Page 1

Operating Instructions

Contents

GB

English, 1

RO

Română,32

KN6G210/UA

RS

РУССКИЙ,11

UA

Украінська,22

Installation, 2-5

Positioning and levelling

Electrical connections

Gas connection

Adapting to different types of gas

Technical data

Table of burner and nozzle specifications

Description of the appliance,6

Overall view

Control panel

Start-up and use, 7-8

Using the hob

Using the oven

Oven cooking advice table

COOKER

GB

KN6G21/UA

Precautions and tips, 9

General safety

Disposal

Respecting and conserving the environment

Maintenance and care, 10

Switching the appliance off

Cleaning the appliance

Gas tap maintenance

Replacing the oven light bulb

Assistance

Page 2

Installation

GB

! Before operating your new appliance please read

this instruction booklet carefully. It contains

important information concerning the safe installation

and operation of the appliance.

! Please keep these operating instructions for future

reference. Make sure that the instructions are kept

with the appliance if it is sold, given away or moved.

! The appliance must be installed by a qualified

professional according to the instructions provided.

! Any necessary adjustment or maintenance must be

performed after the cooker has been disconnected

from the electricity supply.

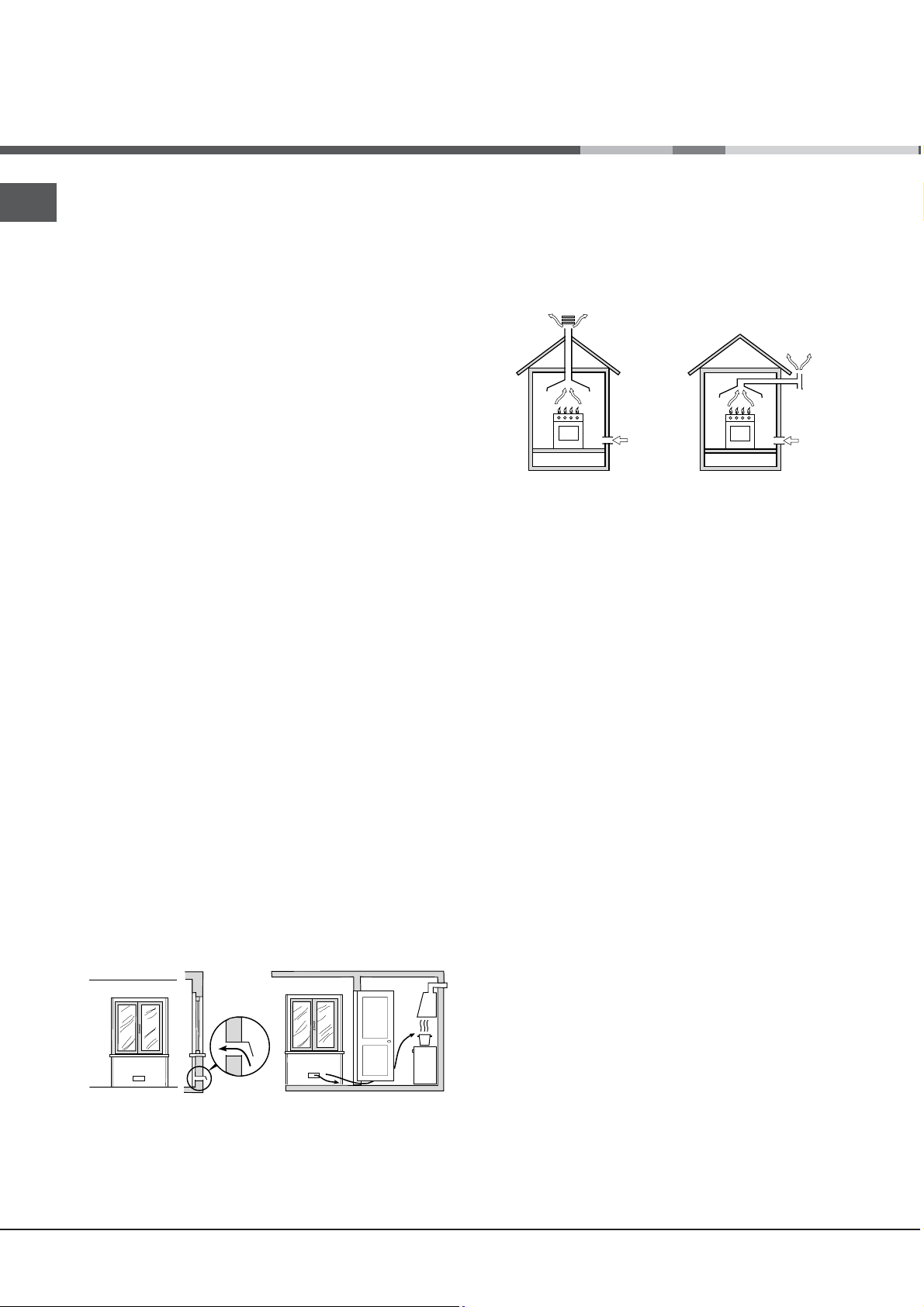

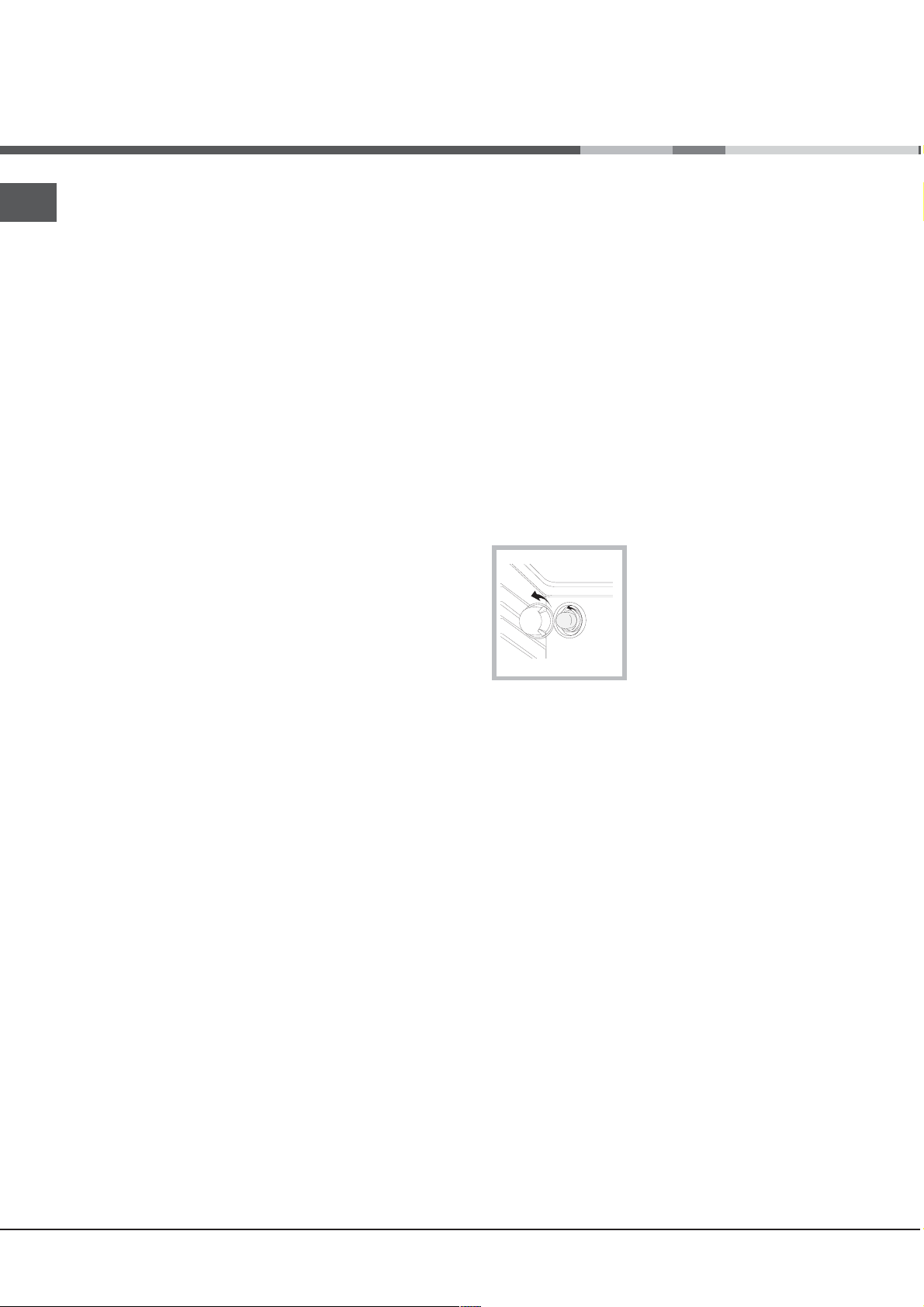

Room ventilation

The appliance may only be installed in permanentlyventilated rooms, according to current national

legislation. The room in which the appliance is

installed must be ventilated adequately so as to

provide as much air as is needed by the normal gas

combustion process (the flow of air must not be

lower than 2 m

3

/h per kW of installed power).

The air inlets, protected by grilles, should have a

duct with an inner cross section of at least 100 cm

2

and should be positioned so that they are not liable

to even partial obstruction (

see figure A

).

These inlets should be enlarged by 100% - with a

minimum of 200 cm

2

- whenever the surface of the

hob is not equipped with a flame failure safety

device. When the flow of air is provided in an

indirect manner from adjacent rooms (

see figure B

),

provided that these are not communal parts of a

building, areas with increased fire hazards or

bedrooms, the inlets should be fitted with a

ventilation duct leading outside as described above.

Adjacent room Room requiring

ventilation

A B

Disposing of combustion fumes

The disposal of combustion fumes should be

guaranteed using a hood connected to a safe and

efficient natural suction chimney, or using an electric

fan that begins to operate automatically every time

the appliance is switched on (

Fumes channelled

straight outside

see figure

).

Fumes channelled through

a chimney or a branched

flue system (reserved for

cooking appliances)

! The liquefied petroleum gases are heavier than air

and collect by the floor, therefore all rooms

containing LPG cylinders must have openings

leading outside so that any leaked gas can escape

easily.

LPG cylinders, therefore, whether partially or

completely full, must not be installed or stored in

rooms or storage areas that are below ground level

(cellars, etc.). Only the cylinder being used should

be stored in the room; this should also be kept well

away from sources of heat (ovens, chimneys,

stoves) that may cause the temperature of the

cylinder to rise above 50°C.

Positioning and levelling

! It is possible to install the appliance alongside

cupboards whose height does not exceed that of the

hob surface.

! Make sure that the wall in contact with the back of

the appliance is made from a non-flammable, heatresistant material (T 90°C).

A

Ventilation opening for

comburent air

Increase in the gap between

the door and the flooring

! After prolonged use of the appliance, it is

advisable to open a window or increase the speed of

any fans used.

