Ingersoll-Rand 1100, 1200, 1300, 1000, 1600 Operator's Manual

...

NIRVANA CYCLING REFRIGERATED DRYER

MODELS 1000-1600

OPERATORS MANUAL

C.C.N. : 80442791

DATE : DECEMBER 2006

REV. : A

Ensure that the operator reads and understands the

decals and consults the manuals before maintenance

or operation.

Ensure that the Operation and Maintenance manual is

not removed permanently from the machine.

Ensure that maintenance personnel are adequately

trained, competent and have read the Maintenance

Manuals.

a

1

Nirvana Cycling Refrigerated Dryer Models 1000-1600

http://air.irco.com

CONTENTS PAGE

1.0 CONTENTS 1

2.0 INTRODUCTION 2

3.0 WARRANTY 2

4.0 REFRIGERATED DRYER

NOMENCLATURE 2

5.0 RECEIVING AND INSPECTION 3

5.1 INSPECTIONS

5.2 UNPACKING AND HANDLING

6.0 SAFETY AND OPERATION

PRECAUTIONS 3

7.0 PRINCIPLES OF OPERATION 5

7.1 INTRODUCTION

7.2 AIR SYSTEM

7.3 MOISTURE REMOVAL SYSTEM

7.4 REFRIGERATION SYSTEM

7.5 THERMAL MASS CIRCULATING

SYSTEM

7.6 CONTROLS

7.6.1 BASIC USER INTERFACE

7.6.2 DISPLAY PARAMETERS

7.6.3 DRYER SET POINTS

AND ALARMS

7.6.4 ADJUSTING SET POINTS

7.6.5 ALARMS AND

THEIR FUNCTIONS

7.6.6 START MODES

7.6.6.1 Manual Mode

7.6.6.2 Auto Restart Mode

7.6.6.3 Remote Automatic Mode

CONTENTS PAGE

8.0 INSTALLATION AND

INITIAL START-UP 9

8.1 LOCATION AND MOUNTING

8.2 PIPING AND VALVES

8.3 FILTRATION

8.4 ELECTRICAL CONNECTION

8.5 INITIAL START-UP

8.5.1 START- UP SEQUENCE

9.0 SCHEDULED MAINTENANCE 12

9.1 INTRODUCTION

9.2 REFRIGERANT CONDENSER

9.3 CONDENSATE DISCHARGE

SYSTEM

9.4 PREFILTERS AND

AFTERFILTERS

9.4.1 THREADED FILTERS

9.4.2 FLANGED FILTERS

10.0 TECHNICIAN MODE 16

11.0 TROUBLESHOOTING 18

11.1 INTRODUCTION

11.2 PROBLEM / ACTION GUIDE

12.0 WIRING DIAGRAMS 20

13.0 GENERAL ARRANGEMENT 21

14.0 REPLACEMENT PARTS 22

15.0 ENGINEERING

SPECIFICATIONS 23

CONTENTS

The Ingersoll Rand Nirvana Cycling refrigerated air dryer removes

moisture, oil vapor, and other contaminants from compressed air. These

contaminants are detrimental to pneumatically operated appliances,

controls, instruments, machinery and tools. This is accomplished by

cooling the air with a refrigeration unit to a temperature at which

moisture in the air is condensed and separated from the airstream. The

temperature the air is cooled to, normally between 36 and 40°F, is

known as dew point. This dryer can be easily installed into various

2

Nirvana Cycling Refrigerated Dryer Models 1000-1600

http://air.irco.com

pneumatic systems in which dry air is required or desired. Please refer

to Principles of Operation for complete operating details.

• For warning label information with French translations, refer to pages

5 and 6.

• Pur obtenir l’informatione des etiquettes dangereuses avec la

traductione en francais, s’il vous plait consul ter les pages 5 and 6.

The Company warrants that the equipment manufactured by it and

delivered hereunder will be free of defects in material and workmanship

for a period of twelve months from the date of placing the Equipment in

operation or eighteen months from the date of shipment from the factory,

whichever shall first occur. The Purchaser shall be obligated to promptly

report any failure to conform to this warranty, in writing to the Company

in said period, whereupon the Company shall, at its option, correct such

nonconformity, by suitable repair to such equipment or, furnish a

replacement part F.O.B. point of shipment, provided the Purchaser has

stored, installed, maintained and operated such Equipment in

accordance with good industry practices and has complied with specific

recommendations of the Company. Accessories or equipment furnished

by the Company, but manufactured by others, shall carry whatever

warranty the manufactures have conveyed to the Company and which

can be passed on to the Purchaser. The Company shall not be liable for

any repairs, replacements, or adjustments to the Equipment or any costs

of labor performed by the Purchaser or others without Company's prior

written approval.

