Page 1

Interlude Series

IL60 L/R

Powered Loudspeaker

Service Manual

Infinity Systems, Inc

250 Crossways Park Dr.

Woodbury, New York 11797

REV 5 5/2005

Page 2

IL60

CONTENTS

SPECIFICATIONS …….……………………………………………….3

DETAILED SPECIFICATIONS …………………….…………………4

CONTROLS and CONNECTIONS …………………….….…………6

OPERATION……………………………………..………..…….……..10

BASS OPTIMIZATION SYSTEM……………………….….…………10

MECHANICAL PARTS LIST…………………….……………………12

EXPLODED VIEW ……………………………………….……………13

EXPLODED VIEW OF AMPLIFIER…………………….……………14

SERVICE TIPS……………………………..……………………….…15

TEST SET UP PROCEDURE……………………..…….……………16

IL60 ADJUST BIAS PROCEDURE………………..…………………17

SERVICE BULLETIN INF2000-04…….…………….….……………18

SERVICE BULLETIN INF2001-04…….…………….….……………19

TECH TIP INFTT2003-03…….…………….…………………………21

PACKAGING …………………………….………………………….…22

PRINTED CIRCUIT BOARD DIAGRAMS………………..…………23

ELECTRICAL PARTS LIST (120v)…………………….….…………27

INTEGRATED CIRCUIT DIAGRAMS ………………………………33

WIRING DIAGRAM CROSSOVER NETWORK SCHEMATIC..….34

IL60 SCHEMATICS…………..………….……………………………35

2

Page 3

IL60 L/R

3

Specifications

IL60 L/R Frequency Response: 28Hz - 22,000Hz (±3dB)

Recommended Amplifier Power Range 15-175 watts*

Subwoofer Amplifier Output: 500 watts (In to 8Ω from 20 Hz - 100Hz

with no more than 0.1% THD)

Sensitivity: 89dB (2.83V @ 1 meter)

Nominal Impedance: 8Ω

Crossover Frequencies: 150Hz; 500Hz,2800Hz, 24dB/octave

Low-Frequency Driver: 12" C.M.M.D., magnetically shielded

Mid-Bass Driver: 6-1/2” C.M.M.D., magnetically shielded

Midrange Driver: 4” C.M.M.D., magnetically shielded

High-Frequency Driver: 1” C.M.M.D., magnetically shielded

Dimensions (H x W x D): 48" x 9-1/4" x 17-1/4"

(1219mm x 235mm x 438mm)

Weight: 75 lb (34kg)

* The maximum recommended amplifier power rating will ensure proper system headroom to allow

for occasional peaks. We do not recommend sustained operation at these maximum power levels.

Page 4

Detailed Specifications

IL60 L/R

4

Page 5

IL60 L/R

5

Detailed Specifications (Cont.)

Page 6

IL60 L/R

6

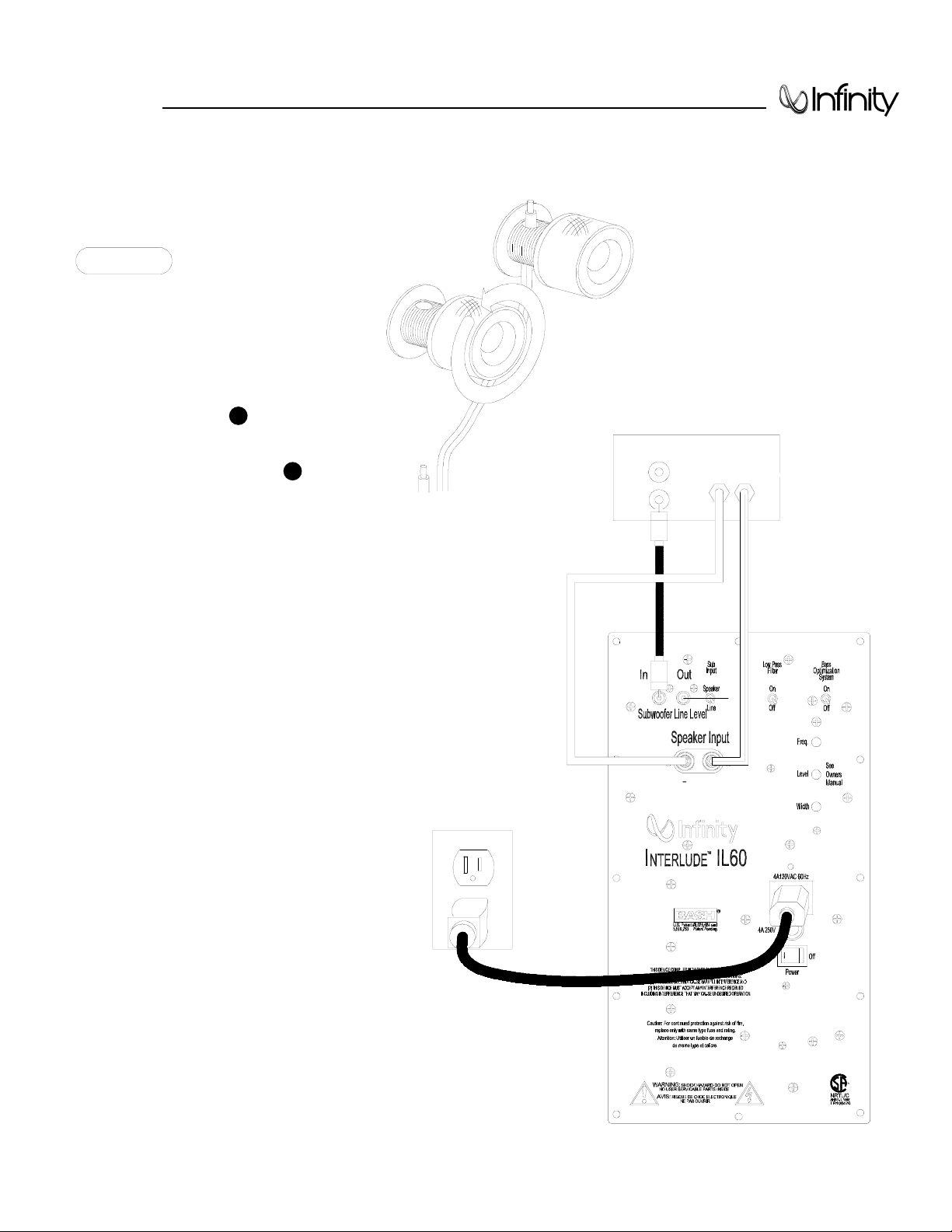

Controls and Connections

Page 7

IL60 L/R

7

Controls and Connections

SPEAKER

OUTPUTS

+- +-

SPEAKER

OUTPUTS

+- +-

(ONE CHANNEL SHOWN)

