Inficon IRwin S, IRwin SX, IRwin SXT, IRwin SXG, 580-000 Original Operating Instructions

...Page 1

Original operating instructions

IRwin S/SX/SXT/SXG/SXGT

Portable Methane Leak Detector

mina66en1-12-(1802)

580-000, 580-010, 580-015, 580-020, 580-030, 580-712

From software version:

2.01.01

Page 2

INFICON GmbH

Bonner Strasse 498

50968 Cologne, Germany

Page 3

INFICON Table of Contents

IRwin-Operating-instructions-mina66en1-12-(1802) iii

Table of Contents

1 About these instructions ...................................................................................................................................6

1.1 Target groups ...........................................................................................................................................6

1.2 Warnings...................................................................................................................................................6

2 Safety ...............................................................................................................................................................7

2.1 Intended use .............................................................................................................................................7

2.2 Special conditions for safe use .................................................................................................................8

2.2.1 Intrinsic Safety (Ex protection) ......................................................................................................8

2.2.2 Certified Gas Measurement ..........................................................................................................8

2.3 Owner/supervisor responsibilities .............................................................................................................9

2.4 Duties of the operator .............................................................................................................................10

2.5 Safe operation ........................................................................................................................................10

3 Scope of delivery ............................................................................................................................................11

4 Description......................................................................................................................................................12

4.1 Function ..................................................................................................................................................12

4.2 Design of the leak detector .....................................................................................................................13

4.3 Probes ....................................................................................................................................................14

4.4 Display ....................................................................................................................................................16

4.5 Technical data ........................................................................................................................................19

4.5.1 EX certification (intrinsic safety).................................................................................................. 21

4.5.2 Sensors....................................................................................................................................... 21

4.6 Factory settings ......................................................................................................................................26

4.7 Concentration of calibration and test gases............................................................................................28

5 Getting started ................................................................................................................................................29

5.1 Charging the battery ...............................................................................................................................29

5.2 Assembling the probe system.................................................................................................................32

5.3 Transfer data to computer ......................................................................................................................34

5.3.1 Install software for data transfer.................................................................................................. 34

5.3.2 Pairing the leak detector with computer via Bluetooth interface .................................................34

5.3.3 Transfer log files from leak detector to computer........................................................................ 35

5.3.4 Real-time streaming from leak detector to computer ..................................................................35

6 Operation........................................................................................................................................................37

6.1 Switch ON...............................................................................................................................................37

6.2 Initial setup..............................................................................................................................................38

6.2.1 Adjust the local time.................................................................................................................... 38

Page 4

Table of Contents INFICON

iv IRwin-Operating-instructions-mina66en1-12-(1802)

6.2.2 Setting the language ...................................................................................................................38

6.2.3 Change permission level............................................................................................................. 38

6.2.4 Screensaver timeout ...................................................................................................................39

6.2.5 Configure data logging................................................................................................................ 39

6.2.6 Enable dead band suppression (IRwin SXnn only)..................................................................... 40

6.2.7 Setting the Function Test interval ............................................................................................... 40

6.2.8 Calibration................................................................................................................................... 40

6.2.8.1 Standard calibration procedures ........................................................................................42

6.2.8.2 Setting of calibration gas concentrations ...........................................................................43

6.2.9 Adjust calibration reminder ......................................................................................................... 44

6.3 Operating modes ....................................................................................................................................45

6.3.1 Select operating mode ................................................................................................................45

6.3.2 Operating mode “Above Ground”................................................................................................ 45

6.3.3 Operating mode “Bar Hole”......................................................................................................... 47

6.3.3.1 Automatic “Bar Hole” testing ..............................................................................................48

6.3.3.2 Setting parameters for “Auto Bar Hole”..............................................................................49

6.3.4 Operating mode "GC Ethane Analysis" ...................................................................................... 50

6.3.5 Operating mode “Confined Space” .............................................................................................52

6.3.6 Operating mode "House" ............................................................................................................54

6.3.7 Operating mode "Gas Purity” ...................................................................................................... 55

6.3.8 Operating mode "Ex" .................................................................................................................. 57

6.3.9 Operating mode "Ex Tox” ........................................................................................................... 60

6.3.9.1 Change gas type for %LEL measurement .........................................................................62

6.3.10 IR Ethane Analysis and compensation .......................................................................................63

6.3.10.1 Entering ethane concentration manually............................................................................63

6.3.10.2 Setting reminder for IR Ethane Analysis ............................................................................64

6.3.10.3 Performing IR Ethane Analysis after automatic reminder ..................................................64

6.3.10.4 Starting IR Ethane Analysis manually................................................................................65

6.3.10.5 Viewing IR Ethane Analysis info ........................................................................................66

6.3.11 Set limits and alarm levels ..........................................................................................................66

6.3.12 Set the brightness of the display................................................................................................. 67

6.3.13 Performing function tests ............................................................................................................67

6.4 Measuring ...............................................................................................................................................68

6.5 Perform self test......................................................................................................................................69

6.6 Viewing Status menu ..............................................................................................................................69

6.7 Logging data to file .................................................................................................................................69

6.8 Viewing logfile list ...................................................................................................................................69

6.9 Information..............................................................................................................................................70

6.9.1 Retrieve information and statistics ..............................................................................................70

6.9.2 Viewing the Service Screen ........................................................................................................70

Page 5

INFICON Table of Contents

IRwin-Operating-instructions-mina66en1-12-(1802) v

6.10 Activating Auto-Rotate Screen................................................................................................................70

6.11 Resetting to factory settings ...................................................................................................................71

6.12 Switching OFF ........................................................................................................................................71

6.13 Warnings and error messages................................................................................................................71

7 Maintenance ...................................................................................................................................................76

7.1 Maintenance plan ...................................................................................................................................76

7.2 Spare parts list........................................................................................................................................76

7.3 Maintenance of the leak detector............................................................................................................77

7.3.1 Seasonal shut-down ................................................................................................................... 77

7.3.2 Change the cigarette filter in the sample inlet............................................................................. 77

7.4 General check of the probe system ........................................................................................................77

7.5 Maintenance of the hand probe ..............................................................................................................79

7.5.1 Replace cigarette filter in the hand probe ...................................................................................79

7.6 Change the inline filter of the carpet probe.............................................................................................79

7.7 Maintenance of the bell probe ................................................................................................................79

7.7.1 Change the filter discs in the bell ................................................................................................79

7.7.2 Change the paper filter in the bell ...............................................................................................81

8 Decommissioning the leak detector................................................................................................................82

8.1 Sending in the leak detector ...................................................................................................................82

8.2 Disposing of the equipment ....................................................................................................................84

