Ingersoll-Rand 4575759 User Manual

Sensor I® Expert Electronic Wrenches

USER MANUAL

SENSOR I® Expert

User Manual

04575759

Form 7266

Version 005, 08/04

Sensor I® Expert User Manual

NOTE

The wrench should only be used for its intended purpose, i.e., for

tightening, loosening and auditing purposes. It should be operated

using a smooth steady pull at moderate speed on the wrench handle

with both feet firmly placed on floor. Specifications apply to the

wrench only (without additional apparatus). Accuracies cannot be

specified when the wrench is used with torque multipliers or if the

wrench is operated incorrectly.

NOTE

The used of universal joints is not recommended. Use of such devices

may cause inaccuracies in torque and/or angle measurements. The use

of extensions to the handle, or application of force to other parts of the

wrench may cause damage, result in personal injury, or may result in

inaccurate tightenings.

NOTE

Exceeding the maximum torque noted on the wrench may cause damage

to wrench or loss of calibration.

NOTE

Always make sure that the socket is fully engaged on the joint before

tightening begins. Failure to do so may cause inaccuracies in torque

and/or angle measurements.

Sensor I® Expert User Manual

NOTE

If the wrench fails to operate using the recommended procedures

described in this manual, the cause of malfunction should be corrected

by an authorized Ingersoll-Rand technician. For a list of authorized

Ingersoll-Rand technician. For a list of authorized Ingersoll-Rand

service centers, see Appendix D.

NOTE

If calibration equipment is not available, it is recommended that the

wrench be returned to an authorized Ingersoll-Rand service center for

an annual recalibration.

Sensor I® Expert User Manual

Application Guidelines for Accurate Use of the Expert Wrench

To all Expert wrench users

February 15, 1999

What distinguishes the Expert wrench from dial wrenches or other digital

torque wrenches is one very significant feature: angle. The angle

measurement allows users to accurately audit torque dynamically and

perform sophisticated tightening methods such as angle and yield control.

The EZ Angle sensor is a major improvement over previous technology. The

most obvious change is the removal of the external arm on the ratchet

head-eliminating the space constraint. In addition, users no longer need to

find a suitable place to attach the reference arm magnet.

Although the Expert wrench is a rugged industrial tool, to achieve precision

results, it needs to be treated as a precision instrument. The following

outline summarizes the ideal method of use:

Wrench Reset:

The reset process sets the zero reference for both torque and angle. The

wrench must be held steady with no torque applied to achieve a good reset.

It will indicate a fault if excessive torque or angle is applied while resetting.

For best results, attach the socket to the wrench and place it on the

fastener or rest the ratchet head on a table. Hold in the Reset button until

the green Run light illuminates and release. You can then move the wrench

to the fastener, or begin tightening immediately. To achieve angle accuracy

that is better than the documented performance specification place the

entire wrench on a table and hold it completely still during reset. This will

improve the angle accuracy to better than ±2% of the final angle.

Sensor I® Expert User Manual

Dynamic Audit:

The Dynamic Audit feature of the Expert wrench audits residual torque

currently on the fastener after relaxation and other effects have taken

place. On a very hard joint that is audited soon after tightening, this will

consistently equate to installation torque. On a very soft joint or a joint

audited long after the initial tightening, it may be considerably reduced.

Standard methods are open to variance from operator influence. Experienced

auditors try to overcome these difficulties by watching the socket very

closely and moving very cautiously. Other operators may have a tendency to

pull the wrench until the expected value is reached. Although that specific

bolt may end up with the correct torque, it does not tell Quality Control

about any possible problems that are occurring with the fastening

equipment on line.

The Expert wrench helps eliminate this operator influence by capturing the

residual torque after a very small angle is turned regardless of how far or

fast the wrench is pulled. In other words, all that is required is a quick pull

and the processor takes a "snapshot" of the dynamic torque at the pre-set

angle of turn.

To Dynamically Audit Residual Torque:

A table of audit angle values is provided for your convenience. The guiding

principle is to set a sufficient angle of turn to ensure the bolt threads are

moving when the torque snapshot occurs. The longer the fastener, the

greater the required angle.

To ensure that an accurate reading is received, the following procedure

should be followed:

Sensor I® Expert User Manual

1. Set the snug torque to approximately 50% of the expected final torque

reading.

2. Set the capture angle (see chart).

3. The operator must then pull the wrench approximately 30° over a period

of no more than 2 seconds. Pulling the wrench past the desired audit

angle will not have an adverse effect on the audit reading - it will be

"captured" at the correct audit angle. The captured torque can be viewed

when the parameter shown on the display is "Tq".

