Page 1

IBM Ethernet Switch s-series

Installation and User Guide

Service information: 4003-S08, -S16

GC27-2243-00

Page 2

Page 3

IBM Ethernet Switch s-series

Installation and User Guide

Service informatio n: 400 3-S08 , -S16

GC27-2243-00

Page 4

The following paragraph does not apply to any country (or region) where such provisions are inconsistent with local

law.

INTERNATIONAL BUSINESS MACHINES CORPORATION PROVIDES THIS PUBLICATION ″AS IS″ WITHOUT

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some states (or regions) do

not allow disclaimer of express or implied warranties in certain transactions; therefore, this statement may not apply

to you.

Order publications through your IBM representative or the IBM branch office serving your locality.

© Copyright International Business Machines Corporation 2009.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract

with IBM Corp.

Page 5

Contents

Figures ............................ix

Tables ............................xi

Preface ...........................xiii

Safety notices .........................xiii

Safety notices and labels ....................xiii

Notes ..........................xiv

Attention notices ......................xiv

Caution notices.......................xiv

Danger notices .......................xv

Safety labels .......................xviii

Rack safety .........................xx

Rack installation ......................xx

Rack relocation (19″ rack)...................xxi

Product recycling and disposal ...................xxi

Product documents .......................xxii

Software documents ......................xxii

Getting help .........................xxiii

Taiwan Contact Information ...................xxiii

How to send your comments ...................xxiv

Chapter 1. About This Guide ...................1

Audience ...........................1

Nomenclature ..........................1

Chapter 2. Product Overview ...................3

Hardware benefits ........................3

POE port density ........................4

Supported configurations......................4

Software features........................4

Power over Ethernet (POE) applications ................5

Support for IPv6 modules .....................5

IPv6 hardware support guidelines ..................5

Hardware features ........................5

B08S .............................6

B16S .............................7

Management modules.......................9

B08S and B16S management modules ...............10

10/100/1000 GbE copper port on the B08S and B16S management

modules ........................11

10-GbE ports on the B08S and B16S 2-port 10-GbE management modules 11

LEDs on the B08S and B16S management modules .........11

Console port ........................12

Reset button ........................12

Switch fabric modules ......................12

LEDs on the switch fabric module .................13

Interface modules ........................13

Hot swap support .......................13

24-port 10/100/1000 Mbps Ethernet RJ45 copper interface module.....14

LEDs for 24-port 10/100/1000 Mbps Ethernet RJ45 copper interface

module .........................14

24-port 100/1000 Mbps Ethernet hybrid fiber (SFP) interface module ....15

© Copyright IBM Corp. 2009 iii

Page 6

Support for 100Base-FX on the 100/1000 interface module ......16

2-port 10-Gigabit Ethernet interface modules .............16

LEDs for 2-port 10-Gigabit Ethernet module ............17

Network interfaces .......................17

Port regions ..........................17

Power supplies .........................18

About replacement power supplies ................21

Power supply LEDs ......................22

About redundant power supplies and power supply failure ........23

What happens when one or more system power supplies fail ......23

What happens when one or more POE power supplies fail .......23

Cooling system .........................24

Built-in mounting brackets .....................25

Layer 3 routing protocol table sizes .................25

Chapter 3. Installing the Chassis .................27

Summary of installation tasks ...................27

Unpacking a system .......................28

Installation precautions ......................28

General precautions .......................28

Power precautions and warnings ..................29

Preparing the installation site....................29

Cabling infrastructure .....................29

Installation location ......................29

Removing extra shipment screws (B08S only) ............29

Installing a chassis in a rack ....................30

Installing mounting brackets on the B16S ...............32

Removing the slot panels .....................32

Installing the management and interface modules ............33

Attaching a management station ..................37

Attaching a PC or terminal to the console port or 10/100/1000 copper port . . . 37

