Page 1

GB

Operator’s manual

Please read the operator’s manual carefully and make sure you understand the instructions before using the machine.

ES

DE

FR

Manual de instrucciones

Lea detenidamente el manual de instrucciones y asegúrese de entender su contenido antes de utilizar la máquina.

WS 482 HF

Bedienungsanweisung

Lesen Sie die Bedienungsanweisung sorgfältig durch und machen Sie sich mit dem Inhalt vertraut, bevor Sie das Gerät benutzen.

Manuel d’utilisation

Lire attentivement et bien assimiler le manuel d’utilisation avant d’utiliser la machine.

GGGGBBBB EEEESSSS DDDDEEEE FFFFRR

RR

Page 2

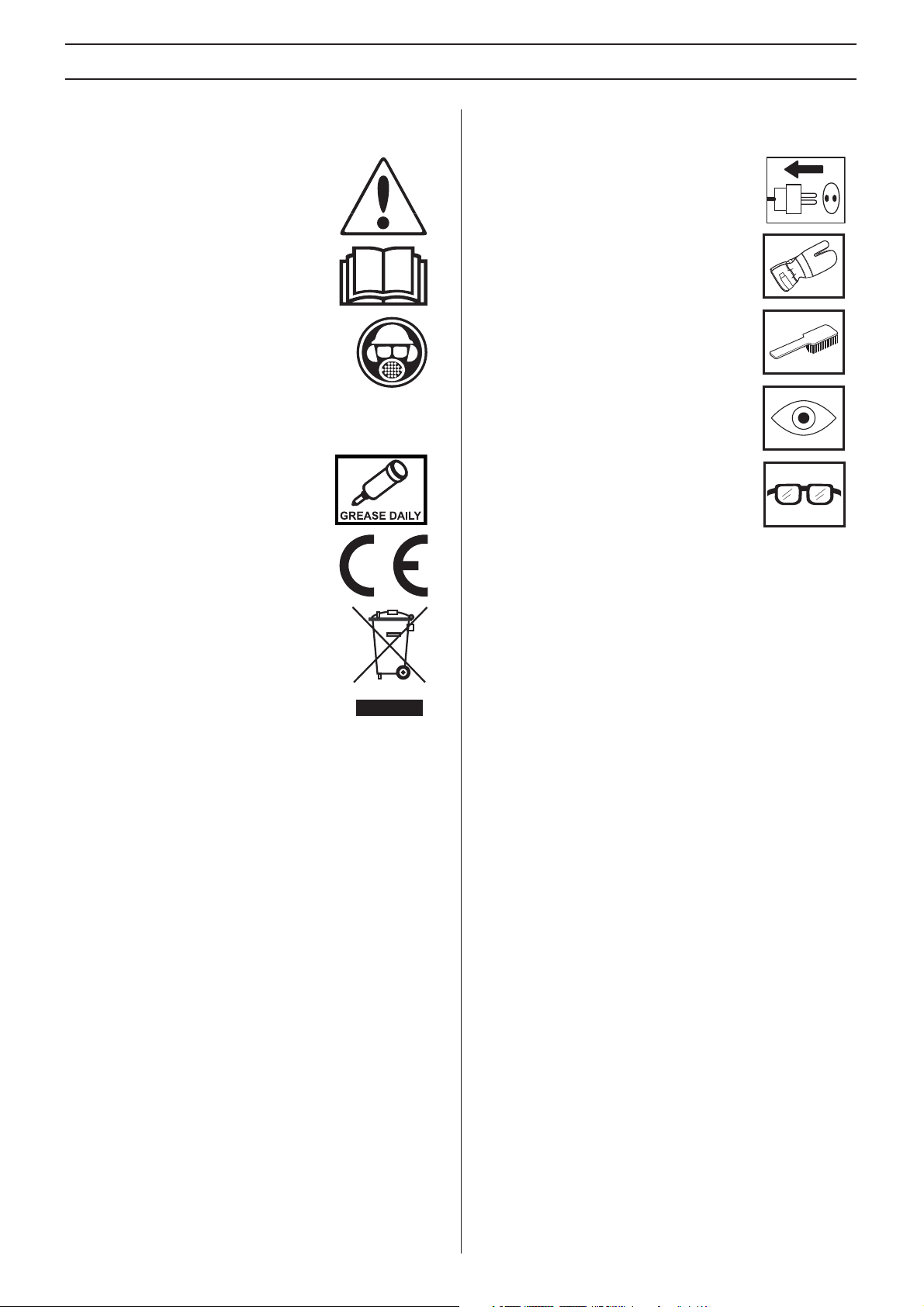

KEY TO SYMBOLS

Symbols on the machine:

WARNING! The machine can be a

dangerous tool if used incorrectly or

carelessly, which can cause serious or

fatal injury to the operator or others.

Please read the operator’s manual

carefully and make sure you understand

the instructions before using the machine.

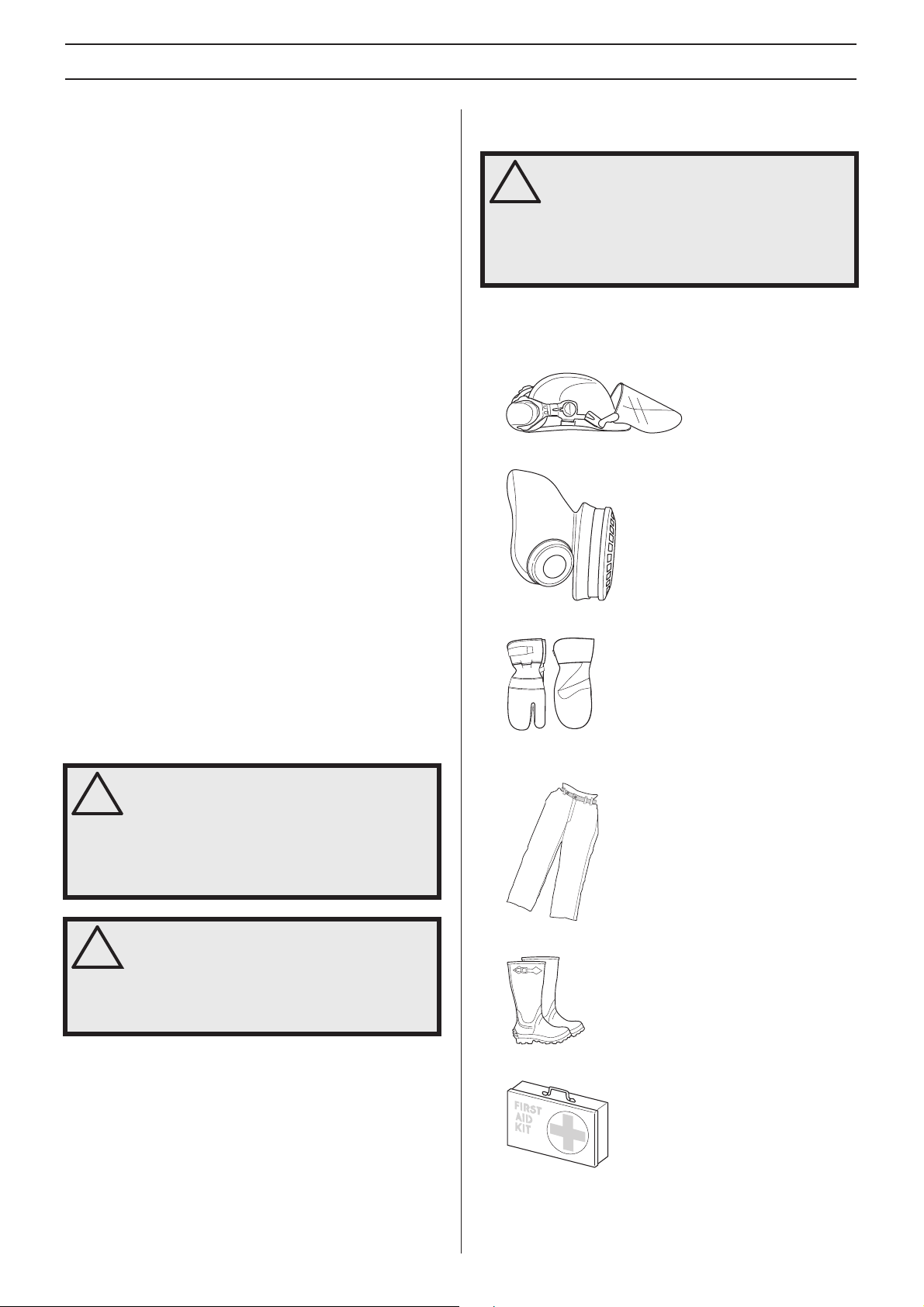

Always wear:

• Approved protective helmet

• Approved hearing protection

• Protective goggles or a visor

• Breathing mask

Grease daily.

This product is in accordance with

applicable EC directives.

Symbols in the operator’s manual:

Inspection and/or maintenance shall be

carried out with the motor switched off and

the plug to the power unit disconnected.

Always wear approved protective gloves.

Regular cleaning is required.

Visual check.

Protective goggles or a visor must be worn.

Environmental marking. Symbols on the

product or its packaging indicate that this

product cannot be handled as domestic

waste. It must instead be submitted to an

appropriate recycling station for the recovery

of electrical and electronic equipment.

By ensuring that this product is taken care of

correctly, you can help to counteract the

potential negative impact on the environment and people that

can otherwise result through the incorrect waste

management of this product.

For more detailed information about recycling this product,

contact your municipality, your domestic waste service or the

shop from where you purchased the product.

2 – English

Page 3

CONTENTS

Contents

KEY TO SYMBOLS

Symbols on the machine: ............................................. 2

Symbols in the operator’s manual: ............................... 2

CONTENTS

Contents ...................................................................... 3

WHAT IS WHAT?

What is what on the wall saw? ..................................... 4

SAFETY INSTRUCTIONS

Steps before using a new wall saw .............................. 5

Personal protective equipment ..................................... 5

General safety precautions .......................................... 6

General working instructions ....................................... 6

Basic working techniques ............................................ 7

PRESENTATION

WS 482 HF .................................................................. 8

ASSEMBLY

Mount wall mountings and rail ..................................... 9

Mount the saw carriage and saw ................................. 9

Fit the blade ................................................................. 10

Flush cutting ................................................................ 10

Fit the blade guard ....................................................... 11

Connect the power unit ................................................ 11

SETTINGS AND ADJUSTMENTS

Gear knob .................................................................... 12

Adjusting the guide wheels .......................................... 12

Adjust the saw carriage ................................................ 12

STARTING AND STOPPING

Before starting ............................................................. 13

Starting ........................................................................ 13

Stopping ....................................................................... 13

Dismantling the saw ..................................................... 13

Cleaning ....................................................................... 13

MAINTENANCE

Service ......................................................................... 14