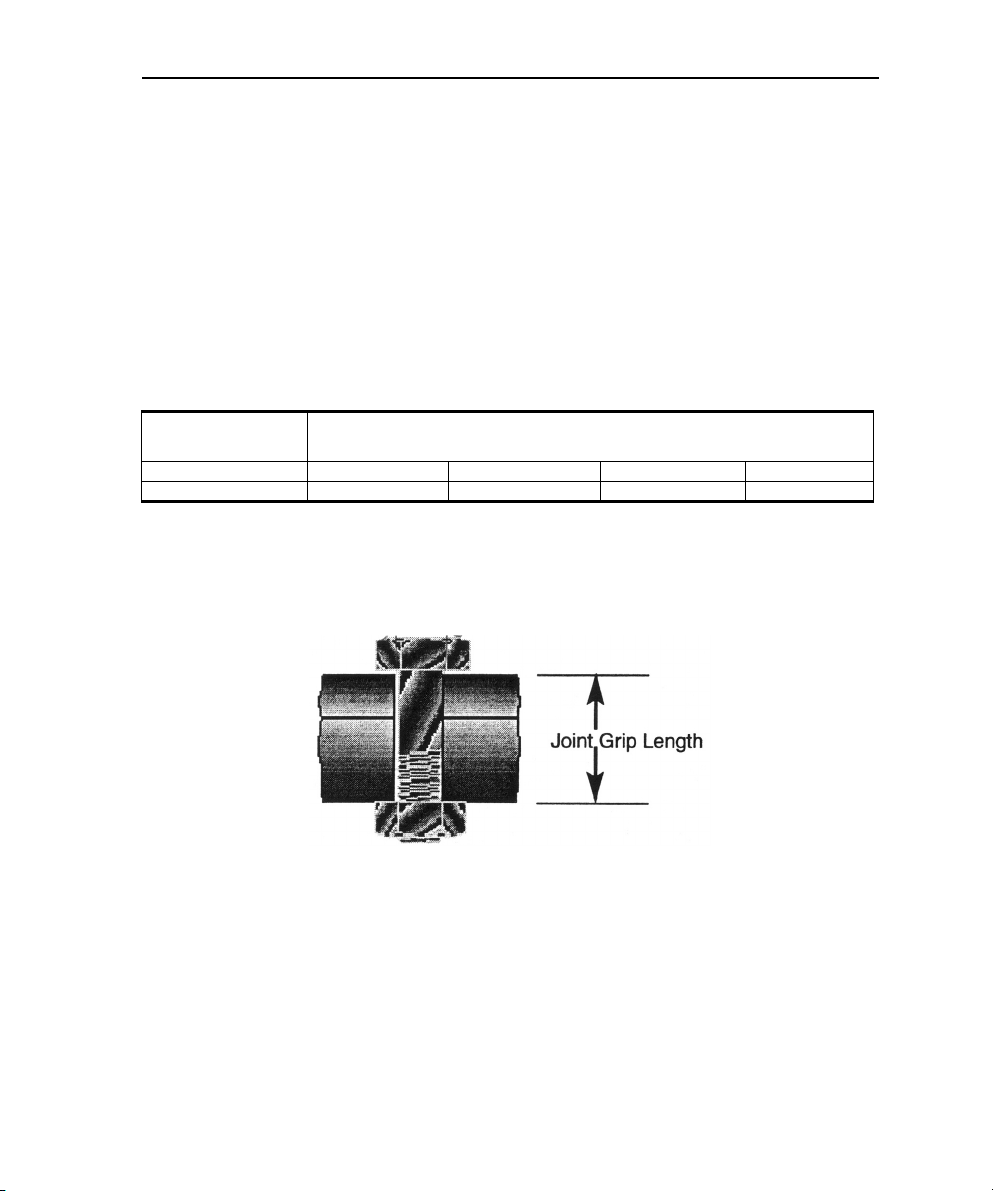

Joint Grip Length* (d = bolt diameter)

Joint Type

Hard/Medium 2° 3° 4° 6°

Soft 2° 4° 6° 8°

2d

≤

*The grip length is the total length of the bolt located within the assembly

pieces. Keep in mind that adding socket extensions will also call for an

increase in angle.

2d - 5d 5d - 10d >10d

This chart is offered as a guideline only. The optimum value for the capture

angle will be influenced by the overall joints stiffness, joint configuration,

and frictional conditions. Application testing is recommended to determine

the most accurate value for the specific joint under audit.

Sensor I® Expert User Manual

To Tighten to a Torque

Set the torque value to your target torque, and set high and low torque and

angle limits if desired. Snug is set automatically to a default value. This is

the point from which the angle is activated. The default snug values for all

models are listed in the TOLL DESCRIPTION Technical data table in Chapter

2. Reset the wrench before tightening. The OK light will go on and an alarm

will sound when the target is reached. If the wrench is pulled too slowly for

a long period (<10° per second for model 40, <5° per second for more than

5 seconds for all other models), the wrench will signal an error by sounding

several short beeps.

To Tighten to an Angle

Set the snug torque and target angle as well as any high and low torque and

angle limits. Reset the wrench before tightening. The Ok light will go on and

an alarm will sound when the target is reached. If the wrench is pulled too

slowly for a long period (<10° per second for 5 seconds for model 40, <5°

per second for more than 5 seconds for all other models), the wrench will

signal an error by sounding several short beeps.

To Tighten to Yield

Snug torque should be set to approximately 50% of the expected proof load

torque of the bolt in use. Set any required torque or angle limits, and select

your joint type-hard, normal or soft. Reset the wrench before tightening.

