Page 1

Operator’s manual

Read these instructions carefully and make sure

you understand them before using the TS 355.

Manual

Lea cuidadosamente estas instrucciones y asegúrese

de que las comprende bien antes de usar el TS 355.

Manuel d’utilisation

Veuillez lire attentivement ces instructions et assurez-vous deVeuillez lire attentivement ces instructions et assurez-vous de

bien les comprendre avant d’utiliser la machine modèle FS 4800.

del operador

TS 355,

TS 355 G

1

Page 2

EVERY MACHINE IS THOROUGHLY TESTED BEFORE LEAVING THE FACTORY. EACH MACHINE IS SUPPLIED WITH A COPY OF THIS MANUAL. OPERATORS OF THIS EQUIPMENT MUST READ AND BE FAMILIAR WITH THE SAFETY WARNINGS. FAILURE TO OBEY WARNINGS MAY RESULT IN INJURY OR DEATH.

FOLLOW INSTRUCTIONS STRICTLY TO ENSURE LONG SERVICE IN NORMAL OPERATION.

CONTENTS

Symbol Denitions ............................................................................................................................................. 3 - 6

Hearing Hazard Warnings ................................................................................................................................. 6

Decal Descriptions and Locations ..................................................................................................................... 7

Specications & Power Sources........................................................................................................................ 8

Saw Dimensions ................................................................................................................................................ 9

Safety Warnings - Do's and Do Not's ................................................................................................................ 10 - 11

Reference Figures: 1 - 13 .................................................................................................................................. 12 - 14

Pre Operation Checklist..................................................................................................................................... 15

Instructions:

1 - Features ......................................................................................................................................... 16

2 - Assembly ........................................................................................................................................ 16 - 17

3 - Check Before Operating ................................................................................................................. 18

4 - Fitting the Blade ............................................................................................................................. 18

5 - Operating Instructions .................................................................................................................... 18 - 20

6 - Incidents During Operation............................................................................................................. 20

7 - Maintenance ................................................................................................................................... 20 - 21

8 - V-Belt Tension ................................................................................................................................ 21

9 - Important Advice............................................................................................................................. 21 - 22

10 - Accessories .................................................................................................................................... 22

11 - Repairs ........................................................................................................................................... 22

12 - Spare Parts .................................................................................................................................... 22

Diagrams and Spare Parts ................................................................................................................................ 40 - 47

Wiring Diagrams ................................................................................................................................................ 48 - 49

ANTES DE COMENZAR: Lea y comprenda todas las advertencias e instrucciones antes de operar la máquina

que se describe en este manual. ¡LAS ADVERTENCIAS Y PRECAUCIONES DE ESTE MANUAL DEBEN SER

COMPRENDIDAS Y CUMPLIDAS! SI NO SE OBEDECEN LAS ADVERTENCIAS, SE PUEDEN PRODUCIR

SERIAS LESIONES O LA MUERTE. ES SU RESPONSABILIDAD el asegurarse que las personas que usen

esta máquina hayan leído este manual.

CONTENIDO

Denición de Símbolos ...................................................................................................................................... 3 - 6

Advertencias Auditivas de Peligro ..................................................................................................................... 6

Calcomanís - Descripciones y Ubicaciones ......................................................................................................7

Especiciones y Fuentes de Energía ................................................................................................................ 24

Dimensiones de la Sierra ..................................................................................................................................25

Advertencias de Seguridad - Los SI y Los NO .................................................................................................. 26 - 27

Ilustraciones de Referencia: 1 - 13 ................................................................................................................... 28 - 30

Lista de Comprobaciones Previas a la Operación ............................................................................................31

Instrucciones:

1 - Usos ............................................................................................................................................... 32

2 - Armado ........................................................................................................................................... 32 - 34

3 - Verique Antes De Operar..............................................................................................................34

4 - Colocación De La Hoja................................................................................................................... 34 - 35

5 - Instrucciones De Operación ........................................................................................................... 35 - 36

6 - Incidentes Durante La Operación................................................................................................... 36 - 37

7 - Mantenimiento ................................................................................................................................ 37 - 38

8 - Tensión De La Cinta En V .............................................................................................................. 38

9 - Consejo Importante ........................................................................................................................ 38 - 39

10 - Accesorios ...................................................................................................................................... 39

11 - Reparaciones ................................................................................................................................. 39

12 - Piezas De Repuesto....................................................................................................................... 39

Diagramas de Cableado .................................................................................................................................... 48 - 49

2

Page 3

SYMBOL DEFINITIONS

DEFINICIÓN DE SIMBOLOS

• Please read the instructions for use prior to operating the machine for the rst time.

• Antes de la puesta en marcha, lea detenidamente las instrucciones y familiaricese con la máquina.

• Mandatory

• Obligatorio

• Indication

• Indicación

• Prohibition

• Prohibición

• Warning Triangle

• Triángwulo De Advertencia

• Wear Eye Protection

• Usar Gafas De Protección

• Wear Head Protection

• Usar Casco De Protección

• Wear Breathing Protection

• Usar Máscara De Protección

• The Use Of Ear Protection Is Mandatory

• Es Obligatorio El Uso De Protección Auditiva

• Wear a Hard Hat

• Usar Casco Duro

• Wear Safety Shoes

• Usar Zapatos De Seguridad

• Wear Appropriate Clothing

• Usar Ropa Adecuada

• Remove The Blade Prior To Hoisting, Loading, Unloading And Transporting The Machine On Jobsite.

• Desmontar El Disco Antes De Desplazar, Cargar, Descargar O Transportar La Máquina En La Obra.

3

Page 4

• Motor Off

• Parar El Motor

• Use In Well Ventilated Area

• Usar En Una Área Bien Ventilada

• Do Not Use In Flammable Areas

• No Usar In Áreas Inamables

• Machinery Hazard, Keep Hands And Feet Clear.

• Máquina Peligrosa - Mantenga Manos Y Pies Alejados De La Máquina

• Danger, Poison Exhaust Gas

• Peligro, Gases De Escape Tóxicos

• No Non-working Personnel In Area

• Prohibido Para Personas Ajenas A La Obra

• No Smoking

• No Fumar

• Do Not Operate Without All Guards In Place

• No Operar Sin Todas Las Protecciones In Su Sitio

• Always Keep the Blade Guards In Place

• Mantenga Siempre Las Protecciones De La Hoja En Su Sitio

• Water Supply On

• Suministro De Agua Conectado

• Water Supply Off

• Suministro De Agua Desconectado

• Water Supply

• Suministro De Agua

• Keep Work Area Clean/Well Lit, Remove All Safety Hazards

• Mantenga Limpio El Sitio De Trabajo/Bien Iluminado, Elimine Todos Los Riesgos De Seguridad

4

Page 5

• Dangerously High Noise Level

• Nivel De Ruido Elevadamente Peligroso

• Pay Extreme Attention To The Care And Protection Of The Machine Before Starting Up

• Ponga Extrema Atención Al Cuidado Y Preparación De La Máquina Antes De Ponerla En Marcha

• Remove Tools From Area and Machine

• Elimine Las Herramientas Del Área Y De La Máquina

• Oil Pressure

• Presión De Aceite

• Oil Required

• Necesita Aceite

• Dipstick, Maintain Proper Oil Level

• Varilla De Control, Mantenga El Nivel De Aceite Correcto

• Lubrication Point

• Punto De Lubrication

• Unleaded Fuel Only

• Solamente Combustible Sin Plomo

• Repairs Are To Be Done By An Authorized Dealer Only

• Las Reparaciones Deben Ser Efectuadas Únicamente Por Un Distribuidor Autorizado

• Diamond Blade

• Sierra Diamantada

• Blade Diameter

• Diámetro De La Hoja

• Pulley Diameter

• Diámetro De La Correa

5

Page 6

• Number of Revolutions Per Minute, Rotational Speed

• N° De Revoluciones Por Minuto, Velocidad De Rotación

• Blade Flange Diameter

• Diámetro De La Brida De La Hoja

• Machine Mass (lbs)

• Masa De La Máquina (lbs)

• Engine

• Motor

• Engine Speed Revolutions/Minute

• Velocidad Del Motor En Revoluciones Por Minuto (RPM)

• Engine Start

• Arranque Del Motor

• Electric Motor

• Motor Electrica

WARNING

HEARING HAZARD

DURING NORMAL USE OF THIS MACHINE, OPERATOR MAY BE EXPOSED TO A NOISE

LEVEL EQUAL OR SUPERIOR TO 85 dB (A)

ATENCION

RIESGO DE DAÑO AUDITIVO

EN CONDICIONES NORMALES DE UTILIZACIÓN, EL OPERADOR DE ESTA MÁQUINA PUEDE

ESTAR EXPUESTO A UN NIVEL DE RUIDO IGUAL O SUPERIOR A 85 dB (A)

DUST WARNING

Cutting, especially when DRY cutting, generates dust that comes from the material being cut, which

frequently contains silica. Silica is a basic component of sand, quartz, brick clay, granite and numerous other

minerals and rocks. Exposure to excessive amount of such dust can cause:

• Respiratory diseases (affecting your ability to breath), including chronic bronchitis, silicosis and pulmonary brosis from exposure to silica. These diseases may be fatal;

• Skin irritation and rash; and

• Cancer according to NTP* and IARC*

* National Toxicology Program, International Agency for Research on Cancer

Take precautionary steps

• Avoid inhalation of and skin contact with dust, mist and fumes;

• Wet cut when feasible, to minimize dust;

• Wear and ensure that all bystanders wear appropriate respiratory protection such as dust masks de-

signed to lter out microscopic particles. (See OSHA 29 CFR Part 1910.1200)

California Prop 65 Warning:

Use of this product can cause exposure to materials known to the State of California to cause cancer and/or birth

defects or other reproductive harm.

