Page 1

Page 2

Customer Engineering

Issued

Branch

Department:

Address:

to:

Office:

____________

____________

__________

___________

Manual

If this

manual

return

it

to

the

of

is

mislaid,

above

Instruction

_

---:-_

_

_

please

address.

Card

Sorting Machine

Page 3

This edition, Form 225-8766-4,

but does not obsolete Form

PAGE

22 to end Deletion of all material that is

22-8766-3. Principal changes in this edition are:

76 Added instructions for the 978 Card

MINOR REVISION (May 1957)

is

a minor revision of the preceding edition

SUBJECT

82-80-75

Counting

C.B.

Reference Manual

Unit

in

the

© 1952, 1953, 1956

by

International Business Machines Corporation

Page 4

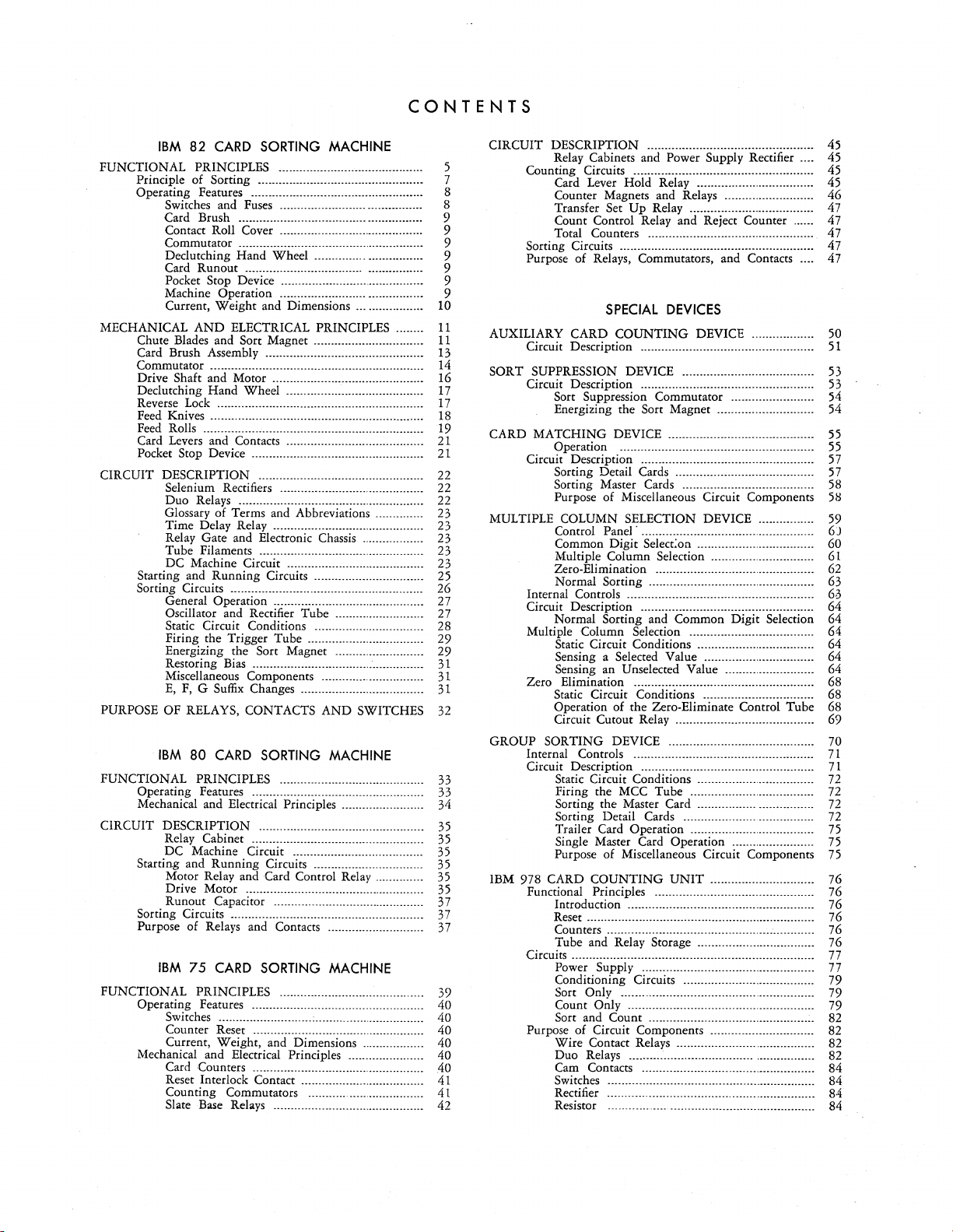

CONTENTS

IBM

82

CARD

SORTING MACHINE

FUNCTIONAL PRINCIPLES .......................................... 5

Principle of Sorting ................................................ 7

Operating Features ........... ....................................... 8

Switches and

Card Brush .................. ................... ................ 9

Contact Roll Cover ....... ............ ....................... 9

Commutator ..................................... ................. 9

Declutching Hand Wheel ............... ................ 9

Card Runout .................................. ................ 9

Pocket Stop Device ......................... .............. ... 9

Machine Operation ......................... ............. ... 9

Current, Weight and Dimensions ... ................

MECHANICAL

Chute Blades and Sort Magnet ......................... .......

Card Brush Assembly ..............................................

Commutator ..............................................................

Drive Shaft and Motor ............................................ 16

Declutching Hand Wheel........................................

Reverse

Feed Knives .............................................................. 18

Feed Rolls ................................................................ 19

Card Levers and Contacts ...... ...... ............................

Pocket Stop Device ................ ................... ........ .......

CIRCUIT DESCRIPTION ................................................

Star~ing

SortIng Circuits ....................... ................................. 26

PURPOSE OF RELAYS, CONTACTS AND SWITCHES

FUNCTIONAL PRINCIPLES ......................................... .

Operating Features ................................................. .

Mechanical and Electrical

CIRCUIT DESCRIPTION ............................................... .

Starting and Running Circuits ............................... .

AND

Lock

Selenium Rectifiers ..........................................

Duo Relays ......................................................

Glossary of Terms and Abbreviations ..............

Time Delay Relay............................................

Relay Gate and Electronic Chassis ...........

Tube Filaments ................................................

DC Machine Circuit ........................................

a!ld

General Operation ............................................

Oscillator and Rectifier Tube ................

Static Circuit Conditions ................................

Firing the Trigger Tube .................................. 29

Energizing the Sort Magnet .......................... 29

Restoring

Miscellaneous Components . ....... ...... ...... ...... ....

E,

F, G Suffix

IBM

80

Relay Cabinet .................................

DC Machine Circuit ..................................... .

Motor Relay and Card Control Relay ............. .

Drive Motor ................................................... .

Sorti~U~~~~ui~a~.~~!.~~.~

Purpose of Relays and Contacts ........................... .

IBM

75

FUNCTIONAL PRINCIPLES .......................................... 39

Operating Features .................................. _...............

Switches ....................... _.................................... 40

Counter Reset ............. ....... ..... ......... ......... ... .... 40

Current, Weight, and Dimensions

Mechanical and Electrical Principles ...................... 40

Card Counters

Reset Interlock Contact ....... ...... ...... .................

Counting Commutators

Slate

Fuses

......................... ... ............. 8

ELECTRICAL PRINCIPLES ........

.................... ........................................

~unning

CARD

CARD

Base

Circuits .. ............... ...............

Bias

.............. ....................................

Changes ....................................

SORTING MACHINE

Principles ....................... .

__

.............. .