The OK light will go on and an alarm will sound when the target is reached.

If the wrench is pulled too slowly for a long period (<10° per second for 5

Sensor I® Expert User Manual

seconds for model 40, <5° per second for more than 5 seconds for all other

models), the wrench will signal an error by sounding several short beeps.

NOTE

When using EVS-models, avoid ratcheting when the torque is in the

vicinity of the snug torque and between snug and the yield point.

Sensor I® Expert User Manual

TABLE OF CONTENTS

Sensor I® Expert User Manual

TABLE OF CONTENTS

CHAPTER 1: INTRODUCTION ........................................................... 1

CHAPTER 2: TOOL DESCRIPTION ..................................................... 3

Functions of Components

CHAPTER 3: WRENCH OPERATION INSTRUCTIONS ............................. 15

General Information .................................................... 15

Operation ................................................................... 15

Primary Operation Modes .............................................. 15

Setting Torque Units

Torque Control Tightening Procedure

Dynamic Audit

Yield Control

Angle Control

CYCLE COUNTER ........................................................... 25

Resetting the Cycle Counter

QUALITY CONTROL LIMITS AND STATISTICS ...................... 26

Setup and Viewing Quality Control Limits

Deleting Quality Control Limits

Use of Quality Control Limits

Statistics

CUSTOM TIGHTENING MODES ......................................... 30

Setup and Storage of Custom Tightening Modes

Retrieving Custom Tightening Modes

Identifying Custom Tightening Modes

Clearing Custom Tightening Modes

DATA STORAGE AND RETRIEVAL ...................................... 33

Setup of Wrench for Data Upload

Data Out During Tightening

Data Out at End of Tightening

Parameter Dump

End of Tightening Data Dump

Tightening Curve Storage

Tightening Curve Data Dump

i

Sensor I® Expert User Manual

TORQUE MULTIPLIER FUNCTION ...................................... 40

Setup of a Torque Multiplier

Use of a Torque Multiplier

LEFT HAND FASTENERS ................................................. 42

RESET ADJUSTMENT (EVS-models only) ............................ 43

CHAPTER 4: BATTERY CHARGING .................................................... 51

CHAPTER 5: DIAGNOSTICS AND TROUBLESHOOTING .......................... 49

Introduction

Torque Channel A/D Display

Angle Reference Arm Test Mode

Battery Level Test Mode

EZ Angle Test Mode

Membrane Keypad Test Mode

Head Position Test

Buzzer and LED Test Mode

Display/Serial Link Test Mode

Software Version Number Test

Time-out Adjustment

CHAPTER 6: CALIBRATION ............................................................. 53

General Information .................................................... 53

Torque Calibration ....................................................... 54

Angle Reference Arm Calibration (EA - models) ................ 56

EZ Angle Calibration (EVS - models) ............................... 56

Appendix A ................................................................................. 62

Sample Reports ........................................................... 62

Parameter Dump .......................................................... 62

End of Tightening Data Dump ........................................ 63

Tightening Curve Data Dump ......................................... 65

Data Out During Tightening .......................................... 66

Data Out at End of Tightening ....................................... 66

Appendix B ................................................................................. 67

Appendix C ................................................................................. 69

Appendix D ................................................................................. 77