The effects of corrosion, erosion and normal wear and tear are

specifically excluded. Performance warranties are limited to those

specifically stated within the Company's proposal. Unless responsibility

for meeting such performance warranties are limited to specified tests,

the Company's obligation shall be to correct in the manner and for the

period of time provided above.

THE COMAPANY MAKES NO OTHER WARRANTY OR

REPRESENTATION OF ANY KIND WHATSOEVER, EXPRESSED OR

IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE HERBY DISCLAIMED.

Correction by the Company of nonconformities whether patent or latent,

in the manner and for the period of time provided above, shall constitute

fulfillment of all liabilities of the Company for such nonconformities

whether based on contract, warranty negligence, indemnity, strict liability

or otherwise with respect to or arising out of such Equipment.

The Purchaser shall not operate Equipment which is considered to be

defective, without first notifying the Company in writing of its intention to

do so. Any such use of Equipment will be at Purchaser's sole risk and

liability.

Note that this is Ingersoll Rand standard warranty. Any warranty in force

at the time of purchase of the equipment or negotiated as part of the

purchase order may take precedence over this warranty.

2.0 INTRODUCTION

3.0 WARRANTY

4.0 REFRIGERATED DRYER NOMENCLATURE

NOMINAL*

FLOW CONDENSER

PREFIX (SCFM) TYPE RATING POWER

NVC 1000-1600 A = AIR (BLANK) = NEMA 1 (BLANK) = 460-3-60

W = WATER N4 = NEMA 4 230-3-60

575-3-60

380-3-50

220-3-50

* Nominal Flows indicated are for 100°F inlet temperature, 100°F ambient temperature and 100 psig compressed air pressure.

3

Nirvana Cycling Refrigerated Dryer Models 1000-1600

http://air.irco.com

5.1 INSPECTION

Upon receiving your Ingersoll Rand air dryer, please inspect the unit

closely. If rough handling has been detected, please note it on your

delivery receipt, especially if the dryer will not be immediately uncrated.

Obtaining the delivery person's signed agreement to any noted

damages will facilitate any insurance claims

5.2 UNPACKING AND HANDLING

a

WARNING

Under no circumstances should any person attempt to lift heavy

objects without proper lifting equipment (i.e., crane, hoist, slings or fork

truck). Lifting any unit without proper lifting equipment, can cause

serious injury.

5.0 RECEIVING AND INSPECTION

All dryer packages have been mounted on a base which provides for

forklifting between the two base channels to facilitate handling during

shipment. Forks should extend all the way through forklift channels to

reduce unnecessary forces to the dryer during moving. Slings can be

used to lift the crates, but spreader bars must be used to prevent the

slings from exerting a force against the sides of the crates.

6.0 SAFETY AND OPERATION PRECAUTIONS

Because an air dryer is pressurized and contains rotating parts, the

same precautions should be observed as with any piece of machinery

of this type where carelessness in operation or maintenance could be

hazardous to personnel. In addition to obvious safety rules that should

be followed with this type of machinery, safety precautions as listed

below must be observed:

1. Only qualified personnel shall be permitted to adjust, perform

maintenance or repair this air dryer.

2. Read all instructions completely before operating unit.

3. Pull main electrical disconnect switch and disconnect any separate

control lines, if used, before attempting to work or perform

maintenance on the unit.

4. Do not attempt to service any part while machine is in an operational

mode.

5. Do not attempt to remove any parts without first relieving the entire

air system of pressure.

6. Do not attempt to remove any part of the refrigeration system without

removing and containing refrigerant in accordance with the EPA and

local regulations.

7. Do not operate the dryer at pressures in excess of its rating.

8. Do not operate the dryer without guards, shields and screen in place.

9. Inspect unit daily to observe and correct any unsafe operating

conditions.