Attaching a switch to an Ethernet port ................38

Powering on the system .....................38

Connecting AC power to the chassis .................38

Verifying proper operation .....................40

Observing the LEDs .......................40

Displaying the module status ....................42

Chapter 4. Connecting Network Devices and Checking Connectivity ...45

Assigning permanent passwords ..................45

Configuring IP addresses .....................46

IPv4 devices ..........................46

IPv4 devices running layer 3 software ...............46

IPv4 devices running layer 2 software ...............47

IPv6 devices ..........................48

IPv6 devices running Layer 3 software ...............48

IPv6 devices running Layer 2 software ...............49

Connecting network devices ....................50

Cable specifications .......................50

Connecting to Ethernet or fast Ethernet hubs ..............50

Connecting to workstations, servers, or routers .............51

Connecting a network device to a fiber port on the device .........52

Installing a fiber optic module ..................52

Cabling a fiber optic module

Cleaning fiber optic modules ...................53

Automatic MDI/MDIX detection ...................53

iv Ethernet Switch s-series Installation and User Guide

...................52

Page 7

Using a CX4 transceiver .....................53

Testing network connectivity ....................54

Pinging an IP address .....................54

Observing LEDs .......................54

Tracing a route ........................55

Troubleshooting network connections................56

Digital optical monitoring .....................56

Chapter 5. Managing the Chassis and Modules ............57

Displaying chassis status and temperature readings ...........57

Managing the cooling system ...................61

Configuring the cooling system ..................61

Thermal planes .......................61

Fan speed modes ......................61

Changing temperature thresholds for thermal planes and fan speeds on

the on the B16S .....................62

Changing temperature thresholds for thermal planes and fan speeds on

the B08S ........................64

Shutdown warning messages .................67

Changing the temperature polling interval .............68

Manually setting the fan speed .................68

Monitoring the cooling system ...................68

Displaying the temperature ...................68

Displaying fan status and speed .................69

Displaying temperature warnings .................69

Displaying the syslog configuration and static and dynamic buffers ......70

Static and dynamic buffers ...................70

Syslog messages for PCI (hardware) errors ..............71

Managing the switch fabric modules .................71

Displaying management module CPU usage ..............72

Removing MAC address entries ..................72

Chapter 6. Using a redundant management module ..........75

How management module redundancy works .............75

Management module redundancy overview ..............75

Management module switchover ..................76

Unavailable active module....................76

Manual switchover ......................76

Removal and replacement of a management module ..........76

Removal and replacement of an active management module ......76

Removal and replacement of a standby management module......77

Switchover implications ......................77

Management sessions .....................77

Syslog and SNMP traps ....................78

MAC address changes .....................78

Management module redundancy configuration .............78

Changing the default active chassis slot................78

Managing management module redundancy ..............78

File synchronization between the active and standby management modules 79

Manually switching over to the standby management module ........80

Rebooting the active and standby management modules .........81

Hitless management support ....................81

What happens during a hitless OS upgrade and hitless switchover ......81

How a hitless OS upgrade and hitless switchover impacts system functions 82

Syslog message for hitless OS upgrade and hitless switchover .......83

Layer 2 hitless switchover

.....................83

Contents v

Page 8

Executing a Layer 2 hitless switchover ...............83

Layer 2 hitless OS upgrade ....................84

Configuration considerations ...................85

Configuration steps ......................86

Loading the software onto the switch ................86

Executing the hitless-reload command ...............86

Verifying the new software image .................87

Monitoring management module redundancy ..............87

Determining management module status ...............87

Status LED .........................87

Software ..........................87

Displaying temperature information .................88

Displaying switchover information ..................88

Chapter 7. Maintaining the hardware ................91

Hardware maintenance schedule ..................91

Cleaning the fiber optic connectors .................91

Replacing a management module ..................91

Installation precautions ......................91

Removing a management module ..................92

Installing a new management module ................92

Replacing a switch fabric module ..................94

Removing a switch fabric module .................94

Installing a new switch fabric module ................95

Replacing an interface module ...................97

Precautions .........................97

Before removing an interface module................97

Removing an interface module ..................98

Installing a new interface module .................98

Configuring a LAN/WAN PHY interface module ............101

Enabling the LAN/WAN PHY module ...............101

Setting the WAN PHY mode ..................101

Disabling and re-enabling an interface module .............101

Installing or replacing a POE daughter card ..............102

Replacing a copper or fiber optic module ...............105

Removing a copper or fiber optic module ...............105

Installing a new copper or fiber optic module .............106

Cabling a fiber optic module ...................106

Installing or replacing a power supply ................107

Determining which power supply failed................107

Removing an AC power supply ..................108

Removing a replacement power supply ..............108

Removing an original power supply ................109

Installing a new power supply ...................110

Installing a replacement power supply ...............110

Installing an original power supply ................111

Connecting AC power to the chassis ................112

Verifying proper operation of the power supply .............114

Displaying the status of the power supplies ..............115

Replacing the B08S fan tray ...................116

Replacing the B16S fan assemblies .................117

Upgrading the device to run Layer 3 software

.............119

Chapter 8. Hardware specifications ................121

Physical dimensions ......................121

Environmental considerations ...................121

vi Ethernet Switch s-series Installation and User Guide

Page 9

Cooling ...........................122

Fan tray for the B08S .....................122

Cooling system on the B16S ..................123

Maximum power consumption ...................124

Power source interruptions ....................125

Pinouts and signalling ......................125

Serial (console) port pinouts ..................125

10/100 and Gigabit port pinouts .................126

Cable specifications ......................127

Power cords .........................128

Power supply specifications....................129

Physical dimensions and weight of power supplies ...........129

Environmental considerations for power supplies ............129

Electrical specifications .....................130

Input connector and plug .....................131

Notices ...........................133

Trademarks..........................134

Electronic emission notices ...................135

Federal Communications Commission (FCC) Class A statement ......135

Industry Canada Class A emission compliance statement .........135

Avis de conformité à la réglementation d’Industrie Canada ........135

European Union (EU) electromagnetic compatibility directive .......135

Germany electromagnetic compatibility directive ............136

People’s Republic of China Class A electronic emission statement .....137

Taiwan Class A warning statement .................137

Japan VCCI Class A ITE electronic emission statement .........137

Korea Class A electronic emission statement .............137

Index ............................139

Contents vii

Page 10

viii Ethernet Switch s-series Installation and User Guide

Page 11

Figures

1. B08S ...................................6

2. B08S slots .................................7

3. B16S ...................................8

4. B16S chassis slots ..............................9

5. B08S and B16S management module with no ports ..................11

6. B08S and B16S management module with two 10-GbE ports ..............11

7. B08S and B16S switch fabric module .......................13

8. IPv4 24-port Gigabit Ethernet copper module front panel ................14

9. IPv4 100/1000 Hybrid Fiber interface module ....................15

10. IPv4 2-port 10-Gigabit Ethernet module’s front panel..................16

11. Power supply placement in the B08S .......................20

12. Power supply placement in the B16S .......................20

13. Comparison of 90-240 VAC SYS power supplies ...................21

14. Side-by-Side Comparison of 90-240 VAC POE power supplies ..............21

15. Replacement power supplies. ..........................21

16. Removing the extra screws used for shipment ....................30

17. Positioning two of four mounting screws in a rack. ..................31

18. Front-mount-rack-installation into chassis ......................31

19. Installing the mounting brackets on an B16S ....................32

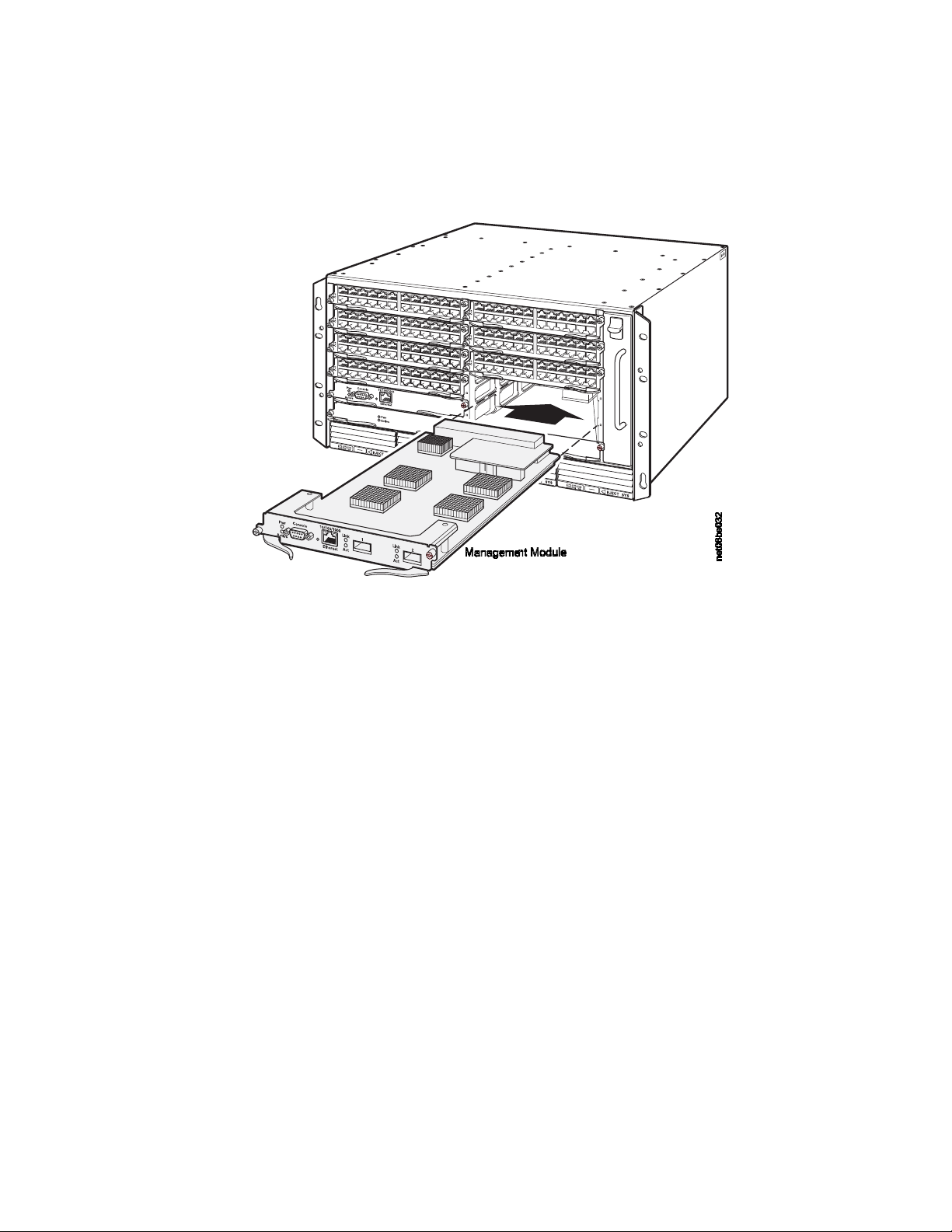

20. Installing a management module in the B08S ....................34

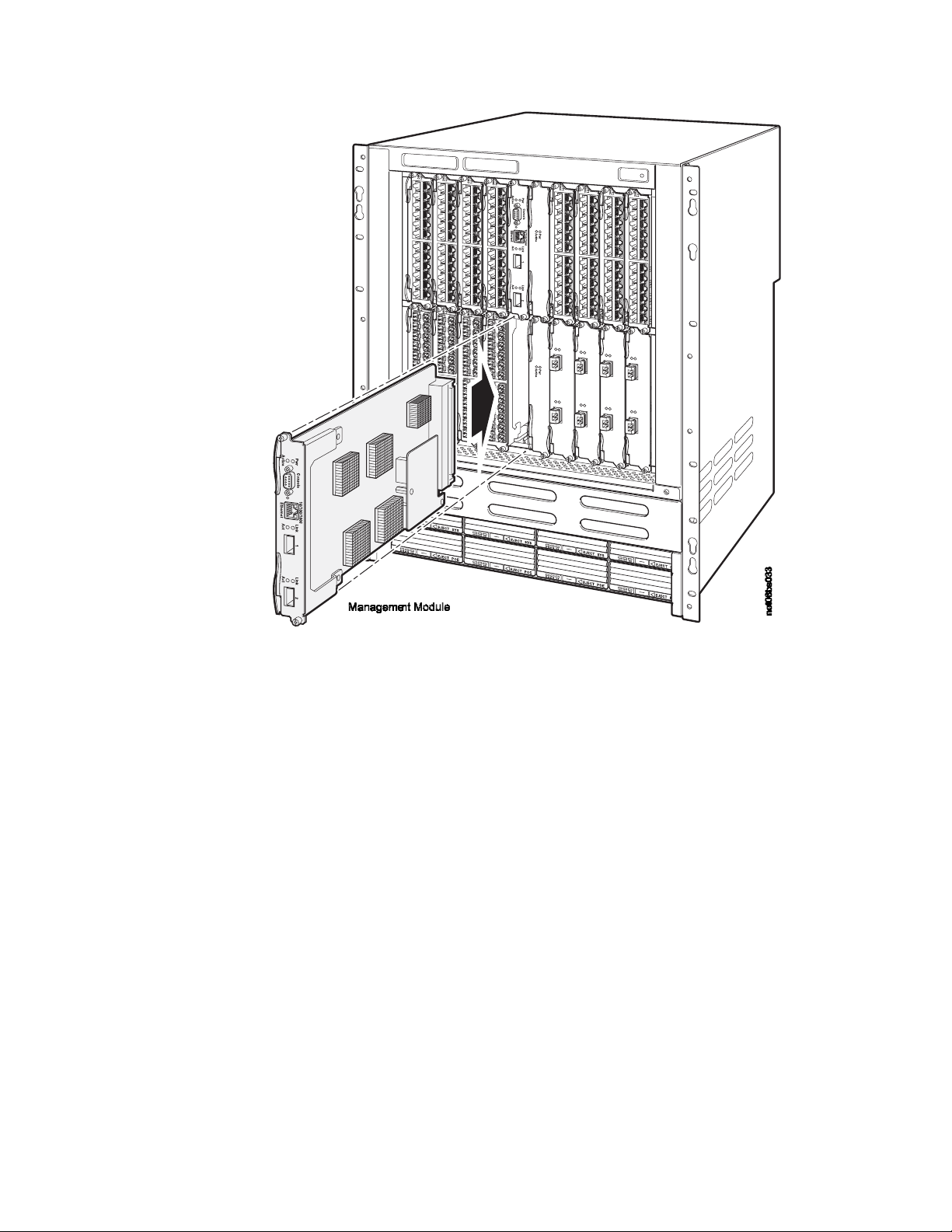

21. Installing a management module in the B16S chassis .................35

22. Installing an interface module in the B08S .....................36

23. Installing an interface module in the B16S .....................36

24. Connecting AC power to a B08S .........................39

25. Connecting AC power cords to a B16S chassis....................40

26. UTP crossover cable .............................51

27. Cat-5 crossover cable for 1000Base-T .......................51

28. CX4 transceiver ...............................53

29. CX4 transceiver cable .............................54

30. Fan speeds and temperature thresholds on the B16S .................63

31. Fan speeds and temperature thresholds on the B08S .................65

32. Active and standby management module file synchronization ..............80

33. Installing a management module in the B08S ....................93

34. Installing a management module in the B16S ....................94

35. Installing a switch fabric module in the B08S ....................96

36. Installing a switch fabric module in the B16S ....................96

37. Installing an interface module in the B08S .....................100

38. Installing an interface module in the B16S .....................100

39. Connector slots for POE daughter card ......................103

40. POE daughter card key detail..........................104

41. Installing the POE daughter card ........................104

42. Bail latch mechanism on the SFP ........................105

43. Movement of the bail latch ...........................106

44. Placement of the power supply in the B08S ....................107

45. Placement of the power supply in the B16S ....................108

46. Replacement AC power supply .........................108

47. Original power supplies ............................109

48. Power supply removal ............................109

49. Replacement AC power supply .........................110

50. Installing a replacement power supply .......................111

51. Original power supplies

52. Location of AC power connection on B08S .....................113

53. Attaching AC power cords to a B16S .......................114

............................112

© Copyright IBM Corp. 2009 ix

Page 12

54. Location of shipping screws to be removed.....................116

55. Removing the fan tray ............................117

56. Removing and replacing a B16S fan assembly. ...................118

57. Internal Airflow in the B08S ..........................122

58. Internal airflow in the B16S ..........................124

59. Serial port pin and signalling details .......................126

60. Console Port Pin Assignments Showing Cable Connection Options to a Terminal or PC ....126

61. Pin assignment and signalling for 10/100Base-TX and 1000Base-T ports..........127

62. AC power cable plug and input connector for 90-240 VAC SYS and 90-240 VAC POE power

supplies..................................131

63. AC power cable plug and input connector - male and female ..............132

x Ethernet Switch s-series Installation and User Guide

Page 13

Tables

1. Comparable IBM and Brocade products. ......................xxii

2. Maximum number of POE class 3 (15.4W) ports per power supply .............4

3. Configurations supported on the devices ......................4

4. Details regarding the management modules for the B08S and B16S ............10

5. LED status information for B08S and B16S management modules ............12

6. Front panel switch fabric LED status .......................13

7. Interface modules ..............................13

8. LEDs for 10/100/1000 copper ports ........................15

9. LED on the 2-port 10-Gigabit Ethernet module ....................17

10. Network interfaces ..............................17

11. Power supplies supported in the devices ......................18

12. LED status and meanings ...........................22

13. Installation tasks for your switch and locations of more detailed information .........27

14. Module Installation ..............................33

15. Desired and possible abnormal LED states after system power-on ............41

16. Connecting network devices...........................45

17. Network Connection-Related LED States ......................55

18. Chassis status and temperature Information .....................59

19. Temperature thresholds for each thermal plane and fan speed in the B16S .........64

20. Fan speed, temperature thresholds and fan noise levels on the B08S ...........65

21. Acceptable settings for low temperature thresholds and fan speed ............66

22. Unacceptable settings for low temperature thresholds and high fan speed ..........67

23. Information displayed regarding fan status .....................69

24. Syslog display configuration information ......................70

25. Hitless OS upgrade and hitless switchover impacts ..................82

26. Information regarding Layer 2 hitless OS upgrades ..................84

27. Power supply LED operating status .......................115

28. Physical dimensions and weight for each chassis and devices .............121

29. Environmental Conditions for the Chassis .....................121

30. B16S Fan Operating Noise ..........................123

31. Maximum power consumption for devices .....................124

32. Protection against power surges and drops.....................125

33. Cable length summary table ..........................127

34. Physical dimensions and weight of the power supplies ................129

35. Environmental Considerations for Power Supplies ..................129

36. Electrical specifications for power supplies .....................130

37. AC Input connector properties for power supplies ..................131

© Copyright IBM Corp. 2009 xi

Page 14

xii Ethernet Switch s-series Installation and User Guide

Page 15

Preface

Safety notices

This publication is provided for use with your particular IBM®Ethernet switch or

router product or product family. It provides information on installing, configuring,

maintaining, and using your product. Please retain this publication and the

accompanying documentation CD in a convenient location for easy reference and

future use.

The following sections provide information on safety and environmental

considerations, related publications and resources, as well as how to get

assistance, and how to send IBM feedback on this publication.

v “Safety notices”

v “Product recycling and disposal” on page xxi

v “Product documents” on page xxii

v “Getting help” on page xxiii

v “How to send your comments” on page xxiv

This section contains important safety information that should be read before

starting any installation or service procedure.

v “Safety notices and labels,” including:

– “Notes” on page xiv

– “Attention notices” on page xiv

– “Caution notices” on page xiv

– “Danger notices” on page xv

– “Safety labels” on page xviii

v “Rack safety” on page xx

Safety notices and labels

When using this product, observe the danger, caution, and attention notices

contained in this guide. The notices are accompanied by symbols that represent the

severity of the safety condition. The danger and caution notices are listed in

numerical order based on their IDs, which are displayed in parentheses, for

example (D004), at the end of each notice. Use this ID to locate the translation of

these danger and caution notices in the IBM Systems Safety Notices (G229–9054)

publication, which is on the product documentation CD that accompanies this

product.