ii

Sensor I® Expert User Manual

CHAPTER 1

Introduction

Sensor I® Expert User Manual

INTRODUCTION

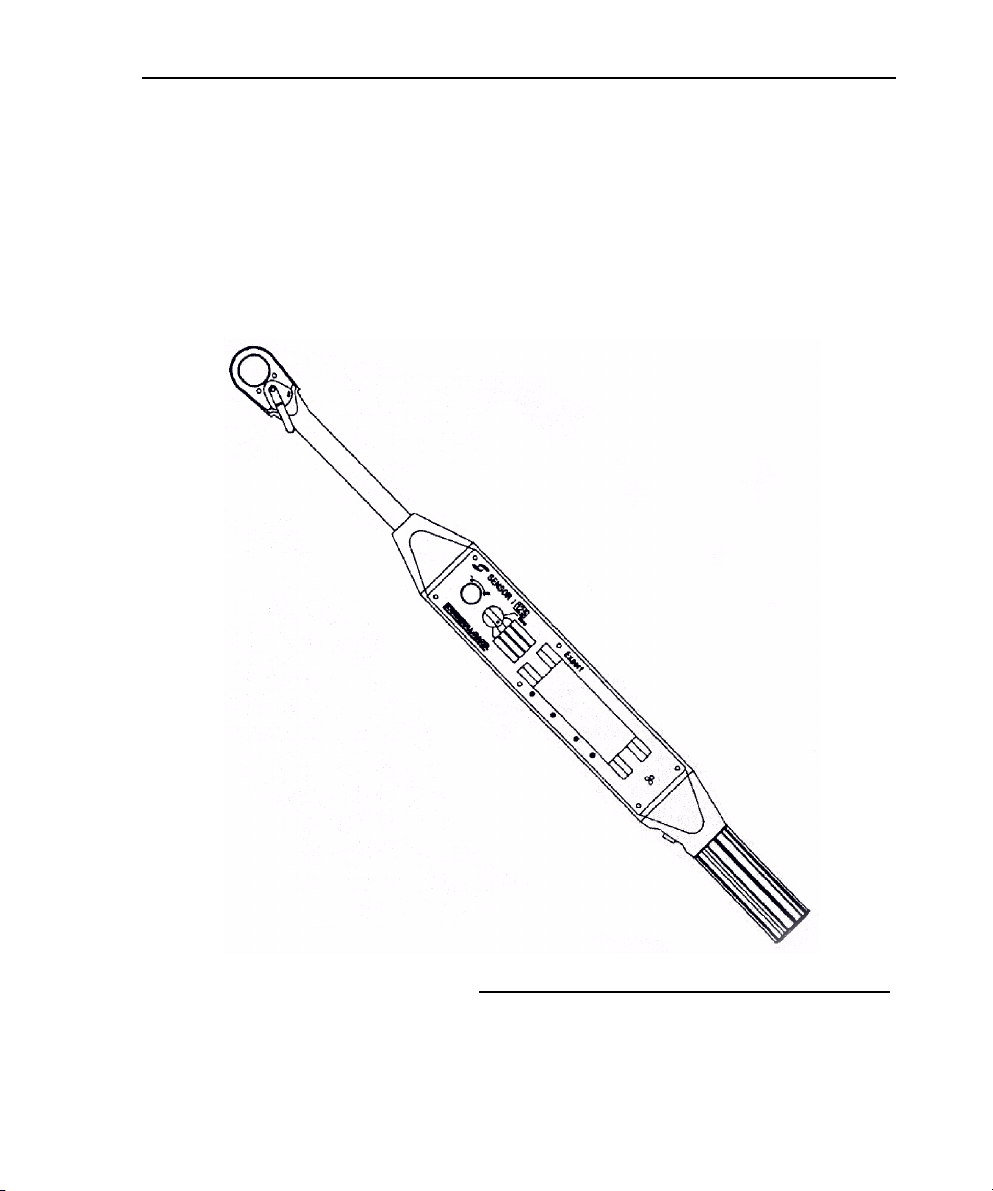

The SENSOR 1® EXPERT WRENCH is a hand-operated portable tightening

system with a battery-powered microprocessor control system. In addition

to standard torque and angle control tightening capabilities, it provides a

Yield Control mode of tightening and Dynamic Torque Auditing. It is suitable

for laboratory, production, quality control, maintenance and field service.

The control system is powered by a rechargeable NiMH battery located

inside the wrench handle (model 125, 250 & 400) or in the lower portion of

the control unit (model 40). The wrench has a toggle lever used to select

the ratchet direction. Angle reference is either measured internally by the EZ

angle or via an attachable spring arm with a magnet (EA-models).

Attachable spring arms can be fitted with options such as suction cups or

alligator clips.

The digital display shows a digital readout of either dynamic torque peak

torque, or angle. Audible signals and displays indicate the completion of

tightening for Dynamic Torque Audit, Torque Control, Yield Control (elastic

limit of bolt), or Angle Control procedures.

