Indesit K1G2S-HU User Manual

Cooker

Installation and use

K onyhabútor

Beépítés és használat

K1G2S/HU

Cooker with gas oven

Instructions for installation and use

Gáz sütõvel rendelkezõ tûzhely

Használati útmutató

3

12

Important safety warnings

T o maintain the EFFICIENCY and SAFETY of this appliance, we recommend:

• call only the Service Centers authorized by the manufacturer

• always use original Spare Parts

1 This appliance is intended for nonprofessional use within the home.

2 These instructions are only for those countries whose symbols appear in

the booklet and on the serial no. plate of the appliance.

3 This owner’s man ual is for a class 1 appliance (insulated) or

class 2, subclass 1 appliances (installed between two cabinets.

4 Before using your appliance, read the instructions in this own-

er’s manual carefully since it pro vides all the information you

need to ensure safe installation, use and maintenance. Always k eep this owner’ s manual close to hand since you ma y

need to refer to it in the future.

5 When you have removed the packing, check that the appli-

ance is not damaged. If y ou hav e any doubts, do not use the

appliance and contact your nearest Ariston Service Centre.

Never lea ve the packing components (plastic bags , polystyrene foam, nails, etc.) within the reach of children since they

are a source of potential danger.

6 The appliance must be installed only by a qualified techni-

cian in compliance with the instructions provided. The manufacturer declines all liability for improper installation, which

may result in personal injury and damage to property .

7 Before plugging the appliance into the mains, check that the

specifications indicated on the date plate (on the appliance

and/or packaging) correspond with those of the electrical

and gas systems in your home.

8 Do not leave the appliance plugged in if it is not in use . Switch

off the main switch and gas supply when you are not using

the appliance.

9 The openings and slots used for ventilation and heat dispersion must never

be covered.

10 This appliance must be used for the purpose for which it was expressly

11 T o avoid accidental spillage do not use cookware with uneven or deformed

12 Some parts of the appliance remain heated for a long time after use. Make

13 Never use flammable liquids such as alcohol or gasoline,

14 When using small electric appliances near the hob, keep the

15 Make sure the knobs are in the “•”/” ¡” position when the ap-

16 When the appliance is in use, the heating elements and some

17 Gas appliances require regular air exchange to ensure

18 If the cooker is placed on a pedestal, take the necessary

designed. Any other use (e.g. heating rooms) is considered to be improper

and consequently dangerous. The manufacturer declines all liability for

damage resulting from improper and irresponsible use.

bottoms on the burners. T urn the handles of pots and pans inwards to avoid

knocking them over accidentally.

sure not to touch them.

etc. near the appliance when it is in use.

supply cord away from the hot parts.

pliance is not in use.

parts of the oven door become extremely hot. Make sure

you don’t touch them and keep children well away.

trouble-free performance. When installing the cooker,

follow the instructions pr ovided in the paragraph on “P ositioning” the appliance.

precautions to prevent the same from sliding off the pedestal

itself.

3

Installation

All instruction on the following pages must be carried out

by a competent person (corgi registered) in compliance

with gas safety (installation and use) regulation 1984.

Important: disconnect the cooker from the electrycity

and gas supply when any adjustment, etc.

Positioning your appliance

Y our cook er is designed with a degree of protection against

overheating in class X; the appliance can therefore be

installed next to cabinets, provided the height does not

exceed that of the hob. The wall touching the bac k panel of

the cooker should be non-inflammable. Remember that

during use, the back panel of the cooker ma y reach a temperature up to 50°C above that of the room temperature .

Important: this appliance may be installed and used only

in permanently ventilated rooms in compliance with current

directives. The follo wing precautions should be tak en:

a) The room must be provided with an external exhaust

system obtained with a hood or with an electric

ventilator that goes on automatically each time the unit

is switched on.

d) The liquefied petroleum gases, which are heavier than

air, stagnate tow ards the ground. Theref ore, the rooms

containing LPG cans must have openings tow ards the

outside in order to allow the venting from the ground of

eventual gas leak. Thus, the LPG cans must not be

installed or settled in rooms that are below the ground

level, (cellar, etc.) whether the cans are empty or

partially full. It is advisable to keep in the room only the

can which is being used, and it must be placed away

from direct heat sources (ovens, fireplaces, stoves,

etc.) that could make the can reach temperatures

higher than 50°C.