6

Page 7

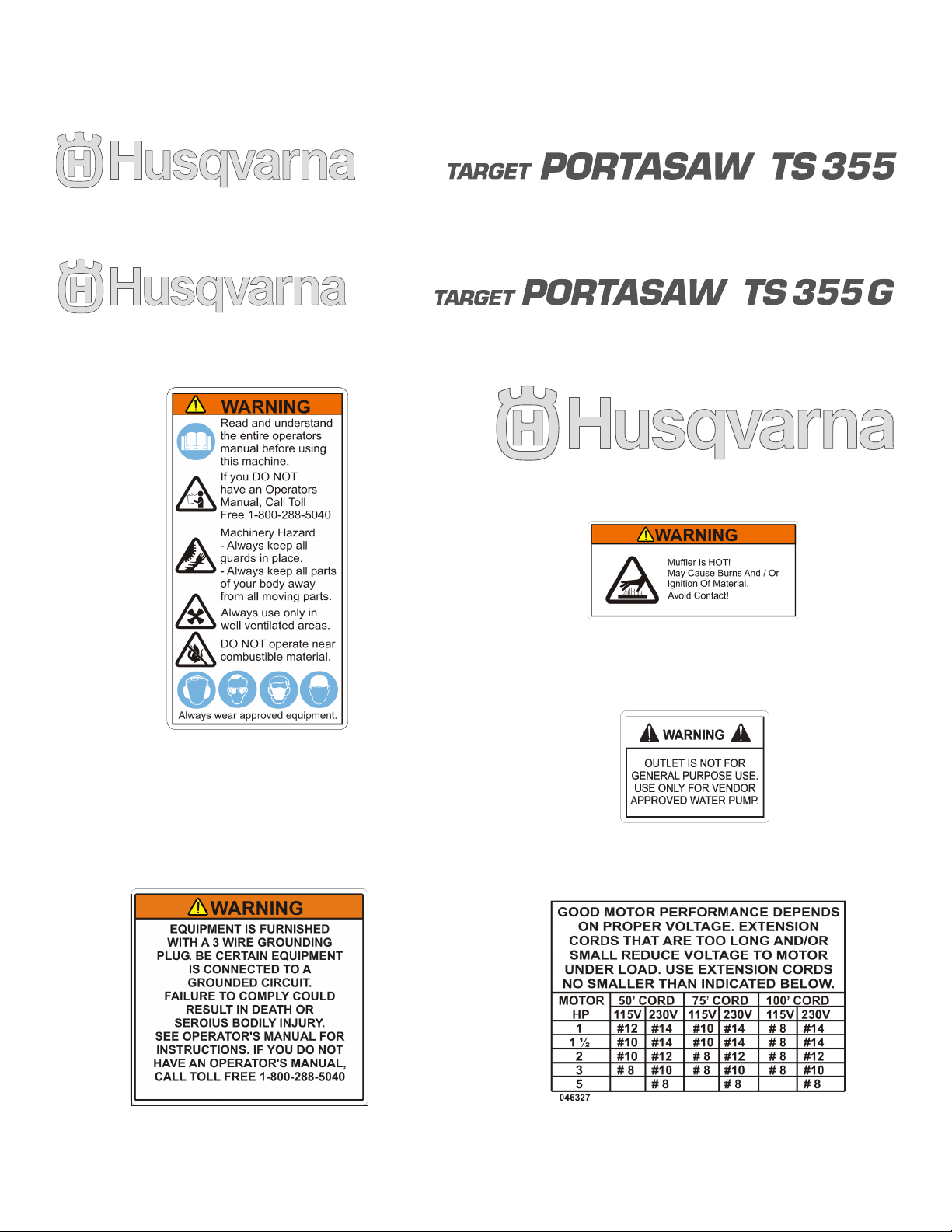

DECAL DESCRIPTIONS AND LOCATIONS

DESCRIPCIÓN DE CALCAMONIAS Y UBICACIONES

P/N 542 19 07-28

Location: Water Pan Sides, (Qty. 2) TS 355 Only

P/N 542 19 07-27

Location: Water Pan Sides, (Qty. 2) TS 355 G Only

542 19 07-33

Location: Front of Pan, Belt Guard, All Models (Qty. 2)

P/N 542 17 75-88

Location: Blade Guard (Qty. 1) All Models

P/N 169065

Location: Mufer

(Qty. 1) Gas Models

P/N 542 18 92-47*

Location: Motor

(Qty. 1) Electric Models

P/N 542 04 63-26

Location: Motor

(Qty. 1) Electric Models

P/N 542 04 63-27*

Location: Motor

(Qty. 1) Electric Models

7

Page 8

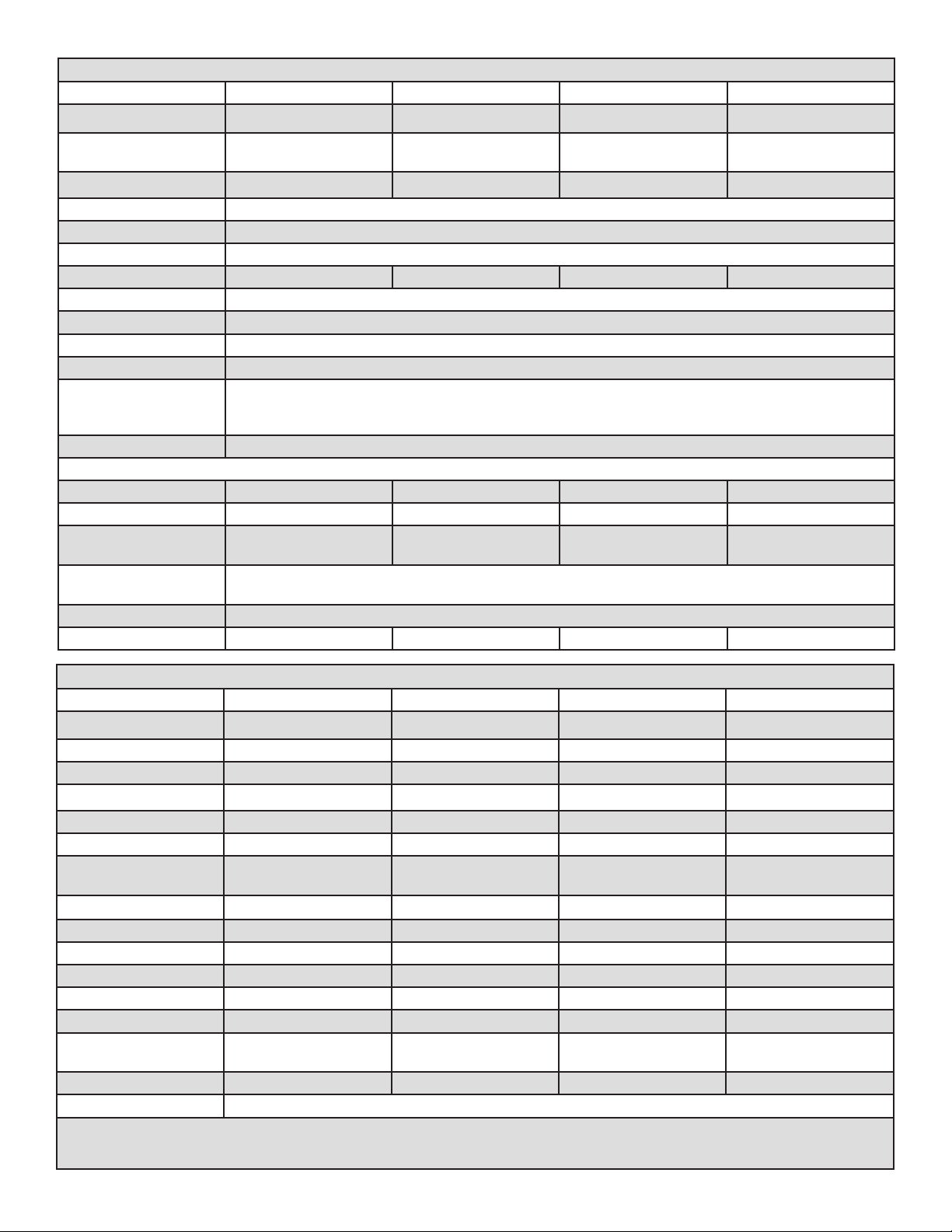

Specications

MODEL NO. TS 355 TS 355 TS 355 TS 355 G

TYPE 1-1/2 HP-115V Electric 2 HP Electric 3 HP Electric 5.5 HP Gasoline

Blade Guard

Capacity

Blade Shaft RPM: 2509 2509 2509 2950

Max. Depth of Cut: 5.0" (127 mm)

Blade Arbor Size: 1.00" (25.4 mm)

Blade Shaft: Sealed Ball Bearings

Blade Shaft Drive: Two 4L370 V-Belts Two 4L370 V-Belts Two 4L370 V-Belts 3VX V-Belt (2 Band)

Blade Guard: One Piece Steel, Sta-LevelTM Design, 14" (350 mm) Maximum Capacity

Blade Coolant: Water

Water Pan: 3.86 x 17.73 x 30.73 Inch (98 x 450 x 780.5 mm), 6.75 Gallon (25 Liter) Capacity (At 3" Depth)

Conveyor Cart: Cast Aluminum w/ Vulcanized Rubber Top, Adjustable Measuring Rule, 45° / 90° Cutting Guide

Water Pump:

Electric Models:

Gasoline Model:

Frame: Heavy duty, Jig Welded “X” Braced Steel, Open Throat Design For Unlimited Ripping

Weight Pounds (kg):

Saw Crated: 171 (77.7) 182 (82.7) 192 (87.3) 209 (95.0)

Saw Uncrated: 160 (72.7) 169 (76.8) 181 (82.3) 198 (90.0)

Saw Operating

(Water in Pan):

Folding Stand

(Unboxed):

Foot Pedal Kit (Boxed): 14 (6.4)

Electric Cord: 0.40 (.18 ) N / A N / A N / A

10 - 14"

(250 - 350 mm)

300 Gallons / Hour, Submersible, Totally Epoxy Sealed, Thermal Over Load Protected

8 GPM, Belt Drive, Solid Bronze, With Strainer & Built-In Priming Pump with Check Valve

221 (100.5) 230 (104.5) 242 (110.0) 259 (117.7)

10 - 14"

(250 - 350 mm)

24 (10.9)

10 - 14"

(250 - 350 mm)

14" Only

(350 mm)

Power Source

MODEL NO. TS 355-15 TS 355-2 TS 355-3 TS 355 G

TYPE: Electric Electric Electric Gasoline

Engine / Motor: Baldor Baldor Baldor Honda

Horsepower (kw): 1-1/2 (1.1) 2 (1.5) 3 (2.2) 5.5 (4.0)

RPM: 3450 3450 3450 3500

Specications: T.E.F.C. T.E.F.C. T.E.F.C. ———

Voltage: 115 / 208-230 115 / 208-230 208-230 ———

Cycle (Hz) /

Current / Phase:

Displacement: ——— ——— ——— 9.9 cu. Inch (163 cc)

Bore: ——— ——— ——— 2.7 inch (68 mm)

Stroke: ——— ——— ——— 1.8 inch (45 mm)

Cylinders / Cycle: ——— ——— ——— 1 / 4

Fuel Capacity: ——— ——— ——— .95 Gallon (3.6 liter)

Oil Capacity: ——— ——— ——— .63 Quart (.6 liter)

Air Filter: ——— ——— ———

Starter: Capacitor Capacitor Capacitor Recoil

Coolant: Air

* 50 cycle motors available upon special request: 2 HP model is 240 Volt, 3 HP model is 220-380 Volt

** 3 phase motor available upon special request - specify 230 or 460 volts for factory wiring.

Note: For item numbers on motors / engine see parts list section of this document. Specications are subject to change without notice.

