Page 1

Air Grinder, Die Grinders and Sanders CA Angle Series

Part s Information

16574014

Edition 1

June 2006

Save These Instructions

Page 2

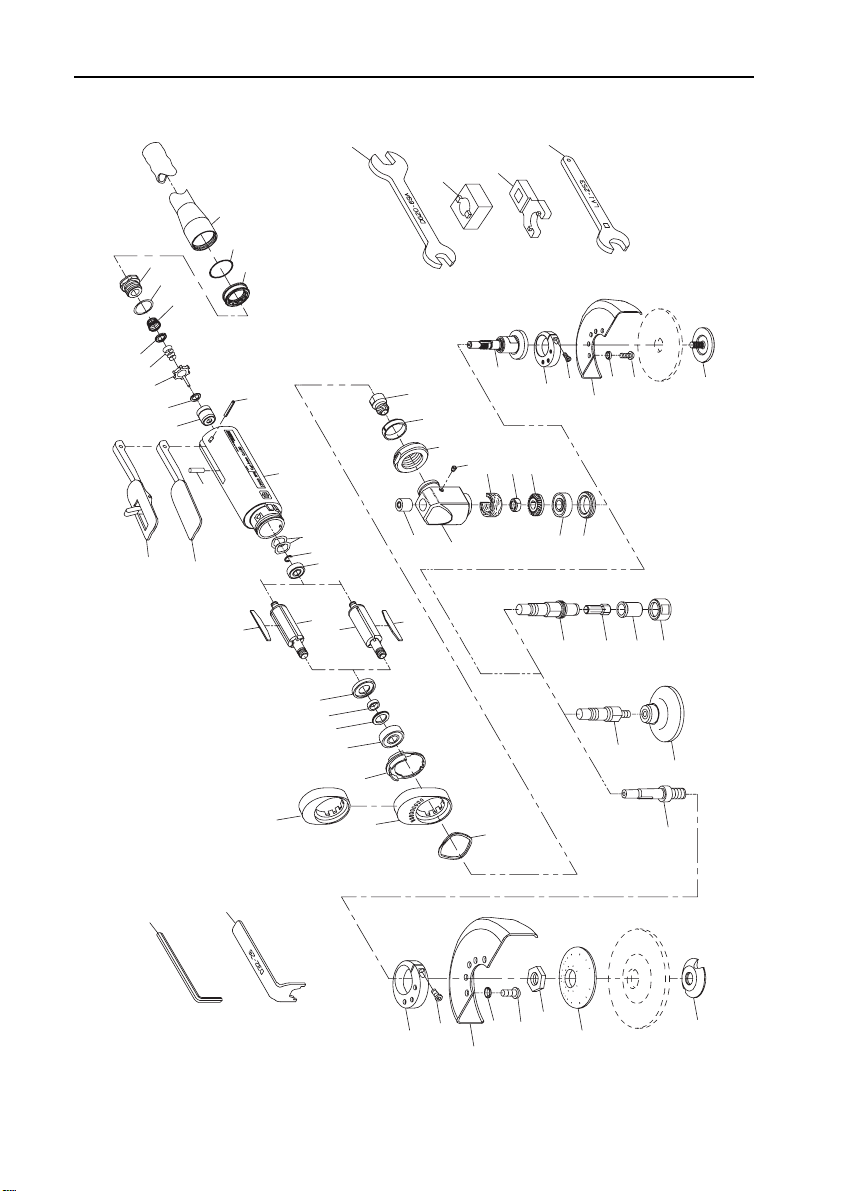

CA Angle Air Grinder, Die Grinder and Sander Exploded Diagram

46

31

28

21

27

ENDING IN G4,

G4C OR G4L

FOR MODELS

47

42

41

29

30

31

ENDING IN S4,

S4C OR S4L

36

37

35

32

33

31

39

34

43

44

46

52

1

3

4D

4C

4B

4A

4

6A

51

50

2

FOR MODELS

ENDING IN H63

H63C OR H63L

7

8

6

5

10

11

CA120

13

9

CA200

12

12

14

15

16

17

21

23

24

25

26

22

13

18

FOR MODELS

19A

48

49

19

41

20

36

42

35

FOR MODELS

ENDING IN P63,

P63C OR P63L

40

37

38

31

39

(Dwg. TPA1268-6)