AMPLIFIER/RECEIVER

LEFT RIGHT

AMPLIFIER/RECEIVER

SPEAKER OUTPUTS

(ONE CHANNEL SHOWN)

PREAMP OUTPUTS AMPLIFIER INPUTS

L

RR

L

®

O

+

1. LOOSEN TERMINALS

2. INSERT BARE END:

TIGHTEN TERMINALS

3. SET

INPUT SUB

TO "LINE LEVEL"

4. SET

LOW-PASS FILTER

"ON"

METHOD 2

NO STRIPE = -

BLACK = -

STRIPE= +

RED = +

O

00354

+

®

00359-2

1. LOOSEN TERMINALS

2. INSERT BARE END:

TIGHTEN TERMINALS

3. SET

INPUT SUB

TO "SPEAKER"

4. SET

LOW-PASS FILTER

"ON"

METHOD 1

NO STRIPE = -

BLACK = -

STRIPE= +

RED = +

AC CORD

AC CORD

The Interlude IL50 and IL60 offer unprecedented flexibility for connecting the

system to any type of audio or home-theater system. Consult the table at right

to determine which system description most closely matches your own, then

follow the hook-up method corresponding to that system.

If none of these system configurations seem to match yours, consult your dealer

or Infinity customer service for direction on how best to hook up your system.

For methods 2, 3a, 3b and 4, make sure all bass-management features are

properly set. The Audio channels should all be set to “Small” or “High-Pass”

and the subwoofer set to “On.”

2-Channel receiver or integrated amplifier 1

that has no subwoofer output or

Pre-out/Main-In connectors

2-Channel receiver or integrated amplifier 2

with preamp output and input connectors

2-Channel system with separate preamplifier 2

and power amplifier

Dolby* Pro Logic* with THX®, Dolby Digital, 3a

or DTS®receiver with a filtered subwoofer

(or LFE) output connector

Dolby Digital or DTS processor with separate 3b

power amplifiers or multichannel amplifier

Non-THX certified Dolby Pro Logic receiver 4

with full-range subwoofer outputs

System Type

Connection

Methods

4

3

4

3

Page 8

IL60 L/R

8

METHOD 3a

NO STRIPE = -

BLACK = -

STRIPE= +

RED = +

O

00354

+

®

O

+

®

STRIPE = +

METHOD 3b

BLACK = -

NO STRIPE = -

RED = +

Controls and Connections (Cont.)

4

4

3

3

Page 9

IL60 L/R

9

Controls and Connections (Cont.)

+-

SUBWOOFER

OUTPUTS

(ONE CHANNEL SHO WN)

RECEIVER

SPEAKER

OUTPUTS

L

R

O

+

®

1. LOOSEN TERMINALS

2. INSERT BARE END :

TIGHTEN TERMINALS

3. SET

INPUT SUB

TO "LINE LEVEL"

4. SET

LOW-PASS FILTER

TO "ON"

METHOD 4

STRIPE = +

NO STRIPE= -

BLACK = -

RED = +

AC CORD

00395-4

Final Positioning

After correctly connecting the loudspeaker and

verifying that both the subwoofer and main section

portions are playing, it is time to optimize the

system for your particular listening room.

Earlier, you placed the loudspeakers in their general

location. Finding the exact location for optimum

performance sometimes only involves moving the

speakers a few inches in any direction. We urge

you, therefore, to experiment with placement until

your speakers deliver their full potential. When the

speakers are moved inward (toward each other)

there is generally better focus of instruments and

vocalists; however, moving the speakers too close

together can reduce the spaciousness of the stage

effect and you may need to experiment with the

trade-off between focus and imaging. If your

listening room is larger than average and your

listening position is relatively far from the speakers,

wider placement of the speakers may be required.

3

4

Page 10

IL60 L/R

10

Operation/Bass Optimization System

TM

Page 11

IL60 L/R

11

Bass Optimization System

TM

(Cont.)

NOTE:It is important that you make the same adjustments to both loudspeakers.

Set the Bass Optimization System Bandwidth adjustments to a middle position (10 clicks from a

fully clockwise position) and set Level adjustments for a –6dB (8 clicks from a fully clockwise

position). Then,while the music is playing,sit in your favorite chair and have somebody else slowly

adjust the Frequency controls from fully clockwise to fully counter-clockwise. At a certain

frequency, you should hear the problem lessen and the overall bass performance improve. When

you are satisfied that you have found the best frequency, have your assistant vary the Levels

slowly up and down until you have maximized the improvement.If you have really keen ears, you

can also have the Bandwidth controls adjusted for maximum benefit.

While the Bass Optimization System allows the listener to fine-tune the bass response to sound best

in a particular room,some listeners don’t have the skill or desire to adjust their system by ear. In

order to facilitate quicker and more accurate results, Infinity has developed an optional test and

measurement kit that allows the user to perform a series of measurements and aids him/her in

properly setting the Bass Optimization System controls. With the addition of this kit,the Bass

Optimization System becomes truly room-adaptive.

The kit consists of the following:a test CD, a sound-level meter that is specifically calibrated for low

frequencies, and something we call a “Q-Finder, ”a device to help find the width of the measured

curve and, finally, a measurement template. It works as follows. The listener plays the tones from

the test CD and records the relative output level of each test tone, using the sound-level meter, on

the provided measurement template. After all the tones are complete, the template contains a

response curve for the frequencies below 100Hz. The user simply notes the frequency of the largest

bass peak,calculates the correct amount of attenuation,and uses the “Q-Finder” to determine the

width of the curve. These three values are dialed into the Bass Optimization System controls located

on the speaker.The entire process takes less than twenty minutes.

If your dealer does not stock the Bass Optimization System test and measurement kit,you may

purchase it directly from Infinity. U.S. residents can visit our Web site at www.infinitysystems.com or

call 1-800-553-3332.Canadian residents should contact their dealer or call 1-800-567-3275.

Ask for Infinity part number 335852-002.

