Hyundai HYW11120, HYW10200, HYW13170-3 User Manual

ELECTRIC HOT WATER

PRESSURE WASHER

Models HYW11120 - HYW10200 - HYW13170-3

User Manual

IMPORTANT: Read these instructions carefully before first use

Hot water high-pressure cleaner

Congratulations, you have chosen a cleaner that is easy to handle and to use.

This

hot water cleaner will assist you professionally for all washing, de-scaling, cleaning and

wet sandblasting purposes.

These cleaners are recommended for use in all fields of industry, agriculture, building trade

and tourism.

These cleaners can meet all your cleaning requirements, both hobby and professional, being

light and handy, easy to use and to service.

The wide range of models perfectly fits each kind of use.

INDICE

Warnings……………………………………………………………………………………… page 2

Warranty rules ...........................................................................................................… page 3

Description and envisaged conditions of use ...........................................................… page 3

General view – Marking and identification………………………………………………. page 4

Operating features ...............................................................................................…..... page 5

Technical specification table .................................................................................….... page 5

Improper use ............................................................................................................…. page 6

Incorrect use ..........................................................................................................…... page 6

Packing – Transport ..........................................................................................………. page 6

Commissioning ..........................................................................................................… page 7

Installation – Use .......................................................................................................… page 8

Prohibited operations - Safety rules ..........................................................................… page 11

Precautions for the use of high-pressure hose..........................................................… page 12

Accessories ................................................................................………….……………. page 12

Routine maintenance …………..................................................................................... page 12

Troubleshooting ........................................................................................................... page 15

Disposal of the machine …........................................................................................... page 16

Ecological information ……………

.......................................…...................................... page 16

Declaration of conformity .............................................................................................. page 16

Wiring diagram ...................................................................…....................................... page 17

WARNINGS

Carefully read the warnings given in these instructions since they

provide important details concerning the safety, use and maintenance.

Get acquainted with the appliance to be able to quickly switch it off

and eliminate the pressure.

Make sure you refer to section “Prohibited operations - Safety rules”.

These instructions are an integral and essential part of the product that, as provided for by the

directive 2006/42/CE, must be delivered to the user in order to ensure fulfilment as regards

training/informing the personnel assigned to use the machine.

The manufacturer shall not be held liable for any injury or damage, even to the appliance itself,

if the machine is used incorrectly regardless of the instructions given. Keep these instructions

with care for future reference.

Check the model of high-pressure cleaner you have purchased, reading the data on the

appliance rating plate. Upon delivery, check that the machine has not suffered any damage

during transport and that there are the required accessories. Any complaints may only be

accepted in writing within 8 days of the date of delivery.

Page 2

WARRANTY RULES

1) Hyundai high-pressure cleaners are covered with a 1 year warranty for trouble deriving from

manufacturing defects. Warranty does not apply to normal wearing parts, in particular:

pistons, seal rings, gaskets, and electrical components.

Repairs carried out by unauthorized personnel void the warranty.

2) Hyundai obligations are restricted to replacement of defective parts. Replacement or repair

of defective parts depends on the unquestionable decision of Hyundai.

Transport costs and risks, removal and installation of the machines and any

other cost directly or indirectly associated with the repair of this product are not covered by

warranty.

3) All repairs under warranty must be carried out by Hyundai or by a Technical Support Service

authorized by Hyundai. Repairs carried out by unauthorized technicians shall not be

reimbursed. If said repairs cause damage to the machine, this is not covered by warranty.

4) Regular checks, maintenance and tampering are not covered by warranty.

DESCRIPTION

Cold and hot water high-pressure cleaner composed of a metal chassis with castors and a

handle for moving; generator for the production of hot water; diesel burner; diesel tank; steam

exhaust vent; motor-pump for inlet of pressurized water; mains plug-in power supply; power

cable and switchboard; cover and washing spray gun (or other accessories).

