Page 1

8239 Token-Ring Stackable Hub ÉÂÔ

Setup and User’s Guide

GA27-4209-00

Page 2

Page 3

8239 Token-Ring Stackable Hub ÉÂÔ

Setup and User’s Guide

GA27-4209-00

Page 4

Note

Before using this document, read the general information under “Notices” on page ix.

First Edition (June 1998)

This edition applies to the 8239 Token-Ring Stackable Hub and to all subsequent releases and modifications until otherwise indicated

in new editions or technical newsletters.

Order publications through your IBM representative or the IBM branch office serving your locality. Publications are not stocked at the

address below.

IBM welcomes your comments. A form for readers' comments is provided at the back of this publication. If the form has been

removed, you may address your comments to:

International Business Machines Corporation

Design and Information Development

Department CGF

P.O. Box 12195

Research Triangle Park, NC 27709-9990

U.S.A.

When you send information to IBM, you grant IBM a nonexclusive right to use or distribute the information in any way it believes

appropriate without incurring any obligation to you.

Copyright International Business Machines Corporation 1998. All rights reserved.

Note to U.S. Government Users — Documentation related to restricted rights — Use, duplication or disclosure is subject to

restrictions set forth in GSA ADP Schedule Contract with IBM Corp.

Page 5

Contents

Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Safety Information Booklet .............................. ix

Power Disconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Electronic Emission Notices .............................. xiv

Federal Communications Commission (FCC) Statement ........... xiv

Industry Canada Class A Emission Compliance Statement .......... xv

Avis de conformité aux normes d'Industrie Canada .............. xv

European Community (CE) Mark of Conformity Statement .......... xv

Japanese Voluntary Control Council for Interference (VCCI) Statement ... xvi

Taiwanese Class A Warning Statement ..................... xvi

Battery Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

How This Manual Is Organized ............................ xvii

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Visit our Web Site .................................. xviii

Chapter 1. Introduction and Planning ...................... 1-1

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Concentrator Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Device and Network Management .......................... 1-3

Cable Types and Distances .............................. 1-4

Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Stack Unit Cabling ................................. 1-4

RI/RO Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Service Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Chapter 2. Installing the 8239 Hardware ..................... 2-1

Preparing for Setup .................................. 2-1

Verifying the Shipment ................................. 2-1

Installing Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Placing the 8239 .................................... 2-2

Surface-Mounting the 8239 ............................ 2-2

Rack-Mounting the 8239 .............................. 2-2

Connecting the Cables ................................. 2-4

Connecting Stations to the 8239 ......................... 2-4

Cabling a Stack ................................... 2-5

Connecting an ASCII Terminal or Modem to the EIA-232 Port ........ 2-5

Powering On the 8239 ................................. 2-6

Copyright IBM Corp. 1998 iii

Page 6

Chapter 3. Installing Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

16-Port Expansion Feature .............................. 3-1

Removing a 16-Port Expansion Feature ..................... 3-1

Installing a 16-Port Expansion Feature ...................... 3-1

RI/RO Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Removing a RI/RO Module ............................ 3-2

Installing a RI/RO Module ............................. 3-3

Chapter 4. Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Using the Command Interface ............................ 4-1

Login Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Management Using Emulation Software ..................... 4-1

Management Using Telnet ............................. 4-2

Command Interface Conventions ......................... 4-2

Verifying, Saving, and Restoring Parameters .................. 4-4

Configuring the 8239 .................................. 4-4

Configuring the 8239 for Out-of-Band Connectivity ............... 4-5

Configuring the 8239 for In-Band Connectivity ................. 4-5

Configuring for Network Monitoring ........................ 4-7

Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Chapter 5. Problem Determination Procedures ................ 5-1

Using the LEDs to Diagnose Problems ....................... 5-1

Power Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Box Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Ring Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Port Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

RI/RO Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Stack In/Stack Out Status ............................. 5-7

LCD and LED Codes ................................ 5-14

POST Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14

Operational Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15

Chapter 6. Concentrator Functions . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Port Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Port Configuration Options ............................. 6-1

Inserting/Deinserting a Station ........................... 6-3

Port Operational Status and Port LEDs ..................... 6-4

Address-to-Port Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Fanout Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

MAC-less Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Accessing the Address-to-Port Mapping Information .............. 6-6

Port Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Identifying which MAC Addresses are Authorized ............... 6-7

Configuring the Action on Intrusion ........................ 6-8

Enabling Port Security ............................... 6-8

Ring In/Ring Out Concepts (8239 Model 1 only) .................. 6-8

RI/RO Configuration Options ........................... 6-9

Unwrapping the RI/RO onto the Stack Data Ring ............... 6-10

RI/RO Operational Status and RI/RO LEDs .................. 6-10

Stack Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

SI/SO Configuration Options ........................... 6-11

SI/SO LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Beacon Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12

iv 8239 Setup and User’s Guide

Page 7

Data In/Data Out Connection .......................... 6-12

Port Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Management Interface (8239 Model 1 only) .................. 6-13

Ring In/Ring Out Connection (8239 Model 1 only) .............. 6-14

Within the 8239 .................................. 6-14

Chapter 7. 8239 Device Management ...................... 7-1

Connectivity Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Out-of-Band Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

In-Band Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Access Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Scripts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Creating Scripts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Editing Scripts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Running Scripts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Trap Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Methods of Viewing Traps ............................ 7-11

Configuring for Trap Generation and Accessing Trap Information ..... 7-12

MAC Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Chapter 8. Network Management . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Accessing Network Management Data ....................... 8-1

IEEE 802.5 Token Ring MIB (RFC 1748) ...................... 8-2

Configuring the 8239 Model 1 to Support the 802.5 MIB ........... 8-2

Accessing 802.5 Information ............................ 8-2

MIB-II (RFC 1213) ................................... 8-4

Configuring the 8239 Model 1 to Support MIB-II ................ 8-4

Accessing MIB II Information ........................... 8-4

Remote Monitoring: RMON, RMON 2, ECAM ................... 8-5

RMON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

RMON 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

ECAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

IBM Token-Ring Surrogate MIB and Surrogate Trap MIB ............ 8-11

Surrogate Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Configuration Report Server (CRS) ....................... 8-13

Ring Error Monitor (REM) ............................ 8-13

Ring Parameter Server (RPS) .......................... 8-16

Chapter 9. Planning Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

8239 Cabling Chart ................................... 9-1

Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Ring Connection for Optional RI/RO Module .................. 9-1

Token-Ring Port Connections ........................... 9-1

Additional Ports with Optional 16-Port Expansion Feature ........... 9-1

8239 SNMP Agent Configuration Parameters Worksheet ............. 9-2

Appendix A. Warranty Information . . . . . . . . . . . . . . . . . . . . . . . A-1

Customer Carry-In Exchange via Mail-In ..................... A-1

Statement of Limited Warranty ........................... A-2

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-5

Contents v

Page 8

vi 8239 Setup and User’s Guide

Page 9

Figures

1-1. 8239 Model 1 ................................. 1-1

1-2. 8239 Model 2 ................................. 1-2

1-3. 8239 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2-1. Rotating the Rack-Mounting Brackets ................... 2-3

2-2. Attaching the Cable Management Bracket ................ 2-4

2-3. Connecting Stations to the 8239 ...................... 2-4

2-4. Stack Building . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2-5. Power on the 8239 ............................. 2-7

3-1. 16-Port Expansion Feature ......................... 3-1

3-2. RI/RO Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-3. Cabling for the Optical Fiber RI/RO Module ............... 3-3

3-4. Cabling for the RJ-45 RI/RO Module ................... 3-4

5-1. 8239 Model 1 LEDs and LCD ....................... 5-1

5-2. 8239 Model 2 LEDs ............................. 5-2

5-3. Port Status LEDs .............................. 5-3

5-4. RI/RO LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5-5. Stack In/Stack Out LEDs .......................... 5-8

Copyright IBM Corp. 1998 vii

Page 10

viii 8239 Setup and User’s Guide

Page 11

Notices

References in this publication to IBM products, programs, or services do not imply

that IBM intends to make these available in all countries in which IBM operates.

Any reference to an IBM product, program, or service is not intended to state or

imply that only IBM’s product, program, or service may be used. Any functionally

equivalent product, program, or service that does not infringe any of IBM’s

intellectual property rights may be used instead of the IBM product, program, or

service. Evaluation and verification of operation in conjunction with other products,

except those expressly designated by IBM, are the user’s responsibility.

IBM may have patents or pending patent applications covering subject matter in

this document. The furnishing of this document does not give you any license to

these patents. You can send license inquiries, in writing, to the IBM Director of

Licensing, IBM Corporation, 500 Columbus Avenue, Thornwood, NY 10594 USA.

Safety Information

Read this important safety information before using the 8239.

Safety Information Booklet

Danger: Before you begin to install this product, read the safety information

in

Caution: Safety Information—Read This First

safe procedures for cabling and plugging in electrical equipment.

Gevaar: Voordat u begint met de installatie van dit produkt, moet u eerst de

veiligheidsinstructies lezen in de brochure

eerst,

SD21-0030. Hierin wordt beschreven hoe u electrische apparatuur op een

veilige manier moet bekabelen en aansluiten.

Danger: Avant de procéder à l'installation de ce produit, lisez d'abord les

consignes de sécurité dans la brochure

lire au préalable,

connecter les appareils électriques en toute sécurité.

