Page 1

现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

Preliminary Datasheet TLE6288 R

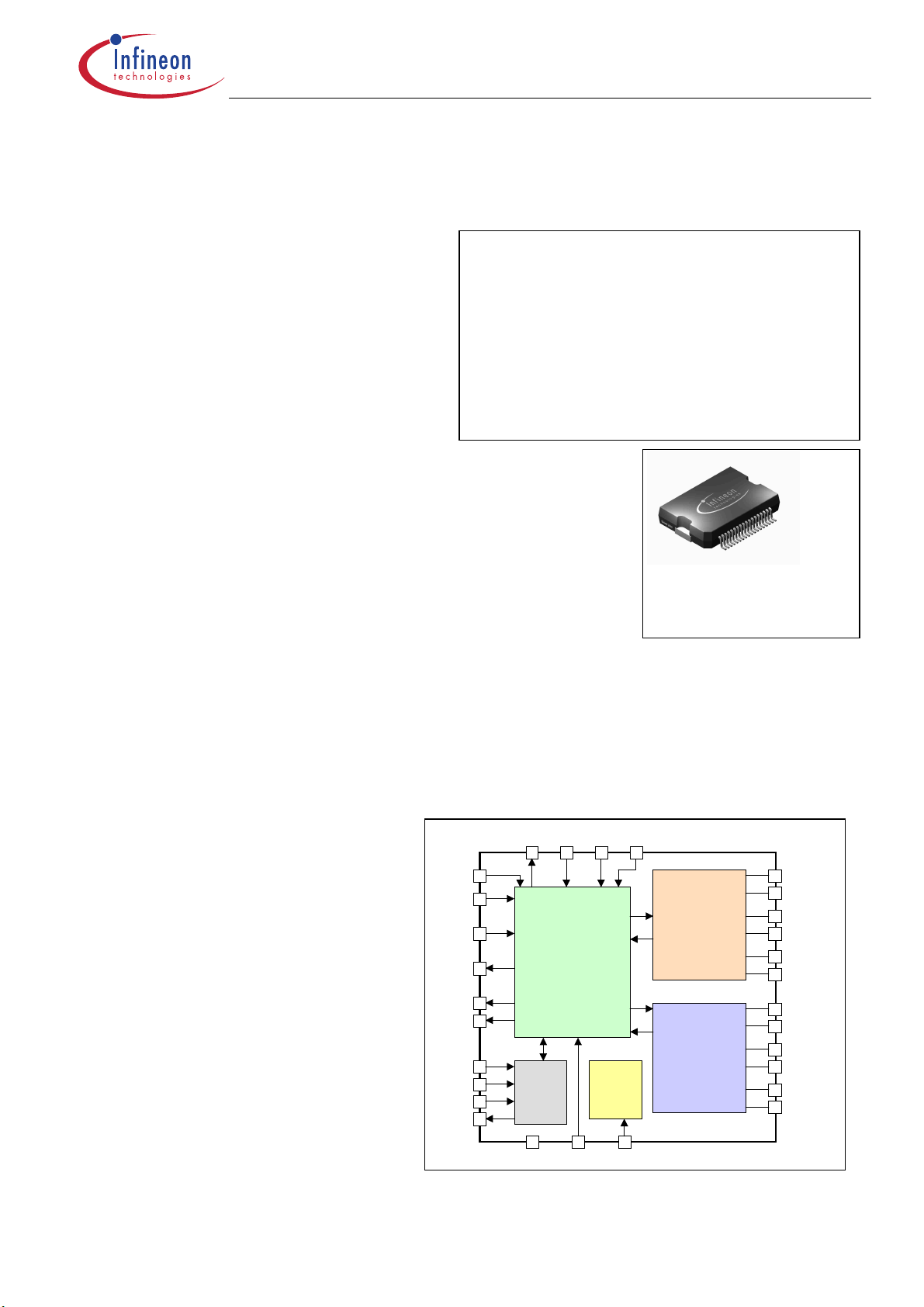

TLE 6288 R : Smart 6 Channel Peak&Hold Switch

Features Product Summary

• 3 Channel high side with adjustable P&H current control

• 3 Channel high / low side configurable

• Protection

Over Current (current limitation)

Overtemperature

Overvoltage (active clamping)

• Diagnosis

Over Current

Over Temperature

Open Load (Off-State)

Short to Ground (Off-state, lowside configuration)

Short to Vbb (Off-state, highside configuration)

• Interface and Control

16 Bit Serial Peripheral Interface (2bit/CH)

Device programming via SPI

Separate diagnosis output for each CH ( DIAG1 – 6)

General Fault Flag + Overtemperature Flag

Direct parallel control of all channels

General enable signal to control all channels simultaneously

• Low Quiescent Current

• Compatible with 3.3V and 5V Microcontrollers

• Electostatic discharge (ESD) protection of all pins

Application

Supply voltage V

On resistance R

Lowside clamping voltage V

Highside clamping voltage V

Peak current range Ipk 1.2 - 3.6 A

Hold current range Ihd 0.7 - 2 A

Peak time range Ip 0 - 3.6 ms

Fixed off time range I

4.5 – 5.5 V

S

ON 1-6

+55 V

cll (max)

clh (max)

fo

P-DSO 36-12

Ordering Code:

0.15 Ω

-19 V

100 – 400 µs

• Solenoids, Relays and Resistive Loads

• Fast protected Highside Switching (PWM up to >10kHz)

• Peak and Hold Loads (valves, coils)

General description

The TLE6288 R is a 6-channel (150mΩ)

Smart Multichannel Switch in SPT4 Technology. The IC has embedded protection,

diagnosis and configurable functions.

Channel 1-3 are highside channels with

integrated charge pump and can be programmed individually to do autonomous

peak and hold current regulation with

PWM. Channel 4-6 (also with integrated

charge pump) can be configured to work

as highside Switch or lowside Switch. This

IC can be used to drive standard automotive loads in highside or lowside applications with switching frequencies up to

10kHz. In addition the TLE6288R can be

used to drive autonomously up to 3 inductive Peak&Hold (valves, coils) loads with

programmable peak and hold current values.

CLKProg

IN 1

IN 6

DIAG 1

DIAG 5

DIAG 6

Overtemp.