2

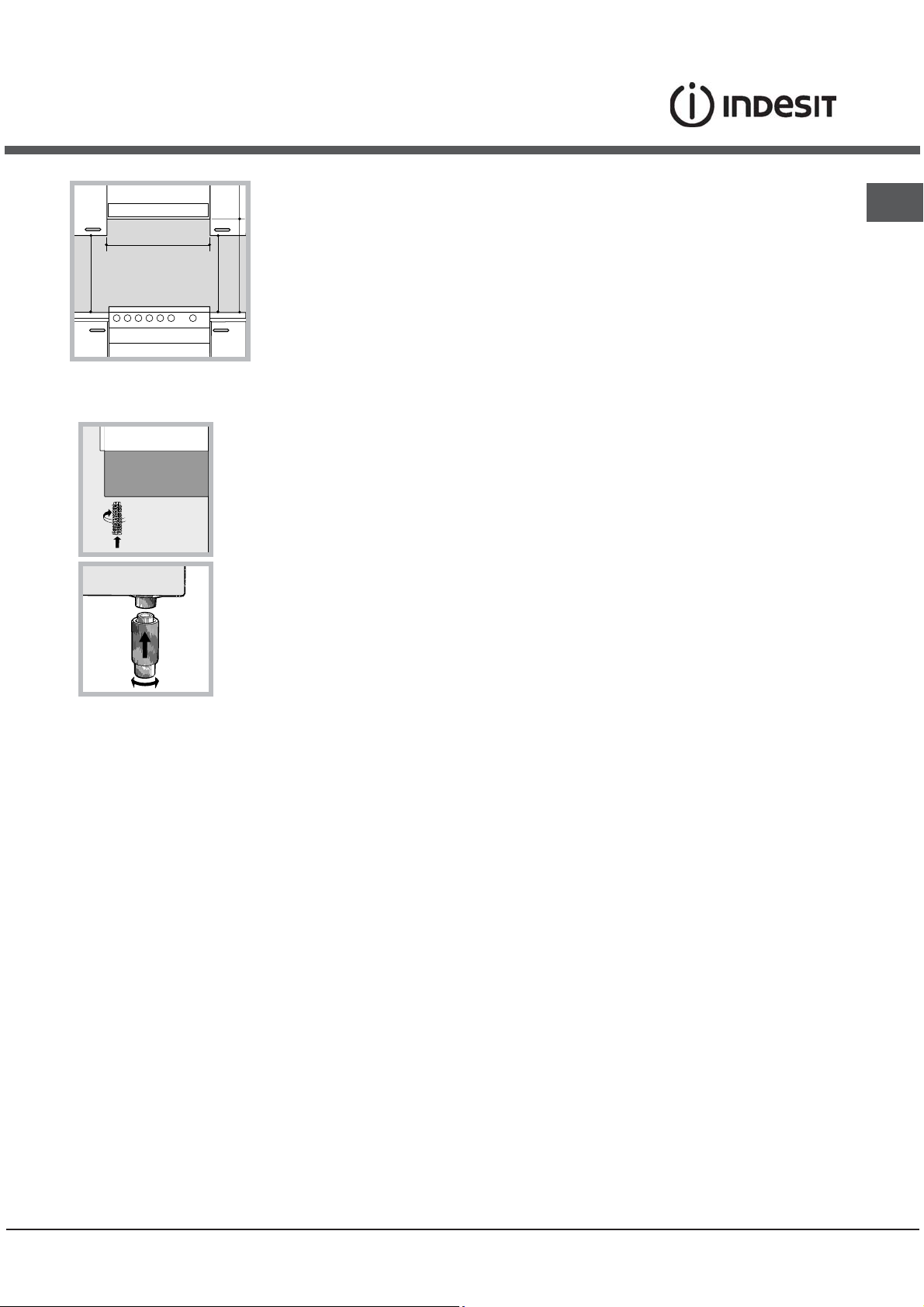

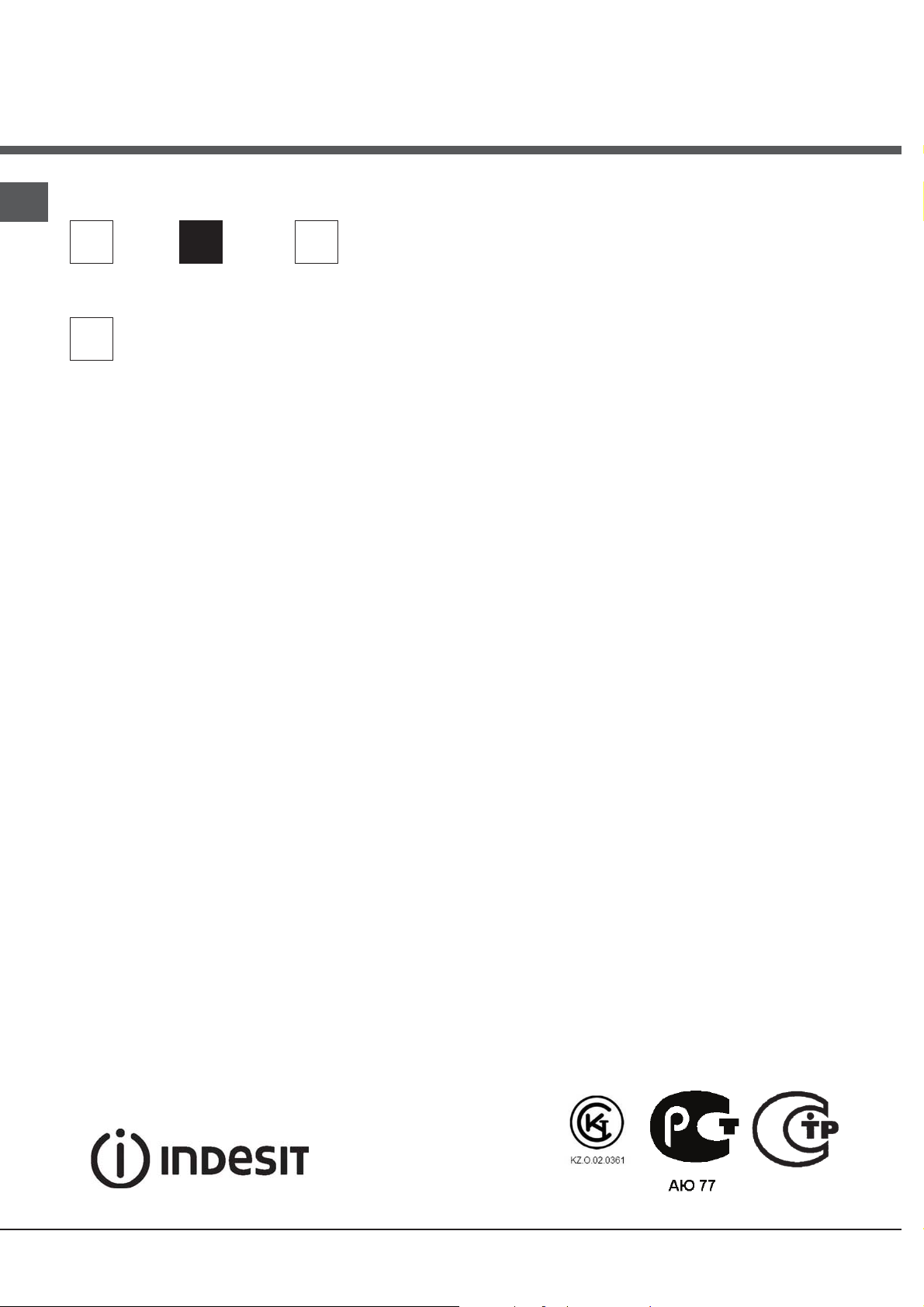

To install the appliance correctly:

• Place it in the kitchen, dining room or the bed-sit

(not in the bathroom).

• If the top of the hob is higher than the cupboards,

the appliance must be installed at least 600 mm

away from them.

• If the cooker is installed underneath a wall

cabinet, there must be a minimum distance of 420

mm between this cabinet and the top of the hob.

This distance should be increased to 700 mm if the

wall cabinets are flammable (

see figure

).

Page 3

mm.

420

Min.

Levelling

HOOD

Min. mm.

600

• Do not position

blinds behind the

cooker or less than 200

mm away from its

sides.

mm. with hood

420

Min. mm.

• Any hoods must be

mm. without hood

650

700

installed according to

min.

min.

the instructions listed in

the relevant operating

manual.

If it is necessary to level the

appliance, screw the

adjustable feet into the

places provided on each

corner of the base of the

cooker (

see figure

).

The legs* fit into the slots on

the underside of the base of

the cooker.

plug, ask an authorised technician to replace it.

Do not use extension cords or multiple sockets.

! Once the appliance has been installed, the power

supply cable and the electrical socket must be

easily accessible.

! The cable must not be bent or compressed.

! The cable must be checked regularly and replaced

by authorised technicians only.

! The manufacturer declines any liability should

these safety measures not be observed.

Gas connection

Connection to the gas network or to the gas cylinder

may be carried out using a flexible rubber or steel

hose, in accordance with current national legislation

and after making sure that the appliance is suited to

the type of gas with which it will be supplied (see the

rating sticker on the cover: if this is not the case

). When using liquid gas from a cylinder, install a

below

pressure regulator which complies with current national

regulations. To make connection easier, the gas

supply may be turned sideways*: reverse the position

of the hose holder with that of the cap and replace the

gasket that is supplied with the appliance.

see

GB

Electrical connection

Install a standardised plug corresponding to the

load indicated on the appliance data plate (

Technical data table

).

The appliance must be directly connected to the mains

using an omnipolar circuit-breaker with a minimum

contact opening of 3 mm installed between the

appliance and the mains. The circuit-breaker must be

suitable for the charge indicated and must comply with

current national legislation (the earthing wire must not

be interrupted by the circuit-breaker). The supply cable

must be positioned so that it does not come into

contact with temperatures higher than 50°C at any point.

Before connecting the appliance to the power

supply, make sure that:

• The appliance is earthed and the plug is compliant

with the law.

• The socket can withstand the maximum power of

the appliance, which is indicated by the data plate.

• The voltage is in the range between the values

indicated on the data plate.

• The socket is compatible with the plug of the

appliance. If the socket is incompatible with the

see

! Check that the pressure of the gas supply is

consistent with the values indicated in the Table of

burner and nozzle specifications (

see below

). This

will ensure the safe operation and durability of your

appliance while maintaining efficient energy

consumption.

Gas connection using a flexible rubber hose

Make sure that the hose complies with current

national legislation. The internal diameter of the hose

must measure: 8 mm for liquid gas supply; 13 mm

for methane gas supply.

Once the connection has been performed, make

sure that the hose:

• Does not come into contact with any parts that

reach temperatures of over 50°C.

• Is not subject to any pulling or twisting forces and

that it is not kinked or bent.

• Does not come into contact with blades, sharp

corners or moving parts and that it is not

compressed.

* Only available in certain models

3

Page 4

GB

• Is easy to inspect along its whole length so that

its condition may be checked.

• Is shorter than 1500 mm.

• Fits firmly into place at both ends, where it will be

fixed using clamps that comply with current

regulations.

! If one or more of these conditions is not fulfilled or if

the cooker must be installed according to the conditions

listed for class 2 - subclass 1 appliances (installed

between two cupboards), the flexible steel hose must

be used instead (

see below

).

Adjusting the hob burners’ minimum setting:

1. Turn the tap to the minimum position.

2. Remove the knob and adjust the regulatory

screw, which is positioned inside or next to the tap

pin, until the flame is small but steady.

! If the appliance is connected to a liquid gas

supply, the regulatory screw must be fastened as

tightly as possible.

3. While the burner is alight, quickly change the position

of the knob from minimum to maximum and vice versa

several times, checking that the flame is not

extinguished.

Connecting a flexible jointless stainless steel

pipe to a threaded attachment

Make sure that the hose and gaskets comply with

current national legislation.

To begin using the hose, remove the hose holder on

the appliance (the gas supply inlet on the appliance

is a cylindrical threaded 1/2 gas male attachment).

! Perform the connection in such a way that the hose

length does not exceed a maximum of 2 metres,

making sure that the hose is not compressed and

does not come into contact with moving parts.

Checking the tightness of the connection

When the installation process is complete, check the

hose fittings for leaks using a soapy solution. Never

use a flame.

Adapting to different types of gas

It is possible to adapt the appliance to a type of gas

other than the default type (this is indicated on the

rating label on the cover).

