Hyundai HD78 User Manual

Brake System

(WABCO ABS)

General

Description.................................................... BR -3

Components ................................................. BR -14

Dignosis ........................................................ BR -16

On-Vehicle Inspection And Adjustment ....... BR -20

Specifications ............................................... BR -22

Vacuum Assisted Hydraulic Brake

Brake Pedal

Components............................................ BR -27

Removal .................................................. BR -28

Installation ............................................... BR -28

Adjustment .............................................. BR -28

Brake Booster

Component ............................................. BR -30

Removal .................................................. BR -31

Installation ............................................... BR -32

Inspection ................................................ BR -33

Brake Master Cylinder

Components............................................ BR -36

Removal .................................................. BR -37

Installation ............................................... BR -38

Load Sensing Proportioning Valve(LSPV)

Components............................................ BR -39

Removal .................................................. BR -40

Inspection ................................................ BR -40

Front Brake Assembly

Disc Brake

Components............................................ BR -41

Removal .................................................. BR -42

Installation ............................................... BR -43

Disassembly............................................ BR -44

Reassembly ............................................ BR -45

Inspection ................................................ BR -46

Drum Brake

Components............................................ BR -48

Removal .................................................. BR -49

Replacement ........................................... BR -50

Installation ............................................... BR -51

Parking Brake System

Components ................................................. BR -52

Removal ....................................................... BR -53

Installation .................................................... BR -54

Adjustment .................................................... BR -56

Rear Brake Assembly

Drum Brake

Components............................................ BR -57

Removal .................................................. BR -58

Replacement........................................... BR -59

Installation ............................................... BR -61

Exhaust Brake

Component Location .............................. BR -62

Components............................................ BR -63

Replacement........................................... BR -67

Disassembly............................................ BR -68

Reassembly ............................................ BR -68

Inspection ................................................ BR -70

ABS(Anti-Lock Brake System)

Specifications ............................................... BR -72

Description.................................................... BR -72

Using Blink Code Diagnostics ..................... BR -76

DTC Troubleshooting ................................... BR -83

Repair Instruction ......................................... BR -88

Connector Configurations ............................ BR -90

Full Circuit Diagram ..................................... BR -91

Inspection ..................................................... BR -91

Adjustment .................................................... BR -92

ABS Modulator

Removal .................................................. BR -94

Installation ............................................... BR -94

Wheel Speed Sensor

Description .............................................. BR -95

Replacement........................................... BR -95

ABS Control Module

Removal .................................................. BR -97

Installation ............................................... BR -98

Schematic Diagrams .............................. BR -99

DTC Chart ............................................... BR -104

0000 ........................................................ BR -107

0001 ........................................................ BR -110

0002 ........................................................ BR -113

0003 ........................................................ BR -116

0004 ........................................................ BR -119

0009 ........................................................ BR -122

000A ........................................................ BR -125

000B ........................................................ BR -128

000C ........................................................ BR -131

000D ........................................................ BR -134

000E ........................................................ BR -137

000F ........................................................ BR -140

0010 ........................................................ BR -143

0011 ........................................................ BR -146

0017 ........................................................ BR -149

0018 ........................................................ BR -152

0019 ........................................................ BR -155

001A ........................................................ BR -158

001B ........................................................ BR -161

001C ........................................................ BR -164

001D ........................................................ BR -167

001E ........................................................ BR -170

001F ........................................................ BR -173

0020 ........................................................ BR -176

0021 ........................................................ BR -179

0022 ........................................................ BR -182

0023 ........................................................ BR -185

0024 ........................................................ BR -188

0029 ........................................................ BR -191

002A ........................................................ BR -194

002B ........................................................ BR -197

002C ........................................................ BR -200

002D ........................................................ BR -203

002E ........................................................ BR -206

002F ........................................................ BR -209

0030 ........................................................ BR -212

0032 ........................................................ BR -215

0033 ........................................................ BR -218

0037 ........................................................ BR -221

0038 ........................................................ BR -223

0039 ........................................................ BR -225

003B ........................................................ BR -227

003C ........................................................ BR -230

003D ........................................................ BR -233

003F ........................................................ BR -235

0040 ........................................................ BR -237

0041 ........................................................ BR -240

0042 ........................................................ BR -243

0043 ........................................................ BR -246

0044 ........................................................ BR -249

0045 ........................................................ BR -252

0046 ........................................................ BR -255

0047 ........................................................ BR -257

0049 ........................................................ BR -260

004A ........................................................ BR -263

004B ........................................................ BR -266

004C ........................................................ BR -269

004D ........................................................ BR -272

004E ........................................................ BR -275

004F ........................................................ BR -278

0050 ........................................................ BR -281

0051 ........................................................ BR -284

0052 ........................................................ BR -287

0053 ........................................................ BR -290

0054 ........................................................ BR -293

0055 ........................................................ BR -296

0056 ........................................................ BR -299

0057 ........................................................ BR -302

0058 ........................................................ BR -305

0059 ........................................................ BR -308

005A ........................................................ BR -311

005B ........................................................ BR -314

005C ........................................................ BR -317

005D ........................................................ BR -320

General

DESCRIPTION

BRAKE SYSTEM

The service brakes are internally expanding type

hydraulic brakes acting on all w h e els. The brakes for the

front wheels are 2-leading type and those for the rear

wheels are duo-servo or dual 2-leading type.

The brake booster gives faster hydraulic pressure

buildup. Tandem type brake master cylinder also

contributes to safety. The brake pedal, which is

easy-to-operate pendant type, transmits depression force

via operating rod, etc. to the BRAKE BOOSTER, which

boosts it and drives the master cylinder.

The BRAKE BOOSTER vacuum line is equipped with a

vacuum tank which minimizes negative pressure change

even in the case of repeated and frequent braking

operation.

Brake Booster

1. When not in Operation

When not in operation, no force acts on the operating

rod and hence the valve plunger is seated on the

poppet to open the negative pressure valve and to

close the atmospheric valve.

Negative pressure generated by the engine draws out

air from the chamber on the left side of the

diaphragm plate. And as the chamber on the right

side of the diaphragm plate is also evacuated via the

vacuum channel and the negative pressure valve that

is opened. As a result, the diaphragm plate is

pressed tightly onto the rear shell surface by the

diaphragm plate return spring. Atmosphere goes

through the air filter into space around the operating

rod but does not flow further as the atmospheric

valve of the valve plunger is closed.

2. When in Operation

When the brake pedal depression force overcomes

the valve return spring force, the operating rod, valve

plunger and poppet now move to the left and the

poppet is pressed tightly onto the valve plunger seat

by the poppet spring, closing the negative pressure

valve. When the brake pedal is further depressed

following closure of this valve, the valve plunger

clears the poppet to open the atmospheric valve and

atmosphere now flows through the channel into the

chamber on the right side of the diaphragm.

This flow of atmosphere produces the pressure

difference across the diaphragm and the force

resulting from such pressure difference overcomes

the piston return spring force. As a result, the

diaphragm pushes the push rod as it moves from

right to left. The push rod thus pushes the master

cylinder piston, generating high fluid pressure from

low pedal depression force.

SUDBR9016L

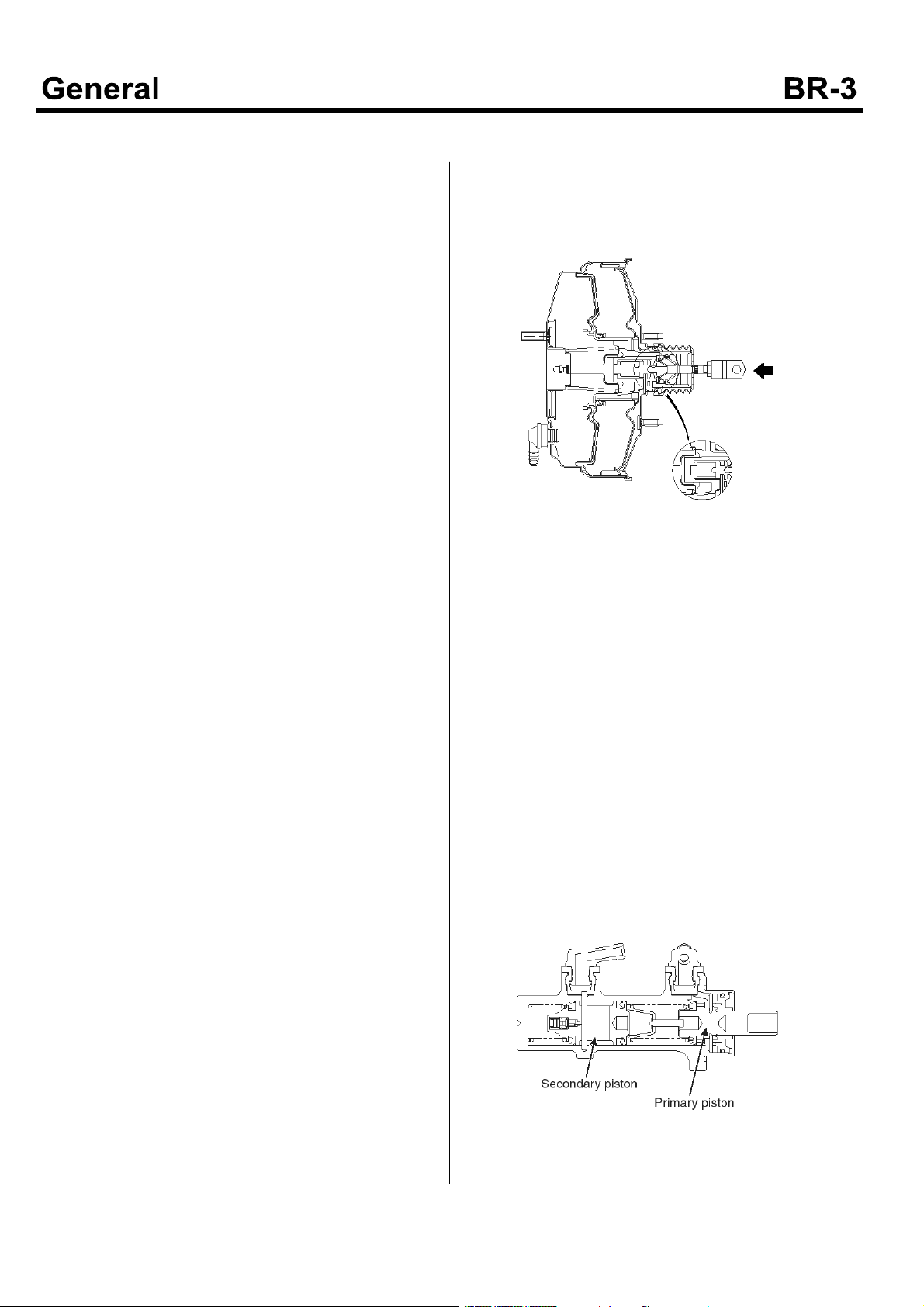

Brake Master Cylinder

1. Normal Operation

The tandem type brake master cylinder has

independent hydraulic systems for front and rear

brakes.

Should one of the two hydraulic systems fail, braking

by survived system (front or rear wheels) ensures

safety. When the brake pedal is depressed, the

primary piston is pushed to left, developing hydraulic

pressure in the pressure chamber on the primary

side. This pressure directly acts on the secondary

piston to push the secondary piston to left,

developing hydraulic pressure also in the pressure

chamber on the secondary side. As a result, each

piston pressurizes brake fluid to generate hydraulic

pressure in both front and rear brake systems.

SUDBR9017L

2. When fluid leaks are caused in front brake system

In this case, depression of the brake pedal to push

the push rod does not develop hydraulic pressure as

the brake fluid leaks from the front brake system.

Therefore, the primary piston compresses the

primary return spring and the retainer pushes the

secondary piston, which then pressurizes brake fluid

in space between the secondary piston and cylinder

body, thus generating hydraulic pressure in the rear

brake system only.