OSHA

Heading Descriptions

a

WARNING

“Warning” is used to indicate a hazardous situation which has some

probability of death or severe injury. Warning should not be considered

for property damage accidents unless personal injury risk is present.

a

CAUTION

“Caution” is used to indicate a hazardous situation which may result in

minor or moderate injury.

a

NOTICE

“Notice” is used to indicate a statement of company policy as the

message relates directly or indirectly to the safety of personnel or

protection of property. Notice should not be associated directly with a

hazard or hazardous situation and must not be used in place of

“Danger,” “Warning,” or “Caution.”

a

NOTICE

The user of any air dryer manufactured by Ingersoll Rand, is hereby

warned that failure to follow the above Safety and Operation

Precautions may result in personal injury or equipment damage.

However, Ingersoll Rand does not state as fact, nor does it mean to

imply, that the preceding list of Safety and Operating Precautions is all

inclusive, and further, that the observance of this list will prevent all

personal injury or equipment damage.

Nirvana Cycling Refrigerated Dryer Models 1000-1600

http://air.irco.com

4

6.0 SAFETY AND OPERATION PRECAUTIONS

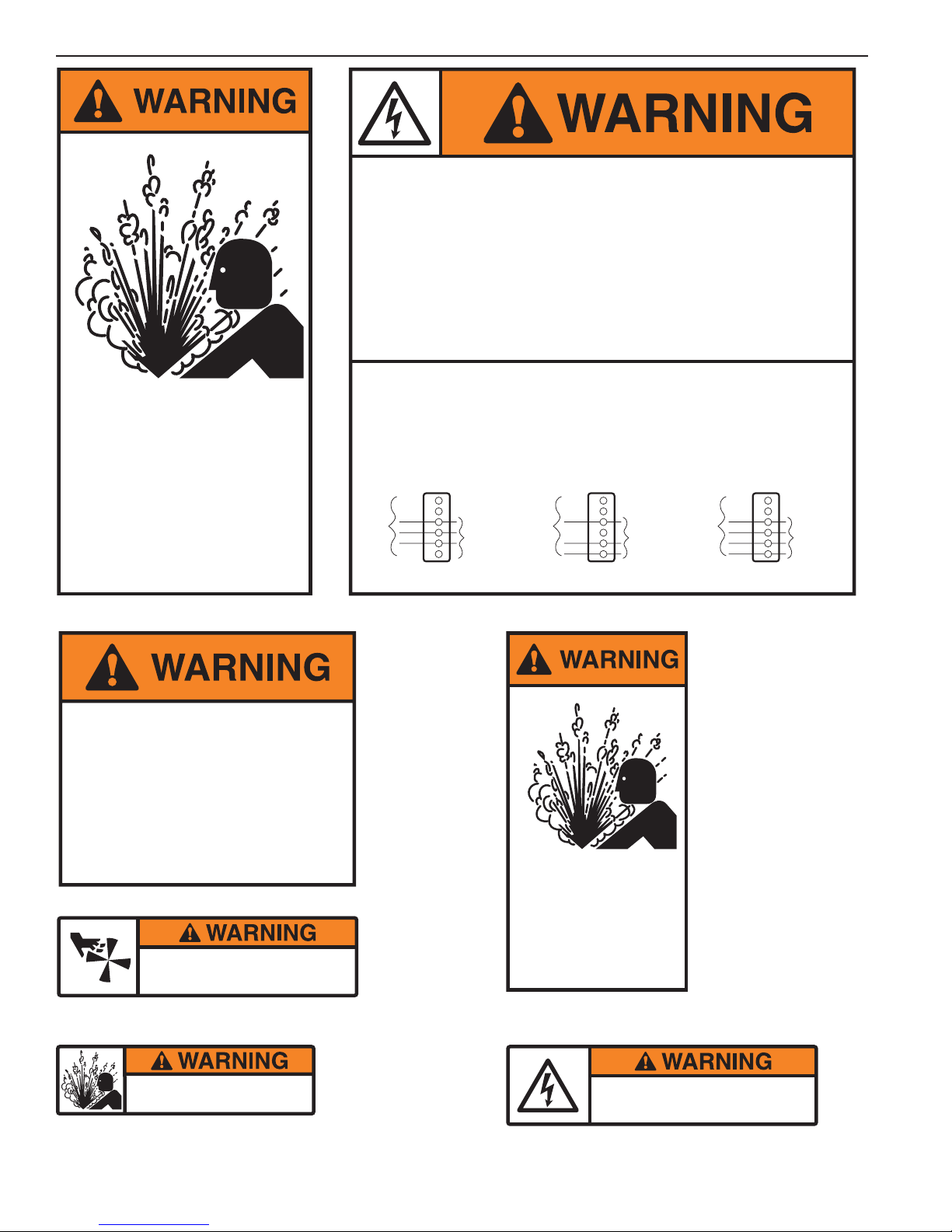

ELECTRICAL CONNECTION BOX

CONTAINS HIGH VOLTAGE

• Turn Off Power And Lock Out At ALL Sources Before Opening

To Perform Service.

