Page 1

User’ s Manual

Thank you very much for purchasing the product.

• To ensure correct and safe usage with a full understanding of this product's performance, please be sure to read through this

manual completely and store it in a safe location.

• Unauthorized copying or transferral, in whole or in part, of this manual is prohibited.

• The contents of this operation manual and the specifications of this product are subject to change without notice.

• The operation manual and the product have been prepared and tested as much as possible. If you find any misprint or error,

please inform us.

• Roland DG Corp. assumes no responsibility for any direct or indirect loss or damage which may occur through use of this

product, regardless of any failure to perform on the part of this product.

• Roland DG Corp. assumes no responsibility for any direct or indirect loss or damage which may occur with respect to any

article made using this product.

Page 2

For the USA

FEDERAL COMMUNICATIONS COMMISSION

RADIO FREQUENCY INTERFERENCE

STATEMENT

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules.

These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated

in a commercial environment.

This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference

to radio communications.

Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Unauthorized changes or modification to this system can void

the users authority to operate this equipment.

The I/O cables between this equipment and the computing

device must be shielded.

For Canada

CLASS A NOTICE

This Class A digital apparatus meets all requirements of the

Canadian Interference-Causing Equipment Regulations.

CLASSE A AVIS

Cet appareil numérique de la classe A respecte toutes les

exigences du Règlement sur le matériel brouilleur du

Canada.

ROLAND DG CORPORATION

1-6-4 Shinmiyakoda, Hamamatsu-shi, Shizuoka-ken, JAPAN 431-2103

MODEL NAME : See the MODEL given on the rating plate.

RELEVANT DIRECTIVE : EC MACHINERY DIRECTIVE (98/37/EC)

EC LOW VOLTAGE DIRECTIVE (73/23/EEC)

EC ELECTROMAGNETIC COMPATIBILITY DIRECTIVE (89/336/EEC)

WARNING

This is a Class A product. In a domestic environment this product may cause radio interference in which

case the user may be required to take adequate measures.

Page 3

GENERAL SAFETY RULES

WARNING ! Read and understand all instructions. Failure to follow all instructions listed below, may

result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS.

Work Area

Keep your work area clean and well lit. Cluttered benches

and dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust.

Power tools create sparks which may ignite the dust or fumes.

Keep bystanders, children, and visitors away while

operating a power tool. Distractions can cause you to lose

control.

Electrical Safety

Grounded tools must be plugged into an outlet properly

installed and grounded in accordance with all codes and

ordinances. Never remove the grounding prong or modify

the plug in any way. Do not use any adaptor plugs. Check

with a qualified electrician if you are in doubt as to whether

the outlet is properly grounded. If the tools should electrically

malfunction or break down, grounding provides a low resistance

path to carry electricity away from the user.

Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk

of electric shock if your body is grounded.

Don't expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

Do not abuse the cord. Never use the cord to carry the tools

or pull the plug from an outlet. Keep cord away from heat,

oil, sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electric shock.

When operating a power tool outside, use an outdoor

extension cord marked "W-A" or "W." These cords are rated

for outdoor use and reduce the risk of electric shock.

Personal Safety

Stay alert, watch what you are doing and use common sense

when operating a power tool. Do not use tool while tired or

under the influence or drugs, alcohol, or medication. A

moment of inattention while operating power tools may result in

serious personal injury.

Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair , clothing, and gloves away

from moving parts. Loose clothes, jewelry, or long hair can be

caught in moving parts.

Avoid accidental starting. Be sure switch is off before

plugging in. Carrying tools with your finger on the switch or

plugging in tools that have the switch on invites accidents.

Remove adjusting keys or switches before turning the tool

on. A wrench or a key that is left attached to a rotating part of

the tool may result in personal injury.

Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance enables better control of the

tool in unexpected situations.

Use safety equipment. Always wear eye protection. Dust

mask, non-skid safety shoes, hard hat, or hearing protection

must be used for appropriate conditions.

Tool Use and Care

Use clamps or other practical way to secure and support

the workpiece to a stable platform. Holding the work by hand

or against your body is unstable and may lead to loss of control.

Do not force tool. Use the correct tool for your application.

The correct tool will do the job better and safer at the rate for

which it is designed.

Do not use tool if switch does not turn it on or off. Any tool

that cannot be controlled with the switch is dangerous and must

be repaired.

Disconnect the plug from the power source before making

any adjustments, changing accessories, or storing the tool.

Such preventive safety measures reduce the risk of starting the

tool accidentally.

Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools, with sharp cutting edges are less

likely to bind and are easier to control.

Check for misalignment or binding of moving parts,

breakage of parts, and any other condition that may affect

the tools operation. If damaged, have the tool serviced

before using. Many accidents are caused by poorly maintained

tools.

Use only accessories that are recommended by the

manufacturer for your model. Accessories that may be suitable

for one tool, may become hazardous when used on another

tool.

SERVICE

Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified

personnel could result in a risk of injury.

When servicing a tool, use only identical replacement parts.

Follow instructions in the Maintenance section of this

manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk or electric shock or

injury.

Page 4

RÉGLES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT ! Vous devez lire et comprendre toutes les instructions. Le non-respect, même

partiel, des instructions ci-après entraîne un risque de choc électrique, d'incendie et/ou de blessures graves.

CONSERVEZ CES INSTRUCTIONS

Aire de travail

Veillez à ce que l'aire de travail soit propre et bien éclairée.

Le désordre et le manque de lumière favorisent les accidents.

N'utilisez pas d'outils électriques dans une atmosphère

explosive, par exemple en présence de liquides, de gaz ou

de poussières inflammables. Les outils électriques créent des

étincelles qui pourraient enflammer les poussières ou les

vapeurs.

Tenez à distance les curieux, les enfants et les visiteurs

pendant que vous travaillez avec un outil électrique. Ils

pourraient vous distraire et vous faire une fausse manoeuvre.

Sécurité électrique

Les outils mis à la terre doivent être branchés dans une

prise de courant correctement installée et mise à la terre

conformément à tous les codes et réglements pertinents.

Ne modifiez jamais la fiche de quelque façon que ce soit,

par exemple en enlevant la broche de mise à la terre.

N'utilisez pas d'adaptateur de fiche. Si vous n'êtes pas

certain que la prise de courant est correctement mise à la

terre, adressez-vous à un électricien qualifié. En cas de

défaillance ou de défectuosité électrique de l'outil, une mise à

la terre offre un trajet de faible résistance à l'électricité qui

autrement risquerait de traverser l'utilisateur.

Évitez tout contact corporel avec des surfaces mises à la

terre (tuyauterie, radiateurs, cuisinières, réfrigérateurs, etc.).

Le risque de choc électrique est plus grand si votre corps est en

contact avec la terre.

N'exposez pas les outils électriques à la pluie ou à l'eau. La

présence d'eau dans un outil électrique augmente le risque de

choc électrique.

Ne maltraitez pas le cordon. Ne transportez pas l'outil par

son cordon et ne débranchez pas la fiche en tirant sur le

cordon. N'exposez pas le cordon à la chaleur, à des huiles,

à des arêtes vives ou à des pièces en mouvement.

Remplacez immédiatement un cordon endommagé. Un

cordon endommagé augmente le risque de choc électrique.

Lorsque vous utilisez un outil électrique à l'extérieur,

employez un prolongateur pour l'extérieur marqué "W-A"

ou "W". Ces cordons sont faits pour êntre utilisés à l'extérieur

et réduisent le risque de choc électrique.

Sécurité des personnes

Restez alerte, concentrez-vous sur votre travail et faites

preuve de jugement. N'utilisez pas un outil électrique si vous

êtes fatigué ou sous l'influence de drogues, d'alcool ou de

médicaments. Un instant d'inattention suffit pour entraîner des

blessures graves.

Habillez-vous convenablement. Ne portez ni vêtements

flottants ni bijoux. Confinez les cheveux longs. N'approchez

jamais les cheveux, les vêtements ou les gants des pièces

en mouvement. Des vêtements flottants, des bijoux ou des

cheveux longs risquent d'être happés par des pièces en

mouvement.

Méfiez-vous d'un démarrage accidentel. Avant de brancher

l'outil, assurez-vous que son interrupteur est sur ARRÈT.

Le fait de transporter un outil avec le doigt sur la détente ou de

brancher un outil dont l'interrupteur est en position MARCHE

peut mener tout droit à un accident.

Enlevez les clés de réglage ou de serrage avant de démarrer

l'outil. Une clé laissée dans une pièce tournante de l'outil peut

provoquer des blessures.

Ne vous penchez pas trop en avant. Maintenez un bon appui

et restez en équilibre en tout temps. Un bonne stabilité vous

permet de mieux réagir à une situation inattendue.

Utilisez des accessoires de sécurité. Portez toujours des

lunettes ou une visière. Selon les conditions, portez aussi un

masque antipoussière, des bottes de sécurité antidérapantes,

un casque protecteur et/ou un appareil antibruit.

Utilisation et entretien des outils

Immobilisez le matériau sur une surface stable au moyen

de brides ou de toute autre façon adéquate. Le lait de tenir

la pièce avec la main ou contre votre corps offre une stabilité

insuffisante et peut amener un dérapage de l'outil.

Ne forcez pas l'outil. Utilisez l'outil approprié à la tâche.

L'outil correct fonctionne mieux et de façon plus sécuritaire.

Respectez aussi la vitesse de travail qui lui est propre.

N'utilisez pas un outil si son interrupteur est bloqué. Un

outil que vous ne pouvez pas commander par son interrupteur

est dangereux et doit être réparé.

Débranchez la fiche de l'outil avant d'effectuer un réglage,

de changer d'accessoire ou de ranger l'outil. De telles

mesures préventives de sécurité réduisent le risque de

démarrage accidentel de l'outil.

Rangez les outils hors de la portée des enfants et d'autres

personnes inexpérimentées. Les outils sont dangereux dans

les mains d'utilisateurs novices.

Prenez soin de bien entretenir les outils. Les outils de coupe

doivent être toujours bien affûtés et propres. Des outils bien

entretenus, dont les arêtes sont bien tranchantes, sont moins

susceptibles de coincer et plus faciles à diriger.

Soyez attentif à tout désalignement ou coincement des

pièces en mouvement, à tout bris ou à toute autre condition

préjudiciable au bon fonctionnement de l'outil. Si vous

constatez qu'un outil est endommagé, faites-le réparer

avant de vous en servir. De nombreux accidents sont causés

par des outils en mauvais état.

N'utilisez que des accessoires que le fabricant recommande

pour votre modèle d'outil. Certains accessoires peuvent

convenir à un outil, mais être dangereux avec un autre.

RÉPARATION

La réparation des outils électriques doit être confiée à un

réparateur qualifié. L'entretien ou la réparation d'un outil

électrique par un amateur peut avoir des conséquences graves.

Pour la réparation d'un outil, n'employez que des pièces

de rechange d'origine. Suivez les directives données à la

section "Réparation" de ce manuel. L'emploi de pièces non

autorisées ou le non-respect des instructions d'entretien peut

créer un risque de choc électrique ou de blessures.

Page 5

Table of Contents

About the Documentation for This Machine.................................................................................................. 4

Documentation Included with the Machine..................................................................................................................4

Viewing Manuals in Electronic Format........................................................................................................................ 5

To Ensure Safe Use....................................................................................................................................... 6

About the Labels Affixed to the Unit ........................................................................................................................... 9

Pour utiliser en toute sécurité...................................................................................................................... 10

À propos des étiquettes collées sur l'appareil ............................................................................................................. 13

1. Getting Started................................................................................................ 15

1-1. Included Items and Accessories .......................................................................................................... 16

1-2. Names and Functions .......................................................................................................................... 17

1-3. Installation and Cable Connections ..................................................................................................... 19

Installation Site and Operating Environment ............................................................................................................. 19

Connecting the Cables................................................................................................................................................. 20

2. Basic Operation .............................................................................................. 23

2-1. Emergency Stop to Ensure Safety....................................................................................................... 24

How to Perform an Emergency Stop .......................................................................................................................... 24

To Cancel an Emergency Stop .................................................................................................................................... 24

Opening and Closing the Spindle Cover ....................................................................................................................24

2-2. Switching the Power On and Off.......................................................................................................... 25

Switching On the Power ............................................................................................................................................. 25

Switching Off the Power ............................................................................................................................................. 25

2-3. Moving the Spindle Head ..................................................................................................................... 26

Moving the Spindle Head ........................................................................................................................................... 26

Moving the Spindle Head Out of the Way Quickly ................................................................................................... 27

2-4. Starting and Stopping Spindle Rotation............................................................................................... 28

Using Buttons to Start and Stop Rotation................................................................................................................... 28

Adjusting the Spindle Rotating Speed........................................................................................................................ 28

Forced Stop of Spindle Rotation................................................................................................................................. 29

2-5. Menu Operations.................................................................................................................................. 30

Displaying the Menus ................................................................................................................................................. 30

Basic Menu Operations ............................................................................................................................................... 30

2-6. Care and Handling of Memory Cards .................................................................................................. 31

Types of Memory Cards You Can Use ....................................................................................................................... 31

Memory-card Writers You Can Use............................................................................................................................ 31

Inserting and Removing a Memory Card ................................................................................................................... 32

Formatting a Memory Card......................................................................................................................................... 34

3. Preparations.................................................................................................... 35

3-1. Selecting the Cutter Installation Method .............................................................................................. 36

Cutter Types and What They Are Suited For.............................................................................................................. 36

3-2. Cutter Installation Method 1 (With Nose Unit) ..................................................................................... 37

Installing a Character Cutter (With Nose Unit)..........................................................................................................38

Cutting Parameters When Using the Nose Unit ......................................................................................................... 41

3-3. Cutter Installation Method 2 (No Nose Unit) ........................................................................................ 42

Installing a Character Cutter (With No Nose Unit)....................................................................................................43

3-4. Cutter Installation Method 3 (Diamond Scraper) ................................................................................. 46

Installing a Diamond Scraper...................................................................................................................................... 47

Cutting Parameters for the Diamond Scraper............................................................................................................. 50

3-5. Cutter Installation Method 4 (End Mill)................................................................................................. 51

Installing an End Mill ................................................................................................................................................. 52

3-6. Loading Material and Setting the Reference Point for Cutting ............................................................ 55

Loading Material ......................................................................................................................................................... 55

The Loaded Position of the Workpiece....................................................................................................................... 56

Setting the Reference Point for the Cutting Position ................................................................................................. 56

Table of Contents

1

Page 6

Table of Contents

4. Performing Cutting Using a Computer ......................................................... 57

4-1. Procedures for Performing Cutting Using a Computer ........................................................................ 58

4-2. Setting the Cutting Parameters............................................................................................................ 59

Types of Cutting Parameters....................................................................................................................................... 59

Differences in Setting Items Between Programs........................................................................................................ 59

Making the Settings on the Machine .......................................................................................................................... 60

4-3. Installation and Overview of the Included Software............................................................................. 62

Software Included with the Machine .......................................................................................................................... 62

Installation and Setup .................................................................................................................................................. 62

4-4. Executing Cutting Data Saved on a Memory Card..............................................................................65

Working with Cutting Data on a Memory Card .........................................................................................................65

Requirements for Saving Cutting Data....................................................................................................................... 65

Saving Cutting Data .................................................................................................................................................... 66

Importing and Executing Memory-card Data............................................................................................................. 69

Important Notes When Saving Cutting Data .............................................................................................................. 70

5. The Teaching Feature ..................................................................................... 71

5-1. Overview of the Teaching Feature ....................................................................................................... 72

What Is the Teaching Feature? .................................................................................................................................... 72

Important Notes When Using the Nose Unit.............................................................................................................. 72

5-2. Basic Steps for Creating and Executing a Sequence..........................................................................73

Step 1 Decide on the Mode of Operation and the Origin Points ..............................................................................73

Step 2 Create the Sequence........................................................................................................................................ 74

Step 3 Save the Sequence...........................................................................................................................................76

Step 4 Execute the Sequence .....................................................................................................................................76

5-3. Correcting a Sequence ........................................................................................................................ 77

If You Make a Mistake in Input ..................................................................................................................................77

Revising a Saved Sequence.........................................................................................................................................79

5-4. Detailed Description of the Sequence Editing Screen......................................................................... 80

Screen Layout and Button Operations ........................................................................................................................ 80

Setting a Label............................................................................................................................................................. 81

5-5. Detailed Information on Saving a Sequence ....................................................................................... 82

Destinations for Saving Sequences............................................................................................................................. 82

Backing Up a Sequence .............................................................................................................................................. 83

Deleting a Sequence .................................................................................................................................................... 84

5-6. Coordinate Systems Used with the Teaching Feature......................................................................... 85

Cutting Positions Used with the Teaching Feature .................................................................................................... 85

Optional Origins .......................................................................................................................................................... 85

I Level and R Level ..................................................................................................................................................... 86

5-7. List of Commands ................................................................................................................................ 87

5-8. Sample Sequences .............................................................................................................................. 98

Example of a Sequence Using Optional Origins........................................................................................................ 98

6. Detailed Description of Functions .............................................................. 101

6-1. Coordinate Systems and Origin Points.............................................................................................. 102

Workpiece Coordinates and Machine Coordinates .................................................................................................. 102

The Machine's Workpiece Origin Point.................................................................................................................... 102

Unit of Measurement for Coordinate Values ............................................................................................................ 102

6-2 Detailed Description of the Nose Unit................................................................................................. 103

Amount of Height Displacement That Can Be Tracked .......................................................................................... 103

Limitations on Cutting ..............................................................................................................................................103

6-3. Menu Flowchart.................................................................................................................................. 104

2

Table of Contents

Page 7

Table of Contents

6-4. Detailed Description of the Menus ..................................................................................................... 108

Main Menu ................................................................................................................................................................ 108

[I/O] Submenu ........................................................................................................................................................... 109

[OTHERS] Submenu................................................................................................................................................. 110

[SELF] Submenu ....................................................................................................................................................... 111

Teaching Menu.......................................................................................................................................................... 112

[RUN] Submenu........................................................................................................................................................ 114

X/Y-axis Origin-point Setting Menu ........................................................................................................................ 115

Z-axis Origin-point Setting Menu............................................................................................................................. 115

Pause Menu ............................................................................................................................................................... 115

Copy Menu ................................................................................................................................................................ 116

Language Menu ......................................................................................................................................................... 116

Initialize Menu .......................................................................................................................................................... 116

7. Maintenance...................................................................................................117

7-1. Daily Care............................................................................................................................................118

7-2. Maintenance and Inspection .............................................................................................................. 120

Spindle Maintenance ................................................................................................................................................. 120

Maintenance of the Z-axis Screw .............................................................................................................................121

8. Troubleshooting............................................................................................ 123

8-1. Problems with Engraving ................................................................................................................... 124

8-2. Problems with Operation.................................................................................................................... 126

8-3. Responding to an Error Message ...................................................................................................... 128

9. Appendix ....................................................................................................... 133

9-1. Examples of Settings for Cutting Parameters.................................................................................... 134

Sample Settings for Engraving .................................................................................................................................134

Tips for Fine-tuning .................................................................................................................................................. 134

9-2. The Nose Unit .................................................................................................................................... 135

Considerations for Fluctuations in Workpiece Thickness........................................................................................ 135

Structure of the Nose Unit ........................................................................................................................................135

9-3. Optional Items .................................................................................................................................... 136

9-4. Dimensional Drawings ....................................................................................................................... 137

9-5. List of Supported Commands ............................................................................................................ 138

RML-1 Commands.................................................................................................................................................... 138

Device Control Commands ....................................................................................................................................... 140

9-6. Specifications ..................................................................................................................................... 141

Main Unit Specifications .......................................................................................................................................... 141

Interface Specifications............................................................................................................................................. 142

Windows and Windows NT are registered trademarks or trademarks of Microsoft® Corporation in the United States and/or other countries.

