Page 1

45481785

March 2007

Air Impact Wrench

2131 Series

Maintenance Information

Edition 1

Save These Instructions

Page 2

2 45481785_ed1

WARNING

Always wear eye protection when operating or performing maintenance on this tool.

NOTICE

NOTICE

NOTICE

NOTICE

NOTICE

NOTICE

NOTICE

POWER

MANAGEMENT

DIAL

NOTICE

NOTICE

Always turn o the air supply and disconnect the air supply hose before installing, removing or adjusting any accessory on this tool or

before performing any maintenance on this tool.

Note: When reading the instructions, refer to exploded diagrams in parts Information Manuals when applicable (see under Related

Documentation for form numbers).

Disassembly

General Instructions

1. Do not disassemble the tool any further than necessary to replace

or repair damaged parts.

2. Whenever grasping a tool or part in a vise, always use leathercovered vise jaws to protect the surface of the part and help

prevent distortion. This is particularly true of threaded members

and housings.

4. With the Anvil removed, lift out the two Hammer Pins.

The twin hammers are now free to slide from the Hammer Frame.

Be careful not to drop them.

Disassembly of the Motor

Always use leather-covered vise jaws when clamping the handle

in a vise. Leather will conform to the shape of the handle and

allow the tool to be held securely. To prevent damage to the

exhaust diuser, never clamp only the bottom of the handle.

3. Do not remove any part which is a press t in or on a

subassembly unless the removal of that part is necessary for

repairs or replacement.

4. Do not disassemble the tool unless you have a complete set of

new gaskets and O-rings for replacement.

Disassembly of the Impact Wrench

1. Clamp the handle of the impact wrench in a vise with leathercovered jaws with the square driver positioned horizontally.

Avoid excessive clamping pressure which can damage the

Housing and can cause diculty when removing the parts.

2. Unscrew and remove the four Hammer Case Screws (11).

3. While lightly tapping on the end of the Anvil (8) with a plastic

hammer, lift o the Hammer Case (15) and Hammer Case Gasket (18).

The Front End Plate (2) might come o during the removal of the

Hammer Case. Make sure that it does not drop on the oor or

strike a hard or metallic surface since it might be damaged.

4. Grasp the Hammer Frame (12) and carefully lift o the entire impact

mechanism, making certain not to drop the two Hammer Pins (13).

Disassembly of the Impact Mechanism

1. Set the mechanism, driver end up, on the workbench.

Note the twin hammers within the Hammer Frame. These are

identical, but must be placed in the Hammer Frame in a certain

relationship. Using a felt-tipped pen, mark he top “T” hammer

and the bottom hammer “B” with the arrows pointing upward.

Mark both Hammers on the same end.

2. With the mechanism sitting upright on the workbench, slowly

rotate the Anvil in a clockwise direction until it comes up solid.

When pulling, disassembling or assembling the motor, we

recommend replacement of the Motor Gasket (7).

