RS/6000 44P Series Model 170 User’s Guide

User’s Guide

IBM

Note to Printer:

Print Graphic between registration marks

Book trim size is 7 3/8 x 9 inches

Front Cover is 10pt.Carolina stock or equivalent C1S (coated one side)

Use Color Graphic cvtestd.ps on front cover - User Book

SA38-0559-01

RS/6000 44P Series Model 170 User’s Guide

User’s Guide

IBM

SA38-0559-01

Second Edition (October 2000)

Before using this information and the product it supports, read the information in “Safety Notices” on page xi,

“Appendix A. Environmental Notices” on page 161, and “Appendix B. Notices” on page 163.

©International Business Machines Corporation 2000. All rights reserved.

Note to U.S. Government Users - Documentation related to restricted rights - Use, duplication, or disclosure is subject

to the restrictions set forth in the GSA ADP Schedule Contract with IBM Corp..

Contents

Safety Notices ........................xi

Electrical Safety........................xi

Unit Emissions ........................xii

Laser Safety Information.....................xii

Data Integrity and Verification ..................xiii

About This Book .......................xv

ISO 9000..........................xv

Online Publications ......................xv

Related Publications ......................xv

Trademarks .........................xv

Chapter 1. Introducing the 44P Model 170 ..............1

System Features .......................1

Bus Architecture.......................1

Microprocessor .......................1

Memory.........................1

Media Drives ........................1

Other Drives ........................2

Power Supply .......................2

Keyboard .........................2

Mouse ..........................2

Operator Panel .......................2

Input/Output Ports ......................2

Security Features ......................2

Front View.........................3

RearView.........................4

Operator Panel .......................6

Chapter 2. Using the 44P Series Model 170 ..............7

Starting the System Unit .....................7

Stopping the System Unit.....................7

Reading the Operator Panel Display .................8

Operator Panel .......................8

Using the Keyboards ......................9

Using the Three-Button Mouse ..................10

Handling the Mouse Correctly ..................10

Caring for the Mouse.....................10

Cleaning the Mouse .....................11

Using the 3.5-Inch Diskette Drive..................1212

Write-Protecting 3.5-Inch Diskettes ................13

Loading and Unloading the 3.5-Inch Diskette .............14

Using the CD-ROM Drive ....................14

Front View of CD-ROM Drive ..................15

Understanding the Status Lights .................15

Handling Compact Discs ...................16

iii

Other Handling Considerations .................16

Loading a Compact Disc ...................17

Opening the Tray Manually ...................18

Playing an Audio CD .....................18

General Information for the 8mm Tape Drive ..............18

Front View of the 8mm Tape Drive ................19

Operating Recommendations ..................20

8 mm Tape Cartridge Types ..................20

Tape Cartridge Compatibility ..................21

Setting the Write-Protect Tab on 8 mm Tape Cartridges .........21

Environmental Considerations for 8 mm Data Cartridges .........22

Operating the 8mm Tape Drive in Harsh Environments .........22

Erasing 8 mm Data Cartridge ..................22

Using the 8mm Tape Drive ....................23

Status Lights .......................23

Liquid Crystal Display ....................24

Changing the Display Language .................24

Loading the 8 mm Tape Cartridge ................25

Unloading the 8 mm Tape Cartridge ................26

Cleaning the Tape Drive....................27

Obtaining Additional Tape Cartridges ...............29

General information for the 12/24GB 4mm Tape Drive ...........29

Front View of the 12/24GB 4mm Tape Drive .............30

Using the 12/24GB 4mm Tape Drive.................30

Operating Recommendations ..................30

12/24 GB 4 mm Tape Cartridge Types ...............31

Tape Cartridge Compatibility ..................31

4 mm Tape Write Density Setting.................31

Setting the Write-Protect Tab on 12/24 GB 4 mm Tape Cartridges ......32

Erasing 12/24 GB 4 mm Data Cartridge ..............32

Environmental Considerations for 12/24 GB 4 mm Data Cartridges .....32

Operating the 12/24GB 4mm Tape Drive in Harsh Environments ......33

Status Lights .......................33

Status Light States .....................34

Loading the 12/24 GB 4 mm Tape Cartridge .............35

Unloading the 12/24 GB 4 mm Tape Cartridge ............36

Cleaning the Tape Path on the 12/24GB 4mm Tape Drive ........37

Obtaining Additional Tape Cartridges ...............38

Using the Service Processor and Service Director Features .........38

Service Processor......................38

Service Director ......................39

Chapter 3. Using the Service Processor...............41

Service Processor Menus ....................42

Service Processor Menu Inactivity ................42

Accessing Service Processor Menus Locally .............42

Accessing Service Processor Menus Remotely ............42

General User Menu ......................43

Privileged User Menus .....................44

MainMenu........................44

iv 44P Series Model 170 User’s Guide

Service Processor Setup Menu .................45

Passwords ........................45

Serial Port Snoop Setup Menu .................47

System Power Control Menu ..................48

System Information Menu ...................50

Language Selection Menu ...................53

Call-In/Call-Out Setup Menu ..................54

Modem Configuration Menu ..................54

Serial Port Selection Menu ...................55

Serial Port Speed Setup Menu .................55

Telephone Number Setup Menu .................56

Call-Out Policy Setup Menu ..................57

Customer Account Setup Menu .................58

Reboot/Restart Policy Setup Menu ................59

Service Processor Functions ...................60

System Power-On Methods ...................61

Service Processor Call-In Security .................62

Service Processor Reboot/Restart Recovery ..............63

Boot (IPL) Speed ......................63

Failure During Boot Process ..................63

Failure During Normal System Operation ..............63

Service Processor Reboot/Restart Policy Controls ...........63

Processor Boot-Time Deconfiguration (CPU Repeat-Gard) ........63

Processor Run-Time Deconfiguration (CPU-Gard) ...........64

Memory Boot-Time Deconfiguration (Memory Repeat-Gard) ........64

Service Processor System Monitoring - Surveillance ...........65

System Firmware Surveillance..................65

Operating System Surveillance .................65

CallOut.........................66

Console Mirroring .......................67

Service Processor Firmware Updates ................67

Service Processor Error Log ...................68

System POST Errors ......................69

Service Processor Operational Phases ................69

Pre-Standby Phase .....................69

Standby Phase.......................70

Bring-Up Phase ......................70

Run-time Phase ......................71

Service Processor Procedures in Service Mode .............71

Chapter 4. System Management Services ..............73

Graphical System Management Services ...............73

Config...........................75

Multiboot ..........................76

Utilities ..........................79

Password .........................80

Power-On Password .....................81

Privileged-Access Password ..................83

ErrorLog ..........................85

RIPL...........................86

Contents v

Set Address........................87

Ping ..........................88

Config..........................90

SCSIID..........................91

Firmware Update .......................92

Firmware Recovery .....................93

Text-Based System Management Services ..............94

Display Configuration......................94

Multiboot Menu........................95

Select Boot Device .....................96

Configure Nth Boot Device ...................97

Utilities ..........................98

Set Password and Unattended Start Mode .............98

SCSI Spin Up.......................100

Display Error Log .....................100

Remote Initial Program Load Setup ...............100

Change SCSI ID ......................103

Update System or Service Processor Firmware ...........103

Firmware Recovery .....................104

Select Console ......................104

Select Language.......................104

OpenFirmware.......................105

Chapter 5. Using the Standalone and Online Diagnostics ........107

Standalone and Online Diagnostics Operating Considerations ........107

Selecting a Console Display ..................107

Identifying the Terminal Type to the Diagnostics Programs ........107

Undefined Terminal Types...................108

Resetting the Terminal ....................108

Running Standalone Diagnostics ................108

Running Online Diagnostics ..................108

Running Diagnostics from a TTY Terminal .............109

Online Diagnostics Modes ...................109

Service Mode .......................109109

Concurrent Mode......................110

Running the Online Diagnostics in Concurrent Mode ..........111

Maintenance Mode .....................111

Running the Online Diagnostics in Maintenance Mode .........111

Standalone Diagnostic Operation .................112

Running the Standalone Diagnostics ...............112

Chapter 6. Introducing Tasks and Service Aids ............113

Tasks ..........................113

Add Resource to Resource List ..................114

AIX Shell Prompt.......................115

Analyze Adapter Internal Log...................115

Backup and Restore Media ...................115

Certify Media ........................115

Change Hardware Vital Product Data ................116

Configure Dials and LPFKeys ..................116

vi 44P Series Model 170 User’s Guide

Configure ISA Adapter .....................117

Configure Reboot Policy ....................117

Configure Remote Maintenance Policy ...............118

Configure Ring Indicate Power On Policy...............120

Configure Ring Indicate Power On .................120

Configure Service Processor ...................120

Surveillance Setup .....................121

Modem Configuration ....................121

Call In/Out Setup .....................121

Site-Specific Call In/Out Setup .................121

Reboot/Restart Policy Setup ..................122

Configure Surveillance Policy ..................123

Create Customized Configuration Diskette ..............123

Delete Resource from Resource List ................123

Disk Maintenance ......................124

DisktoDiskCopy.....................124

Display/Alter Sector ......................125

Display Configuration and Resource List ...............125

Display Firmware Device Node Information ..............125

Display Hardware Error Report ..................125

Display Hardware Vital Product Data ................125

Display Machine Check Error Log .................125

Display Microcode Level ....................126

Display or Change Bootlist ...................126

Display or Change Diagnostic Run-Time Options ............126

Display Previous Diagnostic Results ................127

Display Resource Attributes ...................127

Display Service Hints .....................128

Display Software Product Data ..................128

Display System Environmental Sensors ...............128

Examples ........................129

Display Test Patterns .....................130

Download Microcode .....................130

Download Microcode to PCI SCSI RAID Adapter ...........130

Download Microcode to Disk Drive Attached to a PCI SCSI RAID Adapter 130

Download Microcode to a PCI FC-AL Adapter ............130

Download Microcode to Other Devices ..............131

Fiber Channel RAID Service Aids .................131

Flash SK-NET FDDI Firmware ..................132

Format Media........................132

Hardfile Attached to SCSI Adapter (non-RAID) ............132

