HYUNDAI J300 installation Guide

J300 INSTRUCTION MANUAL5

SAFETY

For the Best Results with J300 Series inverter, read this manual and all of the warning sign

attached to the inverter carefully before installing and operating it, and follow the instructions exactly.

Keep this manual handy for your quick reference.

Definitions and Symbols

A safety instruction (message) is given with a hazard alert symbol and a signal word;

WARNING CAUTION

This symbol means hazardous high voltage. It used to call your attention to items or operations

that could be dangerous to your and other persons operating this equipment.

Read these message and follow these instructions carefully.

This is the "Safety Alert Symbol.." This symbol is used to call your attention to items or operations

that could be dangerous to your or other persons operating this equipment.

Read these messages and follow these instructions carefully.

or . Each signal word has the following meaning throughout this manual.

WARNING

CAUTION

NOTE

WARNING

Indicates a potentially hazardous situation which, if not avoided, can result in

serious injury or death.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, can result in minor

to moderate injury, or serious damage of product.

The matters described under may, if not avoided, lead to serious

results depending on the situation. Important matters are described in

(as well as ), so be sure to observe them.

NOTE :

product's capabilities or common errors in operation or maintenance.

WARNING

Notes indicate an area or subject of special merit, emphasizing either the

CAUTION

CAUTION

HAZARDOUS HIGH VOLTAGE

Motor control equipment and electronic controllers are connected to hazardous line voltages.

When servicing drives and electronic controllers, there might be exposed components with cases

or protrusions at or above line potential. Extreme care should be taken to protect against shock.

Stand on an insulating pad and make it a habit to use only one hand when checking components.

Always work with another person in case an emergency occurs. Disconnect power before

checking controllers or performing maintenance. Be sure equipment is properly grounded. Wear

safety glasses whenever working on an electronic controllers or rotating electrical equipment.

J300 INSTRUCTION MANUAL5

PRECAUTIONS

WARNING : This equipment should be installed, adjusted and serviced by qualified electrical

maintenance personal familiar with the construction and operation of the equipment and the hazards

involved. Failure to observe this precaution could result in bodily injury.

WARNING : The user is responsible for ensuring that all driven machinery, drive train mechanism

not supplied by Hyundai, Ltd., and process line material are capable of safe operation at an applied

frequency of 150% of the maximum selected frequency range to the AC motor. Failure to do so

can result in destruction of equipment and injury to personnel should a single point failure occur.

WARNING : For protection, install a leak breaker type with a high frequency circuit

capable of large currents to avoid an unnecessary operation. The ground fault protection circuit is

not designed to protect personal injury.

WARNING : HAZARD OF ELECTRICAL SHOCK. DISCONNECT INCOMING POWER

BEFORE WORKING ON THIS CONTROL.

WARNING : SEPARATE MOTOR OVERCURRENT, OVERLOAD AND OVER HEATING

PROTECTION IS REQUIRED TO BE PROVIDED IN ACCORDANCE WITH THE

SAFETY CODES REQUIRED BY JURISDICTIONAL AUTHORITIES.

CAUTION : These instructions should be read and clearly understood before working on

J300 series equipment.

CAUTION : Proper grounds, disconnecting devices and other safety devices and their

location are the responsibility of the user and are not provided by Hyundai, Ltd.

CAUTION : Be sure to connect a motor thermal switch or overload devices to the J300

series controller to assure that inverter will shut down in the event of an overload or an

overheated motor.

CAUTION : Dangerous voltage exists until charge lamp is off.

CAUTION : Rotating shafts and above ground electrical potentials can be hazardous.

Therefore, it is strongly recommended that all electrical work conform to the National

Electrical Codes and local regulations. installation, alignment and maintenance Should be

performed only by qualified personnel.

Factory recommended test procedures, included in the instruction manual, should be followed.

Always disconnect electrical power before working on the unit.

J300 INSTRUCTION MANUAL5

WARNING : This equipment has high leakage current and must be perminatly hard wired to earth

via two indipendent cable.

MOTORS

a) Class I motor must be connected to protective earth via low resistive path (<0.1 )

b) Any motor used must be of suitable rating.

c) Motors may have hazardous moving parts, in this event suitable protection must be provided.

CAUTION :

Alarm connection may contain hazardous live voltage even when inverter is disconnected.

In case of removing front cover for maintenance or inspection, confirm that incoming power for

alarm connection is surely disconnected.

CAUTION :

Hazardous (main) terminals for any interconnection (motor, contact breaker, filter etc.) must be

inaccessible in end installation

CAUTION :

This equipment should be installed in an enclosure meeting requirements of IP4X (see EN60529).

The end application must be in accordance with BS EN60204-1(with reference to manual page 4-1

and 4-2, the diagram measurements to be suitably amended).

CAUTION :

Connection to field wiring terminals must be reliably fixed having two independent means of

support. Using terminal with cable support (figure below), or cable gland, cable clamp etc.

CAUTION :

A double pole disconnection device must be fitted to the incoming mains supply close to the

inverter. Additionally, a protection device meeting IEC947-1/IEC947-3 must be fitted at this

point (protection device data shown in page 5-8).

CAUTION :

EMI filter is required for EMC directive.

The above instructions, together with any other requirements highlighted in this manual, must be complied

with for continued LVD compliance.

J300 INSTRUCTION MANUAL5

Revision History Table

No

Revision Contents

TheDateoflssue

Operation Manual

Number

J300 INSTRUCTION MANUAL5

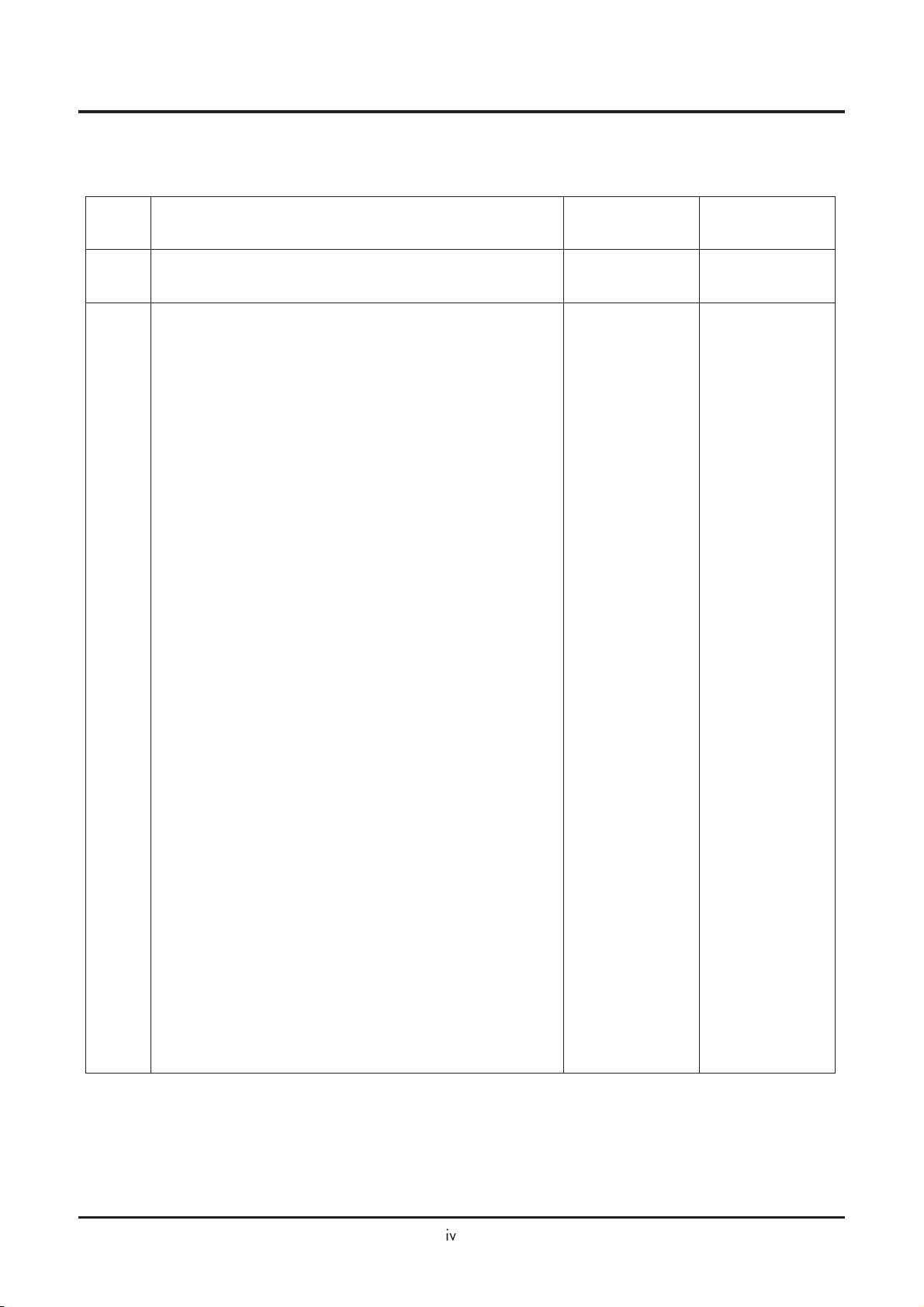

TABLE OF CONTENTS

Page

1. SAFETY PRECAUTIONS

2. INSPECTION UPON UNPACKING

3. APPEARANCE AND NAMES OF PARTS

4. INSTALLATION

5. WIRING

6. OPERATION

7. OPERATION OF THE DIGITAL OPERATOR

8. PROTECTION FUNCTION

9. TROUBLESHOOTING

10. MAINTENANCE AND INSPECTION

11. STANDARD SPECIFICATIONS

1-1

2-1

3-1

4-1

5-1

6-1

7-1

8-1

9-1

10-1

11-1

12. FUNCTIONS WHEN USING THE OPTIONAL REMOTE OPERATOR

APPENDIX 1

APPENDIX 2

APPENDIX 3

APPENDIX 4

APPENDIX 5

APPENDIX 6

APPENDIX 7

APPENDIX 8

12-1

A-1

A-15

A-19

A-20

A-21

A-24

A-25

A-32

J300 INSTRUCTION MANUAL5

1. SAFETY PRECAUTIONS

1. Installation

CAUTION

Be sure to install the unit on flame resistant material such as metal

Otherwise, there is a danger of fire.

Be sure not to place anything inflammable in the vicinity.

Otherwise, there is a danger of fire.

Be sure not to let the foreign matter enter such as cut wire refuse,

spatter from welding, iron refuse, wire, dust, etc.

Otherwise, there is a danger of fire.

Be sure to install it in a place which can bear the weight according to

the specifications in the text (4. Installation)

Otherwise, it may fall and there is danger of injury.

Be sure to install the unit on a perpendicular wall which is not subject

to vibration.

Otherwise, it may fall and there is a danger of injury.

Be sure not to install and operate an inverter which is damaged or

parts of which are missing.

Otherwise, there is a danger of injury.

Be sure to install it in a room which is not exposed to direct sunlight

and is well ventilated. Avoid environments which tend to be high in

temperature, high in humidity or to have dew condensation, as well as

places with dust, corrosive gas, explosive gas, inflammable gas,

grinding-fluid mist, salt damage, etc.

Otherwise, there is a danger of fire.

Be sure that the wall surface is a nonflammable material, such as steel

plate.

P.4-1

P.4-1

P.4-1

P.4-1

P.4-1

P.4-1

P.4-1

P.4-2

2. Wiring

WARNING

Be sure to ground the unit.

Otherwise, there is a danger of electric shock and/or fire.

Wiring work shall be carried out by electrical experts.

Otherwise, there is a danger of electric shock and/or fire.

Implement wiring after checking that the power supply is off.

It might incur electric shock and/or fire.

After installing the main body, carry out wiring.

Otherwise, there is a danger of electric shock and/or injury.

P.5-1

P.5-1

P.5-1

P.5-1

J300 INSTRUCTION MANUAL5

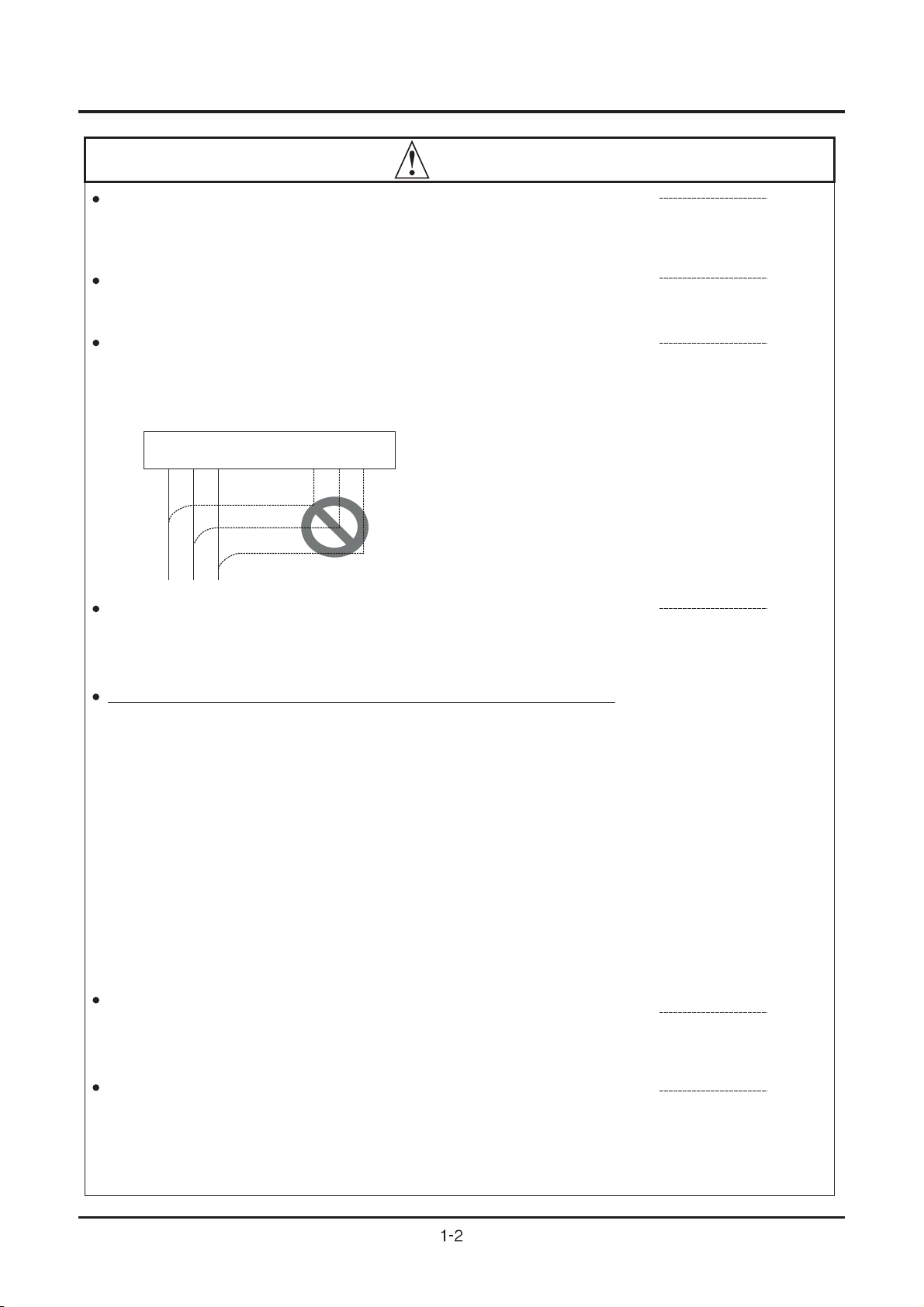

CAUTION

Make sure that the input voltage is :

Three phase 200 to 220V/50Hz, 200 to 230V/60Hz

Three phase 380 to 415V/50Hz, 400 to 460V/60Hz

Be sure not to input a single phase to a 3 phase type.