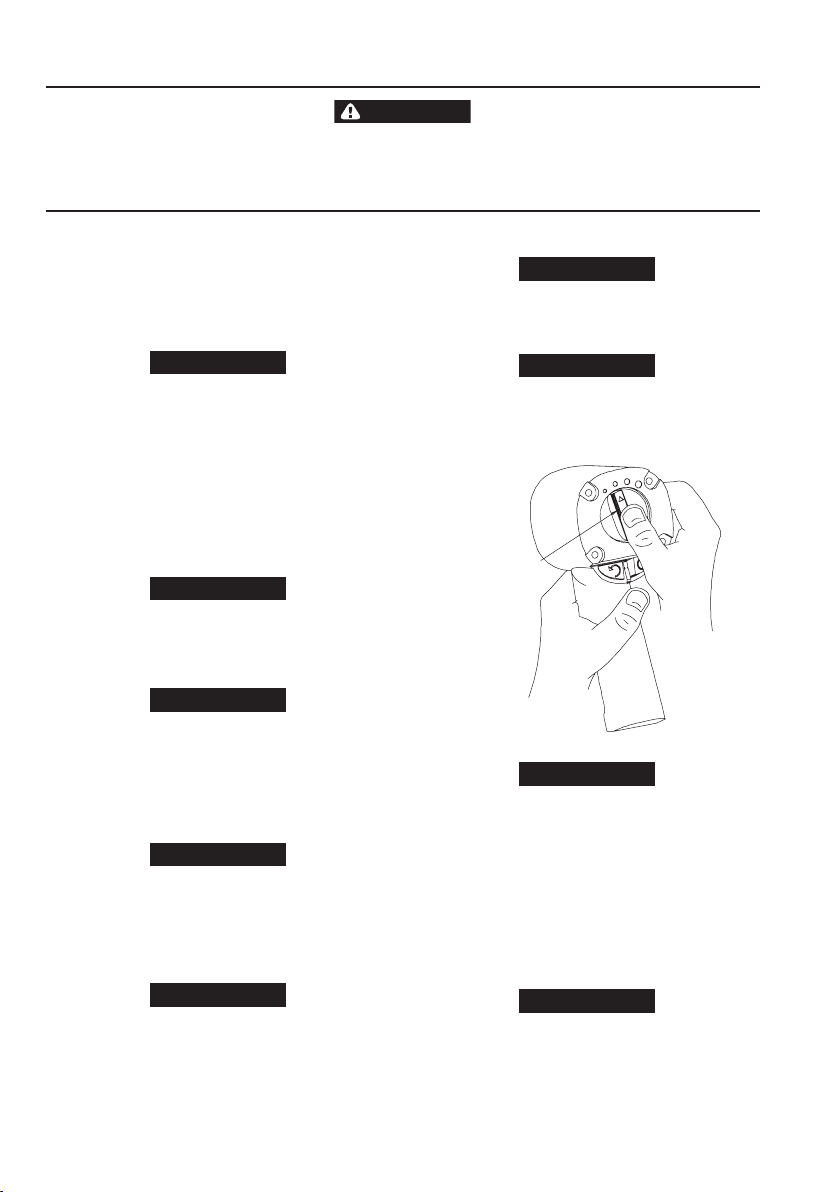

1. Remove the Motor Assembly from the Housing (19) by pushing

on Power Management Dial (35) from the back of the Housing.

Refer to Dwg. TPD1322.

(Dwg. TPD1322)

If the Motor Assembly cannot be removed from the Housing by

pushing, tap the Power Management Dial lightly until the Motor

Assembly is free.

2. Remove the Silencer (6A) from the top of the Cylinder (1). Remove

the Power Management Dial from the rear of the Cylinder (1).

Remove the Power Management Dial Seal (5A) if it needs to be

replaced.