SCLK

CS

SI

SO

Fault

Reset VDO

Logic

Configuration

Current

Regulation

SPI

VCC

Chargepump

VCPGND FSIN

Channel 1-3

Highside 150 m

Peak&Hold

Protection

Diagnosis

Channel 4 -6

Highside/ Lowside

150 m

Ω

Protection

Diagnosis

DOUT 1

SOUT 1

DOUT 2

SOUT 2

DOUT 3 / VB

SOUT 3

DOUT 4

SOUT 4

DOUT 5

SOUT 5

DOUT 6

SOUT 6

Vp2 Page 1 13.01.2003

Page 2

Preliminary Datasheet TLE6288 R

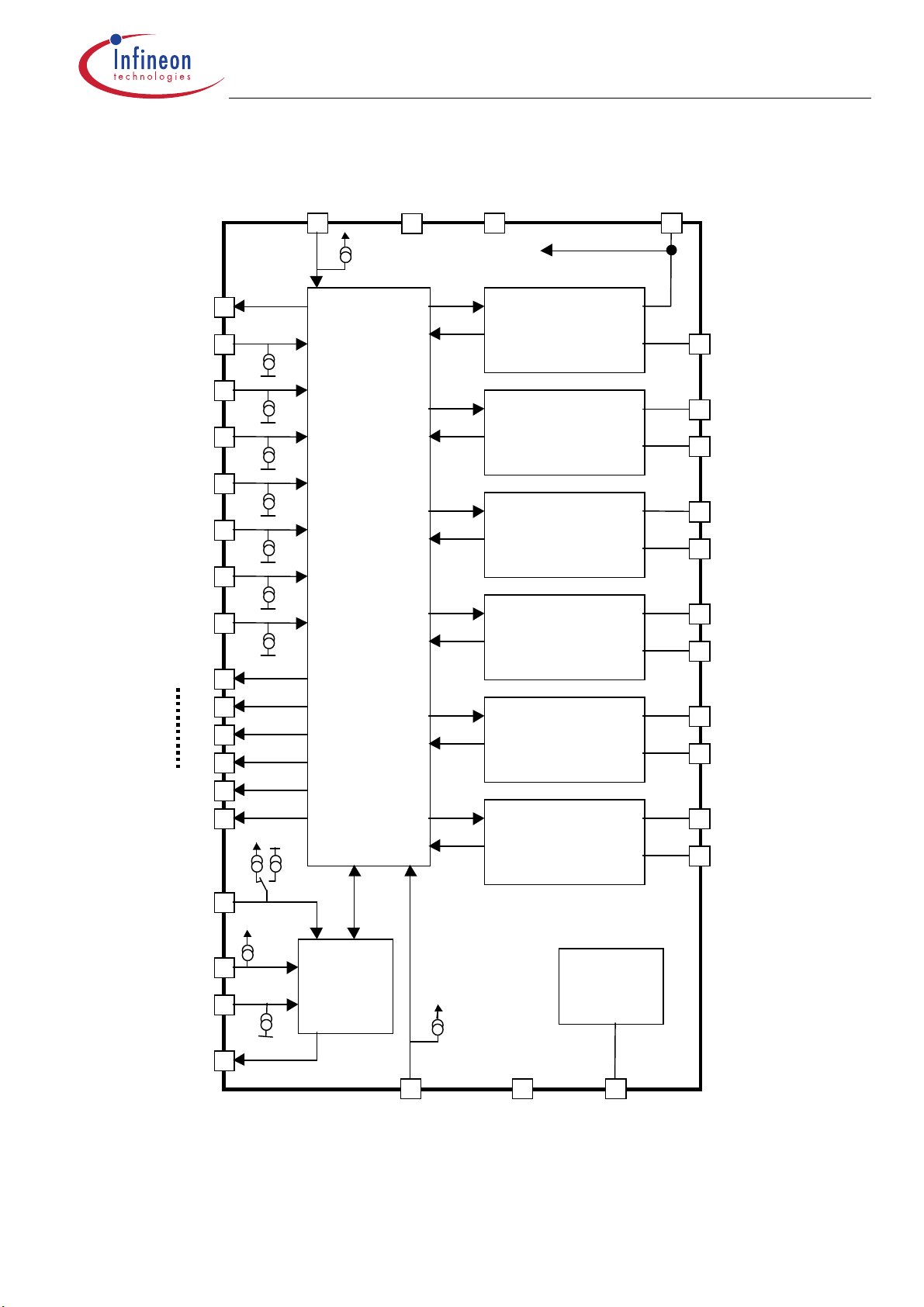

1. Block Diagram

Fault

CLKProg

IN 1

IN 2

IN 3

IN 4

IN 5

IN 6

DIAG 1

Reset VDO

.

.

.

.

.

.

Logic

.

.

Driver

Diagnosis

Vcc

VCC DOUT 3 / VB

VB

Channel 3

Highside 300 m

Peak&Hold

Channel 2

Highside 300 m

Peak&Hold

Channel 1

Highside 300 m

Peak&Hold

Channel 4

Highside/ Lowside

300 m

Ω

Ω

SOUT 3

DOUT 2

Ω

SOUT 2

DOUT 1

Ω

SOUT 1

DOUT 4

SOUT 4

DIAG 5

DIAG 6

Overtemp.

SCLK

CS

SI

SO

Vcc

Vcc

GND

GND

Channel 5

Highside/ Lowside

300 m

Ω

Channel 6

Highside/ Lowside

300 m

Ω

DOUT 5

SOUT 5

DOUT 6

SOUT 6

.

.

.

SPI

Vcc

Charge

pump

.

VCPGNDFSIN

Vp2 Page 2 13.01.2003

Page 3

Preliminary Datasheet TLE6288 R

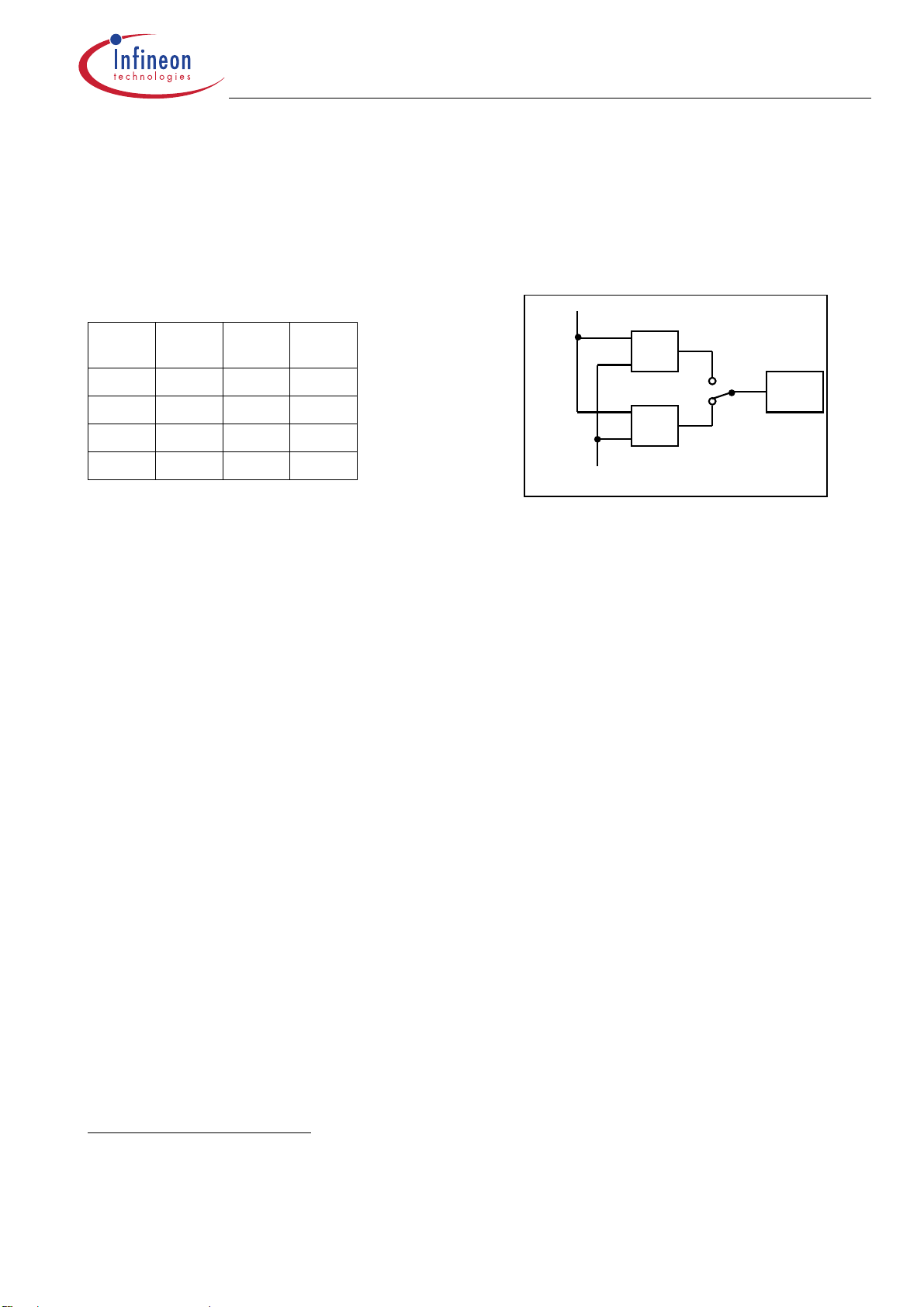

2. Functional description

Block diagram will be added

Channel 1..3:

Only High Side Drive with Charge Pump.

Current Control

Default 2.4A peak and 1A hold with adjustable values by SPI

Types of current control are switched by SPI. ( Refer to Fig. 1)

Current regulation: Peak Current Controller with fixed Off-Time

Peak Current, Peak Time, Hold Current and Off-Time can be selected by SPI

to set average and ripple current for a given load

Channel 4..6:

Either High or Low Side Drive is configurable (by SPI)

Open load detection and switch bypassed detection can be deactivated by SPI

Vp2 Page 3 13.01.2003

Page 4

Preliminary Datasheet TLE6288 R

Protection: The TLE6288R has integrated protection functions1 for overload and short circuit (active

current limitation), Overtemperature, ESD at all pins and overvoltage at the power outputs (zener

clamping).

Output Stage Control: Parallel Control and SPI Control

A Boolean operation (either AND or OR) is performed on each of the parallel inputs IN 1..6 and respective SPI data bits, in order to determine the states of the respective outputs. The type of Boolean operation performed is programmed via the serial interface. Both, parallel inputs and respective SPI databits are high active.

Truth table

parallel

Input

0 0 OFF OFF

0 1 ON OFF

1 0 ON OFF

1 1 ON ON

SPI

Bit

Output

OR

Output

AND

IN 1…6

AND

Output

Driver

OR

Serial Input bits 6 - 11 of comman d

„Ch annels on / off „

Each output is independently controlled by an output latch and a common reset line FSIN, which disables all outputs. A logic high input ‘data bit’ turns the respective output channel ON, a logic low ‘data

bit’ turns it OFF.

Overtemperature Behavior:

Each channel has an overtemperature sensor and is individually protected against overtemperature.

As soon as overtemperature occurs the channel is immediately turned off. In this case here are two

different behavoirs of the affected channel that can be selected by SPI (for all channels generally).

Autorestart: as long as the input signals of the channel remains on (e.g. parallel input high) the channel turns automatically on again after cooling down.

Latching: After overtemperature shutdown the channel stays off until the this ovetemperature latch is

reset by a new LÆH transition of the input signal.

Note: These overtemperature sensors of the channels are only active if the channel is turned on.

An additional overtemperature sensor is located in the logic of the device. I monitors permanently the

IC temperature. As soon as the IC temperature reaches a specified level an overtemperature fault will

be indicated.