11

10

9

10

11

Page 12

IL60 L/R

12

Mechanical Parts List

IL60 Complete Amplifier Ass’y N/A

Grille Set (one Upper and one Woofer):

Grille, Black, Left 336440-072

Grille, Black, Right 336440-071

Grille, Midnight Blue, Left 336440-052

Grille, Midnight Blue, Right 336440-051

Grille, Rich Burgundy, Left 336440-062

Grille, Rich Burgundy, Right 336440-061

Grille, Gray, Left 336440-042

Grille, Gray, Right 336440-041

Mid-Bass, 6-1/2” C.M.M.D., shielded, 4.5 ohms±10% 335741-001

Midrange, 4” C.M.M.D., shielded, 4.6 ohms±10% 335812-002

Woofer, 12”, C.M.M.D., shielded, 3.4 ohms±10% 336056-001

Tweeter, 1”, C.M.M.D., shielded, 3.5 ohms±10% 335225-002

Volume Control Assembly (Left) 336250-002

Volume Control Assembly (Right) 336250-001

Passive Crossover Network 336500-001

Port Tube 336799-001

Pedestal 336255-001

Cup, Grille, (12) 333249-003

Baffle, Front, Left 336442-002

Baffle, Front, Right 336442-001

Bump-On, Foot (8) 330104-001

Midrange Cup 335809-001

Trim Ring, Woofer 336259-001

PACKAGING

Owners Manual, IL50,60 335832-001

Grille Option Literature 336503-002

Grille Assembly See Options Above

Pad, End, Bottom/L 336488-003

Pad, End, Bottom/R 336488-002

Pad, End, Top 336488-001

Protective Corners (4) 335692-003

Outer Carton 336489-001

Survey Card 330033-001

Warranty Card 335841-001

Spike Foot Set 331360-001

Power cord 120v US (15’) 336658-115

RABOS screwdriver w/bag 335848-002

Page 13

IL60 L/R

13

GRILLE, BLACK, LEFT 336440-072

GRILLE, BLACK, RIGHT 336440-071

GRILLE, MIDNIGHT BLUE, LEFT 336440-052

GRILLE, MIDNIGHT BLUE, RIGHT 336440-051

GRILLE, RICH BURGUNDY, LEF T 336440-062

GRILLE, RICH BURGUNDY, RIGHT 336440-061

GRILLE, WARM PLATINUM, LEFT 336440-042

GRILLE, WARM PLATINUM, RIGHT 336440-041

GRILLE, WOOFER,

Part of Set - See

Upper Grille Options

GRILLE CUP, (3)

333249-003

GRILLE CUP, (8)

333249-003

GRILLE

CUP, (1)

333249-003

SCREW, (3)

#8 x 1" PPH, BLK

900101-016

SCREW, (3)

#8 x.75" PPH BLK

900101-012

SCREW, (12)

#8 x.75" PPH BLK

900101-012

SCREW, (4)

#8 x.75" PPH BLK

900101-012

SCREW, (6)

#6 x .75" PPH BLK

903401-012

SCREW, (4)

#4-24"x .375 PPH BLK

907801-006

SPIKE (2)

331360-001

BUMP-ON (8)

330104-001

PEDESTAL,

336255-001

PORT TUBE,

336799-001

(ROTATED)

VOLUME

CONTROL ASS'Y

w/CABLE,

336250-001,R

336250-002,L

AMPLIFIER,

NOT FOR SALE

MIDRANGE

TRANSDUCER,

335812-002

MIDBASE

TRANSDUCER

335741-001

ISOLATION

CUP

335809-001

TWEETER,

335225-002

BAFFLE,

336442-001, R

336442-002, L

WOOFER,

336056-001

TRIM

RING,

336259-001

00415

SCREW, (8)

#6 x .75" PPH BLK

903401-012

SCREW, (4)

#6 x .75" PPH BLK

903401-012

SCREW, (10)

#8 x .75" PPH BLK

900101-012

CABINET

NOT FOR SALE

CROSSOVER

NETWORK

336500-001

Exploded View

Page 14

IL60 L/R

14

LINEAR

BOARD

FEATURE

BOARD

RABOS

BOARD

POWER

SUPPLY

BOARD

NETWORK,

336500-001

RCA SINGL E

PC MT (2)

(JC0091)

SWITCH,

SPDT TOGGLE

(SR0007)

PAIR BINDI NG

POSTS GOLD

(JC0104)

FUSE HOLDER

PANEL MT SEALED

(FH0012)

FUSE, 4A 250V

1.25X.25 SLO-B LO

(FS0026)

AC (120V)

IEC SOCKET

(JC0129)

SWITCH,

ROCKER POWER

(SR0032)

FRONT VIEW

00420

EMI

BOARD

Exploded View of Amplifier

Page 15

IL60 L/R

15

Service Tips

Page 16

IL60 L/R

16

Test Set Up and Procedure

SYSTEM AURAL SWEEP TEST

Equipment needed:

• Function/signal generator/sweep generator

• Integrated Amplifier

• Multimeter

• Speaker cables

General Unit Function (UUT = Unit Under Test)

Switches on the amplifier faceplate:

Sub Input to “Line Level”

Low Pass Filter to OFF

Bass Optimization system to OFF

1. From the signal generator, connect one line level (RCA) cable to the IL60 Line Level Input jack on the UUT.

2. On the front of the unit, turn the LEVEL control full counterclockwise (1).

3. Turn on generator, adjust to 100mV, 40 Hz.

4. Plug in UUT; turn the power switch ON. LED should be Red. Turn LEVEL control full clockwise (10).

5. LED should now be Green; immediate bass response should be heard and felt from rear port tube opening.

6. Turn off generator, turn LEVEL control fully counterclockwise (1), disconnect RCA cable.

7. Connect one pair of speaker cables to Speaker Level input terminal on UUT. Cables should be connected to

an integrated amplifier fed by the signal generator.

8. Switch Sub Input on the amplifier faceplate to “Speaker”.

9. Turn on generator and adjust so that speaker level input at the amplifier is 1.5V, 50 Hz. Turn LEVEL control

full clockwise (10).

10. Green LED should light, immediate bass response should be heard and felt from the port tube opening.

Sweep Function

1. Follow steps 7-10 above, using a sweep generator as a signal source.

2. Sweep generator from 20Hz to 20kHz. Listen to the cabinet and drivers for any rattles, clicks, buzzes or any

other noises. If any unusual noises are heard, remove woofer and test.

Driver Function (Woofer)

1. Remove woofer from cabinet; detach + and - wire clips.

2. Check DC resistance of woofer; it should be 3.4 ohms ±10%.

3. Connect a pair of speaker cables to driver terminals. Cables should be connected to an integrated amplifier

fed by a signal generator. Turn on generator and adjust so that speaker level output is 5.0V.

4. Sweep generator from 20Hz to 1kHz. Listen to driver for any rubbing, buzzing, or other unusual noises.

SIGNAL

GENERATOR

AMPLIFIER

AC VOLT

METER (10V)

IL60

UNDER TEST

OUTPUT FROM GENERATOR/AMPLIFIER

O

+

®

00345

Page 17

IL60

17

IL60 ADJUST BIAS PROCEDURE

(Mandatory when any output MOSFET transistors Q3,4,7,8 are replaced)

1. Amplifier should be unplugged and OFF.

2. Remove Amp assembly from cabinet; remove rear plastic cover if present. All wires exiting

the cover can remain connected unless they will prevent you from removing the amplifier or

accessing potentiometers on the Linear board PCB in the following steps.