Otherwise, there is a danger of fire.

Be sure not to connect AC power supply to the output terminals

[U (T1), V(T2), W(T3)].

Otherwise, there is a danger of injury and/or fire.

INPUT

Note)

(L1)

R

Power supply

(L2)

(L3)

T

S

(T1)

U

OUTPUT

(T3)

(T2)

V

W

R(L1), S(L2), T(L3) : Three phase 200 to 220V/50Hz

Note:

Fasten the screws with the specified fastening torque. Check so that

there is no loosening of screws.

Otherwise, there is a danger of tire.

P.5-2

P.5-2

P.5-2

200 to 230V/50Hz

Three phase 380 to 415V/50Hz

400 to 460V/60Hz

P.5-2

Remarks for using earth leakage circuit breakers in the mains supply:

Frequency inverters with CE-filters (RFI-filter) and screened motor

cables have a higher leakage current against earth. Especially in the

moment of switching on this can cause unintentional triggerings of

earth leakage circuit breakers. Because of the rectifier on the input

side of the inverter there is the possibility to stall the switch-off

function through amounts of DC-current. The following should be

observed:

Only short time-invariant and pulse current-sensitive earth leakage

circuit breakers with higher trigger current should be used.

Other components should be secured with separate earth leakage

circuit breakers.

Earth leakage circuit breakers in front of an inverter are not an

absolute protection against direct touching.

Be sure to set the fuse(s) (the same phase as the main power supply)

in the operation circuit.

Otherwise, there is a danger of fire.

As for motor leads, earth leakage breakers and electromagnetic

contactors, be sure to use the equivalent ones with the specified

capacity (rated).

Otherwise, there is a danger of fire.

P.5-2

P.5-2

J300 INSTRUCTION MANUAL5

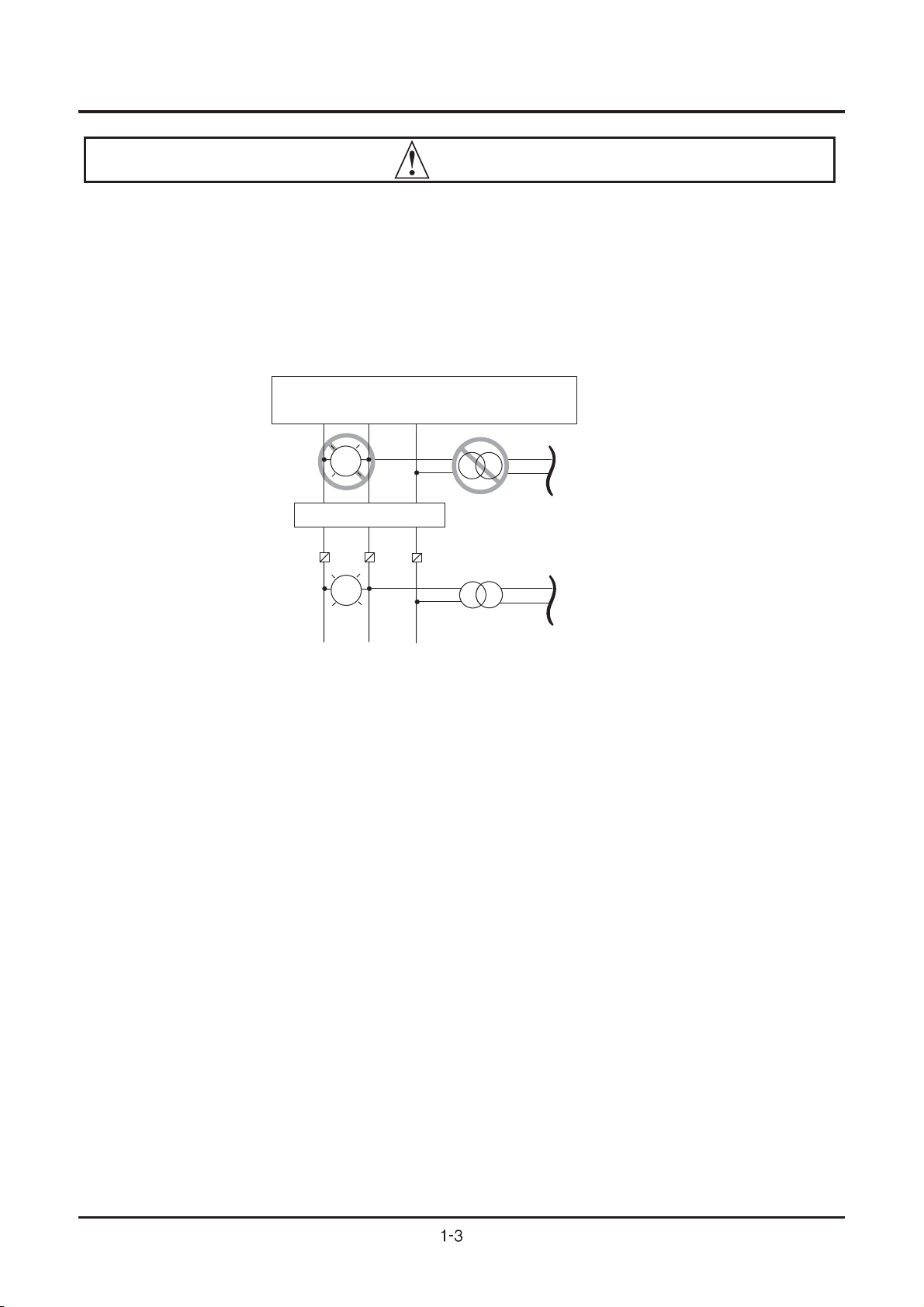

CAUTION

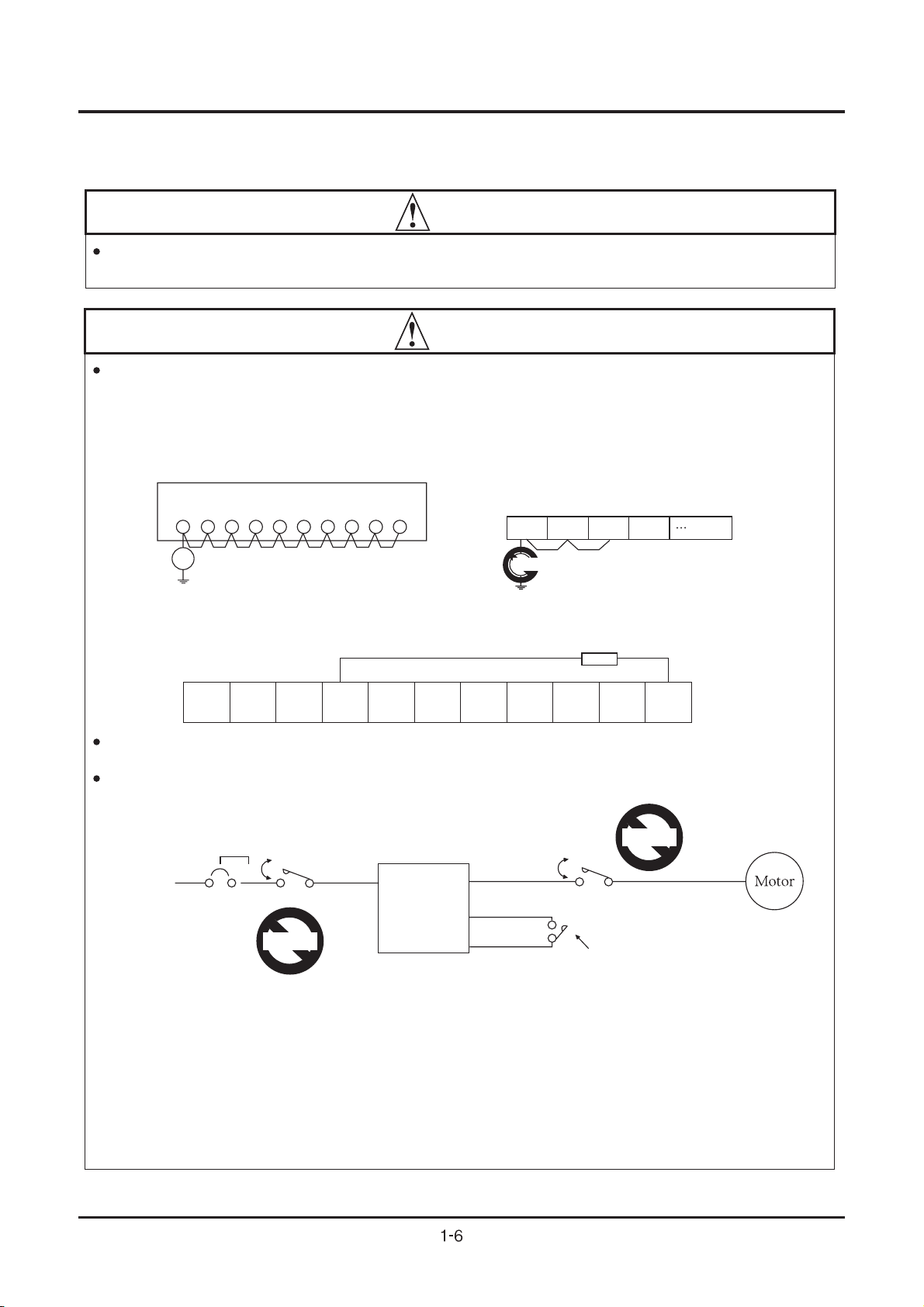

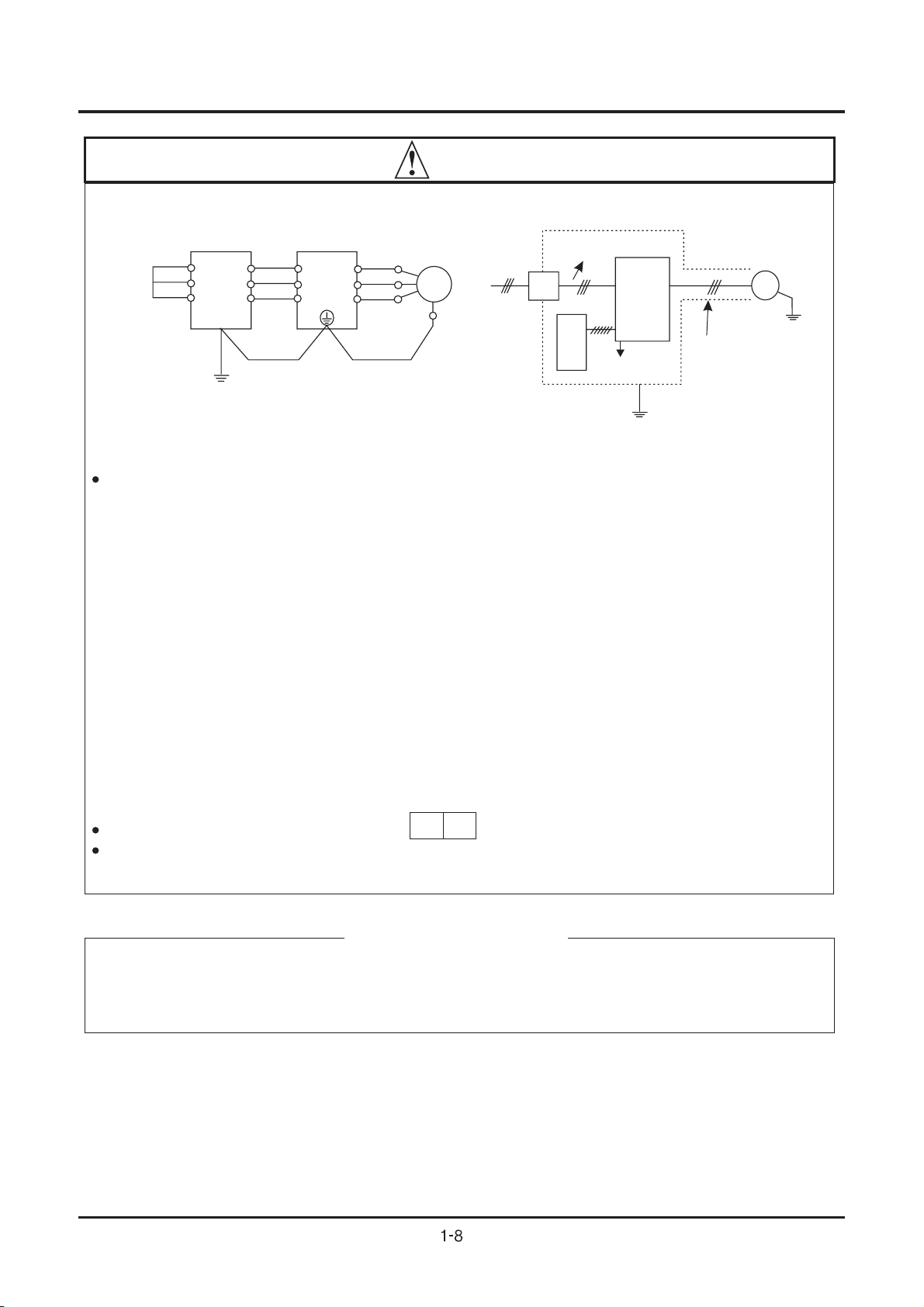

Input phase failure protection

(1) J300-5 version inverter are provided with the phase failure protection on the power supply.

(2) When a buzzer, lamp, noise filter or transformer is connected between the input power

terminals (L1, L2, L3) and input power fuses, input phase failure cannot be protected.

(L2)

(L1)

R

(L3)

S

T

Fuse

L

Noise filter

L

Power supply

(Bad example)

(Good example)

J300 INSTRUCTION MANUAL5

3. Control and operation

WARNING

Be sure to turn on the input power supply after mounting the surface cover.

