Page 1

36 785 00

IKA®RV 10 basic

IKA®RV 10 digital

042009

Reg.-No. 4343-01

Betriebsanleitung DE 5

Operating instructions EN 17

Mode d’emploi FR 29

Instrucciones de manejo ES 41

Page 2

Contents

EN

Page

CE-Declaration of conformity 3

Safety instructions 17

Correct use 18

Unpacking 18

Useful information 18

Setting up 19

Drive RV 10 basic/ digital

Heating bath

Glassware

Hose system

Safety instructions

For your protection

• Read the operating instructions in full before starting up and

follow the safety instructions.

• Keep the operating instructions in a place where they can be accessed by everyone.

• Ensure that only trained staff work with the appliance.

• Follow the safety instructions, guidelines, occupational health

and safety and accident prevention regulations. When working

under a vacuum in particular!

•

Wear your personal protective equipment in accordance with the

hazard category of the medium to be processed. Otherwise there

is a risk of:

- splashing liquids,

- body parts, hair, clothing and jewellery getting caught,

- injury as a result of glass breakage.

• CAUTION! Inhalation of or contact with media such as poisonous

liquids, gases, spray mist, vapours, dusts or biological and microbiological materials can be hazardous to user.

• Set up the device in a spacious area on an even, stable, clean,

non-slip, dry and fireproof surface.

• Ensure that there is sufficient space above the device as the glass

assembly may exceed the height of the device.

• Prior to each use, always check the device, accessories and especially the glass parts for damage. Do not use damaged components.

• Ensure that the glass assembly is tension-free! Danger of cracking

as a result of:

- stress due to incorrect assembly,

- external mechanical hazards,

- local temperature peaks.

Ensure that the stand

•

spectively unbelance.

• Beware of hazards due to:

- flammable materials,

- combustible media with a low boiling temperature,

- glass breakage.

• CAUTION! Only process and heat up media that has a flash point

higher than the adjusted safe temperature limit of the heating bath

that has been set.

The safe temperature limit of the heating bath must always be

set to at least 25 °C lower than the fire point of the media used.

•Do not operate the appliance in explosive atmospheres, with ha-

zardous substances or under water.

• Only process media that will not react dangerously to the extra

energy produced through processing. This also applies to any

extra energy produced in other ways, e.g. through light irradiation.

Tasks with the device must only be performed when operation

•

is monitored.

•

Operation with excess pressure is not permitted (for cooling

water pressure see "Technical Data").

• Do not cover the ventilation slots of the device in order to ensure

adequate cooling of the drive.

• There may be electrostatic discharges between the medium and

the drive which could pose a direct danger.

• The appliance is not suitable for manual operation.

•

Safe operation is only guaranteed with the accessories described

in the ”Accessories” chapter.

•

Refer to the operating instructions for the HB 10 basic/ digital heating bath.

•

Refer to the operating instructions for the accessories, e.g. vacuum pump.

•

Position the positive pressure outlet of the vacuum pump under

a fume hood.

042009

does not start to move due to vibrations re-

Interfaces and outputs 22

Commissioning 23

Maintenance and cleaning 24

Accessories 25

Error codes 27

Technical data 27

Solvent table (excerpt) 28

Warranty 28

•

Use the HB 10.2 cover or the HB 10.1 spray guard.

• Only use

•

•

•

•

•

•

•

• ATTENTION! Avoid delayed boiling! Never heat the evaporating

•

•

•

•

•

•

the device under an all side-closed exhaust, or a compa rable protective device.

Adapt the quantity and the type of distilland to the size of the distillation equipment. The cooler must work properly. Monitor

the coolant flow rate at the cooler outlet.

The glass equipment must always be ventilated when working

under normal pressure (e.g. open outlet at cooler) in order to

prevent a pressure build-up.

Please note that dangerous concentrations of gases, vapours or

particulate matter can escape through the outlet at the cooler. Take

appropriate action to avoid this risk, for example, downstream cold

traps, gas wash bottles or an effective extraction system.

Evacuated glass vessels must not be heated on one side; the

evaporating flask must rotate during the heating phase.

The glassware is designed for operation under a vacuum of up

to 10 mbar.

(see chapter ”Commissioning”). The equipment must only be

aired again after cooling. When carrying out vacuum distillation,

uncondensed vapours must be condensed out or safely dissipated. If there is a risk that the distillation residue could disintegrate in the presence of oxygen, only inert gas must be admitted

for stress relief.

CAUTION! Avoid peroxide formation. Organic peroxides can accumulate in distillation and exhaust residues and explode while

decomposing!

Keep liquids that tend to form organic peroxides away from light,

in particular from UV rays and check them prior to distillation and exhaust for the presence of peroxides. Any existing peroxides must

be eliminated. Many organic compounds are prone to the formation

of peroxides e.g. dekalin, diethyl ether, dioxane, tetrahydrofuran,

as well as unsaturated hydrocarbons, such as tetralin, diene, cumene and aldehydes, ketones and solutions of these substances.

DANGER OF BURNING! The heating bath, tempering medium,

evaporator piston and glass assembly can become hot during operation and remain so for a long time afterwards! Let the components cool off before continuing work with the device.

flask in the heating bath without switching on the rotary drive!Sudden foaming or exhaust gases indicate that flask content is beginning to decompose. Switch off heating immediately. Use the lifting

mechanism to lift the evaporator piston out of the heating bath.

Evacuate the danger zone and warn those in the surrounding area!

When the device is switched off or the power supply disconnected, the internal safety lift removes the evaporator piston from the

heating bath. The maximum load (evaporator piston and contents)

is 1.5 kg for a permissible safety lift with no power.

