IKA Rotavisc lo-vi, Rotavisc me-vi, Rotavisc hi-vi I, Rotavisc hi-vi II Operating Instructions Manual

Page 1

20000009673

Rotavisc lo-vi_me-vi_hi-vi I_hi-vi II_042018

IKA Rotavisc lo-vi

IKA

IKA

IKA

Rotavisc me-vi

Rotavisc hi-vi I

Rotavisc hi-vi II

Page 2

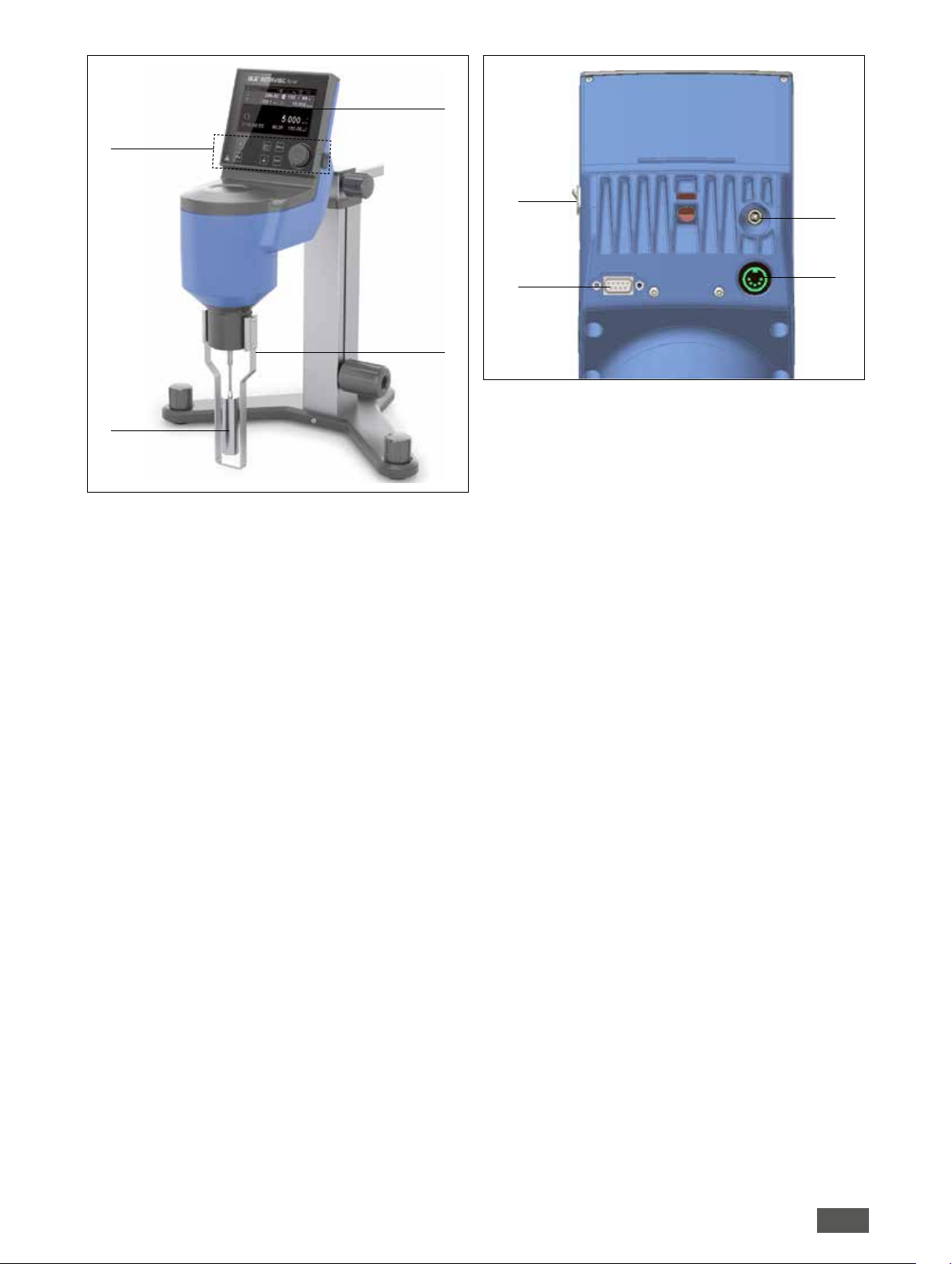

Fig. 1

1

Fig. 2

4

5

8

6

3

1 Control panel

2

2 Spindle

3 Guard rail

4 Display

5 USB interface

6 RS 232 interface

7 Connection socket for temperature sensor

8 Connection socket for power cord

7

2

Page 3

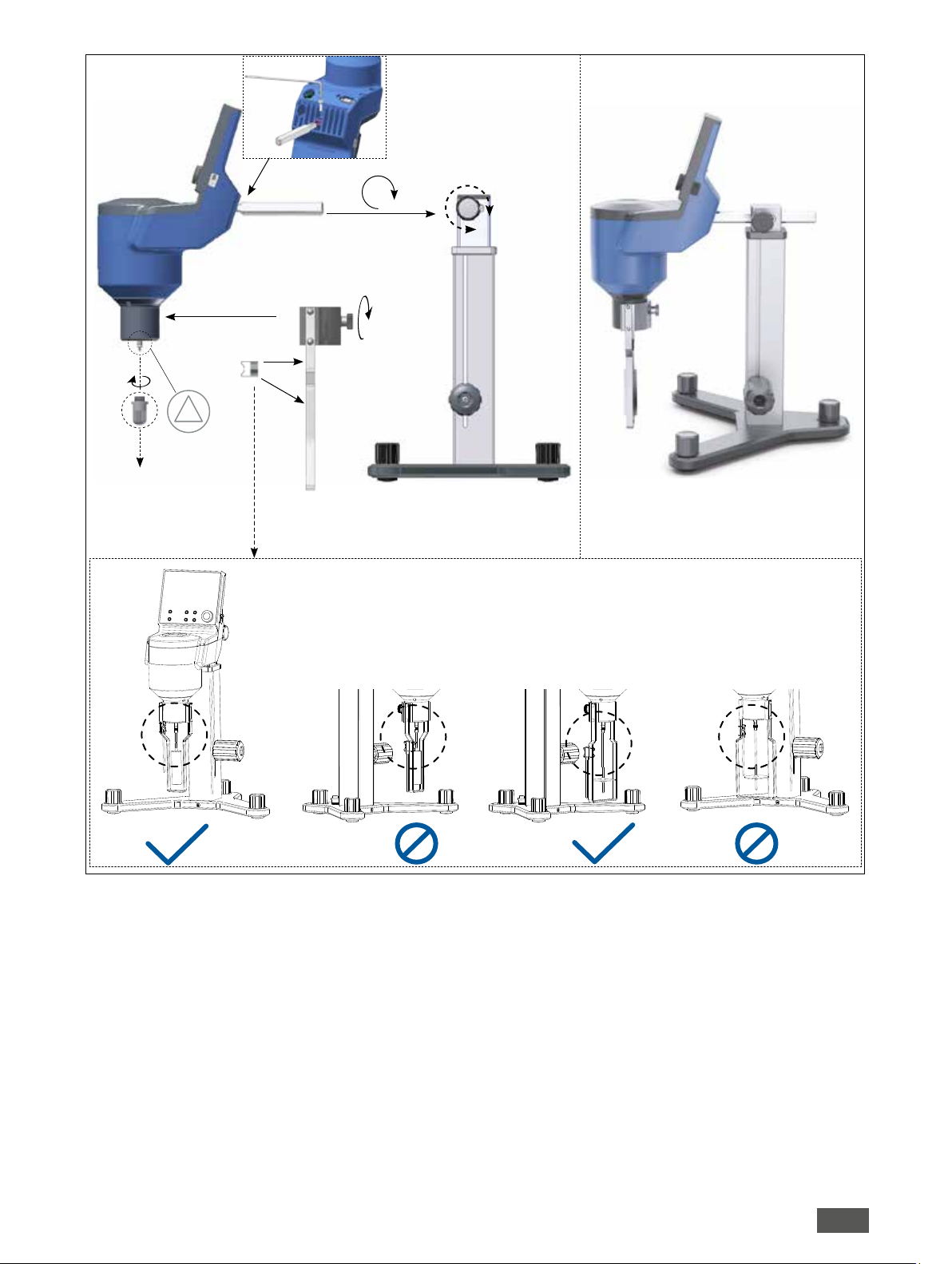

Fig. 3

lo-vi

!