While being energized, be sure not to remove the cover.

Otherwise, there is a danger of electric shock.

Be sure not to operate the switches with wet hands.

Otherwise, there is a danger of electric shock.

While the inverter is energized, be sure not to touch the inverter terminals

even during stoppage.

Otherwise, there is a danger of electric shock.

If the retry mode is selected, it may suddenly restart during the trip stop.

Be sure not to approach the machine. (Be sure to design the machine so

that personnel safety will be secured even if it restarts.)

Otherwise, there is a danger of injury.

Even if the power supply is cut for a short period of time, it may restart

operation after the power supply is recovered if the operation command is

given. If it may incur danger to personnel, be sure to make a circuit so that

it will not restart after power recovery.

Otherwise, there is a danger of injury.

The Stop Key is effective only when the function is set.

Be sure to prepare the Key separately from the emergency stop.

Otherwise, there is a danger of injury.

P.6-1

P.6-1

P.6-1

P.6-1

P.6-1

P.6-1

After the operation command is given, if the alarm reset is conducted,

it will restart suddenly. Be sure to set the alarm reset after checking the

operation command is off.

Otherwise, there is a danger of injury.

Be sure not to touch the inside of the energized inverter or to put a

bar into it.

Otherwise, there is a danger of electric shock and/or fire.

When the power is turned on when ther running command is on, the motor

starts rotation and it is dangerous. Before turning the power on, confirm that

the running command is not on.

When the Stop key function is ineffective, pressing the Stop key does not

cancel the stop and trip.

Be sure to provide an emergency stop switch separately. When the operation

command destination is a digital operator, this selection es ineffective.

P.6-1

P.6-1

P.6-1

P.6-1

J300 INSTRUCTION MANUAL5

CAUTION

Radiating fin and discharging resistor will have high temperature.

Be sure not to touch them.

Otherwise, there is a danger of getting burned.

Low to high speed operation of the inverter can be easily set. Be sure to

operate it after checking the tolerance of the motor and machine.

Otherwise, there is a danger of injury.

If a motor is operated at a frequency higher than 60Hz, be sure to check

the speeds of the motor and the machine with each manufacturer, and after getting

their consent, operate them.

Otherwise, there is a danger of machine breakage.

Check the following before and during the test run.

Otherwise, there is a danger of machine breakage.

Was the short-cut bar between +1and+connected?

Was the direction of the motor correct?

Was the inverter tripped during acceleration or deceleration?

Were the rpm and frequency meter correct?

Were there any abnormal motor vibrations or noise?

4. Maintenance, inspection and part replacement

P.6-2

P.6-2

P.6-2

P.6-3

WARNING

After a lapse of more than 10 minutes after turning off the input power

supply, perform the maintenance and inspection.

Otherwise, there is a danger of electric shock.

Make sure that only qualified persons will perform maintenance,

inspection and part replacement. (Before starting the work, remove metallic

objects from your person (wristwatch, bracelet, etc.)

(Be sure to use tools protected with insulation.)

Otherwise, there is a danger of electric shock and/or injury.

CAUTION

When removing connectors, never pull the wires. (Wires for cooling fan

and thermal relay)

Otherwise, there is a danger of fire due to wire breakage and/or injury.

P.10-1

P.10-1

P.10-1

J300 INSTRUCTION MANUAL5

5. Others

WARNING

Never modify the unit.

Otherwise, there is a danger of electric shock and/or injury.

CAUTION

Withstand voltage tests and insulation resistance tests (megger tests) are executed before the

units are shipped, so that there is no need to conduct these tests before operation.

When conducting megger tests as a part of daily inspection, be sure that these tests are only

executed between the main circuit and the ground. Do not execute megger tests on the control

circuit.

(L1) (L2) (L3) (+1) (+) (-) (T1) (T2) (T3)

RBRS TPDPNUVW

FW

P24

PLC

FM

Megohm-meter

Megohm-meter

Remove the ZNR connecting between G(PE) to T(L3) terminal before conducting the tests.

After tests, be sure to attach the ZNR again.

ZNR

(T1)

RB

(L1)

R

(L2)

(L3)T(+1)PD(+)

S

(-)

N

P

(T2)V(T3)W(PD)

U

G

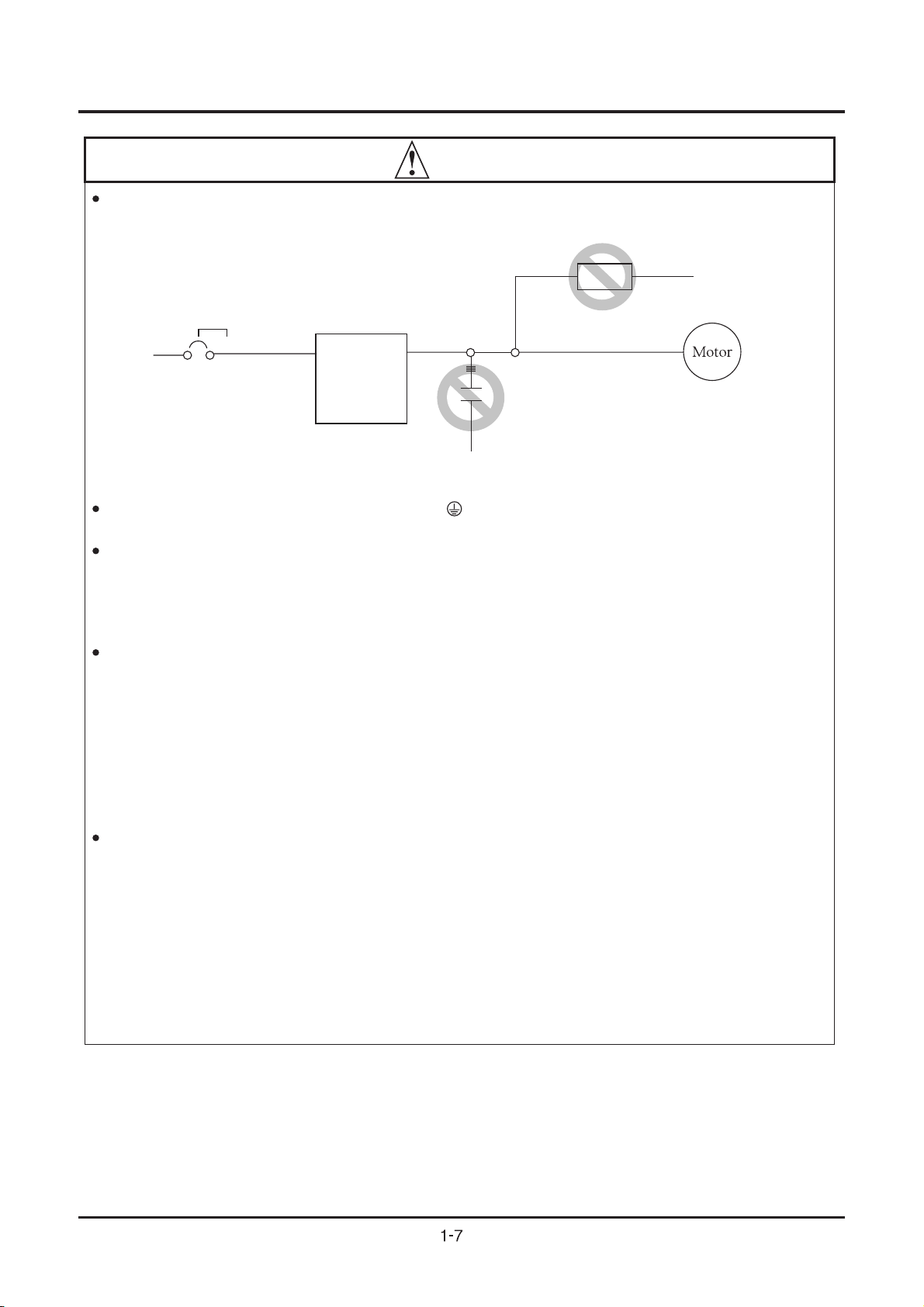

Do not attach or remove wiring or connectors when power is applied. Also, do not check

signals during operation.

Do not stop operation by switching off the electromagnetic contactors on the primary or

secondary sides of the inverter.

Earth

Power

supply

leakage

breaker

W

Mc0

ON,

(L1)(L2)(L3)

R, S, T

OFF

INV

(T1)(T2)(T3)

U, V, W

FW

CM1

Mc2

ON,

OFF

Turn ON and OFF

(Good example)

When there has been an instantaneous power failure, and if an operation instruction has been

given, then the unit may restart operation after the power failure has ended.

If there is a possibility that such an occurrence may harm humans, than install an electromagnetic

contactor (Mc0) on the power supply side, so that the circuit does not allow automatic restarting

after the power supply recovers. If the optional remote operator is used and the retry function has

been selected, this will also cause automatic restarting when an operation instruction has been

input, so please be careful.

J300 INSTRUCTION MANUAL5

CAUTION

Do not insert leading power factor capacitors or surge absorbers between the output

terminals of the inverter and the motor.

Surge absorber

Power

supply

Earth

leakage

breaker

W

(L1)(L2)(L3)

R, S, T

(T1) (T2) (T3)

U, V, W

INV

Leading power factor capacitor

Be sure to ground the grounding terminal,

When inspecting the unit, after turning the power supply off be sure to wait unitl the

CHARGE lamp beside the control terminal is off before opening the cover.

(If the lamp is lit or still flickering, then the internal capacitor's residual voltage is still dangerous.)

MOTOR TERMINAL SURGE VOLTAGE SUPPRESSION FILTER

(FOR THE 400V CLASS)

In a system using an inverter of the voltage control PWM system, a surge voltage caused by the

cable constants such as the cable length (especially when the distance between the motor and

inverter is 10m or more) and cabling method may occur at the motor terminal.

A dedicated filter of the 400V class for suppressing this surge voltage is available, please order

one.

PROTECTION AGAINST NOISE INTERFERENCE FROM INVERTER

The inverter uses many semiconductor switching elements such as transistors and IGBTs. Thus, a

radio set or measuring instrument located near the inverter is susceptible to noise interference.

To protect the instruments from erroneous operation due to noise interference, they should be

installed well apart from the inverter. It is also effective to shield the whole inverter structure.

Addition of an EMI filter on the input side of the inverter also reduces the effect of noise from

commercial power line on external devices.

Note that external dispersion of noise from the power line can be minimized by connecting an

EMI filter on the primary side of inverter.

J300 INSTRUCTION MANUAL5

CAUTION

Power

source

EMI filter

R1

S1

T1

R2

S2

T2

Inverter

R(L1)

S(L2)

T(L3)

(T1)

U

U

(T2)

V

V

(T3)

W

Motor

W

Terminal

for

grounding

Power

source

EMI filter

Noise

Inverter

operator

Remote

Noise

Completely ground the shield made

of metal screen, enclosed panel, etc.

with as short a wire as possible.

Piping

(to be grounded)

or shielded wire

Motor

Ground the

frame.

EFFECTS OF DISTRIBUTOR LINES ON INVERTERS

In the cases below involving a general-purpose inverter, a large peak current flows on the power

supply side, sometimes destroying the converter module. Where such situations are foreseen, or

the paired equipment must be highly reliable, install an AC reactor between the power supply and

the inverter.

(A) The unbalance factor of the power supply is 3% or higher.

(B) The power supply capacity is at least 10 times greater than the inverter capacity (and the

power supply capacity, 500kVA or more).

(C) Abrupt power supply changes are expected.

Examples:

(1) Several inverters are interconnected with a short bus.

(2) A thyristor converter and an inverter are interconnected with a short bus.

(3) An installed phase advance capacitor opens and closes.

In cases (A), (B) or (C), we recommend installing an AC reactor of 3%(in a voltage drop at

rated current) with respect to the supply voltage on the power supply side.

8

When occurring an EEPROM error ( ), be sure to confirm the setting value again.

E

When setting b contact to the reverse command ([REV] terminal), the inverter state

automatically. Do not set to b contact.

GENERAL CAUTION

In all the illustrations in this manual, covers and safety devices are occasionally removed to describe

the details. When the product is operated, make sure that the covers and safety devices are placed

as they were specified originally and operate it according to the instruction manual.

J300 INSTRUCTION MANUAL5

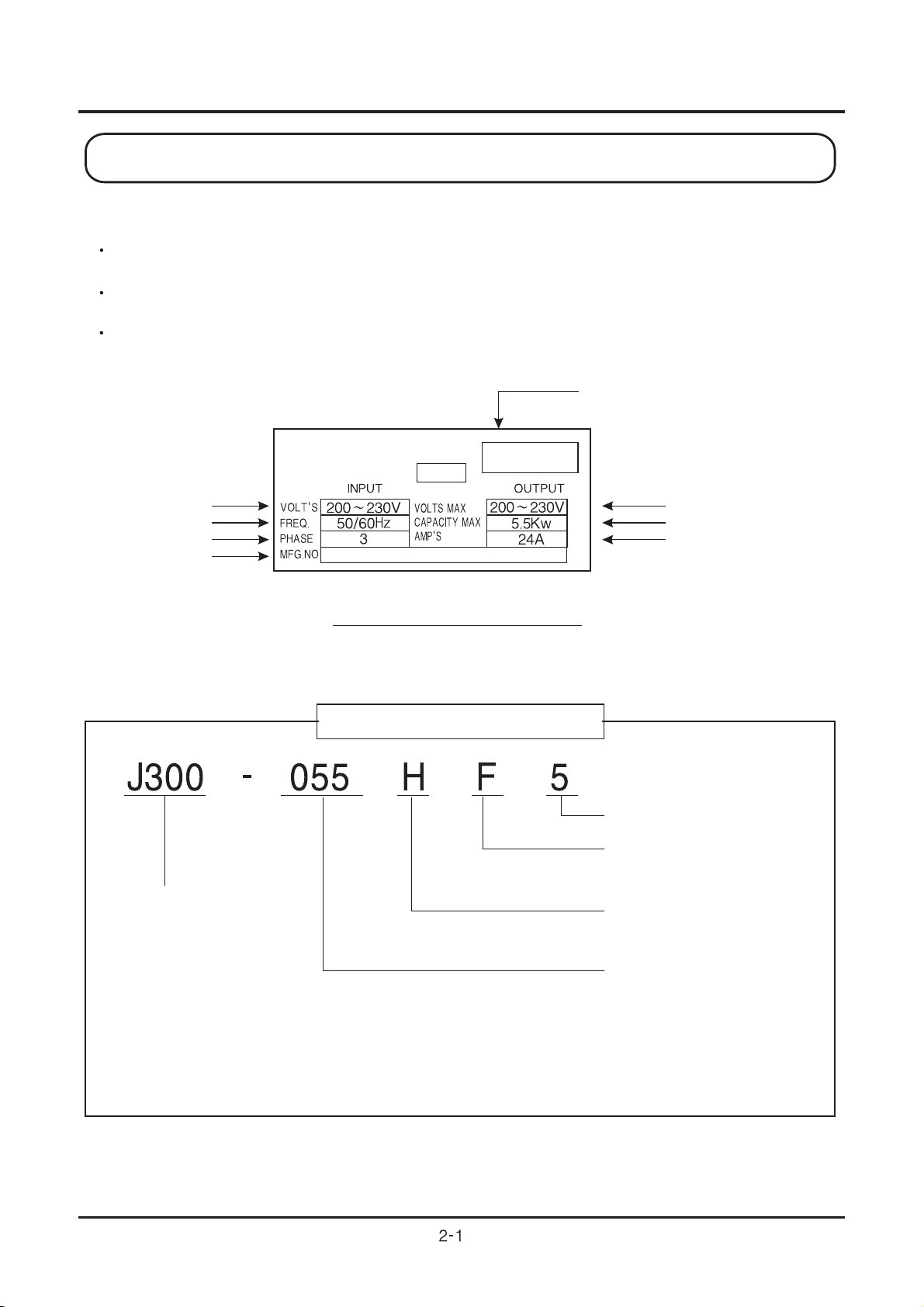

2. INSPECTION UPON UNPACKING

Before installation and wiring, be sure to check the following.

