Page 1

03539905

Form P7109

Edition 2

March, 1999

OPERATION AND MAINTENANCE MANUAL

FOR MODEL 1712B2/VW–1035

IMPACT WRENCH

Ingersoll–Rand is not responsible for customer modification of tools for applications on

which Ingersoll–Rand was not consulted.

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATING TOOL.

IT IS THE RESPONSIBILITY OF THE EMPLOYER TO PLACE THE INFORMATION

IN THIS MANUAL INTO THE HANDS OF THE OPERATOR.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

PLACING TOOL IN SERVICE

• Always operate, inspect and maintain this tool in

accordance with American National Standards

Institute Safety Code for Portable Air Tools

(ANSI B186.1).

• For safety, top performance, and maximum

durability of parts, operate this tool at 90 psig (6.2

bar/620 kPa) maximum air pressure at the inlet

with 3/4” (19 mm) inside diameter air supply hose.

• Always turn off the air supply and disconnect the

air supply hose before installing, removing or

adjusting any accessory on this tool, or before

performing any maintenance on this tool.

• Do not use damaged, frayed or deteriorated air

hoses and fittings.

• Be sure all hoses and fittings are the correct size

and are tightly secured. See Dwg. TPD905–1 for a

typical piping arrangement.

• Always use clean, dry air at 90 psig maximum air

pressure. Dust, corrosive fumes and/or excessive

moisture can ruin the motor of an air tool.

• Do not lubricate tools with flammable or volatile

liquids such as kerosene, diesel or jet fuel.

• Do not remove any labels. Replace any damaged

label.

USING THE TOOL

• Always wear eye protection when operating or

performing maintenance on this tool.

• Always wear hearing protection when operating

this tool.

• Keep hands, loose clothing and long hair away from

rotating end of tool.

• Note the position of the reversing lever before

operating the tool so as to be aware of the direction

of rotation when operating the throttle.

• Anticipate and be alert for sudden changes in

motion during start up and operation of any power

tool.

• Keep body stance balanced and firm. Do not

overreach when operating this tool. High reaction

torques can occur at or below the recommended air

pressure.

• Tool shaft may continue to rotate briefly after

throttle is released.

• Air powered tools can vibrate in use. Vibration,

repetitive motions or uncomfortable positions may

be harmful to your hands and arms. Stop using any

tool if discomfort, tingling feeling or pain occurs.

Seek medical advice before resuming use.

• Use accessories recommended by Ingersoll–Rand.

• Use only impact sockets and accessories. Do not use

hand (chrome) sockets or accessories.

• Impact wrenches are not torque wrenches.

Connections requiring specific torque must be

checked with a torque meter after fitting with an

impact wrench.

• This tool is not designed for working in explosive

atmospheres.

• This tool is not insulated against electric shock.

The use of other than genuine Ingersoll–Rand replacement parts may result in safety hazards, decreased tool

performance, and increased maintenance, and may invalidate all warranties.

Repairs should be made only by authorized trained personnel. Consult your nearest Ingersoll–Rand Authorized

Servicenter.

Refer All Communications to the Nearest

Ingersoll–Rand Office or Distributor.

Ingersoll–Rand Company 1999

Printed in U.S.A.

Page 2

WARNING LABEL IDENTIFICATION

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

WARNING

Always wear eye protection

when operating or performing maintenance on this

tool.

WARNING

Air powered tools can vibrate

in use. Vibration, repetitive

motions or uncomfortable positions may be harmful to your

hands and arms. Stop using

any tool if discomfort, tingling

feeling or pain occurs. Seek

medical advice before resuming use.

90 psig

(6.2bar/620kPa)

WARNING

Keep body stance balanced

and firm. Do not overreach

when operating this tool.