Levelling your appliance (only on a fe w models)

Y our cook er is supplied with feet for le velling the appliance.

If necessary , these feet can be screwed into the housings

in the corners of the cooker base.

In the case of chimneys or flues Directly to the

with branches (for cookers) exterior

b) The room must be provided with a system for air inflow

which is necessary for a regular combustion. The air

flow necessary for the combustion should be at least 2

m3/h for kW of installed power. The system may be

realized by drawing the air directly from outside the

building through a pipe that has at least a 100 cm

useable section and which must not be accidently

obstructed (Fig. A). And further it may be realized

indirectly from other adjacent rooms which are provided

with a ventilation pipe for the e xpulsion of the fumes to

the outside of the building as foresaid, and which must

not be part of the building in common use or rooms

with risk of fire, or bedrooms (Fig. B).

Detail A Adjacent Room to

room be ventilated

A

Fig. A Fig. B

Examples of ventilation openings Increased opening between

for the comburent ai r the door and and floor

c) During prolonged use of the appliance you may

consider it necessary to open a window to the outside

to improve ventilation.

Mounting the legs (only on a few models)

Press-fit legs are supplied which fit under the base of your

cooker.

2

Installation of the cooker

The appliance can be installed next to furniture units which

are no taller than the top of the cooker hob. The wall in

direct contact with the back panel of the cooker must be

made of non-flammable material. During operation the

back panel of the cooker could reach a temperature of

50°C above room temperature. For proper installation of

the cooker, the following precautions must be taken:

a) The appliance can be placed in a kitchen, dining room

or bedsit, but not in a bathroom.

b) All furniture around the appliance must be placed at

least 200 mm from the top of the cooker, should the

surface of the appliance be higher than the worktop of

this furniture. Curtains should not be placed behind

the cooker or less than 200 mm away from the sides

of the appliance.

c) Any hoods must be installed according to the require-

ments in the installation manual for the hoods themselves.

d) If the cooker is installed beneath a wall cabinet, the

latter must be situated at a minimum of 420 mm above

4

the hob. The minimum distance between the worktop

and kitchen units made of combustible material is 700

mm.

e) The wall in direct contact with the back panel of the

cooker must be made of non-flammable materials.

HOOD

Min. mm.

600

mm.

420

Min.

mm. with hood

420

650

Min. mm.

min.

mm. without hood

700

min.

Connecting the gas

The appliance should be connected to the mains or to a

gas cylinder in compliance with current directives. Bef ore

making the connection, check that the cooker is regulated

for the gas supply you are using. If not, follow the

instructions indicated in the paragraph “Adapting to

different types of gas”. On some models the gas supply

can be connected on the left or on the right, as necessary;

to change the connection, reverse the position of the hose

holder with that of the cap and replace replace the gasket

(supplied with the appliance). When using liquid gas from

a cylinder, install a pressure regulator which complies with

current directive.

Important: check that the supply pressure complies with

the values indicated in table 1 “Characteristics of the

burners and nozzles” since this will ensure saf e operation,

correct consumption and ensure a longer life to your

appliance.

Connection with hose

Make the connection using a gas hose complying with

the the characteristics provided in current directive. The

internal diameter of the pipe used is as follows:

- 8mm for liquid gas;

- 13mm for methane gas.

When installing the hose, remember to take the following

precautions:

• No part of the hose should touch parts whose tempe-

rature exceeds 50°C;

• The length of the hose should be less than 1500 mm;

• The hose should not be subject to twisting or pulling,

and should not have bends or kinks.

• The hose should not touch objects with sharp edges,

any moving parts, and it should not be crushed;

• The full length of the hose should be easy to inspect in

order to check its condition;

Check that the hose fits firmly into place at the two ends

and fix it with clamps complying to current directive.If any

of the above recommendations can not be adopted, fle xible

metal pipes should be used.

Should the cooker be installed according to the conditions

of Class 2, subdivision 1, only a flexible metal pipe which

is in compliance with current safety standards should be

used to make the connection to the gas mains.

