Page 1

RS/6000 7025 F50 Series IBM

Service Guide

SA38-0541-01

Page 2

Second Edition (February 1998)

The following paragraph does not apply to the United Kingdom or any country where

such provisions are inconsistent with local law: THIS PUBLICATION IS PROVIDED “AS

IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. Some states do not allow disclaimer of express or implied

warranties in certain transactions, therefore, this statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are

periodically made to the information herein; these changes will be incorporated in new editions

of the publication. The manufacturer may make improvements and/or changes in the

product(s) and/or the program(s) described in this publication at any time, without notice.

It is possible that this publication may contain reference to, or information about, products

(machines and programs), programming, or services that are not announced in your country.

Such references or information must not be construed to mean that these products,

programming, or services will be announced in your country. Any reference to a specific

licensed program in this publication is not intended to state or imply that you can use only that

licensed program. You can use any functionally equivalent program instead.

Requests for technical information about products should be made to your authorized reseller

or marketing representative.

International Business Machines Corporation 1997, 1998. All rights reserved.

Note to U.S. Government Users -- Documentation related to restricted rights -- Use,

duplication or disclosure is subject to restrictions set forth is GSA ADP Schedule Contract with

IBM Corp.

Page 3

Contents

Communications Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Federal Communications Commission (FCC) Statement .............. vii

International Electrotechnical Commission (IEC) Statement ............ vii

United Kingdom Telecommunications Safety Requirements ............ vii

European Union (EU) Statement ............................ viii

Avis de conformité aux normes du ministère des Communications du Canada . viii

Canadian Department of Communications Compliance Statement ........ viii

VCCI Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Radio Protection for Germany ............................. ix

European Union (EU) Statement ............................. x

VCCI Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Safety Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

Laser Safety Information ................................ xiii

About This Book .................................... xv

ISO 9000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Chapter 1. Reference Information . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Unit Locations .................................. 1-1

System Data Flow .................................... 1-8

Typical Boot Sequence for RS/6000 7025 F50 Series ............... 1-9

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Service Inspection Guide ............................... 1-13

Chapter 2. Maintenance Analysis Procedures (MAPs) ............. 2-1

Entry MAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

MAP 1020: Problem Determination .......................... 2-6

MAP 1520: Power ................................... 2-12

MAP 1540: Minimum Configuration ......................... 2-17

SSA Maintenance Analysis Procedures (MAPs) .................. 2-35

MAP 2010: SSA Hot-Swap Disk Drive–Start .................... 2-37

Chapter 3. Error Code to FRU Index ........................ 3-1

Firmware/POST Error Codes .............................. 3-2

Bus SRN to FRU Reference Table .......................... 3-27

Checkpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Location Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

Preface iii

Page 4

Physical Location Codes ............................... 3-46

AIX and Physical Location Code Reference Table ................. 3-48

AIX Location Codes .................................. 3-54

SSA Location Code Format .............................. 3-58

SSA Loops and Links ................................. 3-59

SSA Service Aids .................................... 3-64

Service Aid Error Codes ................................ 3-83

Using the Service Aids for SSA-Link Problem Determination ........... 3-84

Finding the Physical Location of a Device ..................... 3-90

Microcode Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-92

Vital Product Data (VPD) ............................... 3-93

Chapter 4. Loading the System Diagnostics ................... 4-1

Chapter 5. System Management Services ..................... 5-1

Graphical System Management Services ....................... 5-1

Config . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

MultiBoot: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Error Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

RIPL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

SCSI ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-21

Update . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-22

Text-Based System Management Services ..................... 5-24

Chapter 6. Removal and Replacement Procedures ............... 6-1

Handling Static–Sensitive Devices ........................... 6-2

Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

CD-ROM Drive, Tape Drive, Diskette Drive ..................... 6-19

Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-20

Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22

Memory Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-26

Memory Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-29

I/O Planar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-31

Processor Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-35

Service Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-37

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-38

Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-42

Operator Panel Display ................................ 6-44

Operator Panel Control Assembly .......................... 6-45

Serial/Parallel Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-46

iv Service Guide

Page 5

Chapter 7. Parts Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Appendix A. SSA Problem Determination Procedures ............ A-1

Disk Drive Module Power-On Self-Tests (POSTs) ................. A-1

Adapter Power-On Self-Tests (POSTs) ....................... A-2

Service Request Numbers (SRNs) .......................... A-3

SSA Loop Configurations That Are Not Valid .................... A-15

Appendix B. Service Processor Menus ..................... B-1

Service Processor Menus ............................... B-3

General User Menus .................................. B-4

Privileged User Menus ................................. B-6

Service Processor Functions and Features ..................... B-24

Appendix C. Service Processor Setup and Test ................ C-1

Testing the Setup .................................... C-2

Appendix D. Modem Configurations . . . . . . . . . . . . . . . . . . . . . . . D-1

Sample Modem Configuration Files ......................... D-1

Configuration File Selection .............................. D-2

Seamless Transfer of a Modem Session ...................... D-6

Modem Configuration Samples ............................ D-9

Appendix E. Service Processor Operational Phases ............. E-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-1

Reader's Comments — We'd Like to Hear From You ............. X-3

Preface v

Page 6

vi Service Guide

Page 7

Communications Statements

Federal Communications Commission (FCC) Statement

Note: This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the

interference at his own expense.

Properly shielded and grounded cables and connectors must be used in order to

meet FCC emission limits. Neither the provider nor the manufacturer are responsible

for any radio or television interference caused by using other than recommended

cables and connectors or by unauthorized changes or modifications to this

equipment. Unauthorized changes or modifications could void the user's authority to

operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) this device may not cause harmful interference,and (2)

this device must accept any interference received, including interference that may

cause undesired operation.

International Electrotechnical Commission (IEC) Statement

This product has been designed and built to comply with IEC Standard 950.

United Kingdom Telecommunications Safety Requirements

This equipment is manufactured to the International Safety Standard EN60950 and

as such is approved in the UK under the General Approval Number

NS/G/1234/J/100003 for indirect connection to the public telecommunication network.

The network adapter interfaces housed within this equipment are approved

separately, each one having its own independent approval number. These interface

adapters, supplied by the manufacturer, do not use or contain excessive voltages. An

excessive voltage is one which exceeds 70.7 V peak ac or 120 V dc. They interface

with this equipment using Safe Extra Low Voltages only. In order to maintain the

separate (independent) approval of the manufacturer's adapters, it is essential that

Preface vii

Page 8

other optional cards, not supplied by the manufacturer, do not use main voltages or

any other excessive voltages. Seek advice from a competent engineer before

installing other adapters not supplied by the manufacturer.

European Union (EU) Statement

This product is in conformity with the protection requirements of EU Council Directive

89/336/EEC on the approximation of the laws of the Member States relating to

electromagnetic compatibility.

Neither the provider nor the manufacturer can accept responsibility for any failure to

satisfy the protection requirements resulting from a non–recommended modification

of the product, including the fitting of option cards not supplied by the manufacturer.

This product has been tested and found to comply with the limits for Class B

Information Technology Equipment according to CISPR 22 / European Standard EN

55022. The limits for Class B equipment were derived for typical residential

environments to provide reasonable protection against interference with licensed

communication devices.

Avis de conformité aux normes du ministère des Communications du

Canada

Cet appareil numérique de la classe A respecte toutes les exigences du Réglement

sur le matériel brouilleur du Canada.

Canadian Department of Communications Compliance Statement

This Class A digital apparatus meets the requirements of the Canadian

Interference–Causing Equipment Regulations.

VCCI Statement

The following is a summary of the VCCI Japanese statement in the box above.

viii Service Guide

Page 9

This is a Class B product based on the standard of the Voluntary Control Council for

Interference from Information Technology Equipment (VCCI). If this is used near a

radio or television receiver in a domestic environment, it may cause radio

interference. Install and use the equipment according to the instruction manual.

When used near a radio or TV receiver, it may become the cause of radio

interference.

Read the instructions for correct handling.

Radio Protection for Germany

Dieses Gerät ist berechtigt in Übereinstimmung mit dem deutschen EMVG vom

9.Nov.92 das EG–Konformitätszeichen zu führen.

Der Aussteller der Konformitätserklärung ist die IBM Germany.

Dieses Gerät erfüllt die Bedingungen der EN 55022 Klasse B.

