Ingersoll-Rand 1875CXXXXXX User Manual

OPERATOR’S MANUAL 1875CXXXXXX

INCLUDING: SERVICE KITS, TROUBLESHOOTING, PARTS LIST,

DISASSEMBLY & REASSEMBLY.

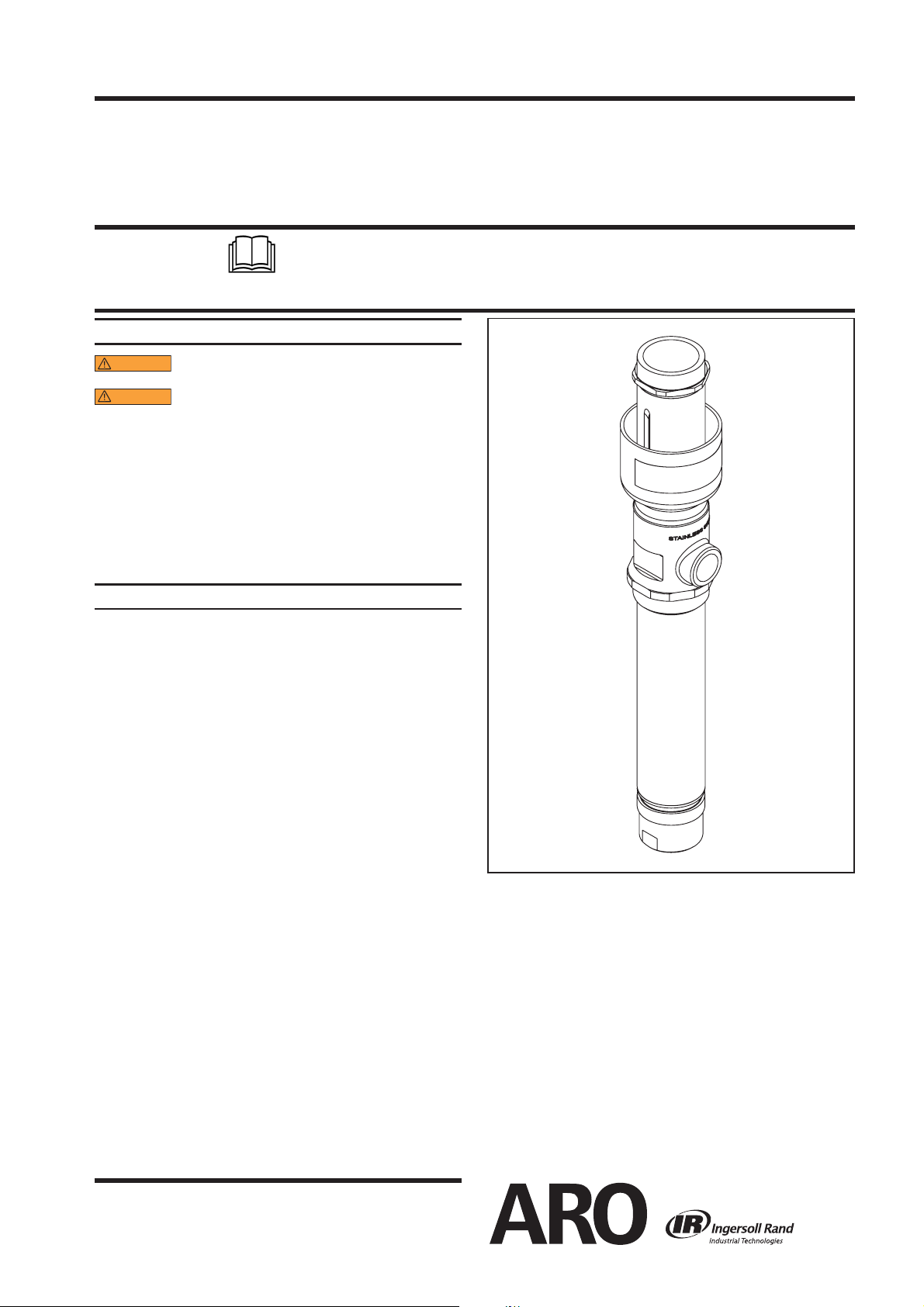

1875CXXXXXX

LOWER PUMP END

Also covers K1875CXXXXXX service kits

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

The original language of this manual is English.

GENERAL DESCRIPTION

RELEASED: 9-15-10

(REV. 01)

WARNING

SURE AS INDICATED ON PUMP MODEL PLATE.

WARNING

ADDITIONAL SAFETY PRECAUTIONS AND IMPORTANT INFORMATION.

This manual covers the lower pump section. It is one of four

documents which support an ARO pump. Replacement copies

of these forms are available upon request.

DO NOT EXCEED MAXIMUM OPERATING PRES-

REFER TO GENERAL INFORMATION SHEET FOR

Pump Model Operator’s Manual.

General Information for Air / Hydraulically Operated Piston

Pumps.

Lower Pump End Operator’s Manual.

Air / Hydraulic Motor Operator’s Manual.

MAINTENANCE

The air / hydraulic motor is completely separate from the lower

pump end. This helps to keep the motor from being contaminated

by the material being pumped. Periodically, flush entire pump

system with a solvent that is compatible with the material being

pumped.

Keep solvent cup filled with this compatible solvent. This will

keep the material from drying on the plunger, which would drag

through the packings, ruin them and eventually scour the plunger.

Provide a clean work surface to protect sensitive internal moving

parts from contamination from dirt and foreign matter during disassembly and reassembly.

