Hyundai HD-65, HD-72, HD-78 Wiring Diagram

INTRODUCTION E103F6A0

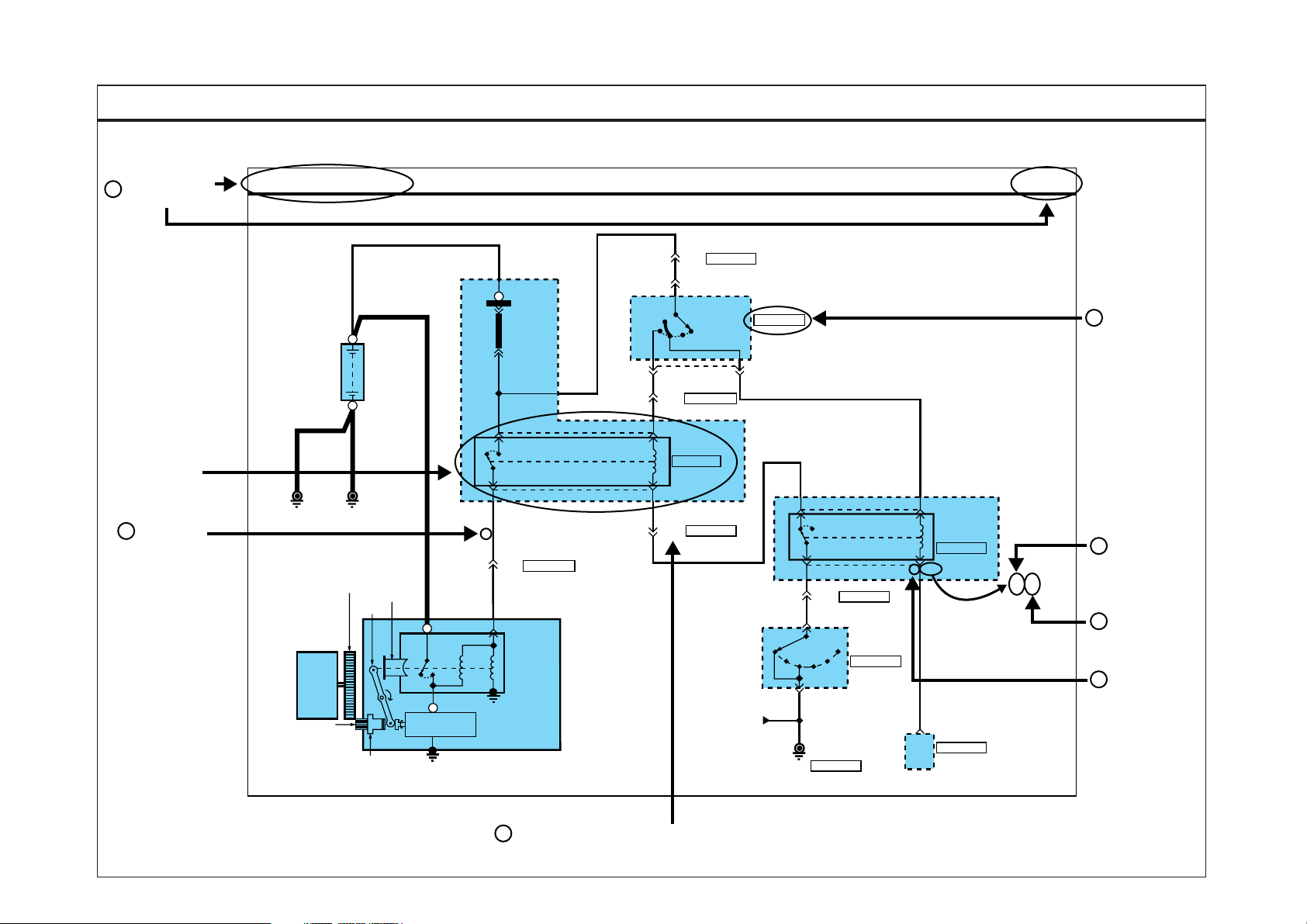

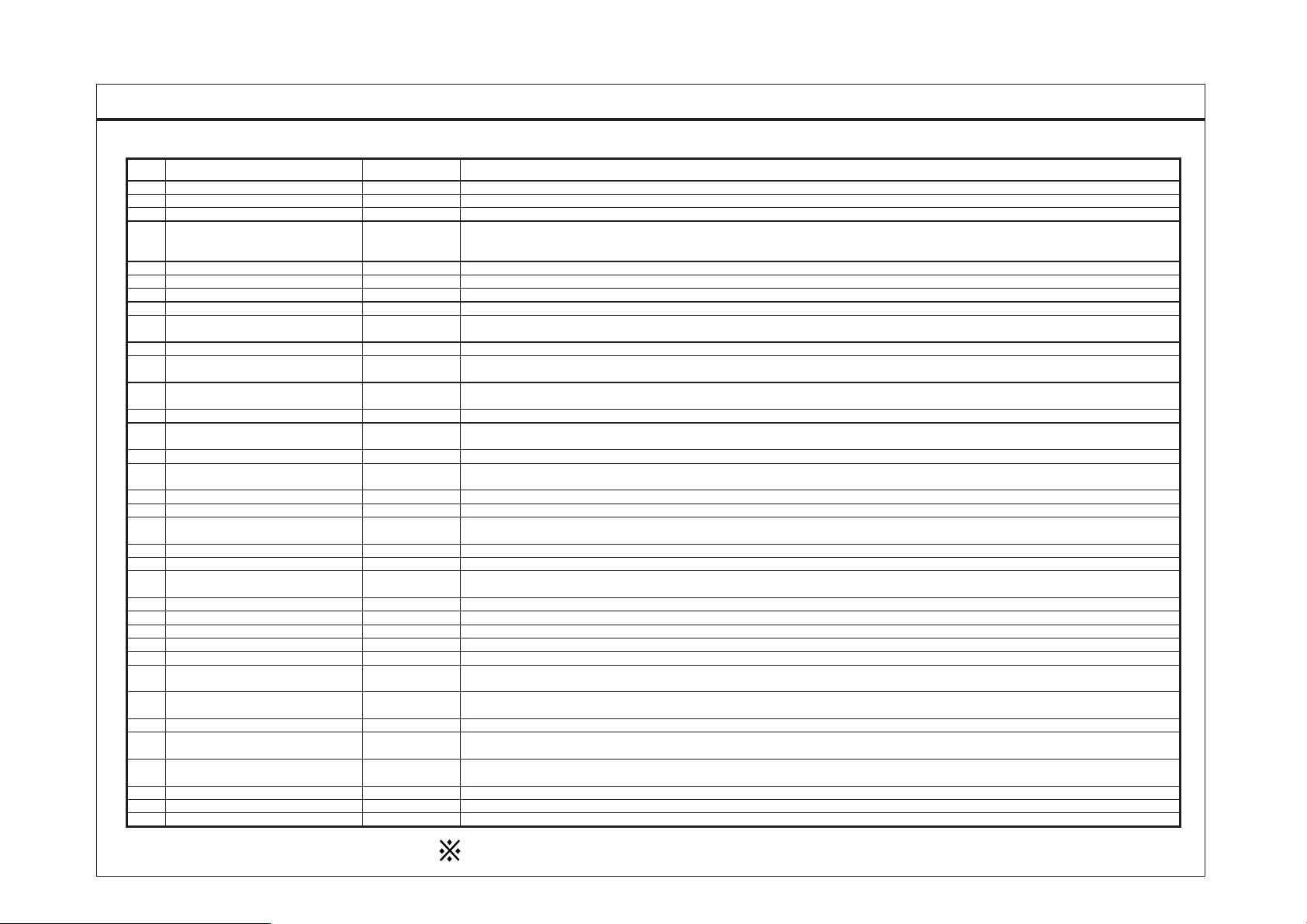

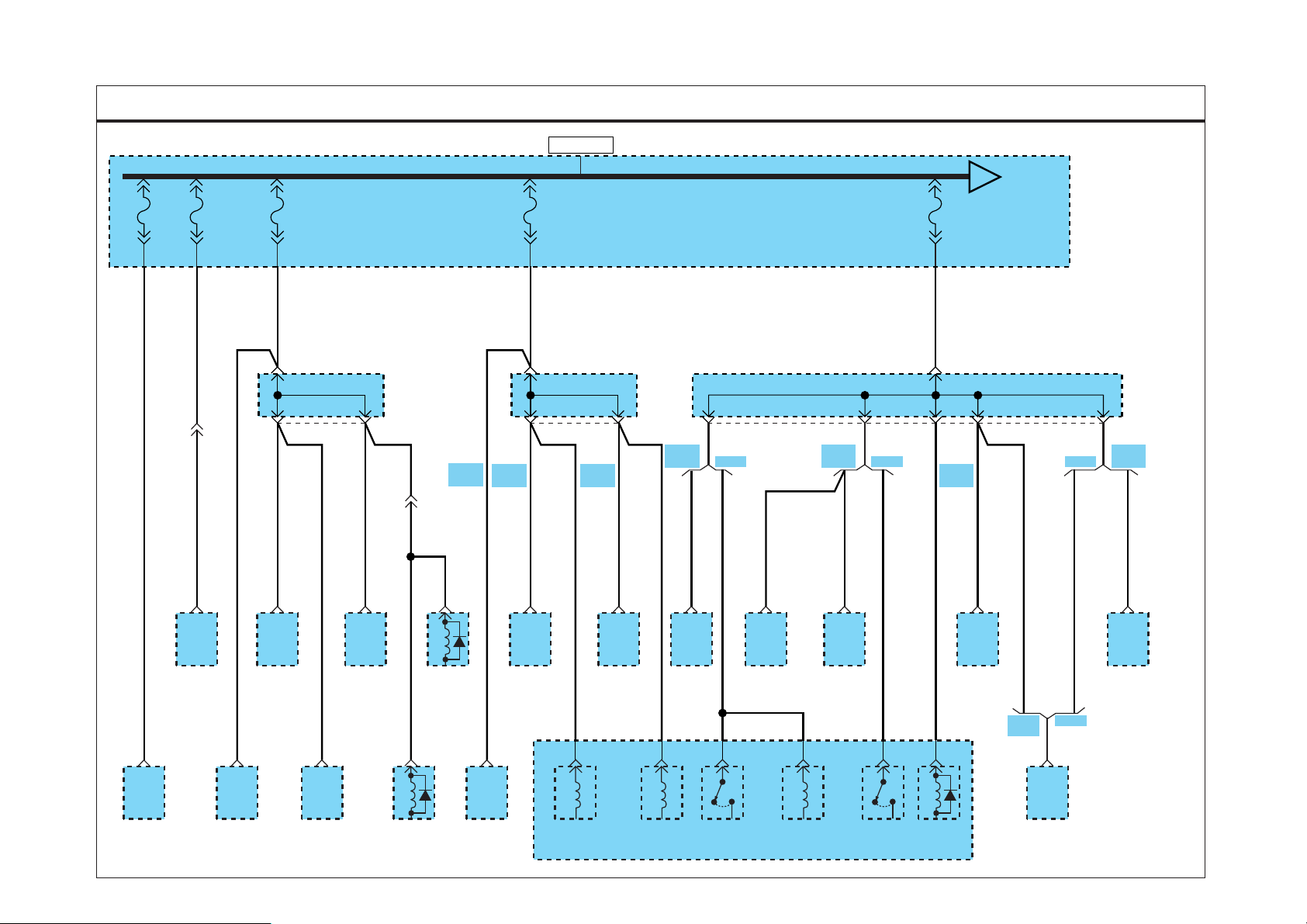

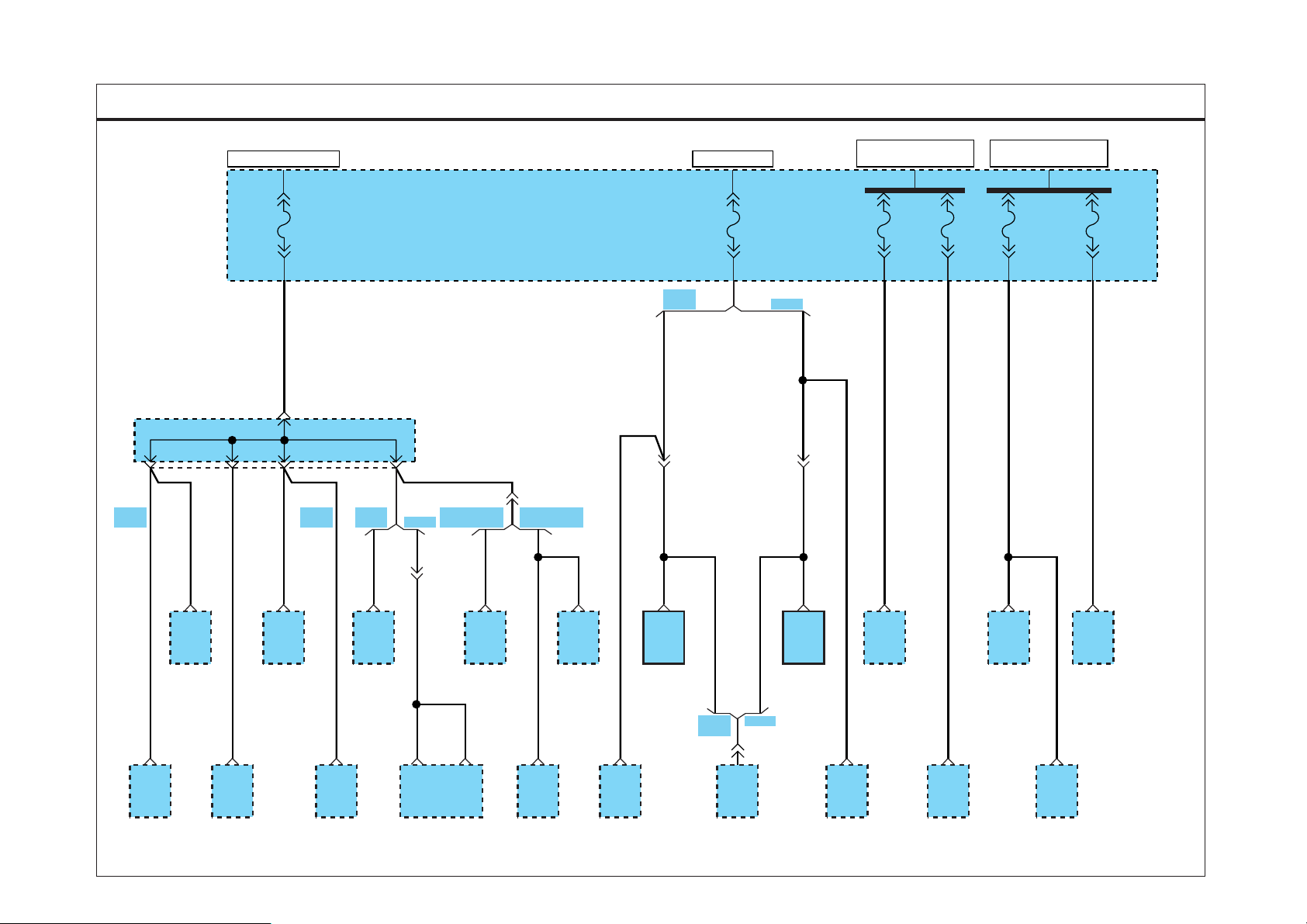

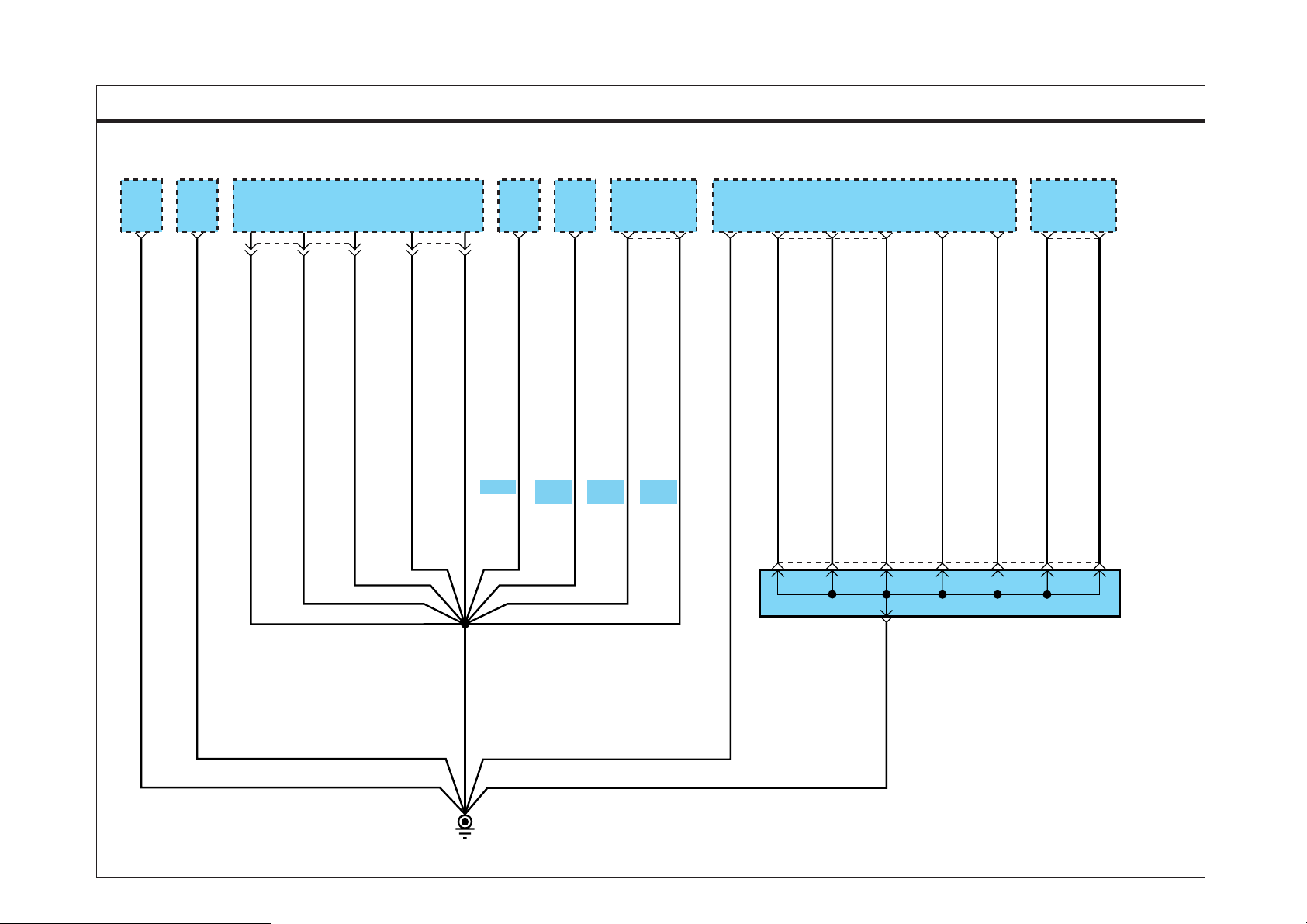

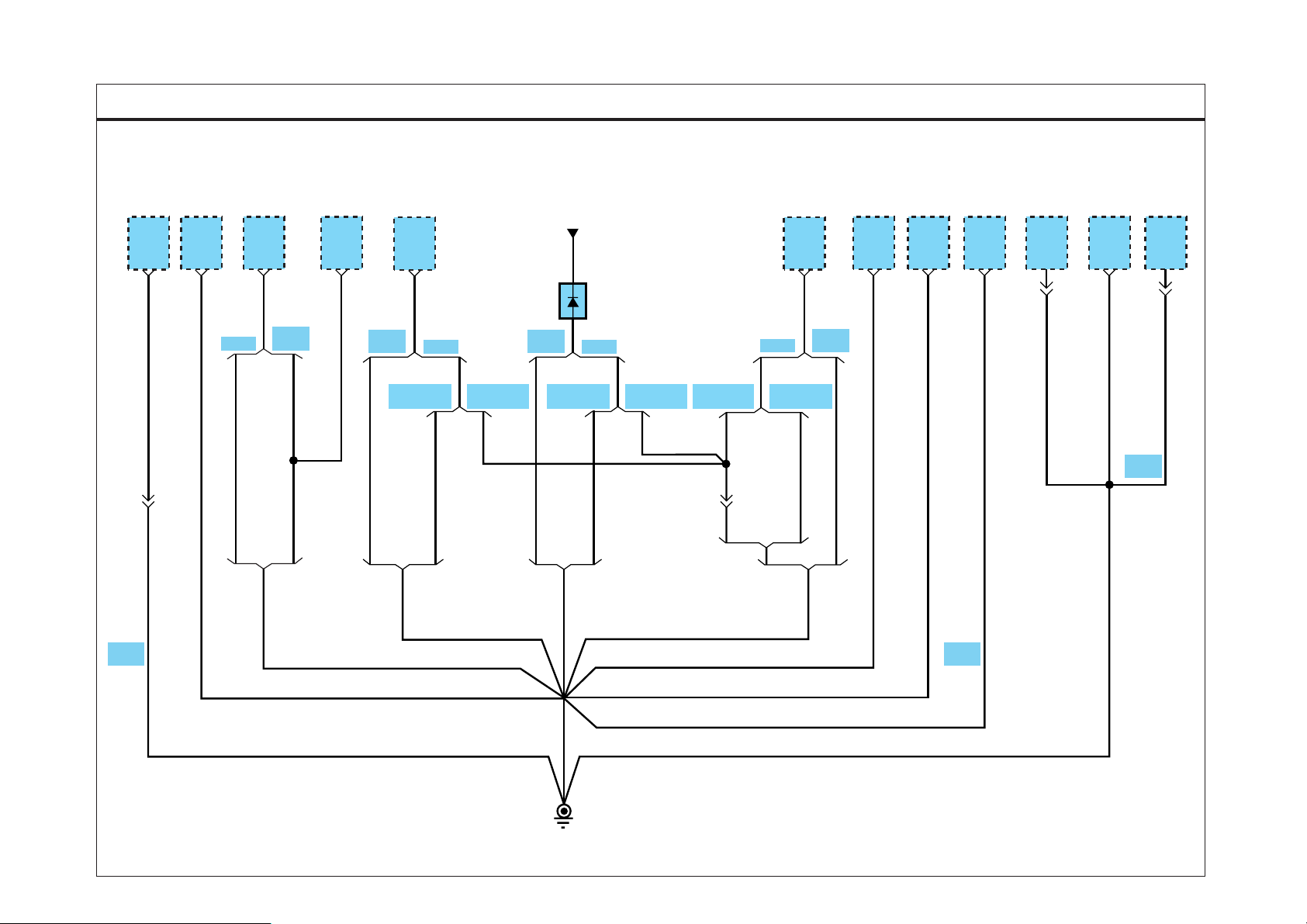

STARTING SYSTEM

System name/

1

System code

Component

symbol

Wire color

6

STARTING SYSTEM (1)