Perigo: Antes de começar a instalar este produto, leia as informações de

segurança contidas em

Primeiro,

instalação de cabos e conexões em equipamentos elétricos.

SD21-0030. Esse folheto descreve procedimentos de segurança para a

, SD21-0030. This booklet describes

PAS OP! Veiligheidsinstructies—Lees dit

ATTENTION: Consignes de sécurité—A

SD21-0030. Cette brochure décrit les procédures pour câbler et

Cuidado: Informações Sobre Segurança—Leia Isto

Copyright IBM Corp. 1998 ix

Page 12

Fare! Før du installerer dette produkt, skal du læse sikkerhedsforskrifterne i

NB: Sikkerhedsforskrifter—Læs dette først

SD21-0030. Vejledningen beskriver den

fremgangsmåde, du skal bruge ved tilslutning af kabler og udstyr.

Gevaar Voordat u begint met het installeren van dit produkt, dient u eerst de

veiligheidsrichtlijnen te lezen die zijn vermeld in de publikatie

Information - Read This First

, SD21-0030. In dit boekje vindt u veilige procedures

Caution: Safety

voor het aansluiten van elektrische appratuur.

VAARA: Ennen kuin aloitat tämän tuotteen asennuksen, lue julkaisussa

Varoitus: Turvaohjeet—Lue tämä ensin

, SD21-0030, olevat turvaohjeet. Tässä

kirjasessa on ohjeet siitä, miten sähkölaitteet kaapeloidaan ja kytketään turvallisesti.

Danger : Avant d'installer le présent produit, consultez le livret

Informations pour la sécurité — Lisez-moi d'abord

, SD21-0030, qui décrit les

Attention :

procédures à respecter pour effectuer les opérations de câblage et brancher les

équipements électriques en toute sécurité.

Vorsicht: Bevor mit der Installation des Produktes begonnen wird, die

Sicherheitshinweise in

Achtung: Sicherheitsinformationen—Bitte zuerst lesen,

IBM

Form SD21-0030. Diese Veröffentlichung beschreibt die Sicherheitsvorkehrungen

für das Verkabeln und Anschließen elektrischer Geräte.

x 8239 Setup and User’s Guide

Page 13

Vigyázat: Mielôtt megkezdi a berendezés üzembe helyezését, olvassa el a

Caution: Safety Information— Read This First,

biztonsági információkat. Ez a könyv leírja, milyen biztonsági intézkedéseket kell

megtenni az elektromos berendezés huzalozásakor illetve csatlakoztatásakor.

Pericolo: prima di iniziare l'installazione di questo prodotto, leggere le

informazioni relative alla sicurezza riportate nell'opuscolo

di sicurezza — Prime informazioni da leggere

il cablaggio ed il collegamento di apparecchiature elettriche.

SD21-0030 könyvecskében leírt

Attenzione: Informazioni

in cui sono descritte le procedure per

Fare: Før du begynner å installere dette produktet, må du lese

sikkerhetsinformasjonen i

SD21-0030 som beskriver sikkerhetsrutinene for kabling og tilkobling av elektrisk

utstyr.

Notices xi

Advarsel: Sikkerhetsinformasjon — Les dette først

,

Page 14

Perigo: Antes de iniciar a instalação deste produto, leia as informações de

segurança

Cuidado: Informações de Segurança — Leia Primeiro

, SD21-0030. Este

documento descreve como efectuar, de um modo seguro, as ligações eléctricas

dos equipamentos.

Peligro: Antes de empezar a instalar este producto, lea la información de

seguridad en

Atención: Información de Seguridad — Lea Esto Primero,

SD21-0030.

Este documento describe los procedimientos de seguridad para cablear y enchufar

equipos eléctricos.

Varning — livsfara: Innan du börjar installera den här produkten bör du läsa

säkerhetsinformationen i dokumentet

först,

SD21-0030. Där beskrivs hur du på ett säkert sätt ansluter elektrisk

Varning: Säkerhetsföreskrifter— Läs detta

utrustning.

xii 8239 Setup and User’s Guide

Page 15

Power Disconnection

Danger: The main power disconnect for this unit is the appliance inlet

located on the back of the machine. Therefore, the machine should be installed in

such a way that the appliance inlet can be accessed.

DANGER. Le dispositif permettant de couper l'alimentation principale de

cette unité se situe à l'arrière de la machine. Ce dispositif doit donc être accessible.

Vorsicht: Der Hauptschalter zur Unterbrechung der Stromversorgung für

diese Einheit ist der Schalter, der sich auf der Rückseite der Maschine befindet. Die

Maschine sollte daher so aufgestellt werden, daß dieser Schalter jederzeit

zugänglich ist.

Pericolo: Per scollegare questa unità, occorre staccare la spina posta sul

retro della macchina; pertanto la macchina deve essere installata in modo tale che

tale spina sia accessibile.

Fare: Denne enheten frakobles hovednettet via apparatinntaket på baksiden

av maskinen. Derfor må maskinen installeres slik at apparatinntaket er lett

tilgjengelig.

Notices xiii

Page 16

Perigo: Para desligar a alimentação principal desta unidade é necessário

desconectar o cabo da tomada eléctrica localizada na parte posterior da máquina.

Por consequência, a máquina deve ser instalada de modo a permitir o fácil acesso

a essa tomada.

ОПАСНО: Разъем для отключения питания данного блока

расположен на задней стенке. Поэтому устанавливайте

машину так, чтобы разъем питания был доступен.

Peligro: El interruptor principal de desconexión de esta unidad es la entrada

de conexión del aparato situado en la parte trasera de la máquina. Por lo tanto, la

máquina debe instalarse de modo que la entrada de conexión del aparato sea

accesible.

FARA: Brytning av huvudströmmen till den här enheten görs vid

elanslutningen på baksidan av maskinen. Placera därför maskinen så att

elanslutningen är lättåtkomlig.

Electronic Emission Notices

Federal Communications Commission (FCC) Statement

Note:This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause

harmful interference, in which case the user will be required to correct the

interference at his own expense.

Properly shielded and grounded cables and connectors must be used in order to

meet FCC emission limits. IBM is not responsible for any radio or television

interference caused by using other than recommended cables and connectors or by

unauthorized changes or modifications to this equipment. Unauthorized changes or

modifications could void the user’s authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1)this device may not cause harmful interference, and

(2)this device must accept any interference received, including interference that

may cause undesired operation.

xiv 8239 Setup and User’s Guide

Page 17

Industry Canada Class A Emission Compliance Statement

This Class A digital apparatus complies with Canadian ICES-003.

Avis de conformité aux normes d'Industrie Canada

Cet appareil numérique de la classe A est conform à la norme NBM-003 du

Canada.

European Community (CE) Mark of Conformity Statement

This product is in conformity with the protection requirements of EU Council

Directive 89/336/EEC on the approximation of the laws of the Member States

relating to electromagnetic compatibility. IBM cannot accept responsibility for any

failure to satisfy the protection requirements resulting from a non-recommended

modification of the product, including the fitting of non-IBM option cards. This

product has been tested and found to comply with the limits for Class A Information

Technology Equipment according to CISPR 22/European Standard EN 55022. The

limits for Class A equipment were derived for commercial and industrial

environments to provide reasonable protection against interference with licensed

communication equipment.

Attention: This is a Class A product. In a domestic environment this product may

cause radio interference in which case the user may be required to take adequate

measures.

Zulassungsbescheinigung laut dem Deutschen Gesetz über die

elektromagnetische Verträglichkeit von Geräten (EMVG) vom 30. August 1995

(bzw. der EMC EG Richlinie 89/336).

Dieses Gerät ist berechtigt in Übereinstimmung mit dem Deutschen EMVG das

EG-Konformitätszeichen - CE - zu führen.

Verantwortlich für die Konformitätserklärung nach Paragraph 5 des EMVG ist die

IBM Deutschland Informationssysteme GmbH, 70548 Stuttgart.

Informationen in Hinsicht EMVG Paragraph 3 Abs. (2) 2:

EN 55022 Klasse A Geräte müssen mit folgendem Warnhinweis versehen werden:

“Warnung: dies ist eine Einrichtung der Klasse A. Diese Einrichtung kann im

Wohnbereich Funkstörungen verursachen; in diesem Fall kann vom Betreiber

verlangt werden, angemessene Maßnahmen durchzuführen und dafür

aufzukommen.”

EN 50082-1 Hinweis: “Wird dieses Gerät in einer industriellen Umgebung betrieben

(wie in EN 50082-2 festgelegt), dann kann es dabei eventuell gestört werden. In

solch einem Fall ist der Abstand bzw. die Abschirmung zu der industriellen

Störquelle zu vergrößern.”

Anmerkung: Um die Einhaltung des EMVG sicherzustellen sind die Geräte, wie in

den IBM Handbüchern angegeben, zu installieren und zu betreiben.

Notices xv

Page 18

Japanese Voluntary Control Council for Interference (VCCI) Statement

This product is a Class A Information Technology Equipment and conforms to the

standards set by the Voluntary Control Council for Interference by Technology

Equipment (VCCI). In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

Taiwanese Class A Warning Statement

Battery Disposal

The 8239 Model 1 contains a clock module that has an embedded lithium battery.

This battery is not replaceable. Please dispose of this module in accordance with

local ordinances.

Trademarks

IBM and Nways are trademarks of the IBM Corporation in the United States or

other countries or both.