Maintenance ................................................................ 14

Daily maintenance ....................................................... 14

TECHNICAL DATA

WS 482 HF .................................................................. 15

EC-declaration of conformity ........................................ 17

English – 3

Page 4

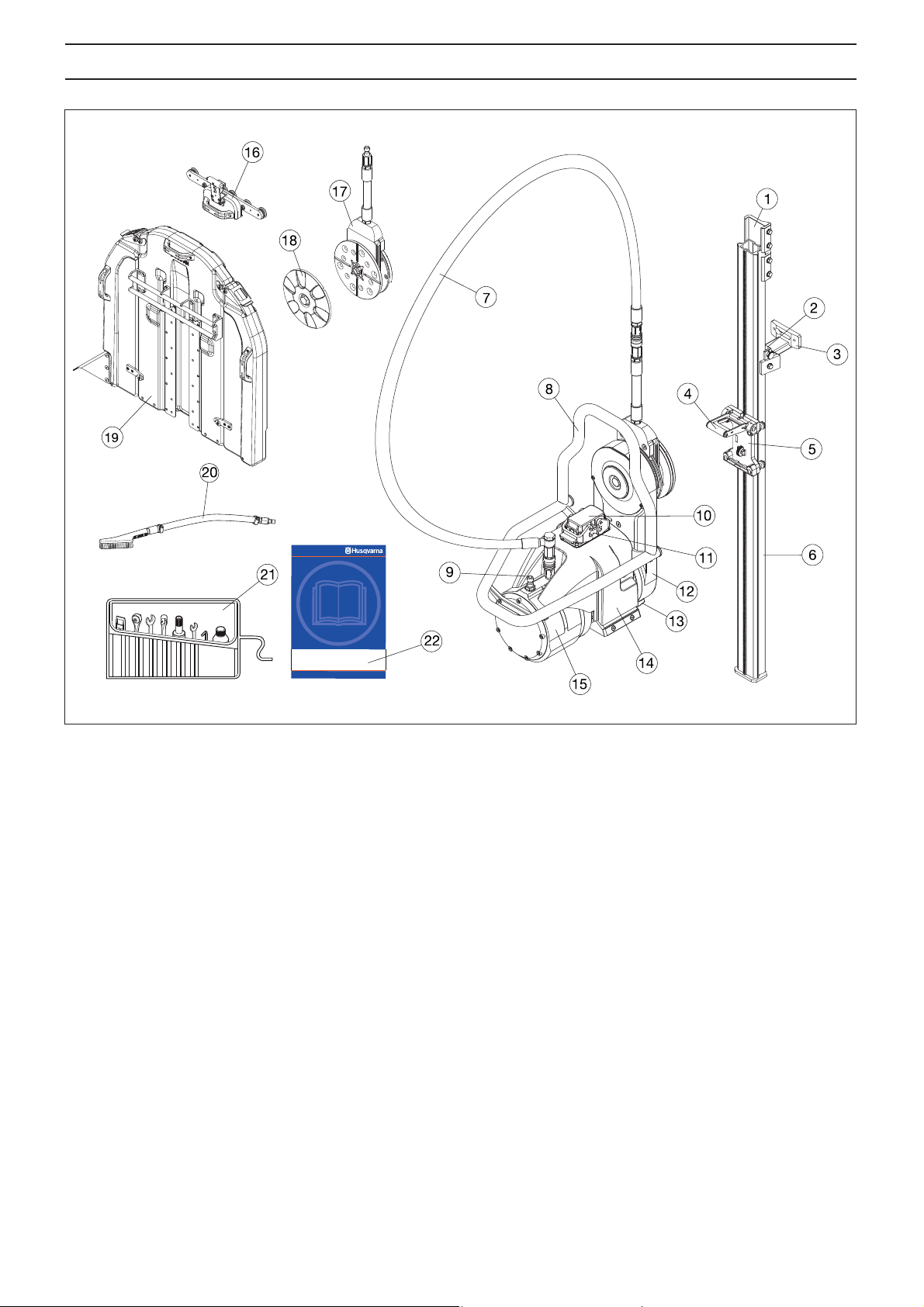

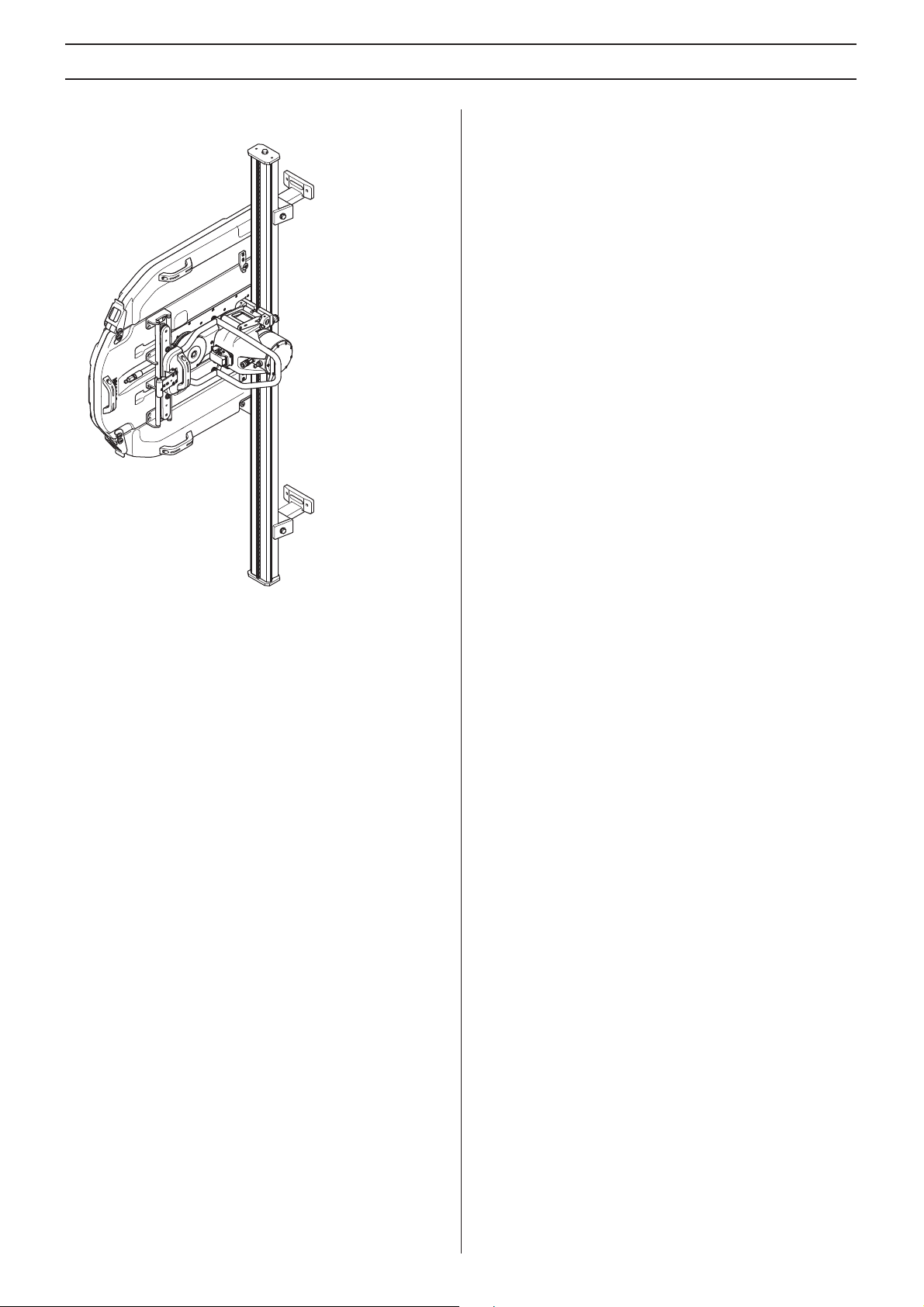

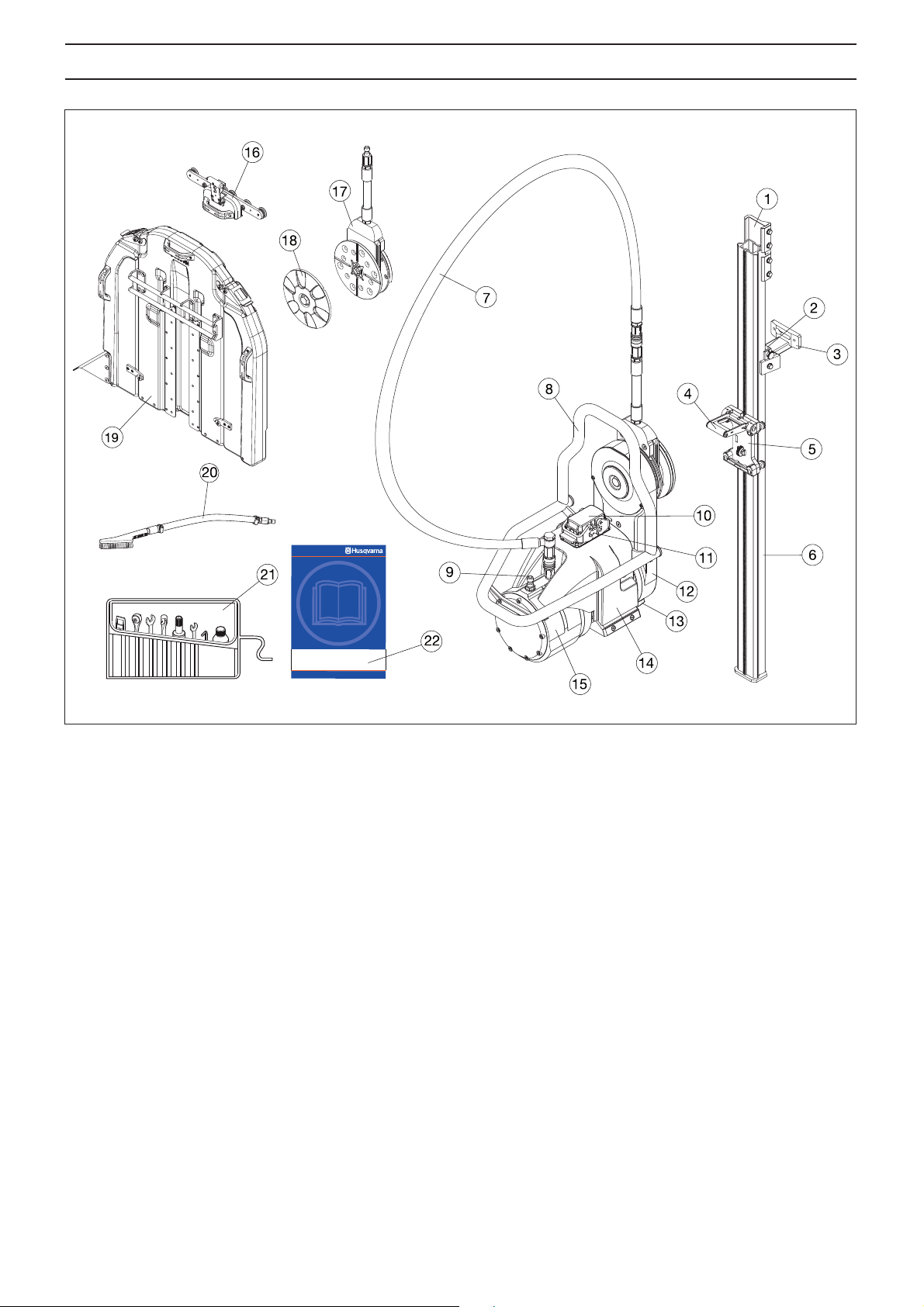

WHAT IS WHAT?

What is what on the wall saw?

1 Connector

2 Track holder

3 Wall mounting

4 Locking handle

5 Saw carriage

6Track

7 Water hose

8 Handle/blade guard mount

9 Hose connection, water in

10 Protective cover

11 Cable connection

12 Cutting arm

13 Gear knob

14 Saw unit

15 Propulsion engine, blade

16 Blade guard guide

17 Blade flange hub

18 Outer blade flange

19 Blade guards

20 Cleaning brush

21 Tool kit

22 Operator′s manual

4 – English

Page 5

SAFETY INSTRUCTIONS

Steps before using a new wall saw

• Please read the operator’s manual carefully and make

sure you understand the instructions before using the

machine.

• This machine is only intended for use together with a

power pack Husqvarna PP 480 HF. All other use is

forbidden.

• Read through the manual supplied with the power unit

before starting to use the machine. See the supplied DVD

for working technique tips.

• The machine can cause serious personal injury. Read the

safety instructions carefully. Learn how to use the

machine.

• This machine is designed for and intended for sawing

concrete, brick and different stone materials. All other use

is improper.

Always use common sense

It is not possible to cover every conceivable situation you can

face. Always exercise care and use your common sense.

Avoid all situations which you consider to be beyond your

capability. If you still feel uncertain about operating

procedures after reading these instructions, you should

consult an expert before continuing.

Do not hesitate to contact your dealer if you have any more

questions about the use of the machine. We will willingly be of

service and provide you with advice as well as help you to use

your machine both efficiently and safely.

Let your Husqvarna dealer regularly check the machine and

make essential adjustments and repairs.

All information and all data in the Operator’s Manual were

applicable at the time the Operator’s Manual was sent to print.

WARNING! Under no circumstances should

you modify the original design of the

!

machine without approval from the

manufacturer. Always use original spare

parts. Unauthorized modifications and/or

accessories may lead to serious injury or

death to the user or others.

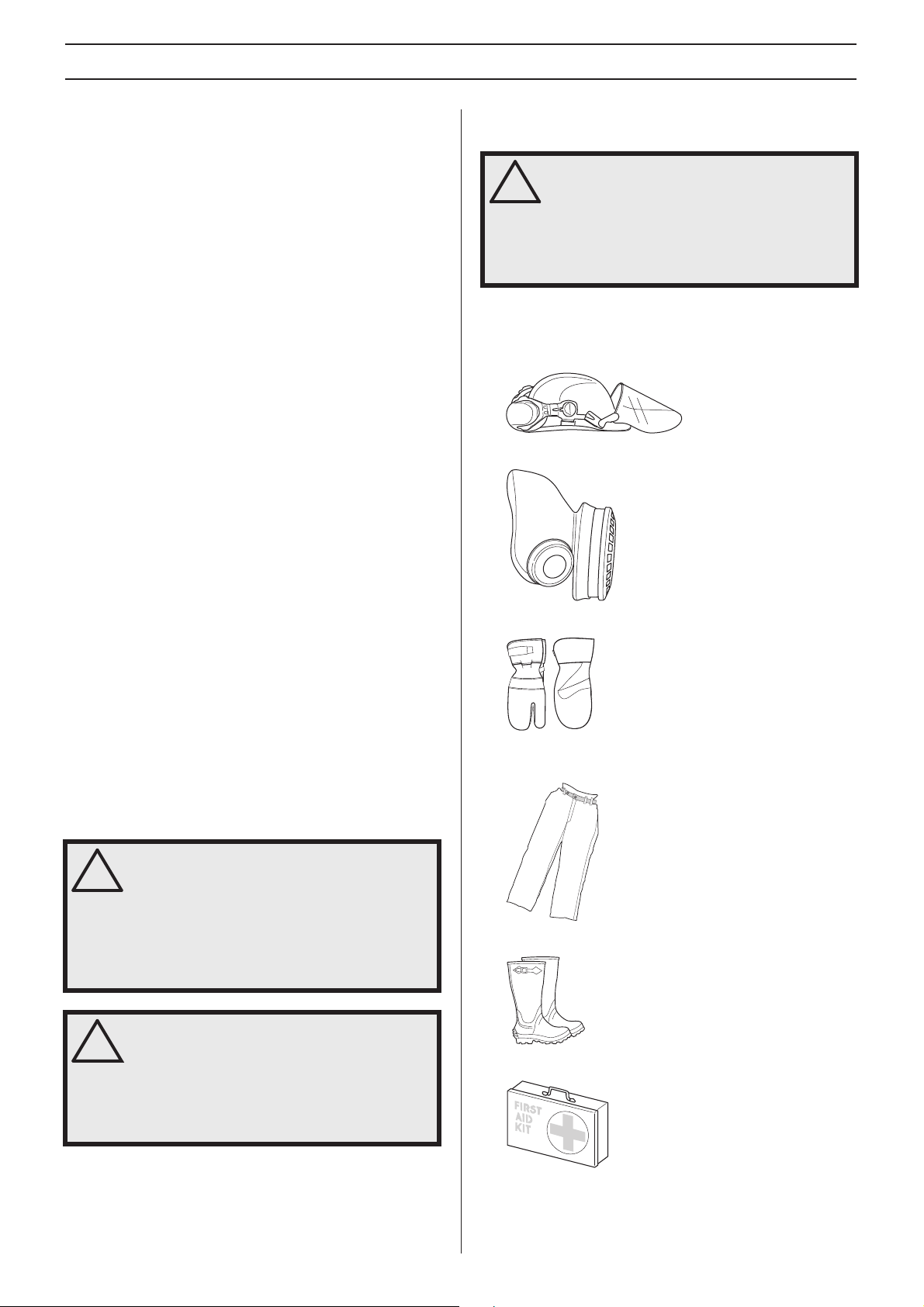

Personal protective equipment

WARNING! You must use approved personal

protective equipment whenever you use the

!

machine. Personal protective equipment

cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident

does happen. Ask your dealer for help in

choosing the right equipment.

• Protective helmet

• Hearing protection

• Protective goggles or a visor

• Breathing mask

• Heavy-duty, firm grip gloves.

• Tight-fitting, heavy-duty and comfortable clothing that

permits full freedom of movement.

WARNING! Use of products which cut, grind,

drill, sand or shape material can generate

!

dust and vapors which may contain harmful

chemicals. Know the nature of the material

being worked on and wear appropriate dust

mask or respirator protection.

• Boots with steel toe-caps and non-slip sole.

• Always have a first aid kit nearby.

English – 5

Page 6

SAFETY INSTRUCTIONS

General safety precautions

WARNING! Do not use the machine without

first reading and understanding the contents

!

of this Operator’s Manual.

There is always a risk of shocks from

electrically powered machines. Avoid

unfavourable weather conditions and body

contact with lightning conductors and metal

objects. Always follow the instructions in the

Operator’s manual to avoid damage.

WARNING! There is always a risk of crush

injuries when working with products

!

containing moving parts. Wear protective

gloves to avoid body injuries.

• Never use the machine if you are tired, if you have drunk

alcohol, or if you are taking medication that could affect

your vision, your judgement or your co-ordination.

• Wear personal protective equipment. See instructions

under the heading ”Personal protective equipment”.

• Never carry the machine by holding the cable and never

pull the plug by pulling the cable.

• Keep all cables away of water, oil and sharp edges. Make

sure the cable is not pinched in doors, fences or the like.

It can cause the object to become live.

• Check that the cables are intact and in good condition.

Use cable intended for outdoor use.

• Never use the machine if any cable is damaged, but hand

it in to an authorized service workshop for repair.

• The machine should be connected to an earthed outlet

socket.