1

Sensor I® Expert User Manual

CHAPTER 2

Tool Description

Sensor I® Expert User Manual

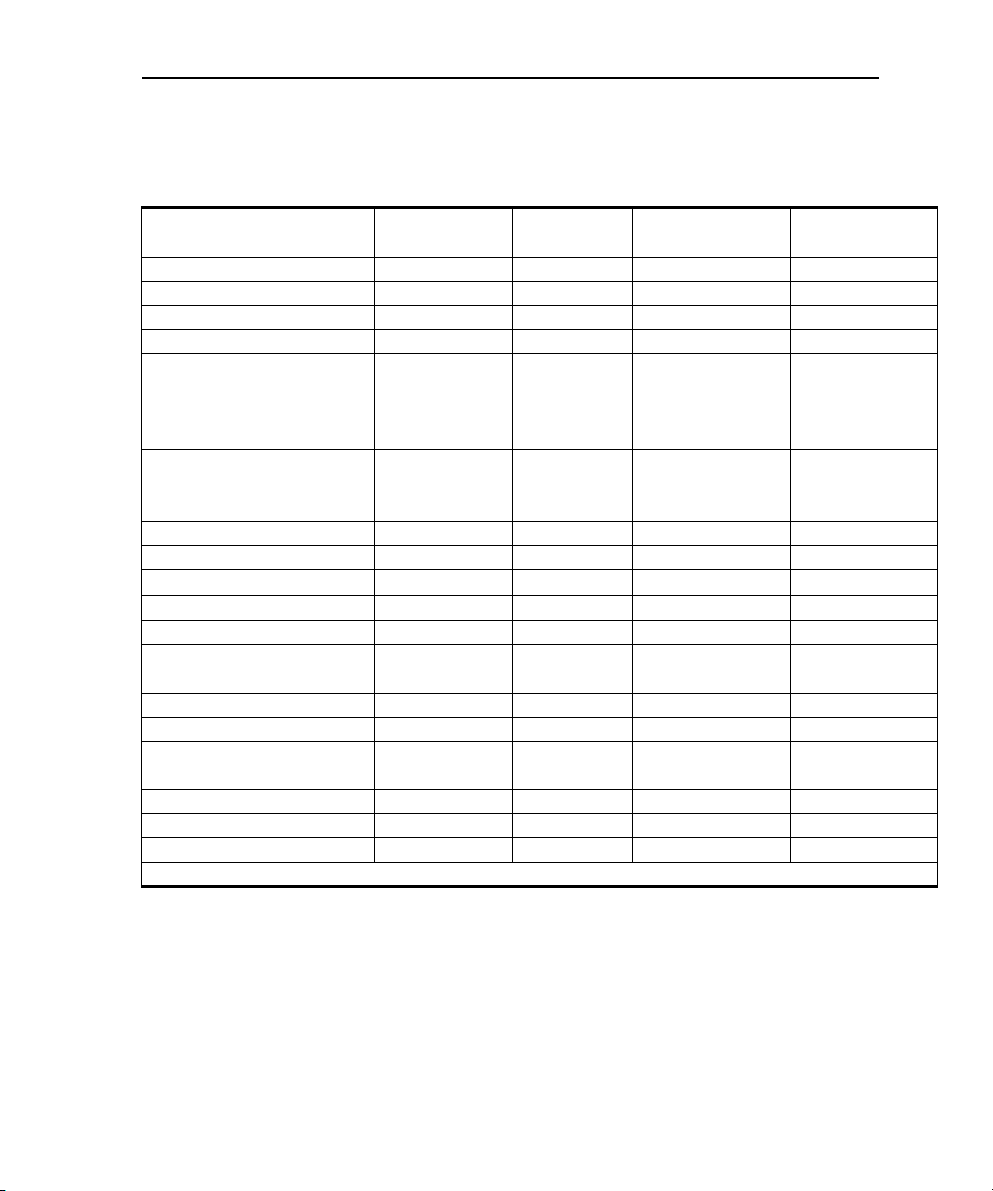

TOOL DESCRIPTION

Technical Data 40 125 250 400

Length: 13.5” (343 mm) 26” (665 mm) 42.5” (1080 mm) 48.5” (1232 mm)

Square Drive: 3/8” (9.5 mm) 1/2” (12.5 mm) 3/4” (19mm) 3/4” (19 mm)

Weight:

Tool 2.4 lb (1.1 Kg) 5 lb (2.3 Kg) 12 lb (5.5 Kg) 13.8 lb (6.3 Kg)

Control Unit 2.2 lb (1.0 Kg)

Torque Operational Range: 4.5-45 Nm 20 - 170 Nm 108-340Nm 130-540 Nm

(45-450 dNm) 15 - 125 lb.ft. (80-250 lb.ft) 100-400 lb.ft

3.3-33 lb.ft.

(40-400 in-lb)

Minimum Snug Torque 2.3 Nm (23 dNm) 10 Nm 24 Nm 24 Nm

(default value for 1.7 lb.ft. (7 lb.ft.) (18 lb.ft.) (18 lb.ft.)

Torque control mode) (20 in-lb)

Torque Resolution: 1 in-lb 0.1 Nm 0.1 Nm 0.1 Nm

Torque Accuracy: Full Scale ± 1 % ± 0.5 % ± 0.5 % ± 0.5 %

Maximum Angle:

Angle Resolution:

Angle Accuracy:

Angle Reference

Arm (EA-models)

EZ Angle* (EVS-models) ±4 % ±4 % ±4 % ±4 %

Power Supply Voltage 7.5 V 7.5 V 7.5 V 7.5 V

Operating time between 5.5 hours 5.5 hours 5.5 hours 5.5 hours

charges

Charging time 14 hours 14 hours 14 hours 14 hours

Battery Charger Input Voltage 220/110 V 220/110 V 220/110 V 220/110 V

Operating Temperature Range

* Under recommended conditions

o

1999

o

1

o

±1

0

0-50

C0-50

1999

o

1

o

±1

o

0

C0-50

o

1999

o

1

o

±1

0

C0-50

1999

o

1

o

±1

o

0

C

3

Sensor I® Expert User Manual

NOTE

These specifications apply to the wrench and its control system only

(without additional apparatus). Accuracies cannot be specified when

the wrench is used with torque multipliers or if the wrench is operated

incorrectly.

NOTE

The use of universal joints is not recommended. Use of such devices

may cause inaccuracies in torque and/or angle measurements.

NOTE

Exceeding the maximum torque, noted on the wrench, may cause

damage to wrench or loss of calibration.

4

Sensor I® Expert User Manual

Functions of Components

Expert 125, 250 and 400 Models

Wrench Housing

Incorporates all the electronics and digital display.

Wrench Handle

Houses the charger/data port connector for battery charging and serial

port communications.

Wrench Head

Contains the angle reference arm potentiometer (EA-models) and ratchet

head. The wrench head can be indexed 600 either side of the wrench body

for ease of reading the display.