..........

~~~~

......

~

........

~~

..................

~~

..

SORTING MACHINE

...

...... ..... .... 40

..

............ ............ ......... ........ ... .... 40

..

Relays ............................................

......... ....... ........ ... ....

_......

...

... ....

::::::::::::::

10

11

11

13

14

17

17

21

21

22

22

22

23

23

23

23

23

25

27

27

28

31

31

31

32

33

33

34

35

35

35

35

35

35

37

37

37

40

41

41

42

CIRCUIT DESCRIPTION ................................................ 45

AUXILIARY CARD

SORT SUPPRESSION DEVICE ......................................

CARD MATCHING

~elay

CountIng Circuits ................................................. ...

Card Lever Hold Relay.................................. 45

Counter Magnets and Relays

Transfer Set

Count Control Relay and Reject Counter ...... 47

Total Counters ................................................ 47

Sorting Circuits ........................................................ 47

Purpose of Relays, Commutators, and Contacts .... 47

Circuit Description ..................................................

Circuit Description ..................................................

Sort Suppression Commutator . ....... ................ 54

Energizing the Sort Magnet ...... ........... ...... ..... 54

Circu?tPg:~~~?Pti~~··::::::::::::::::::::::::::::::::::::::::::::::::::

Sorting Detail Cards . .......... ....... ................. .....

Sorting Master Cards ......................................

Purpose of Miscellaneous Circuit Components

MULTIPLE COLUMN SELECTION DEVICE ................

GROUP SORTING DEVICE .......................................... 70

IBM 978 CARD COUNTING

Control Panel' ..................................................

Common Digit Select:on .................................. 60

Multiple Column Selection ..............................

Zero-Elimination ............................. _................ 62

Normal Sorting ................................................ 63

Internal Controls ......... ...................... ........ ...............

Circuit Description .................................................. 64

Normal Sorting and Common Digit Selection 64

Multiple.

Static

Sensing a Selected

Sensing an Unselected

Zero Elimination ....................... .............. .......... ..... 68

Static Circuit Conditions ................................ 68

Operation of

Circuit Cutout Relay........................................ 69

Internal Controls . ........... ...... ....... ...... ..... ...... ....... ...

Circuit

I?esc~ipti?n

Static

Firing the MCC Tube ....................................

Sorting the Master Card ...............................

Sorting Detail Cards ..................................... 72

Trailer Card Operation ....................................

Single Master Card Operation ........................

Purpose of Miscellaneous Circuit Components

Functional

Introduction . ................ ....... ....... .... ................... 76

Reset .................................................................. 76

Counters ............................................................ 76

Tube and Relay Storage .................................. 76

Circuits ......................................................................

Powe~

ConditiOning

Sort

Count Only...................................................... 79

Sort and Count ..... .................... ..... .................. 82

Purpose of Circuit Components .............................. 82

Wire Contact Relays ............... ......................... 82

Duo Relays ..................................... ................. 82

Cam Contacts ................................................... 84

Switches

Rectifier

Resistor ...... ............ ......... ................................. 84

~abi!lets

Col.umi?'

CirCUit

CirCUit

Principles .............................................. 76

.

Only.......

and Power Supply Rectifier .... 45

..

Up Relay.................................... 47

SPECIAL

COUNTING

DEVICE ..........................................

Supply:

.... ...... ....... .......................... ................. 84

. .... ....... ....... .... ........ ...... ...... .......... ....... 84

DEVICES

Select.i~n

Condltlons ... .......................... ..... 64

Value ................................ 64

.the

Zero-Eliminate Control Tube 68

...... :.:.........................................

Condltlons ..................................

UNIT

..... :........................................... 77

CirCUits

...... ...... ............... ........... 79

................................................. 79

...... .................. 46

DEVICE ..................

.................................... 64

Value .......................... 64

.............................. 76

45

50

51

53

53

55

~~

57

58

51:!

59

6J

61

6.3

71

71

72

72

_.

72

75

75

75

77

Page 5

IBM

82

CARD

SORTING

MACHINE

Page 6

IBM

82

CARD

SORTING

MACI-tINI:

FUNCTIONAL

THE THREE machines necessary

operations required in punched card accounting are the

punch, the sorter, and the accounting machine. The

punch establishes the records, the sorter arranges or

classifies them, and the accounting machine produces

the printed reports.

In

punched card accounting systems, thousands of

cards may

final

reports.

be

involved daily in the

In

most

cases,

to

perform the basic

taJSk

of preparing

these cards must

be

classi-

PRINCIPLES

fied

properly prior to the preparation of each report on

accounting machines. Classification of such a large

number of cards manually would present an immense

task which would consume many man hours of work

and would

The Type 82 Card Sorting Machine affords a speedy

and accurate method of arranging cards into

sequence. The

be

greatly subjected to human errors.

operation of the Type 82 Sorter

any desired

is

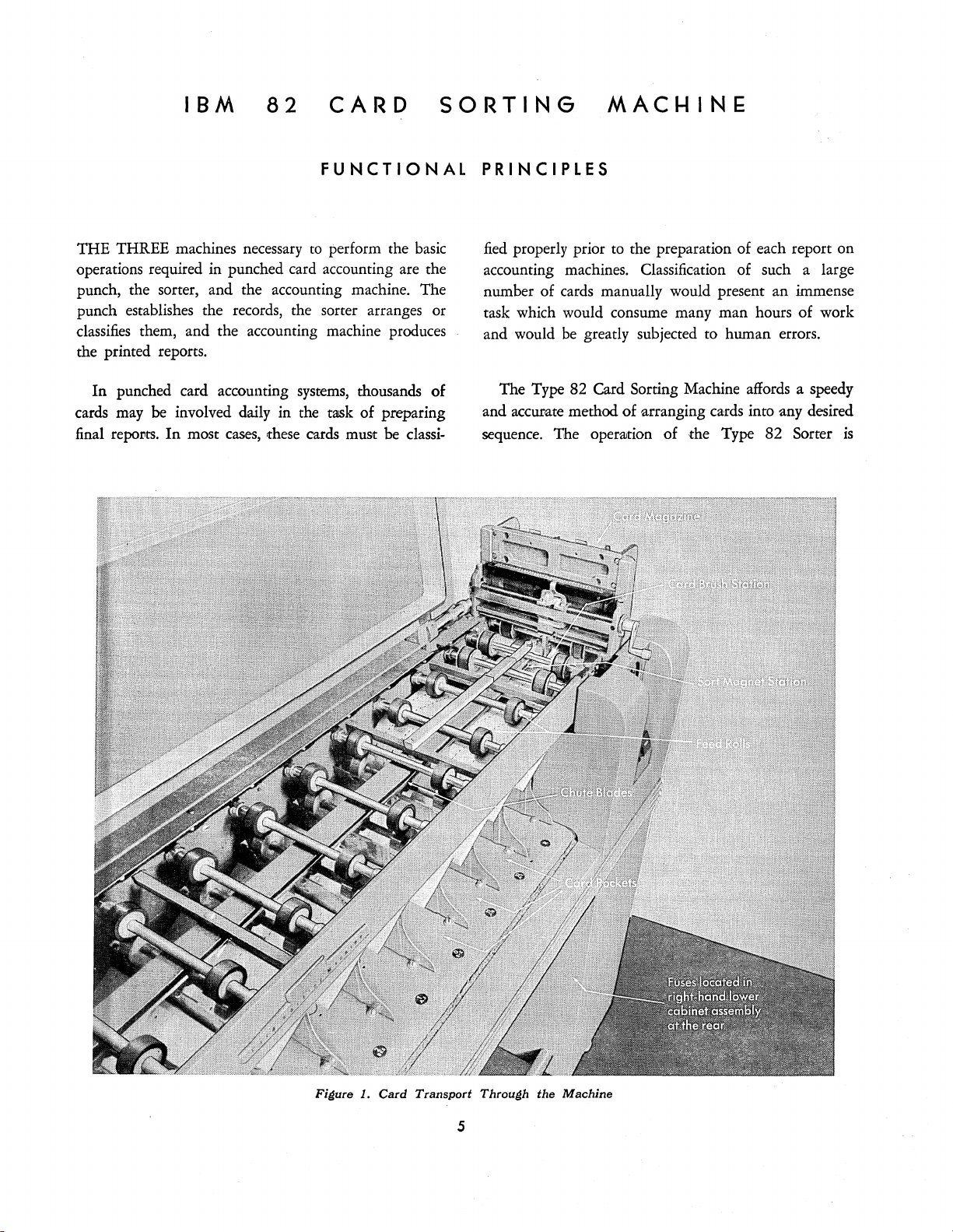

Figure 1. Card Transport Through

the

Machine

Page 7

6

CARD

SORTING

MACHINE,

TYPE

82

entirely automatic, except for the removal and replenishing of cards in the machine.

Sorting cards on the Type 82 machine consists of

running the cards through the machine once for each

is

column in the field being classified. This

comparable

to scanning a series of printed figures with the human

eye, except here an electric sensing brush becomes the

eye.

This brush can sort on only one column at a time.

However, it

tion the brush to sort on

positions on the IBM card. The machine

13

with

each digit value

is

movable,

so

that the operator may posi-

anyone

of the 80 column

is

equipped

pockets for dispersal of cards; one pocket for

0 through

12

and one reject pocket

for cards unpunched in the column being sorted.

By

means of feed knives, cards are

fed

one at a time

from the bottom of the pack in the card magazine on

1).

the right end of the machine (Figure

After leaving

the card magazine, they are gripped between sets of

constantly revolving feed rolls and are fed from the

As

right to the left of the machine.

from right to left, they first

pass

the cards travel

the card brush station,

located between the first and second sets of feed rolls.

Here the punching in the card column being sorted

sensed

by

means of a brush projecting through the holes

is

in the card and making contact on a common roll.

at

Sensing of card punching

the card brush station sets

up the proper combination of raised or lowered chute

blades at the sort magnet station, located between the

is

is

traveling

accom-

to

second and third sets of feed rolls. This setup

as

plished

the leading edge of the card

under the chute blades. The chute blades, according

their setup, then direct the' card

is

(the card

If

a 1 punch

still being carried

is

sensed at the card brush station, the

to

its

proper pocket

by

the feed rolls).

chute blade combination setup will be such that the

If

card will be directed to the 1 pocket.

is

sensed at the card brush station, the chute blade

an 8 punch

combination setup will be such that the card will be

directed to the 8 pocket.

no punching

is

sensed

at

If

the card brush station, all chute blades will remain in

to

a raised position, and the card will be directed

the

reject pocket.

23

13

13

--~

"3" Pocket

12

"2" Pocket

Cards

22

12

22

now

12

22

22

in

order

FIRST

21

"1" Pocket

in

units position

SORT

2

~

112

2 2

3

1

2

1

2 1)

3

1

2 2)

2 1

1

1

1 2

2,2

2 3

2 1

2 2