• Check that the mains voltage corresponds with that stated

on the rating plate on the machine.

• Keep all parts in good working order and ensure that all

fixtures are properly tightened.

• Never use a machine that is faulty. Carry out the checks,

maintenance and service instructions described in this

manual. Some maintenance and service measures must

be carried out by trained and qualified specialists. See

instructions under the heading Maintenance.

• Do not modify safety equipment. Check regularly that they

function as they should. The machine must not be run with

defective or disassembled safety equipment.

• Never allow anyone else to use the machine without first

ensuring that they have understood the contents of the

operator’s manual.

• People and animals can distract you causing you to lose

control of the machine. For this reason, always remain

concentrated and focused on the task.

• Be careful as clothing, long hair, and jewellery can get

caught in moving parts.

• Observe care when lifting. You are handling heavy parts,

which implies the risk of pinch injuries or other injuries.

Transport and storage

• Always switch of the power unit and pull out the electric

cable before moving the equipment.

• Dismount the blade and blade guard before transport and

storage.

• Store the equipment in a lockable area so that it is out of

reach of children and unauthorized persons.

• If there is a risk of freezing, the machine must be drained

of any remaining water coolant.

• Use the cases provided to store the equipment.

General working instructions

WARNING! This section describes basic

safety directions for using a wall saw. This

!

information is never a substitute for

professional skills and experience. If you get

into a situation where you feel unsafe, stop

and seek expert advice. Contact your dealer,

service agent or an experienced user. Do not

attempt any task that you feel unsure of!

• All operators shall be trained in the use of the machine.

The owner is responsible for ensuring that the operators

receive training.

• Check that the blade guard is not damaged and that it has

been fitted correctly.

• Never use blades other than original blades designed for

the machine. Check with your Husqvarna dealer to see

which blades are best suited for your usage.

• Never use a damaged or worn blade.

• Never mount or dismount the blade or blade guard without

first pulling out the power cable running to the saw unit.

• Never pull out the power cable without first switching off

the power unit and waiting for the engine to come to a

complete halt.

• Never cut without using the blade guard.

• Check that the blade is not in contact with anything when

the machine is started.

• Remain at a distance from the blade when the engine is

running.

• Water cooling must always be used. This cools the blades

and increases their life and prevents dust build-up.

• Check that all couplings, connections and cables are

intact and free from dirt.

• Do not use hoses that are distorted, worn or damaged.

• Clearly mark out all cuts to be made before you start

sawing, plan these so they can be carried out without

danger to persons or the machine.

• Firmly secure or anchor concrete blocks before cutting.

The heavy weight of cut material can cause extensive

damage if it is not moved under controlled conditions.

• Always check the back of the wall where the blade comes

out when cutting through. Secure, cordon off and make

sure that no people can be injured or materials damaged.

6 – English

Page 7

SAFETY INSTRUCTIONS

• Always check and mark out where gas pipes are routed.

Cutting close to gas pipes always entails danger. Make

sure that sparks are not caused when cutting in view of

the risk of explosion. Remain concentrated and focused

on the task. Carelessness can result in serious personal

injury or death.

• Make sure that no pipes or electrical cables are routed in

the area to be cut.

• Check that electrical cables within the working area are

not live.

• Never leave the machine unsupervised with the motor

running.

• Never saw in such a way that you cannot easily reach the

emergency stop on the remote control or on the power

unit. See power unit manual.

• Make sure that there is always another person close at

hand when you use the machines, so that you can call for

help if an accident should occur.

• People that need to be in close proximity of the machine

must wear hearing protection as the sound level when

cutting exceeds 85 dB(A).

• Make sure that no people or animals come closer than 4

m (15 ft) when the machine is running.

• Do not use the machine in bad weather, such as dense

fog, rain, strong wind, intense cold, etc. Working in bad

weather is tiring and can lead to dangerous conditions,

e.g. slippery surfaces.

• Ensure that the working area is sufficiently illuminated to

create a safe working environment.

• Always ensure you have a safe and stable working

position.

• Observe care when lifting. You are handling heavy parts,

which implies the risk of pinch injuries or other injuries.

Basic working techniques

• Always start by cutting a pilot cut. This is done by feeding

the blade 3-7 cm (1,2”-2,8”). Now make the pilot cut. The

cut should not be made at maximum speed, but with care

in order to obtain a straight cut and with that a basis for the

next cut. The cutting arm allows blades up to 1 000 mm

(40”) to be used as the start blade. It is, however,

recommended to start cutting with an 800 mm (31.5”)

blade.

• When the pilot cut is finished, a deeper cut can be made.

The depth of these is determined from instance to

instance and depends on factors such as hardness of the

concrete, existence of reinforcing bar, etc.

When cutting in hard concrete, a lower speed or a more

shallow cut is required compared to cutting in soft

concrete. This enables a high travel feed speed which

results in a more effective and straight cut. Max. diameter

of the blade for deeper cuts is 1,600 mm (63”).

• If you change blades to cut deeper in the same cut, make

sure the segment width of the blade matches the width of

the groove.

• Let the machine work without forcing or pressing the

blade.

• Firmly secure or anchor concrete blocks before cutting.

The heavy weight of cut material can cause extensive

damage if it is not moved under controlled conditions.

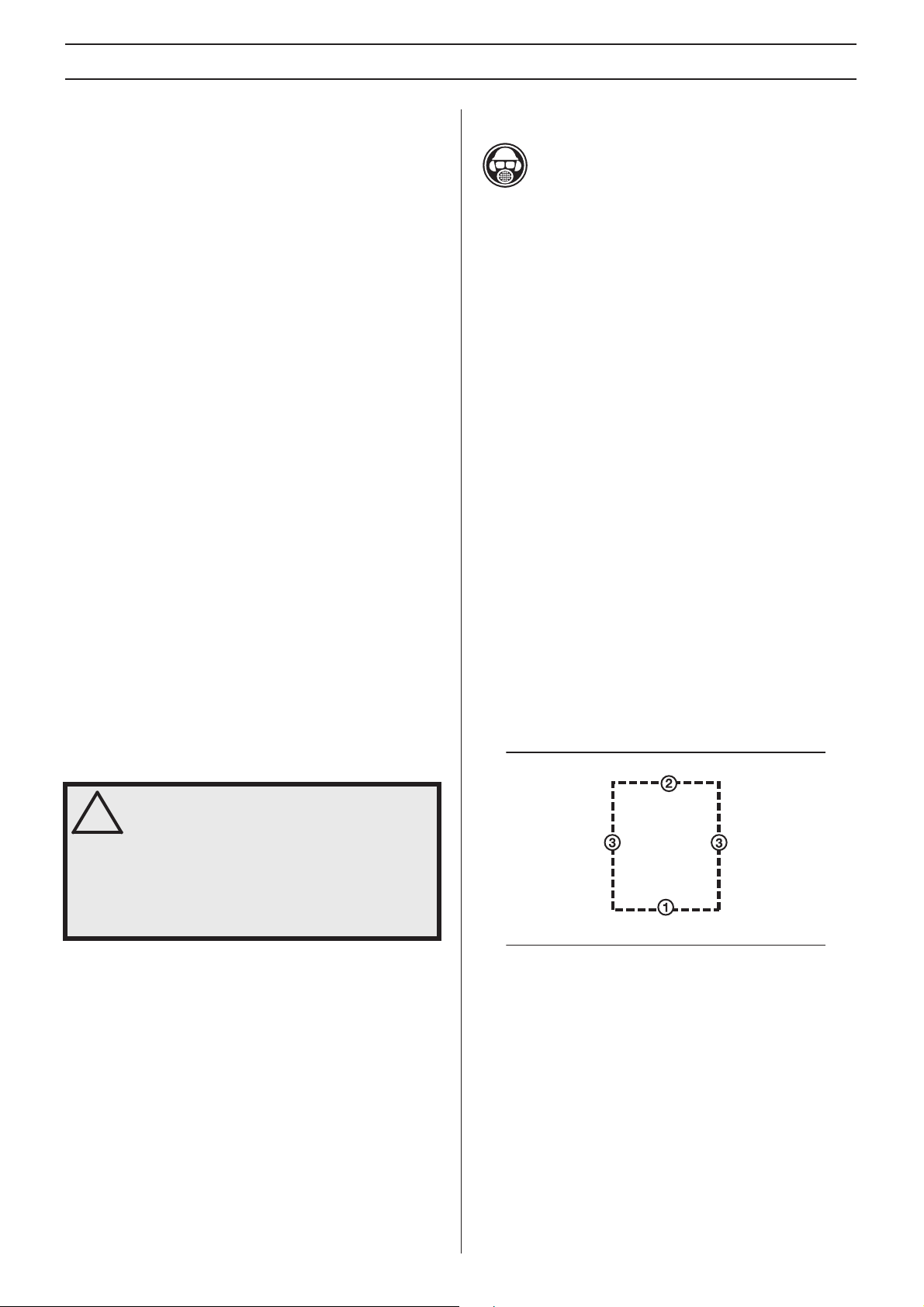

Cutting of blocks

• First make the lower horizontal cut. Now make the upper

horizontal cut. Finish with the two vertical cuts.

WARNING! Never use a blade for any other

materials than that it was intended for.

!

Operating saw blades at rotational speeds

greater than those recommended by the

manufacturer can cause blade damage and

possibly subsequent injury. See the

Technical data section.

• If the upper horizontal cut is made before the lower

horizontal cut, the work piece will fall on the blade and jam

it.

• When making the last cut, the saw should be mounted on

an adjacent fixed wall.

• As the rail is symmetrical, the saw unit can be turned to

make a new cut on the other side of the rail. In this way a

cut piece is obtained that is in an easily handled size,

making it easier to remove from the workplace.

• Since the blade rotation direction can be selected, the

water spray from the blade can also be selected

regardless of how the saw is turned on the rail.

English – 7

Page 8

PRESENTATION

WS 482 HF

It is our wish that you will be satisfied with your product and

that it will be your companion for a long time. Think of this

operator′s manual as a valuable document. By following its′

content (using, service, maintenance etc) the life span and

the second-hand value of the machine can be extended. If

you will sell this machine, make sure that the buyer will get the

operator′s manual.

A purchase of one of our products gives you access to

professional help with repairs and services. If the retailer who

sells your machine is not one of our authorised dealers, ask

him for the address of your nearest service workshop.

Husqvarna Construction Products has a policy of continuous

product development. Husqvarna reserves the right to modify

the design and appearance of products without prior notice

and without further obligation introduce design modifications.

Complete saw equipment consists of:

• One saw

• One track 1.2 m + saw carriage

• One track 2 m + saw carriage

• Four wall mountings

• One track holder

• One connector

• One blade guard 800 or one blade guard 1000

• One blade guard guide

• One tool kit

• One bottle of Husqvarna oil 150

• Transport cases for the different units.

• Cleaning brush

• Screws for flush cutting.

The saw carriage is mounted on both the long and short rails

at the factory to make cutting as easy as possible.

As a large part of the sawing work consists transporting, the

saw equipment is supplied in specially produced cases. The

cases provide good protection during transport and reduced

the number of packages that need to be moved between the

workplaces, which makes the work more effective.

General

• The powerful, water-cooled electric motor produces an

impressive 19 kW to the spindle, even though the saw

weighs just 27 kg (59,5 lbs).

• The spindle speed is electrically adjustable and can be

operated from the power unit´s remote control.

• Short distance between blade and track, for a straighter

cut.

• Slip clutch for all movable components.

• The blade direction and the direction of the water spray

can be operated from the power unit´s remote control.

• The spindle speed is controlled with a mechanical gear on

the cutting arm of the saw unit, and electrically with a

potentiometer on the remote control.

• Equipped with automatic blade brake that stops the blade

within a few seconds.

8 – English

Page 9

ASSEMBLY

Mount wall mountings and rail

Fit the wall mounting as set out below:

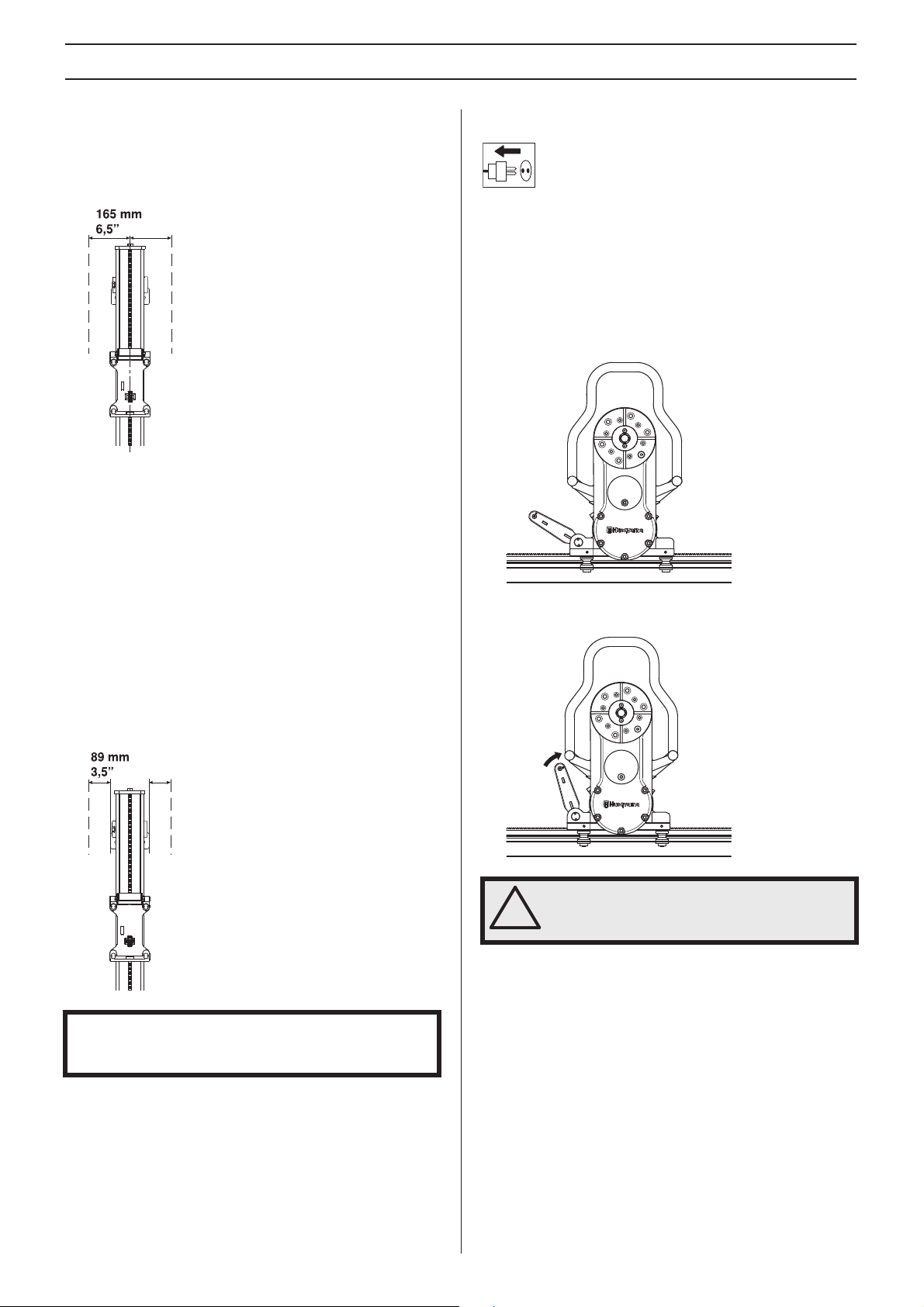

1 Mark off the cutting line and mark off the expander bolts

holes 165 mm (6.5") from the cutting line.