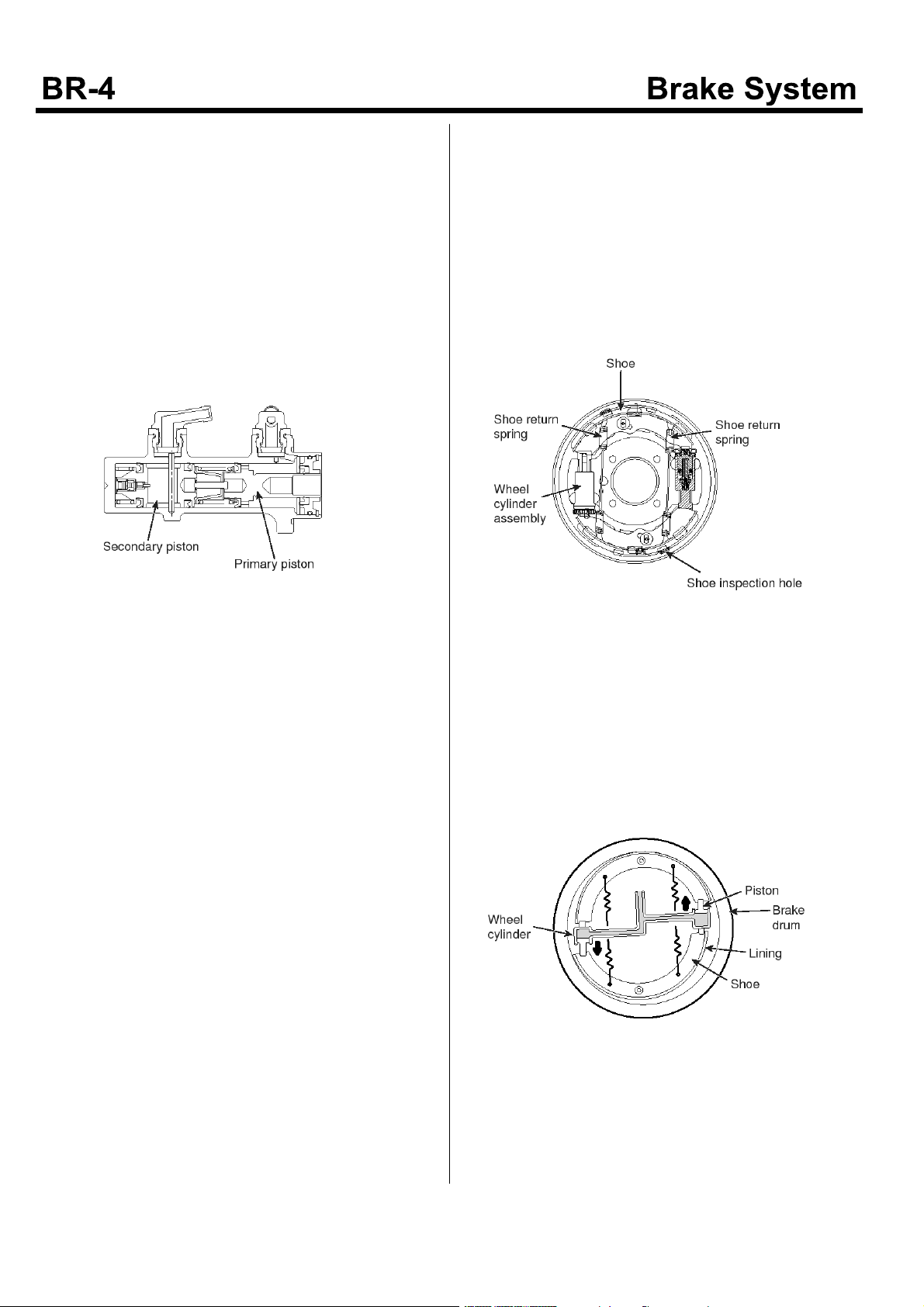

Front And Rear Wheel Brakes

Front wheel Brakes

The wheel cylinder is so constructed that the piston

extends in one direction only to push the shoes which are

held down to the backing plate by the shoe hold down

pin. The return springs mounted on the shoe fixed and

moving sides cause contraction of the shoe and wheel

cylinder piston when the brake is released.

When the vehicle is running forward, both shoes work as

leading shoes.

SUDBR9018L

3. When fluid leaks are caused in rear brake system

In this case, when the brake pedal is depressed to

push out the push rod, the secondary piston end

comes into contact with the cylinder body since brake

fluid in the rear brake system leaks. When the push

rod is further pushed, the primary piston pressurizes

brakefluidinthespacebetweentheprimaryand

secondary pistons, generating hydraulic pressure in

the front brake system only.

EMTBR5004A

When the pedal is depressed, brake fluid supplied under

pressure from the master cylinder enters the wheel

cylinder, of which piston moves the shoe moving side so

thattheliningispressedagainstthedruminside.

Resultant friction between the lining and drum causes the

shoe to try to turn with the drum, thus boosting the

braking force.

EMTBR5005A

Rear Wheel Brake

Dual 2-leading Brake

The wheel cylinders are installed at front and rear and

the pistons extend in both upward and downward

directions to push the shoes from both directions. The

shoes are held down to the backing plate by shoe hold

down pins and the return springs mounted on the shoes

causing contraction of the shoe and wheel cylinder piston

when the brake is released. During both forward and

reverse operation of the vehicle, the shoes work as

leading shoes.

EMTBR5004A

When the pedal is depressed, brake fluid supplied under

pressure from the master cylinder enters the wheel

cylinder, of which piston causes the shoe to expand in

both directions to press the lining against the drum

inside. Resultant friction between the lining and drum

causes the shoe to try to turn with the drum, thus

boosting the braking force.

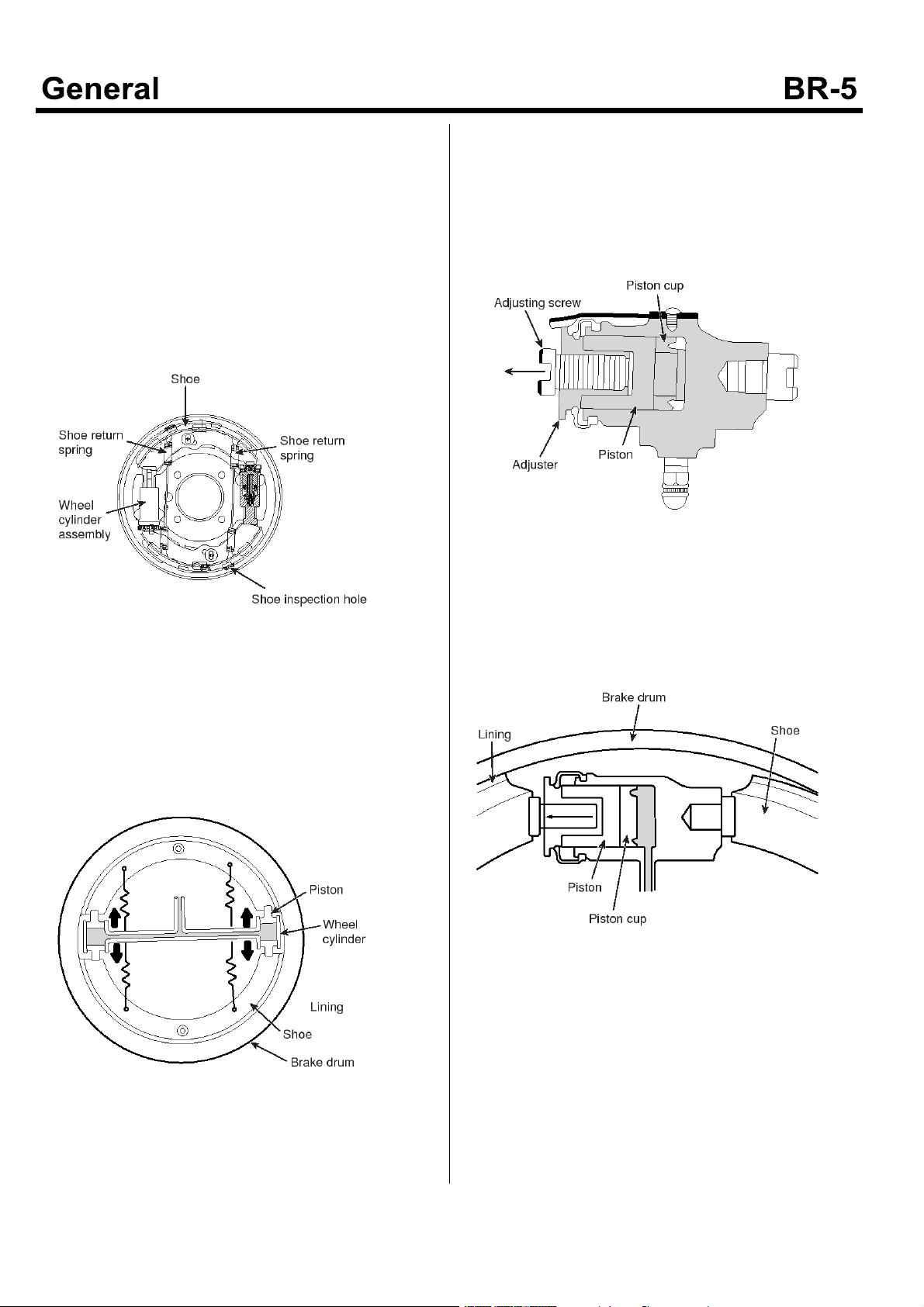

Wheel Cylinder

The wheel cylinder driven by hydraulic pressure

generated by the brake master cylinder presses the shoe

(lining) against the brake drum.

There are following two types of wheel cylinder according

to the method of pushing the shoe.

EMTBR5007A

1. 2-leading type : Front brake

In pedaling brake, oil pressure rising is master

cylinder goes into wheel cylinder and pushes piston.

Shoe contacting with the end of piston sticks to brake

drum and generates frictional force.

EMTBR5006A

EMTBR5008A

2. Dual 2-leading type : rear brake

EMTBR5009A

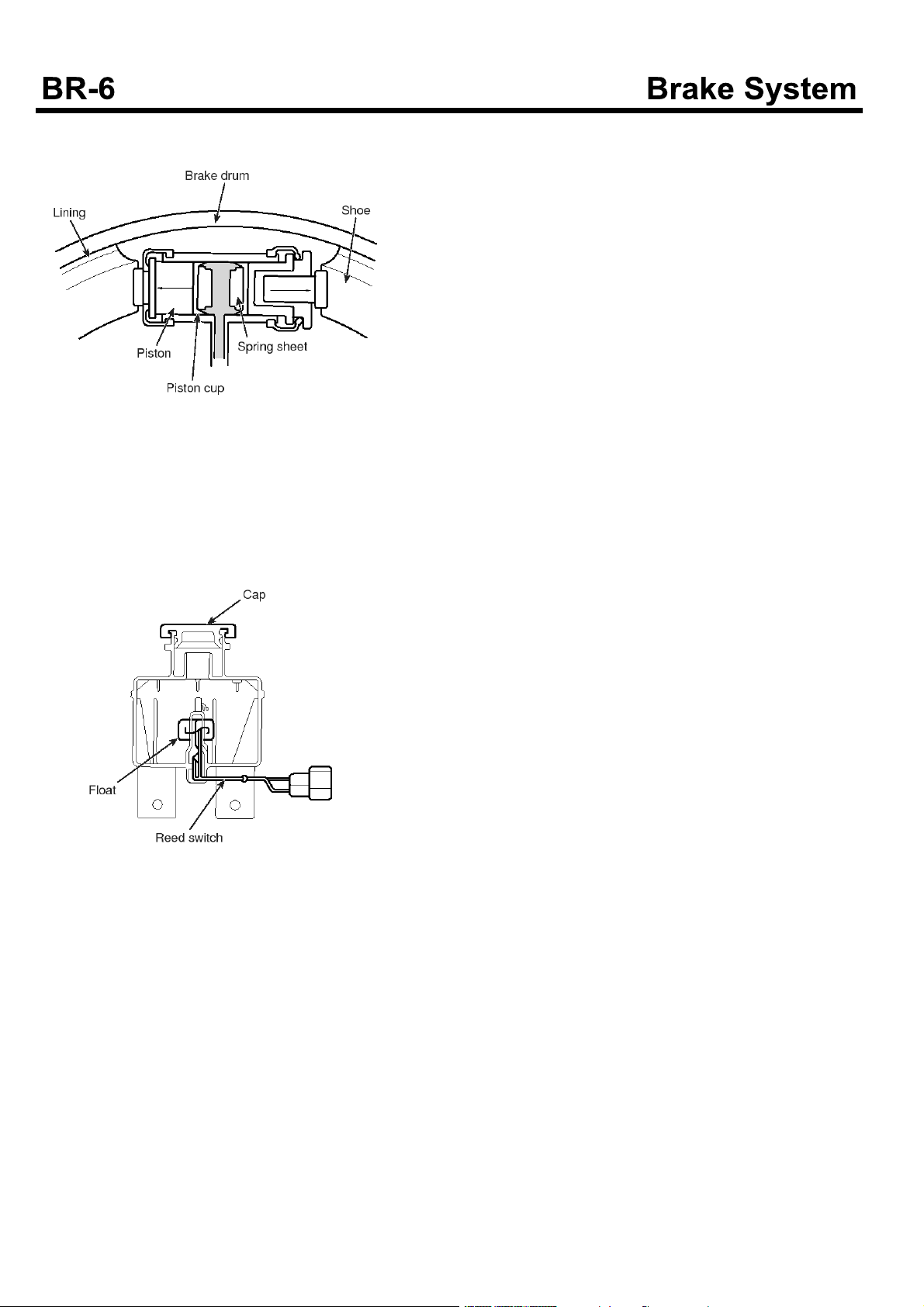

Brake Fluid Level Sensor

The brake fluid level sensor installed in the brake fluid

tank senses the brake fluid level in the tank. When the

fluid level drops to a preset level, the sensor operates to

turn on the warning lamp in the cluster to warn low brake

fluid level.

