Ingersoll-Rand 132 User Manual

03528072

Form P6374

Edition 6

September, 2001

OPERATION AND MAINTENANCE MANUAL FOR

MODEL 132 SUPER DUTY AIR HAMMER

Model 132 Super Duty Air Hammer is designed for front end work, heavy exhaust work,

riveting, king pin removal, bushing driving and bolt shearing.

Ingersoll--Rand is not responsible for customer modification of tools for applications on which

Ingersoll--Rand was not consulted.

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATING TOOL.

IT IS THE RESPONSIBILITY OF THE EMPLOYER TO PLACE THE INFORMATION

IN THIS MANUAL INTO THE HANDS OF THE OPERATOR.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

PLACING TOOL IN SERVICE

• Always operate, inspect and maintain this tool in

accordance with American National Standards

Institute Safety Code for Portable Air Tools

(ANSI B186.1).

• For safety, top performance, and maximum durability

of parts, operate this tool at 90 psig (6.2 bar/620 kPa)

maximum air pressure at the inlet with 5/16” (8 mm)

inside diameter air supply hose.

• Always turn off the air supply and disconnect the air

supply hose before installing, removing or adjusting

any accessory on this tool, or before performing any

maintenance on this tool.

• Do not use damaged, frayed or deteriorated air hoses

and fittings.

• Be sure all hoses and fittings are the correct size and

are tightly secured. See Dwg. TPD905--1 for a typical

piping arrangement.

• Keep clear of whipping air hoses. Shut off the

compressed air before approaching a whipping air

hose.

• Always use clean, dry air at 90 psig maximum air

pressure. Dust, corrosive fumes and/or excessive

moisture can ruin the motor of an air tool.

• Do not lubricate tools with flammable or volatile

liquids such as kerosene, diesel or jet fuel.

• Do not remove any labels. Replace any damaged label.

USING THE TOOL

• Always wear eye protection when operating or

performing maintenance on this tool.

• Always wear hearing protection when operating this

tool.

• Keep hands, loose clothing, long hair and jewelry

away from rotating end of tool.

• Keep body stance balanced and firm. Do not overreach

when operating this tool. Anticipate and be alert for

sudden changes in motion, reaction torques, or forces

during start--up and operation.

• Tool shaft may continue to impact briefly after

throttle is released.

• Air powered tools can vibrate in use. Vibration,

repetitive motions or uncomfortable positions may be

harmful to your hands and arms. Stop using any tool

if discomfort, tingling feeling or pain occurs. Seek

medical advice before resuming use.

• Use accessories recommended by Ingersoll--Rand.

• Never operate a Percussion Tool unless an accessory

is properly installed and the tool is held firmly against

the work.

• Always use a retainer in addition to proper barriers

to protect persons in surrounding or lower areas from

possible ejected accessories.

• This tool is not designed for working in explosive

atmospheres.

• This tool is not insulated against electric shock.

• Prevent exposure and breathing of harmful dust and

particles created by power tool use:

Some dust created by power sanding, sawing,

grinding, drilling and other construction

activities contains chemicals known to cause

cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

-- lead from lead based paints,

-- crystalline silica from bricks and cement and

other masonry products, and

-- arsenic and chromium from chemically

treated lumber .

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well

ventilated area, and work with approved safety

equipment, such as those dust masks that are

specially designed to filter out microscopic

particles.

The useof other than genuine Ingersoll--Rand replacement parts may result insafety hazards, decreased tool performance,and

increased maintenance, and may invalidate all warranties.

Repairs should be made only by authorized trained personnel. Consult your nearest Ingersoll--Rand Authorized Servicenter.

Refer All Communications to the Nearest

Ingersoll--Rand Office or Distributor.

Ingersoll--Rand Company 2001

PrintedinU.S.A.

WARNING SYMBOL IDENTIFICATION

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

WARNING

Always wear eye protection

when operating or performing maintenance on this tool.