BATTERY

GROUND

ENGINE

PINION

GEAR

B

BODY

GROUND

FLYWHEEL

LEVER

OVERRUNNING

CLUTCH

BATTERY

MAGNETIC

WBB

MOTOR

B/Y

R

R

1

2

L

1

FUSIBLE

LINK(IGN)

30A

EE01

PHOTO 07

START

SOLENOID

START

MOTOR

5

W

1

W

P

P

ST

5

3

ON

EM01

E27

E27

EM025

R

1

R

6

EM03

M11

AM

LOCK

ACC

PHOTO 08

START

RELAY

PHOTO 02

PHOTO 08

PHOTO 08

4

G

See

Ground

Distribution

IGNITION

SWITCH

PHOTO 01

M11

E/R

RELAY &

FUSE

BOX

P

R

Gr

Gr

7

B

B

G10

4

8

N

C34

MC027

PHOTO 09

C34

L

2

D

PHOTO 05

TRANSAXLE

RANGE

SWITCH

PHOTO 04

51

3

W

6

M19

BURGLAR

ALARM

RELAY

PHOTO 03

M19

M70-1

ETACM

PHOTO 06

SD360-1

I/P

JUNCTION

BOX

M19

Picture number

4

for component

locations

Harness

7

classification

Connector

classification

8

number

Connector

5

terminal

number

GI-1INTRODUCTION (1)

3

Distinguish harness from harness connection connector

E2RG360A

EVT GI70001L

INTRODUCTION

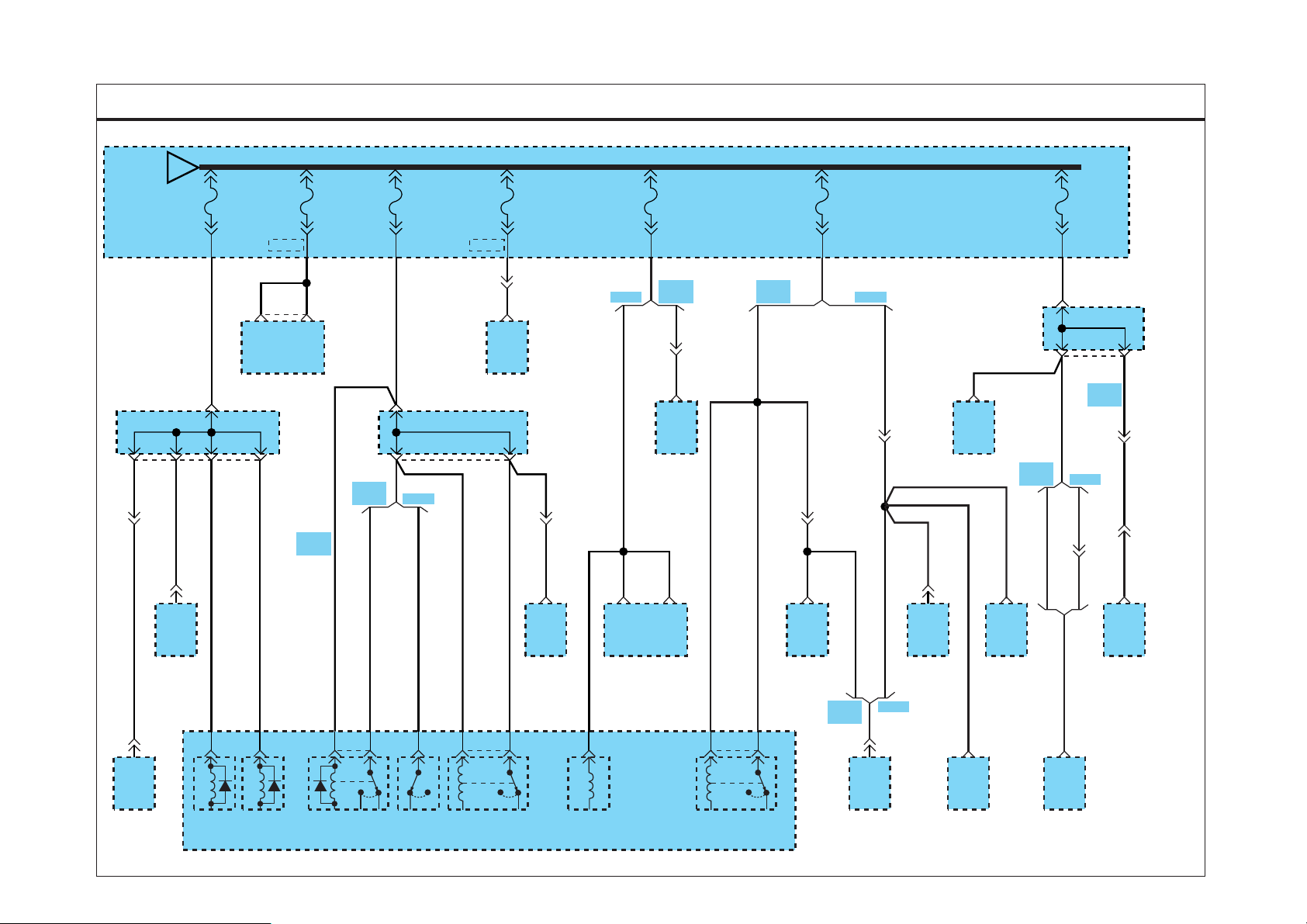

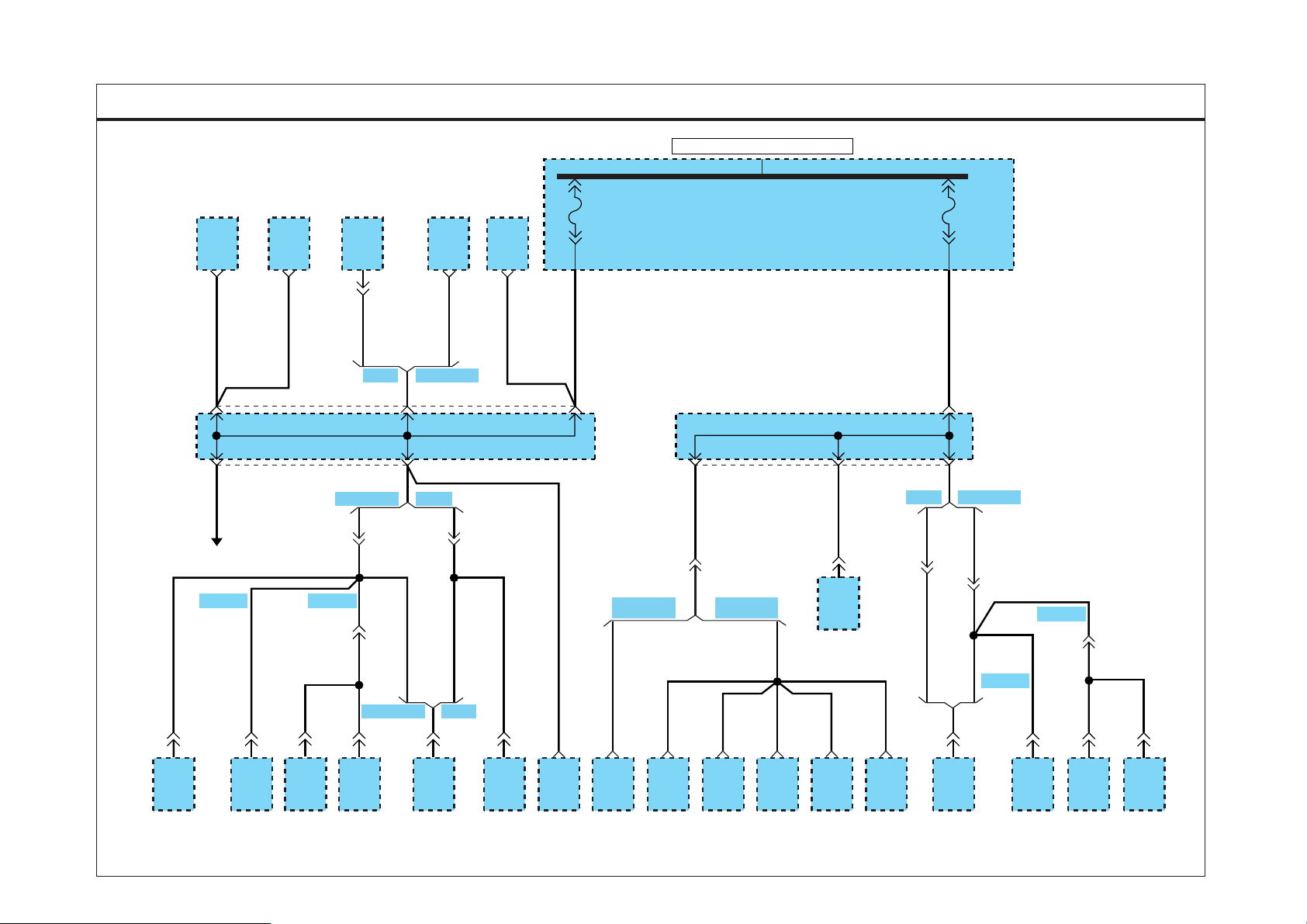

STARTING SYSTEM

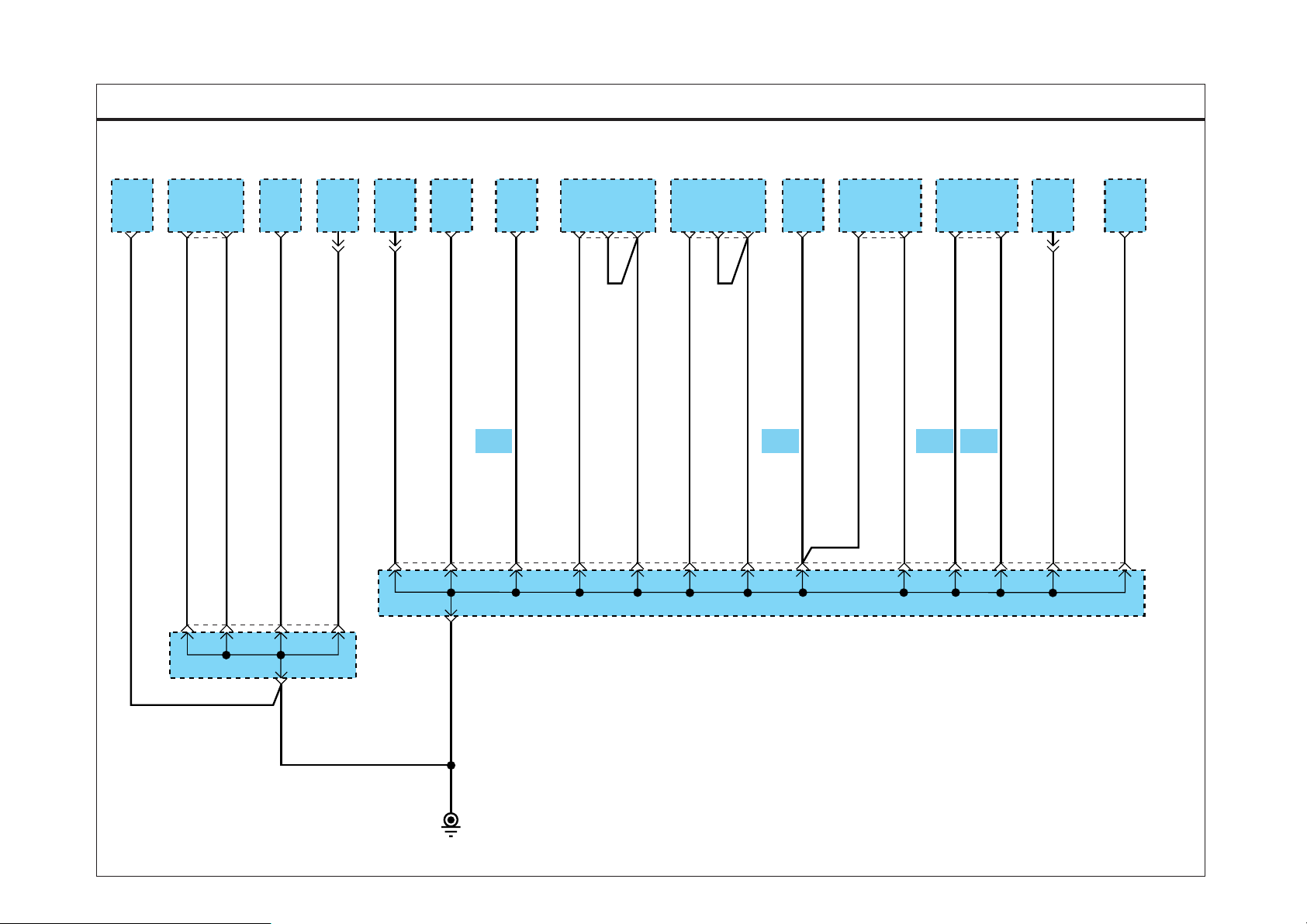

STARTING SYSTEM (2)

M05

GI-2INTRODUCTION (2)

SD360-2

M06 M11 M13

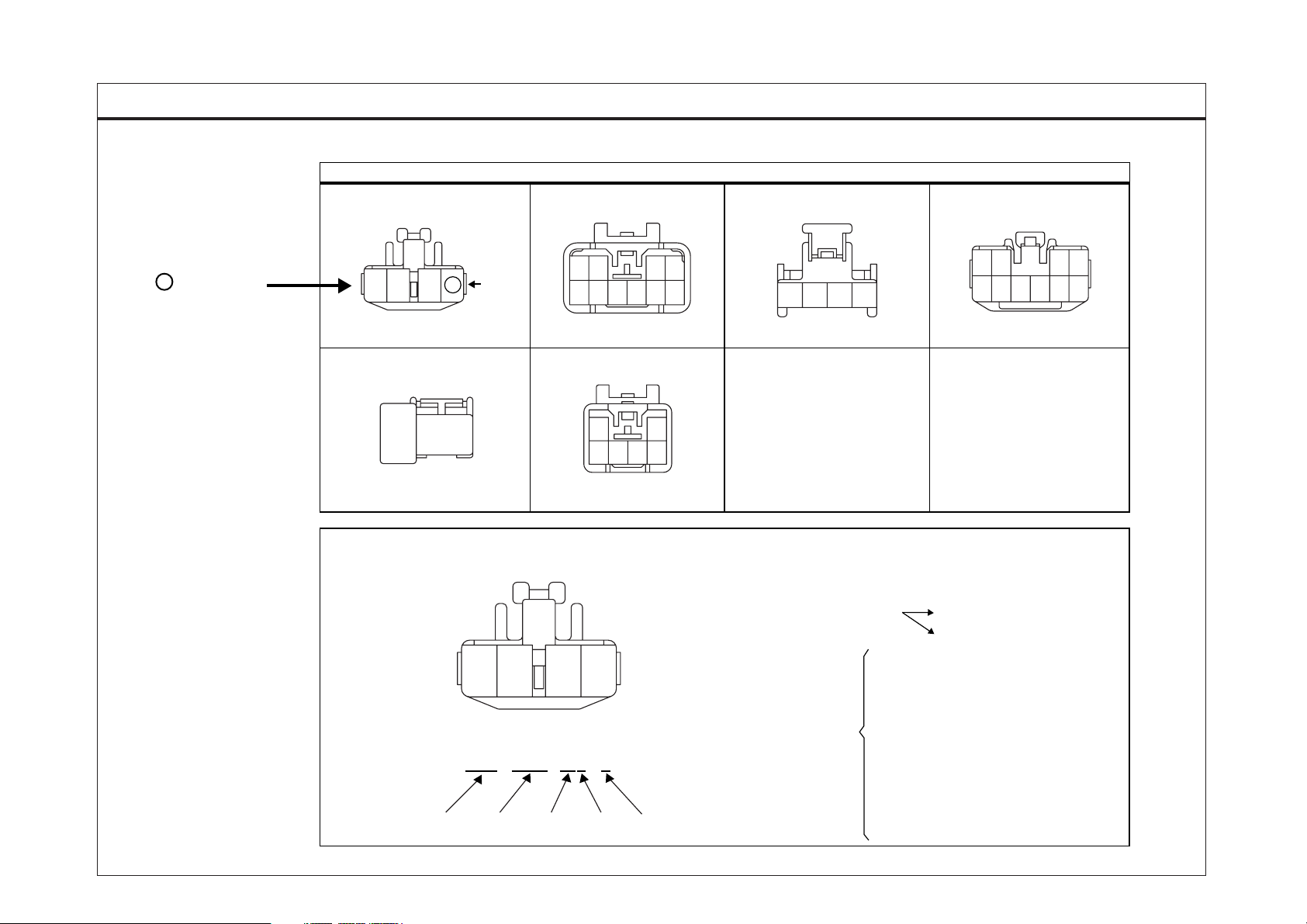

Connector

2

configurations

(components)

Explanation of

connector code

234

KET_090II_04F_W KET_090II_10M_W

AMP_PLM2_02F_B KET_090II_06M_W

Unused

pin

*

12

12

56 8910

*

M81M67

12

3456

4

*

M05

1

234

KET_090II_04F_W

a

b

cde

1234

KUM_AR_04F_W KET_090II_10F_W

BLANK BLANK

a : Connector manufacturer

b : Terminal series number

c : The number of connector terminals

d : Connector distinguishing

B (Black)

Br (Brown)

e : Connector color

abbreviations

G (Green)

Gr (Gray)

L (Blue)

R (Red)

W (White)

Y (Yellow)

Female Pin : F

Male Pin : M

134

*

**

5678

E2RG360B

EVT GI70002L

INTRODUCTION

1

Pages by system/ Name of Schematic diagram

Each page is consisted of circuits by system. This schematic

diagram includes the path of electricity flow, connection condition

for each switch, and the function of other relevant circuits at once.

