Page 1

Enterprise Server S80

pSeries 680 Model S85

Installation Guide

IBM

SA38-0582-00

Page 2

First Edition (November 2000)

Before using this information and the product it supports, read the information in “Safety Notices” on page v,

“Appendix B. Environmental Notices” on page 43, and “Appendix C. Notices” on page 45.

©International Business Machines Corporation 2000. All rights reserved.

Note to U.S. Government Users - Documentation related to restricted rights - Use, duplication, or disclosure is subject

to the restrictions set forth in the GSA ADP Schedule Contract with IBM Corp.

Page 3

Contents

Safety Notices ........................v

Electrical Safety ........................v

Laser Safety Information .....................vi

Data Integrity and Verification ..................vii

About This Book .......................ix

ISO 9000 ..........................ix

Online Publications.......................ix

Related Publications ......................ix

Trademarks .........................x

Chapter 1. System Installation Procedure ..............1

Step 1. Inventory .......................1

Step 2. Observe this Safety Notice During Installation ...........1

Step 3. Check the Customer Environment ...............2

Step 4. Check Customer Outlets ..................3

Step 5. Set Up the System Racks ..................4

Step 6A. Attach the I/O Rack to a Concrete Floor.............7

Attaching the I/O Rack to a Concrete Floor ..............8

Attaching the I/O Rack to a Concrete Floor Beneath a Raised Floor .....10

Step 6B. Attach the System Rack to a Concrete Floor ...........14

Attaching the System Rack to a Concrete Floor .............15

Attaching the System Rack to a Concrete Floor Beneath a Raised Floor.....16

Step 7. Attach the Front Electrical Outlet ...............18

Step 8. Attach the Rear Electrical Outlet ...............22

Step 9. Remove the Shipping Brackets and Install Covers.........26

Step 10. Install the I/O Rack Door Guide ...............27

Step 11. Connect the Operator Panel Cable and the JTAG Cable Between the

Racks ..........................28

Step 12. Connect RIO and SPCN Cables Between the Racks ........28

Step 13. Set Up Attached Devices .................28

Step 14. Update the Device Records ................29

Step 15. Attach External Devices..................29

Step 16. Connect the Power ...................29

Step 17. Power On and Check Out the System .............29

Checklist If Problems Occur ...................29

Step 18. Service Processor Setup and Test ..............30

Step 19. Install the Modem and Electronic Service Agent ..........30

Step 20. Finish the Installation ..................30

Chapter 2. Using the System Verification Procedure ..........33

Chapter 3. Installing Options for Your System ............37

Appendix A. Communications Statements ..............39

Federal Communications Commission (FCC) Statement ..........39

33

33

iii

Page 4

European Union (EU) Statement ..................39

International Electrotechnical Commission (IEC) Statement .........40

United Kingdom Telecommunications Safety Requirements .........40

Avis de conformité aux normes du ministère des Communications du Canada. . . 40

Canadian Department of Communications Compliance Statement .......40

VCCI Statement .......................40

Electromagnetic Interference (EMI) Statement - Taiwan ..........41

Radio Protection for Germany ...................41

Appendix B. Environmental Notices ................43

Product Recycling and Disposal ..................43

Environmental Design .....................43

Unit Emissions ........................43

Appendix C. Notices .....................45

Appendix D. Cabling the System Rack and I/O Rack ..........47

Connecting JTAG and Operator Panel Cables .............48

I/O Rack Rear Locations ....................49

I/O Drawer Locations......................50

10 EIA Unit I/O Drawer Front View ................50

10EIAUnitI/ODrawerRearView................51

10 EIA Unit I/O Drawer System board Locations............53

Service Processor Card Locations ................55

Fan Monitor Control (FMC) Card Locations (10 EIA Unit I/O Drawer) .....56

Power Distribution Board Locations ................56

Connecting RIO and SPCN Cables .................57

Appendix E. System Records ..................63

Record the Identification Numbers .................63

S80 and S85 System Rack...................63

S80 and S85 System Rack Memory Configuration ...........63

S80 and S85 System Rack Cabling Configurations - RIO Cabling ......63

S80 and S85 System Rack Cabling Configurations - SPCN Cabling .....64

Primary I/O Drawer Device Records.................65

Additional I/O Drawer Device Records ................68

Index ...........................71

Reader’s Comments — We’d Like to Hear From You ..........73

iv S80, S85 Installation Guide

Page 5

Safety Notices

A

danger

death or serious personal injury.

A

caution

moderate or minor personal injury.

Electrical Safety

Observe the following safety instructions any time you are connecting or disconnecting

devices attached to the workstation.

DANGER

An electrical outlet that is not correctly wired could place hazardous voltage

on metal parts of the system or the devices that attach to the system. It is the

responsibility of the customer to ensure that the outlet is correctly wired and

grounded to prevent an electrical shock.

Before installing or removing signal cables, ensure that the power cables for

the system unit and all attached devices are unplugged.

When adding or removing any additional devices to or from the system,

ensure that the power cables for those devices are unplugged before the

signal cables are connected. If possible, disconnect all power cables from the

existing system before you add a device.

notice indicates the presence of a hazard that has the potential of causing

notice indicates the presence of a hazard that has the potential of causing

Use one hand, when possible, to connect or disconnect signal cables to

prevent a possible shock from touching two surfaces with different electrical

potentials.

During an electrical storm, do not connect cables for display stations, printers,

telephones, or station protectors for communication lines.

CAUTION:

This product is equipped with a three–wire power cable and plug for the user’s

safety. Use this power cable with a properly grounded electrical outlet to avoid

electrical shock.

DANGER

To prevent electrical shock hazard, disconnect the power cable

CAUTION:

This unit has more than one power supply cord. To reduce the risk of electrical

shock, disconnect two power supply cords before servicing.

v

Page 6

Laser Safety Information

The optical drive in this system unit is a laser product. The optical drive has a label that

identifies its classification. The label, located on the drive, is shown below.

The optical drive in this system unit is certified in the U.S. to conform to the

requirements of the Department of Health and Human Services 21 Code of Federal

Regulations (DHHS 21 CFR) Subchapter J for Class 1 laser products. Elsewhere, the

drive is certified to conform to the requirements of the International Electrotechnical

Commission (IEC) 825 (1st edition 1984) and CENELEC EN 60 825:1991 for Class 1

laser products.

CAUTION:

A class 3 laser is contained in the device. Do not attempt to operate the drive

while it is disassembled. Do not attempt to open the covers of the drive as it is

not serviceable and is to be replaced as a unit.

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

APPAREIL A LASER DE CLASSE 1

IEC 825:1984 CENELEC EN 60 825:1991

Class 1 laser products are not considered to be hazardous. The optical drive contains

internally a Class 3B gallium-arsenide laser that is nominally 30 milliwatts at 830

nanometers. The design incorporates a combination of enclosures, electronics, and

redundant interlocks such that there is no exposure to laser radiation above a Class 1

level during normal operation, user maintenance, or servicing conditions.

vi S80, S85 Installation Guide

Page 7

Data Integrity and Verification

IBM computer systems contain mechanisms designed to reduce the possibility of

undetected data corruption or loss. This risk, however, cannot be eliminated. Users who

experience unplanned outages, system failures, power fluctuations or outages, or

component failures must verify the accuracy of operations performed and data saved or

transmitted by the system at or near the time of the outage or failure. In addition, users

must establish procedures to ensure that there is independent data verification before

relying on such data in sensitive or critical operations. Users should periodically check

the IBM support websites for updated information and fixes applicable to the system and

related software.

vii

Page 8

viii S80, S85 Installation Guide

Page 9

About This Book

This book provides information on how to setup and install the system, use diagnostics,

use service aids, and verify system operation. This book also provides information to

help you solve some of the simpler problems that might occur.

ISO 9000

ISO 9000 registered quality systems were used in the development and manufacturing

of this product.

Online Publications

RS/6000 publications are available online. To access the online books, visit our Web

site at: http://www.rs6000.ibm.com/resource/hardware_docs/

Related Publications

The following publications are available:

v The

SA38-0560, contains reference information, maintenance analysis procedures

(MAPs), error codes, removal and replacement procedures, and a parts catalog.

v The

contains diagnostic information, service request numbers (SRNs), and failing function

codes (FFCs).

v The

Systems,

and cables for your system. This manual is intended to supplement the service

information found in the

v The

specifications to help you do space and environmental planning before your system

is installed.

v The

information about slot requirements for installing PCI adapters. This book is intended

to be used to help plan and install PCI adapters for maximum performance from your

system.

v

SSA Adapters User’s Guide and Maintenance Information

is intended to help users and service representatives work with and diagnose

problems with SSA adapters and devices.

v The

Scalability Installation and Administration Guide

for HACMP/ES planning information.

v The

order number SC23-4277, is needed for HACMP/ES planning information.

Enterprise Server S80, p Series 680 Model S85 Service Guide

Diagnostic Information for Multiple Bus Systems

IBM RS/6000 Adapters, Devices, and Cable Information for Multiple Bus

order number SA38-0516 contains information about adapters, devices,

Diagnostic Information for Multiple Bus Systems

Site and Hardware Planning Information

PCI Adapter Placement Reference

High Availability Cluster Multi-Processing for AIX, Version 4.3: Enhanced

High Availability Cluster Multi-Processing for AIX, Version 4.3: Planning Guide

, order number SA38-0508, contains

, order number SA38-0538, contains

, order number SA38-0509,

, order number SA33-3272,

, order number SC23-4284, is needed

, order number

.

,

ix

Page 10

Trademarks

v The

7133 SSA Disk System: Operator Guide

to operate the 7133 SSA Disk System and how to install or replace disk drives to the

system, and how to deal with problems encountered when using the system.

v The

7133 SSA Disk Subsystem: Service Guide

the service technician to repair system failures in the 7133 SSA Disk System.

The following trademarks apply to this information:

v AIX is a registered trademark of the International Business Machines Corporation.

v IBM is a registered trademark of the International Business Machines Corporation.

v Velcro is a trademark of Velcro Industries.

, order number xxxxxxx, describes how

, order number xxxxxxx, is used by

x S80, S85 Installation Guide

Page 11

Chapter 1. System Installation Procedure

Follow the procedures in this chapter to install the Enterprise Server S80 and the p

Series 680 Model S85. The estimated installation time for the system is:

Install Activity 3.5 Hours

Planning Activity 2.0 Hours

________________ _________

Total Time 5.5 Hours

Step 1. Inventory

v The

About Your Machine

carton. Check the listing to verify that you have all the items that were shipped with

the system.

v AIX operating system publications

v Enterprise Server S80, p Series 680 Model S85 User’s Guide, order number

SA38-0557

v Enterprise Server S80, p Series 680 Model S85 Service Guide, SA38-0560

v Enterprise Server S80, p Series 680 Model S85 Installation Guide, order number

SA38-0582 (this book)

v

Diagnostic Information for Multiple Bus Systems

IBM RS/6000 Adapters, Devices, and Cable Information for Multiple Bus Systems,

v

order number SA38-0516

PCI Adapter Placement Reference

v

v System Unit Safety Information, order number SA23-2652

Electronic Service Agent for RS/6000 User’s Guide

v

v Support Information and Warranty.

listing is in a plastic bag attached to the outside of the

, order number SA38-0538.

, order number SA38-0509

, order number ZA38-0383

Verify with the customer that the following items are available. You will need them to

complete this installation.

1. A floor plan, showing where to place each rack.

2. A console, including cables and a power source.

3. A modem for the electronic customer-support function (if the customer ordered this

function). This includes the correct telephone jack, cables, and a power source.

Step 2. Observe this Safety Notice During Installation

Note: For a translation of this notice, see the

System Unit Safety Information

manual.

1

Page 12

DANGER

An electrical outlet that is not correctly wired could place hazardous voltage

on metal parts of the system or the devices that attach to the system. It is the

responsibility of the customer to ensure that the outlet is correctly wired and

grounded to prevent an electrical shock.

Before installing or removing signal cables, ensure that the power cables for

the system unit and all attached devices are unplugged.