1

Integrated protection functions are designed to prevent IC destruction under fault conditions described in the data sheet. Fault conditions are

considered as "outside" normal operating range. Protection functions are not designed for continuous repetitive operation

Vp2 Page 4 13.01.2003

.

Page 5

Preliminary Datasheet TLE6288 R

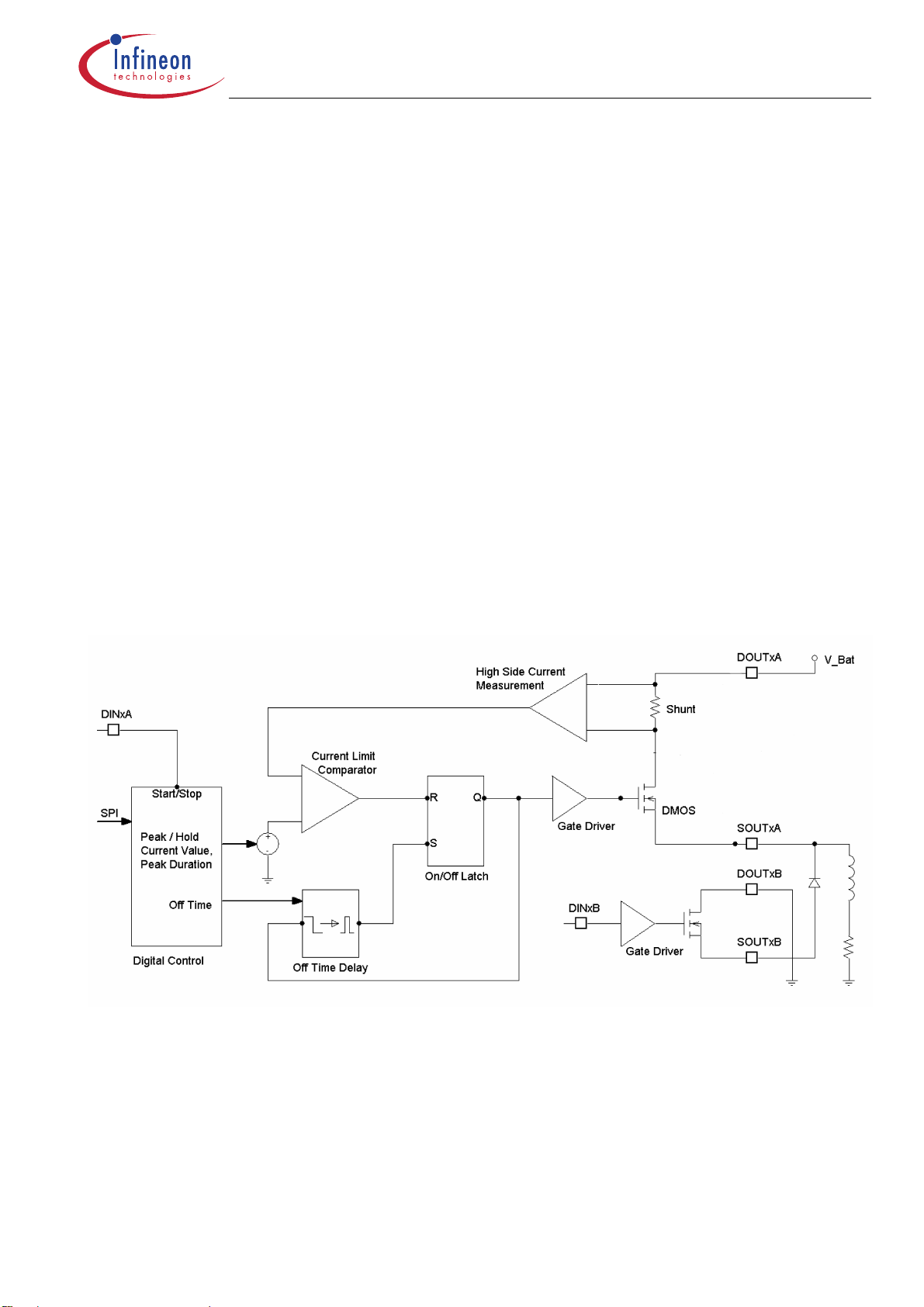

Current Regulator : Peak current control with fixed off-time

Hold only : When the channel is turned on externally (SPI or parallel input) the current rises to the programmed hold current level. Then the channel is internally turned off and a timer is started for a constant off-time (e.g. 200µs). After this time the channel is internally turned on again until the hold current

level is reached again and so on. This regulation workes automatically until the channel is turned of

externally.

Peak and hold mode with minimum peak time: When the channel is turned on the current rises to the

programmed peak current level. Then the channel is internally turned off, the current regulator changes

to hold current values and a timer is started for a constant off-time. After this time the channel is internally turned on again until the hold current value is reached and then again turned off for the fixed off

time. This regulation workes automatically until the channel is turned of externally.

Peak and hold mode with programmed peak time: When the channel is turned on the current rises to

the programmed peak current level. Then the channel is internally turned off and a timer is started for a

constant off-time. After this time the channel is internally turned on again until the peak current value is

reached and then again turned off. This works until the programmed peak time is over. Then the current regulator changes to hold current values and workes as described under "hold only".

Peak Current, Peak Time, Hold Current and fixed Off-Time can be set via SPI.

To avoid regulation disturbances by current transients during switching (e.g. caused by ESD capacitors

at the outputs) the current regulator has a "leading edge blanking" of typical 20µs in all three regulation

modes. After turning on the DMOS (internally or externally) the current regulation circuit is deactivated

for the first 20µs. This guarantees that switching of the DMOS itself or charging of small capacitors at

the output (e.g. ESD) is not disturbing the current regulation.

Simplified functional block diagram:

Vp2 Page 5 13.01.2003

Page 6

Preliminary Datasheet TLE6288 R

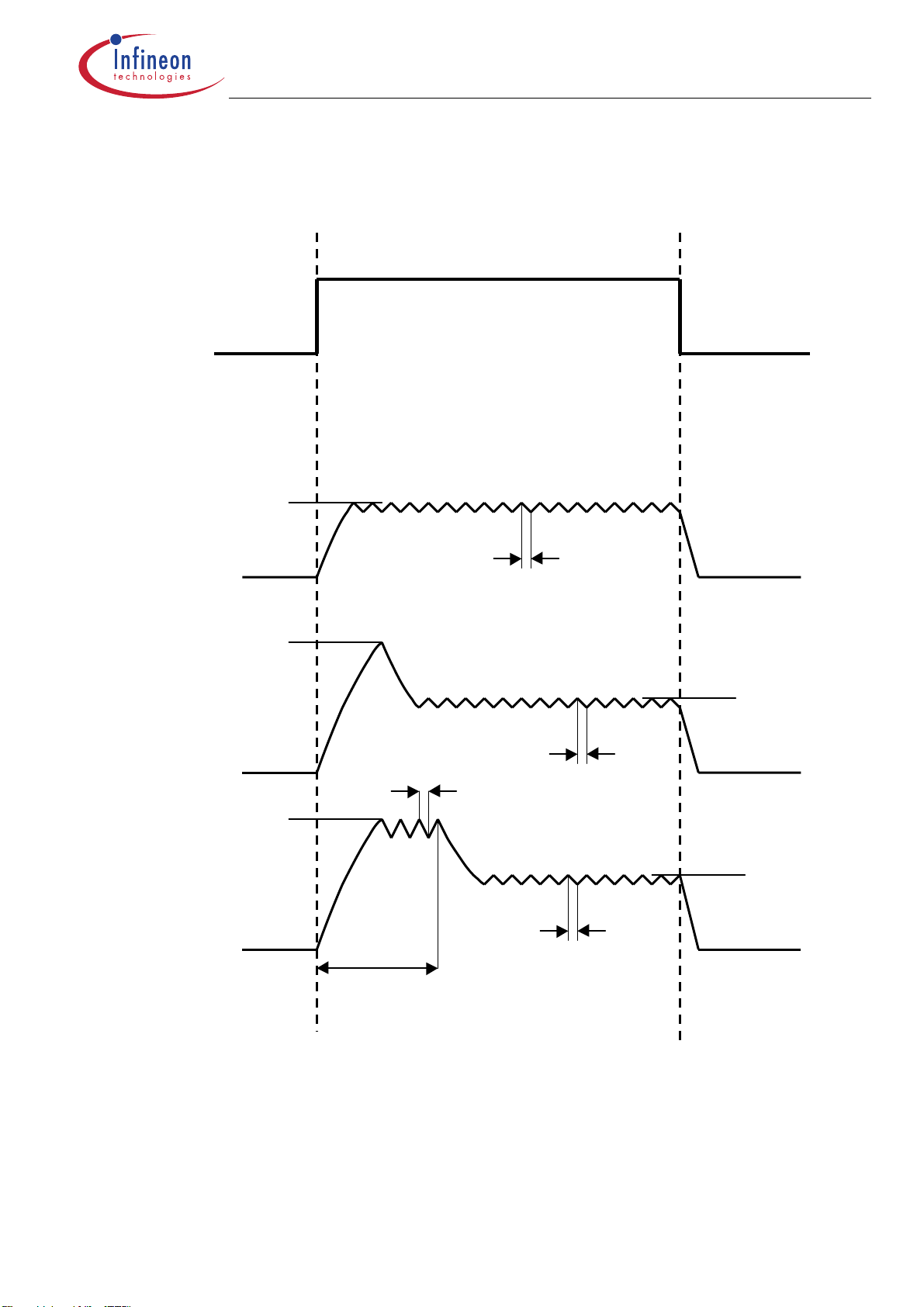

Current Waveforms of the different current control modes

Input Signal

No Regulation Current defined only by load

I

hd

Hold only

I

pk

Peak & Hold

with min. peak time

I

pk

Peak and Hold

with set peak time

t

fo

I

hd

t

fo

t

fo

I

hd

t

t

p

fo

Fig.1

Current forms of the different current control modes of channel 1-3

Vp2 Page 6 13.01.2003

Page 7

Preliminary Datasheet TLE6288 R

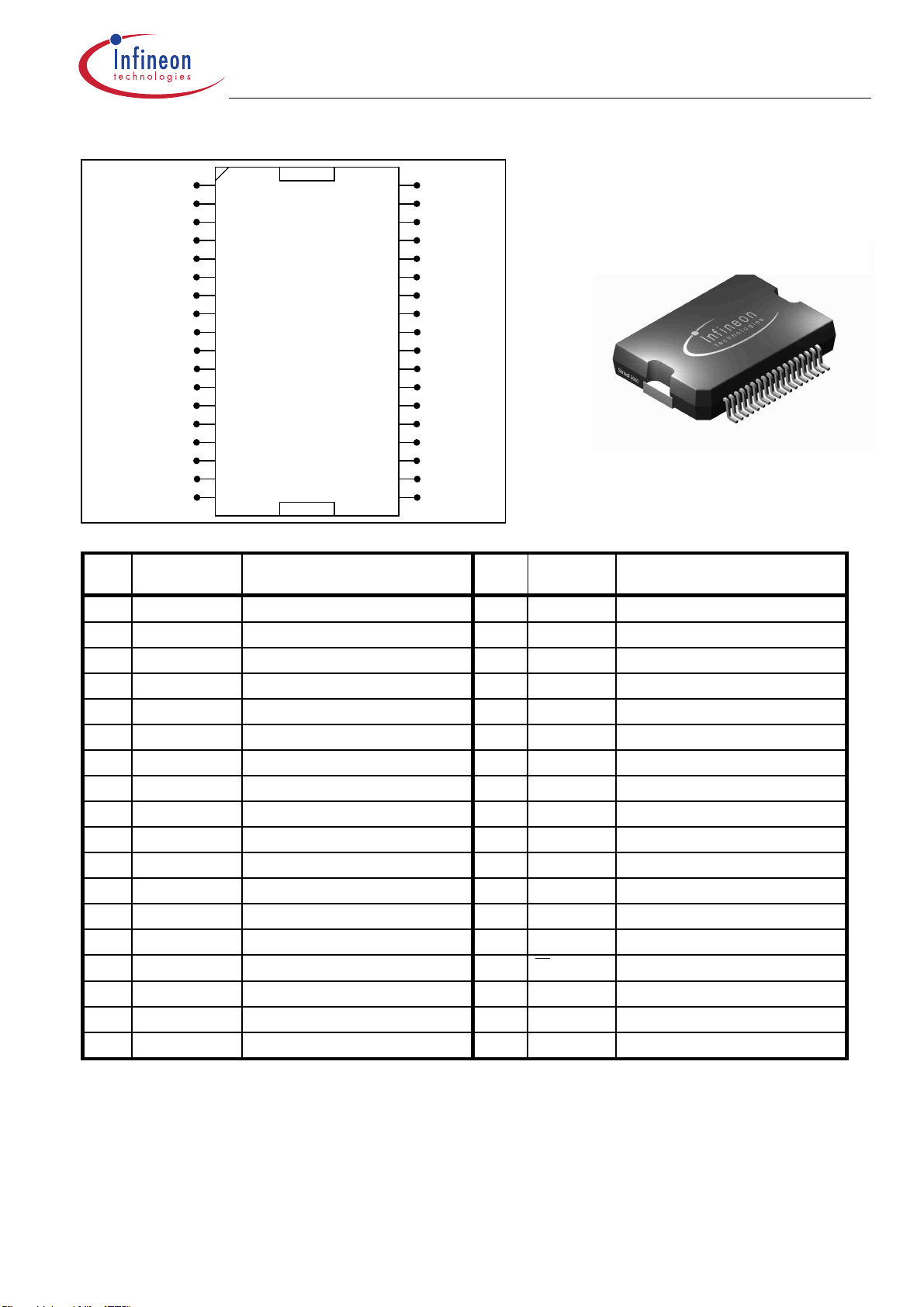

3. Pin Configuration

SOUT4

DOUT4

DOUT1

SOUT1

DIAG1

DIAG2

DIAG3

DIAG4

DIAG5

DIA6/Overtemp

SOUT2

DOUT2

DOUT5

SOUT5

Pin

Name Function Pin Nr. Name Function

Nr.

SOUT4 Source Output CH 4 (high / low side)

1

DOUT4 Drain Output CH 4 (high / low side)

2

DOUT1 Drain Output CH 1(high side)

3

SOUT1 Source Output CH 1 (high side)

4

IN4 Control Input Channel 4

5

IN1 Control Input Channel 1

6

DIAG1 Diagnostic Output CH 1

7

DIAG2 Diagnostic Output CH 2

8

DIAG3 Diagnostic Output CH 3

9

DIAG4 Diagnostic Output CH 4

10

DIAG5 Diagnostic Output CH 5

11

DIAG6/Overtemp Diagnostic Output CH 6 / Overtemp

12

IN2 Control Input Channel 2

13

IN5 Control Input Channel 5

14

SOUT2 Source Output CH 2 (high side)

15

DOUT2 Drain Output CH 2(high side)

16

DOUT5 Drain Output CH 5 (high / low side)

17

SOUT5 Source Output CH 5 (high / low side)

18

IN4

IN1

IN2

IN5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

TLE6288 R

(S0999)

36

35

34

33

32

31

30

29

28

23

22

21

20

19

27

26

25

24

SOUT6

DOUT6

SI

_CS

SCLK

CLK Prog

SO

VDO

VCC

Reset

IN6

IN3

Fault

GND

FSIN

VCP

DOUT3

SOUT3

Package: Power-P-DSO-36

0.65mm Pitch

SOUT3 Source Output CH 3 (high side)

19

DOUT3 Drain Output CH 3(high side)

20

VCP Charge Pump pin

21

FSIN All Channels Enable / Disable

22

GND Logic Ground

23

Fault General Fault Flag

24

IN3 Control Input Channel 3

25

IN6 Control Input Channel 6

26

Reset Reset pin (+ Standby Mode)

27

VCC Logic Supply Voltage (5V)

28

VDO Supply Pin for digital outputs

29

SO SPI Serial Data Output

30

CLKProg Program pin of SPI Clock

31

SCLK SPI Serial Clock

32

33

34

35

36

CS

SI SPI Serial Data Input

DOUT6 Drain Output CH 6 (high / low side)

SOUT6 Source Output CH 6 (high / low side)

SPI Chip Select

Vp2 Page 7 13.01.2003

Page 8

Preliminary Datasheet TLE6288 R

4. Pin description:

DOUT 1-3 – Drain of the 3 highside channels. These pins must always be connected to the same

power (battery) supply line.

SOUT 1-3 – Source of the three highside channels. Outputs of the highside channels where the load is

connected.

DOUT 4-6 – Drain pins of the three configurable channels. In highside configuration they must be con-

nected to the same voltage as DOUT 1-3. In lowside configuration they are the output pins and connected to the load.

SOUT 4-6 – Source of the three configurable channels. In highside configuration they are the outputs

and connected to the load. In lowside configuration they must be connected with GND.

IN 1-6 – Parallel input pins for the 6 power outputs. These pins have an internal pull down structure.

GND – Logic ground pin.

FSIN – Disable pin. If the FSIN pin is in a logic low state, it switches all outputs OFF. An internal pull-up

structure is provided on chip.

Reset – Reset pin. When the reset is low all channels are off, the internal biasing is deactivated, all

internal registers are cleared and the supply-current consuption is reduced (standby mode). An internal

pull-up structure is provided on chip.

Fault – General Fault pin.

as soon as an error is latched into the diagnosis register. When the diagnosis register is cleared this

flag is also reset (high state). This fault indication can be used to generate a µC interrupt.

CLKProg – Programming pin for the SPI Clock signal.

nal input of the SPI. In low state the SPI will read data at the rising clock edge and write data at the

falling clock edge. In high state the SPI will read data at the falling clock edge and write data at the rising clock edge The pin has an internal pull down structure.