CAUTION! Never operate the device when the evaporator piston

is rotating and the lift is raised. Always lower the evaporator piston

into the heating bath first before starting the rotation drive. Otherwise hot tempering medium may be sprayed out!

Set the speed of the drive so no tempering medium is sprayed

out as a result of the evaporator piston rotating in the heating bath.

If necessary reduce the speed.

Do not touch rotating parts during operation.

Imbalance may result in uncontrolled resonance behaviour of the

device or assembly. Glass apparatus may be damaged or destroyed. In the event of unbalance or unusual noises, switch off

the appliance immediately or reduce the speed.

The appliance does not start up again automatically following a cut

in the power supply.

The

equipment must be evacuated prior to heating

17

Page 3

•

The device is only disconnected from the power supply network

if the device power switch is off or the plug is pulled out.

• The socket for the mains cord must be easily accessible.

Correct use

For protection of the equipment

•

The voltage stated on the type plate must correspond to the mains

voltage.

•

Socket must be earthed (protective ground contact).

•

Removable parts must be refitted to the appliance to prevent the

infiltration of foreign objects, liquids etc.

• Protect the appliance and accessories from bumps and impacts.

• The appliance may only be opened by experts.

• Use

Together with the accessories recommended by IKA, the device

is suitable for:

- quick and gentle distillation of liquids

- evaporation of solutions and suspensions

- crystallisation, synthesis or cleaning of fine chemicals

- drying of powder and granulate material

- recycling of solvents

Mode of operation: Tabletop device

• Range of use

- Laboratories - Schools

- Pharmacies - Universities

Unpacking

• Unpacking

- Please unpack the device carefully

- In the case of any damage a fact report must be set immediately (post, rail or forwarder)

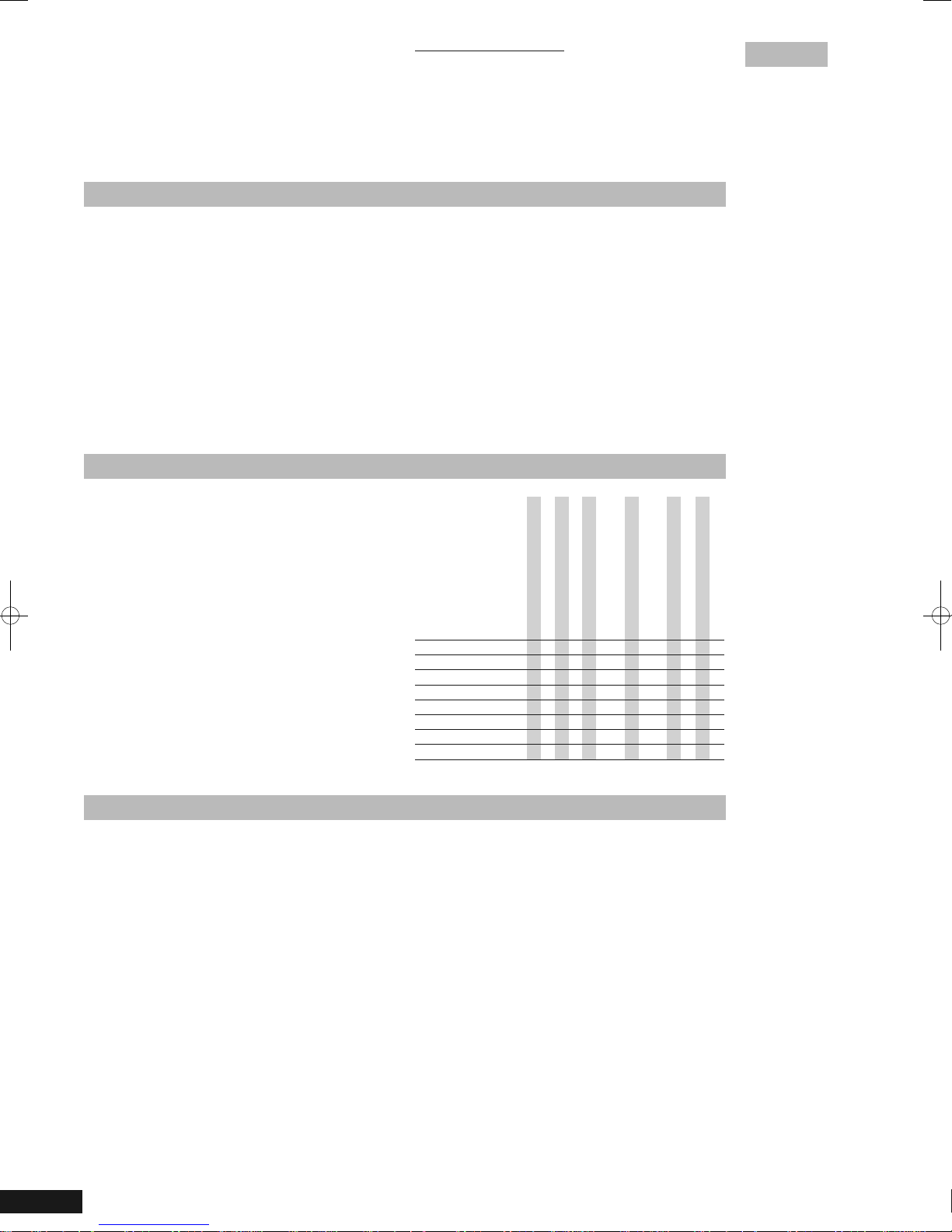

• Delivery scope

see table

The safety of the user cannot be guaranteed if the appliance is operated with accessories that are not supplied or recommended by

the manufacturer or if the appliance is operated improperly contrary

to the manufacturer’s specifications.