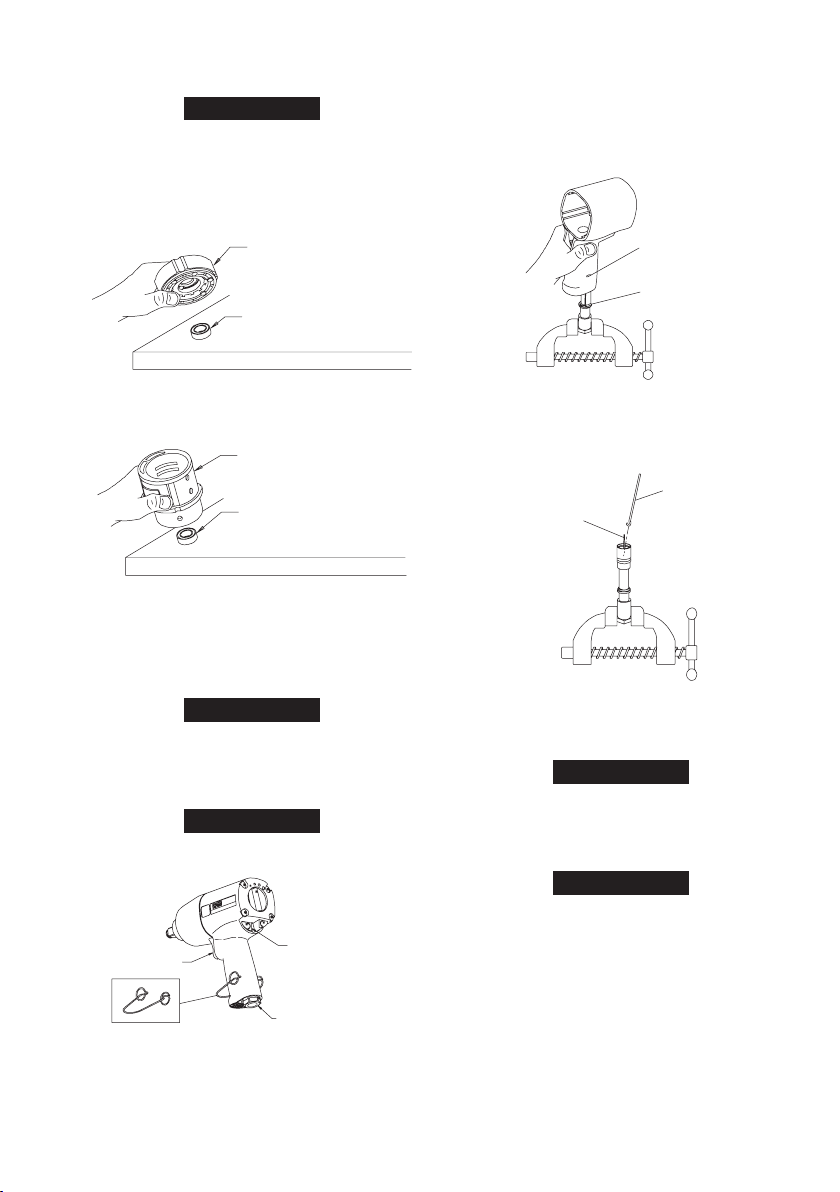

3. Remove the Front End Plate (2) from the Cylinder by tapping the

splined end of the Rotor (5) with a plastic hammer. If the Front

End Plate does not come loose, secure a center punch in a vise

with the point angled downward and outward from the vise.

Grasp the Cylinder and Front End Plate in one hand and position

the hole in the end of the Rotor against the punch.

If you continue to rotate the Anvil, it will cam the Hammers out

of engagement. Don’t do this; merely rotate the Anvil until it

comes up solid.

3. Hold the Hammer Frame rmly and without disturbing the

hammers, gently lift the Anvil while simultaneously rotating it

clockwise about 1/8 of a turn, from the Hammer Frame.

Be careful not to drop the Cylinder since it can be damaged by

hitting a hard surface.

Using the other hand, tap the punch with a hammer while pressing

the Rotor against the punch. After a few taps, the Front End Plate will

slide o of the Cylinder.

Page 3

NOTICE

To prevent damage to the Cylinder, do not tap or strike Cylinder on

FRONT END PLATE

FRONT ROTOR BEARING

BENCH WITH NONMETALLIC SURFACE

CYLINDER

REAR ROTOR BEARING

BENCH WITH NONMETALLIC SURFACE

NOTICE

NOTICE

LEFT-HAND BUTTON

INLET BUSHING

INLET CLIP

REMOVAL TOOL

ASSEMBLY

TRIGGER

SLOT FOR TAB

(BOTH SIDES)

TAB ON INLET

RETAINER CLIP

(BOTH SIDES)

TILT VALVE STEM

HOOKED TOOL

NOTICE

NOTICE

a hard or metallic surface when removing the Rotor Bearings (3).