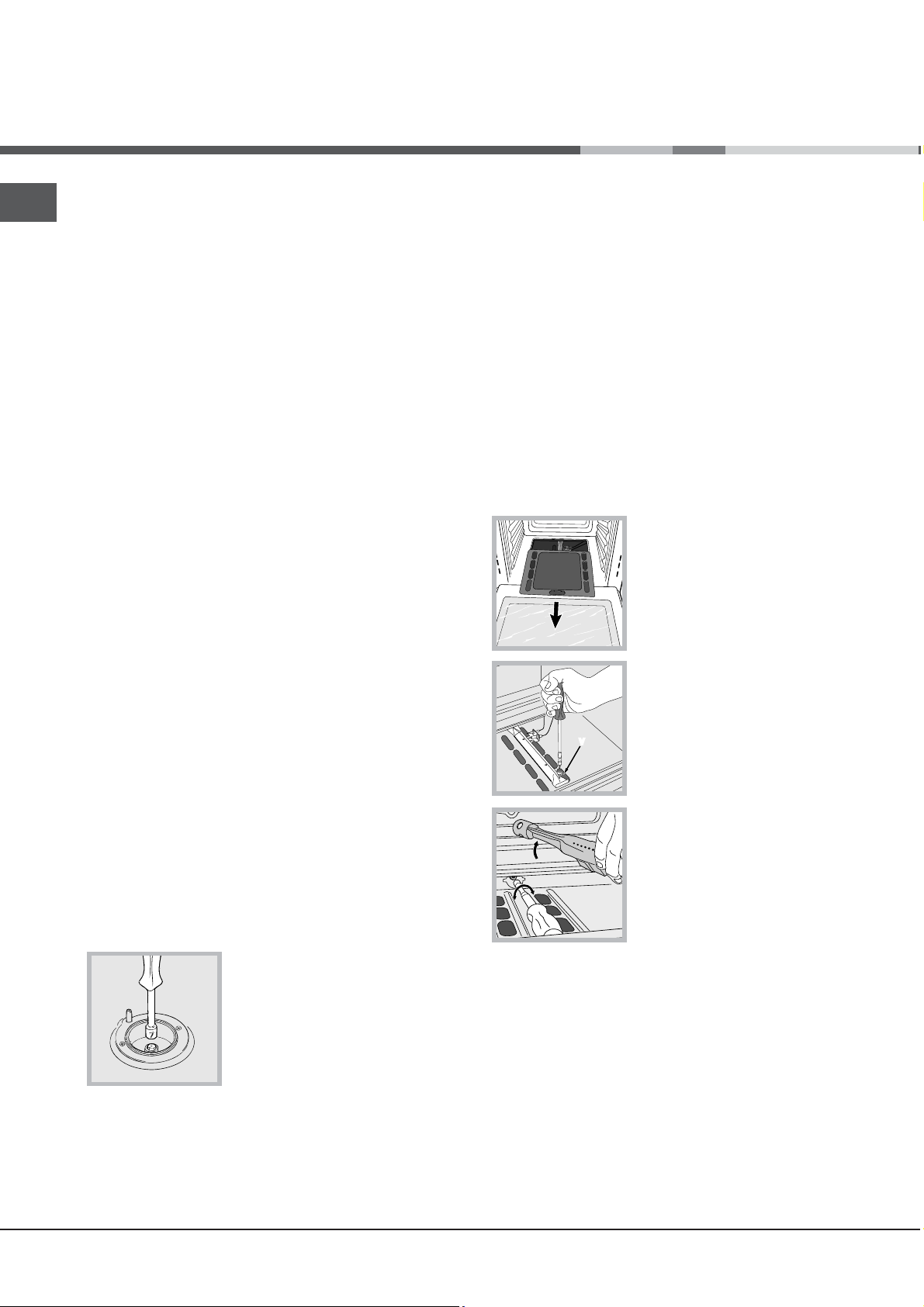

Adapting the hob

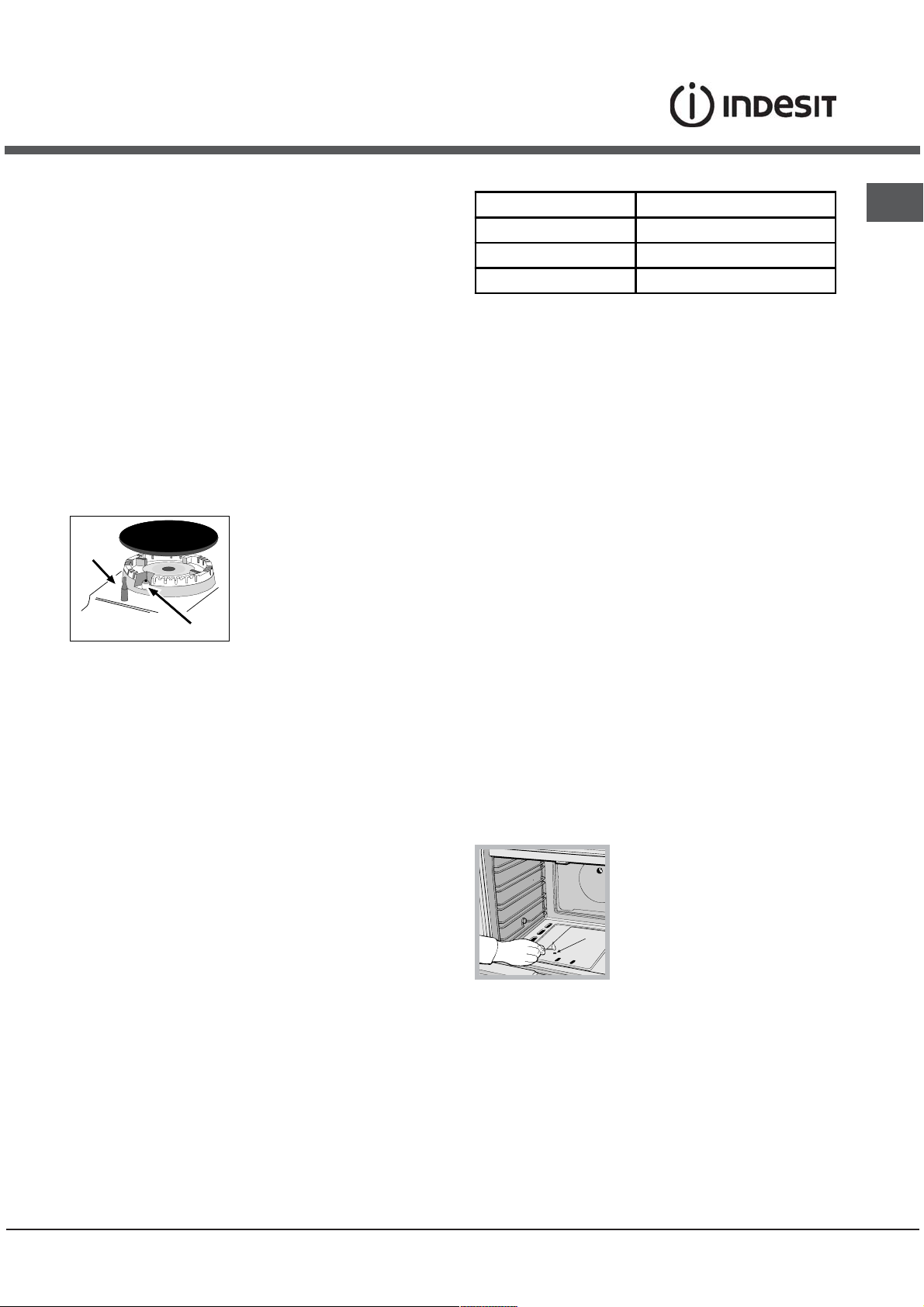

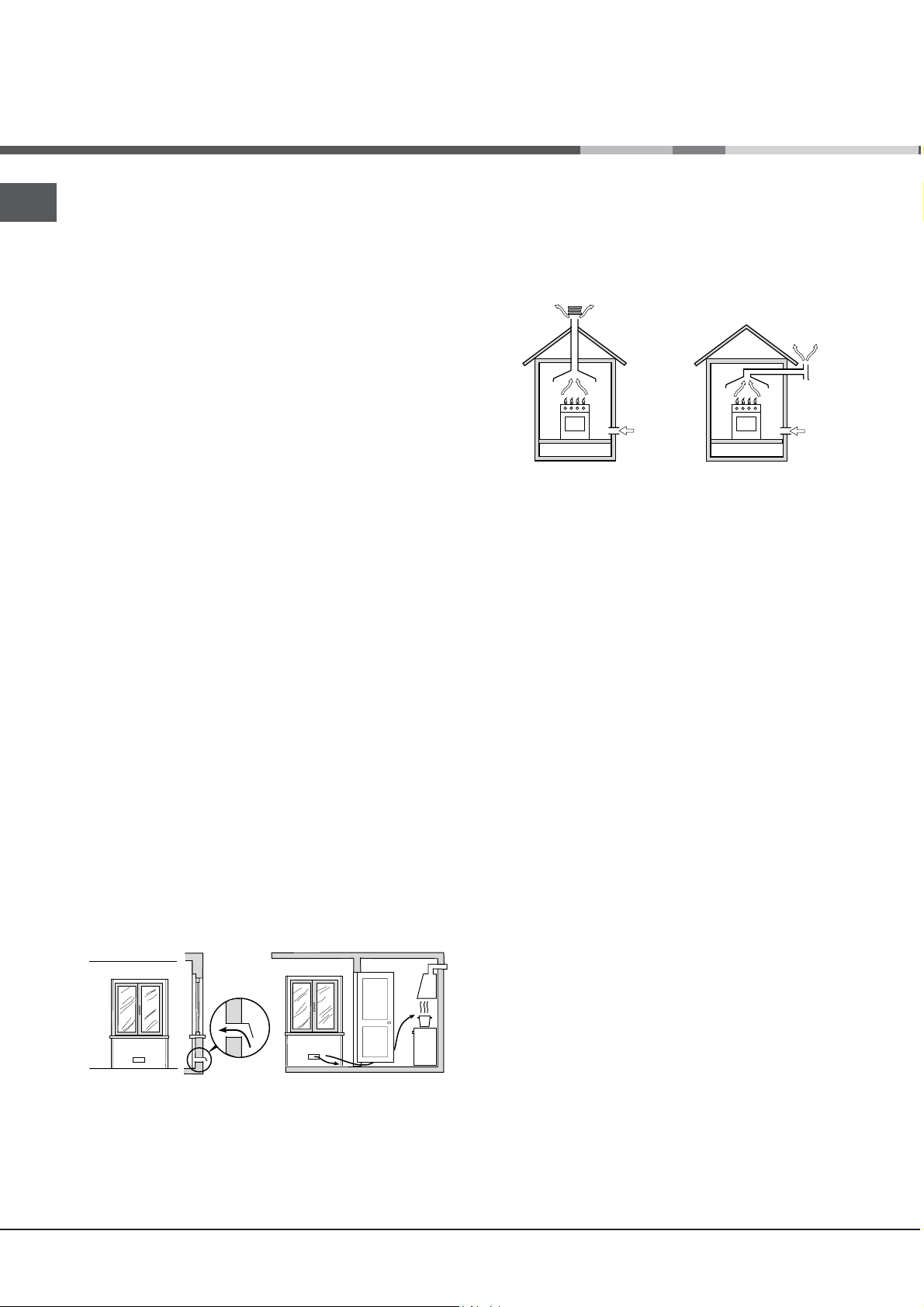

Replacing the nozzles for the hob burners:

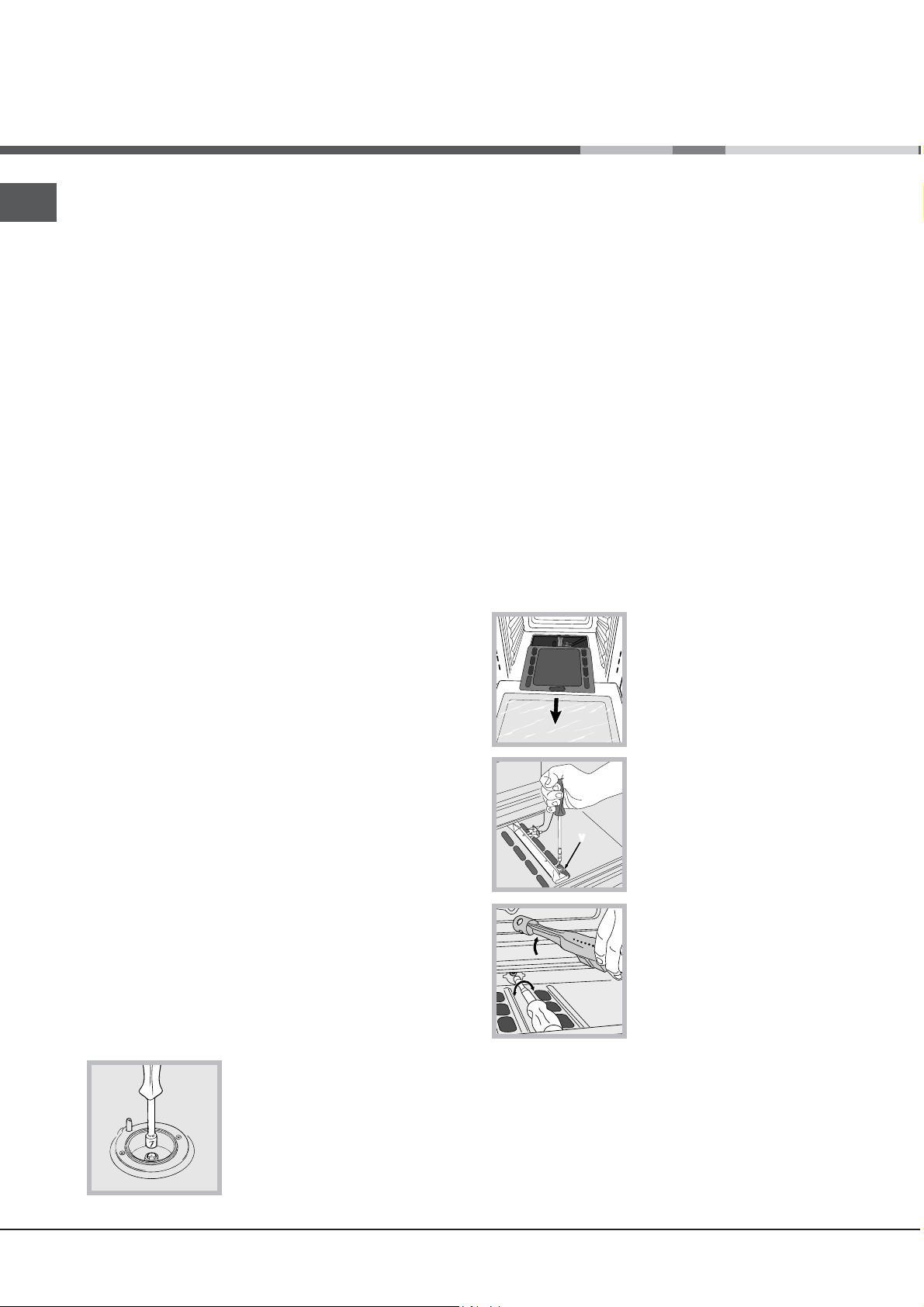

1. Remove the hob grids and

slide the burners off their

seats.

2. Unscrew the nozzles using

a 7 mm socket spanner (

), and replace them with

figure

nozzles suited to the new type

of gas (

see Burner and nozzle

specifications table

3. Replace all the components by following the

above instructions in reverse.

see

).

! The hob burners do not require primary air adjustment.

Adapting the oven

Replacing the oven burner nozzle:

1. Open the oven door fully

2. Pull out the sliding oven

bottom (

3. Remove the oven burner

after unscrewing the screws V

see figure

(

V

4. Unscrew the nozzle using a

special nozzle socket spanner

see figure

(

socket spanner, and replace it

with a new nozzle that is

suited to the new type of gas

(

see Burner and nozzle

specifications table

Adjusting the gas oven burner’s minimum

setting:

1. Light the burner (

2. Turn the knob to the minimum position (MIN) after

it has been in the maximum position (MAX) for

approximately 10 minutes.

3. Remove the knob.

4. Tighten or loosen the adjustment screws on the

outside of the thermostat pin (

flame is small but steady.

! In the case of natural gas, the adjustment screw must

be unscrewed by turning it anti-clockwise.

).

see Start-up and Use

see diagram

).

) or with a 7 mm

).

see figure

) until the

).

4

Page 5

TECHNICAL DATA

Oven Dimensions

HxWxD

GB

31x43,5x43,5 cm

5. Turn the knob from the MAX position to the MIN

position quickly or open and shut the oven door,

making sure that the burner is not extinguished.

Table of burner and nozzle specifications

Volume

Useful

measurements

relating to the

oven compartment

Voltage and

frequency

Burners

58 l

width 46 cm

depth 42 cm

height 8,5 cm

see data plate

may be adapted for use with any

type of gas shown on the data

plate.

EC Directives 2006/95/EC dated

12/12/06 (Low Voltage) and

subsequent amendments 04/108/EC dated 15/12/04

(Electromagnetic Compatibility)

and subsequent amendments 2009/142/EC dated 30/11/09 (Gas)

and subsequent amendments 90/68/EEC dated 22/07/93 and

subsequent amendments. 2002/96/EC.

1275/2008(Stand-by/Off-mode)

Table 1 Liquid Gas Natural Gas

Burner

Diameter

(mm)

Thermal Power

kW (p.c.s.*)

By Pass

1/100

Nozzle

1/100

Flow*

g/h

Nozzle

1/100

Flow*

l/h

Nozzle

1/100

Flow*

l/h

Nominal Reduced (mm) (mm) *** ** (mm) (mm)

Fast

(Large)(R)

Semi Fast

(Medium)(S)

Auxiliary

(Small)(A)

100 3.00 0.7 41 86 218 214 116 286 143 286

75 1.90 0.4 30 70 138 136 106 181 118 181

55 1.00 0.4 30 50 73 71 79 95 80 95

Oven - 2.60 1.0 52 78 189 186 119 248 132 248

Supply

Pressures

Nominal (mbar)

Minimum (mbar)

Maximum (mbar)

28-30

20

35

37

25

45

20

17

25

13

6,5

18

* At 15°C 1013 mbar-dry gas *** Butane P.C.S. = 49,47 MJ/Kg

** Propane P.C.S. = 50,37 MJ/Kg Natural P.C.S. = 37,78 MJ/m³

S

WARNING! The glass lid canWARNING! The glass lid can

WARNING! The glass lid can

WARNING! The glass lid canWARNING! The glass lid can

break in if it is heated up.break in if it is heated up.

break in if it is heated up.

break in if it is heated up.break in if it is heated up.