Make sure that there was no damage during transportation the unit.

After unpacking the unit, make sure that the package contains one inverter and one operation manual

Make sure that the product is the one you ordered by checking the specifications label on the front

of the cover.

Model abbreviation

(The example is for the J300-055HFE4)

Input Voltage

Input frequency

Phase

Manufacturing number

HYUNDAI

inverter

J300

055LF5

Contents of Specifications Label

If you discover any problems, contact your sales agent immediately.

Description of Inverter Model

Series name

Output Voltage

Maximum applicable motor(4P, kw)

Rated output current

Version number

Structure type

F : with digital operator

(Semi-closed, open type)

Input voltage

H : Three phase 400V class

L : Three phase 200V class

Applicable motor capacity (4P, kw)

055 : 5.5kw 550 : 55kw

075 : 7.5kw 750 : 75kw

110 : 11kw 900 : 90kw

150 : 15kw 1100 : 110kw

220 : 22kw 1320 : 132kw

300 : 30kw 1600 : 160kw

370 : 37kw 2200 : 220kw

450 : 45kw

J300 INSTRUCTION MANUAL5

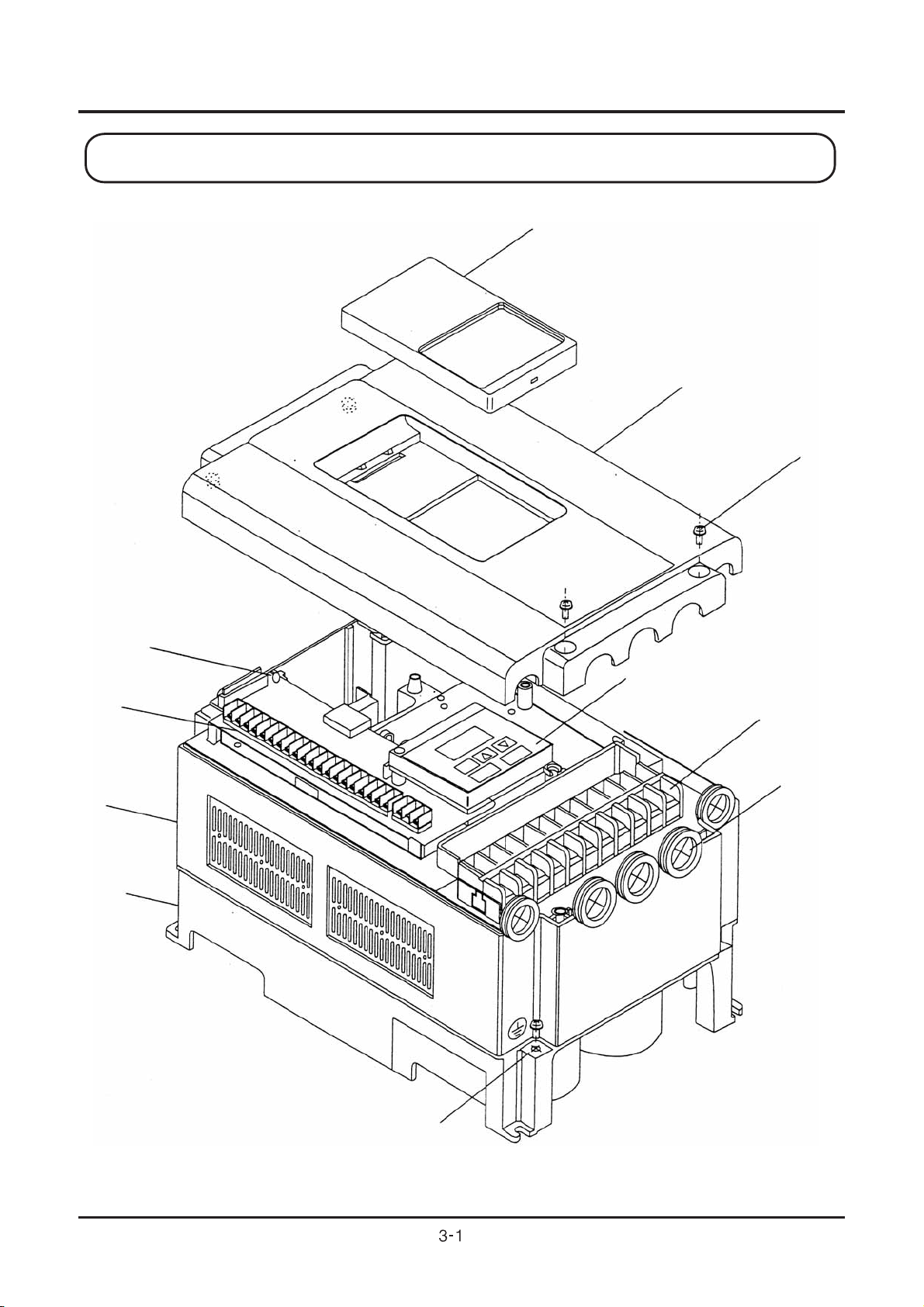

3. APPEARANCE AND NAMES OF PARTS

3.1 Names of Parts

Charge lamp(LED)

Blind cover

Front cover

Aset

screw

Control circuit

terminals

Cover

Case

Digital operator

Main circuit

terminals

Wiring

holes

Earth terminal

J300 INSTRUCTION MANUAL5

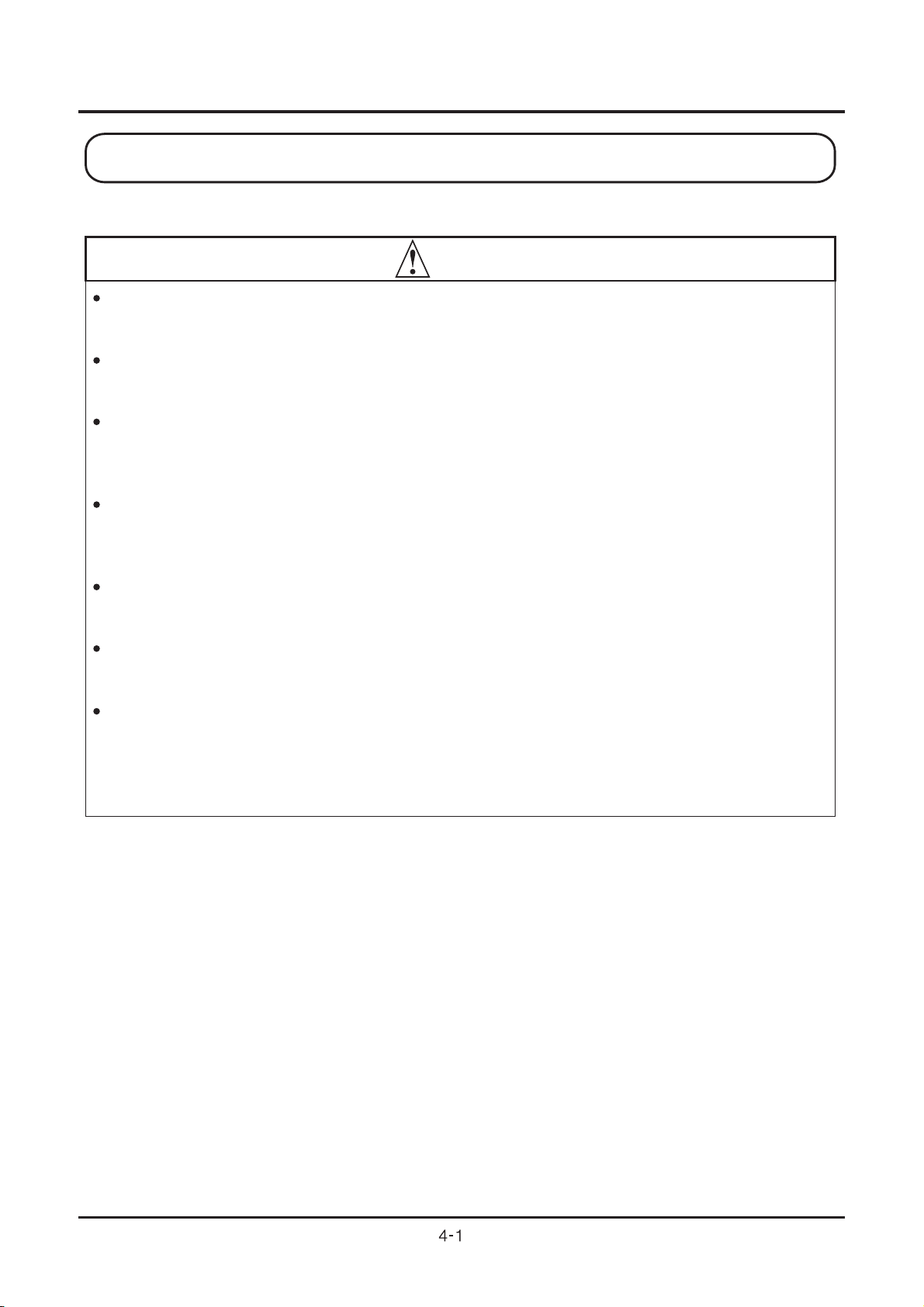

4. INSTALLATION

CAUTION

Be sure to install the unit on flame resistant material such as metal.

Otherwise, there is a danger of fire.

Be sure not to place anything inflammable in the vicinity.

Otherwise, there is a danger of fire.

Be sure not to let the foreign matter enter such as cut wire refuse, spatter from welding, iron

refuse, wire, dust, etc.

Otherwise, there is a danger of fire.

Be sure to install it in a place which can bear the weight according to the specifications in the

text(4. Installation).

Otherwise, it may fall and there is a danger of injury.

Be sure to install the unit on a perpendicular wall which is not subject to vibration.

Otherwise, it may fall and there is a danger of injury.

Be sure not to install and operate an inverter which is damaged or parts of which are missing.

Otherwise, there is a danger of injury.

Be sure to install it in a room which is not exposed to direct sunlight and is well ventilated.

Avoidenvironmentswhichtendtobehighintemperature,highinhumidityortohavedew

condensation, as well as places with dust, corrosive gas, explosive gas, inflammable gas, grindingfluid mist, salt damage, etc.

Otherwise, there is a danger of fire.

J300 INSTRUCTION MANUAL5

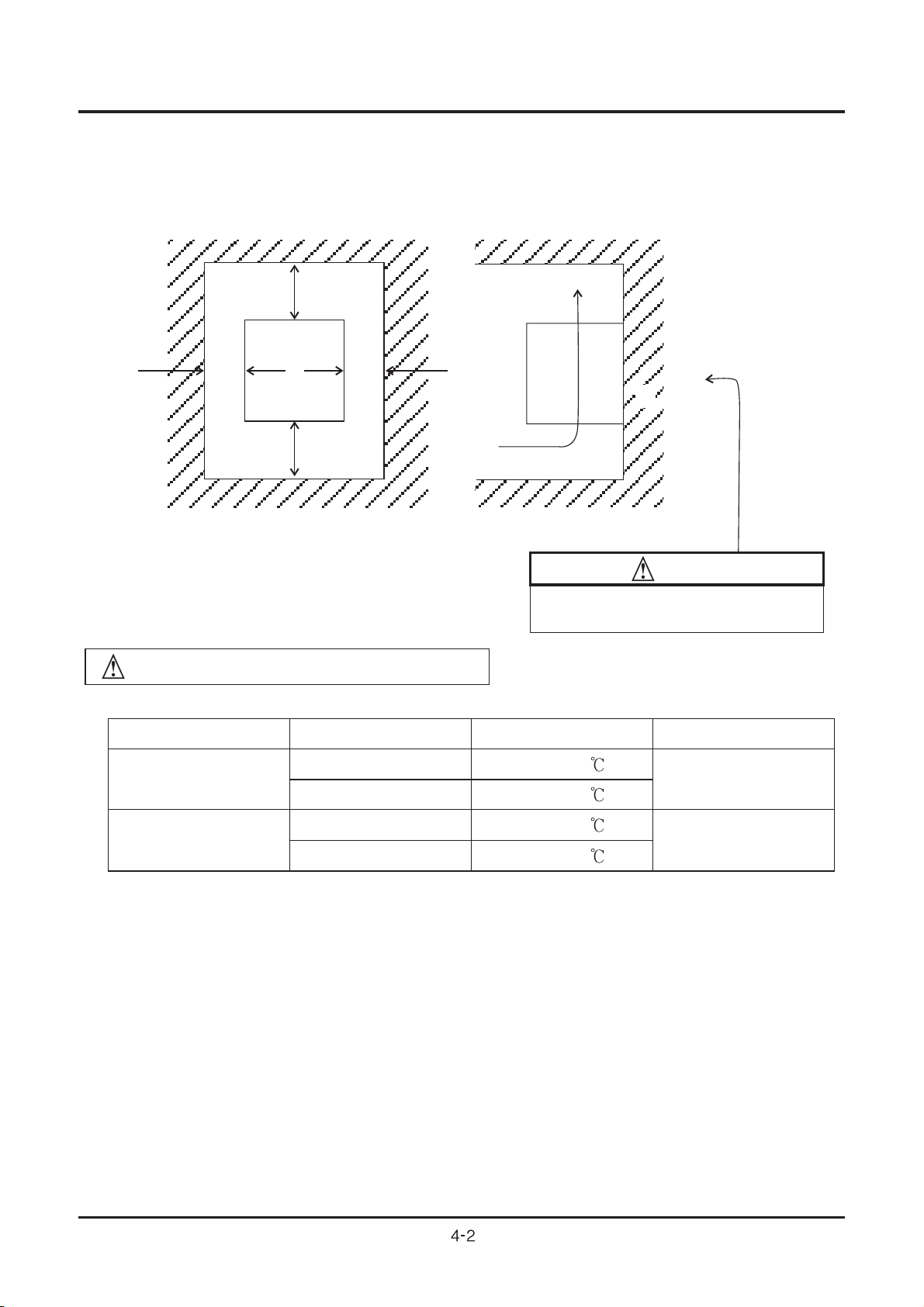

For cooling purposes, be sure that the inverter is installed vertically. In addition, be sure that it is

separated from other components and walls. If foreign matter is introduced into the interior of the

inverter, this may cause malfunctions, so make sure that no foreign matter can enter it.