DIAG1..5; DIAG6 / Overtemp. – Parallel diagnostic pins (push-pull) change state according to the input signal of the corresponding channel. As soon as an error occurs at the corresponding channel (

Overload and overtemperature is detected in on state and open load /switch bypass in off state) the

DIAG output shows the inverted input signal. An fault is detected only if it lasts for longer than the fault

filtering time. The fault information is not latched in a register.

If DIAG6 is configured as Overtemperature Flag: This is a general fault pin which shows a high to low

transition as soon as an overtemperature error occurs for any one of the six channels (for longer than

the fault filtering time) or the IC logic. This fault indication can be used to differ between overload and

overtemperature errors in one of the six channels or to detect a general IC overtemperature.

VCP – Pin to connect the external capacitor of the integrated charge pump.

VDO – Supply pin of the push-pull digital output drivers. This pin can be used to vary the high-state

output voltage of the SO pin and the DIAG1-6 pins.

VCC – Logic supply pin. This pin is used to supply the integrated circuitry.

There is a general fault pin (open drain) which shows a high to low transition

This pin can be used to configure the clock sig-

– Chip Select of the SPI

CS

SO – Signal Output of the Serial Peripheral Interface

SI – Signal Input of the Serial Peripheral Interface. The pin has an internal pull down structure.

SCLK – Clock Input of the Serial Peripheral Interface. The pin has an internal pull up structure (if

CLKProg=L) or an pull down structure (if CLKProg=H).

For more details about the SPI see Chapter 9.SPI.

Vp2 Page 8 13.01.2003

Page 9

Preliminary Datasheet TLE6288 R

5. Maximum ratings

No. Parameter Symbol Value Unit Pin / Comment

1 Power Supply Voltage 1 static

dynamic : 1min. 0°C

dynamic : Test cond. Fig.1

V

V

VB

B

B

-0.3 …20

24

37

V

V

V

DOUT1-3

DOUT1-3

DOUT1-3

2 Power Supply Voltage 2 VCC, VDO- 0.3 ... 7 V VCC, VDO

3a Continuous Drain Source

Voltage (lowside configuration)

3b Continuous Source Voltage

(Highside configuration)

V

40 V DOUT – SOUT

DSL

(channel 4-6)

V

SH

-9 ... VB V SOUT - GND

(channel 4-6)

4 Input Voltage VIN -0.3 … VCC+ 0.3 V IN1-6, Reset, FSIN, CS,

SCK, SI, CLKProg

5a Output Voltage V

5b Output Voltage V

5c Output Voltage V

-0.3 … VCC+ 0.3 V Fault

OUT

-0.3 … VDO+ 0.3 V DIAG1-6, SO

OUT

CP OUT

VB +10 V VCP ; no voltage must

be applied

6 Operating Temperature Ta

T

7 Storage Temperature T

8 Power Dissipation

(R

(R

= 20K/W)

thja

= 30K/W)

thja

9 Reverse Current (1ms) I

P

rev

-40 … +105

j

-55 … +150 °C

stg

dmax

-40 … +150

2,25

1,5

-4 A between DOUT and-

°C

°C

W

SOUT; Channel 4 to 6

10 ESD (Human Body Model)

2000 V

V

ESDb

C= 100pF, R=1.5kΩ

Applied to all terminals 3 times

11 ESD (Machine Model)

250 V

V

ESDm

C= 200pF, R=0Ω

Applied to all terminals 3 times

12 Single Switch off load Inductance see Fig.2 DOUT, SOUT

Fig.2

37V

10 times

(once/ 30sec)

added after characterisation

12V

160ms

350ms

Test cond. Fig.1

Vp2 Page 9 13.01.2003

Page 10

Preliminary Datasheet TLE6288 R

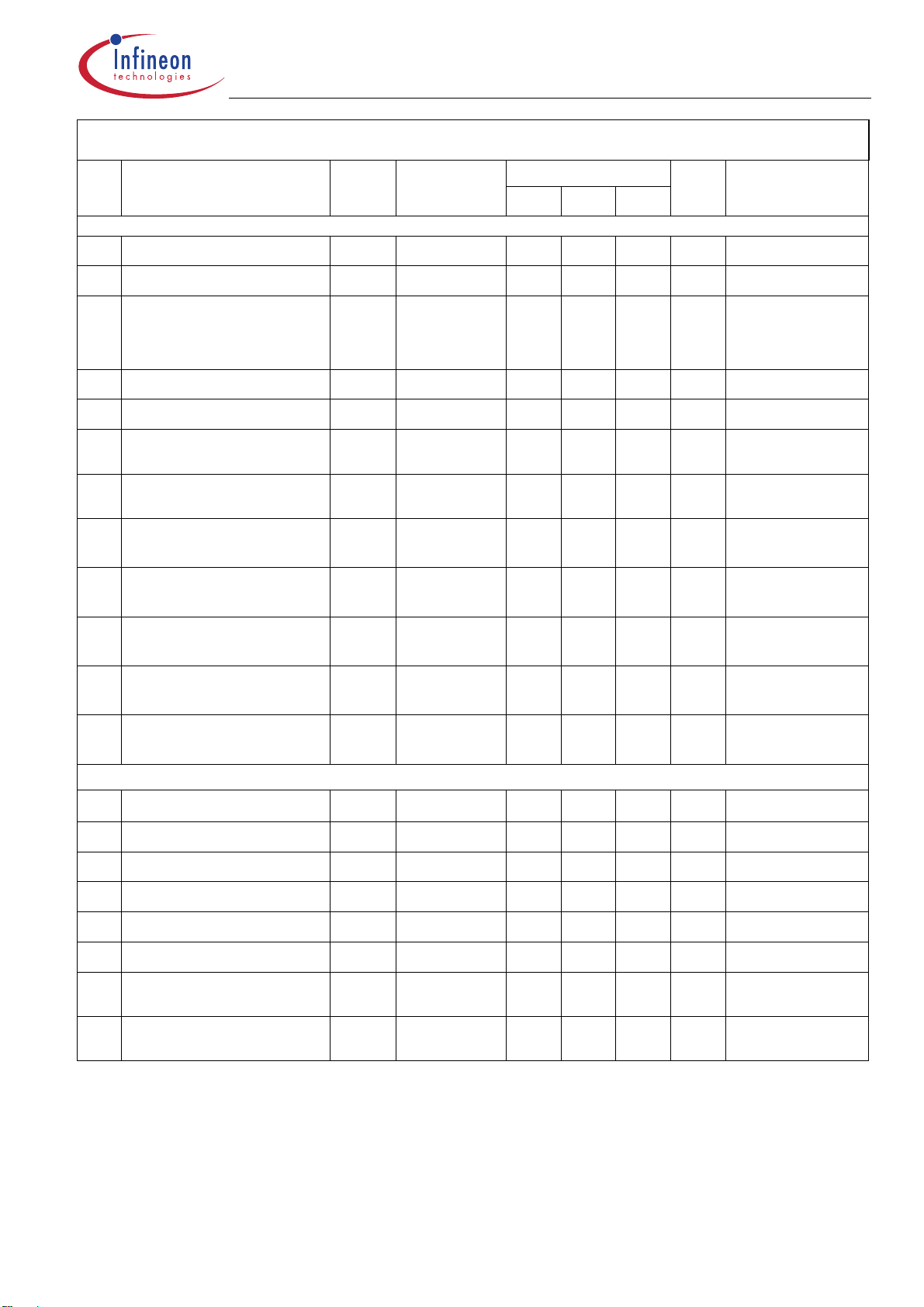

6. Electrical Characteristics

VCC = 4.5 to 5.5 V ; Tj = - 40 °C to + 150 °C ; VB = 6V to 16V ; Reset = H ; VDO = VCC

(unless otherwise specified)

Value No. Parameter Symmin typ max

Unit Pin /

Power Supply, Reset

1

Condition

bol

Comment

Power Supply Current 1 I

1.1

Power Supply Current 2 I

1.2

Power Supply Current 3

1.3

in Standby Mode

1.4

Minimum Reset Duration t

1.5

Wake up time after reset t

Power Outputs

2

On Resistance R

2.1

Forward Voltage Revers

2.2

Diode

Peak Current range I

2.3

Peak Current accuracy I

2.4

Hold Current range I

2.5

Ch1-Ch6:

b

10 mA DOUT1-3

Off

10 mA VCC

cc

I

Reset = L 50 µA DOUT1-3, VCC

cc+Ib

Re-

set,min

wakeup

DS(ON)ID

V

RDf

1.2 --

pk

50 µs

Ccp = 10 nF 5 ms

=2.4A

=10V

V

B

ID = -4A

= 150°C

T

j

350 mΩ DOUTx – SOUTx

2 V SOUTx – DOUTx

A

3.6

Tj= 25, 150°

pka

Tj=-40

0.7 --2 A

hd

± 15

± 20

%

Hold Current accuracy I

2.6

Peak time range t

2.7

Peak time accuracy t

2.8

Fixed off Time range t

2.9

Fixed off Time accuracy t

2.10

Fixed off Time accuracy 200µs-

2.11

hda

0.8 --

p

pa

100 -

fo

foa

Tj= 25, 150°

Tj=-40

3.6

400

100µs

400µs

± 15

%

± 20

ms

±20

%

µs

±30

±20

%

%

Vp2 Page 10 13.01.2003

Page 11

Preliminary Datasheet TLE6288 R

VCC = 4.5 to 5.5 V ; Tj = - 40 °C to + 150 °C ; VB = 6V to 16V ; Reset = H ; VDO = VCC