• Remote Alarm Contact Wiring Has Control Power From

Separate Source.

READ TECHNICAL MANUAL

Air Under Pressure Will Cause

Injury, Death Or Property Damage.

• Do Not Exceed Pressure Rating.

• Relieve Press. Before Servicing.

• Do Not Modify/Repair/Rework

ASME Coded Pressure Vessels

As Insurance Rating Affected.

READ TECHNICAL MANUAL

Removing fuses will not disconnect

power from dryer. Always disconnect

power from ALL sources before

performing service.

READ TECHNICAL MANUAL

FAN MAY AUTOMATICALLY

START AT ANY TIME

ELECTRICAL CONNECTION BOX

All Customer Connections To Be Made At This Location.

•

See Terminal Connection Diagrams, below.

•

Be Certain To Follow All NEC, State, Local and Other Applicable

•

Codes During Installation.

FACTORY

WIRING

GRN

WHT

BLK

100-125VAC / 1 PH

1

2

G

3

N

4

L1

5

6

INCOMING

LINE VOLTAGE

100-125VAC

1PH/50-60HZ

(BY OTHERS)

(REFER TO UNIT

NAMEPLATE FOR

POWER

REQUIREMENTS)

FACTORY

WIRING

Air Under Pressure Will Cause

Injury, Death Or Property Damage.

• Relieve Press. Before Servicing.

• Condensate Drain Discharges

Under Pressure.

• Drain Requires Periodic

Cleaning (Service).

READ TECHNICAL MANUAL

GRN

BLK

RED

200-240VAC / 1 PH

1

2

G

3

4

L1

5

L2

6

INCOMING

LINE VOLTAGE

200-240VAC

1PH/50-60HZ

(BY OTHERS)

(REFER TO UNIT

NAMEPLATE FOR

POWER

REQUIREMENTS)

FACTORY

WIRING

GRN

RED

WHT

BLK

200-575VAC / 3 PH

1

2

G

3

L1

4

L2

5

L3

6

INCOMING

LINE VOLTAGE

200-575VAC

3PH/50-60HZ

(BY OTHERS)

(REFER TO UNIT

NAMEPLATE FOR

POWER

REQUIREMENTS)

This unit is charged with

refrigerant under high pressure.

HIGH VOLTAGE

5

7.1 INTRODUCTION

Ingersoll Rand Nirvana Cycling™ dryers remove moisture from

compressed air by cooling the air temperature to between 36° and 40°F

(2 and 4°C). This causes vapors to condense into liquid droplets which

can then be easily removed from the air. The major systems of the dryer

which contribute to its operation are the Air System, the Moisture

Removal System, the Refrigeration System, the Thermal Mass

Circulating System and the Controls. The following paragraphs

describe each of the systems in greater detail.