Hardfile Attached to PCI SCSI RAID Adapter ............133

Optical Media .......................134

Diskette Format ......................134

Generic Microcode Download ..................134

Local Area Network Analyzer...................135

Log Repair Action ......................135

Periodic Diagnostics .....................135

PCI RAID Physical Disk Identify..................136

Process Supplemental Media ..................136

Contents vii

Run Diagnostics .......................136

Run Error Log Analysis ....................136

Run Exercisers .......................136

Exerciser Commands (Cmd) ..................136

Acronyms ........................137

Memory Exerciser .....................137

Save or Restore Hardware Management Policies ............138

Save or Restore Service Processor Configuration ............138

SCSI BUS Analyzer......................138

SCSI Device Identification and Removal ...............139

SCSI Tape Drive Service Aid ...................139

Spare Sector Availability ....................141

SSA Service Aid .......................141

Update Disk-Based Diagnostics ..................141

Update System or Service Processor Flash ..............141

Update System Flash .....................142

7135 RAIDiant Array Service Aid .................142143

7318 Serial Communications Network Server Service Aid .........143

Chapter 7. Using the System Verification Procedure ..........145

Step 1. Considerations before Running This Procedure ..........145

Step 2. Loading the Diagnostics..................145

Step 3. Running System Verification ................146

Step 4. Additional System Verification................146

Step 5. Stopping the Diagnostics .................147

Chapter 8. Hardware Problem Determination ............149

Problem Determination Using the Stand-alone or Online Diagnostics .....149

Step 1. Considerations before Running This Procedure ..........149

Step 2 ..........................149

Step 3 ..........................150

Step 4 ..........................150

Step 5 ..........................150

Step 6 ..........................151

Step 7 ..........................151

Step 8 ..........................151

Step 9 ..........................152

Step 10 ..........................152

Step 11 ..........................152

Step 12 ..........................153

Step 13 ..........................153

Step 14 ..........................154

Step 15 ..........................154

Step 16 ..........................154

Step 17 ..........................155

Problem Determination When Unable to Load Diagnostics .........156

Step 1. Considerations before Running This Procedure ..........156

Step 2 ..........................156

Step 3 ..........................156

Step 4 ..........................157

viii 44P Series Model 170 User’s Guide

Step 5 ..........................157

Step 6 ..........................159

Step 7 ..........................159

Appendix A. Environmental Notices................161

Product Recycling and Disposal..................161

Environmental Design .....................161

Appendix B. Notices .....................163

Appendix C. Checking the Current Firmware Levels ..........165

Appendix D. General Attributes Required When Using a TTY Terminal ...167

Additional Communication Attributes ................168

Additional Keyboard Attributes ..................169

Additional Printer Attributes ...................170

Appendix E. Modem Configurations................171

Sample Modem Configuration Files ................171

Configuration File Selection ...................171

Examples for Using the Generic Sample Modem Configuration Files ....173

Customizing the Modem Configuration Files.............173

IBM 7852-400 DIP Switch Settings................174

Xon/Xoff Modems .....................174

Ring Detection ......................175

Terminal Emulators .....................175

Recovery Procedures ....................175

Transfer of a Modem Session ..................175

Recovery Strategy .....................176

Prevention Strategy .....................177

Modem Configuration Samples .................177

Index ..........................191

Reader’s Comments — We’d Like to Hear From You..........195

Contents ix

x 44P Series Model 170 User’s Guide

Safety Notices

Danger notices appear on the following pages:

v xi

v xii

A

moderate or minor personal injury.

Caution notices appear on the following pages:

v xii

v xii

Note: For a translation of these notices, see

Electrical Safety

Observe the following safety instructions any time you are connecting or disconnecting

devices attached to the workstation.

DANGER

caution

An electrical outlet that is not correctly wired could place hazardous voltage

on metal parts of the system or the devices that attach to the system. It is the

responsibility of the customer to ensure that the outlet is correctly wired and

grounded to prevent an electrical shock.

Before installing or removing signal cables, ensure that the power cables for

the system unit and all attached devices are unplugged.

When adding or removing any additional devices to or from the system,

ensure that the power cables for those devices are unplugged before the

signal cables are connected. If possible, disconnect all power cables from the

existing system before you add a device.

notice indicates the presence of a hazard that has the potential of causing

System Unit Safety Information

number SA23-2652

, order

Use one hand, when possible, to connect or disconnect signal cables to

prevent a possible shock from touching two surfaces with different electrical

potentials.

During an electrical storm, do not connect cables for display stations, printers,

telephones, or station protectors for communication lines.

xi

CAUTION:

This product is equipped with a three–wire power cable and plug for the user’s

safety. Use this power cable with a properly grounded electrical outlet to avoid

electrical shock.

DANGER

To prevent electrical shock hazard, disconnect the power cable

Unit Emissions

The unit-related emission value is equal to or lower than 70dB(A).

Der Geräuschpegel der Einheit ist kleiner oder gleich 70 db(A).

Laser Safety Information

The optical drive in this system unit is a laser product. The optical drive has a label that

identifies its classification. The label, located on the drive, is shown below.

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

APPAREIL A LASER DE CLASSE 1

IEC 825:1984 CENELEC EN 60 825:1991

The optical drive in this system unit is certified in the U.S. to conform to the

requirements of the Department of Health and Human Services 21 Code of Federal

Regulations (DHHS 21 CFR) Subchapter J for Class 1 laser products. Elsewhere, the

drive is certified to conform to the requirements of the International Electrotechnical

Commission (IEC) 825 (1st edition 1984) and CENELEC EN 60 825:1991 for Class 1

laser products.

CAUTION:

A class 3 laser is contained in the device. Do not attempt to operate the drive

while it is disassembled. Do not attempt to open the covers of the drive as it is

not serviceable and is to be replaced as a unit.

Class 1 laser products are not considered to be hazardous. The optical drive contains

internally a Class 3B gallium-arsenide laser that is nominally 30 milliwatts at 830

nanometers. The design incorporates a combination of enclosures, electronics, and

redundant interlocks such that there is no exposure to laser radiation above a Class 1

level during normal operation, user maintenance, or servicing conditions.

xii 44P Series Model 170 User’s Guide

Data Integrity and Verification

IBM computer systems contain mechanisms designed to reduce the possibility of

undetected data corruption or loss. This risk, however, cannot be eliminated. Users who

experience unplanned outages, system failures, power fluctuations or outages, or

component failures must verify the accuracy of operations performed and data saved or

transmitted by the system at or near the time of the outage or failure. In addition, users

must establish procedures to ensure that there is independent data verification before

relying on such data in sensitive or critical operations. Users should periodically check

the IBM support websites for updated information and fixes applicable to the system and

related software.

xiii

xiv 44P Series Model 170 User’s Guide

About This Book

This book provides information on how to use the system, use diagnostics, use service

aids, and verify system operation. This book also provides information to help you solve

some of the simpler problems that might occur.

ISO 9000

ISO 9000 registered quality systems were used in the development and manufacturing

of this product.

Online Publications

RS/6000 publications are available online. To access the online books, visit our Web

site at: http://www.rs6000.ibm.com/resource/hardware_docs/

Related Publications

The following publications provide additional information about your system unit:

v The

SA38-0561,contains reference information, maintenance analysis procedures (MAPs),

error codes, removal and replacement procedured, and a parts catalog.

v The

SA38-0560,contains reference information, maintenance analysis procedures (MAPs),

error codes, removal and replacement procedured, and a parts catalog.

v The

contains diagnostic information, service request numbers (SRNs), and failing function

codes (FFCs).

v The

SA38-0516, contains information about adapters, devices, and cables for your

system. This manual is intended to supplement the service information found in the

Diagnostic Information for Multiple Bus Systems

v The

information to help you plan your installation.

RS/6000 44P Series Model 170

RS/6000 44P Series Model 170 Service Guide

Diagnostic Information for Multiple Bus Systems

Adapter, Device, and Cable Information for Multiple Bus Systems

Site and Hardware Planning Guide

Installation Guide, order number

, order number

, order number SA38-0509 ,

.

, order number SA38-0508, contains

, order number

Trademarks

The following terms are trademarks of International Business Machines Corporation in

the United States, other countries, or both:

v AIX

v IBM

v RS/6000

v PowerPC

xv

Other company, product, and service names may be trademarks or service marks of

others.

xvi 44P Series Model 170 User’s Guide

Chapter 1. Introducing the 44P Model 170

The 7044 Model 170 servers combine PowerPC 604e microprocessor performance and

system expandability, ensuring that your server adapts to handle ever-changing

operating requirements. The 7044 Model 170 servers are specifically designed to

support the demands of network environments.

The 7044 Model 170 servers incorporate the peripheral component interconnect (PCI)

bus, which is faster than the industry standard architecture (ISA) bus.

This book helps you use the system, use diagnostics, use service aids, and verify

system operation. This book also provides information to help you solve some of the

simpler problems that might occur, and how to obtain assistance and service.

System Features

Bus Architecture

Six PCI slots are available:

v Two 64-bit PCI full-size slots at 50 MHz (can also run at 33MHz), 3.3 volts

v Four 32-bit PCI full-size slots at 33 MHz, 5 volts

Microprocessor

v One 333 MHz Power3+ microprocessor with 32KB instruction, 64KB data and 1MB

L2 cache, OR

v One 400 MHz Power3+ microprocessor with 32KB instruction, 64KB data and 4MB

L2 cache

v One 450 MHz Power3+ microprocessor with 32KB instruction, 64KB data and 8MB

4-way L2 cache

Memory

Media Drives

v 256 MB (minimum)-2GB(maximum).

Up to four dual inline memory-modules, installed in pairs, to support 128MB, 256MB

or 512MB (must be installed in matched pairs).

v 3.5-inch, 1.44 MB Diskette Drive (standard)

v Internal Hard Disk Drives:

– 9.1 GB Ultra SCSI Drive (standard)

– 18.2 GB Ultra SCSI Drive

Note: Larger sizes may be available. Contact your representative for additional

information.

– Two media bays available

1

v 32x speed CD-ROM drive with sliding tray.

Other Drives

Drive bays can accommodate 5.25-inch or 3.5-inch drives such as hard disk drives,

CD-ROM drives, tape drives, or other removable media drives.

Power Supply

v 390-watt, usable with 100-127 V ac (low voltage) or 200-240 V ac (high voltage).