Pentium are registered trademarks of Intel Corporation in the United States.

IBM is a registered trademark of International Business Machines Corporation.

Multi Media Card is a trademark of Infineon Technologies AG.

Other company names and product names are trademarks or registered trademarks of their respective holders.

Copyright© 2002 Roland DG Corporation http://www.rolanddg.com/

Table of Contents

3

Page 8

About the Documentation for This Machine

Documentation Included with the Machine

User's Manual (this manual)

This describes important notes for ensuring safe use, and explains how to install the machine and how to install and set

up the included programs. Be sure to read it first.

It does not describe how to operate your computer or how to use the programs.

Dr. Engrave User's Manual (electronic-format manual)

This manual explains how to use the included engraving program. It describes procedures ranging from how to design a

nameplate or the like to engraving operations. Read it if you're using this program.

The manual is in electronic format, and no printed document is included. You can find it on the included Roland Software

Package CD-ROM.

3D Engrave User's Manual (electronic-format manual)

This manual explains how to use the included program for three-dimensional engraving and for creating reliefs. It describes procedures ranging from how to design reliefs and the like to cutting operations. Read it if you're using this

program.

The manual is in electronic format, and no printed document is included. You can find it on the included Roland Software

Package CD-ROM.

Cutting Tips (electronic-format manual)

This is a collection of hints and tips for the procedures of three-dimensional cutting. Read it as a reference when you're

cutting three-dimensional objects.

Like the other manuals in electronic format, it is a PDF document, and Acrobat Reader is required to view it. You can find

it on the Roland Software Package CD-ROM, inside [Document], in the [Cuttips] folder.

Other Information

For descriptions of other programs and drivers, refer to the online help.

4

About the Documentation for This Machine

Page 9

About the Documentation for This Machine

About Adobe Acrobat Reader

Acrobat Reader is a program required to view files in PDF format. Installing and setting up Acrobat Reader 4.0, found on

the included CD-ROM, lets you view the manual easily on any computer. Acrobat Reader 4.0 is available in versions for

Windows 95 or later.

* Acrobat Reader is a product of Adobe Systems Incorporated. For detailed information on how to use it, go to the

Acrobat Reader menu and select [Help] to view the online help.

Viewing Manuals in Electronic Format

You can view the manuals in electronic format on a computer running Windows (Windows 95 or later).

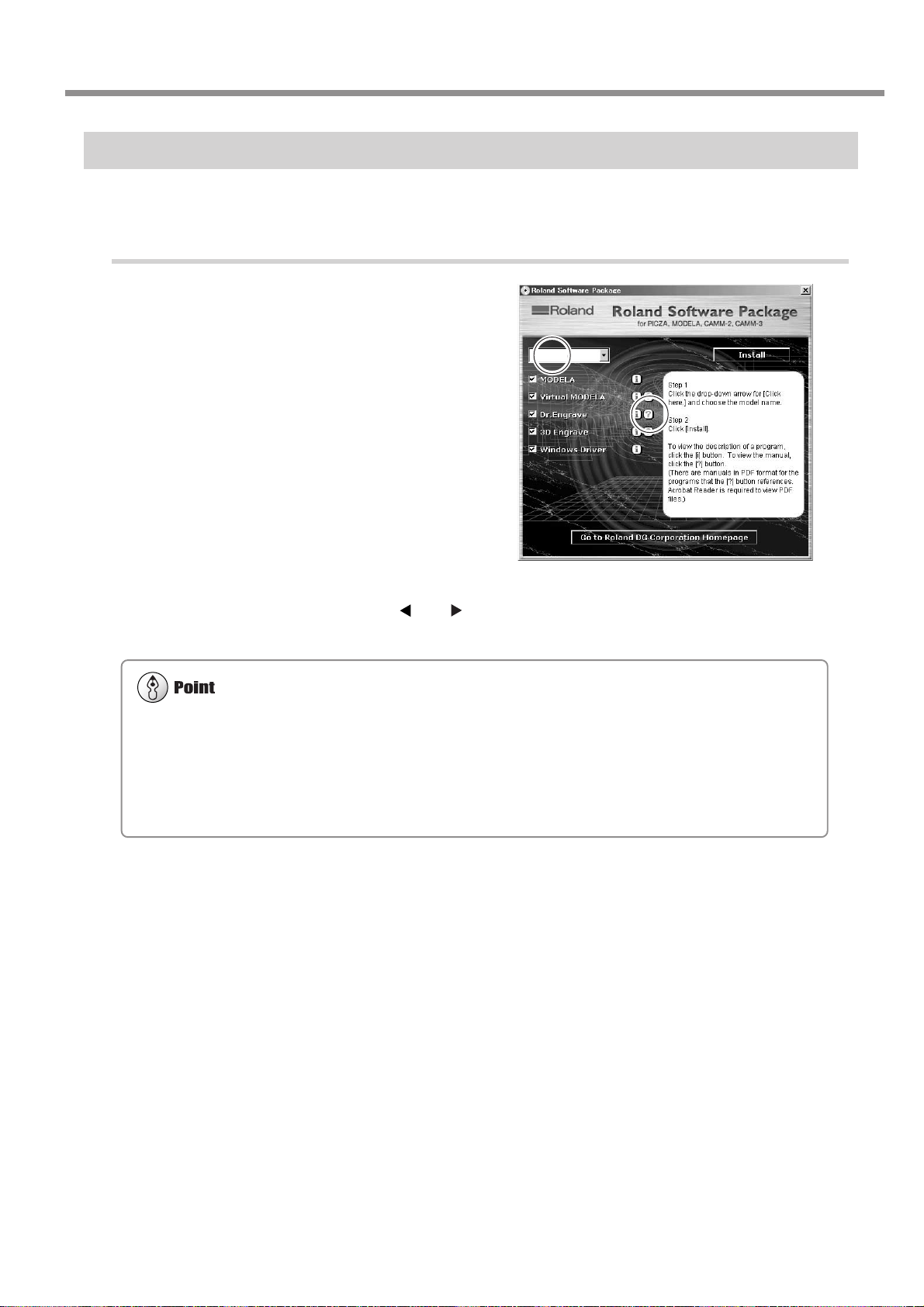

Procedures for Viewing Manuals in Electronic Format

Place the Roland Software Package in the CD-

1

ROM drive. The menu screen appears automatically.

Click the [Click here] message, then choose the

2

name of the model you're using (EGX-600 or

EGX-400).

Click the [?] button. Acrobat Reader starts and

3

the user's manual is displayed.

When you click the button for the first time, the program

for installing and setting up Acrobat Reader may start.

Follow the on-screen instructions to proceed with installation and setup.

EGX-600

You can use the left and right arrow keys on

4

the computer keyboard to advance to the next

page or go back to the previous page.

You can also do the same thing using the [ ] and [ ]

buttons on screen.

About the Documentation for This Machine

5

Page 10

To Ensure Safe Use

About and Notices

Used for instructions intended to alert the user to the risk of death or severe

injury should the unit be used improperly.

Used for instructions intended to alert the user to the risk of injury or material

damage should the unit be used improperly.

* Material damage refers to damage or other adverse effects caused with

respect to the home and all its furnishings, as well to domestic animals or

pets.

About the Symbols

The symbol alerts the user to important instructions or warnings. The specific meaning of

the symbol is determined by the design contained within the triangle. The symbol at left means

"danger of electrocution."

The symbol alerts the user to items that must never be carried out (are forbidden). The

specific thing that must not be done is indicated by the design contained within the circle. The

symbol at left means the unit must never be disassembled.

The symbol alerts the user to things that must be carried out. The specific thing that must

be done is indicated by the design contained within the circle. The symbol at left means the

power-cord plug must be unplugged from the outlet.

Do not disassemble, repair, or modify .

Doing so may lead to fire or abnormal operation resulting in injury.

Do not use with any electrical power

supply that does not meet the ratings

displayed on the unit.

Use with any other power supply may lead

to fire or electrocution.

Use only with the power cord included

Ground the unit with the ground wire.

Failure to do so may result in risk of electrocution in the event of a mechanical problem.

Do not use while in an abnormal state

(i.e., emitting smoke, burning odor,

unusual noise, or the like).

Doing so may result in fire or electrocution.

Immediately switch off the power , unplug the

power cord from the electrical outlet, and

contact your authorized Roland DG Corp.

dealer or service center.

with this product.

Use with other than the included power cord

may lead to fire or electrocution.

6

To Ensure Safe Use

Page 11

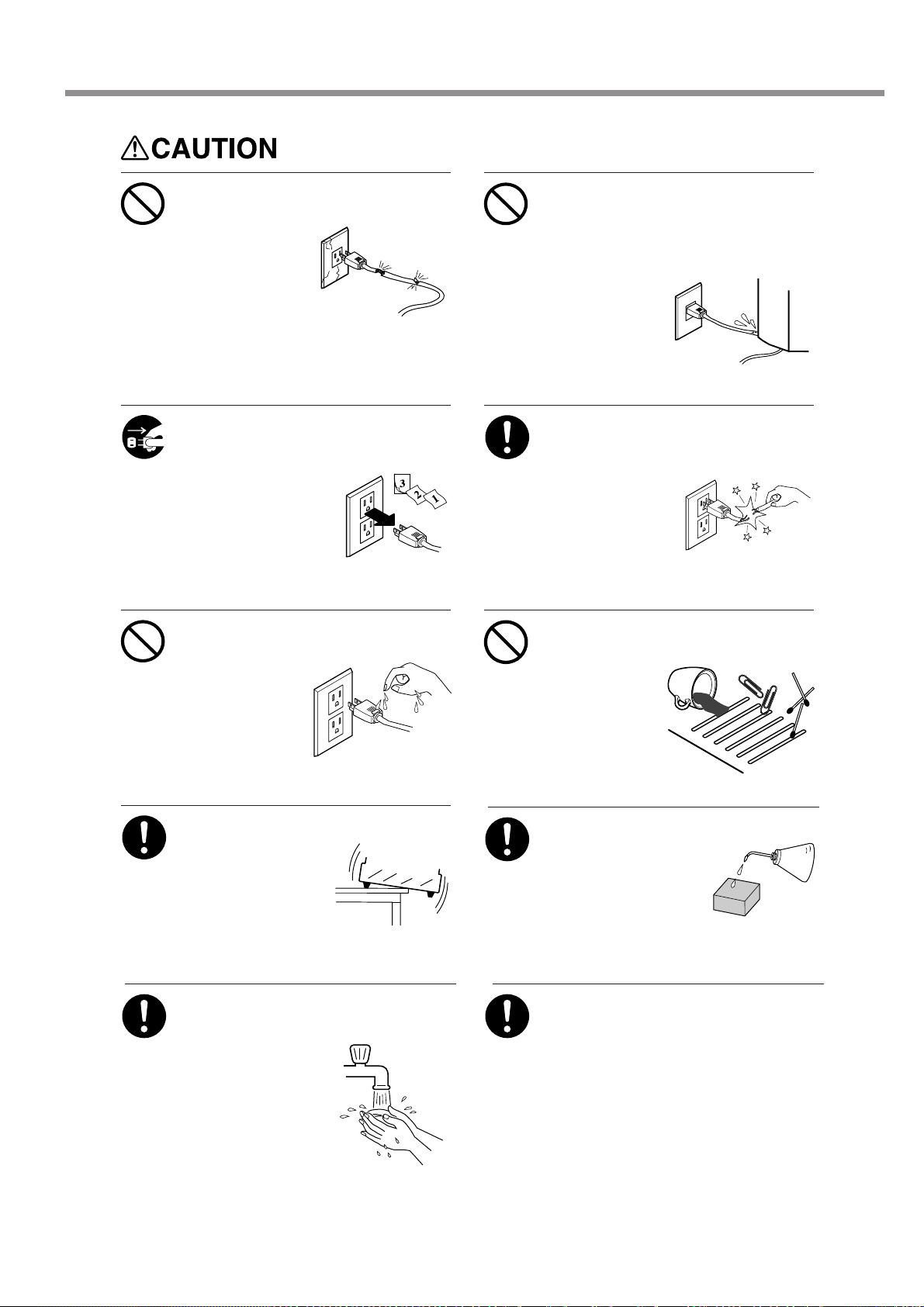

To Ensure Safe Use

Do not use with a damaged power

cord or plug, or with a loose electrical outlet.

Doing so may lead to

fire, electrical shock,

or electrocution.

When not in use for extended periods,

unplug the power-cord plug from the

electrical outlet.

Failure to do so may result in danger of electrical shock, electrocution,

or fire due to deterioration

of electrical insulation.

Do not attempt to unplug the powercord plug with wet hands.

Doing so may result

in electrical shock

or electrocution.

Do not damage or modify the electrical power cord, subject it to excessive bending, twisting, pulling, binding, or pinching, or place any object

or weight on it.

Doing so may damage the electrical

power cord, leading

to fire, electrical

shock, or electrocution.

When unplugging the electrical power

cord from the power outlet, grasp the

plug, not the cord.

Unplugging by pulling

the cord may damage it, leading to fire,

electrical shock, or

electrocution.

Do not allow liquids, metal objects or

flammables inside the machine.

Such materials

can cause fire.

Install on a stable surface.

Failure to do so may

result in the unit tipping

over, leading to injury.

When you're finished, wash your

hands to rinse away all cuttings.

Perform dry cutting with no cutting oil.

Such materials can cause fire.

Please use a vacuum cleaner to remove cutting dust.

Do not use any blower like airbrush.

Otherwise, dust spread in the air may harm

your health.

To Ensure Safe Use

7

Page 12

To Ensure Safe Use

Use a commercially available brush

to remove metal cuttings.

Attempting to use a

vacuum cleaner to

take up metal cuttings

may cause fire in the

vacuum cleaner.

Do not carelessly insert the hands

while in operation.

Doing so may result in injury.

Do not touch the tip of the blade with

your fingers.

Doing so may

result in injury.

Wear dust goggles and mask during

use.

Cutting dust may scatter, causing bodily injury.

Unpacking, installation, and moving

are operations that must be carried out

by four or more persons.

Failure to do so may result in falling of the

unit, leading to injury.

Fasten the spindle, tool, and material

securely in place.

Otherwise they may come loose during cutting, resulting in injury.

Do not operate beyond capacity or

subject the tool to undue force.

The tool may break or fly off in a random direction. If cutting beyond capacity is mistakenly started, immediately turn off the EMERGENCY STOP switch.

Switch off the machine and unplug the

power cord from the electrical outlet

before performing cleaning or maintenance.

Failure to do so may result in injury or electrical shock.

Do not wear gloves, a necktie or widesleeved clothing.

They may become caught in the tool, resulting in injury.

Do not operate if a spindle cover is

cracked or broken.

If the spindle is cracked, contact a service

agent immediately for repairs.

Do not touch the tool immediately after cutting operating stops.

The tool may have become hot due to friction heat and may cause burns if touched.

Do not touch the spindle motor immediately after a cutting operation has

ended.

Doing so may result in burns.