UNIX is a registered trademark in the United States and other countries licensed

exclusively through X/Open Company Limited.

Microsoft, Windows, Windows NT, and the Windows 95 logo are trademarks or

registered trademarks of Microsoft Corporation.

Other company, product, and service names may be trademarks or service marks

of others.

xvi 8239 Setup and User’s Guide

Page 19

Preface

This manual contains information for anyone who is planning to install, configure, or

manage an 8239 Token-Ring Stackable Hub (8239).

How This Manual Is Organized

This manual contains the following sections:

¹ Chapter 1, “Introduction and Planning” on page 1-1 introduces the functions,

models, and physical requirements. It also contains configuration and network

planning information.

¹ Chapter 2, “Installing the 8239 Hardware” on page 2-1 gives instructions for

setting up the 8239.

¹ Chapter 3, “Installing Features” on page 3-1 provides information needed to

install the optional features.

¹ Chapter 4, “Configuration” on page 4-1 describes the configuration process.

¹ Chapter 5, “Problem Determination Procedures” on page 5-1 provides problem

determination procedures and lists all error codes.

¹ Chapter 6, “Concentrator Functions” on page 6-1 describes the concentrator

functions provided by the 8239.

¹ Chapter 7, “8239 Device Management” on page 7-1 explains how to

implement management of the device.

¹ Chapter 8, “Network Management” on page 8-1 contains information about

accessing network management data.

¹ Chapter 9, “Planning Charts” on page 9-1 contains charts to help with planning

for cabling and configuration.

¹ Appendix A, “Warranty Information” on page A-1 provides details about your

warranty.

Related Publications

The following publications are shipped with the product in displayable softcopy form

on the 8239 Token-Ring Stackable Hub Softcopy Library CD-ROM (08L3308):

8239 Token-Ring Stackable Hub Setup and User’s Guide,

8239 Token-Ring Stackable Hub Command Reference,

This CD-ROM is shipped with initial orders for the 8239.

GA27-4209

GA27-4208

These additional publications are shipped in hard copy:

¹

8239 Token-Ring Stackable Hub Quick Reference,

¹

Caution: Safety Information - Read This First,

¹

License Agreement for Machine Code

For general information about token-ring architecture, see

Architecture

Copyright IBM Corp. 1998 xvii

GX27-4047

SD21-0030

, Z125-5468

Token-Ring Network

, SC30–3374.

Page 20

Visit our Web Site

This IBM web page provides product information:

http://www.networking.ibm.com/support

xviii 8239 Setup and User’s Guide

Page 21

Chapter 1. Introduction and Planning

This chapter describes the functions of and the physical requirements for the IBM

8239 Token-Ring Stackable Hub (8239). It also contains planning information.

The 8239 is a stackable concentrator, allowing token-ring stations to share a

network. Up to eight 8239s can be interconnected to form a stack. The stack

connection provides a control path as well as a token-ring data path. The control

path is an internal token-ring segment used by the stack units to communicate with

each other. The token-ring data path connects the stack units into a shared

token-ring network for user traffic. The 8239 is available in two models and

provides a range of network management functions.

Models

Both models of the 8239:

¹ Support basic concentrator functions, such as attachment of port stations,

beacon recovery, address-to-port mapping, and so on

¹ Attach up to 16 workstations

¹ Allow you to attach up to 32 workstations with an optional port expansion

feature

¹ Provide configuration and status information for each device through an

out-of-band connection

Figure 1-1. 8239 Model 1

Copyright IBM Corp. 1998 1-1

Page 22

Features

Figure 1-2. 8239 Model 2

The Model 1, in addition:

¹ Supports additional concentrator functions

¹ Provides network management functions

¹ Supports in-band connectivity

¹ Supports connection to other compatible concentrators

The following optional features are available for the 8239.

¹ 16-Port Expansion Feature

The 16-Port Expansion Feature contains 16 RJ-45 token-ring ports, increasing

the supported number of ports in a single 8239 from 16 to 32. The 16-Port

Expansion Feature can be installed in the feature slot of the 8239.

¹ RI/RO Module (Model 1 only)

Use the Ring In/Ring Out Module (RI/RO Module) to connect to another 8239

stack or to other compatible concentrators, such as:

– Token-Ring 8228 Multistation Access Unit

– 8230 Token-Ring Network Controlled Access Unit

– 8238 Token-Ring Stackable Hub

– 8260 Nways Multiprotocol Switching Hub

It is installed in the RI/RO Module slot on the Model 1. There are two types of

RI/RO Module:

– RJ-45 RI/RO Module, providing an RJ-45 copper interface

– Optical Fiber RI/RO Module, providing an ST-connector optical fiber

interface

1-2 8239 Setup and User’s Guide

Page 23

Configuration

The 8239 is shipped with a default configuration. If this configuration is acceptable,

you need only power on the 8239 and connect the cables. The configuration

parameters along with their default values are listed in “Configuration Parameters”

on page 4-9.

If you need to change the configuration, you can do so using:

¹ EIA-232 terminal interface (both models)

¹ Telnet terminal interface (Model 1 only)

¹ SNMP (Model 1 only)

¹ BOOTP (Model 1 only)

¹ Configuration setup file loaded via XMODEM (both models) or TFTP (Model 1

only)

Concentrator Functions

Each 8239 provides 16 RJ-45 token-ring ports. Cabling may be either unshielded

twisted pair (UTP) or shielded twisted pair (STP). The 8239 has an expansion slot

that allows you to add 16 additional RJ-45 ports, for a total of 32 ports. Up to eight

8239 can be connected to form a single stack using the stack-in and stack-out

ports. Thus, there can be up to 256 token-ring ports supported in an 8239 stack.

Any combination of 8239 Model 1s and 8239 Model 2s can make up a stack.

The 8239 provides address-to-port mapping information that identifies which MAC

addresses are attached to which ports on the 8239. Fanout devices and MAC-less

devices attached to 8239 ports also are supported by this mapping feature.

The 8239 provides port security. Port security allows you to identify specific MAC

addresses that are permitted to insert at a given port. You can configure a port to

respond to a security intrusion by:

¹ Disabling the port

¹ Reporting the intrusion attempt

¹ Disabling and reporting the intrusion attempt

The 8239 provides automatic beacon recovery when hard-error faults occur.

Hard-error faults are automatically detected and isolated to minimize the impact on

the network.

Device and Network Management

The 8239 can be managed in these ways:

¹ Out-of-band access through the EIA-232 port

¹ In-band access using Telnet, SNMP, PING, and TFTP (8239 Model 1 only)

Device management consists of configuring the stack, obtaining status information

from the stack, and loading code on the stack.

The network management functions supported by the 8239 Model 1 are:

¹ IEEE 802.5 Token Ring MIB

Chapter 1. Introduction and Planning 1-3

Page 24

¹ MIB II

¹ Remote Monitoring (RMON)

¹ RMON 2

¹ Enterprise Communications Analysis Module (ECAM)

¹ IBM Token Ring Surrogate MIB and Surrogate Trap MIB

Cable Types and Distances

This section gives information about supported cable types and maximum cable

distances.

Ports

Table 1-1 shows the types of cable and maximum distances supported for port

cabling.