Cards

in

Magazin

2.

Principle

e

23

23

22

of

Cards

Sorting

22 13

22

22

21

21

21

"2" Pocket

in

order

13

12

12

12

11

"I"

Pocket

in

units and tens position (sub classification)

SECOND

SORT

(in miscellaneous

order)

21

11

21

Figure

g)3

1 3

1

2 3

1 2

2 2

1 2

2 2

1

2 2

2 2

2 1

2 1

1

2

Cards in

order

position

(in

miscellaneous 0

in

tens position)

3

2

1

1

in u

nits

rder

Page 8

FUNCTIONAL

PRINCIPLES

7

During the time that the punching in the card

is

sensed and the proper chute blade combinations are

set up, the card

continually moving from right

to

is

left under control of the constantly running feed rolls.

Speed

cards per minute.

is

Numerical Sorting

and

Capacity

The speed of the Type 82 machine

The

capacity of the card magazine

550 cards.

PRINCIPLE

OF

SORTING

is

650 to 660

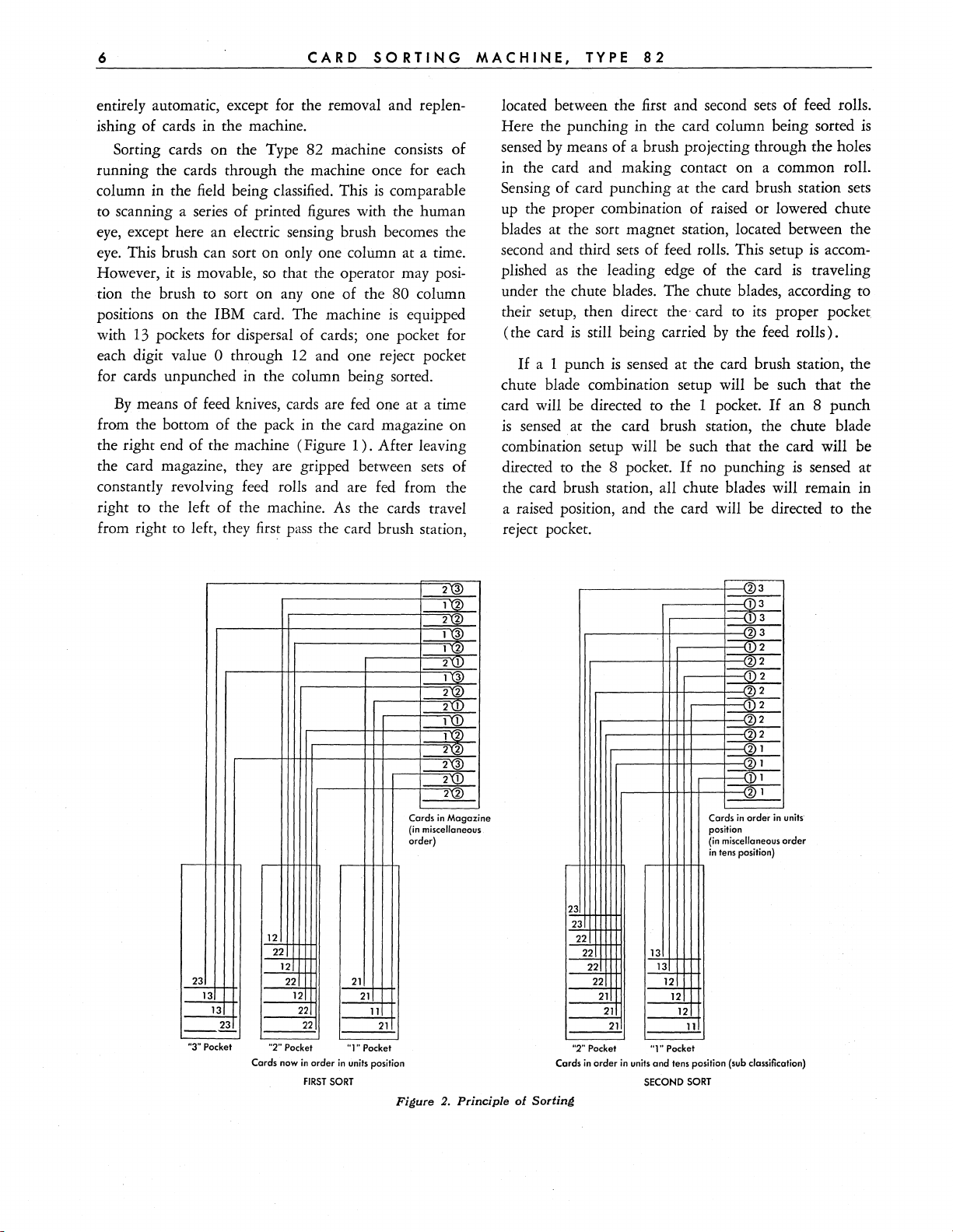

Sorting multiple digit fields when only one column

be

may

sorted

group of cards, punched

at

a time is illustrated in Figure

11

through 23 in a two digit

2.

A

field, are arranged in miscellaneous order and placed

The

in the card magazine of the sorter.

is

sorted first by positioning the card brush

units position

on

that

column and running the cards through the machine.

All cards punched with a 1 in the units column will fall

into the 1 pocket, all cards punched with a 2 in the

units column will fall into the 2 pocket, etc.

When

all the cards have been run through the

machine for sorting on the units position, the card

is

brush

shifted to the tens column position and the

cards removed from the pockets. To remove cards from

l's

the pockets in proper sequence, the

face

first and placed

down in the card magazine, the

are removed

2's are removed next and placed face down on the

l's, the 3's

face

down on the 2's, etc. This

is

common

practice but cards may be removed in descending order

by

starting with the 9's and keeping the cards face up

in the palm of the hand instead of face down. The

important item during removal

is

to keep the cards

in sequence.

After all cards have been removed from the pockets

and replaced in the card magazine, and the card brush

has been located on the tens column position, the

is

machine

restarted and sorting of the tens position

takes place. Those cards punched with a 1 in the tens

position fall into the 1 pocket, the 2's into the 2 pocket,

By

etc.

ing order

removing the cards from the pockets in ascend-

as

was

done on the first sort,

(l's

ahead of

the 2's) the original group of miscellaneous cards will

be

found to be in numerical sequence froni

The sorting process could be illustrated further

the

use

of a larger field, but from the foregoing example

be

it will

observed that, upon completion of the second

11

to 23.

by

sort, all cards will appear in groups arranged in correct

numerical sequence.

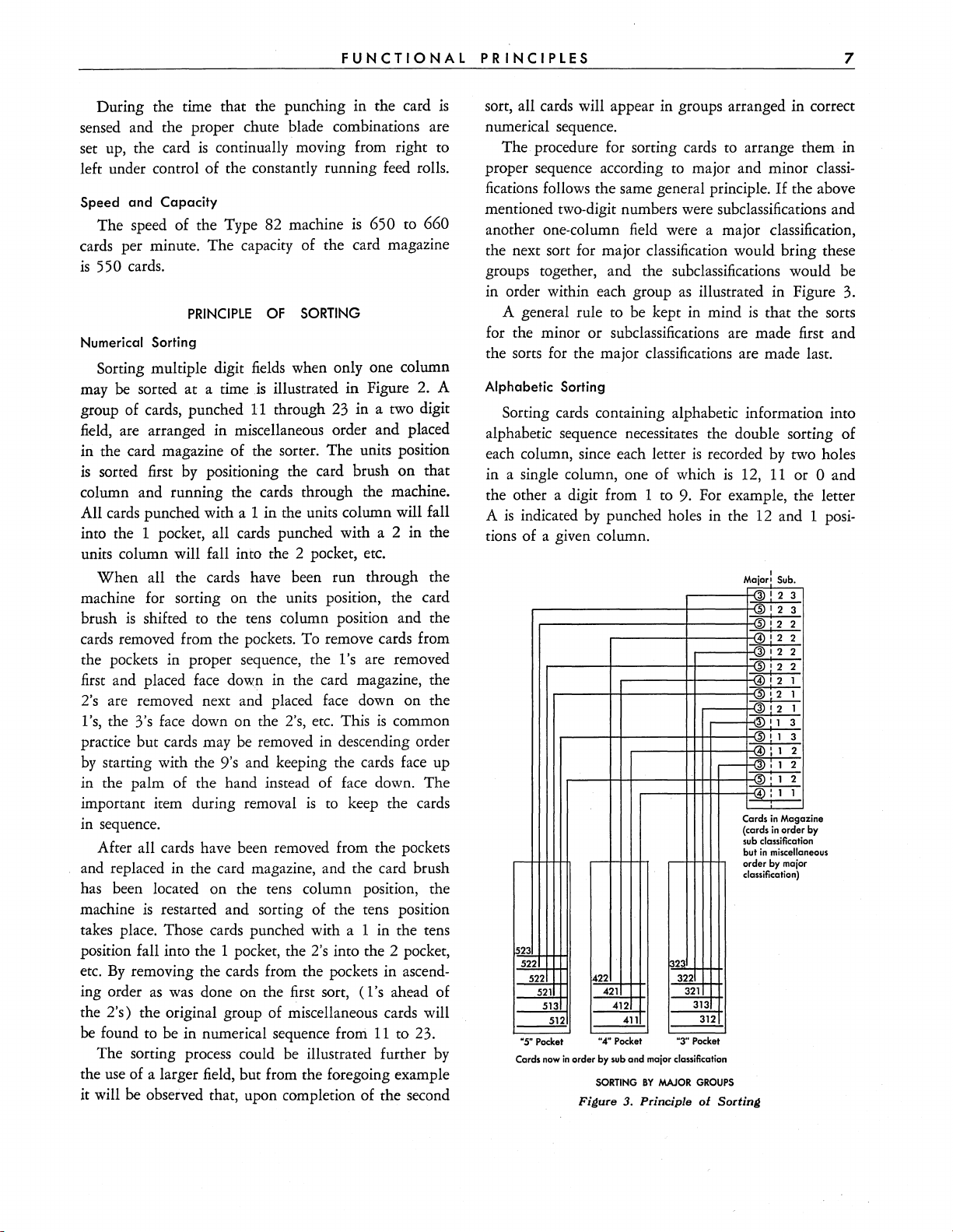

The procedure for sorting cards to arrange them in

proper sequence according to major and minor classi-

If

fications follows the same general principle.

the above

mentioned two-digit numbers were subclassifications and

another one-column field were a major classification,

the next sort for major classification would bring these

groups together, and the subclassifications would be

as

in order within each group

A general rule to be kept in mind

or

for the minor

the

SOrts

for the major classifications are made last.

subclassifications are made first and

illustrated in Figure 3.

is

that the sorts

Alphabetic Sorting

Sorting cards containing alphabetic information into

alphabetic sequence necessitates the double sorting of

is

each column, since each letter

in a single column, one of which

the other a digit from 1 to

is

A

indicated

by

punched holes in the 12 and 1 posi-

recorded by two holes

is

12,

11

or 0 and

9.

For example, the letter

tions of a given column.

Major! Sub

3

3)

! 2

12

5

3

1

5

2

12

4

2

12

12

3

2

1

2

12

4

1

'2

1

1

'2

,

3

1

12

3

: 1

3

i 1

2

: 1

: 1 2

,

, 1

2

1

4Y:

1

Cards

in

Maga

zine

by (cards

in

order

sub

1523

522

522

521

513

"5"

Pocket

Cards now

422 322

512

in

order

SORTING

Figure

421

412

"4"

Pocket

by sub

411

and

major classification

BY

MAJOR

3.

Principie

1323

"3"

321

313

312

Pocket

GROUPS

of

but

order

classification)

Sorting

classificatio

in

miscella

by

major

n

ne~us

Page 9

8

CARD

SORTING

MACHINE,

TYPE

82

The cards are sorted in the normal manner

ing to the digits 1 to 9 in the first column to

zone

The

is

then moved

contact bar on the commutator (Figure

to

the center of the commutator and

the complete sorting operation repeated on the

card column. Positioning the

zone

contact bar in this

accord-

be

sorted.

4)

same

manner suspends sorting for all values of punching

except

pocket will contain the letters A to I

sequence; those in the

and those in the

columns are each sorted in the

the digits 1

punchings

from the pockets following a

cards should be placed

0,

11

and 12. Those

to

0,

cards

which fall in the

in

alphabetic

11

pocket, the letters J

to

° pocket, the letters S to Z. Succeeding

same

9

first,

followed

11

and 12. When cards

face

down

manner

by

sorting of the zone

zone

sort, the

in the card magazine,

are

as

above;

removed

12

12

R;

zone

11

zone

the

cards next; and the °

zone

cards

last in

preparation for digit sorting on the next column.

In

most

cases,

it

is

not necessary to sort on all columns

of a name field to place the cards

in alphabetic order.

Usually sorting on the first three or four characters in

be

a group of names will

OPERATING

REFER

to Figure 4 for the location of the major oper-

sufficient.

FEATURES

ating features.

Switches

and

Fuses

There are 3 operating switches located on the front

right end of the machine. The main line switch, when

turned

on,

furnishes power to the machine and

com-

Fi4ure 4. Operatinl1 Features

Page 10

FUNCTIONAL

PRINCIPLES

.,

pletes a circuit to the filaments of the tubes.

completes a circuit to the time delay relay.

The start button, when depressed, sets up circuits

which energize the drive motor, and it causes the

chine

to

operate. The start button

approximately

line switch because of the delay caused

relay. This delay

filaments to reach proper operating temperature before

the machine

The stop button causes immediate stopping of the

machine.

out feature of the machine

the machine stops

friction.

The fuses are located on the inner side of the right

hand lower cabinet assembly in the position shown in

Figure

Card

may be set on any column to

card brush lifting handle near the front of the card

magazine. Each rotation of the handle moves the brush

one column. The brush may

columns

and sliding the brush holder to the desired column while

pressing down the finger lever at the top of the brush

assembly. A column indicator guide and pointer

located above the brush in a position readily visible

to the operator for convenient setting of the brush on

the column to be sorted.

Contact

before the start key can become operative. This

safety cover which operates two microswitches.

ing of these microswitches when the contact roll cover.

is

Commutator

commutator on which

bar are mounted. The contact bars on the commutator

When

the outside of the commutator, all holes punched in

the card column being sorted are sensed and cause the

card to sort to

1.

Brush

The card brush senses the punching in the card.

The plastic cover. over the contact roll must

raised interrupts the running and sorting circuits.

On

the front end of the first lower

vertical position in the card) and an alphabetic zone

are accessible through the large hole

all of the commutator contact bars are toward

50 seconds after turning on the main

is

necessary to allow the electron tube

is

started.

When

by

Roll

the

stOP

button

is

rendered inoperative, and

as

soon

as

its inertia

be

be

rotating the handle to the upper position

Cover

12

contact bars (one for each

its proper pocket. However,

is

ineffective for

by

the time delay

is

depressed, the run-

is

sorted

by

moved across several

in

the switch plate.

It

overcome

rotating the

be

down

Open-

feed

roll

if

the 4 and

also

ma-

by

It

is

is

is

o contact bars, for example, were moved to the center

of the commutator, sorting of 4's and

suspended. Any 4 or

being sorted would not be sensed and the card would