8

To Ensure Safe Use

Page 13

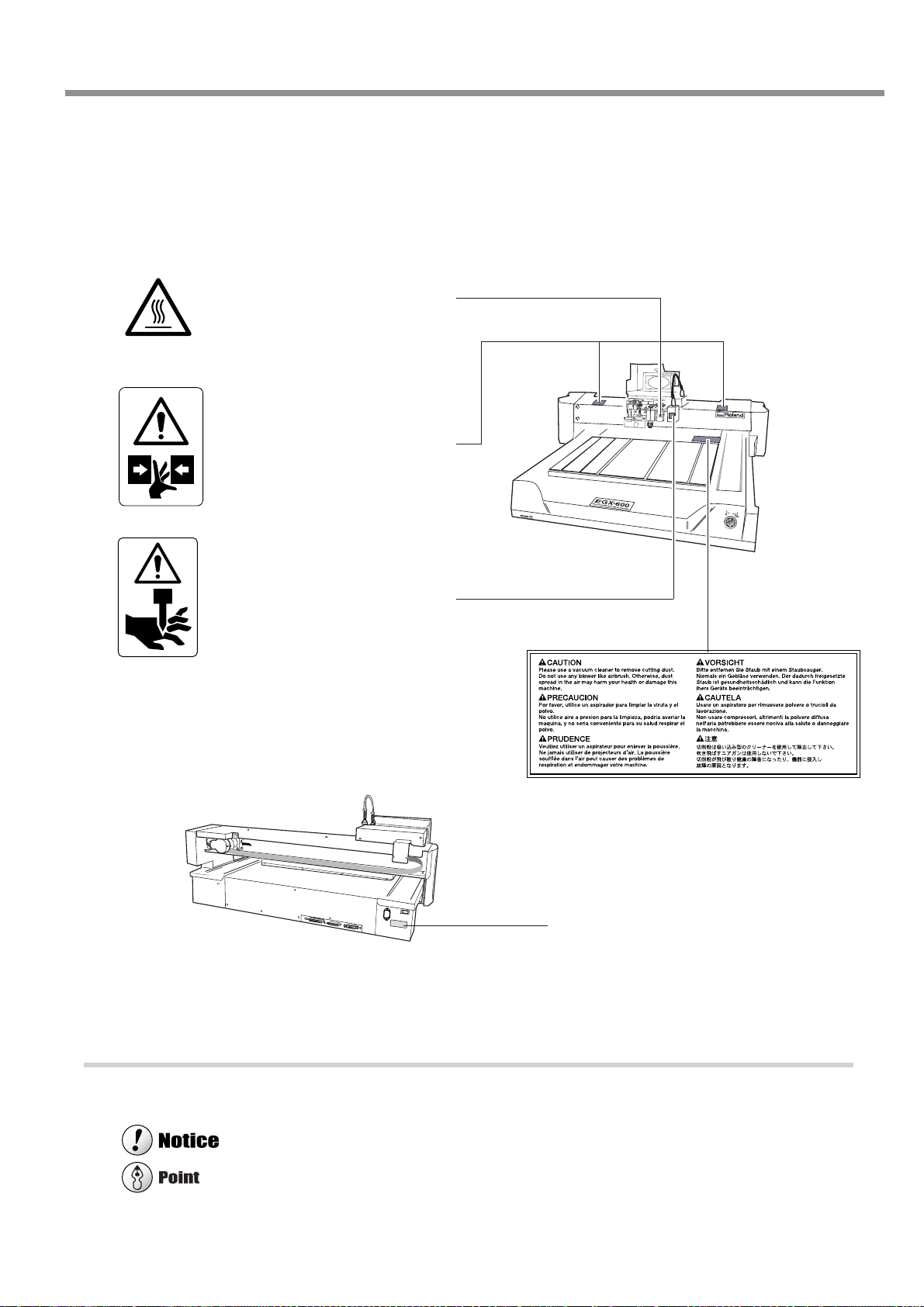

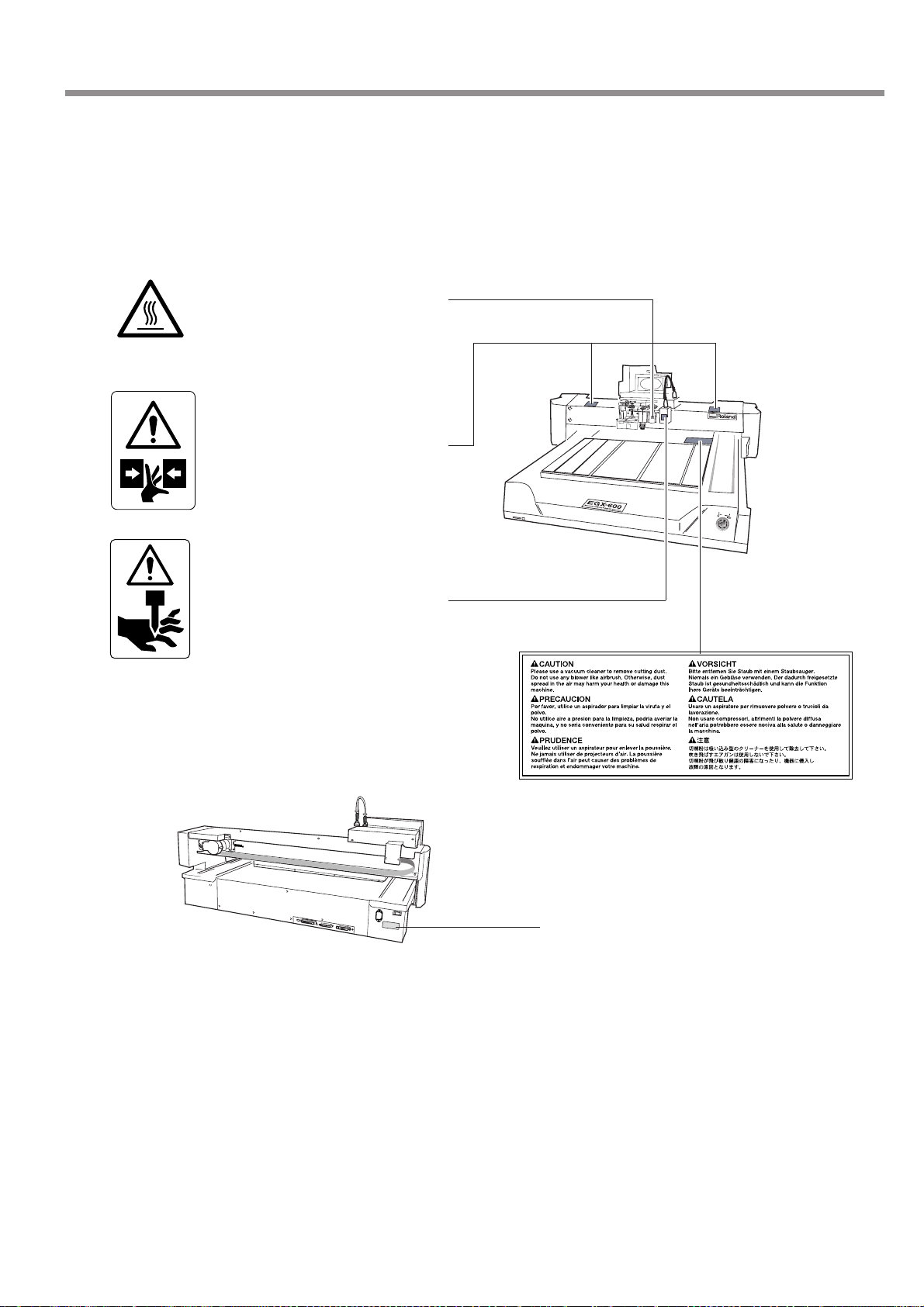

About the Labels Affixed to the Unit

These labels are affixed to the body of this product.

The following figure describes the location and content of these messages.

Caution: high temperatures. Do

not touch immediately after a cutting operation has ended.

Use care to avoid being pinched.

Keep hands away during operation.

To Ensure Safe Use

Use caution when handling or

working with the blade. Careless

handling may result in injury.

Model name

Rating plate

Use a rated power supply.

In addition to these symbols, the symbols shown below are also used.

: Indicates information to prevent machine breakdown or malfunction and ensure correct use.

: Indicates a handy tip or advice regarding use.

To Ensure Safe Use

9

Page 14

Pour utiliser en toute sécurité

Avis sur les avertissements

Utilisé pour avertir l'utilisateur d'un risque de décès ou de blessure grave en

cas de mauvaise utilisation de l'appareil.

Utilisé pour avertir l'utilisateur d'un risque de blessure ou de dommage

matériel en cas de mauvaise utilisation de l'appareil.

* Par dommage matériel, il est entendu dommage ou tout autre effet

indésirable sur la maison, tous les meubles et même les animaux

domestiques.

À propos des symboles

Le symbole attire l'attention de l'utilisateur sur les instructions importantes ou les

avertissements. Le sens précis du symbole est déterminé par le dessin à l'intérieur du triangle.

Le symbole à gauche signifie "danger d'électrocution".

Le symbole avertit l'utilisateur de ce qu'il ne doit pas faire, ce qui est interdit. La chose

spécifique à ne pas faire est indiquée par le dessin à l'intérieur du cercle. Le symbole à

gauche signifie que l'appareil ne doit jamais être démonté.

Le symbole prévient l'utilisateur sur ce qu'il doit faire. La chose spécifique à faire est

indiquée par le dessin à l'intérieur du cercle. Le symbole à gauche signifie que le fil électrique

doit être débranché de la prise.

Ne pas démonter, réparer ni modifier .

Démonter, réparer ou modifier l'appareil risque de provoquer un incendie ou de causer

un fonctionnement anormal entraînant des

blessures.

Ne pas utiliser avec une source

d'alimentation électrique non

conforme à la norme indiquée sur

l'appareil.

Utiliser l'appareil avec une autre source

d'alimentation risque de provoquer un

incendie ou de causer une électrocution.

Utiliser l'appareil uniquement avec le

fil électrique fourni.

Utiliser l'appareil avec un autre fil risque de

provoquer un incendie ou une électrocution.

Mettre l'appareil à la terre avec le fil

de mise à la terre.

Ne pas respecter cette consigne peut créer

un risque d'électrocution en cas de panne

mécanique.

Ne pas utiliser l'appareil s'il est dans

un état anormal (p.ex., émission de

fumée, odeur de brûlé, bruit inhabituel

ou autre anomalie).

Ne pas respecter cette consigne risque de

provoquer un incendie ou une électrocution.

Couper immédiatement l'alimentation

électrique, débrancher le fil de la prise et

communiquer avec le revendeur ou le centre de service autorisés de la société Roland

DG.

10

Pour utiliser en toute sécurité

Page 15

Pour utiliser en toute sécurité

Ne pas utiliser si le fil ou la fiche

électriques sont endommagés; ne

pas brancher dans une prise mal

fixée.

Négliger de suivre

cette consigne

risque de provoquer

un incendie ou

decauser une

décharge électrique

ou une électrocution.

Si l'appareil reste inutilisé pendant de

longues périodes, débrancher la fiche

de la prise.

Négliger de suivre cette consigne peut

créer un risque de décharge électrique ou

d'électrocution ou

provoquer un incendie

à cause de la

détérioration de

l'isolant électrique.

Ne pas endommager ni modifier le fil

électrique. Ne pas le plier, le tordre,

l'étirer , l'attacher ou le serrer de façon

excessive. Ne pas placer d'objet ou

de poids sur le fil.

Négliger de suivre cette consigne peut

endommager le fil électrique, ce qui risque

de provoquer un

incendie ou de

causer une

décharge électrique

ou une électrocution.

Pour débrancher l'appareil, saisir la

fiche et non le fil électrique.

Tirer sur le fil peut l'endommager, ce qui

risque de provoquer un incendie ou de

causer une

décharge

électrique ou une

électrocution.

Ne pas débrancher le fil avec des

mains mouillées.

Ne pas respecter

cette consigne risque de provoquer

des décharges

électriques ou une

électrocution.

Installer sur une surface stable.

Sinon, l'appareil risque

de se renverser et de

causer des blessures.

Quand vous avez terminé d'utiliser

l'appareil, laver vos

mains pour bien

enlever tous les

copeaux.

Ne pas laisser de liquides ni d'objets

métalliques ou inflammables

s'infiltrer dans l'appareil.

De telles infiltrations peuvent

provoquer un

incendie.

Faire des coupes à sec, sans huile de

coupe.

L'huile de coupe peut

provoquer un incendie.

Utiliser un aspirateur pour nettoyer

les copeaux. N'utiliser aucun appareil

soufflant de l'air comme un sèchecheveux.

La poussière répandue dans l'air pourrait

nuire à votre santé.

Pour utiliser en toute sécurité

11

Page 16

Pour utiliser en toute sécurité

Utiliser une brosse du commerce pour

retirer les rognures de métal.

Tenter de retirer les

rognures de métal à

l’aide d’un aspirateur

peut faire naître un

incendie dans

l’aspirateur.

Faire attention de ne pas insérer ses

mains pendant le fonctionnement.

Ne pas respecter cette consigne peut

provoquer des blessures.

Ne pas toucher à l’extrémité de la lame

avec vos doigts.

Vous risqueriez

de vous blesser

en y touchant.

Lorsque vous déplacez l'appareil, le

saisir par sa base en aluminium et le

transporter à 4 personnes ou plus.

Si l'appareil est saisi par la plaque du dessus,

il peut tomber et entraîner des blessures.

Fixer fermement le mandrin, l'outil et

le matériel à leur place.

Sinon, ces éléments risquent d'avoir du jeu

lors des coupes, ce qui entraînerait des

blessures.

Ne pas utiliser l'appareil au-dessus de

ses capacités ou le soumettre à une

force excessive.

L'outil pourrait se briser ou être projeté dans

une direction indéterminée. Si vous

commencez par inadvertance une coupe audessus de la capacité de l'appareil, l'éteindre

immédiatement à l'aide du bouton d'urgence.

Porter des lunettes de travail et un

masque durant l'utilisation.

Des copeaux pourraient être projetés et vous

blesser.

Ne pas porter de gants, de cravate ou

de vêtement à manches amples.

Ils pourraient se prendre dans l'appareil et

entraîner des blessures.

N'utilisez pas l'appareil si le couvercle

de l'axe est fissuré ou brisé.

Si le couvercle de l'axe est fissuré,

communiquez immédiatement avec un agent

de service pour faire effectuer les

réparations.

Couper le contact et débrancher le

câble d’alimentation du réceptacle

avant de procéder au nettoyage ou à

l’entretien de l’appareil.

Une négligence à ce niveau pourrait

provoquer des blessures ou une

électrocution.

Ne pas toucher l'outil immédiatement

après une coupe.

L'outil pourrait avoir chauffé avec la friction

et vous causer des brûlures.

Ne touchez pas le moteur de l'axe

immédiatement après avoir terminé

une coupe.

Vous risqueriez alors de vous brûler.

12

Pour utiliser en toute sécurité

Page 17

Pour utiliser en toute sécurité

À propos des étiquettes collées sur l'appareil

Ces étiquettes sont collées à l'extérieur de l'appareil.

Les dessins suivants indiquent l'endroit et le contenu des messages.

Attention : températures élevées.

Ne touchez pas immédiatement

après avoir effectué une coupe.

Soyez prudent et évitez les

pincements. Éloignez les mains

pendant le fonctionnement.

Soyez prudent lorsque vous

manipulez ou utilisez la lame,

sinon vous risquez de vous

blesser.

Nom du modèle

Étiquette des caractéristiques électriques

Utiliser l'alimentation appropriée

Pour utiliser en toute sécurité

13

Page 18

14

Page 19

1. Getting Started

This chapter describes the procedures extending from unpacking

the machine to installing it, and also explains such matters as required terminology and other background knowledge.

15

Page 20

1-1. Included Items and Accessories

Follow the steps in "Unpacking and Repacking" on the packing carton to take out the included items and accessories.

Before you attempt installation, make sure all the included items are present.

Operation panel : 1 Operation-panel

connector cable : 1

Nut

Bolt

Solid collet : 1 (*1)

Hexagonal wrench

(3 mm) : 1

Clamps : 4 (*2)

Roland Software Package

CD-ROM : 1

Power cord : 1 Depth regulator

nose unit : 1

Wrenches

(17 mm : 1, 10 mm : 1)

User's Manual

(this manual) : 1

Hexagonal screw driver

(2 mm) : 1

16

*1 This is for diameter 4.36 mm character cutters and flat cutters. It cannot be used with diamond scrapers or end mills.

*2 The bolts and nuts are installed on the machine. (They are used for attaching the packing retainers.)

* This machine does not come with a cutter or cutter holder.