It is applicable to real service work.

It is very important to understand relevant circuits exactly before

troubleshooting diagnosis.

Circuits by system depends upon part number and are indicated

on schematic diagram index.

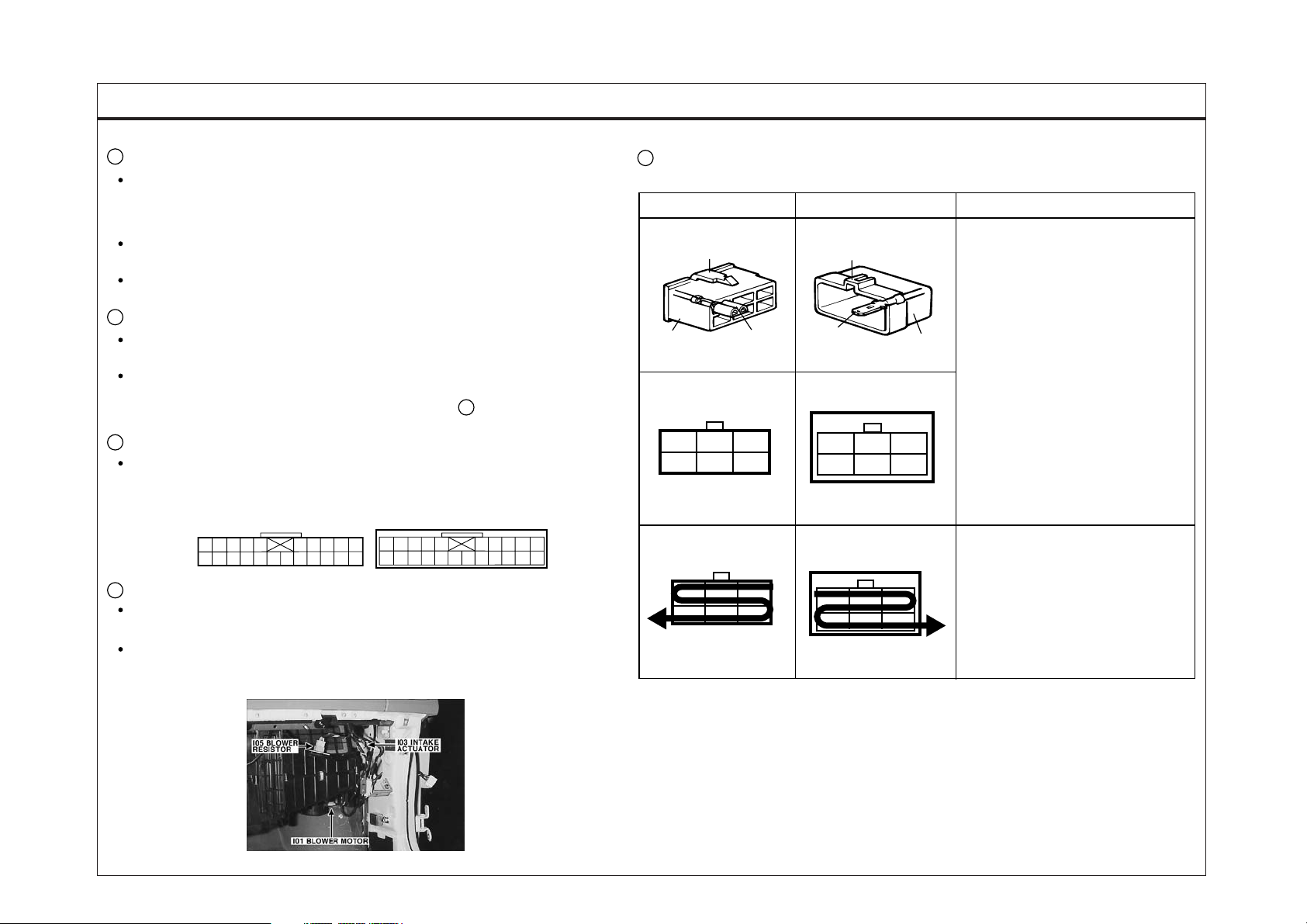

2

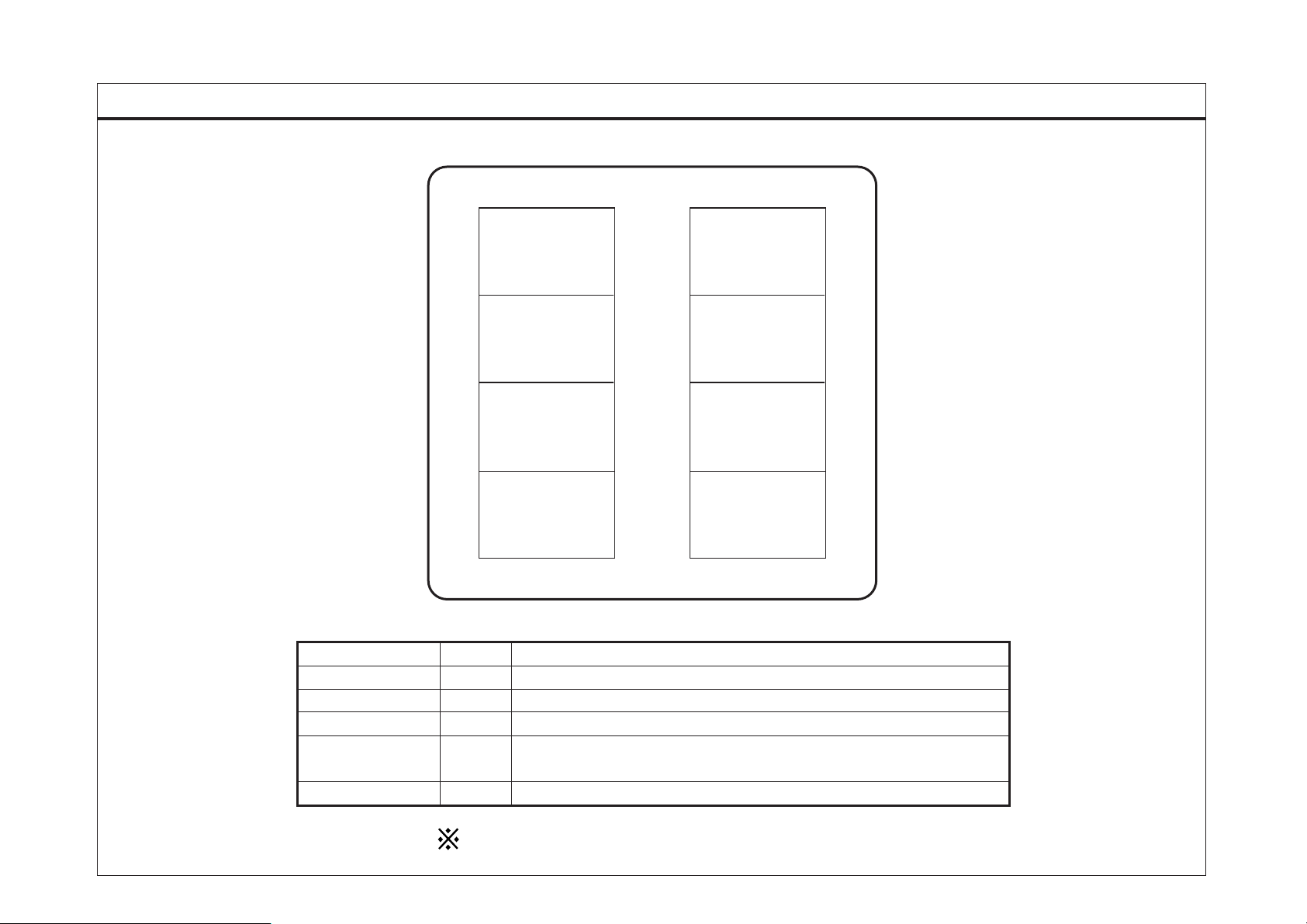

Connector configuration (components)

The connector figure of components in the schematic diagram

by system is indicated on the last page of schematic diagram.

It shows the front of the connector on the harness side when not

to the harness connector. The terminal number on each connector

can be obtained by following the pattern used in 5 connector view

and numbering order. Unused terminals are marked with an asterisk ( ).

3

Connector configurations (connection between harnesses)

When connecting the harness with connector between harnesses,

it shows female and male connectors and indicates them on the

connector configurations group.

EM02

GI-3INTRODUCTION (3)

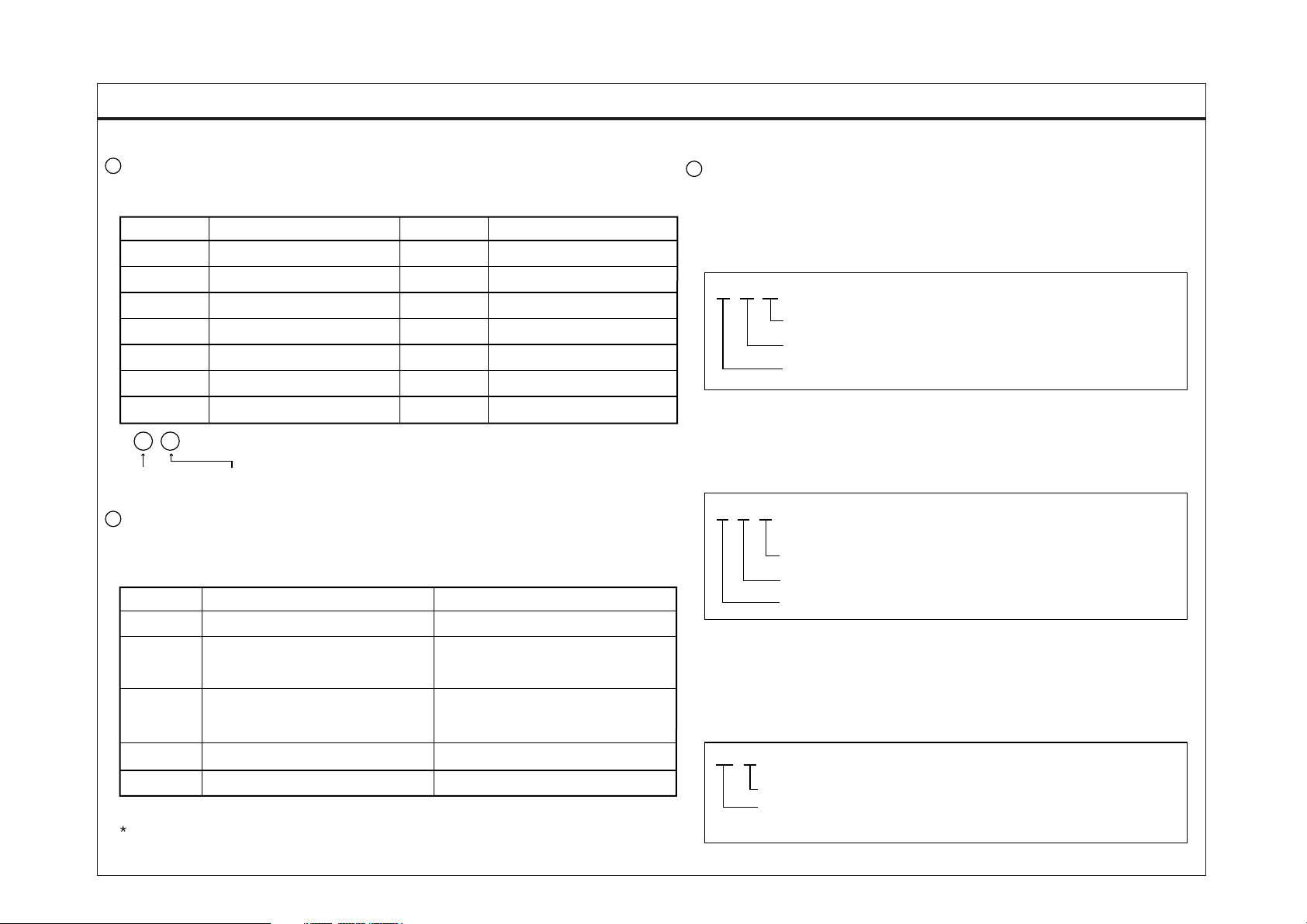

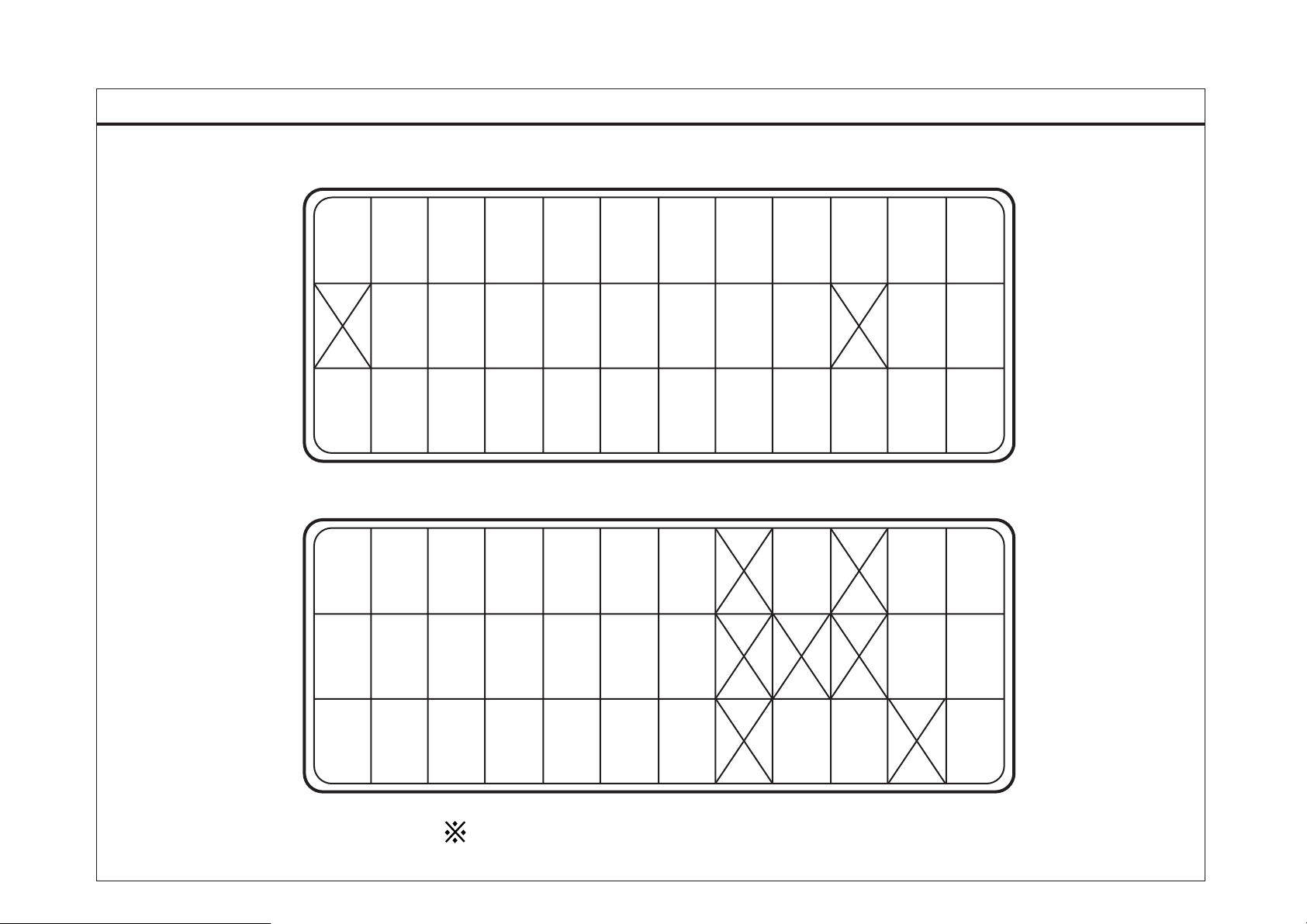

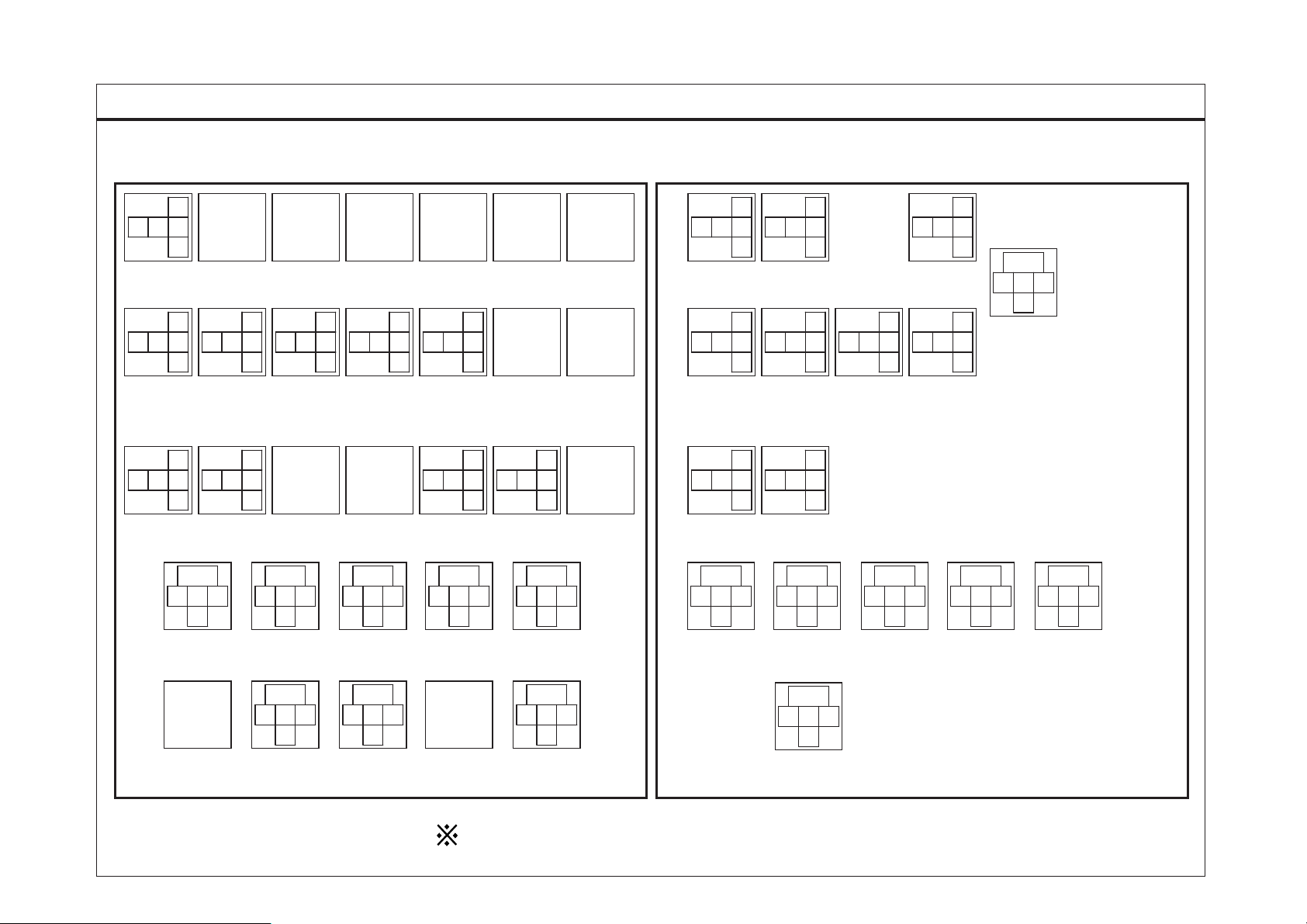

5

CONNECTOR VIEW AND NUMBERING ORDER

Female

Locking point

Housing Pin

*

321

654

Male

Locking point

Pin

123

456

Housing

Remarks

It is not the shape of the connector

housing, but the connector pin

that distinguishes between male

or female connectors.