WARNING

Air powered tools can vibrate

in use. V ibration, repetiti ve

motions or uncomfortable

positions may be harmful to

your hands and arms. Stop

using any tool if discomfort,

tingling feeling or pain occurs.

Seek medical advice before resuming use.

90 psig

(6.2bar/620kPa)

WARNING

Keep body stance balanced

and firm. Do not overreach

when operating this tool.

PERCUSSIVE TOOL SPECIFIC WARNINGS

• When wearing gloves and operating models with

inside trigger, always be sure that the gloves will not

prevent the trigger from being released.

• Wear safety shoes, hard hat, safety goggles, gloves,

dustmask and any other appropriate protective

clothing while operating the tool.

• Do not indulge in horseplay. Distraction can cause

accidents.

• Keep hands and fingers away from the throttle lever

until it is time to operate the tool.

• Never rest the tool or chisel on your foot.

• Never point the tool at anyone.

• Compressed air is dangerous. Never point an air hose

at yourself or co--workers.

• Never blow clothes free of dust with compressed air.

• Be sure all hose connections are tight. A loose hose

not only leaks but can come completely off the tool

and while whipping under pressure, can injure the

operator and others in the area. Attach safety cables

to all hoses to prevent injury in case a hose is

accidentally broken.

• Never disconnect a pressurized air hose. Always turn

off the air supply and bleed the tool before

disconnecting a hose.

WARNING

Always wear hearing

protection when operating

this tool.

WARNING

Do not carry the tool by the

hose.

WARNING

Operate at 90 psig (6.2 bar/

620 kPa) Maximum air pressure.

• The operator must keep limbs and body clear of the

chisel. I f a chisel breaks, the tool with the broken

chisel projecting from the tool will suddenly surge

forward.

• Do not ride the tool with one leg over the handle.

Injury can result if the chisel breaks while riding the

tool.

• Know what is underneath the material being worked.

Be alert for hidden water, gas, sewer, telephone or

electric lines.

• Use only proper cleaning solvents to clean parts. Use

only cleaning solvents which meet current safety and

health standards. Use cleaning solvents in a well

ventilated area.

• Do not flush the tool or clean any parts with diesel

fuel. Diesel fuel residue will ignite in the tool when

the tool is operated, causing damage to internal parts.

When using models with outside triggers or throttle

levers, take care when setting the tool down to prevent

accidental operation.

• Do not operate the tool with broken or damaged

parts.

• Never start the tool when it is lying on the ground.

WARNING

Always turn off the air supply and disconnect the air

supply hose before installing, removing or adjusting

any accessory on this tool,

or before performing any

maintenance on this tool.

WARNING

Do not use damaged, frayed

or deteriorated air hoses

and fittings.