EMTBR5010A

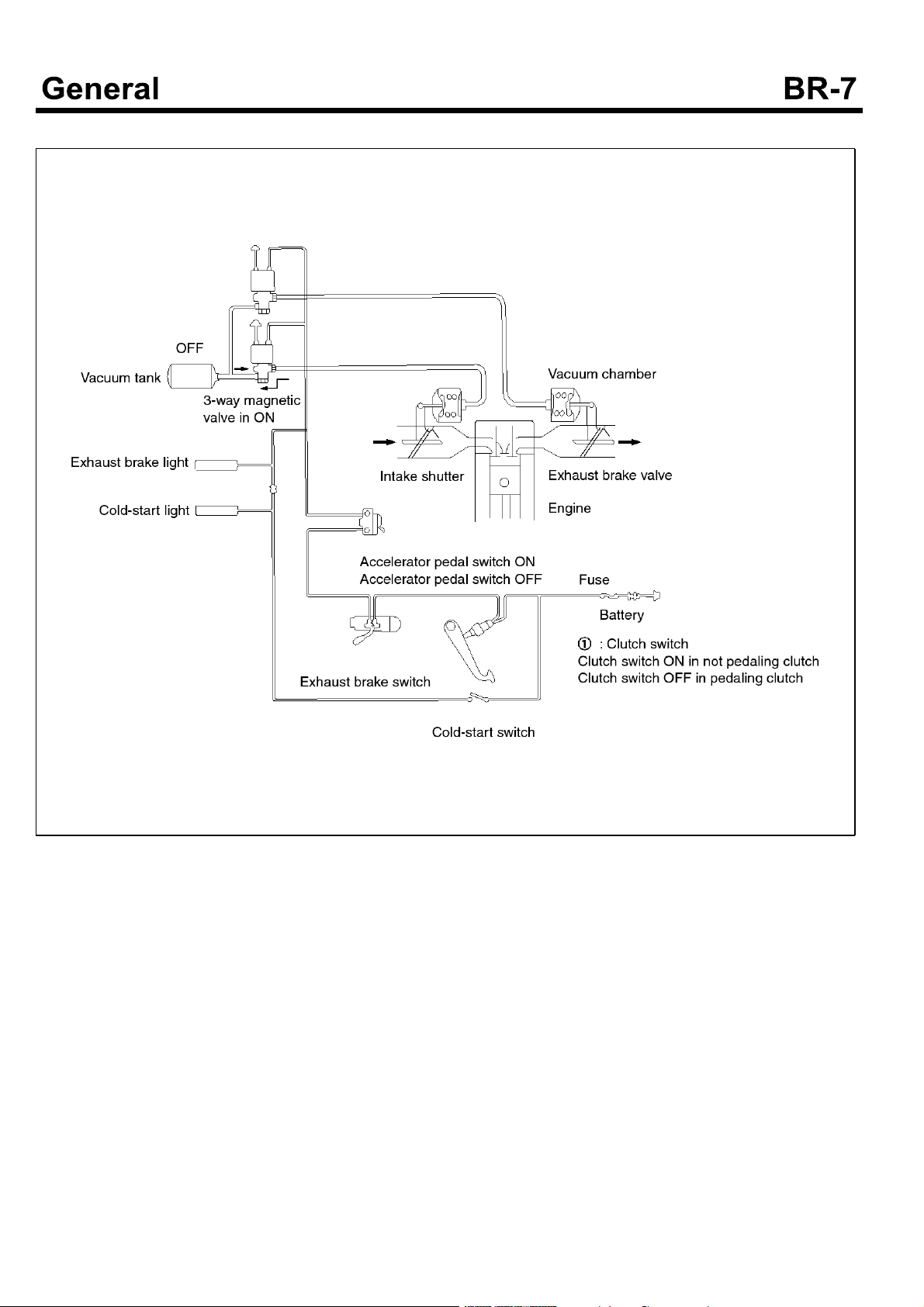

Exhaust Brake

The exhaust brake system, as an assistant function of

the service brake, comprises of the exhaust brake device

installed at the middle portion of the exhaust pipe and the

intake shutter installed at the intake manipulate to reduce

the intake air noise.

When the exhaust brake device close the butterfly valve,

the pressure inside of the pipe increases. This increased

pressure influences to the piston to get the braking force.

At that time, the intake shutter is also closed. When the

clutch pedal, the accelerator pedal or the exhaust brake

switch is released, the electric circuit is OFF and the

exhaust brake is released.

The exhaust brake is the vacuum type assistant device

which uses the negative pressure.

SUDBRA015L

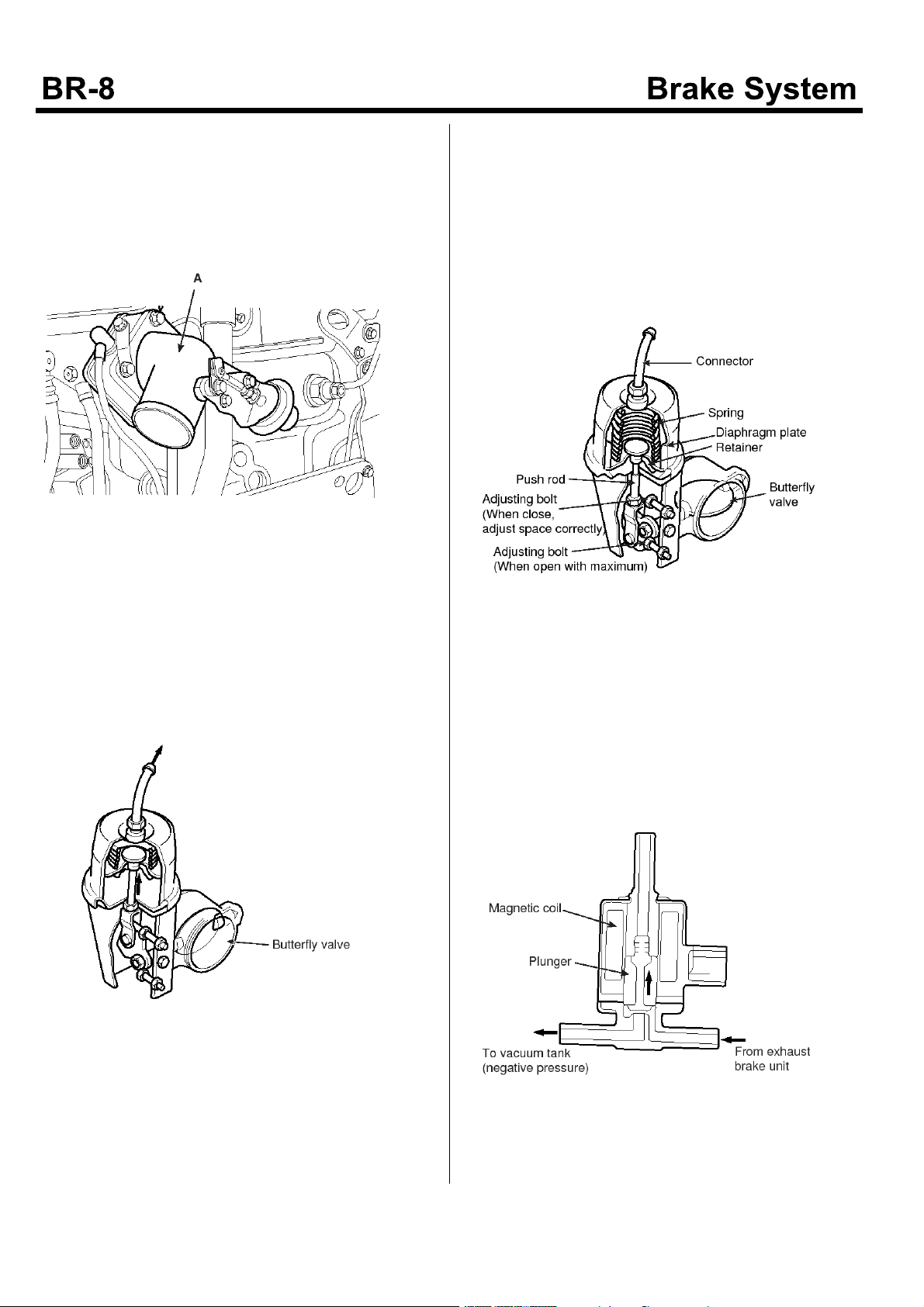

Intake Shutter

When the exhaust brake is operating, the intake

shutter(A) reduces the amount of the intake air through

the intake manipulate so as that the exhaust pressure is

operated to the piston effectively. As a result, the noise

will be reduced and the brake will be more effective.

KMTBR5513A

Exhaust Brake Unit

1. At Working

If the exhaust brake switch is ON, the three-way

magnetic valve is opened. The vacuum pressure of

the vacuum tank is applied to the exhaust brake unit

so as to pull the piston.

Asaresult,thebutterflyvalvelinkedtothepushrod

is closed so that the exhaust brake is working.

2. At releasing

If the exhaust brake switch, the clutch switch and the

accelerator switch are OFF, the 3-way magnetic

valve closes the circuit to the vacuum tank and opens

the atmosphere circuit.

Therefore, the atmospheric pressure is applied to the

exhaust brake unit. Due to the spring tension, the

butterfly valve is opened. The exhaust brake is

released.

EMTBR5013A

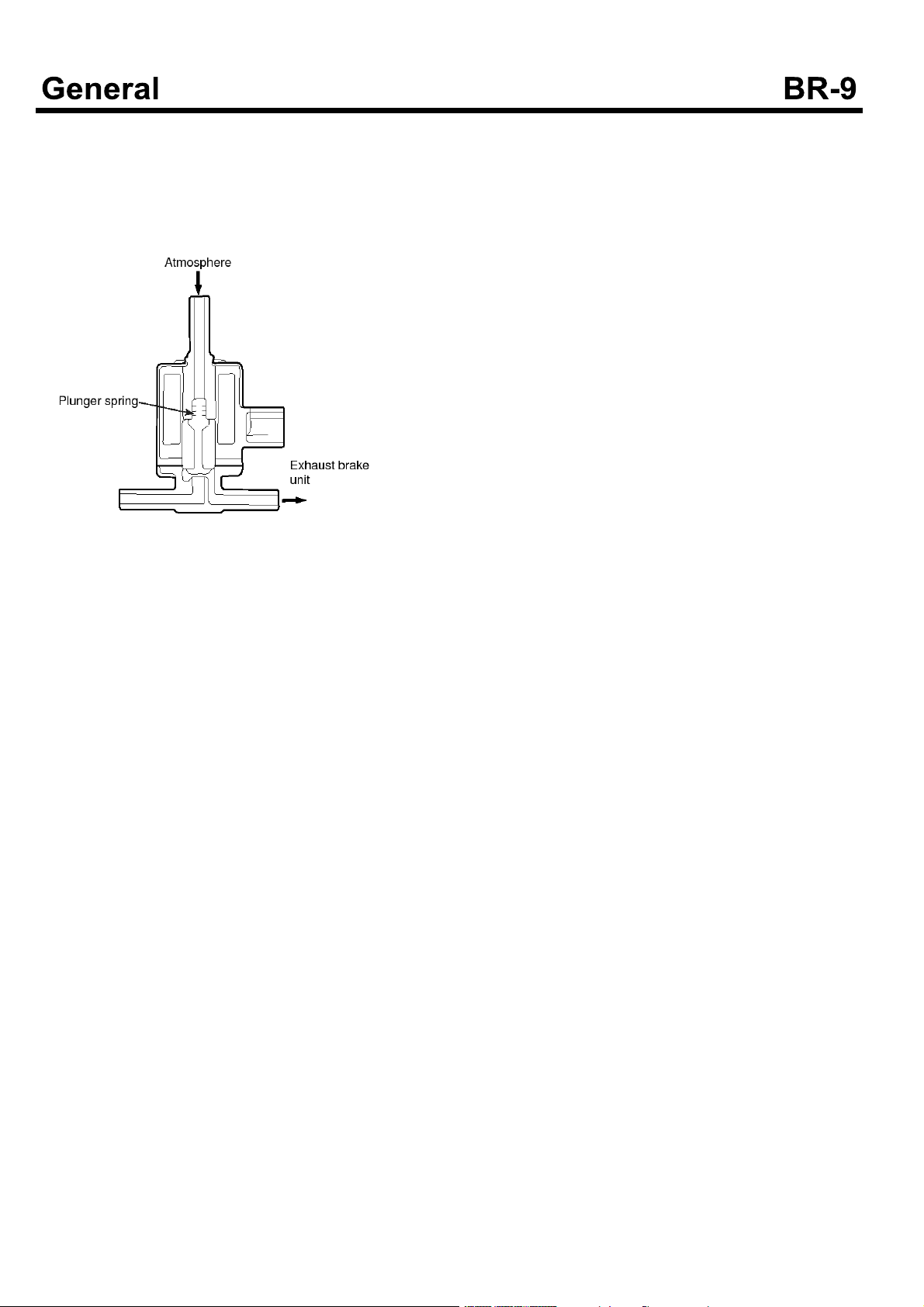

The 3-way Magnetic Valve

1. At working

If the exhaust brake switch is ON, an electric current

will flow through the coil and then a magnetic field is

formed. The magnetic force pulls the plunge to

upward. At that time, the valve seat at the plunger

closes the way to the atmosphere pressure while it

opens the way linking the vacuum tank and the brake

chamber.

EMTBR5012A

EMTBR5014A

2. At releasing

If the exhaust brake switch is OFF, the electric

current flowing through the coil is shut down. Due to

the spring tension, the plunger will be pushed so as

to close the way to vacuum tank while the way to the

atmosphere pressure and the brake chamber.