Chapter 1 - Getting Started

Page 21

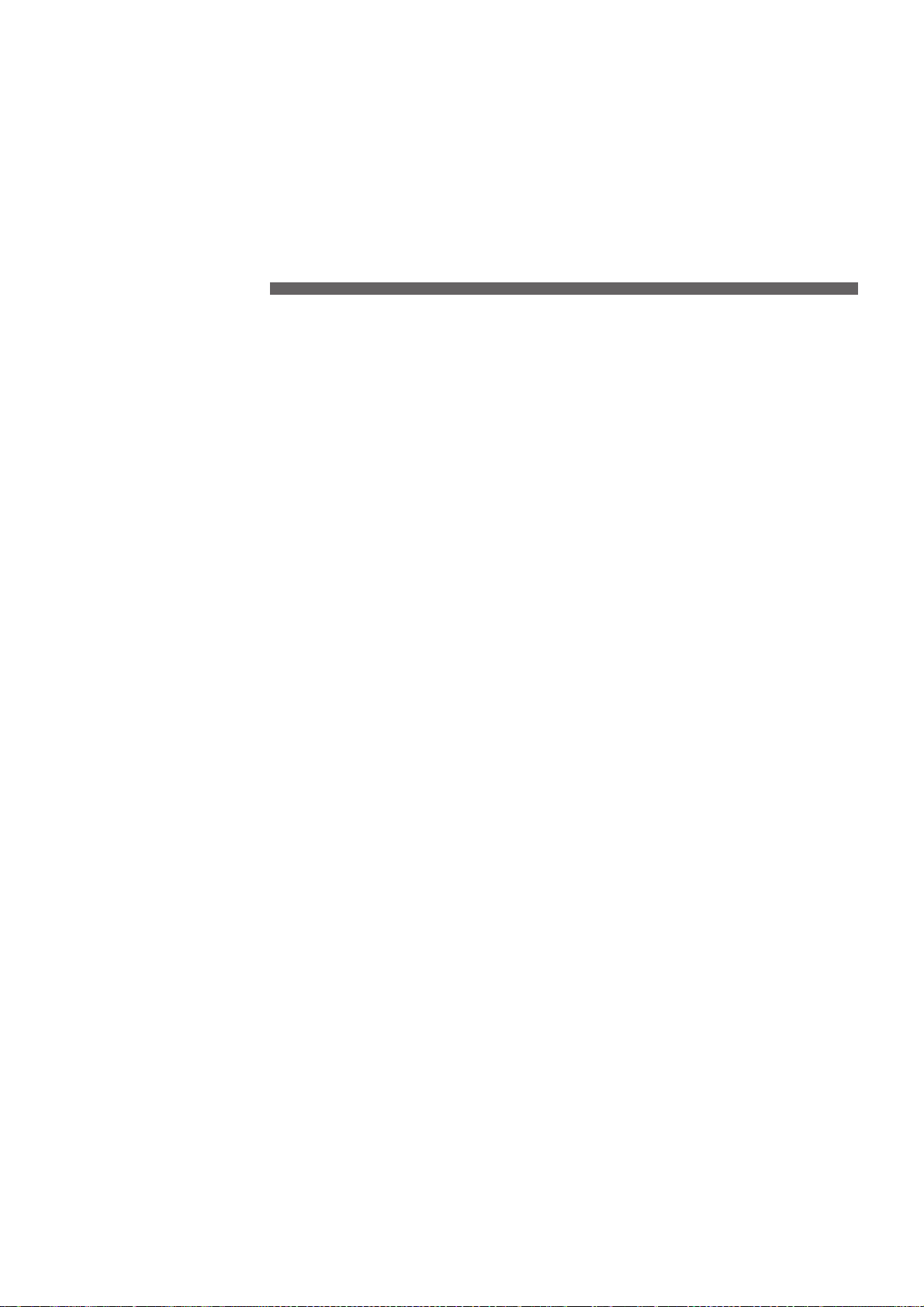

1-2. Names and Functions

Front

Spindle cover

Pulley

Lock nut

Belt

Spindle motor

Spindle unit

Depth regulator nose unit

(Nose unit)

Spindle head

T slot

Bed

Slot cover

Memory-card slot

Operation-panel

connector

Rail cover

Guide

Guide securing

screws

X-axis rail

Arm

Table

Emergency stop

switch

Depth regulator

nose unit

(Nose unit)

Micrometer dial

Nose cone

Retainer nut

Chapter 1 - Getting Started

17

Page 22

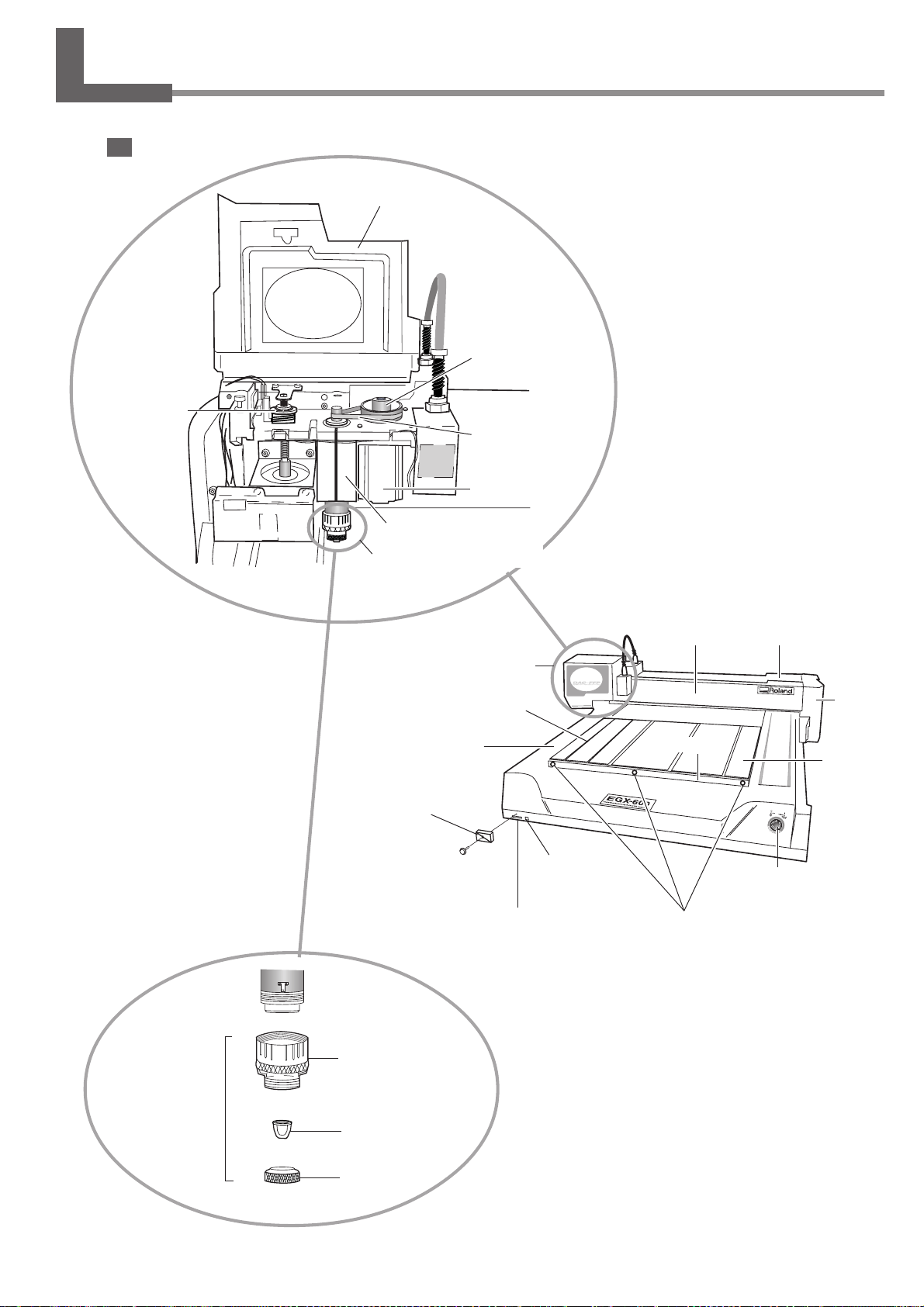

1-2. Names and Functions

Rear

Expansion connector 1

This connector is for transmitting the

rotation of the spindle to an external

device.

Parallel connector

This connector is for

connection to the printer

port on the computer.

Operation Panel

Power-cord connector

Expansion connector 2

This is for communication with an

external device using the teaching

feature.

Serial connector

This connector is for

connection to the COM

port on the computer.

ENTER/PAUSE button

This enables values you enter. Pressing it while

cutting is in progress pauses operation.

Power switch

Menu button

This displays the main menu.

Connector

X/Y-axis Origin Set button

This sets the reference point for the

cutting position.

Z-axis Origin Set button

This makes settings such as for the

reference point for aligning the

cutter.

Copy button

This calls up the menu for the copy

feature.

Movement buttons

These move the spindle head forward

and backward and to the left and right.

They are also used for menu operations.

Spindle button

This starts and stops rotation of

the spindle.

Display

Dial

This adjusts the spindle rotating

speed. It is also used for menu

operations.

Z-axis Movement buttons

These move the spindle head up

and down.

Feed button

This is used in combination with

the movement buttons.

18

Chapter 1 - Getting Started

Page 23

When the spindle motor is run at high speed while at a low temperature, rotation may be unstable for some time. In such

cases, allow to warm up by running at about 15,000 rpm with no load for around 15 minutes.

1-3. Installation and Cable Connections

Install on a stable surface.

Failure to do so may result in the unit tipping over, leading to injury.

Unpacking, installation, and moving are operations that must be carried out by four or more persons.

Failure to do so may result in falling of the unit, leading to injury.

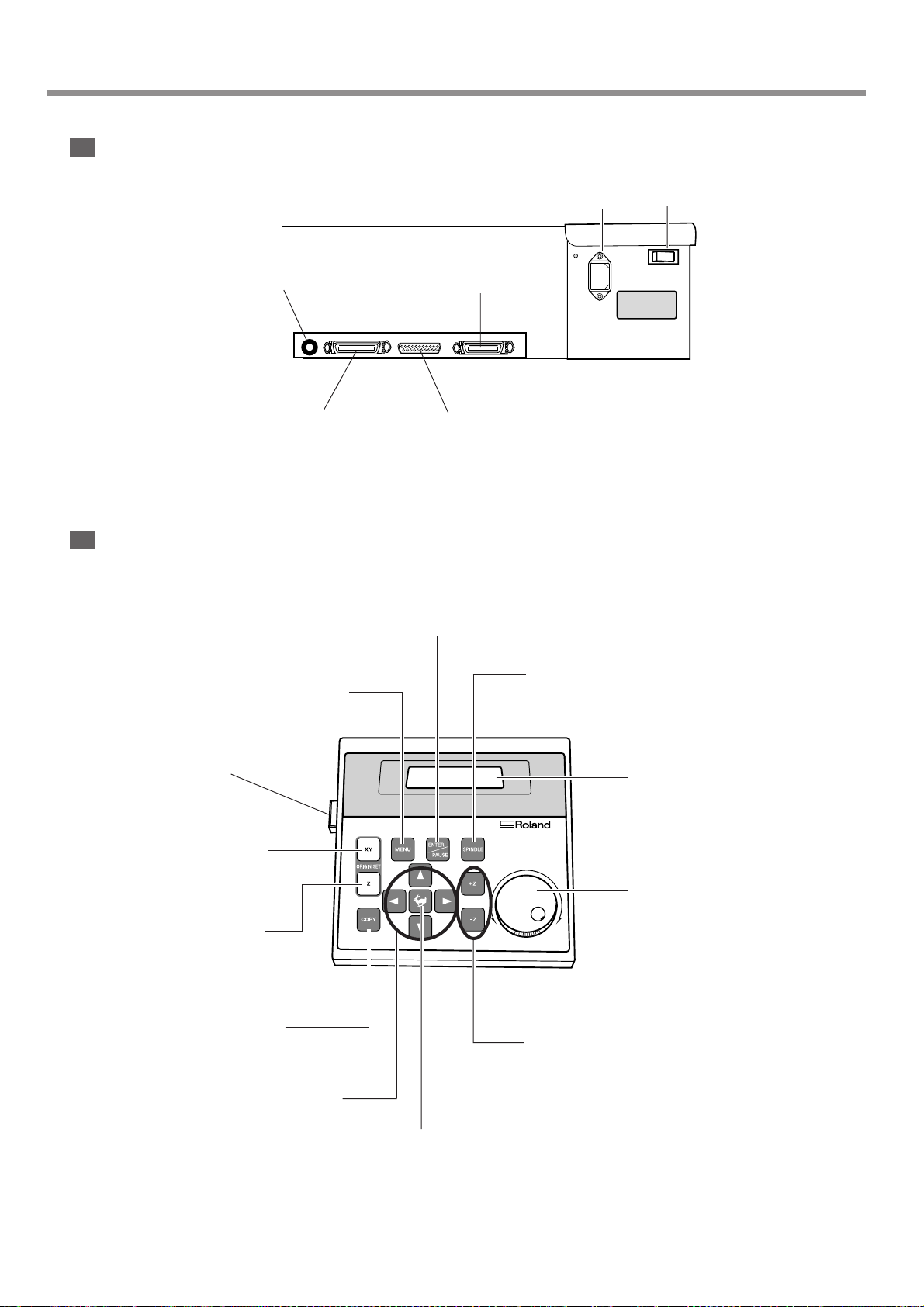

Installation Site and Operating Environment

Use this machine in an environment that meets the following conditions.

• Temperature of 5 to 40 ˚C (41 to 104 ˚F) and relative humidity of 35 to 80% (with no condensation).

• A level location with no wobble.

• Little dust.

• Little vibration.

• Good ventilation and heat dissipation.

• Low electrical noise. For example, avoid installing near an electric motor.

Also ensure that the following amount of space is available.

Maintenance space

Installation space

900 mm / 900 mm

(35 in./ 35 in.)

(Rear)

Main unit

(Front)

1200 mm / 1000 mm

(48 in./ 40 in.)

2100 mm / 1900 mm

(83 in./ 75 in.)

EGX-600 / EGX-400

2600 mm / 2500 mm

(103 in./ 100 in.)

1200 mm / 1000 mm

(48 in./ 40 in.)

Chapter 1 - Getting Started

19

Page 24

1-3. Installation and Cable Connections

Make sure the power to the machine is switched off before attempting to connect or disconnect the cables. Connect securely to ensure

that accidental disconnection does not occur during operation.

When the connection uses a serial cable, you need to make sure the communication parameters for the machine match the

communication parameters for the computer. For more information about the computer's communication parameters, refer to

the documentation for the program. The defaults for the programs included with this machine are set up to match without

modification.

Configuring the Communication Parameters for the Machine

☞ See p.109 "I/O Submenus"

Ground the unit with the ground wire.

Failure to do so may result in risk of electrocution in the event of a mechanical problem.

Use only with the power cord included with this product.

Use with other than the included power cord may lead to fire or electrocution.

Do not use with any electrical power supply that does not meet the ratings displayed on the unit.

Use with any other power supply may lead to fire or electrocution.

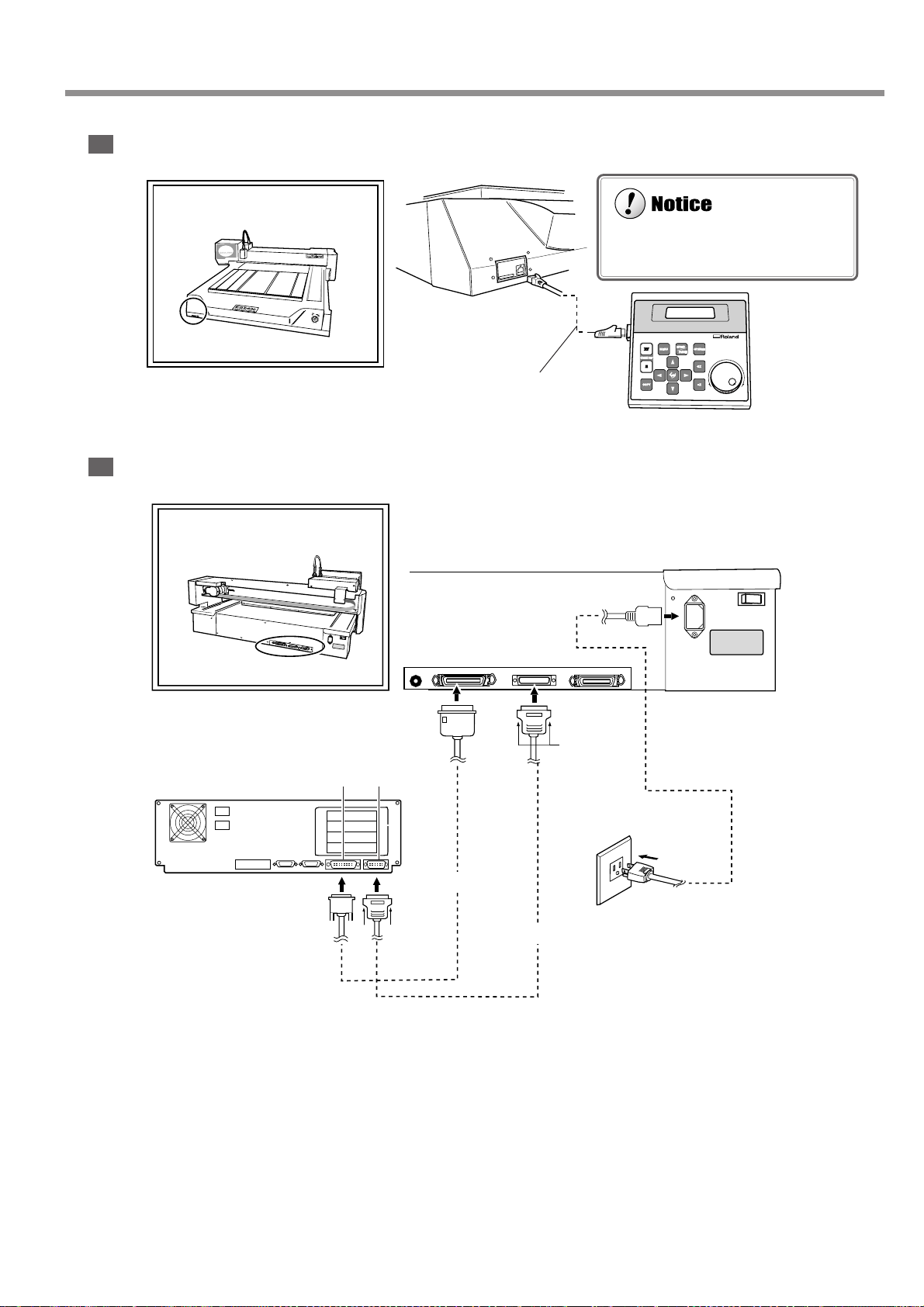

Connecting the Cables

Connect the operation panel and the power cable. If you're using a computer, then also connect a printer cable or serial

cable.