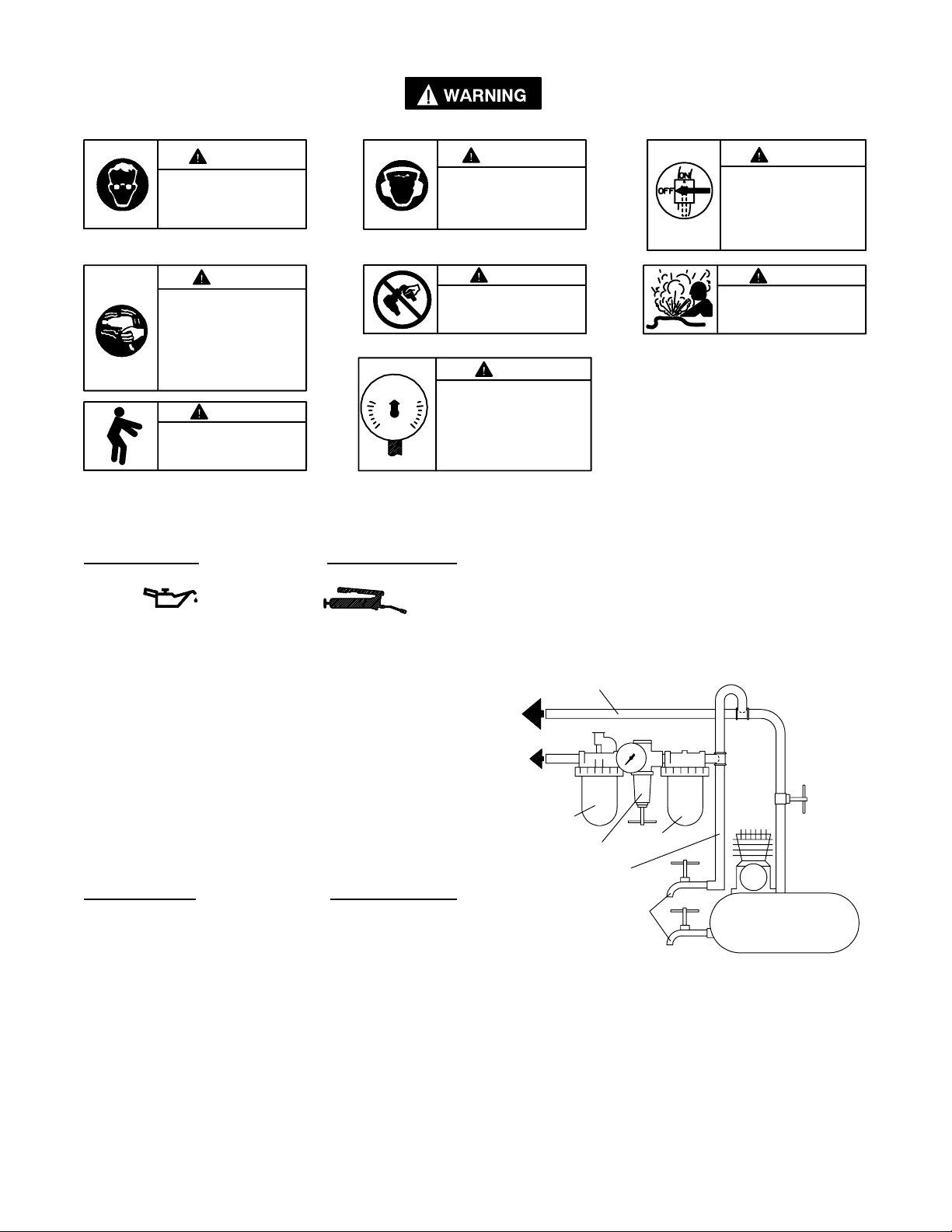

PLACING TOOL IN SERVICE

LUBRICATION

Ingersoll–Rand No. 50 Ingersoll–Rand No. 100

Always use an air line lubricator with this tool.

We recommend the following Filter–Lubricator–Regulator

Unit:

For USA – No. C31–06–G00

WARNING

Always wear hearing

protection when operating

this tool.

WARNING

Do not carry the tool by

the hose.

WARNING

Operate at 90 psig (6.2 bar/

620 kPa) Maximum air pressure.

An air line filter can greatly increase the life of an air tool.