EMTBR5060A

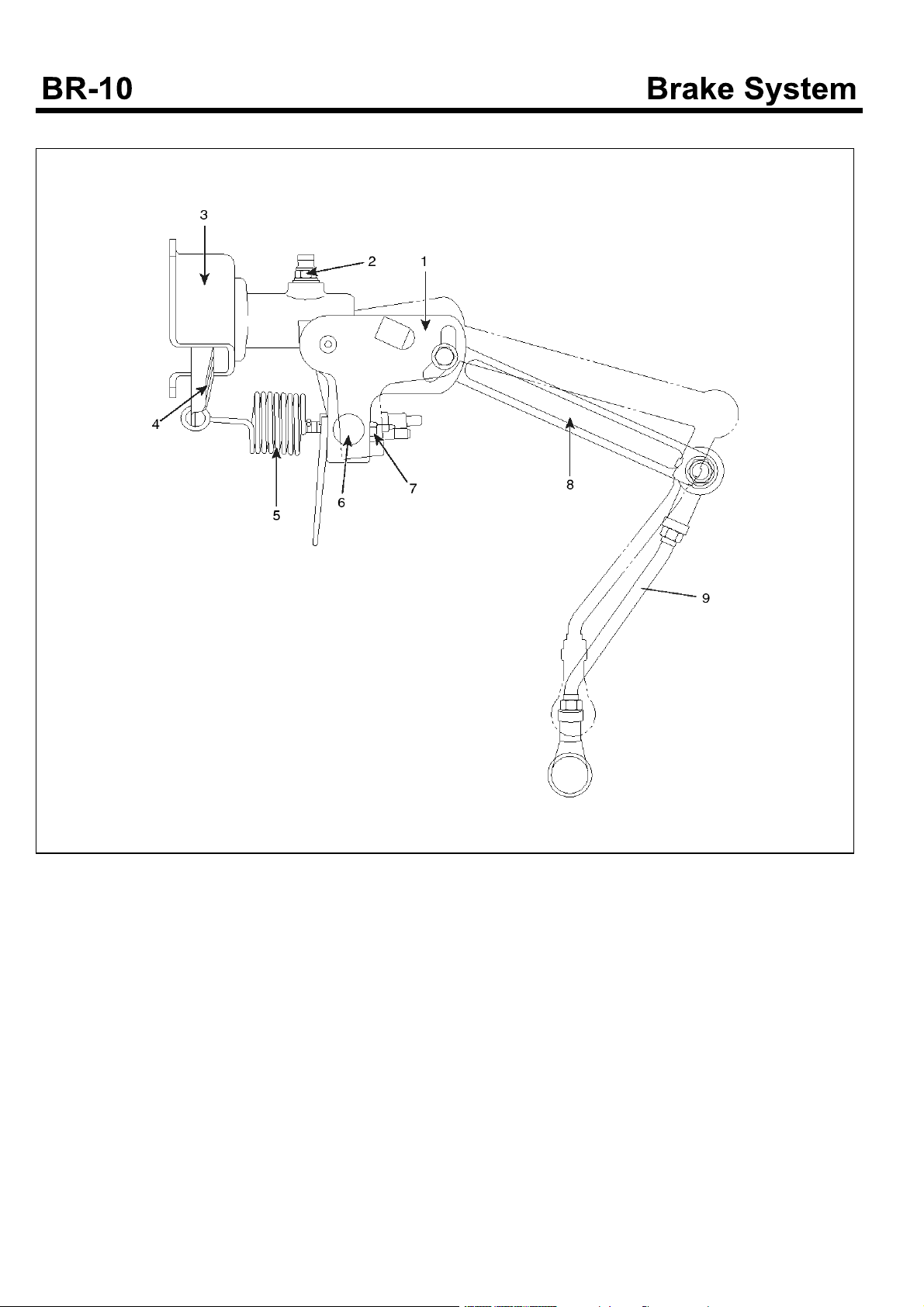

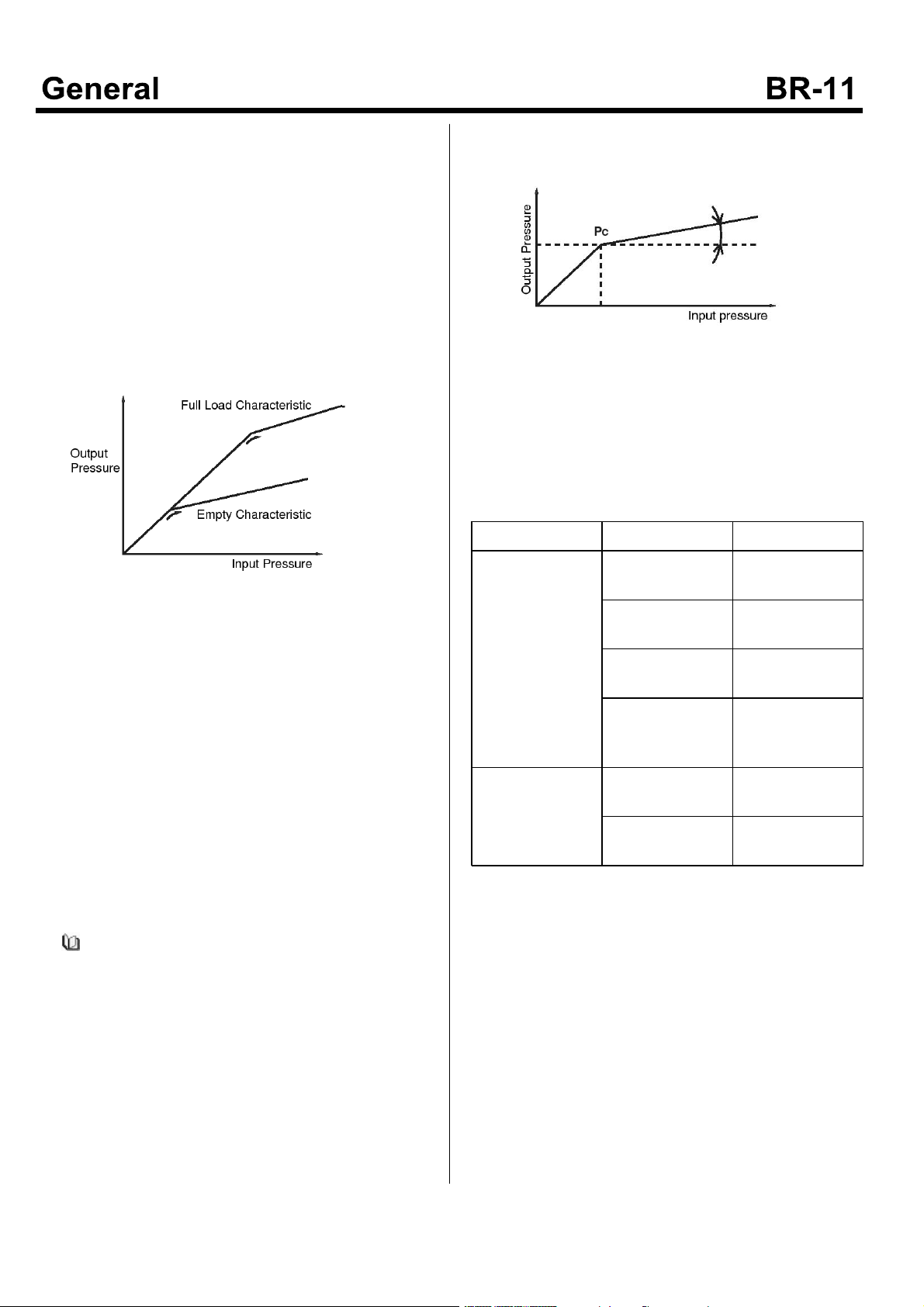

LOAD SENSING PROPORTIONING VALVE

1. LSPV assembly

2. Bleeder screw

3. Bracket

4. Lever assembly

5. Sensor spring

6. Spring guide

SUDBRA021L

7. Adjusting nut

8. Operating lever

9. Connecting link assembly

Construction

LSPV is consist of sensor part and pressure controller

part.

1. Sensor part

It consists of spring, operating lever, link. It senses

the height of vehicle with varying according to the

amount loads

2. Pressure controller part

It consists of valve stem mechanism for proportioning

control of sensor force.

SUDBR9036L

Service and Inspection of the LSPV

Check the LSPV as below when replace the sensor

spring, valve body assembly or reinstall the rear axle,

rear spring.

EMTBR5016A

Operating Principle

LSPV body is mounted in the frame and the end of the

link is mounted in the rear axle. With varying of amount

of vehicle load changes the relative position of frame and

rear axle, so sensor spring force varies to the valve stem.

It controls the rear axle brake fluid pressure.

1. Unloaded status

The sensor spring presses the valve stem slightly, so

the brake fluid pressure is set weakly.

2. Loaded status

The sensor spring presses the valve stem strongly,

sothebrakefluidpressureissethighly.

NOTICE

Don't loose or don't retighten the adjusting nut

crimping.

Symptom

Braking force is i nsufficient.

Rear brake is locktoofast.

Probable Cause Remedy

Insufficient air bl-

Air bleeding

eeding

Maladjusted sen-

Readjust

sor spring

Sensor spring broken

Oil leakage in the

brake fluid line or

LSPV assembly

Maladjusted sen-

Replace valve assembly

Tighten brake fluid line or replace

LSPV assembly

Readjust

sor spring

Inner fault the LSPV

Replace LSPV assembly

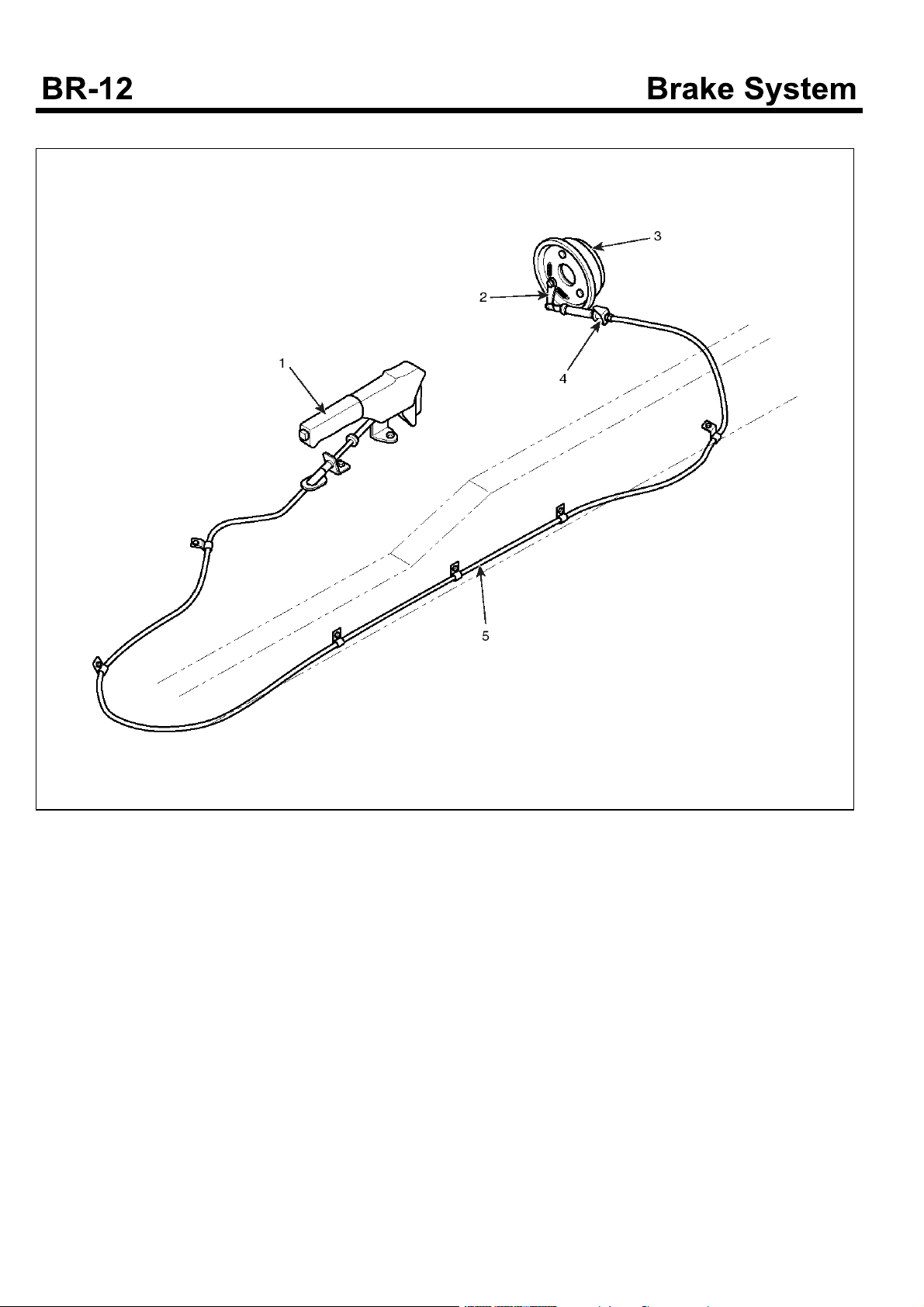

PARKING BRAKE GENERAL

1. Parking brake lever assembly

2. Cam lever

3. Parking brake drum

4. Adjusting nut

5. Parking brake cable

The parking brake installed behind the transmission is an

internal expansion type acting on the propeller shaft.

It controls propeller shaft rotation to work as a parking

brake.

The control is wire mechanical type; brake shoes are

pressedviaawiretocontrolthepropellershaft.

SUDBRA022L

Parking Brake Proper

When the lever at the driver's seat is pulled, the cam

lever is actuated via a wire cable and resultant cam

rotation causes the brake shoes to expand and be forced

against the brake drum. The braking force is thus

obtained by friction between the shoes and drum. When

the lever is released, the cam lever returns to the initial

position and the braking force is released by the brake

shoe return springs.