The following notices and statements are used in IBM documents. They are listed

below in order of increasing severity of potential hazards. Follow the links for more

detailed descriptions and examples of the notes, attention notices, caution, and

danger notices in the sections that follow.

v “Notes” on page xiv: These notices provide important tips, guidance, or advice.

v “Attention notices” on page xiv: These notices indicate potential damage to

programs, devices, or data.

v “Caution notices” on page xiv: These statements indicate situations that can

be potentially hazardous to you.

© Copyright IBM Corp. 2009 xiii

Page 16

v “Danger notices” on page xv: These statements indicate situations that can be

potentially lethal or extremely hazardous to you. Safety labels are also attached

directly to products to warn of these situations.

v In addition to these notices, “Safety labels” on page xviii may be attached to the

product to warn of potential hazards.

Notes

Notes can provide tips, guidance, suggestions, or advice for simplifying procedures,

clarifying information, or avoiding potential problems. A sample note follows.

Note: The POE LEDs work only when POE is enabled on your device.

Attention notices

An attention notice indicates the possibility of damage to a program, device, or

system, or to data. An exclamation point symbol may accompany an attention

notice, but is not required. A sample attention notice follows:

Attention: Do not bend a fibre cable to a radius less than 5 cm (2 in.); you can

damage the cable. Tie wraps are not recommended for optical cables because they

can be easily overtightened, causing damage to the cable.

ESD precautions: Attention: Many of the field replaceable units (FRUs) are

sensitive to electrostatic discharge (ESD), and can potentially be damaged by

improper handling. Wear a wrist grounding strap connected to chassis ground (if the

device is plugged in) or a bench ground. Store all ESD-sensitive components in

antistatic packaging.

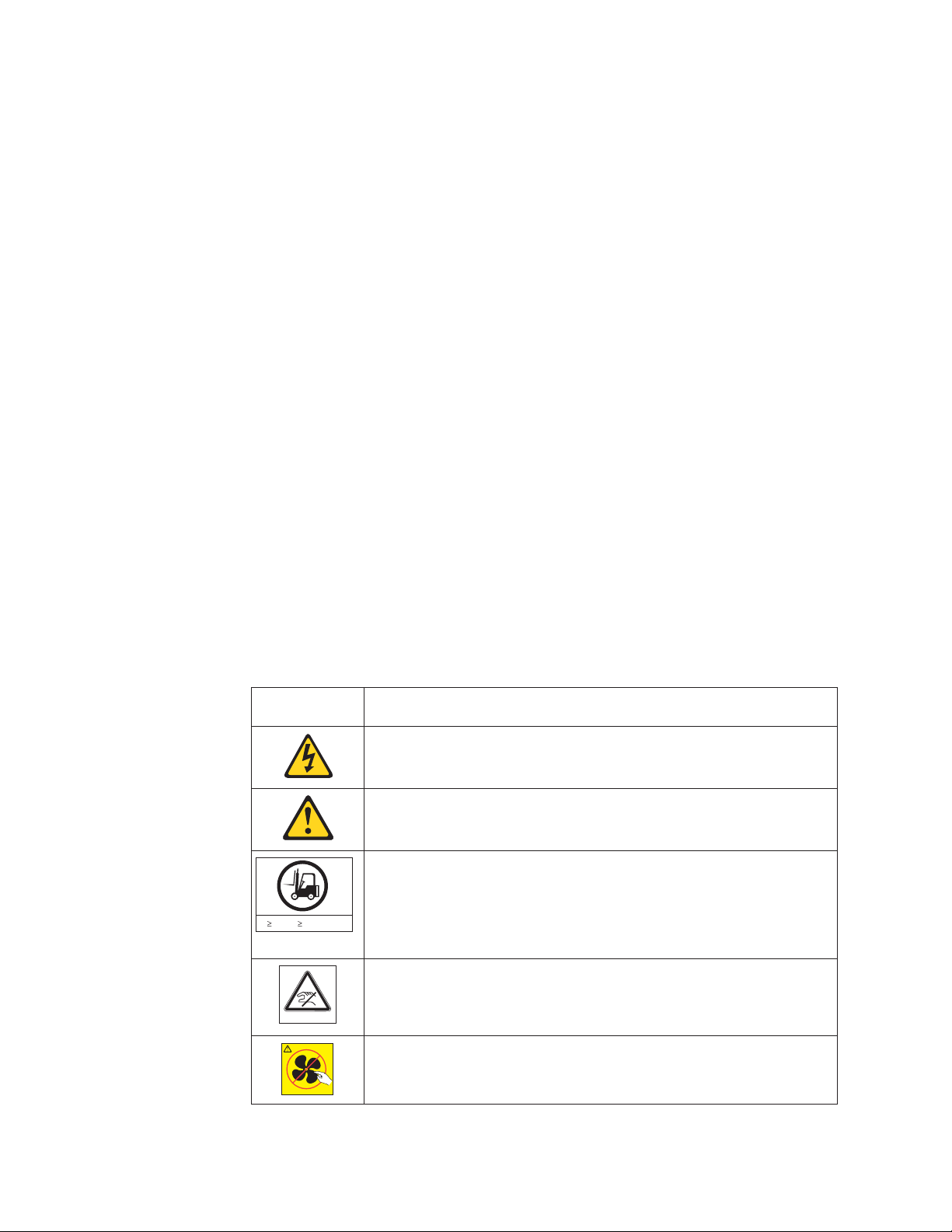

Caution notices

A caution notice calls attention to a situation that is potentially hazardous to people

because of some existing condition. A caution notice can be accompanied by

different symbols, as in the examples below:

If the symbol

is... It means....

A hazardous electrical condition with less severity than electrical danger.

A generally hazardous condition not represented by other safety symbols.

A specification of product weight that requires safe lifting practices. The

weight range of the product is listed below the graphic, and the wording

of the caution varies, depending on the weight of the device.

55 kg ( 121.2 lbs)

>55kg (121.2 lb)

P/N 18P5850-B

svc00169

A potential hazard of pinching the hand or other body parts between

parts.

SJ000752

A hazardous condition due to moving parts nearby.

xiv Ethernet Switch s-series Installation and User Guide

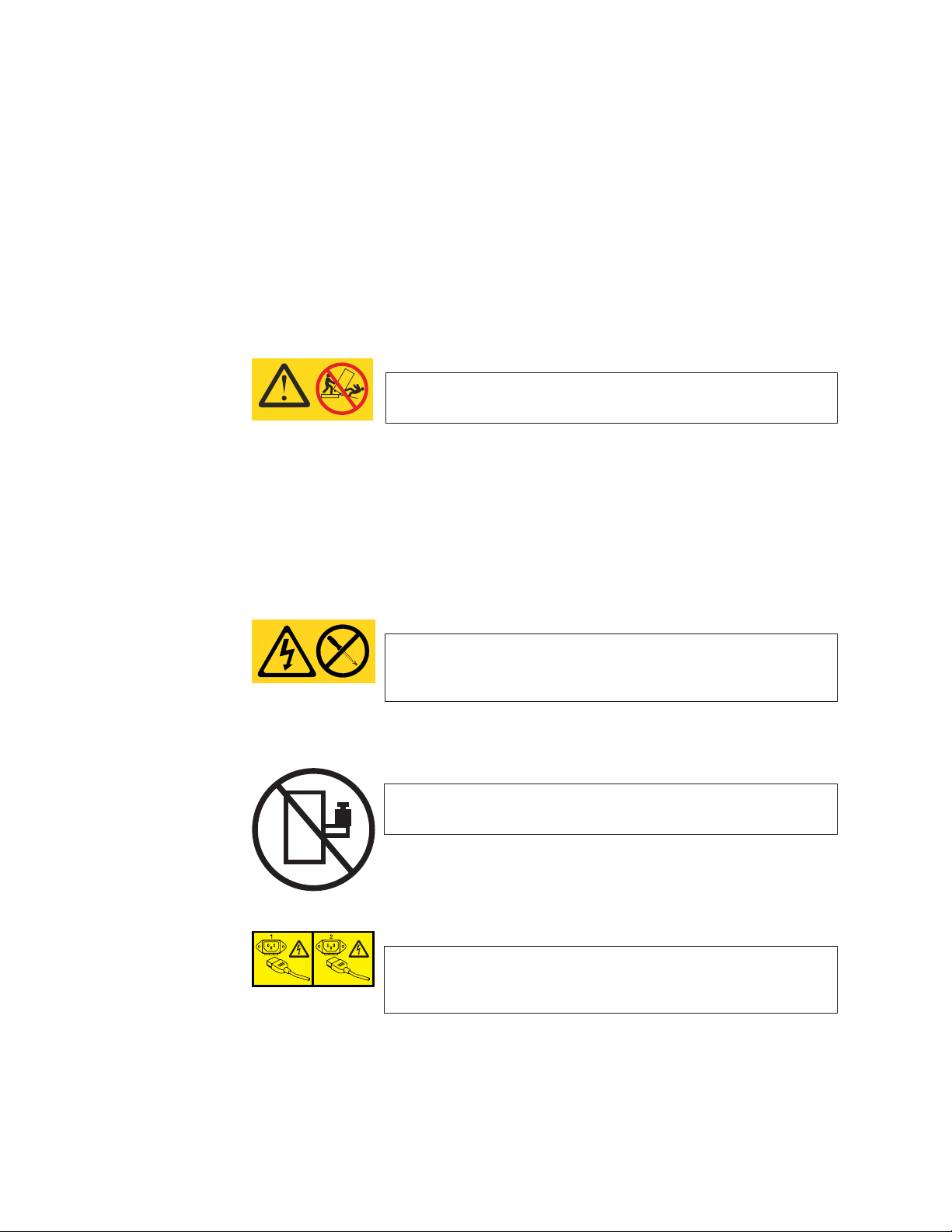

Page 17

If the symbol

is... It means....

A hazardous condition due to the use of a laser in the product. Laser

symbols are always accompanied by the classification of the laser as

defined by the U.S. Department of Health and Human Services (for

example, Class I, Class II, and so forth).

Read and comply with the following caution notices before installing or servicing this

device.

CAUTION:

Energy hazard present. Shorting may result in system outage and

possible physical injury. Remove all metallic jewelry before

servicing. (C001)

CAUTION:

The weight of this part or unit is between 32 and 55 kg (70.5 and

121.2 lb). It takes three persons to safely lift this part or unit. (C010)

32-55 kg (70.5-121.2 lbs)

svc00168

32-55 kg

(70.5-121.2 lb)

CAUTION:

The weight of this part or unit is more than 55 kg (121.2 lb). It takes

specially trained persons, a lifting device, or both to safely lift this

part or unit. (C011)

55 kg ( 121.2 lbs)

svc00169

>55kg (121.2 lb)

CAUTION:

This product is equipped with a 3-wire (two conductors and ground)

power cable and plug. Use this power cable with a properly

grounded electrical outlet to avoid electrical shock. (C018)

CAUTION:

Servicing of this product or unit is to be performed by trained

service personnel only. (C032)

Danger notices

A danger notice calls attention to a situation that is potentially lethal or extremely

hazardous to people. A lightning bolt symbol accompanies a danger notice to

represent a dangerous electrical condition. Read and comply with the following

danger notices before installing or servicing this device.