2 16574014_ed1

Page 3

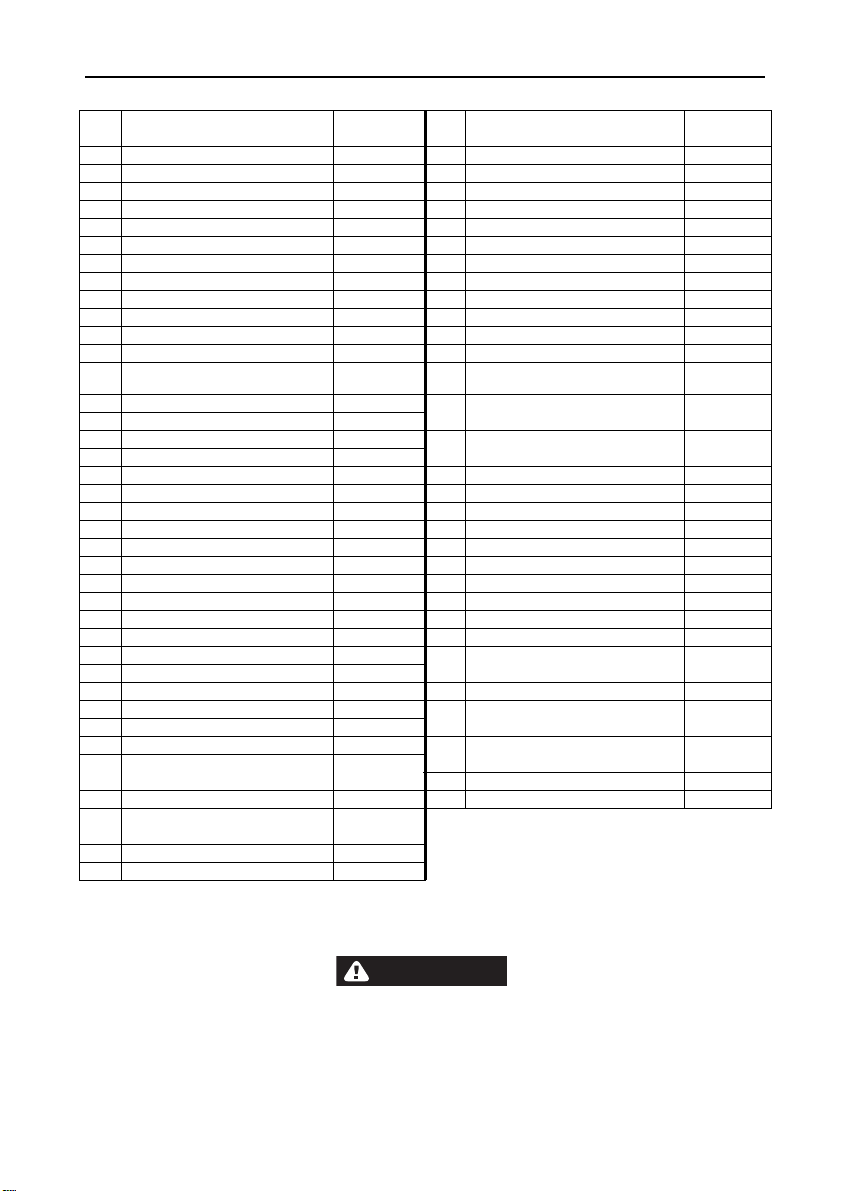

CA Angle Air Grinder, Die Grinder and Sander Parts List

Item Part Description Part Number Item Part Description Part

Common parts for ALL CA Grinders 22 Angle Housing Assembly LA1-A550S

1 Inlet Assembly LG1-A465A 23 Clamp Spacer LA1-46

2 Inlet Screen R1602-61 24 Clamp Nut LG1-27

• 3 Inlet Seal 85H-167 25 Grease Fitting D0F9-879

Throttle Valve Cartridge Kit LG1-K300 26 Upper Arbor Bearing AG210-693

4 Throttle Valve Cartridge Case LG1-300A ¤ 27 Wick

4A Throttle Val ve S eat LG1-303 for CA120 LA1-560

4B Throttle Val ve AG210-302 for CA200 LA1-561

4C Throttle Valve Spring 7L-51 28 Bevel Gear Nut AG210-578A

4D Throttle Valve Spring Seat LG1-592 29 Lower Arbor Bearing AG210-24

5 Motor Housing LG1-40 30 Arbor Bearing Cap AG210-531

6 Throttle Lever LG1-273 31 Arbor

6A Locking Throttle Lever Assembly

(for models ending in L, C, ML or MC)

* Lever Lock LG1-402 for all models ending in

* Lock Spring LG1-405

* Lock Pin 5UT-757 for all models ending in

7 Throttle Lever Pin 61H-120

8 Throttle Valve Plunger LG1-191 H63, H63C or H63L LA1-103-1

9 Rear Rotor Bearing DG230-22 * Warning Label

• 10 Rear Rotor Bearing Spacer (2) DG20-278 for models ending in P63-EU EU-63--99

• 11 Rear Rotor Bearing Retainer LG1-118 for all other models ending in-EU EU-99

12 Rotor for all other models LG1-99

for CA120 (5 vane slots) LG1-53-5 * Nameplate

• 13 Vane Packet (set of 5 Vanes) LG1-42-5 for all other CA120 models LA112-301

• 16 Front Seal Cup LG1-32 Additional parts for all collet

# 19A Low Profile Concentric Flange

* Not illustrated.

• To keep downtime to a minimum, it is desirable to have on hand certain repair parts. We recommend that you stock one

(pair or set) of each part indicated by a bullet (•) for every four tools in service.