Preface ix

Page 10

Note: If any of the following Feature Codes are installed:

3615, 4356, 4357, 4358, 4359, 6218, 8130, or 8134,

or if a configuration using more than one SysKonnect FDDI adapter (Feature

Codes 2741, 2742, or 2743) where any one of them is Feature Code 2743

(SysKonnect SK-NET FDDI-UP SAS PCI), the following statement applies:

European Union (EU) Statement

This product is in conformity with the protection requirements of EU Council Directive

89/336/EEC on the approximation of the laws of the Member States relating to

electromagnetic compatibility. The manufacturer cannot accept responsibility for any

failure to satisfy the protection requirements resulting from a non-recommended

modification of the product, including the fitting of option cards supplied by third

parties. Consult with your dealer or sales representative for details on your specific

hardware.

This product has been tested and found to comply with the limits for Class A

Information Technology Equipment according to CISPR 22 / European Standard EN

55022. The limits for Class A equipment were derived for commercial and industrial

environments to provide reasonable protection against interference with licensed

communication equipment.

Attention: This is a Class A product. In a domestic environment this product may

cause radio interference in which case the user may be required to take adequate

measures.

VCCI Statement

The following is a summary of the VCCI Japanese statement in the box above.

This is a Class A product based on the standard of the Voluntary Control Council for

Interference by Information Technology Equipment (VCCI). If this equipment is used

in a domestic environment, radio disturbance may arise. When such trouble occurs,

the user may be required to take corrective actions.

x Service Guide

Page 11

Safety Notices

A

danger

death or serious personal injury.

notice indicates the presence of a hazard that has the potential of causing

caution

A

moderate or minor personal injury.

Electrical Safety

Observe the following safety instructions any time you are connecting or

disconnecting devices attached to the workstation.

DANGER

notice indicates the presence of a hazard that has the potential of causing

An electrical outlet that is not correctly wired could place hazardous

voltage on metal parts of the system or the devices that attach to the

system. It is the responsibility of the customer to ensure that the outlet

is correctly wired and grounded to prevent an electrical shock.

Before installing or removing signal cables, ensure that the power

cables for the system unit and all attached devices are unplugged.

When adding or removing any additional devices to or from the system,

ensure that the power cables for those devices are unplugged before

the signal cables are connected. If possible, disconnect all power

cables from the existing system before you add a device.

Use one hand, when possible, to connect or disconnect signal cables

to prevent a possible shock from touching two surfaces with different

electrical potentials.

During an electrical storm, do not connect cables for display stations,

printers, telephones, or station protectors for communication lines.

CAUTION:

This product is equipped with a three–wire power cable and plug for the user's

safety. Use this power cable with a properly grounded electrical outlet to avoid

electrical shock.

Preface xi

Page 12

DANGER

To prevent electrical shock hazard, disconnect the power cable from

the electrical outlet before relocating the system.

xii Service Guide

Page 13

Laser Safety Information

The optical drive in this system unit is a laser product. The optical drive has a label

that identifies its classification. The label, located on the drive, is shown below.

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

APPAREIL A LASERDE CLASSE1

IEC 825:1984 CENELEC EN 60 825:1991

The optical drive in this system unit is certified in the U.S. to conform to the

requirements of the Department of Health and Human Services 21 Code of Federal

Regulations (DHHS 21 CFR) Subchapter J for Class 1 laser products. Elsewhere,

the drive is certified to conform to the requirements of the International

Electrotechnical Commission (IEC) 825 (1st edition 1984) and CENELEC EN 60

825:1991 for Class 1 laser products.

CAUTION:

A class 3 laser is contained in the device. Do not attempt to operate the drive

while it is disassembled. Do not attempt to open the covers of the drive as it

is not serviceable and is to be replaced as a unit.

Class 1 laser products are not considered to be hazardous. The optical drive

contains internally a Class 3B gallium-arsenide laser that is nominally 30 milliwatts at

830 nanometers. The design incorporates a combination of enclosures, electronics,

and redundant interlocks such that there is no exposure to laser radiation above a

Class 1 level during normal operation, user maintenance, or servicing conditions.

Preface xiii

Page 14

xiv Service Guide

Page 15

About This Book

This book provides maintenance information that is specific to the system unit,

adapters, and attached devices that do not have their own service information. It also

contains Maintenance Analysis Procedures (MAPs) that are not common to other

systems.

MAPs that are common to all systems are contained in the

Information for Multiple Bus Systems

This book is used by the service technician to repair system failures. This book

assumes that the service technician has had training on the system unit.

ISO 9000

ISO 9000 registered quality systems were used in the development and

manufacturing of this product.

Related Publications

The following publications are available for purchase:

The

The

The

IBM RS/6000 7025 F50 Series User's Guide

users set up, install options, configure, modify, and solve minor problems.

IBM RS/6000 Diagnostic Information for Multiple Bus Systems

common diagnostic procedures, error codes, service request numbers, and

failing function codes. This manual is intended for trained service technicians.

IBM RS/6000 Adapter, Device, and Cable Information for Multiple Bus

Systems

manual is intended to supplement information found in the

contains information about adapters, external devices, and cabling. This

Diagnostic Information for Multiple Bus Systems

.

.

IBM RS/6000 Diagnostic

contains information to help

contains

IBM RS/6000

The

Preface xv

Site and Hardware Planning Information

plan your installation.

contains information to help you

Page 16

xvi Service Guide

Page 17

Chapter 1. Reference Information

System Unit Locations

Front View with Media Door Off

Chapter 1. Reference Information 1-1

Page 18

Rear View

1-2 Service Guide

Page 19

SCSI IDs and Bay Locations

Note: The SCSI bus ID's in Bays A1, B1 and B2 are the recommended values.

Features installed at the manufacturing site correspond to these IDs. Field

installations may not comply with these recommendations.

Chapter 1. Reference Information 1-3

Page 20

I/O Planar Locations

J1, J2 64-bit PCI connectors

J3, J4, J5, J6, J7, J8P, J9P 32-bit PCI connectors

J8I, J9I ISA connectors

J10 Service Processor

J11 External SCSI connector

J12 Fan #1 (Bottom Fan)

J13 Diskette Drive connector

J15 Fan #3

J16 SCSI Security Jumper

J17 Fan #2

J18 Ethernet connector (thick)

1-4

Service Guide

Page 21

J19 Fan #4 (Top Fan)

J21 Ethernet connector (twisted pair)

J22A Operator Panel

J23 Keyboard connector

J25 Internal SCSI connector (port 1)

J26 System Card connector

J27 Mouse connector

J30 Internal SCSI connector (port 2)

J41 Serial connector (serial port 1 and 2)

J43 Battery Socket

J47 Parallel connector

J50 Serial connector (serial port 3)