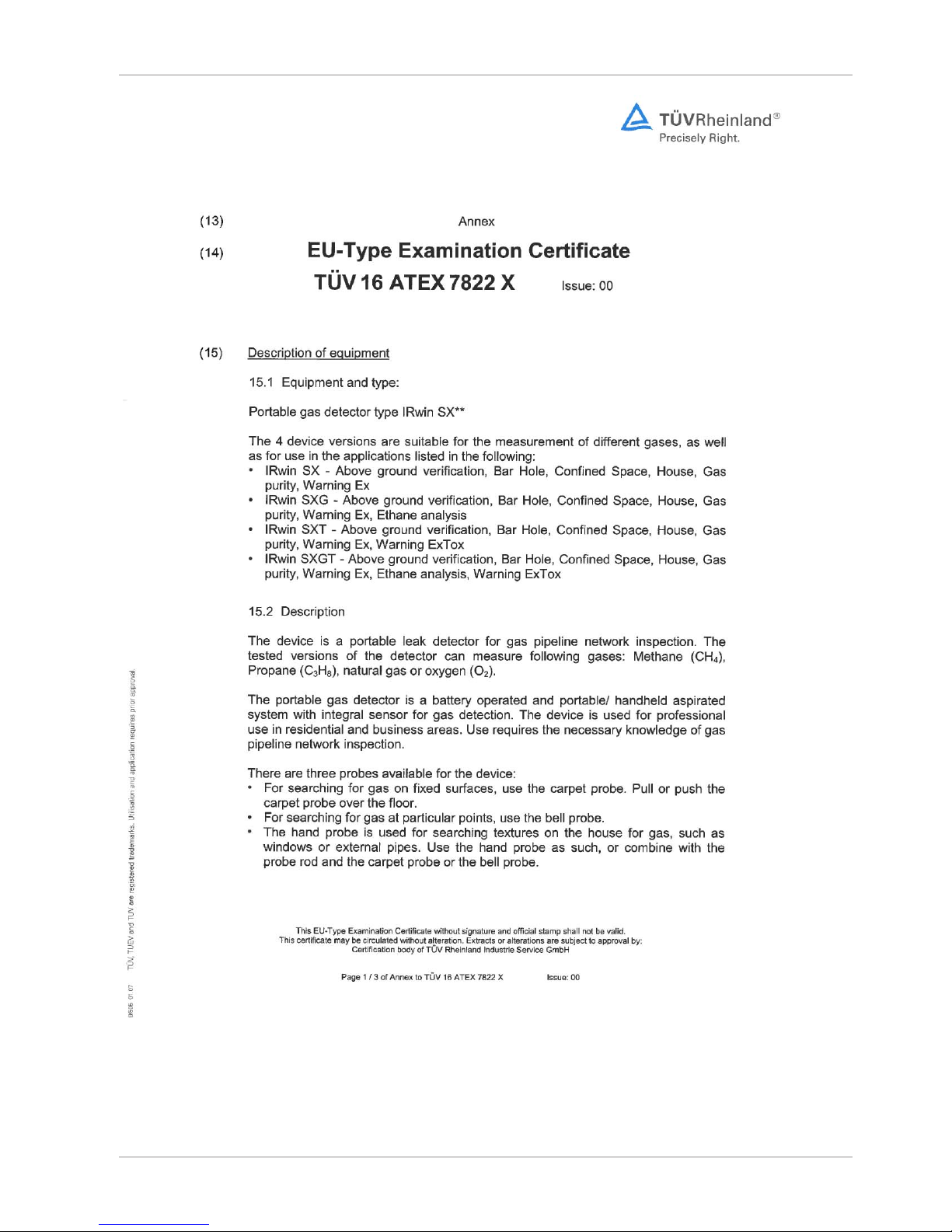

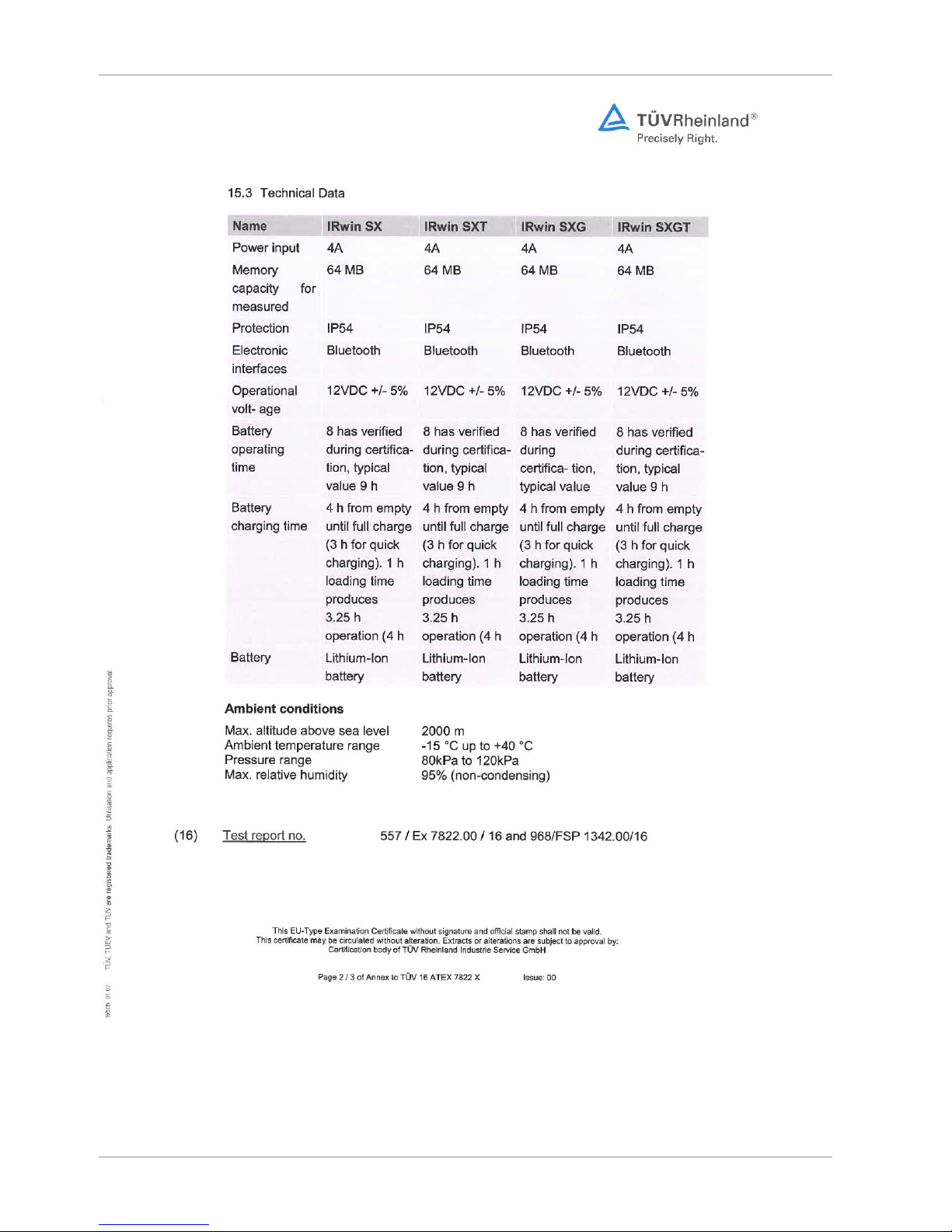

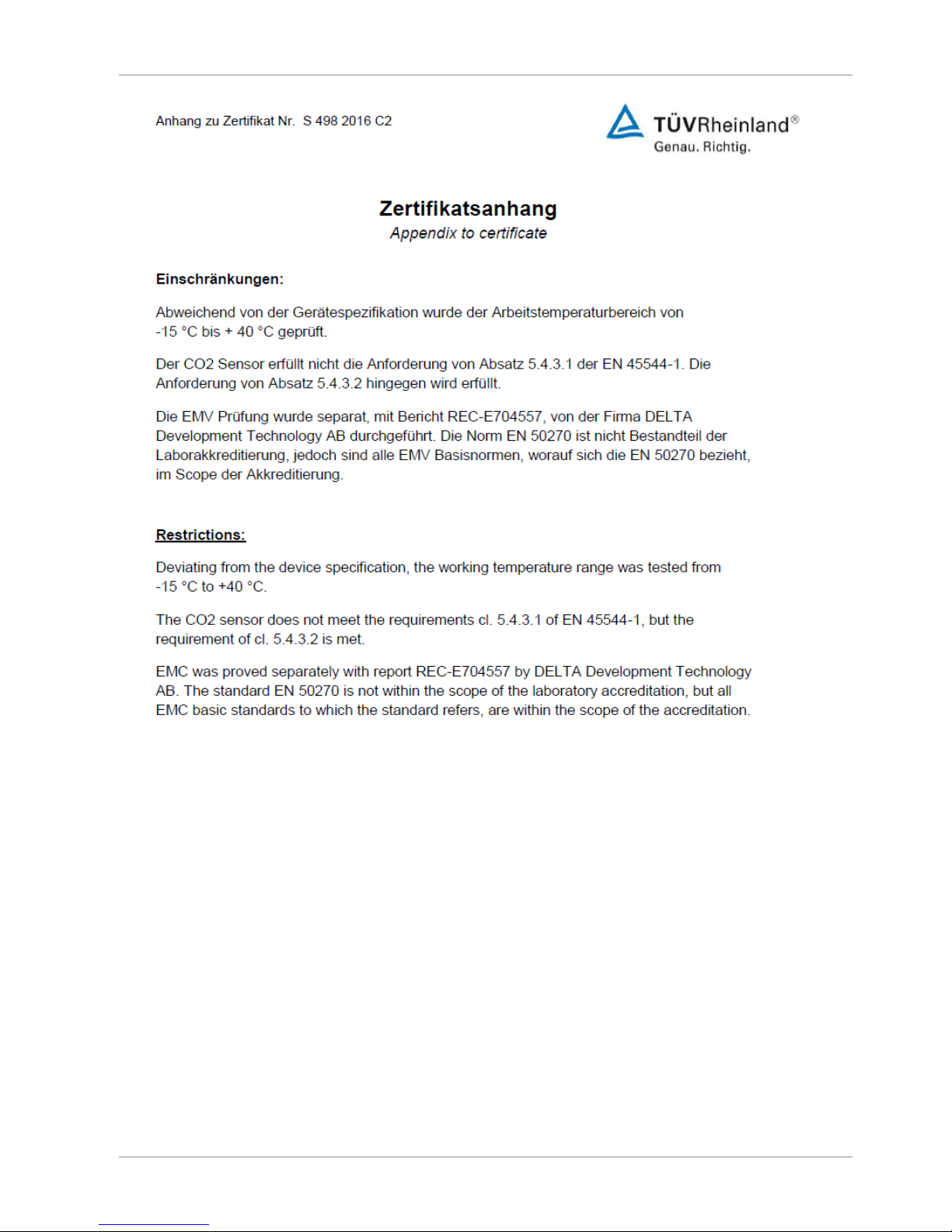

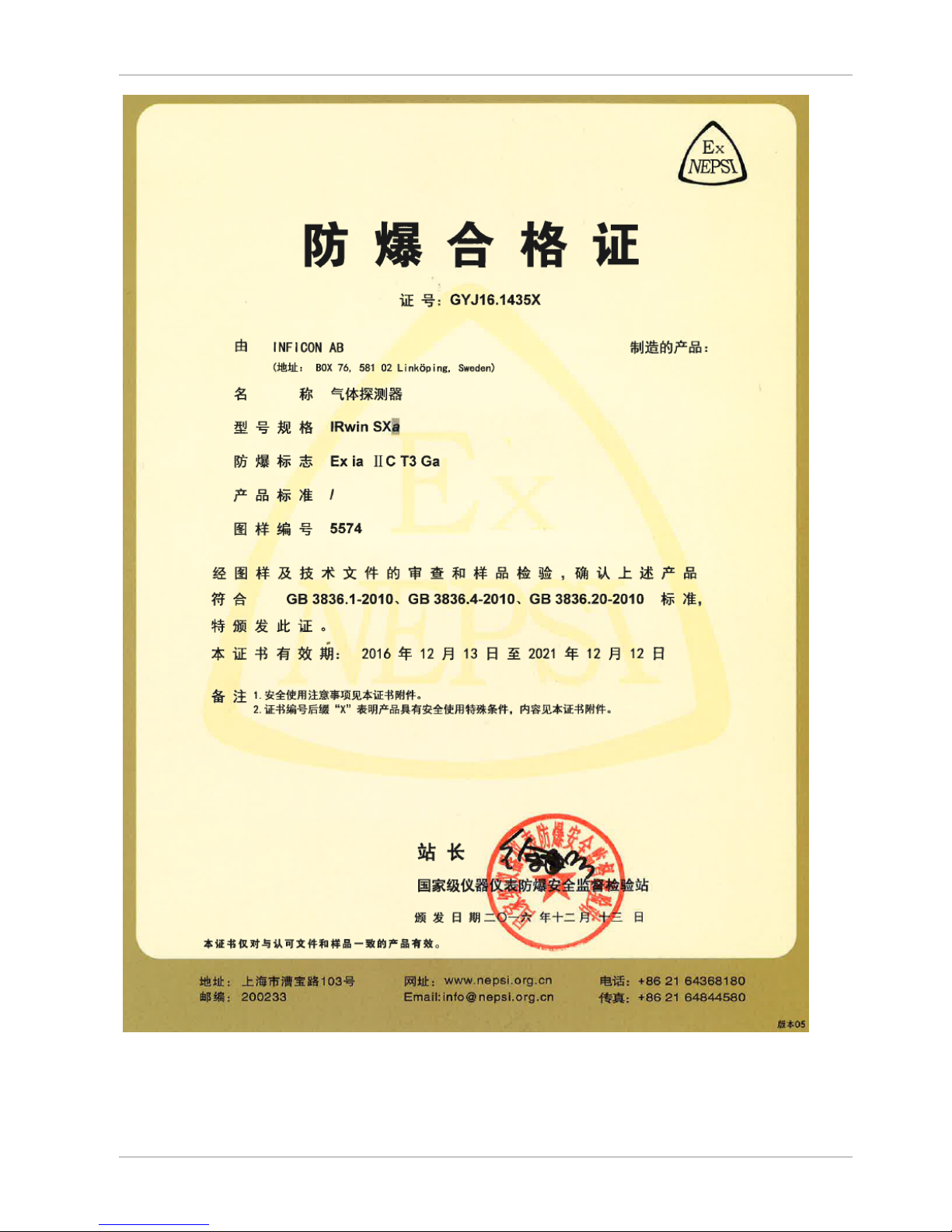

9 Certificates......................................................................................................................................................85

9.1 TÜV, Certificate for lower explosive limit (LEL) ......................................................................................86

9.2 Certificate for oxygen and toxic gases....................................................................................................90

9.3 Certificate for software for Ex/ExTox ......................................................................................................92

9.4 ATEX certificate for explosion protection (IRwin SXnn)..........................................................................93

9.5 CSA (US/Canada) certificate for explosion protection (IRwin SXnn)......................................................94

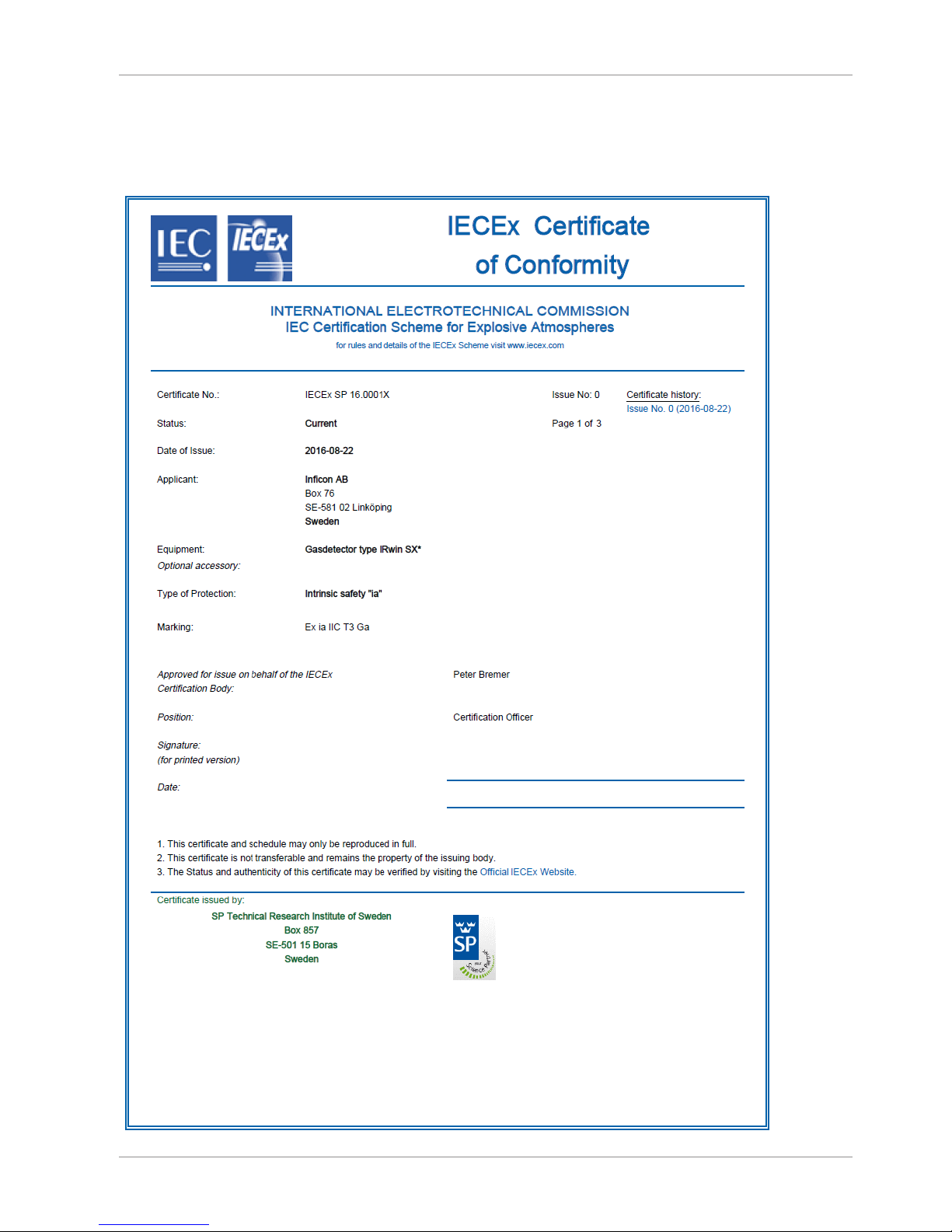

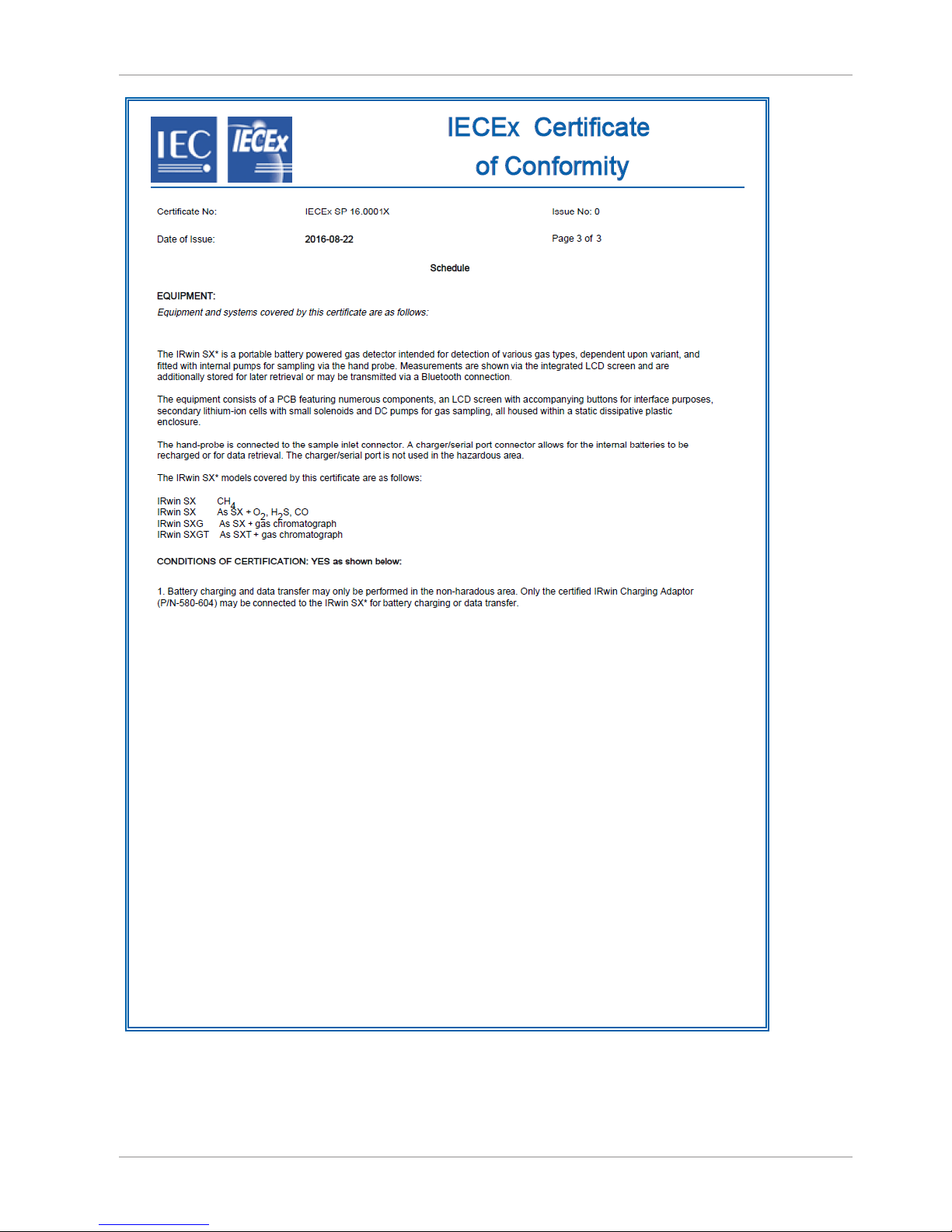

9.6 IECEx certificate for explosion protection (IRwin SXnn).........................................................................95

9.7 NEPSI (China) certificate for explosion protection..................................................................................98

9.8 CE Declaration of Conformity ...............................................................................................................104

Index.............................................................................................................................................................108

Page 6

1 | About these instructions INFICON

6 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

1 About these instructions

This document applies to the software version stated on the title page.