2 Drill 15 mm (5/8”) holes for the M12 (1/2”) expander bolts.

3 Hang the wall mountings loosely from the expander bolts,

using M6S 12 x 70 (1/2”x2”) or similar.

4 Place the rail in the wall mountings and tighten the

compression washers.

For vertical cuts, the rail must be mounted with the saw

carriage lock handle upwards. This to facilitate fitting the

saw unit.

5 Check that the rail is properly aligned with the tracks on

the wall mounts before tightening the screws.

6 Adjust the distance between the cutting line and the wall

mounting. The distance between the edge and the inner

face of the saw cut should be 89 mm (3.5"). Tighten the

expander bolts.

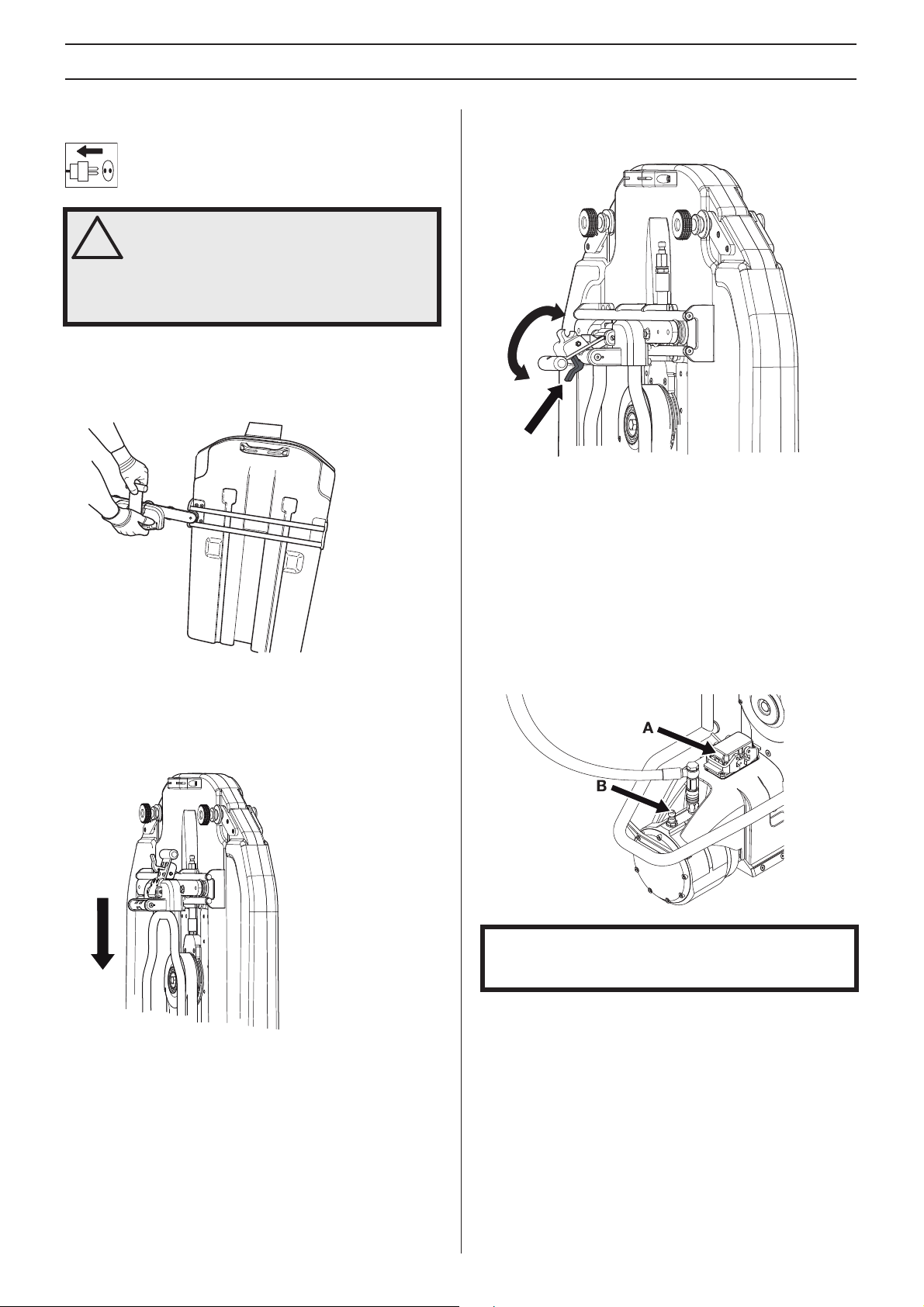

Mount the saw carriage and saw

The saw carriage is mounted on the rail at delivery. The

carriage can be dismounted from the rail by removing the end

stop on the rail and pulling the carriage away.

1 Fit the saw body in the saw carriage by lifting the saw body

into position. When the saw is lifted into position, the

locking handle moves up into an intermediate position. In

this position the saw remains in the saw carriage without

it needing to be held. However, it is not sufficiently secured

to begin cutting.

2 To secure the saw, lift the locking handle towards the saw

until the handle locks.

IMPORTANT! Only use the connectors supplied when

purchasing the saw as older connectors are not designed

for the WS 400 series.

WARNING! To cut without the saw securely

assembled in the saw carriage and rail is

!

associated with mortal danger.

English – 9

Page 10

ASSEMBLY

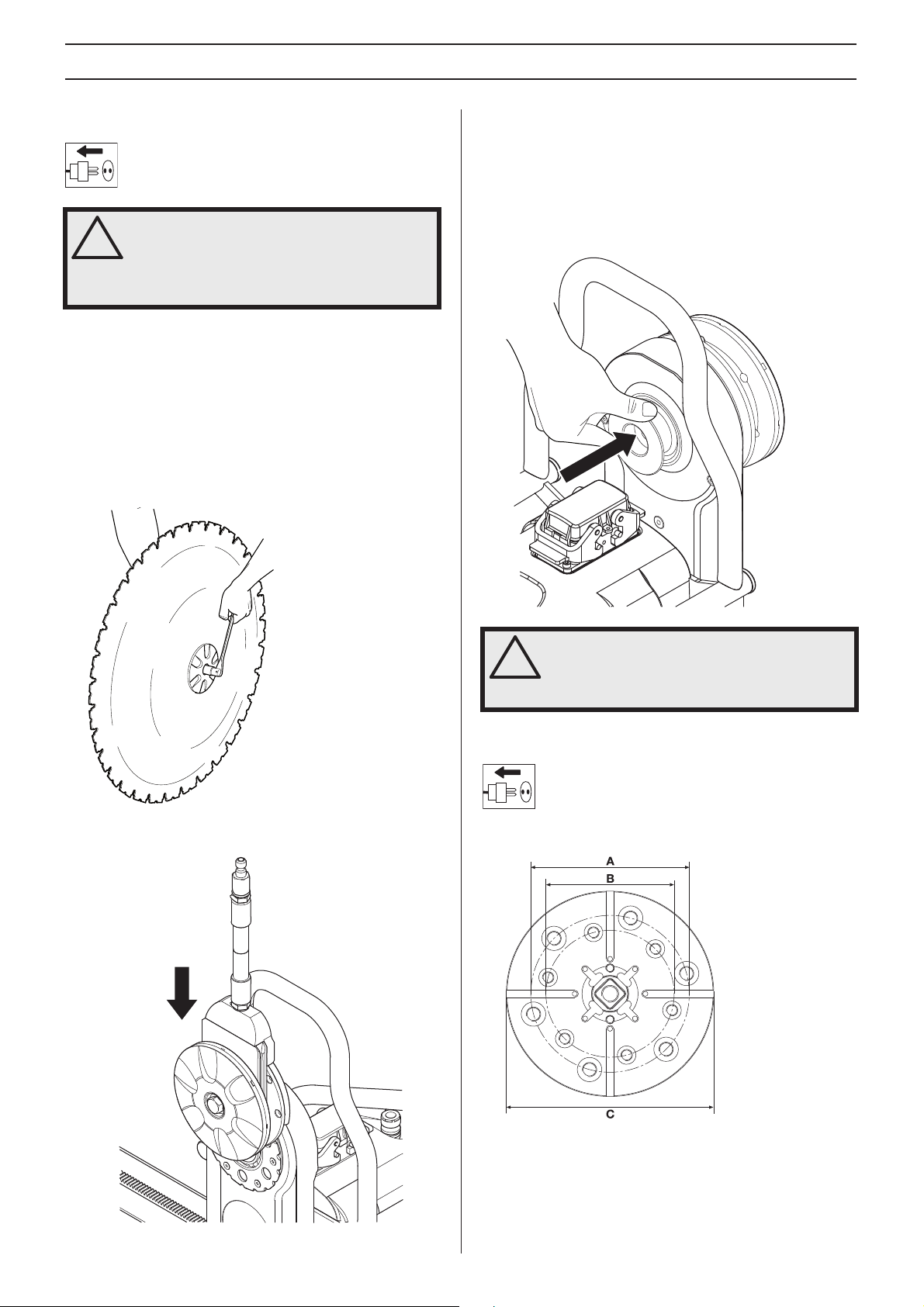

Fit the blade

WARNING! Never mount or dismount the

blade or blade guard without first pulling out

!

the power cable running to the saw unit.

Carelessness can result in serious personal

injury or even death.

1 Start by removing any dirt from the contact surfaces on

the blade flange and blade.

2 Check the blade’s direction of rotation. The blade shall

rotate with the exposed part of the diamond in the

rotational direction of the blade. Since the blade rotation

direction can be selected, the water spray from the blade

can also be selected regardless of how the saw is turned

on the rail.

3 Screw together the outer blade flange, blade and blade

flange hub (tightening torque 70-80 Nm).

5 Turn the blade flange hub carefully so that it slides into

one of the tracks in the pivot arm and lands in the correct

position to be screwed fast.

6 Press in the blade spindle into the cutting arm at the same

time as the blade is rotated carefully. When the blade

spindle can no longer be pressed in by hand it should be

tightened using the supplied 18-spanner until it is properly

secured (tightening torque 70-80 Nm).

4 Hang the blade with the blade flange and blade flange hub

fitted on the cutting arm (blade is not shown in the figure).

WARNING! Exercise care when assembling

the blade so that it does not risk becoming

!

loose when cutting. Carelessness can result

in serious personal injury or even death.

Flush cutting

Screw off the outer blade flange and mount the blade on the

blade flange hub.

10 – English

A=110 mm/4.33 inch, 6xM10

B=89 mm/3.5 inch, 6xM8

C=144 mm/5.7 inch

Page 11

ASSEMBLY

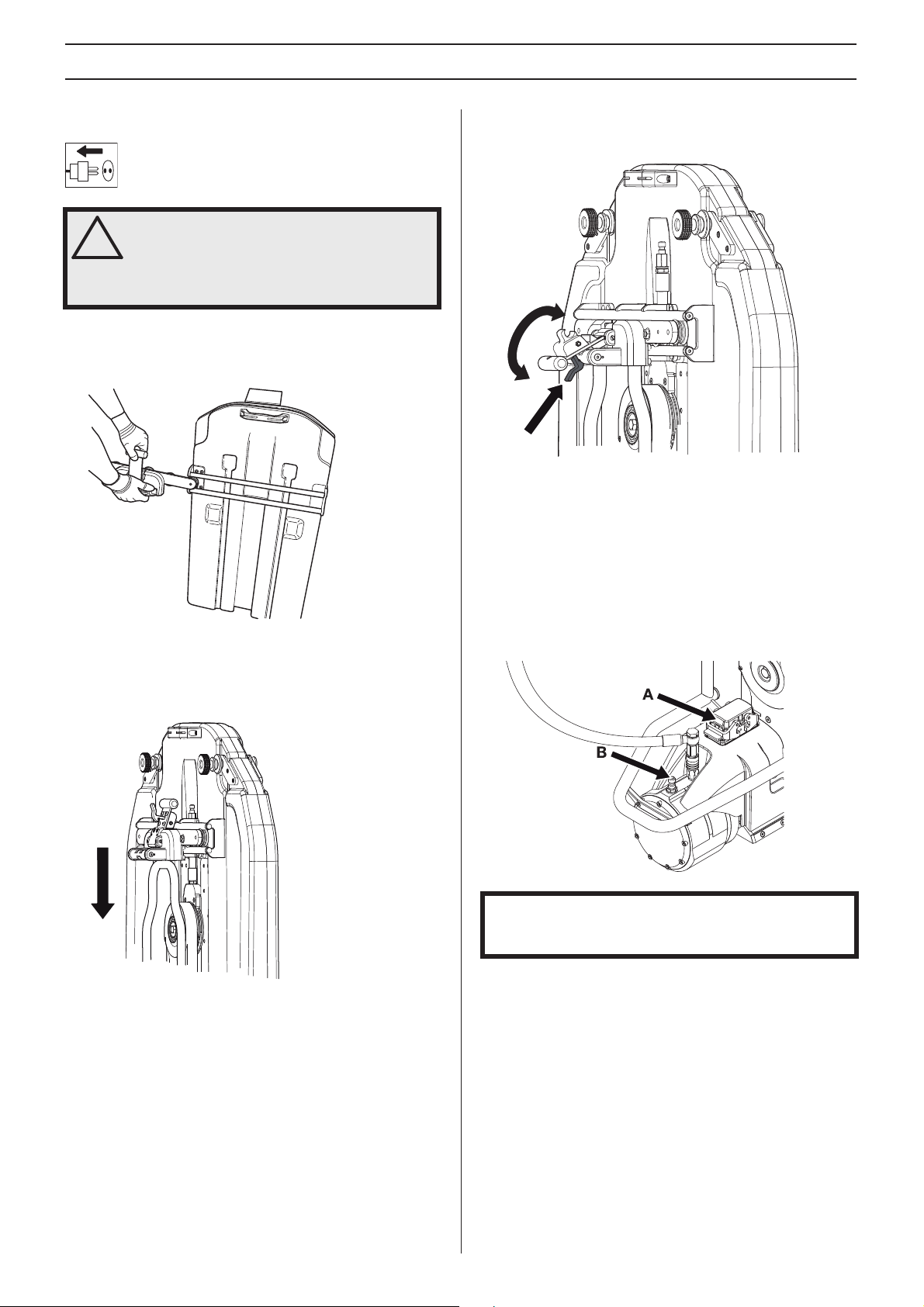

Fit the blade guard

WARNING! Never mount or dismount the

blade or blade guard without first pulling out

!

the power cable running to the saw unit.