When adding or removing any additional devices to or from the system,

ensure that the power cables for those devices are unplugged before the

signal cables are connected. If possible, disconnect all power cables from the

existing system before you add a device.

Use one hand, when possible, to connect or disconnect signal cables to

prevent a possible shock from touching two surfaces with different electrical

potentials.

During an electrical storm, do not connect cables for display stations, printers,

telephones, or station protectors for communication lines.

CAUTION:

This product is equipped with a three–wire power cable and plug for the user’s

safety. Use this power cable with a properly grounded electrical outlet to avoid

electrical shock.

CAUTION:

This unit has more than one power supply cord. To reduce the risk of electrical

shock, disconnect two power supply cords before servicing.

CAUTION:

Energy hazard, remove power before servicing. Disconnect two power supply

cords.

Step 3. Check the Customer Environment

1. Verify with your Installation Planning Representative or the customer that any

station-protector boxes used are correctly installed according to the Site and

Hardware Planning Information manual.

2. Make sure the customer is aware that the recommended temperature for IBM

products is 24° C (75° F) and the recommended relative humidity is 45%. The

acceptable operating temperature range is 10° C (50° F) to 38° C (100° F), and the

acceptable operating humidity range is 8% to 80%.

3. Make sure the customer is aware that the front and rear service clearances around

the system rack and I/O rack should be 36 inches (900mm). The service clearances

are important for proper air circulation, weight distribution, and the safety of both the

service representative and the customer.

2 S80, S85 Installation Guide

Page 13

Refer to ″Specifications″ in the Enterprise Server S80 p Series 680 Model S85

Service Guide, order number SA38-0560, for more planning information.

Step 4. Check Customer Outlets

Note: For a translation of this notice, see the

order number SA23-2652.

CAUTION:

Do not touch the receptacle or the receptacle faceplate with anything other than

your test probes before you have met the requirements in Step 8 below.

__ 1. Have the customer locate and turn off the branch circuit CB (circuit breaker).

Attach tag S229-0237, which reads “Do Not Operate.”

Note: All measurements are made with the receptacle faceplate in the normal

installed position.

__ 2. Some receptacles are enclosed in metal housings. On receptacles of this type,

perform the following steps:

a. Check for less than 1 volt from the receptacle case to any grounded metal

structure in the building, such as a raised-floor metal structure, water pipe,

building steel, or similar structure.

b. Check for less than 1 volt from receptacle ground pin to a grounded point in

the building.

Note: If the receptacle case or faceplate is painted, be sure the probe tip

penetrates the paint and makes good electrical contact with the metal.

__ 3. Check the resistance from the ground pin of the receptacle to the receptacle

case. Check resistance from the ground pin to building ground. The reading

should be less than 1.0 ohm, which indicates the presence of a continuous

grounding conductor.

__ 4. If any of the three checks made in substeps 2 and 3 are not correct, ask the

customer to remove the power from the branch circuit and make the wiring

corrections; then check the receptacle again.

System Unit Safety Information

manual,

Note: Do not use the digital multimeter to measure grounding resistance.

__ 5. Check for infinite resistance between the phase pins. This is a check for a wiring

short.

Note: For a translation of this notice, see the

manual, order number SA23-2652.

CAUTION:

If the reading is other than infinity, do not proceed! Have the customer

make necessary wiring corrections before continuing. Do not turn on the

branch circuit CB until all the above steps are satisfactorily completed.

System Unit Safety Information

Chapter 1. System Installation Procedure 3

Page 14

__ 6. Have the customer turn on the branch circuit CB. Measure for appropriate

voltages between phases. If no voltage is present on the receptacle case or

grounded pin, the receptacle is safe to touch.

__ 7. With an appropriate meter, verify that the voltage at the outlet is correct.

__ 8. Verify that the grounding impedance is correct by using the ECOS 1020, 1023,

B7106, or an appropriately approved ground impedance tester.

Note: Do

not

use the 120-volt convenience outlets inside a machine to power

the tester.

Step 5. Set Up the System Racks

Note: For a translation of this notice, see the

CAUTION:

The stabilizer must be firmly attached to the bottom of the I/O rack to prevent the

rack from turning over when the drawers are pulled out of the rack. Do not pull

out or install any drawer or feature if the stabilizer is not attached to the rack.

Shipping material must be removed, and the system rack and I/O rack and place them

where they are to be installed before installation can begin. If this has not been done,

consult the customer and the marketing representative as necessary.

1. Remove all packing and tape, if present, from the system rack and the I/O rack.

2. Position the racks according to the customer floor plan.

Note: As viewed from the front, position the primary I/O rack (the primary I/O rack

contains the service processor) on the right side of the system rack. A

clearance of 10 cm (4 inches) between the racks is required to allow access

to the I/O rack door.

If you are attaching the racks to a concrete floor or a raised floor, refer to

“Step 6A. Attach the I/O Rack to a Concrete Floor” on page 7, and then

return here.

3. On both racks, lock each caster wheel by tightening the thumbscrew on the caster.

System Unit Safety Information

manual.

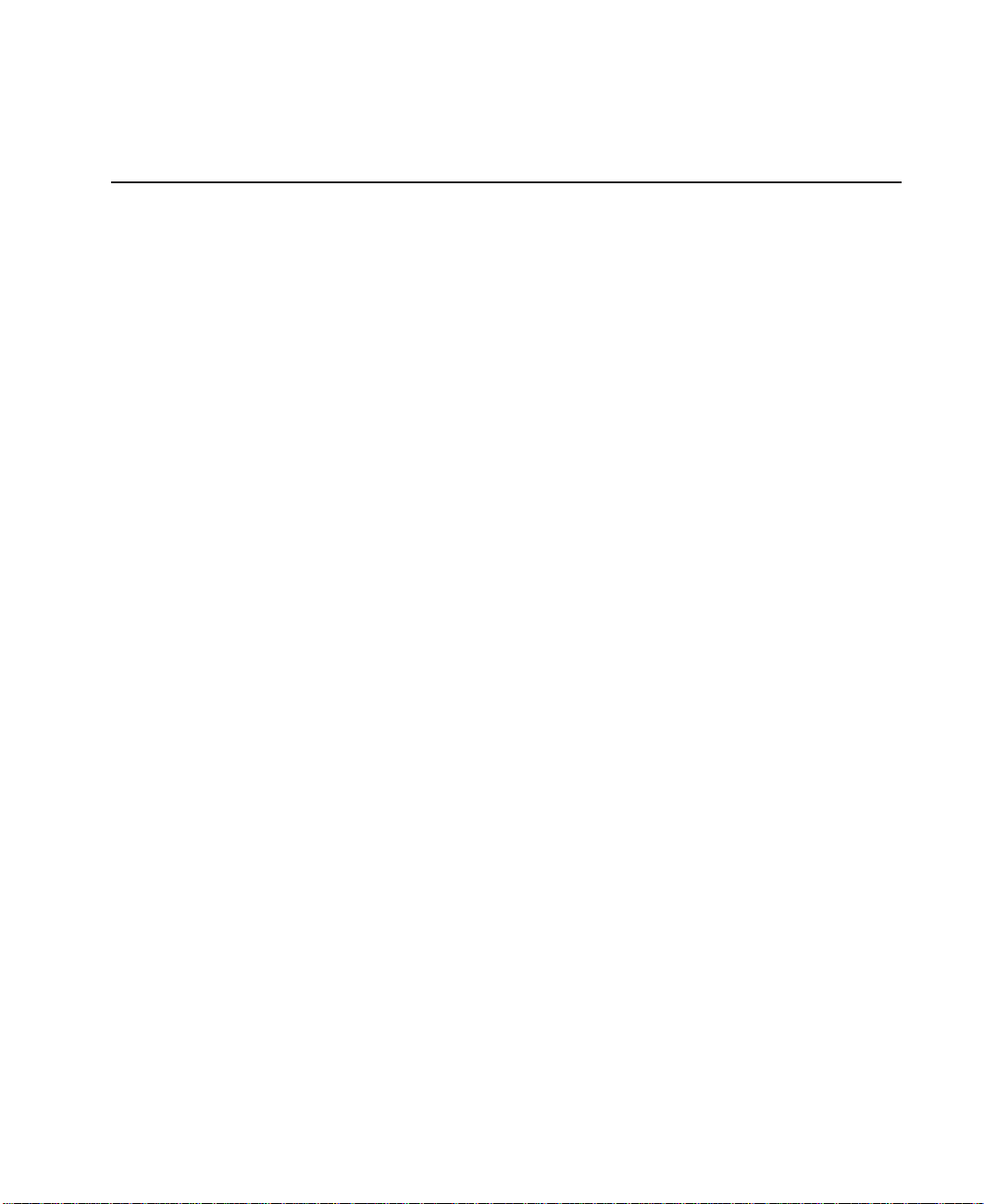

4. Adjust the leveling feet on the I/O rack by doing the following:

a. Loosen the locking nut by turning the locking nut counter-clockwise (away from

the bottom of the rack).

4 S80, S85 Installation Guide

Thumbscrew

Page 15

b. Adjust the height of the leveling feet by rotating the leveling feet either upward

or downward according to the level of the surface on which the rack is placed.

Repeat this for the remaining leveling feet as needed.

c. When the rack is leveled, tighten the locking nuts on all of the leveling feet.

Locking Nut

Leveling Feet (4)

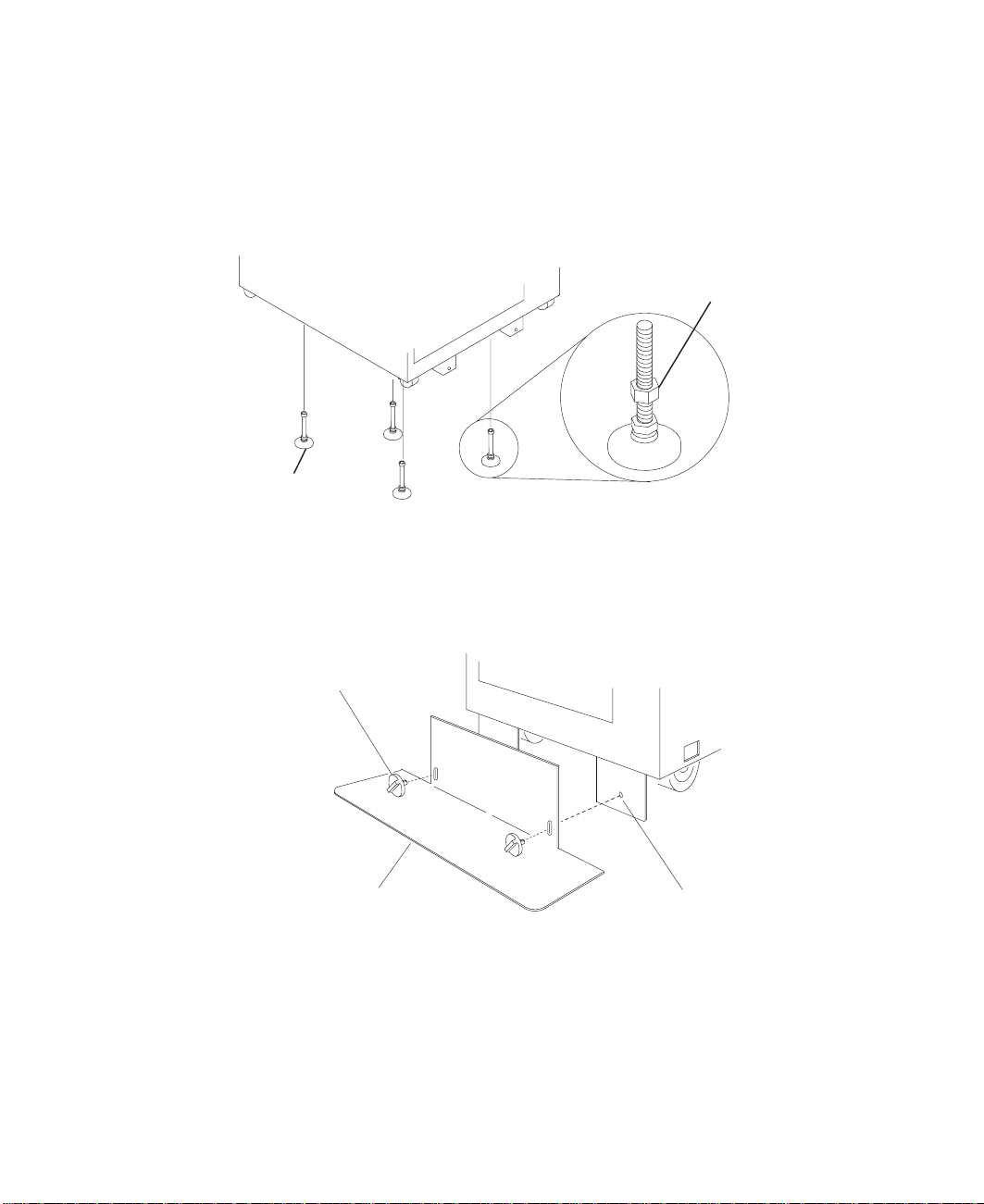

5. Align the slots in the stabilizer with the mounting holes in the bottom front of the

I/O rack.