The filter removes dust and moisture. Be sure all hoses and

fittings are the correct size and are tightly secured. See

Dwg. TPD905–1 for a typical piping arrangement.

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

TO

AIR

SYSTEM

TO

AIR

TOOL

WARNING

Always turn off the air supply and disconnect the air

supply hose before installing, removing or adjusting

any accessory on this tool,

or before performing any

maintenance on this tool.

WARNING

Do not use damaged, frayed

or deteriorated air hoses

and fittings.

After each eight hours of operation, or as experience

indicates, inject about 1–1/2 cc of Ingersoll–Rand

No. 50 Oil into the air inlet.

INSTALLATION

Air Supply and Connections

Always use clean dry air. Dust, corrosive fumes and/or

excessive moisture can ruin the motor of an air tool.

LUBRICATOR

REGULATOR

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY

2

FILTER

COMPRESSOR

(Dwg. TPD905–1)

Page 3

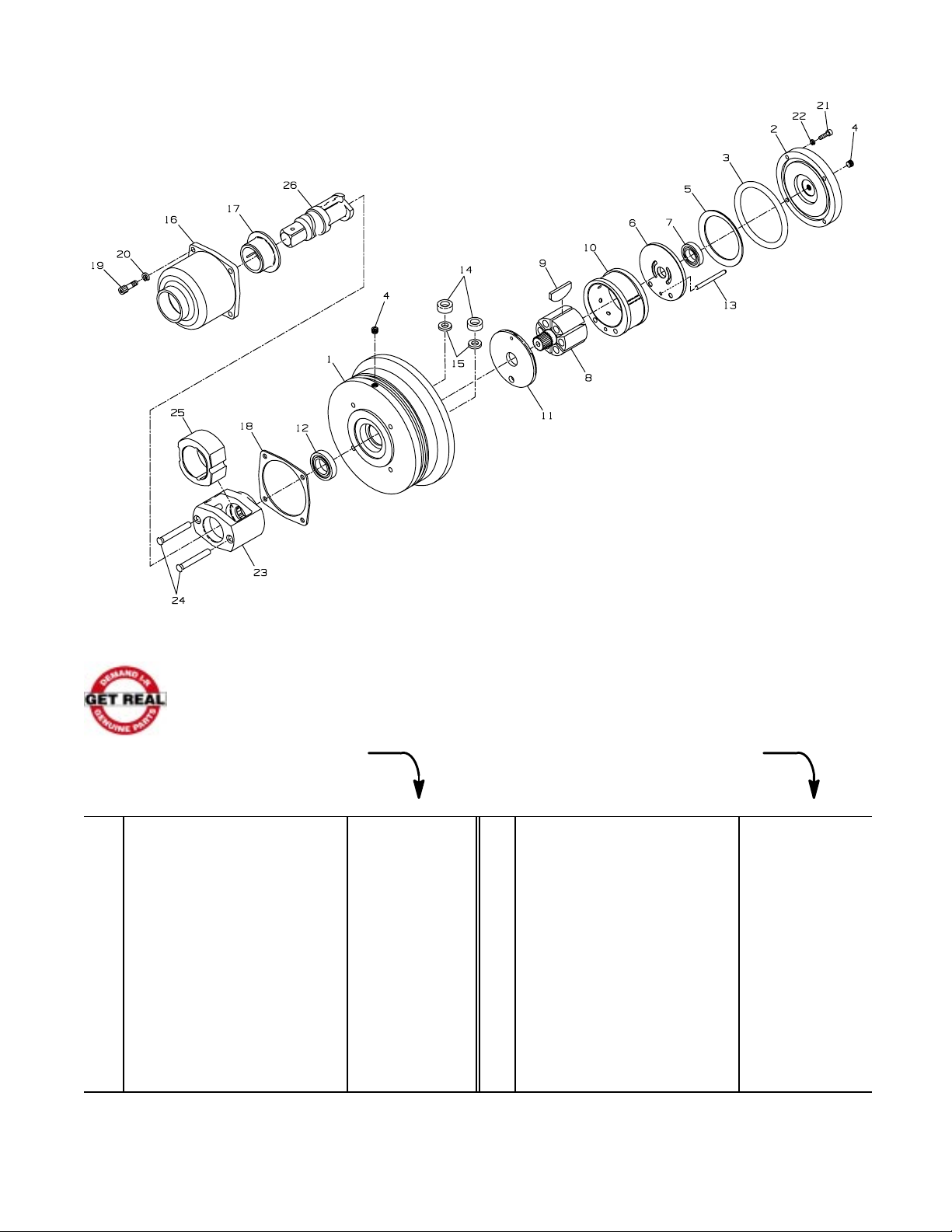

MAINTENANCE SECTION

(Dwg. TPA1387)

PART NUMBER FOR ORDERING PART NUMBER FOR ORDERING

1 Motor Housing . . . . . . . . . . . . . . VW–1036 15 Gasket Support (2) . . . . . . . . . . . 2940–200

2 Back Cap . . . . . . . . . . . . . . . . . . VW–1037 16 Hammer Case Assembly . . . . . . VW–1065

3 Seal . . . . . . . . . . . . . . . . . . . . . . . 588–216 17 Hammer Case Bushing . . . . . 2934–641

4 Plug (2) . . . . . . . . . . . . . . . . . . . . R2–227 * Hammer Case Label . . . . . . . WARNING–2–99

5 Clamp Washer . . . . . . . . . . . . . . 2934–207 18 Hammer Case Gasket . . . . . . . . . 2934–36

6 Rear End Plate . . . . . . . . . . . . . . 2934–12 19 Hammer Case Cap Screw (4) . . . 834–638

7 Rear Rotor Bearing . . . . . . . . . . 508–97 20 Hammer Case Lock Washer (4) . 34U–58

8 Rotor . . . . . . . . . . . . . . . . . . . . . VW–1043 21 Back Cap Cap Screw (4) . . . . . . P225–146