To remove the Front Rotor Bearing, hold the Front End Plate with

Front Rotor Bearing down and tap the Front End Plate on a at,

nonmetallic surface such as a work bench. This will loosen the Front

Rotor Bearing so that it will drop out of the Front End Plate. Refer to

Dwg. TPD1323.

1. Secure the Inlet Bushing in a vise. Press in both tabs of the Inlet

Retainer Clip (27) and pull upward on the Housing (19). This

will allow the Inlet Bushing to come free from the Handle of the

Housing. Refer to Dwg. TPD1326.

2. Pull the Trigger (28) from the front of the Housing and remove

the Trigger O-ring (2A).

(Dwg. TPD1323)

4. Remove the Rear Rotor Bearing Retainer (6) from the rear of

the Rotor (5). The Rotor can now be removed from the Cylinder.

Remove the Vanes (4) from the Rotor if they need to be replaced.

(Dwg. TPD1324)

5. To remove the Rear Rotor Bearing, hold the Cylinder with the Rear

Rotor Bearing down and tap the Cylinder on a at, nonmetallic

surface such as a work bench. This will loosen the Rear Rotor

Bearing so that it will drop out of the Cylinder. Refer to Dwg.

TPD1324.

6. Working from the rear of the Housing, push out the Motor Gasket (7).

When removing the Motor Gasket, do not use a screwdriver or

any other sharp object which could damage the Gasket and/or

Housing.

Disassembly of the Throttle Mechanism

For ease of disassembly, we recommend using the Inlet Clip

Removal Tool (36). See Dwg. TPD1681.

(Dwg. TPD1681)

45481785_ed1 3

(Dwg. TPD1326)

3. With the Inlet Bushing still in the vise, remove the Tilt Valve Seat

Retainer (1G) and Tilt Valve Seat Support (1F). Use a hooked tool

with no sharp edges to remove the Tilt Valve Seat (1E) from the

Inlet Bushing. Refer to Dwg. TPD1327.

(Dwg. TPD1327)

4. Remove the Tilt Valve (1D) and Tilt Valve Spring (1C) if damaged.

5. Remove the Inlet Bushing Seal (1B) and Inlet Retainer Clip (27) if

damaged. Remove Washer (1A).

Do not remove the Inlet Bushing Screen (20A) from the Inlet

Bushing unless it is damaged. Clean the Inlet Bushing Screen by

using a suitable cleaning solution in a well ventilated area.

Disassembly of the Reverse Valve Mechanism

The Reverse Valve Assembly cannot be removed without rst

removing the Forward and Reverse Buttons (4A) and (4B).

Therefore, it is important that the procedure below be followed

exactly.

1. Notice the notches on either side of the partition. These notches

indicate the correct location for insertion of a thin-bladed

screwdriver used for removing the Forward and Reverse Buttons.

Insert the screwdriver between the partition and the Button

which is fully extended. Gently pry against the Button to

disengage the detent so that the Button can be removed. After

the Button is removed, reach inside the Housing and rotate the

Reverse Valve to extend the remaining Button. Repeat the above

procedure for the remaining Button. Refer to Dwg. TPD1328.

Page 4

4 45481785_ed1

REMOVAL OF

FORWARD/

REVERSE

BUTTONS

(Dwg. TPD1328)

REVERSE

VALVE

NOTICE

NOTICE

NOTICE

EARS

DOWEL

2. Insert thumb into the front of the Housing and push down on the

Reverse Valve so that it can be removed through the bottom of

the handle. Refer to Dwg. TPD1329.

Assembly

General Instructions

1. Whenever grasping a tool or part in a vise, always use leathercovered vise jaws to protect the surface of the part and help

prevent distortion. This is particularly true of threaded members

and housings.

Always use leather-covered vise jaws when clamping the handle

in a vise. Leather will conform to the shape of the handle and

allow the tool to be held securely. To prevent damage to the

exhaust diuser, never clamp only the bottom of the handle.

2. Always clean every part and wipe every part with a thin lm of oil

before installation.