6. Ensure that the base of the stabilizer rests firmly on the floor.

7. Install the two mounting screws and hand-tighten.

Mounting Screw

Stabilizer

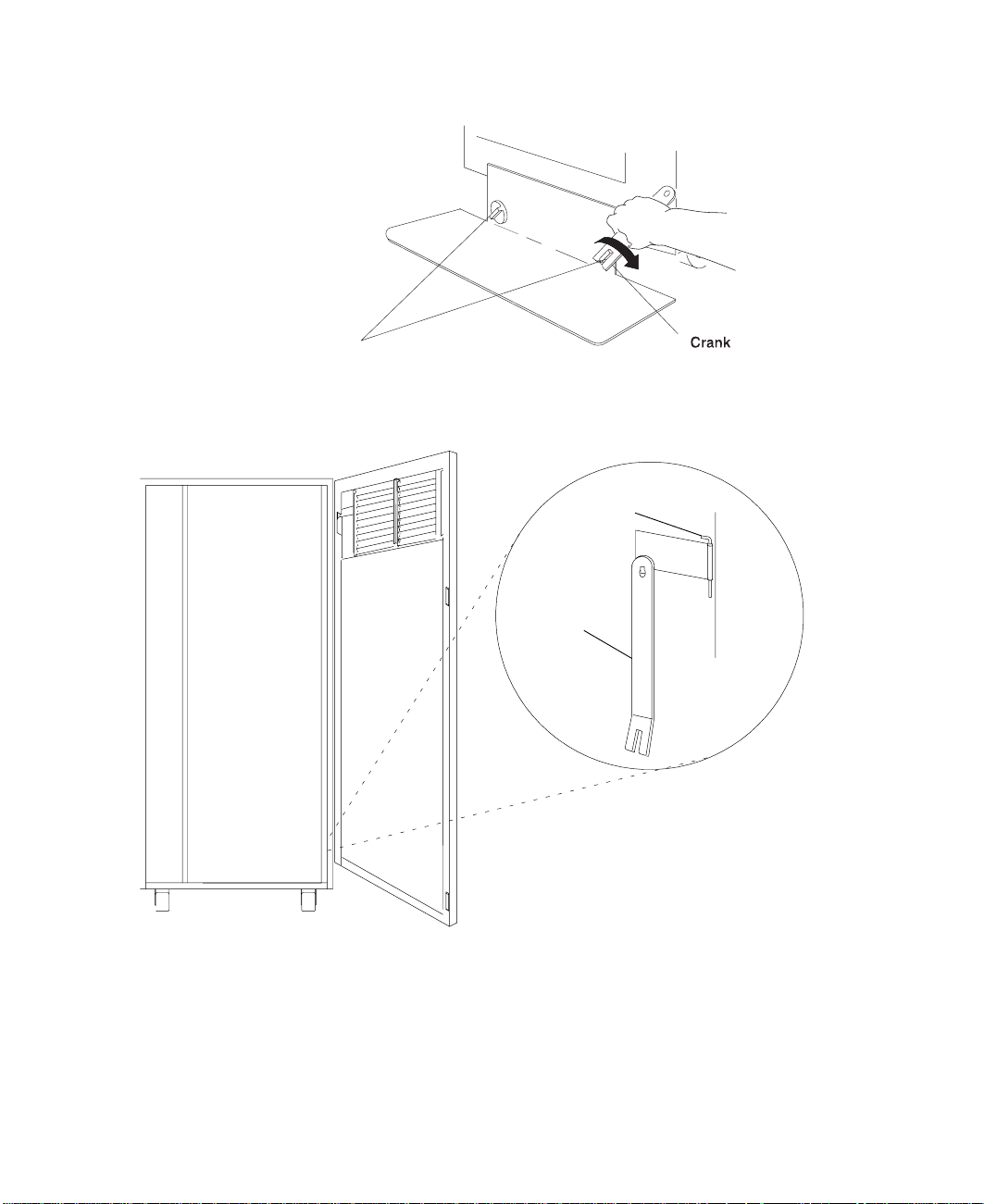

8. Use the crank supplied with the system unit to alternately tighten the mounting

screws until they are firmly seated.

Mounting Hole

Chapter 1. System Installation Procedure 5

Page 16

Mounting Screw

9. Hang the crank and tightening rod on the bracket near the bottom of the right wall

inside the back of the rack.

Tightening

Rod

Crank

10. Install the rear stabilizer on the I/O rack, as follows:

a. Loosen the lower screws on the stabilizer assembly.

b. Slide the stabilizer assembly onto the bottom of the rack.

c. Install screws at the top of the stabilizer assembly and tighten.

d. Tighten the lower screws on the stabilizer assembly.

6 S80, S85 Installation Guide

Page 17

e. Adjust the bolts to the floor to ensure that the stabilizer is level and does not

move.

11. If head protectors are installed, remove them from diskette drives.

Step 6A. Attach the I/O Rack to a Concrete Floor

Perform this step if the I/O rack is to be attached to a concrete floor or a concrete floor

beneath a raised floor.

Notes:

1. Ensure that the primary I/O rack (the primary I/O rack contains the service

processor) is positioned on the right side of the system rack when viewed from the

front. A clearance of 10 cm (4 inches) between the racks is required to allow access

to the I/O rack door.

2. If you are attaching the I/O rack:

Chapter 1. System Installation Procedure 7

Page 18

v To a concrete floor, continue with “Attaching the I/O Rack to a Concrete Floor”.

v To a concrete floor below a raised floor, go to “Attaching the I/O Rack to a

Concrete Floor Beneath a Raised Floor” on page 10.

If you are not attaching the I/O rack to a concrete floor, continue with “Step 7. Attach

the Front Electrical Outlet” on page 18.

Attaching the I/O Rack to a Concrete Floor

The customer is responsible for attaching the rack-mounting plates to the concrete floor.

Note: Because of the length of the four rack-mounting bolts, the drawer located in the

bottom position of the rack

bolts to the floor.

1. Mark the floor around the edge of each leveling foot.

2. Place the two mounting plates in the approximate mounting locations under the

rack.

3. To align the rack over the mounting plates, do the following:

a. Place the four rack-mounting bolts through the mounting holes at the bottom of

the rack.

b. Position the mounting plates under the four rack-mounting bolts so that the

mounting bolts are centered directly over the tapped holes. Insert the

rack-mounting bolts three or four rotations into the tapped holes.

4. Mark the floor around the edge of both mounting plates.

5. Remove the mounting bolts from the threaded holes.

6. To access the holes in the mounting plates, raise the four leveling feet, and then

move the rack away from the mounting plates.

7. Mark the floor at the center of each hole in the mounting plates (including the

tapped holes).

8. Remove the two mounting plates from the marked locations.

9. At the marked location of the tapped mounting holes, drill two holes approximately

1 inch to allow clearance for the ends of the two rack-mounting bolts. The ends of

the rack-mounting bolts may protrude past the thickness of the mounting plate.

must

be removed to install the four rack-mounting

Note: A minimum of three anchor bolts for each mounting plate must be used to

8 S80, S85 Installation Guide

mount the plates to the concrete floor. Because some of the drilled holes

may be aligned with concrete reinforcement rods below the surface of the

concrete floor, some of the drilled holes may not be usable. For each

mounting plate, select at least three usable holes, two that are on opposite

sides and opposite ends of each other, and one hole at the center.

Page 19

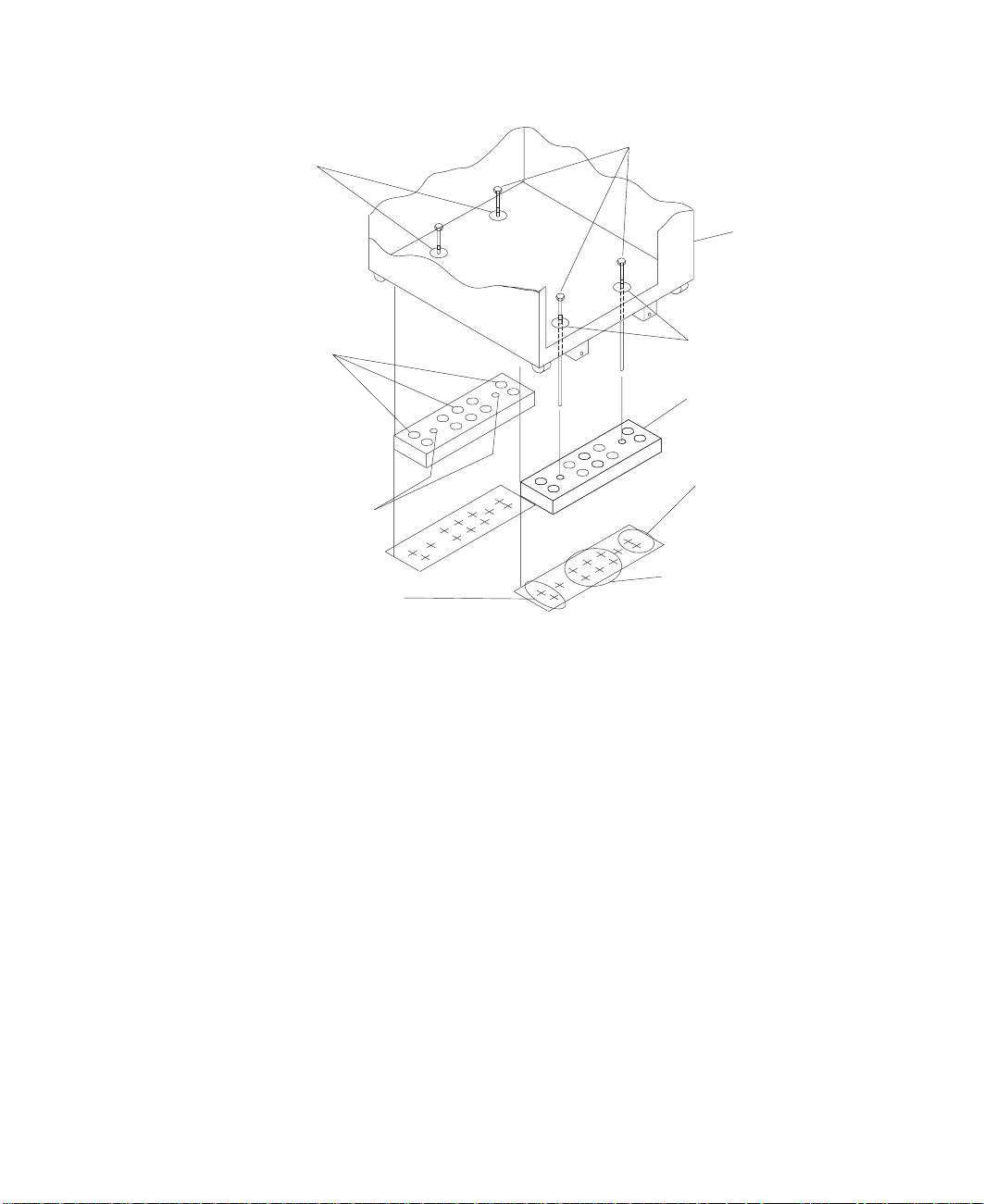

Mounting Holes

Rack Mounting Bolts

Front of

Rack

Holes for Anchor

Bolts (10)

Tapped Holes for

Rack Mounting Bolts

Location Marks (Drill One

of These Two Marks)

10. Drill one hole in each group of anchor bolt location marks as indicated on the

marked floor.