9 Vane Packet (set of 6) . . . . . . . . . 2934–42–6 22 Back Cap Lock Washer (4) . . . . VSM–1453

10 Cylinder . . . . . . . . . . . . . . . . . . . VW–1042 23 Hammer Frame Assembly . . . . . 2934–704

11 Front End Plate . . . . . . . . . . . . . . 2934–11 24 Hammer Pin (2) . . . . . . . . . . 2934–704

12 Front Rotor Bearing . . . . . . . . . . 810–97 25 Hammer . . . . . . . . . . . . . . . . . . . 1712–724

13 Cylinder Dowel . . . . . . . . . . . . . 2934–98 26 1” Square Drive Anvil . . . . . . . . 1712–726

14 Air Port Gasket (2) . . . . . . . . . . . R44H–210A

* Not illustrated.

3

Page 4

MAINTENANCE SECTION

Disassembly of Impact Mechanism

Always wear eye protection when operating or performing maintenance on this tool.

Always turn off the air supply and disconnect the air

supply hose before installing, r emoving or adjusting a n y

accessory on this tool, or before performing any maintenance on this tool.

LUBRICATION

Each time a Series 1712B2/VW–1035 Impactool is disassembled for maintenance and repair or replacement of

parts, lubricate the tool as follows:

1. Work approximately 10 cc of Ingersoll–Rand No. 100

Grease into the impact mechanism. Coat the Anvil

(26) lightly with grease. Also coat the inside of the

Hammer Case Bushing (17) with grease.

2. Use Ingersoll–Rand No. 50 Oil for lubricating the

motor. Inject approximately 3 cc of oil into the air

inlet before attaching the air hose.

DISASSEMBLY

General Instructions

1. Do not disassemble the tool any further than necessary to replace or repair damaged parts.

2. Whenever grasping a tool or part in a vise, always use

leather–covered or copper–covered vise jaws to protect the surface of the part and help prevent distortion. This is particularly true of threaded members

and housings.

3. Do not remove any part which is a press fit in or on a

subassembly unless the removal of that part is necessary for repair or replacement.