Drive RV 10 basic

Drive RV 10 digital

Heating bath HB 10 basic

Heating bath HB 10 digital

Vertical glassware RV 10.1

Vertical glassware RV 10.10,

coated

Diagonal Glassware RV 10.2

Diagonal Glassware RV 10.20,

coated

Woulff bottle

Bracket

Cooler locking device, compl.

RV 10 basic V x x x x x x x

RV 10 basic VC x x x x x x x

RV 10 basic D x x x x x x x

RV 10 basic DC x x x x x x x

RV 10 digital V x x x x x x x

RV 10 digital VC x x x x x x x

RV 10 digital D x x x x x x x

RV 10 digital DC x x x x x x x

Operating instructions

Useful information

Distillation is a thermal separating process for liquid compounds based

on substance-specific, pressure-dependent boiling points through evaporation and subsequent condensation.

The boiling point temperature decreases with decreasing external

pressure which means that work is usually done under reduced

pressure. In this way the heating bath can be maintained at a constant temperature (e.g. 60 °C). Using the vacuum, the boiling point

is set with a steam temperature of approx. 40 °C. The cooling water

for the condensation cooler should not be warmer than 20 °C (6040-20 rule).

A chemical resistant membrane pump with a vacuum controller

should be used to create the vacuum. The pump is protected from

solvent residue by the addition of a Woulff bottle and/or a vacuum

separator.

Working with a jet pump to create a vacuum can only be recommended to a limited extent as the solvents may contaminate the

environment when using these systems

Speed, temperature, piston size and system pressure all affect the

evaporator air capacity.

The optimum capacity of the flow-through condenser is approx.

60%.

18

This corresponds to condensation on approx. 2/3 of the cooling coil.

With larger capacities there is the risk that the uncondensed solvent

vapour will be extracted.

The device is equipped with a piston-operated safety mechanism.

The glass apparatus may contain a vacuum following interruption to

the power supply; vent the system before switching back on. If the

power cuts out, the evaporator piston is automatically lifted out of

the heating bath by an integrated gas spring.

CAUTION! The maximum load (evaporator piston and contents) is

1.5 kg for a permissible safety lift with no power for glass apparatus

with diagonal or vertical condenser.

When using other types of condensers such as dry ice or intensive

condensers as well as when using return distillation distributors with

slip-on condensers, it may be necessary to reduce the mass of the

media to compensate for the mass of this additional glassware.

Thus, prior to distillation, check whether the lift goes up without

power when laden with the glass and distillation material.