The printer cable or serial cable is sold separately. Use a cable that is compatible with the computer.

Printer cable

Use a commercially available printer cable.

Serial cable

If your computer is an IBM AT-compatible personal computer, then use an optionally available XY-RS-34 cable (or

equivalent). A straight cable such as a modem cable will not work.

20

Chapter 1 - Getting Started

Page 25

Do not insert an Ethernet cable or connect to a modular jack.

Front

Rear

1-3. Installation and Cable Connections

Insert until it clicks

into place.

Operation-panel

connector cable

Parallel

connector

Secure with

the clips.

Serial portPrinter port

Printer cable

Connect either a printer cable or

serial cable.

Serial

connector

Serial cable

Power connector

Secure with

the screws.

Power outlet

Power cord

Chapter 1 - Getting Started

21

Page 26

22

Page 27

2. Basic Operation

Operating the buttons makes the machine move. When operating the

buttons, be sure to keep your hands away from the machine.

Do not let your hair, necktie, or the like touch the machine. There is

danger of becoming it caught on the spindle or other moving parts.

This chapter describes what you should know before you try to use

the machine, such as the most basic operations and the procedures

for safe use and handling. Be sure to read this chapter before you go

on to the next step.

23

Page 28

2-1. Emergency Stop to Ensure Safety

How to Perform an Emergency Stop

To stop the machine in an emergency in order to avoid danger, press the emergency stop switch. The machine immediately stops operating and quits cutting. Cutting cannot be resumed.

To Cancel an Emergency Stop

To cancel an emergency stop, turn the emergency stop switch in the direction of the arrow. The machine returns to the

state it was in immediately after powerup.

Opening and Closing the Spindle Cover

Be sure to close the spindle cover before you start cutting, and never open it while operation is in progress. For safety,

opening the spindle cover during operation causes an emergency stop. To recover, switch off the power to the machine.

When the spindle cover is open, only head movement using the movement buttons is possible. You cannot use the buttons

to rotate the spindle or perform cutting.

24

Chapter 2 - Basic Operation

Page 29

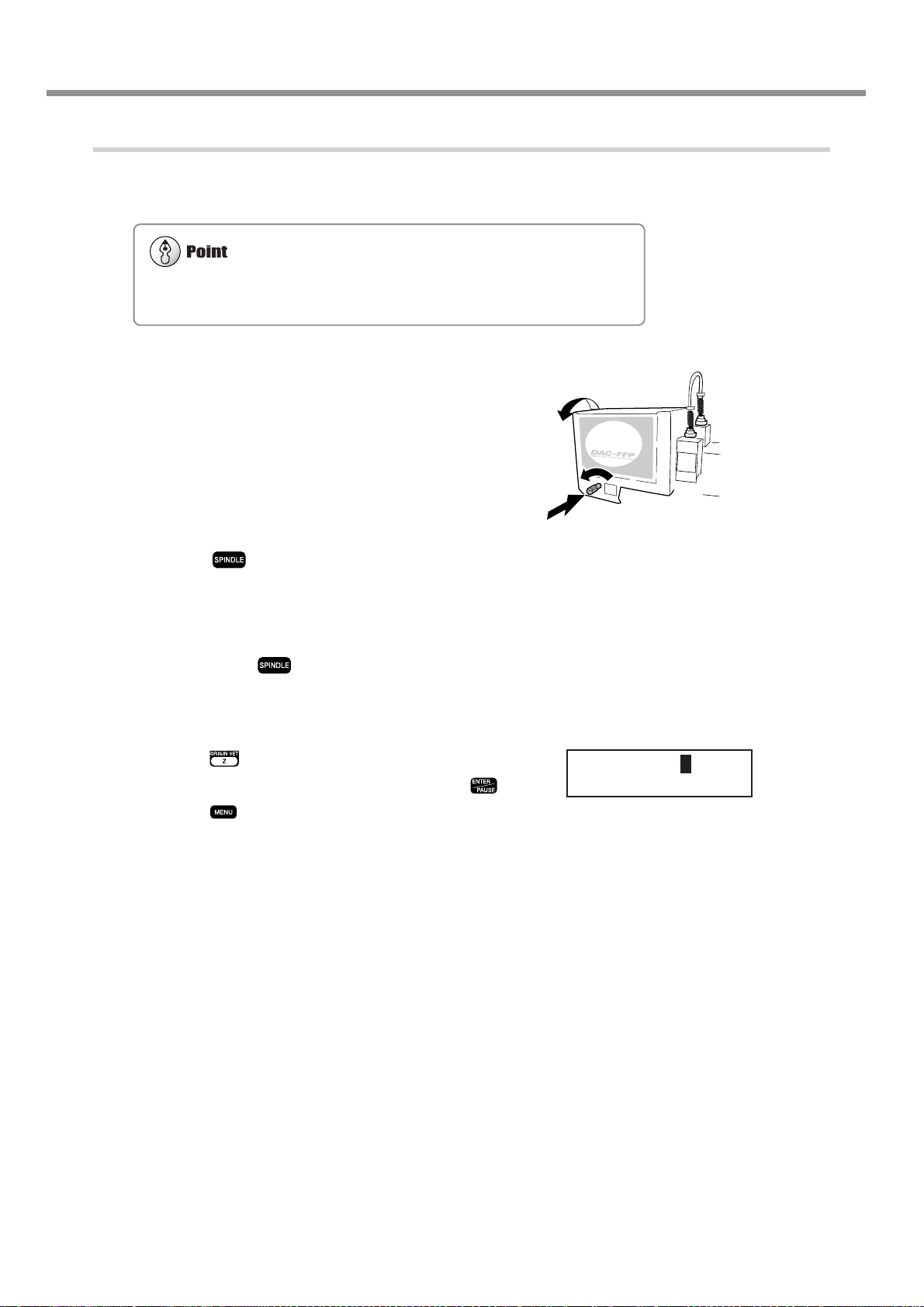

2-2. Switching the Power On and Off

Keep your hands away from the machine when you turn on the power. Also, do not place and objects

where they may obstruct the operation of the spindle head, X-axis rail, bed, or other components.

Switching On the Power

Turning On the Power

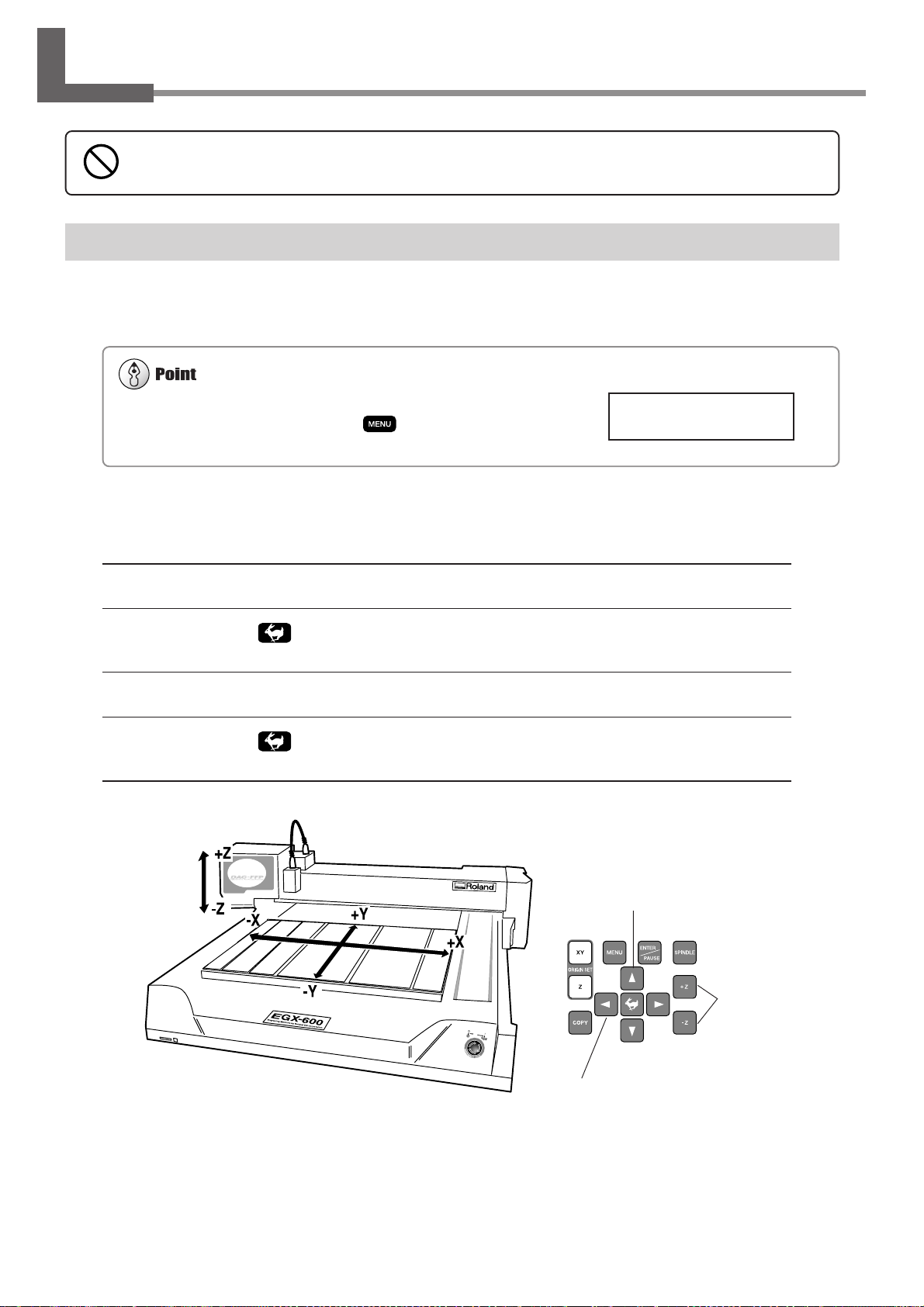

Turn on the power switch on the back of the

1

machine.

The display shows the model name, and while this is displayed, internal initialization is performed. This takes

about ten seconds.

EGX-600

Roland DG Corp.

When the screen shown at right appears, press

2

3

.

This machine operates at this time. The spindle head

moves to the left and back (to the VIEW position), then

stops.

The display changes to the top screen, and

startup ends.

Hit "ENTER" key

X 0 Y 40700

Z 0 8000RPM

Switching Off the Power

Turn off the power switch on the back of the machine. Do not the emer gency stop switch for turning the power on and off

in day-to-day use.

Chapter 2 - Basic Operation

25

Page 30

2-3. Moving the Spindle Head

Do not put the operation panel on the machine while operation. Doing so may result in unexpected problems.

Make sure the display shows the top screen. You cannot perform movement

when any other screen is displayed. Press

several times to display the

top screen.

Moving the Spindle Head

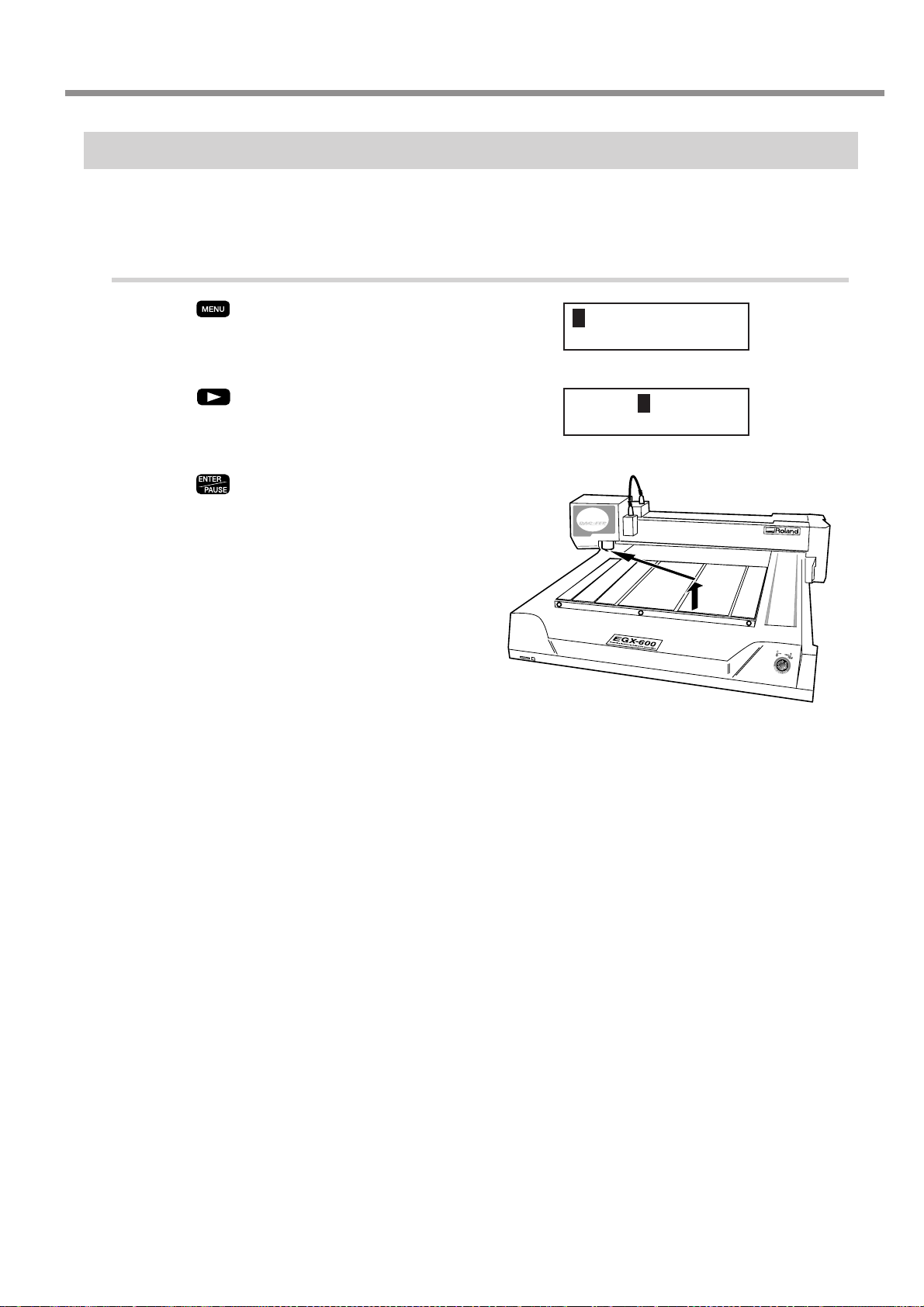

The spindle head moves in three directions, along the X, Y, and Z axes. When the display shows the top screen, pressing

the movement buttons effects movement in the corresponding directions.

X 0 Y 0

Z 0 8000RPM

The speed of movement is determined by how you press the movement buttons, as described below.

Pressing and holding down a movement button

While holding down , pressing and holding down

a movement button

Pressing and releasing a movement button

While holding down , pressing and releasing

a movement button

Slow continuous movement

Fast continuous movement

Movement of 0.01 mm per press

Movement of 0.1 mm per press

Y-axis direction

26

Chapter 2 - Basic Operation

Z-axis direction

X-axis direction

Page 31

2-3. Moving the Spindle Head

Moving the Spindle Head Out of the W ay Quickly

This feature moves the spindle head directly to the back-left position of the table (the VIEW position). This is handy

when loading or detaching a workpiece.

Moving to the VIEW Position

Press until the screen shown at right ap-

1

pears.

Press .

2

The blinking cursor moves to [VIEW].

Press .

3

The spindle head rises to the highest point, then moves

to the VIEW position.

HOME VIEW

Z1 Z0 Z2

HOME VIEW

Z1 Z0 Z2

Chapter 2 - Basic Operation

27

Page 32

2-4. Starting and Stopping Spindle Rotation

When the spindle cover is open, the spindle does not rotate.

A void turning the dial while cutting is in progress. The feed rate drops

momentarily, and the finished results of engraving may be adversely

affected.