60 / A.C. / 1 60 * / A.C. / 1 60 * / A.C. / 1 ** ———

Dry Type Dual Element

with Precleaner

8

Page 9

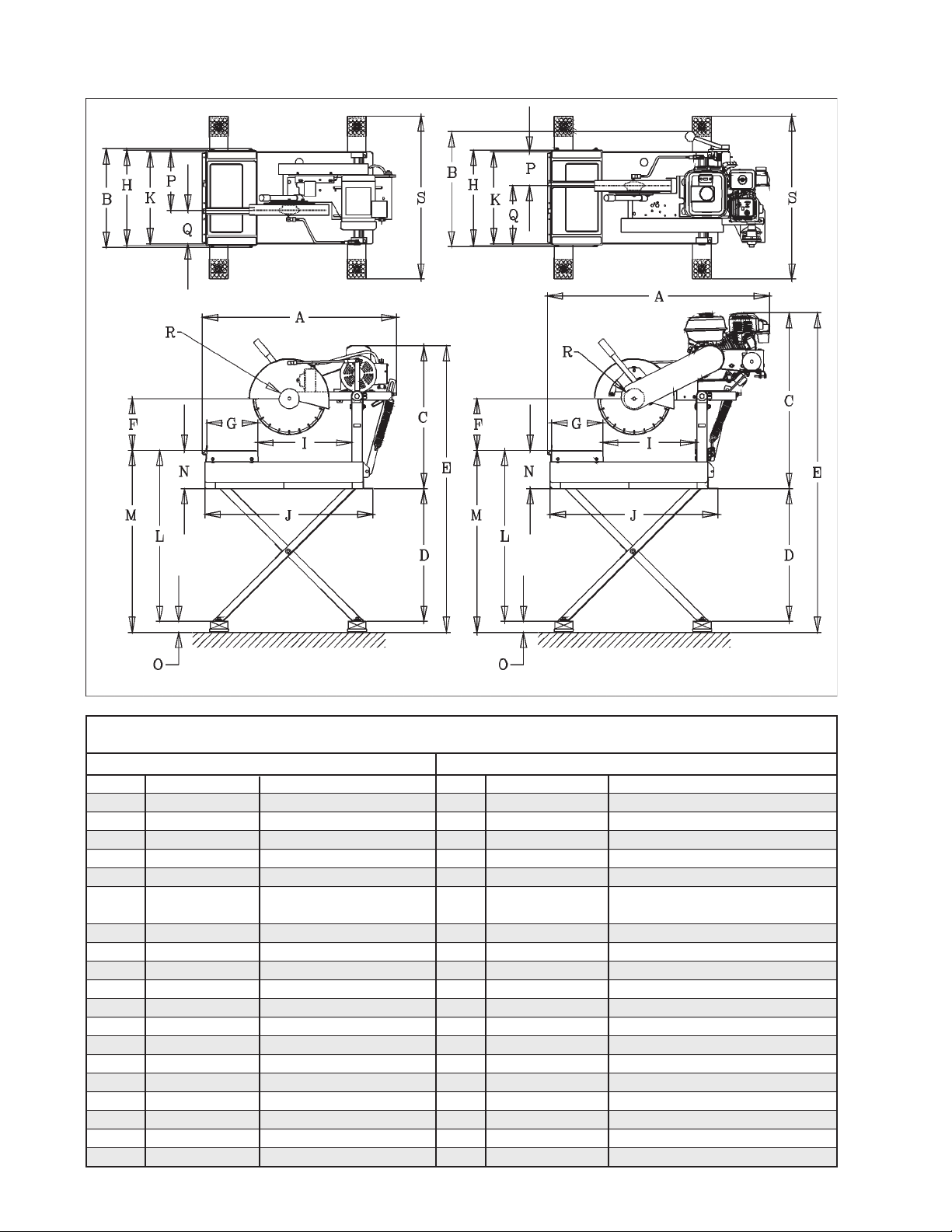

Saw Dimensions

ELECTRIC MODEL

FIGURE A

GASOLINE MODEL

FIGURE B

SAW DIMENSIONS

ELECTRIC MODELS (Figure A) GASOLINE MODEL (Figure B)

Item Length (cm) Description Item Length (cm) Description

A 38.2" (97.0) Saw Length (Maximum) A 43.6" (110.7) Saw Length (Maximum)

B 19.4" (49.3) Saw Width (Maximum) B 22.7" (57.7) Saw Width (Maximum)

C 28.2" (716.3) Saw Height (Minimum) C 34.8" (88.4) Saw Height (Minimum)

D 26.1" (66.3) Stand Height (Optional) D 26.1" (66.3) Stand Height (Optional)

E 56.4" (143.3) Saw Height (Maximum) E 63.0" (160.0) Saw Height (Maximum)

F 3.8 - 15.1" Blade Shaft Height F 6.4 - 15.0" Blade Shaft Height

(9.6 - 38.4) (Minimum - Maximum) (16.2 - 38.2) (Minimum - Maximum)

G 10.0" (25.4) Cart Length G 10.0" (25.4) Cart Length

H 18.7" (47.5) Cart Width H 18.3" (47.5) Cart Width

I 18.5" (47.0) Cart Travel I 18.3" (46.5) Cart Travel

J 33.0" (76.2) Saw Base Length J 33.0" (76.2) Saw Base Length

K 18.0" (45.7) Pan Width K 18.0" (45.7) Pan Width

L 33.7" (85.6) Stand To Cart Top L 33.7" (85.6) Stand To Cart Top

M 35.8" ( 90.9) Skid To Cart Top M 35.8" ( 90.9) Skid To Cart Top

N 7.6" (19.3) Base To Cart Top N 7.6" (19.3) Base To Cart Top

O 2.1" (5.3) Skid Height (Optional) O 2.1" (5.3) Skid Height (Optional)

P 11.5" (29.2) Cart - LH Side P 6.5" (16.5) Cart - LH Side

Q 6.5" (16.5) Cart - RH Side Q 11.5" (29.2) Cart - RH Side

R 4.0" (10.16) Flange Diameter R 4.0" (10.16) Flange Diameter

S 32.0" (81.3) Skid Width (Optional) S 32.0" (81.3) Skid Width (Optional)

9

Page 10

SAFETY FIRST!

WARNINGS

DO’s AND DO NOT’s

WARNING: FAILURE TO COMPLY WITH THESE WARNINGS AND OPERATING

INSTRUCTIONS COULD RESULT IN DEATH OR SERIOUS BODILY INJURY.

DO

DO read this entire operator’s manual before operating this machine. Understand all warnings, instructions, and con-

trols.

DO keep all guards in place and in good condition.

DO wear safety approved hearing, eye, head and respiratory protection.

DO read and understand all warnings and instructions on the machine.

DO read and understand the symbol denitions contained in this manual.

DO keep all parts of your body away from the blade and all other moving parts.

DO know how to stop the machine quickly in case of emergency.

DO shut off the engine and allow it to cool before refueling.

DO inspect the blade, anges and shafts for damage before installing the blade.

DO use only reinforced abrasive blades or steel center diamond blades manufactured for use on masonry saws.

DO use only blades marked with a maximum operating speed greater than the blade shaft speed. Verify speed by check-

ing blade shaft rpm and pulley diameters and blade ange diameters.

DO verify saw drive conguration by checking blade shaft RPM, pulley diameters, and blade ange diameter.

DO read all safety materials and instructions that accompany any blade used with this machine.

DO inspect each blade carefully before using it. If there are any signs of damage or unusual wear, DO NOT USE THE

BLADE.

DO mount the blade solidly and rmly. Wrench tighten the arbor nut.

DO make sure the blade and anges are clean and free of dirt and debris before mounting the blade on the saw.

DO use dry cutting diamond blades with a 1" (diameter arbor only). Never use damaged or worn blade anges.

DO use the correct blade for the type of work being done. Check with blade manufacturer if you do not know if blade is

correct.

DO operate this machine only in well ventilated areas.

DO instruct bystanders on where to stand while the machine is in operation.

DO establish a training program for all operators of this machine.

DO clear the work area of unnecessary people. Never allow anyone to stand in front of or behind the blade while the

engine is running.

DO make sure the blade is not contacting anything before starting the engine.

DO always tie down the machine when transporting.

DO use caution and follow instructions when setting up or transporting the machine.

DO have all service performed by competent service personnel.

DO verify the blade arbor hole matches the machine spindle before mounting the blade.

DO make sure the gas caps of the machine and the fuel can are properly tightened before starting the engine. Move fuel

can at least 10 feet from machine after fueling.

DO clean the machine after each day’s use.

DO remove adjusting keys and wrenches from tool before turning it on.

DO keep the handles dry, clean and free of oil and dirt.

DO carefully maintain and clean for better and safer performance. Follow instructions for changing accessories. Inspect

tool cords periodically and, if damaged, have repaired by authorized service facility.

DO use the proper blade ange size for each blade size. Never use damaged or worn blade anges.

DO use caution when handling fuel.

DO only cut in a straight line.

DO make sure electric powered machines are plugged into a properly grounded circuit.

DO make sure power cords are the proper size and in good condition.

DO follow all electrical codes in your area.

DO use correct voltage and proper extension cords. Never carry tool by cord or yank it to disconnect it from

receptacle. Keep cord away from heat, oil and sharp edges.

DO disconnect tools from power source when not in use, before servicing and, when changing accessories.

DO carefully maintain and clean for better and safer performance. Follow instructions for changing accessories.

Inspect tool cards periodically and, if damaged, have repaired by authorized service facility.

DO always give a copy of this manual to the equipment user. For extra copies, call TOLL FREE 1-800-288-5040.

10

Page 11

SAFETY FIRST!

WARNINGS

DO’s AND DO NOT’s

WARNING: FAILURE TO COMPLY WITH THESE WARNINGS AND OPERATING

INSTRUCTIONS COULD RESULT IN DEATH OR SERIOUS BODILY INJURY.

DO NOT

DO NOT operate this machine unless you have read and understood this operator’s manual.

DO NOT operate this machine without the blade guard, or other protective guards in place.

DO NOT leave this machine unattended while the engine is running.

DO NOT work on this machine while the engine is running.

DO NOT operate this machine when you are tired or fatigued.

DO NOT use a wet blade without adequate water supply to the blade.

DO NOT exceed maximum blade speed shown for each blade size. Excessive speed could result in blade breakage.

DO NOT operate the machine if you are uncertain of how to run the machine.

DO NOT use damaged equipment or blades.

DO NOT touch or try to stop a moving blade with your hand.

DO NOT cock, jam, wedge or twist the blade in a cut.

DO NOT transport a cutting machine with the blade mounted on the machine.

DO NOT use a blade that has been dropped or damaged.

DO NOT use carbide tipped blades.

DO NOT lay power cords in or near water.

DO NOT replace the motor with any motor that does not have a special grounding connection.

DO NOT use segmented diamond blades without water unless specically designed for dry cutting.

DO NOT touch a dry cutting diamond blade immediately after use. These blades require several minutes to cool after

each cut.

DO NOT use damaged or worn blade anges.

DO NOT allow other persons to be near the machine when starting, refueling, or when the machine is in operation.

DO NOT operate this machine in an enclosed area unless it is properly vented.