Product names may occur in the document, which are added for identification purposes only and belong to the respective owner of the rights.

1.1 Target groups

These Operating Instructions are written for trained and experienced gas pipeline survey operators.

1.2 Warnings

DANGER

Imminent hazard resulting in death or serious injuries

WARNING

Hazardous situation potentially resulting in death or serious injuries

CAUTION

Hazardous situation potentially resulting in minor injuries

NOTICE

Risk for damage to property or the environment

Page 7

INFICON Safety | 2

IRwin-Operating-instructions-mina66en1-12-(1802) 7 / 112

2 Safety

2.1 Intended use

The IRwin Methane Leak Detector is intended for professional use in residential and

commercial areas. The operation of the equipment requires sufficient knowledge and

experience in gas pipeline inspection. The different IRwin versions are equipped for

the measurement of different gases, see Technical data [}19] as well as for the applications listed below:

• IRwin S

Above ground, Bar hole

• IRwin SX (EX certified)

Above ground, Bar hole, Confined Space, House, Gas Purity, Ex

• IRwin SXT (EX certified)

Above ground, Bar hole, Confined Space, House, Gas Purity, Ex, Ex Tox

• IRwin SXG (EX certified)

Above ground, Bar hole, Confined Space, House, Gas Purity, Ex, GC Ethane

Analysis

• IRwin SXGT (EX certified)

Above ground, Bar hole, Confined Space, House, Gas Purity, Ex, Ex Tox, GC Ethane Analysis

The IRwin SX, IRwin SXG, IRwin SXT and IRwin SXGT are intrinsically safe and can

be used in areas with potentially explosive atmospheres according to the EX rating

and EX application it is certified for (see EX certification (intrinsic safety) [}21]).

These models are jointly referred to as

IRwin SXnn

in the following.

The IRwin S is not EX certified.

Pay attention to the safety instructions Safe operation [}10].

• You must assemble, operate and maintain the equipment only in compliance with

these operating instructions.

• Use only within the allowed ambient conditions Technical data. Operating or storing the equipment outside the given range can result in erroneous readings and

possible malfunction.

• Use the leak detector exclusively for the detection of the specified gases.

Improper use

• Do not suck liquids into the leak detector.

• Do not suck dirt or sand into the leak detector.

• Do not use the IRwin S in areas with potentially explosive atmospheres.

See also

Page 8

2 | Safety INFICON

8 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

2 Safe operation [}10]

2.2 Special conditions for safe use

2.2.1 Intrinsic Safety (Ex protection)

IRwin is certified intrinsically safe to prevent ignition of flammable atmospheres.

IRwin holds an ATEX certificate for EU and corresponding certificates for several other

regions as shown by the attached certificates, see Certificates [}85]).

For details of rating, see EX certification (intrinsic safety) [}21].

The "X" after the respective type certificate number relates to the following special

conditions for safe use:

The only device allowed to be connected to the charging socket on any of the models

• IRwin SX

• IRwin SXT

• IRwin SXG

• IRwin SXGT

is the Ex Certified IRwin Charging adapter (PN 580-604).

The charger or car adapter is subsequently connected to the inlet of the Ex Certified

IRwin Charging Adapter.

This means that the charger for IRwin S must, under no circumstances, be connected

directly to the charging socket on any of IRwin models SX, SXT, SXG, and SXGT. See

also Charging the battery [}29].

IRwin SXnn is certified as intrinsically safe at an ambient temperature of -20 - +50°C.

Further temperature restrictions apply to oxygen and toxic gas measurment of IRwin

SXT and SXGT. See Certified Gas Measurement.

IRwin SXnn is certified for use in Gas groups IIA, IIB and IIC and in Zones 0, 1 and 2.

The external surface of the enclosure is therefore slightly conductive to prevent electrostatic charging and sparks. Labels added for marking purposes must not be larger

than 400 mm2. If larger the instrument should not be used in gas group IIC, Zone 0 applications. Natural gas applications are not affected by this regulation.

2.2.2 Certified Gas Measurement

IRwin SX, IRwin SXG, IRwin SXT, and IRwin SXGT are certified by TÜV Rheinland to

EN 60079-29-1 for measuring methane (CH4), propane C3H8, butane C4H10 and natural

gas concentration in units of percentage of lower flammability level. In IRwin we use

the more widely known acronym LEL as synonymous with the more correct LFL.

Page 9

Special conditions for safe use

Traduction française pour CANADA

Le X après le numéro de certificat ATEX concerne les conditions particulières suivantes

pour une utilisation en toute sécurité:

Le seul accessoire autorisé à être connecté à la prise de charge sur l'un des modèles

IRwin SX

IRwin SXT

IRwin SXG

IRwin SXGT

est l'adaptateur de recharge Ex certifié IRwin (PN 580-604).

Le chargeur ou l'adaptateur de voiture est ensuite connecté à l'entrée de l'adaptateur de

recharge.

Le chargeur pour IRwin S ne doit en aucun cas être connecté directement à la prise de

charge de l'un des modèles IRwin SX, SXT, SXG ou SXGT.

Page 10

INFICON Safety | 2

IRwin-Operating-instructions-mina66en1-12-(1802) 9 / 112

IRwin SXT and IRwin SXGT are, in addition, also certified by TÜV Rheinland to

EN50104 and EN 45544 for measuring Oxygen (O2), Carbon Dioxide (CO2), Carbon

Monoxide (CO) and Hydrogen Sulfide (H2S).

The certification is valid in an ambient temperature of -15 to +40 °C and subject to periodic calibration, see Calibration [}40]

IRwin S, IRwin SX and IRwin SXG are operable within -20 to +50 °C. The certification

is valid in an ambient temperature of -15 to +40 °C. The accuracy may not be according to specification outside this range.

IRwin SXT and IRwin SXGT are operable within -20 to +40 °C. The certification is

valid in an ambient temperature of -15 to +40 °C.

2.3 Owner/supervisor responsibilities

The following notes are for organizations or any person responsible for the safe and

effective use of this equipment.

Safety conscious operation

• Check that the leak detector is properly calibrated and not damaged before using

it.

• Make sure you operate the leak detector in accordance with this manual.

• Adhere to the following regulations:

– Intended use

– General applicable safety and accident prevention regulations

– International, national and local standards and guidelines

– Additional equipment-related provisions and regulations

• Use only original parts or parts approved by the manufacturer.

• Keep this instruction manual available on site.

Staff qualifications

• Only properly trained staff should be permitted to work with and on the equipment.

The training must cover the actual equipment model used.

• Make sure that users have read and understood the operating instructions and all

other applicable documents.

Non-authorized repairs

forbidden

The manufacturer (INFICON) denies all responsibility for the compliance of this product with any of the type certificates for this product if any repairs or service involving

opening the instrument enclosure (yellow box) has been performed by individuals or

organizations not qualified therefore in writing by INFICON AB, Sweden. The manufacturer (INFICON) denies all responsibility for the compliance of this product with any

of the type certificates for this product if the equipment is used in any way not conforming to the instructions in this User Manual. Replacement of externally accessible

parts such as probes and filters is allowed with the exception of the Hand Probe and

the hose between Hand Probe and IRwin detector. These two parts are certified antistatic and must not be replaced with non-original parts.

Page 11

2 | Safety INFICON

10 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

2.4 Duties of the operator

• Read, observe, and follow the information in this manual and in the work instructions provided by the owner. This concerns in particular the safety instructions and

warnings.

• Always observe the complete operating instructions for all work.

• If you have any questions about operation or maintenance that are not answered

in this manual, please contact Customer Service.

2.5 Safe operation

Hazards due to chemical substances and explosive gases

• Do not expose the leak detector to excess heat or a naked flame.

• Agressive substances such as solvents and other chemicals can damage the

equipment.

• Adhere to the restrictions of use.

• Do not suck liquids into the leak detector. Proper maintenance of all filters reduces

this risk.

Operation mode and

Ex

The safety related modes Ex and Ex Tox has certified safety features. The detector

monitors its functionality and proper function is indicated by an acoustic alive signal

beeping every 20 s and by the LED being green. This requires that the leak detector is

calibrated according to the instructions and intervals stated in this manual.

If the signal LED is red, this indicates an alarm or an error.

Green LED and short beep every 20 s: Function OK.

Red LED: Gas alarm or instrument error.

Yellow LED: Special state Special state indicates functioning system but alarms are

typically not active. This special state may occur for example during calibration or

when changing a setting in the leak detector.

IRwin Methane Leak Detector was built according to the state-of-the-art and the recognized safety regulations. Nevertheless, improper use may result in risk to life and

limb on the part of the user or third parties, or damage to the leak detector or other

property may occur.

Page 12

INFICON Scope of delivery | 3

IRwin-Operating-instructions-mina66en1-12-(1802) 11 / 112

3 Scope of delivery

The following is included in the delivery of IRwin (580-712):

Article (catalog number) Quantity

Harness (580-405) 1

Charger for IRwin S, 100-240V (580-603) 1 (IRwin S only)*

Car adapter for IRwin S, 12V (580-602) 1 (IRwin S only)*

Charger cable for car (591-361) 1

Charger for IRwin SXnn models, 100-240V (580-605) 1

Certified IRwin Charging Adapter (580-604) 1

Operating instructions 1

*Only valid for IRwin S up to serial number 92000700.

The following is included in the delivery of the IRwin Kit in addition to the above:

Article (catalog number) Quantity

Rod 850mm (580-150) 1

Extension Rod 150mm (580-160) 1

Carpet (580-211) 1

Bell (580-301) 1

Carrying Case IRwin (580-450) 1

Filter-kit (580-700) 1

Bar Hole Probe (580-115) 1

Extension Connector (580-220) 1

►

Check that the delivery is complete.

Page 13

4 | Description INFICON

12 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

4 Description

4.1 Function

The IRwin is a portable methane leak detector for gas pipeline survey. It measures following gases depending on the leak detector version:

• Methane

• Carbon dioxide

• Ethane

• Propane

• Butane

• Oxygen

• Hydrogen sulfide

• Carbon monoxide

There are several probes available for the leak detector:

• The carpet probe is used for surveying paved or smooth surfaces. Pull or push the

carpet along the surface.

• Use the bell probe for measuring gas at specific points. Press the bell firmly down

to pull gas through the surface.

• The hand probe is used for checking features on or in buildings. The hand probe

also constitutes the handle for the carpet probe and bell probe.

• The Bar Hole probe is used to sample air from drilled holes. Push into hole and

tighten screw to expand rubber before connecting sample line.

• The optional Hand Probe Flexible Extension can be connected to the hand probe

or rod for easier access.

INFICON single-cell

wide range technology

(patent pending)

IRwin methane leak detector uses the unique INFICON single-cell wide range technology for detecting all concentrations from 1 ppm to 100 Vol% methane. This technology

is very sensitive to the ethane content of natural gas. Therefore, large deviations can

occur at higher methane concentrations if the ethane concentration is not compensated for. The instrument has built-in routines for ethane compensation. The actual

ethane concentration can be determined using the IR Ethane Analysis function. This

can be used to automatically set the compensation concentration. If preferred you can

instead set the ethane content manually. The safety certified modes Ex and Ex Tox

are not affected by this phenomenon. See IR Ethane Analysis and compensation

[}63].

Page 14

INFICON Description | 4

IRwin-Operating-instructions-mina66en1-12-(1802) 13 / 112

IRwin SXG and SXGT models also have GC Ethane Analysis capability for distinguishing between Natural gas (NG), liquid petroleum gas (LPG) and swamp gas by

determining the presence of methane, ethane and propane in the sampled gas.

The GC Ethane Analysis function is not affecting the ethane compensation.

4.2 Design of the leak detector

Fig.1:

Design of the leak detetctor

1 Display 4 Gas outlet

2 Reference inlet 5 Charging socket

3 Gas inlet

Page 15

4 | Description INFICON

14 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

4.3 Probes

WARNING

Risk of explosion due to not approved probe parts.

The original INFICON Hand probe is the only part of the probe system that is certified

for use in potentially explosive areas. Other parts of the probe system, or third party

accessories are not allowed in potentially explosive areas.

► Pay proper attention to safety when using other accessories for locating and pin-

pointing gas leaks in none classified areas.

Carpet probe

When you are looking for gas leaks on paved surfaces, use the Carpet probe. Pull or

push the Carpet probe along the surface.

Fig.2:

Carpet probe

Bell probe

When searching for or measuring gas leaks at particular spots, use the Bell probe.

This can be used to pull gas through most pavings. It is also suitable for emergency

testing if surface is wet.

Fig.3:

Bell probe

Hand probe

You can use the Hand probe to search for gas in building installations. The hand

probe also constitutes the handle for the Carpet probe and for the Bell probe.

Page 16

INFICON Description | 4

IRwin-Operating-instructions-mina66en1-12-(1802) 15 / 112

Fig.4:

Hand probe

Bar Hole Probe

The Bar Hole Probe is used to pump out and take samples from holes drilled in the asphalt or concrete when pin-pointing a leak. Note that the Bell Probe can be used first

to reduce the number of holes.

Fig.5:

Bar Hole Probe

Hand Probe Flexible

Extension

The flexible extension is practical when locating leaks in hard to reach installations.

Use the Extension Connector to attach it to the long rod to reach even further.