Using Buttons to Start and Stop Rotation

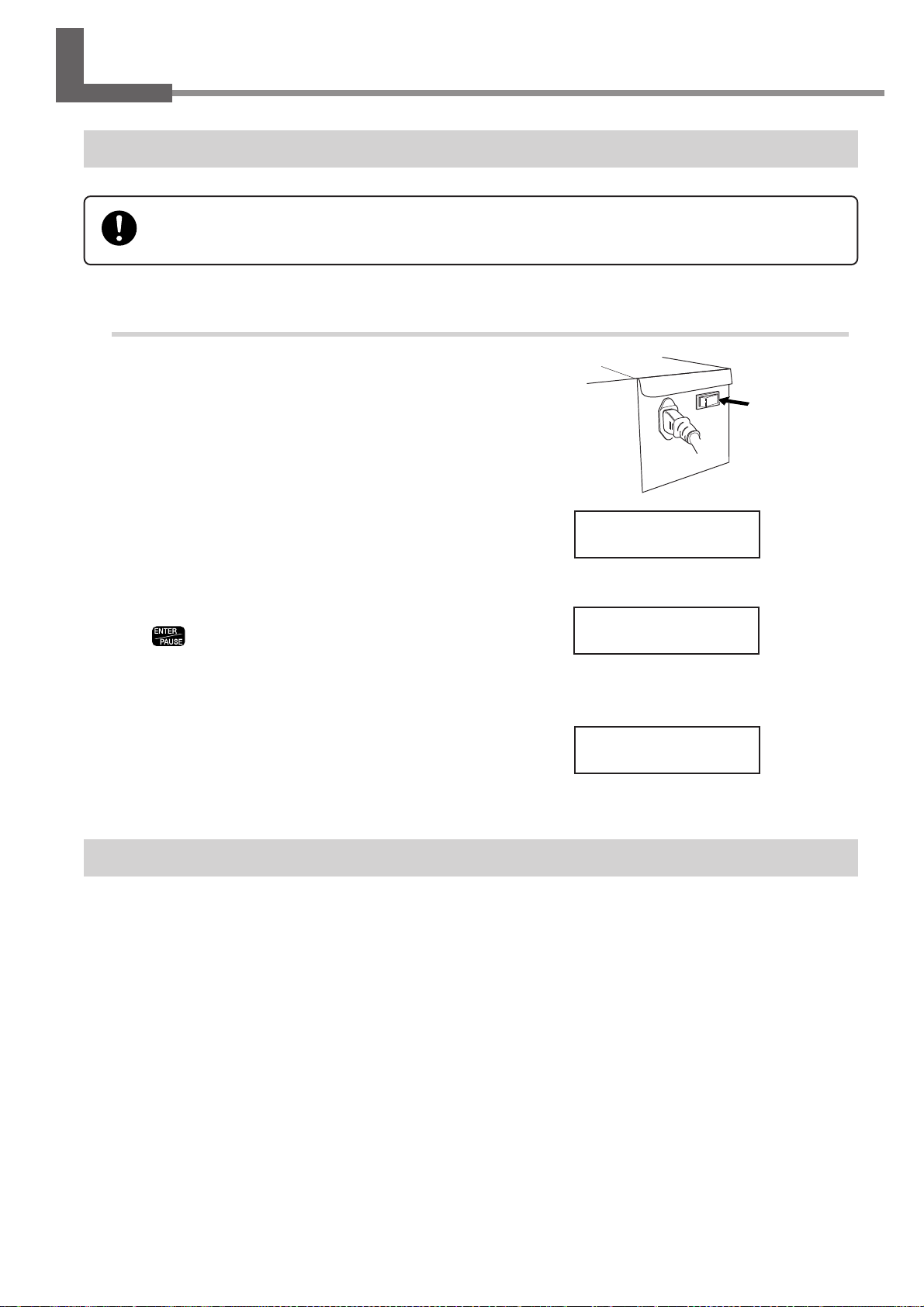

Holding down for 0.5 seconds or longer makes the spindle rotate. Pressing it again stops rotation.

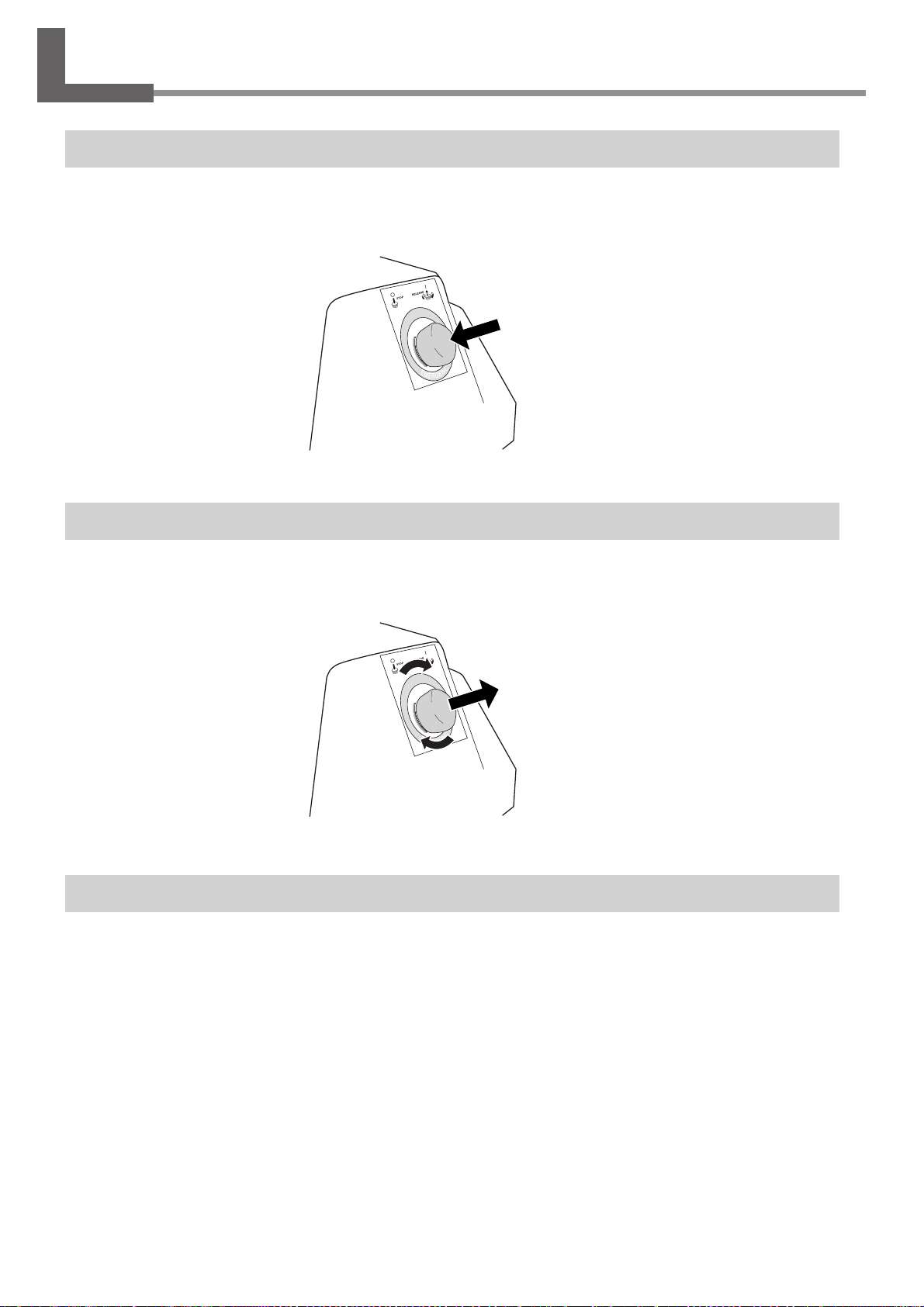

Adjusting the Spindle Rotating Speed

T o adjust the spindle rotating speed, you use the dial on the operation panel. The top screen displays the spindle rotating

speed.

Slow

Spindle rotating speed

Fast

28

Chapter 2 - Basic Operation

Page 33

2-4. Starting and Stopping Spindle Rotation

Forced Stop of Spindle Rotation

With this machine, you can set whether or not the spindle rotates. When it is set to rotate, rotation automatically starts

when a command is received from the computer and stops when cutting ends. When set not to rotate, no rotation at all

takes place. (Rotation does not occur even if you press .)

You use this feature at times such as when you are performing scribing using a diamond scraper.

Making the Setting for Spindle Rotation

Press until the screen shown at right

1

appears.

Press .

2

The blinking cursor moves to [OTHERS].

Press .

3

The screen for setting spindle rotation appears.

Use to move the blinking cursor to

4

[ON] or [OFF]. Press .

[ON] makes the setting for rotation, and [OFF] makes

the setting for forced stop.

I/O OTHERS

TEACHING SELF

I/O OTHERS

TEACHING SELF

REVOLUTION

<ON> OFF

Chapter 2 - Basic Operation

29

Page 34

2-5. Menu Operations

For detailed information on using the menus

☞ See p.104 "Menu Flowchart"

☞ See p.108 "Detailed Description of the Menus"

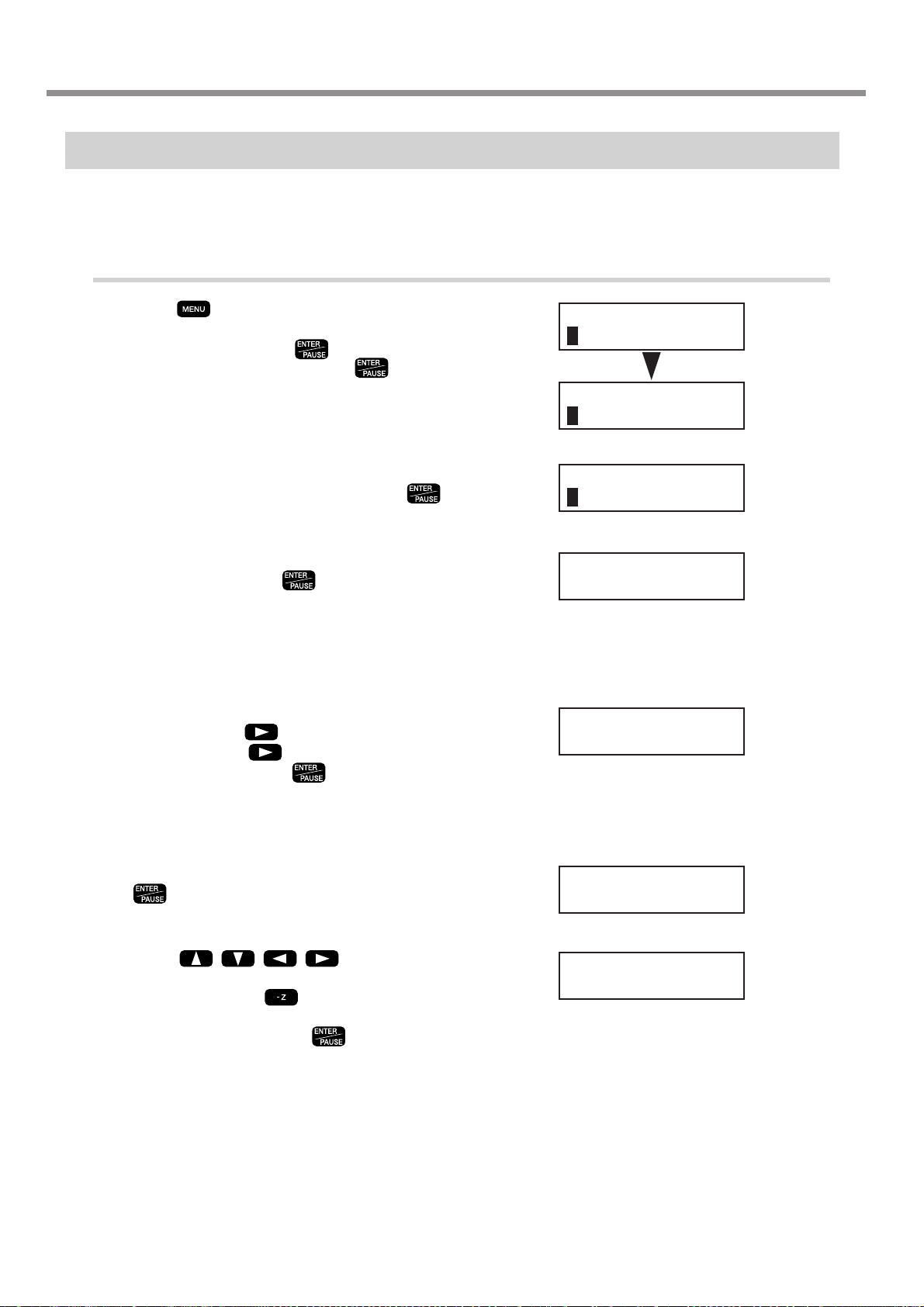

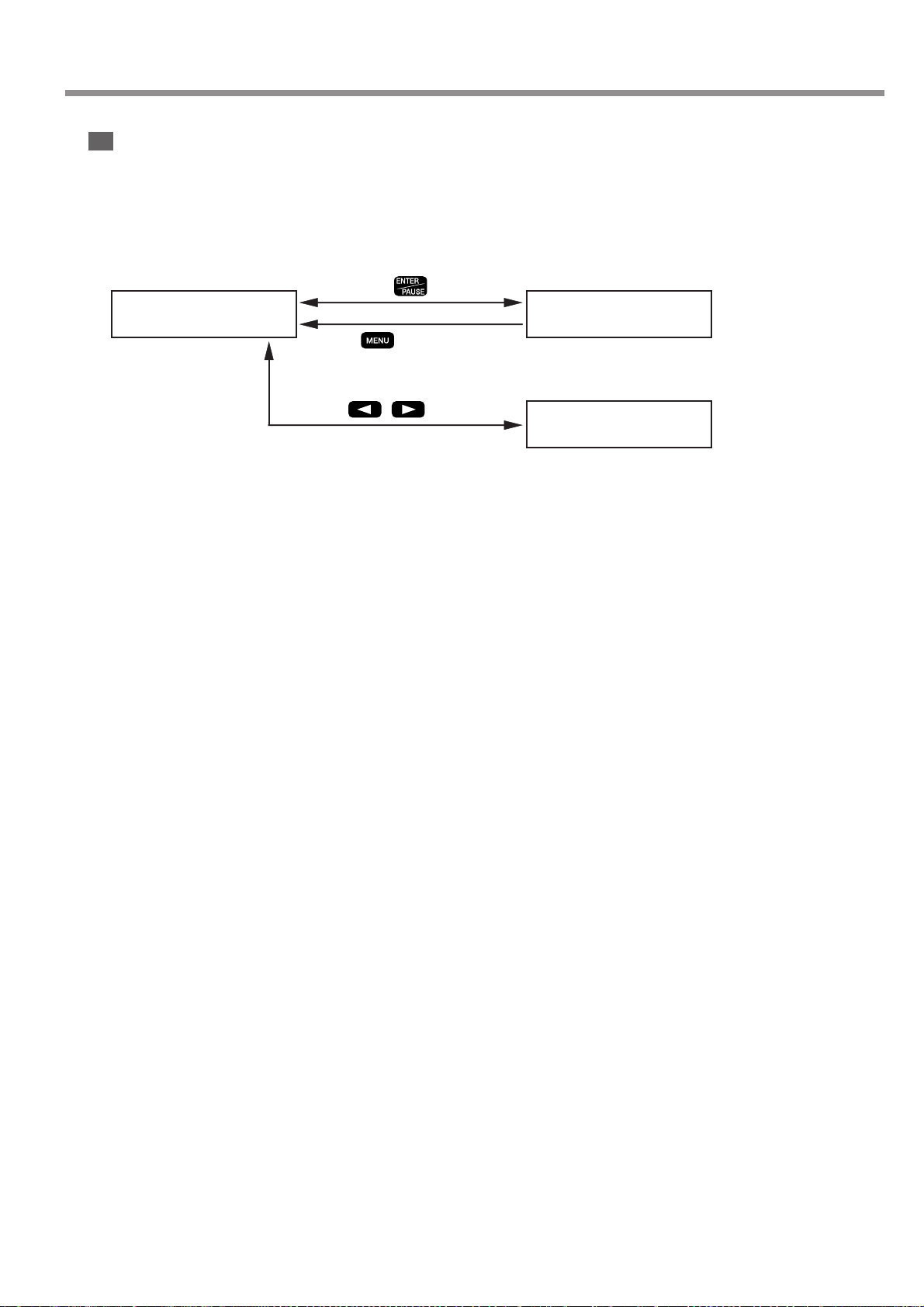

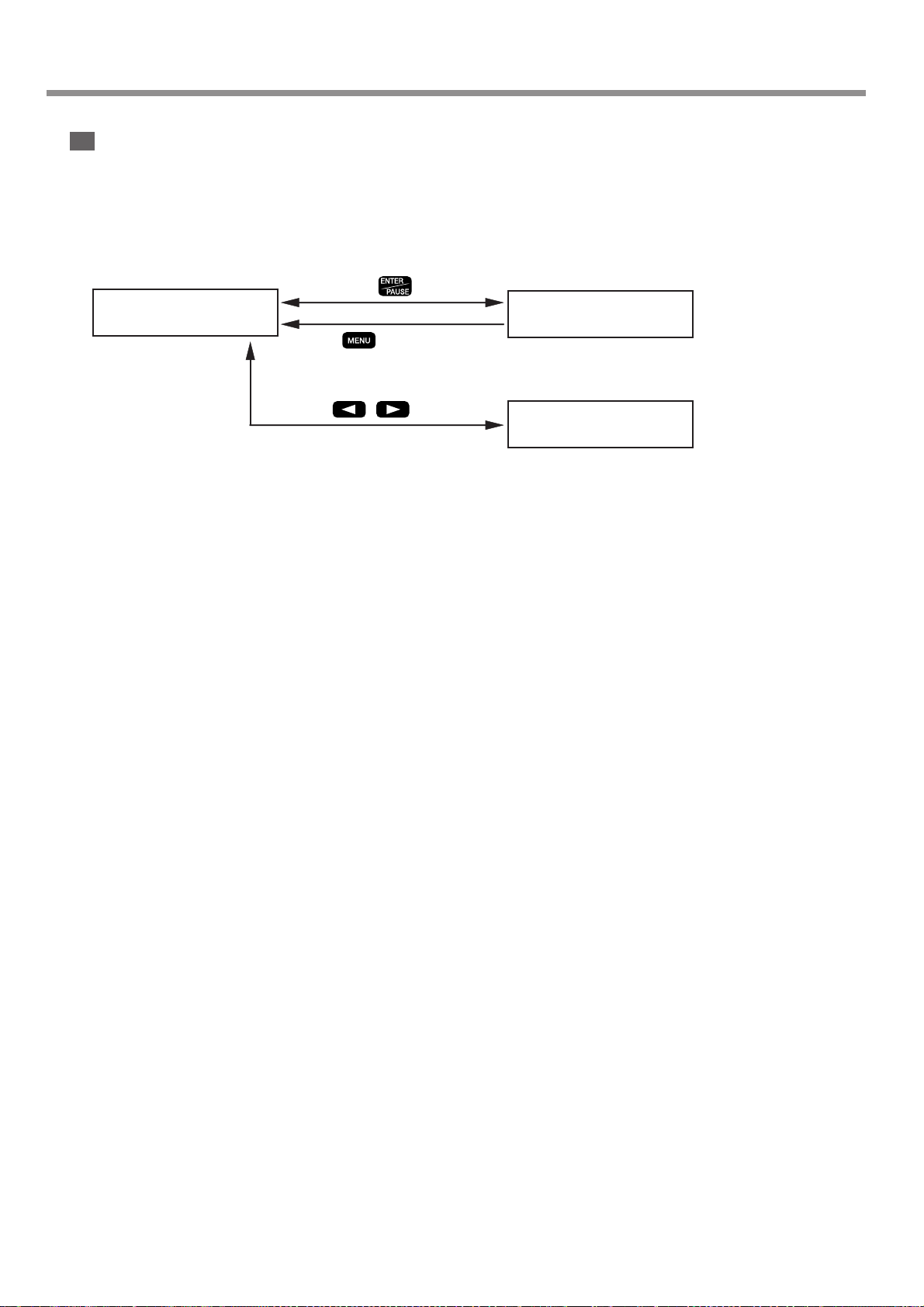

Displaying the Menus

All settings for this machine are made using menus. Pressing the following buttons displays the menu screens.