Do not remove grease from the impact mechanism or Hammer

Case (15). If the impact mechanism has not been disassembled,

inject Ingersoll Rand No. 115-1LB Grease through the Hammer

Case Grease Fitting (17).

When disassembling and assembling the impact mechanism,

remove all grease from the impact mechanism and Hammer Case

and lubricate the impact mechanism and Hammer Case Bushing

(16) with Ingersoll Rand No. 105-1LB Grease or Ingersoll Rand

No. 105-8LB Grease.

3. Apply a lm of o-ring lubricant to all O-rings before nal

assembly.

Assembly of the Reverse Valve Mechanism

1. Install the Bottom Reverse Valve O-ring (3B) (color-coded blue)

and the Top Reverse Valve bring (3A) on the Reverse Valve (30).

2. Insert the Reverse Valve in the bottom of the handle making sure

that two ears on the Reverse Valve are facing downward. Refer to

Dwg. TPD1330.

(Dwg. TPD1329)

Do not try to remove the Reverse Valve by pushing upward. It

can only be removed by pushing it downward and out of the

bottom of the handle. If the Reverse Valve does not come free,

tap the bottom of the handle lightly with a rubber hammer until

it drops out.

3. Remove the Top Reverse Valve O-ring (3A) and the Bottom

Reverse Valve O-ring (3B) from the Reverse Valve.

(Dwg. TPD1330)

Use a wooden dowel to push the Reverse Valve up through

the handle until the top of the Reverse Valve is ush with or

slightly above the bottom of the motor bore in the Housing

(19). Refer to Dwg. TPD1331.

(Dwg. TPD1331)

Page 5

NOTICE

If the Reverse Valve is pushed up too far and becomes wedged,

FRONT OF

HOUSING

APPROX. 1/32”

REVERSE

VALVE

NOTICE

REVERSE

VALVE

FORWARD

BUTTON

REAR OF

HOUSING

TAB

REVERSE

VALVE

REVERSE

BUTTON

TAB

REAR OF

HOUSING

NOTICE

WARNING

WARNING

it will have to be pushed back down through the handle and

re-inserted from the bottom of the handle. The Reverse Valve

cannot be removed by pushing it up through the handle and

into the motor bore. If the Reverse Valve must be removed and

re-installed, make sure that the Top and Bottom Reverse Valve

O-rings have not been rolled o and are in their proper positions

on the Reverse Valve.

3. When the Reverse Valve has been installed, rotate the Reverse

Valve so that the tab on the Reverse Valve is at the rear of the

Housing. Refer to Dwg. TPD1332.

(Dwg. TPD1332)

If the orientation of the Reverse Valve is not correct (tab facing

the rear of the Housing), the Trigger (28) and the Forward and

Reverse Buttons (4A) and (4B) cannot be installed.

4. Install the Trigger O-ring (2A) on the Trigger. Insert the Trigger

Assembly in the front of the Housing.

5. Rotate the Reverse Valve in either direction until an ear comes up

against the Trigger.

6. Look through the Housing from the rear. If the tab on the Reverse

Valve has been rotated to the left, install the right Button in the

Housing. When one Button has been installed, push the Button

in. This will rotate the’ Reverse Valve so that the other Button can

be installed. Refer to Dwg. TPD1333.

(Dwg. TPD1334)

If the Forward/Reverse Buttons will not install easily, move the

Reverse Valve slightly higher in the handle to provide better

alignment with the Buttons.

7. After the Forward/Reverse Buttons have been installed, remove

the Trigger before proceeding with installation of the throttle

mechanism.

Assembly of Throttle Mechanism

1. Using an Inlet Bushing Screen Installation Tool, install the Inlet

Bushing Screen (20A), screened end rst, in the bottom (hex end)

of the Inlet Bushing (20). Insert the rounded end of the tool in the

cone formed by the screen and tap the end of the tool to secure

the rim of the screen in the Bushing. Refer to Dwg. TPD1473.