When numbering female and male

connectors, refer to the numbering

order in the following table.

Some connectors may not follow this

method of numbering order.

For individual detailed numbering,

refer to the CONNECTOR

CONFIGURATIONS.

10 9 8 7

4

Component locations

6543

2122

1718192016 15

2

1314 12 11

2

1

1

13 141211

6

543

17 18 19

16

15

20

10987

21 22

To find the components easily, a component locations diagram is

indicated with "PHOTO NO" on the lower portion of the component name.

To make it easy to distinguish connectors, the connector in the

picture is indicated being installed in the vehicle.

PHOTO 03

Numbered in order from upper

right to lower left

321

654

123

456

Numbered in order from upper

left to lower right

NOTE

UNLESS OTHERWISE STATED, ALL CONNECTOR VIEWS ARE FROM

THE TERMINAL SIDE OF THE CONNECTOR.

EVT GI70003L

INTRODUCTION

6

WIRE COLOR ABBREVIATIONS

The following abbreviations are used to identify wire colors in the

circuit schematics.

Symbol Color of wire Symbol Color of wire

B

Br

G

Gr

L

Lg

T

/ B : Black stripe with yellow ground (2 colors)

Y

*

the color of

background

7

HARNESS CLASSIFICATION

Electrical wiring connectors are classified according to the wiring parts in the

Harness Layouts.

E

M

C

Engine harness

Main, Floor, Floor center,

Roof harness

Chassis, Side marker,

EXH M/V harness

Black

Brown

Green

Gray

Blue

Light Green

Tan

the color of

stripe

O

P

R

W

Y

Pp

LI

LocationHarness nameSymbol

Engine compartment

Passenger compartment,

Floor, Roof

Chassis compartment

Orange

Pink

Red

White

Yellow

Purple

Light Blue

GI-4INTRODUCTION (4)

8

CONNECTOR IDENTIFICATION

A connector identification symbol consists of a wiring harness location

classification symbol corresponding to a wiring harness location and

number corresponding to the connector.

These connector locations can be found in the HARNESS LAYOUTS.

For example:

E 10 -1

Number corresponding to sub-connector (Serial Number)

Number corresponding to main connector (Serial Number)

Symbol indicating wiring harness (Engine wiring harness)

NOTE

Connectors which connect each wiring harness are represented by

the following symbols.

For example:

M R 01

Number corresponding to main connector (Serial Number)

Rear wiring harness

Main wiring harness

JUNCTION BLOCK IDENTIFICATION

A junction block identification symbol consists of a wiring harness

location classification symbol corresponding to a wiring harness location

and number corresponding to the connector in the junction block.

For example:

A

D

It depends on vehicles, it is necessary to check the harness name symbol

on the harness layouts for detailed symbol.

Air con, A.B.S harness

Door harness

Under crash pad and Floor

Door

I/P- A

Connector name

Abbreviation of the word

"Passenger compartment junction block"

EVT GI70004L

INTRODUCTION

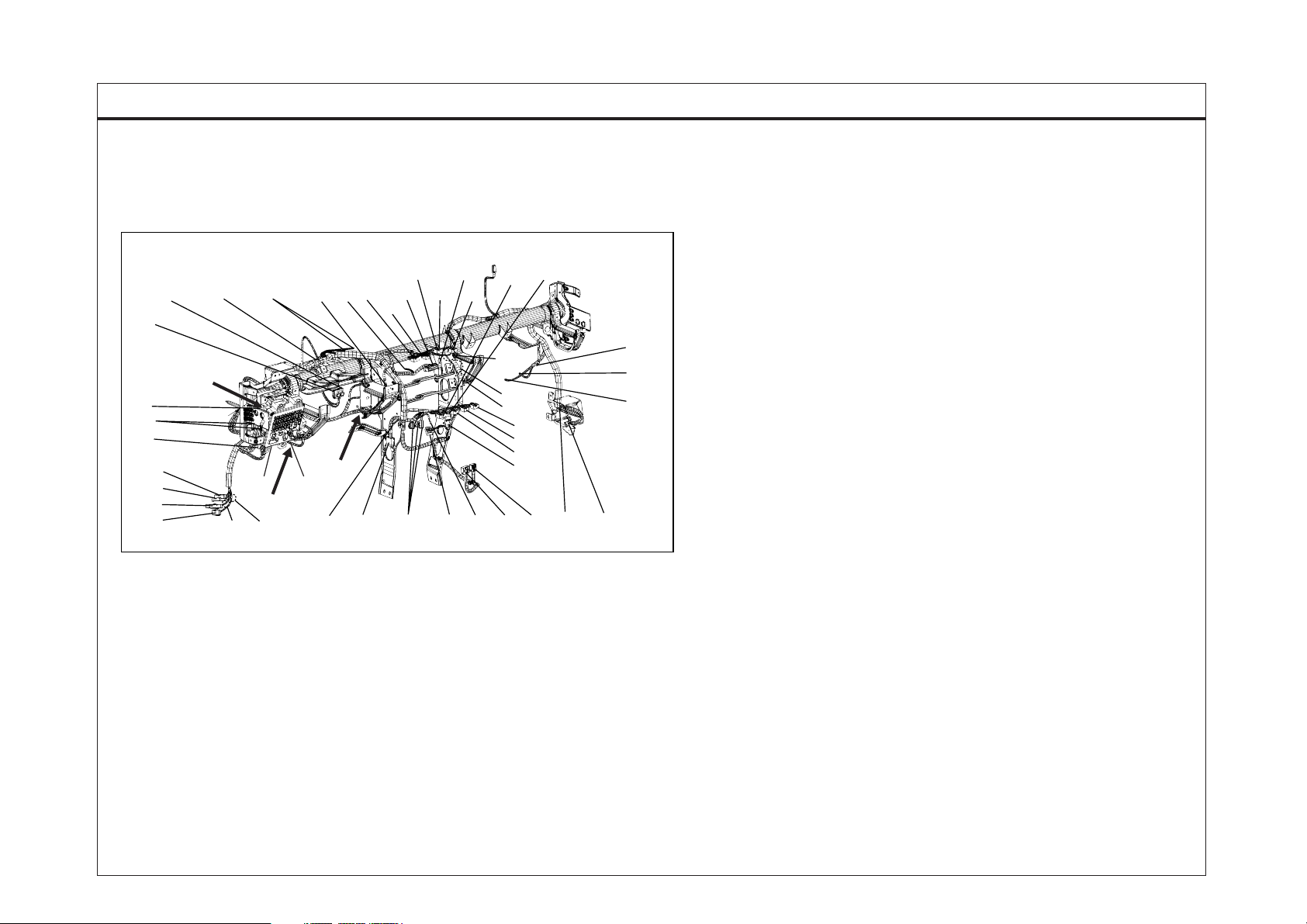

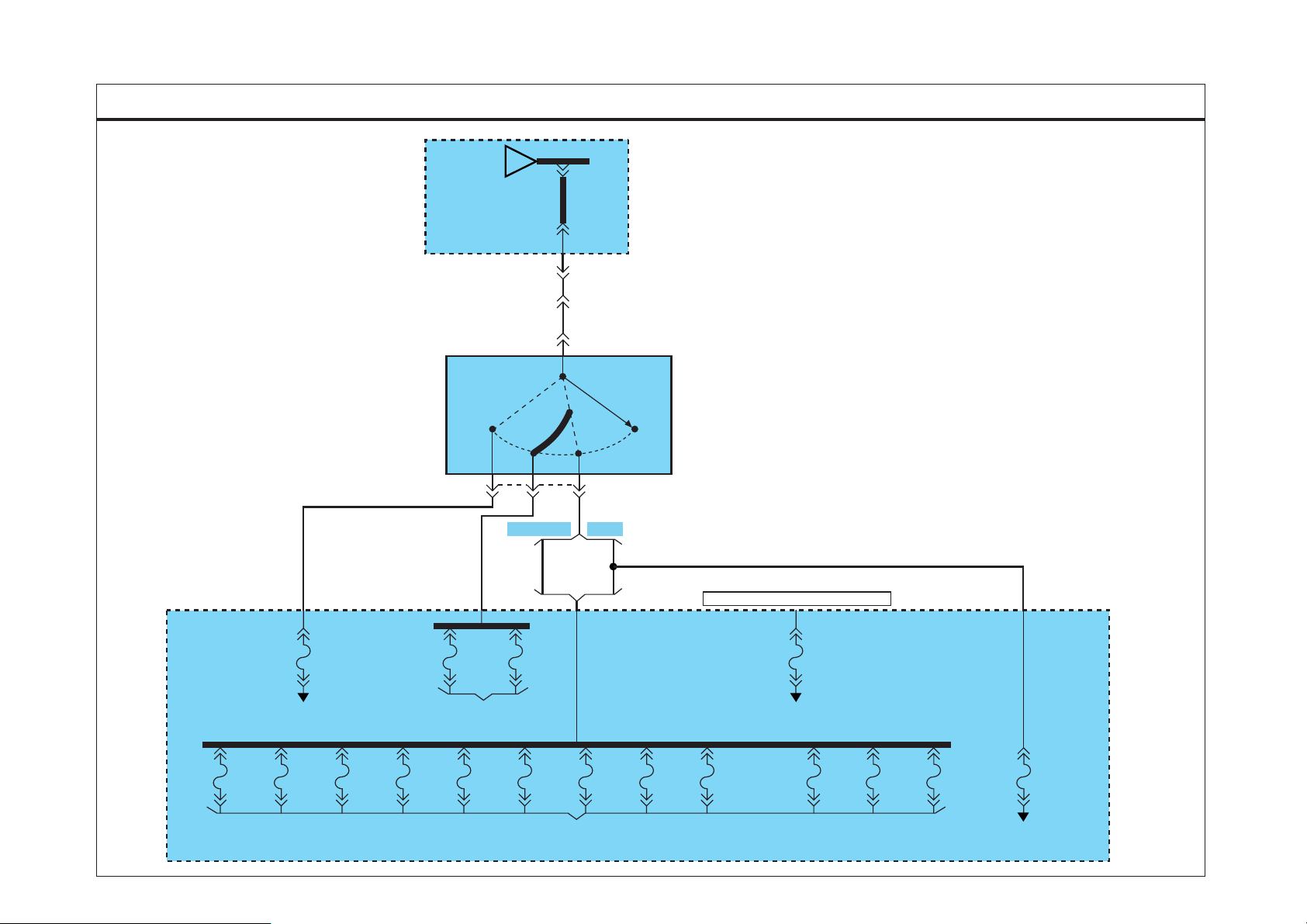

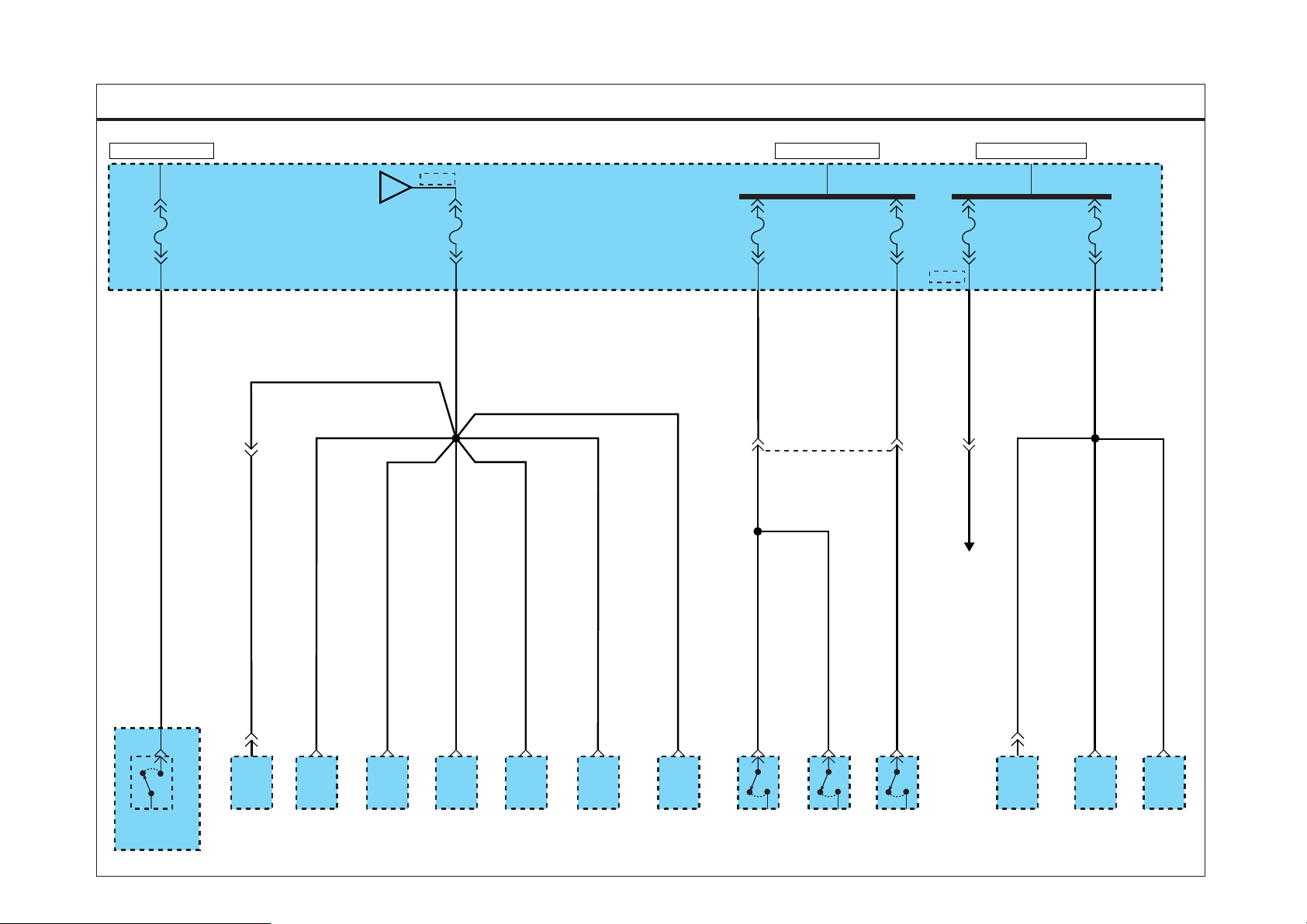

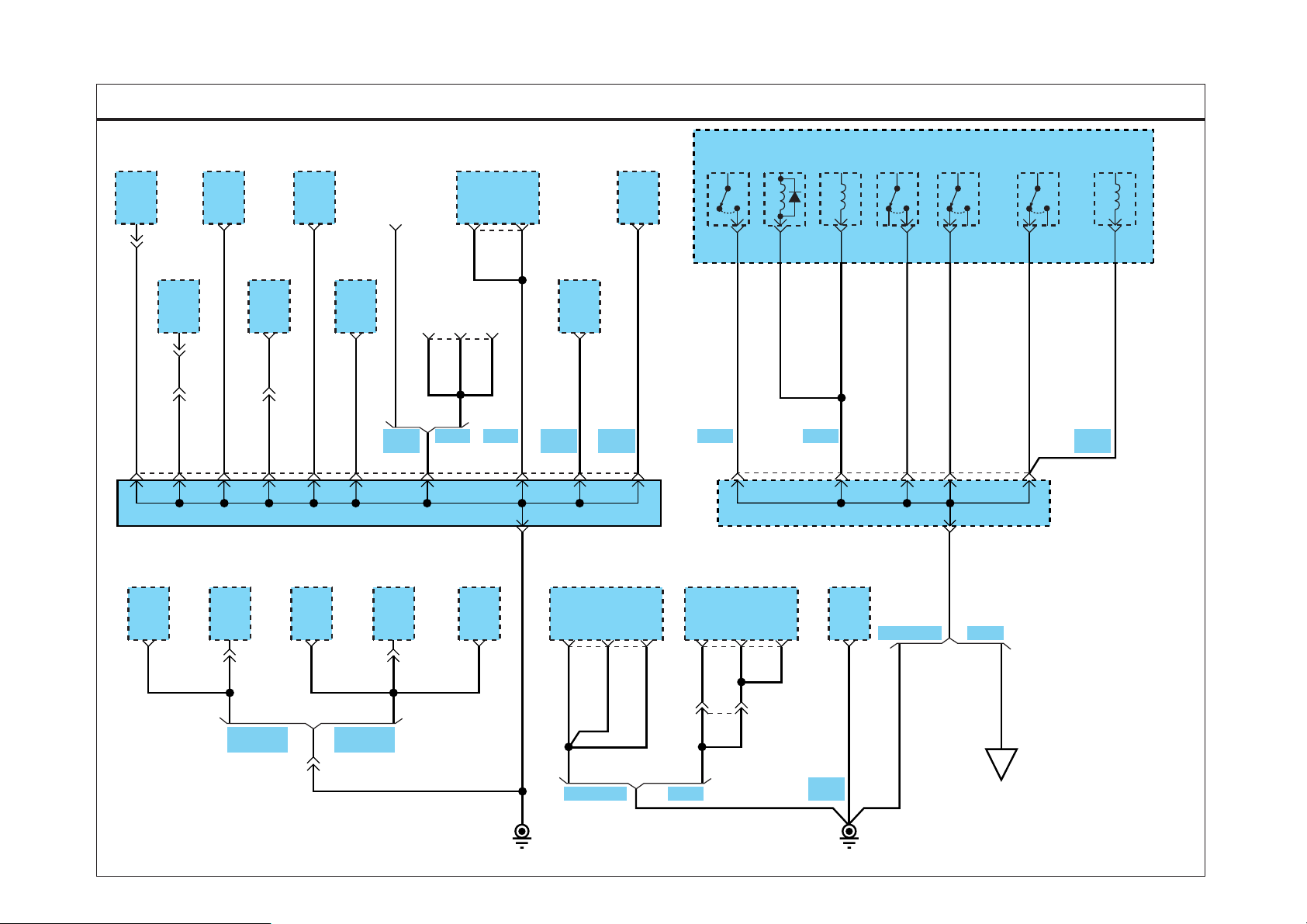

HARNESS LAYOUTS

Harness layouts show the routing of the major wiring harnesses,

the in-line connectors and the splices between the major harnesses.

These layouts will make electrical troubleshooting easier.