EMTBR5019A

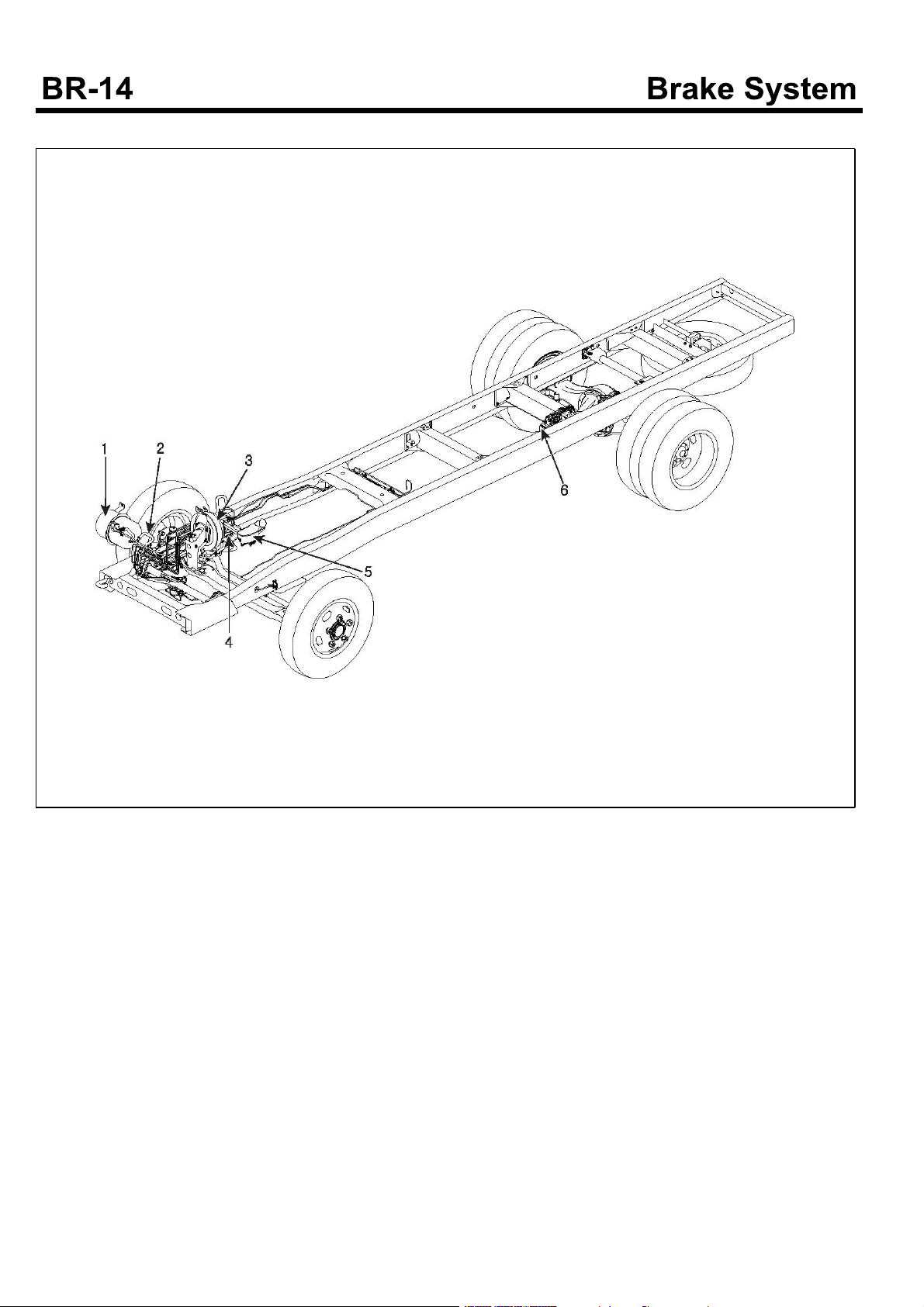

COMPONENTS(LHD)

1. Vacuum tank

2. Vacuum hose

3. Brake booster

4. Master cylinder

5. Reservoir tank

6. A.B.S modulator

SUDBRA001L

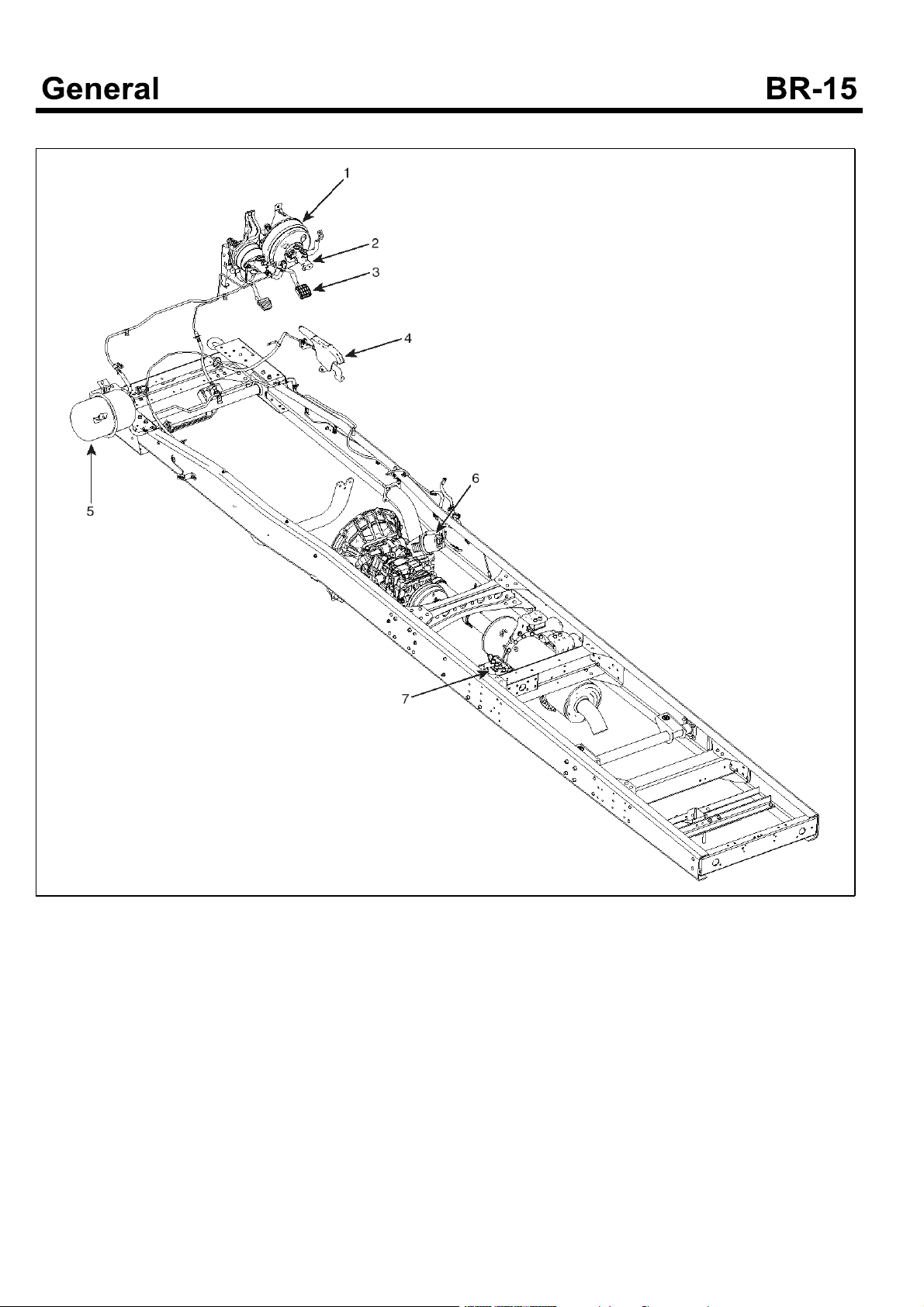

COMPONENTS(RHD)

1. Brake booster

2. Master cylinder

3. Brake pedal

4. Parking brake lever

5. Vacuum tank

6. Exhaust brake

7. ABS HECU(Hydraulic Electrical Control Unit)

SUDBRA002L

Diagnosis

Symptom Causes Remedy Remark

Irregular Braking

Force

After releasing the brake pedal,

the braking force

is release too late.

Unbalance at therightandleft

braking force

The air pressures of tire are different. Adjust the air pressure of tire.

The sizes of the right and left tires are different

.

The adjustment of the wheel bearing is defective.

The sizes of the right and left wheel bases are

different.

The wheel alignment is defective. Adjust

The vertical surface of the back plate is rough.

The operation of the wheel cylinder is defective.Check the contacting, the piston cup and

The return spring is damaged. Replace the spring.

The surface of the lining is contaminated by the oil, grease or water.

The lining is defective or The material of lining

is improper.

Replace the tire.

Adjust (Check the wheel bearing)

Check and adjust the loosening the U-bolt or damages on center bolt.

Replace the back plate or check the lining.

wearing status. If needed, replace it. Check the lining.

If it is contaminated by oil or grease, thenreplaceit.Ifitiscontaminatedbywater

,dryit.

Replace or adjust.

Unstable brakingforce

Improper Lock

Point

The wear is irregular. The surface is rough. Replace the lining. Check the inside of t-

he drum, if needed, replace it.

The lining contact is defective. Adjust the lining with being installed.

The brake drum is worn irregularly. Adjust or replace it.

The brake drum is deformed. Replace

The back plate is deformed or loosened. The

vertical surface of it is rough.

The drum is worn. Adjust or Replace Drum limit

The lining is worn irregularly. Adjust

The lining contact is defective. Adjust with being installed.

If it is loosened, tighten with specified torque. Otherwise, replace it.

STD

:Dia+2mm

(Temperature of lining should be less than 100°C)

Symptom Causes Remedy Remark

Low Braking Force

The clearance between the pedal and the floor is too narrow.

The clearance between the brake pedal and floor is 45mm or more. (at Pressure-600mmHg,

Pressure 50kg)

Refer to the item for decreasing the clearance between the brake pedal and floor.

The lining contact is defective. Adjust with being installed not being dis-

assembled. (Temperature should be 100

°

Corless)

The surface of the lining is contaminated by the oil, grease or water.

The lining is deteriorated.

If it is contaminated by oil or grease, thenreplaceit.Ifitiscontaminatedbywater

,dryit.

The vacuum force is too low. Replace the lining.

The drum surface is rough. Check the pipe or the vacuum pump. If

needed, replace.

The brake booster is defective. Adjust or Replace

The brake oil level is too low. Adjust or Replace

The air intrudes. Refill

Vapor lock Air Exhausting

The adjustment on pedal is defective.

The clearance is too large.

Referring to the brake drawn item, adjust

or replace. And then exhaust the air.

During braking,

the noise and shock are made

abnormally.

The shoe clearance is too large.

Adjust the pedal clearance. Check the total stroke.

The cup of the master cylinder is defective. Adjust the shoe clearance.

If the wear exceeds the limit, replace.

The brake shoe is deformed or damaged. If the tightening does not satisfy the spe-

cifications, replace the kit.

The brake booster is defective. Replace

When the wheel is rotating with being lifted by

jack, there are some noises.

During braking (at low

speed), noise is made

continually.

Foreign materials in drum

Return spring is damaged.

Hold down cup is damaged.

The grease is deficiency in sliding parts.

Improper adjustment

on wheel bearing

Replace

Check that the brake is damaged. Remove the foreign materials.

Check that the parts are damaged by broken parts. If needed, replace.

Check that the parts are damaged by broken parts. If needed, replace.

Check the rotating surface. Adjust

The lining is worn. Replace

The drum inside surface is rough. Apply the grease.

Modify the inner surface with sand paper

The drum is cracked.

.

Replace

Symptom Causes Remedy Remark

The drum is overheated.

The outlet of the brake master cylinder is clogged.

If the booster operating rod is not properly adjusted, adjust the pedal clearance of

the rod clevis to 10~15mm.

The brake does not return. Check the burst of the return spring, the

bearing lubricant, the stop lamp switch adjustment. If needed, adjust.

The booster is defective. Replace

The vertical surface of the back plate is scratched.

If the surface is too rough, replace.

If it is too dry, apply the grease.

The wheel cylinder piston cup is defective. Replace

The oil return has problems due to the over tight of the brake pipe nut.

When the wheel is rotating with being lifted

by jack, the wheel is hardtorotate.

The wheel bearing clearance is too large.

Shoe clearance is improper.

Return spring is defective.

Check the connector hole diameter. If it

is reduced, replace.

Replace bearing or adjust.

Adjust

Check the part damages due to the spring over working. If needed replace.

Brake shoe is worn. Replace

Specific

wheel is overheated.

The pedal returning is defective.

The pedal linkage is rusted or deformed.

It is bursting due to the defectives on the pedal

return spring.

The booster operating rod is pushed.

Disassemble. Adjust or replace. Oil the

grease.

Replace

Adjust the pedal clearance with 10~15

mm.

Brake is vibratin-g.The drum is eccentrically centered. Replace

The drum is deformed. Replace

The king pin bushing is worn. Replace the bushing

The hub bearing is worn.

Adjust (Check the rolling surface) or repl ace.

Brake is drawn. The pedal clearance is too narrow. Adjust the booster working rod.

The shoe clearance is improper. Adjust

The back plate vertical surface is rough. Replace the back plate.

Theshoespringisburst. Replace

The master cylinder or wheel cylinder piston cup is deteriorated and swelled.

Replace

Symptom Causes Remedy Remark

Brake makes noises.

Exhaust brake

does not work.

Brake shoe contacting is defective. Adjust the lining with being installed not

being disassembled (Temperature should be 100°Corless)

Lining is deformed. Replace the lining. Replace the drum if it

has hardened surface.