Inlet Bushing Screen Installation Tool

0

(Dwg. TPD1473)

2. Install the Washer (1A), Inlet Retainer Clip (27), Inlet Bushing Seal

(1B), Tilt Valve Spring (1C), Tilt Valve (1D) Tilt Valve Seat (1E) and

Tilt Valve Seat Support (1F).

The Tilt Valve Seat Retainer (1G) must be properly installed in the

groove in the Inlet Bushing (20). To check for correct installation

of the Retainer, insert a pin into one of the holes in the Retainer

and rotate the Retainer. A correctly installed Retainer will

(Dwg. TPD1333)

If the tab on the reverse Valve has been rotated to the right,

install the left Button. Refer to Dwg. TPD1334.

rotate freely but with some resistance in the groove of the Inlet

Bushing. An incorrectly installed Retainer will pop out of the

Inlet Bushing when the Retainer is rotated.

Do not use compressed air to check installation of the Tilt Valve

Seat Retainer or Inlet Bushing Screen unless the entire Inlet

Bushing Assembly is installed in the tool with the Hammer Case

installed and properly secured to the Motor Housing. Failure to

do so could result in injury.

Install the Tilt Valve Seat Retainer.

45481785_ed1 5

Page 6

6 45481785_ed1

NOTICE

When re-installing the Inlet Bushing Assembly (20), pull the

NOTICE

INSTALLATION

OF MOTOR

GASKET

NOTICE

TOP HAMMER

HALF--ROUND

NOTCH ON RIGHT

BOTTOM HAMMER

HALF--ROUND

NOTCH ON LEFT

NOTICE

Trigger (28) outward and make sure that the Reverse Button (4B)

is depressed before snapping the Inlet Bushing Assembly back

into the Housing.

3. Install the Inlet Bushing Assembly by pushing it into the hole in

the Housing until you see and hear the tabs on Inlet Retainer Clip

snap into place through the slots in Housing handle.

The Reverse Button (left) (4B) must be pushed in before the

Trigger can be installed. Otherwise, the Trigger will be damaged

during installation.

4. Install the Trigger by pushing it into the handle until a click is

heard indicating that it is properly engaged.

(Dwg. TPD1336)

Assembly of the Motor

When disassembling, assembling or pulling the Motor, we

recommend replacement of the Motor Gasket (7).

1. Install the Motor Gasket in the Housing making sure that the

grooves in the tab of the Motor Gasket t around ridge in the

Housing. Refer to Dwg. TPD1336.

2. Install the Rear Rotor Bearing (3) into the rear of the Cylinder (1).

3. Install the Rotor in the Cylinder and secure with the Rear Rotor

Bearing Retainer (6).

4. Install Vanes (4) in the slots in the Rotor (5).

5. Install the Front Rotor Bearing (3) into the Front End Plate (2).

Install the Front End Plate on the Cylinder by pressing on the

inner race of the front Rotor Bearing until the Bearing is seated on

the Rotor Shaft.

6. Install the Power Management Dial Seal (5A) on the Power

Management Dial (35) and install the Dial in the end of the

Cylinder.

7. Clean the Silencer (6A) using a suitable cleaning solution in a

well-ventilated area. Position the Silencer over the top of the

Cylinder and insert the Motor Assembly into the Housing (19),

Power Management Dial end rst.

Assembly of the Impact Mechanism

(Dwg. TPD1535)

1. Coat the Hammers (14) with a light lm of No. Ingersoll Rand

105-1LB Grease or Ingersoll Rand No. 105-8LB Grease.

2. Heavily coat the jaws of the Anvil (8) with Ingersoll Rand No.

105-1LB Grease or Ingersoll Rand No. 105-8LB Grease.

3. Replace the Hammers in the Hammer Frame (12) exactly as they

were when you marked them prior to disassembly.