M37

G11

M29

M30

Passenger

Compartment

Junction Block

(I/P-E,F,G,H,J)

Z02

MI01

M41

MM04

MM03

MM01

MM02

M09-3 M09-1,2

M33

VIEW 'B'

SM01 SM02

M13

MC06

Z03

VIEW 'A'

M36

G14 G12 M26 M31 M34

M15

M16 Z01

M14

M25-1,2,3

M19-2

M11

SM06

SM07

SM08

M23

M21

M22

M32

M35

M20

MC05 MC04

M02

M03-1,2

MI04

MI06

MI03

MI05

GI-5INTRODUCTION (5)

EVT GI70005L

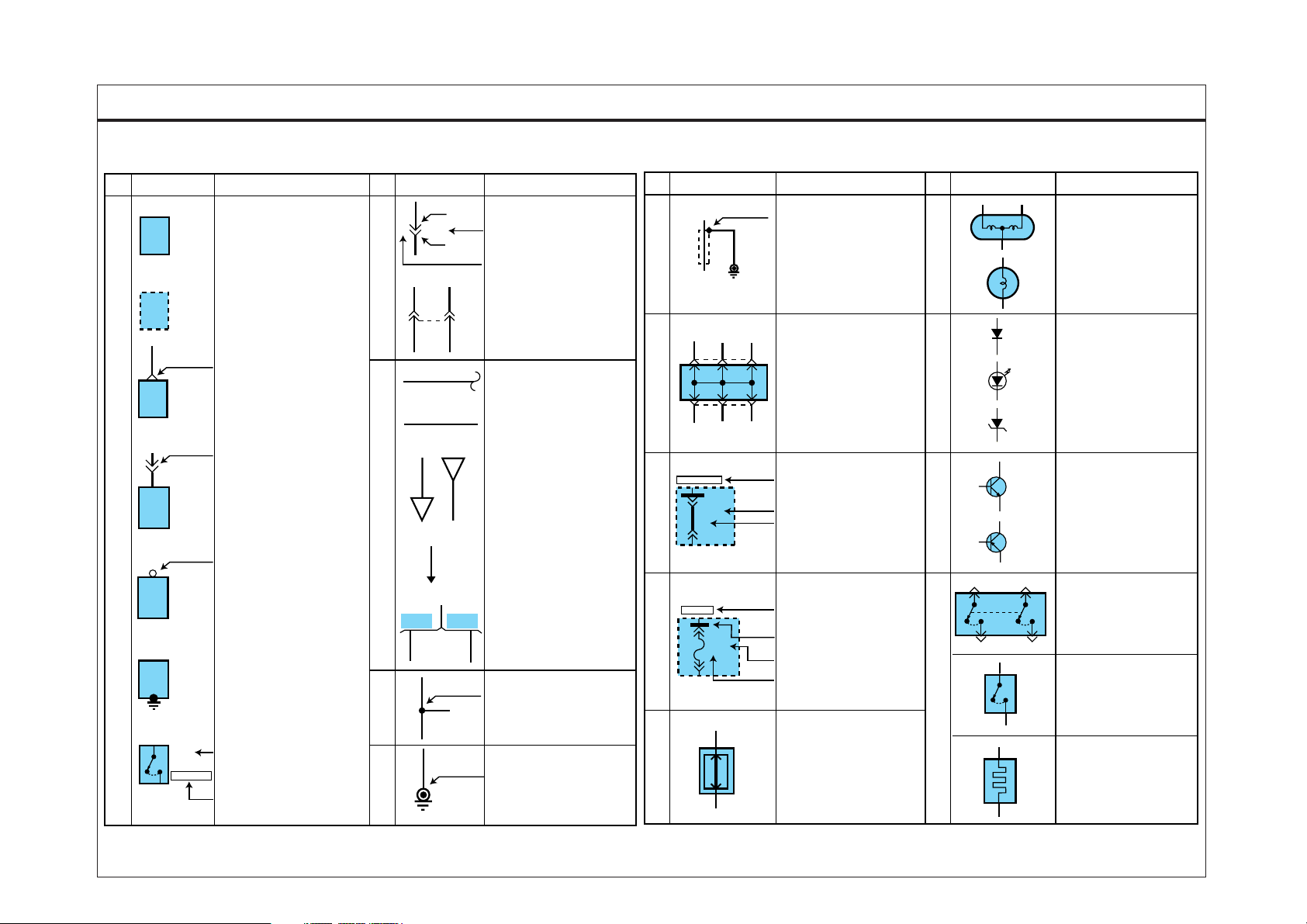

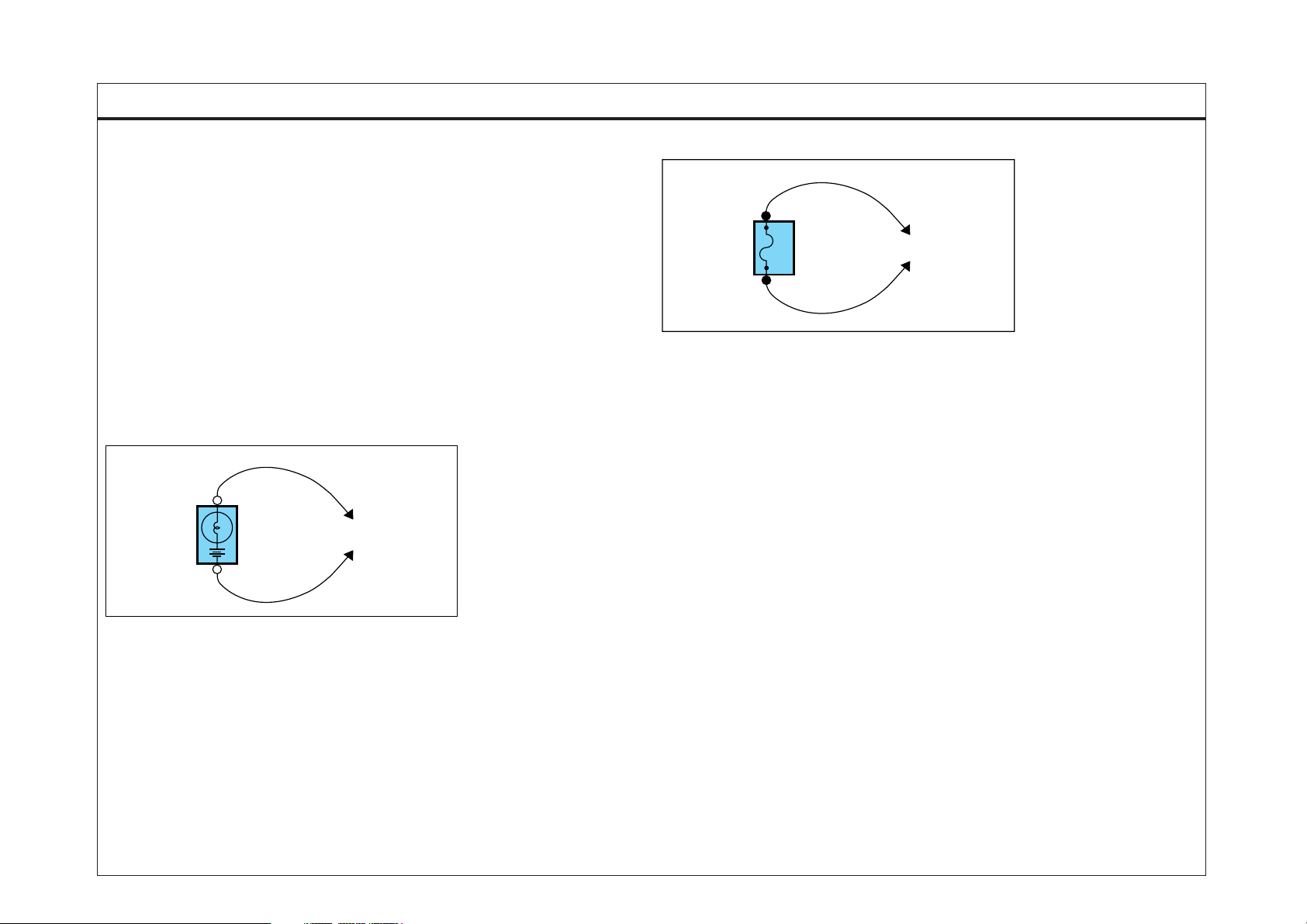

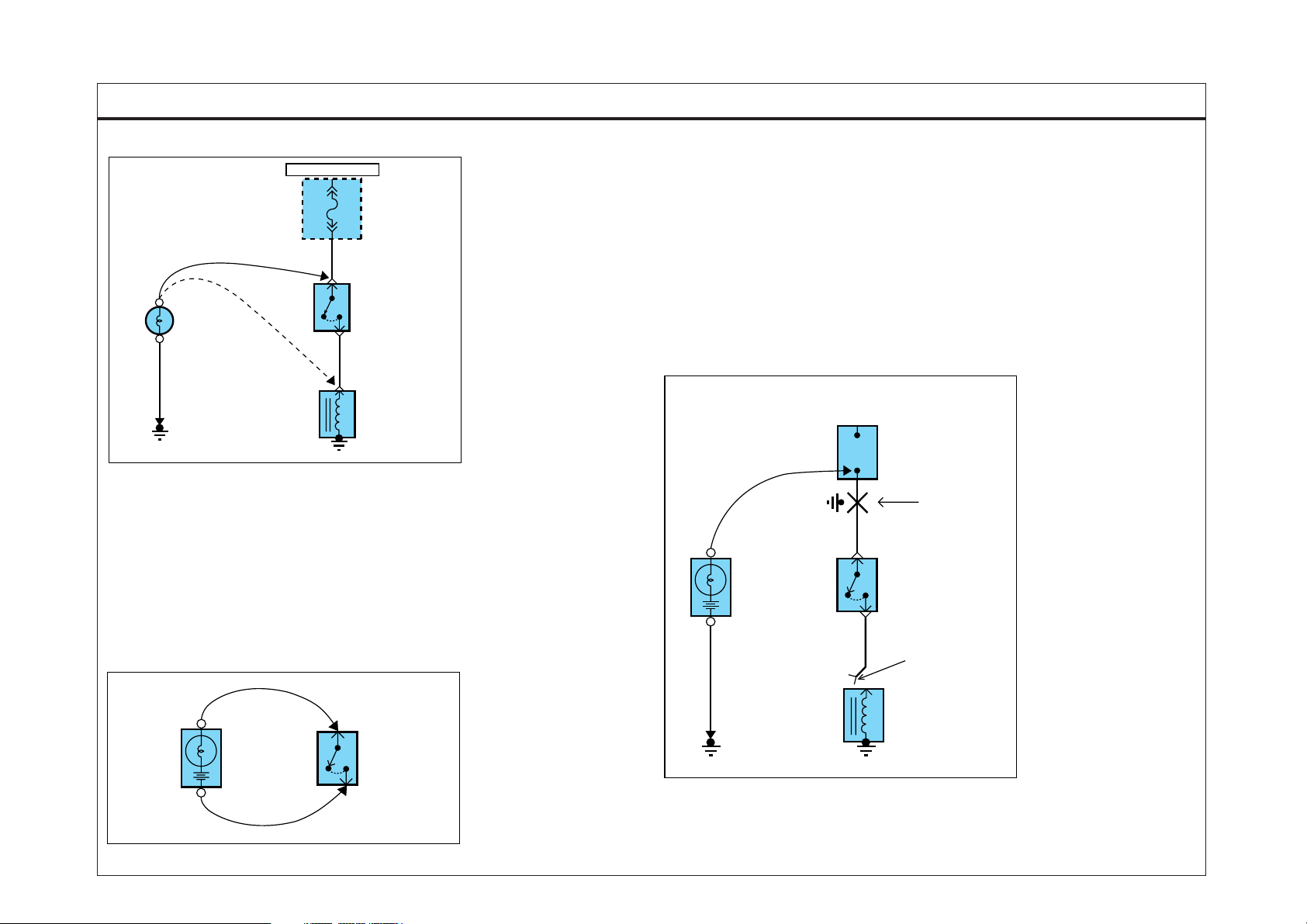

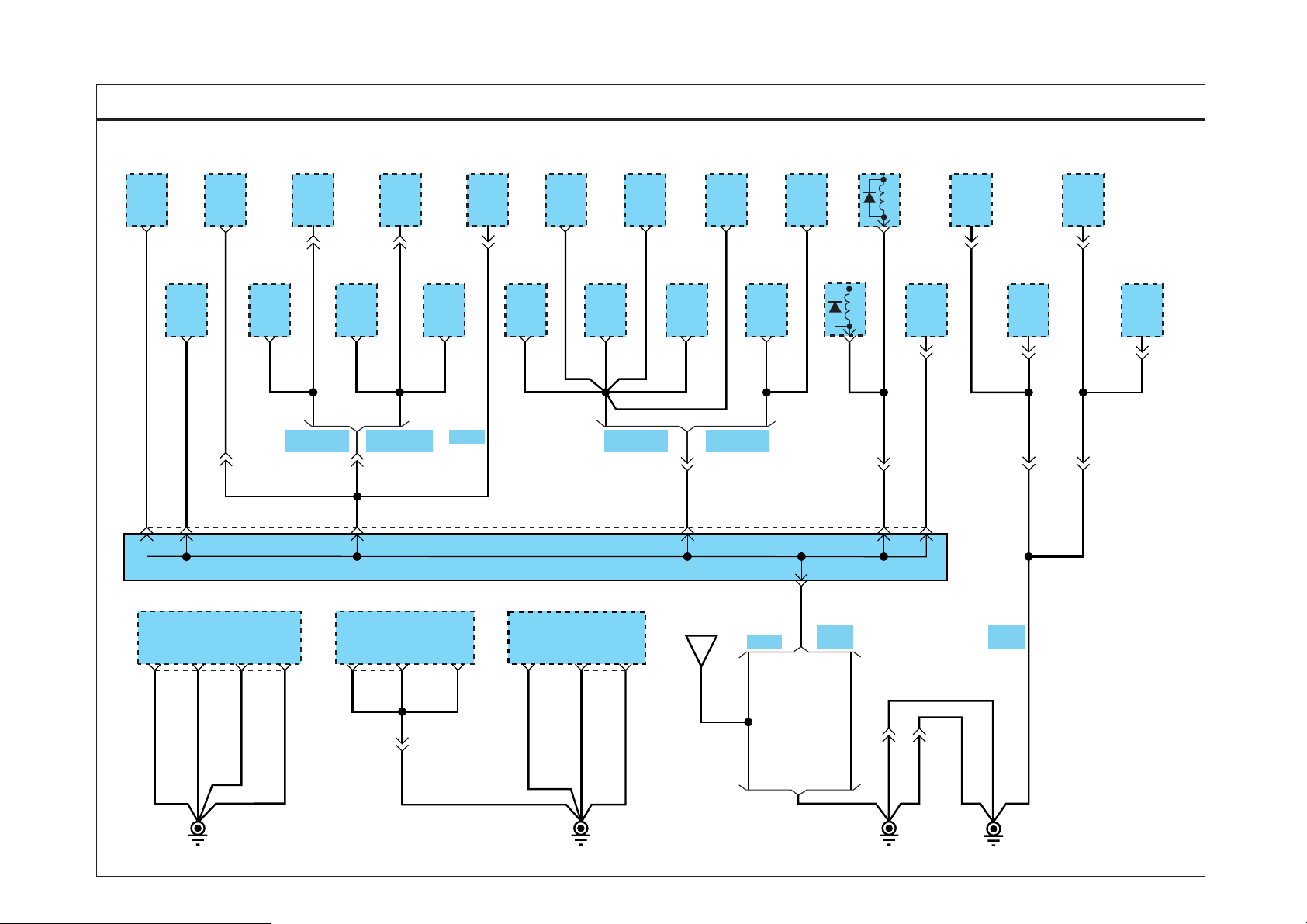

SYMBOLS EBB531CD

GI-6SYMBOLS (1)

Section

C

O

M

P

O

N

E

N

T

Symbol

STOP

LAMP

SWITCH

PHOTO 03

Meaning Symbol Meaning Symbol Meaning Symbol Meaning

A solid line means the entire

component is shown.

A broken line indicates only

part of the component is

shown.

This means the connector

connects directly to the

component.

This indicates the connector

connects to a lead (pigtail),

wired directly to the component.

This indicates a screw terminal

on the component.

This ground symbol (dot and

3 lines overlapping the component) means the housing

of the component is attached

to a metal part of the vehicle.

The name of the component

appears next to its upper right

corner.

Shows the number of pictures

for component location.

Section

Male

10

C

O

N

N

E

C

T

O

R

W

I

R

E

Name of Circuit

S

P

L

I

C

E

S

G

R

O

U

N

D

connector

M05-2

Female

connector

R

Y/L

13

R Y/L

B

Y/R

From C52

A

A

To MC02

R

Automatic

Manual

G

Transaxle

Transaxle

GG

L

L

G06

Shows the name of each connector

on the component location index

for reference.

Indicates the number of

corresponding terminal.

(Only relevant terminal on the

corresponding schematic diagram).

The dashed-line means each of

E35

two wires connect with same

connector(E35)

A wavy line means the

wire is broken but

is to be continued.

Wire insulation is yellow

with a red strip.

Current path is continued on

the same page or another

page.The arrow shows the

direction of current flow.

You should look for the "A"

in the marked position.

A wire connects to another

circuit. The wire is shown

again on that circuit which

the arrow is pointing.

Wire choices for options or

different models are labeled

and shown with a "choice"

bracket like this.

Splices are numbered and

shown as a dot with circle.

The exact location and connection of these splices may

vary among vehicles.

This symbol means the end

of the wire is attached to a

metal part of the vehicle.

Section

S

H

E

L

D

W

R

E

J

O

N

T

C

O

N

N

E

C

T

O

R

S

L

O

W

B

L

O

W

F

U

S

E

P

O

W

E

R

I

I

I

C

O

N

N

E

C

T

O

R

HOT AT ALL TIMES

F/FOG

FUSE

15A

HOT IN ON

FUSE 10

10A

G06

E/R FUSE &

RELAY

BOX

DASH

FUSE

BOX

This represents RFI (Radio

Frequency Interference)

Shielding around a wire.

The shielding is always

connected to ground.

This is a connector showing

the joining wires.

Power supplied at all times.

Name

Capacity

This means power is supplied

with the ignition on position.

This means the short bar

connects to other fuses.

Identification

Current rating

Control battery power at all times

Section

L

A

M

P

D

O

D

E

TR

G

E

N

E

R

A

L

C

O

M

P

O

N

E

N

T

S

Y

M

B

O

L

Double filament

Single filament

Diode

I

Led diode

Zener diode

C

B

B

NPN

E

C

PNP

E

NPN

PNP

These switches move

together:

a dashed line shows a

mechanical connection

between them.

Switch (1 contact point)