Fig.6:

Hand Probe Flexible Extension

Page 17

4 | Description INFICON

16 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

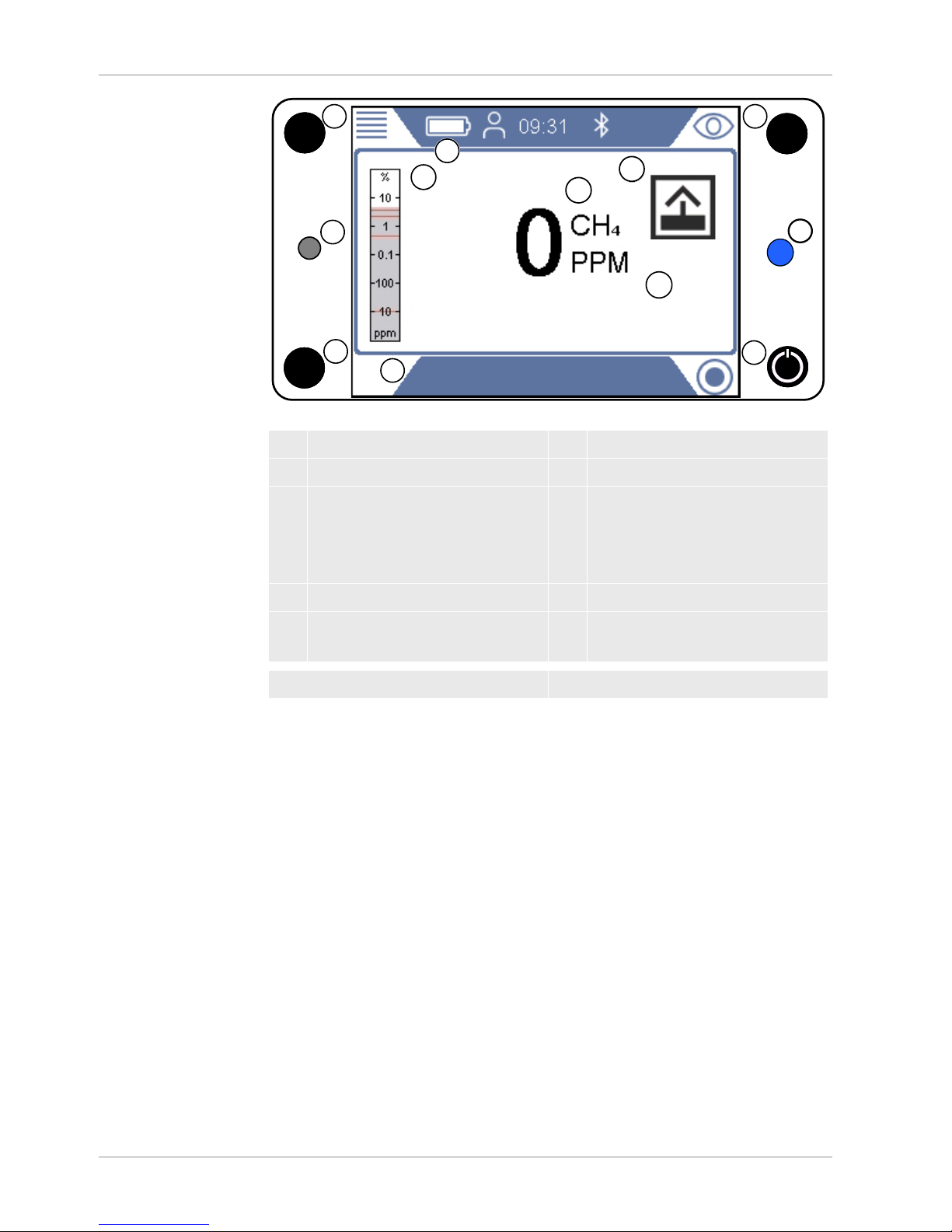

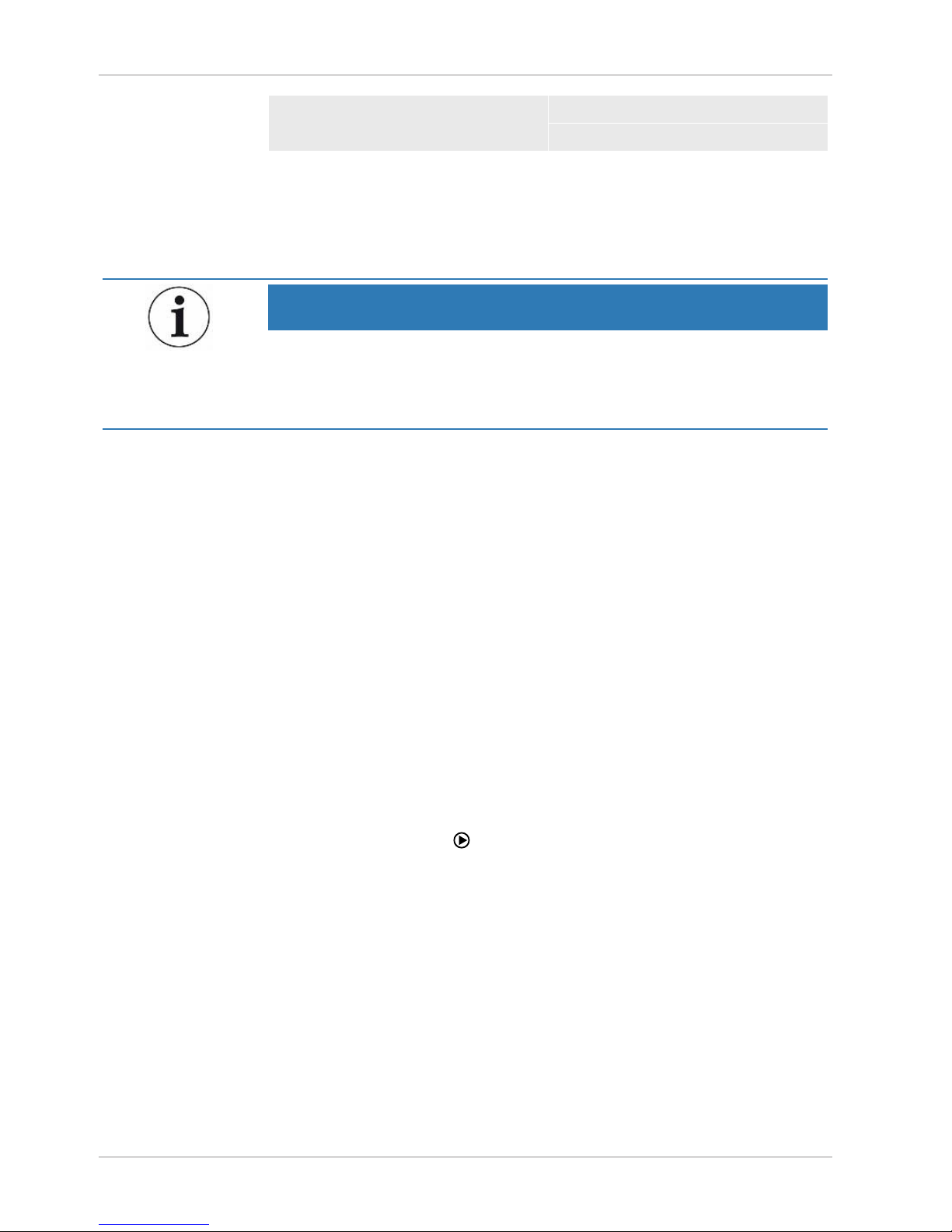

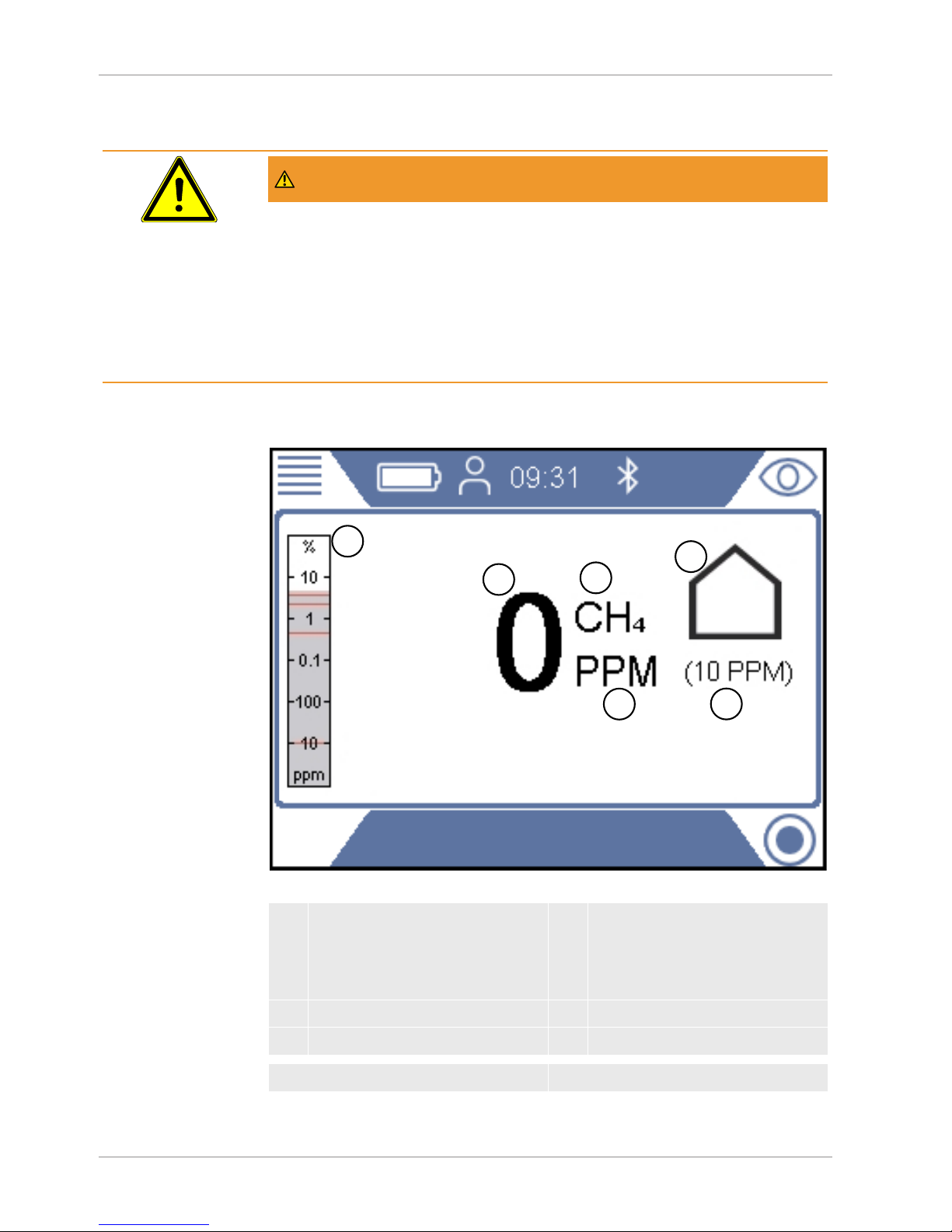

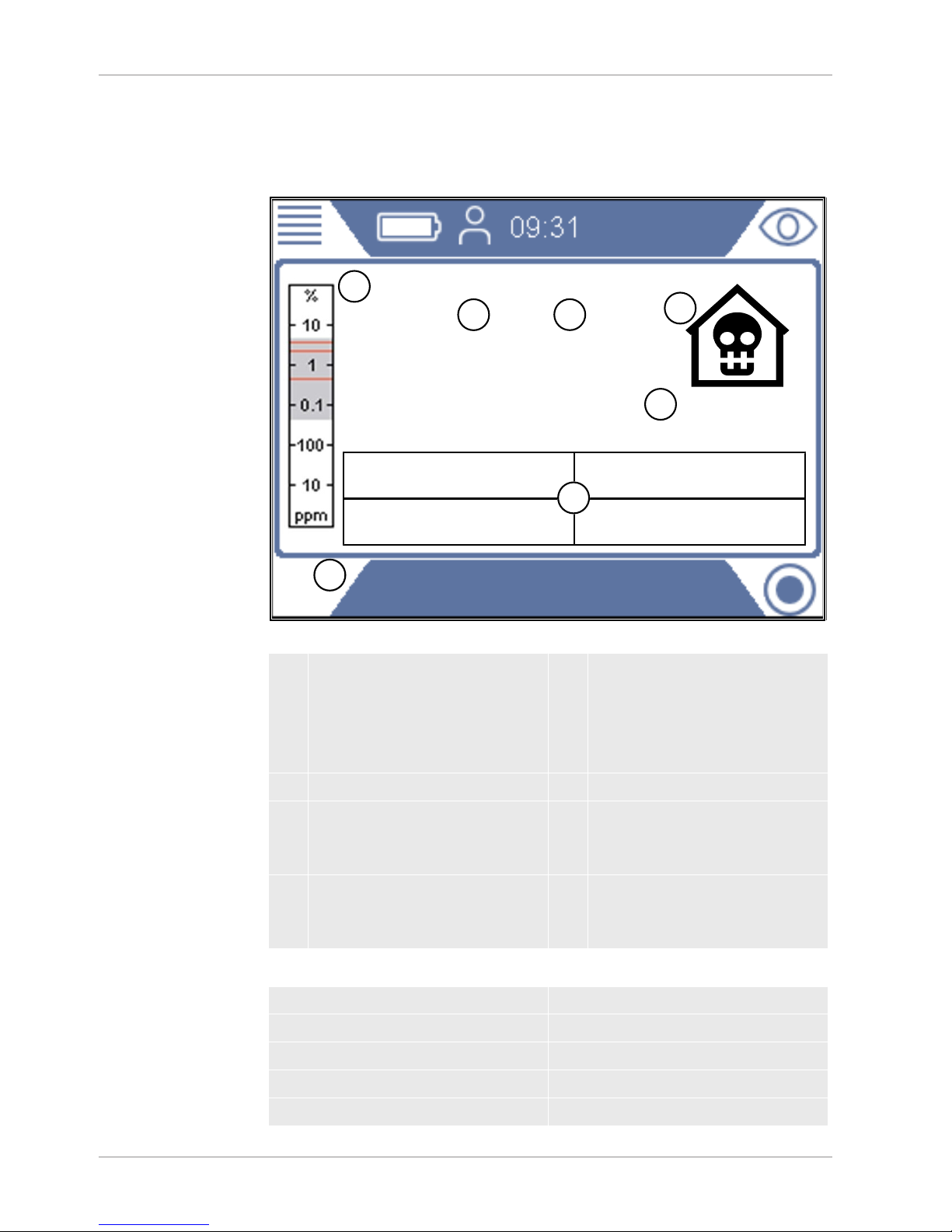

4.4 Display

7

5

1

2

3

4

6

1 1

1

2

3

4

8

9

Above ground

5

(10 PPM)

1010

1 Navigation buttons 2 Navigation and on / off button

3 Battery status indicator 4 Mode icon

5 Measured value, target gas and

unit

6 Measurement range (in % or PPM

CH4 depending on the operation

mode)

7 Status indicator LED 8 Operation mode and menu bar

9 Buzzer 10 PPM threshold in Above Ground

and Confined Space modes.