feed

to the reject pocket just

punched. Sorting of all other digits would be normal.

1£

the zone contact bar (red bar)

center of the commutator, sorting will be suspended

for all punching except

cards that have no

being sorted, will be fed to the reject pocket

they were unpunched.

Declutching Hand Wheel

A declutching hand wheel

the machine over

timings. This hand wheel

of the machine and, when rotated in a clockwise

tion, causes the main drive shaft and its gears to revolve.

The handwheel must be pressed

is

being revolved before the main worm shaft will

rotate.

the handwheel

it from revolving and presenting a hazard.

Card Runout

machine

in the machine keeps the drive motor running for a

long enough period of time to allow all cards to feed

to

runout feature was not present, making it necessary in

many cases to depress the start

the last

a

matic pocket stop. This

matically shuts

when

capacity with cards. Each pocket has a capacity of

a

Machine Operation

When

When

their proper pockets.

Pocket Stop Device

Each pocket of the sorter

anyone

approximately

stopped

can not be restarted

the full pocket or pockets have been emptied.

The main line switch should be turned on first to

allow time for the tubes to heat up while other

tions for starting are

the machine

the card magazine becomes empty while the

is

in operation, a runout feature incorporated

few

cards into their proper pockets.

of the thirteen pockets becomes filled to

by

the activation

0 punching in the card column

as

0,

11

and 12.

0,

11

or

12

punching in the column

is

provided for turning

by

hand to check adjustments and

is

located on the right end

is

operating under power,

is

automatically declutched to keep

On

older sorting machines

key

is

equipped with an auto-

is

a safety device which auto-

off

the current and stops the machine

550 cards. Once the machine has been

of

the pocket stop device, it

by

means of the start key until

being

completed.

O's

though it were un-

is

moved to the

That

to

the left while

long enough to feed

would be

is,

those

as

though

direc-

it

this

prepara-

Page 11

10

Prior

CARD

to

placing cards in the card magazine, they

SORTING

should be carefully joggled against the glass top frame.

Cards are then inserted in the

the 9 edge to the left.

into the magazine. Check to

magazIne,

Do

not drop or force the cards

see

face

down with

that the edges of the

cards are even to assure free movement within the

magazine. Place the card weight on top of the pack

to insure proper feeding

of

the last

few

cards.

After the cards have been placed in the card maga-

zine, the card brush should

be

positioned on the proper

, card column. The contact bars on the commutator

should

or

the card column will be sensed

contact roll cover must be down before the start

be

checked to

OUT

position if desired,

see

that they are in the contacting

so

that all holes punched in

by

the card brush. The

key

can become operative.

Assuming that all of the above conditions have been

satisfied, the start

machine

to

key

may

be

depressed to cause the

operate. This key must be held depressed

until the cards have reached the third set of upper feed

rolls, thus dosing all card lever contacts. Once cards

have reached this position in the machine, it will continue

to

operate automatically until the card magazine

has been emptied of cards, one or more pockets become

full, or the stop

key

is

depressed. The contact roll cover

MACHINE,

must not

since this may

TYPE

be

raised while the machine

cause

82

mis-sorting

is

in operation

as

the machine comes

to a stop.

Care should be exercised when adding

card magazine while

the machine

is

jar the pack of cards already present in

and do not add any

in the machine

the machine

Current,

See

current and

NOTE:

Y2

HP

In

the

under the

to

Weight,

the table below for the operating current, starting

fuse

Some Type 82 machines were produced using

motors equipped with fusetrons instead of

case

of these machines,

1/3

cards jf the pack of cards present

is

small; either procedure may cause

jam.

and

Dimensions

rating of the Type

-the

fusetron racing listed

HP

heading may be used

cards to the

operating. Do not

the machine

82

machine.

as

these values

give enough safety factor due to their time lag char-

aoreristJic.

Weight unpacked Weight packed

Length

Width

Height - - - - - - -

530 pounds

785

pounds

61

inches

16

inches

46 inches

fuses.

----

Voltage Group

Volts

115

230

115

115 50

115

230

230 50

230 60 1 3.7 3.5

208 60

230 25

230 50

230 60

Cycles

DC

DC 3.0

25

60

25

Phases

1

1

1

1 3.7

1

1

3

3

3

Maximum

Operating Current

Amperes

1/2

HP

5.0

6.5

7.0 6.5

6.5

4.0

4.0 3.8

2.1

2.3 2.2

2.1 2.0

1/3

5.0

3.0

6.0

6.1

3.5

3.9

2.0

HP

Maximum

Starting Current

Amperes

1/2

HP

42.9 36.9

21.9

38.9

37.9

39.9

18.6

19.1 13.0

20.1

18.2

12.7

14.6

13.2

1/3

18.9

26.7

25.6

26.9

13.5

15.0

16.6

8.4

9.9

9.1

HP

Main

Fuses

Ampere Rating

1/2

HP

Fuse

12

6

12

12

12

6 4.0

6 4.0

6

6

6 2.5

6 2.5

6

1/3

HP

Fusetron

5.0

3.2

8.0

8.0

8.0

4.0

4.0

2.5

Page 12

MECHANICAL

THE

REAR cover assembly and the covers on the right

AND

and left ends of the machine are each held in place

by

means of concealed latches. These latches may

released

bottom and held in place

by

pressing on the latch cover plate.

The cover over the switch plate

by

a holding screw at the

is

hinged at the

be

upper right hand corner. The right end cover must

is

be removed before this holding screw

accessible.

ELECTRICAL

PRINCIPLES

sort magnet armature. There are two styles of chute

use.

blades in

the new style blade

The old style blade

is

.009" thick. The .009" blade

has better wearing qualities than the

Each blade

which it guides the card.

is

numbered according to the pocket to

In

is

.008" thick and

.008" blade.

guiding a card to the

proper pocket, the card rides immediately over the

chute blade for that pocket.

Four adjustable levelers are furnished with each

machine for the purpose of leveling the machine and

to eliminate excessive vibration caused

by

an uneven

floor surface.

Chute Blades

In

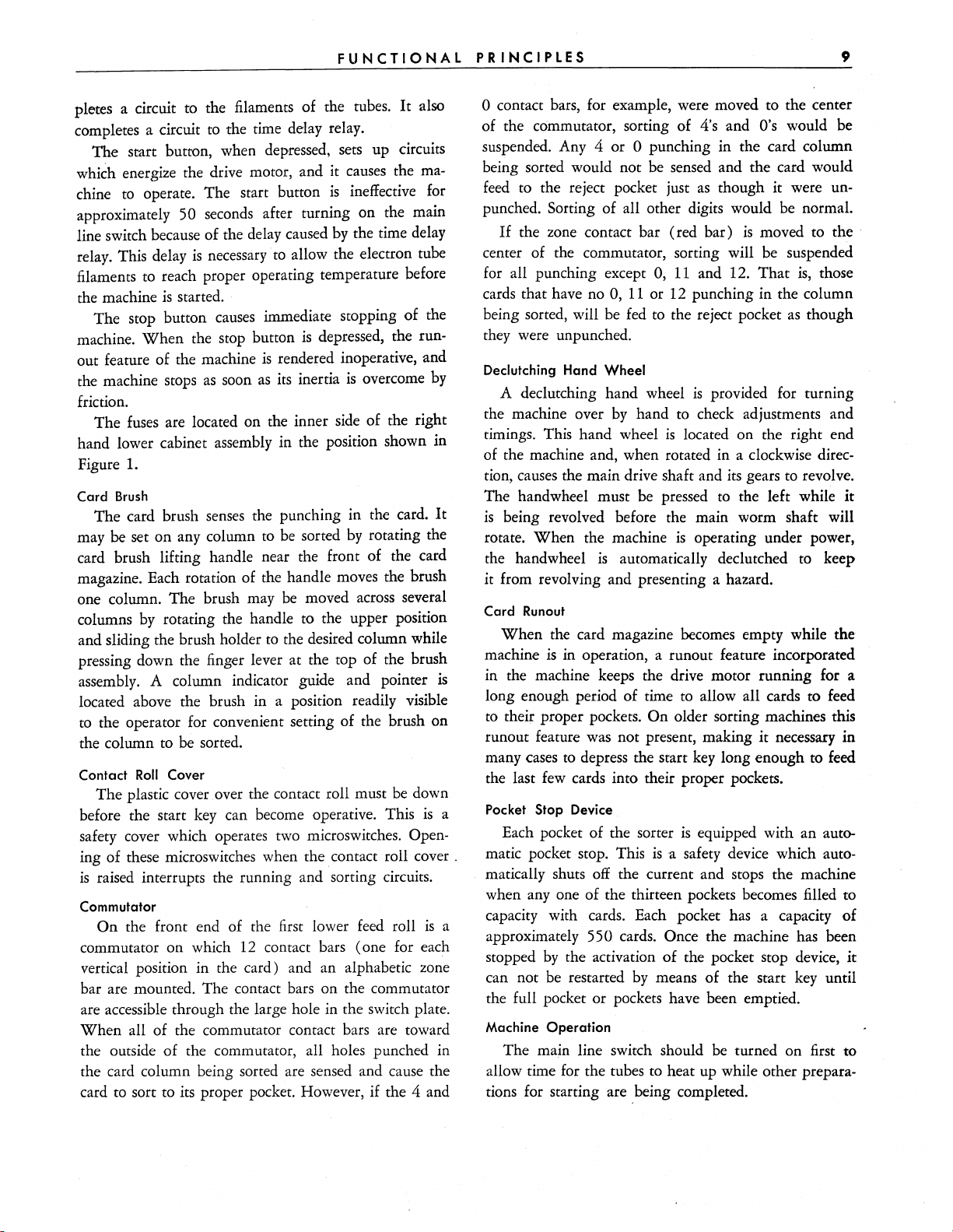

Figure 5, a card

and

Sort

Magnet

is

shown passing between the

card brush and the contact roll just after it has been

fed

from the bottom of the pack in the card magazine. The leading edge of the card

the tips of the chute blades and the card brush

is

passing under

is

wiping across the face of the card in search of punched

holes in the column being sorted.

The

chute blades are formed strips of tempered

spring steel, varying in length, from the opening of

each pocket to a position resting on the top of the

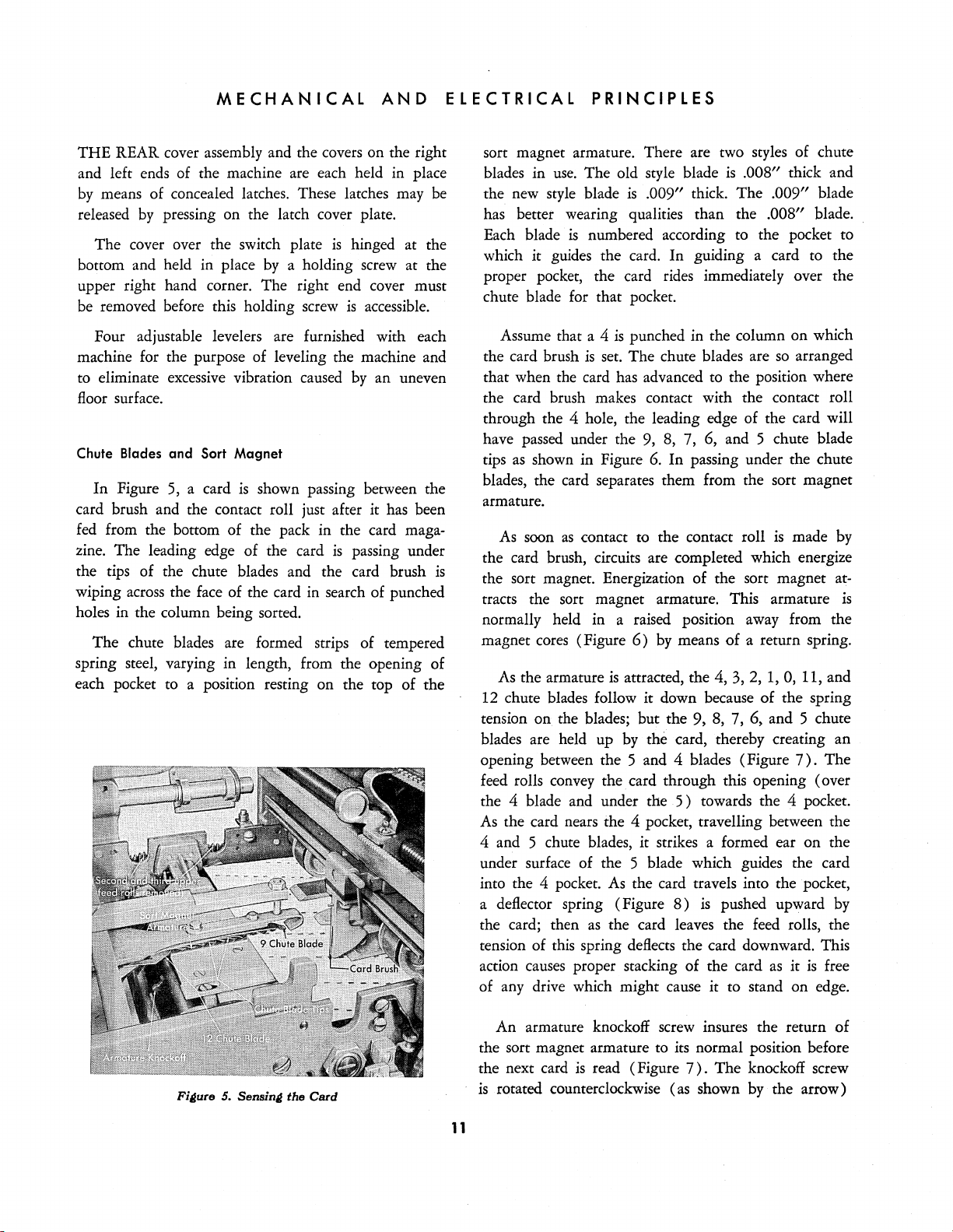

Assume that a 4

the card brush

is

punched in the column on which

is

set. The chute blades are

so

arranged

that when the card has advanced to the position where

the card brush makes contact with the contact roll

through the 4 hole, the leading edge of the card will

have passed under the 9, 8, 7, 6, and 5 chute blade

tips

as

shown in Figure

6.

In

passing under the chute

blades, the card separates them from the sort magnet

armature.

As

soon

as

contact

to

the contact roll

is

made

by

the card brush, circuits are completed which energize

the sort magnet. Energization of the sort magnet attracts the sort magnet armature. This armature

normally held in a raised position away from the

magnet cores (Figure

As the armature

is

means

attracted, the 4,

of

a return spring.

3,2,

1,

0,

11, and

6)

by

12 chute blades follow it down because of the spring

on

tension

the blades; but the 9, 8, 7, 6, and 5 chute

blades are held up by the card, thereby creating an

opening between the 5 and 4 blades (Figure

7).

The

feed rolls convey the card through this opening (over

the 4 blade and under the

As

the card nears the 4 pocket, travelling between the

5)

towards the 4 pocket.

4 and 5 chute blades, it strikes a formed ear on the

under surface of the 5 blade which guides the card

As

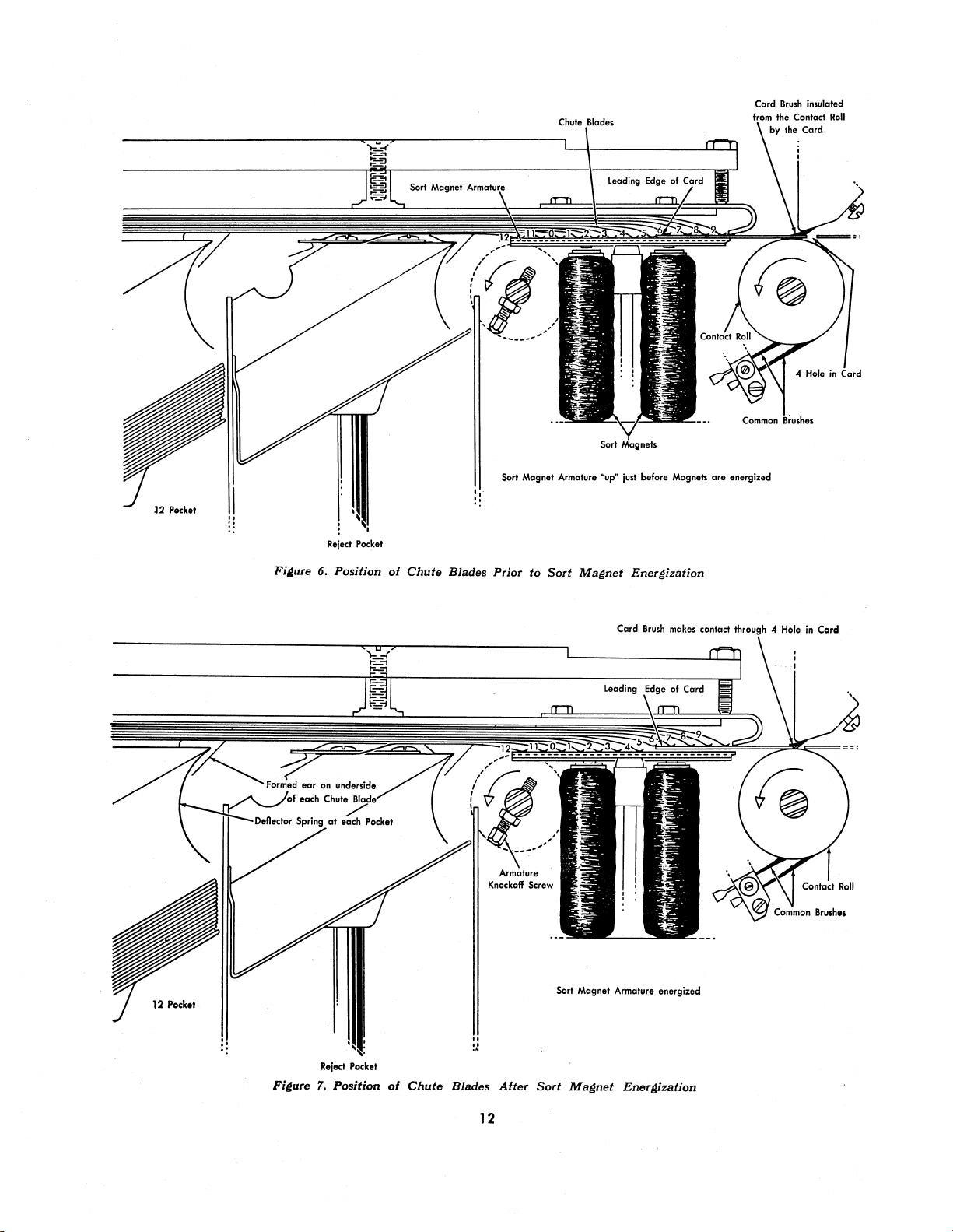

into the 4 pocket.

a deflector spring (Figure

the card; then

the card travels into the pocket,

8)

is

pushed upward by

as

the card leaves the feed rolls, the

tension of this spring deflects the card downward. This

action causes proper stacking of the card

as

it

is

free

of any drive which might cause it to stand on edge.