042009

Page 4

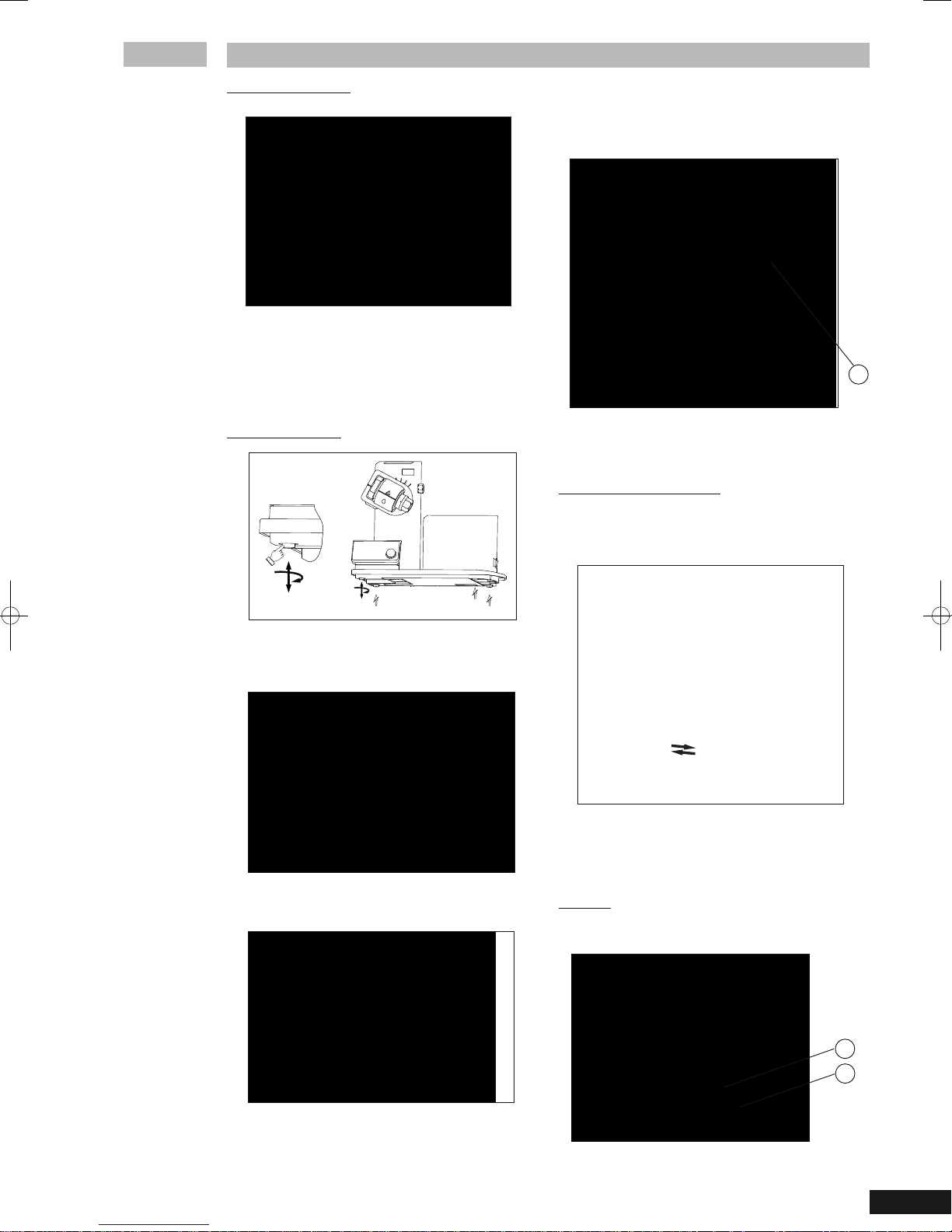

Setting up

IR

Drive RV 10 basic/digital

☞ Remove the clamping device for the angle setting of the rotation

CAUTION! Loosen transportation lock (fig. 4a)!

☞ Set the drive at an angle of approx. 30° (fig. 7).

Fig. 4a

☞ Hold the lift with your hand on the height position and remove the

thumb screw on the back of the appliance (A).

☞ Once the transportation lock has been removed, the lift moves

slowly to its upper end position. The distance is approx. 140 mm.

☞ Connect the device to the power supply (B) using the supplied

power cord (B).

Adjustable base (Fig. 4b)

☞ Then secure the rotation drive from being accidentally turned by

Heating bath HB 10 basic/digital

CAUTION! Refer to the chapter entitled "Commissioning" in the hea-

ting bath instruction manual!

☞ Place the heating bath on the stand of the rotation drive and push

drive on the right side of the lift by rotating the knurled screw

counter clockwise (by lightly pressing and turning at the same

time, the knurled screw comes out farther).

C

Fig. 7

tightening the knurled screw in a clockwise direction.

it into the left position (fig. 8).

Fig. 4b

☞ Attach the bracket for the Woulff bottle to the left side of the lift

(fig. 5).

Note: Data is exchanged between the drive unit and the heating

bath by means of an infrared link. Please note that reliable communication is only guaranteed when the infrared beam has clear

Fig. 5

☞ Insert the bottle and attach the supplied hose connectors to the

bottle (fig. 6).

line-of-sight to the detector.

Glassware

☞ Open the locking device on the drive head by turning it 60° coun-

Fig. 6

Fig. 8

ter clockwise (D), (fig. 9).

D

E

042009

Fig. 9

19

Page 5

☞ Feed the steam pipe in until it stops.

☞ Then lock the locking device by turning it clockwise by 60°

(fig. 10).

Prior to commissioning - Mounting the seal RV 06.15

☞

☞

☞

☞

E

Fig. 10

Insert vapour tube (1).

Insert seal RV 06.15 (2).

Mount the cooler (3a).

Tighten the cap nut hand-screwed. Start the device at 120 rpm for

20 minutes. Then tighten the cap nut firmly (3b)

3a

3b

.

2

1

☞ Check the axial locking device on the steam pipe.

Push-off mechanism

The plastic screw nut (E) helps loosen tight-fitting piston ground-in

connections (Fig. 10).

☞ The plastic screw nut (E) helps loosen tight-fitting piston ground-

in connections (Fig. 10).

☞ To do so, hold the tight-fitting evaporator piston and turn the pla-

stic screw nut (E) until the evaporator piston neck.

Note: Prior to commissioning, hand-tighten the plastic screw nut

Assembling the vertical glassware cooler locking device

☞ Assemble the condenser locking device according to the diagram

☞ Mount the plate (A) using the thumb screw (B).

☞ Put the support rod (C) on the plate (B) and attach it with the

☞ Attach the rubber protector (E).

☞ Fasten the Velcro band (F) to the support rod (C).

☞ Secure the vertical glassware with the Velcro band (F).

(E) left-aligned. This will hold the steam pipe locking device (D)

firmly in place.

Place the RV 06.15 or RV 06.13 condenser seal in the condenser

☞

receptacle and fit the glassware to the device according to the assembly instructions (Fig. 11 a,b and c).

(fig. 12).

screw nut (D).

C

D

Fig. 11c

FE

A

B

20

Fig. 11a

Fig. 12

Fig. 11b

042009

Page 6

Removing the condenser

☞ Use the ring spanner provided to loosen union nuts that are tightly

fitted.

☞ Loosen the union nut by turning anticlockwise.

Hose system

☞ Connect the water hoses to the condenser according to the coun-

ter-flow principle (fig. 14).

☞ Install the vacuum connections to the condenser, Woulff bottle,

vacuum controller with valve and vacuum pump.

☞ Always connect the vacuum hose to the condenser at the high-

test point to minimise solvent losses during suctioning.

☞ Use typical laboratory vacuum hoses with an inside diameter of

8 mm and a wall thickness of 5 mm (see accessories).

Fig.13

Description of special condensers

•

RV10.3 Vertical-intensive condenser with manifold

This vertical-intensive condenser features a double jacket design

for particularly efficient condensation.

Also available with coating (RV10.30)

•

RV10.4 Dry ice condenser

Dry ice condenser for distilling low-boiling solvents.

Cooling by dry ice, no cooling water required. Maximum condensation thanks to low temperatures.

Also available with coating (RV10.40)

Not suitable for use with the RV10 control in automatic mode.

•

RV10.5 Vertical-condenser with manifold and cut-off valve for

reflux distillation

Also available with coating (RV10.50)

•

RV10.6 Vertical-intensive condenser with manifold and cutoff valve for reflux distillation

This vertical-intensive action condenser features a double jacket

design for particularly efficient reflux distillation.