11. Using at least three anchor bolts for each mounting plate, mount the two mounting

plates to the concrete floor.

12. Using the location marks for leveling feet as a guide, reposition the rack over the

mounting plates.

13. Place the four rack-mounting bolts through the four metal washers, and then

through the four plastic isolator washers. The flat side of the plastic isolator washer

must be facing upward.

14. To further align the rack over the mounting plates, do the following:

a. Place the four rack-mounting bolts (with the four plastic isolator washers)

through the mounting holes in the bottom of the rack.

b. Align the four mounting bolts to the location of the four tapped holes in the two

mounting plates.

c. Insert the rack-mounting bolts three to four rotations into the tapped holes.

Mounting Holes

Mounting Plate (2)

Location Marks

(Drill One of

TheseTwo Marks)

Location Marks (Drill

One of These Six Marks)

Note: The bottom of the four leveling feet must be positioned over the four

plastic isolator pads when the rack is leveled.

If you are installing an ac-powered rack, do not use the four plastic

isolator pads.

Chapter 1. System Installation Procedure 9

Page 20

15. Place the four plastic isolator pads under the four leveling feet, and then level the

16. Tighten the locking nuts on the leveling feet.

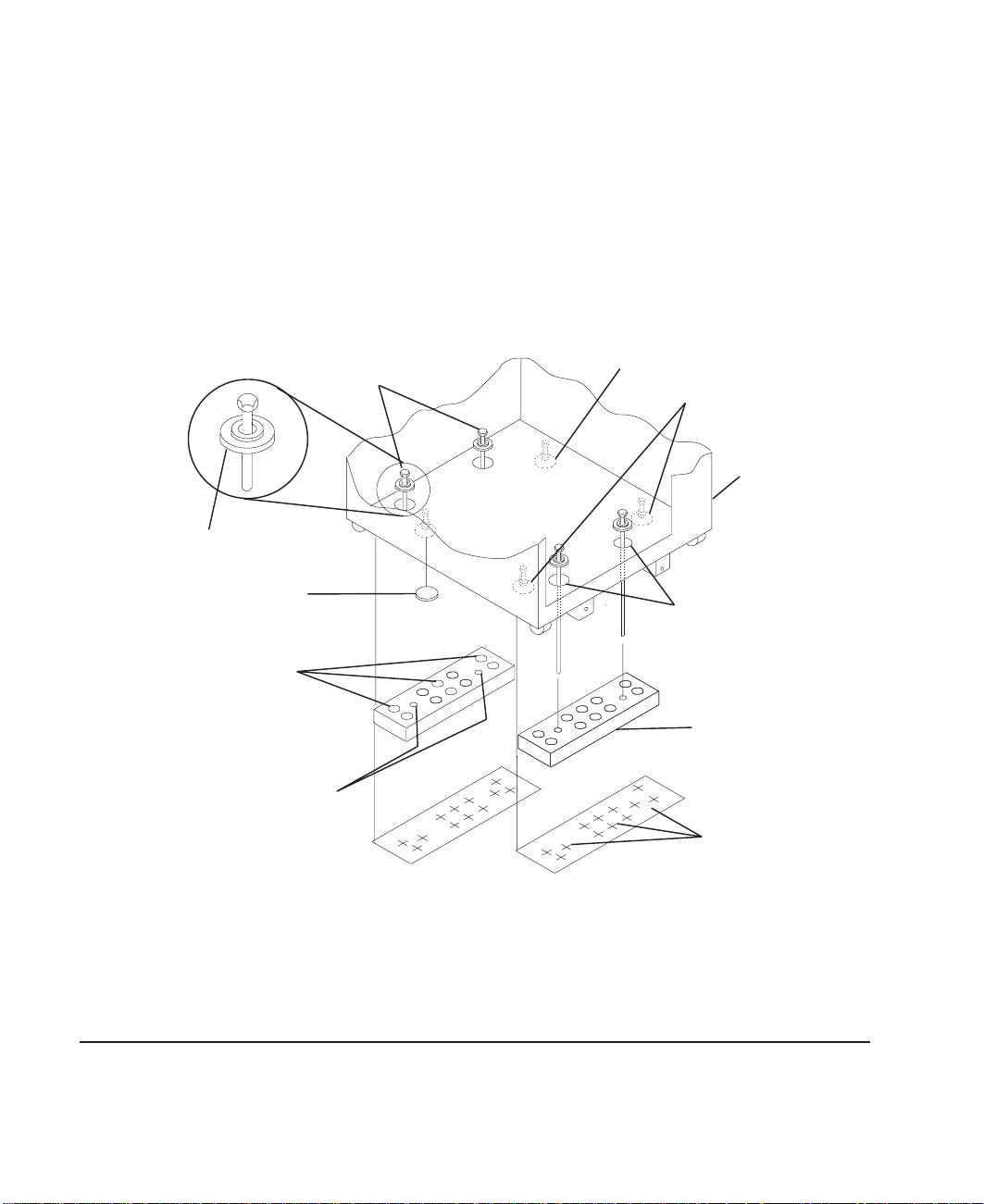

Plastic Isolator

Washer (4)

Plastic Isolator

Pad (4)

Holes for

Anchor Bolts

rack using the four adjustable leveling feet.

Rack-Mounting

Bolts

Leveling Foot (4)

Rack-Mounting

Bolts

Front of

Rack

Mounting

Holes

Mounting

Plates (2)

Tapped Holes for

Rack Mounting Bolts

Location

Marks

17. Tighten the four rack-mounting bolts into the two mounting plates.

18. If a drawer was removed from the bottom position of the rack, reinstall it.

Attaching the I/O Rack to a Concrete Floor Beneath a Raised Floor

The customer is responsible for obtaining the services of a mechanical contractor to

attach the rack-mounting plates on the raised floor with hardware that goes through the

raised floor into the concrete floor below the raised floor. The mechanical contractor

should determine that the raised floor support and the hardware used to attach the rack

mounting plates is sufficient to meet the customer’s requirements for the installation.

Note: Because of the length of the four rack-mounting bolts, the drawer located in the

bottom position of the rack

bolts to the floor.

1. Mark the floor around the edge of each leveling foot.

10 S80, S85 Installation Guide

must

be removed to install the four rack-mounting

Page 21

2. Place the two mounting plates in the approximate mounting locations under the

rack.

3. To align the rack over the mounting plates, do the following:

a. Place the four rack-mounting bolts through the mounting holes at the bottom of

the rack.

b. Position the mounting plates under the four rack-mounting bolts so that the

mounting bolts are centered directly over the tapped holes. Insert the

rack-mounting bolts three or four rotations into the tapped holes.

4. Mark the raised-floor panel around the edge of both mounting plates.

5. Remove the mounting bolts from the threaded holes.

6. To access the holes in the mounting plates, raise the four leveling feet, and then

move the rack away from the mounting plates.

7. Mark the raised-floor panel at the center of each hole in the mounting plates

(including the tapped holes).

8. Remove the two mounting plates from the marked locations.

Chapter 1. System Installation Procedure 11

Page 22

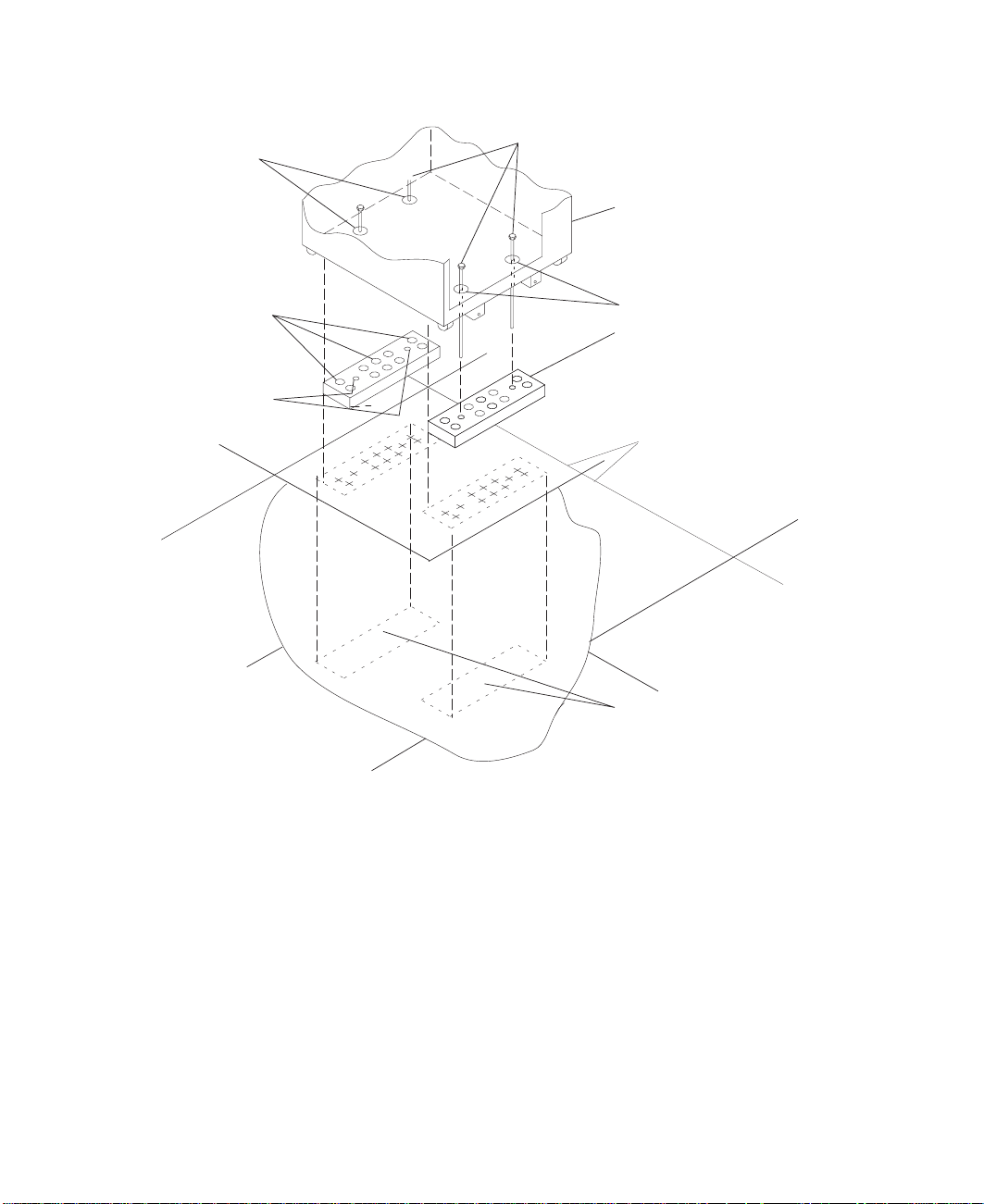

Mounting Holes

Rack Mounting Bolts

Front of

Rack

Holes for Anchor

Bolts (10)

Tapped Holes for

Rack Mounting Bolts

9. At the marked location of the tapped mounting holes, drill two holes approximately

1 inch to allow clearance for the ends of the two rack-mounting bolts. The ends of

the rack-mounting bolts may protrude past the thickness of the mounting plate.

Mounting Holes

Mounting Plate (2)

Raised

Floor Panels

Projection of Mounting

Plates onto Concrete Floor

Note: A minimum of three anchor bolts for each mounting plate must be used to

10. Drill one hole in each group of anchor bolt location marks as indicated on the

marked raised floor panel.