is

Fi~ure

5.

Sensin~

the

Card

An armature knockoff screw insures the return of

the sort magnet armature to its normal position before

is

the next card

is

rotated counterclockwise (as shown by the arrow)

11

read (Figure

7).

The

knockoff screw

Page 13

12

Pock.t

Reject

Pocket

','

"

"

Sort

Magnet Armatur.

·up·

just

before Magne

..

are

Card

energized

Brush

insulated

12

Pock.t

Fi~ure

6, Position

of

Chute

Blades Prior to

Sort

Magnet

Sort Magnet Armature energized

Energization

" Hole

in

Card

Figure

Reject

'1,

Position

Pock.t

of

Chute

Blades

12

After

Sort

Magnet

Enerl1ization

Page 14

Figure 8.

MECHANICAL

Cards

Entering the Pockets

AND

ELECTRICAL

and

is

which

one revolution per card cycle.

off

the armature between the

PRINCIPLES

mounted on the third lower feed roll shaft,

is

driven from the main worm shaft and makes

It

is

timed

12

position of one card

and the 9 position of the following card. Although

the return of the sort magnet armature

is

ated, the knockoff screw

provided to overcome any

is

residual magnetism present in the sort magnet.

If

the card fed

sorted, the card brush fails

contact roll; therefore, the sort magnet

is

its

fed

gized and

the card

is

unpunched in the column being

to

make contact with the

is

armature

is

not attracted. Consequently,

under all the chute blades and deflected

into the R (reject) pocket.

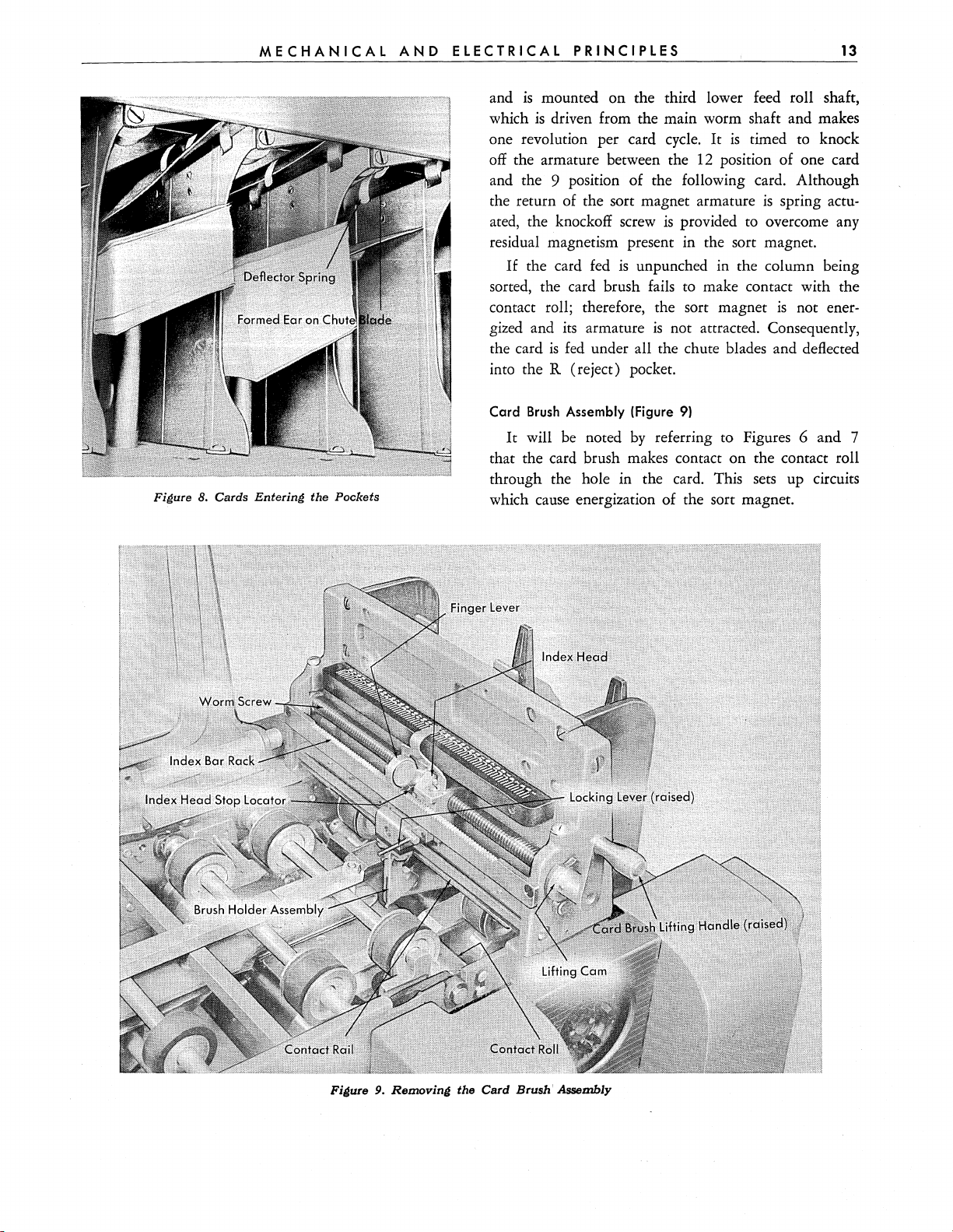

Card

Brush

It

Assembly (Figure

will

be

noted

by

9)

referring to Figures 6 and 7

that the card brush makes contact on the contact roll

through the hole in the card. This sets up circuits

which cause energization of the sort magnet.

13

to

knock

spring actu-

not ener-

Figure 9.

Removing

the Card Brush' Assembly

Page 15

14

CARD

SORTING

MACHINE,

TYPE

82

The card brush· may be positioned at

any

column

desired through manual operation of the card brush

lifting handle and the finger lever on the index head

rack holder (Figure

it

is

necessary that the card brush lifting handle be

in a position with

4).

During a sorting operation,

its

handle downward,

as

this allows

the card brush to rest on the contact roll for the pur-

pose of reading the card.

When

the card brush lifting handle

is

rotated one-

half turn from its normal downward position, the

card brush assembly

by

means of a cam pinned on each end of the worm

screw ( Figure

to raise the worm

held down

by

is

raised clear of the contact roll

9).

These

screw.

cams

operate against rollers

The worm

screw

is

normally

means of a compression spring on each

end.

Rotation of the card brush lifting handle one-half

turn not only raises the brush to clear the contact

roll, but also disengages the index head stop locator

from the index bar rack. This

assembly

is

to be moved. For one column movement,

one complete revolution of the lifting handle

is

necessary if the brush

raises

the

brush, disengages the index head stop locator, moves the

brush one column through the lead of the worm, and

lowers the brush to the contact roll

as

the index head

stop locator seats in the adjacent index bar rack tooth.

Rotation of the card brush lifting handle in a clockwise

direction moves the brush toward the rear of

the machine. Rotation of the handle counterclockwise

moves the brush toward the front of the machine.

To move the card brush assembly a distance of

several columns or more, the lifting handle

one-half turn to

its

raised position.

As

is

rotated

stated above,

this raises the brush from the contact roll and disengages the index head stop locator from the rack.

By

depressing the finger lever on the index head rack

holder, the index head locating nut

from the worm

screw.

This

is

mally held engaged with the worm screw

is

then disengaged

a half nut and

by

is

nor-

means of

a spring. Disengaging the index head locating nut

from the worm screw allows free movement, in either

direction, of the complete index head and brush holder

assemblies

the desired movement has been completed again

gages the locating nut with the worm

returning the lifting handle to

as

a unit. Releasing the finger lever after

screw,

its

downward position

en-

and

readies the brush for sensing the card.

Brush

Block

l!Iongated

Holes

Here

Brush

Holder

Brush

_----1-

F;~ure

10. Card

Brush

Holder

Assembly

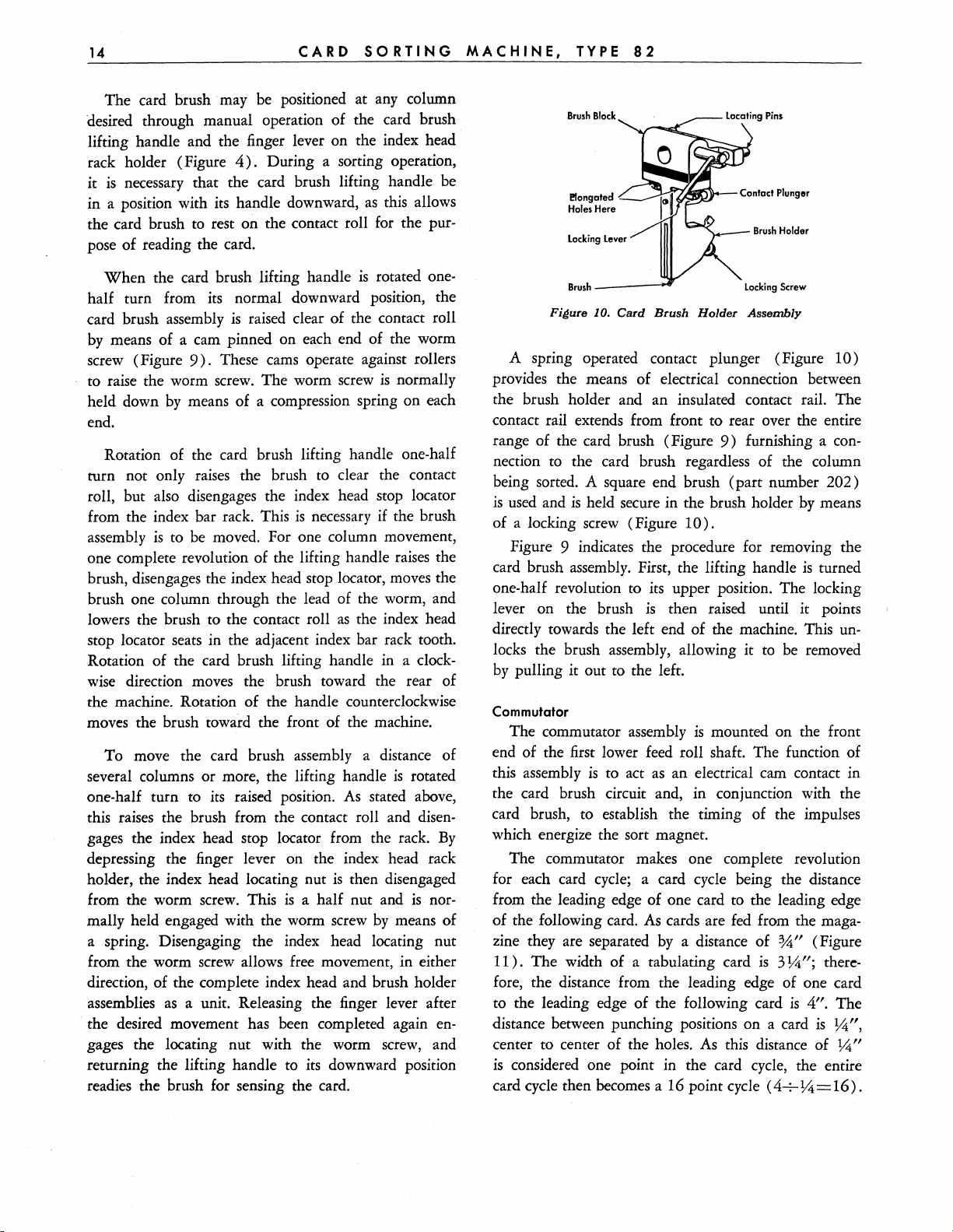

A spring operated contact plunger (Figure 10)

provides the means of electrical connection between

the brush holder and an insulated contact rail. The

contact rail extends from front to rear over the entire

range of the card brush (Figure

nection

to

the card brush regardless of the column

9)

furnishing a con-

being sorted. A square end brush (part number 202)

is

used

and

is

held secure in the brush holder

of a locking screw (Figure

10).

by

means

Figure 9 indicates the procedure for removing the

card brush assembly. First, the lifting handle

one-half revolution to

lever on the brush

its

upper position. The locking

is

then raised until it points

is

turned

directly towards the left end of the machine. This unlocks the brush assembly, allowing it

by

pulling it out to the left.

Commutator

The commutator assembly

is

mounted on the front

to

be removed

end of the first lower feed roll shaft. The function of

this assembly

is

to act

as

an electrical cam contact in

the card brush circuit and, in conjunction with the

card brush, to establish the timing of the impulses

which energize the sort magnet.

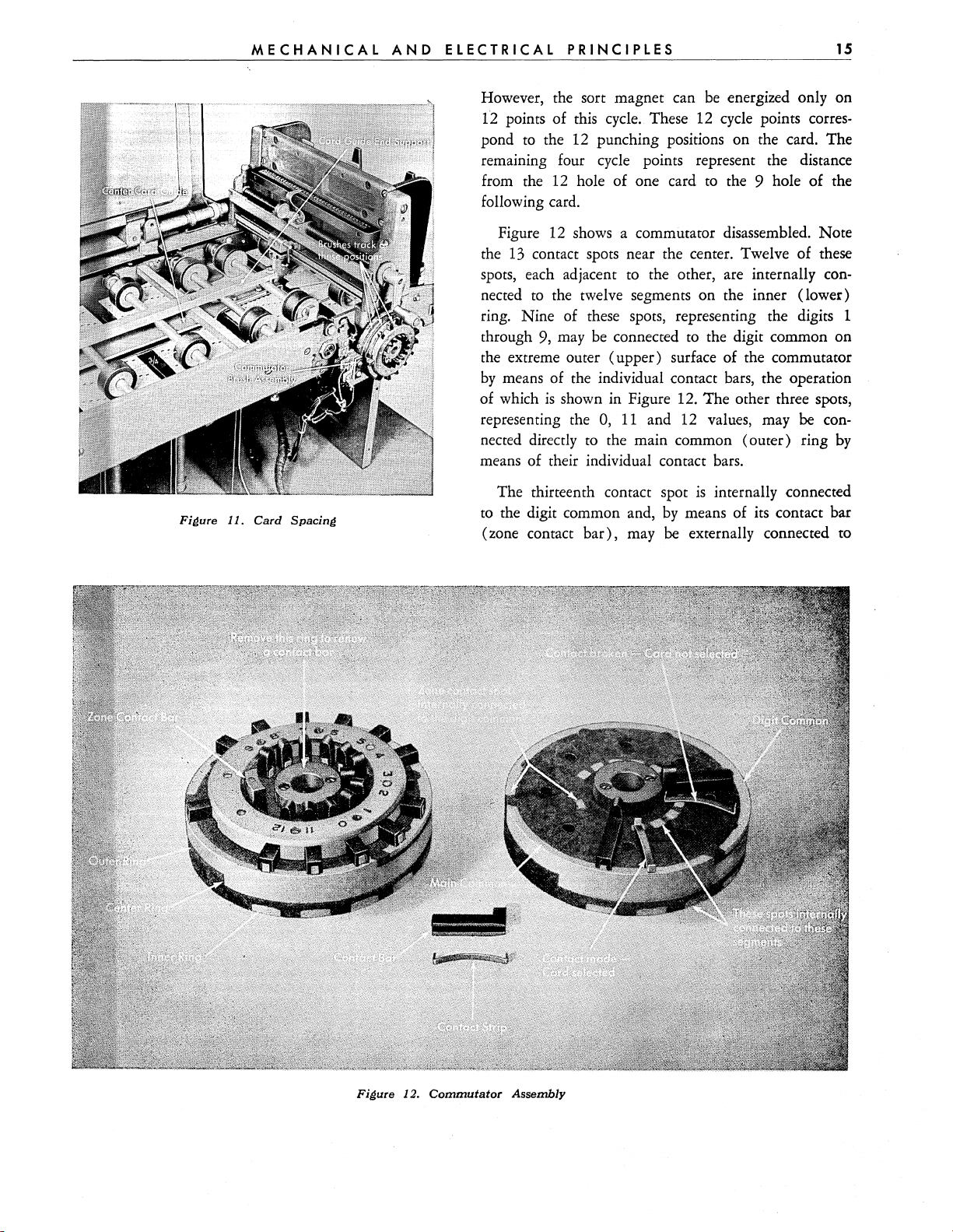

The commutator makes one complete revolution

for each card cycle; a card cycle being the distance

from the leading edge of one card to the leading edge

of the following card.

zine they are separated

11

).

The width of a tabulating card

As

cards are

by

a distance of

fed

from the maga-

%"

is

3

~";

(Figure

there-

fore, the distance from the leading edge of one card

to the leading edge of the following card

distance between punching positions on a card

center to center of the holes.

is

considered one point in the card cycle, the entire

As

this distance of

card cycle then becomes a 16 point cycle

(4-7-

is

~

4".

The

is

~",

~"

= 16) .

Page 16

MECHANICAL

AND

ELECTRICAL

PRINCIPLES

15

Fillure 11. Card Spacing

However, the sort magnet can

12 points of this cycle. These 12 cycle points

pond

to

the 12 punching positions on the card. The

be

energized only on

corres-

remaining four cycle points represent the distance

from the

hole of one card

to

the 9 hole of the

12

following card.

12

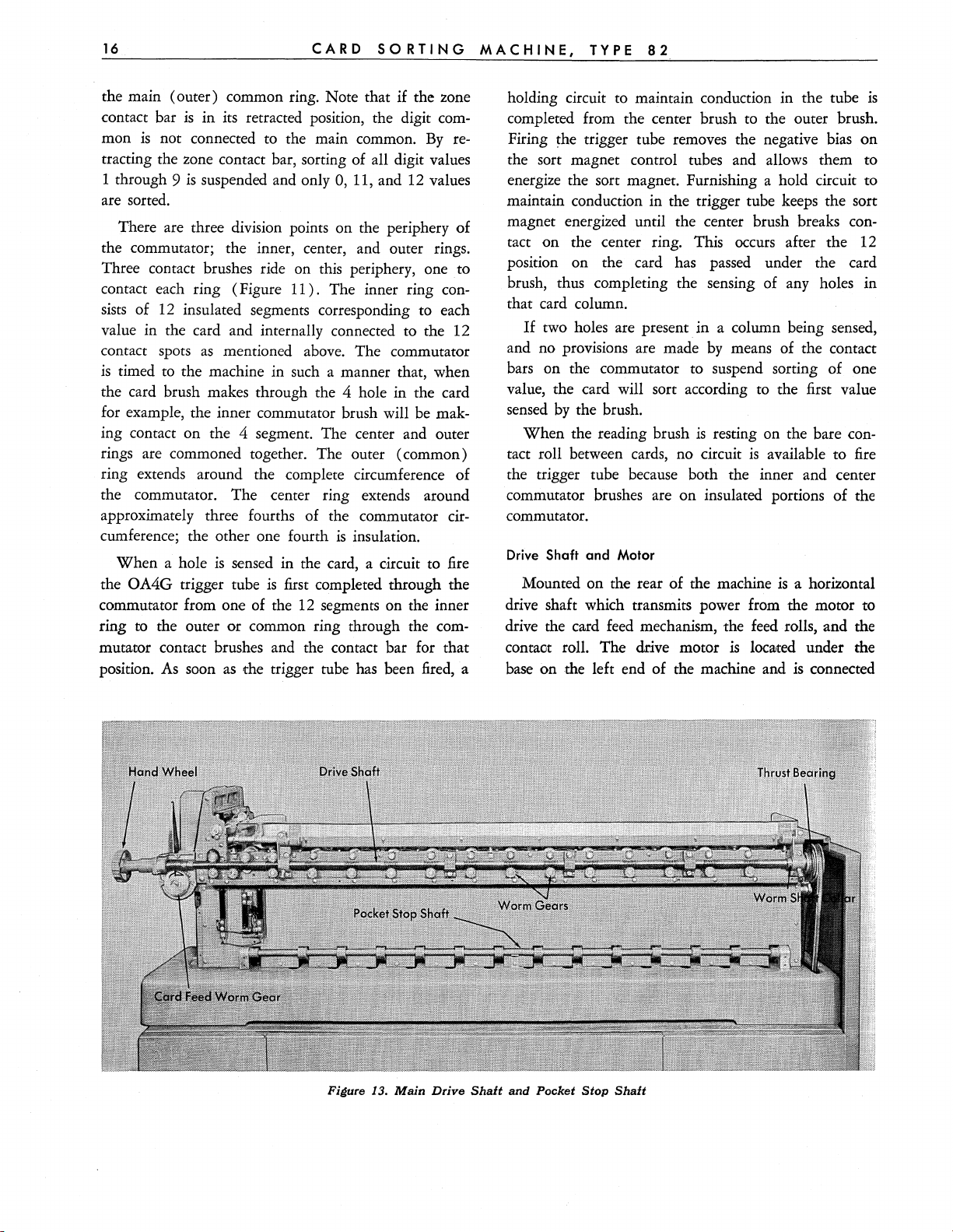

Figure

13

the

spots, each adjacent to the other, are internally

nected

shows a commutator disassembled. Note

contact spots near the center. Twelve of these

con-

to

the twelve segments on the inner (lower)

ring. Nine of these spots, representing the digits 1

to

through 9, may be connected

the digit common on

the extreme outer (upper) surface of the commutator

by

means of the individual contact bars, the operation

is

of which

shown

representing the

nected directly to the main common (outer) ring

in

Figure 12. 'The other three spots,

0,

11

and

12

values, may be con-

by

means of their individual contact bars.

is

The thirteenth contact spot

to

the digit common and,

bar),

(zone contact

maybe

by

internally connected

means of its contact bar

externally connected to

Figure 12.

Commutator

Assembly

Page 17

16

CARD

SORTING

MACHINE,

TYPE

82

the main (outer) common ring. Note that

contact bar

mon

is

in its retracted position, the digit com-

is

not connected

to

the main common.

if

the zone

By

re-

tracting the zone contact bar, sorting of all digit values

1 through 9

is

suspended and only 0, 11, and 12 values

are sorted.

There are three division points

on

the periphery

of

the commutator; the inner, center, and outer rings.

Three contact brushes ride on this periphery, one to

contact each ring (Figure

sists of

12

insulated segments corresponding to each

11).

The inner ring con-

value in the card and internally connected to the 12

contact spots

is

timed to the machine in such a manner that, when

as

mentioned above. The commutator

the card brush makes through the 4 hole in the card

for example, the inner commutator brush will be mak-

ing contact

on

the 4 segment. The center and outer

rings are commoned together. The outer (common)

ring extends around the complete circumference