Connecting a flexible jointless stainless steel pipe to

a threaded attachment

Remove the hose holder fitted on the appliance. The gas

supply pipe fitting is a threaded 1/2 gas cylindrical male

attachment. Only pipes and gaskets complying with current

directives. The full length of the pipe must not exceed 2000

mm.

Tight control

Important: when installation has been completed, check

the pipe fitting for leaks with a soapy solution. Ne ver use a

flame. Once the connection has been made, ensure that

the flexible metal tube does not touch any moving parts

and is not crushed.

Connecting the supply cable to the mains

Install a normalised plug corresponding to the load

indicated on the data plate. When connecting the cable

directly to the mains, install an omnipolar circuit-breaker

with a minimum contact opening of 3 mm between the

appliance and the mains. The omnipolar circuit breaker

should be sized according to the load and should comply

with current regulations (the earth wire should not be

interrupted by the circuit breaker).

The supply cable should be positioned so that it does not

reach a temperature of more than 50°C with respect to

the room temperature, along its length. Before making the

connection, check that:

• the limiter valve and the home system can support the

appliance load (see data plate);

• the mains is properly earthed in compliance with

current directives and regulations;

• there is easy access to the socket and omnipolar circuit

breaker , once the hob has been installed.

N.B: never use reducers, adaptors or shunts since they

can cause heating or burning.

Adapting the cooker to different types of gas

In order to adapt the cooker to a different type of gas with

respect to the gas for which it was produced (indicated on

the label attached to the lid), follow these steps:

a) replace the hose holder mounted on the appliance with

that supplied in the bag of “cooker accessories”.

Important: the hose holder f or liquid gas is marked 8, the

hose holder for methane gas is marked 13. Alwa ys fit the

sealing gasket.

b) Replacing the burner nozzles on the hob:

• remove the grids and slide the burners from their

housings;

• unscrew the nozzles using a 7 mm socket spanner,

and replace them with nozzles for the new type of gas

(see table 1 “Burner and nozzle characteristics”).

• replace all the components by repeating the steps in

reverse order.

5

c) Minimum regulation of the hob burners:

•

turn the tap to minimum;

• remove the knob and adjust the regulation screw , which

is positioned in or next to the tap pin, until the flame is

small but steady.

N.B.: in the case of liquid gas, the regulation screw

must be screwed in to the bottom.

• check that the flame does not turn off when you turn

the tap quickly from high to low.

d) Regulating the primary air of the burners:

The primary air of the burners requires no regulation.

Adapting the gas oven to different types of gas

a) Replacing the oven burner nozzle:

• remove the warming drawer;

• remove the sliding protection “A” (see Fig.C);

• remove the screw and then the oven burner “V”(see

Fig. D). Remove the oven door to facilitate this

operation.

• unscrew the oven burner nozzle using the special

socket spanner for the nozzles (see Fig. E), or better

still a 7 mm socket spanner , and replace it with a nozzle

suited to the new type of gas (see table 1).

V

Fig.E

b) Minimum regulation of the oven burner without

thermostat:

• light the burner as described in the paragraph “the o ven

knob” of the instruction booklet;

• take the knob to minimum, indicated by C.

• remove the knob and turn the regulation screw which

is positioned in or next to the tap pin until the flame is

small but steady.

N.B.: in the case of liquid gas, the regulation screw

must be screwed in to the bottom;

• check that the burner does not turn off when you turn

the knob from high to low or when you open and close

the oven door quickly.

A

Fig. C Fig. D

Pay particular attention to the plug wires and

thermocouple tubes.

Important

On completion of the operation, replace the old rating

sticker with one indicating the new type of gas used. This

sticker is av ailab le from our Service Centres.

Note

Should the pressure of the gas used be different (or vary)

from the recommended pressure, it is necessary to fit a

suitable pressure regulator onto the inlet pipe in

compliance with current National Regulations relative to

“regulators for channelled gas”.