10cm or more

5cm

or

more

10cm or more

5cm

or

more

(a) (b)

Note : Install the inverter vertically.

Do not install it on the floor or horizontally.

Be sure to check the ambient temperature.

Flow of air

Wall

CAUTION

Be sure that the wall surface is a nonflammable

material, such as steel plate.

Place of installation

Within the enclosure

(NOTE 1)

Outside the enclosure

(NOTE 2)

Load characteristics

Constant torque

Variable torque

Constant torque

Variable torque

Ambient temperature

-10 to 50

-10 to 40

-10 to 40

-10 to 40

Applicable model

055 to 2200HF

(NOTE 6)

055 to 150HF

NOTE1:The inverter should be installed in a locked enclosure that meets the requirements in

IP4X(see EN60529).

NOTE2:

When an inverter (055HF to 150HF) is installed outside an enclosure, the top of the

inverter needs to be covered with the optional blind cover.

NOTE3:

The higher the ambient temperature inside the inverter, the shorter its life will be.

If a heat generating unit is used near the inverter, try to keep it as far away as possible.

Also, when installing the inverter in a box, be sure to carefully consider ventilation and

the dimensions.

NOTE4:

NOTE5:

NOTE6:

For EMC directive and Low Voltage directive, do not remove the front cover.

The end application must be in accordance with BS EN60204-1.

Each of inverters 220HF to 2200HF must be installed in a locked enclosure.

J300 INSTRUCTION MANUAL5

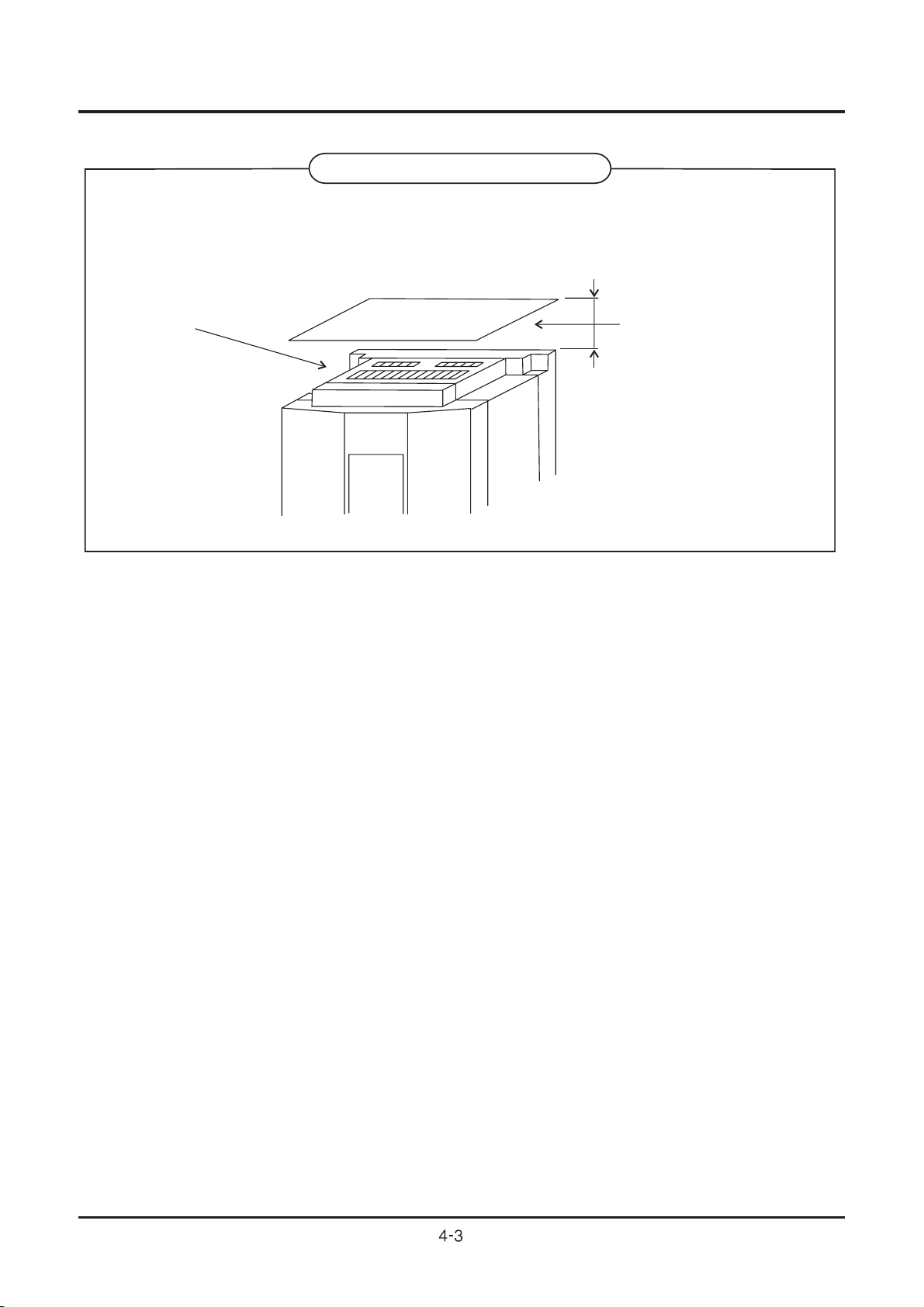

Precaution for installation and wiring

When executing the wiring work or another work, attach a cover on the vent hole (slit) on the top

of the inverter to prevent wire chips, weld spatters, iron scraps, or dust from falling into the

inverter.

15cm or more

Vent hole

Cover (a nonflammable

plate such as an iron plate)

J300 INSTRUCTION MANUAL5

5. WIRING

WARNING

Be sure to ground the unit.

Otherwise, there is a danger of electric shock and/or fire.

Wiring work shall be carried out by electrical experts.

Otherwise, there is a danger of electric shock and/or fire.

Implement wiring after checking that the power supply is off.

It might incur electric shock and/or fire.

After installing the main body, carry out wiring.

Otherwise, there is a danger of electric shock and/or injury.

J300 INSTRUCTION MANUAL5

CAUTION

Make sure that the input voltage is :

Three phase 200 to 220V/50Hz, 200 to 230V/60Hz

Three phase 380 to 415V/50Hz, 400 to 460V/60Hz

Be sure not to input a single phase to a 3 phase type.

Otherwise, there is a danger of fire.

Be sure not to connect AC power supply to the output terminals

[U (T1), V(T2), W(T3)].

Otherwise, there is a danger of injury and/or fire.

Note)

(L1)

R

INPUT

(L2)

S

(L3)

T

(T1)

U

OUTPUT

(T2)V(T3)

W

Note:

R(L1), S(L2), T(L3) : Three phase 200 to 220V/50Hz

200 to 230V/50Hz

Three phase 380 to 415V/50Hz

400 to 460V/60Hz

Power supply

Fasten the screws with the specified fastening torque. Check so that there is no loosening of

screws.

Otherwise, there is a danger of tire.

Remarks for using earth leakage circuit breakers in the mains supply:

Frequency inverters with CE-filters (RFI-filter) and screened motor cables have a higher leakage

current against earth. Especially in the moment of switching on this can cause unintentional

triggerings of earth leakage circuit breakers. Because of the rectifier on the input side of the

inverter there is the possibility to stall the switch-off function through amounts of DC-current.

The following should be observed:

Only short time-inveriant and pulse current-sensitive earth leakage circuit breakers with higher

trigger current should be used.

Other components should be secured with separate earth leakage circuit breakers.

Earth leakage circuit breakers in front of an inverter are not an absolute protection against

direct touching.

Be sure to set the fuse(s) (the same phase as the main power supply) in the operation circuit.

Otherwise, there is a danger of fire.

As for motor leads, earth leakage breakers and electromagnetic contactors, be sure to use the

equivalent ones with the specified capacity (rated).

Otherwise, there is a danger of fire.

Double pole disconnection device must be fitted to the incoming mains supply close to the

inverter. And protection device meeting IEC947-1/IEC947-3 must be fitted at this point.

Connection to wiring terminal must be reliabily fixed with two means of support.

J300 INSTRUCTION MANUAL5

The terminal board will be exposed when the front cover or terminal cover ( 220HF to 2200HF) is

removed. Wire the inverter in this state.

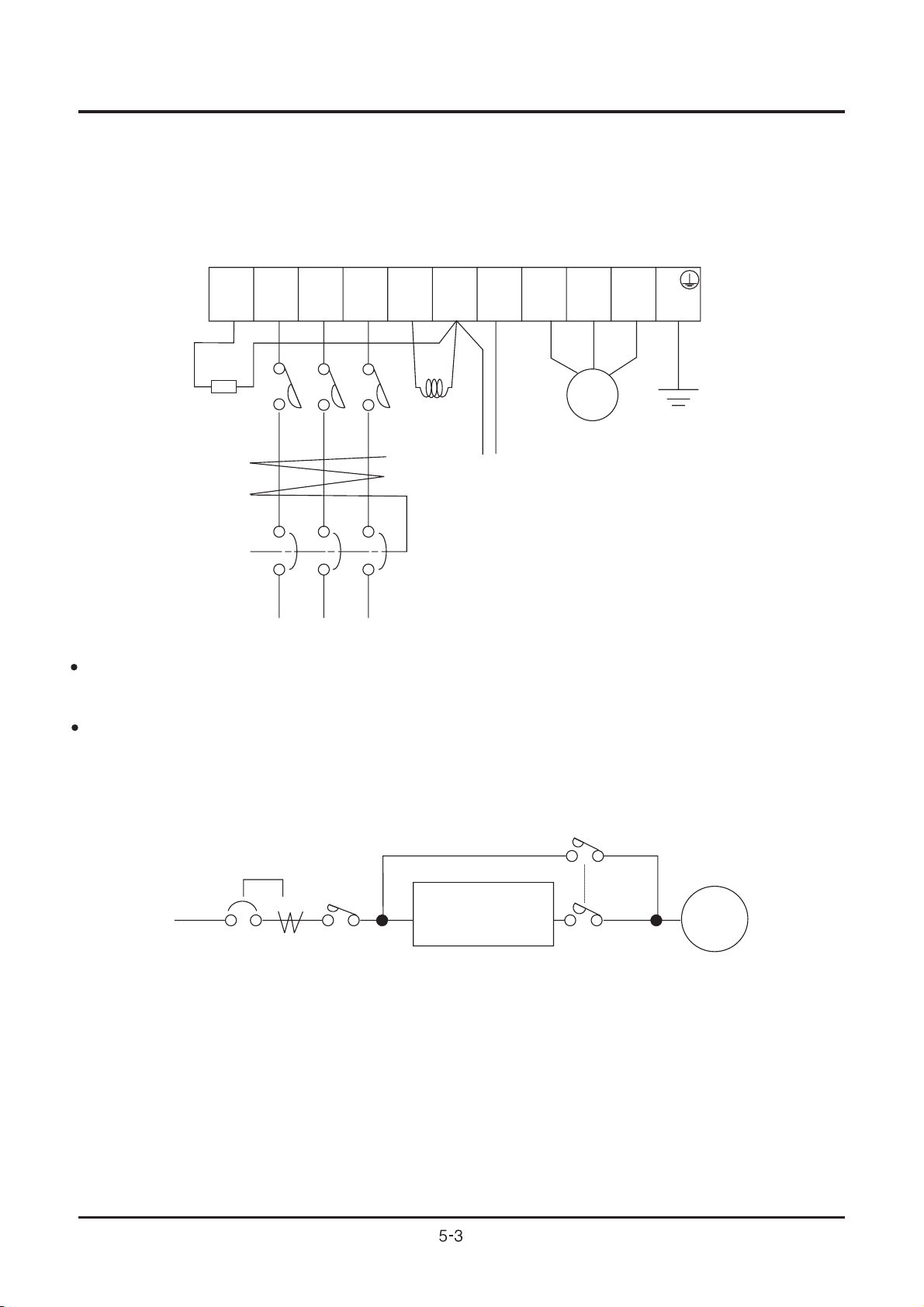

5.1 Wiring the Power Supply and Motor

RB

(RB)R(L1)

Regenerative

resistor

(L2)

Power supply

T

S

(L3)PD(+1)P(+)N(-)U(T1)V(T2)W(T3)

DCL

Braking Units

ELB

G

(PE)

MOTOR

The inverter will be damaged if the power supply is connected to the motor terminals

U(T1), V(T2) and W(T3), so be sure not to make any mistakes.

If multiple motors are to be connected, be sure to attach a thermal relay to each motor.

NOTE1:

Power

supply

NOTE2:

When changing the power supply of the motor between the inverter and commercial

power, be sure to install mechanically interlocked switches Mc1 and Mc2.

Mc1

ELB

Mc0

R(L1)

S(L2)

T(L3)

Inverter

(T1)U

(T2)V

(T3)W

Motor

Mc2

Install an earth leakage breaker at the input of the inverter. (Select an earth leakage breaker

whose sensitive current level is raised in high frequency range.)

When the cable length between the inverter and motor is long (more than 10m), the

thermal relay may malfunction due to higher harmonics. Therefore, install an AC reactor

on the output side of the inverter or use a current sensor in place of the thermal relay.

