-4-C

7 Screw (5/8-11) (2) Y6-105-C

8 Lockwasher (5/8) (2) Y14-625-C

9 Manifold (1) 92380

10 Panel Nut (1) 29661

11 Connector (7) 59688-4

12 Elbow (1/8" NPT) (1) Y43-1-C

13 Shut-off Valve (1) Y28-2

14 Connector (1) Y214-2

15 Tube 2.208 feet (1) 59675 f

16 Regulator (1) R27241-100

17 1/2" Male Swivel (1) 75366

18 Elbow (1/2) (2) Y43-4-C

(QTY)

PART NO.

ITEM DESCRIPTION (SIZE IN INCHES) (QTY) PART NO.

19 Carriage Bolt (1/2-13) (4) Y84-801-C

20 Lockwasher (1/2') (4) Y14-816-C

21 Washer (1/2") (4) Y13-8-C

22 Nut (1/2-13) (4) Y12-8-C

23 Cover (1) 92375

24 Self Tapping Screw (#8-32) (4) Y222-130-C

25 Label (1) 92449

26 Coupler (1) 23103-004

27 Connector (1/2 NPT) (1) 23903-410

28 Filter (1) F25241-100

29 Manifold Kit (1) 104170

j Bulk Tube-100 Ft.Roll 3/16" O.D.- 59690-104

f Bulk Tube-100 Ft.Roll 1/4" O.D.- 59675-100

l Apply Tape to threads.

Z Apply Anaerobic Pipe Thread Sealant to threads.

PTFE

651615-XPAGE 4 OF 8

Page 5

l1

BASIC SINGLE POST RAM/LIFT

10

ASM.

2

3

4

5

6

7

8

9

47

11

3

11

3

11

53

12

13

14

15

FIGURE 3

l17

l18

19

20

21

22

16

23

24

25

26

27l

18l

FIGURE 4

28

29

651615-X

PAGE 5 OF 8

Page 6

PARTS LIST

Single Post Ram/Lift

ITEM DESCRIPTION (SIZE IN INCHES)

30 Thumb Screw (1) Y66-378-C

31 Base (1) 66558

32 Bucket Stop (2) 92565

33 Carriage Bolt (2) Y84-601-C

34 Nut (3/8-6) (2) Y12-6-C

35 Lockwasher (2) Y14-616-C

36 Tube (1) 92378

37 Rod (1) 92379

38 ``O" Ring (3 1/4" O.D.) (1) Y325-336

39 Retaining Ring (1) 90503

40 Plate (1) 91396

41 Screw (4) Y6-42-C

42 Nut (1/4-20) (4) Y12-4-C

43 Washer (1/4") (4) Y13-4-C

44 Bracket (1) 93968

45 Male Fitting (3) 59753-4

46 Elbow (3) 92388

47 ``E" Series 4-Way Valve g (1) E512LM

48 Adapter (3) 6045

49 Plug (1/8" NPT) (1) Y17-50

50 Washer (1) Y13-6-C

51 Spring (1) 38226

(QTY)

PART NO.

ITEM DESCRIPTION (SIZE IN INCHES)

52 Air Regulator (1) 127122-000

53 Hose Coupling (1) 3249

54 Male Tee Fitting (2) 59747-4

55 Tubing 5.37 (1) 44632j

56 Plug (1) 92389

57 ``O" Ring (7/8" O.D.) (1) Y325-18

58 Gauge (1) 100067

59 Coupling (1/4 NPT) (1) Y43-42-C

60 Nipple (1/4 NPT) (1) Y44-11-C

61 Elbow (1/4 NPT) (1) Y43-2-C

62 Nipple (1/4 NPT) (1) Y44-13-C

63 Retaining Ring (1) Y147-200

64 Retaining Washer (1) 90509

65 Retaining Wiper (1) 90508

66 Retaining Washer (1) 90511

67 Unipack Seal (1) 90507

68 Dowel Pin (1) Y148-35

69 Cap & Bearing (1) 66643

70 Column (1) 66557

71 Piston (1) 92376

72 Packing (2) 90506

g Repair kit for Valve E512LM 116722

l Apply Tape to threads.

Z Apply Anaerobic Pipe Thread Sealant to threads.

PTFE

(QTY)

PART NO.

651615-XPAGE 6 OF 8

Page 7

BASIC SINGLE POST RAM/LIFT ASM.

44

46

11

47

l48

45

Z

49

50

51

52

53

54

55

56

67

57

66

58l

59l

60l

61l

62

63

64

65

Z

30

43

42

41

31

40

33

32

34

35

39

38

37

36

68

69

70

Z

71

72

651615-X

FIGURE 5

PAGE 7 OF 8

Page 8

DIMENSIONAL

DA

TA

91396 MOUNTING PLATE

8-3/4"

SQUARE

4-3/8"

5"

1 3/4"

3-1/2"

Material-11 Gauge Steel

66713 PORTABILITY KIT

FIGURE 6

FIGURE 7

PN 97999-604

651615-XPAGE 8 OF 8

Loading...

Loading...