Heater

EVT GI70006L

SYMBOLS

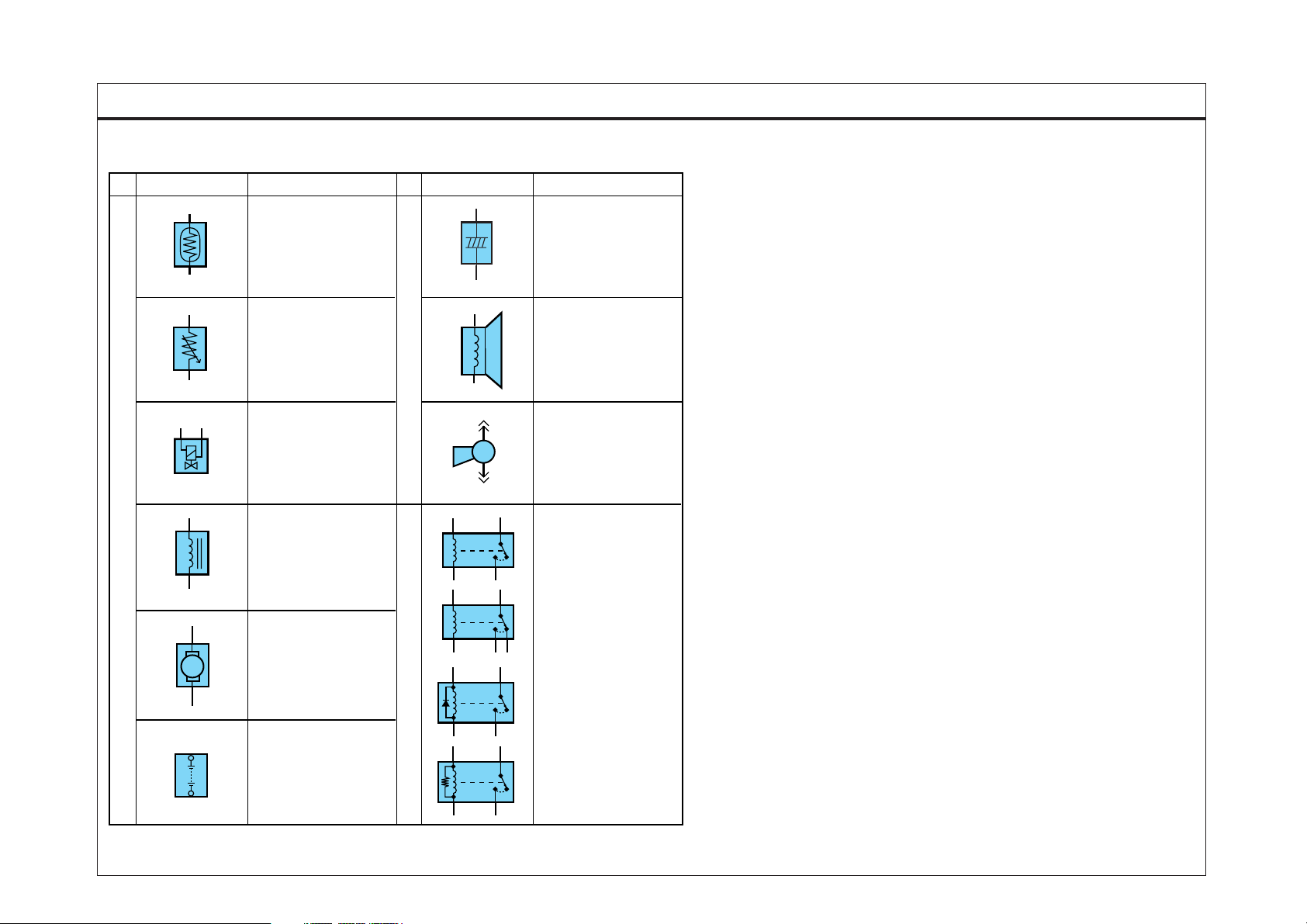

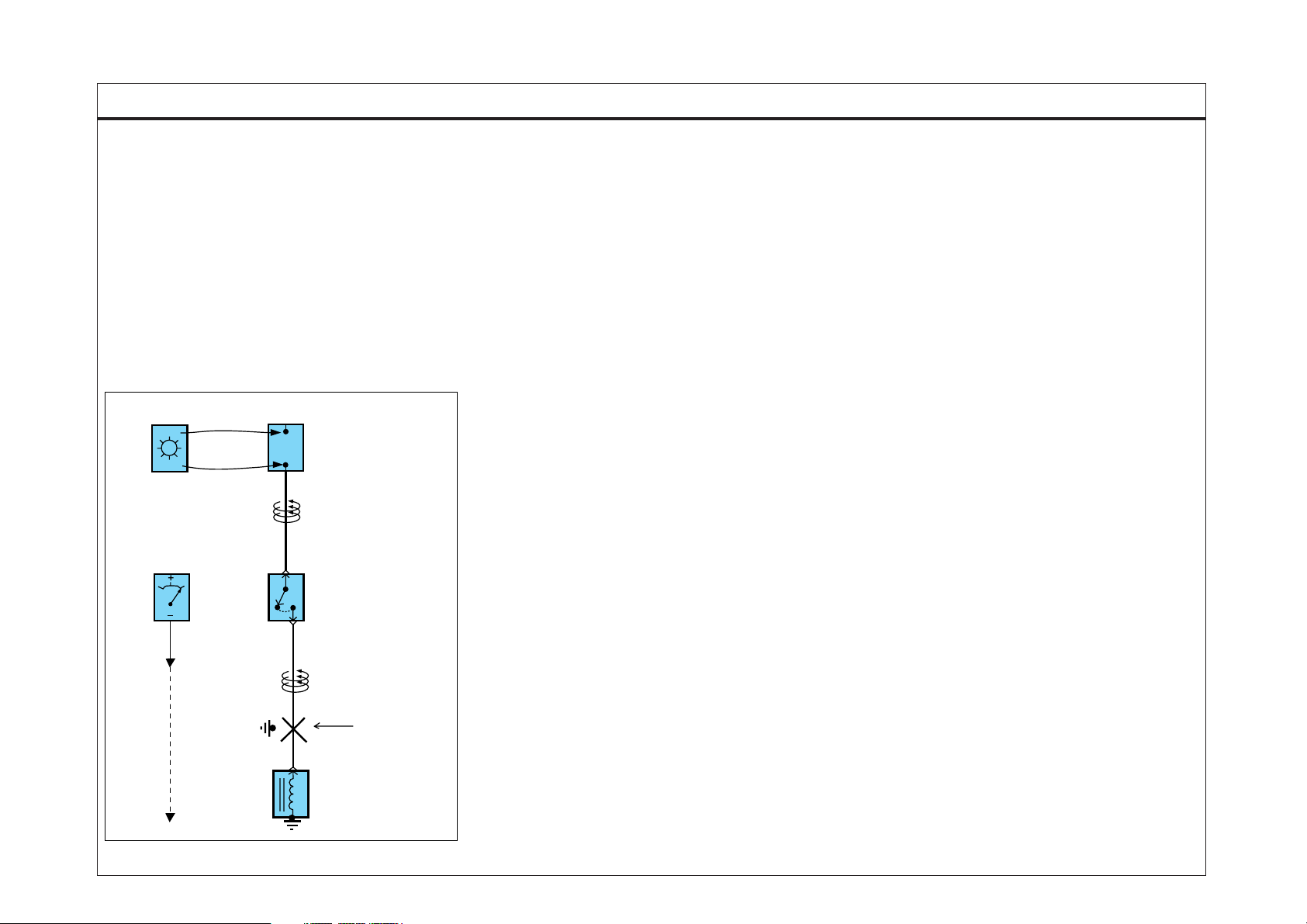

GI-7SYMBOLS (2)

Section

G

E

N

E

R

A

L

C

O

M

P

O

N

E

N

T

S

S

Y

M

B

O

L

Symbol Meaning Symbol Meaning

Sensor

Sender

Injector

Solenoid

M

Motor

Section

G

E

N

E

R

A

L

C

O

M

P

O

N

E

N

T

S

S

Y

M

B

O

L

R

E

L

A

Y

Condenser

Speaker

Horn, Buzzer, Siren,

Chime Bell

Normally open contact

This is a relay shown with no

current flowing through its coil.

When a current flows through

coil, contact will toggle.

Diode interior relay

+

Battery

-

Resistance interior relay

EVT GI70007L

TROUBLESHOOTING INSTRUCTIONS E 69D8CAB

TROUBLESHOOTING INSTRUCTIONS

TROUBLESHOOTING PROCEDURES TROUBLESHOOTING EQUIPMENT

GI-8TROUBLESHOOTING INSTRUCTIONS (1)

The following five-step troubleshooting procedure is recommended.

1. Verify the customer's complaints

Turn on all the components in the problem circuit to check the accuracy of the

customer's complaints. Note the symptoms.

Do not begin disassembly or testing until you have narrowed down the probable

causes.

2. Read and analyze the schematic diagram

Locate the schematic for the problem circuit. Determine how the circuit is

supposed to work by tracing the current paths from the power source through

the system components to ground. If you do not understand how the circuit

should work, read the circuit operation text. Also check other circuits that share

with the problem circuit. The name of circuits that share the same fuse, ground,

or switch, for example, are referred to on each diagram. Try to operate any

shared circuits you did not check in step 1. If the shared circuit works, the

shared wiring is okay, and the cause must be within the wiring used only by the

problem circuit.

If several circuits fail at the same time, the fuse or ground is a likely cause.

3. Inspect the circuit/ component with the problem isolated

Make a circuit test to check the diagnosis you made in step 2. Remember that a

logical, simple procedure is the key to efficient troubleshooting. Narrow down the

probable causes using the troubleshooting hints and system diagnosis charts.

Test for the most likely cause of failure first.

Try to make tests at points that are easily accessible.

VOLTMETER AND TEST LAMP

Use a test lamp or a voltmeter on circuits without solidstate units and use a test

lamp to check for voltage. A test lamp is made up of a 12-volt light bulb with a

pair of leads attached. After grounding one lead, touch the other lead to various

points along the circuit where voltage should be present.

When the bulb goes on, there is voltage at the point being tested.

CAUTION

A number of circuits include solid-state modules, such as the Engine

Control Module(ECM), used with computer command control injection.

Voltage in these circuits should be tested only with a 10-megaohm or

higher impedance digital multimeter. Never use a test lamp on circuits

that contain solid state modules. Damage to the modules may result.

A voltmeter can be used in place of a test lamp. While a test lamp shows

whether the voltage is present or not, a voltmeter indicates how much voltage

is present.

TEST LAMP

4. Repair the problem

Once the problem is found, make the necessary repairs.

5. Make sure the circuit works

Repeat the system check to be sure you have repaired the problem. If the

problem was a blown fuse, be sure to test all of the circuits on that fuse.

SELF-POWERED TEST LAMP AND OHMMETER

Use a self-powered test lamp or an ohmmeter to check for continuity.

The ohmmeter shows how much resistance there is between two points along

a circuit. Low resistance means good continuity.

EVT GI70008L

TROUBLESHOOTING INSTRUCTIONS

CAUTION

Never use a self-powered test lamp on circuits that contain solid state

modules. Damage to these modules may result.

GI-9TROUBLESHOOTING INSTRUCTIONS (2)

An ohmmeter can be used in place of a self-powered test lamp.

The ohmmeter shows how much resistance there is between two points along a

circuit. Low resistance means good continuity.

Circuits which include any solid-state devices should be tested only with a

10-megaohm or higher impedance digital multimeter. When measuring

resistance with a digital multimeter, the battery negative terminal should be

disconnected. Otherwise, there may be incorrect readings. Diodes and

solid-state devices in a circuit can make an ohmmeter give a false reading.

To find out if a component is affecting a measurement, take one reading,

reverse the leads and take a second reading.

If different the solid-state device is affecting the measurement.

SELFPOWERED

TEST LAMP

JUMPER WIRE WITH FUSE

Use a jumper wire with a fuse to by-pass an open circuit.

A jumper wire is made up of an in-line fuse holder connected to a set of test leads.

This tool is available with small clamp connectors providing adaption to most connectors without damage.

CAUTION

5A

SHORT FINDER

A short finder is available to locate a short to ground. The short finder creates a

pulsing magnetic field in the shorted circuit and shows you the location of the

short through body trim or sheet metal.

TROUBLESHOOTING TEST

1. TESTING FOR VOLTAGE

This test measures voltage in a circuit. When testing for voltage at a connector, you do not have to separate the two halves of the connector. lnstead,

probe the connector from the back(backprobe). Always check both sides of

the connector because dirt and corrosion between its contact surfaces can

cause electrical problems.

A. Connect one lead of a test lamp or voltmeter to a ground. If you are using

a voltmeter, be sure it is the voltmeter's negative test lead you have con nected to ground.

B. Connect the other lead of the test lamp or voltmeter to a selected test

point(connector or terminal).

C. If the test lamp glows, there is voltage present. If you are using a

voltmeter, note the voltage reading. A loss of more than 1 volt from

specification indicates a problem.

Do not use a fuse with a higher rating than the specified fuse that protects the

circuit being tested. Do not use this tool in any situation to substitute an input

or output at the solid-state control module, such as ECM, TCM, etc.

EVT GI70009L

TROUBLESHOOTING INSTRUCTIONS

GI-10TROUBLESHOOTING INSTRUCTIONS (3)

ON

TEST LAMP

OR

VOLTMETER

HOT AT ALL TIMES

OFF

R

4

G

DASH

FUSE

BOX

SWITCH

M11

SOLENOID

2. TESTING FOR CONTINUITY

A. Disconnect the battery negative terminal.

B. Connect one lead of a self-powered test lamp or ohmmeter to one end of

the part of the circuit you wish to test. If you are using an ohmmeter, hold

the leads together and adjust the ohmmeter to read zero ohms.

C. Connect the other lead to the other end.

D. If the self-power test lamp glows, there is continuity. If you are using an

ohmmeter, low or zero resistance means good continuity.

3. TESTING FOR SHORT TO GROUND

A. Disconnect the battery negative terminal.

B. Connect one lead of a self-powered test lamp or an ohmmeter to the fuse

terminal on the load side.

C. Connect the other lead to a ground.

D. Beginning near the fuse block move the harness from side to side.

Continue this proceedure(about six inches apart) while watching the

self-powered test lamp or ohmmeter.

E. When the self-powered test lamp glows, or ohmmeter registers, there is a

short to a ground in the wiring near that point.

Battery

disconnected

FUSE BOX

(Fuse removed)

Short to ground

R

1

SELF-POWERED

TEST LAMP

OR

VOLTMETER

M11

4

G

SWITCH

M11

SOLENOID

Load

disconnected

SELFPOWERED

TEST LAMP

OR

OHMMETER

STOP

LAMP

SWITCH

EVT GI70010L

TROUBLESHOOTING INSTRUCTIONS

4. TESTING FOR A SHORT WITH A SHORT FINDER

A. Remove the blown fuse. Leave the battery connected.

B. Connect the short finder across the fuse terminals.

C. Close all switches in series in the circuit that is being testing.

D. Turn on the short circuit locator. It sends pulses of current to the short.

This creates a pulsing magnetic field around the wiring between the fuse

box and the short.

E. Beginning at the fuse box, slowly move the short finder along the circuit

wiring. The meter will show current pulses through sheet metal and body

trim. As long as the meter is between the fuse and the short, the needle

will move with each current pulse. Once the meter is moved past the point

of the short, the needle will stop moving. Check around this area to locate

the cause of the short circuit.

Battery

disconnected

FUSE BOX

(Fuse removed)

SHORT

FINDER

METER

Pulsing

magnetic

field

R

M111

SWITCH

GI-11TROUBLESHOOTING INSTRUCTIONS (4)

Move meter

along wire

Needle stops

moving here

4 M11

G

Pulsing

magnetic

field

SOLENOID

Short to ground

EVT GI70011L

FUSE & REL AY INFORMATION EBF7DCCF

FUSE BOX

SD100-1FUSE & RELAY INFORMATION (1)

<D4DD>

FUSE 1

15A

FUSE 25

10A

FUSE 1

15A

FUSE 13

20A

FUSE 25AFUSE 3

10A

FUSE 14

FUSE 26

FUSE 25AFUSE 3

FUSE 14

15A

10A

10A

FUSE 15

10A

FUSE 27

10A

10A

FUSE 15

10A

FUSE 4

10A

FUSE 16

20A

FUSE 28

10A

FUSE 4

10A

FUSE 16

10A

FUSE 5

15A

FUSE 17

10A

FUSE 29

10A

FUSE 5

15A

FUSE 17

10A

FUSE 65AFUSE 75AFUSE 8

FUSE 18

FUSE 30

15A

10A

FUSE 19

10A

FUSE 31

10A

FUSE 20

FUSE 325AFUSE 33

<D4AF/D4AL>

FUSE 65AFUSE 7

5A

FUSE 18

15A

FUSE 19

15A

10A

20A

FUSE 9

10A

FUSE 21

20A

20A

FUSE 9

15A

FUSE 10

15A

FUSE 34

15A

FUSE 11

10A

FUSE 23

10A

FUSE 35

10A

FUSE 11

10A

FUSE 23

10A

FUSE 12

10A

FUSE 24

15A

FUSE 36

15A

FUSE 12

10A

FUSE 24

15A

FUSE 25

10A

FUSE 26

10A

FUSE 27

10A

FUSE 28

10A

FUSE 29

10A

FUSE 30

10A

FUSE 31

10A

FUSE 33

USE THE DESIGNATED FUSE ONLY

15A

FUSE 34

15A

FUSE 36

15A

EVT SD7100AL

FUSE & REL AY INFORMATION

CIRCUIT

Fuse Description (A) Circuit protected

1

2

3

4

D4DD(TACHOGRAPH, GLOW, ABS),

5

6

7

8

9

10

13

15

17

18

D4DD(STOP LP, HORN, DIAG CONN)

20

21

24

25

26

27

28

29 TAIL LP (LH) 10A

30 TAIL LP (RH) 10A

31

32 D4DD(ENG ECU) 5A(D4DD)

34

35

36

WORKING LAMP

HEAD LP (RELAY)

A/CON

D4AF/D4AL(COLD START),

EXH. BRAKE

WIPER WASHER

A. B. S (ECU)

P. T. O (OPT)

D4DD(ENG ECU)

D4AF/D4AL(SUB START),

D4DD(ENG ECU, EXH BRAKE)

D4DD(SUB START)

D4AF/D4AL(OVERHEAT BZ),

REVERSE LP, SPD SENSOR

D4AF/D4AL(ALTR (R)),

CLUSTER, ETACS

D4AF/D4AL(P/WINDOW)

D4AF/D4AL(STOP LP, HORN)

D4DD(HEAT'G MIRROR)

HAZARD, T/SIG LP, CAB TILT'G

D4AF/D4AL(RR FOG LAMP)

D4DD(P/WINDOW)

C/DOOR LOCK

A. B. S (VALVE)

D4AF/D4AL(HEAT'G MIRROR)

D4DD(ENG ECU)

D4DD(FUEL HEATER)

D4DD(ETACS, TACHOGRAPH),

AUDIO, ROOM LP, CLOCK

START MOTOR

HEAD LP (DIM. LH)

HEAD LP (DIM. RH)

HEAD LP (MAIN. LH)

HEAD LP (MAIN. RH)

FOG LAMP

D4AF/D4AL(CONDENSER FAN)

D4DD(A/C COMP, CONDENSER)

HEATER BLOWER

D4DD(ETACS)

CIGAR, AUDIO, CLOCK

15A

5A

10A

10A

15A

5A

5A

10A(D4DD)

15A(D4AF/D4AL)

10A(D4DD)

15A(D4DD)

10A

10A

20A

10A(D4AF/D4AL)

15A(D4DD)

10A

10A(D4AF/D4AL)

20A(D4DD)

10A

15A

15A(D4AF/D4AL)

10A(D4DD)

20A(D4DD)

20A(D4DD)

10A

15A

10A

10A

10A

10A

10A

15A(D4AF/D4AL)

20A(D4DD)

15A

10A(D4DD)

15A

Working lamp switch

Head lamp leveling actuator(D4AF/D4AL), Head lamp leveling switch(D4AF/D4AL), Head lamp relay(High/Low)

Mode switch, Intake switch, A/C switch, Evaporator sensor, Blower relay, Condenser fan relay

Cold start switch(D4AF/D4AL), Exhaust brake clutch pedal position switch(D4AF/D4AL), Tachograph, High speed warning device(D4AF/D4AL),

High speed warning buzzer(D4AF/D4AL), Glow relay(D4DD), Fuel heater relay(D4DD), Exhaust brake relay(D4DD), ABS relay

Wiper motor, Washer motor, Wiper relay(High/Low)

ABS control module

PTO relay, Dump relay, PTO control switch

Main ECM(D4DD)

Neutral switch(D4AF/D4AL), Main ECM(D4DD), Exhaust brake relay(D4DD)

Neutral switch(D4DD)

Overheat buzzer relay(D4AF/D4AL), Vehicle speed sensor, Back-up lamp switch, Water separator sensor(D4DD), Generator(D4DD)11

Instrument cluster(Indicator), ETACM, Generator(D4AF/D4AL)12

Power window relay(D4AF/D4AL)

Data link connector(D4AF/D4AL), Stop lamp switch(D4AF/D4AL), Horn(D4AF/D4AL), Outside mirror defogger relay(D4DD)14

Cab tilting switch, Flasher unit

Rear fog lamp relay(D4AF/D4AL), Rear fog indicator relay(D4AF/D4AL), Power window relay(D4DD)16

Power door lock relay, Power door unlock relay

ABS relay box(Fail safe relay)

Outside mirror defogger relay(D4AF/D4AL), Data link connector(D4DD), Stop lamp switch(D4DD), Horn(D4DD), Horn relay(D4DD)19

Engine ECM relay(D4DD), Main ECM(D4DD)

Fuel heater relay(D4DD)

Instrument cluster(Clock), ETACM, Audio, Front room lamp, Rear room lamp, Tachograph23

ETACM(D4AF/D4AL), Start solenoid, Sub start switch, Main ECM(D4DD)

Head lamp LH(Lo)

Head lamp RH(Lo)

Head lamp LH(Hi), Instrument cluster(High-beam indicator)

Head lamp RH(Hi)

Hazard switch, Defogger switch, A/C switch, Front fog lamp switch, License lamp, Rear combination lamp LH, Rear fog lamp switch(D4AF/D4AL),

Rear marker lamp LH(D4AF/D4AL), Front outside marker lamp(D4AF/D4AL), Cigarette lighter(D4DD)

Position lamp RH, Front room lamp, Endout marker lamp, Rear combination lamp RH, Rear marker lamp RH(D4AF/D4AL),

Rear outside marker lamp(D4AF/D4AL)

Front fog lamp relay

Engine PTO cab in switch(D4DD), Accelerator pedal sensor(D4DD), Exhaust brake clutch pedal position switch(D4DD), Stop lamp switch(D4DD),

Multifunction switch(Exhaust brake switch)(D4DD), Idle up/down switch(D4DD)

Condenser fan relay, A/C relay33

Blower relay

Not used(D4DD)