3. Locate the Linear board assembly (PCB with the output transistors)

4. Adjust R11 and R27 fully Counter Clockwise. See diagram below.

5. Apply 120 VAC power to unit, Turn power switch ON.

6. Verify LED illuminates on the front gain control dial unless you have disconnected the plug.

7. Connect voltmeter set to DC millivolt range to twin pins on terminal J7, on Linear board

8. Verify initial voltage is less then 0.1 mV.

9. Adjust R11 Clockwise until voltmeter reads 0.3 mV + the initial current from step #8.

10. Adjust R27 Clockwise until voltmeter now reads 0.6 mV + the initial current from step #8.

11. Turn amplifier OFF. Disconnect AC power to unit.

12. Remove voltmeter from terminal J7.

13. Replace cover (if present), wires if disconnected, and replace amplifier back into cabinet.

Page 18

IL60

18

Service Bulletin

Service Bulletin INF2000-04 - December 2000 Warranty labor rate: MINOR repair

To: All Infinity Service Centers

Model: Interlude IL60

Subject: Air Leak or Buzzing from Front Baffle

Some early versions of the Interlude IL60 loudspeaker may need an additonal gasket surrounding

the tweeter. The original gasket is located behind and is affixed to the front baffle.

In the event you receive an Interlude IL60 loudspeaker with the complaint: “There is buzzing

or an air leak coming from the upper part of the front baffle”, perform the following

modification:

1) Remove the loudspeaker grille.

2) Extract the (8) grille cups from their cavities with a needle-nosed pliers or similar tool.

3) Remove the (8) Phillips screws holding the front baffle to the cabinet

4) Remove the front baffle; unplug the two faston connections to the tweeter terminals.

5) Apply a new rectangular gasket, Infinity part# 336050-003, on top of the present gasket,

surrounding the tweeter. Final gasket(s) height should rise above the plastic “ledge” surrounding

the tweeter.

6) Plug both faston connections back on the tweeter terminals.

7) Replace the front baffle, Phillips screws, grille cups, and front grille.

Page 19

IL60

Service Bulletin

Service Bulletin INF2001-04 Rev2 – May 2005

To: All Infinity Service Centers

Model: Interlude and Intermezzo IL50, IL60, IL100s, IL120s, IM1.2s, IM4.1t

Subject: No Output

In the event you receive an Interlude or Intermezzo loudspeaker with the complaint: “There is no

output, and the LED on the volume control does not light, red or green”, check the item listed below:

1) Check the line fuse to make sure it’s not damaged. Replace if necessary

IL50, IL100s 3A Infinity part # FS0022

IL60, IL120s 4A Infinity part # FS0026

IM1.2s, IM 4.1t 6A Infinity part# FS0027

If the f use is inta ct, or the unit still does not function, check the power supply portion of the amplifier

circuit, described below:

2) Refer to the Exploded view page for detailed instructions on amplifer removal from the enclosure.

3) Remove all connectors and screws necessary to detach the Power Supply PCB from the main chassis

heatsink. Squeeze the heads of the plastic standoffs with long-nosed pliers to detach the PCB from the

heatsink.

4) Refer to the illustration on page 2. Check the DC resistance of following parts, in circuit, with a DMM:

IRF740 MOSFETS Q501, Q502

Infinity part# QM0055

IL120s

IL60

22 Ohm 0.6W Resistors R506, R503

Infinity part# RM0340

422 Ohm 1/4 watt Resistors R505, R502

Infinity part# RM0397

IRF740 MOSFETS Q4, Q5

Infinity part# QM0055

IL50

IL100s

22 Ohm 0.6W Resistors R17, R20

Infinity part# RM0340

475 Ohm 1/4 watt Resistors R16, R19

Infinity part# RM0075

IRF740 MOSFETS Q403,404,406,407

Infinity part# QM0055

IM1.2s

IM4.1t

22 Ohm 0.6W Resistors R407,410,414,417

Infinity part# RM0340

365 Ohm 1/4 watt Resistor

R408,411,415,418

Infinity part# RM0072

5) Replace any defective parts above that show measured values lower than normal.

6) Reconnect J505 or J6 multicolor ribbon cable connector; remount the Power supply PCB; reconnect

J501/502 or J4/J5 black/red Faston connectors.

7) All models except IM1.2S, IM4.1t: temporarily DO NOT connect the pair of black/red “CD±” leads on

the linear PCB). Isolate the ends so they are not touching each other, or any conductive material. (For

models IM1.2S, IM4.1t procedure is finished; replace amplifier).

Warranty labor rate: MINOR repair

D to S or S to D

G to S or S to G

D to G or G to D

Should measure >28K ohms*

Should measure >400 ohms

Should measure >28K ohms*

Should measure 22 ohms ±1%

Should measure 422 ohms ±1%

D to S or S to D

G to S or S to G

D to G or G to D

Should measure 22 ohms ±1%

Should measure 475 ohms ±1%

D to S or S to D

G to S or S to G

D to G or G to D

Should measure 22 ohms ±1%

Should measure 365 ohms ±1%

Should measure >28K ohms*

Should measure >400 ohms

Should measure >28K ohms*

Should measure >28K ohms*

Should measure >400 ohms

Should measure >28K ohms*

* The two

transistor leads

should be shorted

together before

these

measurements are

taken; the DMM

leads will “charge”

the circuit and the

value may change,

but should match

the values above.

Very low values

that do not change

indicate a shorted

MOSFET.

19

Page 20

IL60

8) Connect the subwoofer amplifier to an AC power source; turn the unit ON. Measure the DC voltage at

the “CD±” wires; it should be 10-20 volts.

9) If it is 25 volts or greater, turn the amplifier OFF, disconnect from the power source, and replace:

IL120S, IL60: Q504,Q507 IRF640 on the Power Supply PCB, Infinity part# QM0015.

IL50, IL100s: Q1 IRF540 on the Power Supply PCB, Infinity part# QM0020.

10) If the voltage is normal, turn the amplifier OFF, disconnect from the power source, and reconnect the

“CD±” leads.

11) Finish reassembling the amplifier, remount the heatsink, replace the amplifier in the cabinet and test

the subwoofer.

20

Page 21

IL60

21

TECH TIPS

Troubleshooting tips and solutions to common service problems

For models: IL50, IL100s, MSW-1, IL60, IL120s, IM2.6, IM3.5c TIP# INFTT2003-03

Intermezzo, Interlude and Modulus MSW-1 Power Supply Repair

Recommended for instances where the PCB has been damaged, for the above models only

1) Change all MOSFETS, even for one device failure.

2) Clean and repair the PC board if required (See Tech Tip HCG2002-01 - Damaged Printed Circuit

Boards).