Before reassembling, lubricate parts as required. When assembling

“O” rings, or parts adjacent to “O” rings, exercise care to prevent

damage to “O” rings and “O” ring groove surface.

Figure 1

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX (800) 892-6276

www.ingersollrandproducts.com

© 2010 CCN 46730388

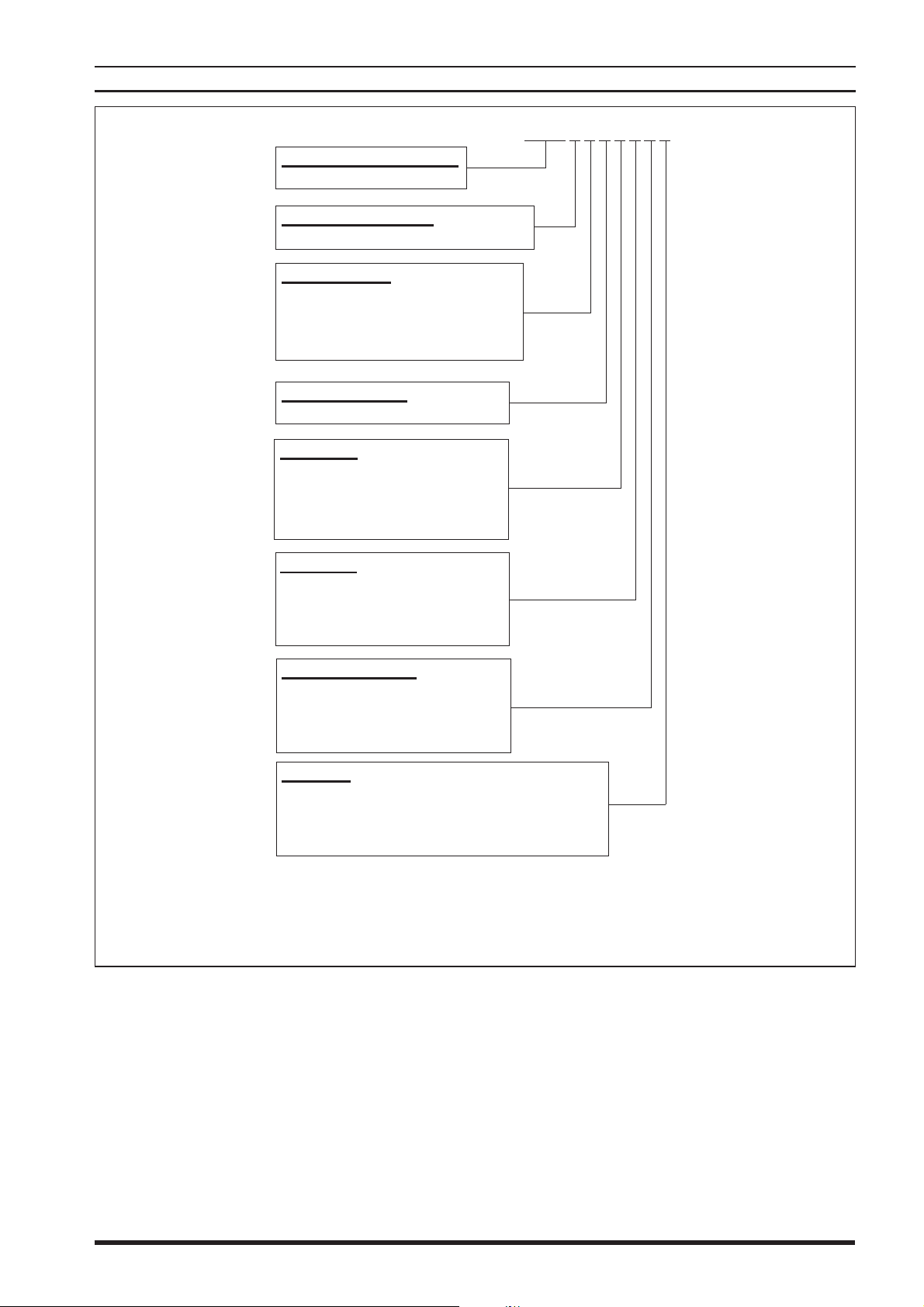

MODEL DESCRIPTION CHART

Inside Diameter of Pump Cylinder

1875 - 1.875” I.D.

Check Type / Wetted Material

C - Two Ball, 300 Series / CF8M Stainless Steel

Container Suitability

1 - Remote Mounting

5 - 55 gallon

8 - Remote Mounting with Optional Inlet

9 - 5 gallon with Optional Piston

Inlet / Outlet Tread Type

1 - SAE

Upper Packing

B - Buna “N”

E - EPR

F - UHMW-PE

S - Virgin PTFE

V - Viton

1875 C X X X X X X

Lower Packing

B - Buna “N”

E - EPR

F - UHMW-PE

S - Virgin PTFE

Spring Type / Solvent Cup

1 - No Spring, Standard Solvent Cup

2 - Coil Spring, Standard Solvent Cup

L - Coil Spring, No Solvent Cup

W - No Spring, No Solvent Cup

Plunger Type

2 - 316 Stainless Steel

9 - 304 Stainless Steel, Ceramic coated

E - 316 Stainless Steel Rod, Ceramic coated Tube

F - 304 Stainless Steel, Ceramic coated, Plain Tube

1875CXXXXXX (en) Page 2 of 4

Loading...

Loading...