DO NOT operate this machine in the vicinity of anything that is ammable. Sparks could cause a re or an explosion.

DO NOT allow blade exposure from the guard to be more than 180 degrees.

DO NOT operate this machine with the belt guard or blade guard removed.

DO NOT operate this machine unless you are specically trained to do so.

DO NOT use a blade that has been over heated (Core has a bluish color).

DO NOT jam material into the blade.

DO NOT grind on the side of the blade.

DO NOT start cutting with a saw until you have a clear work area and secure footing.

DO NOT operate this machine while under the inuence of drugs or alcohol.

This saw was designed for certain applications only. DO NOT modify this saw or use for any application other than

for which is it was designed. If you have any questions relative to its application, DO NOT use the saw until you

have written Diamant Boart, Inc. and we have advised you.

Husqvarna Construction Products, North America

17400 West 119th Street

Olathe, Kansas 66061

In USA 1-800-288-5040

11

Page 12

FIGURES

12

Page 13

13

Page 14

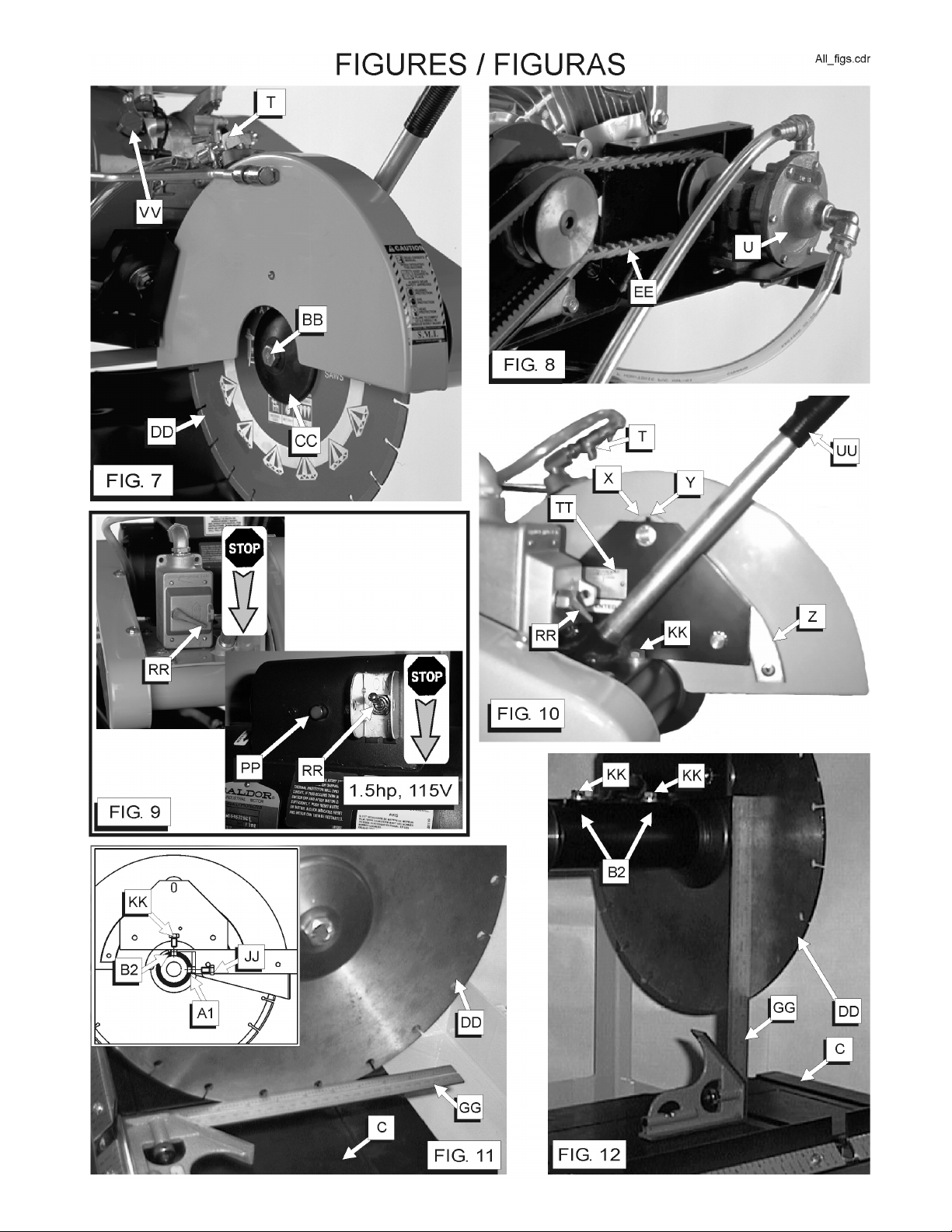

Parts Identication:

YY

XX

YY

FIGURES

A. Pan Weldment

B. Head Platform Assembly

C. Conveyor Cart Assembly

D. Folding Stand (Optional)

E. Skid Kit (Optional)

F. Foot Pedal Kit (Optional)

G. Bearing Clamps

H. Bearings

I. ———————————

J. Pivot Blocks

K. Knobs (or Capscrews)

L. Counterbalance Arm

M. Capscrew

N. Lower Bracket

O. ———————————

P. Lock Handle

Q. Spring

R. Eyebolt

S. Strainer (Gasoline Model)

T. Water Valve

U. Water Pump

V. Primer Bulb (Gasoline Model)

W. Isolator (Gasoline Model)

X. Wheel (Blade Guard Pivot)

Y. Setscrew (Blade Guard Pivot)

Z. Track Bar

AA. Engine Base

BB. Capscrew (Blade Shaft)

CC. Outer Flange

DD. Diamond Blade

EE. Water Pump Belt (Gasoline Model)

FF. Upper Spring Support

GG. Square

HH. Shims (Not Shown In Figures)

II. ———————————

JJ. Capscrews (Blade Shaft Housing- Rear)

KK. Capscrews (Blade Shaft Housing- Top)

LL. Wrench

MM. Splash Curtain

NN. Electrical Cord (Water Pump)

OO. Electrical Plug (Electrical Models)

PP. Reset Button (Electric Models)

QQ. ———————————

RR. Power Switch (Electric Models)

SS. Belt Tensioning Bolt

TT. Serial Number Plate

UU. Hand Grip

VV. Engine Stop Switch (Gasoline Model)

WW. Oil Drain Hose

XX. Lifting Handles

YY. Handle Mounting Hardware

14

Page 15

PRE OPERATION CHECKLIST

Before leaving our factory, every machine is thoroughly tested. Follow our instructions strictly and

your machine will give you long service in normal operating conditions.

Before starting up the machine, make sure you read this entire Operation’s Manual and are familiar with the operation of the machine.

WITH MACHINE COLD AND SETTING LEVEL:

1. Gasoline Models: Check engine oil. Fill to the full mark on dip stick with 10W30 oil, class MS, SD, SE or better.

2. Electric Models: Verify all electrical connections are intact.

1 - 2 HOUR OPERATION CHECK LIST:

ALWAYS place the machine on a level surface with the engine/motor “OFF", the ignition switch set in

the “OFF” position and disconnected from the power source before performing any maintenance. Let

the machine cool down!!

1. Check the engine air cleaner hose clamps. Tighten as required.

2. Tension the blade drive V-belts. DO NOT over tension!!

Before performing any maintenance, ALWAYS place the machine on a level surface with the

engine/motor “OFF” and the ignition switch set in the “OFF” position.

SERVICE DAILY:

SCHEDULED MAINTENANCE QUICK REFERENCE:

1. Check engine oil level.

2. Check blade guard for damage.

3. Check hoses and clamps for damage

or looseness. Tighten or replace as necessary.

4. Check air cleaner. Clean or replace as required.

5. Clean the reservoir pan frequently.

6. At the end of each day, ush clean water through the

water pump and hoses

SERVICE EVERY 50 HOURS:

1. Replace engine oil and lter.

2. Clean engine air ns.

3. Check blade drive V-belt tension.

DO NOT over tension!!!

4. Clean engine fuel bowl.

15

Page 16

MANDATORY

WARNING

These signs will give

advice for your safety

Before leaving our factory every machine is

thoroughly tested.

Follow our instructions strictly and your machine

will give you long service in normal operating

conditions.

INDICATION

IN F OR MAT IO N

INSTRUCTION

PROHIBITION

The operator must

wear protective clothing

appropriate to the work he

is doing.

Any persons not involved in the work should

leave the area.

Use only blades marked with a maximum

operating speed greater than the blade shaft

speed.

2 Assembly

All Models: (FIGS. 1, 2, 3, 4 and 13)

1 Features

Use: Wet or Dry sawing of masonry and refractory materi-

als such as brick and block. Not for use with material

shapes that are unstable on a at surface, such as rocks,

natural stone, molded shapes, etc.

Tools: Diamond blades — dry or water cooled,

Ø: 10" (250 mm), 12" (300 mm), and

14" (350 mm), with Arbor Ø 1" (25.4 mm).

(For information contact your Dealer)

Depth of Cut (Maximum):

5.00" (127 mm) with Ø 14" (350 mm) blade

Maximum Material Size:

8" x 8" x 16" (20.3 x 20.3 x 40.6 cm) block

Block must be rotated 180 degrees to complete

cutting through 8" (20.3 cm) depth.

Nominal Weight: See “Specications”

Operating Weight: See “Specications”

Dimensions: See “Saw Dimensions”

Blade Guard Capacity:

Electric Models: 10" (250 mm), 12" (300 mm) &

14" (350 mm) Ø Blades.

Gas Model: 14" (350 mm) Ø Only. Smaller Blade

Diameter not recommended because blade will not

cut through material. Head tilt is limited because the

maximum engine inclination angle is 20 degrees.

Before starting up the machine, make sure

you read this entire manual and are familiar

with the operation of this machine.

The working area must be completely clear,

well lit and all safety hazards removed.

• When unpacked, this unit consists of four (4) major parts:

Pan Weldment (A), Head Platform Assembly (B) Cart

Assembly (C) and Lifting Handles (XX) (FIG. 1).

• If this unit is to use the optional Folding Stand (D) (See

Fig. 1) and Skid Kit (E) (See FIG. 2) assemble these

items rst. Follow the instructions provided with these

options.

• Set the Pan Weldment (A) on a table or on the optional

Folding Stand / Skid Kit (D / E) as shown in FIG. 1. It is

very important that the Pan Weldment (A) be assembled

on the Folding Stand (D) as shown in Fig. 1, or the

optional Foot Pedal Kit (F) CAN NOT be assembled

onto the unit.

• Attach the Lifting Handles (XX) as shown in FIG. 13 using

the Mounting Hardware (YY) that is provided. Mount the

hardware with the nuts toward the outside of the frame

and the capscrews toward the inside of the frame. This

will simplify mounting the saw on the Optional Stand.

Four washers are to be assembled over the "slots" in

the frame. Four of the eight washers are not required,

but can be used if desired over the remaining holes.

Tighten the hardware securely.