3) Replace the Hybrid Bash Controller IC:

:

U1 in models:

U501 in models:

Infinity part # HC1011

FAILURE TO FOLLOW THE INSTRUCTIONS ABOVE MAY RESULT IN UNIT FAILURE WHEN THE

AMPLIFIER IS POWERED UP

IL50,IL100s,MSW-1,IM2.6,IM3.5c

IL60, IL120s

Page 22

Packaging

IL60

22

Page 23

Volume Left/Right Boards

IL60

23

Page 24

IL60 L/R

IL60

24

EMI FILTER/RABOS PCBs

Page 25

IL 500W Linear/Feature Boards

IL60

25

Page 26

500W HC BASH Power Supply (120V/230V Selectable)

IL60

26

Page 27

IL60 Electrical Parts List

Part# Reference Designator Qty Description

Feature PCB Assembly

SEMICONDUCTORS

DS0001 D9,D100,D101,D102,D103, 9 RECT, 100mA 75V SIGNAL 1N4148T

D104,D105,D200,D201

QM0035 Q5 1 JFET, N-CH J111 TO92 TR

UA0003 U5,U6 2 OPAMP, QUAD 14PIN DIL LM324N

UA0009 U1,U2 2 OPAMP, QUAD 14P DIL TL074/084

UA0010 U7 1 OPAMP, DUAL 8PIN DIL TL082

DZ0014 Z100 1 ZENER, 500MW 14V 5% 1N5244B

DZ0002 Z200 1 ZENER, 500mW 12V 5% 1N5242B

CAPACITORS

CC0020 C200 1 CAP, CA470PF 100V 5%

CC0025 C203 1 CAP, CA1000PF 100V 10%

CC0072 C1, C2, C4, C20, C100, C101 6 CAP, CA100PF 100V 10%

CC0082 C201 1 CAP, CA.1UF 50V 20%

CE0013 C204 1 CAP, E 47UF 50V 20% 5MMLS

CE0101 C16, C19 2 CAP, E 4.7UF 50V 85D 5X11 5MML

CE0103 C102 1 CAP, E 100UF 35V 85DEG 5MMLS

CE0106 C5 1 CAP, E 22UF 35V BP 8X11 5MMLS

CE0108 C3 1 CAP, E 4.7UF 16V BIPOLAR 5X11

CF0045 C7, C9, C10, C11 4 CAP, F .1UF 63DC 5% 5MMLS

CF0055 C6, C8 2 CAP, F .22UF 63V 10% 5MMLS

CF0078 C12, C13 2 CAP, F .47UF 63V 10% 5MMLS

RESISTORS

RC0001 R211 1 RES, CF 1K0 1/2W 5%

RC0192 R3 1 RES, CF 2K00 1/2W 5%

RC0273 R19A, R19B, R19C, R19D, R20, R24, 10 RES, ZERO OHM 1/4W

R33, R36, R39, R79

RC0290 R206 1 RES, CF 9M1 1/4W 5%

RM0002 R12, R17, R22, R100, R101, R102, R208, R209 8 RES, MF 10K0 1/4W 1%

RM0003 R16, R210 2 RES, MF 15K0 1/4W 1%

RM0011 R1,R4,R103,R105,R201 5 RES, MF 100K 1/4W 1%

RM0012 R14,R30 2 RES, MF 100R 1/4W 1%

RM0016 R104 1 RES, MF 13K0 1/4W 1%

RM0020 R28,R29 2 RES, MF 1K40 1/4W 1%

RM0024 R207 1 RES, MF 2K21 1/4W 1%

RM0031 R204 1 RES, MF 3K32 1/4W 1%

RM0035 R200 1 RES, MF 4K75 1/4W 1%

RM0075 R205 1 RES, MF 475R 1/4W 1%

RM0085 R107 1 RES, MF 2K00 1/4W 1%

RM0097 R35 1 RES, MF 6K19 1/4W 1%

RM0106 R26 1 RES, MF 14K0 1/4W 1%

RM0120 R9,R10 2 RES, MF 30K1 1/4W 1%

RM0136 R202 1 RES, MF 150K 1/4W 1%

RM0156 R108 1 RES, MF 392K 1/4W 1%

RM0158 R27 1 RES, MF 28K0 1/4W 1%

RM0171 R31,R203 2 RES, MF 475K 1/4W 1%

RM0188 R106 1 RES, MF 499R 1/4W 1%

RM0191 R32 1 RES, MF 20K5 1/4W 1%

RM0263 R11 1 RES, MF 48K7 1/4W 1%

RM0361 R76 1 RES, MF 2K10 1/4W 1%

RM0402 R18,R23 2 RES, MF 11K5 1/4W 1%

RM0404 R2 1 RES, MF 54R9 1/4W 1%

MISCELLANEOUS

480113 J1 1 SUB, #18B 6 1/4 STRIP BOTH

480114 J2 1 SUB, #18R 6 1/4 STRIP BOTH

JC0091 J5, J6 2 CNCTR, RCA SINGLE PC MT

JH0006 J9 1 CNCTR, HEADER 4PIN .100CTR

JH0074 J7, J10 2 CNCTR, HEADER 8PIN LOCKING .1C

MT0003 J17 1 TERM, FASTON MALE PCMT 250X032

IL60

27

Page 28

IL60 Electrical Parts List (Cont.)