DANGER

To prevent a possible shock from touching two surfaces with

different protective ground (earth), use one hand, when possible,

to connect or disconnect signal cables. (D001)

Preface xv

Page 18

DANGER

Overloading a branch circuit is potentially a fire hazard and a

shock hazard under certain conditions. To avoid these hazards,

ensure that your system electrical requirements do not exceed

branch circuit protection requirements. Refer to the information

that is provided with your device or the power rating label for

electrical specifications. (D002)

DANGER

If the receptacle has a metal shell, do not touch the shell until

you have completed the voltage and grounding checks. Improper

wiring or grounding could place dangerous voltage on the metal

shell. If any of the conditions are not as described, STOP. Ensure

the improper voltage or impedance conditions are corrected

before proceeding. (D003)

DANGER

An electrical outlet that is not correctly wired could place

hazardous voltage on metal parts of the system or the devices

that attach to the system. It is the responsibility of the customer

to ensure that the outlet is correctly wired and grounded to

prevent an electrical shock. (D004)

The following general electrical danger notice provides instructions on how to avoid

shock hazards when servicing equipment. Unless instructed otherwise, follow the

procedures in this danger notice.

xvi Ethernet Switch s-series Installation and User Guide

Page 19

DANGER

When working on or around the system, observe the following

precautions:

Electrical voltage and current from power, telephone, and

communication cables are hazardous. To avoid a shock hazard:

v Connect power to this unit only with the IBM provided power

cord. Do not use the IBM provided power cord for any other

product.

v Do not open or service any power supply assembly.

v Do not connect or disconnect any cables or perform

installation, maintenance, or reconfiguration of this product

during an electrical storm.

v The product might be equipped with multiple power cords. To

remove all hazardous voltages, disconnect all power cords.

v Connect all power cords to a properly wired and grounded

electrical outlet. Ensure that the outlet supplies proper voltage

and phase rotation according to the system rating plate.

v Connect any equipment that will be attached to this product to

properly wired outlets.

v When possible, use one hand only to connect or disconnect

signal cables.

v Never turn on any equipment when there is evidence of fire,

water, or structural damage.

v Disconnect the attached power cords, telecommunications

systems, networks, and modems before you open the device

covers, unless instructed otherwise in the installation and

configuration procedures.

v Connect and disconnect cables as described below when

installing, moving, or opening covers on this product or

attached devices.

To Disconnect:

1. Turn off everything (unless instructed otherwise).

2. Remove the power cords from the outlets.

3. Remove the signal cables from the connectors.

4. Remove all cables from the devices.

To Connect:

1. Turn off everything (unless instructed otherwise).

2. Attach all cables to the devices.

3. Attach the signal cables to the connectors.

4. Attach the power cords to the outlets.

5. Turn on the devices.

(D005)

If the weight of the product is greater than 227 kg (500 lb), the following statement

and notice apply. This could apply if multiple products are installed in a single

cabinet, and that cabinet and products needs to be moved.

Preface xvii

Page 20

Delivery and subsequent transportation of the equipment: The customer

should prepare his environment to accept the new product based on the installation

planning information provided, with assistance from an IBM Installation Planning

Representative (IPR) or IBM authorized service provider. In anticipation of the

equipment delivery, the final installation site should be prepared in advance such

that professional movers/riggers can transport the equipment to the final installation

site within the computer room. If for some reason, this is not possible at the time of

delivery, the customer will need to make arrangements to have professional

movers/riggers return to finish the transportation at a later date. Only professional

movers/riggers should transport the equipment. The IBM authorized service provider

will only perform minimal frame repositioning within the computer room, as needed,

to perform required service actions. The customer is also responsible for using

professional movers/riggers in the case of equipment relocation or disposal.

DANGER

Heavy equipment—personal injury or equipment damage might

>(>)500 lbs. 227 kg.

result if mishandled. (D006)

a69i0333

Safety labels

As an added precaution, safety labels are often installed directly on products or

product components to warn of potential hazards. These can be either danger or

caution notices, depending upon the level of the hazard.

The actual product safety labels may differ from these sample safety labels:

DANGER

Hazardous voltage, current, or energy levels are present inside

any component that has this label attached. Do not open any

cover or barrier that contains this label. (L001)

DANGER

Rack-mounted devices are not to be used as a shelf or work

space. (L002)

DANGER

Multiple power cords. The product might be equipped with

multiple power cords. To remove all hazardous voltages,

disconnect all power cords. (L003)

xviii Ethernet Switch s-series Installation and User Guide

Page 21

DANGER

Hazardous voltage present. Voltages present constitute a shock

hazard, which can cause severe injury or death. (L004)

CAUTION:

Hazardous energy present. Voltages with hazardous energy might

cause heating when shorted with metal, which might result in

splattered metal, burns, or both. (L005)

CAUTION:

Hazardous moving parts nearby (L008)

P/N 18P5850-B

CAUTION:

Pinch hazard. (L012)

SJ000752

Preface xix

Page 22

Rack safety

Rack installation

DANGER

Observe the following precautions when working on or around your IT rack system:

v Heavy equipment—personal injury or equipment damage might result if

mishandled.

v Always lower the leveling pads on the rack cabinet.

v Always install stabilizer brackets on the rack cabinet.

v To avoid hazardous conditions due to uneven mechanical loading, always install

the heaviest devices in the bottom of the rack cabinet. Always install servers and

optional devices starting from the bottom of the rack cabinet.

v Rack-mounted devices are not to be used as shelves or work spaces. Do not

place objects on top of rack-mounted devices.

v Each rack cabinet might have more than one power cord. Be sure to disconnect

all power cords in the rack cabinet when directed to disconnect power during

servicing.

v Connect all devices installed in a rack cabinet to power devices installed in the

same rack cabinet. Do not plug a power cord from a device installed in one rack

cabinet into a power device installed in a different rack cabinet.

v An electrical outlet that is not correctly wired could place hazardous voltage on

the metal parts of the system or the devices that attach to the system. It is the

responsibility of the customer to ensure that the outlet is correctly wired and

grounded to prevent an electrical shock.

(R001 part 1 of 2)

CAUTION:

v Do not install a unit in a rack where the internal rack ambient temperatures will

exceed the manufacturer’s recommended ambient temperature for all your

rack-mounted devices.

v Do not install a unit in a rack where the air flow is compromised. Ensure that air

flow is not blocked or reduced on any side, front, or back of a unit used for air flow

through the unit.

v Consideration should be given to the connection of the equipment to the supply

circuit so that overloading of the circuits does not compromise the supply wiring or

overcurrent protection. To provide the correct power connection to a rack, refer to

the rating labels located on the equipment in the rack to determine the total power

requirement of the supply circuit.

v (For sliding drawers) Do not pull out or install any drawer or feature if the rack

stabilizer brackets are not attached to the rack. Do not pull out more than one

drawer at a time. The rack might become unstable if you pull out more than one

drawer at a time.

v (For fixed drawers) This drawer is a fixed drawer and must not be moved for

servicing unless specified by the manufacturer. Attempting to move the drawer

partially or completely out of the rack might cause the rack to become unstable or

cause the drawer to fall out of the rack.

(R001 part 2 of 2)

xx Ethernet Switch s-series Installation and User Guide

Page 23

Rack relocation (19″ rack)

CAUTION:

Removing components from the upper positions in the rack cabinet improves

rack stability during relocation. Follow these general guidelines whenever you

relocate a populated rack cabinet within a room or building:

v Reduce the weight of the rack cabinet by removing equipment starting at

the top of the rack cabinet. When possible, restore the rack cabinet to the

configuration of the rack cabinet as you received it. If this configuration is

not known, you must do the following:

– Remove all devices in the 32U position and above.

– Ensure that the heaviest devices are installed in the bottom of the rack

cabinet.

– Ensure that there are no empty U-levels between devices installed in the

rack cabinet below the 32U level.

– If the rack cabinet you are relocating is part of a suite of rack cabinets,

detach the rack cabinet from the suite.

– Inspect the route that you plan to take when moving the rack to

eliminate potential hazards.

– Verify that the route that you choose can support the weight of the

loaded rack cabinet. Refer to the documentation that came with your

rack cabinet for the weight of a loaded rack cabinet.

– Verify that all door openings are at least 760 x 2030 mm (30 x 80 in.).

– Ensure that all devices, shelves, drawers, doors, and cables are secure.

– Ensure that the four leveling pads are raised to their highest position.

– Ensure that there is no stabilizer bracket installed on the rack cabinet

during movement.

– Do not use a ramp inclined at more than 10 degrees.

– Once the rack cabinet is in the new location, do the following:

- Lower the four leveling pads.

- Install stabilizer brackets on the rack cabinet.

- If you removed any devices from the rack cabinet, repopulate the rack

cabinet from the lowest position to the highest position.

– If a long distance relocation is required, restore the rack cabinet to the

configuration of the rack cabinet as you received it. Pack the rack

cabinet in the original packaging material, or equivalent. Also, lower the

leveling pads to raise the casters off of the pallet and bolt the rack

cabinet to the pallet.

(R002)

Product recycling and disposal

Refer to the IBM Systems Environmental Notices and User Guide (Z125-5823) on

the product documentation CD for translated environmental statements and

information regarding product recycling and disposal.

Preface xxi

Page 24

Product documents

The following documents contain information related to this product. The

documentation may be printed material or may be on the documentation CD that is

shipped with the product.

v IBM Ethernet Switch s-series Installation and User Guide, GC27-2243 (this

document)

v IBM Systems Safety Notices, G229–9054

v IBM Systems Environmental Notices and User Guide, Z125-5823

v IBM Ethernet Switch and Router 4002 and 4003 Statement of Limited Warranty,

GC27-2239

Software documents

IBM Ethernet switch and router products use software licensed from Brocade

Communications Systems, Inc. You can find software publications that support your

product on the CD-ROM supplied with this product.

The software publications associated with this product are:

v FastIron Configuration Guide

v IronWare MIB Reference

These publications reflect only the original Brocade products names. Use the

cross-reference of products in Table 1 to assist you when determining which

information in those publications applies to your product. Brocade products with no

IBM equivalents are not listed in the table. Note that the IBM products can be

ordered with additional features, while Brocade products with those additional

features may be offered as separate models.