4. Do not disassemble the tool unless you have a complete set of new gaskets and O–rings for replacement.

Disassembly of the Tool

1. Grasp the tool in leather–covered or copper–covered

vise jaws with the square drive upward.

2. Using a hex wrench, unscrew and remove the four

Hammer Case Cap Screws (19), and Hammer Case

Cap Screw Lock Washers (20).

3. While lightly tapping the end of the Anvil (26) with a

plastic hammer, lift off the Hammer Case

Assembly (16).

4. Remove the Hammer Case Gasket (18).

1. Remove the Anvil by rotating it as it is lifted out of

the Hammer Frame Assembly (23)..

2. Lift the Hammer Frame Assembly off the rotor shaft.

3. Push the two Hammer Pins (24) out of the Hammer

Frame and slide the Hammer (25) out of the Frame.

Disassembly of the Motor

1. Lightly clamp the Motor Housing in leather–covered

or copper–covered vise jaws with the Back Cap (2)

upward.

2. Using a hex wrench, unscrew and remove the Cap

Screws (21) and Lock Washers (22).

3. Lift the Back Cap off the Housing. Remove the Seal

(3) from the inside of the Back Cap.

4. Remove the Clamp Washer (5) from the Housing.

5. Remove the assembled motor from the vise jaws and

using a plastic hammer, tap the splined shaft of the

Rotor (8) to dislodge the Rotor from the Front Rotor

Bearing (12).

6. Lift the Motor Housing off the Rotor, Rear End Plate

(6) and Rear Rotor Bearing (7). The Rear End Plate

and Rear Rotor Bearing will remain together as a

unit.

7. Remove the Vanes (9) from the Rotor.

8. Pull the Rear End Plate off the Rotor.

9. Open a set of vise jaws wide enough to clear the hub

of the Rear End Plate and sharply rap the hub end of

the End Plate on the top of the jaws to dislodge the

Rear Rotor Bearing.

10. Remove the Cylinder Dowel (13) and lay the Motor

Housing on top of the vise jaws with the Front Rotor

Bearing (12) downward between the jaws. Using a

soft drift pin, tap the Bearing out of the Housing.

11. To remove the Cylinder (10) and Front End Plate

(11), thread four 1/4”–20 thread socket head cap

screws that are at least 3” (75 mm) long into the Back

Cap end of the Housing. Grasping the Housing with

the installed screws downward, sharply strike the

heads of the screws on a sturdy table to dislodge the

Cylinder. The Cylinder should drop out of the Housing after a few impacts. If it does not, proceed as follows:

The following procedure requires the use of heat.

Take all precautions necessary to prevent being

burned.

4

Page 5

MAINTENANCE SECTION

a. Carefully heat alternate sides of the Housing until

it is very warm.

b. Using thick, heavy gloves to avoid being

burned, grasp the Housing and repeat the attempt

to dislodge the Cylinder.

12. Remove the two Air Port Gaskets (14) and Gasket

supports (15) from the Housing.

ASSEMBLY

General Instructions

1. Always press on the inner ring of a ball–type bearing

when installing the bearing on a shaft.

2. Always press on the outer ring of a ball–type bearing

when pressing the bearing into a bearing recess.

3. Whenever grasping a tool or part in a vise, always use

leather–covered or copper–covered vise jaws. Take

extra care with threaded members and housings.

4. Always clean every part and wipe every part with a

thin film of oil before installation.

5. Apply a film of O–ring lubricant to all O–rings before

final assembly.

Assembly of the Motor

1. Press the Front Rotor Bearing (12) into the

recess at the hammer case end of the Motor Housing

(1).

2. Slide the Front End Plate (11), bronze face first, over

the spline hub of the Rotor (8).

3. Stand the assembled Rotor and End Plate upright,

grasping the rotor spline with leather–covered or

copper–covered vise jaws.

4. Place a Vane (9) in each slot in the Rotor.

5. Slide the Cylinder (10) down over the Rotor, aligning

the holes in the Cylinder with those in the Front End

Plate.

6. Using a sleeve that will contact only the outer ring of

the Rear Rotor Bearing (7), press the Bearing into the

Rear End Plate (6).