WARNING: Make sure that Handle Mounting

Hardware (YY) is securely tightened before

transport of the frame or re-assembly of the

complete unit. Failure to do so could result

in serious injury to the operator or other

persons in the work area!

• Remove the Cart Assembly (C) from its shipping

carton. Set the Cart Assembly (C) onto the Pan Weldment (A) so that the wheels of the Cart Assembly (C) roll

along the sides of the Pan Weldment (A) (FIG. 1).

• Make sure that the left and right Bearing Clamps (G)

on the Pan Weldment (A) are pivoted into their lowered

position (FIG. 3). Carefully pick up the Head Platform

Assembly (B) and mount it to the Pan Weldment (A) such

that the Bearings (H) (on Head Platform) are resting in

the Pivot Blocks (J) (on Pan Weldment) and that the

blade shaft end of the Head Platform (B) is resting on

the Cart Assembly (C) (FIG. 3).

16

Page 17

• Pivot the left and right Bearing Clamps (G) into their upper position, and tighten the Knobs (K) [or Capscrews

(K) depending on the date of manufacture] until the Head

Platform (B) is secured to Pan Weldment (A) (FIG. 4).

• Note: If the unit uses Capscrews (K) to hold the Bearing

Clamps (G) in place, tighten them with the 1/2" end of

the Wrench (LL) provided with the saw (FIG. 4).

Electric Models (FIG. 5):

• Install the Counterbalance Arm (L): Place the slotted

end of the Counterbalance Arm onto the stud located

on the Left Hand Rear Corner of the Head Platform

Assembly (B). Be sure to put 1/2" Washers on both side

of the ARM before installation. Note that the lower hole

of the ARM is positioned toward the Pan Weldment (A).

A capscrew holds the ARM to the brackets on the back

of the Pan Weldment through this lower hole.

• Install the Lock Handle (P) onto the stud on the Left

Hand corner of the Head Platform Assembly (B).

Tighten the Lock Handle (P) so that the Head Platform

Assembly (B) is securely locked with the blade shaft in

the maximum upper position.

• Make sure that the Eyebolt (R) is securely fastened

onto the Arm (L), and note that the eye of the Eyebolt

(R) should be aligned with the spring mounting hole in

the Head Platform Assembly (B).

• Attach the top of the Spring (Q) through the hole in the

rear ange of the Head Platform Assembly (B). With a

tool (such as a screwdriver), stretch the lower end of the

Spring (Q) so that it is hooked over the Eyebolt (R).

• Install the Water Pump (U) by plugging its Electrical

Cord (NN) into the electric motor pigtail cord. Install the

hose barb tting onto the Water Pump (U), then push

on the hose. Route hose & electrical cord above the

cross-brace of the Pan Weldment (B) to avoid contact

with the blade during operation and so that the splash

curtain can be easily installed (NOT as shown in Figure

5). Place the Electric Water Pump (U) in the bottom

of the Pan Weldment (A). Hook the top of the Splash

Curtain (MM) over the head pivot bar, & place the

bottom of the Splash Curtain (MM) in the pan

(Fig. 1).

• Single phase masonry saw motors are furnished with

the correct NEMA configuration Plug (OO) on the

motor pigtail. The matching connectors are as follows:

Electric Motor Plugs & Connectors

Motor

Wired For

Voltage

Motor Pigtail

Plug

(NEMA No.)

Connector

Required

(NEMA No.)

1-1/2 HP 115 V L5-20P L5-20R

2 HP 230 V L6-15P L6-15R

3 HP 230 V L6-30P L6-30R

To change operation to either 115, or 230 V, the 1-1/2 and

2 HP motors have a voltage change switch mounted on the

terminal box. This switch must be changed to either 115, or

230 Volt, to match the voltage supply. Local electrical codes

may require changing the plug on the motor to the proper

NEMA connector to match the voltage supply.

WARNING: Always make sure the saw is

connected to a properly grounded electrical

outlet. Failure to comply with this warning

could result in serious bodily injury or death!

WARNING: DO NOT operate on low voltage!

Low voltage causes loss of power, motor

overheating, and possibly motor winding

burnout. Voltage should be checked at the

motor while it is operating.

Good motor performance depends on proper voltage.

Extension cords that are too long and / or too small reduce

the voltage to a motor under load. Use extension cords NO

SMALLER than the sizes indicated in the chart shown:

EXTENSION CORD SIZE (A.W.G. Minimum)

Motor

HP

50 ft Long 75 ft Long 100 ft Long

115 V 230 V 115 V 230 V 115 V 230 V

1-1/2 HP #10 #14 #10 #14 #10 #14

2 HP #10 #12 #10 #12 #10 #12

3 HP --- #10 --- #10 --- #10

Gasoline Model (Fig. 6):

• Assemble the Upper Spring Support (FF) using the

two (2) 3/8"-16UNC x 1.00" Long Capscrews and 3/8"16UNC Locknuts provided.

• Install the Counterbalance Arm (L). Loosely assemble

the 3/8" x 1.00" Long Capscrew (M) and 3/8"-16UNC

Locknut through the Lower Bracket (N) and the lower

end (13/32" diameter hole) of the Counterbalance

Arm (L).

• Raise the Head Platform Assembly (B) until the slot in

the Arm (L) can be put onto the 1/2" Stud on the Upper Spring Support (FF). Be sure to install the 1/2" at

Washers (Supplied) on both sides of the Arm (L).

• Mount and secure the Lock Handle (P) onto the 1/2"

Stud of the Upper Spring Support (FF). Tighten the

3/8" x 1.00" Long Capscrew (M) and 3/8"-16UNC

Locknut previously installed at the Lower Bracket (N).

• Install the upper end of the Spring (Q) in the hole in

the rear of the Upper Spring Support (FF). Loosen the

Lock Handle (P) and pivot the Head Platform Assembly

(B) so that the blade shaft is in the upper position, then

tighten the Lock Handle (P) securely. Using a tool (such

as a screwdriver or pliers) stretch the lower end of the

Spring (Q) so that it is secured into the Eyebolt (R) on

the Lower Bracket (N).

• Install the hoses to the water pump. They must be

connected together as shown in the parts list section of

this document. Place the Strainer (S) in the bottom of

the Pan Weldment (A) after connecting the hose. Hook

the top of the Splash Curtain (MM) over the head pivot

bar, & place the bottom of the curtain in the pan

(FIG. 1).

• When the unit is fully assembled, but before starting

the engine, verify that the engine does NOT exceed 20

degrees angle of inclination in any position of the Head

Platform [Use an angle measuring gauge (customer

supplied) held at against the Engine Platform (AA)].

CAUTION: Engine inclination angles greater

than 20 degrees could cause severe engine

damage and void your engine warranty!

17

Page 18

3 Check Before Operating

All Models:

WARNING: Conventional “Wet” diamond

blades MUST be used with water. DO NOT use

conventional “Wet” diamond blades without

water. Using conventional “wet” diamond

blades without water can result in injury or

death of the operator or persons in the work

area!

Warning: Use only Abrasive blades of a

reinforced type.

• Take into account the working conditions from a health

and safety point of view.

• For start up refer to the engine or motor manual.

Electric Models Only:

• Make sure that the extension cord length is properly

sized for the motor used on this saw. See the chart in

Section 2 of this document.

WARNING: Make sure the unit is connected to

a properly grounded outlet. Failure to comply

with this warning could result in serious bodily

injury or death!

Gasoline Model Only:

• Fuel: Check the engine operation manual. Unleaded

gasoline is recommended.

• Oil: Lock the Head Platform Assembly (B) with the

engine in a horizontal position, then, check that the

engine oil level is correct. Check the oil level frequently

to ensure that the level never falls below that specied

in the engine operation manual. If the oil level is low,

add SAE 10W30, service classication SF or SG oil

(for normal conditions) as recommended in the engine

operation manual. DONOToverllenginewithoil!

4 Fitting The Blade (Figure 7)

Electric Models Only:

• Mount the Diamond Blade (DD):

1. Using the Wrench (LL) provided (or one of your own)

loosen the Capscrew (BB) by turning it CounterClockwise (Electric Models Only).

CAUTION: Note that on Electric Models the

Capscrew (BB) has RIGHT HAND THREADS.

Installation of the wrong capscrew could

damage the blade shaft!

2. Remove the outer Flange (CC) and make sure the

outer Flange (CC), the Inner Flange (Not Shown),

and arbor shaft (Not Shown) are clean and not

damaged.

3. Mount the Diamond Blade (DD) to the arbor and

install the outer Flange (CC). Install and tighten

Capscrew (BB) by turning it in a Clockwise

direction (Right Hand Thread). Use the Wrench

(LL) to rmly tighten the Capscrew (BB) to the

arbor shaft.

Gasoline Model Only:

Always set the Engine Key Switch (VV) to the

"OFF" position BEFORE mounting the blade

• Mount the Diamond Blade (DD):

1. Using the Wrench (LL) provided (or one of your own)

loosen the Capscrew (BB) by turning it Clockwise

(Gasoline Model Only).

All Models:

• The blade rotates in a “down-cut” direction. This means

that the front of the blade is moving downward while

the rear of the blade is moving upward. Mount the

Diamond Blade (DD) so that the arrow on the blade

rotates in this “down-cut” direction. The Diamond

Blade (DD) can be installed / removed by using the 3/4"

(19 mm) end of the Wrench (LL) provided (Fig. 4).

• After mounting the blade, it should align over the top

of the wooden insert in the Conveyor Cart (C). If this

is not true, loosen the setscrews that secure the Bearings (H) to the Head Platform Assembly (B) (Fig. 3).

Position the Head Platform Assembly (B) to the left or

right until the Diamond Blade (DD) is aligned over the

top of the wooden insert, then re-tighten the Bearing (H)

setscrews. During operation of this unit, the blade can,

and should, pass into the wooden insert, but NOT into

the cast aluminum part of the Conveyor Cart (C).

18

CAUTION: Note that on Gasoline Models the

Capscrew (BB) has LEFT HAND THREADS.

Installation of the wrong capscrew could

damage the blade shaft!

2. Remove the outer Flange (CC) and make sure the

outer Flange (CC), the Inner Flange (Not Shown),

and arbor shaft (Not Shown) are clean and not

damaged.

3. Mount the Diamond Blade (DD) to the arbor and

install the outer Flange (CC). Install and tighten the

Capscrew (BB) by turning it in a Counter-Clockwise

direction (Left Hand Thread). Use the Wrench (LL)

to rmly tighten the Capscrew (BB) to the arbor

shaft.

5 Operating Instructions

All Models: (See Figures 5 & 6)

• Congure the saw for the type of operation required, wet

or dry. Note that the saw is factory assembled for wet

operation.

Page 19

WetConguration:

• Fill the water reservoir pan [Pan Weldment (A)] with

water to within 1 inch (25 mm) of the top. Be sure that

the water pump intake Strainer (S) (Figure 6 - Gasoline

Model) or Electric Water Pump Intake (U) (Figure 5

- Electric Model) is fully immersed in water at all times.