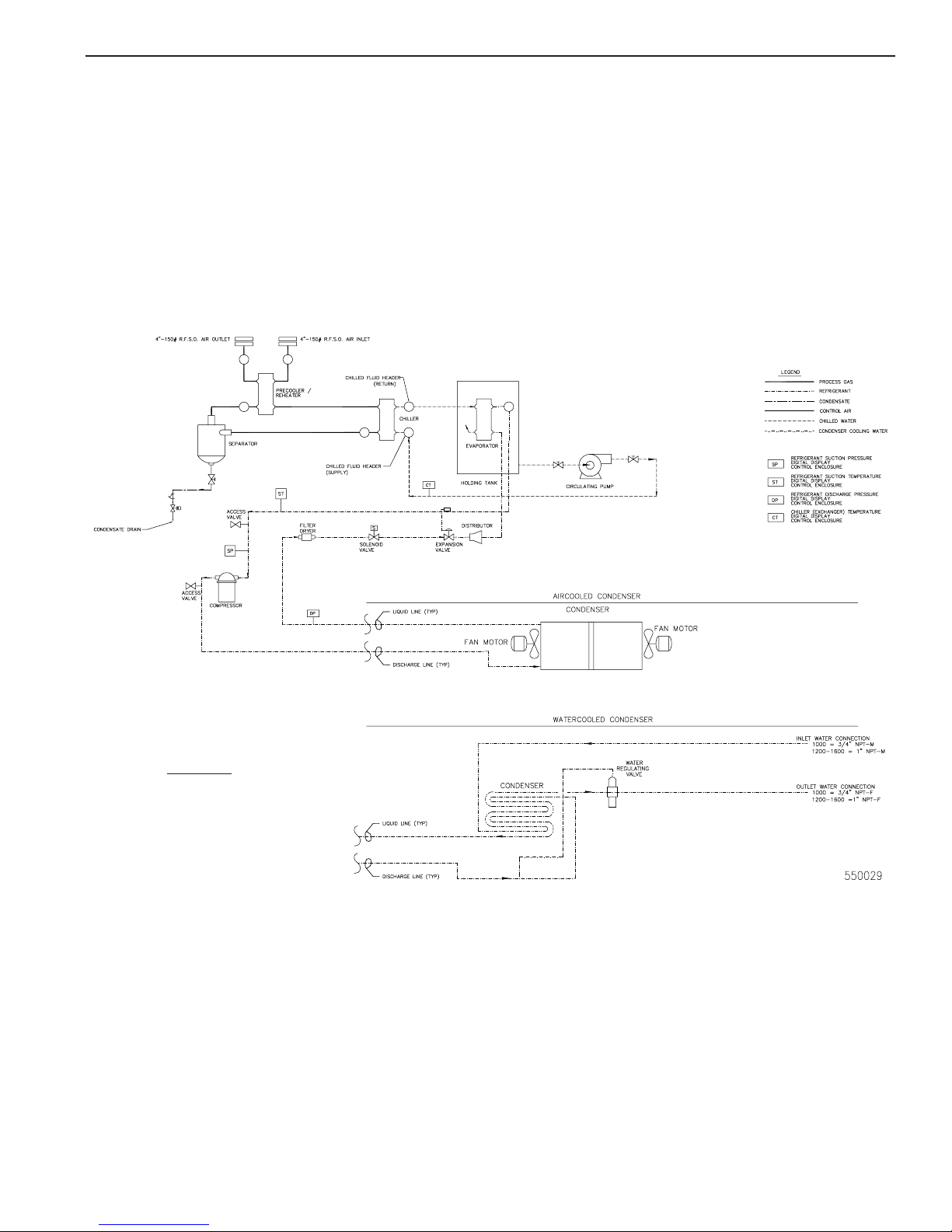

7.2 AIR SYSTEM

The air system consists of the dryer components which are in contact

with the compressed air. Referring to Figure 1 and following the bold

7.0 PRINCIPLES OF OPERATION

“AIR FLOW,” hot saturated air from the compressor enters the

precooler/reheater where the air temperature is reduced prior to

entering the chiller by the cool air exiting the air/moisture separator. This

precooling allows for the use of a smaller refrigeration system. The air

then goes into the chiller section where it is further cooled to the desired

dew point by a thermal mass fluid. The temperature of the thermal mass

fluid is maintained by the refrigeration circuit and controls. The air

continues to the separator where moisture is removed, thereby, allowing

the cool, dry air to return back to the precooler/reheater to be heated by

the incoming moist hot air. The air exiting the “reheater” portion of the

dryer should be approximately 15°- 20°F lower than the inlet air

temperature based on standard conditions at full rated flow.

FIGURE 1

FLOW DIAGRAM

7.3 MOISTURE REMOVAL SYSTEM

Ingersoll Rand condensate drains discharge condensed moisture and

lubricants (condensate) from compressed air equipment. The

condensate drain operates as a zero-air-loss drain, returning air that is

displaced in the drain bowl back into the compressed air system.

Consistent discharging of condensate from compressed air equipment

is essential for proper equipment operation and performance.

The condensate drain uses a unique sensing method to determine the

level of condensate in the drain bowl. A transducer located in the drain

bowl continuously sends out a signal 50 times per second. Once the

transducer determines that the level of condensate has reached a

predetermined level within the drain bowl, a signal is sent to the no-loss

drain valve to open. This operation permits removal of condensate of up

to 80 gallons per hour.

The drain also features a test button that permits manual operation of

the no-loss drain valve. Depressing the test button illuminates the LED

and energizes the solenoid valve. The LED illuminates to indicate

"POWER ON" and goes off when the no-loss drain valve is operated by

the transducer or manual test button.