Navigation buttons

Menu Upper left

Settings Upper left after pressing “Menu”

Operation Upper right

Information Lower left after pressing “Menu”

Diagnosis At lower right after pressing “Menu”

Table1:

Navigation buttons

To select a menu, press the navigation button to go to desired tab or field.

Press check mark button , select or open a highlighted option.

Function buttons

OK/Select/Confirm

Navigation buttons (in this case go right)

Cancel process

Start process

Start data logging

Stop data logging

Page 18

INFICON Description | 4

IRwin-Operating-instructions-mina66en1-12-(1802) 17 / 112

Mute the alarm

Table2:

Function buttons

Symbols of the status

bar

Bluetooth activated

Symbol ON = GPS connected and

tracking

Symbol flashing = GPS not connected

Battery status indicator

The color of the battery status indicator shows the remaining runtime before shutdown:

White: > 1h remaining

Orange: < 1h remaining

Red flashing: < 10 min remaining

Progress bars for calibration processes etc.

White bar: Process has not yet started

Light green bar: Process running

Dark green bar: Process completed

Red bar: Process failed

Table3:

Status indicators

Mode icons

• Operation mode- Above ground

• Operation mode- Bar hole

• Operation mode- Confined Space

• Operation mode- House

• Operation mode- Gas Purity

• Operation mode- Ex

• Operation mode- Ex Tox

• Operating mode- GC Ethane Analysis

Permission levels

Symbol Permission level Password

Basic none

Intermediate 1111

Advanced 1422

Table4:

Permission levels

Page 19

4 | Description INFICON

18 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

Status LED

Green • Leak detector is charging normal

(power off)

• Normal operation in the modes Ex and

Ex Tox.

Cyan Leak detector is charging fast.

Blue Normal operation

(in all operation modes except Ex and Ex

Tox)

Red • Alarm

• Error message

Yellow The leak detector is in a state in which

functions like for example alarms could

be disabled. For example, during warm

up or calibration.

Page 20

INFICON Description | 4

IRwin-Operating-instructions-mina66en1-12-(1802) 19 / 112

4.5 Technical data

Mechanical data

580-000 580-010 580-015 580-020 580-030

Name IRwin S IRwin SX IRwin SXT IRwin SXG IRwin SXGT

Weight 1,4 kg (3 lb.) 1.6 kg (3.5 lb.) 1.6 kg (3.5 lb.) 1.6 kg (3.5 lb.) 1.6 kg (3.5 lb.)

Dimensions

(lxwxh)

197 x 256 x 62

mm (6.6 x 9.7 x

2.3 in.)

197 x 256 x 62

mm (6.6 x 9.7 x

2.3 in.)

197 x 256 x 62

mm (6.6 x 9.7 x

2.3 in.)

197 x 256 x 62

mm (6.6 x 9.7 x

2.3 in.)

197 x 256 x 62

mm (6.6 x 9.7 x

2.3 in.)

Electrical data

580-000 580-010 580-015 580-020 580-030

Name IRwin S IRwin SX IRwin SXT IRwin SXG IRwin SXGT

Power input 4 A 4 A 4 A 4 A 4 A

Memory capacity for measured

data

64 MB 64 MB 64 MB 64 MB 64 MB

Type of protection

IP54 IP54 IP54 IP54 IP54

Electronic interfaces

Bluetooth 3.0

Class 1

Bluetooth 3.0

Class 1

Bluetooth 3.0

Class 1

Bluetooth 3.0

Class 1

Bluetooth 3.0

Class 1

Battery operating time

8 h as verified

during certification, typical value

9 h

8 h as verified

during certification, typical value

9 h

8 h as verified

during certification, typical value

9 h

8 h as verified

during certification, typical

value 9 h

8 h as verified

during certification, typical value

9 h

Battery charging

time

4 h from empty

to full charge (3

h for fast charging). 4 hours operation by 1 hour

fast loading

4 h from empty

to full charge (3

h for fast charging). 4 hours operation by 1 hour

fast loading

4 h from empty

to full charge (3

h for fast charging). 4 hours operation by 1 hour

fast loading

4 h from empty

to full charge (3

h for fast charging). 4 hours operation by 1 hour

fast loading

4 h from empty

to full charge (3 h

for fast charging). 4 hours operation by 1 hour

fast loading

Battery Lithium-Ion Lithium-Ion Lithium-Ion Lithium-Ion Lithium-Ion

Physical data

580-000 580-010 580-015 580-020 580-030

Name IRwin S IRwin SX IRwin SXT IRwin SXG IRwin SXGT

Noise level < 70 dB (A) < 70 dB (A) < 70 dB (A) < 70 dB (A) < 70 dB (A)

Page 21

4 | Description INFICON

20 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

580-000 580-010 580-015 580-020 580-030

Detectable

gases

Methane, ethane, propane,

butane, carbon

dioxide

Methane, carbon

dioxide, ethane,

propane, butane

Methane, carbon

dioxide, ethane,

propane, butane,

oxygen, hydrogen sulfide, carbon monoxide

Methane, carbon

dioxide, ethane,

propane, butane

Methane, carbon

dioxide, ethane,

propane, butane,

oxygen, hydrogen sulfide, carbon monoxide

Gas flow through

sniffer line

Typically 60 l/h Typically 60 l/h Typically 60 l/h Typically 60 l/h Typically 60 l/h

Ambient conditions

580-000 580-010 580-015 580-020 580-030

Name IRwin S IRwin SX IRwin SXT IRwin SXG IRwin SXGT

Max. altitude

above sea level

2000 m 2000 m 2000 m 2000 m 2000 m

Permissible ambient temperature (during operation)

-20° - +50°C (-4

- 122°F)

-20 - 50°C (-4 122°F)

-15 - 40°C (-5 104°F)

-20 - 50°C (-4 122°F)

-15 - 40°C (-5 104°F)

Storage temperature

-25 - +70°C (-13

- 158°F)

-25 - 70°C (-13 158°F)

-25 - 70°C (-13 158°F)

-25 - 70°C (-13 158°F)

-25 - 70°C (-13 158°F)

Pressure range 80 kPa - 120

kPa

80 kPa - 120

kPa

80 kPa - 120

kPa

80 kPa - 120

kPa

80 kPa - 120

kPa

Max. relative humidity

95% (non-condensing)

95% (non-condensing)

95% (non-condensing)

95% (non-condensing)

95% (non-condensing)

Page 22

INFICON Description | 4

IRwin-Operating-instructions-mina66en1-12-(1802) 21 / 112

4.5.1 EX certification (intrinsic safety)

Type certificate

Type certificates, see Certificates [}85]

The products:

• IRwin SX 580-010,

• IRwin SXT 580-015,

• IRwin SXG580-020,

• IRwin SXGT580-030,

are Ex certified with rating according to the following table. The IRwin S 580-000 is not

Ex certified.

EX rating

EX rating Ex ia IIC T3, T

amb

: -20°C - +50°C,

II 1G (EPL Ga)

USA: Intrinsically safe, Class I, Division 1, Groups A,

B, C and D.

EX ranges of applications • Zones: 0, 1 and 2

• Gas groups: IIA, IIB and IIC

• Temperature classes: T1, T2 and T3

• USA: Zone 0, Class I, Division 1, Groups A, B, C

and D.

4.5.2 Sensors

Basic sensor data

Gas (measurement range) Sensor Warm up time

CH4, C2H

6

Infrared (IR) < 30 s

CO

2

Infrared (IR) < 30 s

O2, CO, H2S Electrochemical < 120 s

O2 sensor: 1 - 12 hours if

stored with flat battery.

Sensor performance

data

The calibration gases defined below are the typical gases and gas mixes used to calibrate the different modes. For optimum performance adjust these settings to the actual concentrations of the gases used. See Calibration [}40].

Above ground mode:

Measurement

principle

Infrared (IR)

Measurement

range

CH4, C3H8, C4H10: 1 ppm - 5 Vol%

Resolution 1 ppm (0 - 100 ppm), 10 ppm (110 - 990 ppm), 0,1 Vol% (0,1 - 5

Vol%)

Page 23

4 | Description INFICON

22 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

Measurement error

+5/-2 ppm (<20 ppm) +/-10% (20 - 50 ppm) +/-5% (50 ppm - 2.2

Vol%) +/-20% (2.2 - 5 Vol%)

Response time t50 <3 s, t90 <5 s

Recovery time t50 <3 s, t10 <5 s

Cross sensitivity All hydrocarbons CxHy

Lifetime Guaranteed 1 years, expected > 2 years

Calibration

gases

Fresh air, CH4 in air: 10 ppm, 100 ppm, 2.2 Vol%

Bar hole mode:

Measurement

principle

Infrared (IR)

Measurement

range

CH4, C3H8, C4H10: 0.5 - 100 Vol%

C2H6 content in CNG: 0.5 - 8 Vol%

CO2: 0.1 - 20 Vol%

Resolution CH4 & CO2: 0.1 Vol% (0.1 - 1 Vol%), 1 Vol% (>1 Vol%)

C2H6: 0.1 Vol% (Auto test) 0.5 Vol% (manual selection)

Measurement error

CH4: ±3 Vol%

CO2: +/-1% (<10 Vol%), +/-20% (>10 Vol%)

Response time t50 <5 s, t90 <10 s

Recovery time t50 <5 s, t10 <10 s

Cross sensitivity All hydrocarbons CxHy

CO2: Negligible

Lifetime Guaranteed 1 years, expected > 2 years

Calibration

gases

Fresh air, CH4 in air: 2.2 Vol%, 100 Vol%. CO2, 20 Vol%

GC Ethane Analysis mode:

Measurement

principle

Gas Chromatography separation with semiconductor detector

Measurement

range

1000 ppm gas needed in sample. This refers to total hydrocarbon content (i.e., natural gas, swamp gas or LPG etc.).

Capability Can identify Natural Gas at 0.5% C2H6level.

Automatic interpretation of result as either of:

• NG with Ethane detected

• Swamp gas detected

• LPG detected

Page 24

INFICON Description | 4

IRwin-Operating-instructions-mina66en1-12-(1802) 23 / 112

• Gas type not identified (given if result is not clear)

Cycle time*: Ethane only: 2 min at 25°C, 3 min at 0°C

Ethane and Propane: 5 min at 25°C, Propane detection not possible at 0°C

Purge time (before new GC

test):

3 min

Lifetime Separation column: Guaranteed 3 years, expected > 10 years

Semiconductor sensor: Guaranteed 1 year, expected 3 years.

* Times given are valid after 1 h operation in given ambient temperature. Times include 30 s sensor purge before analysis. Three minutes column purge after analysis is

not included. The column purge can be postponed.

House mode:

Measurement

principle

Infrared (IR)

Measurement

range

CH4, C3H8, C4H10: 1 ppm - 5 Vol%

Resolution 1 ppm (0 - 100 ppm), 10 ppm (110 - 990 ppm), 0.1 Vol% (0.1 - 1

Vol%), 1 Vol% (>1 Vol%)

Measurement error

+5/-2 ppm (<20 ppm) +/-10% (20 - 50 ppm) +/-5% (50 ppm - 2.2

Vol%) +/-20% (2.2 - 5 Vol%)

Response time t50 <3 s, t90 <5 s

Recovery time t50 <3 s, t10 <5 s

Cross sensitivity All hydrocarbons CxHy

Lifetime Guaranteed 1 years, expected > 2 years

Calibration

gases

Fresh air, CH4 in air: 10 ppm, 100 ppm, 2.2 Vol%

Confined Space mode:

Measurement

principle

Infrared (IR)

Measurement

range

CH4, 1 ppm – 100 Vol% for natural gas with up to 8% C2H6 (ethane) content

Resolution 1 ppm (0 - 100 ppm), 10 ppm (110 - 990 ppm), 0.1 Vol% (0.1 - 1

Vol%), 1 Vol% (>1 Vol%)

Measurement error

+5/-2 ppm (<20 ppm) +/-10% (20 - 50 ppm) +/-5% (50 ppm - 2.2

Vol%) +/-3 Vol% (2.2 - 100 Vol%)

Response time t50 <5 s, t90 <10 s

Page 25

4 | Description INFICON

24 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

Recovery time t50 <5 s, t10 <10 s

Cross sensitivity All hydrocarbons CxHy

Lifetime Guaranteed 1 years, expected > 2 years

Calibration gas Fresh air, CH4 in air: 10 ppm, 100 ppm, 2.2 Vol%, 100 Vol%

Gas Purity mode:

Measurement

principle

Infrared (IR)

Measurement

range

CH4: 0.5 - 100 Vol%

Resolution 0.5 Vol% (0.5 - 1 Vol%), 1 Vol% (>1 Vol%)

Measurement ±3 Vol%

Response time t50 <5 s, t90 <10 s

Recovery time t50 <5 s, t10 <10 s

Cross sensitivity All hydrocarbons CxHy

Lifetime Guaranteed 1 years, expected > 2 years

Calibration gas Fresh air, CH4 in air: 2.2 Vol%, 100 Vol%

Ex mode:

Measurement

principle

Infrared (IR)

Measurement

range

CH4, C3H8, C4H10: 1 - 100% LEL

Resolution 1%LEL

Measurement error

±5%LEL

Response time CH4: t50 = 3 s, t90 = 5 s

Recovery time t50 <3 s, t10 <5 s

Cross sensitivity All hydrocarbons CxHy

Lifetime Guaranteed 1 years, expected > 2 years

Calibration gas Fresh air, CH4: 2.2 Vol%

Ex Tox mode:

Measurement

principle

Infrared (IR)

Measurement

range

CH4, C3H8, C4H10: 1 - 100% LEL

CO2: 0.1 - 5 Vol%

Page 26

INFICON Description | 4

IRwin-Operating-instructions-mina66en1-12-(1802) 25 / 112

O2: 0.1 - 25 Vol%

CO: 1 - 500 ppm

H2S: 1 - 400 ppm

Resolution CH4, C3H8, C4H10: 1% LEL

CO2: 0.05 Vol%

O2: 0.1 Vol%

CO: 1 ppm

H2S: 0.1 ppm

Measurement error

CH4: ±5 % LEL C3H8: +/-40% of indicated value C4H10: +/-50% of

indicated value

CO2: ±0.1 Vol%

O2: ±0.3 Vol%

CO: ±3 ppm

H2S: ±0.5 ppm

Response time CH4: t50 <3 s, t90 <5 s

O2: t50 <16 s, t90 <40 s

CO: t50 < 15 s, t90 <30 s

CO2: t50 <12 s, t90 <36 s

H2S: t50 <18 s, t90 <66 s

Recovery time CH4: t50 <3 s, t10 <5 s

CO2: t50 <12 s, t10 <36 s

O2: t50 <16 s, t10 <39 s

CO: t50 <15 s, t10 <30 s

H2S: t50 < 18 s, t10 <66 s

Sensitivity drift CH4, C3H8, C4H10: <±5 %LEL in 1 month

CO2: <±5 Vol% in 1 month

O2: <±1 Vol% in 3 months

CO: <±4% in 12 months

H2S: <±2% in 12 months

Cross sensitivity CH4: All hydrocarbons CxHy.