(unless otherwise specified)

Value No. Parameter Sym-

min typ max

Unit Pin /

Output ON Delay time1 t

2.12

Condition

bol

Fig.3 10 µs

dON

Comment

Output ON Rise time1 t

2.13

Output OFF Delay time1 t

2.14

Output OFF Fall time1 t

2.15

Leackage Current Reset = L 10 µA

2.16

Leak Current in OFF

2.17

Fig.3 10 µs

r

Fig.3

dOFF

HS- Mode

LS- Mode

Fig.3 10 µs

f

I

-250 µA SOUT1-6

loff

20

20

µs

(highside configuration)

Leak Current in OFF

2.18

I

500 µA DOUT4-6

loff

(lowside configuration)

Output Clamp Voltage

2.19

Highside Configuration

Output Clamp Voltage

2.20

Lowside Configuration

Current limitation

2.21

V

Referes to

clh

GND level

V

Referes to

cll

GND level

I

Dlim1-3

4 6 A

-9 -14 -19 V SOUT1-6

40 55 V DOUT4-6

(Channel 1-3)

Current limitation

2.22

I

Dlim4-6

3 6 A

(Channel 4-6)

2.23

IC Overtemp. Warning

Hysteresis

T

ot

T

hys

160

10

180 °C

°C

Digital Inputs

3

Input Low Voltage V

3.1

Input High Voltage V

3.2

Input Voltage Hysteresis V

3.3

Input Pull Down current I

3.4

Input Pull Up current I

3.5

SPI Input Pull Down

3.6

current

SPI Input Pull Up current I

3.7

1 V all digit. inputs

INL

2 V all digit. inputs

INH

100 mV all digit. inputs

INHys

V

pd

VIN = GND 20 50 100 µA Reset; FSIN

pu

I

V

pd

= 5V 20 50 100 µA IN1-6; CLKProg

IN

= 5V 10 20 50 µA SI, SCLK

IN

(CLKProg=H)

V

pd

= GND 10 20 50 µA CS;SCLK

IN

(CLKProg=L)

Vp2 Page 11 13.01.2003

Page 12

Preliminary Datasheet TLE6288 R

VCC = 4.5 to 5.5 V ; Tj = - 40 °C to + 150 °C ; VB = 6V to 16V ; Reset = H ; VDO = VCC

(unless otherwise specified)

Value No. Parameter Sym-

min typ max

Unit Pin /

Digital Outputs

4

Condition

bol

Comment

SO Low State Output

4.1

Voltage

SO High State Output

4.2

Voltage

DIAG Low State Output

4.3

Voltage

DIAG High State Output

4.4

Voltage

Fault Low Output Voltage V

4.5

Fault Output leak Current I

4.6

Diagnostic Functions

5

5.1

Open Load Detection

Voltage

5.2

Open Load Detection

Voltage

5.3

Output Open Load diagnosis Current

5.4

Fault Filter Time

V

V

SOL

SOH

I

I

=2.5mA 0.4 V SO

SOL

=-2mA VDO-

SOH

V SO

0.4V

I

DIAGL

=

0.4 V DIAG1-6

50µA

I

I

ol

Output :OFF

oh

=

DIAGH

-50µA

= 1mA 0.4 V Fault

out

VDO-

0.4V

V DIAG1-6

1 µA Fault

V

=5V

(fault)

V

DS(OL)

lowside con-

5.5 V

figuration,

Vbat=12V

V

DS(OL)

highside

4.5 V

configuration,

Vbat=12V

I

d(OL)

Vbat=Vout=

20 100 500 µA

12V

t

f(fault)

50 100 200 µs

5.5

Switch Bypass Detec-

I

d(SB)

250 µA

tion Current

5.6

Overload Detection

Threshold (Channel 1-3)

5.7

Overload Detection

Threshold (Channel 4-6)

Input Voltage

Output Voltage

(Highside configuration)

t

dON

t

r

I

Dd(lim1-

3)

I

Dd(lim 4-

6)

Vp2 Page 12 13.01.2003

4 6 A

3 6 A

t

dOFF

70%

Fig.3 : Turn on/off timings with resistive load

30%

t

f

Page 13

Preliminary Datasheet TLE6288 R

VCC = 4.5 to 5.5 V ; Tj = - 40 °C to + 150 °C ; VB = 6V to 16V ; Reset = H ; VDO = VCC

(unless otherwise specified)

Condition

bol

SPI Timing

6

f

Serial Clock Frequency (de-

6.1

SCK

DC -- 5

pending on SO load)

Serial Clock Period (1/fclk) t

6.2

200 -- -- ns

p(SCK)

Value No. Parameter Sym

min typ max

Unit Pin /

MHz

Comment

Serial Clock High Time t

6.3

Serial Clock Low Time t

6.4

Enable Lead Time

6.5

(falling edge of

to falling

CS

edge of SCLK)

Enable Lead Time

(falling edge of

to rising

CS

edge of SCLK)

Enable Lag Time (rising edge of

6.6

SCLK to rising edge of

CS

)

Enable Lag Time (falling edge

of SCLK to rising edge of

Data Setup Time (required time

6.7

CS

)

SI to rising of SCLK)

Data Setup Time (required time

SI to falling of SCLK)

Data Hold Time (rising edge of

6.8

SCLK to SI)

Data Hold Time (falling edge of

SCLK to SI)

Disable Time t

6.9

Transfer Delay Time

6.10

2

50 -- -- ns

SCKH

50 -- -- ns

SCKL

t

CLKProg=L 200 -- -- ns

leadL

t

CLKProg=H 200 -- -- ns

leadH

CLKProg=L 200 --- -- ns

t

lagL

CLKProg=H 200 --- -- ns

t

lagH

t

CLKProg=L 20 -- -- ns

SUL

t

CLKProg=H 20 -- -- ns

SUH

t

CLKProg=L 20 -- -- ns

HL

tHH CLKProg=H 20 -- -- ns

-- 200 ns

DIS

t

200 -- -- ns

dt

CS high time between two

(

accesses)

Data Valid Time

6.11

= 50 pF to 100pF

C

L

C

= 220 pF

L

t

valid

--

--

--

--

120

150

ns

1)

To get the correct diagnostic information, the transfer delay time has to be extended to the maximum fault delay

time t

f(fault)max

Vp2 Page 13 13.01.2003

= 200µs.