The condensate flows through the feed line into the drain unit and

accumulates in the container. A capacitive sensor continuously registers

the liquid level and passes a signal to the electronic control as soon as

the container is filled. The pilot valve is then activated and the

diaphragm opens the outlet line for discharging the condensate. When

the drain unit has been emptied, the outlet line is closed again quickly

and tightly without wasting compressed air.

Nirvana Cycling Refrigerated Dryer Models 1000-1600

http://air.irco.com

6

Nirvana Cycling Refrigerated Dryer Models 1000-1600

http://air.irco.com

7.0 PRINCIPLES OF OPERATION

7.4 REFRIGERATION SYSTEM

The Refrigeration System consists of all the components which handle

R-22. This is a hermetically sealed closed-loop system. Referring to

Figure 1 and following the phantom “

REFRIG

(R-22) FLOW,” refrigerant is

shown leaving the evaporator section where, in the process of removing

heat, it is changed from a low pressure liquid into a low pressure gas.

This gas enters the suction side of the compressor where it is

compressed into a high pressure gas. The high pressure gas is cooled

in the air cooled or water cooled condenser section until it becomes a

high pressure liquid. It then goes through a permanent filter dryer that

ensures the refrigeration system is free of contaminants. A thermostatic

expansion valve meters the refrigerant for introduction into the

evaporator. The refrigerant pressure is reduced upon entering the

evaporator where as it evaporates, heat is removed from the thermal

mass fluid. A solenoid valve in the liquid line eliminates the possibility of

flooded starts.

7.5 THERMAL MASS CIRCULATING SYSTEM

The thermal mass fluid in a Ingersoll Rand Nirvana Cycling™ dryer is

continuously circulated in a closed pump loop system. Referring to

Figure 1 and following the dashed “

THERMAL MASS FLUID” line, the heat is

removed from the fluid in the evaporator by the refrigeration system.

The thermal mass reservoir is sized to minimize refrigeration cycles

during reduced air load periods. The thermal mass fluid is pulled from

the bottom of the reservoir and pumped through the chiller, removing

heat from the air and returned to the evaporator. The pump utilized on

Ingersoll Rand Nirvana Cycling™ dryer is a maintenance-free, quiet

cartridge circulator pump similar to those used in residential water

systems. While the refrigeration system cycles on and off based on

loading conditions, the circulating pump runs continuously to maintain

flow through the chiller at all times.

7.6 CONTROLS

Ingersoll Rand 1000-1600 Refrigerated Compressed Air Dryers are

equipped with the Microprocessor Control. This advanced

microprocessor-based controller has been engineered by Ingersoll

Rand exclusively for use with Ingersoll Rand Compressed Air Dryers.

The Microprocessor Control cycles the refrigeration system based on

the dryer's Chiller Temperature. A temperature sensor samples the

thermal mass temperature as it enters the chiller exchanger. The

Chiller Temperature Set point is a user adjustable set point that is used

to set the Refrigeration Compressor Off temperature. Once the Chiller

Temperature has fallen below the Chiller Temperature Set point, the

refrigeration compressor will de-energize. The Operating Temperature

Differential is factory set at 4°F above the Chiller Temperature Set point.

Therefore, if a user adjusts the Chiller Temperature at 36°F, the

Refrigeration Compressor On temperature will be 40°F.

In addition to the operation of the Nirvana Cycling™ dryers as described

above, the Microprocessor Control permits monitoring of dryer

parameters and enunciation of alarm conditions.

The list below summarize the features the Microprocessor Control:

• 2 X 16 Character Backlit LCD Display - Easy-to-read display provides

continuous indication of dryer default parameter. Standard backlight

permits viewing of critical information in low light environments.

• Remote Start / Stop: Microprocessor Control-equipped dryers offer a

unique remote start / stop feature. This feature allows the dryer to be

operated via a remote user-supplied switch.

• Remote Alarm Contact: Microprocessor Control-equipped dryers

include a remote alarm contact to provide indication of any of the

dryers alarms described later in this manual. Contact rated for 2A /

120V max.

The Microprocessor Control features three levels of access. The default

level CUSTOMER MODE permits adjustment of dryer parameters to

address seasonal variations for drain timing and pressure dew point

temperature. A password protected FACTORY MODE is also included

for use with Ingersoll Rand Service Personnel for troubleshooting the

dryer.