Turn off all the burners andTurn off all the burners and

Turn off all the burners and

Turn off all the burners andTurn off all the burners and

the electric plates beforethe electric plates before

the electric plates before

the electric plates beforethe electric plates before

closing the lid. *Applies to theclosing the lid. *Applies to the

closing the lid. *Applies to the

closing the lid. *Applies to theclosing the lid. *Applies to the

models with glass cover only.models with glass cover only.

models with glass cover only.

models with glass cover only.models with glass cover only.

KN6G210/UA

KN6G21/UA

S

R

A

5

Page 6

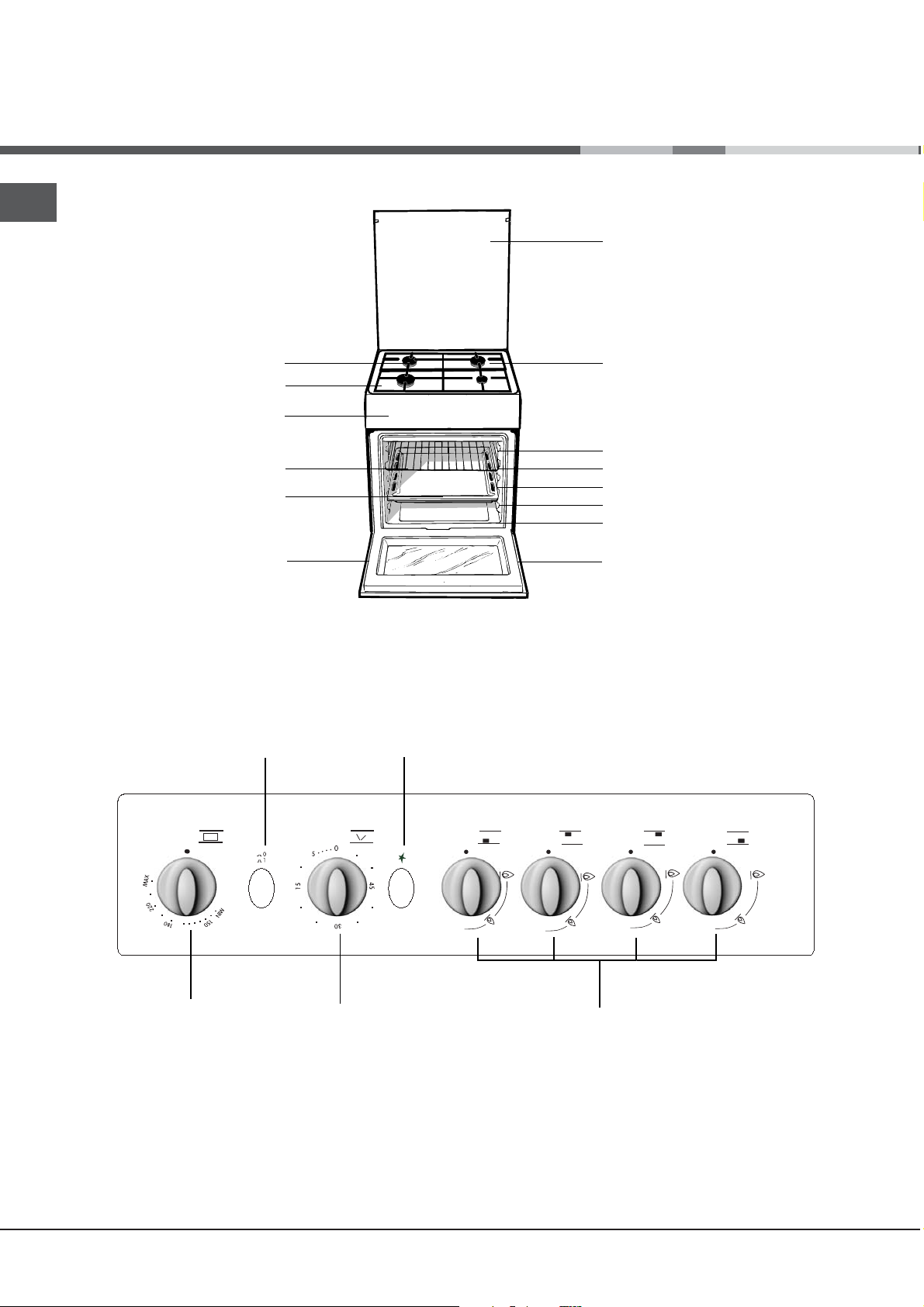

Description of the

appliance

GB

Overall view

DRIPPING PAN

Gas burner

Hob grid

Control panel

GRILL rack

Adjustable foot

Glass cover

Containment

surface for spills

GUIDE RAILS

for the sliding racks

position 5

position 4

position 3

position 2

position 1

Adjustable foot

*

Control panel

Button for

Oven Light

Oven

Control Knob

Electronic Lighting

for Hob Burners

Timer Knob

Control Knobs for Gas

Burners on Hob

Only available in certain models.

*

6

Page 7

Start-up and use

X

C

Using the hob

Lighting the burners

For each BURNER knob there is a complete ring

showing the strength of the flame for the relevant

burner.

To light one of the burners on the hob:

1. Bring a flame or gas lighter close to the burner.

2. Press the BURNER knob and turn it in an

anticlockwise direction so that it is pointing to the

maximum flame setting E.

3. Adjust the intensity of the flame to the desired

level by turning the BURNER knob in an

anticlockwise direction. This may be the minimum

setting C, the maximum setting E or any position in

between the two.

If the appliance is fitted with

an electronic lighting

device* (

ignition button*, marked with

the symbol

BURNER knob down and

turn it in an anticlockwise

direction, towards the maximum flame setting, until

the burner is lit.The burner may be extinguished

when the knob is released. If this occurs, repeat the

operation, holding the knob down for a longer period

of time.

! If the flame is accidentally extinguished, switch off

the burner and wait for at least 1 minute before

attempting to relight it.

C

), press the

hold the

1

Burner ø Cookware diameter (cm)

Fast (R) 24 - 26

Semi Fast (S) 16 - 20

Auxiliary (A) 10 - 14

To identify the type of burner, please refer to the

diagrams contained in the “Burner and nozzle

specifications”.

! On the models supplied with a reducer shelf,

remember that this should be used only for the

auxiliary burner when you use casserole dishes with

a diameter under 12 cm.

Using the oven

! The first time you use your appliance, heat the

empty oven with its door closed at its maximum

temperature for at least half an hour. Ensure that the

room is well ventilated before switching the oven off

and opening the oven door. The appliance may emit

a slightly unpleasant odour caused by protective

substances used during the manufacturing process

burning away.

! Before operating the product, remove all plastic

film from the sides of the appliance.

! Never put objects directly on the bottom of the

oven; this will avoid the enamel coating being

damaged. Only use position 1 in the oven when

cooking with the rotisserie spit.

Lighting the oven

GB

If the appliance is equipped with a flame failure

safety device (X)*, press and hold the BURNER

knob for approximately 2-3 seconds to keep the

flame alight and to activate the device.

To switch the burner off, turn the knob until it

reaches the stop position

Practical advice on using the burners

For the burners to work in the most efficient way

possible and to save on the amount of gas

consumed, it is recommended that only pans that

have a lid and a flat base are used. They should also

be suited to the size of the burner.

Only available in certain models.

*

•.

If the appliance is fitted with an electronic lighting

device*, press the ignition button*, marked with the

symbol

turn it in an anticlockwise direction, towards the MAX

position, until the burner is lit. If, after 15 seconds,

the burner is still not alight, release the knob, open

the oven door and wait for at least 1 minute before

trying to light it again. If there is no electricity the

burner may be lit using a flame or a lighter, as

described above.

,then hold the OVEN control knob and

1

To light the oven burner, bring

a flame or gas lighter close to

opening F (

press the OVEN control knob

while turning it in an

F

anticlockwise direction until it

reaches the MAX position.

see figure

) and

7

Page 8

GB

! The oven is fitted with a safety device and it is

therefore necessary to hold the OVEN control knob

down for approximately 6 seconds.

! If the flame is accidentally extinguished, switch off

the burner and wait for at least 1 minute before

attempting to relight the oven.

Adjusting the temperature

Oven light

The light may be switched on at any moment by

pressing the OVEN LIGHT button.

Timer

To activate the Timer proceed as follows:

1. Turn the TIMER knob in a clockwise direction 4

for almost one complete revolution to set the buzzer.

2. Turn the TIMER knob in an anticlockwise direction

5 to set the desired length of time.

To set the desired cooking temperature, turn the

OVEN control knob in an anticlockwise direction.

Temperatures are displayed on the control panel and

may vary between MIN (150°C) and MAX (250°C).

Once the set temperature has been reached, the

oven will keep it constant by using its thermostat.

Lower compartment

There is a compartment underneath the oven that

may be used to store oven accessories or deep

dishes.

! The internal surfaces of the compartment (where

present) may become hot.

! Do not place flammable materials in the lower oven

compartment.

Oven cooking advice table

Food to be cooked Wt.

(Kg)

Pasta

Lasagne

Cannelloni

Pasta bakes

2.5

2.5

2.5

Meat

Veal

Chicken

Turkey

Duck

Rabbit

Pork

Lamb

1.7

1.5

3.0

1.8

2.0

2.1

1.8

Fish

Mackerel

Dente x

Trout baked in paper

1.1

1.5

1.0

Pizza

Neapolitan 1.0 3Max 1530-35

Cake

Biscuits

Tarts

Chocolate cake

Raised Cakes

0.5

1.1

1.0

1.0

NB: cooking times are approximate and may vary according to personal taste. When cooking using the grill, the

dripping pan must always be placed on the 1st oven rack from the bottom.

Cooking position of

shelves from

bottom

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

Temperature

(°C)

210

210

210

230

220

Max

230

230

230

230

210-230

210-230

210-230

180

180

200

200

Pre-heating time

(min)

15

15

15

15

15

15

15

15

15

15

15

15

15

15

15

15

15

Cooking time

(min.)

75-80

75-80

75-80

85-90

110-115

95-100

120-125

105-110

100-110

90-95

55-60

60-65

40-45

30-35

30-35

45-50

50-55

8

Page 9

Precautions and tips

! This appliance has been designed and manufactured in

compliance with international safety standards.

The following warnings are provided for safety reasons and

must be read carefully.

General safety

• These instructions are only valid for the

countries whose symbols appear in the

manual and on the serial number plate.•

The appliance was designed for domestic use inside the

home and is not intended for commercial or industrial use.

• The appliance must not be installed outdoors, even in

covered areas. It is extremely dangerous to leave the

appliance exposed to rain and storms.

• Do not touch the appliance with bare feet or with wet or

damp hands and feet.

• The appliance must be used by adults only for

the preparation of food, in accordance with the

instructions outlined in this booklet. Any other

use of the appliance (e.g. for heating the room)

constitutes improper use and is dangerous.

The manufacturer may not be held liable for

any damage resulting from improper, incorrect

and unreasonable use of the appliance.

• The instruction booklet accompanies a class 1 (insulated)

or class 2 - subclass 1 (recessed between 2 cupboards)

appliance.

• Keep children away from the oven.

• Make sure that the power supply cables of other electrical

appliances do not come into contact with the hot parts of

the oven.

• The openings used for the ventilation and dispersion of

heat must never be covered.

• Do not close the glass hob cover (selected models only)

when the burners are alight or when they are still hot.

• Always use oven gloves when placing cookware in the

oven or when removing it.

• Do not use flammable liquids (alcohol, petrol, etc...) near

the appliance while it is in use.

• Do not place flammable material in the lower storage

compartment or in the oven itself. If the appliance is

switched on accidentally, it could catch fire.

• Always make sure the knobs are in the • position and that

the gas tap is closed when the appliance is not in use.

• When unplugging the appliance, always pull the plug from

the mains socket; do not pull on the cable.

• If the appliance breaks down, under no circumstances

should you attempt to repair the appliance yourself.

Repairs carried out by inexperienced persons may cause

injury or further malfunctioning of the appliance. Contact

Assistance.

• Do not rest heavy objects on the open oven door.

• The appliance should not be operated by people

(including children) with reduced physical,

sensory or mental capacities, by inexperienced

individuals or by anyone who is not familiar with

the product. These individuals should, at the very

least, be supervised by someone who assumes

responsibility for their safety or receive

preliminary instructions relating to the operation of

the appliance.

• Do not let children play with the appliance.

Disposal

• When disposing of packaging material: observe local

legislation so that the packaging may be reused.

• The European Directive 2002/96/EC relating to Waste

Electrical and Electronic Equipment (WEEE) states that

household appliances should not be disposed of using the

normal solid urban waste cycle. Exhausted appliances

should be collected separately in order to optimise the cost

of re-using and recycling the materials inside the machine,

while preventing potential damage to the atmosphere and

to public health. The crossed-out dustbin is marked on all

products to remind the owner of their obligations regarding

separated waste collection.

Exhausted appliances may be collected by the public

waste collection service, taken to suitable collection areas

in the area or, if permitted by current national legislation,

they may be returned to the dealers as part of an

exchange deal for a new equivalent product.

All major manufacturers of household appliances

participate in the creation and organisation of systems for

the collection and disposal of old and disused appliances.

Respecting and conserving the

environment

• You can help to reduce the peak load of the electricity

supply network companies by using the oven in the hours

between late afternoon and the early hours of the morning.

• Check the door seals regularly and wipe them clean to

ensure they are free of debris so that they adhere properly

to the door, thus avoiding

heat dispersion.

GB

• Never perform any cleaning or maintenance work without

having disconnected the appliance from the electricity

mains.

9

Page 10

Care and maintenance

GB

Switching the appliance off

Disconnect your appliance from the electricity supply

before carrying out any work on it.