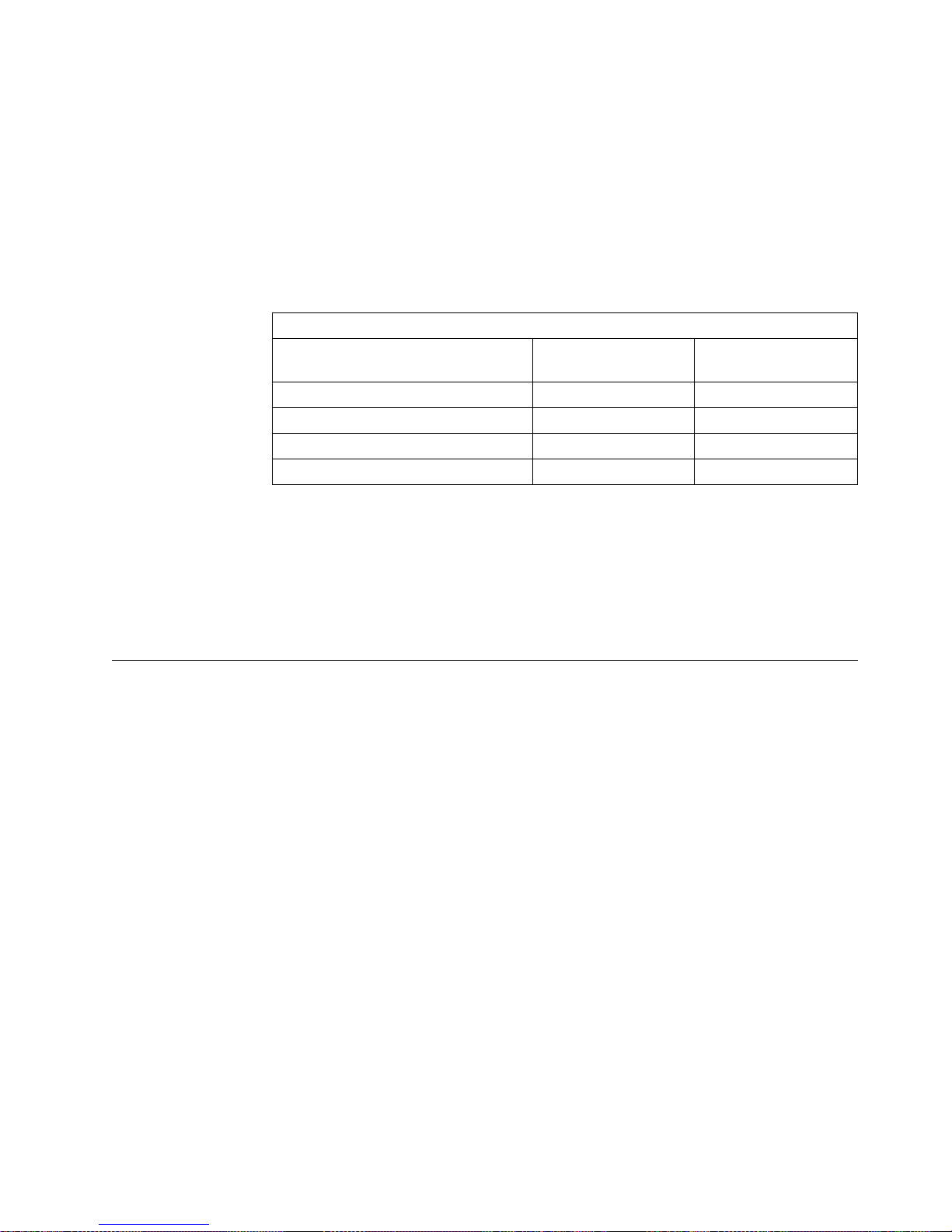

Table 1-1. Port Cabling

Cable Type 4-Mbps Ring Speed 16-Mbps Ring Speed

UTP, ScTP, or FTP Cat 3 250 m (820 ft) 100 m (328 ft)

UTP, ScTP, or FTP Cat 4 425 m (1394 ft) 210 m (689 ft)

UTP, ScTP, or FTP Cat 5 425 m (1394 ft) 225 m (738 ft)

STP or STP-A 750 m (2460 ft) 375 m (1230 ft)

Stack Unit Cabling

You can install up to eight 8239s in a stack, using any combination of 8239 Model

1s and 8239 Model 2s in the stack. Use standard TIA/EIA/ANSI 568A or ISO/IEC

11801 Category 5 cable for your stack.

Determining Maximum Cable Length

Each of the 8239s in a stack can be up to 25m (82 ft) apart without regard to the

total distance among all 8239s in the stack. If distances over 25m are required,

they are supported provided that the sum of all of the stack cable lengths minus the

length of the shortest stack cable does not exceed 210 M (689 ft). For example,

four 8239s have the following stack cables connecting them to form a stack:

Cable 1 connects stack unit 1 to stack unit 2 1 m

Cable 2 connects stack unit 2 to stack unit 3 25 m

Cable 3 connects stack unit 3 to stack unit 4 25 m

Cable 4 connects stack unit 4 to stack unit 1 150 m

To see if this configuration is allowable, use this formula:

(Total length of stack cables) - (length of shortest cable) < 210 m

Substituting the values in the example in this formula:

1 + 75 + 90 + 150 - 1 = 200

Because 200 m is less than 210 m, this configuration is allowable. In this case,

even though there are lengths of cable that are greater than 25 m, the configuration

is still acceptable because the total distance is less than 210 m.

Attention: To prevent ring disruptions, be sure you connect Stack-In and Stack-Out

cables at both ends.

1-4 8239 Setup and User’s Guide

Page 25

RI/RO Module

This section describes cabling for the RJ-45 RI/RO Module and the Optical Fiber

RI/RO Module.

RJ-45 RI/RO Module

Table 1-2 shows the types of cable and maximum distances supported for the

RJ-45 RI/RO Module.

Table 1-2. RJ-45 RI/RO Module Cabling

Cable Type 4-Mbps Ring Speed 16-Mbps Ring

Speed

UTP, ScTP, or FTP Cat 3 250 m (820 ft) 100 m (328 ft)

UTP, ScTP, or FTP Cat 4 425 m (1394 ft) 210 m (689 ft)

UTP, ScTP, or FTP Cat 5 425 m (1394 ft) 225 m (738 ft)

STP or STP-A 750 m (2460 ft) 375 m (1230 ft)

Optical Fiber RI/RO Module

The recommended maximum fiber length that can be used between Ring In and

Ring Out fiber connections is 2 km (1.2 miles) of 62.5/125-micron multimode optical

fiber cable. This distance applies to both 4-Mbps and 16-Mbps rings. See

Cabling System Optical Fiber Planning and Installation

information about optical fiber.

Physical Specifications

This section gives the physical specifications, environmental requirements, and

power requirements of the 8239.

Dimensions

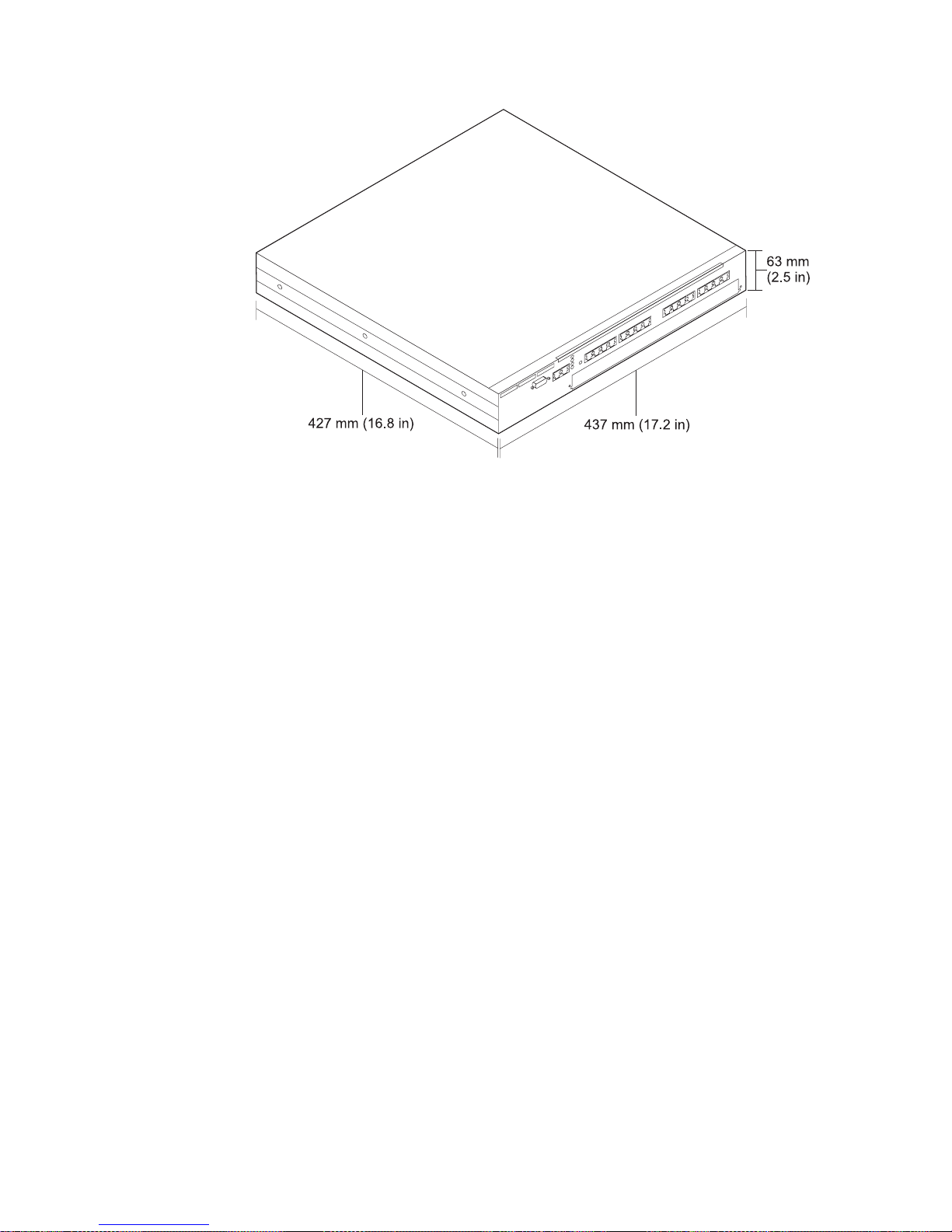

Figure 1-3 on page 1-6 shows the exterior dimensions of the 8239.

IBM

, GA27–3943, for more

Chapter 1. Introduction and Planning 1-5

Page 26

Figure 1-3. 8239 Dimensions

Placement

The 8239 can be placed on a tabletop or installed in a customer-supplied rack.

To surface-mount the 8239, choose a flat horizontal surface sturdy enough to

support the weight of the 8239. Do not mount the 8239 vertically.

The 8239 can be installed in a standard, open, EIA 19-in. rack in a wiring-closet

environment. The rack must meet the requirements of ANSI/EIA RS-310-C. The

8239 requires 1.5 rack units.