NOTE

Factory Calibration of models 125, 250 and 400 was conducted with the

wrench head in the normal, non-indexed position. This position is

recommended where high accuracy of angle values is required. If the

wrench is to be used in the ±60o indexed position and angle accuracies

equal to or better than ±10% are required, then recalibration of angle

in the indexed position is recommended.

Torque accuracy remains unaffected by indexing the wrench head.

5

Sensor I® Expert User Manual

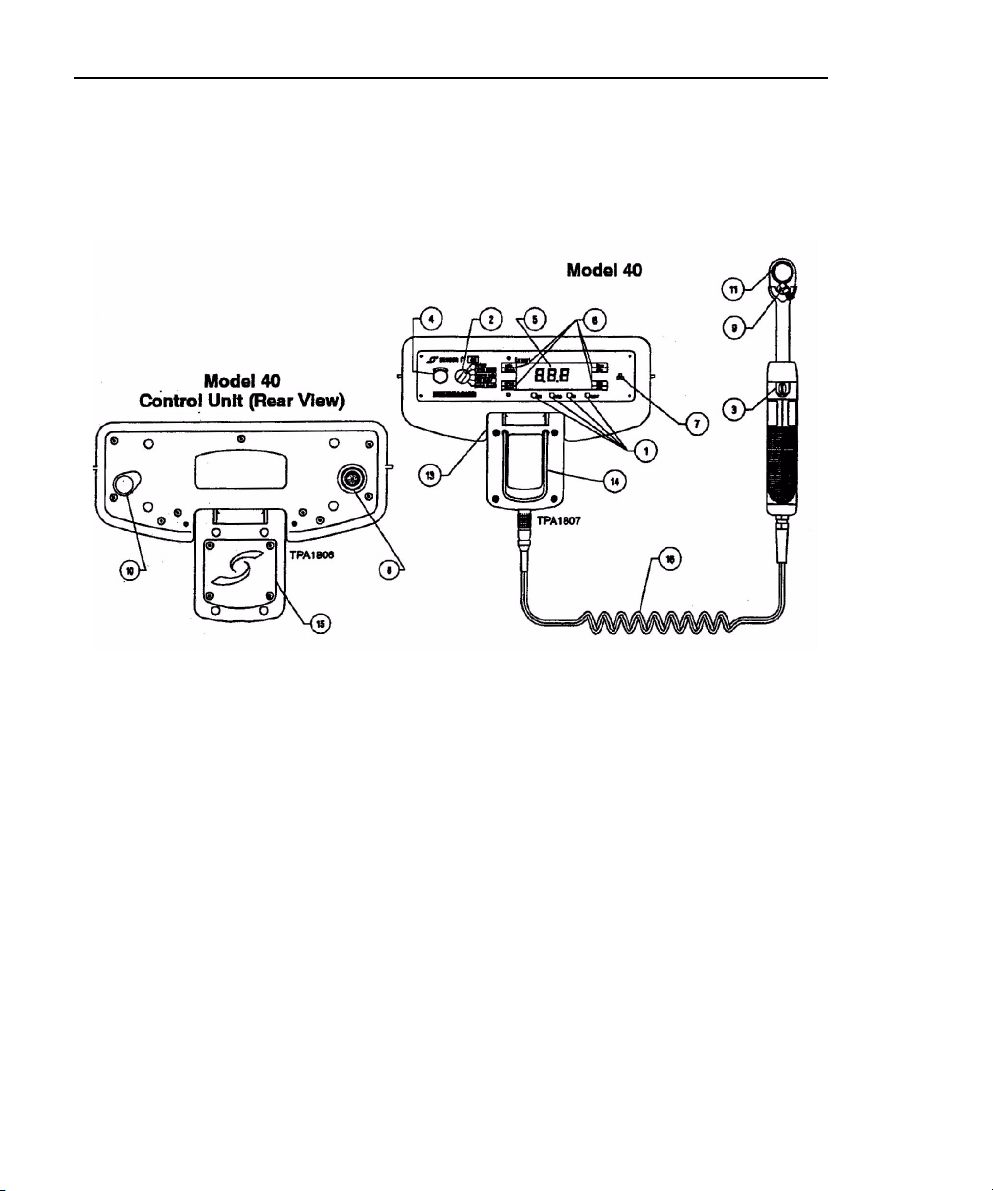

Functions of Components

Expert 40

Handheld Tool

Consists of the ratchet head, reset switch, cable and the angle

measurement device. The head cannot be indexed relative to the handle.

The plug at the end of the tool cable connects to the receptacle on the

lower portion of the Control Unit.

Control Unit

Houses the electronics, power supply and interface connectors for the tool

cable and battery charger/data communications port. The tool connects

to the receptacle in the lower portion of the Control Unit. The front panel

on the upper portion of the Control Unit is the same as all other Expert

Wrenches.