Cleaning the appliance

! Do not use abrasive or corrosive detergents such as

stain removers, anti-rust products, powder detergents or

sponges with abrasive surfaces: these may scratch the

surface beyond repair.

! Never use steam cleaners or pressure cleaners on the

appliance.

• It is usually sufficient simply to wash the hob using a

damp sponge and dry it with absorbent kitchen roll.

• The stainless steel or enamel-coated external parts and

the rubber seals may be cleaned using a sponge that

has been soaked in lukewarm water and neutral soap.

Use specialised products for the removal of stubborn

stains. After cleaning, rinse well and dry thoroughly. Do

not use abrasive powders or corrosive substances.

• The hob grids, burner caps, flame spreader rings

and the hob burners can be removed

to make cleaning easier; wash them in hot water and

non-abrasive detergent, making sure all burnt-on

residue is removed before drying them thoroughly.

Inspecting the oven seals

Check the door seals around the oven periodically. If the

seals are damaged, please contact your nearest

Authorised After-sales Service Centre. We recommend

that the oven is not used until the seals have been

replaced.

Gas tap maintenance

Over time, the taps may become jammed or difficult to

turn. If this occurs, the tap must be replaced.

This procedure must be performed by a qualifiedThis procedure must be performed by a qualified

!

This procedure must be performed by a qualified

This procedure must be performed by a qualifiedThis procedure must be performed by a qualified

technician who has been authorised by thetechnician who has been authorised by the

technician who has been authorised by the

technician who has been authorised by thetechnician who has been authorised by the

manufacturer.manufacturer.

manufacturer.

manufacturer.manufacturer.

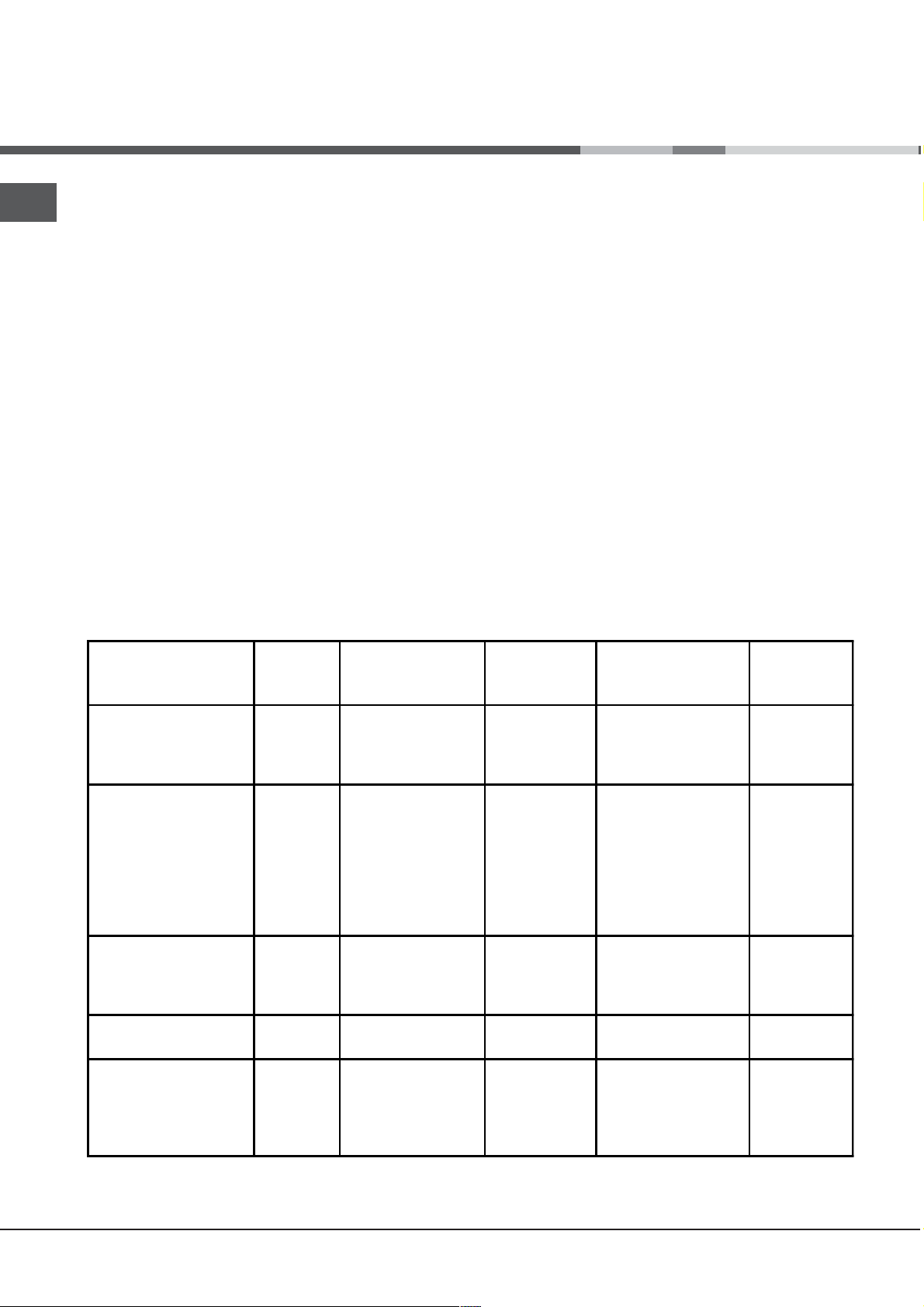

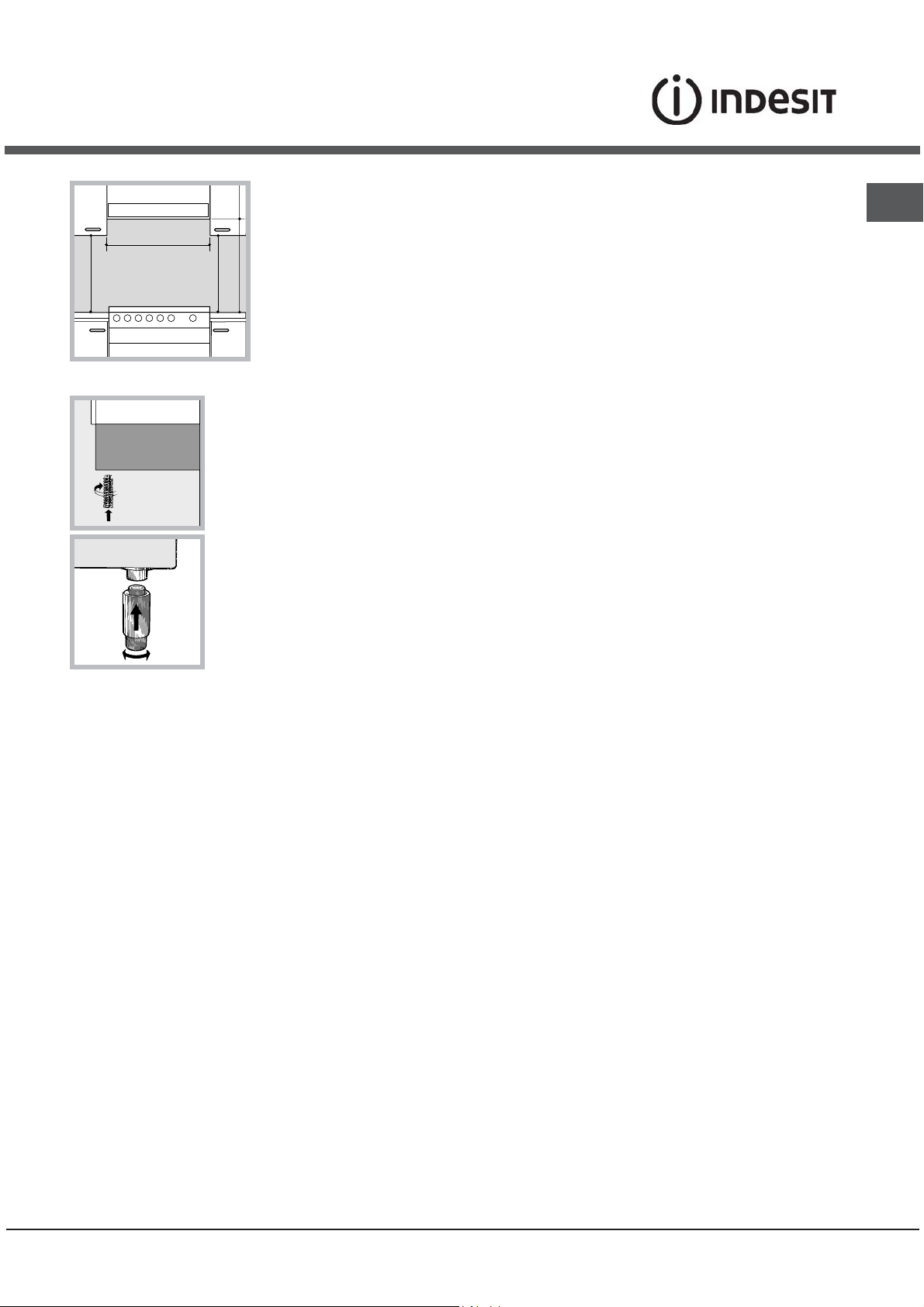

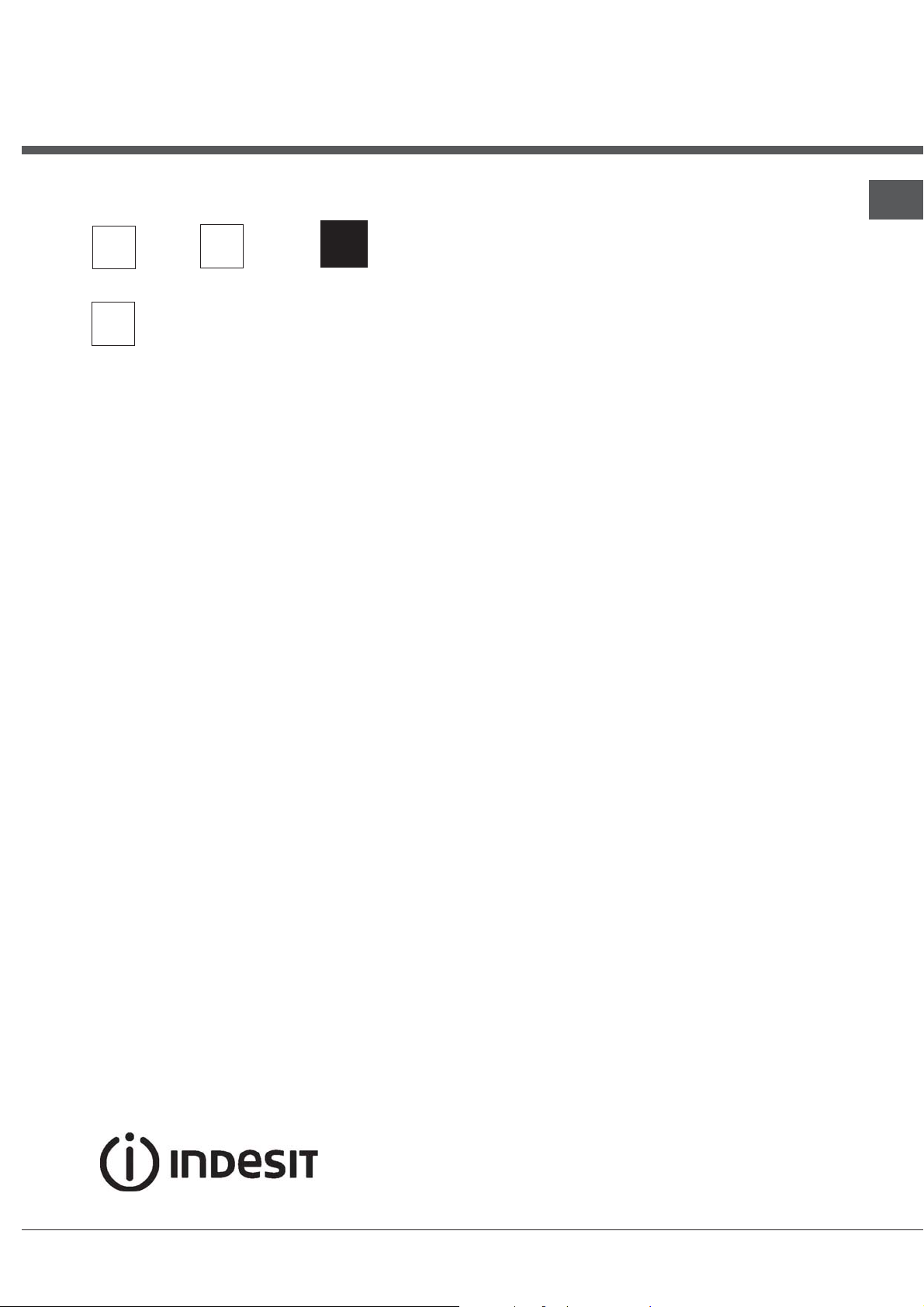

Replacing the oven light bulb

1. After disconnecting the oven

from the electricity mains, remove

the glass lid covering the lamp

socket (

2. Remove the light bulb and

replace it with a similar one:

voltage 230 V, wattage 25 W, cap

E 14.

3. Replace the lid and reconnect the oven to the electricity

supply.

see figure

).

• For hobs with electronic ignition, the terminal part of the

electronic lighting devices should be cleaned

frequently and the gas outlet holes should be checked

for blockages.

• The inside of the oven should ideally be cleaned after

each use, while it is still lukewarm. Use hot water and

detergent, then rinse well and dry with a soft cloth. Do

not use abrasive products.

•

Clean the glass part of the oven door using a sponge

and a non-abrasive cleaning product, then dry

thoroughly with a soft cloth. Do not use rough abrasive

material or sharp metal scrapers as these could

scratch the surface and cause the glass to crack.