Keyboard

v Standard: 101-key Enhanced Keyboard

v 101/102 or 106-key Enhanced Keyboard

Mouse

v 3-button

Operator Panel

v 32-character LED diagnostics display

v Power and Reset buttons

Input/Output Ports

v 25-pin Parallel

v 9-pin Serial (2)

v 8-pin Tablet

v Keyboard

v Mouse

v Ultra2 SCSI - LVD

v 10Base5 Ethernet

v 10BaseT or 100BaseTX Ethernet

v Audio Line-in

v Audio Line-out

v Microphone

v Headphone

Security Features

v Power-on password

v Privileged-access password

v Security Bolt (optional)

v Key lock

v Unattended start mode

2 44P Series Model 170 User’s Guide

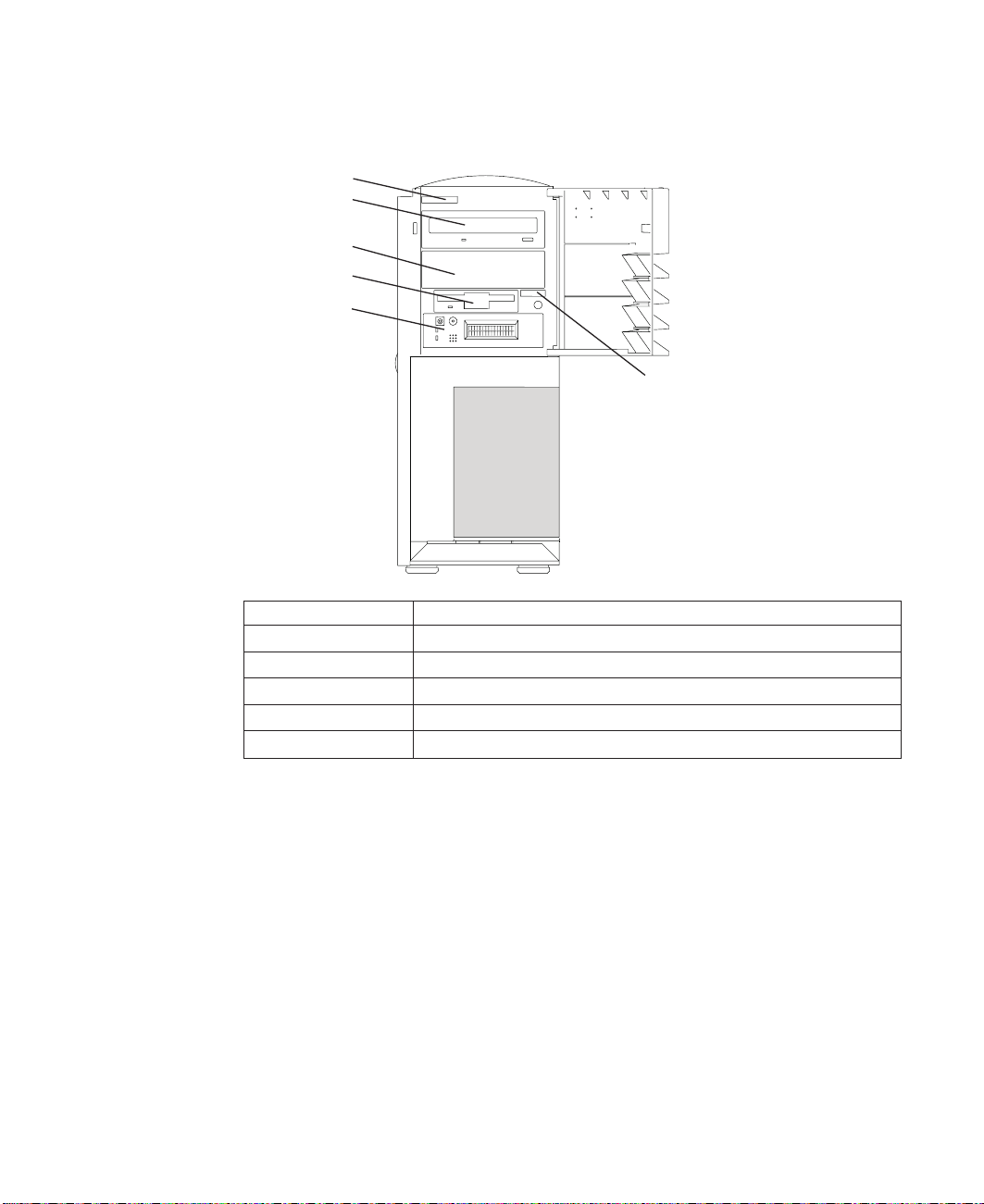

Front View

1

2

3

4

5

6

1 System Type and Model Number Identification Tag

2 CD-ROM Drive

3 Optional Media Bay

4 Diskette Drive

5 Operator Panel

6 System Serial Number

Chapter 1. Introducing the 44P Model 170 3

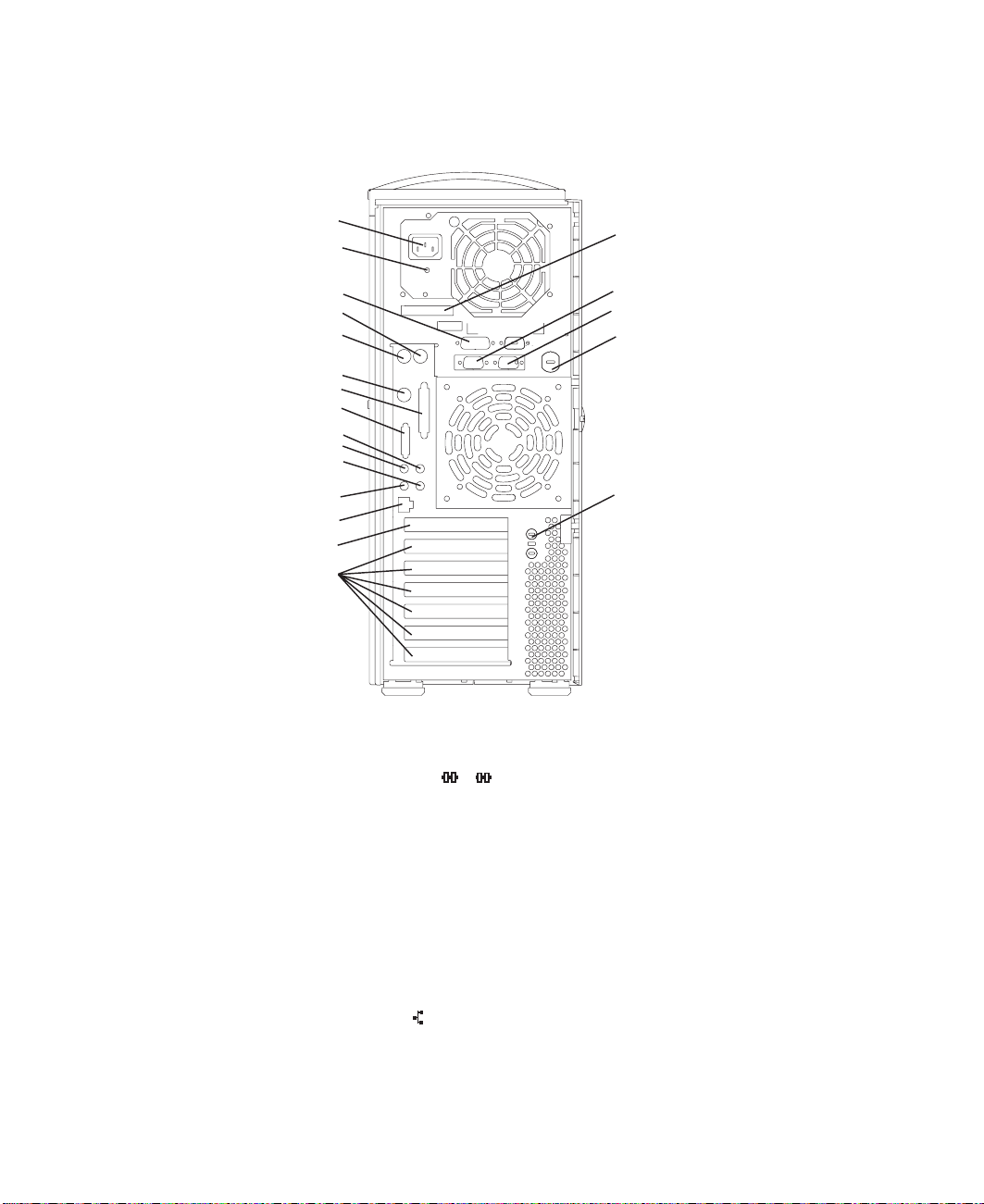

Rear View

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

1 Serial Number Label: For machine identification.

1

2

3

4

5

2 and 3 9-Pin Serial Ports (

devices.

4 Keylock: For security.

5 Security Bolt: Optional security measure.

6 Adapter Slots (6): For adding PCI adapters.

7 Empty Slot: This slot is not used.

8 Ethernet Connector (

connection through a 10baseT connector.

9 Headphones: For connecting headphones.

10 Microphone: For connecting a microphone.

4 44P Series Model 170 User’s Guide

2

1

):For a TTY terminal, modem, or other serial

):For attaching your computer to an Ethernet/Twisted pair

11 and 12 Audio Ports:

Audio line out

Audio line in

13 External SCSI Port ( ):For connecting external SCSI devices.

14 Parallel Port (

15 Tablet Port (

16 Mouse Port (

17 Keyboard Port (

18 10Base5 Ethernet Port (

):For connecting a parallel printer or other parallel devices.

):For attaching a digitizing tablet to your computer.

):For mouse connection.

):For keyboard connection.

):For attaching your computer to an Ethernet thick

connection (or Ethernet thin connection, using an optional transceiver) through a

10base5 connector.