6

Sensor I® Expert User Manual

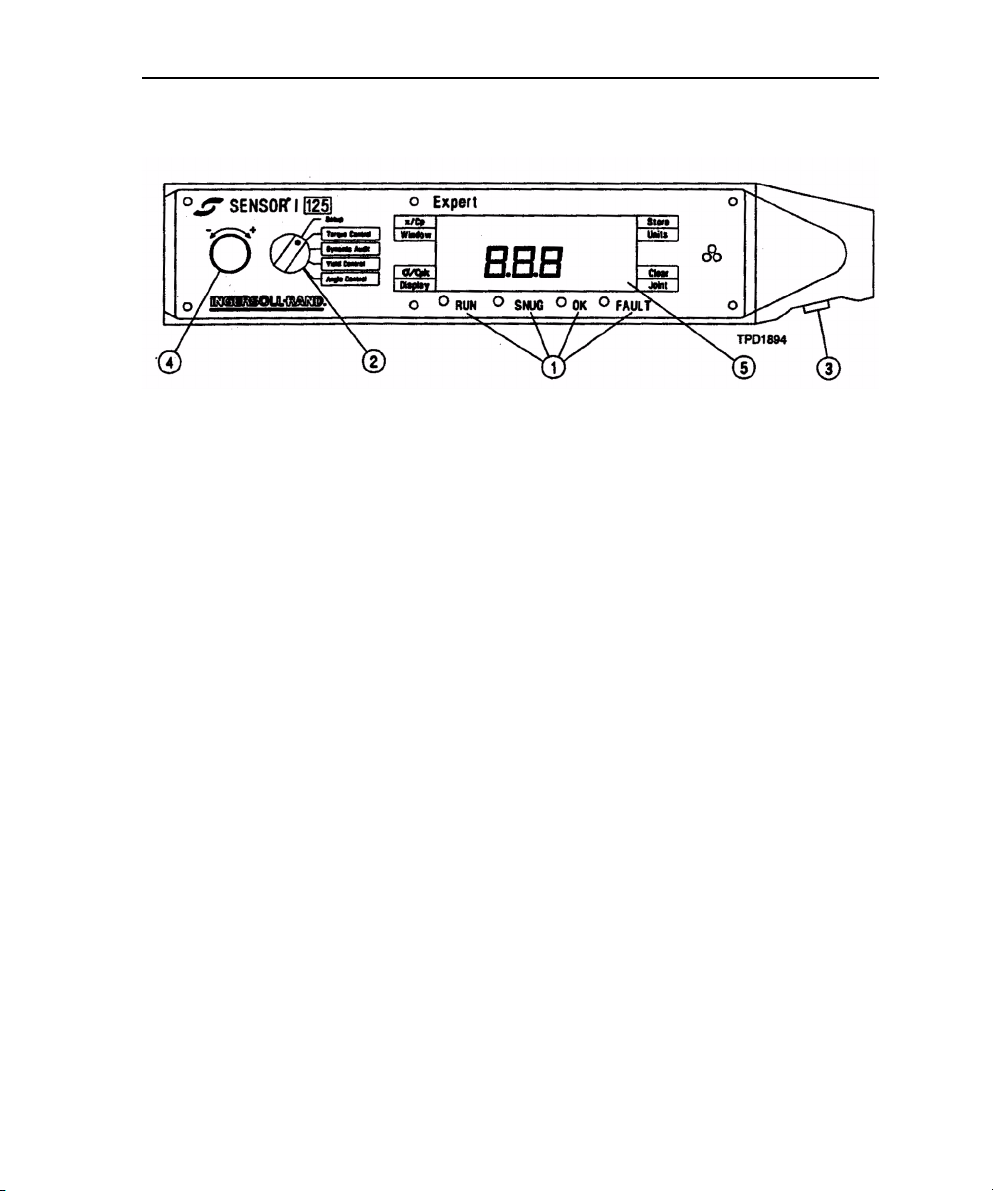

1. Control System Status Lights

These lights are used to signal operating status:

RUN The control system is ready to begin a cycle.

SNUG The torque applied to the fastener has reached the snug torque setting.

OK The fastener has been tightened correctly in the selected tightening mode.

FAULT One or several of the following fault conditions has occurred:

a) Operator Error

b) Low Battery

c) Torque Overrange

d) System Failure

e) Wrench not held steady enough during calibration (Reset)

f) Wrench is being pulled too slowly.

g) The mode or parameter adjustment knob has been changed since last reset.

h) Ratchet head has been indexed since last reset.

7

Sensor I® Expert User Manual

2. Mode Selector Switch

Selects the particular tightening mode: Torque Control, Dynamic Audit,

Yield Control and Angle Control. This switch also allows you to select

the Setup mode to adjust communications parameters, setup and

restore custom modes, and perform diagnostics

3. Reset Button

Used to power up the wrench, reset the wrench before every new

tightening procedure, to set torque and angle values, and to clear

certain fault conditions. When the Reset button is held in, the top

functions on the membrane key pad can be selected.

4. Parameter Adjustment Knob

When the Reset button is held in, this knob adjusts the value of the

parameter being displayed.