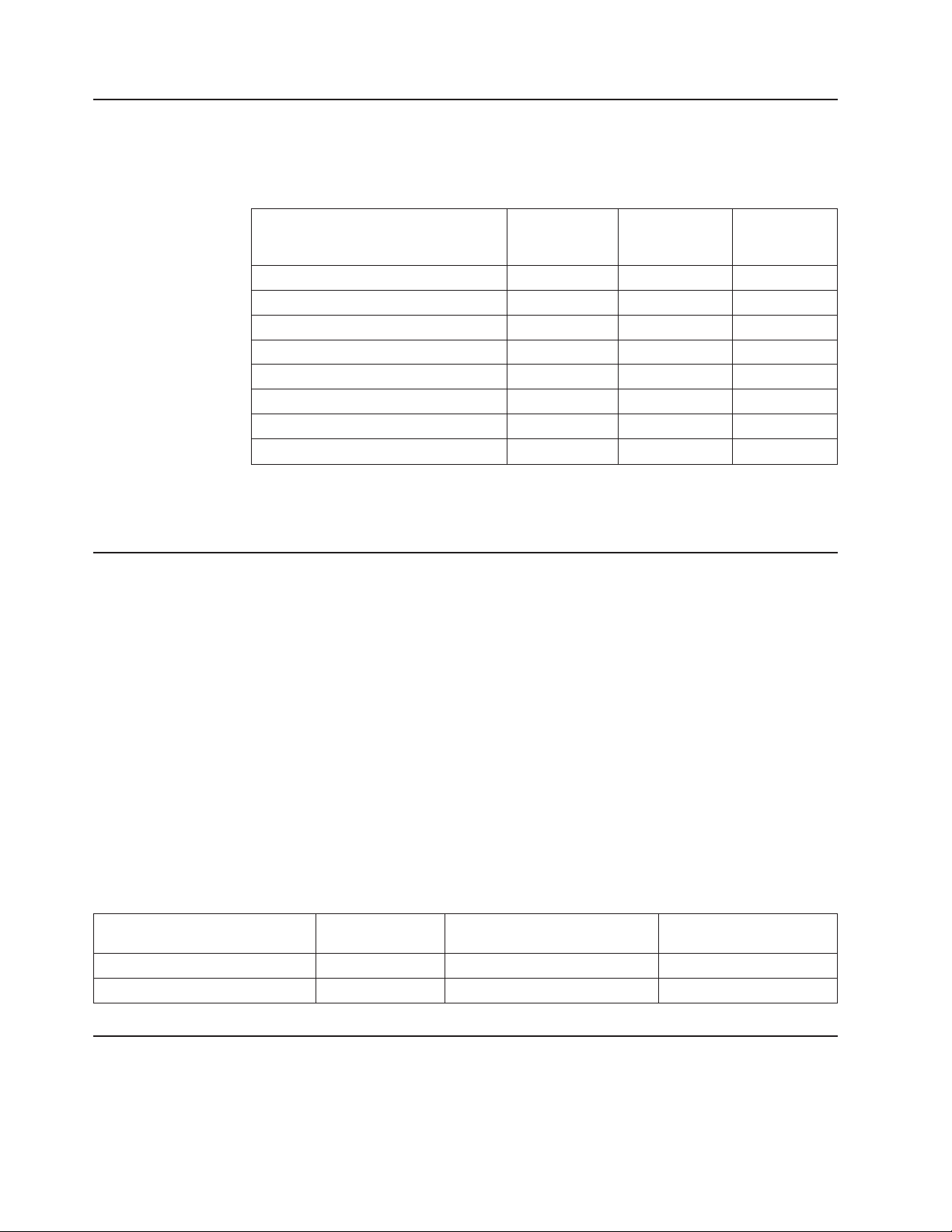

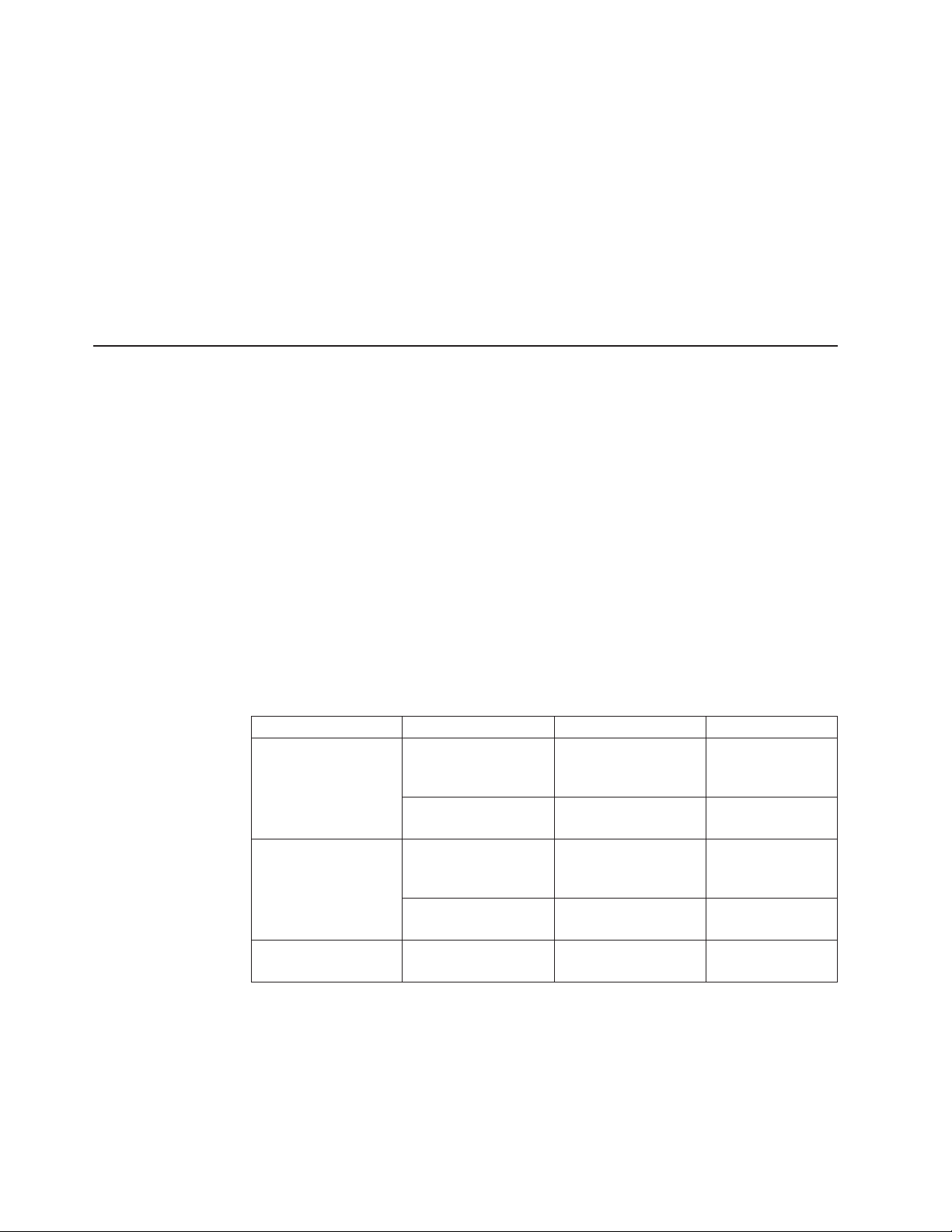

Table 1. Comparable IBM and Brocade products.

IBM product

name

Ethernet Router

B04M

Ethernet Router

B08M

Ethernet Router

B16M

Ethernet Switch

B08S

Ethernet Switch

B16S

Ethernet Switch

B48C

IBM

machine

type

4003 M04 4U modular Ethernet router with 4

4003 M08 7U modular Ethernet router with 8

4003 M16 14U modular Ethernet router with 16

4003 S08 6U modular Ethernet switch with 8

4003 S16 14U modular Ethernet switch with 16

4002 C4A (4002AC4) 1U Ethernet switch with forty-eight

4002 C4B, (4002BC4) 1U Ethernet switch with forty-eight

IBM model

(HVEC model in

parentheses) Brief product description

Brocade product

name

NI-MLX-4-AC

interface slots

NI-MLX-8-AC

interface slots

NI-MLX-16-AC

interface slots

FI-SX800-AC

interface slots

FI-SX1600-AC

interface slots

NI-CES-2048C-AC

10/100/1000 Mbps RJ45 ports and 4

combination 100/1000 SFP Ethernet ports

NI-CES-2048F-AC

100/1000 SFP Ethernet ports

xxii Ethernet Switch s-series Installation and User Guide

Page 25

Table 1. Comparable IBM and Brocade products. (continued)

IBM product

name

Ethernet Switch

B50C

Ethernet Switch

B48G

Ethernet Switch

B50G

IBM

machine

type

4002 C5A, (4002AC5) 1U Ethernet switch with forty-eight

4002 C5B, (4002BC5) 1U Ethernet switch with forty-eight

4002 G4A, (4002AG4) 1.5U Ethernet switch with forty-eight

4002 G5A, (4002AG5) 1.5U stackable Ethernet switch with

IBM model

(HVEC model in

parentheses) Brief product description

10/100/1000 RJ45 ports and two 10G

XFP uplink ports

100/1000 SFP Ethernet ports and two

10G XFP uplink ports

10/100/1000 Mbps RJ45 ports and 4

combination 100/1000 SFP Ethernet ports

forty-eight 10/100/1000 Mbps RJ45 ports,

4 combination 100/1000 SFP Ethernet

ports, and a two port CX4 module

Getting help

For the latest version of your product documentation, visit the web at

www.elink.ibmlink.ibm.com/public/applications/publications/cgibin/pbi.cgi. Search by

form number or title.

Brocade product

name

NI-CES-2048CX-AC

NI-CES-2048FX-AC

FGS648P

FGS648P-STK

For more information about this and other IBM products, visit the IBM web site:

www.ibm.com/

For support information for this product and other IBM products, see the following

Web site: www.ibm.com/systems/support/. Select your product family, and follow the

web navigation to your specific product.

You can also contact IBM within the United States at 1-800-IBMSERV

(1-800-426-7378). For support outside the United States, you can find the service

number at: www.ibm.com/planetwide/.

Visit www.ibm.com/contact for the contact information for your country or region.

Taiwan Contact Information

IBM Taiwan Product Service Contact Info:

IBM Taiwan Corporation

3F, No 7, Song Ren Rd., Taipei Taiwan

Tel: 0800-016-888

Preface xxiii

Page 26

How to send your comments

Your feedback is important in helping us provide the most accurate and high-quality

information. If you have comments or suggestions for improving this document,

send us your comments by e-mail to starpubs@us.ibm.com or use the Readers’

Comments form at the back of this publication. Be sure to include the following:

v Exact publication title

v Form number (for example, GC26-1234-02)

v Page numbers to which you are referring

If the Reader Comment Form in the back of this manual is missing, you can direct

your mail to:

International Business Machines Corporation

Information Development

Department GZW

9000 South Rita Road

Tucson, Arizona 85744-0001 U.S.A.

When you send information to IBM, you grant IBM a nonexclusive right to use or

distribute the information in any way it believes appropriate without incurring any

obligation to you.

xxiv Ethernet Switch s-series Installation and User Guide

Page 27

Chapter 1. About This Guide

This guide includes procedures for installing the hardware and configuring essential

parameters such as permanent passwords and IP addresses for the IBM Ethernet

Switch B08S and B16S products. The basic software configuration procedures

show how to perform tasks using the CLI. This guide also includes instructions for

managing and maintaining the hardware. For a summary of installation tasks see

Table 13 on page 27.

Audience

This guide is designed for network installers, system administrators, and resellers

who install the hardware. This guide assumes a working knowledge of Layer 2 and

Layer 3 switching and routing concepts.

Nomenclature

This guide uses the following typographical conventions to show information:

Italic highlights the title of another publication and occasionally emphasizes a word

or phrase.

Bold highlights a CLI command.

Bold Italic highlights a term that is being defined.

© Copyright IBM Corp. 2009 1

Page 28

2 Ethernet Switch s-series Installation and User Guide

Page 29

Chapter 2. Product Overview

This chapter contains an overview of the IBM Ethernet Switch B08S and B16S

Layer 2 and Layer 3 switches. Designed for medium to large enterprise backbones,

these devices are modular switches that provide the enterprise network with a

complete end-to-end Enterprise LAN solution, ranging from the wiring closet to the

LAN backbone.

Through the remainder of this guide, these products will be referred to as the B08S

and the B16S. When reference to a specific model is not required, the general

terms switch, product, or device will be used to refer to all the models. The term

s-series may also be used to collectively refer to these switch products.

Hardware benefits

The s-series switches provide the following benefits:

v The management module is non-blocking, with a adjustable switch fabric module

and twelve combination Gigabit Ethernet (GbE) copper or fiber ports that provide

connectivity to your existing management network.

v The management modules have a console port and a 10/100/1000 port that

provide connectivity to your existing management network. The management

modules optionally support 2-port 10-GbE ports or 8-port GbE fiber and copper

ports.

v The management modules are interchangeable between the IBM Ethernet Switch

s-series models. However, you cannot mix IPv4 and IPv6 modules together in the

same chassis.

v Optional dual management modules provide 100% redundancy.

v The crossbar (xbar) architecture enables the management module to switch 30

Gigabits per second between each interface module and within the management

module.

v The interface modules and power supplies are interchangeable between the IBM

Ethernet Switch s-series models. However, you cannot mix IPv4 and IPv6

modules together in the same chassis.

v The management, switch fabric, and interface modules are hot swappable, which

means you can remove and replace them while the chassis is powered on and

running.

v The devices have a passive backplane.

v Completely separate data and control planes, which results in uncompromised

switching performance, increased reliability of both planes, and increased

security of the control plane in the event of a Denial of Service (DoS) attack on

the data plane.

v Distributed data and control planes, which results in uncompromised wire-speed

performance for the data plane and faster and more efficient performance of

management functions for the control plane.

© Copyright IBM Corp. 2009 3

Page 30

POE port density

Table 2 details the maximum number of POE class 3 (15.4W) ports allowed per

power supply used.

Table 2. Maximum number of POE class 3 (15.4W) ports per power supply

Power Supply

1250 W 1 70 70

1250 W 2 140 140

1250 W 3 N/A 210

1250 W 4 N/A 280

2500W 220V POE Power Supply 1 140 140

2500W 220V POE Power Supply 2 280 280

2500W 220V POE Power Supply 3 N/A 420

2500W 220V POE Power Supply 4 N/A 560

Note: B08S supports a maximum of 192 POE ports. The B16S supports a

Number of

Power

Supplies B08S B16S

maximum of 384 POE ports.

Supported configurations

Standard devices support Layer 2 and base Layer 3 switching. All standard devices

can be upgraded to full Layer 3 multiprotocol routing through the purchase of an

upgrade feature, at which time they are considered to be premium devices.