Carelessness can result in serious personal

injury or even death.

1 Slip in the blade guard guide between the stays on the

blade guard. Place the blade guard guide in the middle.

Lock the plastic heel on the handle to the upper stay on

the blade guard.

4 To remove the guard, release the latch and pull the handle

upwards and inwards to the guard. Lock the plastic heel

on the upper stay.

5 Connect the water hose from the out-coupling on the saw

motor to the in-coupling on the blade flange hub.

Connect the power unit

2 Make sure that the pivot arm is positioned vertically. Lift

the blade guard over the blade and hang the guard in the

blade guard holder on the saw. Exercise care so that the

runners on the blade guard are positioned in the slots on

the water block.

3 Lock the blade guard by pulling the handle out of the

guard and then down towards the saw unit so that the

latch locks the handle.

1 Read through the manual supplied with the power unit

before starting to use the machine.

2 When the saw unit, the blade and the blade guard are

mounted, the power cable (A) and the water cooling (B)

should be connected to the power unit.

IMPORTANT! This machine is only intended for use

together with a power pack Husqvarna PP 480 HF. All other

use is forbidden.

English – 11

Page 12

SETTINGS AND ADJUSTMENTS

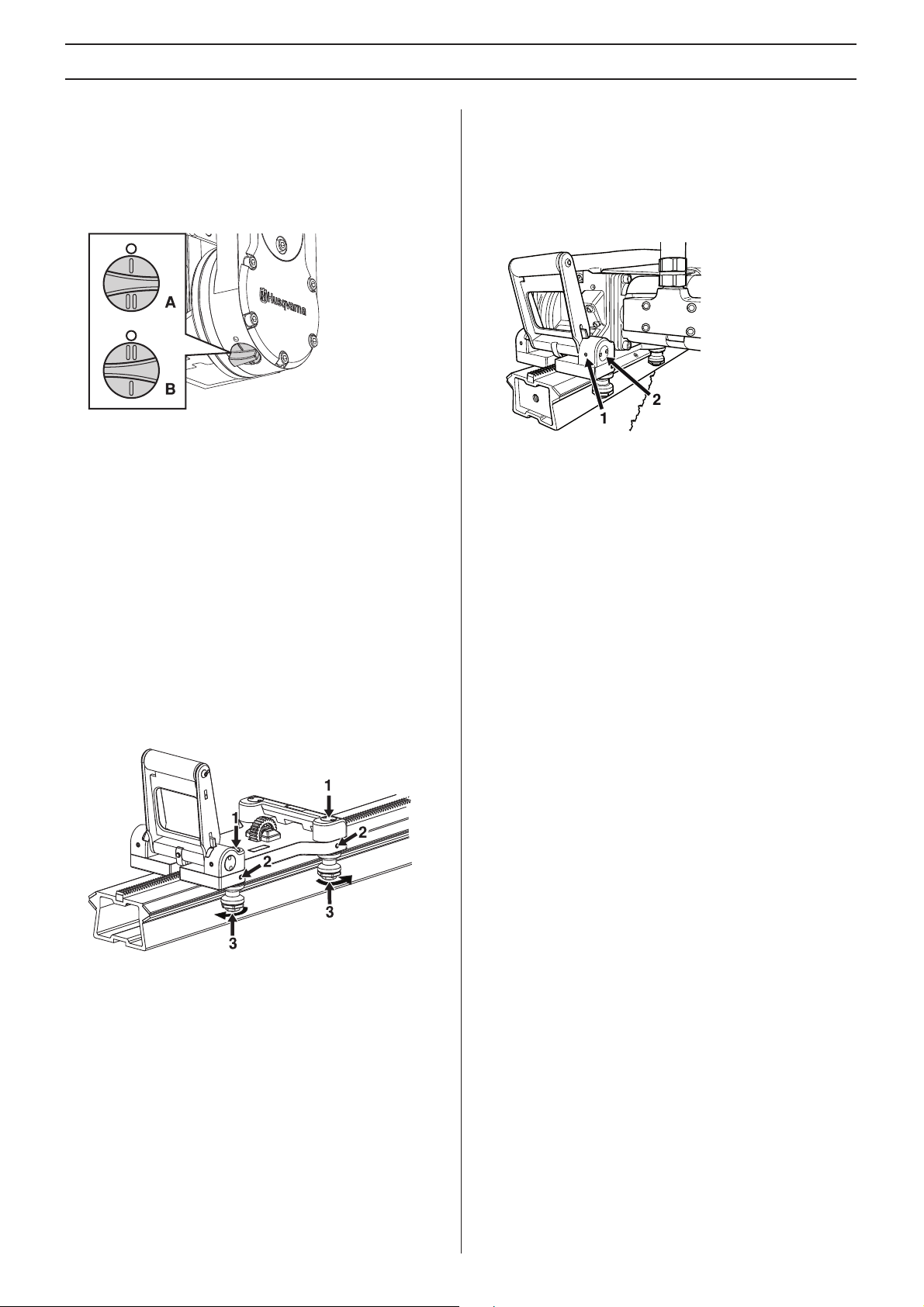

Gear knob

Choose gear for the required speed. On gear 1, the speed

range is 600-900 rpm and on gear 2 the speed range is 8001200 rpm. For more information on recommended blades and

speeds, see "Recommended blade speeds" in the "Technical

data" section.

A - Gear 1

B - Gear 2

NOTICE! Make sure the gear knob is positioned as shown in

the image. If the knob is between gears, it can cause damage

to the gearbox.

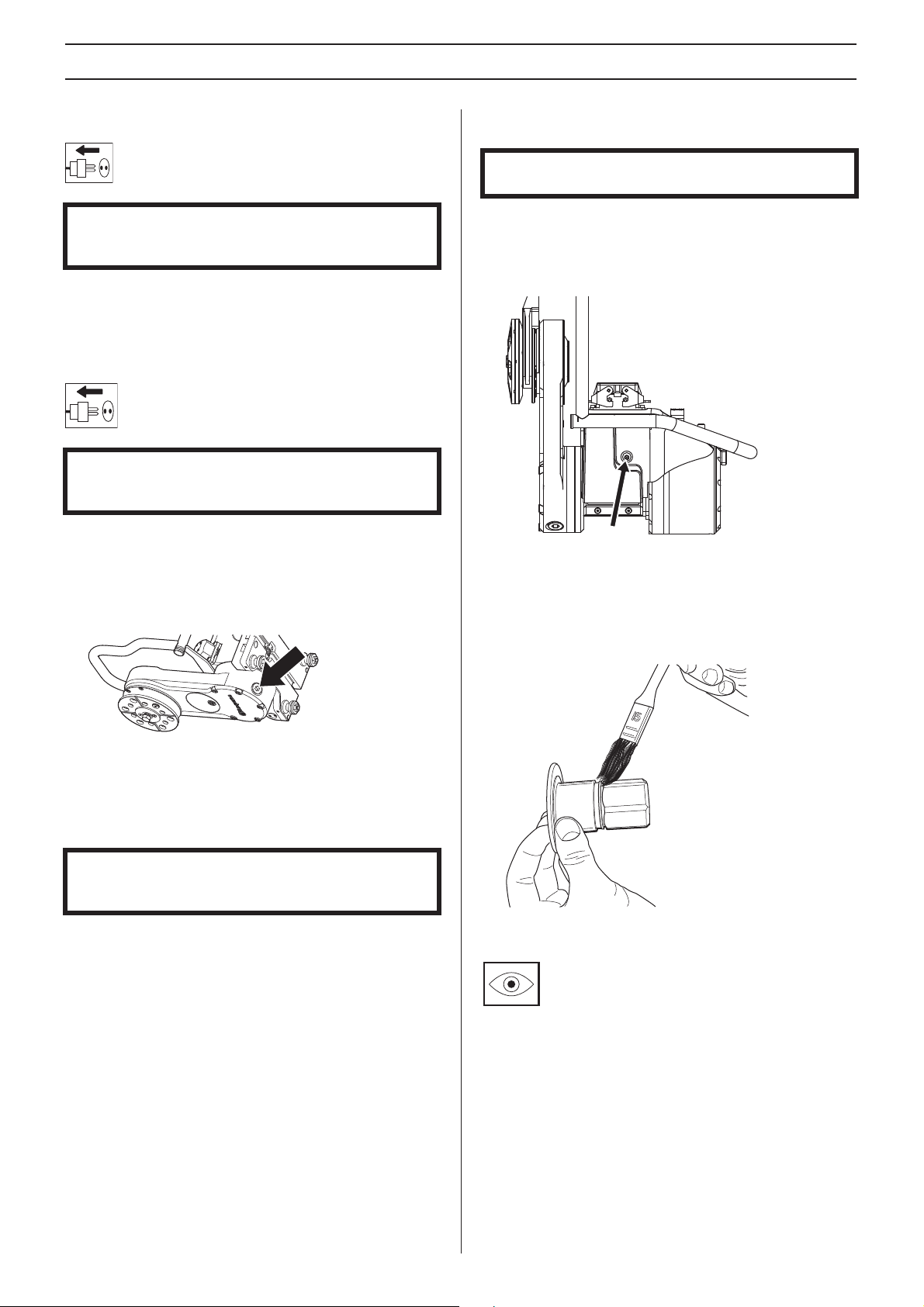

Adjusting the guide wheels

Adjust the saw carriage

As the saw wears, after a number of hours working, it can be

a good idea to ensure that the saw sits firmly in the saw

carriage and rail. If not, the handle probably needs adjusting:

• Loosen the marked (1) socket headed screw (one on each

side of the handle).

• Turn the eccentric axles (2) with the help of the supplied

special tool until the axle lies tight and parallel against the

saw.

• Now tighten the socket headed screw.

In order for the saw to run stably and saw a straight cut, the

four guide wheels must rest against the rail and not have too

much play.

Check the guide wheels before each cut. When there is too

much play between the saw carriage and rail the guide

wheels must be adjusted:

• Start by loosening the marked nuts (1) with the supplied

special tool.

• Now loosen the two stop screws (2).

• Adjust the guide wheels with the M10 nut (3) located on

the rear side of the guide wheel until the play disappears.

Turn the nuts outwards for each other.

• Hold the guide wheels and screw in the stop screw.

• Now tighten the nuts to secure the guide wheels in the

new position.

12 – English

Page 13

STARTING AND STOPPING

Before starting

• Enclose the area to be cut so that unauthorised persons

can not be injured or disturb the operator.

• Check that the blade and th blade guard is not damaged

or cracked. Replace the blade or the blade guard if it is

exposed to impact or is cracked.

• Check that all cables and the water supply are correctly

connected to the machine before starting it.

• If cutting is to begin in another position than where the

saw unit is located, run the saw unit to the start position.

• Choose gear for the required speed.

Starting

Follow the instructions for starting in the manual supplied with

the power unit.

Stopping

• Once cutting is completed, remove the blade from the wall

and shut down the blade rotation and the water flow.

• Turn off the power unit.

Dismantling the saw

1 Allow the motor to stop completely.

2 Disengage the power supply for the power unit.

3 Turn off and disconnect inflowing water to the power unit.

4 Disengage the power cable and the water hose from the

saw unit.

5 The other steps are done in the reverse order to

assembling.

Cleaning

The saw should be cleaned once cutting is finished. It is

important to clean all the saw equipment. The saw is best

cleaned with the supplied cleaning brush by connecting it to

the water hose.

IMPORTANT! Do not use a high pressure washer to clean

the saw.

English – 13

Page 14

MAINTENANCE

Service

IMPORTANT! All types of repairs may only be carried out by

authorised repairmen. This is so that the operators are not

exposed to great risks.

After 100 hours of operation, the message "Time for

servicing" is displayed. The entire equipment shall then be

taken to an authorized Husqvarna dealer for servicing.

Maintenance

IMPORTANT! Inspection and/or maintenance should be

carried out with the motor switched off and the plug

disconnected.

Oil change cutting arm

Lubrication of feeder gears

IMPORTANT! If the gears are not lubricated regularly, their

lifespan will shorten considerably.

• There are two grease nipples on every saw unit. Through

these the gears for the feeding engines can be lubricated.

Lubricate daily or at least every 30 hours of operation.

Use PETRO CANADA PERLESS OG2 or corresponding

grease.

• There is an oil plug for draining the oil located on the

cutting arm. This plug should be cleaned when changing

the oil. The new oil is filled through the hole where the oil

plug sits.

• The cutting arm contains 3 dl of Husqvarna Oil 150, a

transmission oil of the type EP 150. The oil should be

replaced for the first time in connection with the first

service. A 3 dl bottle of oil is supplied when the machine

is new.

IMPORTANT! Used engine oil and transmission oil is

hazardous to health and must not be disposed of in the

ground or out of doors.

Grease the blade spindle

• In order for the blade spindle to be fitted as easily as

possible, it may be necessary to grease the hexagonal

blade spindle. At the same time check that the hexagon is

not damaged.

Daily maintenance

14 – English

1 Check that all couplings, connections and cables are

intact and free from dirt.

2 Clean the outside of the machine. Do not use a high

pressure washer to clean the saw.

3 Check that the blade and th blade guard is not damaged

or cracked. Replace the blade or the blade guard if it is

exposed to impact or is cracked.

Page 15

TECHNICAL DATA

WS 482 HF

Weight

Saw carriage, kg/lbs 3,7/8,2

Saw unit, kg/lbs 27/59,5

Blade guard 800 mm, kg/lbs 13/28,7

Blade guard 1000 mm, kg/lbs 16/35,3

Track 1200 mm (47”) kg/lbs 9,5/20,9

Track 2000 mm (79”) kg/lbs 19/41,9

Blade size

Blade size - max, mm/inches 1600/63

Blade size - min, mm/inches 600/23,6

Starting blade - max, mm/inches 1000/39,4

Saw depth - max, mm/inch 730/28,5

Motor for saw blade drive PM High cycle

Spindle output - max, kW 19

Power train Gear drive

Output speed, rpm 0-1200

Feedingsystem/control Electric/auto

Drive torque at saw blade - max, Nm 230

Starting torque, Nm 150

Cooling water pressure - max, bar 7

Water coolant flow min., l/min 3,5

Cooling water temp. in at 3,5 l/min - max, C 25

Protection class IP 65

Noise emissions (see note 1)

Sound power level, measured dB(A) 108

Sound power level, guaranteed LWA dB(A) 109

Sound levels (see note 2)

Sound pressure level at the operators ear, dB(A) 85

Note 1: Noise emissions in the environment measured as sound power (LWA) in conformity with EN 15027/A1.

Note 2: Noise pressure level according to EN 15027/A1. Reported data for noise pressure level has a typical statistical dispersion

(standard deviation) of 1.0 dB(A).