P1, P2 Power Supply

Chapter 1. Reference Information 1-5

Page 22

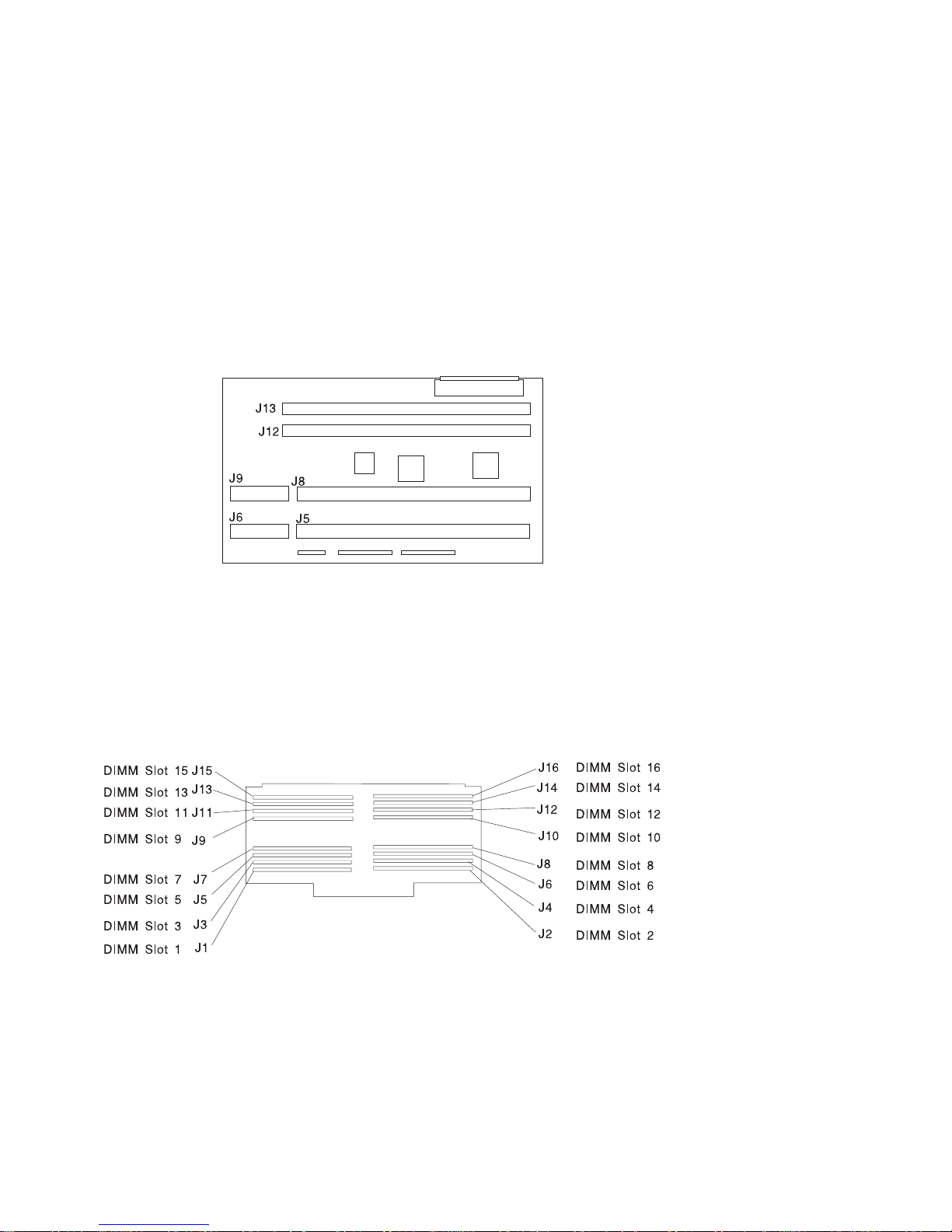

System Card Locations

J5, J6 Processor card connector #2

J8, J9 Processor card connector #1

J12 Memory card connector #1

J13 Memory card connector #2

Memory Card Locations

1-6 Service Guide

Page 23

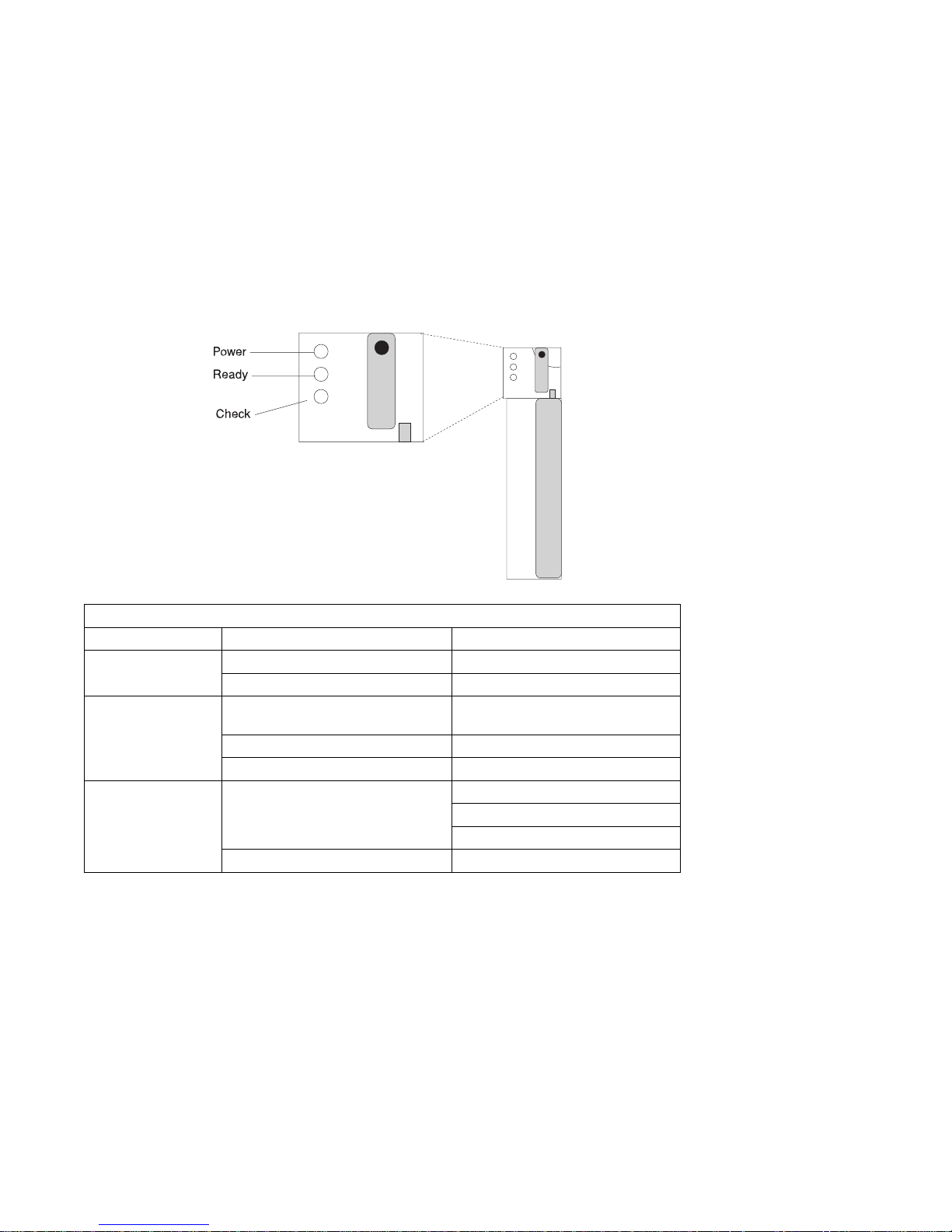

Operator Panel

Chapter 1. Reference Information 1-7

Page 24

System Data Flow

1-8 Service Guide

Page 25

Typical Boot Sequence for RS/6000 7025 F50 Series

After the A/C power is turned on, the System Support Controller (SSC) startup

begins, and releases reset to the Service Processor. If the SSC cannot

communicate with the Service Processor, the LCD displays 4BA00000. If the

Service Processor is not present, the LCD displays 4BA00001.

1. Service Processor Self Test

Service Processor card performs self test and NVRAM initialization.

LCD Code range is E000 - E07F.

LCD code is "OK" when complete.

2. Service Processor in Standby Mode

You can enter the Service Processor menus whenever the LCD code is

"OK", "STBY", or has an eight digit error code on the LCD display by

pressing the enter key on an ASCII terminal connected to serial port 1.

3. Built-In-Self-Test (BIST)

The Service Processor initiates Built-In-Self-Test (BIST) on the Central

Electronics Complex (CEC) chips when the POWER Button is pressed.

The VPD data is read and the CRC is checked.

The CPU compatibility test is run.

LCD Code range is E0A0 - E0E1.

4. System Initialization

System firmware begins to execute and initializes system registers after LCD

code E0E1.

LCD Code range is E1XX - E2XX.

5. Memory Test

The system firmware tests the system memory and identifies failing memory

cards and memory module locations.

LCD Code range is E3XX.

6. Device Configuration and Test

System firmware checks to see what devices are in the system and performs

a simple test on them.

The system firmware displays the device name or device icon being tested.

After the keyboard name or icon appears, the user can enter the Systems

Management Services menu by hitting the "1" key (if ASCII terminal) or the

"F1" key (if Graphics terminal).

The user can also enter one of the following:

– "5" or "F5" to start the Stand-alone Diagnostics (CD or Tape).

– "6" or "F6" to start the On-line Diagnostics (Hard Disk)

Chapter 1. Reference Information 1-9

Page 26

7. IPL Boot Code

The system firmware attempts to boot from the devices listed in the Boot

List.

LCD Code range is E1XX.

8. Boot Image Execution

Once a boot image is located on a device in the Boot List, the system

firmware code hands off control to the AIX Boot code.

– LCD Code E105 for Normal Boot or

– E15B for Service Mode Boot.

The AIX Boot code indicates LCD progress codes in the range from 05XX to

09XX.

9. AIX Boot Complete

The AIX login prompt appears on the main console.