The IBM Ethernet Switch s-series can be configured with either all IPv4

management and IPv4 interface modules, or all IPv6 management and IPv6

interface modules. You cannot mix IPv4 and IPv6 modules within a chassis.

Depending on the type of management module installed in the device, IPv6

premium devices support either:

v IPv4 multiprotocol routing and IPv6 host and management features, or

v IPv6 and IPv4 multiprotocol routing and IPv6 host and management features

The devices optionally support Power over Ethernet (POE), providing the means for

integrating data, voice, and video over existing Ethernet cables.

Table 3. Configurations supported on the devices

Power over Ethernet

Device Standard Premium

B08S Yes Yes Yes

B16S Yes Yes Yes

(POE)

Software features

Software features differ depending on the software version that is loaded on the

device and the type of management module that is installed in the chassis. See the

Configuration Guide for a complete list of software features supported on your

device.

4 Ethernet Switch s-series Installation and User Guide

Page 31

Power over Ethernet (POE) applications

B08S and B16S devices with Power over Ethernet (POE) are compliant with the

standards described in the IEEE 802.3af specification for delivering in-line power.

The 802.3af specification defines the standard for delivering power over existing

network cabling infrastructure, enabling multicast-enabled full streaming audio and

video applications for the following converged services:

v Voice over IP (VoIP)

v WLAN access points

v IP surveillance cameras

v IP technology devices

POE technology eliminates the need for an electrical outlet and dedicated UPS near

IP powered devices. With POE power sourcing devices, power is consolidated and

centralized in the wiring closets, improving the reliability and resiliency of the

network. Because POE can provide power over Ethernet cable, power is

continuous, even in the event of a power failure.

For POE port density, see “POE port density” on page 4.

For more information about POE and how to configure it, see the Configuration

Guide.

Support for IPv6 modules

The B08S and B16S support IPv6 management and interface modules starting with

software release 04.0.00.

For details about IPv6 modules, see the following sections in this chapter:

v “IPv6 hardware support guidelines”

v “Hardware features”

v “Interface modules” on page 13

IPv6 hardware support guidelines

Note the following guidelines and restrictions with IPv6 Management and Interface

modules:

v IPv4 interface modules must only be matched with IPv4 management modules

and IPv4 interface modules within the same chassis.

v If you install dual IPv6 management modules, the modules must be identical. For

example, you cannot install one 2-port management module and one 8-port

management module together in the same chassis. The modules must be of

like-kind.

Hardware features

The s-series switches include the following major hardware components:

v Chassis

v Management module with optional support for dual management modules that

provide 100% redundancy

v Separate switch fabric modules

v Interface modules

Chapter 2. Product Overview 5

Page 32

B08S

v Power supplies

v Fan tray in the B08S composed of six five-speed fans and a fan control module

v Air filter in the bottom front of the B16S chassis and two fan trays at the rear of

the chassis

v Adjustable mounting brackets on the B08S The B16S has adjustable mounting

brackets.

The following sections provide more information about these components.

For details about physical dimensions, power supply specifications, and pinouts,

see Chapter 8, “Hardware specifications,” on page 121.

The B08S is 6 rack units in height and consists of the following:

v Two half slots for the management modules

v Two half slots for the switch fabric modules

v Eight half slots for the interface modules

v Four slots for power supplies along the bottom of the card shelf. The power

supply slots add an additional rack unit (RU) to the height of the chassis.

Figure 1 shows the B08S

Figure 1. B08S

The B08S ships from the factory with the following components installed:

v Two switch fabric modules

v A slot panel in each interface module slot and power supply slot that does not

currently have a module or power supply installed in it. The slot panel ensures

proper airflow within the chassis.

v One AC System power supply (SYS)

v A fan tray assembly which contains the cooling system for the chassis

6 Ethernet Switch s-series Installation and User Guide

net08bs003

Page 33

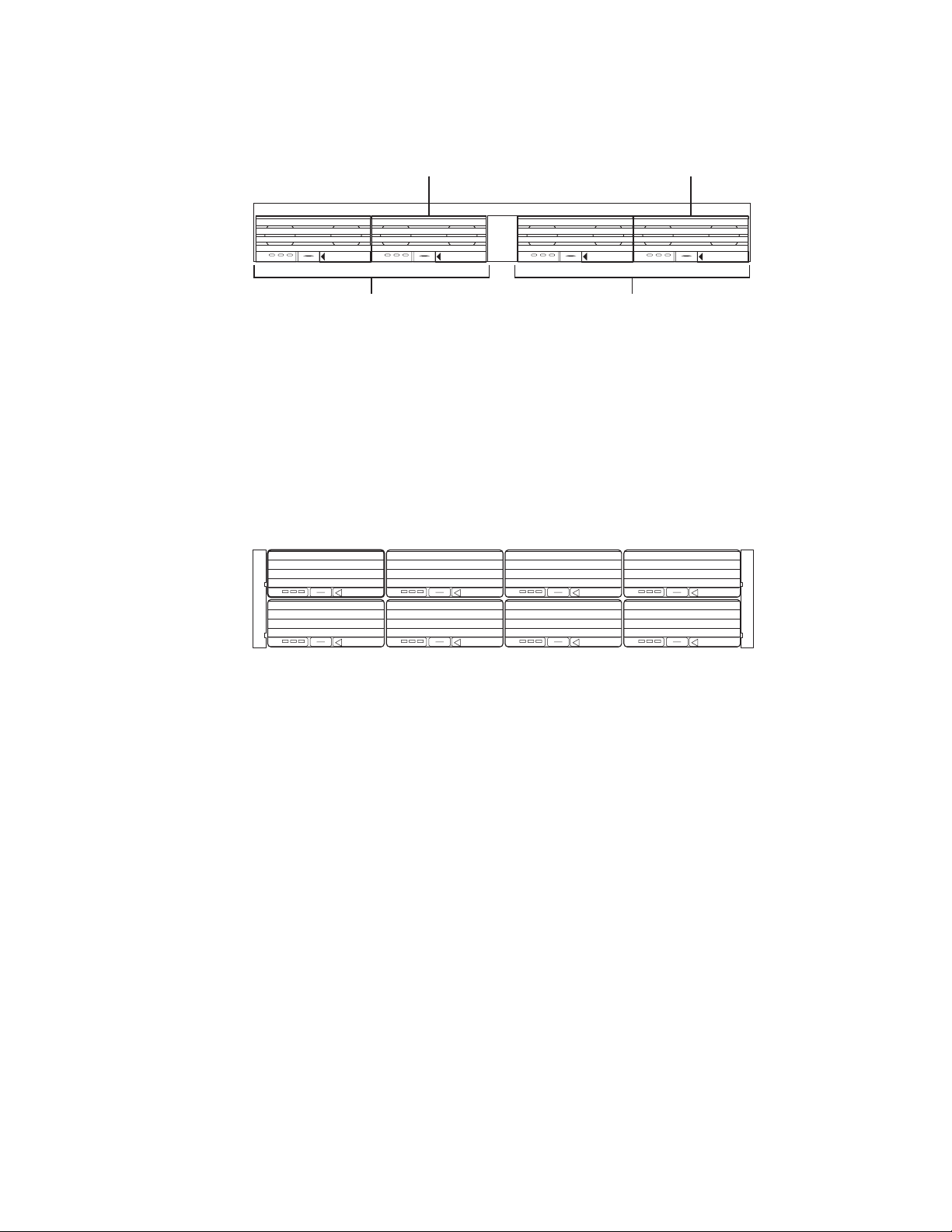

In the B08S slots, you can install the following:

v Up to two management modules

v Up to eight interface modules

v Up to four AC power supplies: two System (SYS) power supplies and two Power

over Ethernet (POE) power supplies

Before installing any modules or power supplies, you must remove the slot panel.

Attention: If you do not install a module in a slot, you must keep the slot panel in

place. If you run the chassis with an uncovered slot, the system will overheat.

Figure 2 shows the B08S and the slots into which you can install the various

modules and power supplies.

Slot 1 Slot 2 FanTray

B16S

F1

424C

F1

Slot 3 Slot 4

Slot 5

Slot 7

Slot 9

Switch

Fabr ic

424C

F1

424C

F1

424C

10/100/1000

Console

Pwr

Active

Ethernet

Pwr

Active

Slot 1

AC OKDC OKALM

EJECT POE

AC OKDC OKALM

EJECT POE

F1

424C

F1

424C

F1

424C

F1

424C

10/100/1000

Console

Pwr

Active

Ethernet

Pwr

Active

Slot 6

Slot 8

Slot 10

Switch

Fabric

Slot 2

AC OKDC OKALM

EJECT SYS

AC OKDC OKALM

EJECT SYS

ESD Connector

Figure 2. B08S slots

Figure 2 also shows an electrostatic discharge (ESD) connector, into which you can

plug an ESD wrist strap to ground yourself while handling and installing modules.

CAUTION:

For safety reasons, the ESD wrist strap should contain a series 1 meg ohm

resistor.

net08bs004

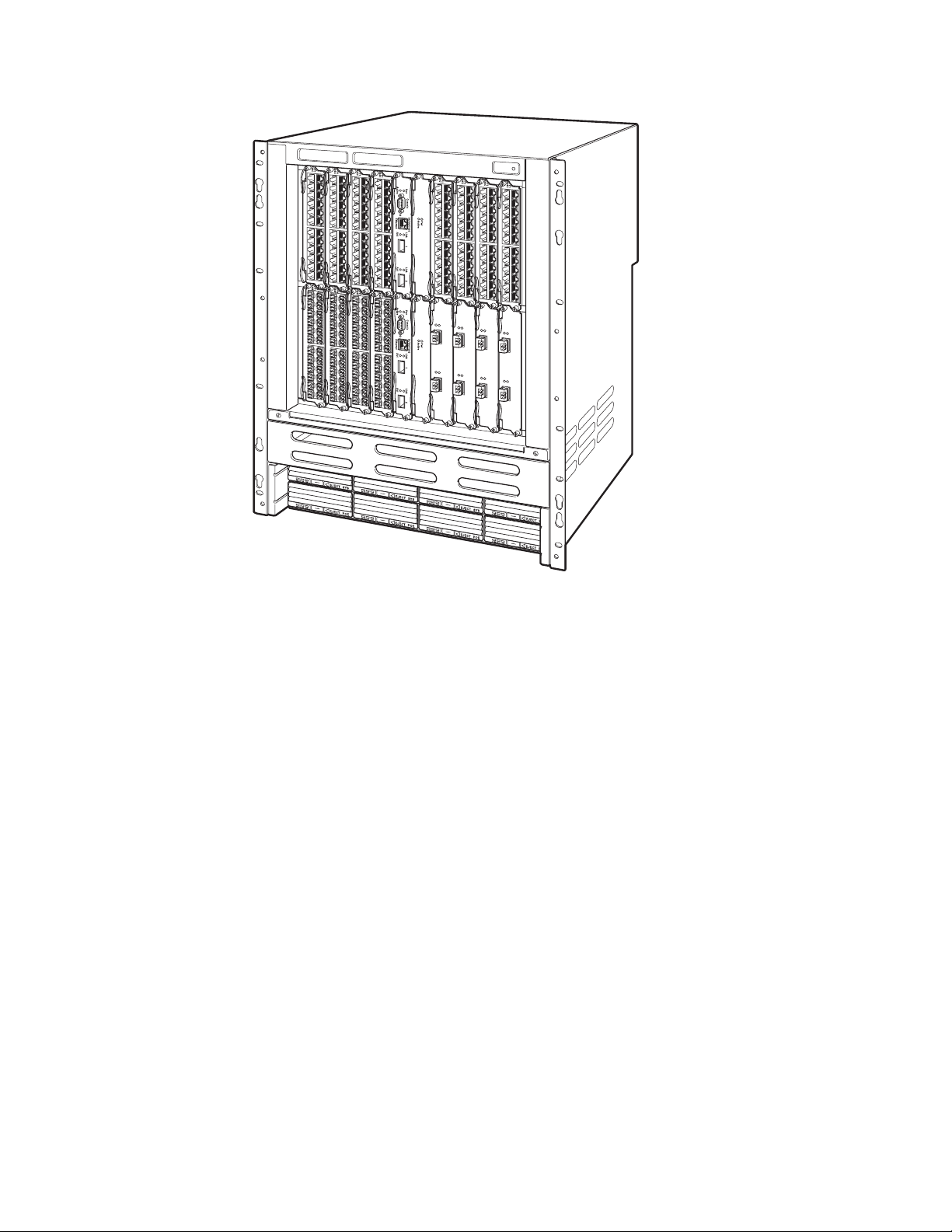

The IBM B16S is a 14 rack unit and consists of the following:

v Two half slots for the management modules

v Two half slots for the switch fabric modules

v Sixteen half slots for the interface modules

v Eight slots for power supplies along the bottom of the card shelf.