English – 15

Page 16

TECHNICAL DATA

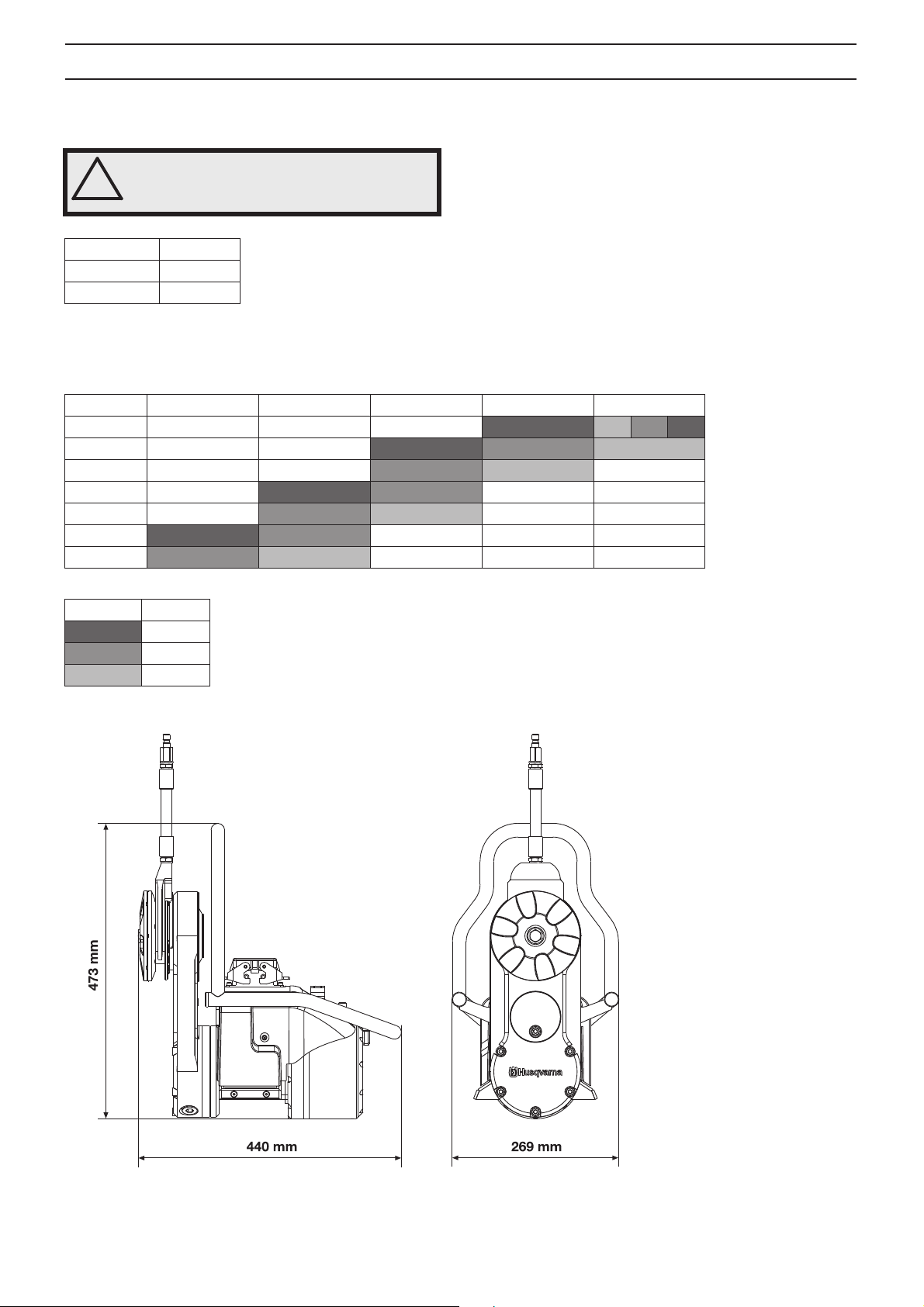

Recommended blade speed

WARNING! Cutting at too high revs can

cause damage to the blade and lead to

!

personal injury.

Speed, rpm

Gear 1 600-900

Gear 2 800-1200

When sawing at 800-900 rpm, a higher sawing output is obtained if gear 1 is used.

Follow the blade manufacture´s recommendations regarding material and blade speed when choosing blade. When cutting in hard

concrete, a lower speed or a more shallow cut is required compared to cutting in soft concrete.

600 mm (24”) 800 mm (32”) 1000 mm (40”) 1200 mm (48”) 1600 mm (63”)

600 rpm

700 rpm

800 rpm

900 rpm

1000 rpm

1100 rpm

1200 rpm

Concrete

Hard

Medium

Soft

Dimensions

16 – English

Page 17

TECHNICAL DATA

EC-declaration of conformity

(Applies to Europe only)

Husqvarna AB, SE-433 81 Göteborg, Sweden, tel: +46-31-949000, declares under sole responsibility that the wall

sawHusqvarna WS 482 HF , from 2010´s serial numbers and onwards (the year is clearly stated in plain text on the rating plate

with subsequent serial number), conforms with the requirements of the COUNCIL´S DIRECTIVE:

• of May 17, 2006 "relating to machinery" 2006/42/EC

• of December 15, 2004 ”relating to electromagnetic compatibility” 2004/108/EC.

• of December 12, 2006 ”relating to electrical equipment” 2006/95/EC.

The following standards have been applied: EN ISO 12100:2003, EN 55014-1:2006, EN 55014-2/A1:2001, EN 61000-3-11:2000,

EN 15027/A1:2009.

Huskvarna December 29, 2009

Henric Andersson

Vice President, Head of Power Cutters and Construction Equipment

Husqvarna AB

(Authorized representative for Husqvarna AB and responsible for technical documentation.)

English – 17

Page 18

ACLARACIÓN DE LOS SÍMBOLOS

Símbolos en la máquina:

¡ATENCIÓN! La máquina, si se utiliza de

forma errónea o descuidada, puede ser

una herramienta peligrosa que puede

causar daños graves e incluso la muerte al

usuario y a otras personas.

Lea detenidamente el manual de

instrucciones y asegúrese de entender su

contenido antes de utilizar la máquina.

Utilice siempre:

• Casco protector homologado

• Protectores auriculares homologados

• Gafas protectoras o visor

• Máscara respiratoria

Debe engrasarse a diario.

Este producto cumple con la directiva CE

vigente.

Símbolos en el manual de instrucciones:

El control y/o mantenimiento de la máquina

debe hacerse con el motor parado y el

enchufe de la unidad eléctrica

desenchufado.

Utilice siempre guantes protectores

homologados.

La máquina debe limpiarse regularmente.

Control visual.

Debe utilizarse gafas protectoras o visor.

Etiquetado ecológico. El símbolo en el

producto o en su envase indica que no se

puede tratar este producto como desperdicio

doméstico. Deberá por lo tanto depositarse

en un centro de recogida adecuado para el

reciclado de equipos eléctricos y

electrónicos.

Haciendo que este producto sea manipulado

adecuadamente, se ayuda a evitar consecuencias negativas

potenciales para el medio ambiente y las personas, lo que

puede ocurrir con la manipulación inadecuada como residuos

del producto.

Para obtener información más detallada sobre el reciclado de

este producto, contacte con la oficina municipal local, con el

servicio de eliminación de desperdicios domésticos o con la

tienda donde compró el producto.

18 – Spanish

Page 19

ÍNDICE

Índice

ACLARACIÓN DE LOS SÍMBOLOS

Símbolos en la máquina: ............................................. 18

Símbolos en el manual de instrucciones: .................... 18

ÍNDICE

Índice ........................................................................... 19

¿QUÉ ES QUÉ?

¿Componentes de la sierra de pared? ........................ 20

INSTRUCCIONES DE SEGURIDAD

Pasos necesarios antes de utilizar una sierra de pared

nueva ...........................................................................

Equipo de protección personal .................................... 21

Instrucciones generales de seguridad ......................... 22

Instrucciones generales de trabajo .............................. 22

Técnica básica de trabajo ............................................ 23

PRESENTACIÓN

WS 482 HF .................................................................. 24

MONTAJE

Riel y accesorios del soporte de pared ....................... 25

Instalación del carro y de la sierra ............................... 25

Monte el disco .............................................................. 26

Corte liso ...................................................................... 26

Monte la protección del disco ...................................... 27

Conecte la unidad eléctrica ......................................... 27

REGLAJES Y AJUSTES

Manija de cambio ......................................................... 28

Ajuste de las ruedas de guía ....................................... 28

Ajuste la sierra en el carro ........................................... 28

ARRANQUE Y PARADA

Antes del arranque ....................................................... 29

Arranque ...................................................................... 29

Parada ......................................................................... 29

Desmontaje de la sierra ............................................... 29

Limpieza ...................................................................... 29

MANTENIMIENTO

Servicio ........................................................................ 30

Mantenimiento ............................................................. 30

Mantenimiento diario ................................................... 30

DATOS TECNICOS

WS 482 HF .................................................................. 31

Declaración CE de conformidad .................................. 33

21

Spanish – 19

Page 20

¿QUÉ ES QUÉ?

¿Componentes de la sierra de pared?

1 Conector

2 Soporte del riel

3 Soportes de pared

4 Empuñadura de bloqueo

5 Carro de la sierra

6 Riel

7 Manguera de agua

8 Soporte de la protección del disco / empuñadura

9 Conexión de la manguera, entrada de agua

10 Cubierta protectora

11 Conexión del cable

12 Brazo de corte

13 Manija de cambio

14 Unidad de sierra

15 Motor de propulsión, disco

16 Guía de la protección del disco

17 El cubo de brida de disco

18 Brida exterior de acoplamiento de discos

19 Protección del disco de corte

20 Cepillo de limpieza

21 Juego de herramientas

22 Manual de instrucciones

20 – Spanish

Page 21

INSTRUCCIONES DE SEGURIDAD

Pasos necesarios antes de utilizar una sierra de pared nueva

• Lea detenidamente el manual de instrucciones y

asegúrese de entender su contenido antes de utilizar la

máquina.

• Esta máquina está pensada para ser utilizada con una

unidad de alimentación Husqvarna PP 480 HF. Está

prohibida cualquier otra aplicación.

• Lea el manual de instrucciones suministrado con la

unidad eléctrica antes de utilizar la máquina. Consulte el

DVD suministrado para obtener consejos sobre técnicas

de funcionamiento.

• La máquina puede ocasionar lesiones graves. Lea

atentamente las instrucciones de seguridad. Aprenda a

utilizar la máquina.

• Esta máquina está diseñada y prevista para serrar

hormigón, ladrillos y distintos tipos de piedra. Cualquier

otro uso se considerará inadecuado.

Emplee siempre el sentido común

Es imposible abarcar todas las situaciones en las que puede

encontrarse. Utilice siempre el equipo con cuidado y sentido

común. Evite todas aquellas situaciones que considere que

sobrepasan sus capacidades. Si, después de leer estas

instrucciones, no está seguro del procedimiento que debe

seguir, consulte a un experto antes de utilizar el equipo.

No dude en ponerse en contacto con su distribuidor si tiene

preguntas acerca del uso de la máquina. Estaremos

encantados de poder aconsejarle y ayudarle a utilizar la

máquina de manera eficaz y segura.

Diríjase a su distribuidor de Husqvarna para que revise la

máquina regularmente y para que realice ajustes y

reparaciones básicas.

Toda la información y todos los datos contenidos en este

manual de instrucciones son vigentes en la fecha de

impresión del manual.

Equipo de protección personal

¡ATENCIÓN! Para trabajar con la máquina

debe utilizarse un equipo de protección

!

personal homologado. El equipo de

protección personal no elimina el riesgo de

lesiones, pero reduce su efecto en caso de

accidente. Pida a su distribuidor que le

asesore en la elección del equipo.

• Casco protector

• Protectores auriculares

• Gafas protectoras o visor

• Máscara respiratoria

• Guantes resistentes de agarre seguro.

• Prendas de vestir ceñidas, resistentes y cómodas que

permitan una libertad de movimientos total.

¡ATENCIÓN! No está permitido modificar el

diseño original de la máquina, por ningún

!

motivo, sin la autorización del fabricante.

Utilice siempre accesorios originales. Las

modificaciones y/o el uso de accesorios no

autorizados comportan riesgo de daöos

personales graves y peligro de muerte para

el usuario y otras personas.

¡ATENCIÓN! El uso de productos de corte,

amolado, taladrado, lijado o formación de

!

materiales puede generar polvo y vapores

que pueden contener productos químicos

perniciosos. Averigüe la índole del material

de trabajo y utilice una máscara contra

polvo o respiratoria adecuada.

• Botas con puntera de acero y suela antideslizante.

• Tenga siempre a mano el equipo de primeros auxilios.

Spanish – 21

Page 22

INSTRUCCIONES DE SEGURIDAD

Instrucciones generales de seguridad

¡ATENCIÓN! No utilice la máquina sin haber

leído y comprendido el contenido de este

!

manual de instrucciones.

Existe siempre riesgo de sacudidas

eléctricas al usar máquinas eléctricas. No

usar la máquina en condiciones climáticas

desfavorables y evitar el contacto del cuerpo

con pararrayos y objetos metálicos. Seguir

siempre las instrucciones del manual para

evitar daños.

¡ATENCIÓN! Existe siempre riesgo de

accidentes por apriete al trabajar con

!

aparatos con piezas móviles. Usar guantes

protectores para evitar lesiones.

• Nunca utilice la máquina si está cansado, si ha ingerido

alcohol o si toma medicamentos que puedan afectarle la

vista, su capacidad de discernimiento o el control del

cuerpo.

• Utilice el equipo de protección personal. Vea las

instrucciones bajo el título ”Equipo de protección

personal”.

• No lleve nunca la máquina agarrando el cable y no tire del

cable para desenchufarla.

• Mantenga todos los cables apartados del agua, el aceite

y los bordes agudos. Proceda con cuidado para evitar que

el cable se enganche en puertas, vallas o similares. Hay

riesgo de cargar objetos con electricidad.

• Compruebe que los cables están intactos y en buen

estado. Utilice el cable proporcionado para el uso externo.

• Si se daña un cable, no utilice la máquina. Llévela a

reparar a un taller de servicio oficial.

• La máquina se debe enchufar a un enchufe con masa.

• Compruebe que la tensión de red concuerda con la que

se indica en la placa de características de la máquina.

• Mantener todas las piezas en perfecto estado y

comprobar que todos los elementos de fijación estén bien

apretados.

• No utilice nunca una máquina defectuosa. Siga las

instrucciones de mantenimiento, control y servicio de este

manual. Algunas medidas de mantenimiento y servicio

deben ser efectuadas por especialistas formados y

cualificados. Vea las instrucciones bajo el título

Mantenimiento.

• No modificar nunca los dispositivos de seguridad.

Comprobar regularmente que funcionan como es debido.

La máquina no se debe operar con dispositivos de

seguridad defectuosos o ausentes.

• Nunca deje que terceros utilicen la máquina sin

asegurarse primero de que hayan entendido el contenido

de este manual de instrucciones.