Specifications

The mechanical packaging, cooling, power supply, and environmental requirements

for the server is shown in the following:

Dimensions

Height - 620 mm (24.3 inches)

Depth - 695 mm (27.3 inches)

Width - 245 mm (9.6 inches)

Weight

Configuration dependent

Operating Environment - Class B

Temperature - 16° to 32°C (60° to 90°F)

Humidity - 8% to 80% noncondensing

Maximum Altitude - 2135 m (7000 feet)

1-10

Service Guide

Page 27

Power Source Loading

Typical EMC Configuration - 0.28 kVA

Maximum - 0.65 kVA

Power Requirements

Typical - 154 watts

Maximum - 450 watts

Power Factor

0.8 - 0.98

Operating Voltage

100 to 127V ac; 50 to 60 Hz

200 to 240V ac; 50 to 60 Hz

Heat Output (Maximum)

Typical - 800 BTU/hr

Maximum - 2300 BTU/hr

Acoustics

6.0 Bels operating

5.5 Bels idle

Chapter 1. Reference Information 1-11

Page 28

Power Cables

To avoid electrical shock, a power cable with a grounded attachment plug is

provided. Use only properly grounded outlets.

Power cables used in the United States and Canada are listed by Underwriter's

Laboratories (UL) and certified by the Canadian Standards Association (CSA).

These power cords consist of:

Electrical cables, Type SVT or SJT.

Attachment plugs complying with National Electrical Manufacturers Association

(NEMA) 5-15P. That is:

"For 115 V operation, use a UL listed cable set consisting of a minimum 18 AWG,

Type SVT or SJT three-conductor cord a maximum of 15 feet in length and a parallel

blade, grounding type attachment plug rated at 15 A, 125 V."

"For 230 V operation in the United States use a UL listed cable set consisting of a

minimum 18 AWG, Type SVT or SJT three-conductor cable a maximum of 15 feet in

length, and a tandem blade, grounding type attachment plug rated at 15 A, 250 V."

Appliance couplers complying with International Electrotechnical Commission

(IEC) Standard 320, Sheet C13.

Power cables used in other countries consist of the following:

Electrical cables, Type HD21.

Attachment plugs approved by the appropriate testing organization for the

specific countries where they are used.

"For units set at 230 V (outside of U.S.): use a cable set consisting of a minimum 18

AWG cable and grounding type attachment plug rated 15 A, 250 V. The cable set

should have the appropriate safety approvals for the country in which the equipment

will be installed and should be marked HAR'."

Refer to Chapter 7, “ Parts Information” on page 7-1 to find the power cables that

are available.

1-12

Service Guide

Page 29

Service Inspection Guide

Perform a service inspection on the system when:

The system is inspected for a maintenance agreement.

Service is requested and service has not recently been performed.

An alterations and attachments review is performed.

Changes have been made to the equipment that may affect the safe operation of

the equipment.

External devices with their own power cables have those cables attached.

If the inspection indicates an unacceptable safety condition, the condition must be

corrected before anyone can service the machine.

Note: The correction of any unsafe condition is the responsibility of the owner of the

system.

Perform the following checks:

1. Check the covers for sharp edges and for damage or alterations that expose the

internal parts of the system unit.

2. Check the covers for proper fit to the system unit. They should be in place and

secure.

3. Gently rock the system unit from side to side to determine if it is steady.

4. Set the power switch of the system unit to Off.

5. Remove the covers.

6. Check for alterations or attachments. If there are any, check for obvious safety

hazards such as broken wires, sharp edges, or broken insulation.

7. Check the internal cables for damage.

8. Check for dirt, water, and any other contamination within the system unit.

9. Check the voltage label on the back of the system unit to ensure that it matches

the voltage at the outlet.

10. Check the external power cable for damage.

11. With the external power cable connected to the system unit, check for 0.1 ohm

or less resistance between the ground lug on the external power cable plug and

the metal frame.

12. Perform the following checks on each device that has its own power cables:

a. Check for damage to the power cord.

Chapter 1. Reference Information 1-13

Page 30

b. Check for the correct grounded power cable.

c. With the external power cable connected to the device, check for 0.1 ohm or

less resistance between the ground lug on the external power cable the

metal frame of the device.

13. Install the covers.

1-14

Service Guide

Page 31

Chapter 2. Maintenance Analysis Procedures (MAPs)

Entry MAP

Use the following table to determine your starting point.

Note: When possible, run Online Diagnostics in Service Mode. Online Diagnostics

perform additional functions, compared to Standalone Diagnostics. This ensures that

the error state of the system is captured in NVRAM for your use in fixing the

problem. The AIX error log and SMIT are only available when diagnostics are run

from the hard drive.

Notes:

1. If more than eight digits are displayed in the operator panel, use only the first

eight digits to find the error in the tables. The digits that display beyond the first

eight digits are location codes that can assist you in diagnosing the problem. See

“Location Codes” on page 3-46.

2. Licensed programs frequently rely on network configuration, and system

information stored on the VPD on the operator panel control assembly (connector

U2). If the MAPs indicate that the Operator Panel Control Assembly should be

replaced, swap the VPD from the old operator panel to the new one. If the old

VPD module has to be replaced call technical support for recovery instructions.

If recovery is not possible, notify the system owner that new keys for licensed

programs may be required.

3. If a network adapter, or the I/O planar is replaced, the network administrator

must be notified so that the client IP addresses used by the server can be

changed. In addition, the operating system configuration of the network

controller may need to be changed in order to enable system startup. Also

check to ensure that any client or server that addresses this system is updated.

Symptom Action

You have parts to exchange or a corrective

action to perform.

You need to verify that a part exchange or

corrective action corrected the problem.

Chapter 2. Maintenance Analysis Procedures 2-1

Service Actions

1. Go to the

Procedures

2. Go to "MAP 410: Repair Checkout" in the

IBM RS/6000 Diagnostic Information for

Multiple Bus Systems

Go to "MAP 410: Repair Checkout" in the

RS/6000 Diagnostic Information for Multiple Bus

Systems

Removal and Replacement

.

.

IBM

.

Page 32

Symptom Action

You need to verify correct system operation.

Go to "MAP 410: Repair Checkout" in the

IBM

RS/6000 Diagnostic Information for Multiple Bus

Systems

You have OK displayed The Service Processor (SP) is ready. The

You have STBY displayed The Service Processor (SP) is ready. The

You do not have a determined symptom. Go to “MAP 1020: Problem Determination” on

You have an 8-digit error code displayed. Record the error code. Go to Chapter 3, “Error

You have an SRN. Go to the Fast Path MAP in the

.

Symptom Analysis

system is waiting for power on.

system was shutdown by the operating system

and is still powered on. This condition can be

requested by a privileged system user with no

faults. See SP error log for possible operating

system fault indications.

page 2-6.

Code to FRU Index” on page 3-1.

IBM RS/6000

Diagnostic Information for Multiple Bus Systems

The system POST indicators are displayed on

the system console, the system pauses and

then restarts. The term "POST indicators" refer

to the icons (graphic display) or device

mnemonics (ASCII terminal) that appear during

the power-on self-test (POST).

The system stops and POST indicators are

displayed on the system console. The term

"POST indicators" refer to the icons (graphic

display) or device mnemonics (ASCII terminal)

that appear during the power-on self-test

(POST).

The system stops and the message "STARTING

SOFTWARE PLEASE WAIT..." is displayed on

Go to “E1xx Code Boot Problems” on

page 3-44.

1. Use MAP 1540 to isolate the problem.

Go to “Checkpoints” on page 3-29.

.

ASCII terminal, the boot indicator ( ) is

displayed on a graphics terminal.

2-2 Service Guide

Page 33

Symptom Action

The system does not respond to the password

being entered or the system login prompt is

displayed when booting in service mode.

Nothing is displayed on the system console, and

the operator panel is blank.

All display problems. 1. If using a graphics display, go to the

Verify that the password is being entered from

the ASCII terminal or keyboard defined as the

system console. If so, then the keyboard or its

controller may be faulty.

1. If entering the password from the keyboard

which is attached to the system, replace the

keyboard. If replacing the keyboard does not

fix the problem, replace the I/O planar. (See

notes on 2-1.)

2. If entering the password from a keyboard

which is attached to a ASCII terminal,

suspect the ASCII terminal. Use the

Problem Determination Procedures for the

terminal. Replace the I/O planar if these

procedures do not reveal a problem.

1. If using a graphic display, go to the

Determination Procedures

2. If you do not find a problem then replace the

display adapter.

3. Go to “MAP 1540: Minimum Configuration”

on page 2-17.

for the display.

Problem Determination Procedures

display.

2. If you do not find a problem then replace the

display adapter.

3. If the problem is with the ASCII terminal:

a. Make sure that the ASCII terminal is

connected to S1.

888 is displayed in the control panel followed by

additional error codes.

b. If problems persist, go to the

Determination Procedures

terminal.