• The accessories can be washed like everyday

crockery, and are even dishwasher safe.

• Stainless steel can be marked by hard water that has

been left on the surface for a long time, or by

aggressive detergents containing phosphorus. After

cleaning, rinse well and dry thoroughly. Any remaining

drops of water should also be dried.

Assistance

Please have the following information handy:

• The appliance model (Mod.).

• The serial number (S/N).

This information can be found on the data plate located on

the appliance and/or on the packaging.

10

Page 11

Руководство по

RS

эксплуатации

GB RS

English, 1 РУССКИЙ, 11

RO

Română,32

KN6G210/UA

KN6G21/UA

UA

Украінська,22

КУХОННАЯ ПЛИТА

Содержание

Монтаж, 12-15

Расположение и нивелировка

Электрическое подсоединение

Подсоединение к газопроводу

Настроика на различные типы газа

Технические данные

Таблица характеристик горелок и форсунок

Описание изделия, 16

Общии вид

Панель управления

Включение и эксплуатация,17-18

Эксплуатация варочнои панели

Эксплуатация духового шкафа

Таблица приготовления в духовом шкафу

Предосторожности и рекомендации, 19

Общие требования к безопасности

Утилизация

Экономия электроэнергии и охрана окружающеи

среды

Техническое обслуживание и уход,20-21

Отключение электропитания

Чистка изделия

Уход за рукоятками газовои варочнои панели

Порядок замены лампочки в духовом шкафу

Техническое обслуживание

Page 12

Установка

RS

! Важно сохранить данное руководство для его

последующих консультаций. В случае продажи,

передачи или переезда проверьте, чтобы данное

руководство сопровождало изделие.

! Внимательно прочитайте инструкции: в них

содержатся важные сведения об установке,

эксплуатации и безопасности изделия.

! Установка изделия производится в соответствии

с данными инструкциями квалифицированными

специалистами.

! Любая операция по регуляции

или техническому

обслуживанию должна производиться только

после отсоединения кухонной плиты от сети

электропитания.

Вентиляция помещений

Изделие может быть установлено в помещениях с

постоянной вентиляцией в соответствии с

действующими национальными нормативами. В

помещении, в котором устанавливается изделие,

должен быть обеспечен приток воздуха в объеме,

необходимом для оптимального горения газа

(расход воздуха не должен быть меньше 2

м<+>3/час на 1 кВт установленной мощности).

Вентиляционные отверстия, защищенные

решетками, должны иметь воздуховод площадью

не менее 100 мм

2

полезного сечения и

распологаться таким образом, чтобы их нельзя

было закрыть, даже частично (см. рисунок А).

Эти отверстия должны быть увеличины на 100% - то

есть иметь минимальную площадь 200 см

2

- если

варочная панель не оснащена предохранительным

устройством отсутствия пламени, и если воздух в

помещение поступает из смежных помещений (см.

рисунок В), которые не должны быть общими зонами

дома, пожароопасными помещениями или спальнями,

оснащенных вентиляционным воздуховодом,

выходящим на улицу, как описано выше.

A

A

Вентиляционные

отверстия для притока

Смежное

помещение

B

Увеличение зазора между

дверью и полом

Вентилируемое

помещение

воздуха

! После продолжительного использования изделия

рекомендуется открыть окно или включить более

интенсивный

режим вентиляторов.

Дымоудаление

Дымоудаление должно осуществляться через

вытяжной зонт, соединенный с эффективным

дымоходом с натуральной тягой, или посредством

электровентилятора, который автоматически

включается каждый раз при включении изделия

(см. рисунок).

Прямое

дымоудаление в

атмосферу

Дымоудаление через камин или

дымоход с медным покрытием

(для кухонных устроиств для

приготовления пищи)

! Сжиженные натуральные газы тяжелее воздуха,

застиваются внизу, по этой причине помещения

для хранения баллонов с СПГ должны иметь

внетиляционные отверстия у пола для вентиляции

возможных

утечек газа.

Баллоны с СПГ, полные или частично

израсходованные, не дожны размещаться или

храниться в помещениях или хранилищах,

расположенных в подземных помещениях

(подвалы, и т.д.). Храните в помещении только

рабочий баллон, установив его вдали от источников

тепла (духовок, каминов, печей), которые могут

нагреть его до температуры выше 50°C.

Расположение и нивелировка

! Изделие может быть установлено рядом с

кухонными элементами, высота которых не

превышает поверхность варочной панели.

! Проверьте, чтобы стена, к которой прилегает

задняя часть изделия, была из невозгораемого

материала и устойчивой к теплу (Т 90°C).

Правильный порядок монтажа:

• изделие может быть установлено на кухне, в

столовой или в однокомнатной квартире (не в

ванной

• если варочная панель кухонной плиты выше

кухонных элементов, необходимо отодвинуть их

от плиты на расстояние не менее 600 мм.

• если кухонная плита устанавливается под

навесным кухонным шкафом, он должен

располагаться на высоте не менее 420 мм от

поверхности варочной панели.

Это расстояние должно быть 700 мм, если

навесные кухонные шкафы выполнены из

возгораемого материала (см.

комнате);

рисунок);

12

Page 13

• не заправляйте

mm.

420

Min.

HOOD

Min. mm.

600

420

Min. mm.

занавески за

кухонную плиту и не

приближайте их на

расстояние меньше

mm. with hood

mm. without hood

200 мм.

650

700

min.

• возможная

min.

кухонная

вытяжка

должна быть

установлена в

соответствии с

инструкциями,

приведенными в

техническом руководстве к

вытяжке.

Нивелировка

При необходимости

выровнять изделие вкрутите

в специальные отверстия по

углам в основании кухонной

плиты прилагающиеся

нивелировочные ножки (см.

рисунок).

Прилагающиеся ножки*

вставляются под основание кухонной плиты.

Электрическое подсоединение

Установите на кабель электропитания

нормализованную штепсельную вилку,

расчитанную на нагрузку, указанную на

паспортной табличке изделия (см. табличку с

техническими данными).

В случае прямого подключения к сети

электропитания между кухонной плитой и сетью

необходимо установить мультиполярный

выключатель с минимальным расстоянием между

контактами 3 мм, расчитанный на данную нагрузку

и соответствующий действующим нормативам

(выключатель не должен размыкать провод

заземления). Сетевой шнур должен быть

расположен таким образом, чтобы ни в одной

точке его температура не превышала температуру

помещения более чем на 50°C.

Перед подсоединением сетевого шнура проверьте

следующее:

• сетевая розетка должна быть соединена с

заземлением и соответствовать нормативам;

• сетевая розетка должна быть рассчитана на

максимальную потребляемую мощность

изделия, указанную на паспортной табличке;

• напряжение и частота тока сети должны

соответствовать электрическим данным

изделия;

• сетевая розетка должна быть совместима со

штепсельной вилкой изделия. В противном

случае замените розетку или вилку; не

используйте удлинители или тройники.

! Изделие должно

быть установлено таким

образом, чтобы сетевой шнур и сетевая розетка

были легко доступны.

! Сетевой шнур изделия не должен быть согнут

или сжат.

! Регулярно проверяйте состояние сетевого шнура

и при необходимости поручайте его замену только

уполномоченным техникам.

! Фирма снимает с себя всякую ответственность

в случае несоблюдения вышеописанных правил.

Подсоединение к газопроводу

Подсоединение к газопроводу или к газовому

баллону выполняется посредством гибкого

резинового или стального шланга в соответствии с

действующими национальными нормативами,

после проверки настройки изделия на тип

используемого газа (см. этикетку настройки на

крышке: в противном случае см. ниже). В случае

использования сжиженного газа из баллона

необходимо установить регуляторы давления,

соответствующие действующему национальному

нормативу. Для облегчения

газовый патрубок является ориентируемым*:

поменяйте местами крепежную блокировочную

гайку на заглушку и замените прилагающееся

уплотнение.

! Для надежного функционирования,

рационального использования энергии и более

длительного срока службы изделия проверьте,

чтобы давление подачи газа соответствовало

значениям, указанным в таблице «Характеристики

газовых конфорок и форсунок» (см. ниже).

Газовое подсоединение посредством

резинового шланга

Проверьте, чтобы шланг

действующим национальным нормативам.

Внутренний диаметр шланга должен быть: 8 мм

для сжижженного газа; 13 см для газа метана.

подсоединения

соответствовал

RS

*Имеется только в некоторых моделях

После подсоединения проверьте, чтобы шланг:

13

Page 14

RS

• не касался частей, температура которых может

превысить 50°C;

• не был растянут, перекручен, сжат или

заломлен;

• не касался режущих предметов, острых углов,

подвижных предметов и не

был сжат;

• был легко доступен для проверки по всей

длине;

• не был длиннее 1500 мм;

• был прочно закреплен с обоих концов при

помощи хомутов, соответствующих

действующим национальным нормативам.

! Если одно или несколько из вышеописанных

условий не будет соблюдено, и если кухонная

плита устанавливается в условиях класса 2,

подгруппа 1 (изделие, встроенное между двух

кухонных

элементов), необходимо использовать

гибкий стальной шланг (см. ниже).

Газовое подсоединение посредством шланга

из нержавеющей стали со сплошной оплеткой

с резьбовыми соединениями.

3. восстановите на место все комплектующие,

выполняя операции в обратном порядке по

отношению к описанным выше.

Порядок регуляции минимального пламени

конфорок на варочной панели:

1. поверните рукоятку в положение минимального

пламени;

2. снимите рукоятку и поверните регуляционный

винт, расположенный внутри или рядом со

стержнем крана, вплоть до получения стабильного

малого пламени.

! В случае использования

сжиженного природного

газа винт регуляции должен быть отвинчен против

часовой стрелки;

3. проверьте, чтобы конфорка не гасла при резком

повороте крана из положения максимального

пламени в положение минимального пламени.

! Конфорки варочной панели не нуждаются в какой-

либо регуляции первичного воздуха.

Настройка духового шкафа

Проверьте, чтобы шланг и уплотнения соответствовали

действующим национальным нормативам.

Для подсоединения шланга снимите блокировочную

гайку с изделия (патрубок подачи газа в изделие

имеет цилиндрическу резьбу Ѕ газ «папа»).

! Длина подсоединяемого шланга

не должна

превышать 2 метра при максимальном

растяжении. Проверьте, чтобы шланг не касался

подвижных деталей, которые могут его сжать.

Проверка уплотнения

По завершении подсоединения проверьте

прочность уплотнения всех патрубков при помощи

мыльного раствора, но никогда не пламенем.

Настройка на различные типы газа

Изделие может быть настроено на тип газа,

отличающийся от оригинального (указан на

этикетке настройки на крышке).

Настройка варочной панели

Порядок замены форсунок конфорок на варочной

панели:

1. снимите решетки с варочной панели и выньте

горелки из своих гнезд;

2. отвинтите форсунки при

помощи полого ключа 7 мм

(см. рисунок) и замените их на

форсунки, расчитанные

новый тип газа (см. таблицу

Характеристики горелок и

форсунок);

на

Порядок замены форсунки газовой горелки

духового шкафа:

1. полностью откройте дверцу

духового шкафа;

2. выньте съемное дно

духовки (см. рисунок);

3. отвинтите крепежные винты

горелки и снимите горелку

духового шкафа, сняв винт V;

V

4. отвинтите форсунку горелки

при помощи специального

полого ключа для форсунок

(см. рисунок) или полого

ключа 7 мм и замените

форсунку на новую,

расчитанную на новый тип

газа (см. таблицу

Характеристики горелок и форсунок).

Регуляция минимального пламени

горелки

духового шкафа:

1. включите горелку (см. Пуск и Эксплуатация);

2. оставьте рукоятку примерно в течение 10 минут

в положении максимального пламени (МАКС),

затем поверните ее в положение минимального

14

Page 15

пламени (МИН);

3. снимите рукоятку;

4. поверните регулировочный винт,

расположенный внутри стержня термостата (см.

рисунок), вплоть до получения малого стабильного

пламени.

! В случае использования сжиженного природного

газа винт регуляции должен быть отвинчен против

часовой стрелки;

5. проверьте, чтобы горелка не гасла при резком

вращении рукоятки-регулятора из положения МАКС

в положение МИН или

при резком открывании или

закрывании дверцы духовки.

Характеристики горелок и жиклеров

Изделие : Комбинированная плита

Торговая марка:

Торговый знак изготовителя:

Модель:

Изготовитель: Indesit Company

Страна-изготовитель: Польша

Габаритные размеры духового

шкафа / Объем:

Номинал ьное знач ение

напряжения эл ектропитания или

диапаз он напряжения

Условное обозначение рода

электрического тока или

номиналь ная час тота переменного

тока

Класс зашиты от поражения

электрическим током

Класс энер гопотре бления

ТАБЛИЧКА С ЭЛЕКТРИЧЕСКИМИ

ДАННЫМИ

В случае необходимости

получения информации по

сертификатам соответствия или

получения копий сертиф икатов

соответствия на данную те хнику,

Вы можете отправить запрос по

электронному адресу

cert.r us@ind esit.co m.

Дату пр оизводства данной техники

можно получить из серийного

номера, рас положе нного по д

штрих-кодом (S/N XXXXXXXXX *

XXXXXXXXXXX), следующи м

образом:

Производитель:

Импортер: ООО "Индезит РУС"

С вопросами (в России)

обращаться по адресу:

KN6G210/UA; KN6G21/UA

31x43,5x43,5 см / 58 л

220-240 V ~

50/60Hz

Класс защи ты I

Директив а ЕС: Дир ектива ЕС: 2006/95/EC от

12/12/06 (Низкое напряжение) с

последующими изм енениями – 2004 /108/ ЕC

от 15/12/04 (Электромагнитная

совместимость) с после дующими

изменени ями – 20 09/142 /ЕC от 30/11/09 (Газ) 90/68/СЕЕ от 22/07/93 с последующими

изменени ями – 20 02/96/ ЕС.