• Las personas y los animales pueden distraer y hacer

perder el control de la máquina. Por consiguiente, el

operador debe estar siempre concentrado en su trabajo.

• Tener en cuenta que las ropas, el pelo largo y las joyas

pueden atascarse en piezas móviles.

• Proceda con cuidado en las elevaciones. Las piezas son

pesadas, por lo que hay riesgo de daños por apriete y

daños personales de otro tipo.

Transporte y almacenamiento

• Desconecte siempre la unidad eléctrica y el cable

eléctrico antes de mover el equipo.

• Desmonte el disco y el protector del disco antes de

transportar y almacenar el equipo.

• Guarde el equipo en un lugar seguro fuera del alcance de

los niños y las personas no autorizadas.

• Si existe riesgo de congelación, drene el agua

refrigeradora restante del dispositivo.

• Utilice las cajas suministradas para guardar el equipo.

Instrucciones generales de trabajo

¡ATENCIÓN! Este capítulo trata las normas

de seguridad básicas para trabajar con la

!

sierra de pared. Esta información no

sustituye en ningún caso los conocimientos

y la experiencia de un profesional. Si se

enfrenta a alguna situación que le haga

sentirse inseguro, deténgase y consulte a un

experto. Consulte a su distribuidor, al taller

de servicio técnico o a un usuario

experimentado. No emplee la máquina en

aplicaciones para las que no se considere

plenamente cualificado.

• Todos los operadores deben ser formados en el empleo

de la máquina. El propietario es responsable de la

formación de los operadores.

• Compruebe que la protección del disco no esté rota y que

está correctamente montada.

• Nunca utilice discos de corte distintos a los discos

originales destinados a la máquina. Consulte con su

distribuidor de Husqvarna acerca del disco más

adecuado para su aplicación.

• No utilice nunca un disco de corte dañado o gastado.

• Nunca monte ni desmonte el disco ni el protector del

disco sin haber desconectado antes el cable que va hasta

la unidad de serrado.

• Nunca desconecte el cable sin desconectar antes la

unidad eléctrica y esperar a que la máquina se detenga

por completo.

• No corte nunca sin utilizar el protector.

• Asegúrese de que el disco no toca en ningún objeto al

arrancar la máquina.

• Manténgase alejado del disco mientras el motor esté en

marcha.

• Debe emplearse siempre refrigeración por agua. Así se

enfrían los discos de corte, se aumenta su durabilidad y

se reduce la formación de polvo.

• Compruebe que todas las juntas, conexiones y cables

están intactos y limpios.

• No utilice mangueras torcidas, gastadas o defectuosas.

• Antes de empezar a cortar, todos los cortes que se van a

hacer deben marcarse con claridad y planificarse para

que se puedan hacer sin riesgo de dañar a personas o la

máquina.

22 – Spanish

Page 23

INSTRUCCIONES DE SEGURIDAD

• Sujete o ancle con firmeza los bloques de hormigón antes

de cortarlos. El elevado peso del material cortado puede

causar daños importantes si no se desplaza en

condiciones controladas.

• Controle siempre la parte posterior de la pared en la que

sale la sierra al penetrar. Impida el acceso cercando y

asegúrese de que no haya riesgo de daños personales o

materiales.

• Averigüe y marque siempre la ubicación del trazado de

las tuberías de gas. El corte cerca de las tuberías de gas

siempre es peligroso. Procure que no se generen chispas

al cortar, debido al riesgo de explosición. Trabaje

concentrado en su tarea. La negligencia comporta riesgo

de daños personales graves y peligro de muerte.

• Use la máquina exclusivamente en lugares con buena

ventilación. Los descuidos pueden ocasionar daños

graves o mortales.

• Compruebe que los cables eléctricos que haya en el área

de trabajo no tengan tensión.

• Mantenga bajo vigilancia la máquina siempre que el

motor esté en marcha.

• Nunca utilice la sierra sin tener al alcance el botón de

parada de emergencia del control remoto o de la unidad

eléctrica. Consulte el manual de la unidad eléctrica.

• Al trabajar con las máquinas, procure siempre que haya

alguien cerca, que pueda prestar ayuda en caso de

accidente.

• Las personas que deban permanecer cerca deben usar

protectores auriculares porque el nivel sonoro al cortar es

superior a 85 dB(A).

• Cerciórese de que ninguna persona ni animal se

aproxime más de 4 m (15 ft) a la máquina cuando la

misma esté en funcionamiento.

• No usar en condiciones climáticas desfavorables. Por

ejemplo, niebla densa, lluvia, viento fuerte, frío intenso,

etc. Trabajar con mal tiempo es cansador y puede crear

condiciones peligrosas, por ejemplo suelo resbaladizo.

• Controle que la zona de trabajo esté bien iluminada para

lograr un entorno seguro.

• Cerciórese siempre de tener una posición de trabajo

segura y firme.

• Proceda con cuidado en las elevaciones. Las piezas son

pesadas, por lo que hay riesgo de daños por apriete y

daños personales de otro tipo.

Técnica básica de trabajo

• Empiece siempre cortando un surco de guía. Esto se

hace insertando el disco 3-7 cm (1,2”-2,8”). A

continuación, corte el surco de guía. El corte no se debe

hacer a velocidad máxima, sino de forma cuidadosa para

conseguir un corte recto y facilitar así el corte siguiente.

El brazo de corte permite utilizar discos de hasta 1000

mm (40 in) como disco de inicio. Sin embargo, se

aconseja comenzar a cortar con un disco de 800 mm

(31,5 in).

• Cuando esté terminado el corte de guía, se pueden hacer

cortes más profundos. La profundidad de los mismos se

determina según el caso y depende de factores como la

dureza del hormigón, la presencia de hierros de

armadura, etc.

Deberá utilizarse una velocidad más baja o realizarse un

corte más superficial al cortar en hormigón duro que al

cortar en hormigón blando. Ello permite una velocidad del

motor de avance alta, que da como resultado un corte

más efectivo y recto. El diámetro máximo del disco para

los cortes más profundos es de 1600 mm (63 in).

• Si cambia los discos para que trabajen a mayor

profundidad en el mismo corte, asegúrese de que la

anchura del segmento del disco se corresponde con el

ancho del surco.

• Deje que la máquina trabaje sin forzar ni presionar el

disco.

• Sujete o ancle con firmeza los bloques de hormigón antes

de cortarlos. El elevado peso del material cortado puede

causar daños importantes si no se desplaza en

condiciones controladas.

Tronzado de bloques

• Primero, haga el corte horizontal inferior. A continuación,

haga el corte horizontal superior. Finalmente, haga los

dos cortes verticales.

¡ATENCIÓN! No utilice nunca un disco de

corte para ningún material para el que no

!

esté destinado.

La utilización de las hojas de la sierra a una

velocidad superior a la recomendada por el

fabricante puede dañar la sierra e incluso

puede causarle lesiones. Vea el capítulo

Datos técnicos.

• Si el corte horizontal superior se hace antes del corte

horizontal inferior, la pieza de trabajo cae sobre el disco y

lo aprieta.

• Cuando realice el último corte, la sierra deberá instalarse

en una pared fija adyacente.

• Dado que el riel es simétrico, la unidad de serrado puede

girarse para realizar un nuevo corte en el otro lado del riel.

De esta manera, se obtendrá una pieza de corte con un

tamaño fácilmente manejable, lo que hará que sea más

sencillo retirarla del lugar del trabajo.

• Puesto que puede seleccionar el sentido de rotación de la

hoja, la pulverización de agua también puede

seleccionarse independientemente de como esté

colocada la sierra en el riel.

Spanish – 23

Page 24

PRESENTACIÓN

WS 482 HF

Esperamos que su máquina le proporcione plena satisfacción

y le sirva de ayuda por mucho tiempo en adelante. Tenga en

cuenta que este manual de instrucciones es un documento

de valor. Siguiendo sus instrucciones (de uso, servicio,

mantenimiento, etcétera) puede alargar considerablemente

la vida útil de la máquina e incrementar su valor de reventa.

Si vende su máquina, entregue el manual de instrucciones al

nuevo propietario.

La adquisición de alguno de nuestros productos da acceso a

asistencia profesional con reparaciones y servicio. Si la

máquina no fue adquirida en un distribuidor oficial, preguntar

en la tienda de compra la dirección del taller de servicio más

cercano.

Husqvarna Construction Products se esfuerza

constantemente por mejorar la construcción de sus

productos. Por consiguiente, Husqvarna se reserva el

derecho a introducir modificaciones de diseño sin previo

aviso y sin compromisos ulteriores.

Generalidades

• El eficaz motor con refrigeración hidráulica transmite una

impactante potencia de 19 kW al husillo, aunque la sierra

pese solo 27 kg (59,5 lb).

• La velocidad del husillo se ajusta eléctricamente y puede

controlarse con el control remoto de la unidad eléctrica.

• Reduzca la distancia entre el disco y la banda de

rodadura para que el corte sea más recto.

• Embrague deslizante para todas las piezas móviles

• La dirección del disco y la dirección del pulverizador de

agua puede controlarse con el control remoto de la

unidad eléctrica.

• La velocidad del eje se controla con un engranaje

mecánico en el brazo de corte de la unidad de serrado y

con un potenciómetro eléctrico en el control remoto.

• Equipada con freno de hoja automático que detiene la

hoja en pocos segundos.

Un equipo de sierra completo consta de:

• Una unidad de sierra

• Un riel de 1,2 m + carro de la sierra

• Un riel de 2 m + carro de la sierra

• Cuatro soportes de pared

• Un soporte de riel

• Un empalme

• Una protección de disco de 800 ó 1.000

• Una guía de protección de disco

• Un juego de herramientas

• Una botella con aceite Husqvarna 150

• Cajas de transporte para las diferentes unidades.

• Cepillo de limpieza

• Tornillos para corte liso.

El riel corto y el riel largo tienen un carro montado en fábrica

para facilitar al máximo posible el corte.

Dado que una gran parte del trabajo de corte consta de

transportes, el equipo de sierra se entrega en unas cajas

especiales. Las cajas proporcionan una buena protección

durante el transporte y reducen el número de bultos a

desplazar entre los lugares de trabajo, con lo que se aumenta

la eficacia.

24 – Spanish

Page 25

MONTAJE

Riel y accesorios del soporte de pared

Procedimiento de montaje del soporte de pared:

1 Marque la línea de corte y los agujeros para pernos de

expansión a 165 mm (6,5”) de la línea de corte.

2 Taladre agujeros de 15 mm (5/8”) para los pernos de

expansión M12 (1/2”).

3 Cuelgue los soportes de pared sueltos en los pernos de

expansión: se recomienda M6S 12 x 70 (1/2”x2”).

4 Ponga el riel entre los soportes de pared y apriete las

arandelas de fijación.

Para cortes verticales, coloque el riel con la palanca de

bloqueo del carro de la sierra hacia arriba. Así se facilita

el ajuste de la unidad de serrado.

5 Compruebe que el riel está bien alineado con las bandas

en los soportes de pared antes de apretar los tornillos.

6 Ajuste la distancia entre el corte y el soporte de pared. La

distancia entre el borde del soporte de pared y el borde

interior del corte debe ser de 89 mm (3,5”). Apriete el

perno de expansión.

Instalación del carro y de la sierra

El carro de la sierra se recibirá montado en el riel. Para

desmontar el carro del riel, retire el tope y a continuación

extraiga el carro del riel.

1 Monte el cuerpo de sierra en el carro, elevándolo y

colocándolo en su sitio. Cuando se coloca la sierra en su

sitio, la empuñadura de bloqueo sube a una posición

intermedia. En esta posición, la sierra permanece

suspendida en el carro sin que sea necesario sujetarla.

Sin embargo, no está lo suficientemente fijada para

cortar.

2 Para fijar la sierra, eleve la empuñadura de bloqueo hacia

la misma hasta que quede bloqueada.

¡IMPORTANTE! Use solamente el empalme incluido en la

entrega de la sierra, puesto que los empalmes antiguos no

están adaptados para la serie WS 400.

¡ATENCIÓN! El corte sin que la sierra esté

bien fijada en el carro y el riel comporta

!

peligro de muerte.

Spanish – 25

Page 26

MONTAJE

Monte el disco

¡ATENCIÓN! Nunca monte ni desmonte el

disco ni el protector del disco sin haber

!

desconectado antes el cable que va hasta la

unidad de serrado. La utilización del equipo

sin el debido cuidado puede causar lesiones

graves e incluso la muerte.

1 Empiece limpiando toda la suciedad de las superficies de

contacto de la brida de disco y del disco.

2 Compruebe el sentido de rotación del disco. La hoja

girará con la parte visible de diamante siguiendo la

dirección de rotación de la hoja. Puesto que puede

seleccionar el sentido de rotación de la hoja, la

pulverización de agua también puede seleccionarse

independientemente de como esté colocada la sierra en

el riel.

3 Atornille la brida de disco exterior, el disco y el cubo de

brida de disco (par de apriete, 70-80 Nm).

5 Gire cuidadosamente el cubo de brida de disco de

manera que se deslice en uno de los rieles del brazo

pivotante y alcance la posición correcta para atornillarlo.

6 Inserte a presión el eje del disco en el brazo de corte,

girando con cuidado al mismo tiempo el disco. Cuando ya

no se pueda seguir presionando a mano el eje del disco,

apriételo con la llave 18 incluida en la entrega hasta que

esté bien fijado (par de apriete, 70-80 Nm).

4 Fije el disco suspendido con una brida de disco montada

y el cubo de brida de disco en el brazo de corte (el disco

no está ilustrado en la figura).

¡ATENCIÓN! Monte el disco minuciosamente

para que no haya riesgo de que se suelte al

!

cortar. La utilización del equipo sin el debido

cuidado puede causar lesiones graves e

incluso la muerte.

Corte liso

Desatornille la brida de disco exterior y monte el disco en el

cubo de brida de disco.

26 – Spanish

A = 110 mm / 4,33 in, 6 M10

B = 89 mm / 3,5 in, 6 M8

C = 144 mm / 5,7 in

Page 27

MONTAJE

Monte la protección del disco

¡ATENCIÓN! Nunca monte ni desmonte el

disco ni el protector del disco sin haber

!

desconectado antes el cable que va hasta la

unidad de serrado. La utilización del equipo

sin el debido cuidado puede causar lesiones

graves e incluso la muerte.

1 Deslice la guía del protector del disco entre los tirantes del

protector del disco. Coloque la guía del protector del

disco en el centro. Cierre el talón de plástico de la

manivela sobre el tirante superior del protector del disco.

4 Para quitar el protector, suelte el pestillo y tire de la

palanca hacia arriba y hacia el interior hasta el protector.

Bloquee el talón de plástico sobre el tirante superior.

5 Conecte la manguera de agua procedente de la conexión

exterior de la motor de serrado a la conexión interior del

cubo de brida de disco.