Cigarette lighter, Audio, Instrument cluster(Clock)

SD100-2FUSE & RELAY INFORMATION (2)

USE THE DESIGNATED FUSE ONLY

EVT SD7100BL

FUSE & REL AY INFORMATION

SD100-3FUSE & RELAY INFORMATION (3)

FUSIBLE LINK BOX

ABS

30A

A/CON

30A

IGN SW

30A

CIRCUIT

Description (A) Circuit protected

ABS

A/CON

IGN SW

ALTERNATOR

30A

30A

30A

40ABODY

60A

ABS relay box(Pump motor relay)

Fuse box(Fuse 33, Fuse 34)

Ignition switch

Relay box(Head lamp relay (High/Low), Tail lamp relay),

Fuse box(D4AF/D4AL(Fuse 13~19), D4DD(Fuse 15~21), Fuse 31)

Generator

BODY

40A

ALTERNATOR

60A

USE THE DESIGNATED FUSE ONLY

EVTSD7100CL

FUSE & REL AY INFORMATION

SD100-4FUSE & RELAY INFORMATION (4)

3

12

*

5

M01

FRONT FOG

LAMP RELAY

3

14

*

5

M15

ABS

RELAY

3

14

*

5

M08

PTO

RELAY

RELAY (HIGH)

124

POWER

DOOR

LOCK

RELAY

14

DUMP

RELAY

1

234

5

M11

WIPER

M05

*

M09

3

5

3

5

124

M06

POWER

DOOR

UNLOCK

RELAY

1

234

5

M12

WIPER

RELAY (LOW)

<D4DD> <D4AF/D4AL>

3

5

DEFOGGER

HEAD LAMP

RELAY (HIGH)

12

M07

OUTSIDE

MIRROR

RELAY

1

24

*

5

M13

3

12

*

5

RELAY

12

EXHAUST

BRAKE RELAY

HEAD LAMP

RELAY (LOW)

M88

HORN

M93

1

*

5

M14

3

*

5

3

12

*

5

24

WINDOW RELAY

M94

GLOW

RELAY

POWER

3

*

5

1

*

5

M04

RELAY BOX

24

3

12

*

5

M01

FRONT FOG

LAMP RELAY

3

14

*

5

M15

ABS

RELAY

3

124

5

M08

PTO

RELAY

1

234

5

M11

WIPER

RELAY (HIGH)

3

12

*

5

M16

REAR FOG

LAMP RELAY

3

124

5

M05

POWER

DOOR

LOCK

RELAY

3

14

*

5

M09

DUMP

RELAY

1

5

M12

WIPER

RELAY (LOW)

124

POWER

UNLOCK

RELAY

234

BUZZER RELAY

3

5

M06

DOOR

1

*

5

M13

HEAD LAMP

RELAY (HIGH)

14

OVERHEAT

12

OUTSIDE

MIRROR

DEFOGGER

RELAY

24

3

*

5

M97

3

*

5

M07

M14

HEAD LAMP

RELAY (LOW)

TAIL LAMP

1

24

*

5

1

24

*

5

M02

RELAY

M04

POWER

WINDOW RELAY

1

24

*

5

1

24

*

5

M90

FUEL HEATER

RELAY

1

24

*

5

M91

ENGINE

ECM RELAY

1

*

5

M02

TAIL LAMP

RELAY

24

1

24

*

5

M86

REAR FOG

INDICATOR RELAY

USE THE DESIGNATED FUSE ONLY

EVTSD7100DL

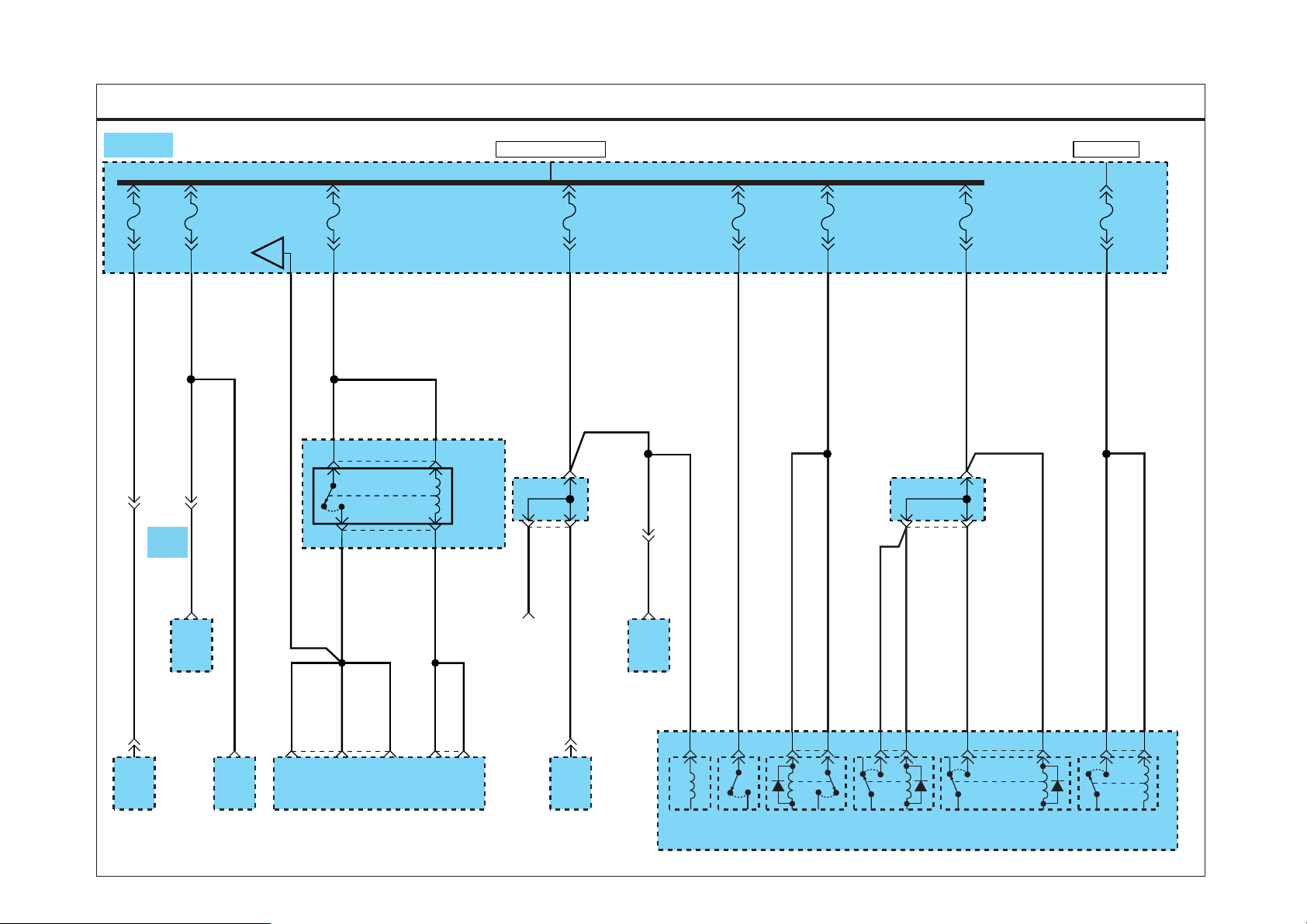

POWER DISTRIBUTION E A007534

SD110-1POWER DISTRIBUTION (1)

8.0W

1

C13

+

-

+

BATTERY

BATTERY

3.0Y

1

ABS

FUSIBLE

LINK

30A

CC03

2

8.0L

8.0L

2

ALTERNATOR

FUSIBLE

LINK

60A

CC01

5.0W

EC03

1

3.0G

3.0G

1

1

A/CON

FUSIBLE

LINK

30A

2.0R

BODY

FUSIBLE

LINK

40A

CC02

2

3.0R

3

2.0L 2.0L

3.0R

5

3.0R

1.25G

1

A

M14

M14

HEAD

LAMP

RELAY

(LOW)

To IGN SW

Fusible Link 30A

(SD110-2)

M13

5

M13

1

1.25O

FUSIBLE

LINK

BOX

HEAD

LAMP

RELAY

(HIGH)

3.0L3.0R

MC03

6

3.0L

2.0L 0.5L

5

1

See Tail, Parking

& License Lamps

(SD928-1)(SD928-2)

1.25G/O

RELAY

BOX

M02

2

TAIL

LAMP

RELAY

M02

4

3.0L

FUSE BOX

-

BATTERY

GROUND

START

MOTOR

FUSE 33

8.0W

C34-2

1

ABS

RELAY

BOX

8.0L

E17

1

GENERATOR

15A(D4AF/D4AL)

20A(D4DD)

See Passenger

Compartment Fuse Details

(SD120-7)

FUSE

FUSE

16

15

20A

10A

FUSE 34

15A

Compartment Fuse Details

D4DD D4AF/D4AL

FUSE

FUSE

17

18

10A

15A

FUSE 23

10A

See Passenger

(SD120-5)

FUSE

19

10A

FUSE

FUSE

20

21

20A

20A

See Passenger

Compartment Fuse Details

(SD120-3)(SD120-4)

FUSE

FUSE

26

25

10A

10A

See Passenger

Compartment Fuse Details

(SD120-5)(SD120-6)

FUSE

FUSE

13

14

20A

10A

FUSE

27

10A

FUSE

15

10A

FUSE

28

10A

FUSE

16

10A

FUSE

29

10A

FUSE

17

10A

FUSE

30

10A

FUSE

FUSE

18

19

15A

15A

See Passenger

Compartment Fuse Details

(SD120-7)

FUSE

31

10A

EVT SD7110AL

POWER DISTRIBUTION

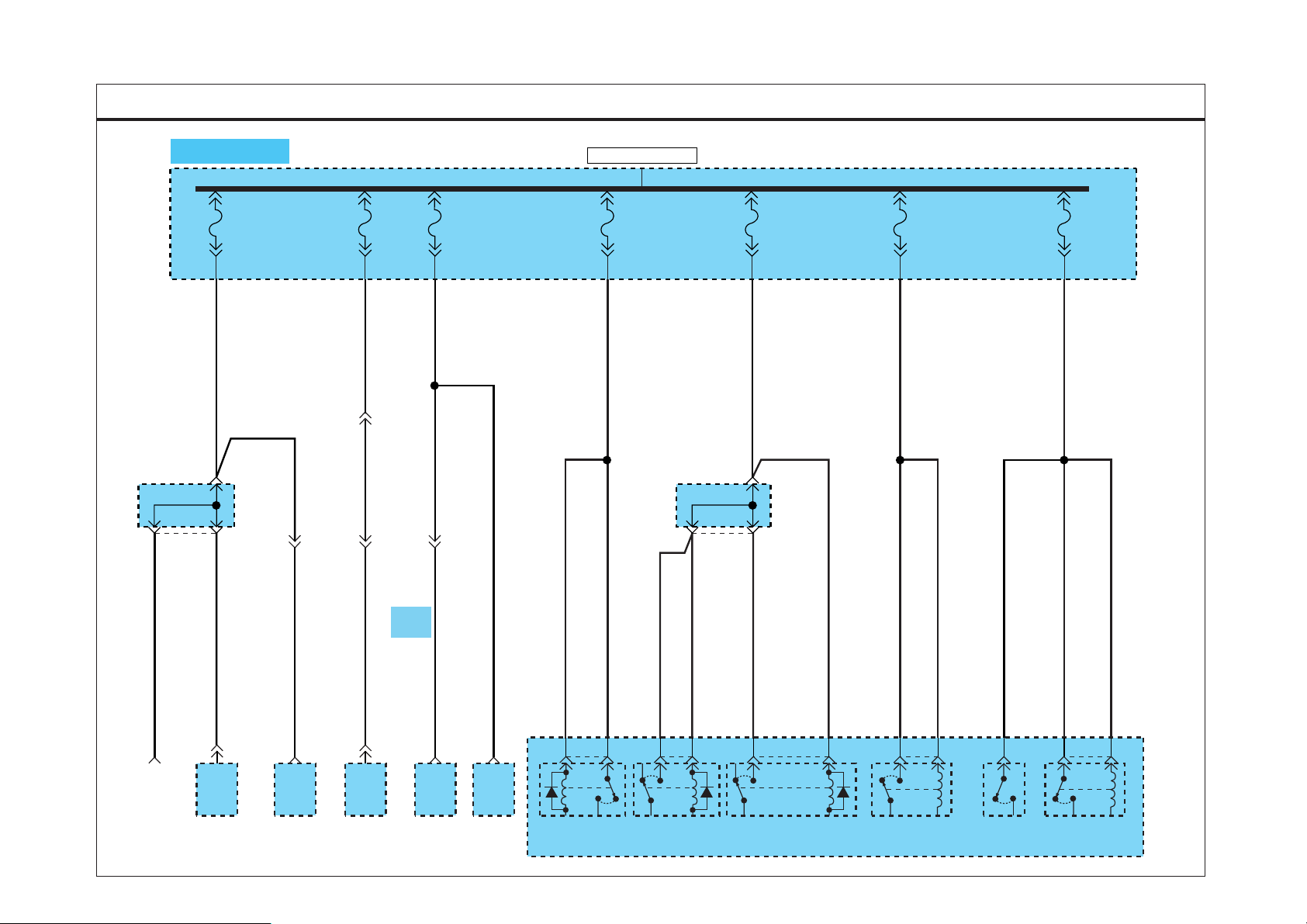

SD110-2POWER DISTRIBUTION (2)

Battery Power

(SD110-1)

START

2.0G 2.0L

From

A

1

3.0W

5

3.0W

6

AM

ACC ON

2 4 3

D4AF/D4AL D4DD

3.0O

FUSIBLE

LINK

BOX

IGN SW

FUSIBLE

LINK

30A

CC01

MC03

M42

IGNITION

SWITCH

LOCK

M42

3.0O

3.0O 3.0O

HOT WITH ENGINE ECM RELAY ON

FUSE

BOX

FUSE 24

15A

See Passenger

Compartment Fuse Details

(SD120-5)

FUSE 1

15A

FUSE 2

5A

FUSE 3

10A

FUSE 35

10A

See Passenger

Compartment Fuse Details

(SD120-7)

FUSE 4

10A

FUSE 5

15A

Compartment Fuse Details

FUSE 36

15A

FUSE 65AFUSE 75AFUSE 8

See Passenger

(SD120-1)(SD120-2)

10A

FUSE 32

5A

See Passenger

Compartment Fuse Details

(SD120-7)

FUSE 9

15A(D4AF/D4AL)

10A(D4DD)

FUSE 10

15A

FUSE 11

10A

FUSE 12

10A

See Passenger

Compartment Fuse Details

FUSE 14

15A

(SD120-3)

EVT SD7110BL

PASSENGER COMPARTMENT FUSE DETAILS EC996EE F

SD120-1PASSENGER COMPARTMENT FUSE DETAILS (1)

1.25W

FUSE 1

15A

1.25Br

1.25Br

1

1

FUSE 6

5A

MA01

0.5O

A01

0.85O

13

0.5O

12

1

FUSE 3

10A

M80

0.5O

M28

11

0.85O

M80

0.5L/B

M21

5

JOINT

CONNECTOR

0.5O

MA02

4

0.5R

0.5R

4

D4AF/

D4AL

0.85Br

A15

0.5Br

10

D4AF/

D4AL

0.85Br

9

1

HOT IN ON

FUSE 2

5A

M54

0.5Br

M60

D4AF/

D4AL

0.5Br

8

4

JOINT

CONNECTOR

M54

0.5Br

M44

D4AF/

D4AL

0.5L

3

1

D4AF/

0.5L

D4AL

4

M73

D4DD D4DD

0.5L

0.5L

M47

M24

3

4

0.5L

0.5L

0.5L

6

FUSE 4

10A

M78

D4AF/

D4AL

0.5L

25

1

A

M22

To FUSE 5

15A

(SD120-2)

0.5L

0.5L

FUSE

BOX

D4DD

3

M78

0.5L

D4AF/

D4AL

1

JOINT

CONNECTOR

M49

M75

1

WORKING

LAMP

SWITCH

ABS

CONTROL

MODULE

ACTUATOR

2

MODE

SWITCH

M33

INTAKE

EVAPORATOR

M64

1

A/C

SWITCH

SENSOR

BLOWER

RELAY

A16

4

CONDENSER

FAN RELAY

HEAD LAMP

LEVELING

ACTUATOR RH

M53

1

HEAD LAMP

LEVELING

ACTUATOR LH

HEAD LAMP

LEVELING

SWITCH

M13

2

HEAD

LAMP RELAY

(HIGH)

COLD

START

SWITCH

M14

2

HEAD

LAMP RELAY

(LOW)

TACHOGRAPH

(ELECTRONIC)

0.5L 0.5L

M94

1

GLOW

RELAY

HEATER

RELAY

HIGH SPEED

WARNING

2 M90

FUEL

DEVICE

M93

1

EXHAUST

BRAKE

RELAY

HIGH SPEED

M15

5

ABS

RELAY

WARNING

BUZZER

RELAY

BOX

PEDAL POSITION

D4AF/

TACHOGRAPH

(CASSETTE TYPE)

D4AL

D4DD

M45

8

EXHAUST

BRAKE CLUTCH

SWITCH

EVT SD7120AL

PASSENGER COMPARTMENT FUSE DETAILS

SD120-2PASSENGER COMPARTMENT FUSE DETAILS (2)

From

HOT IN ON

(SD120-1)

0.85L 0.5R

7

0.85L

97

MM02

1.25L

5

A

FUSE 5

15A

1.25L

M80

10

0.85L 0.85L

M31

D4DD

22

MAIN ECM

M80

58

FUSE 8

10A

0.5R

0.5R0.5R

M99-2

12

JOINT

CONNECTOR

D4AF/

D4AL

0.5R

0.5R

M54

17

15

D4AF/

D4AL

0.5R 0.5R

FUSE 7

5A

D4DD

0.5R

D4DD

1.25R

11

0.85R

1

NEUTRAL

SWITCH

16

0.5R

FUSE 10

15A

MC06

C11

JOINT

CONNECTOR

M54

0.85R

MC01

5

(D4AF/D4AL)

MC05(D4DD)

4

C14

2

FUSE

BOX

FUSE 9

15A(D4AF/D4AL)

10A(D4DD)

D4AF/

D4AL

0.85Br/O1.25Y

0.85Br/O

0.85Br/O

0.85Br/O

7

D4AF/

D4AL

2.0R

2

2.0R

2

NEUTRAL

SWITCH

0.85Br/O 0.85Br/O

1.25Y

M99-3

1

MC01

C11

M99-2

D4DD

1.25Y0.85Y

11

MC01

0.85Br/O

C57

3

FUSE 11

10A

D4DD

0.85Br/O

0.85Br/O

0.85Br/O

2

MC05

0.5Br/O

0.5O

INSTRUMENT

0.85Br/O

C45

1

M36-3

2

CLUSTER

0.85Br/O

D4AF/

D4AL

C39

1

0.85O

14

16

0.5O

0.5O

FUSE 12

10A

M78

D4DD

100.5O

D4AF/

D4AL

0.85O

0.85O

MM07

0.5R

JOINT

CONNECTOR

M78

15

MC01

16

EC02

1

E10

1

M107

2

WASHER

MOTOR

WIPER

MOTOR

M12

2

WIPER

RELAY

(LOW)

M11

2

WIPER

RELAY

(HIGH)

5

PTO

RELAY

PTO

CONTROL

SWITCH

M08

1

RELAY

1

PTO

M08

5

DUMP

RELAY

M09

1

EXHAUST

BRAKE

RELAY

5

M93

MAIN ECM

5

OVERHEAT

BUZZER

RELAY

1

M97

VEHICLE

SPEED

SENSOR

RELAY

BOX

D4AF/

D4AL

BACK-UP

SWITCH

2

LAMP

WATER

SEPARATOR

SENSOR

D4DD

C12

GENERATOR

C57

1

VEHICLE

SPEED

SENSOR

M56-2

6

ETACM

GENERATOR

EVT SD7120BL

PASSENGER COMPARTMENT FUSE DETAILS

SD120-3PASSENGER COMPARTMENT FUSE DETAILS (3)