me-vi

lo-vi

lo-vi me-vi me-vi

3

Page 4

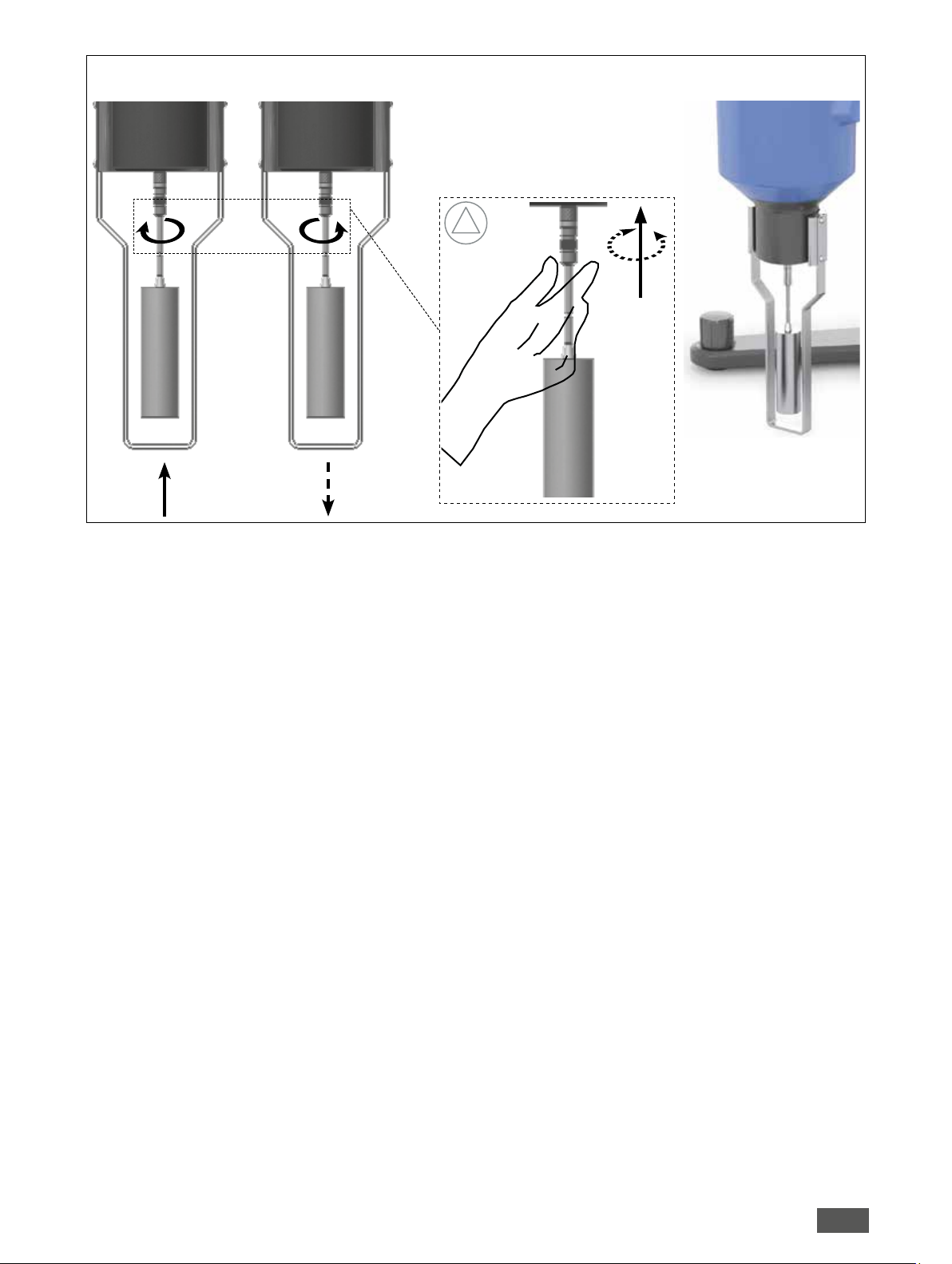

Fig. 4

!

4

Page 5

Source language: German

Contents

Page

Declaration of conformity 5

Safety instructions 5

Correct use 6

Unpacking 7

Mounting 7

Switching on the device 8

Useful information 9

Operation 10

Interfaces and outputs 16

Declaration of conformity

EN

Maintenance and cleaning 17

Accessories 17

Error message 17

Warranty 18

Technical data 18

Appendix A “Range coecient“ 19

Appendix B “ASTM specifications“ 21

We declare under our sole responsibility that this product corresponds to the regulations 2014/35/EU, 2006/42/EC, 2014/30/EU and

2011/65/EU and conforms with the standards or standardized documents: EN 61010-1 and EN 61326-1.

A copy of the complete EU Declaration of Conformity can be requested at sales@ika.com.

Safety instructions

Explication of warning symbols

Indicates an (extremely) hazardous situation, which, if not avoided, will result in death, serious injury.

Indicates a hazardous situation, which, if not avoided, can result in death, serious injury.

Indicates a potentially hazardous situation, which, if not avoided, can result in injury.

Indicates practices which, if not avoided, can result in equipment damage.

!

General information

Read the operating instructions completely before starting up and follow the safety instructions.

Keep the operating instructions in a place where it can be accessed by everyone.

Ensure that only trained staff work with the device.

Follow the safety instructions, guidelines, occupational health, safety and accident prevention regulations.

The viscometer is designed to to be operated indoors!

Device configuration

Set up the stand in a spacious area on an even, stable, clean, non-slip, dry and fireproof surface.

5

Page 6

Work with the device

Danger! ( )

› Wear your personal protective equipment in accordance with the hazard category of the medium to be processed, otherwise there

is a risk of:

- splashing of liquids

- projectile parts

- body parts, hair, clothing and jewelry getting caught.

› Do not operate the device in explosive atmospheres, with hazardous substances or under water.

Warning! (

› There may be electrostatic activity between the medium and the spindle which could cause a direct danger.

Caution! (

› The user should ensure that the substances under testing do not release poisonous, toxic or flammable gases at the temperatures

)

)

which they are subjected to during the testing.

› Protect the device and accessories from bumping and impacting.

Note! ( )

› Covering or parts that are capable of being removed from the unit without accessory reattached to the unit for safe operation in

order to prevent, for example, the ingress of fluids, foreign matter, etc.

› The spindle connector (left-hand thread M2.5 LH) is a sensitive coupling! No impact force action is allowed!

› Always hold the spindle connector by hand while attaching or loosening the measurment spindle, otherwise it will damage the pivot

and the jewel bearing inside the viscometer.

Do not put the viscometer in direct contact with sunlight or in the middle of any air flow (the temperature of the sample can be easily

influenced by the surrounding conditions).