Weight

8239 Model 1: 7.0 kg (15.4 lb) when empty; 7.4 kg (16.4 lb) when fully loaded

8239 Model 2: 7.0 kg (15.4 lb) when empty; 7.4 kg (16.4 lb) when fully loaded

Service Clearances

Front Adequate space to view LEDs

Sides Minimum of 50 mm (2 in.) for cooling purposes

Rear Minimum of 130 mm (5 in.) to provide for cables

Environmental Requirements

Operating Temperature 10°— 40° C (50°—104° F)

Storage Temperature -40°—60° C (-40°—140° F)

Humidity 20°—85%

1-6 8239 Setup and User’s Guide

Page 27

Power Requirements

The 8239 requires input ac voltage within the range of 88 V ac to 265 V ac at a

frequency of 47 Hz to 63 Hz.

The maximum power consumption of an 8239 that is fully populated with features is

85 W.

Chapter 1. Introduction and Planning 1-7

Page 28

1-8 8239 Setup and User’s Guide

Page 29

Chapter 2. Installing the 8239 Hardware

This chapter provides instructions for setting up the 8239.

Before installing the 8239, be sure to read “Safety Information” on page ix.

Preparing for Setup

Complete the following tasks before beginning the setup process:

¹ Verify that appropriate power outlets are available.

¹ Gather network documentation identifying devices and specifying port

connections. The network administrator is responsible for network planning.

Worksheets for planning your 8239 installation are provided in Chapter 9,

“Planning Charts” on page 9-1.

¹ You will need access to a local ASCII terminal or to the terminal that is being

used for remote access.

Verifying the Shipment

After you have unpacked the shipping container, use the following Inventory

Checklist to verify that you have the items listed.

Inventory Checklist

¹ Hardware

__ 8239 Model 1 or Model 2

__ Power cord (U.S., Canada, and Latin America)

__ Stack Cable (standard Category 5 UTP)

__ Cable management bracket

¹ Media

__CD containing this information:

8239 MIB

¹ Printed publications

__

__

__

__

__

8239 Token-Ring Stackable Hub Setup and User’s Guide

8239 Token-Ring Stackable Hub Command Reference

License Agreement for Machine Code

8239 Token-Ring Stackable Hub Quick Reference

Caution: Safety Information - Read This First

Network Management

README file

trial offer

(this book)

Copyright IBM Corp. 1998 2-1

Page 30

Installing Features

The following features may be installed in the 8239:

¹ Optical Fiber RI/RO Module (Model 1 only)

¹ RJ-45 RI/RO Module (Model 1 only)

¹ 16-Port Expansion Feature

For instructions for the installation of these features, go to Chapter 3, Installing

Features.

Placing the 8239

The 8239 can be placed on a tabletop or installed in a customer-supplied rack.

If you are installing this 8239 in a rack, go to “Rack-Mounting the 8239.” Otherwise,

continue with “Surface-Mounting the 8239.”

Surface-Mounting the 8239

Place the 8239 on a flat horizontal surface sturdy enough to support its weight. The

8239 is not designed for vertical mounting.

Continue with “Connecting the Cables” on page 2-4.

Rack-Mounting the 8239

The 8239 can be installed in a standard, open, EIA 19–in. rack in a wiring-closet

environment.

2-2 8239 Setup and User’s Guide

Page 31

Figure 2-1. Rotating the Rack-Mounting Brackets

1. Using a Phillips screwdriver, remove the four screws, two on each side, that

attach the mounting brackets to the sides of the 8239, as shown in Figure 2-1.

2. Rotate the brackets and reattach them.

3. Refer to your network documentation to determine where in the rack to mount

the 8239.

4. Gather the rack-mounting screws (not provided) and place them within reach.

5. Hold the 8239 in position in the rack and start the lower of the two screws that

will secure the left bracket.

6. On the right side, align the lower screw holes in the mounting bracket and the

cable management bracket with the correct hole of the rack; then start the

screw as shown in Figure 2-2 on page 2-4.

Chapter 2. Installing the 8239 Hardware 2-3

Page 32

Figure 2-2. Attaching the Cable Management Bracket

7. Tighten the screws on each side.

Connecting the Cables

Use this section to connect cables to the 8239 and any attaching devices.

Connecting Stations to the 8239

Figure 2-3. Connecting Stations to the 8239

1. Refer to your network documentation to determine each cable’s port

assignment.

2. Connect the lobe cable (not provided) to a lobe port on the 8239.

2-4 8239 Setup and User’s Guide

Page 33

Cabling a Stack

3. Label the cable at the lobe port with a unique identifier so that it will be easy to

identify the location of the device at the other end of the cable should you have

to troubleshoot a network problem.

4. Connect the other end of the cable to the end station faceplate or other

intermediate connection point, as required.

Label the cables at the attaching-device end.

Note: The stack cable shipped with the 8239 Model 1 is longer than the cable

shipped with the Model 2, providing the means to connect the top 8239 to

the bottom 8239.

To build a hub stack containing two to eight 8239s:

1. Beginning with the 8239 at the top of the stack, use a stack cable to connect

stack OUT on the top 8239 to stack IN on the next hub below in the stack.

Figure 2-4. Stack Building

2. Using stack cables, continue to connect stack OUT on each 8239 to stack IN

on the next 8239 in the stack.

3. Use the stack cable to connect stack IN on the top 8239 to stack OUT on the

bottom 8239.

To prevent network disruptions, be sure you connect stack cables at both ends.

Connecting an ASCII Terminal or Modem to the EIA-232 Port

If you are going to access the 8239 without using the data network, you must

attach either an ASCII terminal for local access to the 8239 or a modem for remote

access.

ASCII Terminal

To attach an ASCII terminal, follow these steps:

1. Connect one end of the special null-modem cable (not provided) to the EIA-232

port of the 8239 that is going to be used.

2. Connect the other end of the cable to the communications port of your ASCII

terminal

Chapter 2. Installing the 8239 Hardware 2-5

Page 34

Modem

To attach a modem, follow these steps:

1. Unpack the modem and install it according to the manufacturer’s instructions.

2. Connect one end of the standard modem DTE cable (not provided) to the

EIA-232 port on the 8239.

3. Connect the other end of the cable to the modem.

4. Configure the modem to use the same settings as those on the 8239 you are

using (refer to “Management Using Emulation Software” on page 4-1).

5. Place the modem in auto-answer mode.

6. Set up the remote modem and data terminal.

7. Establish a modem link as described in the modem user documentation.

Note: Configuration command syntax varies from modem to modem. Make sure

that the modem has the following characteristics:

¹ asynchronous mode

¹ disable modem responses

¹ disable flow control (for example, AT \Q)

¹ disable echo (for example, AT Q1)

¹ auto-answer mode on second ring (for example, AT S0=2)

After configuring the modem, save its configuration.

Powering On the 8239

2-6 8239 Setup and User’s Guide

Page 35

Figure 2-5. Power on the 8239

1. Connect the power cord to the connector at the rear of the 8239.

2. Plug the power cord into the power outlet.

Because the 8239 has no power switch, the power-on self-test (POST) begins as

soon as you plug in the power cord. POST requires up to 2 minutes. At the end of

POST, the LCD on the 8239 Model 1 shows the operational code version for about

5 seconds. A successful power-on is indicated when the green OK light-emitting

diode (LED) is lit and the yellow OK LED is off.

Chapter 2. Installing the 8239 Hardware 2-7

Page 36

2-8 8239 Setup and User’s Guide

Page 37

Chapter 3. Installing Features

16-Port Expansion Feature

To install or remove a 16-Port Expansion Feature, follow the directions in this

section. The 16-Port Expansion Feature is hot pluggable, so you do not need to

disconnect the 8239 power cord.

Figure 3-1. 16-Port Expansion Feature

Removing a 16-Port Expansion Feature

1. If you intend to replace the 16-Port Expansion Feature, label the cables

attached to it to ensure that you reconnect the cables correctly.

2. Disconnect the cables from the 16-Port Expansion Feature.

3. Loosen the two thumbscrews by turning them counterclockwise until the screws

are loose enough to remove the card from the 8239.

4. Remove the 16-Port Expansion Feature from the 8239 by pulling on the thumb

screws.

5. If you are not replacing the 16-Port Expansion Feature immediately, install an

expansion slot cover.

Installing a 16-Port Expansion Feature

Perform these steps to install a 16-Port Expansion Feature:

1. If a 16-Port Expansion Feature was not already installed in this 8239, remove

the slot cover and store it in a safe place.

2. Slide the 16-Port Expansion Feature along the grooves in the slot until it is

seated and flush with the front panel.

3. Tighten the thumbscrews by turning them clockwise.

4. After the adapter is seated, all of the yellow port LEDs are on briefly, indicating

that diagnostic tests are in progress.

5. The diagnostic tests for the 16-Port Expansion Feature will complete in less

than 5 seconds.

Copyright IBM Corp. 1998 3-1

Page 38

RI/RO Module

6. Use the DISPLAY INVENTORY terminal interface command to verify that the

8239 recognizes the 16-Port Expansion Feature.

To install or remove a Ring In/Ring Out Module, follow the directions in this section.

Attention: You must power off the 8239 before installing or removing a Ring

In/Ring Out Module.

You do not need to remove the 8239 from a rack to remove or install a RI/RO

Module.

Figure 3-2. RI/RO Module

Removing a RI/RO Module

1. Remove power from the 8239 by unplugging the power cord.

2. If you intend to replace the RI/RO Module, label the cables attached to it. This

precaution will ensure that you reconnect the cables correctly.

3. Disconnect the cables from the RI/RO Module.

4. Loosen the two thumbscrews by turning them counterclockwise until the screws

are loose enough to remove the module from the 8239.