O2: negligible

CO: <12% of applied H2S concentration, <8% of applied H2 concentration

H2S: <1.5% of applied CO concentration, <0.3% of applied H

2

concentration

CO2: negligible

Page 27

4 | Description INFICON

26 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

Lifetime CH4, C3H8, C4H10: Guaranteed 1 years, expected > 2 years

CO2: Guaranteed 1 years, expected > 2 years

O2: Guaranteed 4 years, expected > 5 years

CO: Guaranteed 2 years, expected > 3 years

H2S: Guaranteed 2 years, expected > 3 years

Calibration gas Fresh air, ToxMix (CH4 2.2 Vol%, CO2 2 Vol%, CO 40 ppm, H2S

40 ppm, O2 0 Vol% in N2)

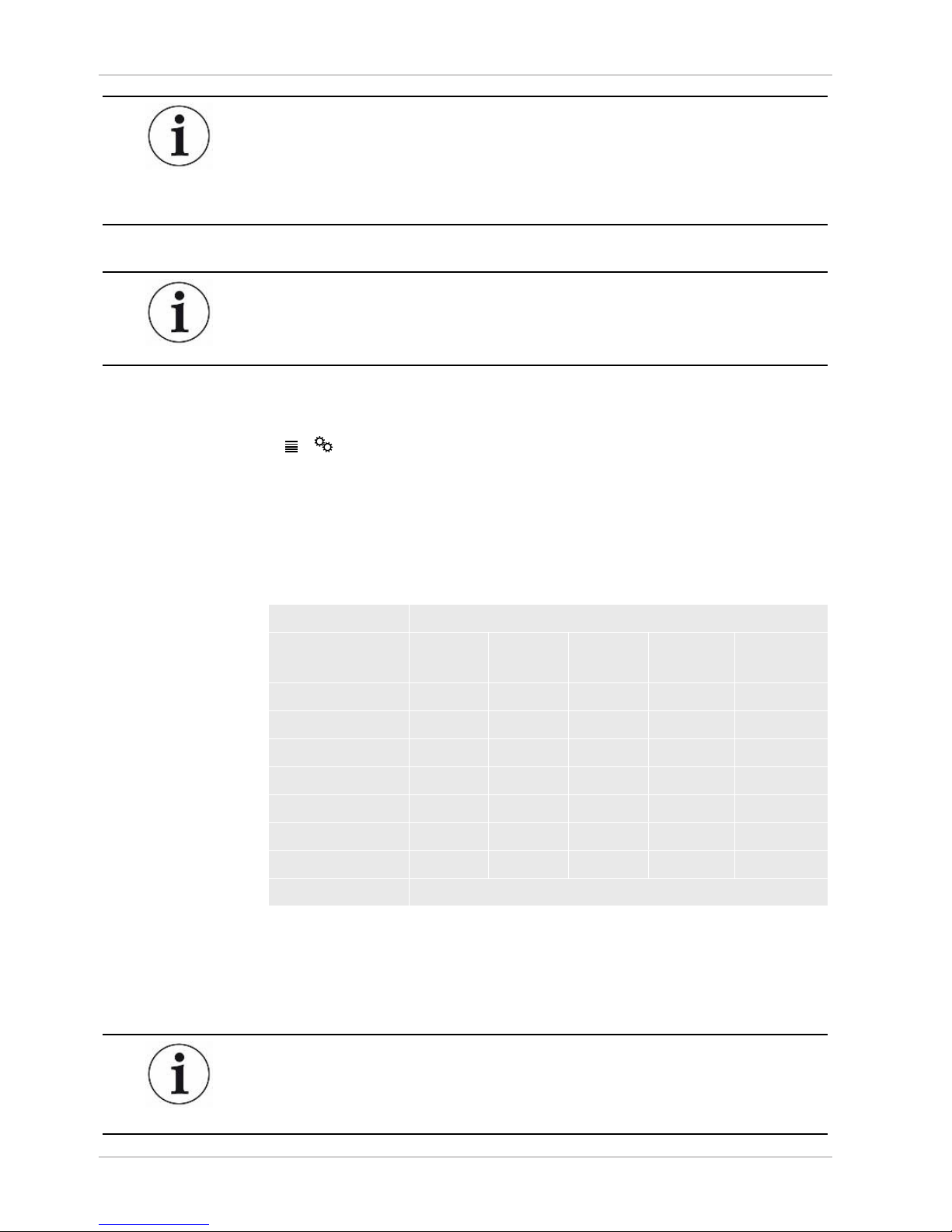

4.6 Factory settings

Parameter Factory Setting Options

Screen timeout (auto

standby)

30 s Off

5, 30 s

1, 2, 5, 10, 20, 30 min

1, 2

Brightness 10 1 -10

Screensaver (IRwin S only) enabled enabled or disabled

CH4 PPM Alarm 10 PPM 3, 5, 10, 15, 20, 25, 50,

100

CH4 AL1

CH4 AL2

CH4 AL3

10% LEL

50% LEL

100% LEL

3, 5, 10

30, 40, 50

80, 90, 100

C3H8 PPM alarm 10 PPM 3, 5, 10, 15, 20, 25, 50,

100

C3H8 AL1

C3H8 AL2

C3H8 AL3

10% LEL

50% LEL

100% LEL

3, 5, 10

30, 40, 50

80, 90, 100

C4H10 PPM alarm 10 PPM 3, 5, 10, 15, 20, 25, 50,

100

C4H10 AL1

C4H10 AL2

C4H10 AL3

10% LEL

50% LEL

100% LEL

3, 5, 10

30, 40, 50

80, 90, 100

CO2 AL1

CO2 AL2

CO2 AL3

CO2 STEL

CO2 LTEL

0.5 Vol%

1.0 Vol%

5 Vol%

1.0 Vol%

0.5 Vol%

0.1, 0.2, 0.3, 0.4, 0.5

0.6, 0.7, 0.8, 0.9, 1.0

1.0, 2.0, 3.0, 4.0, 5.0

0.5, 0.6, 0.7, 0.8, 0.9, 1.0

0.1, 0.2, 0.3, 0.4, 0.5

Page 28

INFICON Description | 4

IRwin-Operating-instructions-mina66en1-12-(1802) 27 / 112

Parameter Factory Setting Options

CO AL1

CO AL2

CO AL3

CO STEL

CO LTEL

30 ppm

60 ppm

500 ppm

30 ppm

30 ppm

10, 20, 30

40, 50, 60

100, 200, 300, 400, 500

10, 20, 30

10, 20, 30

H2S AL1

H2S AL2

H2S AL3

H2S STEL

H2S LTEL

10 ppm

20 ppm

100 ppm

10 ppm

10 ppm

3, 5, 7, 10

10, 15, 20

50, 60, 70, 80, 90, 100

3, 5, 7, 10

3, 5, 7, 10

O2 AL1

O2 AL2

O2 AL3

10 Vol%

18 Vol%

23 Vol%

3, 5, 10, 15

16, 17, 18, 19, 20

21, 22, 23, 24, 25

Calibration reminder Off Off, 1 - 7, 14, 30 days

Function test reminder Off Off, 2, 4, 8 h.

Time UTC +2 h. -11 - +12 h.

Language English English, Deutsch, Italiano,

Nederlands, Polskie

Ethane % 0% 0 - 8% (in increments of

0.5%)

Log to file enabled enabled / disabled

Logging Interval (log file

period)

1 s 1, 2, 3, 5, 10, 30 s, 1 min

Start menu Ex, (Above ground in IRwin

S)

Autorotations Off On, Off

Re-test C2H6 in Bar Hole Off Off, startup, always

Measuring duration (Auto

bar hole)

10 s 10, 15, 20, 25, 30 s

Evacuation duration (Auto

bar hole)

3min 3, 4, 5, 10, 15 min

CO2-limit at evacuation

(Auto bar hole)

Off Off, 1, 2, 3, 4, 5%

Page 29

4 | Description INFICON

28 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

4.7 Concentration of calibration and test gases

Calibration routine Gases Default Options

Above Ground

10 ppm CH

4

10 ppm 8 - 15 ppm in 0.1

ppm increments

100 ppm CH

4

100 ppm 90 - 110 ppm in 1

ppm increments

2.2 Vol% CH

4

2.2 Vol% 2.0 - 2.5 Vol% in

0.1 Vol% increments

Ex Tox (Tox)

Mixture of:

2.2 Vol% CH

4

2.2 Vol% 1.4 - 2.5 Vol% in

0.1 Vol% increments

2.0 Vol% CO

2

2.0 Vol% 0.5 - 3.0 Vol% in

0.1 Vol% increments

0 Vol% O

2

0.0 Vol% 0.0 - 18.0 Vol% in

0.1 Vol% increments

40 ppm H2S 40 ppm 4 - 50 ppm in 1 ppm

increments

40 ppm CO 40 ppm 20 - 160 ppm in 1

ppm increments

Balance: N

2

Not applicable Not applicable

Ex

2.2 Vol% CH

4

2.2 Vol% 2.0 - 2.5 Vol% in

0.1 Vol% increments

Bar Hole CO

2

20.0 Vol% CO

2

20.0 Vol% 10.0 - 20.0 Vol% in

0.1 Vol% increments

Bar Hole CH

4

2.2 Vol% CH

4

2.2 Vol% 2.0 - 2.5 Vol% in

0.1 Vol% increments

100 Vol% 100 Vol% 80 - 100 Vol% in 1

Vol% increments

GC Ethane analysis

*

Mixture of:

1 Vol% CH

4

Not applicable Not applicable

50 ppm C2H

6

Not applicable Not applicable

*Used only for Function Test of GC Ethane Analysis.

Balance gas is Synthetic Air if nothing else stated (Ex Tox balance is N2).

Page 30

INFICON Getting started | 5

IRwin-Operating-instructions-mina66en1-12-(1802) 29 / 112

5 Getting started

5.1 Charging the battery

WARNING

Explosion hazard

The equipment for charging IRwin is not ATEX certified/ex-protected.

► Never charge IRwin (all models) in potentially explosive atmospheres.

WARNING

Using the wrong charger could damage the explosion protection of IRwin

SXnn models.

The only equipment allowed to be connected to the Charging socket of any of the IRwin SXnn models is the Ex Certified IRwin Charging Adapter. Connect this adapter to

the leak detector first and then connect the charger or car cable to the adapter.

NOTICE

Fast charging reduces the lifetime of the battery.

► Do not use fast charging regularly.

► The ambient temperature during the charging process should be between 10 and

30 °C.

Page 31

5 | Getting started INFICON

30 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

Accessories for charging for IRwin S up to serial number 929000704

Charger for IRwin S, 100-240V

(580-603)

or

Car adapter for IRwin S, 12V

(580-602)

Charge IRwin S

1

Switch off IRwin S.

2

Connect the "Charger for IRwin S, 100-240V (580-603)" or "Car adapter for IRwin S, 12V (580-602)" to the charging inlet of IRwin S. Align the red marks of the

charging socket and charging plug with each other.

ð The status LED is green when the battery charges normal.

Fast charging IRwin S

1

For charging the leak detector faster switch on the IRwin S.

2

Connect the "Charger for IRwin S, 100-240V (580-603)" or "Car adapter for IRwin S, 12V (580-602)" to the charging inlet of IRwin S.

3

Select fast charge when the pop-up is shown on the display.

ð The signal LED is turquoise when the battery is charging at a fast rate.

Page 32

INFICON Getting started | 5

IRwin-Operating-instructions-mina66en1-12-(1802) 31 / 112

Accessories for charging for IRwin SXnn and IRwin S from serial

number 929000705

Charger for IRwin SXnn models,

100-240V (580-605)

Certified IRwin Charging Adapter

(580-604)

or

Charger cable for car (591-361)

Charging IRwin SXnn and IRwin S from serial number 929000705

1

Switch off IRwin SXnn.

2

Connect the “Certified IRwin Charging Adapter (580-604)“ to the charging inlet

of IRwin SXnn. Align the red markings of the charging socket and charging plug

to each other.

3

Connect the "Charger for IRwin SXnn models, 100-240V (580-605)" or "Charger

cable for car (591-361)" to the “Certified IRwin Charging Adapter (580-604)".

ð The status LED is green when battery is charging normally. The status LED goes

out when charging is completed.

Page 33

5 | Getting started INFICON

32 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

Fast charging IRwin SXnn

►

When the signal LED is green and indicating normal charge, press the upper right

button.

ð The detector is now charging fast and the status LED turns cyan.

Normal Fast charge

100% 4 h from empty to full

charge produces 9.5 h operation time

3 h from empty to full

charge produces 9 h operation time

Short charge 1 h charging gives >3.25 h

of operation

1 h charging gives 4 h of

operation

5.2 Assembling the probe system

WARNING

Risk of explosion due to not approved probe parts.