11. Ensure that the marks for the holes for the anchor bolts in the concrete floor align

with the holes in the raised floor panel.

12. Drill the holes in the concrete floor for the anchor bolts.

12 S80, S85 Installation Guide

mount the plates to the raised-floor panel. For each mounting plate, select

at least three usable holes, two that are on opposite sides and opposite

ends of each other, and one hole at the center.

Page 23

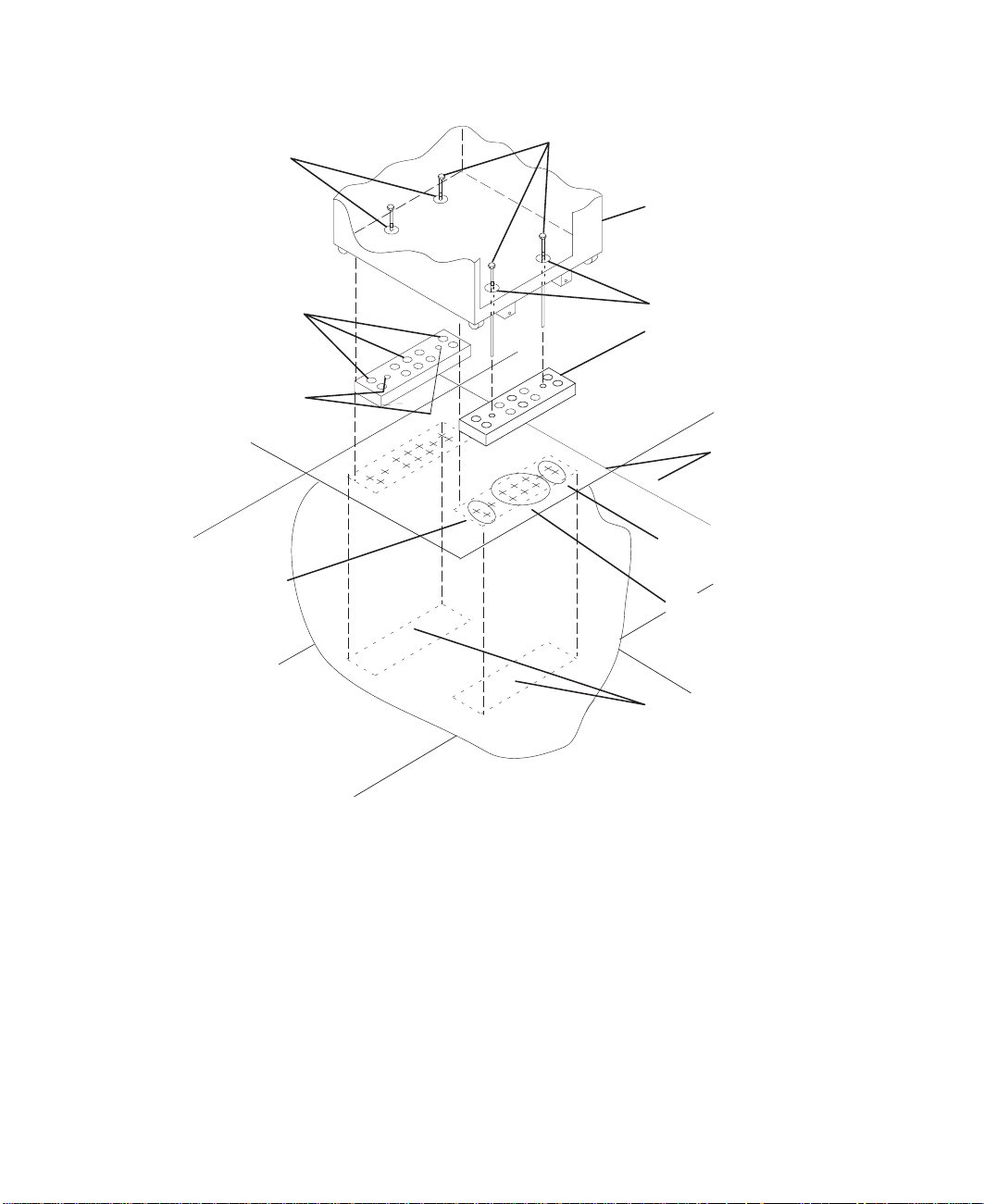

Mounting Holes

Rack Mounting Bolts

Front of

Rack

Holes for Anchor

Bolts (10)

Tapped Holes for

Rack Mounting Bolts

Location Marks

(Drill One of

These Two Marks)

13. Place the two mounting plates on the locations indicated on the marked

raised-floor panel.

14. Using at least three anchor bolts for each mounting plate, mount the two mounting

plates through the raised-floor panel to the concrete floor.

15. Using the location marks for leveling feet as a guide, reposition the rack over the

mounting plates.

16. Place the four rack-mounting bolts through the four metal washers, and then

through the four plastic isolator washers. The flat side of the plastic isolator washer

must be facing upward.

17. To further align the rack over the mounting plates, do the following:

a. Place the four rack-mounting bolts (with the four plastic isolator washers)

b. Align the four mounting bolts to the location of the four tapped holes in the two

Mounting Holes

Mounting Plate (2)

Raised

Floor Panels

Location Marks

(Drill One of

These Two Marks)

Location Marks

(Drill One of

These Six Marks)

Projection of Mounting

Plates onto Concrete Floor

through the mounting holes in the bottom of the rack.

mounting plates.

Chapter 1. System Installation Procedure 13

Page 24

18. Place the four plastic isolator pads under the four leveling feet, and then level the

19. Tighten the locking nuts on the leveling feet.

Plastic Isolator

Washer (4)

Plastic Isolator

Pad (4)

c. Insert the rack-mounting bolts three to four rotations into the tapped holes.

Note: The bottoms of the four leveling feet must be positioned over the four

plastic isolator pads when the rack is leveled. If you are installing an AC

powered rack, do not use the four plastic isolator pads.

rack using the four adjustable leveling feet.

Leveling Foot (4)

Rack-Mounting

Bolts

Rack-Mounting

Bolts

Front of

Rack

Mounting

Holes

Holes for

Anchor Bolts

Tapped Holes for

Rack Mounting Bolts

20. Tighten the four rack-mounting bolts into the two mounting plates.

21. If you are attaching an electrical outlet and mounting plate, skip to “Step 7. Attach

the Front Electrical Outlet” on page 18 or “Step 8. Attach the Rear Electrical Outlet”

on page 22 as appropriate, then return here.

22. If a drawer was removed from the bottom position of the rack, reinstall it.

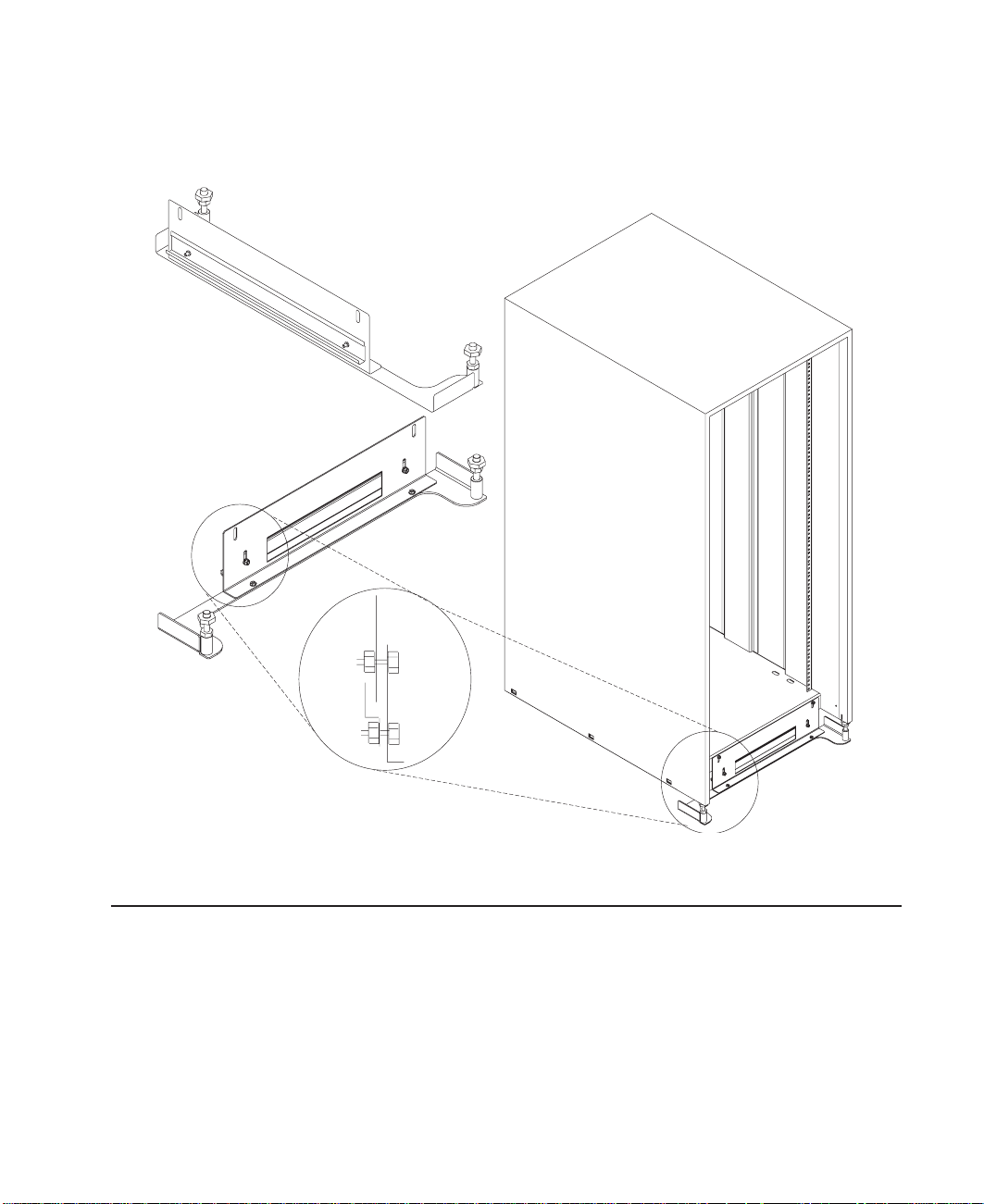

Step 6B. Attach the System Rack to a Concrete Floor

Perform this step if the system rack is to be attached to a concrete floor or a concrete

floor beneath a raised floor.

14 S80, S85 Installation Guide

Mounting

Plates (2)

Location

Marks

Page 25

Notes:

1. Ensure that the primary I/O rack (the primary I/O rack contains the service

processor) is positioned on the right side of the system rack when viewed from the

front. A clearance of 10 cm (4 inches) between the racks is required to allow access

to the I/O rack door.

2. If you are attaching the system rack:

v To a concrete floor, continue with “Attaching the System Rack to a Concrete

Floor”.

v To a concrete floor below a raised floor, go to “Attaching the System Rack to a

Concrete Floor Beneath a Raised Floor” on page 16.

If you are not attaching the system rack to a concrete floor, continue with “Step 7.

Attach the Front Electrical Outlet” on page 18.

Attaching the System Rack to a Concrete Floor

The customer is responsible for attaching the rack-mounting plates to the concrete floor.

1. Install the 4 plate assemblies with the leveling feet, bushings and washers. Make

sure that the leveling feet are backed off the floor level to allow space for the

mounting plates.

2. Place the mounting plates, front and rear, (note that they are different) in the

approximate mounting position under the system rack.

3. To align the system rack over the mounting plate, do the following:

a. Place the four rack-mounting bolts through the plate assembly holes at the

bottom of the rack (install the bushings and washers to ensure bolt

positioning).

Chapter 1. System Installation Procedure 15

Page 26

b. Position the mounting plates under the four rack-mounting bolts so that the

mounting bolts are centered directly over the tapped holes.

c. Insert the rack-mounting bolts three or four rotations into the tapped holes.