5. Pull the RI/RO Module along the grooves of the guide rail and remove it from

the 8239.

6. If you are not replacing the RI/RO Module immediately, install a slot cover and

provide power to the 8239.

3-2 8239 Setup and User’s Guide

Page 39

Installing a RI/RO Module

Perform these steps to install a RI/RO Module:

1. Remove power from the 8239 by unplugging the power cord.

2. If a RI/RO Module was not already installed in this 8239, remove the slot cover

and store it in a safe place.

3. Slide the module into the slot along the grooves of the guide rail until it is

seated and flush with the front panel.

4. Tighten the thumbscrews by turning them clockwise.

5. Connect the cables connecting RI on the 8239 RI/RO Module to RO on the

external device and RO on the 8239 RI/RO Module to RI on the external

device.

¹ For the Optical Fiber RI/RO Module:

Figure 3-3. Cabling for the Optical Fiber RI/RO Module

¹ For the RJ-45 RI/RO Module:

Chapter 3. Installing Features 3-3

a. Connect the RI receive port to the RO transmit port on the external

device.

b. Connect the RI transmit port to the RO receive port on the external

device.

c. Connect the RO receive port to the RI transmit port on the external

device.

d. Connect the RO transmit port to the RI receive port on the external

device.

Page 40

Figure 3-4. Cabling for the RJ-45 RI/RO Module

a. Connect RI on the 8239 to RO on the external device.

b. Connect RO on the 8239 to RI on the external device.

Attention:

¹ Be sure that you connect RI/RO cables at both ends before enabling these

interfaces. Any of these interfaces that are not going to be used should be

administratively disabled.

¹ Use caution when implementing a network with more than one RI/RO

interface per stack. Multiple RI/RO connectors between two ring segments

or between two 8239 Model 1s in the same stack can cause undesirable

results, such as a division of the ring into two independent segments.

6. Provide power to the 8239.

The RI/RO ports are disabled by default. To enable them, issue the ENABLE

RING_IO command or the UNWRAP RING_IO command; these commands are

equivalent.

3-4 8239 Setup and User’s Guide

Page 41

Chapter 4. Configuration

This chapter describes the configuration procedures you need to perform before

you can manage the 8239.

When you install an 8239, it contains factory-default parameters. Depending on

your needs, you might want to change these defaults. For a listing of the default

values, go to “Configuration Parameters” on page 4-9.

Using the Command Interface

Employ the command interface using a terminal emulation program that supports

VT100 emulation or using Telnet over an IP connection.

Login Access

To use the terminal interface, you must enter a login name and password. There

are two access types associated with a login name:

¹ Admin, which allows you to issue all commands

¹ User, which allows you to issue a subset of the commands allowed under

Admin access.

Configuration changes made with User access can be saved only under Admin

access. The SAVE command is not allowed for User access.

The default login name is “admin” with no password. It is recommended that you

change the 8239 login password to a more secure password.

Management Using Emulation Software

You can use terminal emulation software in one of two ways:

¹ Using a direct, null-modem cable connection

¹ Using a public telephone network via a modem and a standard EIA-232 cable

The default terminal baud setting is 9600 bps. This value can be changed using

the SET TERMINAL BAUD command. Initialization and diagnostic messages are

displayed at 9600 bps; once the 8239 is operational, the configured terminal baud

setting is used.

Using a Null-Modem Cable

To communicate with the 8239 for the first time, configure the terminal emulation

application with:

¹ 9600 bps

¹ No parity

¹ 8 data bits

¹ 1 stop bit

¹ No flow control

¹ VT100 emulation

¹ The communications port of the workstation that you have configured in the

emulation software

Copyright IBM Corp. 1998 4-1

Page 42

Using a Modem

If you will be communicating with the 8239 by means of a modem connection, you

will need to install a second modem and connect it to your workstation.

Configure the terminal emulation application with:

¹ 9600 bps

¹ No parity

¹ 8 data bits

¹ 1 stop bit

¹ No flow control

¹ VT100 emulation

¹ The workstation’s communication port that will be used

Establishing a Session

To establish a session:

1. Invoke emulation software to establish direct connection by means of the

null-modem cable, or invoke the emulation software and dial the number of the

modem attached to the 8239.

2. After the connection is established, you will see either:

¹ The login prompt or trap messages (if the 8239 is already powered on)

¹ Diagnostic messages (if you provide power after establishing the

connection)

3. Press Enter two or three times.

4. At the login prompt, type admin and then press Enter (ADMIN is the default

user name).

5. You are now logged on.

Management Using Telnet

You can access the 8239 in-band using Telnet to an 8239 Model 1. To configure

the 8239 Model 1 for in-band connectivity, go to “Configuring the 8239 for In-Band

Connectivity” on page 4-5.

Command Interface Conventions

The main panel of the command interface for an 8239 Model 1 is shown below.

8239 Login Prompt

Login:admin

Password:mypassword

Main Menu - Accepted inputs:

1) bootp 10) replicate

2) clear 11) reset_hub

3) disable 12) restore_to_factory_default

4) display 13) retrieve

5) enable 14) save

6) help 15) set

7) load 16) script

8) logout 17) unwrap

9) ping 18) wrap

Type 'help' for information

?=Help>

4-2 8239 Setup and User’s Guide

Page 43

Note: When the password is null (the default value), the line that prompts for

password may not appear.

Once you have logged on to the 8239, manage the stack using the command

interface. Use these guidelines, special keys, and short cuts:

¹ Pressing Esc returns you to the terminal prompt.

¹ Pressing shift and ? displays a list of the values that you can enter for a

particular command.

¹ Default values or current settings are shown in brackets.

¹ Pressing Enter accepts the value shown in brackets.

¹ Commands are not case sensitive.

¹ Commands can be issued by:

– Typing the entire command.

– Typing part of the command and pressing the space bar.

– Typing the number shown next to the command. The numbers representing

a command are not the same on the 8239 Model 1 and the Model 2.

¹ Pressing Tab selects the first command that matches what you typed.

Repeatedly pressing Tab cycles through the possible commands that match

what you typed.

¹ Entering help at the terminal prompt displays hints about performing routine

tasks.

Examples

The following table describes how to perform some common management tasks

using the terminal interface. The examples assume this stack configuration:

¹ The stack consists of one 8239 Model 1 and two 8239 Model 2s.

¹ The 8239 Model 1’s hub ID is 1; the hub IDs of the 8239 Model 2s are 2 and 3.

¹ Hub 1 contains the RI/RO Module.

¹ IP is to be configured on hub 1. The IP address is 9.197.4.67, the subnet mask

is 255.255.255.0, and the default gateway is 9.197.4.1.

¹ The ASCII terminal is connected to the 8239 Model 1s (hub 1) EIA-232 port.

Chapter 4. Configuration 4-3

Page 44

Task Action

Remove an external device and its

ports from the stack data ring

Insert an external device and its ports

into the stack data ring

Remove hub 2 from the stack data

ring

Insert hub 2 into the stack data ring Type unwrap data_io both 2 and press

Set up IP on hub 1 Type set ip 1 and press Enter.

Get status for the stack Type display stack and press Enter.

Get status for hub 2 Type display hub 2 and press Enter.

Get status for port 4 on hub 2 Type display port 2.4 and press Enter.

Enable all ports on hub 1 Type enable port 1.all and press Enter.

Disable port 4 on hub 2 Type disable port 2.4 and press Enter.

Type wrap ring_io both 1 and press Enter.

Type unwrap ring_io both 1 and press

Enter.

Type wrap data_io both 2 and press Enter.

Enter.

When prompted, enter the following

information, pressing Enter after each value:

IP address: Type 9.197.4.67

Subnet mask: Type 255.255.255.0

Default gateway: Type 9.197.4.1

Verifying, Saving, and Restoring Parameters

Verifying Parameters

To verify parameters that you have entered, type the appropriate DISPLAY

command.

Saving Parameters

If you change configuration settings and then the 8239 Model 1 loses power or is

reset before you save the changes, the changes are lost; the last-saved

configuration settings are used. For this reason, you should save configuration

information frequently.

To save the current configuration for all the 8239s in the stack, type save and

press Enter.

Restoring Parameters

To restore the last-saved configuration for all hubs in the stack, reset the 8239

without saving the configuration.

Configuring the 8239

This section explains how to configure the 8239 for:

¹ Out-of-band connectivity

¹ In-band connectivity

¹ Network monitoring

See “Configuration Parameters” on page 4-9 for a list of configuration parameters.

4-4 8239 Setup and User’s Guide

Page 45

Configuring the 8239 for Out-of-Band Connectivity

The 8239 supports out-of-band access on both models through the EIA-232 port.

You can attach either an ASCII terminal for local access or a modem for remote

access. The 8239 default settings support out-of-band connectivity. To change any

configuration settings, use the SET TERMINAL command. See “Connecting an

ASCII Terminal or Modem to the EIA-232 Port” on page 2-5 for instructions for

connecting to the EIA-232 port. See “Using the Command Interface” on page 4-1

for information about the command interface.

Configuring the 8239 for In-Band Connectivity

In-band connectivity lets you access the 8239 Model 1 from a remote station using

the Token-Ring network rather than an EIA-232 port. In order to use in-band

connectivity, the 8239 Model 1 must be configured with IP information. You can

configure IP information initially using either of these methods:

¹ BOOTP

¹ Terminal interface commands via the EIA-232 port

BOOTP

If you do not plan to use BOOTP, you should use the DISABLE BOOTP command

in order to reduce network traffic. Continue with this section only if you are

interested in in-band connectivity; otherwise, go to “Using the Command Interface”

on page 4-1.