2

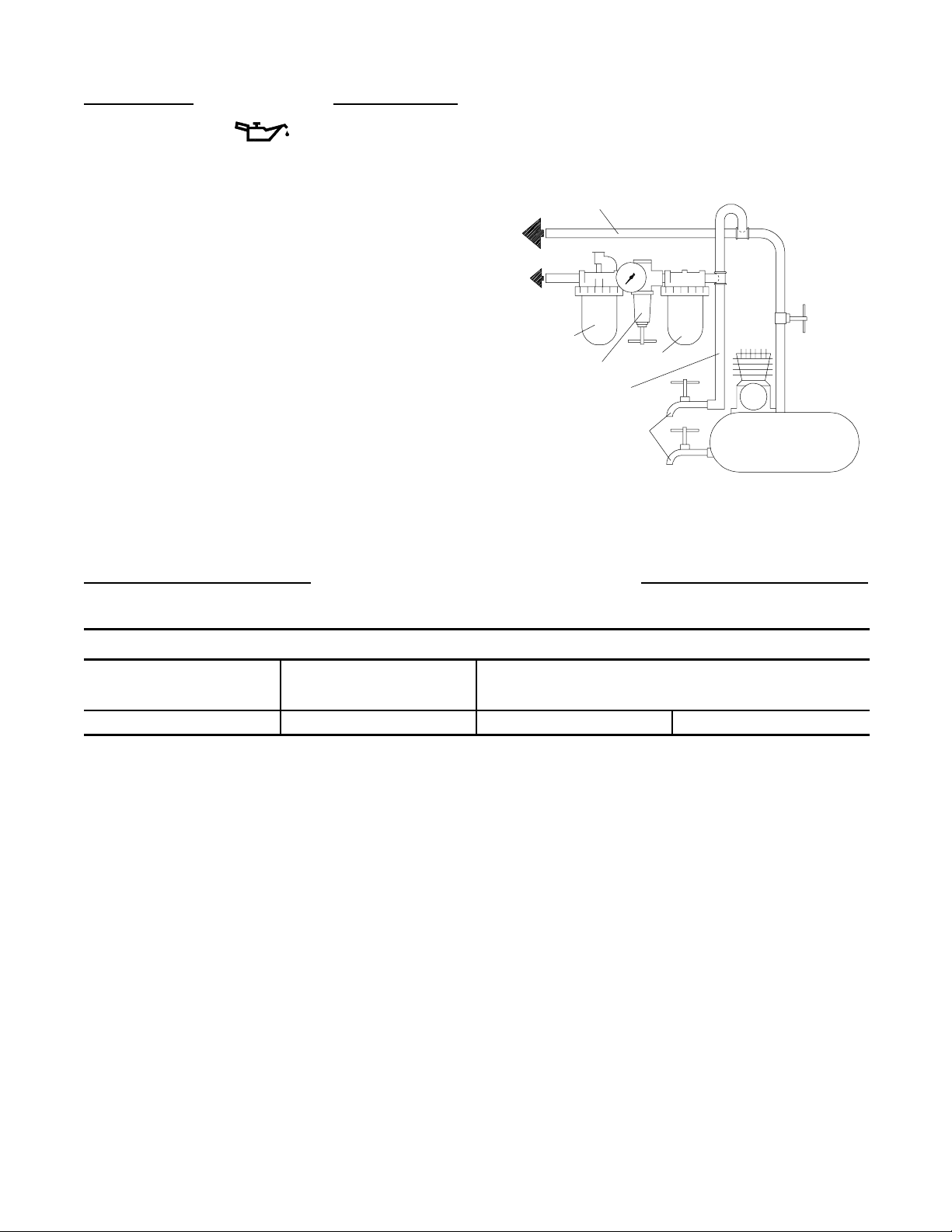

PLACING TOOL IN SERVICE

LUBRICATION

Ingersoll--Rand No. 10

Always use an air line lubricator with these tools.

We recommend the following Filter--Lubricator-- Regulator

Unit:

F o r U S A -- N o . C 0 8 -- 0 2 -- F K G 0 -- 2 8

Before operating the tool and after each two to three

hours of operation, unless an air line lubricator is used,

detach the air hose and inject several drops of

Ingersoll--Rand No. 10 Oil into the air inlet.

When the tool is to be idle for a period exceeding 24

hours, lubricate it in the regular manner and operate it for

5 seconds. This will coat the internal parts with oil and

prevent rusting while the tool is idle.

Never use a heavy oil or oil that forms a gum.

If the action of the tool becomes sluggish, in a well

ventilated area, remove the air hose, pour about one

teaspoonful of a clean, suitable cleaning solution into the

air inlet and operate the tool for not more than thirty

seconds. Immediately, follow t his treatment with an

injection of Ingersoll--Rand No. 10 Oil.

MAIN LINES 3 TIMES

AIR TOOL INLET SIZE

TO

AIR

SYSTEM

TO

AIR

TOOL

LUBRICATOR

REGULATOR

BRANCH LINE 2 TIMES

AIR TOOL INLET SIZE

DRAIN REGULARLY

FILTER

COMPRESSOR

(Dwg. TPD905--1)

HOW TO ORDER AN AIR HAMMER

PISTOL GRIP WITH TRIGGER THROTTLE

Piston Stroke

Model Impacts/min. in mm

132 1 725 4 101

3

Loading...

Loading...