Check the device and accessories for damage before each use. Do not use damaged components.

Only process media that will not react dangerously to the extra energy produced through processing. This also applies to any extra

energy produced in other ways, e.g. through light irradiation.

Process pathogenic materials only in closed vessels under a suitable fume hood.

If this device is used in a manner not specified by the manufacturer, the protection provided by the device may be impaired.

Do not use the device for any other purpose that is not described in this manual.

Accessories

Safe operation is only guaranteed with the accessories described in the ”Accessories” section.

Always disconnect the device from the mains supply before fitting accessories.

Observe the operating instructions of the accessories.

Power supply/Switching off the device

The device can only be disconnected from the mains supply by pulling out the mains plug or the connector plug.

The socket for the mains cord must be easily accessible.

The voltage stated on the type plate must correspond to the mains voltage.

Maintenance

Warning! ( )

› The machine must only be opened by trained specialists, even during repair. The device must be unplugged from the power supply

before opening. Live parts inside the device may still be live for some time after unplugging from the power supply.

Correct use

Use

The IKA Rotavisc must be used in conjunction with the IKA Rotastand to measure the viscosity of a fluid at the given temperature

and shear rate. The viscosity is a measure of resistance against the

fluid to flow.

Intended use: Stand device

Area of use (only indoors)

- Laboratories - Schools

- Pharmacies - Universities

The device is suitable for use in residential areas and all other areas

The safety of the user cannot be guaranteed:

- If the device is operated with accessories that are not supplied or

recommended by the manufacturer;

- If the device is operated improperly or contrary to the manufacturer’s specifications;

-

If the device or the printed circuit board are modified by the third

parties.

.

6

Page 7

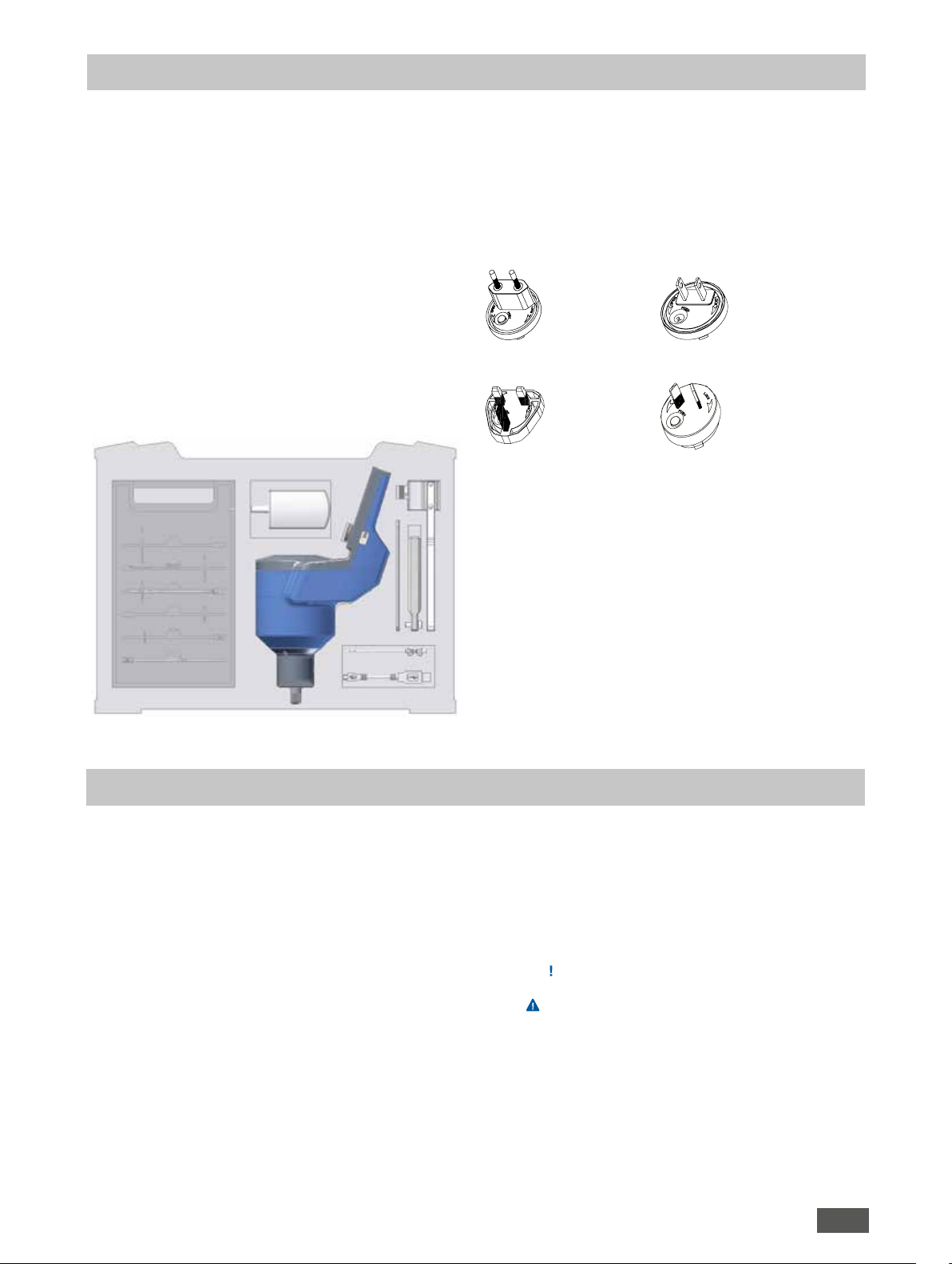

Unpacking

Unpacking

- Unpack the device carefully.

- Any damage should be notified immediately to the shipping

agent (post, rail or logistics company).

Delivery scope

Rotavisc (lo-vi/me-vi/hi-vi I/hi-vi II)

Spindle series lo-vi or me-vi

Temperature probe PT 100

PT 100 clamper

USB cable A – micro B 2.0.

Guard rail

Rod

Wrench

AC/DC adapter

Carrying case

- Operating instructions

- Warranty card

AC/DC adapter (

Adapter

Europe, Switzerland

Adapter

England

):

Adapter

USA, China

Adapter

Australia

Mounting

Secure the rod to the viscometer (see , Fig. 3 )

• Insert the rod to the viscometer and secure it by turning the

screw clockwise to the end position.

Secure the viscometer to the stand (see

• Insert the viscometer to the stand and fasten it by turning the

knob clockwise to the end position.

Secure the guard rail to the viscometer (see

• Place the guard rail on the viscometer and secure it by turning

the screw clockwise to the end position.

• Insert the PT 100 into the clamper. Mount the PT 100 with clam-

per onto the guard rail. For lo-vi rail, clamp at the upper portion,

while for me-vi rail, at the lower portion.

Remove the protection cap from the viscometer (see ,

Fig. 3)

• The protection cap protects the spindle connector from bump-

ing and impacting.

• Besides, the protection cap lifts the inside pivot up from the

, Fig. 3)

, Fig. 3)

jewel bearing when it is tightened to the end position, which

is also a good way to protect the jewel bearing from damage

during transportation.

• Remove the protection cap from the viscometer by carefully

turning it counterclockwise, and then place it in the hole of the

bottom plate .

Attach the spindle to the viscometer (see Fig. 4)

Caution! (

Protect the device and accessories from bumping and impacting.

Note! ( )

The spindle connector (left-hand thread M2.5 LH) is a sensitive coupling! No impact force action is allowed!

Always hold the spindle connector by hand while attaching or

loosening the measurment spindle, otherwise it will damage the

pivot and the jewel bearing inside the viscometer.