BOOTP (boot protocol) is a user datagram protocol/internet protocol

(UDP/IP)-based protocol that allows a 8239 Model 1 to obtain IP information with

the assistance of a BOOTP server; with the IP information, the 8239 can use

in-band connectivity. The 8239 supports BOOTP to facilitate the configuration of

newly installed stacks in remote locations. Every 8239 Model 1 is shipped with the

BOOTP protocol enabled.

If your installation has only 8239 Model 2s, in-band connectivity is not supported.

Configuration Using BOOTP:

BOOTP request over IP when it is powered on or reset. The BOOTP server, using

information from its BOOTPTAB file, provides the 8239 Model 1 with configuration

information. In addition to obtaining the IP address and the subnet mask, the 8239

Model 1 can attach to a configuration server to obtain a configuration file. The

configuration file is an ASCII file containing 8239 commands. The commands are

executed as soon as the configuration file is transferred via TFTP to the 8239. The

8239 Model 1 updates its configuration with the information contained in the

BOOTP message. The following example of a BOOTPTAB file entry contains

configuration information for the 8239:

ibm8239hub1:ha=0006298f0490:ip=200.0.0.163:sm=255.255.255.0

:gw=200.0.0.150:sa=200.0.0.150:bf=/tmp/hub1.pfl:ht=6

where

A newly installed 8239 Model 1 broadcasts a

ha

ip

sm

Chapter 4. Configuration 4-5

Is the hardware address of the 8239

Is the IP address of the 8239

Is the subnet mask of the 8239

Page 46

gw

sa

bf

ht

Configuration information obtained from the BOOTP server is not saved unless you

issue a SAVE command.

If your network administrator is using BOOTP to configure network devices, contact

the administrator to determine if you need to make any configuration changes.

Is the default gateway

Is the server IP address from which the configuration file is transferred

via TFTP

Is the configuration file name

Is the hardware type (“6” specifies Token Ring)

Terminal Interface Commands Through the EIA-232 Port

To remotely manage the 8239 or remotely monitor the network using the EIA-232

port, set the IP addresses of the Management Interface hub:

¹ set ip

hub_id ip_address subnet_mask default_gateway

Management Interface Insertion

Make sure that the Management Interface is inserted into the ring:

set management_interface administrative_mode enable

hub_id

SNMP Access

1. Set the community table information, if appropriate, using the SET

COMMUNITY command. Telnet does not require this information.

2. Set the access control list information, if appropriate, using SET ACCESS

ACCESS_CONTROL_LIST

Note: Because the initial state grants wide access to well-known communities,

it is recommended that you change the 8239 default configuration to a

more secure configuration.

3. Set the trap community information, if appropriate, using SET

TRAP_COMMUNITY.

Changing Token-Ring Options

By default, the 8239 Model 1 is configured as a station on the Token-Ring network

using the ring speed that was configured for the hub and the default MAC address.

However, if you want, you can:

¹ Specify a locally administered MAC address

The 8239 Model 1 is produced with a factory-set MAC address. If you want to

use a locally administered MAC address, follow these steps.

1. Specify the MAC address:

set management_interface locally_administered_address

mac_address_value

hub_id

2. Specify the use of the locally administered MAC address:

4-6 8239 Setup and User’s Guide

set management_interface mac_address_type locally_administered

hub_id

Page 47

Changing the MAC address type to locally administered causes the

Management Interface to close and reopen its adapter.

¹ Set other Token-Ring options.

To set other Token-Ring network options, issue the appropriate SET

MANAGEMENT_INTERFACE command.

Configuring for Network Monitoring

To configure the 8239 for network monitoring, enter these commands.

1. If you are going to use in-band management, configure the 8239 according to

the instructions in “Configuring the 8239 for In-Band Connectivity” on page 4-5.

2. Enable the data-gathering functions that you need:

¹ To enable the 8239 for RMON, go to “Configuring RMON.”

¹ To configure the 8239 as a surrogate function, go to “Configuring for the

Surrogate Agent.”

Configuring RMON

To configure RMON:

¹ Assign IP information if you are accessing RMON information via in-band

connectivity. The RMON manager must have a physical path to the 8239’s

RMON probe.

¹ For security reasons, you may want to change the default community names

and set up access control lists

¹ If source routing is used on the segment and an RPS is not on the ring, you

must set the ring segment number in order for the RMON source routing

statistics to be accurate. For information about setting the ring segment

number, see “Enabling RPS” on page 4-8.

By default, all RMON groups are enabled and some RMON groups are set up

automatically. You can disable individual RMON groups using a terminal interface

command or via SNMP through the 8239 private MIB. For more information, go to

Chapter 7, 8239 Device Management.

Example:

Manager — Remote Monitor (ReMon), follow these steps.

1. Make sure that the 8239 Model 1 that is acting as an RMON probe is

configured with the appropriate IP information by using the DISPLAY IP

ADDRESS command. If a change is necessary, configure the IP information

using the following command:

To configure the 8239 to communicate with an Nways Campus

set ip

hub_id ip_address subnet_mask default_gateway

2. Follow the instructions provided with ReMon to configure or add a device or

probe.

Configuring for the Surrogate Agent

Enabling the Token-Ring surrogate function involves enabling the surrogate group

and, possibly, the CRS, REM, and RPS groups.

Note that almost all information associated with the surrogate agent can also be

accessed via SNMP through the IBM TR Surrogate MIB. Accessible only through

the 8239 MIB are:

Chapter 4. Configuration 4-7

Page 48

¹ surrogate group administrative mode

¹ rps_traps administrative mode

Enabling the Surrogate Group:

Use one of these methods:

¹ Issue this command:

set management_interface surrogate_group enable

¹ Issue this command:

enable tr_surrogate surr_status surr_admin

¹ Use SNMP through the IBM 8239 TR Hub MIB.

Enabling REM

1. Enable the surrogate group as explained in “Enabling the Surrogate Group.”

2. Enable the REM function using this command:

enable tr_surrogate surr_status rem_admin

3. Enable each REM flag that you need using this command:

enable tr_surrogate rem_status

option

Note: rem_traps defaults to enabled; all other flags default to disabled.

Enabling CRS

1. Enable the surrogate group as explained in “Enabling the Surrogate Group.”

2. Use this command to enable the CRS function:

enable tr_surrogate surr_admin crs_admin

3. Enable the CRS to report topology change traps:

enable tr_surrogate crs_traps

The default value for crs_traps is enabled.

Enabling RPS

1. Enable the surrogate group as explained in “Enabling the Surrogate Group.”

2. Enable RPS using this command:

enable tr_surrogate surr_admin rps_admin

3. Use this command to enable RPS to report new stations inserted into the ring:

enable tr_surrogate rps_traps

The default value for rps_traps is enabled.

RPS does not become active until you set the ring segment number. A ring

segment number is the part of the virtual storage ring address needed to refer to a

segment. It is used for identification of Token-Ring segments that are being

remotely monitored. Set the ring segment number if the 8239 Model 1 is acting as

the Ring Parameter Server, or if there is no Ring Parameter Server on the segment

and you are collecting RMON source routing statistics. Use the Token-Ring

Surrogate function to identify or set a ring segment number.

The ring segment number can also be obtained with the Aspen Config MIB.

4-8 8239 Setup and User’s Guide

Page 49

To set the ring segment number, use one of these methods:

¹ Enter the following command:

set tr_surrogate segment_number

segment_number hub_id

¹ Use an application that supports SNMP or use a MIB browser to set the value

in the Token_Ring Surrogate MIB.