Main menu

Pause menu (when pressed during cutting)

Copy menu

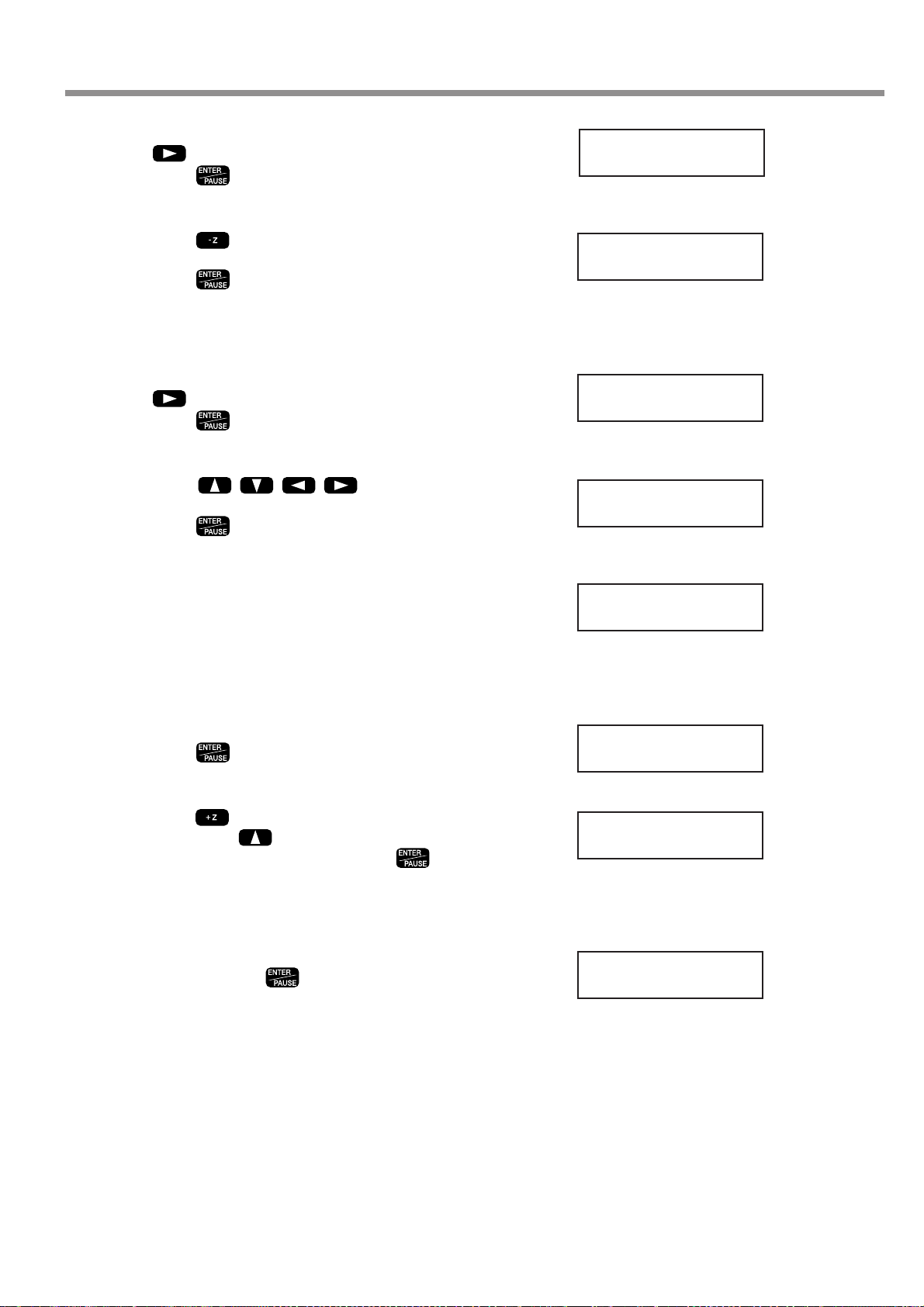

Basic Menu Operations

X/Y-axis origin-point setting menu

Z-axis origin-point setting menu

When you display the menus, the buttons function as follows.

Moving to the next screen

Pressing this several times eventually returns you to the top screen.

Moving the blinking cursor

You use the blinking cursor to select items. In the example at right,

for instance, you can select either [ON] or [OFF].

Raising and lowering numerical values

Pressing either of these buttons while holding down increases or decreases the value by large amounts. Holding down the button makes the value change rapidly.

Confirming and executing the selected item

Operations with do not enable settings, they only select the setting values. A setting is

enabled only when you press . When you enable a setting, the item is displayed enclosed in "< >." You also use

this button to execute things and display submenus.

REVOLUTION

<ON> OFF

30

Chapter 2 - Basic Operation

Page 35

2-6. Care and Handling of Memory Cards

This machine does not detect the write-protect

switch on an SD Memory Card, even when the

switch is set to "LOCK."

Windows must be able to treat the memory card as a single volume. Nearly all memory-card writers that are compatible with

Windows meet this requirement.

This section describes the basic usage and handling of memory cards.

This machine can execute cutting data saved on a memory card, and can save sequences created using the teaching

feature. For more information about these operations, see "Executing Cutting Data Saved on a Memory Card" on p.65

and "The Teaching Feature" on p.71.

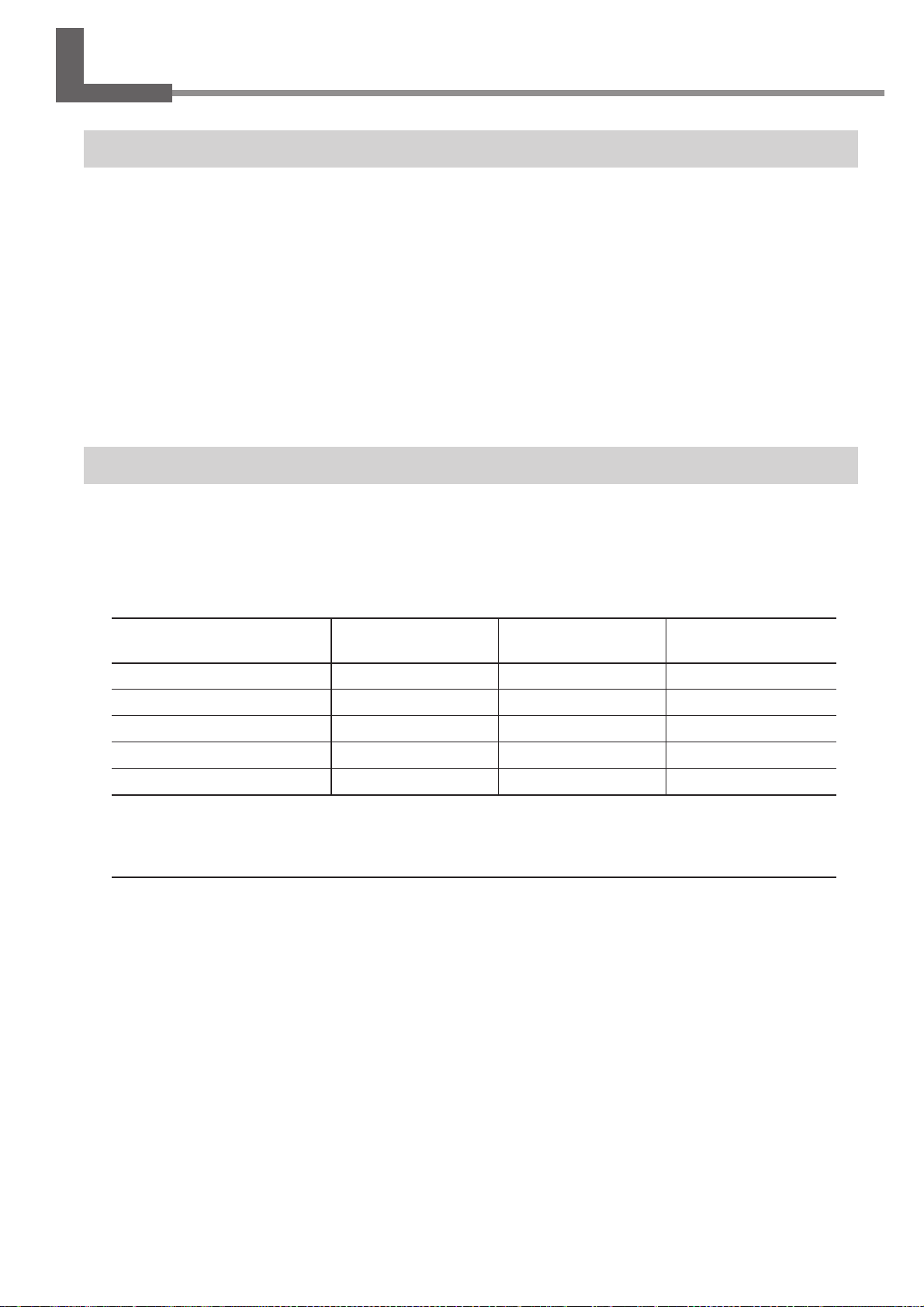

Types of Memory Cards You Can Use

Use commercially available "SD (Secure Digital) Memory Card" or "MultiMediaCard", which are available in sizes of

16 MB, 32 MB, and 64 MB. Note that copyright-protection functions are not used with this machine.

Roland DG Corp. has verified the operation of the following memory cards.

Manufacturer Part number Capacity

SanDisk SDMB-16 16 MB

SDMB-32 32 MB

SDMB-64 64 MB

Panasonic RP-SD016 16 MB

RP-SD032 32 MB

RP-SD064 64 MB

HAGIWARA SYS-COM HPC-MC32M 32 MB

HPC-MC64M 64 MB

Memory-card Writers You Can Use

To save cutting data on a memory card or to format a memory card, you use a commercially available memory-card

writer or adapter. One that meets the following specifications is required.

• Compatible with "SD Memory Card" or "MultiMediaCard" you're using

• Able to be connected to your computer running Windows

• Able to read and write files compatible with Windows

Roland DG Corp. has verified the operation of the following memory-card writers.

Manufacturer Part number Operating environment

VICS Technology RD5 Windows 98/Me/2000/XP

Chapter 2 - Basic Operation

31

Page 36

2-6. Care and Handling of Memory Cards

◆ Be careful to orient the memory card correctly when inserting it. An incorrectly inserted card will not function and may

even cause breakdown.

◆ Before you insert a memory card, carefully clean away any cutting waste from the memory card and the area around the

memory-card slot.

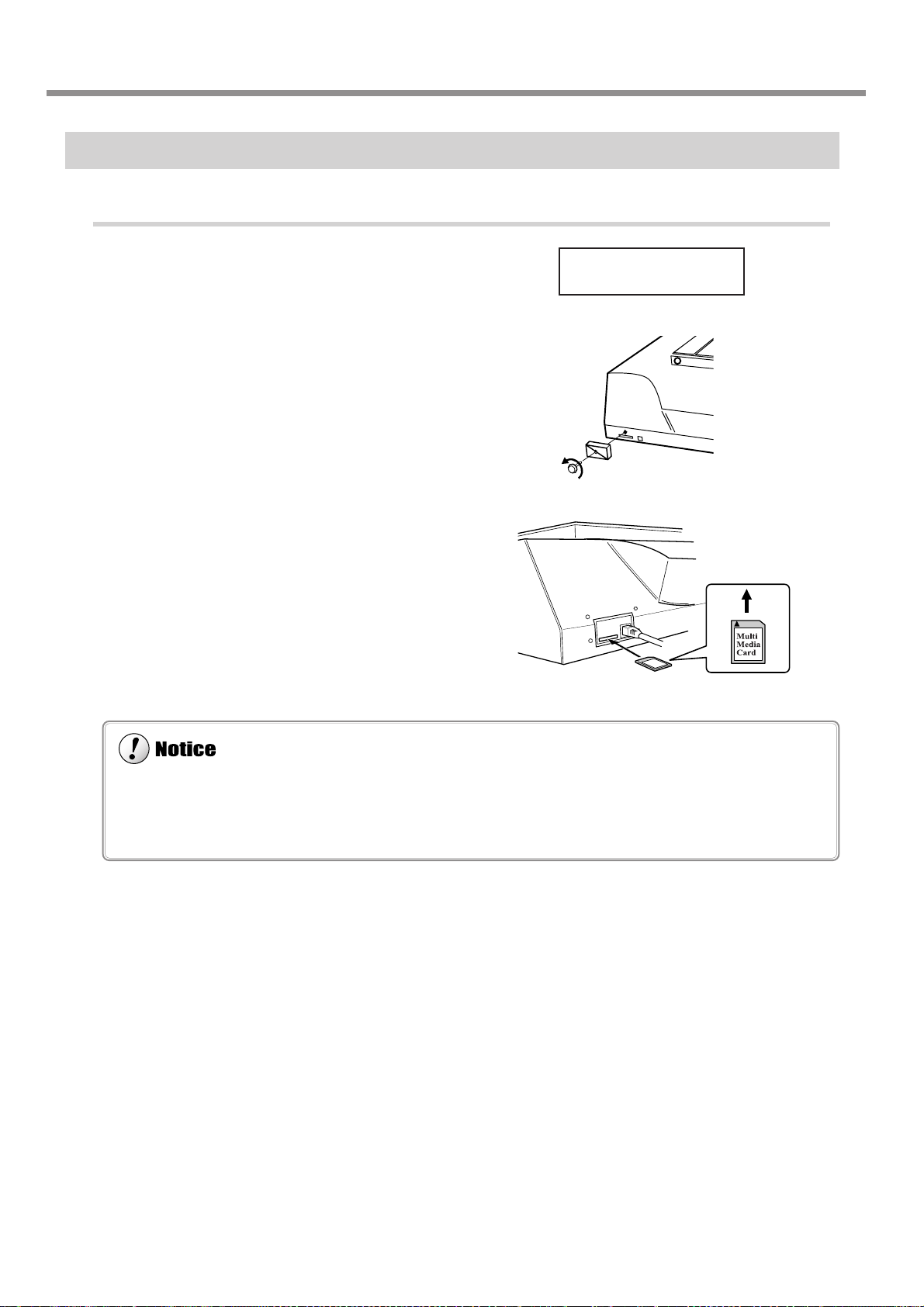

Inserting and Removing a Memory Card

Inserting a Memory Card

Make sure the display shows the top screen.

1

Remove the slot cover.

2

Hold the card with the label side facing up and

3

the notch on the right, and insert it into the

memory-card slot. Press it in gently until it clicks

into place.

Attach the slot cover.

4

X 0 Y 40700

Z 0 8000RPM

32

Chapter 2 - Basic Operation

Page 37

Removing a Memory Card

Do not switch off the power while a memory card is being accessed.

Do not switch off the machine while the display shows a message such as [Now Processing]. Doing so may result in data

corruption or malfunction.

Do not insert or remove a memory card in any of the following circumstances.

◆ After you turn on the machine and before the top screen appears

◆ While the memory card is being accessed (When the display shows a message such as [Now Processing])

◆ While a screen for dating or calling up data is displayed (When the display shows a message such as [Select File])

Doing so may result in data corruption, failure to display the correct file names, or malfunction.