19 Status Light: For indicating power supply status.

20 Power Connector: For connecting the power cable.

Chapter 1. Introducing the 44P Model 170 5

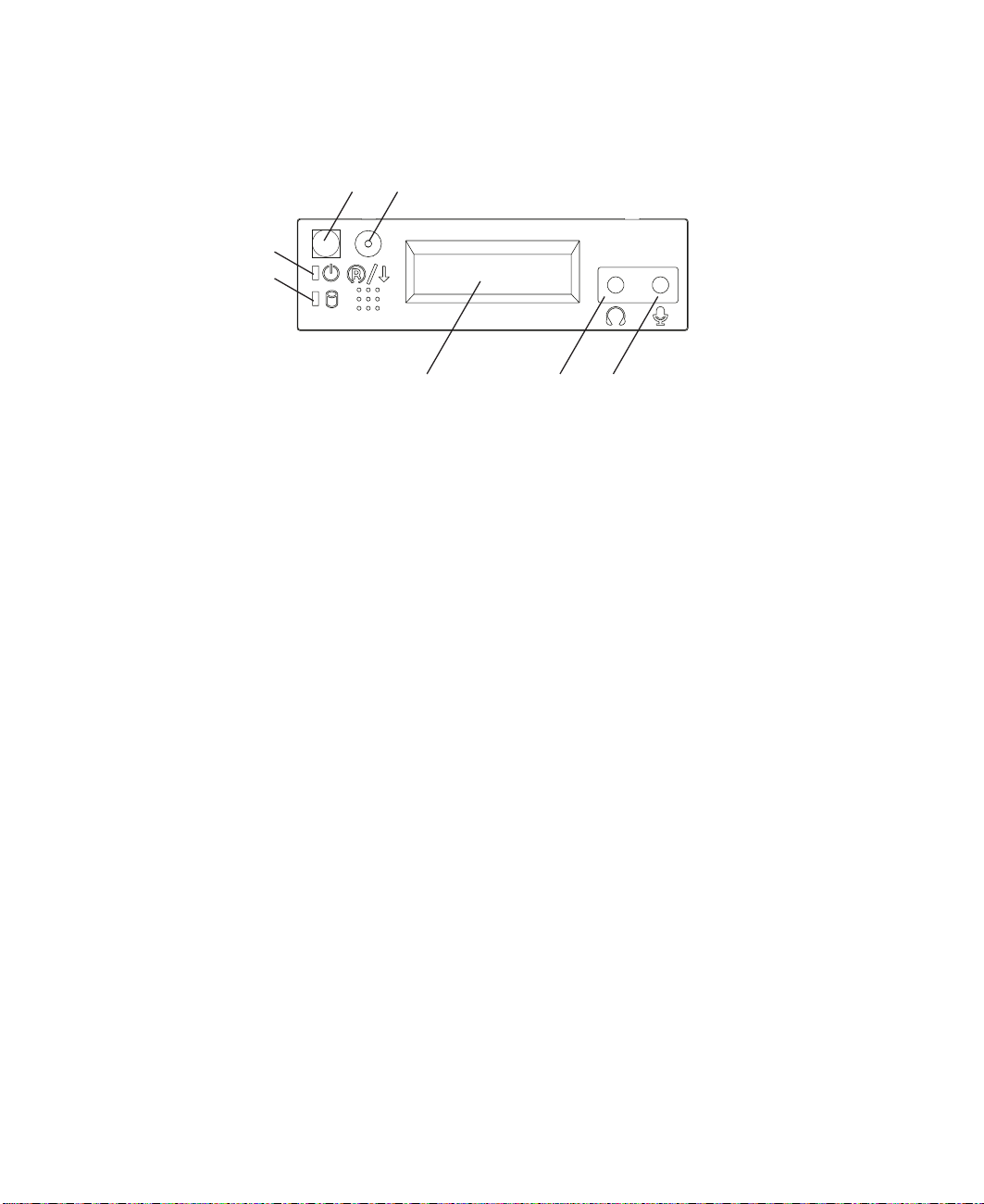

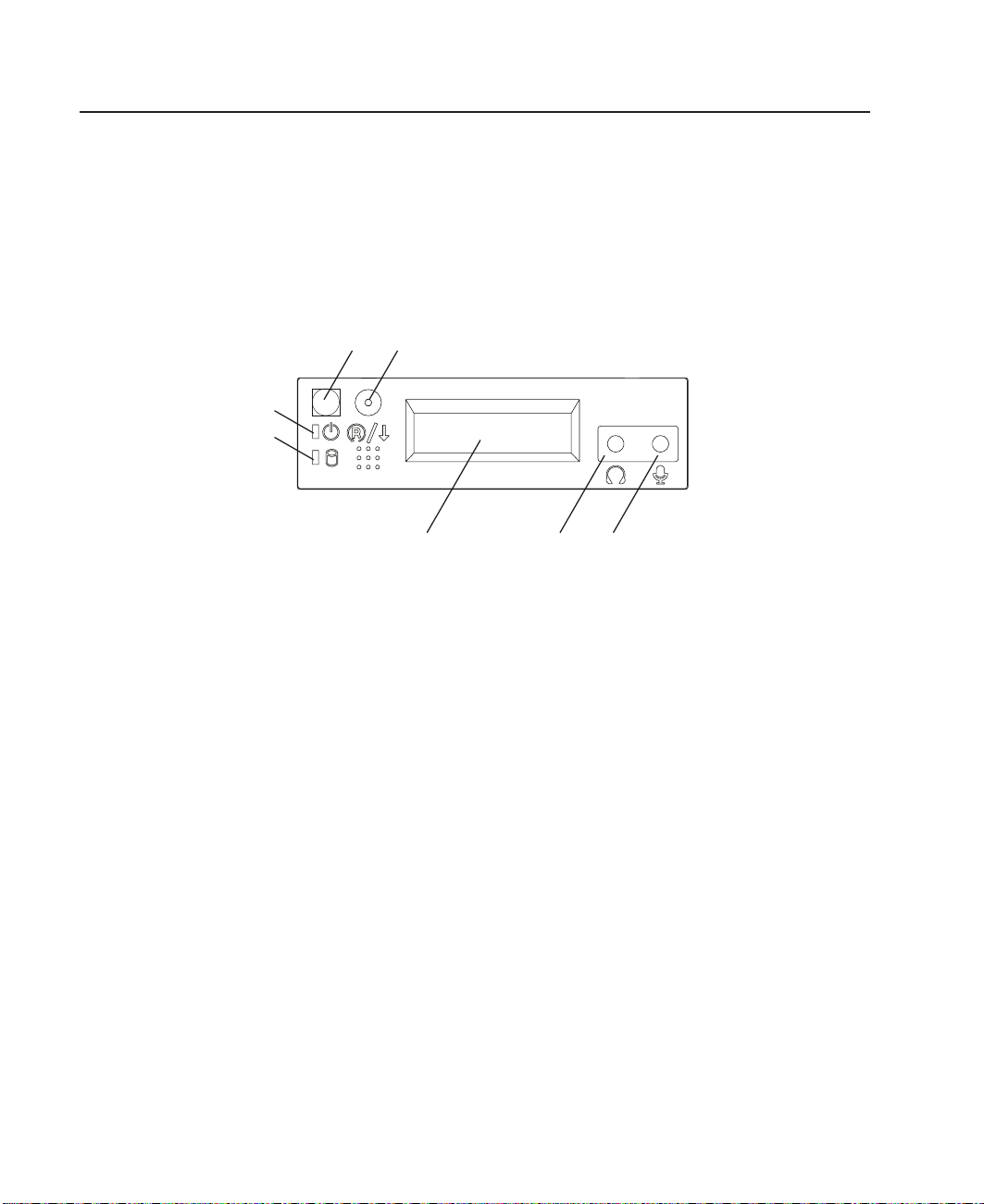

Operator Panel

1

2

3

4

6

5

7

1 Power On Switch: Turns system unit power on and off.

2 Reset Switch: Function depends upon the operating system.

3 Power-On LED: Glows when system unit is on.

4 Hard Disk Drive Status LED: Glows when system unit is reading from or writing to

the disk drive.

5 Operator Panel Display: Displays current status of system unit startup, or

diagnostic information in the event of a hardware problem.

6 Headphone Jack: For connecting audio headphones.

7 Microphone Receptacle: For connecting audio microphone.

6 44P Series Model 170 User’s Guide

Chapter 2. Using the 44P Series Model 170

This chapter provides information on how to start and use the system unit.

Starting the System Unit

1. Set the power switches of the attached devices to On.

Note: When the system is plugged in but not powered on, the Power-On LED

flashes slowly.

2. If the LED is not flashing and OK is not displayed, ensure that the power cord,

located at the back of the system unit, is plugged into a grounded electrical outlet.

3. If this does not solve the problem, go to “Chapter 8. Hardware Problem

Determination” on page 149.

4. Press the Power-On switch (1).

1

2

When you press the Power-On switch (1), the Power-On LED (2) comes on, and

the system starts a POST (power-on self test).

During POST, progress codes display in the operator panel display.

5. If the Power-On LED does not come on and there is no indication of power when

you press the Power-On switch, go to “Chapter 8. Hardware Problem Determination”

on page 149.

Stopping the System Unit

Attention: When you use the shutdown procedure for your system, follow the correct

shutdown procedure before you stop the system unit. Failure to do so can

result in the loss of data. The System unit is powered down by the

shutdown procedure.

1. At a command line, enter shutdown command to stop the operating system.

2. After you shut down the operating system, set the power switches of any attached

devices to Off.

3. If you will be servicing the system unit, unplug the system-unit power cable from the

electrical outlet.

7

Reading the Operator Panel Display

The operator panel display is used to:

v Track the progress of the system unit self-tests and configuration program

v Display codes when the operating system comes to an abnormal end

v Display system messages

Operator Panel

1

2

3

4

1 Power On Switch: Turns system unit power on and off.

2 Reset Switch: Function depends upon the operating system.

6

5

7

3 Power-On LED: Glows when system unit is on.

4 Hard Disk Drive Status LED: Glows when system unit is reading from or writing to

the disk drive.

5 Operator Panel Display: Displays current status of system unit startup, or

diagnostic information in the event of a hardware problem.

6 Headphone Jack: For connecting audio headphones.

7 Microphone Receptacle: For connecting audio microphone.

8 44P Series Model 170 User’s Guide

Using the Keyboards

There are several keyboards available for the system unit. The keyboards have various

keys that enter data and control the cursor location. The keyboards can be engraved for

the languages of different countries.

The functions of each keyboard depend on the software used. The character sets for

the keyboards are contained and explained in the documentation for your operating

system.

Esc F1 F2 F3 F4 F6 F7 F8F5 F9 F10 F11 F12 Pause

!

123

QWER YUIT OP

Tab

Caps

Lock

Shift

Ctrl Alt

Function Keys

$% &

@

#

4567

ASDFGHJK L :

ZXCVBNM

*

8

()

90

<

>

,

_

-

;

Alt Ctrl

Num

Caps

Print

Scroll

Screen

SysRq

+

Backspace

=

"

,

?

Shift

/.

Insert

Delete

Enter

Lock

Lock

Break

Page

Home

Up

Page

End

Down

Lock

Num

/*-

Lock

789

Home PgUp

654

321

End

PgDn

.

0

Ins Del

Scroll

Lock

+

Enter

Typewriter Keys

Control

Keys

Numeric

Keypad

The keyboard is divided into four sections:

v

Function keys

are multipurpose keys and their function is controlled by the operating

system.

v

Typewriter keys

are similar to a standard typewriter. Their function is controlled by

the software.

v

Control keys

move the cursor on the screen and do programmed control functions.

The movement and functions depend upon the application used.

v

Numeric keypad

is arranged like a calculator to help when typing numbers.

On all of the keyboards, you can adjust the tilt position for typing comfort. To tilt the

keyboard, pull out on the keyboard legs. The legs snap into position. To decrease the

tilt of the keyboard, rotate the keyboard legs until they snap into the bottom of the

keyboard case.

The keyboard cable plugs into the keyboard connector at the rear of the system unit.

Chapter 2. Using the 44P Series Model 170 9

Using the Three-Button Mouse

The mouse is a hand-operated locating device. A three-button mouse is available for

use with the system unit. Consult your application publication for the exact use of the

three-button mouse.

You can use the mouse to perform such functions as positioning a cursor, selecting

items from a menu, or moving around in your document much easier and faster than if

you used only the keyboard. The cursor moves exactly as you move the mouse on a

flat surface, such as a desktop.

With the mouse buttons, you can perform functions such as selecting and deselecting

options, extending your selection, or choosing a command. The precise function of your

mouse depends on the software you are using.

The mouse has a cable that plugs into the mouse connector at the rear of the system

unit.

Handling the Mouse Correctly

For best operation, handle the mouse with care. Incorrect handling can damage the

mouse.