8

Sensor I® Expert User Manual

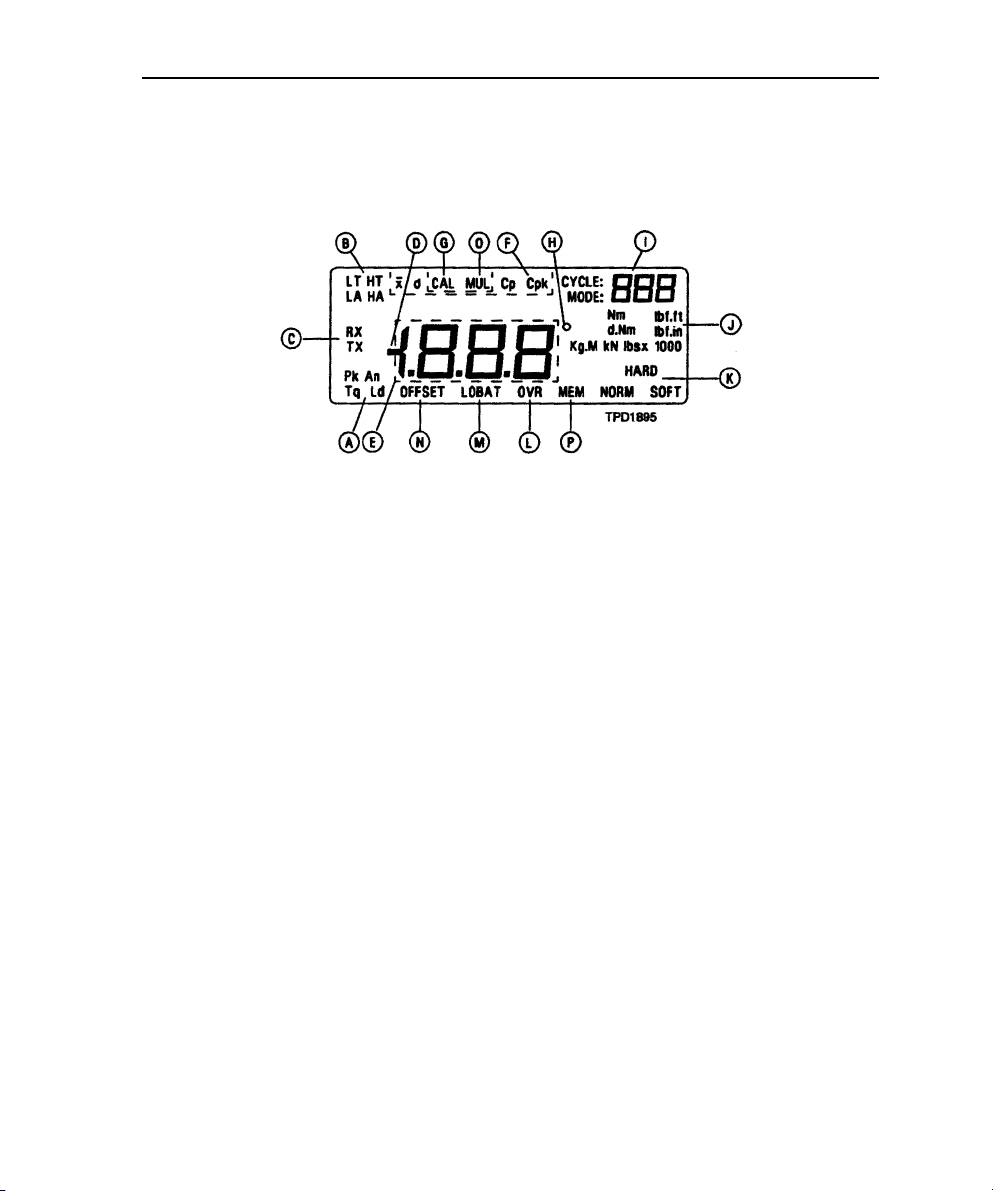

5. Digital Display

Provides a digital readout of parameters selected:

A) These segments show the item being displayed on the main display:

Pk is peak torque

An is angle

Ld not used

Tq is dynamic torque

B) These segments indicate limits:

LT is low torque limit

HT is high torque limit

LA is low angle limit

HA is high angle limit

C) These segments will light when serial data during tightening or serial data at

the end of tightening are selected. They will also flash when data is being sent

through the serial port.

RX = receiving, TX = transmitting

D) This segment will light when CCW ("-LEF") has been selected.

E) These segments display the values of torque and angle.

F) These segments light when statistical information is being shown on the

display.

9

Sensor I® Expert User Manual

G) This segment will light when the wrench is in calibration mode for torque or

angle.

H) This segment indicated that degrees of angle are being displayed on the

screen.

I) These segments indicate the cycle number for the tightening or the mode

number when in setup mode.

J) These segments indicate the units for torque.

K) These segments indicate the joint type selection for yield control.

L) This segment lights when the torque applied to the wrench is over the

maximum allowable limit.

M) This segment indicated a low battery condition.

N) This segment lights when torque and angle offsets are being calculated.

O) This segment will light when a torque multiplier is programmed for use with a

particular fastening mode.

P) This segment will flash when a particular tightening mode has reached its limit

of 1,000 tightenings. This segment will light continuously when the wrench

has reached its limit of 2,500 total tightenings for all the tightening modes.

10

Loading...

Loading...