6

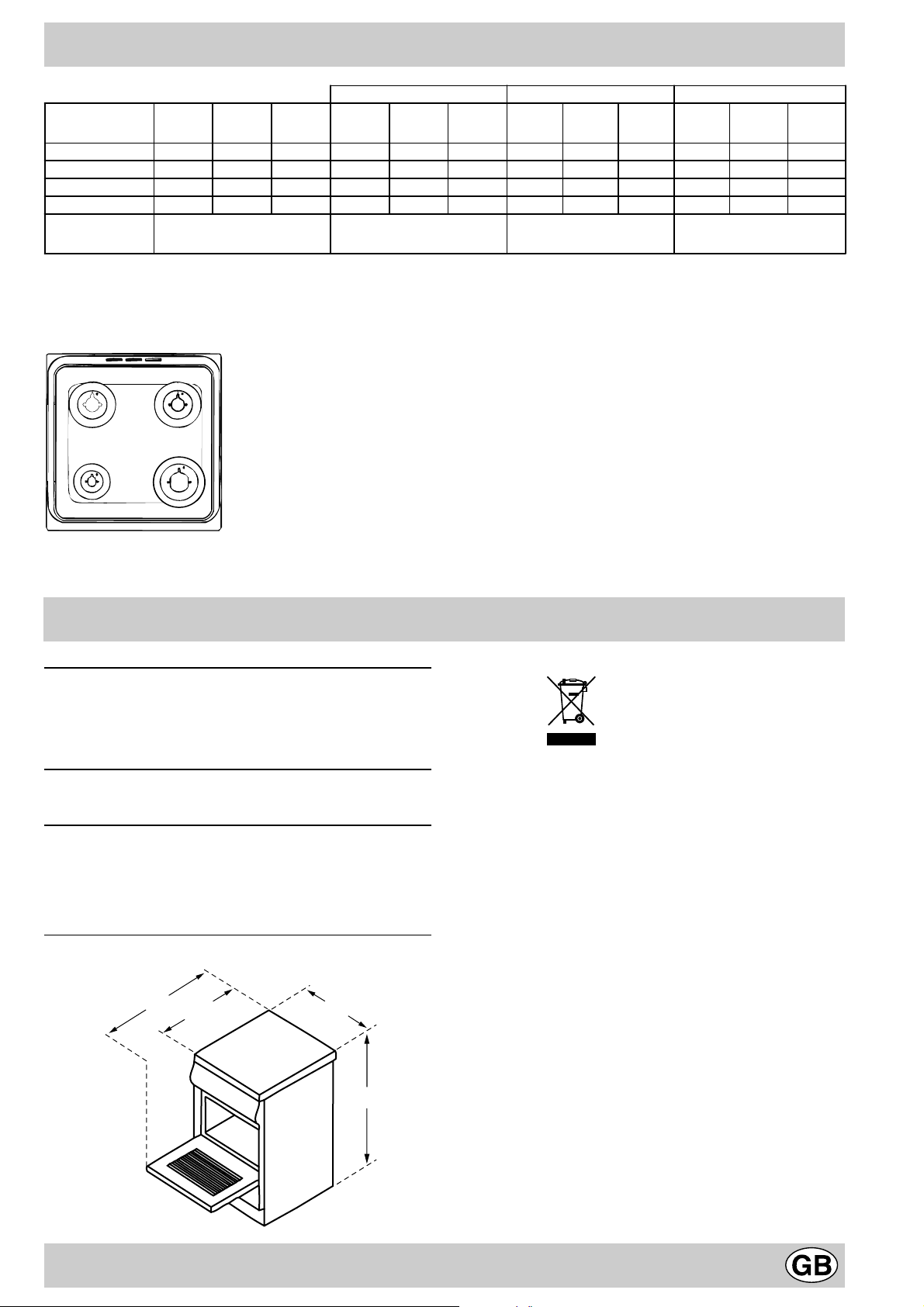

Burner and nozzle characteristics

Table1 (For Hungary)

Burner Diameter

Fast (R) 100 41 0.80 128 3,30 314 128 2,85 262 87 3,00 218

Semi Fast (S) 75 30 0.50 104 2,10 200 104 1,95 179 70 1,90 138

Auxiliary (A) 51 30 0,50 76 1, 15 109 76 1,05 97 52 1,00 73

Oven - 48/49 1,00 107 2,20 209 107 1,95 179 68 2,00 145

Supply pressures

* At 15°C and 1013 mbar-dry gas

P.C.S. G20 37,78 MJ/m

P.C.S. G25.1 39,11 MJ/m

P.C.S. G30 49,47 MJ/kg

S

A

(mm)