Keep the intake screen of these items clean and free of

sludge, slurry, or other foreign material.

DryConguration:

• All Models:

WARNING: Conventional “Wet” diamond blades

MUST be used with water. DO NOT use conventional

“Wet” diamond blades without water. Using conventional “wet” diamond blades without water can

result in injury or death of the operator or persons

in the work area!

CUTTING OPERATIONS:

• Place material on Conveyor Cart (C) and move conveyor

cart to the front of the saw so that the blade DOES NOT

contact the material.

• Cutting Methods: This unit allows three methods for the

blade to contact the material:

1. Fixed Head: Position the head to the desired height,

then tighten the Lock Handle (P) (Figures 5 & 6).

Then the material can be pushed into the blade.

2. Hold the Hand Grip (UU) and lower the blade into

the material (See Fig. 10). The blade will return to

the upper position when force is released.

3.

Push the optional Foot Pedal Kit (F) (Fig. 1) with your foot

to lower the blade into the material. The blade will return

to the upper position when force is released.

Start / Stop (Electric Models): (Figures 9 & 10)

WARNING: When cutting without water use only

diamond blades that are intended to be used dry

(without water). Conventional “Wet” diamond

blades MUST be used with water.

⇒ Hint: To reduce vibration of the saw, the water reservoir

pan [Pan Weldment (A)] can be lled with sand. Be sure

to remove the Water Pump (U) (Electric Models) or the

water pump intake Strainer (S) (Gasoline Model) to avoid

contaminating it with dirt or sand.

WARNING: Always use respiratory protection

when dry sawing.

Electric Model (Figure 5):

Before cutting dry unplug the Water Pump (U) from the

electric motor by disconnecting the Electrical Cord (NN).

Gasoline Model (Figure 8):

Remove the water pump drive V-Belt (EE):

1. Remove the two shields covering the Water Pump

belt drive, and the belt guard (Not Shown).

2. Loosen the two (2) bolts that hold the Water Pump

in position. Loosen the drawbolt that tensions the

water pump belt.

3. Slide the water pump forward and remove the belt

from the water pump pulley.

4. Disassemble the water pump V-Belt (EE):

a. Turn the belt inside out and with one hand

squeeze the two strands of the belt together.

b. Twist one tab 90 degrees so that it is parallel

with the slot in the adjacent link.

c. Pull the end of that link over the tab.

d. Pull belt end through the other two links.

5. Re-install the Belt Guard and water pump shields.

Save the water pump belt so that it can be re-installed if the unit needs to be used for wet cutting.

CAUTION: DO NOT run the Water Pump (U) for

extended periods of time without water! The

Water Pump could be damaged!

• Open the Water Valve (T) fully, and check the water ow

before cutting.

• Start the electric motor by turning the Power Switch (RR)

to the "ON" position.

• Cut the material using one of the Cutting Methods described in the above section.

WARNING: Keep hands clear of rotating

blade during operation. READ ALL SAFETY

WARNINGS before operating this machine.

CAUTION: DO NOT cut into the cast aluminum

area of the Conveyor Cart (C). The blade

should only cut into the wooden insert area of

Conveyor Cart (C)!

STOPPING THE UNIT (Electric Models):

Stop the unit by turning the Power Switch (RR)

to the OFF position. (Fig. 9) Wait for all blade

movement to stop before removing material from

the machine.

Start / Stop (Gasoline Models): (See Figures 1 & 7)

• Open the Water Valve (T) (Fig. 7) and prime the Water

Pump (U) using the Primer Bulb (V) (Fig. 1). Squeeze

the Primer Bulb until water passes through the blade

guard water tubes.

• Start the engine by using the procedure in the engine

operation manual.

• Open the engine throttle full open. All sawing is done

at full throttle. DO NOT change the engine governor

setting — it is factory set for the correct speed. See

the “Specications” section of this document for proper

engine & blade shaft RPM.

WARNING: Keep hands clear of rotating

blade during operation. READ ALL SAFETY

WARNINGS before operating this machine.

• Adjust the water ow with the Water Valve (T), and check

the water ow before cutting.

• Cut the material using one of the Cutting Methods

described in the above section.

19

Page 20

STOPPING THE UNIT (Gasoline Models):

Normal Operation: Stop the unit by following the procedure

in the engine operation manual. Wait for all blade movement

to stop before removing material from the machine.

Emergency: Turn the Engine Stop Switch (VV)

to the OFF position (Fig. 7).

6 Incidents During Operation

• If the engine or motor stops during sawing, check the

following:

Electric Model:

1. Interruption to electrical connection: Check all electrical

connections.

2.

Manual Overload switch has been tripped: Single phase,

60 Hertz motors are equipped with a manual overload Reset

Button (PP) (Fig. 5). If the motor stops because of an electrical

overload and the overload Reset Button (PP) trips, turn the

motor Power Switch (RR) to the OFF position (Fig. 9). Allow

the motor to cool for 5 to 10 minutes, then push the Reset

Button (PP). A click indicates that the motor is reset and ready

for operation. Restart the motor by turning the Power Switch

(RR) to the ON position.

Gasoline Model:

1. Out of fuel: Check fuel level.

2. Low Oil Level: This unit is equipped with a shut

down system that stops the engine if a low oil level is

encountered. Check the engine oil level with the Head

Platform Assembly (B) pivoted so that the engine is in

a horizontal position.

• If the engine, motor or blade stalls for any reason, raise

the blade completely out of the cut, inspect the machine

thoroughly before restarting. When lowering the blade

into a partial cut, align the blade exactly with the cut to

prevent damage to the blade.

• Excessively fast cutting will stall the engine or motor.

• If the blade stops during sawing check that the drive belt

tension is adequate.

7 Maintenance

WA R N I NG : B e for e p e rf or m i n g a n y

maintenance, ALWAYS locate the machine on a

level surface with the engine / motor OFF, and

the start switch in the OFF position, or power

source disconnected.

After each use: CLEAN the machine.

Check Daily (All Models):

• Clean the reservoir pan [Pan Weldment (A)] to remove

sludge and slurry. This concrete slurry is an abrasive

cutting compound and will shorten the life of the Water

Pump (U) and the Diamond Blade (DD). Clean the

reservoir pan twice a day in heavy cutting. Then rell

the water reservoir pan with clean water.

• At the end of each day clean the water reservoir pan [Pan

Weldment (A) ] to remove sludge from the saw. Flush

clean water through the Water Pump (U) and hoses.

20

Gasoline Model:

1. Check engine air cleaner daily! If cutting dry check

engine air cleaner every four hours! Clean or

replace air cleaner element as recommended by the

engine manufacturer.

2. Check engine oil daily. Change engine oil after

every 50 hours of operation. See engine operation

manual for proper care and maintenance.

Gasoline Model:

• Change Engine Oil: Change engine oil after every 50

hours of operation.

• Engine Oil Type: Under normal operating conditions

use SAE 10W30 API service classication SF or SG.

See engine operation manual for other recommended

oil types.

• Engine Oil Capacity (Honda GX160)

0.63 U.S. Quarts, 0.6 Liters, 0.63 Imperial Quarts

Engine Oil Change Procedure:

1. Drain the oil while the engine is still warm to assure rapid

and complete oil drain. Pivot the Head Platform (B) so

that the blade is in the lowered position. Place a bucket

in the Pan Weldment (A) under the Oil Drain Hose (WW)

to catch the used oil. Remove the oil drain plug on the

end of the Oil Drain Hose (WW) [Fig. 1] and wait for all

of the used oil to be drained for the engine.

2. Re-install and securely tighten the plug in the Oil Drain

Hose (WW).

3. Re-ll engine with the recommended oil type. See the

engine operation manual for the oil ll location and

proper oil level. Note that the required oil capacity will

be larger because of the volume of oil contained in the

Oil Drain Hose (WW).

4. Re-install the oil ll cap.

5. Dispose of the used oil in a proper container and in a

manner that is compatible with the environment.

When Required:

• “Sta-Level” Blade Guard (Fig. 10): If the blade guard

becomes loose and pivots too freely the blade guard

rotation can be tightened. Adjust the Top Wheel (X) of

the three (3) wheels behind the blade guard:

1. Loosen the nut holding the Top Wheel (X).

2. Adjust the Setscrew (Y) to force the Top Wheel

(X) down against the Track Bar (Z).

3. Re-tighten the nut holding the Top Wheel (X) in

position.

Blade Alignment (FIGS. 11 & 12):

• The blade shaft arbor on this machine is aligned at the

factory so that a new blade will cut “square” with the

Page 21

material placed on the Cart Assembly (C). If the saw

or Head Platform Assembly (B) is dropped or damaged

the blade could become mis-aligned so that it no longer

cuts “squarely” through the material. If this occurs the

blade shaft should be re-aligned so that the saw will

produce “square” cuts. If the Blade is severely out of

alignment [1/16" (1.5 mm) or more] the Head Platform

Assembly (B) may need to be “bent” so that the blade is

closer to being aligned. In cases of severe damage the

Head Platform Weldment should be replaced. Precise

alignment can be achieved by using Shims (HH) of

various thickness. See the parts list section of this

docum ent for the part numb er and thi ck ness

information about the shims.

⇒ Note: Before starting to align the head platform make

sure the blade is at and is NOT bent or damaged!

⇒ Note: When aligning the blade against the square be

sure to allow for the difference in thickness between the

diamond segment and the center core of the blade!

8 V-Belt Tension

All Models (FIGS. 5 & 6):

• Check V-Belt tension when unit is new and never set

belt tension beyond this point.

• The saw is equipped with high tension V-Belts. The

belts are properly tensioned at the factory, but after a few

hours of operation they will stretch and become loose.

• Tensioning Blade Shaft V-Belts:

1. Loosen the four (4) capscrews that attach the

motor (Electric Models), or the Engine Platform

(Gasoline Models).

2. Tighten the Belt Tensioning Bolt (SS) at the rear

of the saw until the belt a tightened to the original

factory tension.

3. Re-tighten the four (4) capscrews that attach the

motor (Electric Models), or the Engine Platform

(Gasoline Models).

1. Make sure the Conveyor Cart (C) rolls freely along

the pan. If the pan is damaged it must be repaired or

replaced before the blade can be aligned. Lock the

Head Platform Assembly (B) securely in a horizontal

position.

2. PARALLEL ALIGNMENT (Figure 11): Supply a Square

(GG) and place it on the Conveyor Cart (C) and roll the

cart while the Square (GG) rests against the blade. Adjust the Blade Shaft into Parallel Alignment (if required)

by putting Shims (HH) between the blade shaft housing

and the head platform weldment at location “A1” (Figure

11). Loosen, but do not remove, the Capscrews (JJ)

holding the blade shaft in position. Slide a shim, of the

proper thickness, upward and position around the thread

of one of the capscrews. Tighten the hardware and

check the blade alignment. Add more shims if required

until the blade shaft has Parallel Alignment.