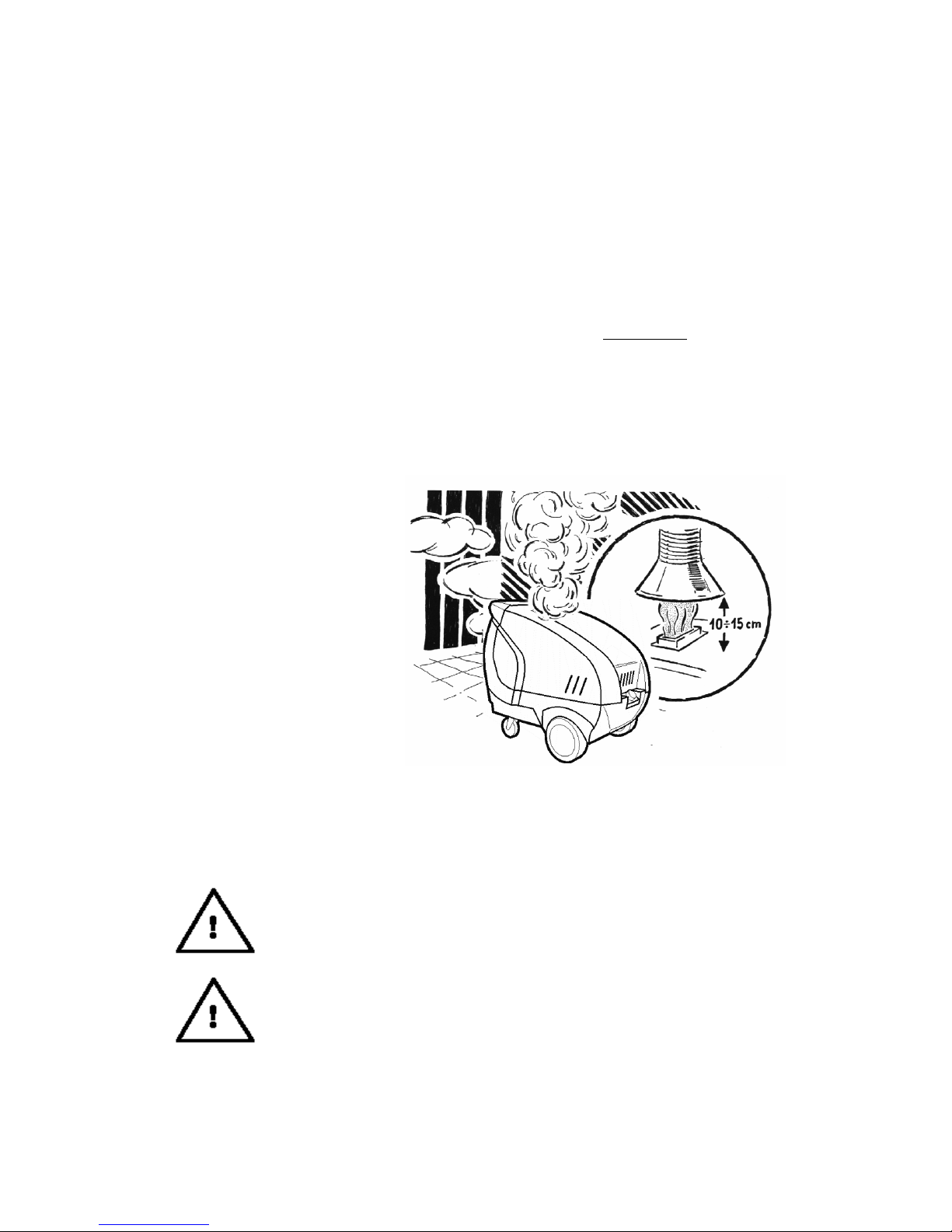

ENVISAGED CONDITIONS OF USE

Use

The cleaner has been developed and manufactured for the use in car-washing, body-shops,

workshops, factories, filling stations, farms, etc. If the machine is used in closed rooms, air shall

be supplied and combustion gases evacuated by means of a good exhaust system to avoid

poisoning. To correctly execute these instructions, please contact our authorised technical

service centre.

The use of cleaning machines or other units with electric motors or other equipment, which can

short-circuit because of water contact, IS FORBIDDEN.

Environment

The power supply with minimal IP 54 protection permits use:

- OUTDOORS ON FLAT SURFACES;

- IN DAMP CONDITIONS.

In any case, for safe and easy manual handling, it is necessary for the floor to be as flat and

even as possible. The machine HAS NOT BEEN DESIGNED to be pushed or towed with

mechanical facilities of any kind.