4. Mark the floor around the edge of the mounting plates.

5. Remove the mounting bolts from the threaded holes.

6. Move the rack away from the mounting plates.

7. Mark the floor at the center of each hole in the mounting plate (including tapped

holes).

8. Remove the mounting plates from the marked locations.

9. At the marked location of the tapped mounting holes, drill two holes approximately

1 inch to allow clearance for the ends of the two rack-mounting bolts. The ends of

the rack-mounting bolts may protrude past the thickness of the mounting plate.

Note: A minimum of three anchor bolts for each mounting plate must be used to

mount the plates to the concrete floor. Because some of the drilled holes

may be aligned with concrete reinforcement rods below the surface of the

concrete floor, some of the drilled holes may not be usable. For each

mounting plate, select at least three usable holes, two that are on opposite

sides and opposite ends of each other, and one hole at the center.

Drill one hole in each group of anchor bolt location marks as indicated on the

marked floor.

10. Using at least three bolts for each mounting plate, mount the mounting plates to

the concrete floor.

11. Reposition the system rack over the mounting plates.

12. Place the four rack-mounting bolts through the plate assemblies with the D-washer

positioned so that the straight side of the washer is facing inward toward the

system rack.

13. Place the isolator bushing inside the leveling foot with a washer between the

isolator bushing and the floor plate.

14. Insert the rack-mounting bolts three or four rotations into the tapped holes.

15. Turn the leveling foot of the plate assembly down until it contacts the mounting

plate, and then level the rack using the four leveling feet.

16. Lock the leveling feet by tightening the lock nut.

17. Tighten the four rack-mounting bolts into the mounting plates.

Attaching the System Rack to a Concrete Floor Beneath a Raised Floor

The customer is responsible for obtaining the services of a mechanical contractor to

attach the rack-mounting plates on the raised floor with hardware that goes through the

raised floor into the concrete floor below the raised floor. The mechanical contractor

should determine that the raised floor support and the hardware used to attach the rack

mounting plates is sufficient to meet the customer’s requirements for the installation.

16 S80, S85 Installation Guide

Page 27

1. Install the 4 plate assemblies with the levelling feet, bushings, and washers. Make

sure that the leveling feet are backed off the floor level to allow space for the

mounting plates.

2. Place the mounting plates, front and rear, (note that they are different) in the

approximate mounting position under the system rack.

3. To align the system rack over the mounting plate, do the following:

a. Place the four rack-mounting bolts through the plate assembly holes at the

bottom of the rack (install the bushings and washers to ensure bolt

positioning).

b. Position the mounting plates under the four rack-mounting bolts so that the

mounting bolts are centered directly over the tapped holes.

c. Insert the rack-mounting bolts three or four rotations into the tapped holes.

4. Mark the raised-floor panel around the edge of both mounting plates.

5. Remove the mounting bolts from the threaded holes.

6. Move the rack away from the mounting plates.

7. Mark the raised floor at the center of each hole in the mounting plates (including

the tapped holes).

8. Remove the two mounting plates from the marked locations.

9. At the marked location of the tapped mounting holes, drill two holes approximately

1 inch to allow clearance for the ends of the two rack-mounting bolts. Tthe ends of

the rack-mounting bolts may protrude past the thickness of the mounting plate.

Note: A minimum of three anchor plates for each mounting plate must be used to

mount the plates to the concrete floor. Because some of the drilled holes

may be aligned with concrete reinforcement rods below the surface of the

Chapter 1. System Installation Procedure 17

Page 28

concrete floor, some of the drilled holes may not be usable. For each

mounting plate, select at least three usable holes, two that are on opposite

sides and opposite ends of each other, and one hole at the center.

10. Drill one hole in each group of anchor bolt location marks as indicated on the

marked raised-floor panel.

11. Project the holes now in the raised-floor panel down to the concrete floor below.

Ensure that the marks for the holes for the anchor bolts in the concrete floor align

with the holes in the raised floor panel.

12. Drill the holes in the concrete floor for the anchor bolts.

13. Place the mounting plates on the locations on the marked raised-floor panel.

14. Using the three anchor bolts for each mounting plate, mount the two mounting

plates through the raised-floor panel to the concrete floor.

15. Reposition the system rack over the mounting plates.

16. Place the four rack-mounting bolts through the plate assemblies with the D-washer

positioned so that the straight side of the washer is facing inward toward the

system rack.

17. Place the isolator bushing inside the leveling foot with a washer between the

isolator bushing and the floor plate.

18. Insert the rack-mounting bolts three or four rotations into the tapped holes.

19. Turn the leveling foot of the plate assembly down until it contacts the mounting

plate, and then level the rack using the four leveling feet.

20. Lock the leveling feet by tightening the lock nut.

21. Tighten the 4 rack-mounting bolts into the mounting plates.

Step 7. Attach the Front Electrical Outlet

Attention: Refer to “Safety Notices” on page v before continuing.

Note: If the rack is on a raised floor without being attached to the concrete floor below

the raised floor, a stabilizer must be installed instead of the front-electrical-outlet

mounting plate. The front-electrical-outlet mounting plate cannot be installed on

the rack when a stabilizer is installed.

1. After the customer has connected the power cable from the customer power source

to the electrical outlet assembly, mount the electrical outlet assembly to the

mounting plate using the two mounting screws (provided by the customer).

18 S80, S85 Installation Guide

Page 29

Power Cable From

Power Source

Mounting Plate

Front of Rack

Electrical Outlet

Assembly

Mounting Screws

2. Place the ground-cable lug through the mounting hole of the mounting plate.

3. Connect the long end of the ground cable to the threaded side of the ground-cable

lug (inside mounting plate), and then install and tighten the ground-lug nut.

Note: The two remaining connections of the ground cable are done in “Step 8.

Attach the Rear Electrical Outlet” on page 22.

Chapter 1. System Installation Procedure 19

Page 30

Front of Rack

Long End of

Ground Cable

Ground Lug Nut

Mounting

Hole

Mounting

Plate

Y-End of

Ground Cable

4. Find the crank (for installing the mounting screws) located inside the rear of the rack

near the bottom of the right wall.

Ground Lug

Long End of Ground

Cable

Ground Connector

(Short End of

Ground Cable)

20 S80, S85 Installation Guide

Page 31

Crank

5. Align the holes of the mounting plate with the holes on the rack, and then install the

two mounting screws.

6. Using the crank, tighten the two mounting screws.

Chapter 1. System Installation Procedure 21

Page 32

Front of Rack

Crank

Mounting

Plate

7. Store the crank inside the rear of the rack near the bottom of the right wall.

Notes:

1. If the customer does not want to connect an electrical outlet to the front mounting

plate, install the mounting plate without the electrical outlet.

2. The customer is responsible for providing and connecting the electrical outlet

assembly.

The customer is also responsible for providing and connecting the power cable from

the customer power source to the front electrical outlet.

Step 8. Attach the Rear Electrical Outlet

Attention: Refer to “Safety Notices” on page v before continuing.

Note: The customer is responsible for providing and connecting the electrical outlet

assembly.

The customer is also responsible for providing and connecting the power cable

from the customer power source to the rear electrical outlet.

1. Open the rear door of the rack.

Mounting

Screws

22 S80, S85 Installation Guide

Page 33

2. After the customer has connected the power cable from the customer power source

to the electrical outlet assembly, mount the electrical outlet assembly to the

mounting plate using the two mounting screws (provided by the customer).

3. Place the ground cable lug through the mounting hole of the mounting plate.

4. Connect the short ground cable to the threaded side of the ground cable lug, and

then install and tighten the ground lug nut.

Chapter 1. System Installation Procedure 23

Page 34

5. Attach the mounting plate to the rack by installing and tightening the three mounting

screws.

24 S80, S85 Installation Guide

Page 35

6. Connect the ground connector of the ground cable to the ground bus bar.

7. If a drawer was removed from the bottom position of the rack, reinstall it.

8. Close the rear door of the rack.

Chapter 1. System Installation Procedure 25

Page 36

Step 9. Remove the Shipping Brackets and Install Covers

1. Remove any shipping materials from the system rack, I/O racks and from the front

and rear of the I/O drawers.

2. Remove the disk drive cover from the front of each I/O drawer. Inspect the disk

drives to ensure that the disk-drive carriers are all seated completely and that the

carrier latch is in the horizontal locked position.

26 S80, S85 Installation Guide

Page 37

3. Install any covers and shields that you have removed, or that were shipped

separately.

10 EIA Unit Drawer

Step 10. Install the I/O Rack Door Guide

1. Locate the I/O rack door guide.

2. Position the door guide as shown.

3. Using a 3mm allen wrench, fasten the door guide to the I/O rack as shown.

Disk Drive

Cover

Chapter 1. System Installation Procedure 27

Page 38

Door Guide

Step 11. Connect the Operator Panel Cable and the JTAG Cable Between the Racks

Using the cables provided, connect the cables between the system rack and the

primary I/O drawer. Refer to “Appendix D. Cabling the System Rack and I/O Rack” on

page 47 for connector locations for these cables.

Step 12. Connect RIO and SPCN Cables Between the Racks

Using the cables provided, connect the RIO and SPCN cables between the system rack

and the I/O drawers. Refer to “Appendix D. Cabling the System Rack and I/O Rack” on

page 47 for valid cabling configurations.

Step 13. Set Up Attached Devices

Note: During the setup of each device, connect only the device end of the signal cable.

Do not

connect the device signal cables to the I/O rack now.

Do the setup procedures in the documentation for each device being attached to

the I/O rack; then return to “Step 14. Update the Device Records” on page 29.

Connect the ASCII terminal to serial port S1. Connect the keyboard, mouse, and

graphics display (if available). Refer to “I/O Drawer Locations” on page 50 for the

locations of the connectors.

28 S80, S85 Installation Guide

Page 39

Step 14. Update the Device Records

External devices used with the S80 and S85 systems are connected to connectors on

the primary I/O drawer or to adapters that are installed inside any of the I/O drawers.

Update the “System Records” in “Appendix E. System Records” on page 63 to reflect

the configuration of the system adapters and devices that are installed.

Step 15. Attach External Devices

External devices used with the S80 and S85 system are connected to connectors on

the primary I/O drawer or to adapters that are installed inside any of the I/O drawers.

Refer to “Appendix E. System Records” on page 63 for listings of installed adapters to

determine where to attach external devices. Attach any external devices now.

Step 16. Connect the Power

1. Plug the drawer power cords into the power distribution bus (PDB) of the I/O rack.

Attention: If the system has the dual line cord feature, be sure that both power

supplies have power cords plugged in.

2. Plug the power cords of the external devices into power outlets.

3. Plug the PDB power cord into the customer’s electrical outlet.

4. Plug the system rack power cord into the customer’s electrical outlet.

Step 17. Power On and Check Out the System

1. If your system is a high-availability system, make sure all power control interface

cables (if installed) are disconnected. High-availability systems usually require

drawers to remain powered on when the system rack is powered off. If the power

control to certain drawers in your system is different from the factory settings, use

your planning information and any documentation supplied for the power control

system to understand power control.

2. Press the white power button on the operator panel. The operator panel is located

inside the front door of the system rack.

3. Go to the chapter titled “Installation Checkout Procedure” in the

Information for Multiple Bus Systems

check out the system.

Diagnostic

manual, and follow the procedures there to

Note: If the SP system attachment adapter is installed in the system, it will not be

recognized until the Parallel System Support Programs (PSSP) software is

installed on the system following attachment to the RS/6000 SP system.

Checklist If Problems Occur

If you have a problem when your try to turn on the system power, check to ensure:

v The EPO switch is on

v Rack power cables are installed

Chapter 1. System Installation Procedure 29

Page 40

v PDB circuit breakers CP1 - CP6 are set correctly (refer to “I/O Rack Rear Locations”

on page 49 for locations)

v Customer’s supply voltage is correct.

If any failures occur, refer to ″Maintenance Analysis Procedures (MAPs)″ in the

Enterprise Server S80 p Series 680 Model S85 Service Guide, order number

SA38-0560.