If you are installing new Hammers or want to change the location

of the existing Hammers to utilize both impacting surfaces, slide

the Hammers in the Hammer Frame so that the half-round notch

on one Hammer is located on one side of the Frame and the

half-round notch on the other Hammer is located on the other

side of the Frame.

4. Replace the Hammer Pins (13).

5. Examine the base of the Anvil (8) and note its contour. While

looking down through the Hammer Frame, swing the top

Hammer to its full extreme one way or another until you can

match the contour of the Anvil. Enter the Anvil into the Hammer

Frame and through the rst Hammer. Swing the bottom Hammer

in the opposite direction from the top Hammer and maneuver

the Anvil slightly until it drops into the bottom Hammer. Refer to

Dwg. TPD1535.

Assembly of the Air Wrench

1. Position the Motor Housing (19) in leather-covered vise jaws with

the splined shaft of the Rotor in a horizontal position.

2. Place the assembled impact mechanism down onto the splined

hub of the Rotor.

3. Position the Hammer Case Gasket (18) against the face of the

Motor Housing.

Page 7

NOTICE

Be sure that the at on the bottom of the Hammer Case Gasket is

FRONT OF

HOUSING

GASKET

FLATS

installed in the corresponding at in the Housing. If the Hammer

Case Gasket is not installed correctly, the Air Wrench will not

function properly.

Refer to Dwg. TPD1335-1.

4. Apply a thin lm of Ingersoll Rand No. 105-1LB Grease or

Ingersoll Rand 105-8LB Grease on inside surface of the Hammer

Case Bushing (16), and place the Hammer Case (15) down over

the Anvil and against the Motor Housing.

(Dwg. TPD1335-1)

5. Install the Hammer Case Screws (11) and tighten them to 25 in-lb

(2.8 Nm) torque.

Troubleshooting Guide

Trouble Probable Cause Solution

Daily, inject 3 cc of Ingersoll Rand No. 50 Oil into the inlet and run the tool to

lubricate the motor.

Install proper air supply and connection. Refer to Dwg. 04581666 on Page 2 of Air

Impact Wrench Product Information Manual Form 04584686.

Using a clean, suitable, cleaning solution in a well ventilated area, clean the Inlet

Bushing Screen.

Examine Cylinder. Check outside and ends for wear or damage and inside for

scored or wavy bore. Replace Cylinder if any of these conditions exist. Replace

End Plates if they are scored.

Disassemble the Tool and clean in a clean, suitable, cleaning solution in a well

ventilated area. Assemble the Tool and inject 3 cc of the recommended oil into

Inlet and run Tool to lubricate internal parts.

Replace Reverse Valve. Refer to Assembly of the Reverse Valve Mechanism.

Refer to “Assembly of the Reverse Valve Mechanism”.

Disassemble motor and replace worn or broken parts and reassemble. Refer to

Assembly of the Motor.

Lubricate impact mechanism through Hammer Case Grease Fitting using the

recommended grease.

Remove Hammer Case Assembly and examine impact

mechanism parts. Replace any worn or broken parts.

Refer to Assembly of the Impact Mechanism.

Low power

Motor will not run

Tool will not impact

Dry Motor

Inadequate air supply

Dirty Inlet Bushing Screen

Worn or broken Vanes Replace a complete set of Vanes.

Worn or broken Cylinder

and/or scored End Plates

Dirty motor parts

Damaged Reverse Valve

Incorrect assembly of motor

Insucient lubricant in impact

mechanism

Broken or worn impact

mechanism parts

Impact mechanism not

assembled correctly

Related Documentation

For additional information refer to:

Air Impact Wrench Product Safety Information Manual Form 04580916.

Air Impact Wrench Product Information Manual Form 04584686.

Air Impact Wrench Parts List Manual Form 04584025.

Manuals can be downloaded from www.irtools.com.

45481785_ed1 7

Page 8

www.irtools.com

© 2007 Ingersoll Rand Company

Loading...

Loading...