2-6. Care and Handling of Memory Cards

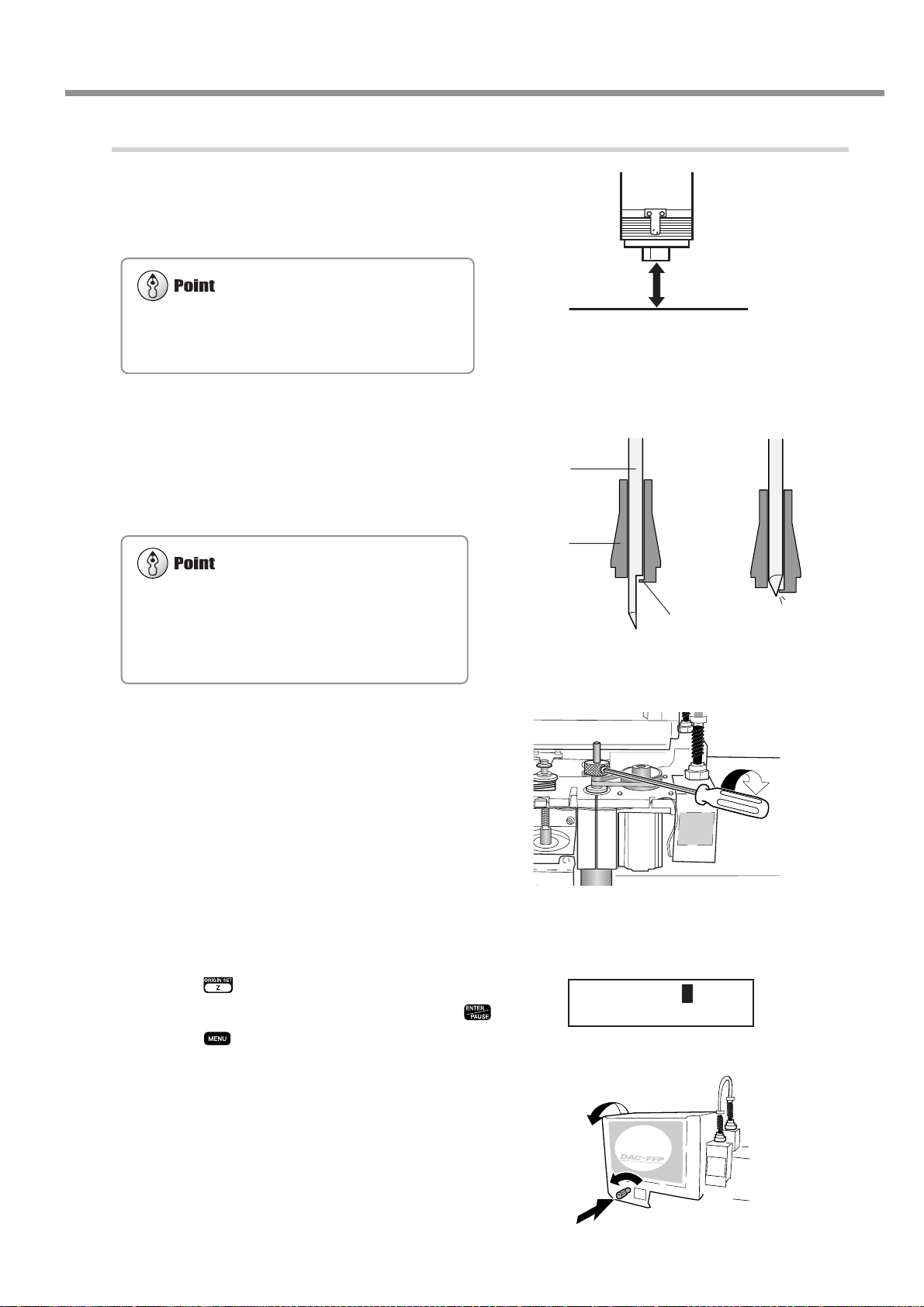

Make sure the display shows the top screen.

1

Remove the slot cover.

2

Gently press the card in until it clicks into place,

3

then pull it out from the memory-card slot.

Attach the slot cover.

4

X 0 Y 40700

Z 0 8000RPM

1. 2.

Chapter 2 - Basic Operation

33

Page 38

2-6. Care and Handling of Memory Cards

Formatting deletes all data saved on the memory card. Before you format the card, make sure that it contains no data you want

to keep.

Formatting a Memory Card

Formatting a memory card is normally not necessary. However, the machine may be unable to use a memory card that

has been reformatted for use with another device, such as a digital camera. In such cases, use the following method to

reformat the card again.

Performing Formatting

To perform formatting, you use a memory-card writer. For information on the specific method, refer to the documentation for the memory-card writer you're using. Also, give attention to the following points when formatting.

For a MultiMediaCard

Use the standard formatter for Windows. (That is, use the same operation as for formatting a floppy disk.) Depending on

the version of Windows you're using, you may be able to choose the file system to use for formatting. In such cases, be

sure to select FAT. Do not format as FAT32 or NTFS.

For an SD (Secure Digital) Memory Card

Perform formatting using the same method as for a MultiMediaCard. If a dedicated SD formatter is available, then use

that.

34

Chapter 2 - Basic Operation

Page 39

3. Preparations

This chapter describes how to install a cutter , how to load a workpiece,

and other preparations you make before you carry out cutting.

35

Page 40

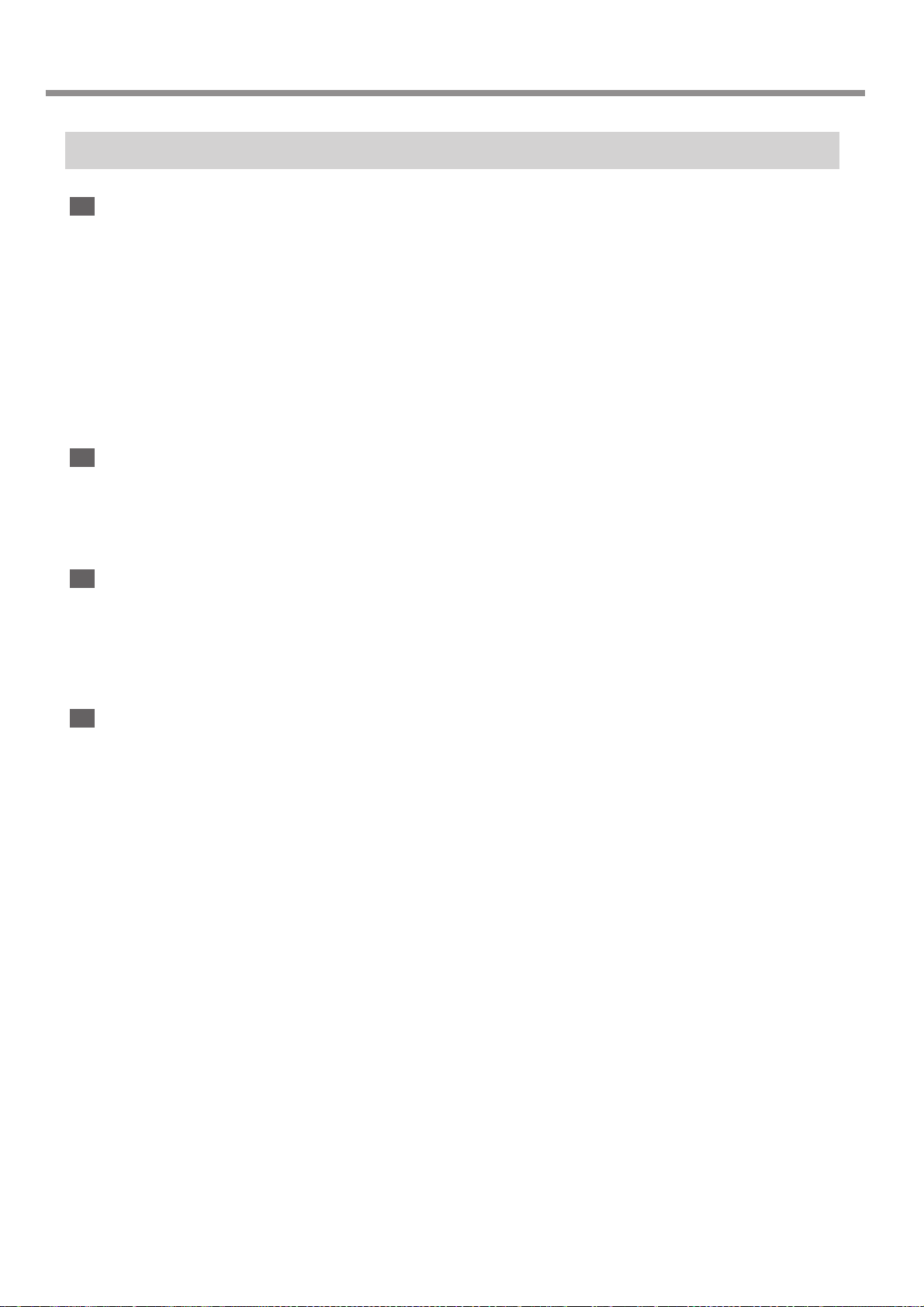

3-1. Selecting the Cutter Installation Method

Cutter Types and What They Are Suited For

You can install any of a wide variety of tools on this machine. You can also choose whether to use the depth regulator

nose unit (nose unit). Choose a tool suited to the task at hand, and decide whether to use the nose unit.

Tool

Character cutter

Flat cutter

Diamond scraper (*2)

With nose unit

◆ Engraving acrylic and other (*1)

plastic plates

☞ p.37 "Cutter Installation Method 1"

◆ Unsuitable

No nose unit

◆ Engraving plates of aluminum or brass

◆ Three-dimensional engraving and creating

reliefs using plastic materials

☞ p.42 "Cutter Installation Method 2"

◆ Scribing plates of aluminum or brass (*2)

☞ p.46 "Cutter Installation Method 3"

End mill (*3)

*1 Use of the nose unit may not be suitable when performing raised engraving of text or flat-drag cutting over a large surface area.

In such cases, use without the nose unit.

*2 This is suited to relatively small text and can produce finished results that are more attractive and have less burring than

engraving with a character cutter. An optionally available solid collet for diamond scrapers is required to install a diamond

scraper.

*3 An optionally available collet set for end mills is required to install an end mill.

◆ Unsuitable

◆ Creating reliefs and performing 3D cutting

using plastic materials

☞ p.51 "Cutter Installation Method 4"

36

Chapter 3 - Preparations

Page 41

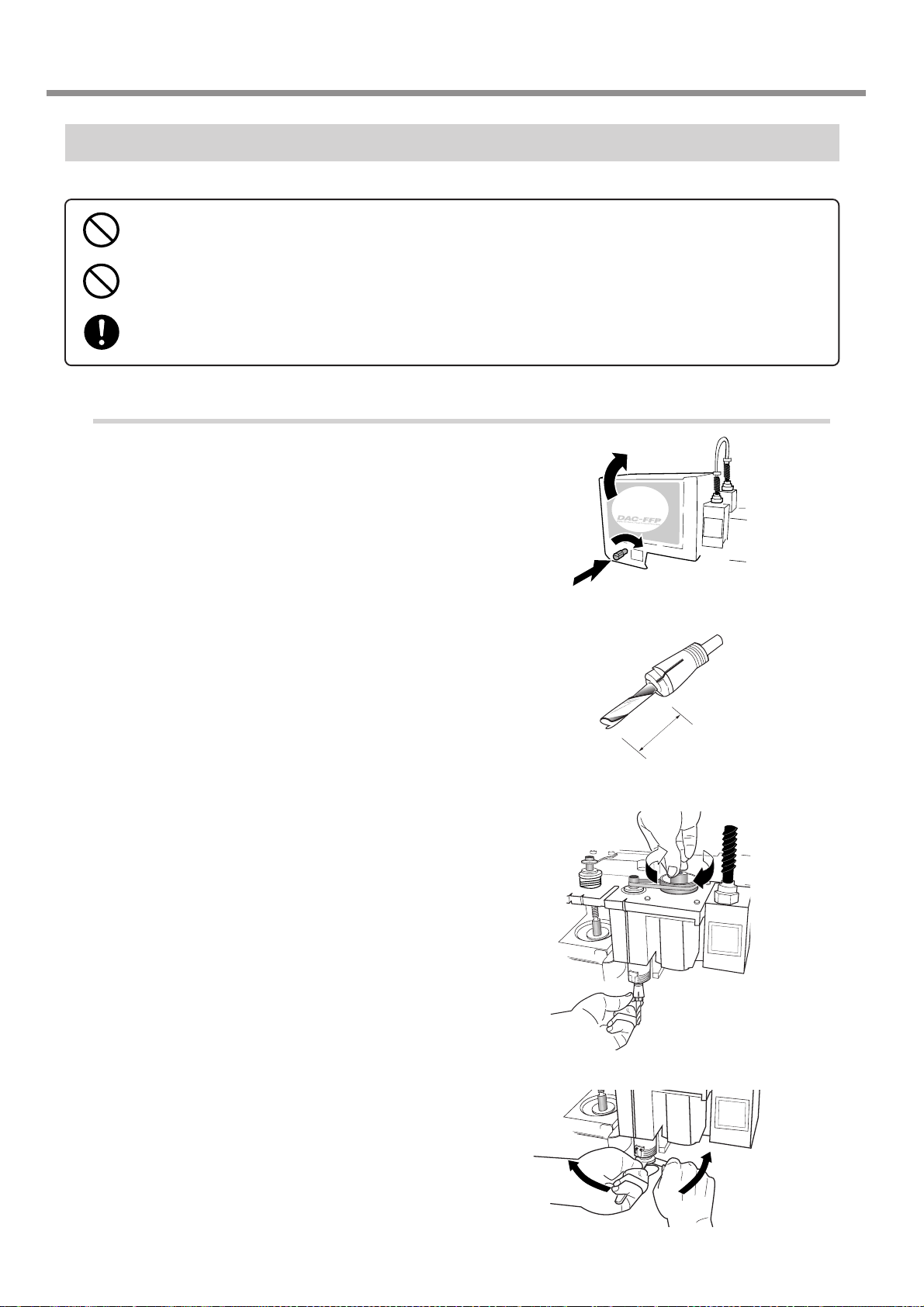

Lock nut : Loosen

[AUTO Z CONTROL] : ON

[REVOLUTION] : ON

3-2. Cutter Installation Method 1 (With Nose Unit)

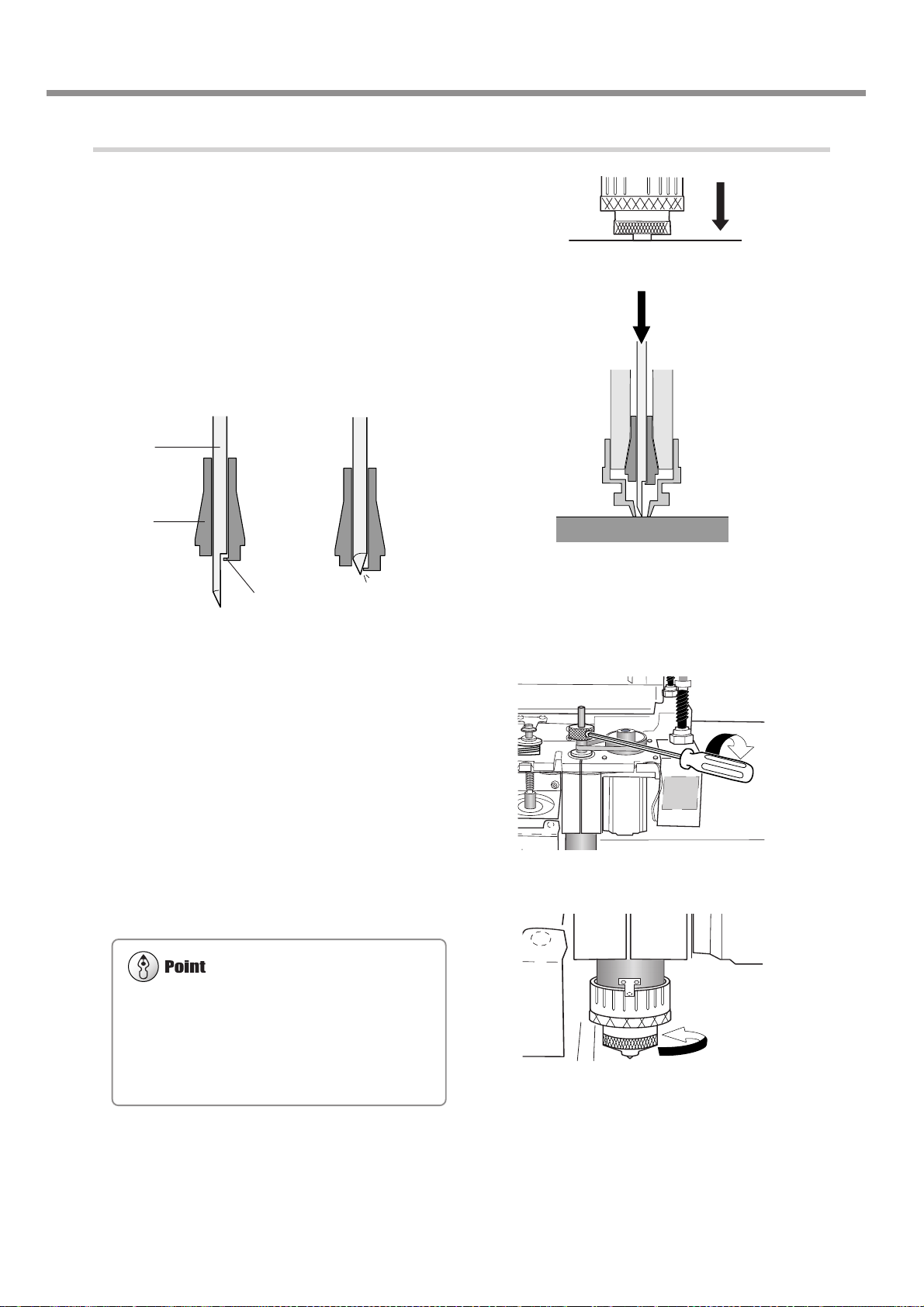

This is for when you perform engraving using the nose unit on an acrylic plate or the like. The tip of the nose traces the

material surface, which facilitates obtaining a uniform cutting-in depth. The tool used is a character cutter or a flat cutter .

This method is not suitable for aluminum, brass, or other materials that are easily scratched.

Character cutter or flat cutter

Lock nut

Cutter holder