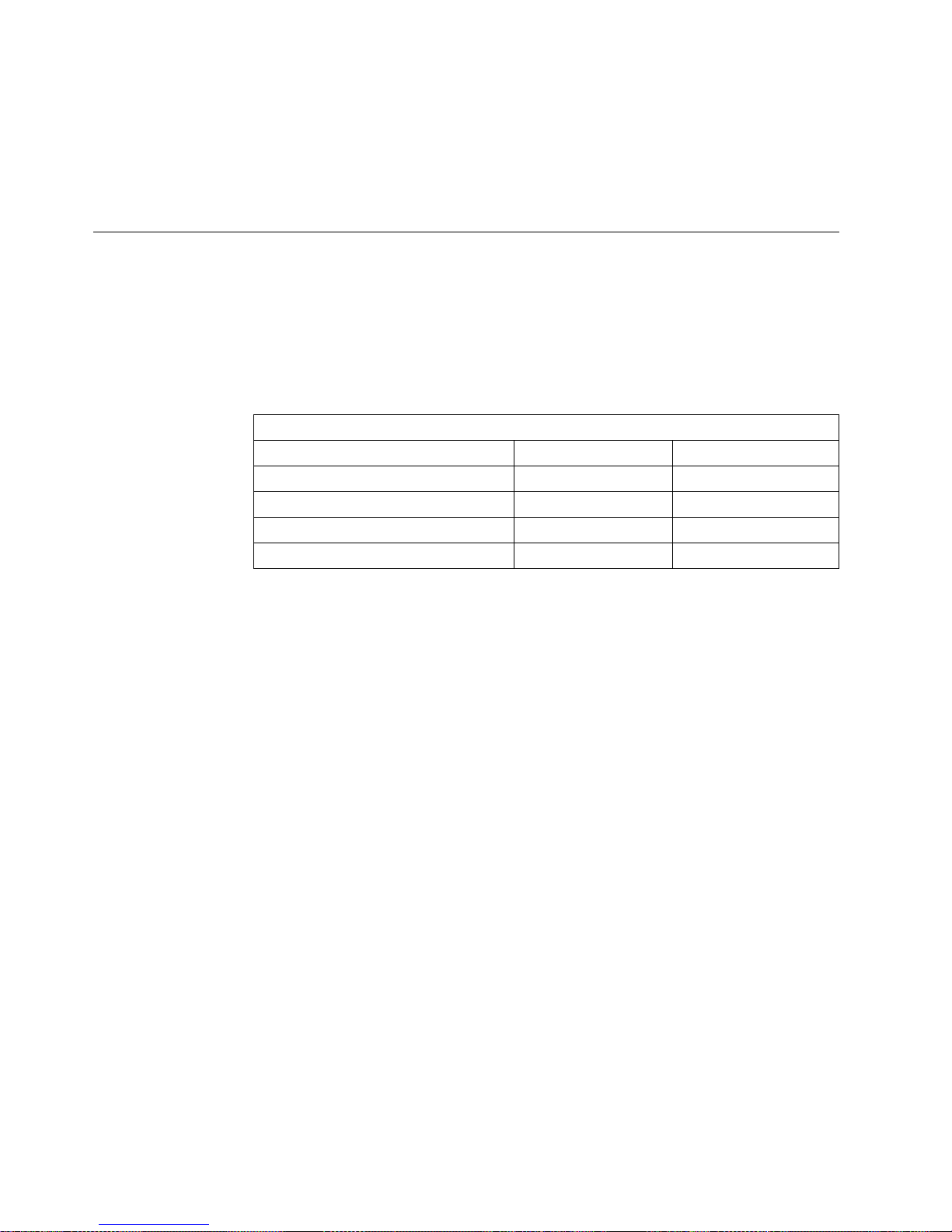

Configuration Parameters

The following table lists all 8239 parameters, their defaults, and whether they are

configurable. An asterisk following a parameter means that the parameter is

configurable from both an 8239 Model 1 and Model 2; otherwise, a parameter is

configurable from a Model 1 only.

Parameters that are not configurable provide status and information. If a parameter

is configurable and the default value is “N/A”, there is no default value and the

parameter must be set. If a parameter is not configurable and the default is “N/A”,

the parameter is read only; the value is provided by the product.

These parameters are accessible using the command interface or using SNMP

through the 8239 MIB.

Parameter Default Value Configurable

Access Control list (level 4) Any IP address with level 4

community name

Access Control list (level 3) Any IP address with level 3

community name

Access Control list (level 2) Any IP address with level 2

community name

Access Control list (level 1) Any IP address with level 1

community name

Beacon threshold* 8 Yes

BOOTP power-up mode ENABLED Yes

BOOTP server IP address 255.255.255.255 Yes

Clock Initially, JAN 21 00:00:00 1997 Yes

Community name (level 1) PUBLIC Yes

Community name (level 2) RMON Yes

Community name (level 3) USER Yes

Community name (level 4) ADMIN Yes

Control In administrative mode* UNWRAPPED Yes

Control Out administrative mode* UNWRAPPED Yes

Data In administrative mode* UNWRAPPED Yes

Data Out administrative mode* UNWRAPPED Yes

Dot5 group DISABLED Yes

Event script N/A Yes

Group mode* N/A Yes

Yes

Yes

Yes

Yes

Chapter 4. Configuration 4-9

Page 50

Parameter Default Value Configurable

Group name* N/A Yes

Group port* N/A Yes

Hub ID* Lowest available value Yes

IP address 0.0.0.0 Yes

IP default gateway 0.0.0.0 Yes

IP subnetwork mask 0.0.0.0 Yes

Login user* ADMIN with no password ID and password

can be configured

Management Interface active monitor

participation

Management Interface Adapter microcode

version

Management Interface Adapter status READ-ONLY No

Management Interface administrative mode ENABLED Yes

Management Interface ARP resolve method SOURCE-ROUTE Yes

Management Interface burned-in MAC address xx-xx-xx-xx-xx-xx No

Management Interface diag wrap None Yes

Management Interface early token release ENABLED Yes

Management Interface locally administered

address

Management Interface MAC address type BURNED-IN Yes

Operational version* Initially, v1.0 No

Port speed detect* ENABLED Yes

Port trap* ENABLED Yes

Port 8228 mode* DISABLED Yes

Port administrative mode* ENABLED Yes

Ports main administrative mode (ports 1-16)* UNWRAPPED Yes

Ports expansion administrative mode (feature

slot)*

Purge on insert* ENABLED Yes

Surrogate REM trap flag ENABLED Yes

REM individual flag settings DISABLED Yes

Ring In administrative mode UNWRAPPED Yes

Ring Out administrative mode UNWRAPPED Yes

Ring segment number Value from RPS, last saved value,

Ring speed* 16Mbps Yes

RMON Alarm group ENABLED Yes

RMON Event group ENABLED Yes

RMON History_ML group ENABLED Yes

RMON History_P group ENABLED Yes

DISABLED Yes

READ-ONLY No

00-00-00-00-00-00 Yes

UNWRAPPED Yes

Yes

or 0

4-10 8239 Setup and User’s Guide

Page 51

Parameter Default Value Configurable

RMON Host group ENABLED Yes

RMON Matrix group ENABLED Yes

RMON RingStation group ENABLED Yes

RMON Statistics Mac_Layer group ENABLED Yes

RMON Statistics Promiscuous group ENABLED Yes

RMON Statistics Sourcerouting group ENABLED Yes

RMON TopN group ENABLED Yes

RMON2 Mode RMON2 Yes

Security action on intrusion* TRAP-ONLY Yes

Security mac_address* N/A Yes

Security mode* DISABLED Yes

Serial port baud rate* 9600 Yes

Serial port data bits* 8 No

Serial port parity* NONE No

Speed mismatch threshold* 8 Yes

Surrogate CRS Admin status DISABLED Yes

Surrogate CRS trap flag ENABLED Yes

Surrogate group DISABLED Yes

Surrogate REM Admin status DISABLED Yes

Surrogate REM trap flag ENABLED Yes

Surrogate RPS Admin status DISABLED Yes

Surrogate RPS trap flag ENABLED Yes

System contact N/A Yes

System description 8239, SW_version, hub_id No

System location N/A Yes

System name 8239 Yes

Terminal prompt* ?=Help> Yes

Terminal timeout No time-out for EIA-232 port; 15

min. for Telnet

TFTP file name N/A Yes

TFTP server IP address N/A Yes

Trap authentication ENABLED Yes

Trap community N/A Yes

Trap console display* ENABLED Yes

Trap control IO status up/down* ENABLED Yes

Trap data IO status up/down* ENABLED Yes

Trap multiple users ENABLED Yes

Trap port security intrusion* ENABLED Yes

Trap port up/down* ENABLED Yes

Trap ring IO status up/down ENABLED Yes

No

Chapter 4. Configuration 4-11

Page 52

Parameter Default Value Configurable

Trap RMON DISABLED Yes

Trap script ENABLED Yes

4-12 8239 Setup and User’s Guide

Page 53

Chapter 5. Problem Determination Procedures

When problems occur, follow this diagnostic approach:

1. Check the front panel LEDs

2. Interpret any LCD messages on the 8239 Model 1 serving as your

management unit

If you are unable to solve a problem, contact your provider of service.

Using the LEDs to Diagnose Problems

All 8239s have LEDs that indicate the status of some of their components. The

following types of LEDs are provided on the front panel of an 8239:

¹ Power indicator

¹ Box status (OK LEDs)

¹ Ring speed indicator

¹ Port status

¹ RI/RO status (Model 1 only)

¹ Stack In/Stack Out status

Figure 5-1. 8239 Model 1 LEDs and LCD

Copyright IBM Corp. 1998 5-1

Page 54

Figure 5-2. 8239 Model 2 LEDs

Power Indicator

Table 5-1. Power Indicator (Green LED)

State Meaning

On 8239 is receiving power.

Off Unit has no power or there is a failure

Cause Action

8239 power cord is disconnected Connect the power cord.

8239 power cable is defective Replace the power cord.

Power outlet is not supplying power Check the power outlet.

Power supply failure If the fans are not running, replace the power

8239 failure Replace the 8239.

LED failure If other LEDs work, the LED has failed. Replace the

Box Status

supply.

8239.

5-2 8239 Setup and User’s Guide

Page 55

Ring Speed

Table 5-2. Box Status (OK LEDs)

Green Yellow Meaning

On Off Unit is operational

Off On During POST, DRAM test is running

Blinking Blinking Boot code or POST is running. If the blinking lasts for more

than 2 minutes, unit not operational; for the cause of this

hardware failure, go to “LCD and LED Codes” on page 5-14.

On On If this LED state lasts for less than 30 seconds, the operating

system is initializing during bringup.

If this state lasts for 30 seconds or more, the unit is not

operational. For the cause of this hardware failure, go to

“LCD and LED Codes” on page 5-14.

On Blinking Unit is executing beacon recovery.