4. If you do not find a problem then suspect

the I/O planar. Go to “MAP 1540: Minimum

Configuration” on page 2-17.

Go to the Fast Path MAP in the

Diagnostic Information for Multiple Bus Systems

Problem

for the

IBM RS/6000

Problem

for the

.

Chapter 2. Maintenance Analysis Procedures 2-3

Page 34

Symptom Action

The system stops and a 4-digit number is

displayed in the operator panel display.

If the number displayed begins with the

character "E0xx" then go to “SP Checkpoints”

on page 3-29. or "E1xx-EFFF" then go to

“Checkpoints” on page 3-29.

For all other numbers record SRN 101-xxx,

where xxx is the last three digits of the four-digit

number displayed in the operator panel, then go

to the Fast Path MAP in the

IBM RS/6000

Diagnostic Information for Multiple Bus Systems

Note: If the operator panel displays 2 sets of

numbers, use the bottom set of numbers as the

error code.

The power light does not come on, or stay on. Go to “MAP 1520: Power” on page 2-12.

The operator panel is blank before the system is

powered on (operator panel should display OK).

No codes are displayed on the operator panel

within a few seconds of turning on the system.

The SMS configuration list or Boot sequence

selection menu shows more SCSI devices

attached to a controller/adapter than are actually

attached.

You cannot load diagnostics. Go to “MAP 1020: Problem Determination” on

You have a problem that does not prevent the

system from booting.

Reseat the operator panel cable.

If problem not resolved, replace in order:

1. Operator Panel Control Assembly. Remove

the VPD module from the old Operator

Panel Control Assembly (connector U2) and

place in the new one.

2. I/O planar (See notes on 2-1.)

A device may be set to use the same SCSI bus

ID as the control adapter. Note the ID being

used by the controller/adapter (this can be

checked and/or changed via an SMS utility), and

verify that no device attached to the controller is

set to use that ID.

If settings do not appear to be in conflict:

1. Replace the SCSI cable.

2. Replace the device.

3. Replace the SCSI adapter (or I/O planar if

connected to one of the two integrated SCSI

controllers on the I/O planar). (See notes

on 2-1 if the I/O planar is replaced.)

Note: In a "Twin-tailed" configuration where

there is more than one initiator device

(normally another system) attached to

the SCSI bus, it may be necessary to

change the ID of the SCSI controller or

adapter with the System Management

Services.

page 2-6.

Go to the Fast Path MAP in the

IBM RS/6000

Diagnostic Information for Multiple Bus Systems

.

.

2-4 Service Guide

Page 35

Symptom Action

You suspect a cable problem. See the

Cable Information for Multiple Bus Systems

You Cannot Find the Symptom in this Table

All other problems. Go to “MAP 1020: Problem Determination” on

page 2-6.

IBM RS/6000 Adapter, Device, and

.

Chapter 2. Maintenance Analysis Procedures 2-5

Page 36

MAP 1020: Problem Determination

Purpose of This MAP

Use this MAP to get an error code if you were not provided one by the customer or

you are unable to load diagnostics. If you are able to load the diagnostics, go to

MAP 0020 in the

The Service Processor may have recorded one or more symptoms in its error log. It

is a good idea to examine that error log before proceeding (see Service Processor

System Information Menu).

The Service Processor may have been set by the user to monitor server operations

and to attempt recoveries. You may wish to disable these actions while you diagnose

and service the system. If you disable them, you should make notes of their current

settings for restoration before you leave. Following are the settings of your interest.

Surveillance From the Service Processor Setup Menu, go to

Unattended Start From the Service Processor System Power

Reboot Policy From the System Power Control Menu, go to

Call Out From the Call-In/Call-Out Setup Menu, go to the

IBM RS/6000 Diagnostic Information for Multiple Bus Systems

the Surveillance Setup Menu and disable

surveillance.

Control Menu, disable unattended start mode.

the Reboot/Restart Policy Setup Menu and set:

1. Number of reboot attempts to 0 (zero)

2. Use OS-Defined restart policy to No

3. Enable supplemental restart policy to No.

Serial Port Selection Menu and disable call-out

on both serial ports.

.

Be prepared to record code numbers and use those numbers in the course of

analyzing a problem. Go to “Step 1020-1.”

Step 1020-1

The following steps analyze a failure to load the diagnostic programs.

Note: You are asked questions regarding the operator panel display. You are also

asked to perform certain actions based on displayed POST indicators.

Please be observant of these conditions.

2-6 Service Guide

Page 37

1. Insert the diagnostic CD-ROM into the CD-ROM drive.

2. Turn the power off.

3. Turn the power on.

4. When the keyboard indicator is displayed (the word keyboard on an ASCII

terminal or the keyboard icon on a graphical display), press the F5 key on the

directly-attached keyboard or the number 5 key on an ASCII terminal.

Chapter 2. Maintenance Analysis Procedures 2-7

Page 38

5. Enter any requested passwords.

6. Wait until the diagnostics are loaded or the system appears to stop.

7. Find your symptom in the following table; then follow the instructions given in the

Action column.

Symptom Action

The diskette LED is blinking rapidly, or EIEA or

EIEB is displayed on the operator panel.

The system stops with a prompt to enter a

password.

The diagnostics loaded. Go to MAP 0020 in the

The system login prompt is displayed. You may not have pressed the correct key or

The system does not respond when the

password is entered.

The system stopped and a POST indicator is

displayed on the system console and an

eight-digit error code is not displayed.

The flash EPROM data is corrupted. The

recovery procedure for the flash EPROM should

be executed. See “Firmware Recovery” on

page 5-23.

Enter the password. You are not allowed to

continue until a correct password has been

entered. When you have entered a valid

password go to the beginning of this table and

wait for one of the other conditions to occur.

IBM RS/6000 Diagnostic

Information for Multiple Bus Systems

you may not have pressed the key soon enough

when you were to indicate a Service Mode IPL

of the diagnostic programs. If this was the case

start over at the beginning of this Step.

Note: Perform the systems shutdown

procedure before turning off the system.

If you are sure you pressed the correct key in a

timely manner, go to “Step 1020-2” on

page 2-10.

Go to “Step 1020-2” on page 2-10.

If the POST indicator represents:

memory, record error code M0MEM002.

keyboard, record error code M0KBD000.

SCSI, record error code M0CON000.

network, record error code M0NET000.

speaker (audio), record error code

M0BT0000.

Go to “Step 1020-3” on page 2-10.

.

2-8 Service Guide

Page 39

Symptom Action

The system stops and a 4-digit number is

displayed in the operator panel display.

If the number displayed begins with the

character "E0xx" then go to “SP Checkpoints”

on page 3-29. or "E1xx-EFFF" then go to

“Checkpoints” on page 3-29.

For all other numbers record SRN 101-xxx,

where xxx is the last three digits of the four-digit

number displayed in the operator panel, then go

to the Fast Path MAP in the

IBM RS/6000

Diagnostic Information for Multiple Bus Systems

Note: If the operator panel displays 2 sets of

numbers, use the bottom set of numbers as the

error code.

All other symptoms. If you were directed here from the Entry MAP,

go to “MAP 1540: Minimum Configuration” on

page 2-17. Otherwise, find the symptom in the

“Entry MAP” on page 2-1.

.

Chapter 2. Maintenance Analysis Procedures 2-9

Page 40

Step 1020-2

There is a problem with the keyboard.

Find the type of keyboard you are using in the following table; then follow the

instructions given in the Action column.

Keyboard Type Action

Type 101 keyboard (U.S.). Identify by the size of

the Enter key. The Enter key is in only one

horizontal row of keys.

Type 102 keyboard (W.T.). Identify by the size of

the Enter key. The Enter key extends into two

horizontal rows.

Type 106 keyboard. (Identify by the Japanese

characters.)

ASCII terminal keyboard Go to the documentation for this type of ASCII

Record error code M0KBD001; then go to

“Step 1020-3.”

Record error code M0KBD002; then go to

“Step 1020-3.”

Record error code M0KBD003; then go to

“Step 1020-3.”

terminal and continue problem determination.

Step 1020-3

Take the following actions:

1. Find the eight-digit error code in Chapter 3, “Error Code to FRU Index” on

page 3-1.

Note: If the eight-digit error code is not listed in Chapter 3, “Error Code to FRU

Index,” look for it in the following:

Any supplemental service manual for the device

The diagnostic problem report screen for additional information

The Service Hints service aid

The CEREADME file (by using the Service Hints service aid).