Also available with coating (RV10.60)

Fig.14

042009

21

Page 7

Interfaces and outputs

IR

Data transfer

HB 10 digital

The heating bath transfers data via IR interfaces. These are located

on the left display side of the heating bath or on the right side of the

drive unit. Do not place any objects between the two operating units

as otherwise the data transfer may be interrupted (fig. 15)!

RV10 digital

The RS 232 interface at the back of the device is fitted with a 9-pole

SUB-D jack and can be connected to a PC. The pins have serial signals. Using the laboratory device software “labworldsoft”, the device can be operated in “Remote” mode.

Note: Please note the system requirements as well as the operating

instructions and help section included with the software.

Serial interface RS 232 (V24)

Configuration

- The functions of the interface lines between the device and the

automation system are a selection from the signals specified in

the EIA standard RS232 C, as per DIN 66 020 Part 1.

- For the electrical characteristics of the interface and the allocation

of signal status, standard RS 232 C applies in accordance with DIN

66 259 part 1.

- Transmission procedure: asynchronous character transmission in

start-stop mode.

- Type of transmission: full duplex.

- Character format: character representation in accordance with data

format in DIN 66 022 for start-stop mode. 1 start bit; 7 character

bits; 1 parity bit (even); 1 stop bit.

- Transmission speed: 9600 bit/s.

- Data flow control: none

- Access procedure: data transfer from the device to the computer

takes place only at the computer’s request.

Command syntax and format

The following applies to the command set:

- Commands are generally sent from the computer (Master) to the

device (Slave).

- The stirrer machine sends only at the computer’s request. Even

fault indications cannot be sent spontaneously from the stirrer machine to the computer (automation system).

- Commands are transmitted in capital letters.

- Commands and parameters including successive parameters are

separated by at least one space (Code: hex 0x20).

Fig.15

- Each individual command (incl. parameters and data) and each re-

- The decimal separator in a number is a dot (Code: hex 0x2E).

The above details correspond as far as possible to the recommendations of the NAMUR working party (NAMUR recommendations for the design of electrical plug connections for analogue

and digital signal transmission on individual items of laboratory

control equipment, rev. 1.1.

The NAMUR commands and the additional specific

mands serve only as low level commands for communication

between the rotary evaporator and the PC. With a suitable terminal or communications programme these commands can be

transmitted directly to the rotary evaporator. The

package, labworld

rotary evaporator and collecting data under MS Windows, and

includes graphical entry features, for motor speed ramps for example.

The following table summarises the (NAMUR) commands understood by the

Abbreviations used

X,y = Numbering parameter (integer)

m = Variable value, integer

n = Variable value, floating-point number

X = 4 Speed

X = 60 Interval time (1-99 seconds, 1 <= m >=99)

X = 61 Timer (1-199 minutes, 1 <= m >=199)

X = 62 Direction of lift (m=2-> lift up , m=1-> lift down)

sponse are terminated with Blank CR Blank LF (Code: hex 0x20

hex 0x0d hex 0x20 hex 0x0A) and have a maximum length of 80

characters.

IKA

co m-

IKA

soft

, provides a convenient tool for controlling

IKA

control equipment.

NAMUR Function

Commands

IN_NAME Request designation

IN_PV_X Read actual value

X = 4

IN_SOFTWARE Request software Id-number,

IN_SP_X Read target value input

X = 4

OUT_SP_X m Set target value to m

X = 1,60,61,62

RESET Switch to normal operation

START_X Switch on appliance (remote) function

X = 4,60,61,62

STATUS Status output

STOP_X Switch off appliance function. The variable

X = 1,60, 61, 62 set with OUT_SP_X remains.

date and version

0:Manual operation without interruption

1:automatic operation Start

(without interruption)

ERROR z (z error number see table)

software

PC 1.1 Cable (Fig. 16)

This cable is required to connect the 9-pin connector to a PC.

22

Fig. 16

042009

Page 8

Commissioning

The unit is ready for service when the

mains plug has been plugged in.

On/Off switch

☞ Switch on the device on the right side of the device.

☞ Device functions activated.

Function keys

•

“Power” key (1)

☞ Press the "Power" key once

☞ “Stand-by” mode

☞ Press the "Power" key again

☞ Device functions reactivated

“Software version” display changes to "Parameter” display.

Note: The device must first be switched on at the on/off switch on

the right side of the device.

Note: The device is not dead or deenergised until the on/off switch

has been switched to off (right side of device)!

•

Lift position key “L“ (2)

☞

When you press the

When you release the

☞

that position.

•

Lift position key “M“ (3)

☞

When you press the

When you release the

☞

that position.

•

Rotating knob (4)

Setting the speed

☞ Turn the rotating knob

☞ Speed setting accuracy: +

Speed range 20-270 rpm

Note: When you select the speed > 100 rpm, smooth start is automatically activated.

Start / Stop Rotation drive

☞ Press the rotating knob

☞ Rotation drive starts

☞ Press the rotating knob again

☞ Rotation drive stops

•

Timer key (5)

☞ Press the “Timer” key.

☞ The timer block appears on the display, the “TIMER” indicator

flashes.

☞ Set the target value “Timer” on the knob by turning (1 to 199 mi-

nutes).

☞ Save the “Timer” target value by pressing the "Timer" key again.

☞ Starting the “Timer” function:

- Automatic when rotation drive is running,

- Start the rotation drive.

Note: Once the timer has run out, there is a beep, the rotation finishes and the lift goes up.

☞ The previously saved value appears on the display.

☞ Deactivate the timer by setting the target value to “0”.

(Fig. 17)

(see page 4)

Fig.17

“L”key, the lift goes up.

“L” key, the lift stops and remains in

“M“key, the lift goes down.