3. PERPENDICULAR ALIGNMENT (Figure 12): Place

the Square (GG) on the Conveyor Cart (C) so that it

is against the saw blade and is below the center of

the blade shaft. If the Square (GG) does NOT contact

the Diamond Blade (DD) along the entire height of the

square, the blade shaft must adjusted into Perpendicular

Alignment. Adjust the blade shaft by putting Shims (HH)

between the blade shaft housing and the head platform

weldment at location “B2” (Figure 12). Loosen, but do

not remove, the Capscrews (KK) that hold the blade

shaft in position. Slide a shim, of the proper thickness,

inward and position around the thread of one of the

capscrews. Tighten the hardware and check the blade

alignment. Add more shims if required until the blade

shaft has Perpendicular Alignment.

Electric Model:

• See “All Models” from above text.

Gasoline Model:

• Blade Shaft V-Belt Tension (FIG. 6): Excessive belt

tension will cause engine misalignment because the

engine is mounted on four (4) rubber vibration Isolators

(W). Stop tensioning the blade shaft drive V-belt when

the center section of the front right hand Isolator (W)

begins to separate from its mounting plate. Tensioning

the Blade Shaft drive V-Belt beyond this point is not

recommended because the front right hand Isolator (W)

will not function properly.

• Water Pump V-Belt (EE) Tension (FIG. 8): May need

to be tightened after a few hours of operation. Over

time this V-Belt may stretch beyond the length of the

adjustment slot. If this happens simply remove the

V-Belt and take out one or more links (as required) from

its length.

9 Important Advice

• Never transport the saw with the cutting head positioned

on the frame. The movement can knock the head out

of alignment.

• When storing for an extended period of time, use a

wire brush to remove hard, caked sludge. Clean and

thoroughly lubricate moving parts - so on the next job

the saw is ready for operation.

• Drive belts must be tight. When the belts are loose,

power is lost. Replace worn belts without delay!

• The blade must t the arbor snugly - especially diamond

blades. Otherwise, pounding will occur and this will

seriously damage the blades. If the arbor shoulder is

grooved where the diamond blade has bound in the cut

as the shaft has continued to turn, the arbor must be

replaced, or the blade life will be severely shortened.

21

Page 22

• Blade anges must be full diameter - minimum of 4"

(100 mm). Replace worn anges at once because

undersized anges shorten blade life and cause blade

breakage.

• Check the conveyor cart condition on a regular basis.

Replace the wheels and the wooden insert frequently.

• Be certain the cutting head is correctly aligned.

Blade misalignment because of handling damage, or

transporting the saw with the cutting head on the frame

can seriously affect blade life.

• Replace noisy bearings immediately! Worn bearings

will quickly destroy the blade.

• Flush clean water through the pump and spray the

assembly after every job to prolong the pump and

blade life.

• Diamond blades may need to be “sharpened”. Blades

may be efciently “dressed” with dressing sticks.

11 Repairs

We carry out all repairs in the shortest possible time and at

the most economical prices. See front cover for our address

and telephone numbers.

12 Spare Parts

For a quick supply of spare parts it is essential to quote the

data shown on the Serial Number Plate (TT) [FIG. 10] xed

to the machine. Make note of this information below for

quick reference:

Reference Information

WARNING: Never use re bricks to “sharpen”

or dress diamond blades!

• Abrasive blades must be a reinforced type. Never use

an abrasive blade with water. These products can be

damaged by operator abuse such as jamming the

material into the blade. This can also be hazardous!

10 Accessories

The following accessories and kits are available for this

machine. See the Parts List section of this document for

the part number. For additional information contact your local dealer or call our Toll free Customer Service Telephone

number shown on the front cover:

• Folding Stand Assembly

• Skid Kit

• Foot Pedal Kit

• Wheel Kit, Conveyor Cart (Set of 4)

• Adapter Cord, 115V, 15 Amp Straight To

20 Amp Twist-Lock (For 1-1/2 HP Motor Only)

• Water Pump Repair Kit *

• Conveyor Cart Kit, Complete *

• Ruler Set, Conveyor Cart *

Model No: __________________________________

Serial No: __________________________________

Date Received: ______________________________

NOTES:

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

* Note: This item has a different part number for the

electric and gasoline units.

The instructions for use and spare parts found in this document

are for information only and are not binding. As part of our product

quality improvement policy, we reserve the right to make any and

all technical modications without prior notice.

The manufacturer accepts no

responsibility caused by unsuitable

useormodications.

22

Page 23

NOTE:

NOTA:

23

Page 24

ESPECIFICACIONES

MODELO NO. TS 355-15 TS 355-2 TS 355-3 TS 355 G

TIPO 1-1/2 HP, Eléctrico 2 HP, Eléctrico 3 HP, Eléctrico 5,5 HP, A Gasolina

Capacidad del

Protector de la Hoja:

10 - 14"

(250 - 350 mm)

10 - 14"

(250 - 350 mm)

10 - 14"

(250 - 350 mm)

14" Only

(350 mm)

RPM del Eje de la Hoja: 2509 2509 2509 2950

Profundidad Máxima

de Corte:

Tamaño del Eje de la

Hoja:

5.0" (127 mm)

1.00" (25.4 mm)

Eje de la Hoja: Cojinetes a Rodillos Sellados

Transmisión del

Eje de la Hoja:

Dos Cintas en V 4L370 Dos Cintas en V 4L370 Dos Cintas en V 4L370

Cinta en V 3VX

(2 Bandas)

Protector de la Hoja: Acero de una Pieza, Diseño Sta-LevelMR, Capacidad Máxima de 14" (350 mm)

Enfriador de la Hoja: Agua

Bandeja para Agua:

Carro Transportador:

Bomba de Agua:

Modelos Eléctricos:

Modelo a Gasolina:

Armazón:

3,86 x 17,73 x 30,73 pulgados (98 x 450 x 780,5 mm), 6,75 galones (25 litros) de capacidad (A 3 "de

profundidad)

Aluminio Fundido con Tope de Goma Vulcanizada, Regla de Medición Ajustable, Guía de Corte de 45° /

90°

300 Galones / Hora, Sumergible, Sellado Totalmente con Epoxy, Protegido Contra Sobrecarga Térmica

8 GPM, Transmisión por Cinta, Bronce Sólido, Con Retén y Bomba con Cebador Incluido con Válvula de

Vericación

De Alta Resistencia, Acero en"X" Reforzado, Soldado con Portapiezas, Diseño de Cuello Abierto para

llimitados Longitudinales

Peso: Libras (kg):

Sierra Embalada: 171 (77.7) 182 (82.7) 192 (87.3) 209 (95.0)

Sierra No Embalada: 160 (72.7) 169 (76.8) 181 (82.3) 198 (90.0)

Sierra En Operación

(Agua en la Bandeja):

Soporte Doblable

(Sin Caja):

Equipo de Pedal

de Pie (En Caja):

Cable de

Conexión Eléctrica:

221 (100.5) 230 (104.5) 242 (110.0) 259 (117.7)

24 (10.9)

14 (6.4)

0.40 (.18 ) N / A N / A N / A

FUENTE DE ENERGIA

MODELO NO. TS 355-15 TS 355-2 TS 355-3 TS 355 G

TIPO: Eléctrico Eléctrico Eléctrico Gasolina

Engine / Motor: Baldor Baldor Baldor Honda

Potencia (kw): 1-1/2 (1.1) 2 (1.5) 3 (2.2) 5.5 (4.0)

RPM: 3450 3450 3450 3500

Especicaciones: T.E.F.C. T.E.F.C. T.E.F.C. ———

Voltaje: 115 / 208-230 115 / 208-230 208-230 ———

Ciclo (Hz)/

Corriente/ Fase:

60 / A.C. / 1 60 * / A.C. / 1 60 * / A.C. / 1 ** ———

Desplazamiento: ——— ——— ——— 9.9 cu. Inch (163 cc)

Diåmetro Interno

del Cilindro:

——— ——— ——— 2.7 inch (68 mm)

Tiempo: ——— ——— ——— 1.8 inch (45 mm)

Cilindros/Ciclo: ——— ——— ——— 1 / 4

Capacidad de

Combustible:

Capacidad de Aceite:

——— ——— ——— 0,95 Galones (3,6 litros)

0,63 Cuartos de

——— ——— ———

Galón (0,6 litros)

Tipo Seco Elemento

Filtro de Aire: ——— ——— ———

Dual

con Pre-limpiador

Arrancador: Capacitor Capacitor Capacitor Retroceso

Enfriador: Aire

* Motores de 50 ciclos disponibles sobre pedido especial: el modelo de 2 HP es de 240 Volitios, el modelo de 3 HP es de 220-380 Volitios.

**Motor de 3 fases disponible sobre pedido especial - especicar 230 ó 460 voltios para el cableado en fábrica.

Nota: Para obtener los números de los articulos en los motores/máquinas, vea la sección de lista de piezas de este documento. Las especicaciones están

sujetas a cambios sin noticación.

24

Page 25

DIMENSIONES DE LA SIERRA

MODELOS ELECTRICOS

FIGURA A

MODELOS A GASOLINA

FIGURA B

DIMENSIONES DE LA SIERRA

MODELOS ELECTRICOS (Illustración A) MODELOS A GASOLIA (Illustración B)

Artículo Longitud (cm) Descripción Artículo Longitud (cm) Descripción

A 38,2" (97,0) Longitud de la Sierra (Máxima) A 43,6" (110,7) Longitud de la Sierra (Máxima)

B 19,4" (49,3) Ancho de la Sierra (Máximo) B 22,7" (57,7) Ancho de la Sierra (Máximo)

C 28,2" (716,3) Altura de la Sierra (Minima) C 34,8" (88,4) Altura de la Sierra (Minima)

D 26,1" (66,3) Altura del Soporte (Opcional) D 26,1" (66,3) Altura del Soporte (Opcional)

E 56,4" (143,3) Altura de la Sierra (Máxima) E 63,0" (160,0) Altura de la Sierra (Máxima)

F 3,8 - 15,1" Altura del Eje de la Hoja F 6,4 - 15,0" Altura del Eje de la Hoja

(9,6 - 38,4) (Minimo - Máxima) (16,2 - 38,2) (Minimo - Máxima)

G 10,0" (25,4) Longitud del Carro G 10,0" (25,4) Longitud del Carro

H 18,7" (47,5) Ancho del Carro H 18,3" (47,5) Ancho del Carro

I 18,5" (47,0) Viaje del Carro I 18,3" (46,5) Viaje del Carro

J 33,0" (76,2) Longitud de la Base de la Sierra J 33,0" (76,2) Longitud de la Base de la Sierra

K 18,0" (45,7) Ancho de la Bandeja K 18,0" (45,7) Ancho de la Bandeja

L 33,7" (85,6) Soporte al Tope del Carro L 33,7" (85,6) Soporte al Tope del Carro

M 35,8" ( 90,9) Patin al Tope del Carro M 35,8" ( 90,9) Patin al Tope del Carro

N 7,6" (19,3) Base al Tope del Carro N 7,6" (19,3) Base al Tope del Carro

O 2,1" (5,3) Altura del Patin (Opcional) O 2,1" (5,3) Altura del Patin (Opcional)

P 11,5" (29,2) Carro - Costado Izquierdo P 6,5" (16,5) Carro - Costado Izquierdo

Q 6,5" (16,5) Carro - Costado Derecho Q 11,5" (29,2) Carro - Costado Derecho

R 4,0" (10,16) Diámetro de la Brida R 4,0" (10,16) Diámetro de la Brida

S 32,0" (81,3) Ancho del Patin (Opcional) S 32,0" (81,3) Ancho del Patin (Opcional)

25

Page 26

¡SEGURIDAD ANTE TODO!