• With one hand, hold the spindle connector of the viscometer.

• With the other hand, insert the spindle into the spindle connector and turn the spindle counterclockwise to attach it to the

viscometer. To detach, turn it clockwise.

)

7

Page 8

Switching on the device

Check that the power supply matches the data on the rating plate.

Plug the AC adapter into a standard mains socket in order to supply the device with power.

Introduction

After switching on the viscometer, the information screen is displayed for 4-5 seconds, showing the device name, software version and series of the viscometer.

To cover a wide range of viscosity, 4 different types of devices are

available.

Depending on the used measurment spindle and the selected

speed, the viscosity range of the specific type varies, which you

may find it via:

lo-vi = low viscosity

me-vi = medium viscosity

hi-vi I = high viscosity I

hi-vi II = high viscosity II

Firmware update screen

The “Firmware update screen“ screen will be shown for 5 seconds.

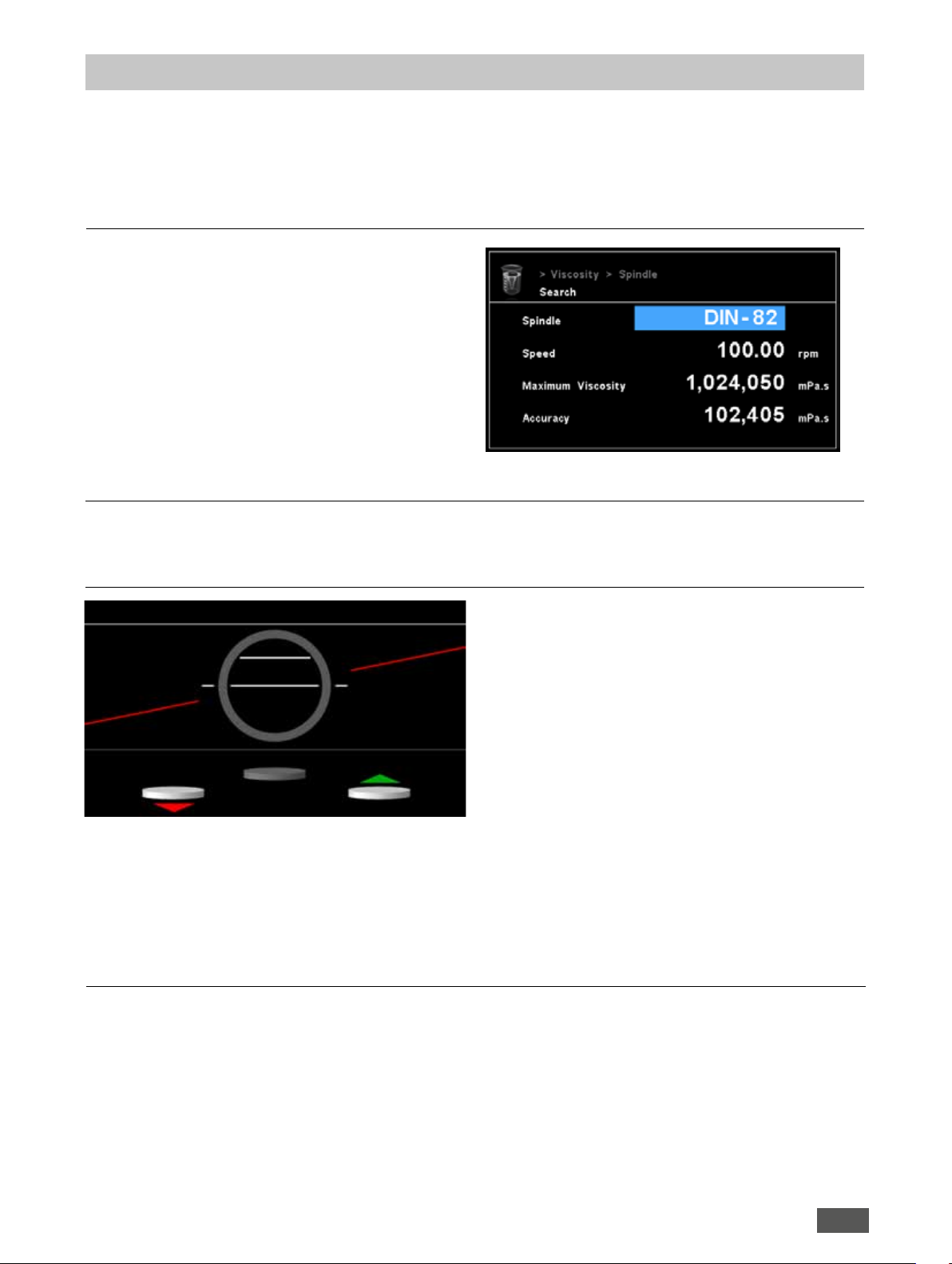

Level meter

Menu -> Viscosity -> Spindle -> Search

Observe the connection values and the ambient conditions (temperature, humidity, etc.) listed under “Technical data”.

Once these conditions are satisfied, and the mains plug has been

plugged in, the device is ready to operate.

Note: Firmware update screen can be modified by:

Menu -> Settings -> Display -> Firmware update screen

There are two moving lines:

• The red angular line pivoting around the center of the circle,

represents the rotation of the device around the X-axis. When

the line is horizontal (matching the white line), the device will be

in balance with the X-axis, and then the line color will turn from

red to green.

Device self checking

• Remove the spindle Press the knob

During this period, the spindle icon will move from the top to

the bottom.

Note: Remove the protection cap from the device.

Remove the spindle from the device.

• Device self checking...

During this period, the spindle icon will rotate.

• The small horizontal white line inside the circle, is moving vertically and it represents the rotation around the Y-axis. When it

matches the white line, the device will be in balance with the

Y-axis, then the line color will turn from white to green.

The three buttons represent the three stand levelers. The arrows

show in which direction they have to be adjusted (green = up;

red = down).

The adjustment steps are as follows:

• It is recommended that you adjust the X-axis first and the Y-axis

afterwards.

• After successfully aligning the X-axis, you can adjust the Y-axis.

If the X-axis gets out of balance while adjusting the Y-axis, go

back to the previous step.

• As soon as the small horizontal red line inside the circle matches

the center line, all the lines will turn green.

Always two possibilities of knob adjusting are shown, because the

knob position could be already at the limit.

When X-axis and Y-axis are both centered, the device is leveled.

Press the knob to confirm OK.

• Device self checking is done. After this step, the screen will

switch to the main screen.

Note: Device self checking will take approx. 30 seconds.

8

Page 9

Measurement principle

Useful information

The measuring principle of IKA Rotavisc is to use the stepping motor to drive a measuring spindle (which is immersed in the test fluid)

through a linearity calibrated spring sensor. The viscous resistance of

the fluid against the spindle is detected by the spring deflection. The

spring deflection is measured with a rotary transducer. The measurement range of IKA Rotavisc is determined by the spring, the spindle

and the speed. Please refer to Appendix B for “Range coefficient”.

There are four basic spring torque series offered by IKA:

Notes

• The viscosity is shown in units of centipoise (shown as “cP”) or

milliPascal-seconds (shown as“mPa•s“).

• The shear stress is shown in units of dynes/square centimeter (“D/

2

cm

”) or Newton/square meter (“N/m2”).

• The shear rate is shown in units of reciprocal seconds (“1/s”).

• The torque is shown in units of dyne-centimeters or Newton-meters.

• The torque percentage is shown as “xx.x %”.