Page 3

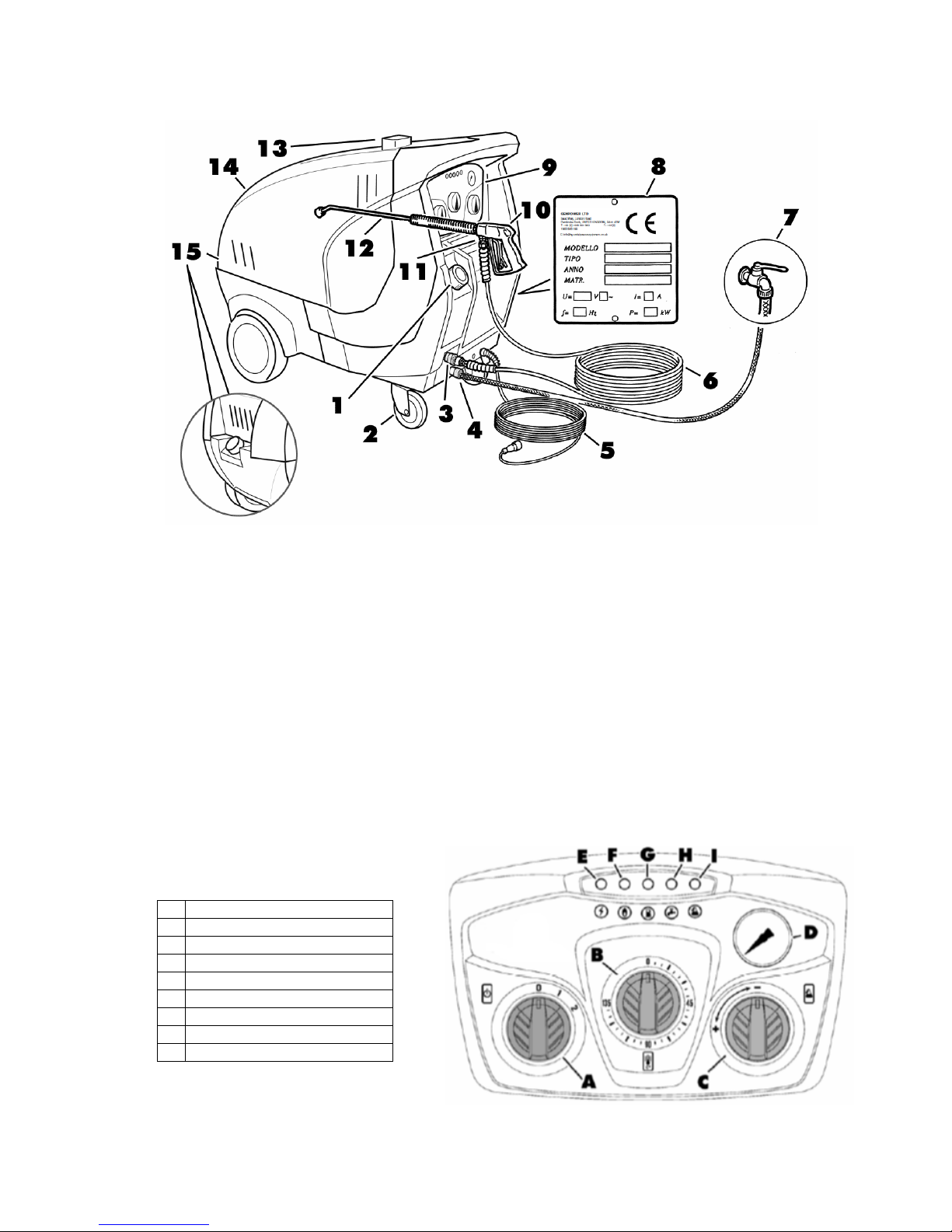

GENERAL VIEW

1 - Detergent tank

2 - Castor with brake

3 - High-pressure hose / machine connection

4 - Water supply hose / machine connection

5 - Power cable

6 - High-pressure hose

7 - Tap and mains wa

ter hose (not supplied)

8 - Rating plate

9 - Switchboard

10 - Automatic gun

11 - High-pressure hose/spray gun connection

12 - Lance handgrip

13 - Steam exhaust vent

14 - Cover

15 - Diesel tank

Switchboard

A Main switch

B Thermostat control

C Detergent regulation

D Pressure gauge

E Power supplywarning light

F Burner warning light

G Fuel warning light

H Water warning light

I Anti-scaling warning light

Page 4

Standard Equipment

The standard equipment includes:

• High-pressure hose

• Washing lance with safety trigger gun

Optional Accessories

Tecno-Mec’s high-pressure cleaners can be equipped with additional accessories according to

your cleaning requirements: ask for them from your local point of sale.

- SANDBLASTING KIT for sandblasting with the power of high pressure

- HOSE-CLEARING KIT for effectively clearing clogged hoses

- ROTATING/FIXED BRUSHES to remove persistent dirt

- FOAM LANCE transforms detergent into a thick foam

- UNDERBODY LANCE to clean the underbody of vehicles

- ROTATING NOZZLE increases water jet and washing efficiency

OPERATING FEATURES

- THREE-PHASE MODELS: supply from three-phase network with protection conductor

(without neutral conductor): 400V+/- 10%; 50Hz

- SINGLE-PHASE MODELS: supply from single-phase network with protection conductor

230V 50Hz (+ - 10%)

- continuous duty;

- maximum ambient temperature: +40°C

- minimum ambient temperature: +5°C

-

maximum humidity: 80%

- sound pressure level: 98 dB(A)

Meticulous compliance with the instructions provided with our materials is a primary condition

for their us

e in complete

safety.