J300 INSTRUCTION MANUAL5

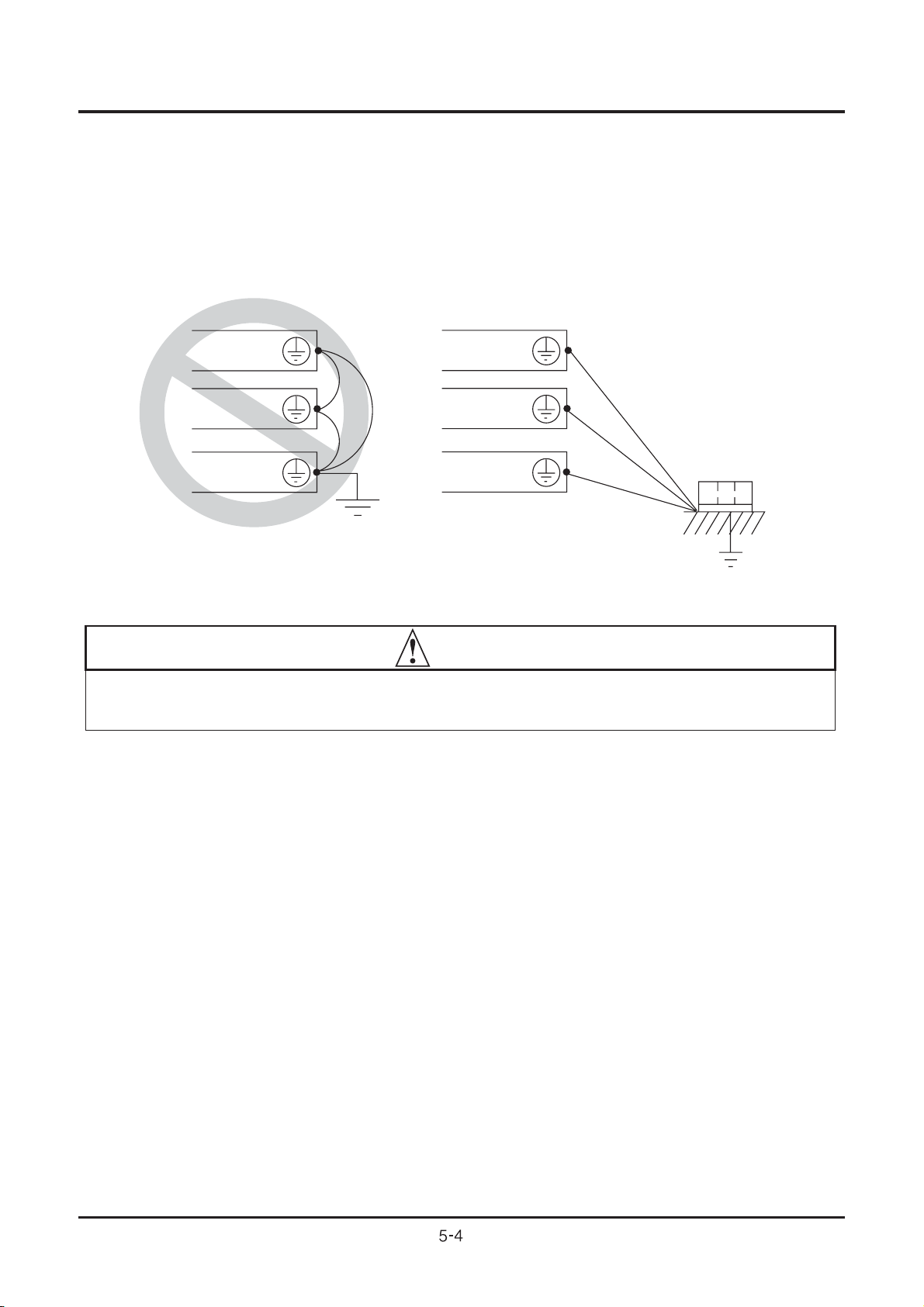

Note 3 : Be sure that the specified grounding is carried out. Be sure to separate the unit's grounding

pole from those of other heavy electric machinery, and avoid using common grounding poles.

If multiple inverters are used, make sure that the grounding connections do not create a loop.

Improper grounding Proper grounding

Inverter

Inverter

Inverter

Inverter

Inverter

Inverter

Grounding bolt

(at the site)

CAUTION

External or remote over load protection required, if multiple motor to be connected.

J300 INSTRUCTION MANUAL5

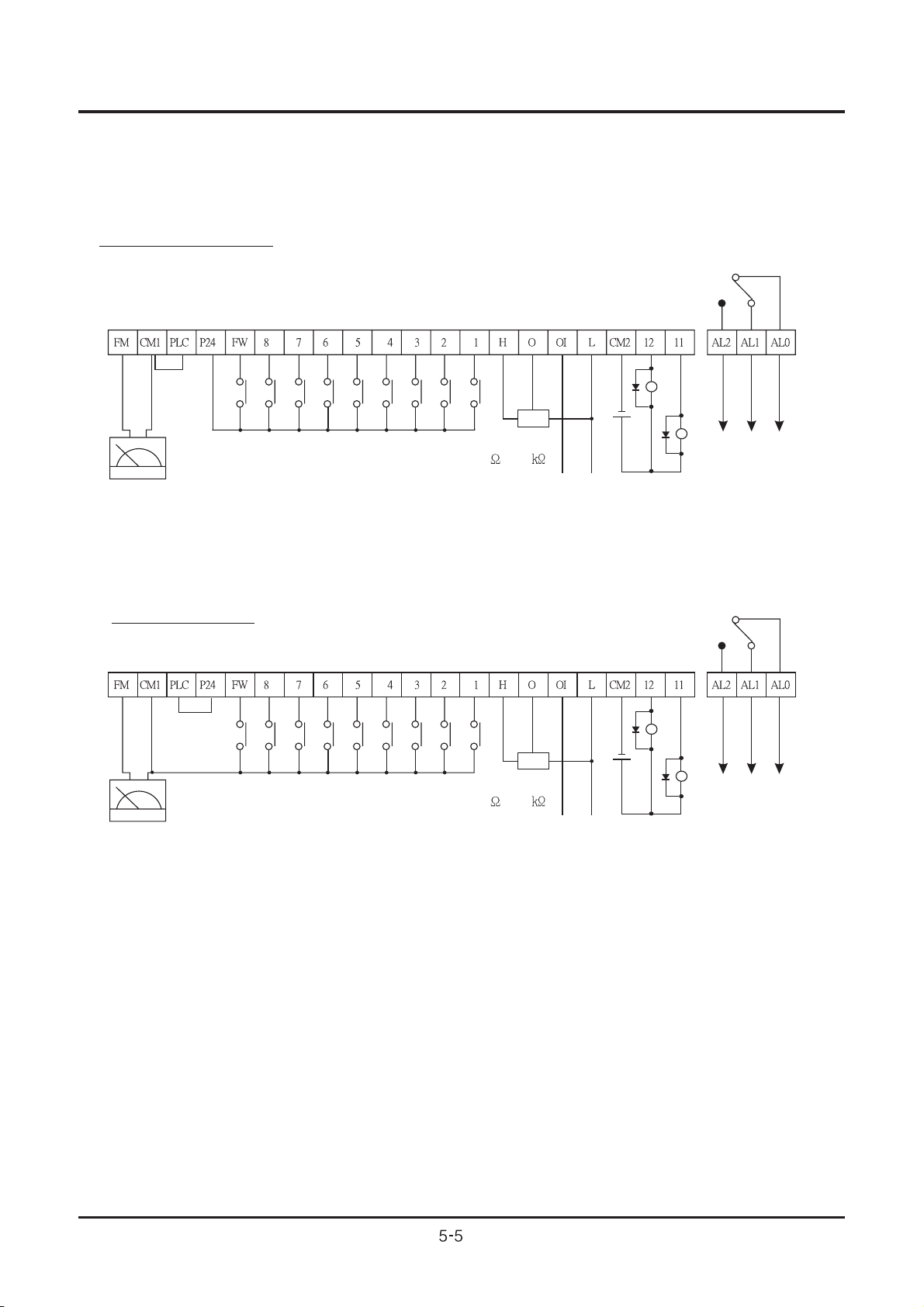

5.2 Wiring of Control Circuit Terminals

SOURCE TYPE wiring

(Factory settings for European version)

Input intelligent terminal Frequency setting

Frequency meter

(500 to 2 )

Current input

DC4to20mA

RY

RY

Failure alarm

For output

Intelligent terminal

27 VDC 50mA

50mA max.

SINK TYPE wiring

Frequency meter

NOTE1:

When an output intelligent terminal is used, be sure to install a surge absorbing diode in

parallel with the relay (RY). Otherwise, the surge voltage created when the relay (RY)

goes ON or OFF may damage the output intelligent terminal circuit.

NOTE2:

Use a twisted and shielded wire for the signal line, and cut the shielded covering as shown

in the diagram below. Make sure that the length of the signal line is 20meters or less.

Input intelligent terminal Frequency setting

(500 to 2 )

Current input

DC4to20mA

RY

RY

Failure alarm

For output

Intelligent terminal

27 VDC 50mA

50mA max.

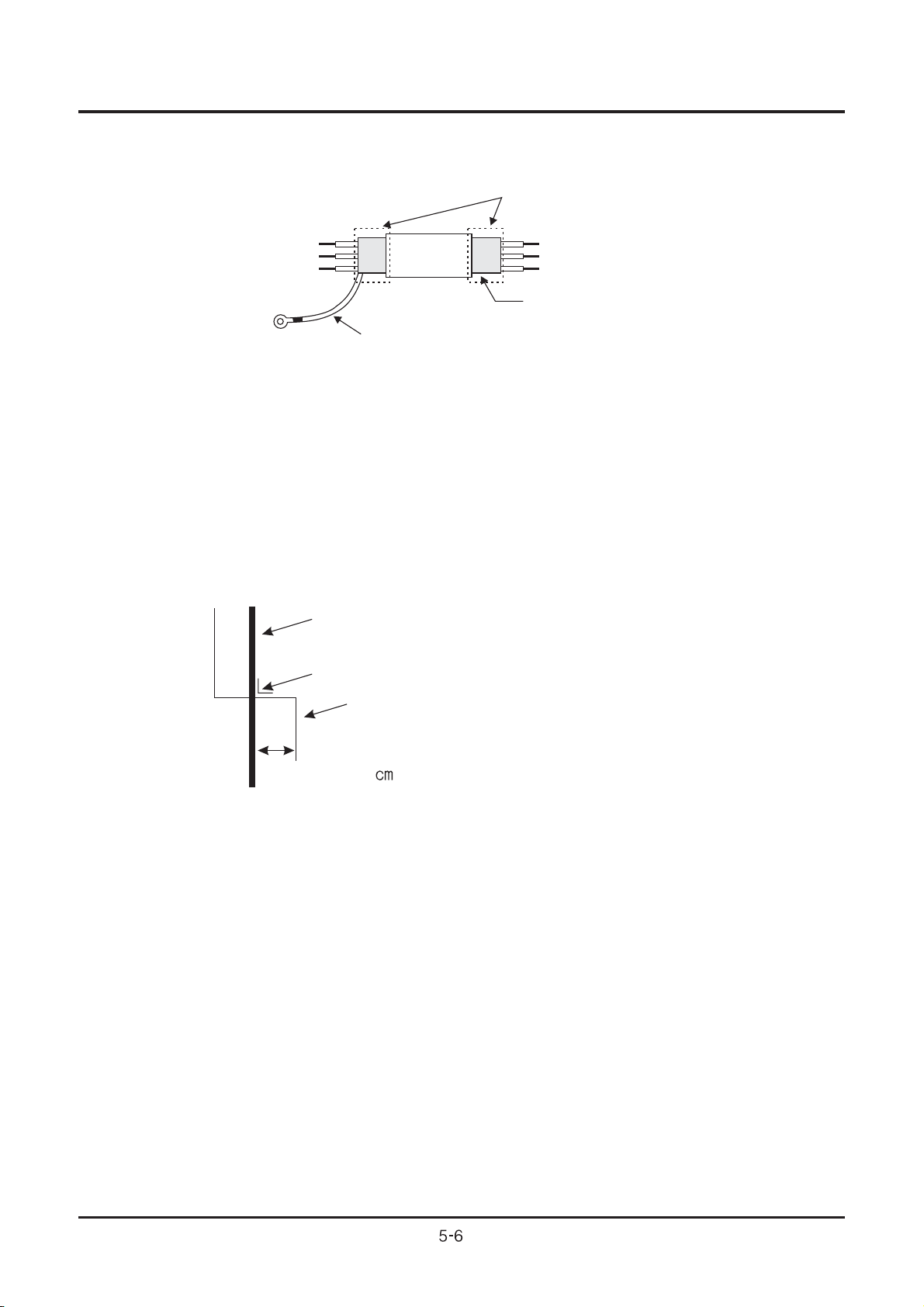

J300 INSTRUCTION MANUAL5

Insulate

No grounding necessary

Connect FG (frame ground) of the inverter.

NOTE3:

NOTE4:

NOTE5:

When the frequency setting signal is turned on and off with a contact, use a relay which

will not cause contact malfunctions, even with the extremely weak currents and voltages,

such as crossbar twin contacts, etc.

Use relays which do not have contact defects at 24V DC, 3mA for the other terminals.

Separate the main circuit wiring from the relay control circuit wiring. If they must cross,

be sure that they cross at a right angle.

Main circuit power line

(R, S, T, U, V, W, P, RB, N, L1, L2, L3, T1, T2, T3, +, -, etc.)

Right angle

Signal input line

(FM,CM1,PLC,P24,FW,8,7,6,5,4,3,2,1

H, O, OI, L, CM2, 12, 11, AL0, AL1, AL2)

Separate by 10 or more.

NOTE6:

NOTE7:Insulate the common terminal L for frequency analog command input and the common

Do not short between the terminals H and L and between the terminals P24 and CM1 of

the control circuit.

terminal (COMMON) of the peripheral equipment such as the sequencer before starting use.