The original INFICON Hand probe is the only part of the probe system that is certified

for use in potentially explosive areas. Other parts of the probe system, or third party

accessories are not allowed in potentially explosive areas.

► Pay proper attention to safety when using other accessories for locating and pin-

pointing gas leaks in none classified areas.

NOTICE

The assembly of the probe system influences the response time stated in the technical

data.

The probe system consists of the hand probe, the probe rod, the probe rod extension,

the carpet probe and the bell probe. Each probe part is equipped with quick couplings

and can be assembled according to the following graphics. The connection to the leak

detector is made with the hand probe in all configurations.

The proper functioning of the system can only be assured with compatible probe systems of the manufacturer.

1

Attach the probe rod to the carpet or the bell probe.

Page 34

INFICON Getting started | 5

IRwin-Operating-instructions-mina66en1-12-(1802) 33 / 112

2

Attach the hand probe to the probe rod.

3

Connect the probe tube of hand probe to the gas inlet of the leak detector, see

Design of the leak detector [}13].

Install the probe rod

extension

To improve the ergonomics of the carpet probe, you can install the "probe rod extension".

1

Remove the male quick fitting (1) from the carpet using as 17 mm wrench.

2

Remove the tape covering the female thread of the extension rod (2).

3

Place the O-ring, found under the tape, flat on the bottom surface of the female

threaded hole.

4

Screw the removed male quick fitting (1) in place in the extension rod (2). Make

sure the O-ring stays in place by holding the extension rod (2)vertical. If desired

you can use nut locking fluid to secure the fitting (1).

Page 35

5 | Getting started INFICON

34 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

5

Remove the O-ring and clean the threaded hole on the black fork on the carpet

(where you removed the connector).

6

Place the O-ring flat on the bottom surface of the threaded hole.

7

Screw the extension rod in place in the carpet fork. Make sure the O-ring stays

in place by holding the fork vertical.

IMPORTANT: Be careful when tightening. The fork is plastic and the threads are

easily destroyed. If desired you can use nut locking fluid to secure the extension

rod (2).

8

Connect the longer rod to the carpet.

5.3 Transfer data to computer

NOTICE

System requirements: Windows 7 or later with Bluetooth interface.

5.3.1 Install software for data transfer

1

Install the IRwin App software on your computer.

2

Follow the instructions on the screen.

More complete information about supporting software can be found in separate documents.

5.3.2 Pairing the leak detector with computer via Bluetooth

interface

ü Set IRwin in one of the following operating modes: Bar Hole, Gas Purity, House,

Above Ground and Confined Space. Bluetooth is active in all these modes.

ü Make sure IRwin App is installed on your computer.

ü Make sure Bluetooth is activated on your computer.

1

Establish a Bluetooth connection. Refer to the instructions on your computer.

When searching for your detector on the computer, locate the correct serial

number of your detector and select that device on the computer. Some computers will prompt you to acknowledge that a connection "password" has been correctly transferred to the detector. You must confirm this on both computer and

detector.

2

Start the program IRwin App on your computer.

3

In the IRwin App on your computer, Click Connection (menu item) > Port and

select your detector.

Page 36

INFICON Getting started | 5

IRwin-Operating-instructions-mina66en1-12-(1802) 35 / 112

ð The serial number of the leak detector is displayed in the drop down menu.

4

Select "Connect" on the menu bar in IRwin App.

5

Click "Start Streaming" on the menu bar of IRwin App.

5.3.3 Transfer log files from leak detector to computer

ü You have installed IRwin App software on your computer.

ü You have recorded at least one log fil in your detector.

ü You have activated the Bluetooth interface on your computer.

1

Switch on the leak detector

2

Perform self-test.

3

Set IRwin in one of the following operating modes: Bar Hole, Gas Purity, House,

Above Ground or Confined Space. Bluetooth is active in all these modes.

4

> > Data output > Files (Tab)

5

Start IRwin App on your computer

6

Select the serial number of your detector in “Port” drop down menu. If not found,

check setting of Bluetooth interface and repeat paring sequence if necessary.

7

Click “Connect” in IRwin App.

8

Select tab “File” in the graphic window in IRwin App.

9

Select the file to transfer. You can only transfer one file at the time.

10

Click “Download File” in IRwin App.

11

IRwin App will confirm when file is transferred.

12

To delete a file, select the file in the IRwin App and click “Delete File”. Reenter

the file list in IRwin to confirm that the file is deleted.

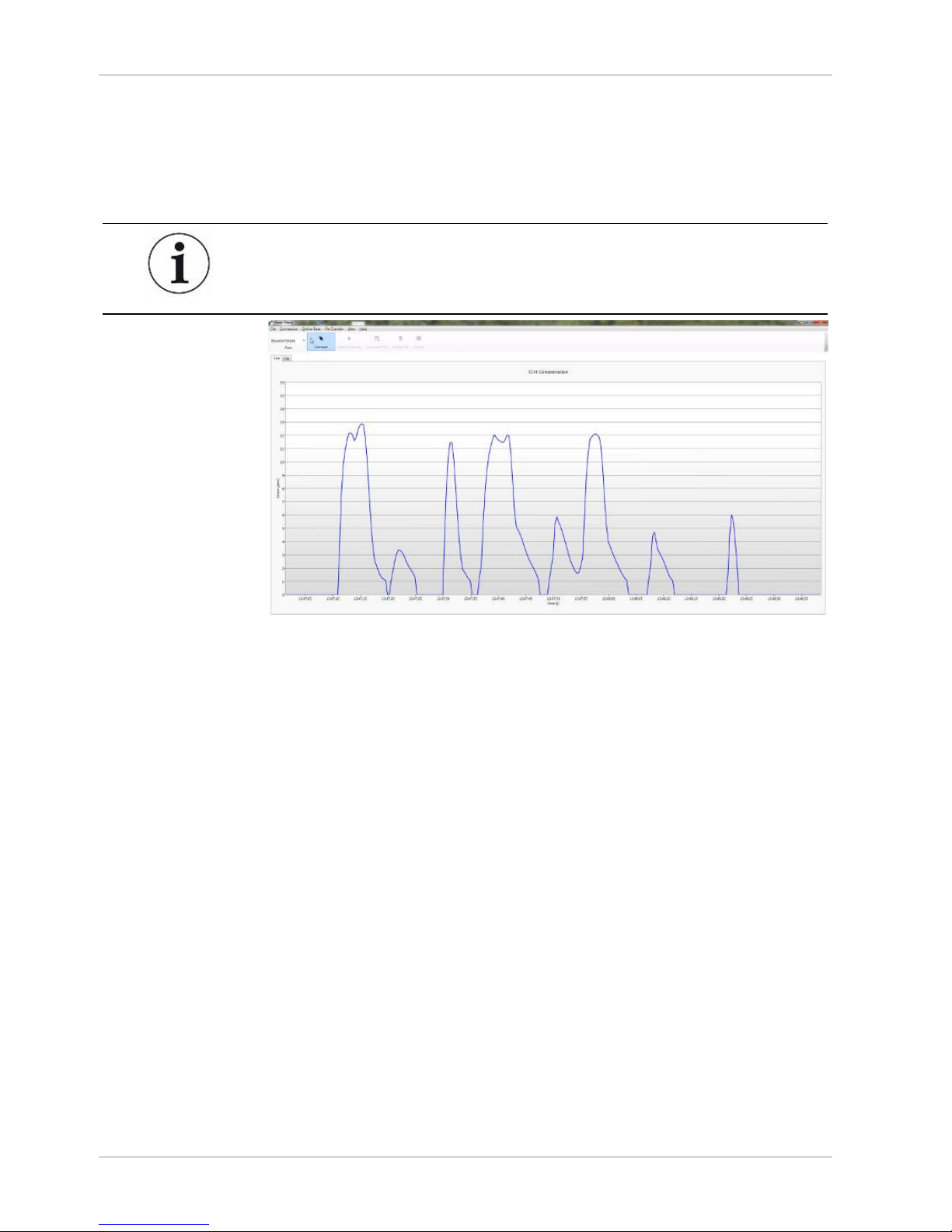

5.3.4 Real-time streaming from leak detector to computer

ü You have installed IRwin App software on your computer.

ü You have activated the Bluetooth interface on your computer.

1

Switch on the leak detector.

2

Perform self-test.

3

Set the leak detector in the desired mode. This must be one of the following operating modes: Bar Hole, Gas Purity, House, Above Ground or Confined Space.

Bluetooth is active in all these modes.

4

Start IRwin App on your computer.

5

Select the serial number of your leak detector in “Port” drop down menu. If not

found, check setting of Bluetooth interface and repeat paring sequence if necessary.

Page 37

5 | Getting started INFICON

36 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

6

Click “Connect” in IRwin App.

7

Select tab “Live” in the graphic window in IRwin App.

8

Click “Start Streaming” in IRwin App.

ð The measurement data is now presented as a graph.

While streaming you can change mode as desired.

Streamed data cannot be saved.

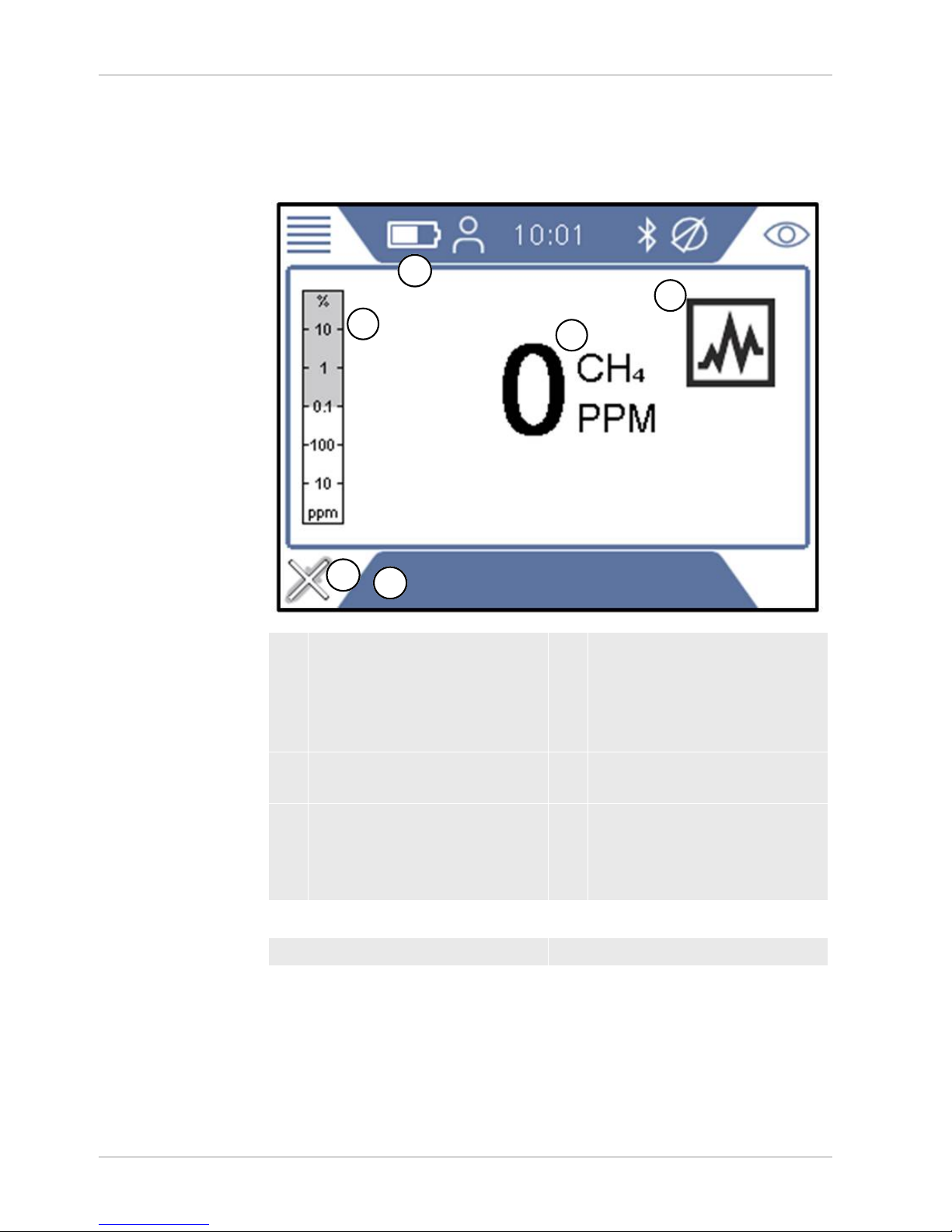

Fig.7:

Streamed measurement data

Page 38

INFICON Operation | 6

IRwin-Operating-instructions-mina66en1-12-(1802) 37 / 112

6 Operation

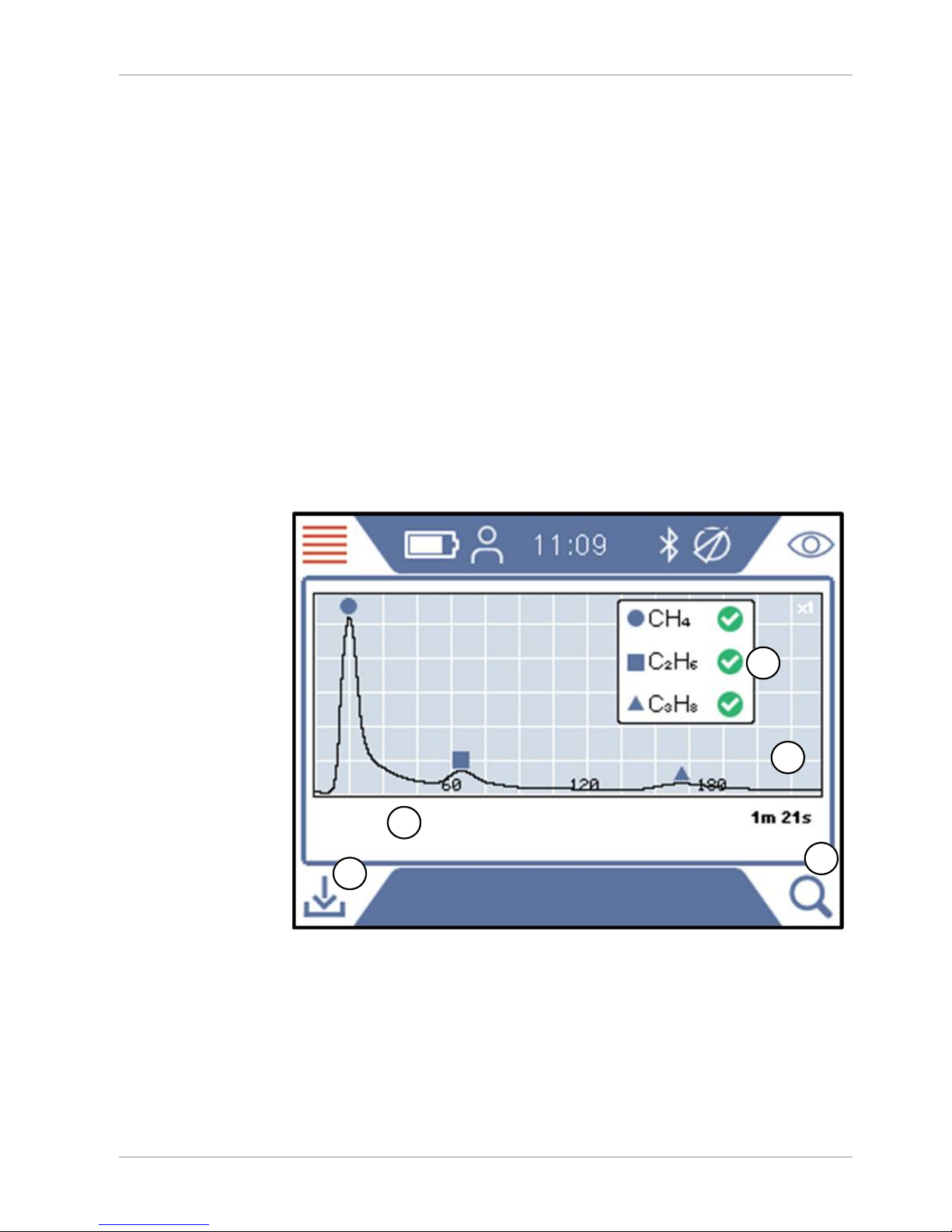

WARNING

Danger to life and limb

Due to incorrect and irregular inspections.