Conecte la unidad eléctrica

2 Asegúrese de que el brazo pivotante se encuentra en

posición vertical. Coloque la protección sobre el disco y

cuélguela en su soporte en la sierra. Procure que las

guías deslizantes de la protección del disco entren en las

ranuras de los bloques de agua.

3 Bloquee el protector de la hoja tirando de la palanca hacia

fuera del protector y después hacia abajo (hacia la unidad

de serrado), hasta que el pestillo bloquee la palanca.

1 Lea el manual de instrucciones suministrado con la

unidad eléctrica antes de utilizar la máquina.

2 Una vez instalados la unidad de serrado, la hoja y el

protector de la hoja, deberá conectar el cable de

alimentación (A) y el sistema de refrigeración hidráulica

(B) a la unidad.

¡IMPORTANTE! Esta máquina está pensada para ser

utilizada con una unidad de alimentación Husqvarna PP

480 HF. Está prohibida cualquier otra aplicación.

Spanish – 27

Page 28

REGLAJES Y AJUSTES

Manija de cambio

Elija el engranaje para la velocidad deseada. En el engranaje

1, el intervalo de velocidad es de 600-900 r/min y en el

engranaje 2, de 800-1200 r/min. Encontrará más información

sobre los discos y la velocidad recomendados en el apartado

«Velocidad de disco recomendada» del capítulo «Datos

técnicos».

A - Engranaje 1

B - Engranaje 2

AVISO Asegúrese de que el mando de las marchas está

colocado como se muestra en la imagen. Si el mando está

entre dos marchas, puede dañar la caja de cambios.

Ajuste de las ruedas de guía

Ajuste la sierra en el carro

Puesto que la sierra se desgasta, después de un

determinado número de horas de empleo puede ser

ventajoso asegurarse de que la unidad de sierra está

montada firmemente en el carro y el riel. De no ser así, es

probable que sea necesario ajustar la empuñadura:

• Afloje los tornillos hexagonales (1) marcados (uno a cada

lado de la empuñadura).

• Gire los ejes excéntricos (2) con la herramienta especial

suministrada hasta que el eje quede apretado y en

paralelo contra la sierra.

• A continuación, vuelva a enroscar los tornillos

hexagonales.

Para que la sierra funcione de forma estable y haga cortes

rectos, es necesario que las cuatro ruedas de guía estén en

contacto con el riel, sin huelgo.

Compruebe las ruedas guía antes de cada corte. Si el carro

tiene huelgo en el riel, hay que ajustar las ruedas de guía:

• Empiece soltando las dos tuercas (1) marcadas con la

herramienta especial incluida en la entrega.

• A continuación afloje los dos tornillos de tope (2).

• Ajuste las ruedas guía con la tuerca M10 (3), situada en

la parte trasera de la rueda guía, hasta que no quede

espacio libre. Gire las tuercas hacia fuera para cada una.

• Sujete las ruedas de guía y vuelva a atornillar el tornillo

de tope.

• A continuación enrosque las tuercas para fijar las ruedas

de guía en la nueva posición.

28 – Spanish

Page 29

ARRANQUE Y PARADA

Antes del arranque

• Cerque el área en que va a cortar para impedir la entrada

de personas ajenas al trabajo y evitar el riesgo de que

sufran daños y que le estorben en el trabajo.

• Asegúrese de que ni el disco ni el protector estén

dañados o agrietados. Sustituya el disco o el protector si

han sufrido golpes o están agrietados.

• Compruebe que todos los cables y el suministro de agua

están correctamente conectados a la máquina antes de

arrancarla.

• Si el corte se va a iniciar en un lugar distinto al que se

encuentra la unidad de sierra, ponga la unidad en la

posición de arranque.

• Elija el engranaje para la velocidad deseada.

Arranque

Siga las instrucciones de arranque proporcionadas en el

manual que acompaña la unidad eléctrica.

Parada

• Cuando termine el corte, saque el disco de la pared y

desactive la rotación del disco y el flujo de agua.

• Apague la unidad eléctrica.

Desmontaje de la sierra

1 Espere a que el motor se pare totalmente.

2 Desconecte la unidad de la alimentación.

3 Apague y desconecte la entrada de agua de la unidad

eléctrica.

4 Desconecte el cable de alimentación y la manguera de

agua de la unidad de serrado.

5 Las demás medidas se hacen en orden inverso al

montaje.

Limpieza

Después de cortar hay que limpiar la sierra. Es importante

limpiar todo el equipo. Para limpiar la sierra, se recomienda

utilizar el cepillo de limpieza facilitado conectándolo a la

manguera de agua.

¡IMPORTANTE! No utilice un equipo de limpieza a alta

presión para limpiar la sierra.

Spanish – 29

Page 30

MANTENIMIENTO

Servicio

¡IMPORTANTE! Las reparaciones de todo tipo deben ser

efectuadas por técnicos autorizados, únicamente. De este

modo se evita someter a los operadores a grandes riesgos.

Después de 100 horas de funcionamiento, se mostrará el

mensaje «Time for servicing» («Efectuar mantenimiento»).

Deberá llevar el equipo a un distribuidor autorizado de

Husqvarna para que efectúe el mantenimiento de la máquina.

Mantenimiento

¡IMPORTANTE! El control y/o mantenimiento de la

máquina debe hacerse con el motor parado y el enchufe

desenchufado.

Cambio del aceite del brazo de corte

Lubricación de los engranajes del alimentador

¡IMPORTANTE! Si no se lubrican de forma regular los

engranajes, su vida útil se reducirá considerablemente.

• Todas las unidades de serrado cuentan con dos boquillas

de engrase. Los engranajes de los motores de

alimentación se lubrican con estas boquillas. Lubríquelos

diariamente o al menos cada 30 horas de funcionamiento.

Utilice PETRO CANADA PERLESS OG2 o el lubricante

correspondiente.

• En el brazo de corte hay un tapón para vaciar el aceite.

Este tapón se debe limpiar al cambiar el aceite. El aceite

nuevo se pone por el agujero del tapón de aceite.

• El brazo de corte contiene 3 dl de aceite Husqvarna Oil

150: un aceite para engranajes tipo EP 150. El primer

cambio de aceite se hace con ocasión del primer servicio.

La entrega de la sierra nueva incluye una botella con 3 dl

de aceite.

¡IMPORTANTE! El aceite de motor y de transmisión es

nocivo para la salud y no debe verterse en el suelo o en el

campo.

Engrase el eje del disco

• Para facilitar al máximo posible el montaje del eje del

disco, a veces puede ser necesario engrasar el eje

hexagonal. Compruebe al mismo tiempo que el eje

hexagonal no esté dañado.

Mantenimiento diario

30 – Spanish

1 Compruebe que todas las juntas, conexiones y cables

están intactos y limpios.

2 Limpie la parte exterior de la máquina. No utilice un

equipo de limpieza a alta presión para limpiar la sierra.

3 Asegúrese de que ni el disco ni el protector estén

dañados o agrietados. Sustituya el disco o el protector si

han sufrido golpes o están agrietados.

Page 31

DATOS TECNICOS

WS 482 HF

Peso

Carro de la sierra, kg/lbs 3,7/8,2

Unidad de sierra, kg/lbs 27/59,5

Protección del disco 800 mm, kg/lbs 13/28,7

Protección del disco 1000 mm, kg/lbs 16/35,3

Riel 1200 mm (47”) kg/lbs 9,5/20,9

Riel 2000 mm (79”) kg/lbs 19/41,9

Tamaño del disco

Tamaño máx. del disco, mm / pulgadas 1600/63

Tamaño máx. del disco, mm / pulgadas 600/23,6

Disco de arranque máx., mm / pulgadas 1000/39,4

Profundidad máxima de la sierra, mm/pulgadas 730/28,5

Motor impulsor del disco de la sierra Ciclo alto de PM

Salida máx. del husillo, kW 19

Mecanismo de transmisión Transmisión

Velocidad de salida, rpm 0-1200

Control / Sistema de alimentación Eléctrico / automático

Par motor máx. en el disco de la sierra, Nm 230

Par de arranque, Nm 150

Presión máx. de la refrigeración hidráulica, bar 7

Caudal mínimo de agua refrigeradora, l/min 3,5

Temperatura máx. de la refrigeración hidráulica a 3,5 l/min,

ºC

Tipo de protección IP 65

Emisiones de ruido (vea la nota 1)

Nivel de potencia acústica medido dB(A) 108

Nivel de potencia acústica garantizado LWA dB(A) 109

Niveles acústicos (vea la nota 2)

Nivel de presión acústica en el oído del usuario, dB(A) 85

Nota 1: Emisiones sonoras en el entorno medidas como potencia sonora (LWA) según la norma EN 15027/A1.

Nota 2: Nivel de presión sonora conforme a EN 15027/A1. Los datos referidos del nivel de presión sonora tienen una dispersión

estadística habitual (desviación típica) de 1,0 dB (A).

25

Spanish – 31

Page 32

DATOS TECNICOS

Velocidad de la hoja recomendada

¡ATENCIÓN! Si corta a revoluciones

demasiado elevadas puede causar daños a

!

la hoja y daños personales.

Velocidad, r/min

Engranaje 1 600-900

Engranaje 2 800-1200

Cuando se sierra a velocidades comprendidas entre las 800 y 900 rpm, se obtiene un resultado de serrado mayor si se utiliza el

engranaje 1.

Siga las recomendaciones del fabricante de la hoja acerca del material y la velocidad cuando elija una hoja. Deberá utilizarse una

velocidad más baja o realizarse un corte más superficial al cortar en hormigón duro que al cortar en hormigón blando.

600 mm (24”) 800 mm (32”) 1000 mm (40”) 1200 mm (48”) 1600 mm (63”)

600 r.p.m.

700 r.p.m.

800 r.p.m.

900 r.p.m.

1000 r.p.m.

1100 r.p.m.

1200 r.p.m.

Hormigón

Duro

Medio

Blando

Dimensiones

32 – Spanish

Page 33

DATOS TECNICOS

Declaración CE de conformidad

(Rige sólo para Europa)

Husqvarna AB, SE-433 81 Göteborg, Suecia, teléfono: +46-31-949000, declara por la presente que la sierra de pared Husqvarna

WS 482 HF, a partir del número de serie del año 2010 en adelante (el año se indica textualmente en la placa de identificación,

seguido del número de serie), cumple con las siguientes disposiciones de la DIRECTIVA DEL CONSEJO:

• 2006/42/CE «relativa a máquinas» del 17 de mayo de 2006.

• 2004/108/CEE, ”referente a compatibilidad electromagnética”, del 15 de diciembre de 2004.

• 2006/95/CE del 12 de diciembre de 2006 relativa a equipos eléctricos.

Se han aplicado las siguientes normas: EN ISO 12100:2003, EN 55014-1:2006, EN 55014-2/A1:2001, EN 61000-3-11:2000, EN

15027/A1:2009.

Huskvarna, 29 de diciembre de 2009

Henric Andersson

Vicepresidente, jefe de la sección de cortadoras y maquinaria para la construcción

Husqvarna AB

(Presentante autorizado de Husqvarna AB y responsable de la documentación técnica.)

Spanish – 33

Page 34

SYMBOLERKLÄRUNG

Symbole am Gerät:

WARNUNG! Das Gerät kann falsch oder

nachlässig angewendet gefährlich sein

und zu schweren oder gar

lebensgefährlichen Verletzungen des

Benutzers oder anderer Personen führen.

Lesen Sie die Bedienungsanweisung

sorgfältig durch und machen Sie sich mit

dem Inhalt vertraut, bevor Sie das Gerät

benutzen.

Benutzen Sie immer:

• Einen zugelassenen Schutzhelm

• Einen zugelassenen Gehörschutz

• Schutzbrille oder Visier

• Atemschutzmaske

Täglich schmieren.

Dieses Produkt stimmt mit den geltenden

CE-Richtlinien überein.

Symbole in der Bedienungsanweisung:

Kontrollen und/oder Wartungsarbeiten sind

bei abgeschaltetem Motor und

abgezogenem Stecker zum Aggregat

durchzuführen.

Stets zugelassene Schutzhandschuhe

tragen.

Regelmäßige Reinigung ist notwendig.

Visuelle Kontrolle.

Schutzbrille oder Gesichtsschutz müssen

benutzt werden.

Umweltkennzeichnung. Das Symbol auf

dem Produkt oder der Verpackung gibt an,

dass dieses Produkt nicht im Hausmüll

entsorgt werden darf. Zur Entsorgung ist es

stattdessen an eine entsprechende

Recyclinganlage für elektrische und

elektronische Geräte zu übergeben.

Durch eine korrekte Entsorgung dieses

Produkts tragen Sie dazu bei, mögliche negative

Auswirkungen auf Ihre Umwelt und Mitmenschen zu

verhindern. Durch eine unsachgemäße Entsorgung dieses

Produkts können Schäden entstehen.

Ausführliche Recyclinginformationen zu diesem Produkt

erhalten Sie von Ihrer Kommune, Entsorgungsunternehmen

für Hausmüll oder dem Geschäft, in dem Sie das Produkt

erworben haben.

34 – German

Page 35

INHALT

Inhalt

SYMBOLERKLÄRUNG

Symbole am Gerät: ...................................................... 34

Symbole in der Bedienungsanweisung: ....................... 34

INHALT

Inhalt ............................................................................ 35

WAS IST WAS?

Was ist was an der Wandsäge? ................................... 36

SICHERHEITSVORSCHRIFTEN

Maßnahmen vor der Benutzung einer neuen Wandsäge

Persönliche Schutzausrüstung .................................... 37

Allgemeine Sicherheitsvorschriften .............................. 38

Allgemeine Arbeitsvorschriften .................................... 38

Grundlegende Arbeitstechnik ...................................... 39

VORSTELLUNG

WS 482 HF .................................................................. 40

MONTAGE

Wandbefestigungen und Schiene montieren ............... 41

Sägewagen und Schneideinheit montieren ................. 41

Klinge montieren .......................................................... 42

Flachschneiden ............................................................ 42

Trennscheibenschutz montieren .................................. 43

Aggregat anschließen .................................................. 43

EINSTELLUNGEN UND JUSTIERUNGEN

Gangwählschalter ........................................................ 44

Führungsräder justieren ............................................... 44

Trennschleifer im Sägewagen justieren ....................... 44

STARTEN UND STOPPEN

Vor dem Start ............................................................... 45

Starten ......................................................................... 45

Stoppen ....................................................................... 45

Demontage des Trennschleifers ................................... 45

Reinigung ..................................................................... 45

WARTUNG

Service ......................................................................... 46

Wartung ....................................................................... 46

Tägliche Wartung ......................................................... 46

TECHNISCHE DATEN

WS 482 HF .................................................................. 47

EG-Konformitätserklärung ........................................... 49

37

German – 35

Page 36

WAS IST WAS?

Was ist was an der Wandsäge?

1 Verbinder

2 Schienenhalte

3 Wandbefestigungen

4 Sperrgriff

5 Sägewagen

6 Schiene

7 Wasserschlauch

8 Befestigung Handgriff/Klingenschutz