Do not:

v Operate the mouse on cloth, unfinished wood, newspaper, or carpet.

v Drop or hit the mouse.

v Carry the mouse by holding onto the cable.

v Expose the mouse to extreme temperatures or direct sunlight.

v Place the mouse in liquid spills.

Caring for the Mouse

The operating surface for the mouse should be smooth, clean, and flat. For example,

you can operate the mouse on the following surfaces:

v Finished wood

v Glass

v Enamel

v Plastic

v Paper (except newspaper)

v Metal

10 44P Series Model 170 User’s Guide

Rough surfaces collect contaminants that can be transferred to the interior of the mouse

by the ball.

Rough surfaces can also cause the pads located on the bottom of the mouse to

prematurely wear. A deeply pitted surface could cause erratic operation of the mouse.

The surface you use should be free from spills, dirt, dust, lint, wax, eraser dust, and

other foreign matter.

To care for the mouse:

v Inspect the work surface for spills or other contaminants.

v Dust the work surface.

v If you are using a paper pad, inspect it for wear and replace it if necessary.

Cleaning the Mouse

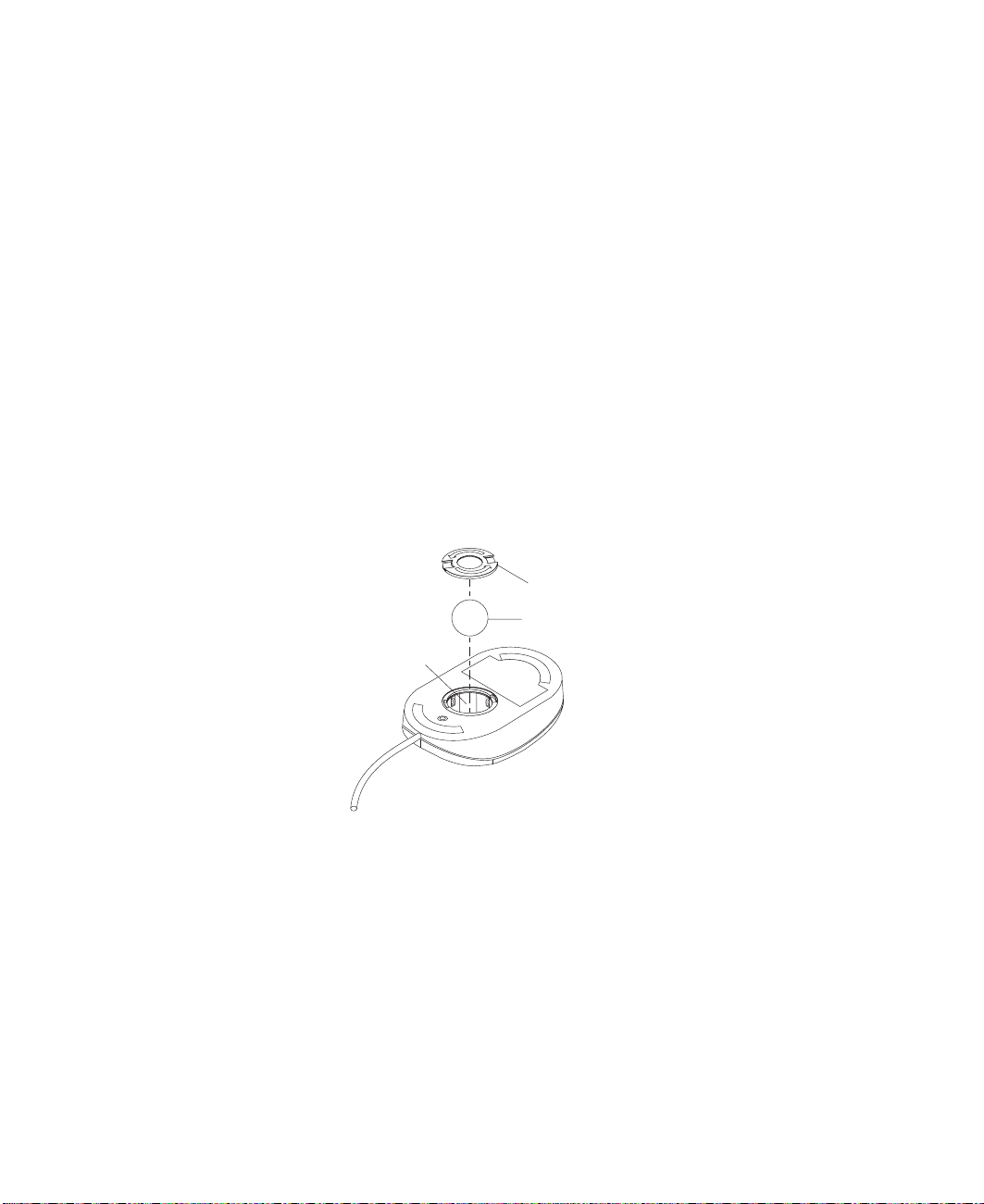

Use the following steps to clean the mMouse:

1. Remove the retaining ring by turning it counterclockwise, in the direction of the

arrow, as shown in the illustration.

Retaining Ring

Ball

Cavity

2. Remove the ball.

3. Inspect the ball for contaminants. Wipe it clean with a dry, lint-free cloth.

4. If the ball is dirty, wash it in warm, soapy water. Rinse and wipe the ball with a

lint-free cloth until dry.

5. Inspect the ball cavity in the mouse for foreign materials. If there are any foreign

materials, remove them.

6. Replace the ball.

Chapter 2. Using the 44P Series Model 170 11

7. Replace the retaining ring on the mouse and align it with the open slots in the ball

cavity.

8. Turn the retaining ring clockwise until the open slots are covered and you hear the

ring snap into place.

Using the 3.5-Inch Diskette Drive

The system unit has a 1.44 MB diskette drive installed vertically in the front.

The 1.44 MB diskette drive can format, read, and write diskettes compatible with the

following diskette drives:

v 1.0 MB diskettes with 720 KB formatted data capacity

v 2.0 MB diskettes with 1.44 MB formatted data capacity (HD)

Format the diskette according to its specified capacity.

12 44P Series Model 170 User’s Guide

Write-Protecting 3.5-Inch Diskettes

Write-protecting diskettes is necessary so that important information is not accidentally

lost. When diskettes are write-protected, you can read information from the diskettes,

but you cannot write information to them.

There is a write-protect tab on the 3.5-inch diskette. To locate the write-protect tab, turn

the diskette over with the label facing down.

To prevent writing onto a diskette, slide the write-protect tab to open the protect slot, as

shown in the illustration.

To allow writing onto a diskette, slide the write-protect tab to cover the protect slot, as

shown in the illustration.

(Slot Open)

Write-Protect Tab

(Slot Closed)

Write-Protect Tab

Chapter 2. Using the 44P Series Model 170 13

Loading and Unloading the 3.5-Inch Diskette

To load a diskette into the drive, insert the diskette in the diskette drive with the labeled

metal shutter first. Push the diskette into the drive until you hear a click. The click

indicates that the diskette is securely in position in the drive.

To unload the diskette, push the diskette-unload button. The diskette unloads partially

from the drive. Remove the diskette.

Using the CD-ROM Drive

CAUTION:

A Class 1 laser is contained in the device. Do not attempt to operate the device

while it is disassembled. Do not attempt to open the covers of the device, as it is

not serviceable and is to be replaced as a unit.

This section describes the features of the 32X SCSI-2 CD-ROM Drive and provides

instructions for handling the drive and CD-ROM discs. The CD-ROM is a half-high,

5.25", 8-bit, single-ended, tray-loading drive. Its features include the following:

v SCSI-2 interface supports both synchronous and asynchronous data transfer

v High-speed data transfer rate of 2100 KB per second (14X) at inner diameter and

4800 KB per second (32X) at outer diameter due to constant RPM spin rate

v High-speed synchronous burst rate of 10 MB per second

v Average random access time of 90 ms

v Loading tray accommodates both 8 cm discs (in the horizontal orientation only) and

12 cm discs

v Reads multi-session discs

v Reads CD-recordable discs

v Reads CD-RW discs

v Supports all major CD-ROM formats: Mode 1, Mode 2, XA, CDDA, and audio

v Contains headphone output and line output for audio

14 44P Series Model 170 User’s Guide

Front View of CD-ROM Drive

1 2

1 Compact Disc Tray

2 Emergency Eject Hole

3 Headphone Jack

4 Volume Control

5 Status Light

6 Load/Unload Button

Understanding the Status Lights

The status lights indicate the operational status of the drive. The various conditions are

explained below.

If light is: Condition is:

Off Drive is in standby mode with or without a disc loaded.

Blinking (green) Any of the following:

On (amber) Hardware error condition found during initialization.

43

v Drive tray is inserted. The light blinks while the drive

v Drive is reading data. The light blinks while data is being

v Drive is in Play Audio Mode. The light blinks while the audio

Note: If this occurs, contact your service representative.

5

completes the initialization checkout.

read.

is playing.

6

Chapter 2. Using the 44P Series Model 170 15

Handling Compact Discs

Compact discs are high-density media that must be handled with care and kept clean to

ensure that they remain readable. Use the following precautions to ensure reliability:

v Hold the compact disc by the edges. Do not touch the surface of the compact disc.

v To remove dust or fingerprints, wipe the compact disc from the center to the outside

of the compact disc as shown, using a lint-free cloth.

Attention: Wiping the compact disc in a circular direction can cause loss of data.

v Do not write on the surface.

v Do not store or place the compact disc in direct sunlight.

v Do not use benzene, thinners, or other cleaners to clean the compact disc.

v Do not bend the compact disc.

Other Handling Considerations

Be sure to take the following additional precautions when you use the 32X SCSI-2

CD-ROM Drive:

v Remove compact discs from the tray before you move the drive anywhere.

v Do not place the drive where any of the following conditions exist:

v High temperature

v High humidity

v Excessive dust

v Excessive vibration or sudden shock

v Inclined surface

v Direct sunlight

v Do not insert foreign objects into the drive.

v Do not remove the drive covers or attempt to service the drive yourself.

16 44P Series Model 170 User’s Guide

Loading a Compact Disc

To load a compact disc into the drive, do the following:

1. Press the Load/Unload button to open the tray. The tray slides out of the drive.

2. Place the compact disc in the tray with the label facing up.

3. Press the Load/Unload button, or gently push in the tray, to close the tray.

Note: Be sure that none of the vertical retaining tabs are extended when you use the

drive in the horizontal position.

Chapter 2. Using the 44P Series Model 170 17

Opening the Tray Manually

The compact disc tray automatically opens when you press the Load/Unload button. If it

does not automatically open, follow these steps to force it open manually:

1. Shut down and turn off the power to your system unit.

2. Insert the straightened end of a paper clip into the emergency eject hole until you

feel some resistance. See “Front View of CD-ROM Drive” on page 15 if you are not

sure where the emergency eject hole is located.