2. Perform the action listed.

2-10 Service Guide

Page 41

Step 1020-4

1. Turn off, then turn on the system unit.

2. When the keyboard indicator appears, press the F1 key on a directly attached

keyboard or the 1 key on an ASCII terminal.

3. When the System Management Services appear, check the error log for any

errors.

Choose Utilities

Choose Error Log

If an error is logged, check the time stamp.

If the error was logged during the current boot attempt, record it.

Look up the error in the Chapter 3, “Error Code to FRU Index” on page 3-1

and do the listed action.

If no recent error is logged in the error log, go to “MAP 1540: Minimum

Configuration” on page 2-17.

Chapter 2. Maintenance Analysis Procedures 2-11

Page 42

MAP 1520: Power

Note: This is not a start of call MAP. Use this Power MAP only if you have been

directed here from a MAP step in the

Multiple Bus Systems

.

This procedure is used to locate power problems in system units. If a problem is

detected, this procedure helps you isolate the problem to a failing unit.

Observe the following safety notice during service procedures.

DANGER

An electrical outlet that is not correctly wired could place hazardous

voltage on metal parts of the system or the devices that attach to the

system. It is the responsibility of the customer to ensure that the outlet

is correctly wired and grounded to prevent and electrical shock.

Before installing or removing signal cables, ensure that the power

cables for the system unit and all attached devices are unplugged.

When adding or removing any additional devices to or from the system,

ensure that the power cables for those devices are unplugged before

the signal cables are connected. If possible, disconnect all power

cables from the existing system before you add a device.

IBM RS/6000 Diagnostic Information for

Use on hand, when possible, to connect or disconnect signal cables to

prevent a possible shock from touching two surfaces with different

electrical potentials.

During an electrical storm, do not connect cables for display stations,

printers, telephones, or station protectors for communication lines.

CAUTION:

This product is equipped with a three–wire power cable and plug for the user's

safety. Use this power cable with a properly grounded electrical outlet to avoid

electrical shock.

DANGER

To prevent electrical shock hazard, disconnect the power cable from

the electrical outlet before relocating the system.

2-12 Service Guide

Page 43

Step 1520-1

You may be directed to this MAP for several reasons:

1. There is no indication of activity when the start/stop switch is pressed. None of

the LEDs light and none of the fans, including the fan in the power supply, start

to turn.

Go to “Step 1520-2.”

2. When the start/stop switch is pressed, the system begins to power on, but the

power LED does not stay on.

Go to “Step 1520-3” on page 2-14.

Step 1520-2

1. Turn the power off.

2. Check that the external power cable to the system unit has continuity.

3. Check that the power outlet has been wired correctly with the correct voltage.

4. Check that the external power cable is plugged into both the system unit and the

power outlet.

Did you find a problem?

NO Go to “Step 1520-3” on page 2-14.

YES Correct the problem. Go to "MAP 410: Repair Checkout" in the

RS/6000 Diagnostic Information for Multiple Bus Systems

Chapter 2. Maintenance Analysis Procedures 2-13

IBM

.

Page 44

Step 1520-3

Note: Either the cooling fans, the power supply, the I/O planar, service processor,

or the system card is defective.

To test each FRU, exchange the FRUs that have not already been exchanged in the

following order.

Verify that the fan jumper is connected to connector J55.

Power supply

I/O planar

Service Processor

System card

Front cooling fans (one at a time)

1. Turn the power off.

2. Unplug the system unit power cable from the wall outlet.

3. Exchange one of the FRUs in the list.

4. Connect the system unit power cable to the wall outlet.

5. Turn the power on.

Does the fan in the power supply turn on and the power LED come on and stay

on?

NO Reinstall the original FRU.

Repeat this step until the defective FRU is identified or all the FRUs have

been exchanged.

If the symptom did not change and all the FRUs have been exchanged,

go to “Step 1520-4” on page 2-15.

YES Go to "MAP 410: Repair Checkout" in the

Information for Multiple Bus Systems

2-14 Service Guide

IBM RS/6000 Diagnostic

.

Page 45

Step 1520-4

1. Turn the power off.

2. Unplug the system unit power cable from the wall outlet.

3. Record the slot numbers of all the ISA and PCI adapters. Label and record the

location of any cables attached to the adapters. Remove all the adapters.

4. Remove all installed memory cards.

5. Remove the CPU card(s).

6. Unplug the power cables from all the SCSI devices.

7. Unplug all the fans, except the fan in the power supply.

8. Connect the system unit power cable to the wall outlet.

9. Turn the power on.

Does the fan in the power supply turn on and the power LED come on and stay

on?

NO Replace the I/O planar. Go to "MAP 410: Repair Checkout" in the

RS/6000 Diagnostic Information for Multiple Bus Systems

.

YES Go to “Step 1520-5” on page 2-16.

IBM

Chapter 2. Maintenance Analysis Procedures 2-15

Page 46

Step 1520-5

One of the parts that was removed or unplugged is causing the problem. Install or

connect the parts in the following order.

1. CPU card(s).

2. Memory cards. (One at a time)

3. SCSI devices, lowest bay to highest bay.

4. PCI cards, lowest slot to highest slot.

5. ISA cards, lowest slot to highest slot.

6. Fans.

Turn the power on after each part is installed or connected. If the system does not

power on or the power LED does not stay on, the most recently installed or

connected part is causing the failure.

1. Turn the power off.

2. Unplug the system unit power cable from the wall outlet.

3. Install or connect one of the parts in the list.

4. Connect the system unit power cable to the wall outlet.

5. Turn the power on.

Does the fan in the power supply turn on and the power LED come on and stay

on?

NO Replace the last part installed.

If the memory card was just installed, remove all of the memory DIMMs. If

the system does not come up, replace the memory card.

Re-install the memory DIMMs, one pair at a time, until the problem recurs.

Replace the memory DIMM pair that was just installed.

Note: The memory DIMM pair must be installed in slots that are next to

each other. For example, install the pair in J1 and J2, not J1 and J3.

Repeat these steps until all the parts have been installed.

If the symptom did not change and all the parts have been replaced, call

your service support person for assistance.

If the symptom has changed, check for loose cards, cables, and obvious

problems. If you do not find a problem, return to “Step 1520-1” on

page 2-13 in this MAP and follow the instructions for the new symptom.

YES Go to "MAP 410: Repair Checkout" in the

Information for Multiple Bus Systems

2-16

Service Guide

IBM RS/6000 Diagnostic

.

Page 47

MAP 1540: Minimum Configuration

Notes:

1. Be sure to unplug the power cable before removing or installing Service

Processor, CPU, System Card or I/O planar to avoid damage to them.

2. This MAP assumes that a CD-ROM drive is installed and connected to the

integrated SCSI adapter, and a Diagnostics CD-ROM is available.

3. If a power-on password or privileged-access password is installed, you are

prompted to enter the password before the diagnostic CD-ROM can load.

4. The term "POST indicators" refer to the icons (graphic display) or device

mnemonics (ASCII terminal) that appear during the power-on self-test (POST).

5. The Service Processor may have recorded one or more symptoms in its error

log. It is a good idea to examine that error log before proceeding (see Service

Processor System Information Menu).

6. The Service Processor may have been set by the user to monitor server

operations and to attempt recoveries. You may wish to disable these actions

while you diagnose and service the system. If you disable them, you should

make notes of their current settings for restoration before you leave. Following

are the settings of your interest.

Surveillance From the Service Processor Setup Menu, go to

the Surveillance Setup Menu and disable

surveillance.

Unattended Start From the Service Processor System Power

Control Menu disable unattended start mode.

Reboot Policy From the System Power Control Menu go to the

Reboot/Restart Policy Setup Menu and set:

1. Number of reboot attempts to 0 (zero)

2. Use OS-Defined restart policy to No

3. Enable supplemental restart policy to No.

Call Out From the Call-In/Call-Out Setup Menu, go to the

Serial Port Selection Menu and disable call-out

on both serial ports.

Purpose of this MAP

This MAP is used to locate defective FRUs not found by normal diagnostics. For this

procedure, diagnostics are run on a minimally-configured system. If a failure is

detected on the minimally-configured system, the remaining FRUs are exchanged

one at a time until the failing FRU is identified. If a failure is not detected, FRUs are

added back until the failure occurs. The failure is then isolated to the failing FRU.

Chapter 2. Maintenance Analysis Procedures 2-17

Page 48

Step 1540-1

1. Ensure that the diagnostics and the operating system are shut down.

2. Insert the diagnostic CD-ROM into the CD-ROM drive.

3. Turn the power off.

4. Turn the power on.

5. When the keyboard indicator is displayed (the word keyboard on an ASCII

terminal or the keyboard and hand icon on a graphical display), press the F5 key

on the directly-attached keyboard or the number 5 key on an ASCII terminal.