If you have a problem when you try to IPL the system, do the following:

v Check signal cables

v Check signal cable terminating plugs

v Verify device addresses

v Verify console has power

v Verify cable networks.

If any failures occur, refer to ″Maintenance Analysis Procedures (MAPs)″ in the

Enterprise Server S80 p Series 680 Model S85 Service Guide, order number

SA38-0560.

Step 18. Service Processor Setup and Test

Refer to ″Service Processor Setup and Test″ in the Enterprise Server S80, p Series 680

Model S85 User’s Guide, order number SA38-0557, and perform the steps necessary to

set up and test the service processor, then return here.

Note: If this system will be attached to an RS/6000 SP system, you only need to

modify the “System Name” parameter. See ″Privileged User Menus″ in the

Enterprise Server S80 p Series 680 Model S85 Service Guide, order number

SA38-0560.

Step 19. Install the Modem and Electronic Service Agent

If you have not yet installed the modem, do so now (see “Step 15. Attach External

Devices” on page 29).

Refer to

and perform the steps necessary to install the Electronic Service Agent for RS/6000,

then return here.

Electronic Service Agent for RS/6000 User’s Guide

Step 20. Finish the Installation

__ 1. Record the system identification numbers.

The system has important identification information that may be needed if service

is required. Record this information in “Appendix E. System Records” on

page 63.

__ 2. The Capacity Upgrade on Demand feature may be installed.

30 S80, S85 Installation Guide

, order number ZA38-0383,

Page 41

If so, see ″Capacity Upgrade on Demand Processor Enabling″ in

Upgrade on Demand Installing and Upgrading Processors,

Capacity

order number

SA38-0583, for information regarding installing and enabling this feature.

__ 3. If you decided to delay installing any optional devices, you might want to install

these now.

Some options you can install may come with a diskette that contains device

drivers, configuration files, or test programs. To install these files (after the

operating system is installed), follow the instructions provided with the option.

__ 4. If this system will be attached to an RS/6000 SP system, continue with

procedures in “Installing SP-Attach Server Cables.”, “Chapter 2, RS/6000 SP

Installation Instructions” in the

Volume 1, Installation and Customer Engineering Operations

RS/6000 SP Maintenance Information Manual,

manual, order

number GC23-3903.

__ 5. To install application programs, follow the instructions supplied with each

application program.

If any failures occur, refer to ″Maintenance Analysis Procedures (MAPs)″ in the

Enterprise Server S80 p Series 680 Model S85 Service Guide, order number

SA38-0560.

Chapter 1. System Installation Procedure 31

Page 42

32 S80, S85 Installation Guide

Page 43

Chapter 2. Using the System Verification Procedure

The system verification procedure is used to check the system for correct operation.

If you are analyzing a hardware problem, see ″Hardware Problem Determination″ in

Enterprise Server S80, p Series 680 Model S85 User’s Guide, order number

SA38-0557.

Step 1. Considerations before Running This Procedure

Notes:

1. If this system unit is directly attached to another system unit or attached to a

network, make sure that communications with the other system unit are stopped.

2. This procedure requires use of all of the system resources. No other activity can be

running on the system while you are doing this procedure.

v This procedure requires a display connected to the video port or an ASCII terminal

attached to the S1 port.

v Before starting this procedure, stop all programs and the operating system.

v This procedure runs the online diagnostics in service mode or standalone

diagnostics. If the online diagnostics are installed, they should be run. See the

operator manual for your type of ASCII terminal to find the key sequences you need

to respond to the diagnostics.

v If you need more information about diagnostics, see the Enterprise Server S80, p

Series 680 Model S85 User’s Guide, order number SA38-0557.

v If a console display is not selected, the diagnostics stop. The instructions for

selecting a console display are displayed on all of the graphic displays and any

terminal attached to the S1 port. Follow the instructions to select a console display.

v Go to Step 2.

Step 2. Loading the Diagnostics

1. Stop all application programs running on the operating system.

2. Stop the operating system.

3. Turn the power off.

4. If you are loading the standalone diagnostics and running them from an ASCII

terminal, do the following:

v The attributes for the terminal must be set to match the defaults of the

diagnostics.

v If you need to change any settings, record the normal settings, and be sure the

terminal attributes are set to work with the diagnostics. If needed, see ″Running

the Diagnostics from a TTY Terminal″ in the Enterprise Server S80, p Series 680

Model S85 User’s Guide, order number SA38-0557.

v Proceed to substep 5 when you finish checking the attributes.

5. Turn the power on.

33

Page 44

a. When the keyboard indicator appears, press the 5 key on the keyboard to load

the standalone diagnostics or press the 6 key to load the online diagnostics.

b. Enter any requested passwords.

c. Follow the instructions to select a console.

6. When the Diagnostic Operating Instructions display, go to “Step 3. Running System

Verification”. If you are unable to load the diagnostics, go to ″Problem Determination

When Unable to Load Diagnostics″ in the Enterprise Server S80, p Series 680

Model S85 User’s Guide, order number SA38-0557.

Step 3. Running System Verification

1. On the Diagnostic Operating Instructions screen, press the Enter key.

2. If the terminal type has not been defined, you must use the Initialize Terminal

option on the Function Selection menu to initialize the operating system

environment before you can continue with the diagnostics.

3. If you want to do a general checkout with minimal operator action, select the

Diagnostic Routines option on the Function Selection menu.

If you want to do a more complete checkout including the use of wrap plugs, select

the Advanced Diagnostics option on the Function Selection menu. The advanced

diagnostics are primarily for the service representative; they may instruct you to

install wrap plugs to better isolate a problem.

4. Select the System Verification option on the Diagnostic Mode Selection menu.

5. If you want to run a general checkout of all installed resources, select the All

Resource option on the Diagnostic Selection menu.

If you want to check one particular resource, select that resource on the Diagnostic

Selection menu.

6. Go to “Step 4. Additional System Verification”.

Step 4. Additional System Verification

The checkout programs end with either the Testing Complete menu and a message

stating No trouble was found or the A Problem Was Detected On (Time Stamp) menu

with an SRN.

1. Press Enter to return to the Diagnostic Selection menu.

2. If you want to check other resources, select the resource. When you have checked

all of the resources you need to check, go to “Step 5. Stopping the Diagnostics”.

Step 5. Stopping the Diagnostics

1. If you are running online diagnostics, shut down the system, using the following

procedure:

a. Press the 3 key repeatedly until you get to the Diagnostic Operating Instructions,

then follow the displayed instructions.

b. Press the 3 key once, and then follow the displayed instructions to shut down

the system.

2. If you changed any attributes on your ASCII terminal to run the diagnostics, change

the settings back to normal.

34 S80, S85 Installation Guide

Page 45

3. This completes the system verification. Report the SRN if you received one to the

service organization. To do a normal boot, turn off the system unit and wait 30

seconds, and then turn the system power on.

Chapter 2. Using the System Verification Procedure 35

Page 46

36 S80, S85 Installation Guide

Page 47

Chapter 3. Installing Options for Your System

There are no customer-installable options for the Enterprise Server S80 or the p Series

680 Model S85.

The Capacity Upgrade On-Demand feature may be installed. See

Demand Installing and Upgrading Processors,

regarding installing and enabling this feature.

order number SA38-0583, for information

Capacity Upgrade on

37

Page 48

38 S80, S85 Installation Guide

Page 49

Appendix A. Communications Statements

The following statement applies to this product. The statement for other products

intended for use with this product appears in their accompanying documentation.

Federal Communications Commission (FCC) Statement

Note: This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Properly shielded and grounded cables and connectors must be used in order to meet

FCC emission limits. Neither the provider nor the manufacturer is responsible for any

radio or television interference caused by using other than recommended cables and

connectors or by unauthorized changes or modifications to this equipment.

Unauthorized changes or modifications could void the user’s authority to operate the

equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause

undesired operation.

European Union (EU) Statement

This product is in conformity with the protection requirements of EU Council Directive

89/336/EEC on the approximation of the laws of the Member States relating to

electromagnetic compatibility. The manufacturer cannot accept responsibility for any

failure to satisfy the protection requirements resulting from a non-recommended

modification of the product, including the fitting of option cards supplied by third parties.

Consult with your dealer or sales representative for details on your specific hardware.

This product has been tested and found to comply with the limits for Class A

Information Technology Equipment according to CISPR 22 / European Standard EN

55022. The limits for Class A equipment were derived for commercial and industrial

environments to provide reasonable protection against interference with licensed

communication equipment.

Attention: This is a Class A product. In a domestic environment this product may

cause radio interference in which case the user may be required to take adequate

measures.

39

Page 50

International Electrotechnical Commission (IEC) Statement

This product has been designed and built to comply with IEC Standard 950.

United Kingdom Telecommunications Safety Requirements

This equipment is manufactured to the International Safety Standard EN60950 and as

such is approved in the UK under the General Approval Number NS/G/1234/J/100003

for indirect connection to the public telecommunication network.

The network adapter interfaces housed within this equipment are approved separately,

each one having its own independent approval number. These interface adapters,

supplied by the manufacturer, do not use or contain excessive voltages. An excessive

voltage is one which exceeds 70.7 V peak ac or 120 V dc. They interface with this

equipment using Safe Extra Low Voltages only. In order to maintain the separate

(independent) approval of the manufacturer’s adapters, it is essential that other optional

cards, not supplied by the manufacturer, do not use main voltages or any other

excessive voltages. Seek advice from a competent engineer before installing other

adapters not supplied by the manufacturer.

Avis de conformité aux normes du ministère des Communications du Canada

Cet appareil numérique de la classe A respecte toutes les exigences du Réglement sur

le matériel brouilleur du Canada.

Canadian Department of Communications Compliance Statement

This Class A digital apparatus meets the requirements of the Canadian

Interference–Causing Equipment Regulations.

VCCI Statement

The following is a summary of the VCCI Japanese statement in the box above.

This is a Class A product based on the standard of the Voluntary Control Council for

Interference by Information Technology Equipment (VCCI). If this equipment is used in a

domestic environment, radio disturbance may arise. When such trouble occurs, the user

may be required to take corrective actions.

40 S80, S85 Installation Guide

Page 51

Electromagnetic Interference (EMI) Statement - Taiwan

The following is a summary of the EMI Taiwan statement above.

Warning: This is a Class A product. In a domestic environment this product may cause

radio interference in which case the user will be required to take adequate measures.

Radio Protection for Germany

Dieses Gerät ist berechtigt in Übereinstimmung mit Dem deutschen EMVG vom

9.Nov.92 das EG–Konformitätszeichen zu führen.

Der Aussteller der Konformitätserklärung ist die IBM Germany.

Dieses Gerät erfüllt die Bedingungen der EN 55022 Klasse A. Für diese von Geräten

gilt folgende Bestimmung nach dem EMVG:

Geräte dürfen an Orten, für die sie nicht ausreichend entstört sind, nur mit besonderer

Genehmigung des Bundesministers für Post und Telekommunikation oder des

Bundesamtes für Post und Telekommunikation betrieben werden. Die Genehmigung

wird erteilt, wenn keine elektromagnetischen Störungen zu erwarten sind.

(Auszug aus dem EMVG vom 9.Nov.92, Para.3, Abs.4)

Hinweis

Dieses Genehmigungsverfahren ist von der Deutschen Bundespost noch nicht

veröffentlicht worden.

Appendix A. Preface 41

Page 52

42 S80, S85 Installation Guide

Page 53

Appendix B. Environmental Notices

Product Recycling and Disposal

This unit contains materials such as circuit boards and connectors with lead that require

special handling and disposal at end of life. Before this unit is disposed of, these

materials must be removed and recycled or discarded according to applicable

regulations. This manual contains specific information on batteries where applicable.

This product may contain nickel-cadmium and/or lithium batteries. The battery(s) must

be recycled or disposed of properly. Recycling facilities may not be available in your

area. In the United States, IBM has established a collection process for reuse,

recycling, or proper disposal of used sealed lead acid, nickel cadmium and nickel metal

hydride batteries and battery packs from IBM equipment. For information on proper

disposal of the nickel cadmium batteries in this product, please contact IBM at

1-800-426-4333. For information on battery disposal outside the United States, contact

your local waste disposal facility.