3

S

R

1/100 (mm)

Nominal (mbar)

Minimum (mbar)

Maximum (mbar)

3

By-pass

Thermal

power kW

Reduced

Nozzle

1/100

(mm)

G 20 G 25.1 G 30

Thermal

power kW

Nominal

25

20

30

Flow*

l/h

Nozzle

1/100

(mm)

Thermal

power kW

25

20

30

Flow*

l/h

Nozzle

1/100

(mm)

Thermal

power kW

Nominal

30

20

35

Flow*

g/h

K1G2S/HU

Technical Specifications

Inner dimensions of the oven:

Width: 39 cm

Depth: 38 cm

Height: 34 cm

Inner Volume of the Oven:

50 lt

Burners:

adaptable for use with all the types of gas indicated on

the data plate situated inside the flap or, once the

dishwarmer drawer has been opened, on the inside wall

of the left-hand side panel.

94

50

50

7

The European Directive 2002/96/EC on Waste Electrical

and Electronic Equipment (WEEE), requires that old

household electrical appliances must not be disposed of

in the normal unsorted municipal waste stream. Old

appliances must be collected separately in order to optimise

the recovery and recycling of the materials they contain

and reduce the impact on human health and the

environment. The crossed out “wheeled bin” symbol on the

product reminds you of your obligation, that when you dispose of the appliance it must be separately collected.

Consumers should contact their local authority or retailer

for information concerning the correct disposal of their old

appliance.

85/90

7

The cooker with gas oven

A. T ray for Catching Overflo ws

B. Gas Burner

D. Top Grate

E. Control P anel

F. Adjustable Feet or Legs

G. Dripping P an or Baking Sheet

J. Flame Failure Device for Cooktop Burners

K. Oven Rack

M. Oven Control Knob

N. Control Knobs for Gas Burners on Hob

J

A

B

E

D

K

G

M

N

The different functions and uses of the oven

The various functions included in the cooker are selected by

operating the control devices located on the cooker control panel.

Control Knobs for the Gas Burners on the Hob (N)

The position of the gas burner controlled by each one of the

knobs is shown by a symbol of a solid ring:•. T o light one of the

burners, hold a lighted match or lighter near the burner. Press

down and turn the corresponding knob in the counter-clockwise

direction to the maximum E setting. Each burner can be operated at its maximum, minimum or intermediate power . Shown

on the knob are the different symbols for off • (the knob is on this

setting when the symbol lines up with the reference mark on the

control panel), for maximum E and minimum C

To obtain these settings, turn the knob counter-clockwise with

respect to the off position. To turn off the burner, turn the knob

clockwise until it stops (corresponding again with the • symbol).

F

production and installation of the appliance.

Attention: Only use the bottom shelf of the oven when using

the rotisserie to cook (where present). For all other types of

cooking, never use the bottom shelf and ne ver place anything

on the bottom of the oven when it is in operation because this

could damage the enamel. Always place your cookware (dishes,

aluminium foil, etc. etc.) on the grate provided with the appliance

inserted especially along the oven guides.

Oven Control Knob (M)

T o light the o ven b urner, apply a lighted match or a lighter

to hole and while pressing in all the way set the oven knob

on maximum E.

Models with Hob Gas Burner Safety Devices to Prevent

Leaks (only on certain models)

These models can be identified by the presence of the device

itself (see detail J).

Important: Since the hob burners are equipped with a safety

device, y ou must hold the control knob in for about 6 seconds

after the burner has been lighted to allow the gas to pass until

the safety thermocouple has heated.

Attention: before using the o ven and grill for the first time , turn

the oven on f or approximately one half hour . Make sure that the

oven is empty, the thermostat on high, the door open, and the

room properly ventilated. The odor which can be detected at

times is due to the ev aporation off the substances used to protect

the oven and the grill during the period between the time of

F

The burner can be used at maximum or intermediate

settings. These settings, maximum E and minimum C

are indicated on the knob, plus off , identified by the symbol

• and operative when this symbol points to the notch.

For the minimum to maximum settings turn the knob

counter clockwise from “Off”.

8

Loading...

Loading...