Part# Reference Designator Qty Description

MT0036 J16 1 TERM, FASTON MALE PCMT 205X032

SR0007 S1,S3,S4 3 SWITCH, SPDT TOGGLE C/W CAP PC

PCB, RABOS Board

SEMICONDUCTORS

UA0009 U1 1 OPAMP, QUAD 14P DIL TL074/084

UA0010 U2 1 OPAMP, DUAL 8PIN DIL TL082

RESISTORS

RC0273 R30,R32,R33 3 RES, ZERO OHM 1/4W

RM0001 R24,R25 2 RES, MF 1K00 1/4W 1%

RM0002 R1,R2,R4,R9,R14,R15,R21,R23 8 RES, MF 10K0 1/4W 1%

RM0003 R8,R13 2 RES, MF 15K0 1/4W 1%

RM0012 R3 1 RES, MF 100R 1/4W 1%

RM0013 R34 1 RES, MF 11K0 1/4W 1%

RM0024 R22 1 RES, MF 2K21 1/4W 1%

RM0042 R26 1 RES, MF 681R 1/4W 1%

RM0080 R5,R10 2 RES, MF 825R 1/4W 1%

RM0260 R36 1 RES, MF 1M0 1/4W 1%

RM0271 R19 1 RES, MF 110K 1/4W 1%

RM0281 R7,R12 2 RES, MF 6K04 1/4W 1

RM0315 R17 1 RES, MF 2K67 1/4W 1%

RM0369 R6,R11 2 RES, MF 340R 1/4W 1%

RM0370 R18 1 RES, MF 9K31 1/4W 1%

RM0377 R16 1 RES, MF 3K57 1/4W 1%

RM0378 R20 1 RES, MF 549R 1/4W 1%

RP0087 R27,R29 2 POT, A10K DUAL 12MM HOR SEL

RP0088 R28 1 POT, C10K DUAL12MM HOR SEL

DNI R31, R35 2 Do Not Insert

CAPACITORS

DNI C3, C4 2 Do Not Insert

CF0045 C1,C2,C5 3 CAP, F .1UF 63DC 5% 5MMLS

MISCELLANEOUS

JH0074 J1 1 CNCTR, HEADER 8PIN LOCKING .1C

PCB, Linear Board

SEMICONDUCTORS

DS0001 D1-11 11 RECT, 100mA 75V SIGNAL 1N4148T

QB0017 Q2, Q6 2 TRANS, NPN 150V 0.6A 2N5551TR

QB0018 Q1, Q5 2 TRANS, PNP 150V 0.6A 2N5401TR

QM0015 Q3, Q7 2 MOSFET, IRF640 T0220AB

QM0034 Q4, Q8 2 MOSFET, IRF9540 T0220AB

QM0054 Q9 1 JFET, N-CH J113 T092

UA0009 U1 1 OPAMP, QUAD 14P DIL TL074/084

UV0015 U2 1 VREG, +18v 500MA LM7818CT

UV0016 U3 1 VREG, -18V 500MA LM7918CT

DZ0011 Z1, Z2 2 ZENER, 500MW 3V 5% 1N5225B

RESISTORS

RM0001 R12-15, R28-31 8 RES, MF 1K00 1/4W 1%

RM0002 R1, R2, R5, R6 4 RES, MF 10K0 1/4W 1%

RM0021 R7, R8, R23, R24 4 RES, MF 1K82 1/4W 1%

RM0024 R17, R18, R33, R34 4 RES, MF 2K21 1/4W 1%

RM0029 R9, R10, R25, R26 4 RES, MF 3K01 1/4W 1%

RM0035 R41, R42 2 RES, MF 4K75 1/4W 1%

RM0039 R47 1 RES, MF 5K11 1/4W 1%

RM0091 R22, R38 2 RES, MF 3K65 1/4W 1%

RM0170 R21, R37 2 RES, MF 59K 1/4W 1%

RM0180 R16, R32 2 RES, MF 4K99 1/4W 1%

RP0059 R11, R27 2 POT, 2K 8MM TOPADJ/COVER

IL60

28

Page 29

IL60 Electrical Parts List (Cont.)

Part# Reference Designator Qty Description

RW0022 R44, R45 2 RES, WW 0R1 2W 5%

RX0055 R39, R40 2 RES, MO 470R 2W 5%

CAPACITORS

CC0025 C15-18 4 CAP, CA1000PF 100V 10%

CC0080 C13, C14 2 CAP, CA 220P 100V 10%

CC0082 C7, C8 2 CAP, CA .1UF 50V 20%

CC0097 C4, C5 2 CAP, C 10P 50V 10

CE0003 C6 1 CAP, E 2.2UF 50V 20% 105C

CE0013 C9, C10, C21, C22 4 CAP, E 47UF 50V 20% 5MMLS

CE0085 C19, C20 2 CAP, E 22UF 16V BP 6X11 5MMLS

CE0103 C11-12 2 CAP, E 100UF 35V 85DEG 5MMLS

CE0116 C1 1 CAP, E 2.2UF 50V BP 6X11 5MMLS

CF0125 C3 1 CAP, F .068UF 100V 5% 5MMLS

CF0128 C2 1 CAP, F .033UF 100V 5% 5MMLS

MISCELLANEOUS

KS0019 R46 1 THERMISTOR, PTH9L04BD22TS2F510

JH0016 J7 1 CNCTR, HEADER 2PIN .100CTR

JH0074 J13, J14 2 CNCTR, HEADER 8PIN LOCKING .1C

MM0025 J9, J10 2 MISC, PC MT SCREW TERM 6-32

MT0003 J1 1 TERM, FASTON MALEPCMT 250X032

MT0023 J3, J6 2 TERM, FASTON MALEPCMT 187X032

MT0036 J2 1 TERM, FASTON MALEPCMT 205X032

TS0016 6 TUBING, #5 BLACK CUT TO .3

810056 6 MET, HTSNK CLIP .9X.5X.2 FET Used on Q3, Q4, Q7,

Q8, U2 & U3

MS0005 2 SILPAD, .009 .3C/W TO3P used with regulators U2 & U3

MS0017 4 MISC, CERAMIC PLATE TO-220 Oxide used with FETs

PCB, Power Supply 500W 230V/120V

SEMICONDUCTORS

DR0077 D506, D507 2 RECT, 1A 100V FASTREC 1N4934

DS0001 D509, D510, D511 3 RECT, 100mA 75V SIGNAL 1N4148T

DS0002 D501, D502, D505 3 RECT, 100MA 200V SIGNAL 1N3070

DD0003 D503 1 RECT, 1A2 60V DIAC

DR0076 D504 1 RECT, 16A 400V ULTRA MUR1640CT

DR0087 D508 1 RECT, 15A 200V ULTRA MUR1540

QB0002 Q505 1 TRANS, NPN 40V .6A TO92 2N4401

QB0014 Q503 1 TRANS, PNP TO92 MPSA92TR

QB0017 Q506 1 TRANS, NPN 150V 0.6A 2N5551

QM0015 Q504, Q507 2 MOSFET, IRF640 TO220AB

QM0055 Q501, Q502 2 MOSFET, IRF740 TO220AB

HC1011 U501 1 HYBRID, THK FILM HC BUCK CNTR

DZ0002 Z501, Z503 2 ZENER, 500mW 12V 5% 1N5242B

DZ0004 Z505 1 ZENER, 500mW 18V 5% 1N5248B

DZ0021 Z502, Z504 2 ZENER, 500MW 15V 5% 1N5245B

DZ0038 Z506 1 ZENER, 500MW 33V 5% 1N5257B

RESISTORS

RC0082 R509 1 RES, CF 100K 1/2W 5%

RC0136 R515 1 RES, CF 160K 1/4W 5%

RC0273 R518, R519 2 RES, ZERO OHM 1/4W

RM0001 R507 1 RES, MF 1K00 1/4W 1%

RM0002 R525 1 RES, MF 10K0 1/4W 1%

RM0050 R531 1 RES, MF 90K9 1/4W 1%

RM0070 R528 1 RES, MF 301R 1/4W 1%

RM0191 R529 1 RES, MF 20K5 1/4W 1%

RM0198 R508 1 RES, MF 205K 1/4W 1%

RM0260 R526 1 RES, MF 1M0 1/4W 1%

RM0337 R530 1 RES, MF 19K6 1/4W 1%

RM0339 R511, R512, R523, R534, R535 5 RES, MF 10R 0.6W 1% FLAMEPROOF

IL60

29

Page 30

IL60 Electrical Parts List (Cont.)