of

the commutator. The center ring extends around

approximately three fourths of the commutator circumference; the other one fourth

When

the

OA4G

a hole

is

trigger tube

sensed in the card, a circuit

is

first completed through the

is

insulation.

to

fire

commutator from one of the 12 segments on the inner

ring to the outer

or

common ring through the commutator contact brushes and the contact bar for that

position.

As

soon as the trigger tube has been fired, a

holding circuit

completed from the center brush

Firing the trigger tube removes the negative bias

to

maintain conduction in the tube

to

the outer brush.

is

on

the sort magnet control tubes and allows them to

energize the

maintain conduction

SOrt

magnet. Furnishing a hold circuit to

in

the trigger tube keeps the sort

magnet energized until the center brush breaks contact

on

the center ring. This occurs after the 12

position on the card has passed under the card

brush, thus completing the sensing of any holes

in

that card column.

If

two holes are present in a column being sensed,

and no provisions are made by means of the contact

bars

on

the commutator to suspend sorting

of

one

value, the card will sort according to the first value

sensed by the brush.

When

the reading brush

tact roll between cards, no circuit

is

resting on the bare con-

is

available to fire

the trigger tube because both the inner and center

commutator brushes are

on

insulated portions

of

the

commutator.

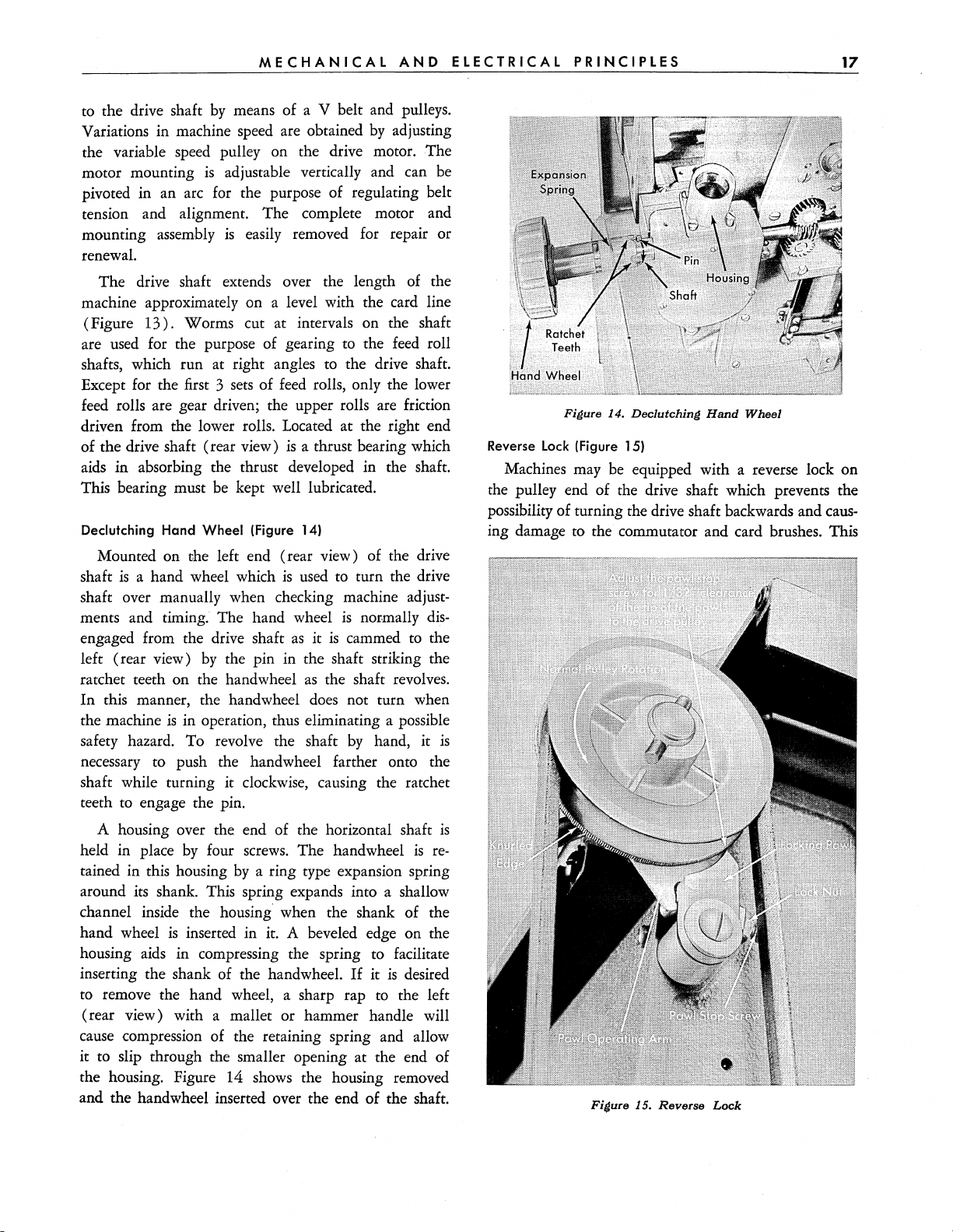

Drive Shaft and

Mounted

Motor

on

the rear of the machine

is

a horizontal

drive shaft which transmits power from the motor to

drive the card feed mechanism, the feed rolls, and the

contaot roll.

base

on

The

drive motor is

the left end

of

the machine and

10C3Jted

is

under the

connected

Figure

13.

Main

Drive

Shaft

and

Pocket

Stop

Shaft

Page 18

MECHANICAL

AND

ELECTRICAL

PRINCIPLES

17

to the drive shaft

Variations in machine speed are obtained

by

means of a V belt and pulleys.

by

adjusting

the variable speed pulley on the drive motor. The

motor mounting

is

adjustable vertically and can be

pivoted in an arc for the purpose of regulating belt

tension and alignment. The complete motor and

mounting assembly

is

easily removed for repair or

renewal.

The drive shaft extends over the length of the

machine approximately on a level with the card line

(Figure

are used for the purpose of gearing to the

13).

Worms cut at intervals on the shaft

feed

roll

shafts, which run at right angles to the drive shaft.

Except for the first 3

sets

of feed rolls, only the lower

feed rolls are gear driven; the upper rolls are friction

driven from the lower rolls. Located at the right end

of the drive shaft (rear view)

is

a thrust bearing which

aids in absorbing the thrust developed in the shaft.

This bearing must be kept well lubricated.

Declutching Hand Wheel (Figure 14)

Mounted on the left end (rear view) of the drive

shaft

is

a hand wheel which

is

used

to turn the drive

shaft over manually when checking machine adjustments and timing. The hand wheel

engaged from the drive shaft

left (rear view)

by

the pin in the shaft striking the

as

ratchet teeth on the handwheel

In

this manner, the handwheel

the machine

is

in operation, thus eliminating a possible

safety hazard. To revolve the shaft

is

normally

it

is

cammed

as

the shaft revolves.

does

not turn when

by

hand, it

to

dis-

the

is

necessary to push the handwheel farther onto the

shaft while turning it clockwise, causing the ratchet

teeth to engage the pin.

Figure 14.

Reverse Lock (Figure 15)

Declutching

Hand

Wheel

Machines may be equipped with a reverse lock on

the pulley end of the drive shaft which prevents the

possibility of turning the drive shaft backwards and

caus-

ing damage to the commutator and card brushes. This

A housing over the end of the horizontal shaft

held in place

tained in this housing

by

four

screws.

by

The handwheel

a ring type expansion spring

is

re-

around its shank. This spring expands into a shallow

channel inside the housing when the shank of the

hand wheel

housing

inserting the shank of the handwheel.

is

inserted in it. A beveled edge on the

aids

in compressing the spring to facilitate

If

it

is

desired

to remove the hand wheel, a sharp rap to the left

(rear view) with a mallet or hammer handle will

cause compression of the retaining spring and allow

it to slip through the smaller opening at the end of

the housing. Figure 14 shows the housing removed

and the handwheel inserted over the end

of

the shaft.

is

Figure 15.

Reverse

Lock

Page 19

18

CARD

SORTING

MACHINE,

TYPE

82

reverse lock

is

in the form of a ratchet knurl cut on the

rim of the drive pulley. A locking pawl operates against

is

the pulley when the force of motion

direction (viewed from the pulley

any actual rotation of the pulley.

is

rotation

end),

counterclockwise (viewed from the pulley

the locking pawl

is

held away from the knurled

end),

When

in a clockwise

thus preventing

the direction of

edge through the action of the pawl operating arm.

The pawl operating arm

actuated

by

a friction contact

is

with the drive pulley. The knurled teeth on the rim

of

the pulley are fine enough to prevent any appre-

ciable motion when the reverse lock operates. Any older

80 machines which are not equipped with the

Type

declutching type of handwheel should have a reverse

lock mechanism.

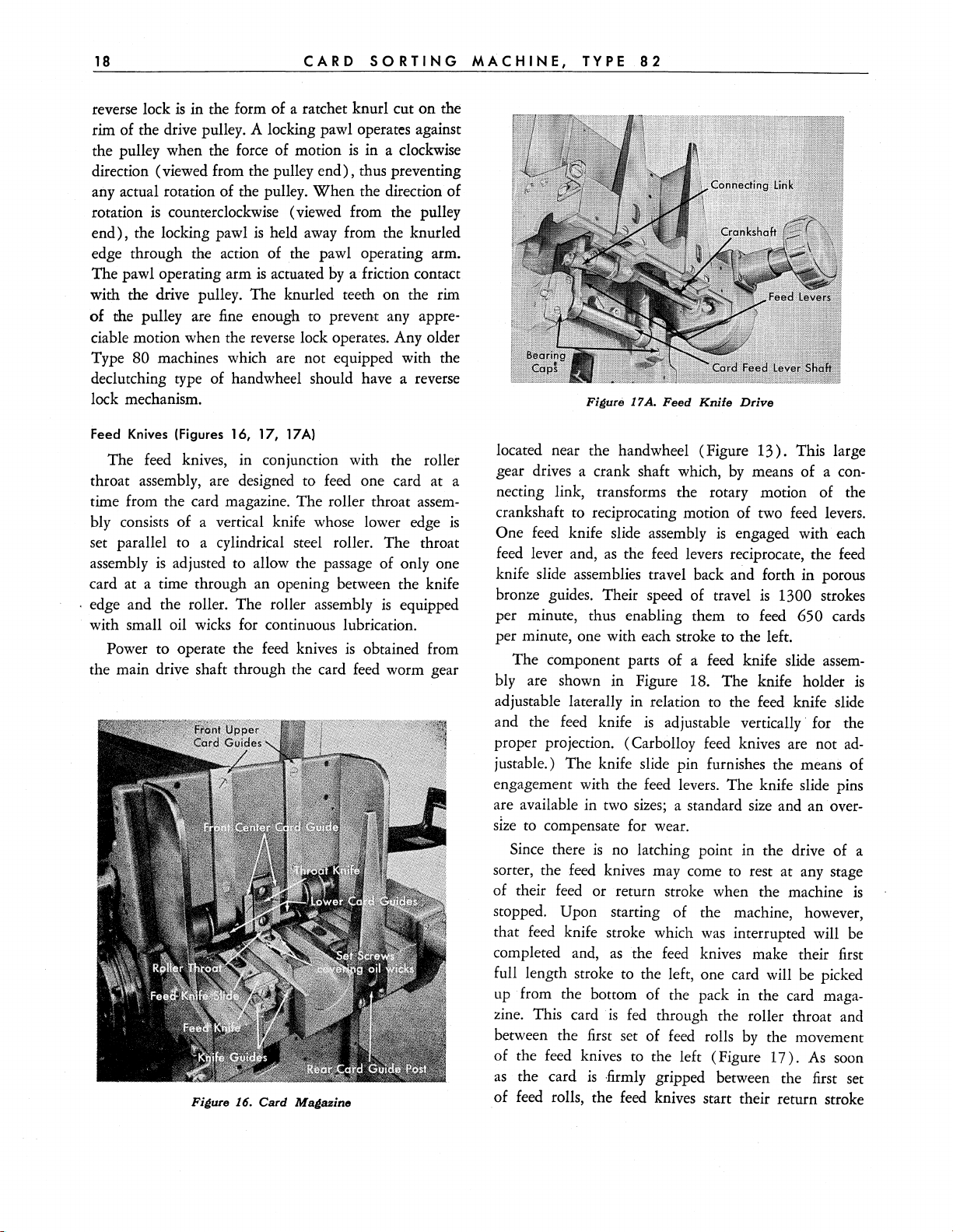

Feed

Knives

The

(Figures 16, 17, 17A)

feed

knives, in conjunction with the roller

throat assembly, are designed to feed one card at a

time from the card magazine. The roller throat

assem-

bly consists of a vertical knife whose lower edge

set parallel

assembly

to

a cylindrical steel roller. The throat

is

adjusted to allow the passage of only one

card at a time through an opening between the knife

is

. edge and the roller. The roller assembly

equipped

with small oil wicks for continuous lubrication.

feed

Power to operate the

knives

the main drive shaft through the card

Figure

16.

Card

Magazine

is

obtained from

feed

worm gear

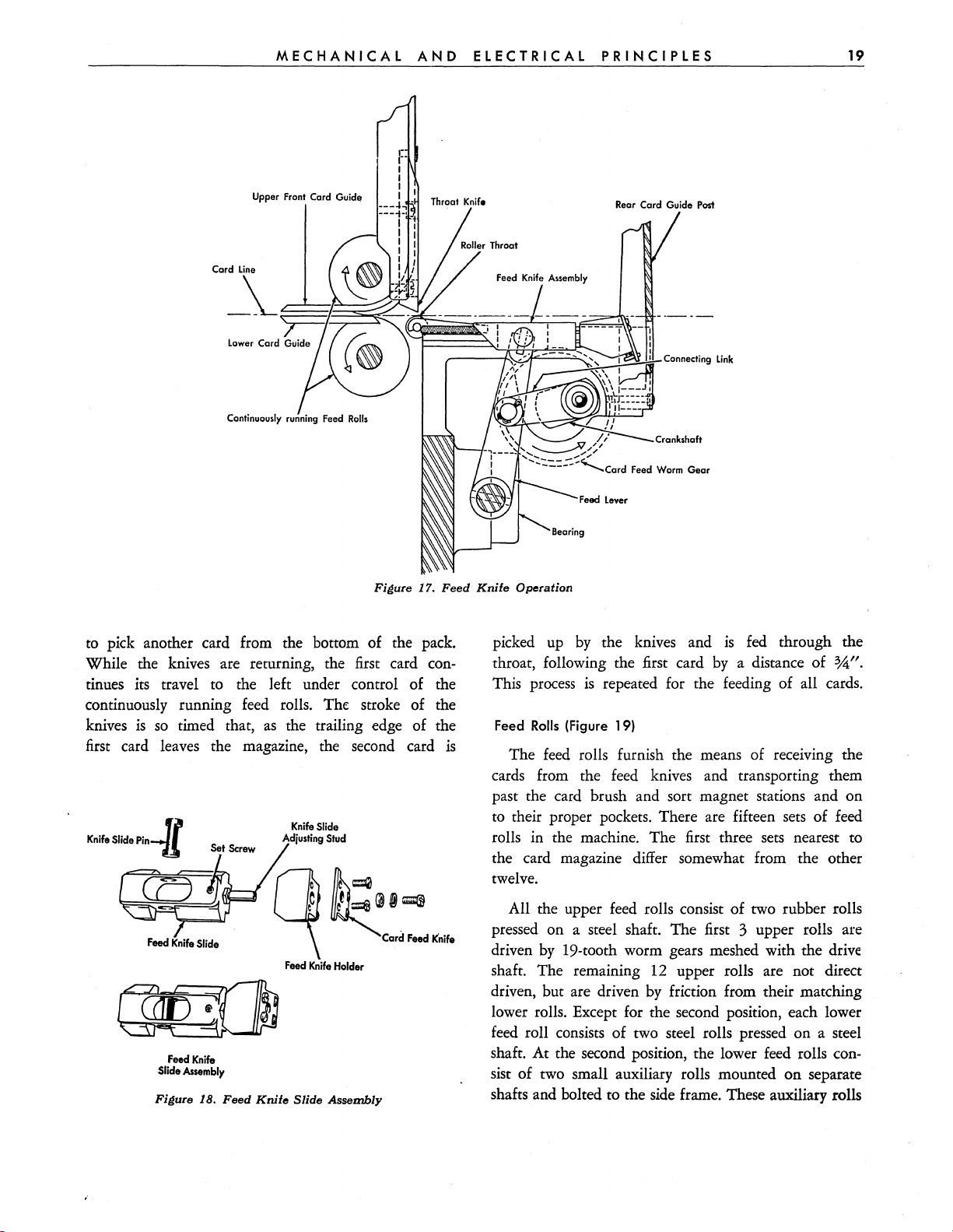

Figure

17A.

Feed

Knife

Drive

located near the handwheel (Figure

gear drives a crank shaft which,

13).

by

means of a con-

necting link, transforms the rotary motion of the

crankshaft to reciprocating motion of two feed levers.

is

One feed knife slide assembly

feed

lever and,

as

the

feed

is

engaged with each

levers reciprocate, the

knife slide assemblies travel back and forth in porous

bronze guides. Their speed of travel

is

per minute, thus enabling them to feed

per minute, one with each stroke to the left.

The component parts of

a feed knife slide

bly are shown in Figure 18. The knife holder

adjustable laterally in relation to the feed knife slide

feed

knife

is

and the

proper projection. (Carbolloy

adjustable vertically' for the

feed

knives are not

justable.) The knife slide pin furnishes the means of

engagement with the feed levers. The knife slide pins

are available in two

SIze

to

compensate for wear.

Since there

sorter, the

of their

is

no latching point in the drive of a

feed

knives may come to rest at any stage

feed

or return stroke when the machine

a standard

size

sizes;

stopped. Upon starting of the machine, however,

feed

that

knife stroke which

completed and,

as

the

was

interrupted will

feed

knives make their first

full length stroke to the left, one card will be picked

up

from the bottom of the pack in the card maga-

zine. This card

between the first set of

is

fed

through the roller throat and

feed

rolls

by

the movement

of the feed knives to the left (Figure

as

the card

feed

of

is

rolls, the

·firmly

feed

gripped between the first set

knives start their return stroke

This large

1300 strokes

650 cards

assem-

and an over-

17).

As

soon

feed

is

ad-

is

be

Page 20

MECHANICAL

AND

ELECTRICAL

PRINCIPLES

19

Upper Front Card Guid"

Continuou.ly running Feed

to

pick another card from the bottom of the pack.

While the knives are returning, the

RollI

Fi~ure

first

Throat

17.

card con-

Feed

tinues its travel to the left under control of the

continuously running

knives

first

is

so

timed that,

card leaves the magazine, the second card

Feed

Knife

Slide Assembly

Fi~ure

18.

Feed

feed

rolls. The stroke of the

as

the trailing edge of the

Knife

Slide

Adjulting

Stud