Page 14

Preliminary Datasheet TLE6288 R

7 Diagnostics

detailled description of the diagnosis will be added

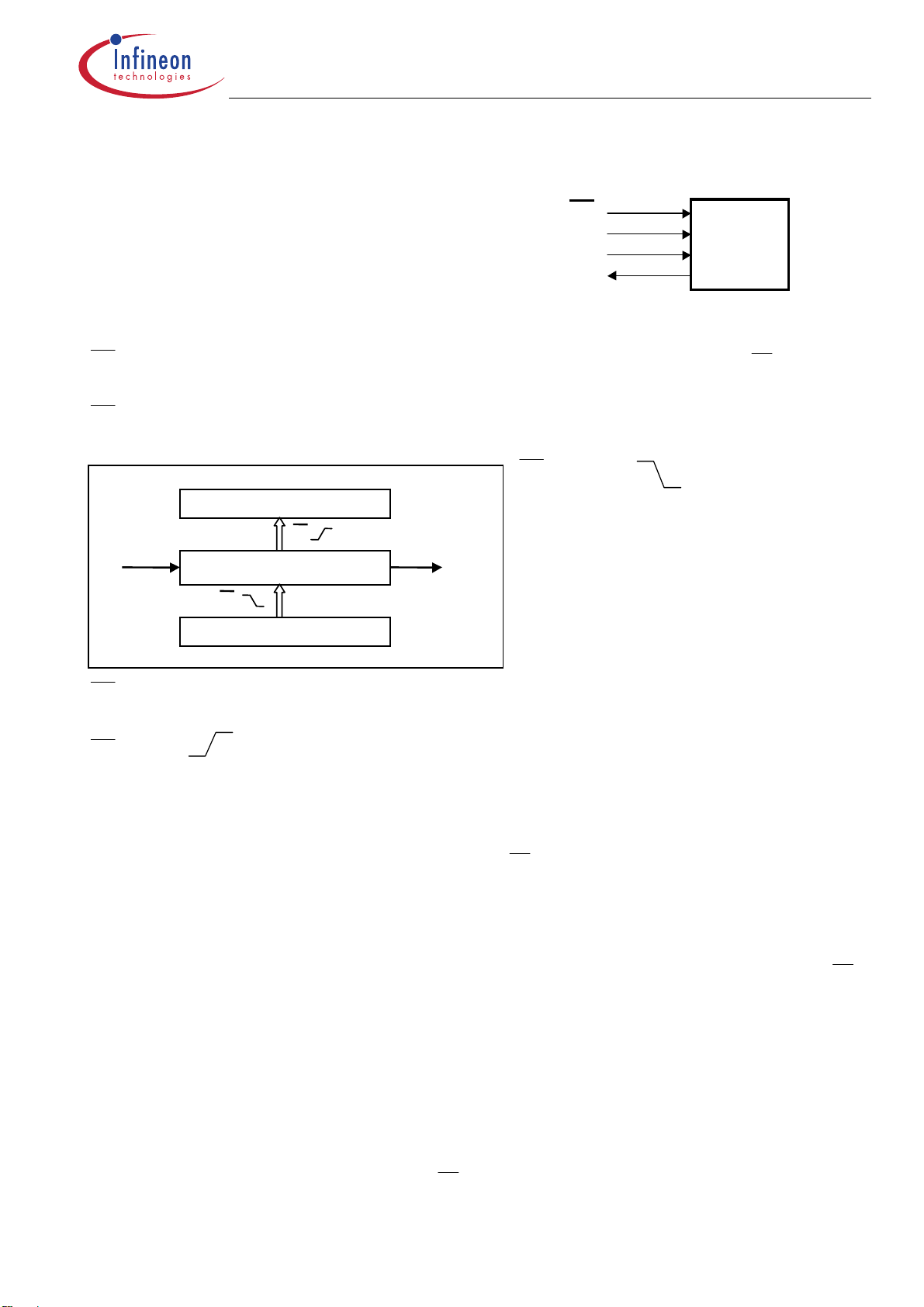

8 SPI

The SPI is a Serial Peripheral Interface with 4 digital pins

and an 16 bit shift register. The SPI is used to configure

and program the device, turn on and off channels and to

read detailled diagnostic information.

CS

SCLK

SI

SO

SPI

8.1 SPI Signal Description:

CS - Chip Select. The system microcontroller selects the TLE 6288 R by means of the

CS

ever the pin is in a logic low state, data can be transferred from the µC and vice versa.

= H : Any signals at the SCLK and SI pins are ignored and SO is forced into a high impedance

CS

state.

LSB

internal logic registers

MSB

CS = HÆL :

• diagnostic information is transferred from

the diagnosis register into the SPI shift

CS

SI SO

Serial input

data MSB first

16 bit SPI shift register

CS

Serial output

(diagnosis)

MSB first

diagnosis register

LSB

MSB

register.

• serial input data can be clocked into the

SPI shift register from then on

• SO changes from high impedance state to

logic high or low state corresponding to

the SO bits

pin. When-

CS = L : SPI is working like a shift register. With each clock signal the state of the SI is read into the

SPI shift-register and one diagnosis bit is written out of SO.

CS = LÆH:

• transfer of SI bits from SPI shift register into the internal logic registers

• reset of diagnosis register if sent command was valid

To avoid any false clocking the serial clock input pin SCLK should be logic high state (if CKLProg=L;

low state if CLKProg=H) during high to low transition of

SCLK - Serial Clock. The serial clock pin clocks the internal SPI shift register of the TLE 6288 R. The

serial input (SI) accepts data into the input SPI shift register on the rising edge of SCLK (if CKLProg=L;

falling edge if CLKProg=H) while the serial output (SO) shifts diagnostic information out of the SPI shift

register on the falling edge (if CKLProg=L; rising edge if CLKProg=H) of serial clock. It is essential that

the SCLK pin is in a logic high state (if CKLProg=L; low state if CLKProg=H) whenever chip select

makes any transition.

SI - Serial Input. Serial data bits are shifted in at this pin, the most significant bit (MSB) first. SI information is read in on the rising edge of SCLK (if CKLProg=L; falling edge if CLKProg=H). Input data is

latched in the SPI shift register and then transferred to the internal registers of the logic.

The input data consist of 16 bit, made up of 4 control bits and 12 data bits. The control word is used to

program the device, to operate it in a certain mode as well as providing diagnostic information (see SPI

Commands).

CS

.

CS

SO - Serial Output. Diagnostic data bits are shifted out serially at this pin, the most significant bit (MSB)

first. SO is in a high impedance state until the

pin goes to a logic low state. New diagnostic data will

CS

appear at the SO pin following the falling edge of SCLK (if CKLProg=L; rising edge if CLKProg=H).

Vp2 Page 14 13.01.2003

Page 15

Preliminary Datasheet TLE6288 R

8.2 SPI Diagnostics:

As soon as a fault occurs for longer than the fault filtering time, the fault information is latched into the

diagnosis register (and the Fault pin will change from high to low state). A new error on the same

channel will over-write the old error report. Serial data out pin (SO) is in a high impedance state when

is high. If CS receives a LOW signal, all diagnosis bits can be shifted out serially. If the sent com-

CS

mand was valid the rising edge of

and restart the fault filtering time. In case of an invalid command the device will ignore the data bits and

the diagnosis register will not be reset at the rising

will reset the diagnosis registers (except the channel OT flag)

CS

edge.

CS

Diagnostic Serial Data Out SO

MSB

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Ch.6 Ch.5 Ch.4 Ch.3

Channel Overtemperature Flag

Ch.2 Ch.1

Bit0 and Bit1

is always 1

LSB

IC Overtemperature Flag

HH Normal function

HL Overload, Shorted Load or Overtemperature

LH Open Load

LL Switch Bypassed

Figure 1: Two bits per channel diagnostic feedback plus two overtemperature flags

For Full Diagnosis there are two diagnostic bits per channel configured as shown in Figure 1.

Diagnosis bit0 and bit1 are always set to 1.

Normal function: The bit combination HH indicates that there is no fault condition, i.e. normal function.

Overload, Shorted Load or Overtemperature: HL is set when the current limitation gets active, i.e.

there is a overload, short to supply or overtemperature condition. The second reason for this bit combination is overtemperature of the corresponding channel.

Open load: LH is set when open load is detected (in off state of the channel)

Switch Bypassed:

Short to GND : in lowside configuration LL is set when this condition is detected

Short to Battery : in highside configuration LL is set when this condition is detected

Channel Overtemperature Flag: In case of overtemperature in any output channel in on state the

overtemperature Flag in the SPI diagnosis register is set (change bit 3 from 0 to 1). This Bit can be

used to distinguish between Overload and Overtemperature (both HL combination) and is reset by

switching OFF/ON the affected channel.

In addition the DIAG6 / Ovtertemp pin is set low (if configured as Overtemp.Flag).

IC Overtemperature Flag: When the IC logic tremperature exceeds typ.170° the non-latching IC

Overtemperature Flag will be set in the SPI diagnosis register(change bit 2 from 0 to 1).

In addition the DIAG6 / Ovtertemp pin is set low (if configured as Overtemp.Flag).

8.3 SPI Commands, Values and Parameters:

Vp2 Page 15 13.01.2003

Page 16

Preliminary Datasheet TLE6288 R

The 16 bit SPI is used to program different IC functions

and values, turn on and off the channels and to get detailled diagnosis information. Therefore 4 command bits

and 12 data bits are used.

The following parameters and functional behavior can be

programmed by SPI:

Current regulation Mode (mode) : for each of the three

highside channels individually the operation mode can be

set. a) "no current regulation

b) Current regulation "hold only

c) Current regulation "peak & hold with minimum

peak time

d) Current regulation "peak & hold with programmed peak time".

Peak Current (I

) : for each of the three highside channels individually the peak current value for P&H

pk

current regulation can be programmed. The current range is 1.2A to 3.6A.

Fixed off time of the current regulator (t

) : for each of the three highside channels (Ch1 - Ch3) indi-

fo

vidually the fixed off time for all modes with current regulation can be programmed from 100µs to

400µs.

Hold Current (I

) : for each of the three highside channels(Ch1 - Ch3) individually the hold current

hd

value for P&H and hold only current regulation can be programmed. The current range is 0.7A to 2.0A

Peak Time (t

) : for each of the three highside channels(Ch1 - Ch3) individually the peak time value for

p

P&H current regulation can be programmed. The time range is 0.8ms to 3.6ms.

Highside / Lowside Configuration ( H/L ) : Each of the three configurable channels (Ch4 – Ch6) can

be programmed for use as Highside Switch or Lowside Switch.

Open load and switch bypassed detection activated or deactivated (OL+SB) : For each of the

three configurable channels(Ch4 – Ch6) the open load and switch bypassed diagnosis can be deactivated. In lowside configuration the open load and the short to GND detection can be deactivated, in

highside configuration the open load and short to battery detection.

Boolean Operation (OR / AND) : For all channels generally the Boolean operation of the parallel input

signal and the SPI bit of the corresponding channel can be defined.

Overtemperature Behavior ( R/L ) : The overtemperature behavior of the channels can be programmed by SPI. Autorestart or latching overtemperature shutdown can be selected (for all channels

the same behavior).