The equivalent units of measurement in the CGS system are calculated using the following conversions:

Torque

Spindle

dyne•cm mNm

lo-vi 673.7 0.0673

me-vi 7187.0 0.7187

hi-vi I 14374.0 1.4374

hi-vi II 57496.0 5.7496

The device measurement range depends on the calibrated torque,

the higher torque means the wider range. All units of measurement

are displayed to either the CGS system or the SI system, which you

can choose via the menu.

SI CGS

Viscosity: 1 mPa•s = 1 cP

Shear stress: 1 Newton/m

2

= 10 Dyne/cm

2

Torque: 1 Newton-m = 107 dyne-cm

References to viscosity throughout this manual are done in SI units.

The IKA Rotavisc provides equivalent information in CGS units.

Base for reliable viscosity measurements is laminar flow! If the measurement spindle turns too fast, turbulence occurs. The result is not

valid.

Always consider a shown torque >10% and less 90%. Smaller and

bigger values will also show non valid viscosity values too.

Effect on accuracy when using accessory devices

The IKA Rotavisc has a stated accuracy of ±1 % of the full scale range

in use. This stated accuracy applies when the viscometer is used in

accordance with the operating instructions and the calibration test

fluid is used in accordance with the instructions provided by the fluid

supplier (including the critical parameters of temperature control and

stated fluid accuracy). IKA’s accuracy statement of ±1 % of the range in use applies to the IKA Rotavisc when used with the standard

spindles supplied with the device in a 600 ml Grin beaker.

IKA offers a range of accessories for use with the IKA Rotavisc to accommodate special measurement circumstances. These accessories,

while offering added capability to you, also contribute to an expanded measurement tolerance beyond the device accuracy of ±1 % of

Guard rail

IKA provides an lo-vi guard rail for lo-vi device and an me-vi guard rail

for me-vi/hi-vi I/hi-vi II devices.

The spindle guard rail protects the spindle from damage and provide

a higher accurancy.

the range in use. This expanded measurement tolerance is a function

of many parameters including spindle geometry, accessory alignment

accuracy, sample volume requirement, and sample introduction techniques. The effect of these elements on measurement tolerance must

be considered when verifying the calibration of your IKA Rotavisc.

Sample temperature in all test circumstances is very important, and

will also add an additional expanded tolerance depending on the

temperature control system and the calibration verification tests begin with the standard viscometer spindles as detailed above.

Viscosity calibration fluids often show an accuracy of ±1% of the nominal volume!

Sample container size

For measurements with standard viscometer models we recommend

a container with an inside diameter of no less than 83 mm. The usual

vessel for this purpose is a 600 ml Grin beaker. Using a smaller container will result in an increase in viscosity readings.

lo-vi

me-vi

9

Page 10

Control panel

A

CB D E F G H

Explanation of symbols on the working screen

Operation

Item Designation Function

A Standby LED Power supply connected.

B “Power” key Power on/off.

C ”Lock” key Enable or disable other keys and the knob function.

D “Graph” key Go to the graph option.

E “Spindle” key Go to select the spindle.

F “Back” key Return to the previous menu level.

G “Menu” key Press it once: main menu is displayed

Press it a second time: back to the working screen

H Rotary/push knob Stop/start the motor during measurements by

pushing the knob;

Change the speed by rotating the knob;

Change the spindle by rotating the knob when the

”Spindle” key is pressed first.

Symbol Description

Ramp controlled

or

PC controlled

Symbol Description

Text next to the profile icons indicates the active profile

Accuracy mode

Level broken

By pressing the ”Lock” key on the control panel, the

”Lock” key icon will be displayed on the main screen

and only the “Power” key is operational. Other keys

or encoder will not be operational

By pressing the ”Lock” key again, the ”Lock” key icon

will disappear from the main screen and all the keys

will be operational

Navigation menu

Communication via USB

User selected spindle

Function “Stop condition”

Shear stress

Shear rate

Temperature value

Density value

Rotation activated

Timer activated

- - - Torque out of measurement range, you need to decrease speed or choose a smaller measuring spindle

• Press the “Menu” key.

• Select the desired menu or sub-menu by turning the rotary/push knob and confirm

by pushing it.

• Press or turn the rotary/push knob again to select the desired menu option and

edit the values or settings, or activate/deactivate a function.

• Turn the rotary/push knob to OK or press the “Back” key or “Menu” key to end the

procedure and return to the previous menu.

Note: The menu option activated is highlighted blue on the display.

Navigation menu: Press the “Menu” key and turn the rotary/push knob

Press the “Back” key or the “Menu” key

Note:

If you press the “Menu” key, the system skips directly back to the working screen.

If you press the “Back” key, the system skips back to the previous display.

10

Page 11

Menu structure

Viscosity

Accuracy

Control mode

Density Value

Accurate

Balanced

Fast

Automatic

Manual

Factory settings

-

-

-

1.000

Menu

Temperature

Spindle

Probe temperature

Display

Calibration

List

Search

me-vi

hi-vi I

hi-vi II

lo-vi

lo-vi-

Spiral

T

ELVAS

DIN

VOL

CPA-CPE

VAN

Actual Temperature

Measuring Temperature

SP-6, SP-7, SP-8, SP-9, SP-10, SP-11, SP-12

SP-6, SP-7, SP-8, SP-9, SP-10, SP-11, SP-12

SP-6, SP-7, SP-8, SP-9, SP-10, SP-11, SP-12

SP-1, SP-2, SP-3, SP-4, SP-5

SP-2C, SP-3C

S-SP

T-A, T-B, T-C, T-D, T-E, T-F

ELVAS-SP

DIN-SP-1, DIN-SP-2, DIN-SP-3, DIN-SP-5, DIN-SP-6,

DIN-SP-7

VOL-SP-2.1, VOL-SP-3.8, VOL-SP-4.2, VOL-SP-6.7,

VOL-SP-7.1, VOL-SP-16.1, VOL-SP-10.4, VOL-SP-11.0,

VOL-SP-13.5, VOL-SP-9.0, VOL-SP-9.4

CP-40, CP-41, CP-42, CP-51, CP-52

VAN-SP-1, VAN-SP-2, VAN-SP-3, VAN-SP-4, VAN-SP-5

Spindle

Speed

Maximum viscosity

Accuracy

-

-

-

SP-1

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Display

Graph

Programs

Temperature

Level meter

Axis assignment

Axis scale

Program

Shear rate

Shear stress

Speed

Temperature

Torque

Viscosity

Time

Program 1-5

Start

Edit

Delete

View

Rename

Infinite loop

Loop count

Edit

Delete

Insert

Save

Speed

Time

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

11

Page 12

Factory settings

Profile

Safety

Settings

Ramp

Stop condition

Profile 1-5

Password

Language

Unit

Ramp 1-5

Timer

Torque

Temperature

Viscosity

None

Temperature

Viscosity

Load

Delete

Rename

English

Deutsch

Français

Español

Italiano

日本語

한국어

中文

Portuguese

русский язык

···

Start

Edit

Delete

hh:mm:ss

Value

Value

Value

Mode

Start

End

Step

Loop back

Total time

ºC

ºF

mPa·s (SI) - Dyn Visc

m2/s (SI) - Kin Visc

cP - Dyn Visc

cSt - Kin Visc

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

000

-

-

-

-

-

-

-

-

-

-

-

-

-

Display

Sound

Factory settings

Communication

Information

Volume

KeyTone

Background

Firmware update screen

Device name

USB

Viscosity Control mode

Spindle

Software Version

Firmware update screen

Black

White

Density

-

100

-

-

-

-

-

-

-

-

12

Page 13

Menu details

1. Viscosity

Accuracy

For detail information please refer to the ”Programs” part follow.