Drum has hardened surface. Replace.

Shoe is deformed. Replace.

Back plate is deformed or installed improperly. Replace or adjust

Front bearing is loosened. Adjust (Check the rolling surface)

Powder from the wear of the lining is adhered. Clear

Lining is worn. Replace.

Vacuum pressure is improper.

Check the vacuum pump or piping. If needed repair.

Electric circuit is defective. Check the clutch switch, the micro switch

and the exhaust brake circuit. If needed,

repair.

Vacuum pipe is damaged. Replace.

3-way magnetic valve does not work. Replace.

Exhaust brake can not be released.

Exhaust brake valve does not work. Replace.

Exhaust brake valve shaft is adhered. Replace.

Power chamber is defective. Disassemble and check.

3-way magnetic valve does not work. Replace.

Exhaust brake valve does not work. Replace.

Exhaust brake valve shaft is adhered. Replace.

Electric circuit is defective. Check the clutch switch, the micro switch

and the exhaust brake circuit. If needed,

repair.

Diagnosis (Parking brake)

Symptom Causes Remedy Remark

Parking brake does not work.

Parking brake can not be released.

Operating

mechanismhasaproblem.

Parking brake is defective.

Operating

mechanismhasaproblem.

When pulling the parking brake with 30kg, there is no lever stroke clearance and shoe clearance.

The locking status between the lever lock latch and Ratchet pull is improper.

Wire is broken or elongated. Replace the cable.

Tolerance between the shoe clearance and the brake lever pulling is

too large.

Drum inner surface is deformed or

twisted.

Lining is irregularly worn. Drum inner surface is contacted irregularly

.

The oil of drum and lining is contaminated.

Return spring is damaged. The tension of the return spring is inferior

.

The inner cable does not move smoothly.

Adjust the shoe clearance and cable.

Adjust the Ratchet pull lock status. Replace it

Adjust the shoe clearance.

Repair the drum inner surface. Replace

the lining.

Replace the lining.

Clear the inner surface of the drum. Replace the lining.

Replace the return spring.

Replace the cable.

After the parking brake is released

, the brake is operating.

Parking brake is defective.

Return spring is damaged. The tension of the return spring is inferior

.

The shoe clearance is too narrow.

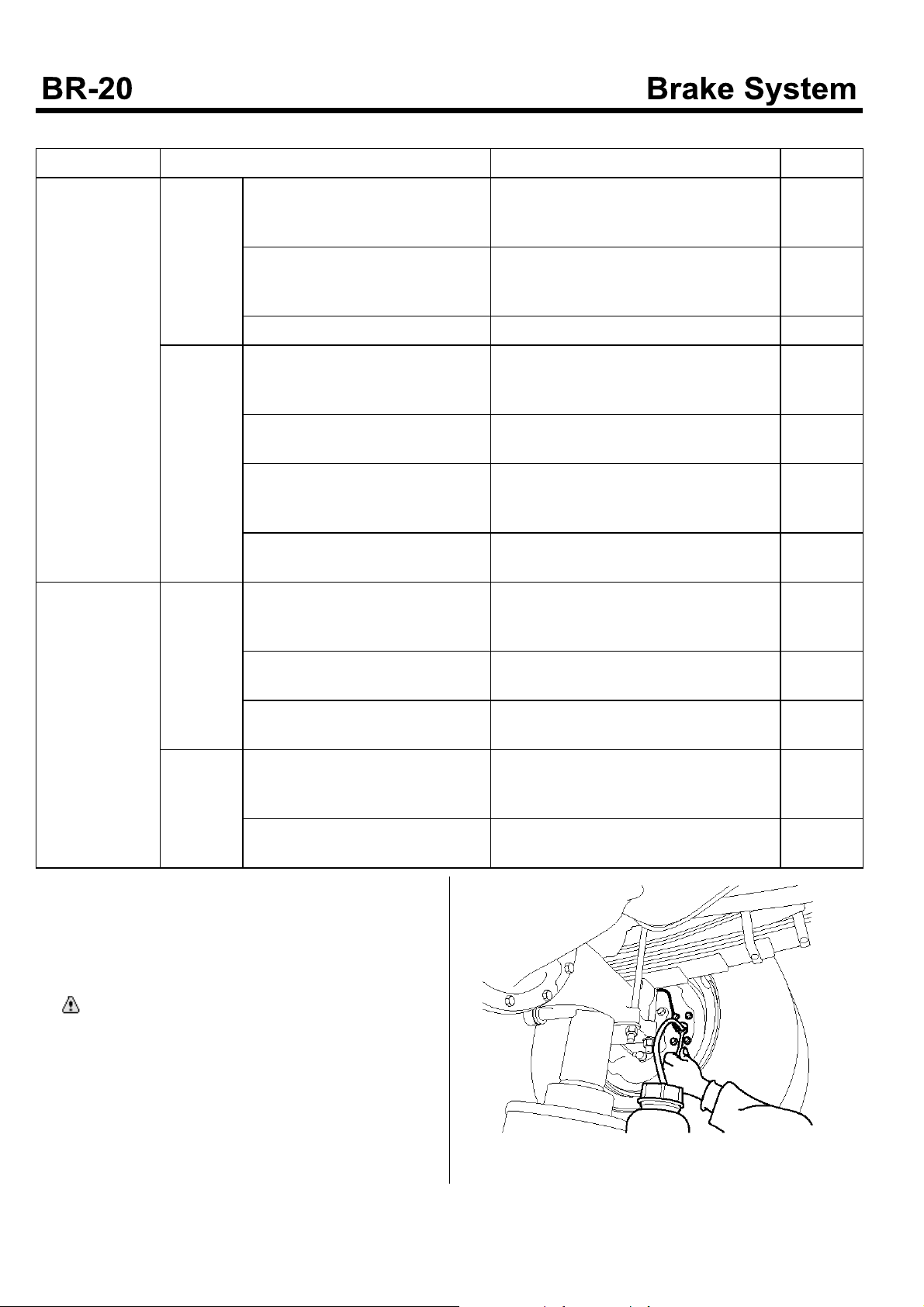

On-Vehicle Inspection and Adjustment

Air bleeding of the Brake

1. Fill up the brake oil tank with the brake oil at the

maximum level. During the air bleeding, if the level is

lowered, refill the brake oil.

CAUTION

Be careful that the brake oil does not drop on the

painted surface. If the brake oil contacts the

painted surface, immediately wash it by water.

2. Connecting an end of transparent vinyl tubes at the

air breather of the front wheel cylinder and the rear

wheel cylinder, put the other end of the tubes into the

transparent container having the brake oil.

Adjust the pulling tolerance limit.

Replace the return spring.

Adjust the shoe clearance.

KMTBR5518A

3. Step on the brake pedal several times. Pressing the

brake pedal at half, loosen the air bleeder screw to

evacuate the air with the brake oil.

And then, pressing the pedal until it reaches to the

floor, tighten the air bleeder screw. Release the

pedal. There procedures should be repeated until any

air bubble is not shown in the brake oil.

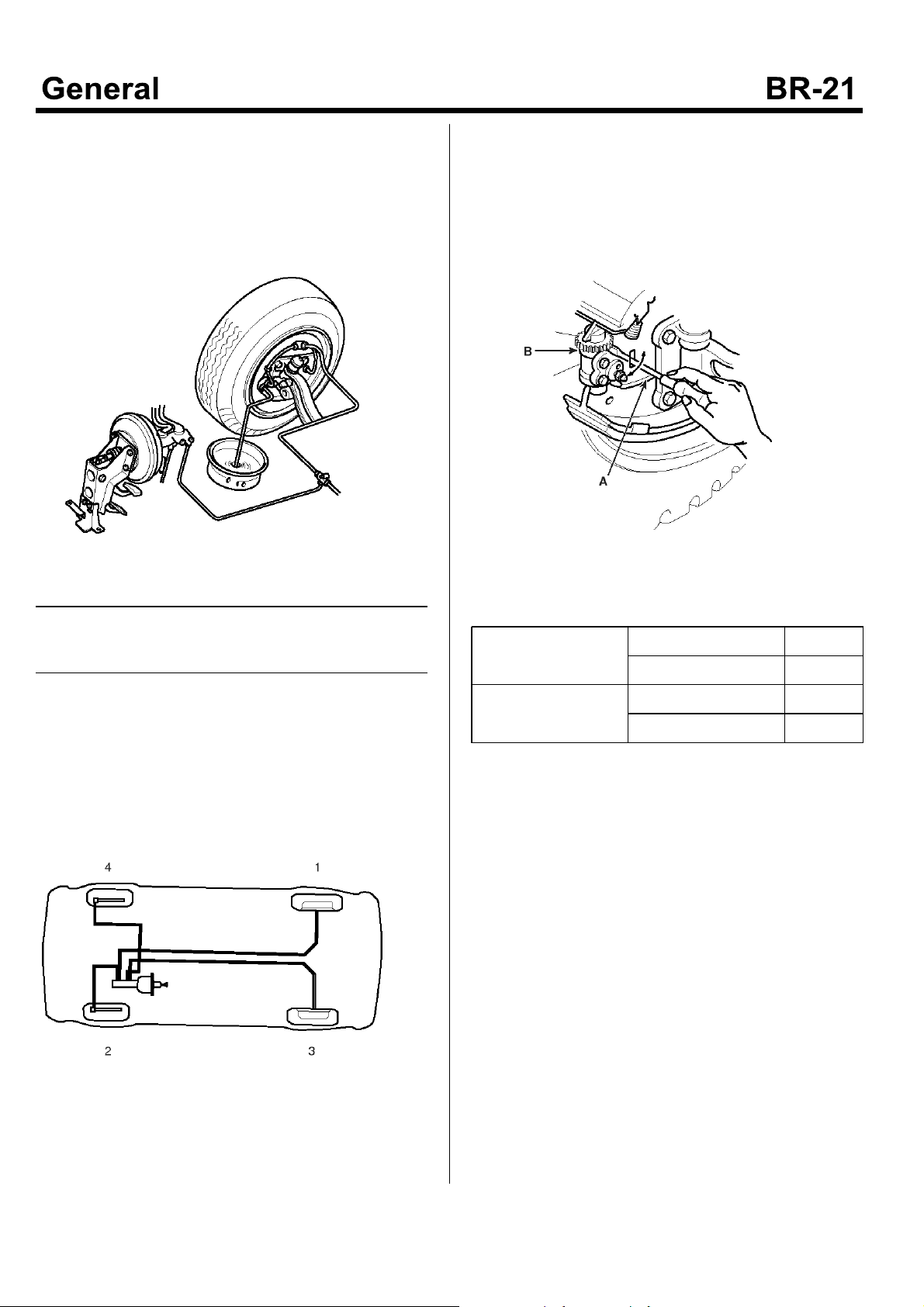

Adjustment of Brake Shoe Gap

1. Using the screw driver(A), turn the wheel cylinder

adjuster(B) to the shoe expansion direction until the

drum is not rotate anymore. Turn the adjuster

reversely with the following notch number. (At that

time, the drag torque between the lining and the drum

should be less than 50kgf.m).

KMTBR5519A

4. Tighten the bleeder screw

Tightening Torque for the bleeder Screw

Front: 6.9~8.8Nm(0.7~0.9kgf.m, 5.1~6.5lb-ft)

Rear : 6.9~8.8Nm(0.7~0.9kgf.m, 5.1~6.5lb-ft)

5. Step on the brake pedal several times. Pressing the

brake pedal at half, loosen the air breather screw to

evacuate the air with the brake oil.

And then, pressing the pedal until it reaches to the

floor, tighten the air breather screw. Release the

pedal. There procedures should be repeated until any

air bubble is not shown in the brake oil.

KMTBR5521A

The Notch Number for reverse rotation of the

Adjuster.