7. Using a sleeve that will contact only the inner ring of

the Rear Rotor Bearing, press the assembled Bearing

and End Plate onto the short hub of the Rotor.

Excessive clamping pressure will distort the Motor

Housing and make motor installation extremely

difficult. Do not insert the hammer case end of the

Motor Housing more than 1” (25 mm) into the vise

jaws.

8. Lightly clamp the Motor Housing in leather–covered

or copper–covered vise jaws with the motor bore

upward.

9. Lubricate and install a new fiber Gasket Support

(15) into each of the air ports inside the Motor Housing.

10. Install an Air Port Gasket (14) into each opening

against the Retainer with the flat end of the Gasket

away from the Retainer.

11. Using an assembly rod that is approximately 3/16”

diameter x 8” long (5 mm diameter x 203 mm long),

insert the rod through cylinder dowel holes in the End

Plates and Cylinder to align the components. Allow

the rod to protrude through the Front End Plate far

enough to enter the dowel hole in the bottom of the

motor bore.

12. Insert the rod into the motor housing dowel hole and

slide the assembled motor along the rod into the Motor Housing. The assembly will be at the proper depth

when the Rear End Plate is slightly below the face of

the Motor Housing. Remove the assembly rod and

insert the Cylinder Dowel (13) into the assembly.

13. Place the Motor Clamp Washer (5), concave side

first, over the hub of the Rear End Plate so that the

outer rim of the Washer contacts the End Plate.

14. Install the Seal (3) on the inside of the Back Cap.

15. Install Back Cap on Housing and secure with Cap

Screws (21) and Lock Washers (22). Tighten to

5–7 ft–lb (6.8–9.5 Nm) torque.

16. If Plugs (4) were removed or are being replaced,

apply pipe thread sealant and tighten to 10–20 ft–lb

(13.5–27 Nm) torque.

5

Page 6

MAINTENANCE SECTION

Assembly of the Impact Mechanism

1. Coat the Hammer (25) with Ingersoll–Rand No. 100

Grease.

2. Position the Hammer inside the Hammer Frame (23)

and install the two Hammer Pins (24).

3. Install the Anvil (26) through the Frame and

Hammer until it bottoms on the lower part of the

Frame.

4. Set the assembled hammer mechanism onto the rotor

shaft spline.

5. Place the Hammer Case Gasket (18) over the

mechanism against the face of the Motor Housing.

6. Grease the Anvil and top of the Hammer Frame with

Ingersoll–Rand No. 100 Grease.

TROUBLESHOOTING GUIDE

Trouble Probable Cause Solution

Low power Worn or broken Vanes Replace complete set of Vanes.

Worn or broken Cylinder and/or

scored End Plates

Dirty motor parts Disassemble tool and clean all parts with a

Motor will not run Incorrect assembly of motor Disassemble motor and replace worn or broken

Insufficient lubricant in the

impact mechanism

Tool will not impact Broken or worn impact

mechanism parts

Impact mechanism not assembled

correctly

Assembly of the Tool

1. Place the Hammer Case Assembly (16) over the

mechanism assembly against the Gasket. Make

certain the Hammer Case Label is at the top of the

tool.

2. Install the Hammer Case Cap Screws (19) and Lock

Washers (20) and using an alternating pattern,

tighten the Cap Screws to 20–25 ft–lb (27–34 Nm)

torque.

Examine Cylinder and replace it if it is worn or

broken or if bore is scored or wavy. Replace End

Plates if they are scored.

suitable cleaning solution. Assemble the tool and

inject 3 cc of recommended oil into Inlet and run

tool to lubricate internal parts.

parts and reassemble as instructed.

Remove Hammer Case Assembly and lubricate

impact mechanism.

Remove Hammer Case and examine impact

mechanism parts. Replace any worn or broken

parts.

Refer to Assembly of the Impact Mechanism.

SAVE THESE INSTRUCTIONS. DO NOT DESTROY.

6

Page 7

7

Loading...

Loading...