Environmental Design

The environmental efforts that have gone into the design of this system signify IBM’s

commitment to improve the quality of its products and processes. Some of these

accomplishments include the elimination of the use of Class I ozone-depleting

chemicals in the manufacturing process and reductions in manufacturing wastes. For

more information, contact an IBM account representative.

Unit Emissions

The unit-related emission value is equal to or lower than 70dB(A).

Der Geräuschpegel der Einheit ist kleiner oder gleich 70 db(A).

43

Page 54

44 S80, S85 Installation Guide

Page 55

Appendix C. Notices

This information was developed for products and services offered in the U.S.A.

The manufacturer may not offer the products, services, or features discussed in this

document in other countries. Consult the manufacturer’s representative for information

on the products and services currently available in your area. Any reference to the

manufacturer’s product, program, or service is not intended to state or imply that only

that product, program, or service may be used. Any functionally equivalent product,

program, or service that does not infringe any intellectual property right of the

manufacturer may be used instead. However, it is the user’s responsibility to evaluate

and verify the operation of any product, program, or service.

The manufacturer may have patents or pending patent applications covering subject

matter described in this document. The furnishing of this document does not give you

any license to these patents. You can send license inquiries, in writing, to the

manufacturer.

The following paragraph does not apply to the United Kingdom or any country

where such provisions are inconsistent with local law: THIS MANUAL IS

PROVIDED ″AS IS″ WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESSED OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. Some states do not allow disclaimer of express or implied warranties in

certain transactions; therefore, this statement may not apply to you.

This information could include technical inaccuracies or typographical errors. Changes

are periodically made to the information herein; these changes will be incorporated in

new editions of the publication. The manufacturer may make improvements and/or

changes in the product(s) and/or the program(s) described in this publication at any

time without notice.

Information concerning products made by other than the manufacturer was obtained

from the suppliers of those products, their published announcements, or other publicly

available sources. The manufacturer has not tested those products and cannot confirm

the accuracy of performance, compatibility or any other claims related to products made

by other than the manufacturer. Questions on the capabilities of products made by other

than the manufacturer should be addressed to the suppliers of those products.

45

Page 56

46 S80, S85 Installation Guide

Page 57

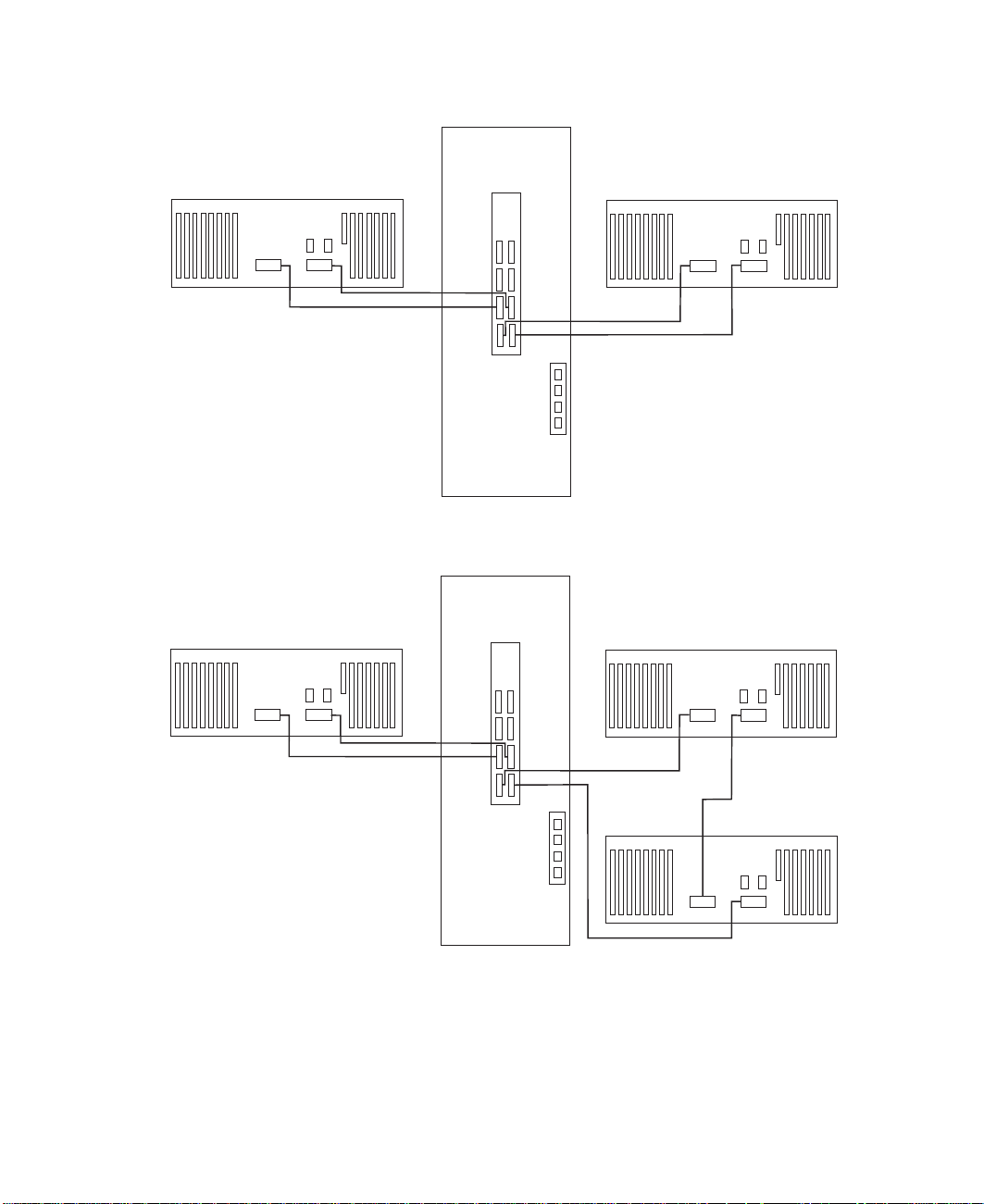

Appendix D. Cabling the System Rack and I/O Rack

The minimum system consists of two racks. The system rack contains the system

processors, memory and supporting hardware. The I/O rack contains I/O drawer(s) with

PCI adapters, disk drives, and media drives. The S80 and S85 must have a minimum

of one I/O drawer. This drawer is called the primary I/O drawer and it contains the

service processor for the system. Additional I/O drawers can be added to the system.

These drawers are called secondary I/O drawers. Secondary I/O drawers are connected

to the system rack but do not contain a service processor. The S80 and S85 support up

to a total of four I/O drawers in various I/O rack configurations.

There are two steps to connecting the system rack to the I/O drawers in their I/O racks.

1. Connect the JTAG cable and the operator panel cable. These two cables are

connected only between the system rack and the primary I/O drawer. See

“Connecting JTAG and Operator Panel Cables” on page 48 for diagrams showing

these cables.

2. Connect the RIO cables and the SPCN cables. These cables connect between the

system rack and all the I/O drawers in loops. See “Connecting RIO and SPCN

Cables” on page 57 for diagrams showing these cables.

47

Page 58

Connecting JTAG and Operator Panel Cables

Use the following figure to connect the JTAG and operator panel (OP) cables.

SAMI Port

Operator Panel

Connector

OP

Rear of Primary

I/O Drawer (Drawer 0)

Front of System Rack

JTAG

Connector

Rear of System Rack

Slot 8

Service Processor Connector

Rear of Primary

I/O Drawer (Drawer 0)

48 S80, S85 Installation Guide

Page 59

I/O Rack Rear Locations

The following figure shows the rear of an I/O rack. 10 EIA unit I/O drawers can be

installed, as shown in the figure.

10 EIA Unit I/O Drawers

Primary

I/O Drawer

Secondary

I/O Drawer

Power

Distribution

Bus

(CP1 - CP6)

Appendix D. Cabling the System Rack and I/O Rack 49

Page 60

I/O Drawer Locations

This section shows component locations for the 10 EIA unit I/O drawer.

10 EIA Unit I/O Drawer Front View

Note: The SCSI IDs shown for media devices indicate how these devices are set when

shipped from the factory.

1. Indicator Panel

2. Blower 1 (left)

3. Blower 3 (center)

4. Blower 2 (right)

5. Hot Swap Disk Drive Bays

6. Media Bay

50 S80, S85 Installation Guide

Page 61

10 EIA Unit I/O Drawer Rear View

1. PCI adapter slots (1 - 7)

2. PCI adapter slot 8, service processor card and JTAG cable in primary I/O drawer

(drawer 0)

3. Parallel connector

4. Keyboard connector

5. Mouse connector

6. Reserved

7. Reserved

8. PCI adapter slots (9 - 14)

9. Right power supply

10. Power cord connector for right power supply

11. Fans (mounted on front end of right power supply)

12. Right power supply, power good LED

13. SPCN2 connector

14. SPCN1 connector

15. Serial port S2*

16. Serial port S1* (Used for TTY terminal connection)

Appendix D. Cabling the System Rack and I/O Rack 51

Page 62

Note: In an RS/6000 SP environment, there is normally a cable attached from this

port to the SP Control Workstation. To directly attach a TTY terminal to this

port, the cable to the SP Control Workstation must be disconnected. Be

sure to reconnect this cable after servicing the system.

17. Operator panel (OP) connector

18. RIO 0 and RIO 1

19. Power cord connector for left power supply

20. Left power supply, power good LED

21. Fans (mounted on front end of left power supply)

22. Left power supply

* Serial ports 1 and 2 can only be used for service processor menus. No “heartbeat”

type devices can be used on these ports.

52 S80, S85 Installation Guide

Page 63

10 EIA Unit I/O Drawer System board Locations

J1 RIO bus

J2 RIO bus

J3 SPCN connector

J4 PCI slot 2, controller 1

J5 PCI slot 3, controller 1

J6 PCI slot 4, controller 1

J7 PCI slot 6, controller 0

J8 PCI slot 7, controller 0

J9 PCI slot 8, controller 0

Appendix D. Cabling the System Rack and I/O Rack 53

Page 64

J10 PCI slot 11, controller 2

J11 PCI slot 12, controller 2

J12 PCI slot 13, controller 2

J13 PCI slot 1, controller 1

J14 PCI slot 5, controller 0

J15 PCI slot 9, controller 3

J16 PCI slot 10, controller 3

J17 PCI slot 14, controller 2

J18 JTAG connector

J19 Display indicator panel (DIP) connector

J21 I35 SCSI backplane connector

J22 Power distribution board (PDB) card connector

J23 PCI slot (1-8) power connector

J24 PCI slot (9-14) power connector

J25 +12 vdc, −12 vdc, and +3.3 vdc, power supply connector

J26 PCI slot power (1-8) +3.3 vdc power connector

J27 Speaker

J30 Reserved

54 S80, S85 Installation Guide

Page 65

Service Processor Card Locations

J1 JTAG connector to system rack

J2 Serial port connector to inside bulkhead card

J3 Speaker connector

J4 Diskette drive connector

J5 Parallel port connector

J6 Keyboard/mouse connector to inside bulkhead card

J16 Write protect DASD FLASH (if jumper is on pins)

J17 Operator panel connector from the system rack

J18 Test Port 0

J19 Test Port 1

J20 Test Port 2

J22 Write protect boot FLASH (if jumper is set between pins 2 and 3)

Appendix D. Cabling the System Rack and I/O Rack 55

Page 66

Fan Monitor Control (FMC) Card Locations (10 EIA Unit I/O Drawer)

J2

J4

J6

J3

J5

J1

J1 To Power Distribution Board

J2 Fan 2 (Left Blower)

J3 Fan 1 (Center Blower)

J4 Fan 3 (Right Blower)

J5 Power Supply and Fans 4, 5, 6, 7 (Power Supply Fan Assemblies)

J6 To PCI Connectors

Power Distribution Board Locations

J1 Power supply docking connector

J2 Power supply docking connector