The Microprocessor Control includes a digital readout for monitoring the

discharge pressure of the refrigerant gas exiting the compressor. This

reading will vary dependent upon condenser type as indicated below:

• For air-cooled applications, condensing fans are cycled on and off by

the Microprocessor Control based on the refrigerant discharge

pressure. Primary fan(s) are cycled on at 235 psig and off at 195 psig.

Should the discharge pressure continue to climb above 265 psig, the

secondary condensing fans will cycle on. As discharge pressure is

reduced below 210 psig, the secondary fan(s) will cycle off. On 1000

and 1200 models, two condensing fans are utilized. The 1600 has

three condenser fans. For the 1600, the center fan is the primary

controlled fan the outside fans are the secondary controlled fans.

• Water cooled condensers utilize a water regulating valve (Note Figure

2). The water regulating valve comes pre-adjusted from the factory at

250 psig discharge pressure. To compensate for water temperature

variation, it may be necessary to adjust the water regulating valve to

maintain a 250 psig discharge pressure. Adjustment can be done by

rotating the adjusting screw counterclockwise for an increase in

discharge pressure. For conditions where low water temperature

and/or high water pressure are expected it is advisable to install a

water pressure regulator ahead of the condenser.

ADJUSTMENT

SCREW

FIGURE 2

WATER REGULATING VALVE

7.6.1 BASIC USER INTERFACE

The Microprocessor Control display provides the user with the

operating parameters and their corresponding values. When

power is supplied to the dryer, the Microprocessor Control will

illuminate and default to the “Standby” mode, displaying the

“Press ON” prompt.

The following illustration summarizes the keypad functions.

7

Nirvana Cycling Refrigerated Dryer Models 1000-1600

http://air.irco.com

7.0 PRINCIPLES OF OPERATION

7.6.2 DISPLAY PARAMETERS

The Microprocessor Control is capable of displaying a number

of system parameters. The following summarizes the

parameters that can be accessed by the user from the

Microprocessor Control:

• Chiller Temperature (CHLLR TEMP): For Nirvana Cycling

Dryers, the Chiller Temperature is the temperature, in

degrees Fahrenheit, of the thermal mass fluid.

• Compressor Status (CMPRSSR): Displays whether the

refrigeration compressor is “ON” or “OFF”.

• Discharge Pressure (P disch): Displays the discharge

pressure of the refrigeration system.

• Suction Temperature (T suction): Displays the suction

temperature, in deg. F, of the refrigeration system. This

value is useful in determining superheat of the refrigerant.

• Suction Pressure (P suction): Displays the suction pressure,

in psig, of the refrigeration system.

• Percent Savings (% SVGS): Displays the length of time the

compressor has been operating versus the length of time

the dryer has been on.

• Cumulative Dryer Hours (CUM DRYER HR): Displays the

length of time, in hours, that the dryer has been operational.

• Cumulative Compressor Operating Hours (CUM CMP HR):

Displays the length of time, in hours, that the refrigeration

compressor has been energized.

Depressing the SELECT DISPLAY button repeatedly scrolls

through the above non-adjustable displays. The Customer

Set Points appear at the end of the list and may be adjusted

by the end user to match seasonal refrigeration and drain

operation. These settings are as follows:

• Chiller Temperature (CHLLR TEMP)

• Drain Interval (DRN INT)

CHLLR TEMP: 37

BUTTONS

• ON

Places the dryer "On Line"; Energizes glycol pump on Nirvana Cycling™

dryers. For Nirvana Cycling™ models, the compressor will operate based on

temperature;

• OFF

Places the dryer "Off Line"; Stops all automatic functions, including circulating

pump operation on Nirvana Cycling™ dryers.

• SELECT DISPLAY

Allows the user to cycle through the available displays. The last display

selected will remain displayed as the default display.

• + / -

Allows user to increase set point values. Set point values cycle through a fixed

range. Also allows entering negative numbers in FACTORY MODE.

• TEST

Allows user to manually activate the drain no-loss drain valve.

• RESET

Pressing once clears the local alarm indication and de-energizes the remote

alarm contact. Should the alarm condition persist, the alarm will return after

the alarm inhibit time has expired.

• SET

Permits the adjustment of parameters in TECHNICAN and FACTORY

MODES. In CUSTOMER MODE, allows user to back through displays,

• ENTER

Used to accept changed parameters and set point values.

• i

Restricted Level access for factory use only. Not used for basic dryer

functions. Not to be used by customer or service technician.

Loading...

Loading...