J300 INSTRUCTION MANUAL5

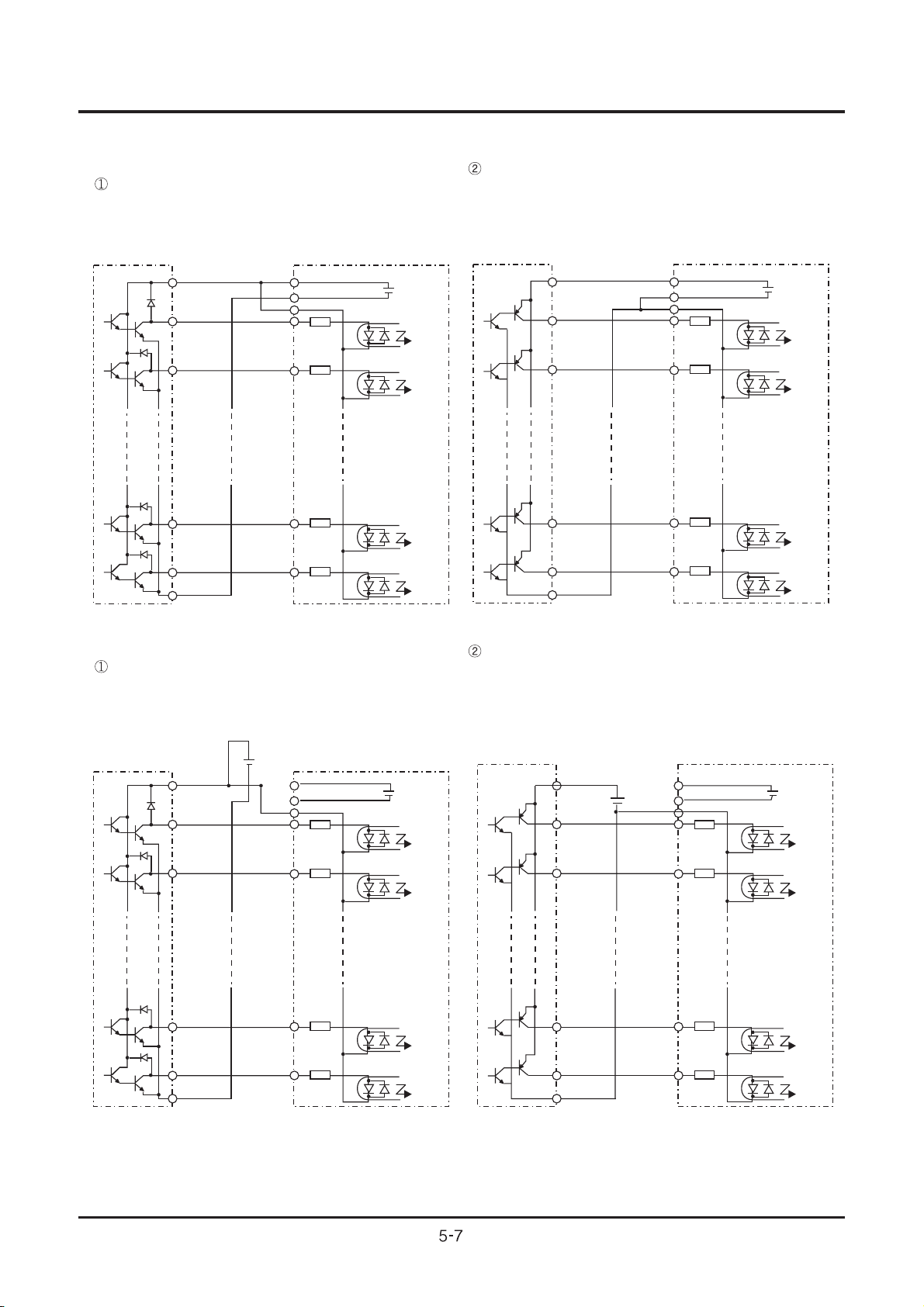

5.3 Connection to the Programmable Controller

(1) When the internal interface power source is used

This is an example when the transistor output(open

sink type

collector output) module of the sequencer is connected

This is an example when the transistor output(open

collector output) module of the sequencer is connected

source type

Note : Make sure of the short-circuit bar or wire between the

terminals PLC and P24.

S

1

2

8

9

COM

YTR48 type output module

P24

CM1

PLC

FW

8

2

1

J300 series

Inverter

+

DC24V

-

(2) When the external interface power source is used

This is an example when the transistor output(open

sink type

collector output) module of the sequencer is connected

Note : Make sure of the short-circuit bar or wire between the

terminals CM1 and PLC.

COM

1

2

8

9

S

YTS48 type output module

This is an example when the transistor output(open

P24

CM1

PLC

FW

8

2

1

source type

J300 series

+

DC24V

-

Inverter

collector output) module of the sequencer is connected

Note : Remove the short-circuit bar or wire between the terminals

CM1andPLCorP24andPLC.

+

DC24V

S

1

2

8

9

-

P24

CM1

PLC

FW

8

2

1

J300 series

+

DC24V

-

COM

YTR48 type output module

Inverter

Note : Remove the short-circuit bar or wire between the terminals

CM1andPLCorP24andPLC.

J300 series

1

2

8

9

COM

+

DC24V

-

P24

CM1

PLC

FW

8

2

1

+

DC24V

-

S

YTS48 type output module

Inverter

Note : Be sure to turn the inverter on after the controller and external power source are turned on.

(Otherwise, the data in the inverter may be changed.)

J300 INSTRUCTION MANUAL5

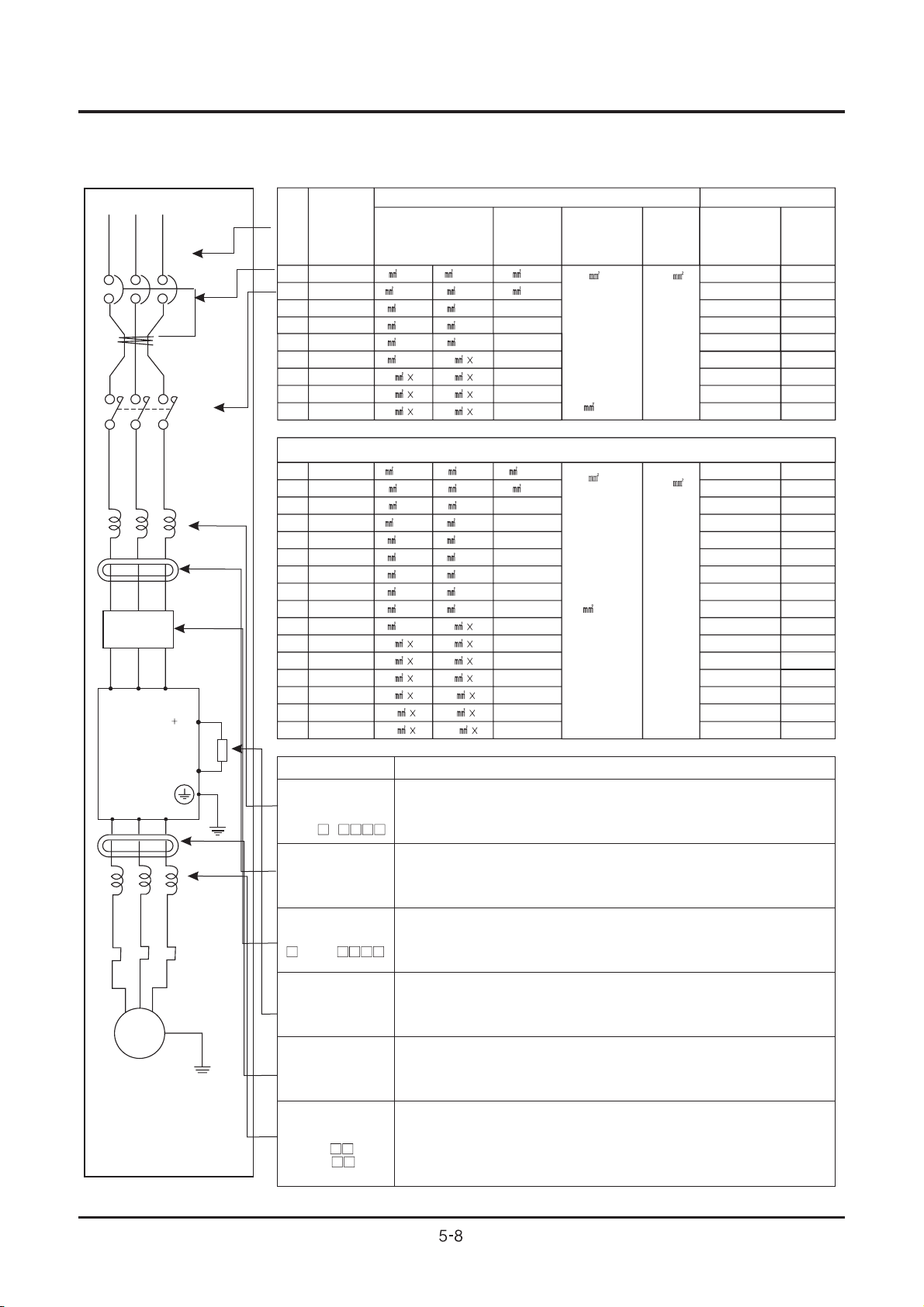

5.4 Wiring Equipment, Options (EMI filter, etc.)

Standard equipment (200V Class)

Power supply

RST

(L1)

(L2)

(L3)

()

Inverter

(T1)

(T2)

UVW

(T3)

ELB

Magnetic

contactor

P

RB

Motor

Inverter

output

model

(kw)

5.5

J300-055LF

7.5

J300-075LF

J300-110LF

11

J300-150LF

15

J300-220LF

22

J300-300LF

30

J300-370LF

37

J300-450LF

45

55

J300-550LF

(400V Class)

5.5

J300-055HF

7.5

J300-075HF

J300-110HF

11

J300-150HF

15

J300-220HF

18.5

J300-220HF

22

J300-300HF

30

J300-370HF

37

J300-450HF

45

55

J300-550HF

75

J300-750HF

J300-900HF

90

J300-1100HF

110

J300-1320HF

132

J300-1600HF

160

J300-2200HF

220

Part description

AC reactor for

improving

the power factor

(ACL- I- )

Power

lines

R, S, T, U, V

W, P, N

5.5 or more

14

or more

22

or more

or more

30

or more

60

38 2

38 2

60

2 or more 2 or more

8

14

22

38

60

38 2

38 2

60

2

60

3.5 or more

or more

or more

or more

or more

or more

2

2

3.5 or more 3.5 or more 3.5 or more

5.5 or more 5.5 or more

8

or more

14

14

22

38

38

60

38 2

38

60

80

100

200

or more

or more

or more

or more

or more

or more

or more

14

or more

14

22

or more

or more

30

or more

38

or more

60

38 2

38

2

60

2

80

2

100

2 150 2

2 2000 2

2

2

2

2

This part is used when the unbalance voltage ratio is 3% or more and power

supply is 500kVA or more, and there is a rapid change in the power supply.

It also improves the power factor.

Wiring

Power lines

Extemol

resistor

RB1, 2, 3,

P, R B

5.5 or more

5.5 or more8 or more

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Signal lines

FM1, CM1,

PCL, FW, 8, 7,

6, 5, 4, 3,

CM2, 12, 11

0.75

shielded wire

when the

number of

shielded wires

to be used is 11

or more, the

section of each

shielded wire

should be

0.5

0.75

shielded wire

when the

number of

shielded wires

to be used is 11

or more, the

section of each

shielded wire

should be

0.5

Function

Signal lines

P24, AL0,

AL1, A2

1.25

or more

1.25

or more

Applicabie equipment

Earth leakage

breaker(ELB)

HBH-53(50A)

HBH-53(50A)

HBH-103(50A)

HBH-103(100A)

HBH-203(150A)

HBH-203(200A)

HBH-203(225A)

HBH-203(225A)

HBH-403(350A)

HBH-33(30A)

HBH-33(30A)

HBH-53(50A)

HBH-53(50A)

HBH-103(75A)

HBH-103(75A)

HBH-103(100A)

HBH-103(100A)

HBH-203(150A)

HBH-203(175A)

HBH-203(225A)

HBH-203(225A)

HBH-403(350A)

HBH-403(350A)

HBH-403(400A)

HBH-603(600A)

Electromagnetic

contactor

HMC 27

HMC 37

HMC

HMC 70

HMC

110

HMC

130

HMC

150

210

HMC

HMC

260

HMC

20

HMC

20

27

HMC

37

HMC

HMC

50

HMC

50

70

HMC

HMC

80

90

HMC

HMC

110

HMC

150

HMC

180

HMC

260

HMC

300

HMC

400

HMC

630

50

IM

Thermal

relay

Motor

Radio noise filter

(Zero phase reactor)

(ZCL-A)

EMI filter for

inverter

( T3AK- )

Regenerative

resistor

(RB0,RB1,RB2,

RB3)

Radio noise filter

(Zero phase reactor)

(ZCL-A)

AC reactor for

reducing vibration

(ACL-L- )

(ACL-H- )

Using the inverter may cause noise on the peripheral equipment through the

power lines.

This part reduces noise.

This part reduces common noise generated between the power supply and the

ground, as well as normal noise.

Put it in the primary side of inverter.

NOTE5

This part is used for applications that needs to increase the brake torque of

the inverter or to frequently turn on and off and to run high inertia load.

This part reduces noise generated at the output of the inverter.

(It is possible to use for both input and output)

Running motors with the inverter generates vibration greater than that with

commercial power supply.

This part installed between the inverter and motor reduces torque ripple.

When the cable length between the inverter and motor is long, a

countermeasure for a malfunction of the termal relay is taken.

J300 INSTRUCTION MANUAL5

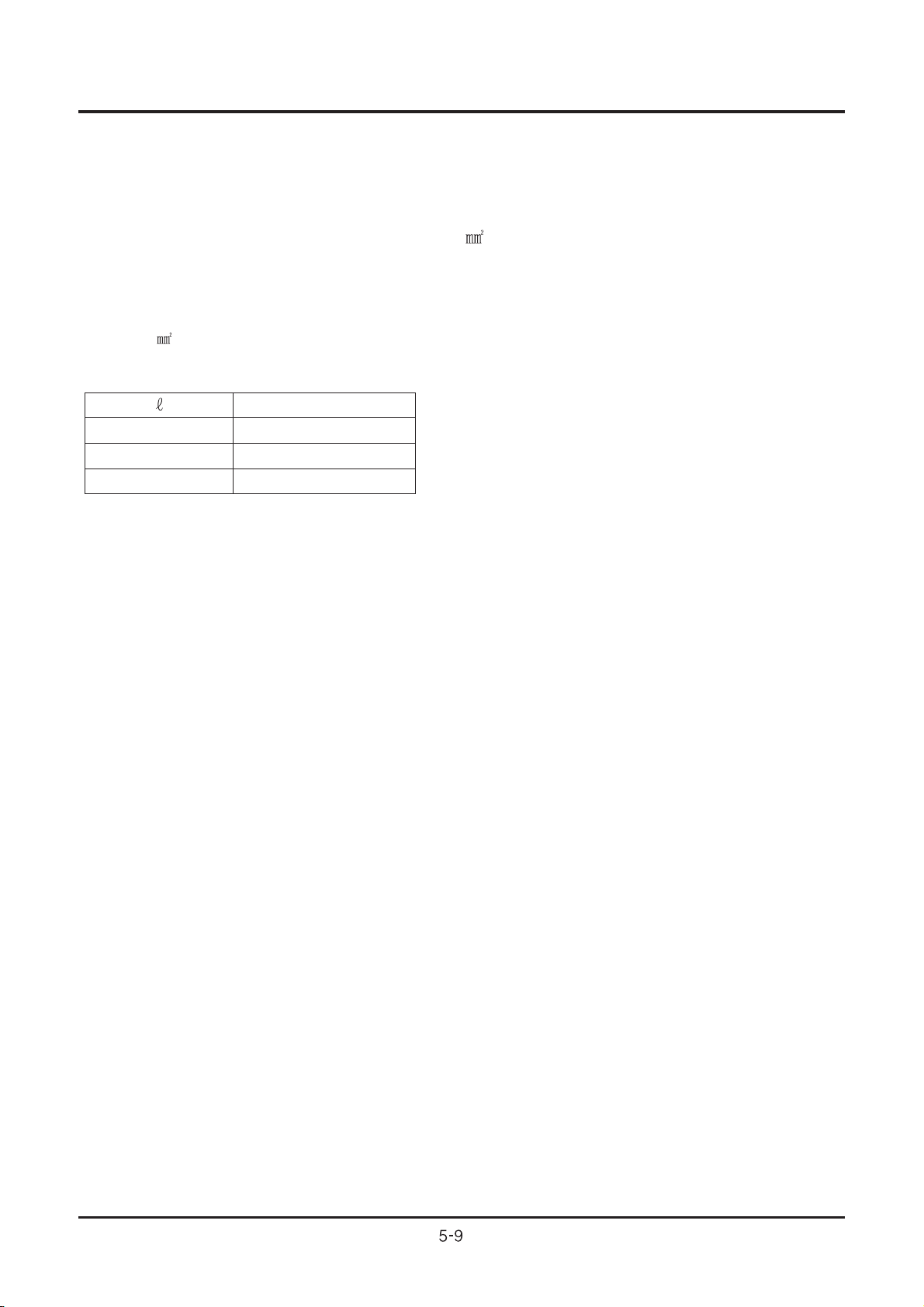

NOTE1:

NOTE2:

NOTE3:

NOTE4:

NOTE5:

NOTE6:

(*)Use 1.25

Classify the detective current of the earth leakage breaker depending on the total

distance between the inverter and the motor.