1275/2008 (Stand-by/ Off mode)

- 1-ая цифр а в S/N соответствует по следней

цифре года,

- 2-ая и 3-я цифры в S/N - порядков ому

номеру месяца года,

- 4-ая и 5-ая цифры в S/N - числу

определ енного месяца и года.

Indes it Compan y S.p.A .

Виале А. Мерл они 47, 60044, Фабриано (АН),

Италия

до 01.01. 2011: Росси я, 129223, Моск ва,

Проспект Мир а, ВВЦ, пав. 46

с 01.01.2011: Россия, 1270 18, Москва, ул.

Двинцев , дом 12, корп . 1

RS

286

181

95

248

ВНИМАНИЕ! При нагреве

* Сухой газ при 15 °С и давлении 1013 мбар

** Пропан P.C.S. = 50,37 MДж/кг

*** Бутан P.C.S. = 49,47 MДж/кг

Природный газ P.C.S. = 37,78 MДж/м

3

стеклянная крышка может

лопнуть. Прежде чем закрыть

ее, выключить все конфорки

или электрические

S

S

R

A

горелки.*Только для моделей

со стеклянной крышкой

KN6G210/UA

KN6G21/UA

15

Page 16

Описание

изделия

RS

Общии вид

Газовая конфорка

Опорная решетка варочной панели

Панель управления

Регулируемая ножка

РЕШЕТКА

ПРОТИВЕНЬ

Стеклянная крышка*

Бортики для сбора

возможных утечек

НАПРАВЛЯЮЩИЕ

для противеней и решеток

положение 5

положение 4

положение 3

положение 2

положение 1

Регулируемая ножка

Панель управления

Рукоятка

управления духовкой

Имеется только в некоторых моделях

*

16

Page 17

Включение и эксплуатация

Эксплуатация варочной панели

Включение конфорок

Напротив каждого рукоятки КОНФОРКИ

закрашенным кружком показано положение

данной конфорки на варочной панели.

Порядок включения конфорки на варочной панели:

1. поднесите к конфорке зажженую спичку или

кухонную зажигалку;

2. нажмите и одновременно поверните против

часовой стрелки рукоятку КОНФОРКИ на символ

максимального пламени E.

3. отрегулируйте нужную мощность пламени,

поворачивая рукоятку КОНФОРКИ против часовой

стрелки

среднюю мощность.

поверните против часовой стрелки рукоятку

КОНФОРКИ на символ максимального пламени

вплоть до зажигания пламени. Может случиться,

что конфорка погаснет в момент, когда вы

отпустите рукоятку. В этом случае повторите

операцию зажигания, удерживая рукоятку нажатой

подольше.

! В случае внезапного гашения пламени

выключите конфорку и подождите примерно 1

минуту перед

Если изделие оснащено предохранительным

устройством* (X)отсутствия пламени, держите

рукоятку КОНФОРКИ нажатой примерно 2-3

секунды для того, чтобы пламя конфорки

активировало это устройство.

: на минимум C, на максимум E или на

Если изделие оснащено

X

ее повторным включением.

электронной системой

зажигания* (C), вначале

нажмите кнопку зажигания,

обозначенную символом

C

, затем нажмите до

1

упора и одновременно

Горелка Диаметр дна посуды, см

Быстрая (R) 24–26

Полубыстрая (S) 16–20

Вспомогательная (А) 10–14

! В моделях, оснащенных дополнительной

решеткой, эта решетка может быть использована

только на вспомогательной конфорке

диаметром меньше 12 см.

с посудой

Эксплуатация духового шкафа

! При первом включении духового шкафа

рекомендуем прокалить его примерно в течение

30 минут при максимальной температуре с

закрытой дверцей. Затем выключите духовой

шкаф, откройте дверцу и проветрите помещение.

Запах, который вы можете почувствовать, вызван

испарением веществ, использованных для

предохранения духового шкафа.

! Перед началом эксплуатации необходимо снять

пленку, наклеенную с боков изделия.

! Никогда

духового шкафа, так как они могут повредить

эмалированное покрытие. Используйте положение

1 настройки духового шкафа только для

приготовления на вертеле.

Включение духового шкафа

не ставьте никаких предметов на дно

Для зажигания горелки

духового шкафа поднесите к

отверстию F (см. рисунок)

зажженную спичку или

кухонную зажигалку, нажмите

и одновременно поверните

F

против часовой стрелки

рукоятку ДУХОВКИ в

положение МАКС.

RS

Для выключения конфорки поверните рукоятку

вплоть до гашения пламени

Практические советы по эксплуатации

газовых конфорок

Для оптимальной работы конфорок и для экономии

газа следует использовать кухонную посуду с

плоским дном, с диаметром, соответствующим

конфорке, и с крышкой:

Для определения типа конфорки смотрите рисунки в

параграфе «Характеристики конфорок и форсунок».

Имеется только в некоторых моделях

*

•.

Если

изделие оснащено электронной системой

зажигания*, вначале нажмите кнопку зажигания,

обозначенную символом

упора и одновременно поверните против часовой

стрелки рукоятку КОНФОРКИ на символ

МАКСИМАЛЬНОГО пламени вплоть до зажигания

пламени. Если по прошествии 15 секунд горелка

не загориться, отпустите рукоятку, откройте дверцу

духового шкафа и подождите примерно 1 минуту

перед повторным зажиганием. В случае

отсутствия электропитания можно включить

горелку от спички или кухонной зажигалки, как

было описано

выше.

, затем нажмите до

1

17

Page 18

RS

Регуляция температуры

Для получения нужнои температуры

приготовления поверните против часовои стрелки

рукоятку ДУХОВКИ. Значения температуры

указаны на панели управления и начинаются с

МИН (140°C) до МАКС (250°C). По достижении

заданнои температуры в духовке она будет

поддерживаться постояннои термостатом.

Таимер

Порядок включения Таимера (часов):

1. поверните по часовои стрелке 4 рукоятку

ТАИМЕР почти на один полныи поворот для

завода таимера

;

Вспомогательная таблица по приготовлению в духовке

2. поверните против часовои стрелки 5 рукоятку

ТАИМЕР, выбрав нужное время.

Нижнии отсек

Снизу духового шкафа имеется отсек, которыи

может быть использован для хранения кухонных

принадлежностеи или кастрюль.

! Не помещаите возгораемых предметов в нижнии

отсек.

! Внутренняя поверхность ящика (если он

имеется) может сильно нагреться.

18

Page 19

Предосторожности и

рекомендации

! Оборудование разработано и изготовлено в соответ ствии

с международными нормами безопасности. Внимательно

прочитайте настоящие предупреждения, приводимые в

целях вашей безопасности.

Основные правила безопасности

•

Данные указания касаются только стран, указанных

в руководстве и табличке технических характеристик,

расположенной на оборудовании.

•

Оборудование разработано для бытового использования в домашних условиях и не предназначено

для применения на предприятиях промышленности

и торговли.

•

Оборудование не должно устанавливаться на открытом воздухе (даже под навесом). Чрезвычайно

опасно оставлять оборудование под воздействием

дождя / грозы.

•

Не касайтесь оборудования, если ваши ноги / руки

мокрые; не пользуйтесь оборудованием, когда Вы

босиком.

•

Оборудование должно использоваться только

взрослыми лицами для приготовления пищи и в

соответствии с инструкциями данного руководства. Любое другое использование оборудования

(напр., для обогрева помещения) является неправильным и опасным. Производитель не несет

ответственности

в результате его неправильного, нецелевого использования.

•

Инструкции руководства относятся к оборудованию

класса 1 (свободная установка) или класса 2 подкласса 1 (установка между двумя шкафами).

Во время работы оборудования нагревательные

•

элементы и некоторые части дверцы духовки сильно

нагреваются. Не прикасайтесь к ним и держите детей

на безопасном расстоянии.

Удостоверьтесь

•

роприборов не соприкасаются с горячими час тями

оборудования.

Не перегораживайте отверстия, предназначенные для

•

вентиляции и отвода тепла.

Пользуйтесь кухонными рукавицами / прихватками,

•

помещая и вынимая посуду из духовки.

•

Не используйте воспламеняющиеся жидкости (спирт,

бензин и т.п.) рядом с включенным оборудованием.

•

Не помещайте в отделение духовки для

горючие материалы: случайное включение оборудования может привести к возгоранию.

Всегда проверяйте, что рукоятки управления нахо-

•

дятся в позиции «z», когда оборудование не используется.

Отключая оборудование от электросети, не тяните

•

за питающий кабель, чтобы вынуть вилку из розетки:

беритесь за вилку.

Перед любыми работами по чистке и обслуживанию

•

оборудования обязательно отключите его от электросети, вынув вилку из розетки.

за по вреждение оборудования

, что питающие кабели других элект-

хранения

•

В случае неисправности, ни при каких обстоятельствах

не пытайтесь починить оборудование самостоятельно.

Ремонт, выполненный неквалифицированными лицами, может безвозвратно повредить оборудование или

стать причиной его неправильного функционирования.

Обратитесь за помощью в Авторизованный

центр.

Не кладите тяжелые предметы на открытую дверцу

•

духовки.

•

Оборудованием не должны пользоваться лица (включая детей) со сниженными физическими, сенсорными

или умственными способностями, а также не знакомые

с инструкциями данного руководства. Использование

ими оборудования допускается только под контролем

лиц, ответственных за их безопасность или после

получения инструкций по работе

•

Не позволяйте детям играть с оборудованием.

•

ВНИМАНИЕ! Доступные части оборудования достигают высокой температуры при работе гриля. Не

подпускайте детей близко к плите.

оборудования.

Утилизация

•

При уничтожении упаковочного материала и в случае

избавления от старого оборудования соблюдайте

действующие требования по их утилизации.

•

Согласно Европейской директиве 2002/96/EC по

утилизации электрического и электронного оборудования (WEEE) старые электробытовые приборы не должны помещаться в общий городской

неотсортированный поток отходов: они должны

собираться отдельно, чтобы оптимизировать восстановление и переработку их

негативное воздействие на здоровье человека и экологию. Указанный на изделии символ перечеркнутого

ведра на колесах напоминает, что при утилизации это

оборудование следует поместить отдельно.

Для получения информации о правильной утилизации

старого оборудования потребители должны обратиться в местные органы управления или в фирмупоставщик.

материалов и уменьшить

Экономия энергии и охрана окружающей

среды

•

Использование оборудования утром или вечером

позволяет снизить пиковую нагрузку на электросеть

и сэкономить потребление энергии.

•

Регулярно проверяйте уплотнители дверцы и протирайте их, очищая от любой грязи и сора: во избежание

утечки тепла уплотнители должны плотно прилегать

к дверце духовки.

RS

сервисный

19

Page 20

Техническое

обслуживание и уход

RS

Отключение оборудования

! Перед любыми работами по обслуживанию обору-

дования отключайте его от электросети.

Чистка оборудования

! Не используйте для чистки оборудования абразив-

ные или агрессивные средства (пятноудалители,

средства для удаления ржавчины, абразивные губки): они могут необратимо повредить поверхность

оборудования.

! Никогда не используйте для чистки духовки пароочистители и аэрозоли.

После каждой готовки протирайте рабочую поверх-

•

ность плиты влажной губкой, затем высушите

кухонным бумажным полотенцем.

Эмалированные

•

ти из нержавеющей стали, а также резиновые

уплотнители очищайте губкой, смоченной в растворе теплой воды с нейтральным мылом, затем

ополосните и тщательно вытрите. Для удаления

устойчивых пятен используйте специальные средства. После очистки ополосните и вытрите насухо.

Не применяйте абразивные порошки или средства,

содержащие агрессивные

Решетки рабочей поверхности, крышки горелок,

•

пламярассекатели и верхние горелки для облегчения чистки можно снять; промойте их теплой водой

с неабразивным моющим средством, удаляя нагар,

затем высушите.

Регулярно следует очищать наконечники устройств

•

безопасности* и проверять, не засорены ли газовые отверстия горелок.

Духовку идеально очищать изнутри после каждого

•

использования, пока

горячую воду и нейтральное моющее средство,

затем хорошо ополосните и вытрите мягкой тканью.

Не используйте абразивные чистящие средства.

Стекло дверцы духовки очищайте с помощью

•

губки и неабразивного чистящего средства, затем

вытрите насухо мягкой тканью. Не используйте

абразивные средства или металлические скребки,

которые могут повредить поверхность и

образованию трещин на стекле.

Принадлежности оборудования можно мыть, как

•

и обычную посуду (даже в посудомоечной машине).

На элементах из нержавеющей стали могут оста-

•

ваться пятна после длительного контакта с жесткой

водой или агрессивными чистящими средствами,

содержащими фосфор. Для очистки компонентов

из нержавеющей стали используйте специальные

чистящие средства, затем тщательно

и вытрите насухо.

внешние части или поверхнос-

вещества.

она не остыла. Используйте

привести

ополосните

Проверка уплотнителей

Регулярно проверяйте уплотнители дверцы по всему

периметру. В случае их повреждения обратитесь

в Авторизованный сервисный центр. Не пользуйтесь

духовкой, пока уплотнители не будут заменены.

Уход за вентилями рукояток

Со временем газовые вентили ( краны) рукояток могут

начать застревать или с трудом проворачиваться.

В этом случае их нужно заменить.

! Эта процедура должна выполняться квалифициро-

ванным техническим персоналом сервисного центра.

Замена лампы освещения

1. Отключите оборудования от

электросети, затем снимите

стеклянный плафон с патрона

лампы.

2. Выверните перегоревшую

лампу и замените ее лампой

с аналогичными характеристиками: напряжение 230 В,

мощность – 25 Вт, тип – Е 14.

3. Установите стеклянный плафон на место и снова

подключите оборудование к электросети.

Помощь

! Не пользуйтесь услугами лиц, не уполномоченных

Производителем. При ремонте требуйте использова-

ния оригинальных запасных частей.

Сообщите в Авторизованный сервисный центр:

•

номер гарантийного документа (сервисной книжки,

сервисного сертификата и т.п.);

•

модель плиты (Мод.) и серийный номер (S/N),

указанные в информационной табличке, расположенной на оборудовании, на упаковке или

в гарантийном документе

.