D4DD

1.25R

9

1.25R

FUSE 18

15A

0.85O

0.5O

MC05

W/O

Double

Cab

0.85O

8

2

FUSE 15

10A

To FUSE

32 5A

(SD120-7)

MM01

0.85O

M104

B

0.85L/G

2.0R/O

1.25G/O

5

FUSE 20

20A

HOT AT ALL TIMES

FUSE 19

10A

0.85Y

0.85R/O2.0R/O

M78

JOINT

CONNECTOR

M78

0.85Y

0.85Y

0.85Y

MC06

6

0.85Y

C18

2

0.5L

2

41

M91

M91

ENGINE

ECM

RELAY

RELAY

BOX

12

0.5Y

0.85Y

M72

9

DATA LINK

CONNECTOR

13

11

1.25W

FUSE 21

20A

1.25Y/O

0.5Y/O 1.25

Y/O

FUSE 16

20A

0.85L 0.5L

0.85L

6

0.85L 0.5L

7

5

FUSE 17

10A

M54

JOINT

CONNECTOR

M54

HOT IN ON

FUSE 14

15A

0.85P

0.85P 0.5P

FUSE

BOX

2

ABS

RELAY

BOX

C34-2

CAB

TILTING

SWITCH

1.25G/O 1.25G/O1.25G/O

M10

6

FLASHER

UNIT

65

MAIN ECM

7

M99-1

0.5L0.5L

M99-3

65

M41

2

STOP

LAMP

SWITCH

HORN

M88

5

HORN

RELAY

M90

5

FUEL

HEATER

RELAY

25

WINDOW

M04

POWER

RELAY

M05

25

POWER DOOR

LOCK RELAY

RELAY BOX

25

POWER DOOR

UNLOCK RELAY

M06

1

OUTSIDE MIRROR

DEFOGGER RELAY

M07

5

EVTSD7120CL

PASSENGER COMPARTMENT FUSE DETAILS

SD120-4PASSENGER COMPARTMENT FUSE DETAILS (4)

D4AF/D4AL

12

0.5Y

0.85Y

13

0.85Y

11

FUSE 14

10A

M78

JOINT

CONNECTOR

M78

0.85Y

0.85Y

HOT AT ALL TIMES

FUSE

BOX

FUSE 18

15A

1.25R

MA01

4

1.25R

1.25R

CA01

6

Double

MC02

5

0.85O

0.5O

0.85O

W/O

Cab

8

FUSE 15

10A

MM01

0.85O

1.25Y/O

0.5Y/O 1.25Y/O

FUSE 13

20A

0.85L 0.5L

0.85L

6

0.85L 0.5L

7

M54

5

FUSE 17

10A

M54

JOINT

CONNECTOR

FUSE 19

15A

0.85P

0.85P 0.5P

0.5R

FUSE 16

10A

0.85R

0.85R 0.5R

M72

9

DATA LINK

CONNECTOR

2

STOP

LAMP

SWITCH

M41

C18

2

HORN

2

ABS

RELAY

BOX

C34-2

M104

2

CAB

TILTING

SWITCH

M10

6

FLASHER

UNIT

25

POWER

WINDOW

M04

RELAY

M05

25

POWER DOOR

LOCK RELAY

25

POWER DOOR

UNLOCK RELAY

M06

OUTSIDE MIRROR

DEFOGGER RELAY

5

M07

M86

5

REAR FOG

INDICATOR

RELAY

1

REAR FOG

LAMP RELAY

1

5

M16

RELAY

BOX

EVTSD7120DL

PASSENGER COMPARTMENT FUSE DETAILS

SD120-5PASSENGER COMPARTMENT FUSE DETAILS (5)

HOT AT ALL TIMES

FUSE 23

10A

0.85Gr 2.0B/O

M77

20

0.5Gr

16

D4AF/

D4AL

0.5Gr

18 19 17

D4AF/

D4AL

0.5Gr

0.5Gr

0.5Gr

D4AF/

0.5Gr

D4AL

M77

D4DD

0.5Gr

1

JOINT

CONNECTOR

Double Cab

0.5G/B

MM07

0.5Gr

W/O

2

MM03

With

Double Cab

0.5R

0.5R 0.5R

0.5B/O

10

2.0B/O

2.0B/O

D4AF/

D4AL

MC01

2.0B/O

HOT IN START

FUSE 24

15A

1.25B/O

D4DD

1.25B/O

1.25B/O

MC05

1

2.0B/O 0.5L/R

2.0B/O

HOT WITH HEAD LAMP

RELAY (LOW) ON

FUSE 25

10A

1.25G

1.25G

HOT WITH HEAD LAMP

RELAY (HIGH) ON

FUSE 26

10A

1.25B/O

1.25B/O

FUSE 27

10A

0.85B/O

1.25Gr

FUSE 28

10A

FUSE

BOX

M56-1

4

ETACM

M26

10

AUDIO

INSTRUMENT

CLUSTER

M45

7

TACHOGRAPH

(CASSETTE TYPE)

M36-3

4

ETACM

M24

1

TACHOGRAPH

(ELECTRONIC)

1

M56-2

0.5Gr

0.5Gr

4

0.5Gr

M56-1

ETACM

FRONT

ROOM

M56-2

1

3

LAMP

M110

M110

3

FRONT

ROOM

LAMP

M114

3

REAR

ROOM

LAMP

M56-2

7

ETACM

C44

1

START

SOLENOID

D4AF/

D4AL

SWITCH

2

SUB

START

D4DD

C01

C44

1

START

SOLENOID

14

MAIN

ECM

1

Low

HEAD

LAMP LH

M99-2

M50

M57

1

Low

HEAD

LAMP RH

M50

3

Hi

HEAD

LAMP LH

HEAD

LAMP RH

M36-1

8

INSTRUMENT

CLUSTER

M57

3

Hi

EVT SD7120EL

PASSENGER COMPARTMENT FUSE DETAILS

REAR

A/C

SWITCH

DEFOGGER

SWITCH

CIGARETTE

LIGHTER

FOG LAMP

SWITCH

HAZARD

SWITCH

FUSE 29

10A

HOT WITH TAIL LAMP RELAY ON

FUSE 30

10A

FUSE

BOX

SD120-6PASSENGER COMPARTMENT FUSE DETAILS (6)

M64

2

0.5G/O

14

15

See Illuminations

(SD941-1)

EUROPE EUROPE

C05

C05-1

1

(EUROPE)

1

0.5G/O

0.85G/W

C52

M65

2

0.85G/O1.25G/O

0.85G/O

0.85G/O

0.85G/W0.85G/O0.85G/O

0.85G/W

C70

1

M68

1

0.5G/O

13

12

D4AF/D4AL D4DD

MC02

1

CC04

1

0.85G/O

D4AF/D4AL D4DD

C72

1

M67

2

0.5G/O

D4AF/D4ALD4DD

M84

0.85G/O

0.85G/O

0.85G/O 0.85G/W

MC05

18

C07

3

M62

2

0.5G/O 1.25G/O

11

0.5G/O

C05

1

2

M84

0.5R/B

M63

JOINT

CONNECTOR

With

Double Cab

0.5G/W

M110

2

0.85G

M112

2

12

1

MM03

W/O

Double Cab

0.85G/W

M113

2

0.5G/W

2

0.5G/W0.85G/W

M120

13

0.85G

1

POSITION

LAMP RH

M121

2

M58

0.5G/W

2

0.85G

M122

17

0.85G

14

M54

M5411

0.85G

MC05

17

0.85G

0.85G0.85G

3

JOINT

CONNECTOR

D4AF/D4ALD4DD

MC01

0.85G

EUROPE

C08

EUROPE

0.85G

1

0.85G/W

0.85G/W 0.85G/W

C53

1

1

CC05

C73

C74

1

LICENSE

LAMP

REAR

MARKER

LAMP LH

FRONT

OUTSIDE

MARKER

LAMP LH

FRONT

OUTSIDE

MARKER

LAMP RH

REAR

COMBINATION

LAMP LH

LICENSE

LAMP

FRONT

FOG LAMP

SWITCH

FRONT

ROOM

LAMP

ENDOUT

MARKER

LAMP 'A'

ENDOUT

MARKER

LAMP 'B'

ENDOUT

MARKER

LAMP 'C'

ENDOUT

MARKER

LAMP 'D'

ENDOUT

MARKER

LAMP 'E'

REAR

COMBINATION

LAMP RH

REAR

MARKER

LAMP RH

REAR

OUTSIDE

MARKER

LAMP LH

REAR

OUTSIDE

MARKER

LAMP RH

EVTSD7120FL

PASSENGER COMPARTMENT FUSE DETAILS

SD120-7PASSENGER COMPARTMENT FUSE DETAILS (7)

0.85W

FUSE 31

10A

0.5L/O

0.85L/O

HOT AT ALL TIMESHOT AT ALL TIMES

From Engine

ECM Relay

(SD120-3)

MC04

8

D4DD

B

0.85L/O

0.5L/O0.85L/O0.5L/O 0.85L/O

FUSE 32

5A

0.5L/O

0.85L/O

FUSE 33

15A(D4AF/D4AL)

20A(D4DD)

0.85G

93

2.0G

0.85G/W2.0G

2.0P

FUSE 34

15A

D4DD

MA02

HOT IN ACC OR ON

FUSE 35

10A

MM06

16

Not used

FUSE

BOX

FUSE 36

15A

0.85L/O0.5L0.85P

0.85L/O 0.5L/O0.85L/O

M01

1

FRONT

FOG LAMP

RELAY

RELAY

BOX

1

PTO

EC04

M39

5

ENGINE

PTO CAB

IN SWITCH

M32

4

ACCELERATOR

PEDAL

SENSOR

M41

4

STOP

LAMP

SWITCH

M43-1

2

MULTIFUNCTION

SWITCH

M17

3

IDLE

UP/DOWN

SWITCH

M49

2

EXHAUST

BRAKE CLUTCH

PEDAL POSITION

SWITCH

A16

3

CONDENSER

FAN

RELAY

A17

3

A/C

RELAY

A15

1

BLOWER

RELAY

M68

3

LIGHTER

M36-3

5

INSTRUMENT

CLUSTER

M26

11

AUDIOCIGARETTE

EVTSD7120GL

PASSENGER COMPARTMENT FUSE DETAILS

MEMO

SD120-8PASSENGER COMPARTMENT FUSE DETAILS (8)

EVTSD7120HL

GROUND DIST RIBUTION E C2E9F76

SD130-1GROUND DISTRIBUTION (1)

BLOWER

SWITCH

3

1.25B

M27

AUDIO

0.5B

MULTIFUNCTION SWITCH INSTRUMENT CLUSTER

M26

7

8

0.5B 0.5B 0.5B 0.5B 0.5B

12

M43-1

14 2 8

UP/DOWN

M43-2

D4DD

IDLE

SWITCH

M17

1

SWITCH

0.5B0.5B

D4AF/

D4AL

COLD

START

M47

1

HEAD LAMP

LEVELING

SWITCH

3

0.5B 0.5B

D4AF/

D4AL

D4AF/

D4AL

PTO SWITCH

M36-2 M36-1

13

10 1

0.5B

M36-1

1

2

0.5B 0.5B 0.5B 0.5B 0.5B 0.5B 0.5B

8

M44

5

M36-4

M37

6

3

7 M762 3 4 81 6

JOINT

CONNECTOR

0.5B

G01(MAIN)

0.5B

M76

5

EVT SD7130AL

GROUND DIST RIBUTION

SD130-2GROUND DISTRIBUTION (2)

MODE

SWITCH

M29

6

M28

2

MODE

ACTUATOR

INTAKE

SWITCH

3

12 13 14

WIPER

CIGARETTE

MOTOR

M33

1

15

M31

2

M77

LIGHTER

M68

2

0.85B

4

JOINT

CONNECTOR

SWITCH

0.5B

10

A/C

6

M64

M84

HEAD LAMP

LEVELING

ACTUATOR RH

M60

3

0.85B

D4AF/

D4AL

1

DEFOGGER

SWITCH

3 5

0.5B

0.5B 0.5B

M65

6

FRONT

FOG LAMP

SWITCH

3 5

0.5B

0.5B 0.5B

6 18

6

M63

D4AF/

D4AL

REAR

FOG LAMP

SWITCH

M67

6

0.5B

9

HAZARD

SWITCH

6

0.85B 0.5B

M62

5

7

TACHOGRAPH

(ELECTRONIC)

5

0.5B 0.5B

D4AF/

D4AF/

D4AL

D4AL

ASHTRAY

M24

4

20

2

0.5B0.5B 0.5B 0.5B 0.85B0.5B

165

TACHOGRAPH

ILL.

(CASSETTE TYPE)

M30

0.5B

9

819

M45

M842 17

JOINT

CONNECTOR

M77

11

0.85B0.5B

0.85B

G01(MAIN)

EVT SD7130BL

GROUND DIST RIBUTION

SD130-3GROUND DISTRIBUTION (3)

POSITION

LAMP LH

M51

2

SEAT BELT

SWITCH

0.5B

0.5B0.5B 0.5B 0.85B 0.5B 1.25B 0.5B

1 7 11 14

SIDE

REPEATER

LAMP LH

FRONT

TURN SIGNAL

LAMP LH

M52

2

POWER

DOOR LOCK

ACTUATOR LH

M102

2

0.85B

MM01

9

5

2

OUTSIDE

MIRROR

DEFOGGER LH ETACM

FLUID LEVEL

D06

3

MD02

4

REPEATER

BRAKE

SENSOR

SIDE

LAMP LH

1

M46

LAMP LH

HEAD

2

DATA LINK

CONNECTOR

M72

16

M50

OUTSIDE

MIRROR

DEFOGGER LH

0.5B 0.5B

D4AF/

D4AL

5

6

ENGINE PTO

CAB IN SWITCH

3

DATA LINK

CONNECTOR

16

0.5B

0.5B

D4DD D4DD D4DDD4DD

POWER

WINDOW

MAIN SWITCH

M86

RELAY

BOX

PTO CLUTCH

PEDAL POSITION

SWITCH

M48

M53

D4AF/

ETACM

0.5B

D4AL

2

49

M38

JOINT

CONNECTOR

M39

6

HEAD LAMP

M38

13

LEVELING

ACTUATOR LH

3

0.85B

D4AF/

D4AL

3

0.5B0.5B

M72

4

0.5B

HORN

RELAY

0.85B

PTO

RELAY

M88

3

1

1

M08

GLOW

RELAY

3

0.5B0.5B

0.5B

2

HIGH SPEED

WARNING

DEVICE

WIPER

RELAY

(LOW)

M94

0.85B 0.85B 0.5B

DOOR LOCK

M124M05

1

4 6

POWER

RELAY

5 M79

POWER

DOOR UNLOCK

RELAY

M06

4

0.85B

M79

7

JOINT

CONNECTOR

REAR FOG

INDICATOR

RELAY

4

D4AF/

D4AL

0.85B

1 D04

0.85B

D02

1

W/O Power

Window

0.85B

0.85B

6

With Power

Window

MD01

0.85B

1.25B0.85B

D4DDD4AF/D4AL

D02

1

3 D051 D04

1.25B

1.25B

1.25B

G01(MAIN) G02(MAIN)

0.5B

0.5B

5

0.5B

20 M56-1

19

0.5B

D4DDD4AF/D4AL

0.5B

18

0.5B

0.5B

5

0.5B

0.5B

0.5B

19 M56-1

20

0.5B/O

MM07

11

0.5B

D4AF/

D4AL

M73

2

0.85B

0.85B

A

To Ground

(SD130-4)

EVTSD7130CL

GROUND DIST RIBUTION

SD130-4GROUND DISTRIBUTION (4)

FRONT

TURN SIGNAL

LAMP RH

2 M59

HEAD

LAMP RH

2 M57

0.5B

1.25B

1

2

ABS CONTROL MODULE

POWER

DOOR LOCK

ACTUATOR RH

3 D16

REPEATER

LAMP RH

0.85B

0.85B

MD04

4

OUTSIDE

MIRROR

DEFOGGER RH

D12

1

SIDE

1 D14

REPEATER

0.85B

0.85B

0.85B 1.25B

W/O Power

Window

0.85B0.5B

0.85B

DEFOGGER RH

SIDE

LAMP RH

1 D14

0.85B

With Power

Window

MD03

6

3

OUTSIDE

MIRROR

D12

1

SUB SWITCH

1.25B 0.5B

MAIN ECM

POWER

WINDOW

3 D15

D4DD

VACUUM

SWITCH

M71

2

0.5B

ENDOUT

MARKER

LAMP 'A'

1 M112

ENDOUT

MARKER

LAMP 'B'

1 M113

0.5B

0.85B

0.85B 0.5B

ENGINE ECM

FRONT

ROOM

LAMP

1 M110

Double Cab

ENDOUT

MARKER

LAMP 'C'

1 M120

0.5B

W/O

ENDOUT

MARKER

LAMP 'D'

1 M121

0.5B

4

0.5B

6

Joint Connector

(SD130-3)

ENDOUT

MARKER

LAMP 'E'

0.5B

With

Double Cab

MM03

From

A

1 M122

0.5B

FRONT

ROOM

LAMP

1 M110

D4DD

REAR

ROOM

LAMP

1 M114

0.5B

5

RELAY

0.5B 0.5B

M81

D4AF/

D4AL

A/C

2

A17

BLOWER

RELAY

A15

2

2

0.5B

7

OUTSIDE MARKER

LAMP RH

POSITION

LAMP RH

M58

2

0.85B 0.85B 0.85B 0.85B

0.5B0.5B

MA02

M81

8

REAR

C74

2

OUTSIDE MARKER

LAMP LH

0.85B 0.85B

1.25B

JOINT

CONNECTOR

D4AF/

D4AL

FRONT

OUTSIDE MARKER

LAMP LH

REAR

2

2

2

C73

CC052CC04

0.85B

C70

FRONT

OUTSIDE MARKER

LAMP RH

C72

2

55

30 29 28

0.85B 0.85B 1.25B 0.85B

A01

4 28

1.25B 0.5B

1.25B

1.25B

1.25B

3

MC04

2

M99-1M99-3

1 4

1.25B

1.25B 1.25B

C10-1C10-2

5

0.85B 1.25B

1.25B

1.25B

2 4

3.0B 2.0B

G02(MAIN)G05(CHASSIS/D4DD)G04(A.B.S)

MC03

2.0B 3.0B

G03(CHASSIS)

1.25B

EVTSD7130DL

GROUND DIST RIBUTION

SD130-5GROUND DISTRIBUTION (5)

TACHO-

METER

SENSOR

1 E05

0.5B

6

0.85B

1.25B

EC02

FRONT

FOG

LAMP RH

1 C19

CONDENSER

FAN

MOTOR

(TCI)

2 C15(D4DD)

C20(D4AL)

D4DD

1.25B1.25B

D4AF/

D4AL

CONDENSER

FAN MOTOR

(NA)

2 C15(D4AF)

0.85B

0.85B 0.85B

INTAKE

SHUTTER

D4AF/

D4AL

Double Cab

See P.T.O Control System/

VALVE

C25

1

D4DD D4DD

W/O

With

Double Cab

Exhaust Parking Brakes

(SD471-1)(SD471-2)

(SD596-1)(SD596-2)

0.85L/B

D4AF/

D4AL

0.85B

DIODE

Z03

With

Double Cab

0.85B

W/O

Double Cab

0.85B0.85B

W/O

Double Cab

0.85B

0.85B

CC06

1

0.85B

EXHAUST

MAGNETIC

VALVE

1

D4DD

With

Double Cab

C26

D4AF/

D4AL

0.85B 0.85B0.85B

PTO

MAGNETIC

VALVE

C24

1

FRONT

FOG

LAMP LH

1 C17

1.25B

IDLE UP

MAGNETIC

VALVE

1 C40

0.85B

WORKING

LAMP

1.25B

DUMP

WARNING

SWITCH

1 C03

0.85B

1.25B

COMBI-

NATION

LAMP RH

1.25B

D4AF/

D4AL

REAR

4 C081 C02

D4AF/

D4AL

1.25B

G03(CHASSIS)

D4AF/

D4AL

EVT SD7130EL

Loading...

Loading...