Control mode

Automatic: In automatic mode, you select the spindle, and the

viscometer will find a suitable motor speed and start measurement.

Manual: In manual mode, you can select the spindle and speed.

2. Temperature

Density

Set the density for kinematic viscosity:

Range: 0-9.999 g/cm3

Steps: 0.001

Spindle

List: Select the spindle from the list.

Search:

- Spindle: Select the spindle by searching

- Speed: Enter speed values for range calculation

Range: 0 - 200.00;

Steps: 0.01 up to 1; 0.10 afterwards

- Maximum viscosity: Available measurement range depends on

the combination of speed and spindle you selected.

Note:

The maximum viscosity (full scale range) can be automatically

calculated basing on the selected spindle, the settled speed and

the integrated spring series (lo-vi/me-vi/hi-vi I/hi-vi II).

- Accuracy: ±1% of full scale range

calibration will be disabled.

Display

The option allows you to specify that the “Probe temperature” is

shown on the display.

Calibration

The option is used for calibration of the temperature sensor.

The temperature difference displayed will be calibrated to zero,

and this action cannot be reversed.

The temperature sensor must be calibrated whenever it is replaced

or changed, or if a new temperature sensor is installed.

Probe temperature

When the temperature probe is not connected, then the probe

temperature will not be displayed on the main screen and the

3. Display 4. Graph

Please contact the Service department.

The temperature sensor supplied with the system is calibrated

exworks.

Temperature

The option allows you to specify that the “Temperature” is shown

on the display.

Level meter

The option allows you to specify that the “Level meter” is shown

on the display.

Axis assignment

In this menu you can select 2 options from the 7 options (shear

rate, shear stress, speed, temperature, torque, viscosity or time)

for axis assignment.

Axis scale

If you select “Time“ as one axis, then “Axis scale” gets enabled

and will be shown as white texts.

If “Time“ is not selected, then it is disabled and texts of ”Axis

scale” will show greyed.

13

Page 14

5. Programs

Program

Program start:

If the selected program is saved, you can run the test. By selecting

START, you can select the number of loops.

Two options will be given here, “Infinite Loop“ & “Loop Count“.

Once you accept the information, program validation will happen

before experiment is started.

Program validation includes:

- Total segment greater than one

- First segment time greater than zero

Note:

If you select “Infinite Loop“, the test runs until you stop it manually

or by other uncontrolled scenarios.

If you select “Loop Count“, he is provided with selection for

number of counts he wishes to run the test. You can select the

loop count from “1“ to “99“.

Program Edit:

If user selects EDIT, he is taken to the screen of segments to enter

the required test conditions.

Different parameters available:

Speed: Set the speed

Time: You can select the segment test time ranging 00:01 to

10:00 hours with resolution of 1 minute.

Edit: You can navigate along the chosen line and edit by selecting

the field. An edit symbol will appear on the screen and the

corresponding field can be changed.

To reset back to navigation one, you have to press the right

encoder button. The edit symbol disappears and the navigation

on the line is activated.

Delete: If “Delete“ is selected, the selected segment with yellow

bar will be deleted and the below segments will be moved one

step above.

Insert: If “Insert“ is selected, a new segment with time vale 00:01

is added below the selected segment. And the segments below

the selected segment will be moved one step below.

A warning is popped, saying “all the segments are full“.

Save: This option allows you to save the edited segment.

If the “Back“ key is pressed after deleting, inserting or editing the

segments, a pop-up warning is displayed to save the changes for

that program.

Program delete:

In program list screen, if “Delete“ is selected, that particular

program data is cleared and the tick mark before it will be deleted.

All the contents of program segments in “EEPROM“ will be reset

to default values.

Program view:

If the selected program is saved and if user selects “View“, he will

be navigated to another screen where he will see the performance

graph of the selected program.

If you press the “enter“ key on this screen, a window will pop

up in view graph screen with the details of the segments of the

program selected.

By rotating the right knob, you can navigate the information

regarding the segments stored. Exceptions:

- It is not allowed to insert a program segment into a program

that has already 10 program segments, as the program is full.

- It is not allowed to delete a program segment from a program

which has only one segment. However, you can delete the

whole program, irrespective of the number of segments.

Program rename:

You can rename the program as needed.

Ramp

Mode:

• Accurate mode:

Take at least 4 signals (1 revolution) for calculation. You can get

more accurate measurement, but this requires more time.

• Balanced mode:

Take at least 2 signals (1/2 revolution) for calculation.

• Fast mode:

Take first signal (1/4 revolution) for calculation. You can get fast

measurement, but this results in lower accuracy.

Start:

0.01 rpm to 200 rpm

End:

0.01 rpm to 200 rpm

Step:

1 to 20 Steps

Loop back:

Option to loop back the ramp

Total time:

Minimum time is decided based on the rpm and the step

Stop condition

Timer:

The option allows you to set a specific time that at which the

measurement will stop.

Torque:

The option allows you to set a specific torque value that at which

the measurement will stop. The display will show the obtained

viscosity at this moment.

Temperature:

The option allows you to set a specific temperature value that

at which the measurement will stop. The display will show the

obtained viscosity at this moment.

Viscosity:

The option allows you to set a specific viscosity value that at which

the measurement will stop. The display will show the obtained

viscosity at this moment.

None:

If this option is activated, the function of “stop condition“ will be

disabled.

14

Page 15

6. Profile

7. Safety

Load

Load the designated profiles as the active profile.

Delete

Delete the profile values and load them with the default ones (Factory settings).

Rename

With this option you can edit the name for the profiles and load

the customized names.

You have to press the encoder to active the keyboard for editing.

You can select the name for the profile, or scroll across the keyboard and select the letters.

This option also informs you about the number of the characters

left to include.

Password is used to protect you from entering into menu screens.

When a user presses the “Menu” key on the main screen, a pass

word screen will pop up if password is enabled.

The password is formed of 3 digital numbers. User can try pass

word any number of times.

Note:

0 0 0 – Will disable the password

Default: 0 0 0

-

-

8. Settings

Language

The “Languages“ option allows you to select the desired language

by turning and pressing the rotary/push knob.

Unit

The ”Units“ option allows you to select the desired units for

displaying the temperature and viscosity. The choice is made by

turning and pushing the rotary/push knob.

Display

The ”Display“ option allows you to change the background color

between ”Black“ and ”White“, and display ”Firmware update

screen“.

Sound

The ”Sound” option allows the user to adjust the sound volume or

activate/deactivate the key tone.

Factory settings

Select the

push knob. The system requests confirmation to restore the factory

settings. Pressing the ”OK” button resets all the system settings to

the original values set at time of delivery (see “Menu structure“).

Communication

Device name: The ”Device name” option allows you to change

the device name.

USB: The ”USB” option allows you to connect the device to PC.

Information

The ”Information” option offers you an overview of the most

important system settings of the device as well as display

”Software version” and ”Firmware update screen“.

”Factory settings” option by turning and pushing the rotary/

15

Page 16

Interfaces and outputs

9

9

6

7

8

9

The device can be operated by computer via an RS 232 or USB

interface using the laboratory software labworldsoft®.

Note! ( )

Please comply with the system requirements together with the

operating instructions and help section included with the software.

USB interface

The Universal Serial Bus (USB) is a serial bus for connecting the

device to the PC. Equipped with USB devices can be connected to

a PC during operation (hot plugging).

Connected devices and their properties are automatically recognized.

Use the USB interface in conjunction with labworldsoft® for operation in “Remote” mode and also to update the firmware.

USB device drivers

First, download the latest driver for IKA devices with USB interface from:

http://www.ika.com/ika/lws/download/usb-driver.zip.