~~~

cO

~j~

~

Feed

Knife

Holder

Knife

Slide

Assembly

Card

Feed

is

Knife

Knife

__

Knife

Operation

picked

throat, following the first card

This

Feed

The

up

process

Rolls

(Figure 19)

feed

Rear Card Guide Post

J«---t-l1

by

the knives and

is

repeated for the feeding of all cards.

Connecting

Link

is

fed through the

by

a distance of

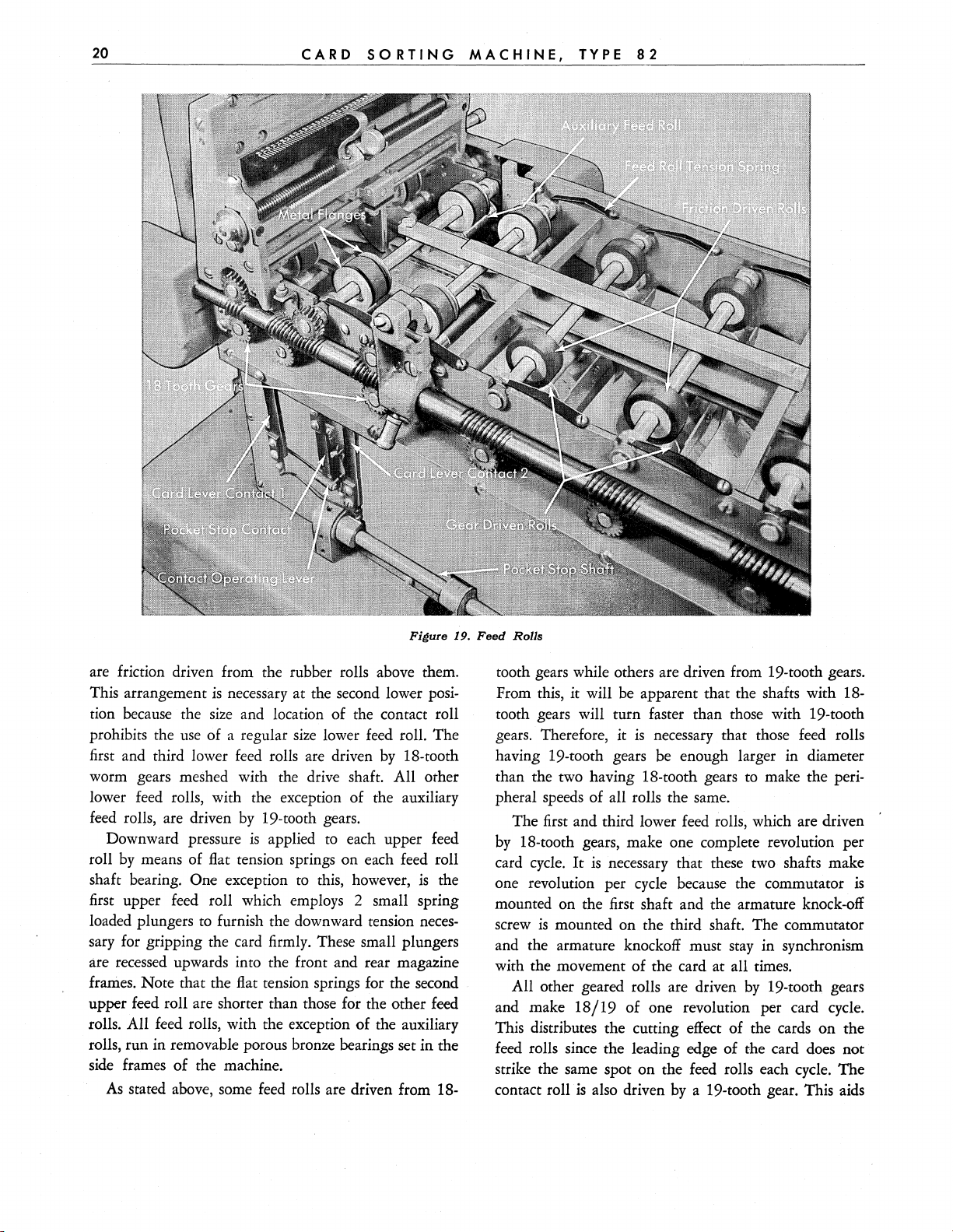

rolls furnish the means of recelvmg the

cards from the feed knives and transporting them

past the card brush and sort magnet stations and on

to their proper pockets. There are fifteen sets of feed

rolls in the machine. The

first

three sets nearest to

the card magazine differ somewhat from the other

twelve.

All the upper

feed

rolls consist of two rubber rolls

pressed on a steel shaft. The first 3 upper rolls are

driven

shaft. The remaining

driven, but are driven

by

19-tooth worm gears meshed with the drive

12

upper rolls are not direct

by

friction from their matching

lower rolls. Except for the second position, each lower

feed

roll consists of two steel rolls pressed on a steel

shafr. At the second position, the lower feed rolls consist of two small auxiliary rolls mounted

on

shafrs and bolted to the side frame. These auxiliary rolls

%0".

separate

Page 21

20

CARD

SO

RTING

MACHINE,

TYPE

8-=2

_________

_

Figure

are friction driven from the rubber rolls above them.

This arrangement

tion because the

prohibits the

first and third lower

is

necessary at the second lower posi-

size

and location of the contact roll

use

of a regular

feed

size

lower

rolls are driven

feed

by

roll. The

18-tooth

worm gears meshed with the drive shaft. All other

lower feed rolls, with the exception of the auxiliary

feed

rolls, are driven

Downward pressure

by

roll

shaft bearing.

means of flat tension springs on each feed roll

One exception

by

19-tooth gears.

is

applied

to

to

each upper feed

this, however,

is

the

first upper feed roll which employs 2 small spring

loaded plungers

furnish the downward tension

neces-

to

sary for gripping the card firmly. These small plungers

are recessed upwards into the front and rear magazine

frames. Note that the flat tension springs for the second

upper feed roll are shorter than those for the other feed

rolls. All feed rolls, with the exception of the auxiliary

rolls, run in removable porous bronze bearings set in the

side frames of the machine.

As

stated above, some

feed

rolls are driven from 18-

19.

Feed

RoIls

tooth gears while others are driven from 19-tooth gears.

From this, it will be apparent that the shafts with 18tooth gears will turn faster than those with 19-tooth

is

gears. Therefore, it

necessary that those feed rolls

having 19-tooth gears be enough larger in diameter

than the two having 18-tooth gears to make the peri-

pheral speeds of all rolls the same.

The first and third lower feed rolls, which are driven

by

18-tooth gears, make one complete revolution per

cycle.

It

is

card

necessary that these two shafts make

one revolution per cycle because the commutator

mounted on the first shaft and the armature knock-off

is

screw

mounted on the third shaft. The commutator

and the armature knockoff must stay in synchronism

with the movement of the card at all times.

by

All other geared rolls are driven

and make

18/19

of one revolution per card cycle.

19-tooth gears

This distributes the cutting effect of the cards on the

feed rolls since the leading edge of the card does not

strike the same spot on the feed rolls each cycle. The

is

contact roll

also driven

by

a 19-tooth gear. This aids

is

Page 22

M E C

HAN I CAL

in the reduction of any possible arcing

by

AND

changing the

point of contact between the card brush and the contact

roll each card cycle.

is

The cutting effect of the card

more pronounced

at the first three feed roll stations than at any others.

For this reason, the rubber feed rolls at these stations

are equipped with metal flanges on either side of the

rubber rolls. These flanges serve to further prevent

by

knicking of the rubber rolls

as

it strikes the roll. At the same time, because of

deflecting the card

the position and diameter of the flanges, the rubber

portions of the rolls are permitted to exert pressure on

the card for feeding even though some wear has taken

place on the rubber rolls.

feed

All feed roll gears are fastened to their

by

shafts

hub.

means of two setscrews through each gear

On recent machines, a hole

is

provided in the rear

roll

magazine frame, permitting the entry of a setscrew

wrench to reach the setscrews in the first upper feed

roll gear.

Card

Levers

and Contacts (Figures 4, 19)

There are two card levers which operate

contact'S

to

govern machine circuits. Card lever 1 is located near

the

rear of the machine between the upper and lower

first

feed rolls and

as

the leading edge of the card enters the first feed rolIs.

Closing of card lever contact 1 allows the sorting

cuits

to

function if a hole

is

operated

to

close

:its

contact just

is

sensed in the card when it

cir-

passes under the card brush.

is

Card lever 2

between the second and third upper feed rolls and

operated to close its contacts

located near the rear of the machine·

is

as

the leading edge of the

card leaves the second feed roll. Closing of card lever

contact 2 governs two machine functions; one of which

is

to complete the circuits necessary for automatic

machine operation after the operator removes his finger

from the start

The second function

is

to maintain

key.

the sorting circuits during sorting of the last card in the

machine.

Once closed, the card lever contacts remain closed

during the time that cards are continuously feeding

through the machine, opening only when the machine

runs out of cards.

E L E C T R

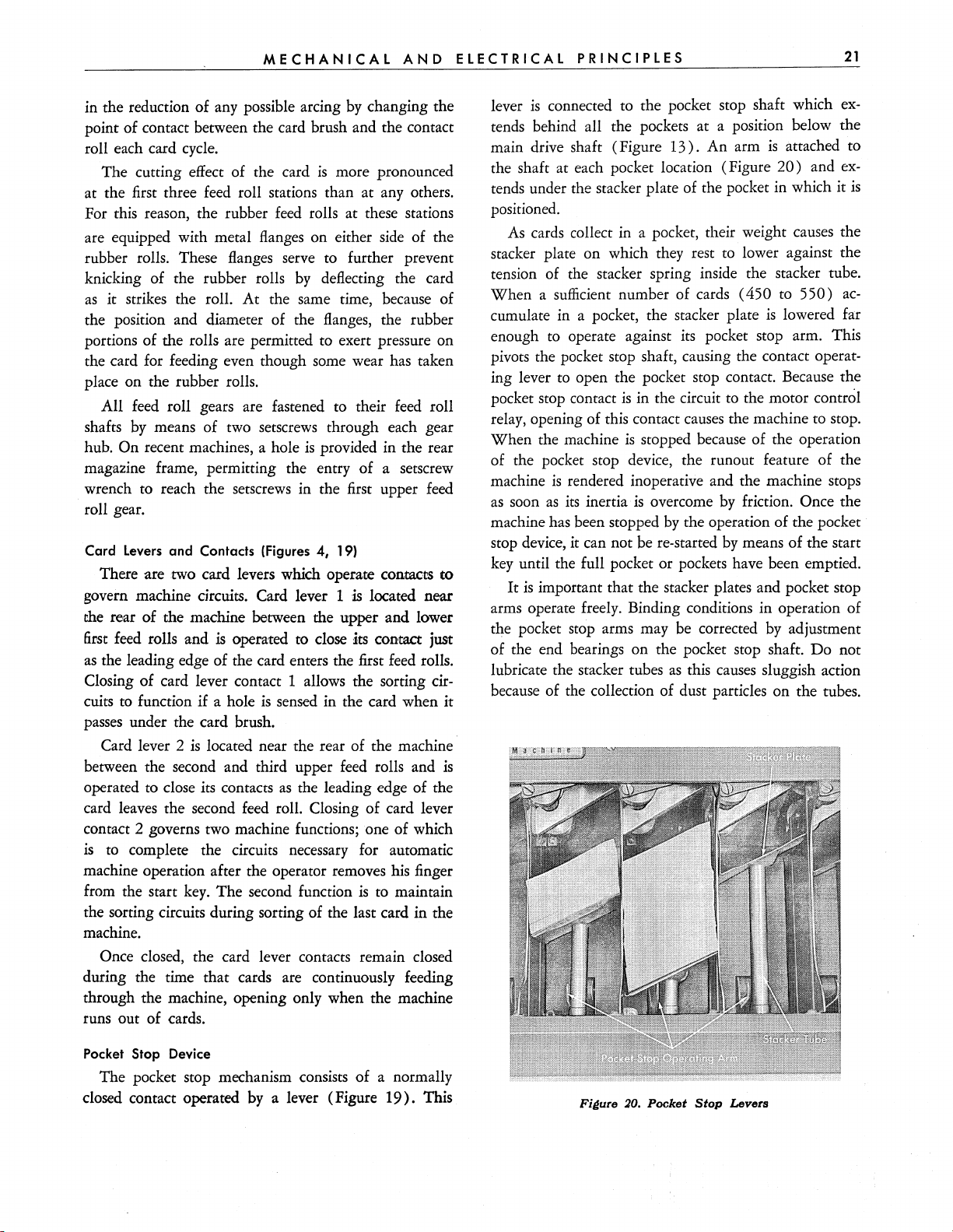

lever

IC

ALP R INC

is

connected to the pocket stop shaft which

I P L E S

tends behind all the pockets at a position below the

13).

main drive shaft (Figure

An arm

the shaft at each pocket location (Figure

is

20)

tends under the stacker plate of the pocket in which it

positioned.

As cards collect in a pocket, their weight causes the

stacker plate on which they rest to lower against the

tension of the stacker spring inside the stacker tube.

When

cumulate in a pocket, the stacker plate

a sufficient number of cards (450 to

is

enough to operate against its pocket stop arm. This

pivots the pocket stop shaft, causing the contact

ing lever to open the pocket stop contact. Because the

is

pocket stop contact

in the circuit to the motor control

relay, opening of this contact causes the machine to stop.

is

When the machine

stopped because of the operation

of the pocket stop device, the runout feature of the

is

machine

as

soon

machine has been stopped

stop device,

rendered inoperative and the machine stops

as

its

inertia

it

can not be re-started

is

overcome

by

by

friction. Once the

the operation of the pocket

by

means of the start

key until the full pocket or pockets have been emptied.

It

is

important that the stacker plates and pocket stop

arms operate freely. Binding conditions in operation of

the pocket stop arms may be corrected

by

of the end bearings on the pocket stop shaft.

as

lubricate the stacker tubes

this causes sluggish action

because of the collection of dust particles on the tubes.

21

ex-

attached

and

to

ex-

is

550)

ac-

lowered far

operat-

adjustment

Do

not

Pocket Stop Device

The pocket stop mechanism consists of a normally

closed contact operated

by

a lever (Figure

19).

This

Fi~ure

:10.

Pocket

Stop

Levers

Page 23

CIRCUIT

DESCRIPTION

ALL

CIRCUITS described in the electrical principles of

Type 82 Card Sorting Machine will refer to wiring

the

diagram

plained will

AC, single phase machine

machine most prominently

for machines using a power supply other than

AC, single phase will

layout except

resistors, filter capacitors, or a transformer

chine power supply. These discrepancies in machine

wiring are noted

diagram.

Direct current

machine circuits with the exception of the motor

cuits and the tube heater circuits. Where the source

voltage

of extra resistors where the DC rating

Where the source voltage

rectifiers are employed to convert the

NOTE:

may

except for

the frame grounded at all

be

the switch

301701-D (Figure

be

the circuits incorporated in a 115 volt

be

for

the addition or subtraction of various

in

sections 3,

is

required

is

DC, there

The machine frame should

be

ungrounded at the customer's option; however,

230 volt DC machines, which must have

touched

by

is

on and the frame grounded.

is

operating personnel can

55).

Those circuits

since

this

is

the type of

in

use

in the

field.

Circuits

115

found to be very similar in

in the

4,

5 and 6 of the wiring

for

the operation of all

no problem except for the

is

230 volts.

is

AC however, selenium

AC

to

DC.

be

grounded.

times.

No point which can

be

hot when

ex-

volt

ma-

cir-

use

It

The connection of selenium rectifiers in an AC

cuit permits current

though the

converting alternating current to pulsating direct

rent. However, because of the limitation in reverse

voltage which each

discs

order to properly rectify a normal source voltage of

115

volts AC which has a peak inverse voltage of

proximately 150 volts. Full wave bridge rectifier circuits with filter capacitors and bleeder resistors are

used

machines.