Front Wheel Cylinder

Auto adjuster type 9~11

Manual adjuster type 4~6

Rear Wheel Cylinder Auto adjuster type 9~11

Manual adjuster type 4~6

KMTBR5520A

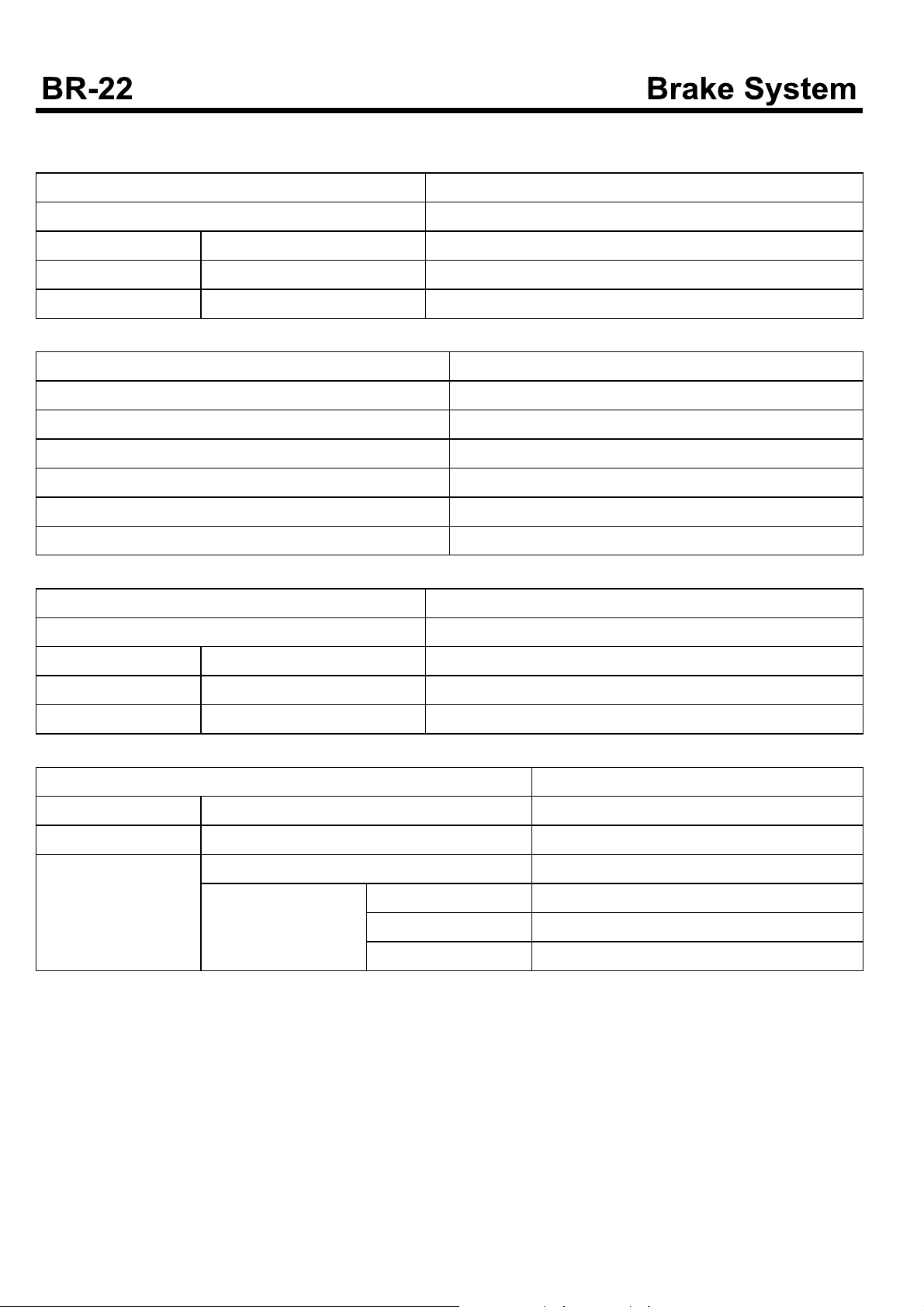

Specifications

Front Wheel Brake (Drum Type)

Item Specifications

Brake type 2-leading Brake

Wheel cylinder Inner diameter 31.75mm

Brake drum Inner diameter 320mm

Brake lining Width x Thickness (mm) 85 x 10(Standard), 110 x 11(Option in case of HD72,78)

Front wheel Brake (Disk Type)

Item Specifications

Cylinder diameter Ø76mm

Effective radius 118 mm

Disk outer diameter Ø304mm

Disk inner diameter Ø164mm

Pad thickness 12.5 mm

Padeffectivethickness 10.5 mm

Rear Wheel Brake

Item Specifications

Brake type 2-leading Brake

Wheel cylinder Inner diameter 28.57mm

Brake drum Inner diameter 320mm

Brake lining Width x Thickness (mm) 85 x 10(Standard), 110 x 11(Option in case of HD72,78)

Brake system

Item Specification

Brake Pedal Total Stroke 140 mm

Booster Total Stroke 31 mm

Master Cylinder Inner Diameter Ø 31.75 mm, Ø 30.15 mm

Stroke Piston 31±1mm

Primary 17±0.5 mm

Secondary 14±0.5 mm

Exhaust Brake

Item Specification

Control System Combination of Electric and Vacuum Type

Exhaust Brake Valve Type Butterfly Valve

Exhaust Brake Chamber

Diaphragm Effective Diameter 76.2mm

With Installing

N(kg)

Spring Tension 90~110 (9.18~11.22)

Rod Tensile Force 142.1(14.5): Vacuum Pressure-400mmHg

Spring Tension 125~153 (12.78~15.62)

Rod Tensile Force 103(10.5) Vacuum Pressure-400mmHg

Parking brake

Item Specification

Type Internalexpansiontypeactingonpropellershaft

Control Mechanical cable

Parking lever Normal stroke 8~9clicks(20kgf)

Parking brake size Drum i.d. x Lining width x Li-

ning thickness

180 x 35 x 5 (T/M : M2S5, M3S5)

190 x 45 x 4 (T/M : M035S5)

230 x 55 x 4 (T/M : T60S5, T60S6)

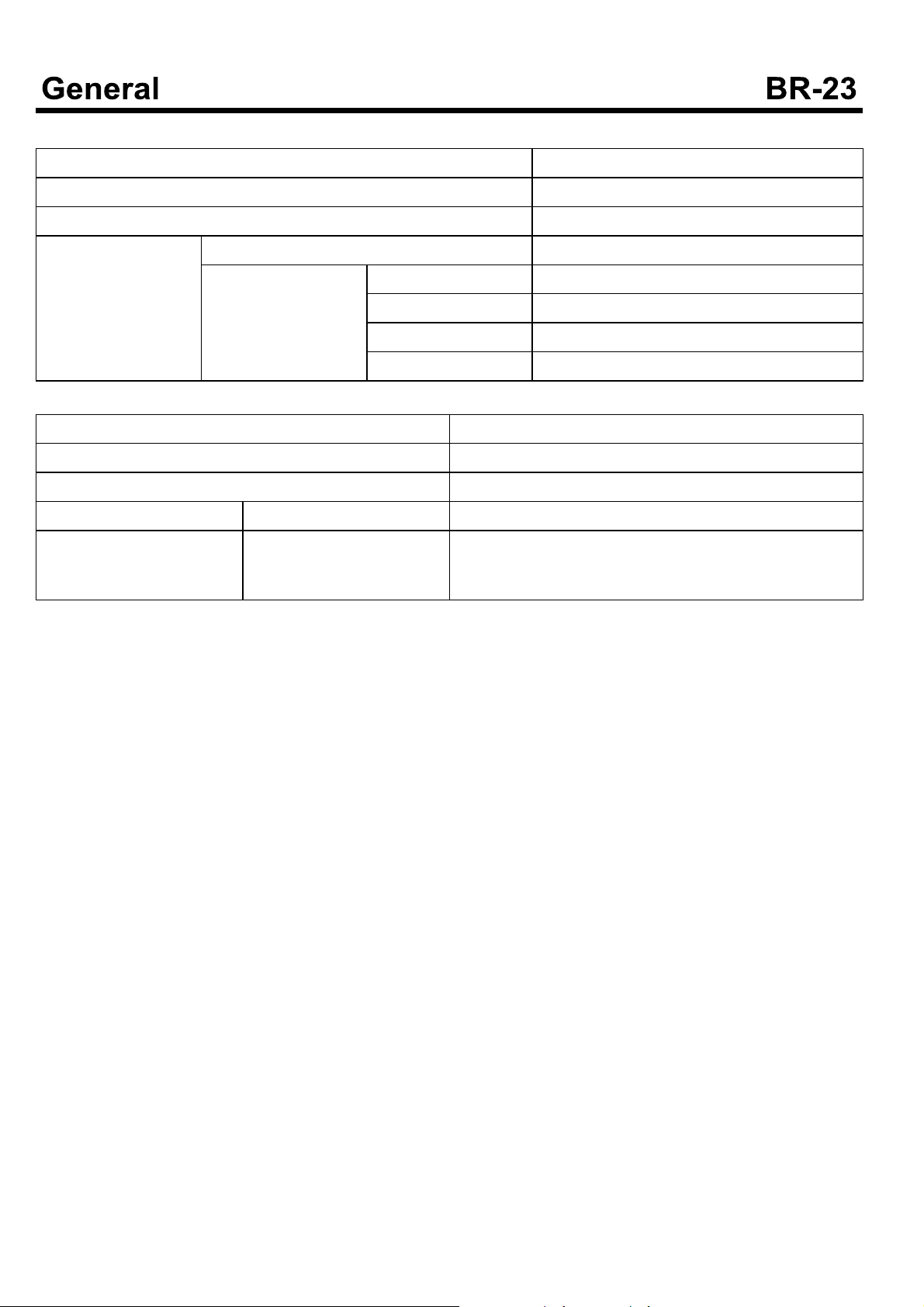

SERVICE STANDARDS

Brake

pedal

Brake

master

cylinder

Front

drum brake

Rear wheel brake

Description

Bushing to collar clearance [16]0.02 to 0.26 0.5 Replace bushing

Brake pedal play 3-8 Adjust

Stop lamp switch installation clearance 0to1 Replace

Primary and secondary piston to cylinder body clearance 0.038~0.145 0.2 Replace

Primary retainer assembly Free length 38.1 Replace

Secondary spring deterioratio-nFree length 37.7 Replace

Brake drum I.D. 320 322 Replace

Brake lining Thickness 10 4 Replace

Return spring 30±3/227 19/227 Replace

Wheel cylinder body to piston clearance [31.75]0.03 to 0.13 0.2 Replace

Brake shoe clearance(No. of notches returned of wheel cylinder adjuster)

Brake drum I.D. 320 322 Replace

Brake lining Thickness 10 4 Replace

Return spring Load N(kgf)/installed length 30±3/227 19/227 Replace

Nominal value, mm

(Basic diameter in [ ])

Auto 9~11 Adjust

Manual 4~6

Limit

(mm)

Correction and

remarks

Wheel cylinder Body to piston clearance 0.02-0.11 0.2 Replace

Brake drum Out of roundness 0.05 - Replace

Brake shoe clearance (number of return notches of wheel

cylinder adjuster)

Auto 9~11 Adjust

Manual 4~6

Description

Nominal value, mm

(Basic diameter in [ ])

Limit

(mm)

Correction and

remarks

Exhaust brake

Power chamber air tightness [15 seconds after application of -67 kPa (-500 mmHg) negative pressure]

Valve to body clearance when butterfly valve is fully closed [at power chamber vacuum -87 to -93 kPa(-650 to -70

0 mmHg)

3-way magnet

valve

Air tightness When -100 kPa (-750 m-

mHg) negative pressure is

applied from vacuum tank side to operate valve with exhaust brake unit side

plugged tightly

When 98 kPa (1 kgf/cm²

air pressure is applied fromatmospheresidetooperate valve with exhaust

brake unit side plugged tightly

Minimum operating voltage

When -100 kPa(-75

0 mmHg) negative

pressure is applied

24V

type

unit

to vacuum tank side

-63 kPa (-475 mmHg) or

Replace

more

0.1 to 0.4mm Replace

Noairtobesuckedinf-

Replace

rom atmosphere side

No air to leak from vacu-

Replace

um tank side

22V or less Replace

When 98 kPa (1 kgf

/cm² air pressure is

applied from atmosphere side with exhaust brake unit side

plugged tightly

24V

22V or less Replace

type

unit

SERVICE STANDARDS (Parking brake)

Description Nominalvalue,mm

(Basic diameter in [ ])

Brake drum I.D. 180 181 Correct to limit,

190 192

230 232

Squareness 0.05 or less Correct or repla-

Concentricity 0.1 or less

Cylindricity 0.1 or less

Static rotation imbalance 0.49 N.cm(50 gf.cm) or l-

ess

Brake lining thickness Model with M2S5 T/M 10~11 4.0 Replace

Brake shoe clearance Model with M2S5 T/M 0.25 to 0.35 Adjust

Brake shoe return spring

Shoe hold down spring

Free length Model with M2S5 T/M 98 -

Load N (kgf)/installed length

Spring A(longer one of free length)

Model with M2S5 T/M 67 to 86 (6.8 to 8.8)/104 104.364

Free length 34.1 Replace

Load N (kgf)/installed length

59 to 69 (6.0 to 7.0)/13.7 59 (6.0)/13.7

Limit

(mm)

(6.5)/104

Correction and

remarks

replace when limit is reached.

ce

Replace

Spring B(shorter one of free length)