Part# Reference Designator Qty Description

RM0340 R503, R506 2 RES, MF 22R 1/4W 1% FLAMEPROOF

RM0397 R502, R505 2 RES, MF 422R 1/4W 1%

RM0399 R527 1 RES, MF 3K48 1/4W 1%

RW0022 R521, R522, R532, R533 4 RES, WW 0R1 2W 5%

RX0046 R514 1 RES, MO 47K 1W 5%

RX0048 R501, R504 2 RES, MO 330R 1W 5%

RX0072 R524 1 RES, MO 100R 1W 5

RX0106 R538 1 RES, MO 15K 2W 5%

CAPACITORS

CE0013 C505, C506 2 CAP, E 47UF 50V 20%

CE0098 C507 1 CAP, E 22UF 50V 20% 5X11 .2LS

CF0019 C501, C502 2 CAP, F 4700PF 100V 5% 5MMLS

CC0040 C503 1 CAP, CA4700PF 100V 10%

CC0059 C518, C519 2 CAP, CA.1UF 100V 20%

CC0082 C521 1 CAP, CA.1UF 50V 20%

CC0021 C516 1 CAP, C 470PF 1KV 10%

CC0130 C524 1 CAP, CY1 4700PF 250V 20% 10MML

CE0040 C504 1 CAP, E 680UF 200V 30X35 85DEG

CE0136 C508, C509 2 CAP, E 820UF 200V 20% 30X35

CF0050 C510, C511, C512, C513, C520 5 CAP, F .1UF 250V 10%

CF0146 C517 1 CAP, F 6.8UF 250V 10% 27MMLS

MISCELLANEOUS

KS0021 R513 1 SURGISTOR, 4R 8A 70J SL154R008

BF0007 L502 1 BEAD, FERRITE

500111 T501 1 XFMR, ETD44

540131 L501 1 IND, 25UH UPRIGHTAIR COIL

TS0016 HtSkTube 6 TUBING, #5 BLACK CUT TO .3 Used on D504, D508,

Q501, Q502, Q504 & Q507

HS0054 4 SCREW, #4 SELF TAP 1/2 PAN PHI USED ON H4, H5,

H6, H7

HS0089 4 SCREW, #4-40X1/2 PAN PHIL ZNP USED ON

HEATSINK

HW0030 4 WASHER, FLAT #8 NYLON USED WITH HS0089 ON

HEATSINK

JH0074 J505 1 CNCTR, HEADER 8PIN LOCKING .1C

MT0023 J501, J502, J503, J504 4 TERM, FASTON MALE PCMT 187X032

810066 Clip 6 MET, HTSNK CLIP HPS SERIES Used on Q501, Q502,

Q504, Q507, D504 & D508

810105 Heatsink 1 Lance and Form Heatsink Primary

810106 Heatsink 1 Lance and Form Heatsink Secondary There should be a

piece of tape in between the heatsink and the PCB.

MS0017 Ceramic 2 MISC, CERAMIC PLATE TO-220 USED ON Q504, Q507

Q508 1 Do not insert

R516, R517, R539, R540, R541, R542, R543, R544 8 Do not insert

U502 1 Do not insert

Z507, Z508 2 Do not insert

PCB, EMI Filter board

SEMICONDUCTORS

DB0009 D5 1 RECT, 6A 400V BRIDGE

RESISTORS

RC0004 R23 1 RES, CF 1M0 1/4W 5%

CAPACITORS

CC0130 C3 1 CAP, CY1 4700PF 250V 20% 10MML

CF0050 C4, C5 2 CAP, F .1UF 250V 10% 10MMLS

CF0057 C2 1 CAP, FX .22UF 250V 10%

IL60

30

Page 31

IL60 Electrical Parts List (Cont.)

Part# Reference Designator Qty Description

MISCELLANEOUS

KV0001 Z4 1 VARISTOR, 275V 100J .6W

MT0023 J5, J6 1 TERM, FASTON MALE PCMT 187X032

480097 J1 1 SUB, #18B 9 187X032/1/4STRP

480090 J2 1 SUB, #18R 9 187X032/1/4STRP

540124 L1 1 IND, CM CHOKE YT7271

810088 1 MET, Heatsink 1x2 Bridge

HN0006 1 NUT, HEX KEP #6-32 ZNP Used with screw HS0066

HS0066 1 SCREW, #6-32X1/2 PAN PHIL BLK Used on the bridge

and heatsink

PCB, VOLUME-LED INTERLUDE LEFT

DL0014 D1,D2 2 LED, 3MM BICOLOR RED/GR

RP0099 R1 1 POT, C10K SINGLE/BRKT D SHAFT

JH0006 J1 1 CNCTR, HEADER 4PIN .100CTR

HS0078 3 SCREW, #4-24X1/2 HLPP BLK USED ON 610043

HW0038 1 WASHER, FLAT .195ID .437OD RB AT PLASTIC

HOUSING FOR CABLE.

1 INTERLUDE VOL-LED MTG PLT LEFT

JC0169A 1 CNCTR, FEM-MAHARNESS 4PSH 15 USED ON

LOCATION J1

MM0065 1 MISC, VOL GASKET L INTERLUDE

RP0104 1 POT, KNOB INTERLUDE LEVEL L

PCB, VOLUME-LED RIGHT

DL0014 D1,D2 2 LED, 3MM BICOLOR RED/GR

RP0097 R1 1 POT, A10K SINGLE/BRKT D SHAFT

JH0006 J1 1 CNCTR, HEADER 4PIN .100CTR

HS0078 3 SCREW, #4-24X1/2 HLPP BLK USED ON 610044

HW0038 1 WASHER, FLAT .195ID .437OD RB AT PLASTIC

HOUSING FOR CABLE.