3. Continue to push in the paper clip while you pull out the tray with your fingernail.

4. Pull the tray completely open and remove the disc. It is normal for the tray to make

a clicking sound while you are pulling it open.

Playing an Audio CD

To play an audio CD, you must have headphones connected to the headphone jack

located on the front of the drive, or connected to the line-out connector located on the

back of the system. You must also have an audio software application installed.

The headphone jack provides the connection for headphones using a 3.5 mm (1/8")

stereo mini-plug. The volume control adjusts the audio output level for the headphones.

General Information for the 8mm Tape Drive

The 8mm Tape Drive is an internal streaming tape drive that provides medium to

high-capacity backup and archival capability, as well as a high data-transfer rate. The

8mm Tape Drive uses wide bus architecture. Communications on the SCSI bus can be

either asynchronous or synchronous. The 8mm Tape Drive is read only compatible with

existing 2.3 GB, 5.0 GB, and 7.0 GB 8 mm tape drives. The 8mm Tape Drive is a boot

device.

The tape drive is used primarily for:

v Saving and restoring system data files

v Archiving important records

v Distributing operating system software upgrades

The drive conforms to the American National Standards Institute (ANSI) SCSI-2

standard.

Features of the 8mm Tape Drive include:

v Use of 8 mm data cartridges.

v Compression capability, effectively doubling the native capacity and data rate. The

actual capacity per cartridge varies depending on the application and the type of data

cartridge being used.

18 44P Series Model 170 User’s Guide

Note: The factory default setting is

by the application software.

v A half-high 5.25-inch form-factor.

v An LCD display that provides operating and error messages.

v Status lights that indicate:

– When it is time to clean the tape drive

– When the tape is in motion

– When the drive is ready to accept tape motion commands

Front View of the 8mm Tape Drive

1 Disturbance (amber)

2 Ready (green)

3 Activity (green)

4 Status lights

5 LCD display

6 Tape drive door

7 Unload button

Activated

. Data compression is usually controlled

Chapter 2. Using the 44P Series Model 170 19

Operating Recommendations

Attention: Be sure to read ″Handling Static-Sensitive Devices″ in the

Series Model 170

Installation Guide, order number SA38-0561, Installing

RS/6000 44P

and Removing devices chapter before you remove the 8mm Tape Drive

from its anti static bag or any time you handle it. For optimum performance,

always follow the recommendations listed below:

v Handle the drive carefully and by its external metal chassis. Keep your hands away

from the printed circuit boards, components, and printed circuit (flex) cables.

v If possible, work on a cushioned surface, and do not drop the tape drive onto the

work surface.

v If you move the tape drive to an environment that is colder or warmer than its

previous environment, keep the drive in its package and allow the package to reach

the current room temperature. This prevents potential data loss or damage to the

tape drive. Allow one hour of acclimation for each 10 degrees C (18 degrees F)

difference between the shipping and/or storage temperature and the room

temperature.

v Use only high-quality data grade 8 mm tape cartridges recommended by the

manufacturer (see “Obtaining Additional Tape Cartridges” on page 29).

v Remove the tape cartridge from the tape drive when it is not in use, and store the

cartridge in the cartridge case.

v Do not open the door on the data tape cartridge. This door covers and protects the

magnetic tape material from dirt, dust, and damage.

v Avoid touching the tape, as doing so can cause loss of data.

v Back up any tape cartridge that repeatedly produces error messages, then discard

the old tape cartridge. Error information is saved in the system error log.

v Clean the tape path regularly according to the cleaning procedure described in

“Cleaning the Tape Drive” on page 27. Use only recommended cleaning cartridges.

Other cleaning cartridges can permanently damage the tape drive.

8 mm Tape Cartridge Types

There are different types of 8 mm tape cartridges that you can use for the following

purposes:

Type Purpose

Test Tape Cartridge Checks the operation of the drive or to run

Data Tape Cartridge Saves your programs or data. This cartridge is

Cleaning Tape Cartridge Cleans the 8 mm tape drive. See “Cleaning the

20 44P Series Model 170 User’s Guide

diagnostics. Do not use it to save programs or

data. This cartridge, which is specially labeled,

is included with the 8mm Tape Drive.

included with the 8mm Tape Drive.

Tape Drive” on page 27. This cartridge is

included with the 8mm Tape Drive.

Tape Cartridge Compatibility

The 8mm Tape Drive is compatible with existing 8 mm tape subsystems that comply to

the American National Standard (ANSI) X3B5–89-136, Rev. 6, Helical-scan Digital

Computer Tape Cartridge, 8 mm for Information Exchange. Refer to the following table

for information about specific tape compatibility.

Format Modes (C=compression mode)

8mm Tape

Drive

2.3 GB Read /

5.0 GB Read /

7.0 GB Read /

20.0 GB Read Only - Read Only Read Only Read Only Read Only Read /

2.3GB 2.3 GB (C) 5.0 GB 5.0 GB (C) 7.0 GB 7.0 GB (C) 20.0 GB 20.0 GB

Write

Write

Write

-------

Read /

Write

Read /

Write

Read /

Write

Read /

Write

Read /

Write

Read /

Write

----

Read /

Write

Read /

Write

Setting the Write-Protect Tab on 8 mm Tape Cartridges

Set the write-protect tab on a tape cartridge so that you do not accidentally lose

information. The window on the tape cartridge controls write-protection. When the

window on a tape cartridge is closed, write-protection is set and information can be

read from the tape, but not written to it. When the window on a tape cartridge is open,

write-protection is not set and information can be read from the tape and written to it.

(C)

--

Write

Read /

Write

1 Window open: Write-protect tab not set

2 Window closed: Write-protect tab set

Chapter 2. Using the 44P Series Model 170 21

Environmental Considerations for 8 mm Data Cartridges

This section describes operating and storage conditions including temperature, relative

humidity, and maximum wet bulb data.

Attention: The manufacturer specifies a set of temperature and humidity ranges in

which the 8 mm data cartridge can operate with ease. Only regular cleaning

procedures are required when operating the cartridge within this range. The

risk of possible data loss is increased if 8 mm tape cartridges are operated,

stored, or shipped outside the temperature or humidity ranges shown in the

following table.

Condition Operating Ranges Storage Shipping

Temperature 60°F-90°F (16°C-32°C) 41°F-90°F (5°C-32°C) -40°F-126°F

Relative Humidity

(non-condensing)

Maximum Wet Bulb 73°F (23°C) 79°F (26°C) 79°F (26°C)

Always let a cartridge acclimate to the operating environment before you use it.

Acclimation is necessary for any data cartridge that has been exposed to a different

humidity environment or to a temperature change of 11°C or 20°F or more. Place the

cartridge, with its container, in the operating environment for as long as it has been

away from the operating environment or for 24 hours, whichever is less.

20%-80% 20%-80% 20%-80%

Operating the 8mm Tape Drive in Harsh Environments

The 8mm Tape Drive is ideally suited to streaming operations rather than tape

movement operations involving multiple stops and starts as well as random searches.

You should use streaming movement whenever possible.

(-40°C-52°C)

Do not use for archiving any tape that was previously used outside the ranges specified

in “Environmental Considerations for 8 mm Data Cartridges” for an extended period of

time. Exposure to the new environment deteriorates the magnetic and physical strength

of the tape. Do not store important data on a tape that was used outside the specified

ranges. For reliable archiving, transfer the data to a new tape.

Erasing 8 mm Data Cartridge

Most bulk eraser devices cannot erase 8 mm data cartridges. To properly erase an 8

mm data cartridge with a bulk eraser device, the erasure rating must be at least 1500

oersted.

22 44P Series Model 170 User’s Guide

Using the 8mm Tape Drive

This section provides information about operating, using, and maintaining your 8mm

Tape Drive.

Status Lights

The 8mm Tape Drive has two green status lights and one amber status light. The on

and off combinations of the status lights indicate the current condition of the tape drive.

Each of the International Organization for Standards (IOS) symbols located next to a

status light indicates a specific condition of the tape drive as follows:

1

2

3

4

1 Disturbance (amber)

2 Ready (green)

3 Activity (green)

4 Status lights

20.0

Chapter 2. Using the 44P Series Model 170 23

Status Disturbance

The power-on self-test (POST) is running or

the system has issued a Reset to the drive.

One of the following has occurred:

v The power is off.

v The POST has completed successfully, but

no tape cartridge has been inserted.

See note 2.

A tape cartridge has been inserted, and the

8mm Tape Drive is ready to receive

commands from the system. See note 2.

A tape cartridge has been inserted, and the

8mm Tape Drive is performing a tape load or

unload operation. See note 2.

The tape is in motion, and the 8mm Tape

Drive is busy running a device operation. See

note 2.

The 8mm Tape Drive has detected an internal

fault that requires corrective action. See note

1.

The tape path requires cleaning. Refer to

“Cleaning the Tape Drive” on page 27.

(amber)

On On On

Off/On Off Off

Off/On On Off

Off/On Off Flashing

Off/On On Flashing

Flashing Off Off

On Off or On Off or Flashing

Ready (green) Activity

(green)

Notes:

1. If a fault or an error condition occurs, press the unload button for approximately 15

seconds to reset the drive. If the disturbance light still flashes after the reset,

contact your service representative for assistance.

2. If the disturbance light is on, cleaning is required. See “Cleaning the Tape Drive” on

page 27.

Liquid Crystal Display

The 8mm Tape Drive features a liquid crystal display (LCD), which is located on the

front panel. The LCD displays operating and error messages.

Changing the Display Language

The text on the 8mm Tape Drive LCD is available in several languages. To change the

language:

1. Press and hold the unload button after you turn the power on to the 8mm Tape

Drive or, if your system unit is already running, press and hold the unload button for

approximately 15 seconds until the LCD displays RESET. Release the unload button

for approximately one second, then press and hold the unload button again.

2. After the LCD cycles through all the reset messages, it cycles through the available

languages. When the desired language displays, release the unload button.

24 44P Series Model 170 User’s Guide

Loading the 8 mm Tape Cartridge

Before loading the tape cartridge, make sure the system unit power is on and that the

write-protect tab on the tape cartridge is properly set. Refer to “Setting the Write-Protect

Tab on 8 mm Tape Cartridges” on page 21. The tape drive loads the tape from the

cartridge and prepares it for reading and writing.

1 Window side of tape cartridge

2 8 mm tape cartridge

3 Write-protect tab

To load the 8 mm tape cartridge:

1. Grasp the edges of the 8 mm tape cartridge with the write-protect tab toward you

and the window side of the cartridge facing up.