Install the driver by running the setup file. Connect the IKA device

through the USB data cable to the PC. The data communication

runs through a virtual COM port.

Configuration, command syntax and commands of the virtual

COM ports are as described in RS 232 interface.

Serial RS 232 interface

Configuration

• The functions of the interface circuit between the laboratory

device and the automation system are a selection from the

signals specified in the EIA standard RS 232 as per DIN 66020

Part 1.

• Standard RS 232, corresponding to DIN 66259 Part 1 is valid

for the electronic characteristics of the interface circuits and

assignment of signal states.

• Transmission process: asynchronous character transmission in

start-stop operation.

• Transmission type: full duplex

• Character format: character composition according to data

format in DIN 66022 for start-stop operation. 1 start bit,

7character bits, 1 parity bit (even), 1 stop bit.

• Transmission speed: 9,600bit/s

• Data flow control: none

• Access method: data transmission from the device to the

computer only occurs after a request from the computer.

Command syntax and format

The following points should be noted for the instruction set:

• Commands are generally sent from the computer (master) to

the lab device (slave).

• The lab device only responds to requests from the computer.

• Commands and parameters, as well as consecutive parameters,

must be separated by at least one space (code: hex 0x20).

• Each individual command including parameters and data and

all responses are completed with CR LF (code: hex 0x0D and

0x0A) and can have a maximum length of 80 characters.

• The dot is used for decimal separators in a floating-point

value (code: hex 0x2E).

The details given above generally comply with the

recommendations of NAMUR (NAMUR recommendations for the

design of electrical plug-in connectors for analogue and digital

signals in laboratory MSR devices. Rev. 1.1).

The NAMUR commands and the additional specific IKA

commands serve only as low level commands for communication

between the device machine and the PC. With a suitable terminal

or communications program these commands can be transmitted

directly to the device. The IKA software package, labworldsoft

®

,

provides a convenient tool for controlling device and collecting

data under MS Windows, and includes graphical entry features,

for motor speed ramps for example.

The following table summarises the (NAMUR) commands

understood by the IKA equipment.

NAMUR Commands Function

IN_PV_3

IN_PV_4

IN_PV_5

IN_PV_80

IN_PV_82

IN_PV_83

IN_PV_84

Read external actual temperature

Read actual speed (rpm)

Read actual torque (%)

Read viscocity

Read shear rate

Read shear stress

Read density

OUT_SP_4 n Set speed (rpm)

OUT_SP_81 n Set spindle

START_4 Start motor

STOP_4 Stop motor

PC 1.1 cable

The PC 1.1 cable is used to connect the 9-pin plug to a PC.

1

2

3

4

5

1

RxD 2

TxD 3

4

GND 5

6

RTS 7

CTS 8

1

2 RxD

3 TxD

4

5 GND

6

7 RTS

8 CTS

5

9

4

8

3

7

2

6

1

PC

USB cable A - micro B 2.0

This cable is required to connect USB interface to a PC.

USB Micro B

USB A

16

Page 17

Maintenance and cleaning

The device is maintenance-free. It is only subject to the natural

wear and tear of components and their statistical failure rate.

Cleaning:

Remove the device from the mains before cleaning.

Dirt Cleaning agent

Dyes Isopropyl alcohol

Building materials

Cosmetics

Food Water containing detergent

Fuels Water containing detergent

Other materials Please consult IKA

- Wear protective gloves during cleaning the devices.

- Electrical devices may not be placed in the cleansing agent for

the purpose of cleaning.

- Do not allow moisture to get into the device when cleaning.

- Before using another than the recommended method for cleaning or decontamination, the user must ascertain with IKA that

this method does not destroy the device.

- Regularly check the spindle’s thread and the viscometer shaft.

During the working life of the viscometer, the device will require

certain check-ups. In this case, please contact the local distributor.

- Regular maintenance is important. We recommended an annual

check-up by the service technician of your local distributor.

- Power supply has double insulation or reinforced insulation for

fastening rod, nut and spindle parts.

Water containing detergent/isopropyl alcohol

Water containing detergent/isopropyl alcohol

Note: Always clean all of the parts after each use!

- Clean the spindles and the spindle protector well and then immediately dry them.

- Make sure that there is not any sample remaining especially in

the delicate zones like the spindle connector.

Ordering spare parts:

When ordering spare parts, please indicate:

- device type.

- serial number, see product label (bottom of product).

- line item and description of spare part, see: www.ika.com.

- software version (upon device starting up).

Repairs:

If you need to send your device to IKA for repairs, you have to

make sure that it has been cleaned and is free from any materials which may constitute a health hazard. The package has to be

marked clearly as safe on the outside.

For this purpose request the form “Safety Declaration

or download the form at: https://www.ika.com/laboratory-equip-

ment/service/repair/.

Fill out the form and follow the return instructions. Attach the in

cluded label “No Danger” to the transport packaging of the unit, so

it is clearly visible to IKA employees.

If you require servicing, return the equipment in its original packaging. Storage packaging is not sucient for shipment. Additionally

use suitable transport packaging.

Due to safety reasons, IKA reserves the right to refuse to service

devices which are not labeled suciently and return them to sender

unopened.

” from IKA

-

Accessories

Rotavisc lo-vi standard spindle series

Rotavisc me-vi standard spindle series

Rotavisc DIN adapter

Rotavisc ELVA adapter

Rotavisc vane spindles

Rotavisc VOL adapter

Rotavisc spiral adapter

For further accessories see www.ika.com.

Error message

The fault is shown by an error code on the display as following if the error occurs.

Proceed as follows in such cases:

- Switch the device off.

- Carry out corrective measures.

- Restart the device.

Error message Cause Effect Correction

Motor error Pivot damaged. Device can’t work.

If the actions described fails to resolve the fault or another error code is displayed then take one of the following steps:

- Contact the service department.

- Send the device for repair, including a short description of the fault.

Send back for repair.

17

Page 18

Warranty

In accordance with IKA warranty conditions, the warranty period

is 24 months. For claims under the warranty please contact your

local dealer. You may also send the machine directly to our factory,

enclosing the delivery invoice and giving reasons for the claim.

You will be liable for freight costs.

The warranty does not cover worn out parts, nor does it apply

to faults resulting from improper use, insufficient care or

maintenance not carried out in accordance with the instructions

in this operating manual.

Technical data

Dynamic viscosity range (lo-vi/me-vi/hi-vi I/hi-vi II) mPa•s 15...6M, 100...40M, 200...80M, 800...320M

(M=106)

Speed range rpm 0.01...200

Speed resolution

0...1 rpm

1...200 rpm

Display TFT

PT 100 interface yes

Temperature display yes

Timer yes

Nominal voltage VAC 100...240

Frequency Hz 50/60

Maximum device power consumption W 24

Maximum motor power consumption W 12

Motor output power W 6

Viscosity accuracy ±1 of full scale range

Viscosity repeatability ±0.2

Fuse (on mains plate) No

Drive Stepping motor

Permissible ambient temperature °C +5...+40

Permissible relative humidity % 80%, +5 °C...+31 °C (50%, +31 °C...+40 °C)

Housing material Coated aluminum casting and thermoplastic plastic

rpm

rpm

0.01

0.1

USB interface Yes

RS 232 interface Yes

Temperature measurement range °C -100...+300

Temperature measurement resolution (-100...+300 °C) K 0.1

Temperature measurement accuracy

-100...+150 °C

150...+300 °C

Dimensions (W x D x H) mm 130x275x305

Weight kg 2.3

Subject to technical changes!