Figure 3 on page 8 shows the front of the B16S.

Chapter 2. Product Overview 7

Page 34

net08bs005

Figure 3. B16S

Units shipped from the factory have the following components installed in the

chassis:

v Two switch fabric modules

v A slot panel in each interface module slot and power supply slot that does not

currently have a module or power supply installed in it. The slot panel ensures

proper airflow within the chassis.

v Two AC System power supplies (SYS)

v A fan tray assembly which contains the cooling system for the chassis

In the chassis slots, you can install the following:

v Up to two management modules

v Up to 16 interface modules

v Up to eight AC power supplies: four System (SYS) power supplies and four

Power over Ethernet (POE) power supplies

Before installing any modules or power supplies, you must remove the slot panel.

Attention: If you do not install a module in a slot, you must keep the slot panel in

place. If you run the chassis with an uncovered slot, the system will overheat.

Figure 4 on page 9 shows the chassis slots into which you can install the various

modules and power supplies. It also shows an electrostatic discharge (ESD)

connector, into which you can plug an ESD wrist strap to ground yourself while

handling and installing modules.

8 Ethernet Switch s-series Installation and User Guide

Page 35

CAUTION:

For safety reasons, the ESD wrist strap should contain a series 1 meg ohm

resistor.

Switch Fabric

Mgmt

Slot 1

Slot 9

Interface

Slot 1

Interface

Slot 3

Interface

Slot 5

Interface

Slot 7

Interface

Slot 11

Active

Pwr

Active

Pwr

Interface

Slot 13

Interface

Slot 15

Interface

Slot 17

ESD

Connector

Interface

Slot 2

Figure 4. B16S chassis slots

Management modules

This section describes the management modules for the devices. The B08S and

B16S each require one management module and optionally support two

management modules for 100% redundancy. Each management module occupies

one half slot.

AC OKDC OKALM

Interface

Slot 4

EJECT SYS

Interface

Slot 6

AC OKDC OKALM

Mgmt

Slot 10

Interface

Slot 8

EJECT SYS

Switch

Fabric

Slot 2

Interface

Slot 12

Interface

Slot 14

net08bs006

Interface

Slot 16

Interface

Slot 18

Chapter 2. Product Overview 9

Page 36

B08S and B16S management modules

The management modules for the B08S and B16S are interchangeable between

devices. Standard management modules provide Layer 2 and base Layer 3

functionality only.

Note: Premium management modules support full Layer 3 functionality.

v The IBM Ethernet Switch B08S and B16S management modules are

interchangeable with each other, and are only supported on these chassis

models.

v You cannot intermix different management modules in the same chassis. For

example, if you have an IPv4 2-port 10 GbE Management Module installed in a

chassis, you must match it with another IPv4 2-port 10 GbE Management Module

within that chassis.

v You cannot mix IPv6 and IPv4 modules in the same chassis. A chassis must

contain either all IPv4 management and IPv4 interface modules, or all IPv6

management and IPv6 interface modules.

Table 4 lists the management modules for the B08S and B16S.

Table 4. Details regarding the management modules for the B08S and B16S

Management Modules Description

IPv4 management modules

Management Module (IPv4) no ports

Management Module 10 GbE

(IPv4)

IPv6 management modules

Management module 10 GbE

(IPv6)

two 10-GbE ports

Contains two 10 GbE ports for network connectivity

512 MB SDRAM enables support for large routing tables (1,000,000 BGP routes)

with the full Layer 3 code.

The B08S and B16S management modules perform the following tasks:

v Control the hardware components

v Control the separate switch fabric modules

v Run the networking protocols

v Provide the real time operating system

B08S management modules are located in slots 9 and 10, just above the switch

module slots; see Figure 2 on page 7.

B16S management modules are located in slots 9 and 10 along the center of the

chassis; see Figure 4 on page 9.

Figure 5 on page 11 shows the front panel of the IPv4 management modules with

no ports.

10 Ethernet Switch s-series Installation and User Guide

Page 37

Pw r

Console

10/100/1000

Acti ve

Ethernet

net08bs011

Figure 5. B08S and B16S management module with no ports

Figure 6 shows the front panel of the IPv4 management modules with two 10-GbE

ports.

Console

Pw r

Acti ve

Figure 6. B08S and B16S management module with two 10-GbE ports

10/100/1000

Ethernet

Link

Act

12

Link

Act

net08bs012

The front panel on the management modules include the following control features:

v A console port and 10/100/1000 RJ-45 copper port allow you to access the

system’s CLI directly from a PC or terminal or via a Telnet connection to the PC

or terminal.

v Depending on the type of management modules installed in the device, the

management modules have the following ports:

– no 10-GbE fiber ports

– two 10-GbE fiber ports

v LEDs for power and active/standby status

v Four LEDs for the two 10-GbE fiber ports (2-port 10-GbE modules only)

v A recessed reset button

10/100/1000 GbE copper port on the B08S and B16S management modules

The 10/100/1000 RJ-45 copper port on the management module enables you to

attach a PC or terminal. From this Ethernet port, you can access the system’s CLI

or Web management interface directly from the PC or terminal or via a Telnet

connection to the PC or terminal.

10-GbE ports on the B08S and B16S 2-port 10-GbE management modules

The B08S and B16S 2-port 10-GbE management modules come with two 10-GbE

fiber ports through which you can connect your device to other network devices at a

speed of 10 Gigabits per second.

The 10-GbE ports support 10-Gigabit Small form Factor Pluggable (XFP)

MSA-compliant transceivers. The transceivers support the fiber optic cabling for

LAN PHY.

LEDs on the B08S and B16S management modules

The management modules provide status information using the LEDs listed in

Table 5 on page 12.

Chapter 2. Product Overview 11

Page 38

Table 5. LED status information for B08S and B16S management modules

LED Description and position State Meaning

Pwr Round LED located to the left

of the console port

Active Round LED located to the left

of the console port

10/100/1000 Copper Port LEDs

Lnk Left-most LED above the port On The port is connected.

Act Right-most LED above the port. On or

10-GbE Port LEDs

Lnk Top-most LED to the left of the

port.

Act Bottom-most LED to the left of

the port.

On

(Green)

Off The module is not receiving

On

(Green)

Off The module is not the active

Off No port connection exists.

Blinking

Off The port is not transmitting or

On Fiber port is connected.

Off No Fiber port connection exists.

On or

Blinking

Off The port is not transmitting or

The module is receiving power.

power.

The module is the active

management module.

management module.

The port is transmitting and

receiving traffic.

receiving traffic.

The port is transmitting and

receiving traffic.

receiving traffic.

Console port

The console port on the management module is a standard DB-9 serial connector

through which you can attach a PC or terminal to configure the system using the

command line interface (CLI).

The console port interfaces the control plane only and not the data plane.

Reset button

The reset button on the management module allows you to restart the system. The

reset button is recessed to prevent it from being pushed accidentally.

The reset button is located next to the console port on the management module.

Switch fabric modules

The switch fabric modules switch user packets from one interface module installed

in the chassis to another. The switch fabric modules in the B08S and B16S are

separate from the management modules and are physically located next to the

management modules.

Figure 7 on page 13 shows the B08S and B16S switch fabric module.

12 Ethernet Switch s-series Installation and User Guide

Page 39

Pw r

Acti ve

Figure 7. B08S and B16S switch fabric module

LEDs on the switch fabric module

The front panel provides status information using the LEDs listed in Table 6.

Table 6. Front panel switch fabric LED status

LED Description and Position State Meaning

Pwr Top-most LED On (Green) The module is receiving power.

Active Bottom-most LED On (Green) The module is functioning properly.

Interface modules

This section describes the interface modules for the following:

v The B08S, in which you can install up to eight Interface modules in the slots

shown in Figure 2 on page 7.

v The B16S, n which you can install up to 16 interface modules in the slots shown

in Figure 4 on page 9.

net08bs014

Off The module is not receiving power.

Off The module is not functioning properly.

Note: You cannot mix IPv4 and IPv6 modules together in the same chassis.

Table 7 lists the supported Interface modules for each type.

Table 7. Interface modules

Interface Module B08S B16S

IPv4 Interface Modules

24-port 10/100/1000 Mbps Ethernet RJ45 copper without POE X X

24-port 100/1000 Mbps Ethernet SFP

2-port 10 Gbps Ethernet XFP X X

IPv6 Interface Modules

IPv6 24-port 10/100/1000 Mbps Ethernet RJ45 copper without POE X X

IPv6 24-port 100/1000 Mbps Ethernet SFP X X

IPv6 2-port 10 Gbps Ethernet XFP X X

XX

Hot swap support

The B08S and B16S support Multi-Service IronWare R05.0.00a and later. Enhanced

Hot Swap is supported, meaning you can remove and replace the interface

modules without powering down the system, and without executing the disable

module command. However, it is recommended that the modules be disabled

through the CLI before removal from the chassis.

Chapter 2. Product Overview 13

Page 40

Attention: It is important to wait a minimum of 10 seconds between the removal

and insertion of a line module. Re-insertion of a line module less than 10 seconds

after the removal of a line module may result in the line module not being properly

recognized.

See “Replacing an interface module” on page 97 for instructions.