2. Slide the tape cartridge into the opening on the front of the 8 mm tape drive until

the loading mechanism pulls the cartridge into the drive and the drive door closes.

The ready status light (green) comes on if the load operation was successful.

The service processor is ready for data operations when the tape cartridge is inserted.

After the cartridge is inserted into the tape drive, the tape takes about 25 seconds to

load.

Commands can be entered while the tape is loading. Any commands to the tape drive

start running once the tape has finished loading. Commands not requiring the tape

cartridge are run immediately.

Chapter 2. Using the 44P Series Model 170 25

Unloading the 8 mm Tape Cartridge

Before you perform the unload operation, make sure the power to the system unit is on.

1 Window side of tape cartridge

2 8 mm tape cartridge

3 Write-protect tab

4 Unload button

To unload and eject the tape cartridge, press the unload button. The service processor

rewinds the tape, then ejects the tape cartridge from the tape drive. After you press the

unload button, the following actions occur:

v The ready status light goes off.

v The read/write status light flashes during the unload operation.

v The read/write status light goes off when the cartridge is ejected from the tape drive.

The time required for a tape to rewind and unload is between 18 seconds and 3

minutes, depending on the position of the tape when you push the unload button.

If a fault or an error condition occurs and you cannot eject the tape, press the unload

button for approximately 15 seconds to reset the drive. If the tape cartridge cannot

unload and has to be removed manually from the drive, contact your service

representative.

26 44P Series Model 170 User’s Guide

Cleaning the Tape Drive

Attention: Do not use video-cleaning cartridges in the 8mm Tape Drive. Video-cleaning

Clean the tape drive:

v After you use a metal particle (MP) tape and before you use an advanced metal

evaporative (AME) tape

v When error rates exceed an acceptable level as indicated by the LED and message

v Every 72 hours of tape motion as indicated by the LED and message

The 8mm Tape Drive counts the number of hours of tape motion. When it is time to

clean the tape path, it displays the message * * CLEAN SOON and turns on the top

status light.

You must clean the tape after using metal particle (MP) media and before using

advanced metal evaporative (AME) tapes. If you use MP media, the LCD prompts you

to clean the tape path by displaying the message MUST CLEAN.

More frequent cleaning may be required if you operate the drive in a dusty environment

or in humid conditions. If you allow dust to accumulate, the drive has to perform more

reads and writes. This can damage the drive or cause data loss, which can be

prevented by regular cleaning.

The cleaning cartridge cleans the 8mm Tape Drive 18 times before you must discard it.

If you attempt to use an 8 mm cleaning cartridge more than 18 times, the tape drive

automatically detects the error, ejects the cleaning cartridge with the amber disturbance

status light remaining on, and displays the message DEPLETED.

cartridges can damage the system drive.

Chapter 2. Using the 44P Series Model 170 27

Before you load the cleaning cartridge, make sure the power to the tape drive is on.

1 Window side of tape cartridge

2 8 mm cleaning cartridge

3 Write-protect tab

To clean the tape path:

1. Grasp the edges of the 8 mm cleaning cartridge with the window side of the

cartridge facing up. Slide the cartridge into the opening on the front of the 8mm

Tape Drive until the loading mechanism pulls it into the drive.

2. After you fully insert the 8 mm cleaning cartridge into the 8mm Tape Drive, the

following cleaning operations are automatically performed:

v The cleaning tape loads into the tape path. The message CLEANING... displays.

The cleaning cycles take approximately two minutes.

v The tape unloads and the cleaning cartridge ejects from the tape drive upon

completion of the cleaning operation.

v The amber disturbance status light goes off if the cleaning operation was

successful.

3. Record the use of the cleaning cartridge on the cartridge.

28 44P Series Model 170 User’s Guide

Obtaining Additional Tape Cartridges

Use only tape cartridges recommended by the manufacturer in the 8mm Tape Drive.

Contact your customer service representative or the place of purchase to obtain the

recommended tape cartridges.

General information for the 12/24GB 4mm Tape Drive

The 12/24GB 4mm Tape Drive is an internal streaming tape drive that provides medium

to high-capacity backup and archival capability as well as high data transfer rate. The

12/24GB 4mm Tape Drive uses NARROW bus (8-bit) architecture. Communications on

the SCSI bus can be either asynchronous or synchronous. The 12/24GB 4mm Tape

Drive is compatible with existing 2.0 GB and 4.0 GB 4 mm tape drives. The 12/24GB

4mm Tape Drive can be used as a boot device.

The tape drive is used primarily for:

v Saving and restoring system data files

v Archiving important records

v Distributing operating system software upgrades.

The drive conforms to the American National Standards Institute (ANSI) SCSI-2

standard.

The 12/24GB 4mm Tape Drive’s features include:

v Use of 12/24 GB 4 mm data cartridges.

v Data rate of 1.1 MB/second.

v Capacity of 12 GB.

v Compression capability, which effectively doubles the native capacity of 12 GB and

the effective data rate. The actual capacity per cartridge varies depending on the

application and the type of data cartridge being used. The default is compressed.

Use SMIT to change the default.

Note: The factory default setting is

by the application software.

v A half-high 5.25-inch form-factor.

v Status lights that indicate:

– When it is time to clean the tape drive

– When the tape is in motion

– When the drive is ready to accept tape motion commands.

Activated

. Data compression is usually controlled

Chapter 2. Using the 44P Series Model 170 29

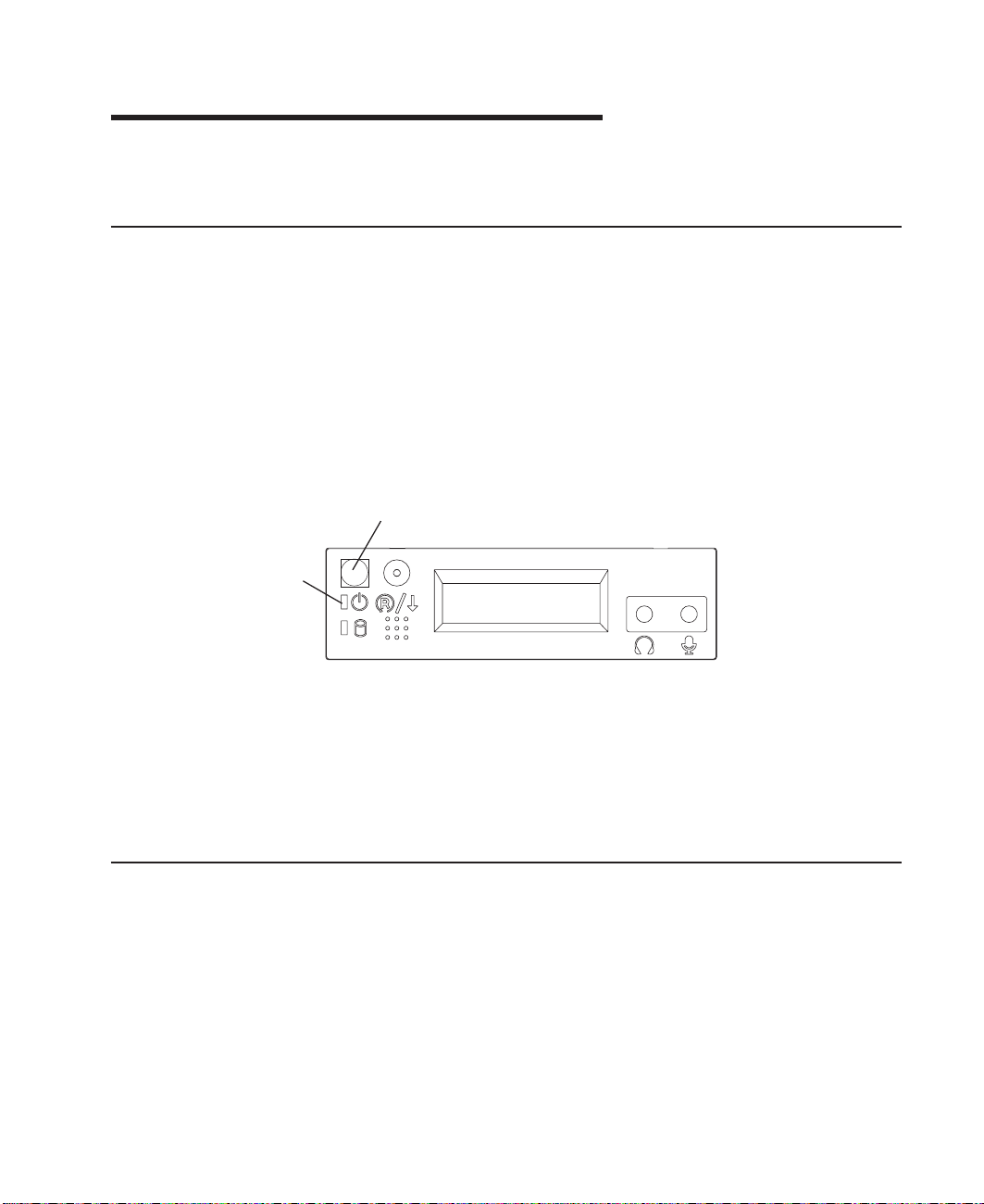

Front View of the 12/24GB 4mm Tape Drive

1

3

4

2

5

1 Tape Drive Door

2 Status lights

3 Ready (green)

4 Tape Motion (green)

5 Disturbance (amber)

6 Unload/Reset button

Using the 12/24GB 4mm Tape Drive

This chapter provides information about operating, using, and maintaining your 12/24GB

4mm Tape Drive.

6

Operating Recommendations

Attention: For optimum performance, always follow the recommendations listed below:

v Use only high-quality data grade 12/24 GB 4 mm tape cartridges recommended by

the manufacturer (see “Obtaining Additional Tape Cartridges” on page 38). Tape

cartridges that do not carry the proper DDS symbol cannot be written to, and their

use causes the 12/24GB 4mm Tape Drive to report an error.

v Remove the tape cartridge from the tape drive when it is not in use, and store the

cartridge in the cartridge case.

v Do not open the door on the data tape cartridge. This door covers and protects the

magnetic tape material from dirt, dust, and damage.

v Avoid touching the tape, as doing so can cause loss of data.

v Back up any tape cartridge that repeatedly produces error messages, then discard

the old tape cartridge. Error information is saved in the system error log.

v Clean the tape path regularly according to the cleaning procedure described in

“Cleaning the Tape Path on the 12/24GB 4mm Tape Drive” on page 37. Use only

recommended cleaning cartridges. Other cleaning cartridges can permanently

damage the tape drive.