► Check all parts of the entire measuring system regularly for damages.

6.1 Switch ON

WARNING

Explosion hazard

IRwin S and any kind of equipment for charging (for all models), are not ex-protected.

► Do not use the IRwin S or any kind of charger for the S and SXnn versions in explo-

sive atmospheres.

The start-up sequence can differ slightly between the individual models.

1

Press the on / off button on the lower right of the display (Design of the leak detector).

ð During start-up, the leak detector passes through a warm-up phase of 2 min-

utes maximum and performs a self-test of software and parameter memories,

battery, display, pumps, valve(s), buzzer, sensors and status LED.

2

To confirm the function of the buzzer, press the button next to check mark (upper right).

3

The status LED lights up in various colors as indicated on the screen. Confirm

each color by pressing the check mark (upper right).

4

Confirm the results of the self test.

ð The measurement screen appears.

5

If you want to check the condition of the leak detector even further, perform a

calibration test (Calibration) or a function test (Performing function tests) before

starting to work.

Page 39

6 | Operation INFICON

38 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

6.2 Initial setup

After 2 minutes of inactivity the menu system exits automatically to the measurement screen.

6.2.1 Adjust the local time

If the time of the leak detector and the local time do not match you can change the

time zone.

1

> > General > Time/Date (Tab).

2

Adjust the local time zone.

ð For the settings, see Factory settings [}26].

3

Leave the view via .

6.2.2 Setting the language

1

> > General > Misc (Tab) > Language

2

Select a language.

3

Leave the view via .

6.2.3 Change permission level

The leak detector has three permission levels “Basic“, “Intermediate“ and “Advanced“.

The leak detector starts with the permission level "Basic". The permission levels “Intermediate“ and “Advanced“ are protected by a password. You can see which permission

level is active in the status line of the display (Display [}16]).

Symbol Permission level Password

Basic none

Intermediate 1111

Advanced 1422

Table5:

Permission levels

Change permission

level

1

> > Password > Login (Tab).

2

Use the navigation buttons to enter the password for the desired permission

level.

3

Leave the view via .

Page 40

INFICON Operation | 6

IRwin-Operating-instructions-mina66en1-12-(1802) 39 / 112

Log out from a higher

permission level

If you want to restore the permission for "Basic", you must log off.

1

> > Password > Logout (Tab).

2

Press the check mark button two times to log out.

6.2.4 Screensaver timeout

You can activate a screen saver that will turn the screen off if there is no alarm or key

action within an adjustable time.

1

> > General > Display (Tab)

2

Select the desired timeout or select "Off" to disable the screensaver.

3

Leave the view via .

Switch on screen ►

To switch the screen back on, press any button. It will switch on automatically if a

gas alarm is triggered.

6.2.5 Configure data logging

You can record and store the following data in the leak detector.

• Date

• Time

• GPS coordinates

Measurement data of the activated mode:

• CH4 and CO2 measurements

• % LEL

• CO, O2 and H2S measurements (IRwin SXT and IRwin SXGT)

The measurement data recording must be configured before the initial use:

ü Login as Intermediate or Advanced

1

> > Data output > Log to File (Tab)

2

Select "Enable log to file" and press the button next to .

3

Select “Log interval” and select a time interval. A blue button is shown in the

lower right corner when data logging is enabled. Press the on / off button to start

and stop logging to file.

The shorter you set the recording interval the more disk space is required. The percentage of disk space used is shown by the bar below, "Used disk space" on the Log

to File tab.

Page 41

6 | Operation INFICON

40 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

6.2.6 Enable dead band suppression (IRwin SXnn only)

For the toxic sensors in the application mode “Ex Tox mode“ a dead band suppression

can be activated. If you activate the dead band suppression, the leak detector will suppress small signal fluctuations around the zero point of the measurement signal.

1

> > General > Misc (Tab) > dead band Suppression.

ð The symbols (top right) and (bottom right) appear.

2

Press the button next to .

6.2.7 Setting the Function Test interval

Determine time interval

of Aufforderung Funktionstest

Consider relevant standards and regulations.

ü Login as Intermediate or Advanced

1

> > Function Test > Interval (Tab)

2

Select the function test and the time interval.

ð IRwin S: You can set a time interval.

ð IRwin SXnn: You can set the time interval individually for the modes “Above

Ground“, “Ex“ and “Ex Tox“.

3

Leave the view via .

6.2.8 Calibration

The built-in calibration routines guide you through the adjustment of the leak detector

sensitivity to the various test gases. You can set calibration intervals for the different

adjustments and will then get a reminder when calibration is due (Adjust calibration reminder).

Allow IRwin to warm up for 1 hour before calibrating for best accuracy.

The calibration intervals for Ex and Ex Tox are based on the TÜV certificates for these

operating modes. For the other modes these time intervals are chosen to give you the

best performance. Use the results of the various function tests to judge whether a calibration is needed. If you want to perform more than one calibration procedure at a

given time you should run them in the following sequence for best performance.

1. Above Ground

2. Ex Tox (IRwin SXT and SXGT only)

3. Ex CH4 (IRwin SX, SXT, SXG and SXGT only)

4. Bar Hole CO

2

5. Bar Hole CH

4

Page 42

INFICON Operation | 6

IRwin-Operating-instructions-mina66en1-12-(1802) 41 / 112

Recommended calibration intervals

• Above Ground CH4 - weekly

For calibration in Above Ground mode you need the following gas concentrations:

10 ppm CH4, 100 ppm CH4, 2.2% CH4.

With this calibration you calibrate the higher range (Vol%) of the modes House

and Bar Hole at the same time.

• Ex Tox - weekly

For calibration in Ex Tox mode you need Tox mix.

The CO2 calibration of other modes is not affected. CH4 of the operation mode Ex

is also calibrated during the Ex Tox calibration. However, for best performance, it

is recommended to perform the Ex calibration after the Ex Tox calibration.

• Ex CH4 - weekly

For calibration in Ex mode you need the following gas concentrations:

2.2% CH4.

• Bar Hole CO2 - monthly

For calibration of the CO2 measurement of Bar Hole you need the following gas

concentrations: 20% CO2.

This calibration does not influence the toxic CO2 calibration (ppm) in the Ex Tox calibration routine.

• Bar Hole CH4 - monthly

For calibration of the CH4 measurement of Bar Hole you need the following gas

concentrations:

2.2% CH4, 100% CH

4.

Beside the calibrations of the application mode “Bar Hole” the application modes

“Gas Purity” and “Confined Space” will be calibrated in the higher measurement

range (Vol%), too.

WARNING

Explosion, asphyxiation, toxic risk

Incorrect calibration leads to incorrect measurement results. Thus you are not properly

warned against any possibly dangerous gas concentrations.

► Calibrate the leak detector only when you have been properly trained.

► Calibrate the detector in well ventilated rooms or outdoors.

Page 43

6 | Operation INFICON

42 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

The methane calibration is possible with gas mixtures in synthetic air only.

The natural background of CO2 (typically 400 ppm) in ambient air will offset the calibration.

Fresh air exposure should, however, always be by ambient air.

After the leak detector has been calibrated with 100% methane it shows a few ppm increase in the measured value for a few minutes. This is a normal behavior of the leak

detector and due to gas residues inside the leak detector.

Retrieving information

about the calibration

The leak detector saves the date and the time of the last successful calibration.

►

> > Calibration > Info (Tab)

6.2.8.1 Standard calibration procedures

Prepare calibration

For a complete calibration you need the gases listed, see Concentration of calibration

and test gases [}28].

It is not necessary that you calibrate all modes at the same time.

Calibration Routine

Mode Above

Ground

Ex Tox Ex Bar Hole

CO2

Bar Hole

CH4

Above Ground X

Bar Hole X X

Confined Space X X

House X

Gas Purity X

Ex X* X

Ex Tox X*

GC Ethane Analysis Not calibrated (qualitative test only)

*Ex Tox calibration routine also calibrates Ex mode.

No need to run Ex calibration routine separately if Ex Tox calibration has been performed.

Calibrate Above Ground first for best performance.

You don’t need to perform any of the calibration routines more than once for a complete instrument calibration.

Page 44

INFICON Operation | 6

IRwin-Operating-instructions-mina66en1-12-(1802) 43 / 112

You can use different calibration stations for the calibration. However, the following requirements have to be fulfilled.

• The gas flow delivered by the calibration station must be higher than the flow aspired by the leak detector. Set the gas flow to at least 80 l/h.

• The gas must be delivered at ambient pressure (i.e., do not push gas into the leak

detector). Normal way to accomplish this is to create an open connection between

gas container and detector inlet so that the excess calibration gas is vented to the

ambient. This exhaust should be placed outside the test room, preferably outdoors.

Calibration

ü Login as Intermediate or Advanced

►

> > Calibration > Calibration (Tab)

ð Select the calibration to perform and click the check mark button.

ð The leak detector leads you through the process by indicating which gas to

deliver to the detector in each step. Make sure that no residual gases are

present in the ambient during Fresh Air step. Most common problems occur if

you used 2.2 Vol% or 100 Vol% methane shortly before the trying to calibrate

with 10 ppm or 100 ppm methane.

ð A successful calibration is confirmed by a green check mark.

ð A failed calibration is indicated by a red cross.

You can continue to use the leak detector even if calibration failed. The previous calibration parameters are restored.

6.2.8.2 Setting of calibration gas concentrations

Accuracy can be affected by calibration gas tolerance.

For optimum performance adjust the concentrations of the calibration gases set in the

leak detector to the actual composition of your calibration gases.

For optimum performance of your leak detector you should use the proposed calibration gases. The exact concentrations of the gas delivered often deviates slightly from

these values due to tolerance factors etc. The exact value is typically stated on the

analysis certificate of the respective gas. You should therefore adjust the concentrations of the calibration gases set in the detector to match the actual composition of

your calibration gases, see "Concentration of calibration and test gases [}28]".

ü Login as Intermediate or Advanced

1

> > Calibration > Settings (Tab)

2

Select calibration routine first and then select the gas to adjust (if several).

3

Confirm your selection with .

Page 45

6 | Operation INFICON

44 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

ð A window appears with controls for adjusting the gas selected.

4

Set the exact gas concentration value via drop-down menus. The leak detector

shows the gas to adjust in the window and the currently stored concentration

appears just below the setting line. You cannot set the concentration outside the

range.

5

Select "Set" to confirm new value or "Reset" to restore the default value.

The "names" for the different calibration routines is not affected by the adjustment of

calibration gas concentrations. The texts displayed during the calibration process will,

however, show the adjusted values.

If using the same gas in several calibration routines, you must adjust the concentration

of that gas in all relevant routines.

6.2.9 Adjust calibration reminder

You can set an Interval for a calibration reminder for each of the calibration types. The

Interval is set to Off as default, meaning no reminder.

Activate calibration reminder

ü Login as Intermediate or Advanced

1

> > Calibration > Interval (Tab)

2

Select the operation mode for which you want to set a calibration reminder and

set the desired period of time.

3

Leave the view via .

The leak detetctor saves the set period of time automatically.

Page 46

INFICON Operation | 6

IRwin-Operating-instructions-mina66en1-12-(1802) 45 / 112

6.3 Operating modes

After 2 minutes of inactivity the menu system exits automatically to the measurement screen.

6.3.1 Select operating mode

After finishing the self test the leak detector goes into the operating mode

"Ex" ("Above ground" IRwin S).

►

Press repeatedly to scroll through the operating modes.

The detector is ready to use when the measurement value(s) turn(s) black and the

status LED illuminates blue (green for Ex and Ex Tox modes).

6.3.2 Operating mode “Above Ground”

This mode is the most sensitive and intended for pipeline survey. This is done by taking samples on the ground surface along the pipe route typically using the carpet

probe.

The detector is ready to use when the measurement value(s) turn(s) black and the

status LED illuminates blue (green for Ex and Ex Tox modes).

WARNING

Do not use Above Ground for safety check.

The accuracy is not certified for LEL measurement.

Observe all safety precautions when alarms are given.

Never open or enter a confined space without first testing LEL level in the Ex or ExTox

mode.

Page 47

6 | Operation INFICON

46 / 112 IRwin-Operating-instructions-mina66en1-12-(1802)

7

5

1