6. Enter the appropriate password when prompted to do so.

Is the "Please define the System Console" screen displayed?

NO Go to “Step 1540-2” on page 2-19.

YES Go to “Step 1540-12” on page 2-31.

2-18

Service Guide

Page 49

Step 1540-2

1. Turn the power off.

2. If you have not already done so, configure the Service Processor with the

instructions on step 6 on page 2-17 and then return here and continue.

3. Exit Service Processor Menus and remove the power cable.

4. Disconnect all external cables.

5. Remove the side cover

6. Record the slot numbers of the ISA and PCI adapters. Label and record the

location of any cables attached to the adapters. Remove all the adapters.

7. Remove the second processor card (if present). [If second processor removed,

ensure first CPU cable is installed.]

8. Record the position of the memory DIMMs. Remove all installed memory DIMMs

except for one pair from the first Memory card.

Note: The memory DIMM pair must be installed in slots that are next to each

other. For example, install the pair in J1 and J2, not J1 and J3.

9. Remove the second Memory card, if present.

10. Disconnect the SCSI cable from the SCSI connectors on the I/O planar.

11. Disconnect the diskette drive cable from the diskette drive connector on the I/O

planar.

12. Disconnect the internal serial and parallel cables.

13. Plug in the power cable (and wait for OK on the operator panel display).

14. Turn the power on.

15. Wait for the operator panel to stabilize at a checkpoint.

Note: Checkpoints E1F2, E1F3 and STBY are stable as soon as they appear.

Other checkpoints may take up to 3 minutes to assure stability, depending on

system configuration.

Does the operator panel stabilize with code E1F2, E1F3, E1F7, or STBY?

NO Go to “Step 1540-3” on page 2-20.

YES Go to “Step 1540-4” on page 2-21.

Chapter 2. Maintenance Analysis Procedures 2-19

Page 50

Step 1540-3

One of the FRUs remaining in the system unit is defective.

If the following steps call for a I/O planar to be replaced, see notes on page 2-1.

Turn the power off, remove the power cable, and exchange the following FRUs in

order:

1. Processor cards

2. Memory DIMMs (pair)

3. Memory card

4. I/O planar (see notes on page 2-1.)

5. System Card

6. Service Processor

Wait for the operator panel to stabilize at a checkpoint.

Note: Checkpoints E1F2, E1F3 and STBY are stable as soon as they appear.

Other checkpoints may take up to 3 minutes to assure stability, depending on system

configuration.

Does the operator panel stabilize with code E1F2, E1F3, E1F7, or STBY?

NO Reinstall the original FRU.

Repeat the FRU replacement steps until the defective FRU is identified or

all the FRUs have been exchanged.

If the symptom did not change and all the FRUs have been exchanged,

call your service support person for assistance.

If the symptom has changed, check for loose cards, cables, and obvious

problems. If you do not find a problem, return to “Step 1540-1” on

page 2-18 in this MAP and follow the instructions for the new symptom.

YES Go to "MAP 410: Repair Checkout" in the

Information for Multiple Bus Systems

2-20

Service Guide

IBM RS/6000 Diagnostic

.

Page 51

Step 1540-4

No failure was detected with this configuration.

1. Turn the power off and remove the power cable.

2. Install a pair of memory DIMMs.

3. Reinstall the power cable.

4. Turn the power on.

5. Wait for the operator panel to stabilize at a checkpoint.

Note: Checkpoints E1F2, E1F3 and STBY are stable as soon as they appear.

Other checkpoints may take up to 3 minutes to assure stability, depending on

system configuration.

Does the operator panel stabilize with code E1F2, E1F3, E1F7, or STBY?

NO Go to “Step 1540-5” on page 2-22.

YES Repeat this step until all the memory DIMMs are installed and tested.

After all the memory DIMMs are installed and tested, record the positions

of the memory DIMMs in the second memory card. Remove all of the

memory DIMMs from the second memory card except 1 pair. Repeat this

step with the second memory card (if previously installed).

Go to “Step 1540-7” on page 2-24.

Chapter 2. Maintenance Analysis Procedures 2-21

Page 52

Step 1540-5

The failure may be caused by the last pair of memory DIMMs installed or the

memory card. To isolate the failing FRU, do the following:

1. Turn the power off and remove the power cable.

2. Exchange the last memory DIMM pair installed.

3. Reinstall the power cable.

4. Turn the power on.

5. Wait for the operator panel to stabilize at a checkpoint.

Note: Checkpoints E1F2, E1F3 and STBY are stable as soon as they appear.

Other checkpoints may take up to 3 minutes to assure stability, depending on

system configuration.

Does the operator panel stabilize with code E1F2, E1F3, E1F7, or STBY?

NO Go to “Step 1540-6” on page 2-23.

YES Go to "MAP 410: Repair Checkout" in the

Information for Multiple Bus Systems

.

IBM RS/6000 Diagnostic

2-22

Service Guide

Page 53

Step 1540-6

One of the FRUs remaining in the system unit is defective.

1. Turn the power off and remove the power cable.

2. Exchange the following FRUs the order listed.

a. Memory card

b. System card

c. I/O planar (See notes on 2-1.)

d. Power supply.

3. Reinstall the power cable.

4. Turn the power on.

5. Wait for the operator panel to stabilize at a checkpoint.

Note: Checkpoints E1F2, E1F3 and STBY are stable as soon as they appear.

Other checkpoints may take up to 3 minutes to assure stability, depending on

system configuration.

Does the operator panel stabilize with code E1F2, E1F3, E1F7, or STBY?

NO Reinstall the original FRU.

Repeat this step until the defective FRU is identified or all the FRUs have

been exchanged.

If the symptom did not change and all the FRUs have been exchanged,

call your service support person for assistance.

If the symptom has changed, check for loose cards, cables, and obvious

problems. If you do not find a problem, return to “Step 1540-1” on

page 2-18 in this MAP, and follow the instructions for the new symptom.

YES Go to "MAP 410: Repair Checkout" in the

Information for Multiple Bus Systems

Chapter 2. Maintenance Analysis Procedures 2-23

IBM RS/6000 Diagnostic

.

Page 54

Step 1540-7

1. Turn the power off.

2. Reconnect the system console.

Notes:

a. If an ASCII terminal has been defined as the system console, attach the

ASCII terminal cable to the to the S1 connector on the rear of the system

unit. Also connect the internal serial and Ethernet cables to the I/O planar.

b. If a display attached to a display adapter has been defined as the system

console, install the display adapter and connect the display to it. Plug the

keyboard into the keyboard connector on the rear of the system unit.

3. Turn the power on.

4. If the ASCII terminal or graphics display (including display adapter) are

connected differently than before, the Console Selection screen appears and

requires that a new console be selected.

5. When the keyboard indicator is displayed, press the F1 key on the directly

attached keyboard or the number 1 key on an ASCII terminal. This triggers the

SMS.

6. Enter the appropriate password when prompted to do so.

7. Wait until the SMS screen is displayed or the system appears to stop.

2-24

Service Guide

Page 55

Is the SMS screen displayed?

NO One of the FRUs remaining in the system unit is defective.

In the following order, exchange the FRUs that have not been exchanged:

1. Go to the Problem Determination Procedures (test procedures) for the

device attached to the S1 serial port or the display attached to the

graphics adapter, and test those devices. If a problem is found,

follow the procedures for correcting the problem on that device.

2. Graphics adapter (if installed).

3. Cable (async or graphics, including internal async cable).

4. I/O planar. (see notes on page 2-1.)

Repeat this step until the defective FRU is identified or all the FRUs have

been exchanged.

If the symptom did not change and all the FRUs have been exchanged,

call your service support person for assistance.

If the symptom changed, check for loose cards and obvious problems. If

you do not find a problem, return to “Step 1540-1” on page 2-18 and

follow the instructions for the new symptom.

YES Go to “Step 1540-8” on page 2-26.

Chapter 2. Maintenance Analysis Procedures 2-25

Page 56

Step 1540-8

1. Make sure the diagnostic CD-ROM is inserted into the CD-ROM drive.

2. Turn the power off and remove the power cable.

3. Plug the internal SCSI cable into the SCSI connector (J25) on the I/O planar.

4. Disconnect the signal and power connectors from all the SCSI devices except

the CD-ROM drive.