30 44P Series Model 170 User’s Guide

12/24 GB 4 mm Tape Cartridge Types

There are different types of 12/24 GB 4 mm tape cartridges that you can use for the

following purposes:

Type Purpose

Test Tape Cartridge Checks the operation of the drive or to run

Data Tape Cartridge Saves your programs or data. This cartridge is

Cleaning Tape Cartridge Cleans the 12/24GB 4mm Tape Drive. See

Tape Cartridge Compatibility

The tape drive is compatible with existing 12/24 GB 4 mm tape subsystems that are

designed to operate with Digital Data Storage approved media (DDS-1, DDS||||, DDS-2,

or DDS-3), which meet the following European Computer Manufacturers Association

(ECMA) standards:

v ECMA–139 “3.81 Wide Magnetic Tape Cartridge for Information Interchange” –

Helical Scan Recording – DDS Format.

v ECMA–139 “3.81 Wide Magnetic Tape Cartridge for Information Interchange” –

Helical Scan Recording – DDS–2 Format.

v ECMA–139 “3.81 Wide Magnetic Tape Cartridge for Information Interchange” –

Helical Scan Recording – DDS–3 Format.

diagnostics. Do not use it to save programs or

data. This cartridge, which is specially labeled,

is included with the 12/24GB 4mm Tape Drive.

included with the 12/24GB 4mm Tape Drive.

“Cleaning the Tape Path on the 12/24GB 4mm

Tape Drive” on page 37. This cartridge is

included with the 12/24GB 4mm Tape Drive.

4 mm Tape Write Density Setting

When reading a tape, the drive automatically determines which format is written on the

tape.

When writing to a tape, use SMIT (System Management Interface Tool) to change the

density setting of the tape drive to correspond to the type of media installed. Refer to

the following table for information about the specific density setting:

Density Settings for 4 mm Media

Media Type Device Compatibility SMIT Density Setting

DDS1 Read Only N/A

DDS|||| Read / Write (2.0 GB Mode Only) 19

DDS2 Read / Write (4.0 GB Mode Only) 36

DDS3 Read / Write (12.0 GB Mode Only) 37

Chapter 2. Using the 44P Series Model 170

31

Setting the Write-Protect Tab on 12/24 GB 4 mm Tape Cartridges

Set the write-protect tab on a tape cartridge so that you do not accidentally lose

information. The write-protect tab on the tape cartridge controls write-protection. When

the write-protect tab on a tape cartridge is closed, information can be read from the

tape and written to it. When the write-protect tab on a tape cartridge is open,

information can be read from the tape, but not written to it.

1 Write-protect tab closed: Write enabled

2 Write-protect tab open: Write disabled

Erasing 12/24 GB 4 mm Data Cartridge

Most bulk eraser devices cannot erase 12/24 GB 4 mm data cartridges. To properly

erase an 12/24 GB 4 mm data cartridge with a bulk eraser device, the erasure rating

must be at least 3900 oersted.

Environmental Considerations for 12/24 GB 4 mm Data Cartridges

This section describes operating and storage conditions including temperature, relative

humidity, and maximum wet bulb data.

Attention: The manufacturer specifies a set of temperature and humidity ranges in

which the 12/24 GB 4 mm data cartridge can operate with ease. Only

regular cleaning procedures are required when operating the cartridge

within this range. The risk of possible data loss is increased if 12/24 GB 4

mm tape cartridges are operated, stored, or shipped outside the

temperature or humidity ranges shown in the following table.

Condition Operating Ranges Storage Shipping

Temperature 60°F-90°F (16°C-32°C) 41°F-90°F (5°C-32°C) -40°F-126°F

Relative Humidity

(non-condensing)

Maximum Wet Bulb 79°F (26°C) 79°F (26°C) 79°F (26°C)

32 44P Series Model 170 User’s Guide

20%-80% 20%-80% 20%-80%

(-40°C-52°C)

Always let a cartridge acclimate to the operating environment before you use it.

Acclimation is necessary for any data cartridge that has been exposed to a different

humidity environment or to a temperature change of 11°C (20°F) or more. Place the

cartridge, with its container, in the operating environment for as long as it has been

away from the operating environment or for 24 hours, whichever is less.

Operating the 12/24GB 4mm Tape Drive in Harsh Environments

The tape drive is ideally suited to streaming operations rather than tape movement

operations involving multiple stops and starts and random searches. You should use

streaming movement whenever possible.

Do not use for archiving any tape that was previously used outside the ranges specified

in “Environmental Considerations for 12/24 GB 4 mm Data Cartridges” on page 32 for

an extended period of time. Exposure to the new environment deteriorates the magnetic

and physical strength of the tape. Do not store important data on a tape that was used

outside the specified ranges. For reliable archiving, transfer the data to a new tape.

Status Lights

The 12/24GB 4mm Tape Drive has two green status lights and one amber status light.

The on and off combinations of the status lights indicate the conditions of the 12/24GB

4mm Tape Drive.

Each of the International Organization for Standards (ISO) symbols located above a

status light indicates a specific condition of the tape drive as follows:

1

3

4

2

5

1 Tape Drive Door

2 Status lights

3 Ready (green)

4 Tape Motion (green)

5 Disturbance (amber)

6 Unload/Reset button

6

Chapter 2. Using the 44P Series Model 170 33

Status Light States

The following tables explain the meaning of the green and amber status lights.

Status Ready (green) Tape Motion (green) Disturbance (amber)

Off No cartridge installed or

error condition

Steady Cartridge installed or

loading/unloading

Flashing Power-on self-test in

progress

Status Lights on the 12/24GB 4mm Tape Drive

Status Ready (green) Tape Motion

LED test On 2 seconds at

The power-on self-test (POST) is running or the

diagnostic cartridge is running.

One of the following has occurred:

v The power is off.

v The POST has completed successfully, but no tape

cartridge has been loaded.

(See note 2 below.)

A tape cartridge has been inserted and the 12/24GB

4mm Tape Drive is ready to receive commands from the

system. (See note 2 below.)

The tape is in motion and the 12/24GB 4mm Tape Drive

is running a device operation or cleaning. (See note 2

below.)

The 12/24GB 4mm Tape Drive has detected an internal

error that requires corrective action such as tape

cartridge failure, high humidity. (See note 1 below.)

The tape path requires cleaning, or a poor quality tape

cartridge is being used. See “Cleaning the Tape Path on

the 12/24GB 4mm Tape Drive” on page 37.

No cartridge or no activity No error condition

Cleaning required or worn

media

Cartridge activity Error condition

(green)

power on

Flashing Off Off

Off Off Off/On

On Off Off/On

On Flashing Off/On

Off Off Flashing

Off or On Off or Flashing On

On 2 seconds at

power on

Disturbance

(amber)

On 2 seconds at

power on

Notes:

1. If a fault or an error condition occurs, press the unload button for approximately 15

seconds to reset the drive. If the disturbance light still flashes after the reset,

contact your service representative for assistance.

2. If the disturbance light is on, cleaning is required. See “Cleaning the Tape Path on

the 12/24GB 4mm Tape Drive” on page 37.

34 44P Series Model 170 User’s Guide

Loading the 12/24 GB 4 mm Tape Cartridge

Before you load the tape cartridge, make sure the power is on and the write-protect tab

on the tape cartridge is properly set. Refer to “Setting the Write-Protect Tab on 12/24

GB 4 mm Tape Cartridges” on page 32. The tape drive loads the tape from the cartridge

and prepares it for reading and writing.

To load the 12/24 GB 4 mm tape cartridge, do the following:

1. Grasp the edges of the 12/24 GB 4 mm tape cartridge with the write-protect tab

towards you and the window side of the cartridge facing up.

2. Slide the tape cartridge into the opening on the front of the 12/24 GB 4 mm tape

drive until the loading mechanism pulls the cartridge into the drive and the drive

door closes. The ready status light (green) goes on if the load operation was

successful.

Window Side of

Tape Cartridge

Ready Status

Light (Green)

4 mm Tape Cartridge

Write-Protect Tab

Unload Button

The 12/24GB 4mm Tape Drive is ready for data operations when the tape cartridge is

inserted. After the cartridge is inserted into the tape drive, the tape takes about 15

seconds to load.

Chapter 2. Using the 44P Series Model 170 35

Unloading the 12/24 GB 4 mm Tape Cartridge

Before performing the unload operation, make sure the power to the system unit is on.

To unload and eject the tape cartridge, press the unload button. The 12/24GB 4mm

Tape Drive rewinds the tape and then ejects the tape cartridge from the tape drive.

After you press the unload button, the following occurs:

1. The Ready status light turns off.

2. The Tape Motion status light flashes during the unload operation.

3. The Tape Motion status light turns off when the cartridge is ejected from the tape

drive.

4 mm Tape Cartridge

Write-Protect Tab

Ready Status

Light (Green)

The time required for a tape to rewind and unload is between 10 seconds and 1.5

minutes, depending on the position of the tape when the unload button is pushed.

If a fault or an error condition occurs and you cannot eject the tape, press the unload

button for approximately 15 seconds to reset the drive.

If the tape cartridge cannot unload and has to be removed manually from the drive,

contact your service representative.

36 44P Series Model 170 User’s Guide

Ready-Write Status

Light (Green)

Unload Button

Cleaning the Tape Path on the 12/24GB 4mm Tape Drive

The 12/24 GB 4 mm tape path should be cleaned either approximately every 30 hours

of tape motion or once a month, whichever occurs first. The 12/24 GB 4 mm tape drive

monitors the recording quality of the tape cartridge and indicates that the tape path

requires cleaning when the disturbance status light (amber) is on.

More frequent cleaning may be required if the drive is operated in a dusty environment

or in humid conditions. If the dust is allowed to accumulate, the drive has to perform

more reads and writes. This can cause data loss, and can be prevented by regularly

scheduled cleaning of the drive. The amber Disturbance status light also comes on

automatically after 30 hours of tape motion without cleaning.

If you attempt to use a 12/24 GB 4 mm cleaning cartridge beyond 20 cleanings, the

tape drive automatically detects an error and ejects the cleaning cartridge with the

disturbance status light (amber) remaining on.

Before you load the cleaning cartridge, make sure the power to the system unit is on.

To load the 12/24 GB 4 mm cleaning cartridge, do the following:

1. Grasp the edges of the 12/24 GB 4 mm cleaning cartridge with the window side of

the cartridge facing up.

2. Slide the cleaning cartridge into the opening on the front of the 12/24 GB 4 mm

tape drive until the loading mechanism pulls the cartridge into the drive.

Window Side of

Cleaning Cartridge

Disturbance Status

Light (Amber)

4 mm Cleaning Cartridge

Unload Button

After the 12/24 GB 4 mm cleaning cartridge has been fully inserted into the 12/24GB

4mm Tape Drive, the following cleaning operations are performed automatically:

1. The cleaning tape is loaded into the tape path. The cleaning cycle lasts

approximately 30 seconds.

2. The tape is unloaded and the cleaning cartridge is ejected from the tape drive when

the cleaning operation is complete.

Chapter 2. Using the 44P Series Model 170 37