K

K

0.1+tolerance PT 100 (DIN EN 60751 class A)

0.2+tolerance PT 100 (DIN EN 60751 class A)

18

Page 19

Appendix A “Range coecient“

Using the “Range coefficient“, the maximum viscosity that can be measured with a specific spindle can be quickly determined.

1. Identify the selected spindle and the viscometer spring sensor (lo-vi/me-vi/hi-vi l/hi-vi ll).

2. Find the “Range coefficient“ in below table.

3. Divide the range coefficient by the spindle speed.

E.g.: If you choose me-vi viscomter with SP-6 spindle: Range coefficient is 10,000. At speed of 10 rpm, the maximum viscosity (mPa•s)

is 10,000/10=1,000 mPa•s

Spindle lo-vi me-vi hi-vi l hi-vi II

SP-6 937 10,000 20,000 80,000

SP-7 3,750 40,000 80,000 320,000

SP-8 9,375 100,000 200,000 800,000

SP-9 18,750 200,000 400,000 1,600,000

SP-10 37,500 400,000 800,000 3,200,000

SP-11 93,750 1,000,000 2,000,000 8,000,000

SP-12 375,000 4,000,000 8,000,000 32,000,000

SP-1 6,000 64,000 128,000 512,000

SP-2 30,000 320,000 640,000 2,560,000

SP-3 120,000 1,280,000 2,560,000 10,240,000

SP-4 600,000 6,400,000 12,800,000 51,200,000

SP-5 1,200,000 12,800,000 25,600,000 102,400,000

SP-2C 30,000 320,000 640,000 2,560,000

SP-3C 120,000 1,280,000 2,560,000 10,240,000

S-SP 98,400 1,050,000 2,100,000 8,400,000

T-A 18,750 200,000 400,000 1,600,000

T-B 37,440 400,000 800,000 3,200,000

T-C 93,600 1,000,000 2,000,000 8,000,000

T-D 187,200 2,000,000 4,000,000 16,000,000

T-E 468,000 5,000,000 10,000,000 40,000,000

T-F 936,000 10,000,000 20,000,000 80,000,000

S-SP 98,400 1,050,000 2,100,000 8,400,000

ELVAS-SP 600 6,400 12,800 51,200

DIN-SP-1 3,470 37,000 74,000 296,000

DIN-SP-2 3,520 37,500 75,000 300,000

DIN-SP-3 11,330 120,900 241,800 967,200

DIN-SP-5 1,144 12,200 24,400 97,600

DIN-SP-6 3,420 36,500 73,000 292,000

DIN-SP-7 11,340 121,300 242,600 970,400

VOL-SP-2.1 117,200 1,250,000 2,500,000 10,000,000

VOL-SP-3.8 46,880 500,000 1,000,000 4,000,000

VOL-SP-4.2 120,000 1,280,000 2,560,000 10,240,000

VOL-SP-6.7 3,000 32,000 64,000 256,000

VOL-SP-7.1 4,688 50,000 100,000 400,000

VOL-SP-16.1 480,000 5,120,000 10.240,000 40,960,000

19

Page 20

Spindle lo-vi me-vi hi-vi l hi-vi II

VOL-SP-10.4 23,440 250,000 500,000 2,000,000

VOL-SP-11.0 46,880 500,000 1,000,000 4,000,000

VOL-SP-13.5 93,750 1,000,000 2,000,000 8,000,000

VOL-SP-9.0 30,000 320,000 640,000 2,560,000

VOL-SP-9.4 60,000 640,000 1,280,000 5,120,000

VAN-SP-1 2,456 26,200 52,400 459,600

VAN-SP-2 10,404 111,000 222,000 888,000

VAN-SP-3 50,146 535,000 1,070,000 4,280,000

VAN-SP-4 508,954 5,430,000 10,860,000 43,4440,000

VAN-SP-5 199,645 2,130,000 4,260,000 8,520,000

For measuring spindles of SP-1, SP-2, SP-6 and ELVAS-SP, experiment has verified approximate turbulence transition situations in the

following conditions:

1. SP-1 lo-vi spindle, 15 mPas at 60 rpm, rpm/mPas = 4;

2. SP-2 lo-vi spindle, 100 mPas at 200 rpm, rpm/mPas = 2

3. SP-6 me-vi spindle, 100 mPas at 50 rpm, rpm/mPas = 0.5

4. ELVAS-SP, 0.85 mPas at 60 rpm, rpm/mPas = 70.6

If the rpm/mPas ratio exceeds above values, turbulent situation may occur to the spindles listed above.

For measuring spindles ranging from VAN-SP-1 to VAN-SP-5:

Artificially higher viscosity readings may be introduced by turbulence at speeds of above 10 rpm.

20

Page 21

Appendix B “ASTM specifications“

The following ASTM specifications describe the use of IKA

C 965-96 Practices for Measuring Viscosity of Glass Above the Softening Point (Reapproved 2002)

C 1276-94 Standard Test Method for Measuring the Viscosity of Mold Powers Above their Melting Point Using a Rotational

Viscometer

D 115-03 Methods of Testing Varnishes Used for Electrical Insulation

D 789-91 Test Methods for Determination of Relative Viscosity, Melting Point, and Moisture Content of Polyamide (PA)

D 1076-88 Specification for Rubber-Concentrated, Ammonia Preserved, Creamed and Centrifuged Natural Latex

D 1084-97 Test Methods for Viscosity of Adhesives

D 1417-90 Methods of Testing Rubber Latices- Synthetic

D 1439-83a Methods of Testing Sodium Carboxymethyl-cellulose

D 1824-90 Test Method for Apparent Viscosity of Plastisols and Organosols at Low Shear Rates by Brookfield Viscometer

D 2196-86 Test Methods for Rheological Properties on Non-Newtonian Materials by Rotational (Brookfield) Viscometer

D 2364-85 Standard Methods of Testing Hydroxyethyl-cellulose

D 2393-86 Test Method for Viscosity of Epoxy Resins and Related Components

D 2556-97 Test Method for Apparent Viscosity of Adhesives Having Shear Rate Dependent Flow Properties

D 2669-87 Test Method for Apparent Viscosity of Petroleum Waxes Compounded With Additives (Hot Melts)

D 2983-03 Test Method for Low-Temperature Viscosity of Automotive Fluid Lubricants Measured by the Brookfield Viscometer

D 3232-88 Method for Measurement of Consistency of Lubricating Greases at High Temperatures

D 3236-88 Test Method for Apparent Viscosity of Hot Melt Adhesives and Coating Materials (Reapproved 1999)

D 3468-99 Standard Specification for Liquid- Applied Neoprene and Chlorosulfonated Polyethylene Used in Roofing and

Waterproofing

D 3716-99 Method of Testing Emulsion Polymers for Use in Floor Polishes

D 3791-90 Standard Practice for Evaluating the Effects of Heat on Asphalts

D 4016-81 Test Method for Viscosity of Chemical Grouts by the Brookfield Viscometer (Laboratory Method)

D 4889-93 Standard Test Methods for Polyurethane Raw Materials: Determination of Viscosity of Crude or Modified Isocyanates

D 5018-89 Standard Test Method for Shear Viscosity of Coal-Tar and Petroleum Pitches (Reapproved 1999)

D 5133-01 Standard Test Method for Low Temperature, Low Shear Rate, Viscosity/Temperature Dependence of Lubricating Oils

Using a Temperature-Scanning Technique

viscometers and accessories.

21

Page 22

Page 23

Page 24

IKA® - Werke GmbH & Co.KG

Janke & Kunkel-Str. 10

D-79219 Staufen

Tel. +49 7633 831-0

Fax +49 7633 831-98

sales@ika.de

www.ika.com

25000452

Loading...

Loading...