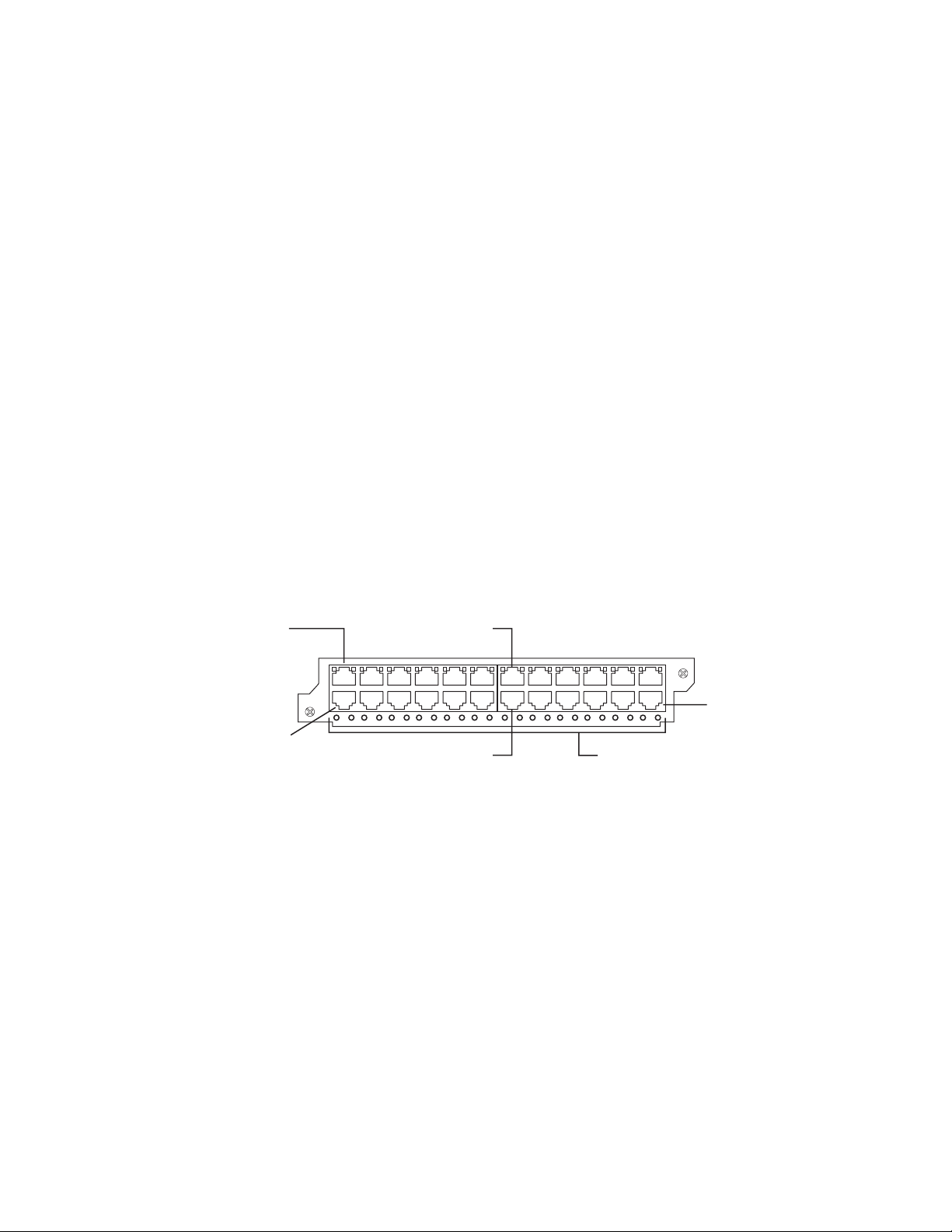

24-port 10/100/1000 Mbps Ethernet RJ45 copper interface module

The 24-port 10/100/1000 Mbps Ethernet RJ45 copper interface module has

twenty-four 10/100/1000 ports with RJ-45 connectors for Cat5 cabling. The copper

ports support automatic MDI/MDIX detection, and use auto-sensing and

auto-negotiating to determine the speed (10, 100, or 1000 Mbps) and duplex mode

(full-duplex or half-duplex) of the port at the other end of the link, and adjust the

port accordingly. Ports operating at 1000 Mbps operate in the full-duplex mode only

and cannot be modified.

This interface module supports Power over Ethernet (POE). You can order an

upgrade kit for your 24-port 10/100/1000 Mbps Ethernet RJ45 copper interface

module that includes a POE daughter card that is installed onto the module. To run

POE on your system, at least one 48-volt POE power supply must also be installed

in the chassis. See “Installing or replacing a POE daughter card” on page 102.

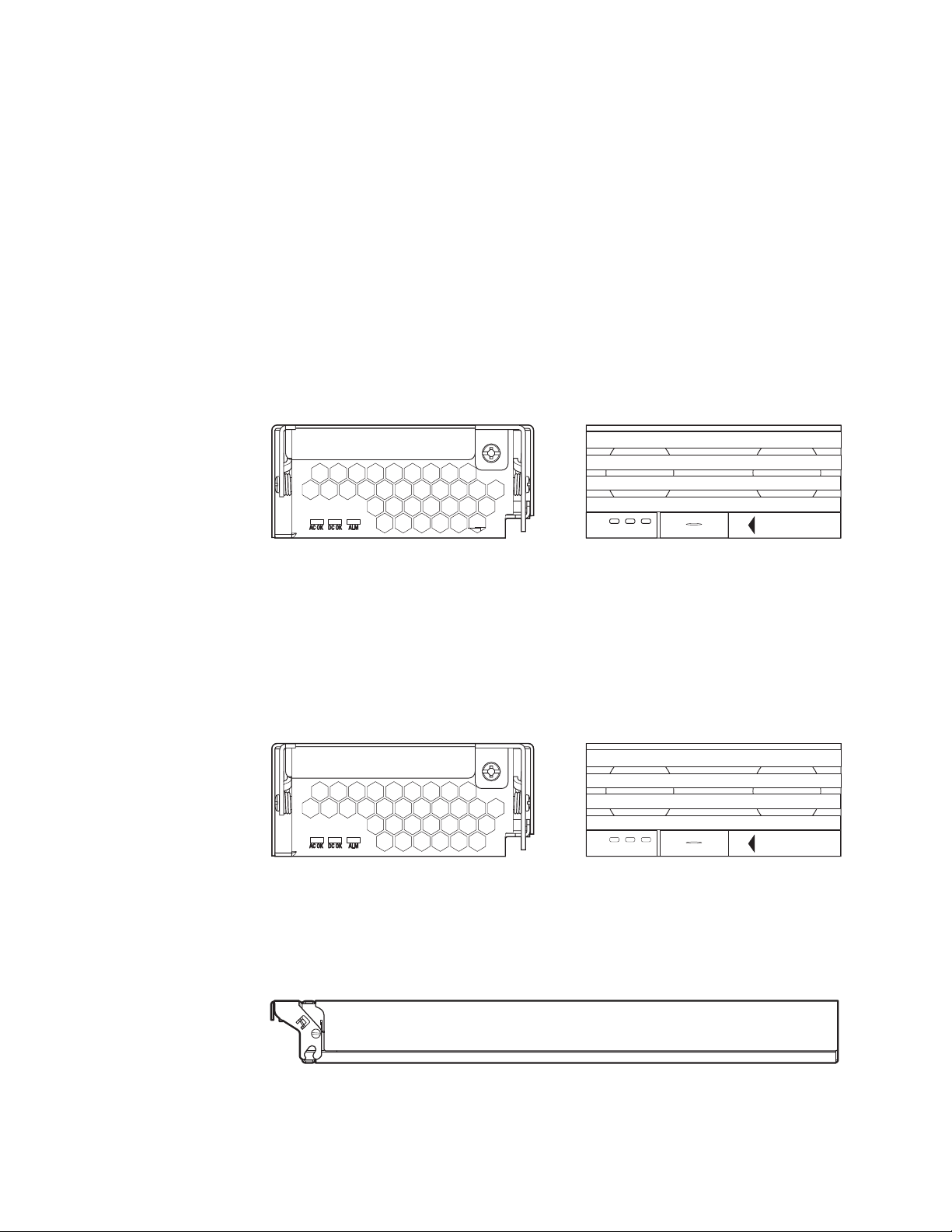

Figure 8 shows the front panel of the IPv4 24-port Gigabit Ethernet copper module.

The IPv6 24-port Gigabit Ethernet copper looks identical except for the 624C label

on the left edge.

Port 1

424C

Port 2

Figure 8. IPv4 24-port Gigabit Ethernet copper module front panel

Port 13

Port 14 POE LEDs

Port 24

net08bs015

The front panel includes the following control features:

v 24 10/100/1000 copper ports

v 24 LEDs for port status

v 24 LEDs for Power over Ethernet (POE) status

Note: The POE LEDs work only when POE is enabled on your device.

LEDs for 24-port 10/100/1000 Mbps Ethernet RJ45 copper interface module

The front panel of the 24-port Gigabit Ethernet copper module includes 24 LEDs

that indicate the status of each port, and 24 LEDs (on bottom) that indicate the

status of POE.

Note: The POE LEDs work only when POE is enabled on your device.

The copper ports also provide status information using the LEDs.

14 Ethernet Switch s-series Installation and User Guide

Page 41

Table 8. LEDs for 10/100/1000 copper ports

LED Position State Meaning

Link/Activity Square LED located on upper

left corner of upper copper

connector for upper copper

connector

Square LED located on upper

right corner of upper copper

connector for lower copper

connector

POE (if applicable) Round LED located beneath the

copper ports

The first (left-most) LED is for

port 1, the second LED is for

port 2, the third LED is for port

3, etc.

On (Green) A link is established with the remote

port.

Blinking The port is transmitting and receiving

traffic.

Off A link is not established with the

remote port.

On (Green) The port is enabled, a

power-consuming device has been

detected, and the module is supplying

power to the device.

Off The port is not providing in-line power.

24-port 100/1000 Mbps Ethernet hybrid fiber (SFP) interface module

The 24-port 100/1000 Mbps Ethernet hybrid fiber (SFP) interface module has 24

ports with connectors for Small form Factor Pluggable (SFP) Multisource Agreement

(MSA)-compliant transceivers.

Figure 9 shows the IPv4 100/1000 hybrid fiber interface module’s front panel. The

IPv6 100/1000 hybrid fiber interface module appears the same as the IPv4 module

except the label on the left end reads ″SX 624HF″ instead of ″SX 424HF".

Port 1

SX

424HF

Port 2

Figure 9. IPv4 100/1000 Hybrid Fiber interface module

Port 13

LEDs

Port 24

net08bs018

The front panel includes the following control features:

v 24 Gigabit Ethernet fiber ports

v 24 LEDs

The ports on the 24-port 100/1000 Gigabit Ethernet Hybrid Fiber module operate at

a fixed speed of 100 or 1000 Mbps (they do not support 10 Mbps connections), and

use auto-negotiation to automatically configure the highest performance mode of

inter-operation with the connected device.

Only supported Brocade-branded fiber-optic transceivers can be used in these

products. The SFP-compliant fiber-optic modules provide an optical transceiver or

physical medium dependent (PMD) interface for single or multi-mode fiber that can

Chapter 2. Product Overview 15

Page 42

be used with the LAN physical layer (PHY) and support optical monitoring

capabilities. Types of Brocade-branded SFP transceivers for the 100/1000 1 GbE

(SFP) interface modules include:

v 1000BaseT SFP Copper, 1 Gbps up to 100 m over CAT5 or higher cabling,

RJ-45 connector

v 1000Base SX 850 nm SFP optic, 1 Gbps up to 550 m over multi-mode fiber, LC

connector

v 1000Base LX 1310 nm SFP optic, 1 Gbps up to 10 km over single-mode fiber,

LC connector

v 1000Base LHA 1550 nm SFP optic, 1 Gbps up to 70 km over single-mode fiber,

LC connector

The slots support the 100Base and 1000Base fiber cabling listed in “Network

interfaces” on page 17.

Support for 100Base-FX on the 100/1000 interface module

The 24-port 100/1000 fiber interface module supports the 100Base FX 1310 nm

SFP optic, 100 Mbps up to 2 km over multi-mode fiber, LC connector.

To enable support for 100BaseFX, enter the CLI command at the interface level of

the CLI. For CLI command details, see the section regarding ″Enabling and

Disabling Support for 100BaseFX″ in the Configuration Guide.

2-port 10-Gigabit Ethernet interface modules

The 2-port 10-Gigabit Ethernet modules contain two physical ports, through which

you can connect the IBM device to other network devices at a speed of 10 Gigabits

per second.

Only supported Brocade-branded fiber-optic transceivers can be used in this

product. The XFP-compliant fiber-optic modules provide an optical transceiver or

physical medium dependent (PMD) interface for single or multi-mode fiber that can

be used with the LAN physical layer (PHY), and support optical monitoring

capabilities. Types of Brocade-branded XFP transceivers for the 10 GbE interface

modules include:

v Short Reach, 850 nm serial pluggable XFP optic, 10 Gbps up to 300 m over

multi-mode fiber, LC connector

v Long Reach, 1310 nm serial pluggable XFP optic, 10 Gbps up to 10 km over

single-mode fiber, LC connector

v Extended Reach, 1550 nm serial pluggable XFP optic, 10 Gbps up to 40 km over

single-mode fiber, LC connector

v 10 Base CX4, XFP transceiver, 10 Gbps up to 15 km, CX connector

Figure 10 shows the IPv4 2-port 10-Gigabit Ethernet module’s front panel.

42XG

Figure 10. IPv4 2-port 10-Gigabit Ethernet module’s front panel

Lnk

Act

1

Lnk

Act

2

net08bs020

16 Ethernet Switch s-series Installation and User Guide

Page 43

The IPv6 version has an identical appearance, except for the label on the left side,

which reads 62XG.

LEDs for 2-port 10-Gigabit Ethernet module

The 10 Gbps ports provide status information using the LEDs . This chapter

highlights the meanings and appearance of the LED on the 2-port 10-Gigabit

Ethernet module.

Table 9. LED on the 2-port 10-Gigabit Ethernet module

LED Position State Meaning

Lnk Top left of connector On Fiber port is connected.

Act Bottom left of