“M“ key, the lift stops and remains in

5 rpm,

☞ Set the target value “Int” on the knob by turning (1 to 60 minu-

☞ Starting the “Int” function

Note: In interval mode the maximum speed is limited to 200 rpm.

☞ Save the “Int” target value by pressing the "Int" key again.

☞ Deactivate the interval by setting the target value to “0”.

Display

•

(only for RV 10 digital)

Remote control via PC in connection with software “labworldsoft”

is active.

•

Current target and actual speed indicator in revolutions per minute

[rpm]. When the device is switched on the most recently selected

target value "speed" appears.

•

Rotation drive active.

•

Time lapse control active.

Indication of remaining distillation time in minutes [min].

Note: With the software "labworldsoft", RV 10 digital can also switch

off the heating bath once the timer has run out.

•

Interval mode activated.

•

--- not pictured --Error codes, see chapter entitled "Error Codes”.

Setting the lower end stop

CAUTION! Depending on the size of the piston, the setting angle of

the rotation drive and the position of the heating bath and lift, the

evaporator piston can be in contact with the bottom of the heating

bath. CAUTION - glass may break!

Limit the lower lift position with the variable end stop.

☞ Press the “M” key until the lift reaches the desired position.

Note: The evaporator piston should be 2/3 immersed in the heating

bath.

☞ To adjust the stop element, press the centre button on the front

☞ Move the stop to the desired position (fig. 19).

☞ Press the “L” key until the lift has reached the upper end stop.

Note: The path is limited from 0 – 6 cm.

tes).

- Automatic when rotation drive is running

- Start the rotation drive

(see page 4)

Display “REMOTE” (10)

Display “888 rpm” (20)

Display (30)

Display “TIMER” (40)

Display “INT” (50)

Display “E01” (20)

of the lift (fig. 18).

B

A

Fig.18

•

Int key (6)

Interval cycle for right-left running (change of direction) of the evaporator piston in seconds.

☞ Press the “Int” key.

☞ The interval block appears on the display, the “INT” indicator flashes.

042009

23

Page 9

Setting up the heating bath

Refer also to the operating instructions for the HB 10 basic /di-

gital heating bath!

☞ Move the lift to the bottom position and check the position of the

☞ Fill the heating bath with the tempering medium until the evapo-

☞ Switch on the rotation drive and slowly increase the speed.

Note: Avoid creating waves.

☞ Switch on the heating bath using the main on/off switch.

Note: Avoid stress on the glass due to different evaporator piston

Fig.19

Check that the limit stop is functioning properly:

☞ Lower the lift by holding down the “M” key.

☞ The drive stops automatically when the preset desired lower end

position has been reached.

☞ Move the drive back to the upper position.

Filling the evaporator piston

Prior to filling the evaporator piston, a vacuum controller is used to regulate the glass apparatus to the target pressure.

☞ Now fill the evaporator piston using the backfeed line.

☞ Due to the vacuum present, the solvent is suctioned into the eva-

porator piston. This enables you to keep solvent loss due to suctioning to a minimum.

☞ You can also fill the evaporator piston manually prior to creating

the vacuum. The evaporator piston should not be filled more than

half its volume.

Note: CAUTION! The maximum allowed load (evaporator piston

and contents) is 3 kg.

and heating bath temperatures when lowering the evaporator piston into the heating bath!

Note: If non-original accessories are used that are not supplied by

IKA, then it is possible that the 50 mm travel range provided by the

heating bath will not be sufficient. This applies in particular when

using 3 L evaporator flasks with foam brake.

Use the IKA RV 10.3000 mounting plate to extend the heating bath

travel range by 150 mm.

heating bath in relation to the evaporator piston. When using larger evaporator pistons (2 or 3 litres) or depending on the angle of

the rotation drive, you can move the heating bath 50 mm to the

right.

rator piston is surrounded by tempering medium to 2/3 of its volume.

Fig. 20

Maintenance and cleaning

The device is maintenance-free. It is subject only to the natural

wear and tear of components and their statistical failure rate.

The seal on the glass condenser should be checked at regular intervals and replaced if necessary.

For cleaning disconnect the main plug.

To clean the device use only water with a detergent that contains

tensides, or use isopropylalcohol for stubborn soiling.

24

parts order

Spare

When ordering spare parts, please give:

- machine type,

- manufacturing number, see type plate,

- item and designation of the spare part, see www.ika.net, spare

parts diagram and spare parts list.

Repair

In case of repair the device has to be cleaned and free from any ma-

terials which may constitute a health hazard.

If you require servicing, return the appliance in its original packaging.

Storage packaging is not sufficient. Please also use suitable transport packaging.

042009

Page 10

Accessories

1

RV 10.1 NS 29/32 Vertical glassware (1)

RV 10.10 NS 29/32 Vertical glassware, coated (1)

RV 10.2 NS 29/32 Diagonal glassware (2)

RV 10.20 NS 29/32 Diagonal glassware, coated (2)

RV 10.700 NS 29/42 Vertical glassware (1)

RV 10.710 NS 29/42 Vertical glassware, coated (1)

RV 10.800 NS 29/42 Diagonal glassware (2)

RV 10.810 NS 29/42 Diagonal glassware, coated (2)

RV 10.900 NS 24/40 Vertical glassware (1)

RV 10.910 NS 24/40 Vertical glassware, coated (1)

2

RV 10.1000 NS 24/40 Diagonal glassware (2)

RV 10.1010 NS 24/40 Diagonal glassware, coated (2)