We will therefore accept no liability for IMPROPER OR INCORRECT USE of our appliances.

To provide a suitable guide for users here we give examples of risky behaviour.

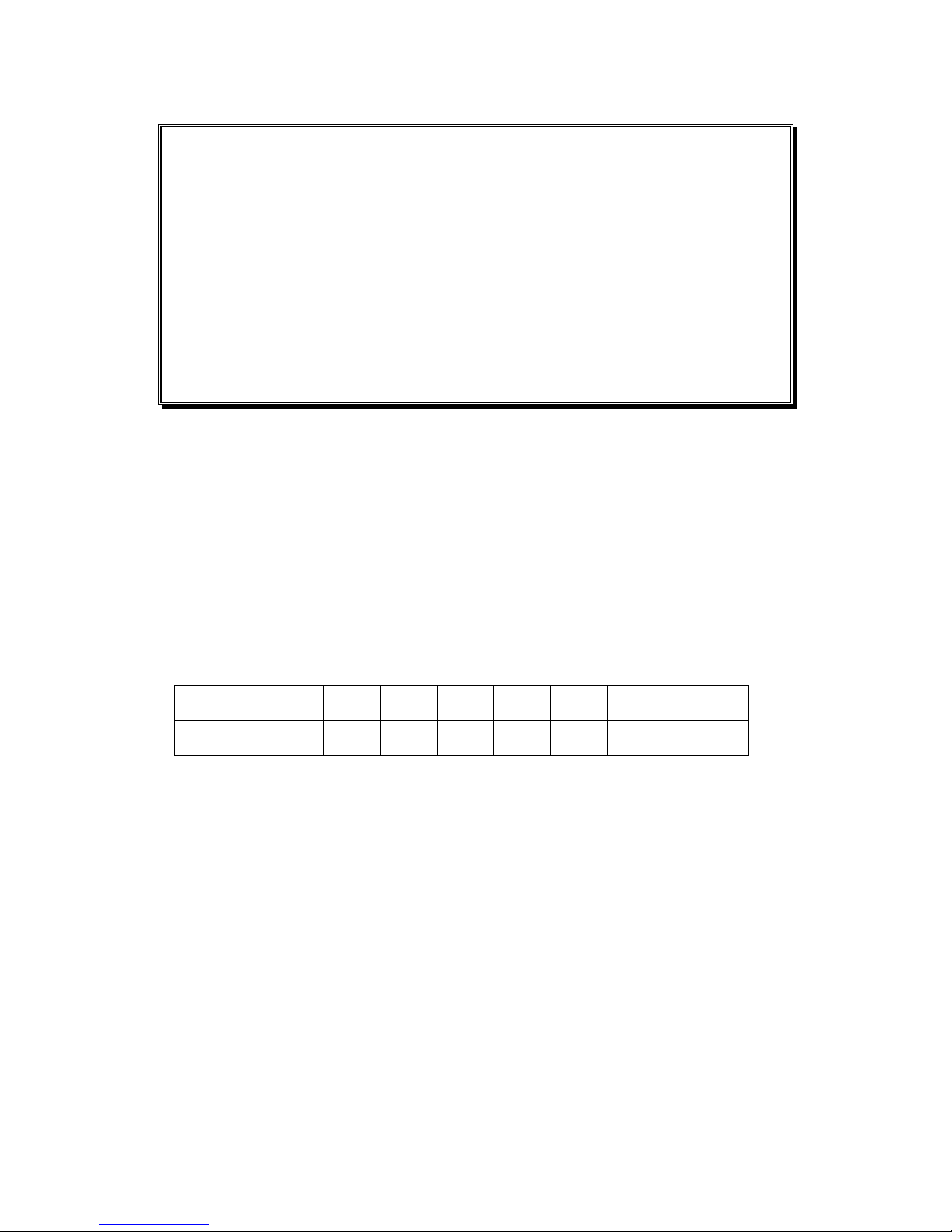

MODEL l/min g/min bar psi HP Kw Supply

HYW11120 11 2.42 120 1740 3 2.2 230V - 13 Amp plug

HYW10200 10 2.20 200 2900 5

3.5

230V - 32 Amp plug

HYW13170-3 13 2.86 170 2456 5.5 4 400V - 3 phase

Page 5

IMPROPER USE

Improper use of our machines is understood to be using them in operations they were not made

for. Improper uses therefore comprise:

- USE IN ROOMS WITH DANGER OF EXPLOSION OR FIRE HAZARD (e.g. paint warehouse,

near petrol pumps, storage of combustible materials such as wood, straw, etc.)