The rectifier output voltage should be between

and

145

200, or 230 volts), with the machine stopped and the

sort magnet continuously energized.

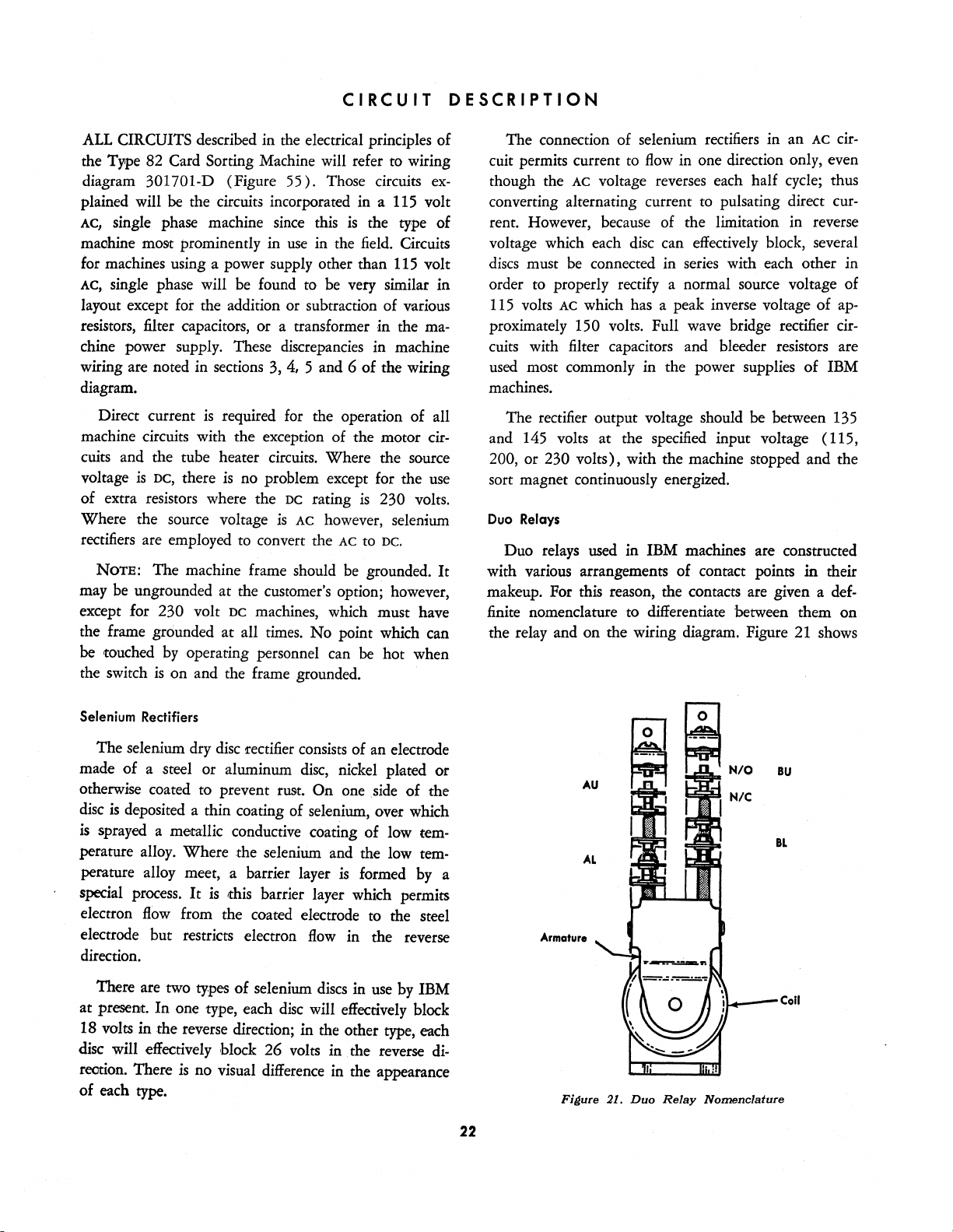

Duo Relays

Duo relays used

with various arrangements of contact points

makeup. For

finite nomenclature

the relay and on the wiring diagram. Figure

AC

must

be

most commonly in the power supplies of IBM

volts at the

this reason, the contacts

to

flow

in

one direction only, even

voltage reverses each half

disc

can effectively block, several

connected in

in

to

series

with each other in

specified

IBM machines are constructed

differentiate between them on

input voltage ( 115,

are

cycle;

given a def-

21

in

shows

cir-

thus

cur-

ap-

135

their

Selenium Rectifiers

The selenium dry

made of a steel or aluminum

otherwise coated to prevent rust. On one

disc

is

deposited

is

sprayed a metallic conductive coating of low tem-

perature alloy. Where the selenium and the low

perature alloy meet, a barrier layer

special

electron

electrode but restricts electron

direction.

at present. In one type, each

18 volts

disc will effectively block 26 volts in. the reverse

reotion. There

of each type.

process.

flow

There are two

in

the reverse direction; in the other type, each

disc

rectifier

a thin coating of selenium, over which

It

is

this barrier layer which permits

from the coated electrode to the steel

types

of selenium

is

no visual difference

disc

consists

disc,

of an electrode

nickel plated or

is

formed

flow

in the reverse

discs

in

will

effeccively

in

the appearance

side

use

of the

by

block

tem-

by

IBM

di-

AU

AL

a

Armature

Fj~ure

~

21.

Duo

~"/C

,-_-Coli

Relay

Nomenclature

BU

BL

22

Page 24

CIRCUIT

DESCRIPTION

23

an armature end

view

of a standard duo relay with the

different contact points properly identified.

Glossary

of

Terms

and

Abbreviations

Listed below are some of the terms and abbreviations

used

in connection with the Type 82 wiring diagram.

NjC

NjO

OjP

VI

VI-4

AC

DC

R2

TD

MC

MC-BL

TD-BU

Time Delay Relay

A time delay relay

render the

Normally Closed Point

Normally Open Point

Operating Point

Tube I .

Tube

1,

Alternating Current

Direct Current

Resistor 2

Time Delay

Motor Control

Motor Control Relay

Time Delay Relay

is

employed in the machine

staJlt

key

inoperative for 50 to 60

Pin 4

BU

BL

Point

Point

to

seconds

after turning on the main line switch. This delay

necessary to allow the electron tube filaments to reach

operating temperature before sorting begins.

strap, composed of two dissimilar metals,

A contact

is

heated by

passing current through a coil of wire wrapped around

the strap. Heating of this strap

definite direction and, after having

enough distance, a contact point riveted

causes

it to flex in a

flexed

a great

1:0 the strap

makes contact with another adjustable contact point

and completes a circuit to pick

The duration of time required

be

relay to pick may

air gap between the A points

the

altered

up the time delay relay.

to

cause the time delay

by

increasing or decreasing

by

means of the

ad-

justing screw on the outer contact strap.

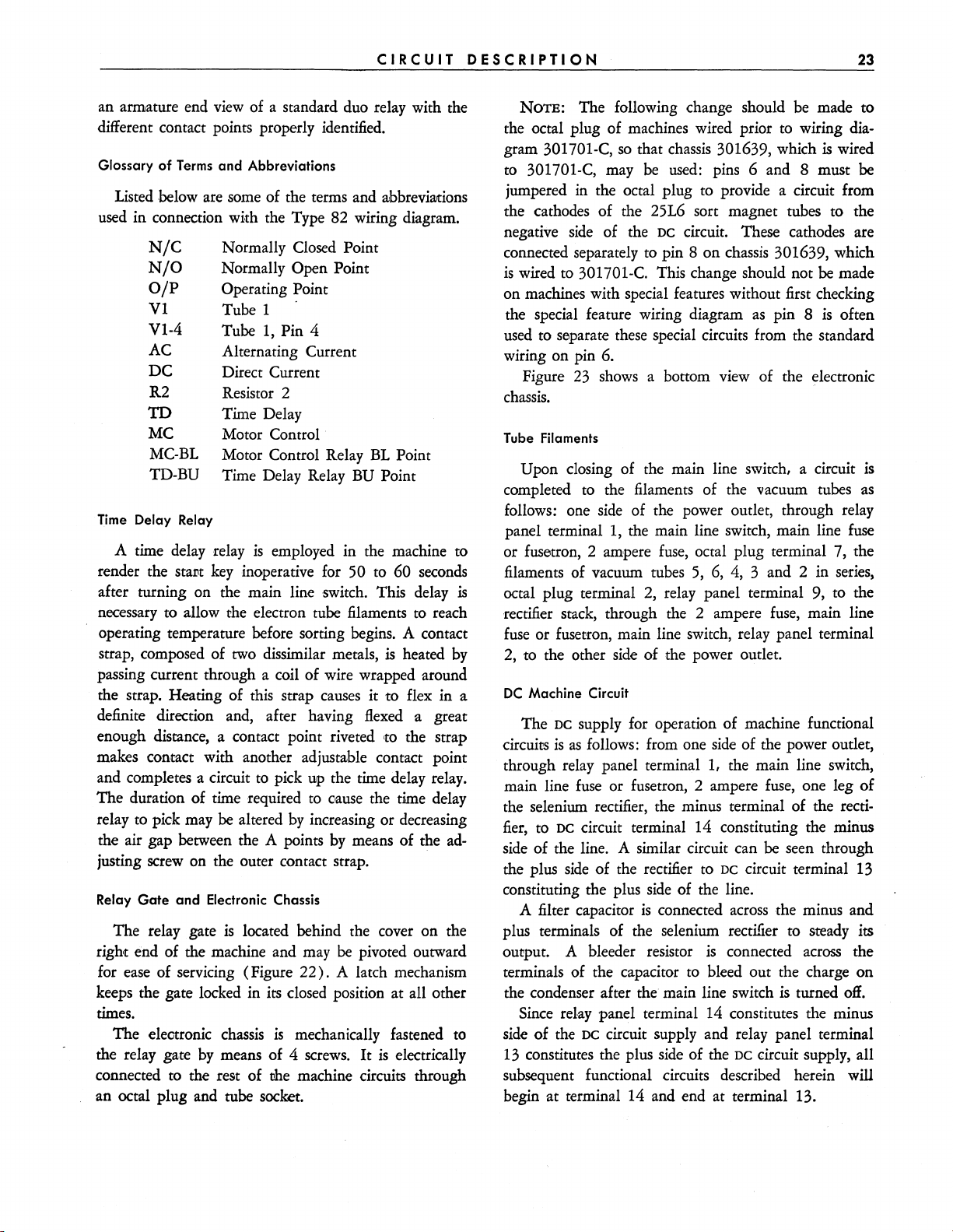

Relay

Gate

and

Electronic Chassis

The relay gate

right

end of the machine and may

for ease of servicing (Figure

keeps the gate locked in

is

located behind the cover on the

be

pivoted outward

22).

A latch mechanism

its

closed position at all other

times.

The electronic

the relay gate

connected

to

chassis

by

means of 4 screws.

the rest of me machine circuits through

is

mechanically fastened

It

is

to

electrically

an octal plug and tube socket.

NOTE:

The following change should be made

the octal plug of machines wired prior to wiring diagram 301701-C,

to

301701-C, may

so

that

be

chassis

used:

301639, which

pins 6 and 8 must be

jumpered in the octal plug to provide a circuit from

the cathodes

negative

connected

is

wired to 301701-C. This change should not be made

of

the 25L6 sort magnet tubes to the

side

of the

DC

circuit. These cathodes are

separately to pin 8 on chassis 301639, which

on machines with special features without first checking

the special feature wiring diagram

used

to separate these special circuits from the standard

as

pin 8

wiring on pin 6.

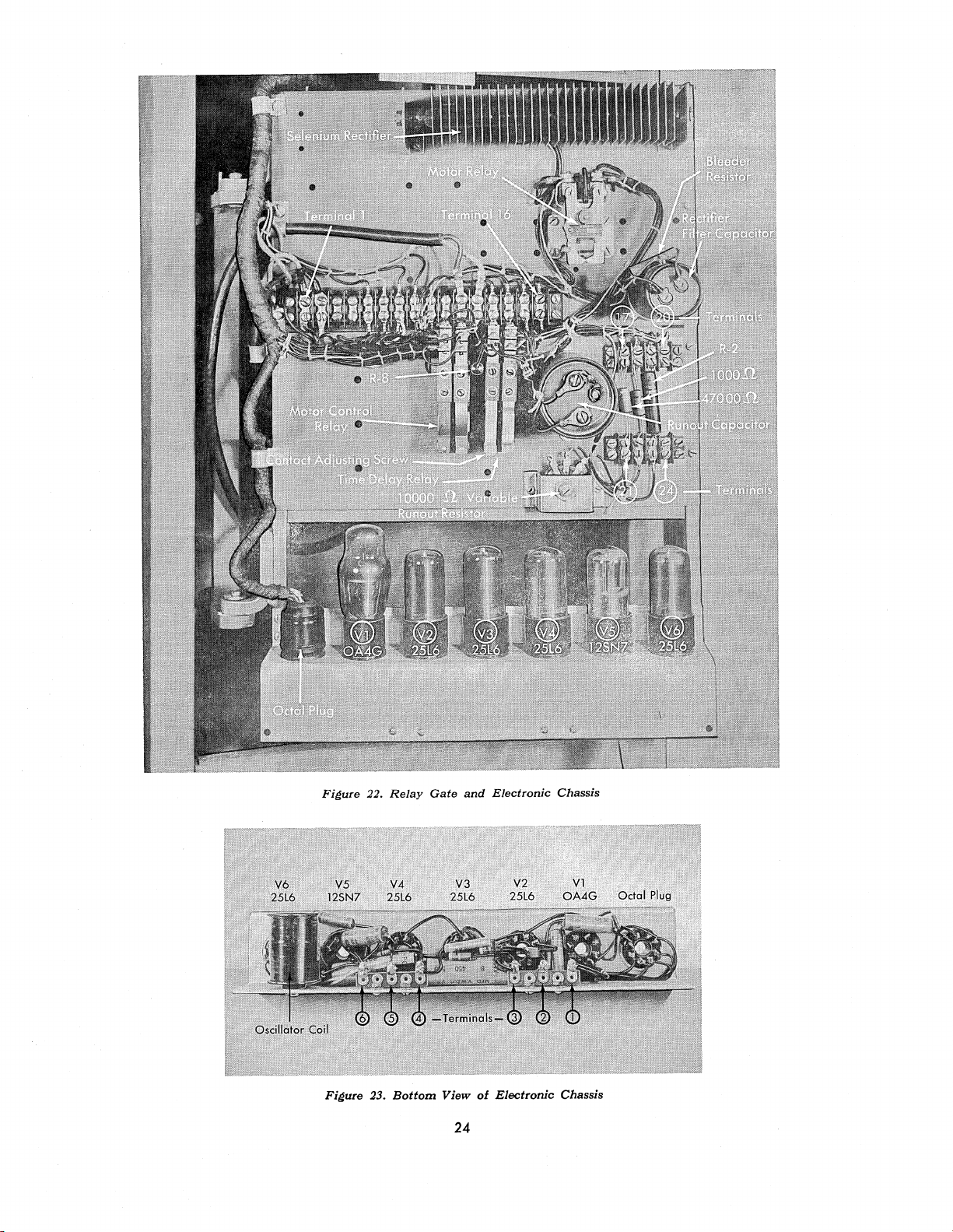

Figure

23

shows

a bottom view of the electronic

chassis.

Tube Filaments

Upon closing of the main line switch, a

completed to the filaments of the vacuum tubes