RV 10.3 Vertical-intensive condenser with manifold

RV 10.30 Vertical-intensive condenser with manifold, coated

RV 10.4 Dry ice condenser

RV 10.40 Dry ice condenser, coated

RV 10.5 Vertical-condenser with manifold and cut-off valve

for reflux distillation

RV 10.50 Vertical-condenser with manifold and cut-off valve

21

3

for reflux distillation, coated

RV 10.6 Vertical-intensive condenser with manifold and cut-off valve

for reflux distillation

RV 10.60 Vertical-intensive condenser with manifold and cut-off valve

for reflux distillation, coated

HB 10.1 Protection shield (Heating bath HB 10)

HB 10.2 Protection cover (Heating bath HB 10)

1

2

RV 10.70 NS 29/32 Steam pipe

RV 10.71 NS 24/29 Steam pipe

RV 10.72 NS 29/42 Steam pipe

RV 10.73 NS 24/40 Steam pipe

RV 10.80 NS 29/32 Evaporator piston 50 ml

RV 10.81 NS 29/32 Evaporator piston 100 ml

RV 10.82 NS 29/32 Evaporator piston 250 ml

RV 10.83 NS 29/32 Evaporator piston 500 ml

RV 10.84 NS 29/32 Evaporator piston 1000 ml

RV 10.85 NS 29/32 Evaporator piston 2000 ml

RV 10.86 NS 29/32 Evaporator piston 3000 ml

RV 10.90 NS 24/32 Evaporator piston 50 ml

RV 10.91 NS 24/32 Evaporator piston 100 ml

RV 10.92 NS 24/32 Evaporator piston 250 ml

RV 10.93 NS 24/32 Evaporator piston 500 ml

RV 10.94 NS 24/32 Evaporator piston 1000 ml

RV 10.95 NS 24/32 Evaporator piston 2000 ml

RV 10.96 NS 24/32 Evaporator piston 3000 ml

RV 10.97 NS 24/40 Evaporator piston 1000 ml

RV 10.2001 NS 29/42 Evaporator piston 50 ml

RV 10.2002 NS 29/42 Evaporator piston 100 ml

RV 10.2003 NS 29/42 Evaporator piston 250 ml

RV 10.2004 NS 29/42 Evaporator piston 500 ml

RV 10.87 NS 29/42 Evaporator piston 1000 ml

RV 10.2005 NS 29/42 Evaporator piston 2000 ml

RV 10.2006 NS 29/42 Evaporator piston 3000 ml

RV 10.2007 NS 24/40 Evaporator piston 50 ml

RV 10.2008 NS 24/40 Evaporator piston 100 ml

RV 10.2009 NS 24/40 Evaporator piston 250 ml

RV 10.2010 NS 24/40 Evaporator piston 500 ml

RV 10.2011 NS 24/40 Evaporator piston 1000 ml

RV 10.2012 NS 24/40 Evaporator piston 2000 ml

RV 10.2013 NS 24/40 Evaporator piston 3000 ml

RV 10.100 KS 35/20 Receiving flask 100 ml

RV 10.101 KS 35/20 Receiving flask 250 ml

RV 10.102 KS 35/20 Receiving flask 500 ml

RV 10.103 KS 35/20 Receiving flask 1000 ml

RV 10.104 KS 35/20 Receiving flask 2000 ml

RV 10.105 KS 35/20 Receiving flask 3000 ml

042009

25

Page 11

RV 10.200 KS 35/20 Receiving flask, coated 100 ml

RV 10.201 KS 35/20 Receiving flask, coated 250 m

RV 10.202 KS 35/20 Receiving flask, coated 500 ml

RV 10.203 KS 35/20 Receiving flask, coated 1000 ml

RV 10.204 KS 35/20 Receiving flask, coated 2000 ml

RV 10.205 KS 35/20 Receiving flask, coated 3000 ml

RV10.300 NS 29/32 Powder piston 500 ml

RV10.301 NS 29/32 Powder piston 1000 ml

RV10.302 NS 29/32 Powder piston 2000 ml

RV10.303 NS 24/29 Powder piston 500 ml

RV10.304 NS 24/29 Powder piston 1000 ml

RV10.305 NS 24/29 Powder piston 2000 ml

RV10.2014 NS 29/32 Powder piston 500 ml

RV10.2015 NS 29/32 Powder piston 1000 ml

RV10.2016 NS 29/32 Powder piston 2000 ml

RV10.217 NS 24/40 Powder piston 500 ml

RV10.218 NS 24/40 Powder piston 1000 ml

RV10.219 NS 24/40 Powder piston 2000 ml

RV10.400 NS 29/32 Evaporator cylinder 500 ml

RV10.401 NS 29/32 Evaporator cylinder 1500 ml

RV10.402 NS 24/29 Evaporator cylinder 500 ml

RV10.403 NS 24/29 Evaporator cylinder 1500 ml

RV10.2020 NS 29/42 Evaporator cylinder 500 ml

RV10.2021 NS 29/42 Evaporator cylinder 1500 ml

RV10.2022 NS 24/40 Evaporator cylinder 500 ml

RV10.2023 NS 24/40 Evaporator cylinder 1500 ml

RV10.500 NS 29/32 Foam brake

RV10.501 NS 24/29 Foam brake

RV10.2024 NS 29/42 Foam brake

RV10.2025 NS 24/40 Foam brake

RV10.600 NS 29/32 Distillation spider with 6 sleeves

RV10.601 NS 29/32 Distillation spider with 12 sleeves

RV10.602 NS 29/32 Distillation spider with 20 sleeves

RV10.603 NS 24/29 Distillation spider with 6 sleeves

RV10.604 NS 24/29 Distillation spider with 12 sleeves

RV10.605 NS 24/29 Distillation spider with 20 sleeves

RV10.2026 NS 29/42 Distillation spider with 6 sleeves

RV10.2027 NS 29/42 Distillation spider with 12 sleeves

RV10.2028 NS 29/42 Distillation spider with 20 sleeves

RV10.2029 NS 24/40 Distillation spider with 6 sleeves

RV10.2030 NS 24/40 Distillation spider with 12 sleeves

RV10.2031 NS 24/40 Distillation spider with 20 sleeves

RV10.610 Distilling sleeve 20 ml

RV10.606 NS 29/32 Distillation spider with 5 flasks 50 ml