- USE IN CLOSED ROOMS NOT PROPERLY VENTILATED

- USE IN CLOSED ROOMS WITHOUT A CONNECTION TO AN EXHAUST DEVICE

-

USE IN THE RAIN OR THUNDERSTORMS

- USE TO CLEAN ANIMALS

- USE BY PEOPLE WHO ARE NOT ADULTS

- WASHING ANY ELECTR

IC-POWERED OBJECT

- WASHING TYRES AT A SPRAYING DISTANCE OF UNDER 30 cm (tyr

es can get

damaged, even internally, by a pressurized water jet, causing them to explode).

- USE WITH OTHER PEOPLE NEARBY WHO COULD GET HIT BY THE DIRT OR PARTS

DETACHED FROM THE OBJECT WASHED

INCORRECT USE

Incorrect use of our machines is understood to be using them without complying with the

operating and maintenance manual (see also section “Prohibited Operations”). Failure to

comply with these instructions may cause injury to the operator and damage the machine. We

shall now give some examples of incorrect use:

- WRONG CONNECTION/USE OF THE ACCESSORIES SUPPLIED

- WRONG SEQUENCE OF STEPS FOR COMMISSIONING

- FAILURE TO USE GENUINE SPARE PARTS

-

USE OF FUEL DIFFERENT FROM DIESEL

- STARTING THE MACHINE WITH DIESEL TANK ON EMPTY

- MAINTENANCE WORK BY UNQUALIFIED PERSONNEL

- USES FOR WHICH THE MACHINE HAS NO

T BEEN DESIGNED (see improper use)

- MAINTENANCE WORK NOT CARRIED OUT

PACKING - TRANSPORT

The machine is fixed to a wooden pallet and covered by a corrugated board packaging, which is

fastened with a high resistance plastic ribbon. The machine packed in this way can be lifted

also by a fork-lift truck. The packaging materials are particularly sensitive to atmospheric agents

such as rain, fog, sun, etc. The packed machine can be lifted by a lift or pallet truck with the

capacity of at least 250 Kg.

Should you transport the machine without its original packaging, make sure it is properly

secured to prevent it from moving.

Put the machine on even floors. During periods when it is not used, keep your high-pressure

cleaner away from atmospheric agents.

WARNING: check that the

capacity of the lifting

equipment is suitable

Page 6

COMMISSIONING

Commissioning must take place in clean and well-lit areas. For the machine parts, refer to page

4 “General view” of this manual.

1 - After removing the packaging, make sure the machine is not damaged. Should you have any

doubt, do not use the machine and call your supplier’s technical support service.

The packaging materials (cardboard, wood, etc.) must be put away in special containers and

kept out of the reach of children as they are a potential source of hazard.

2 - Put the cleaner on a properly arranged place, in any case on an even surface

, locking up the

castors using the brake (Fig. 2).

The work station must be equipped with:

- a mains outlet of 400V/16A 3+PH three-phase or 230V/16A single-phase 2PH+T according to

the models (see technical features

on the rating plate - see section “Marking and

identification”)

- a clean water inlet 1/2”, pressure 0.3 Mpa, with a stop valve

- a connection to the drainage system for the treatment of the waste water.

Arrange for a good exhaust

system to evacuate gases and for

proper ventilation in closed rooms.

3 - Connect the machine water

inlet to the mains

water; this

connection must be made with a

suitable hose, which must be as

short as possible to avoid tripping.

4 - After unscrewing the cap (Fig.

15), fill the tank with automotive

diesel. It is necessary to use clean

fuel; filter it if necessary.

5 - Connect the spray gun to the

high-pressure hose (Fig. 11) using a 17mm-spanner. Connect the latter to the fitting (Fig. 3).

6 - Connect the mains water hose to the quick coupling (Fig. 4) fixing it with a hose clamp. The

mains water hose must be perfectly clean insi

de; use a filter upstream if necessary.

7 - CAUTION! - Before wiring, turn the main switch (Fig. A) to 0/OFF and

make sure the rating plate data (Fig. 8) correspond to those of the mains

power supply. Wiring must be carried out by qualified personnel in

compliance with current national and local regulations.

8 - CAUTION! - Verify that the cross-section of the system cables, their

condition and their current carrying capacity are suitable for the power

absorbed by the machine, indicated on the rating plate. Protect the supply

line by using thermomagnetic releases coordinated with the machine

protection device. The data can be seen on the device itself.

Page 7

Loading...

Loading...