100 m and less

300 m and less

600 m and less

The applicable equipment is for a Hyundai standard four pole squirrel-cage motor.

Be sure to consider the capacity of the circuit breaker to be used.

Be sure to use bigger wires for power lined if the distance exceeds 20m.

Be sure to use an grounding wire of 3.5 or more.

EMI filter is required for EMC directive but others are not for this purpose.

Install an earth leakage breaker meeting requirements of IEC947-1/IEC947-3 at the input.

wire for the alarm signal wire.

()

Detective current(mA)

30

100

200

NOTE7:

NOTE8:

When using CV wire and metal tube,

the leakage current is around 30mA/km.

The leakage current becomes eight times

because IV wires have a high dielectric

constant. Therefore, use an one class

larger earth leakage breaker according

to the left table.

J300 INSTRUCTION MANUAL5

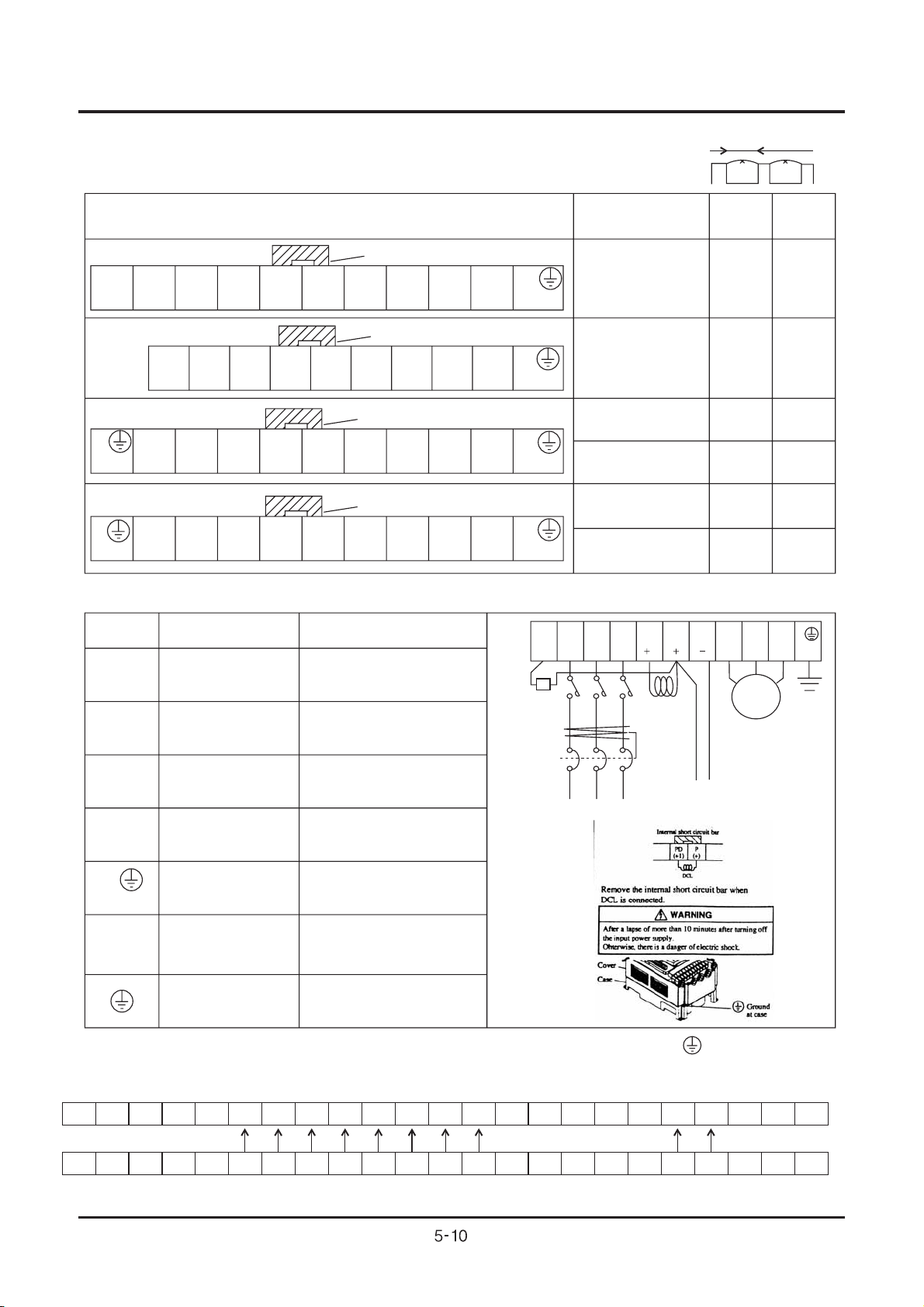

5.4 Terminal

(1) Main circuit terminal

Terminal layout

Insternal short circuit bar

RB R S T PD P N U V W

(L1) (L2) (L3) (+1) (+) (-) (T1) (T2) (T3)

(RB)

Insternal short circuit bar

RSTPDPNUVW

(L1) (L2) (L3) (+1) (+) (-) (T1) (T2) (T3)

Insternal short circuit bar

G

(PE)

G

(PE)

RSTPDPNUV

(L1) (L2) (L3) (+1) (+) (-) (T1) (T2) (T3)

Insternal short circuit bar

RSTPDPNUV

(L1) (L2) (L3) (+1) (+) (-) (T1) (T2) (T3)

W

W

G

(PE)

G

(PE)

G

(PE)

G

(PE)

Type

055, 075LF, HF

110, 150LF, HF

220, 370LF, HF

450, 550LF, HF

750, 900 HF

1100HF-2200HF

Screw

diameter

-

-

M6

M8

M10

M10

Widt h

Width

(mm)

-

-

17.5

23

35

40

Main circuit

Terminal

symbol

R, S, T

(L1),(L2),(L3)

U, V, W

(T1),(T2),(T3)

P, R , B

(+), (RB)

P, N

(+),(-)

G

(PE)

PD

(+1)

NOTE : Only the 055LF, 055HF, 075LF, 075HF are equipped with RB terminals and ground at case.

Terminal description

Main power

Inverter output

External regenerative

resistor

External regenerative

braking unit

Ground

External choke coil

Ground at case

Function

Connect the power supply

Connect the motor

Connect a regenerative

resistor(option) (NOTE)

Connect a regenerative

braking unit (option)

Ground(connect grounding to

avoid electric shock)

Connect a choke coil (DCL)

for harmonics current

reduction

Ground(connect grounding

to avoid electric shock)

RB R

(RB)

Regenerative

resistor

S

(L2)

(L1)

power supply

T

(L3)

PD

(1)

DCL

ELB

PN

()

()

Braking units

UVW

(T1)

(T2)

Motor

(T3)

G

(PE)

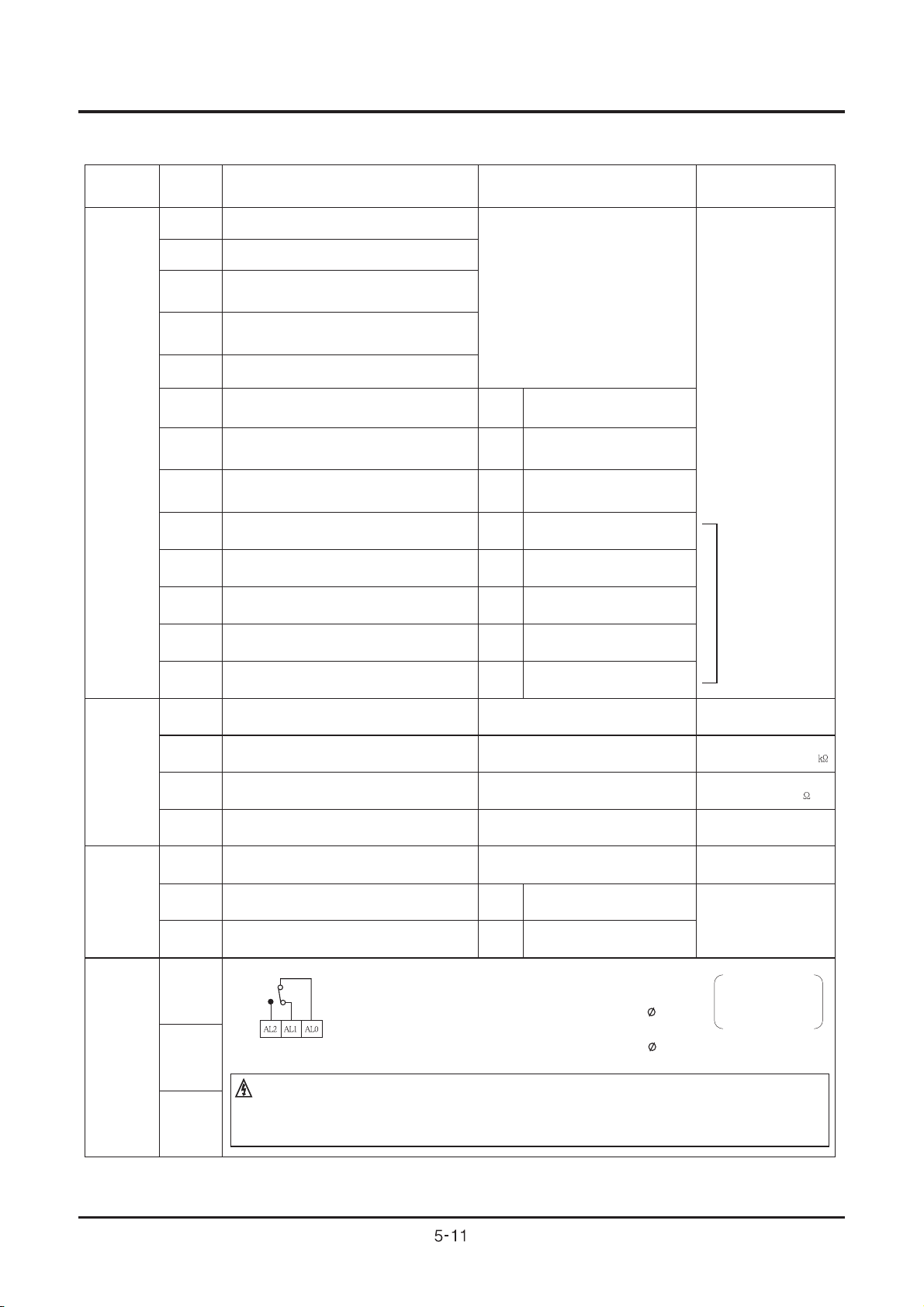

(2) Control circuit terminal

The intelligent I/O terminals 1 to 8 and 11and 12 are initialized as shown below at factory before shipment.

FM CM1 PLC P24 FW REV CF2 CH1 FRS JG AT RS H O OI L

FM CM1 PLC P24 FW H O OI L

CF1

87 65 4321

CM2

CM2

RUN FA1

12 11

AL2

AL2

AL1 AL0

AL1 AL0

J300 INSTRUCTION MANUAL5

Control circuit

Input

monitor

signal

Terminal

symbol

FM

CM1

PLC

P24

FW

8

7

6

5

4

3

2

1

Terminal description and function

Frequency monitor

Common for monitor

Common terminal for the external

power source of the sequencer(PLC)

Internal power source for the frequency

monitor and intelligent input terminal

Forward operation

Intelligent input terminal 8

Intelligent input terminal 7

Intelligent input terminal 6

Intelligent input terminal 5

Intelligent input terminal 4

Intelligent input terminal 3

Intelligent input terminal 2

Intelligent input terminal 1

Standard setting of

intelligent terminal

REV

CF1

CF2

CH1

FRS

JG

AT

RS

Reverse operation

Multistage speed

(First stage)

Multistage speed

(Second stage)

2stage acc./dec.

Free run input signal

Jogging

Current input selection

Reset (NOTE1)

Remarks

Dry contact

Close : ON (run)

Open : OFF (stop)

Min. ON time :

12 ms or more

Note:

If the power is turned

on when the input

terminals 1 to 5 are

kept on, all the data

stored in the inverter

is initialized.

Therefore, never turn

the power on in such

a state.

Frequency

command

input

Output

signal

Fault

alarm

Output

H

O

OI

L

CM2

12

11

AL0

AL1

AL2

Power supply for frequency command

Voltage frequency command

Current frequency command

10 VDC

0-5VDC(nominal), 0-10 VDC

(nominal)(Input impedance 30 )

DC 4-20mA (nominal)

Input impedance 250

Common for frequency command

Common for intelligent output

terminal

Intelligent output signal 12

Intelligent output signal 11

Normal: AL0-AL1 close

Abnormal, Power off :

AL0-AL1 open

CAUTION

Alarm connection may contain hazardous live voltage even when inverter is disconnected.

In case of removing flont cover for maintenance or inspection, confirm that incoming power

for alarm connection is surely disconnected.

RUN

FA1

Run signal

Frequency arrival signal

Contact rating

250 VAC 2.5A (Resistor load)

0.2A (cos =0.4)

30 VDC 3.0A (Resistor load)

0.7A ( cos =0.4)

27 VDC

50 mA max

Min 100VAC

10mA

5VDC

100mA

NOTE 1 : Terminal RS can use only contact a (normally open). It cannot use contact b(normally closed).

Loading...

Loading...