DIAG6 or Overtemperature Flag (D/F) : With this SPI bit the function of the DIAG6/Overtemp pin is

defined. This output can work as diagnosis output of channel 6 or as Overtemperature Flag.

CS

4 Bits 12 Bits

SI

Command Data

SO

SI command : 4 Command Bits program

the operation mode of Channels 1 to 6.

12 Data Bits configure the device and

give the input information (on or off) for

Channel 1 to 6.

SO diagnosis 16 bit diagnosis information

(two bit per channel) of channels 1 to 6 plus

two Overtemperature Flags

Diagnosis (Ch. 1 to 6)

+ 2 Temp. Flags

Vp2 Page 16 13.01.2003

Page 17

Preliminary Datasheet TLE6288 R

8.4 SPI Commands

Command Table

No Command

1 Config. Regulator 1

2 Config. Regulator 2

3 Config. Regulator 3

4 Config. Ch1 - Ch6

5 Set all to Default

6 Diagnosis only

7 Channels on / off

MSB

14 13 12 11 10 9 8 7 6 5 4 3 2 1

1 0 0 1 Mode I

1 0 1 0 Mode I

1 0 1 1 Mode I

1 1 0 0

1 0 0 0

1 1 1 1

1 1 0 1

Ch. 6 Ch. 5 Ch 4 all all

OL+

H/L

SB

X X X X X X X X X X X X

X X X X X X X X X X X X

Ch6 Ch5 Ch4 Ch3 Ch2 Ch1 X X X X X X

H/L

tfo Ihd tp

pk

tfo Ihd tp

pk

tfo Ihd tp

pk

OL+

SB

H/L

OL+

SB

OR/

R/L D/F X X X

AND

DIAG

6

LSB

X

X

X

Legend of SPI Command Table:

Mode: Operation mode of the current regulator:

a) no regulation

b) hold only

c) peak&hold with minimum peak time

d) peak&hold with programmed peak time

I

: Peak current values 1.2A - 3.6A

pk

I

: Hold current values 0.7A - 2A

hd

t

: Peak time value 0.8ms – 3.6ms

p

t

: Fixed off time value 100µs – 400µs

fo

H/L : Channel 1-3 in highside or lowside configuration

OL+SB : open load detection and switch bypassed detection activated or deactivated

OR / AND : Boolean Operation (parallel input and corresponding SPI Bit)

R/L : Autorestart or Latching overtemperature behaviour

D/F : DIAG6/Overtemp pin set as Diagnosis output of channel 6 or as Overtemperature Flag

Ch1-Ch6 : On / Off information of the output drivers (high active)

Command description:

Config. Regulator 1-3: With this command the values for for the current regulation and the functional

mode of the channel is written into the internal logic registers.

Config. Ch1- Ch6 : This command writes the configuration data of the three configurable channels (4-

6) and sets the Boolean operation and overtemperature behavior of all channels. It also and sets the

DIAG6/Overtemp. pin to Diagnosis of channel 6 or Overtemperature Flag.

Set all to default : This command sets all internal logic registers back to default settings.

Diagnosis only : When this command is sent the 12 data bits are ignored. The internal logic registers

are not changed.

Channels on/off : With this command the SPI bits for the ON/OFF information of the 6 Channels are

set

Note: Specified control words (valid commands) are executed and the diagnosis register is reset after

the rising

CS

edge.

Not specified control words are not executed (cause no function) and the diagnosis register is not reset

after the

= LÆH signal.

CS

Vp2 Page 17 13.01.2003

Page 18

Preliminary Datasheet TLE6288 R

8.5 Default settings for the internal logic registers:

Mode :no regulation

Peak Current (Ipeak) :2.4A

Hold Current (Ihold) :1A

Fixed off Time (toff) :200µs

Peak Time (tpeak) :2.8ms

AND / OR :OR

Autorestart / Latch :Restart

Diag6 / Temp. Fault :Diagnosis channel 6

Highside / Lowside (4-6) :Highside

Open load & SB Yes/No (4-6) :Yes (diagnosis active)

Channels 1-6 (ON / OFF) :OFF

SPI :all 0

8.6 Bit Assignment:

Mode 00 no current regulation

01 hold only

10 P&H minimum peak time

11 P&H with programmed times

Peak Current (Ipk):: : 1.2A 1.8A 2.4A 3.6A

2 Bits : 0 0 0 1 1 0 1 1

Hold Current (Ihd) : 0.7A 1A 1.4A 2A

2 Bits : 0 0 0 1 1 0 1 1

Fixed off Time (tfo) : 100µs 200µs 300µs 400µs

2 Bits : 0 0 0 1 1 0 1 1

Peak Time (tp) : 0.8 1.2 1.6 2 2.4 2.8 3.2 3.6 [ms]

3 Bits : 000 001 010 011 100 101 110 111

Boolean operation : OR AND

1 Bit : 0 1

Overtemp. behavior : Restart Latch

1 Bit : 0 1

Diag6 / Overtemp :Diag6 Overtemp. Flag

1 Bit :0 1

Highside/Lowside :Highside Lowside

1 Bit :0 1

Open Load & SB (4-6) :Yes No

1 Bit :0 1

Default settings are pin bold print.

Vp2 Page 18 13.01.2003

Page 19

Preliminary Datasheet TLE6288 R

8.7 SPI Timing Diagrams :

Input Timing Diagram (CLKProg = L)

CS

0.2 V

cc

t

SCKH

SCLK

t

SI

leadL

t

SUL

t

HL

0.7V

0.2V

t

SCKL

0.7V

cc

t

dt

t

gL

la

0.7V

cc

0.2V

cc

cc

cc

SO Valid Time Waveforms Enable and Disable Time Waveforms

(CLKProg = L)

SCLK

SO

SO

0.2 V

cc

t

d

vali

0.7 V

0.2 V

cc

cc

0.2 V

0.7 V

cc

cc

CS

SO

0.2 V

cc

t

Dis

CS

SCLK

4 control bit 12 data bit

C o n t r o l word 11 10 9 8 7 6 5 4 3 2 1 0

SI

MSB

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

SO

LSB

Vp2 Page 19 13.01.2003

Page 20

Preliminary Datasheet TLE6288 R

Input Timing Diagram (CLKProg = H)

CS

0.7V

cc

t

0.2 V

cc

t

gH

la

0.7V

0.2V

cc

SCLK

t

leadH

t

SCKH

t

SUH

t

L

SCK

t

HH

0.7V

cc

SI

0.2V

cc

SO Valid Time Waveforms Enable and Disable Time Waveforms

(CLKProg = H)

dt

cc

0.7 V

SCLK

SO

t

valid

0.2 V

cc

0.7 V

cc

cc

CS

SO

0.2 V

cc

t

Dis

SO

0.7 V

cc

0.2 V

cc

CS

SCLK

C o n t r o l word 11 10 9 8 7 6 5 4 3 2 1 0

SI

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

SO

4 control bit 12 data bi t

MSB

LSB

Vp2 Page 20 13.01.2003

Page 21

Preliminary Datasheet TLE6288 R

9 Typicel Characteristics

9.1 Zth Diagramm

10

.

Conditions:

R

= 3.1 K/W

D = 0.50

T

= 125°C

case

Single Channel Operation

1

0.20

0.10

Zth [K/W]

0.05

Parameters:

tp ..... Pulse Width

D ..... Duty Cycle

0.02

0.1

single

0.01

1.10

5

4

.

1

10

1

.

10

tp [s]

3

0.01 0.1

Vp2 Page 21 13.01.2003

Page 22

Preliminary Datasheet TLE6288 R

10 Package

(all dimensions in mm)

P-DSO 36-12

Vp2 Page 22 13.01.2003

Page 23

Preliminary Datasheet TLE6288 R

Published by

Infineon Technologies AG,

Bereichs Kommunikation

St.-Martin-Strasse 76,

D-81541 München

© Infineon Technologies AG 1999

All Rights Reserved.

Attention please!

The information herein is given to describe certain components and shall not be considered as warranted characteristics.

Terms of delivery and rights to technical change reserved.

We hereby disclaim any and all warranties, including but not limited to warranties of non-infringement,

regarding circuits, descriptions and charts stated herein.

Infineon Technologies is an approved CECC manufacturer.

Information

For further information on technology, delivery terms and conditions and prices please contact your

nearest Infineon Technologies Office in Germany or our Infineon Technologies Representatives worldwide (see address list).

Warnings

Due to technical requirements components may contain dangerous substances. For information on the

types in question please contact your nearest Infineon Technologies Office.

Infineon Technologies Components may only be used in life-support devices or systems with the express written approval of Infineon Technologies, if a failure of such components can reasonably be

expected to cause the failure of that life-support device or system, or to affect the safety or effectiveness of that device or system. Life support devices or systems are intended to be implanted in the human body, or to support and/or maintain and sustain and/or protect human life. If they fail, it is reasonable to assume that the health of the user or other persons may be endangered.

Vp2 Page 23 13.01.2003

Loading...

Loading...