* Для некоторых модификаций модели.

20

Page 21

Мы заботимся о своих покупателях и

стараемся сделать сервисное обслуживание

наиболее качественным. Мы постоянно

совершенствуем наши продукты, чтобы

сделать Ваше общение с техникой простым и

приятным.

Уход за техникой

Продлите срок эксплуатации и снизьте

вероятность поломки техники.

Воспользуйтесь профессиональными средствами

для ухода за техникой от Indesit Professional для

наиболее простого, эффективного и легкого ухода

за Вашей бытовой техникой

.

Продукты Indesit Professional производятся в

Италии с соблюдением высоких европейских

стандартов в области качества, экологии и

безопасности использования и созданы с учетом

многолетнего опыта производителя техники.

Узнайте подробнее на сайте

www.indesit.com в разделе «Сервис» и

спрашивайте в магазинах Вашего города.

RS

Авторизованные сервисные центры

Чтобы быть ближе к нашим потребителям, мы

создали широкую сервисную сеть, особенностью

которой является высокая подготовка,

профессионализм и честность сервисных

мастеров. На сегодняшний день она насчитывает

около 350 сервисных центров на территории

России и СНГ.

Их контакты Вы можете найти в сервисном

сертификате и

на сайтеwww.indesit.com в

разделе «Сервис».

Если вам надо обратиться в сервисный

центр:

Внимание! При ремонте требуйте

использования оригинальных запасных

частей.

Другую полезную информацию и новости Вы

можете найти на сайте

www.indesit.com в разделе «Сервис».

21

Page 22

Інструкціі з експлуатаціі

КУХНЯ

UA

GB

English, 1

RO

Română, 32

KN6G210/UA

KN6G21/UA

RS

РУССКИЙ,11

UA

Украінська,22

Зміст

Встановлення,23-26

Розміщення і вирівнювання

Підключення електроенергіі

Підключення газу

Налаштування на різнi типи газу

Технічні дані

Таблиця характеристик пальників і форсунок

Опис установки, 27

Загальнии вигляд

Панель управління

Включення і використання, 28-29

Користування робочою поверхнею

Користування духовкою

Таблиця приготування в духовці

Запобіжні засоби і поради, 30

Загальна безпека

Утилізація

Охорона і дбаиливе відношення до довкілля

Догляд i технічне обслуговування, 31

Відключення електроживлення

Чищення установки

Технічне обслуговування газових кранів

Заміна лампочки освітлення духовки

Допомога

Page 23

Встановлення

! Важливо зберегти цю брошуру, щоб можна було

до неі звернутися при необхідності у будь-якому

випадку. У разі продажу, передачi iншiи особi або

переізду, переконаитеся в тому, що вона

залишається разом з виробом.

! Уважно прочитаите інструкціі: інформація про

обладнання, використання и безпеку грає дуже

важливу роль.

! Установка вироба має виконуватися

згідно даноі

інструкціі кваліфікованим персоналом.

! Будь-яке втручання в регулювання або технічне

обслуговування має виконуватися на плиті,

відключеніи від електроживлення.

Вентиляція приміщень

Обладнання може бути встановлене тільки у

постіино вентильованих приміщеннях, згідно

діючим нормам в краінi, де вироб буде

викорисовано. У приміщенні, в якому встановлено

обладнання, має відбуватися зміна повітря, у

ступені, необхідному

для нормального горіння

газу (швидкість зміни повітря не має бути меншою

3

2м

/год на кожнии кВт встановленоі потужності).

Вхід приточноі вентиляціі, захищении ґраткою, повинен

мати корисну площу не менше 100 см2 корисного

перетину і має бути розміщении так, щоб він не міг

забитися, навіть частково ( див. малюнок A).

Такии вхід повинен бути збільшении на 100%, тобто

мінімум 200 см2 – якщо робоча поверхня плити не

має пристрою безпеки у разі зникнення полум’я, і

коли можливии непрямии потік повітря із прилеглих

приміщень (див.малюнок B) – якщо це не спільні

частини будівлі, пожежонебезпечне приміщення

або спальні кімнати, обладнані вентиляціиним

трубопроводом назовні, як описано вище.

Прилеглі

A

B

приміщення

Вентильовані

приміщення

з природною тягою з належною ефективністю, або

за допомогою електровентилятора, якии би

включався автоматично кожного разу при

включенні плити (див. малюнки).

Відведення

безпосередньо

назовні

Відведення через канал

або розгалужении димар

(зарезервовании для

кухонного устаткування)

! Зріджені нафтові гази, важчі за повітря,

бираються внизу, тому приміщення, де

знаходяться балони з газом, повинні бути

обладнані

витяжними отворами, що виходять

назовні для евакуаціі знизу при можливому витоку

газу.

Балони із зрідженим нафтовим газом, порожні або

частково повні, не повинні бути встановлені або

берігатися в приміщеннях нижче за рівень грунту

(льохи і т.п.). У приміщенні можна тримати тільки

використовувании балон, далеко від джерел тепла

(печі, каміни, обігрівачі), які нагріваються

вище

від 50°C.

Розміщення і вирівнювання

! Можна встановлювати плиту збоку від меблів, які

не вищі за робочу поверхню.

! Переконаитеся в тому, що поверхня стіни, яка

контактує із задньою частиною плити, виготовлена

з негорючого та теплостіикого матеріалу і витримує

нагрівання (90°C).

UA

A

Вентиляціинии отвір для

відпрацьованого повітря

Збільшення щілини між

дверима і підлогою

! Після тривалого використання плити, доцільно

відкрити вікно або збільшити швидкість

вентиляторів.

Відведення продуктів згорання

Відведення продуктів згорання має бути

забезпечене через витяжку, підключену до каналу

Для правильного встановлення

• розміщуите плиту в кухні, обідніи залі або в

однокімнатніи квартирі-студіі (не у ванні);

• якщо

поверхня плити є трохи вищою, ніж

поверхня меблів, меблі повинні знаходитися не

ближче ніж 200 мм від плити;

• якщо плита буде встановлена під секцією

навісних меблів, esso відстань до іі поверхні не

повинна бути меншою за 420 мм.

Така відстань повинна складати 700 мм, якщо

секція навісних меблів зроблена з горючого

матеріалу (див. малюнок);

23

Page 24

UA

• не розміщуите

занавісок позаду

плити або ближче ніж

200 мм від іі сторін;

• витяжки повинні

mm. with hood

mm. without hood

встановлюватися

650

700

min.

згідно вказівкам

min.

mm.

420

Min.

HOOD

Min. mm.

600

420

Min. mm.

відповідноі інструкціі.

Вирівнювання

Якщо необхідно вирівняти

плиту, вкрутіть регулюючі

ніжки, що входять до

комплекту постачання, у

спеціальні місця, що

знаходяться у кутках основи

(див. малюнок).

Ніжки* вмонтовуються у

гнізда під основою плити.

Підключення електроенергіі

! У встановленіи плиті, має бути забезпечении

легкии доступ до електричного кабелю і розетки.

! Кабель не повинен мати перегинів або бути

стиснутим.

! Кабель має періодично перевірятися і мінятися

тільки фахівцями.

! Підприємство не несе будь-якоі

відповідальності, якщо ці норми не

дотримуватимуться.

Підключення газу

Підключення до газовоі мережі або балона може

виконуватися за допомогою гнучкого гумового

шланга або шланга в сталевому обплетенні, згідно

діючим національним нормам і після того, як

встановлено, що плита була налаштована на тип

газу, на якому вона працюватиме (див.

Калібрувальна бирка на кришці: в іншому випадку

див. нижче). У разі роботи плити від

зрідженим газом, використовуите редуктори

відповідно до діючих норм у странi, де буде

використовано вироб. Щоб полегшити підключення,

живлення газу може подаватися збоку *:

переставте в обратному напрямi утримувач гумки

для підключення замикаючоі пробки і замініть

ущільнювач, що входить у комплект постачання.

балона із

Встановіть на кабелі вилку, розраховану на

навантаження, вказане на табличці з технічними

характеристиками, розміщеніи на плиті (див.

таблицю Технічних Даних).

У разі прямого підключення до мережі необхідно

помістити між плитою і мережею всеполярнии

вимикач з мінімальною відстанню між контактами

3 мм, розраховании на вказане навантаження і

такии, що відповідає нормі NFC 15-100 (дріт

заземлення не повинен перериватися

вимикачем).

Кабель живлення повинен бути розташовании так,

щоб жодна з иого частин не піддавалася нагріванню

вище, ніж на 50°C від температури довкілля.

До виконання підключення переконаитеся, що:

• розетка має заземлення, відповідно до

встановлених норм;

• розетка витримує максимальне навантаження

потужності обладнання, вказане на табличці з

характеристиками;

• напруга живлення знаходиться в межах

значень, вказаних

на табличці;

• розетка сумісна з вилкою плити. В іншому

випадку замініть розетку або вилку; не

використовуите подовжувачі и тріиники.

! Для безперебіиноі роботи, для адекватного

використання енергіі і для більшого

терміну

служби плити, забезпечте тиск подачі газу в

межах значень, вказаних в таблиці Характеристик

пальників і форсунок (див. нижче).

Підключення газу за допомогою гнучкого

гумового шланга

Перевірте, щоб шланг відповідав діючим державним

нормам. Внутрішніи діаметр шланга повинен бути: 8

мм для зрідженого газу; 13 мм для метану.

Виконавши з’єднання, переконаитеся в тому, що

шланг:

• не

торкається частин, які нагріваються вище

температури в 50оC;

• не має будь-якого натягнення або скручування,

не має згинів або стискань;

• не торкається гострих предметів, краів, рухомих

частин і не здавлении;

• може бути легко оглянутии по всіи довжині для

контролю иого стану;

• має довжину меншу ніж 1500 мм;

• добре закріплении на

обох кінцях за допомогою

хомутів, відповідно до діючих державних норм.

* Є лише в деяких моделях.

24

Page 25

! Якщо одна або більше з цих умов не будуть

дотримані, або якщо плита встановлена згідно

умовам класу 2 - підклас 1 (плита, встановлена між

двома шафами), необхідно використовувати

гнучкии шланг в сталевому обплетенні (див. нижче).

!

У разі зріджених газів, регулювальнии гвинт

повинен бути вкручении до упору;

3. перевірте, щоб при швидкому обертанні крана з

максимального в мінімальне положення, пальник

не гаснув.

UA

Підключення газу за допомогою гнучкого

шланга в обплетенні з неіржавіючоі сталі до

безперервноі стіни за допомогою патронів із

різьбою

Перевірте, щоб шланг

і обплетення відповідали

діючим державним нормам.

Щоб підключити шланг, видаліть утримувач гумки, що

міститься в плиті (місце підключення газу до плити має

вигляд цилiндричноі трубки з різьбою папа 1/2 дюима)

! Виконаите з’єднання так, щоб довжина

трубопроводу не перевищувала 2 метрів, при

цьому не допускаите контакту шланга з рухомими

частинами та иого стиснення.

Контроль герметичності

Після повного встановлення перевірте

герметичність всіх з’єднань, використовуючи

тільки мильнии розчин і у жодному випадку сірник.

Адаптація до різних типів газу

Є можливість налаштування плити під тип газу,

відміннии від типу, на якии вона була налаштована

підприємством-виробником (вказании на

калібрувальніи бирці на кришці).

Налаштування робочоі поверхні

Заміна форсунок пальників поверхні:

1. Зніміть ґратки и пальники з іх посадочних місць;

2. Відгвинтіть форсунки,

користуючись трубним

ключем 7 мм (див. малюнок),

і замініть іх форсунками, що

відповідають

(див. таблицю

Характеристики пальників і

форсунок);

3. Встановіть на місце всі компоненти, виконавши

вказані вище операціі у зворотніи послідовності.

новому типу газу

! Пальники робочоі поверхні не потребують

регулювання первинного повітря.

Налаштування духовки

Заміна форсунки пальника духовки:

1. Заміна форсунки пальника

духовки;

2. витягніть висувнии захист

A (див. малюнок);

3. видаліть пальник

духовки

після того, як відкрутите

V

гвинти V (див. малюнок);

процедуру виконати легше,

якщо зняти дверцята

духовки.

4. відгвинтіть форсунку

пальника спеціальним

трубним ключем для форсунок

(див. малюнок) або трубним

ключем 7 мм і замініть іі

форсункою, що відповідає

новому типу газу (див. таблицю Характеристики

пальників і форсунок).

Налаштування мінімального рівня подачі газу

в пальник духовки:

1. запаліть пальник

(див. Включення і Використання);

2. встановіть рукоятку у положення мінімуму (МІН)

після того, як вона залишалася приблизно протягом

10 хвилин у максимальному положенні (MAКС);

3. зніміть рукоятку;

4. користуючись регулювальним гвинтом на

зовнішніи стороні стрижня термостата (див.

малюнки), добиитеся маленького стіикого полум’я.

Налаштування мінімального рівня пальників

поверхні:

1. встановіть кран у мінімальне положення;

2. зніміть рукоятку і користуючись регулювальним

гвинтом, що знаходиться на внутрішніи частині

або збоку на стрижні крана, добиитеся маленького

стабільного полум’я.

25

Page 26

UA

! У разі зріджених газів, регулювальнии гвинт

повинен бути вкручении до упору;

5. Перевірте, щоб, при швидкому обертанні

рукоятки з положення MAКС у положення МІН або

при швидкому відкритті і закриті дверцят духовки

пальник не гаснув.

ТЕХНІЧНІ ДАНІ

Розміри Духовки

ВxШxГ

Об'єм

Корисні

розміри

коробки

духовки

Напруга та

частота

живлення

Пальники

31x 43,5 x43,5 см

літрiв

58

ширина см 42

глибина см 46

висота см 8,5

Див. на табличці з даними

Налаштовуються на всі типи

газу, вказані на табличці з

даними, розташованій в