RV10.607 NS 29/32 Distillation spider with 5 flasks 100 ml

RV10.608 NS 24/29 Distillation spider with 5 flasks 50 ml

RV10.609 NS 24/29 Distillation spider with 5 flasks 100 ml

RV10.2032 NS 29/42 Distillation spider with 5 flasks 50 ml

RV10.2033 NS 29/42 Distillation spider with 5 flasks 100 ml

RV10.2034 NS 24/40 Distillation spider with 5 flasks 50 ml

RV10.2035 NS 24/40 Distillation spider with 5 flasks 100 ml

RV10.3000 Extension plate

1

2

26

RV06.13 FKM seal with PTFE-coating (1)

RV06.15 PTFE seal (2)

PC 1.1 Cable

Labworldsoft

®

042009

Page 12

Error codes

Any malfunctions during operation will be identified by an error message on the display (only for RV 10 digital).

Once a serious error message has been displayed, the lift moves to the top end position and the device can no longer be operated. The lift can

be operated again.

Proceed as follows in such cases:

☞ Switch off device using the main switch (A)

☞ Carry out corrective measures

☞ Restart device

Error code Effect Cause Correction

E01 No or too little rotation - Cable break Reduce the volume in the evaporator piston

E02 No communication with the heating bath Interface hidden or dirty Check / clean the interface

If the actions described fail to resolve the fault or another error code is displayed then take one of the following steps:

- Contact the service department,

- Send the device for repair, including a short description of the fault.

- Load too large

- Motor blocked

Technical Data

Operating voltage range Vac 100 - 230 +

Rated voltage Vac 100 - 230

Frequence Hz 50 / 60

Power input without heating bath

Power input in operation “stand by”

Speed rpm 20-270

Speed display digital

Dimensions of visible display area (W x H) mm 48 x 35

Display 7 segment display

Multiple languages Right and left movement/ interval operation yes

Smooth start ja

Lift automatic

Lifting speed mm/s 50

Stroke mm 140

Setting of lower end stop 60 mm, contactless

Head angle adjustable 0° - 45°

Timer 1-199 Minuten

Interval 1-60 sec

Integrated vacuum controller Interface

Ramp programming

Distillation processes programmable - with accessory labworldsoft

Remote control

Cooling surface cm

Fuse 2xT1, 6A 250V 5x20

Perm. On- time % 100

Perm. ambient temperature °C 5-40

Perm. humidity % 80

Protection acc. to DIN EN 60529 IP 20

Protection class I

Overvoltage category II

Contamination level 2

Weight (no glassware; no heating bath)

Dimensions(W x D x H

Operation at a terrestrial altitude m max. 2000 above sea level

)

W75

W 3,3

2

kg 16,8 17,5

mm 500 x 410 x 430

RV 10 basic RV 10 digital

10%

- RS 232

- with accessory labworldsoft

- with accessory labworldsoft

1200

Subject to technical changes!

042009

27

Page 13

Solvent table (excerpt)

Solvent Formula Pressure for

Acetic acid C2H4O

Acetone C3H6O 556

Acetonitrile C2H3N 226

N-Amylalcohol, C5H12O11

n-Pentanol

n-Butanol C4H

tert. Butanol, C4H10O 130

2-Methyl-2-Propanol

Butylacetate C6H12O

Chlorobenzene C6H5CI 36

Chloroform CHCI

Cyclohexane C6H

Dichloromethane, CH2CI

Methylenechloride

Diethylether C4H10O atm.press.

1,2,-Dichloroethylene (trans) C2H2CI

Diisopropylether C6H14O 375

Dioxane C4H8O

Dimethylformamide (DMF) C3H7NO 11

Ethanol C2H6O 175

2

10

2

3

12

2

2

2

boiling point

40 °C in mbar

44

25

39

474

235

atm.press.

751

107

Ethylacetate C4H8O

Ethylmethylketone C4H8O

Heptane C7H

Hexane C6H

Isopropylalcohol C3H8O 137

Isoamylalcohol, C5H12O14

3-Methyl-1-Butanol

Methanol CH4O 337

Pentane C5H

n-Propylalcohol C3H8O67

Pentachloroethane C2HCI

1,1,2,2,-Tetrachloroethane C2H2CI

1,1,1,-Trichloroethane C2H3CI

Tetrachloroethylene C2CI

Tetrachloromethane CCI

Tetrahydrofurane (THF) C4H8O 357

Toluene C7H

Trichloroethylene C2HCI

Water H2O72

Xylene C8H

Warranty

In accordance with IKA warranty conditions, the warranty period is

24 months. For claims under the warranty please contact your local

dealer. You may also send the machine direct to our factory, enclosing the delivery invoice and giving reasons for the claim. You will

be liable for freight costs.

The warranty does not cover worn out parts, nor does it apply to

faults resulting from improper use, insufficient care or maintenance

not carried out in accordance with the instructions in this operating

manual.

2

16

14

12

5

4

3

4

4

8

3

10

240

243

120

335

atm.press.

13

35

300

53

271

77

183

25

28

042009

Loading...

Loading...