Free length 23.6

Load N (kgf)/installed length

59 to 69 (6.0 to 7.0)/10.5 59 (6.0)/10.5

Tightening torque table

Description Tightening torque

Nm Kgf.m Lb-ft

Mounting nut between the master cylinder and booster 17.7~24.5 1.8~2.5 13~18.1

Master cylinder set bolt 12~16 1.2~1.6 8.7~11.6

Brake booster mounting nut 12.7~15.7 1.3~1.6 9.4~11.8

Brake booster clevis lock nut 15.7~21.6 1.6~2.2 11.6~15.9

Master cylinder outlet port nut 12.7~16.8 1.3~1.7 9.4~12.3

LSPV connecting link mounting bolt 22~33 2.2~3.3 15.9~23.9

LSPV flange bolt mounting bolt 22~33 2.2~3.3 15.9~23.9

Front drum brake air bleeding port 6.9~12.7 0.7~1.3 5.1~9.4

Front spindle mounting bolt 98~137 10~14 72~101

Brake hose to union mounting bolt(Front drum brake) 24.5~29.4 2.5~3 18.1~21.7

Exhaust brake to exhaust pipe mounting bolt 44.1~58.8 4.5~6 32.5~43.4

Vacuum Assisted Hydraulic Brake

Brake Pedal

Component

1. Clevis pin

2. Hose connector

3. Grommet

4. Master cylinder

SUDBRA003L

5. Booster

6. Pedal assembly

7. Return spring

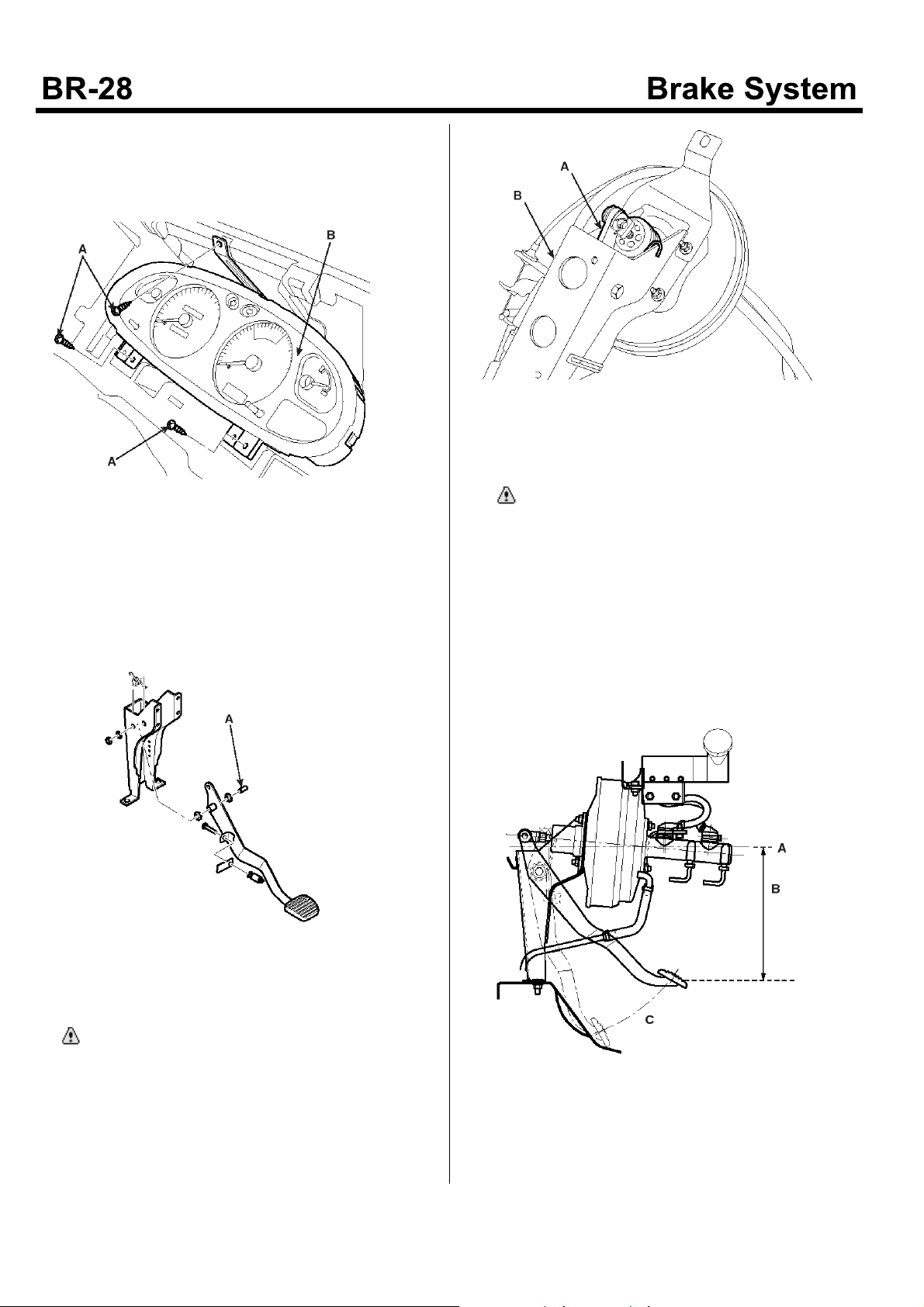

Removal

1. Loosen the steering column assembly mounting bolt.

Pull down the steering column.

2. Loosen the bolt(A), Remove the instrument panel(B).

KMTBR5527A

2. Install the brake light switch.

3. Install the booster and the master cylinder.

KMTBR5003A

3. Remove the master cylinder (Refer to the BR-"Master

cylinder")

4. Remove the brake booster (Refer to the

BR-"Booster")

5. Remove the brake light switch.

6. Remove the shaft bolt(A) connected to the bracket.

CAUTION

Apply the grease on the clevis pin and the

washer

Adjustment

Adjust the height of the brake pedal

1. Turn the booster operating rod so that the distance

from the center of the brake pedal pad to the A point

of the instrument panel lower portion is the 'B'. After

adjusting, fix the clevis with the nut. Check that the

maximum stroke of the pedal is more than 'C' (before

filling the brake oil)

KMTBR5040A

Installation

1. Install the brake pedal assembly(A) to the bracket(B).

CAUTION

Before the assembling, apply the grease inside

of the brake pedal assembly pipe.

SUDBRA004L

Engine B(mm) C(mm)

Non A-BSD4DD, D4GA 280±2 140±4

The others 273±3 140±4

ABS D4DD, D4GA 280±2 140±4

The others 273±2 140±4

Free play clearance of the Brake pedal

1. Setting the brake pedal to the original position, check

if the free play(B) clearance is 5mm at least by

pressing the pedal(A).

If the clearance excesses the reference, re-adjust the

position of the brake pedal.

CAUTION

When checking the free play clearance of the

brake pedal, the master back negative pressure

should be 0.

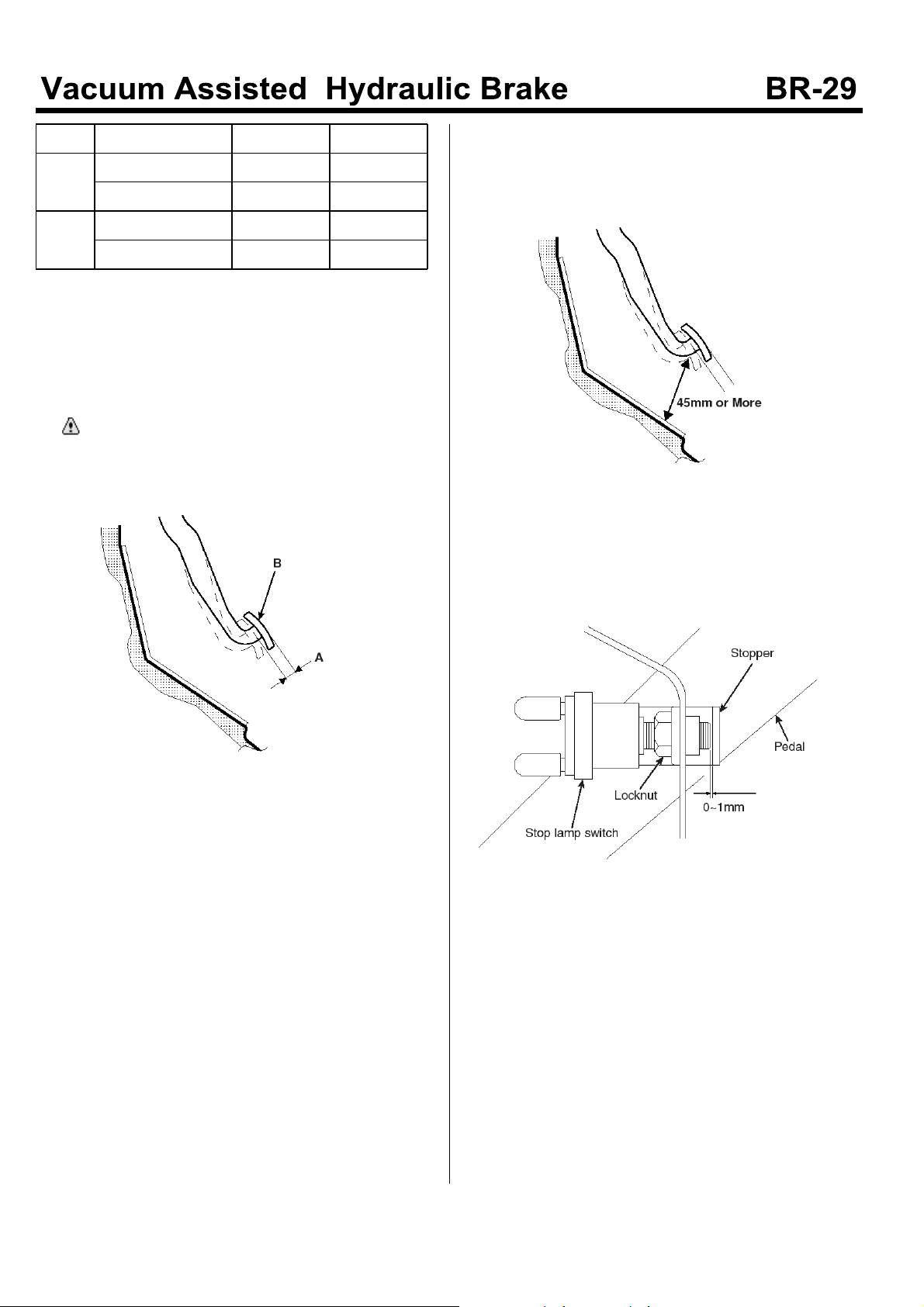

Gap between the brake pedal and the floor.

1. After cranking the engine, check if the gap between

the floor and the pedal is more than 45mm by

pressing the pedal with 50kg.

EMTBR5023A

Stop Lamp Switch

1. Adjusting the gap between the end of the brake. Stop

lamp switch screw and the pedal stopper to 0~1mm,

tighten the locknut.

KMTBR5005A

SUDBR9014L

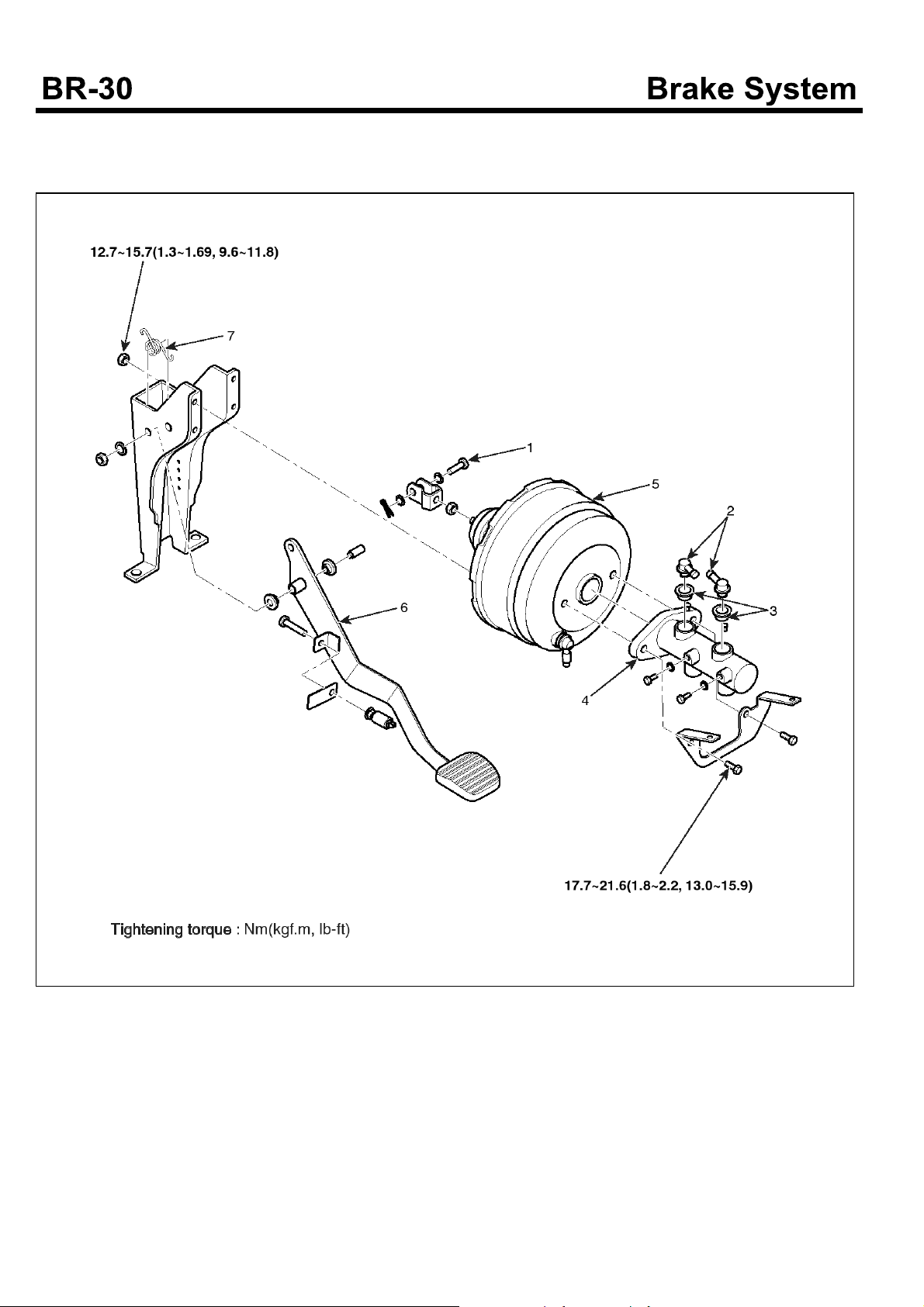

Brake Booster

Components

1. Clevis pin

2. Hose connector

3. Grommet

4. Master cylinder

SUDBRA005L

5. Booster

6. Pedal assembly

7. Return spring

Loading...

Loading...