¤ The LA1-A550S Angle Housing Assembly is furnished with two Wicks. Use Wick (LA1-561) with the notch on CA200 models.

for CA200 (3 vane slots) LG1-53-3 for CA120 models ending in-EU LA112-EU-301

14 Front End Plate LG1-11 for CA200 models ending in-EU LA120-EU-301

15 Front End Plate Spacer DG10-65-5 for all other CA200 models LA120- 301

17 Front Rotor Bearing LG1-24

18 Flow Ring 32 Collet

for CA120 (12000 rpm) (brown) LG1-103-1 for models ending in-EU DG110-700for CA200 (20000 rpm) (red) LG1-103-3 6mm

19 High Profile Flange LG1-23 for all other models DG110-700-

(for all models ending in C)

20 Flange Clamp LG1-29 34 Collet Nut AG210-699A

21 Bevel Pinion and Bevel Gear

(sold only as a matched set)

for CA120 LA1-A552-2.0S

for CA200 LA1-A552-1.5A

LG1-A400 for all models ending in

LG1R-23 G4

G4, G4C or G4L

S4, S4C or S4L

P63, P63C or P63L

models

33 Nosepiece AG210-698A

Number

AG210-4-G4

AG210-4-W2

LA1-6

WARNING

# Always install a Locking Throttle Lever Assembly (6A) on a tool with a Low Profile Concentric Flange (19A). Do not

equip a tool with a standard non-locking Throttle Lever (6) and Low Profile Concentric Flange. This can allow the tool to

continue to run if dropped or set down.

16574014_ed1 3

Page 4

Item Part Description Part Number Item Part Description Part

Additional parts for all

models ending in P63 or H63

35 Wheel Guard AG20-106-3 Ø Piped Away Exhaust Kit LG1-K284

36 Guard Lock Washer (3) R2-320 + 50 Exhaust Hose Adapter LG1-284

37 Guard Mounting Screws (3) LA1-667 + 51 Exhaust Hose Retainer LG1-67

38 Wheel Flange (for P63) R0A2D61-337 + 52 Exhaust Hose 3RL-284

39 Flange Nut * Bur Kit LG1-K1

for P63 AG21-337A-3 * 2” Abrasive Pad Kit LG1-K2

for H63 LA1-388 * 3” Abrasive Pad Kit

40 Flange Spacer (for P63) LA2-111

41 Guard Adapter Assembly LA1-A710 * Shroud Kit (for collet models only) LA1-K980

42 Guard Pinch Bolt 804-634 * No. 10 Oil (4 oz. bottle) 10Z4

Additional parts for

all models ending in S4

43 Sanding Pad

(standard on models ending

in S4M, S4MC or S4ML; optional on

models ending in S4, S4C or S4L)

for CA120 (3” diameter) 3-PAD

for CA200 (2” diameter) 2-PAD

Accessories for CA models

44 Collet Body Wrench/Collet Nut Wrench

(7/16” x 11/16” ) (included with all

models ending in G4, G4C or G4L)

46 Arbor Bearing Cap Wrench

47 Clamp Nut Wrench

48 Arbor Wrench (3/16” hex)

49 Wheel Nut Wrench (included with all

* Not illustrated.

Ø When ordering a Piped-Away Ex haust Kit, make certain the wrench hex on the Inlet Assembly of your tool is threaded. If it is

NOT threaded, order a new Inlet Assembly (Part No. LG1-A465A).

+ Standard equipment on models ending in M, MC or ML and ALL Front Exhaust models; optio nal equipment on all other models.

for models ending in S4, S4C

or S4L

for models ending in H63 LA1-29

(included with all models)

(included with all

models ending in P63, P63C or P 63L)

models ending in P63, P63C or P 63L)

DG20-69A

AG210-29

LA2-253

AG220-340

D32-26

* Variable Speed Control Assembly

(with piped away exhaust)

(for CA120 models only)

* No. 63 Oil (4 oz. bottle) 63Z4

* No. 67 Grease (1 lb. can) 67-1LB

* No. 77 Grease (1 lb. can) 77-1LB

* Shroud Kit (for non- col let mo del s) LA1-K975

Number

LG1-A1015

LG1-K3

Parts and Maintenance

When the life of the tool has expired, it is recommended that the tool be disassembled, degreased and parts be separated by

material so that they can be recycled.

Tool repair and maintenance should only be carried out by an authorized Service Center.

Refer all communications to the nearest Ingersoll Rand Office or Distributor.

Related Documentation

For additional information refer to:

Product Safety Information Manuals 04584959, 04580387 and 04580288.

Product Information Manuals 16576282, 16576308 and 80221096.

Product Maintenance Information Manual 16575060.

Manuals can be downloaded from www.irtools.com.

4 16574014_ed1

Page 5

Notes

16574014_ed1 5

Page 6

Notes

6 16574014_ed1

Page 7

Notes

16574014_ed1 7

Page 8

www.irtools.com

© 2006 Ingersoll Rand Company

Loading...

Loading...