5. Reinstall the power cable.

6. Turn the power on.

7. After the keyboard indicator is displayed, press the F5 key on the

directly-attached keyboard or the number 5 key on an ASCII terminal keyboard.

8. Enter the appropriate password when prompted to do so.

2-26

Service Guide

Page 57

Is the "Please define the System Console" screen displayed?

NO One of the FRUs remaining in the system unit is defective.

In the following order, exchange the FRUs that have not been exchanged:

1. SCSI cable

2. Last SCSI device connected (CD-ROM drive, tape drive, etc.)

3. The graphics adapter, if the system console is defined as a graphical

display.

4. I/O planar (see notes on page 2-1.)

5. Processor card

6. Power Supply.

Repeat this step until the defective FRU is identified or all the FRUs have

been exchanged.

If the symptom did not change and all the FRUs have been exchanged

call your service support person for assistance.

If the symptom has changed, check for loose cards, cables, and obvious

problems. If you do not find a problem, return to “Step 1540-1” on

page 2-18 in this MAP and follow the instructions for the new symptom.

YES Repeat this step, adding one SCSI device at a time, until all the SCSI

devices that were attached to the integrated SCSI adapter are connected

and tested.

Go to “Step 1540-9” on page 2-28.

Chapter 2. Maintenance Analysis Procedures 2-27

Page 58

Step 1540-9

The system is working correctly with this configuration. One of the FRUs (adapters)

that you removed is probably defective.

1. Make sure the diagnostic CD-ROM is inserted into the CD-ROM drive.

2. Turn the power off and remove the power cable.

3. Plug the diskette drive cable into the diskette drive connector on the I/O planar.

4. Reinstall the power cable.

5. Turn the power on.

6. After the keyboard indicator is displayed, press the F5 key on the

directly-attached keyboard or the number 5 key on an ASCII terminal keyboard.

7. Enter the appropriate password when prompted to do so.

Is the "Please define the System Console" screen displayed?

NO One of the FRUs remaining in the system is defective.

In the following order, exchange the FRUs that have not been exchanged.

1. Diskette drive

2. Diskette drive cable

3. I/O planar (see notes on page 2-1).

4. Power supply

Repeat this step until the defective FRU is identified or all the FRUs have

been exchanged.

If the symptom did not change and all the FRUs have been exchanged,

call your service support person for assistance.

If the symptom has changed check for loose cards, cables, and obvious

problems. If you do not find a problem return to “Step 1540-1” on

page 2-18 in this MAP and follow the instructions for the new symptom.

YES Go to “Step 1540-10” on page 2-29.

2-28

Service Guide

Page 59

Step 1540-10

The system is working correctly with this configuration. One of the FRUs (adapters)

that you removed is probably defective,

1. Make sure the diagnostic CD-ROM is inserted into the CD-ROM drive.

2. Turn the power off and remove the power cable.

3. Install the second CPU card if one was removed. If a second CPU card was not

removed, or has already been reinstalled and verified, install an I/O Planar

device (parallel port device, serial port device, keyboard or mouse) that had been

removed and any cables that were attached. If all I/O Planar devices have been

reinstalled and verified, install a FRU (adapter) and connect any cables and

devices that were attached to it.

Note: If the FRU you installed requires supplemental media use the Process

Supplemental Media task to load the supplemental media first.

4. Reinstall the power cable.

5. Turn the power on.

6. If the Console Selection screen displays, choose the system console.

7. After the keyboard indicator displayeds, press the F5 key on the directly-attached

keyboard or the number 5 key on an ASCII terminal keyboard.

8. Enter the appropriate password when prompted to do so.

Is the "Please define the System Console" screen displayed?

NO Go to “Step 1540-11” on page 2-30.

YES Repeat this step until all of the FRUs (adapters) are installed, then go to

"MAP 410: Repair Checkout" in the

for Multiple Bus Systems

Chapter 2. Maintenance Analysis Procedures 2-29

IBM RS/6000 Diagnostic Information

.

Page 60

Step 1540-11

The last FRU installed or one of its attached devices is probably defective.

1. Make sure the diagnostic CD-ROM is inserted into the CD-ROM drive.

2. Turn the power off and remove the power cable.

3. Starting with the last installed adapter, disconnect one attached device and

cable.

4. Reinstall the power cable.

5. Turn the power on.

6. If the Console Selection screen is displayed, choose the system console.

7. After the keyboard indicator appears, press the F5 key on the directly-attached

keyboard or the number 5 key on an ASCII terminal keyboard.

8. Enter the appropriate password when prompted to do so.

Is the "Please define the System Console" screen displayed?

NO Repeat this step until the defective device or cable is identified or all the

devices and cables have been disconnected.

If all the devices and cables have been removed, then one of the FRUs

remaining in the system unit is defective.

To test each FRU, exchange the FRUs in the following order:

1. Adapter (last one installed)

2. I/O planar

If the I/O planar or a network adapter is replaced, see notes on page

2-1.

3. Power supply.

If the symptom did not change and all the FRUs have been exchanged,

call your service support person for assistance.

If the symptom has changed check for loose cards, cables, and obvious

problems. If you do not find a problem return to “Step 1540-1” on

page 2-18 in this MAP and follow the instructions for the new symptom.

YES The last device or cable that you disconnected is defective or if the last

device is the CPU card go to “Step 1540-3” on page 2-20.

Exchange the defective device or cable.

Go to "MAP 410: Repair Checkout" in the

Information for Multiple Bus Systems

2-30

Service Guide

IBM RS/6000 Diagnostic

.

Page 61

Step 1540-12

1. Follow the instructions on the screen to select the system console.

2. When the DIAGNOSTIC OPERATING INSTRUCTIONS screen is displayed,

press Enter.

3. If the terminal type has not been defined, you must use the Initial Terminal option

on the FUNCTION SELECTION menu to initialize the AIX operating system

environment before you can continue with the diagnostics. This is a separate and

different operation than selecting the console.

4. Select Task Selection.

5. When the NEW RESOURCE screen displays select an option from the bottom of

the screen.

Note: Adapters or devices that require supplemental media are not shown in

the new resource list. If the system has adapters or devices that require a

supplemental media, select option 1.

If the adapter or device requires supplemental media select Process

Supplemental Media from the TASKS SELECTION LIST. Follow the instructions

on the screen after testing the adapters and devices listed on the NEW

RESOURCE screen.

Supplemental media must be loaded and processed one at a time.

6. Select Run Diagnostics from the TASK SELECTION LIST.

7. Select All Resources or the Adapter/Device you loaded from the supplemental

media.

Did you get an SRN?

NO Go to “Step 1540-14” on page 2-33.

YES Go to “Step 1540-13” on page 2-32.

Chapter 2. Maintenance Analysis Procedures 2-31

Page 62

Step 1540-13

Look at the FRU part numbers associated with the SRN.

Have you exchanged all the FRUs that correspond to the failing function

codes?

NO Exchange the FRU with the highest failure percentage that has not been

changed.

Repeat this step until all the FRUs associated with the SRN have been

exchanged or diagnostics run with no trouble found. Run diagnostics after

each FRU is exchanged.

If the I/O planar or a network adapter is replaced, see notes on page 2-1.

Go to "MAP 410: Repair Checkout" in the

Information for Multiple Bus Systems

IBM RS/6000 Diagnostic

.

YES If the symptom did not change and all the FRUs have been exchanged,

call your service support person for assistance.

2-32

Service Guide

Page 63

Step 1540-14

Does the system have adapters or devices that require supplemental media?

NO Go to “Step 1540-15.”

YES Go to “Step 1540-16.”

Step 1540-15

Consult the ISA and PCI adapter configuration documentation for your operating

system to verify that all installed adapters are configured correctly.

Go to "MAP 410: Repair Checkout" in the

Multiple Bus Systems

.

IBM RS/6000 Diagnostic Information for

If the symptom did not change and all the FRUs have been exchanged, call your

service support person for assistance.

Step 1540-16

Press Enter to return to the TASKS SELECTION LIST.

Select Process Supplemental Media and follow the on screen instructions to process

the media.

Did the system return to the TASKS SELECTION SCREEN after the

supplemental media was processed?

NO Go to “Step 1540-17” on page 2-34.

YES Go to “Step 1540-12” on page 2-31 substep 6 on page 2-31.

Chapter 2. Maintenance Analysis Procedures 2-33

Page 64

Step 1540-17

The Adapter or device is probably defective.

If the supplemental media is for an adapter replace the FRUs in the following order:

1. Adapter.

2. The planar the adapter is plugged into.