INTERLUDE CUP R 1 INTERLUDE VOL-LED MTG PLT RIGH

JC0169A 1 CNCTR, FEM-MA HARNESS 4PSH 15 USED ON

LOCATION J1

MM0066 1 MISC, VOL GASKET R INTERLUDE

RP0103 1 POT, KNOB INTERLUDE LEVEL R

MISCELLANEOUS

480033 3 SUB, #18R 4 187X032/187X032 1 PCS FOR IEC L TO

FUSE; 1 PCS FOR FUSE TO SWITCH; 1 PCS FOR

SWITCH TO EMI

480048 1 SUB, #18B 9 187X032/187X032 Power Supply CD- TO

LINEAR CD480073 1 SUB, #18R 9 187X032/187X032 Power Supply CD+ TO

LINEAR CD+

480083 2 SUB, #18B 4 187X032/187X032 1 for IEC TO SWITCH; 1

FOR SWITCH TO EMI

480091 1 SUB, #18R 7 187X032/187X032 DC+ TO POWER

SUPPLY

480119 1 SUB, #16B 20 205X032/205X032 XOVER - WIRE;

480120 1 SUB, #16R 20 250X032/250X032 XOVER + WIRE;

480121 1 SUB, #16B 30 205X032/205X032 SPEAKER - WIRE;

480122 1 SUB, #16R 30 250X032/250X032 SPEAKER + WIRE;

480130 1 SUB, #18B 7 187X032/187X032 DC- TO POWER

SUPPLY

810066 6 MET, HTSNK CLIP HPS SERIES USED ON D4, D8, Q1,

Q2, Q4 & Q7

810088 1 MET, HTSNK 1X2 BRIDGE REV 2; USED WITH THE

BRIDGE

810105 1 MET, HTSNK PRI 3FET IL120

810106 1 MET, HTSNK SEC 3FET IL120

810107 1 IL60/120 SHIELD

810108 1 IL60/120 POWER BRACKET

IL60

31

Page 32

IL60 Electrical Parts List (Cont.)

Part# Reference Designator Qty Description

930054 1 CUP, PCBABUCKET C/W GASKET FEATURE BOARD

BOX

930055 1 CUP, AMP BUCKET AC IN W/GASKET AC BOX

FH0012 1 FUSE, HOLDER PANEL MT SEALED

FS0026 1 FUSE, 4A 250V 1.25X.25 GLASS

HN0006 1 NUT, HEX KEP #6-32 ZNP USED WITH THE BRIDGE

HN0015 4 NUT, HEX KEP #8-32 ZNP USED WITH HS0057

HS0004 4 SCREW, #6-32X1/4 PAN PHIL ZNP 1PER USED ON

MZ0040; 1PER USED ON standoff P/N MZ0045; 2PER

USED ON MM0025 for Linear board

HS0041 7 SCREW, #4-3/8 TYPE A PP BLK 2 USED ON EMI

BOARD; 5 USED ON POWER SUPPLY BOARD

HS0057 4 SCREW, #8-32X1/2 PAN PHIL BLK MOUNT BRACKET

TO PANEL

HS0060 3 SCREW, #6-32X3/8 PAN PHIL BLK MOUNT SHIELD TO

BRACKET

HS0062 6 SCREW, #6-1/2 TYPE B PP BLK USED ON FETS

HS0065 3 SCREW, #6-32X1/4 PAN PHIL BLK 1 USED ON MZ0025

for Feature Board, 1 used on MZ0040, 1 used on standoff

P/N NEW

HS0066 1 SCREW, #6-32X1/2 PAN PHIL BLK USED WITH THE

BRIDGE

HS0067 26 SCREW, #6-3/8 TYPE A PP BLK 8 USED WITH 930054;

6 USED WITH 930055; 6pcs used on MZ0030; 3pcs used

on MZ0040; 3 pcs used on MM0025

HS0078 6 SCREW, #4-24X1/2 HLPP BLK 2PER USED ON

BINDING POSTS; 2PER USED ON RCA’S; 2PER USED

ON RABOS STANDOFF

HS0089 4 SCREW, #4-40X1/2 PAN PHIL ZNP TO CONNCT THE

HEATSINKS

IL60 PANEL 1 INTERLUDE IL60 PANEL COMPLETE

JC0071 1 CNCTR, FEM-FEM HARNESS 8PIN 9 USED ON THE

RABOS BOARD TO FEATURE BOARD

JC0104 1 CNCTR, 2PIN BP GOLD C/W TERM

JC0129 1 CNCTR, AC IEC SOCKET .250 2PIN

JC0163A 1 CNCTR, FEM-MALHARNESS 8P 10 J7 ON THE

FEATURE TO J13 ON LINEAR BOARD

JC0163B 1 CNCTR, FEM-FEM HARNESS 8P 10 J7 ON THE

FEATURE TO J13 ON LINEAR BOARD

JC0165 1 CNCTR, FEM-FEM HARNESS 8P 12 Power supply to

Linear

JC0169C 1 CNCTR, FEM-FEM HARNESS 4PS 28 USED ON J9;

MM0069 3 MISC, RUBBER GROMMET IL50/100

MM0076 2 MISC, PANEL GASKET, IL60/IL120

MS0005 7 SILPAD, .009 .3C/W TO3P 3PER USED ON MAIN

BOARD; 4PER USED ON THE LINEAR BOARD;

MZ0003 1 STANDOFF, 6-32 3/8 ROUND AL USED ON AC FILTER

PCB

MZ0030 2 STANDOFF, 3/8 NYLON 2 PER USED ON AC FILTER

BOARD

MZ0040 2 STANDOFF, 30MM NYLON USED ON THE RABOS

BOARD

MZ0045 1 STANDOFF, 6-32X 1-3/16 HEX AL USED WITH THE

RABOS BOARD

SR0032 1 SWITCH, ROCKER TV5 ON THE FRONT PANEL

IL60

32

Page 33

Integrated Circuit Diagrams

IL60

33

Page 34

Wiring Diagram/Crossover Network

+ INPUT

- INPUT

C1

470 mF

100V

L1

2.4 mH

C2

80 mF

100V

GRN

GRN/BLK

250 +MB

205

-MB

C3

14 mF

100V

L2

0.75 mH

C4

8 mF

100V

L3

1.5 mH

R1

3.3 ohms

10W

+MR

250

WHT

WHT/BLK

-MR

205

C5

2 mF

100V

L4

0.18 mH

C6

14 mF

100V

R2

1.8 ohms

10W

YEL

+HF

187

YEL/BLK

-HF

110

AMPLIFIER

BLK

RED

.250

+LF

.205

-LF

WW+

MM+

Y-

T+

IN+

IN-

GRN

GRN/BLK -

+

WHT/BLK

WHT

-

+

YEL/BLK

-

YEL

+

MIDBASS

TRANSDUCER

335741-001

WOOFER

336056-001

TWEETER

335225-002

MIDRANGE

TRANSDUCER

335812-002

AMPLIFIER

NETWORK

336500-001

CROSSOVER NETWORK

SCHEMATIC

WIRING DIAGRAM

BLK

-

RED

+

00419

IL60

34

Page 35

35

IL60

500W EMI/Volume PCB's

Page 36

36

IL60

Page 37

37

IL60

Page 38

IL60

38

Page 39

IL60

39

Page 40

IL60

40

Page 41

41

Loading...

Loading...