ADVERTENCIAS

HACER y NO HACER

ADVERTENCIA: EL NO RESPETAR ESTAS ADVERTENCIAS E INSTRUCCIONES DE

OPERACION PUEDE PROVOCAR GRAVES LESIONES O LA MUERTE.

SI Lea todo el manual antes de manejar esta máquina. Entienda todas las advertencias, instrucciones y controles.

SI Mantenga siempre las protecciones en su lugar y en buenas condiciones.

SI Siempre use protecciones aprobadas para los oídos, ojos, cabeza y respiración.

SI Lea y entienda todas las advertencias e instrucciones sobre la sierra.

SI Lea y entienda las deniciones de los símbolos que aparecen en este manual.

SI Mantenga todas las partes de su cuerpo alejadas de la hoja y de todas las piezas móviles.

SI Aprenda cómo parar la sierra rápidamente en caso de emergencia.

SI Apague el motor y déjelo enfriar antes de cargar combustible.

SI Verique que la hoja, las bridas y los ejes no estén dañados antes de instalar la hoja.

SI Utilice hojas abrasivas reforzadas de alta velocidad, o bien, hojas diamantadas con centro de acero fabricadas para uso en sierraspara hormigón.

SI Utilice solamente hojas abrasivas marcadas para velocidad máxima de funcionamiento mayor que la velocidad del eje de la hoja.

SI Verique la velocidad comprobando las rpm del eje de la hoja, diámetro de las poleas y diámetro de la brida de la polea.

SI Lea toda la literatura e instrucciones de seguridad que acompañan a la hoja utilizada con esta sierra.

SI Inspeccione cuidadosamente cada hoja antes de usarla. Si se observan señales de daño o desgaste poco común, NO USE LA HOJA.

SI Instale la hoja rmemente. Apriete la tuerca del eje con un aprietatuercas.

SI Asegúrese que la hoja y las bridas estén limpias y libres de tierra y suciedad antes de instalar la hoja en la sierra.

SI Utilice el tamaño de brida indicado para cada tamaño de hoja. No use bridas que estén dañadas o desgastadas.

SI Verique que el agujero del eje de la hoja coincida con el portaherramienta de la máquina antes de instalar la hoja.

SI Utilice la hoja correcta para el tipo de trabajo que se vaya a ejecutar. En caso de dudas, consulte con el fabricante de la hoja.

SI Siempre sujete la máquina con ambas manos cuando el motor esté funcionando. Encierre la empuñadura rmemente con los pulgares y dedos.

SI Tenga cuidado y siga las instrucciones cuando cargue y descargue la sierra.

SI Maneje esta máquina solamente en lugares bien ventilados.

SI Indique a las personas dónde situarse mientras la sierra está funcionando.

SI Establezca un programa de entrenamiento para todos los operadores de esta máquina.

SI Despeje el lugar de trabajo de personas innecesarias. No permita que nadie se sitúe delante o detrás de la hoja mientras el motor está funcionan-

do.

SI Maneje el combustible con cuidado.

SI Aleje la máquina por los menos 10 pies (3 m) del punto de abastecimiento de combustible antes de arrancar el motor y asegúrese de apretar

bien la tapa de la gasolina en la sierra y del bidón de combustible.

SI Asegúrese que la hoja no esté haciendo contacto con ninguna cosa antes de arrancar el motor.

SI Tenga cuidado al izar y transportar esta máquina.

SI Siempre levántela del gancho de izar solamente.

SI Siempre amarre la máquina cuando la transporte.

SI Siempre maneje esta máquina con el interruptor de freno de estacionamiento en la posición “Auto”.

SI Pida que todo trabajo de servicio lo haga un personal técnico competente.

SI Asegúrese de enchufar las máquinas eléctricas a un circuito debidamente conectado a tierra.

SI Asegúrese que los cordones eléctricos sean del tamaño correcto y estén en buenas condiciones

SI Cumpla con el reglamento eléctrico de su localidad.

SI Use el voltaje correcto y un cable de extensión adecuado. Nunca transporte la herramienta colgando del cable y nunca tire del cable para

desenchufarlo. Aleje el cable del calor, aceite y de las aristas ludas.

SI Desenchufe los equipos cuando no los usa, antes de hacer mantenimiento y al cambiar accesorios

SI limpie y efectúe un mantenimiento cuidadoso para obtener un rendimiento mejor y más seguro. Siga las instrucciones al cambiar accesorios.

Revise los cables del equipo con frecuencia y, si hay daños, hágalos reparar por un servicio autorizado.

SI Siempre verique si hay cables eléctricos enterrados antes de cortar con la sierra. Si se necesitan ejemplares adicionales, lammar SIN CARGO

26

Page 27

¡SEGURIDAD ANTE TODO!

ADVERTENCIAS

HACER y NO HACER

ADVERTENCIA: EL NO RESPETAR ESTAS ADVERTENCIAS E INSTRUCCIONES DE OPE-

RACION PUEDE PROVOCAR GRAVES LESIONES O LA MUERTE.

NO haga funcionar esta máquina sin antes haber leído y entendido este manual.

NO maneje esta máquina sin tener el protector de la hoja u otras protecciones instaladas en su lugar.

NO se sitúe delante o detrás del paso de la hoja mientras el motor está funcionando.

NO deje esta máquina desatendida mientras el motor está funcionando.

NO trabaje en esta máquina mientras el motor está funcionando.

NO maneje esta máquina si está cansado o fatigado.

NO maneje la máquina si no está seguro de como hacerlo.

NO utilice una hoja de corte húmedo sin tener el suministro adecuado de agua.

NO sobrepase la velocidad máxima indicada para cada tamaño de hoja. El exceso de velocidad puede causar la rotura de la hoja.

NO utilice equipos u hojas que estén dañados.

NO utilice hojas con puntas de carburo.

NO trate de parar con las manos una hoja en movimiento.

NO incline, atasque, encaje o tuerza la hoja en el corte.

NO amontone material en la hoja.

NO deje los córdones eléctricos en o cerca del agua.

NO cambie el motor por alguno que no tenga una conexión especial de tierra de seguridad.

NO transporte una máquina de cortar con la hoja instalada.

NO utilice una hoja que ha sufrido una caída.

NO toque una hoja diamantada de corte en seco inmediatamente después de usarla. Estas hojas se demoran varios minutos en

enfriarse después de cada corte.

NO use una hoja que se ha sobrecalentado. (El núcleo tiene un color azulado.)

NO utilice bridas de hojas que estén dañadas o desgastadas.

NO permita que nadie se acerque a la máquina durante la puesta en marcha, abastecimiento de combustible o mientras la sierra está

funcionando.

NO maneje esta máquina en un lugar encerrado a menos que tenga buena ventilación.

NO maneje esta máquina cerca de ningún objeto que sea inamable. Las chispas podrían causar un incendio o una explosión.

NO permita que la hoja sobresalga más de 180 grados del protector.

NO maneje esta máquina sin que tenga colocado el capó del motor.

NO maneje esta máquina sin que tenga colocado el protector de la transmisión.

NO use los soportes de amarre para izar esta máquina.

NO remolque esta máquina tirada por un vehículo.

NO maneje esta máquina a menos que esté especialmente capacitado para hacerlo.

NO maneje la sierra si está bajo la inuencia de drogas o bebidas alcohólicas.

Estasierrafuediseñadaparaciertasaplicacionessolamente.NOlamodiqueniutiliceparaningunaotraaplicación

salvo aquéllas para las cuales fue diseñada. En caso de dudas respecto a su aplicación, NO use la sierra sin antes

haber consultado por escrito a Diamant Boart, Inc. y haber recibido nuestras indicaciones.

Husqvarna Construction Products, North America

17400 West 119th Street

Olathe, Kansas 66061

USA 1-800-288-5040

27

Page 28

FIGURAS

28

Page 29

29

Page 30

YY

XX

YY

FIGURAS

IdenticacióndePiezas:

A. Estructura Soldada de la Bandeja

B. Conjunto de Plataforma del Cabezal

C. Conjunto del Carro Transportador

D. Soporte Doblable (Opcional)

E. Equipo de Patín (Opcional)

F. Equipo de Pedal de Pie (Opcional)

G. Abrazaderas de Cojinete

H. Cojinetes

I. ———————————

J. Bloques Pivotantes

K. Perillas (o Tornillos de Cabeza Plana)

L. Brazo de Contrabalance

M. Tornillo de Cabeza Plana

N. Ménsula Inferior

O. ———————————

P. Palanca de Traba

Q. Resorte

R. Perno de Ojo

S. Retén (Modelo a Gasolina)

T. Válvula de Agua

U. Bomba de Agua

V. Bulbo del Cebador (Modelo a Gasolina)

W. Aislador (Modelo a Gasolina)

X. Rueda (Pivote del Protector de la Hoja)

Y. Tornillo de Fijación (Pivote del Protector de la

Hoja)

Z. Barra de Trayectoria

AA. Base del Motor

BB. Tornillo de Cabeza Plana (Eje de la Hoja)

CC. Brida Externa

DD. Hoja Diamantada

EE. Cinta de la Bomba de Agua (Modelo a Gaso-

lina)

FF. Soporte de Resorte Superior

GG. Escuadra

HH. Calces (No Mostrado en las Ilustraciones)

II. ———————————

JJ. Tornillos de Cabeza Plana (Carcasa del Eje

de la Hoja - Trasero)

KK. Tornillos de Cabeza Plana (Carcasa del Eje

de la Hoja - Superior)

LL. Llave

MM. Cortina para Salpicado

NN. Cable de Conexión Eléctrica (Bomba de

Agua)

OO. Enchufe Eléctrico (Modelos Eléctricos)

PP. Botón de Reinicio (Modelos Eléctricos)

QQ. ———————————

RR. Perilla de Encendido (Modelos Eléctricos)

SS. Perno de Tensionamiento de la Cinta

TT. Placa de Número de Serie

UU. Asa

VV. Perilla de Apagado del Motor (Modelo a Ga-

solina)

WW. Manguera de Drenaje de Aceite

XX. Mangos Elevadores

YY. Tornellería de Montaje Mango

30

Page 31

LISTA DE COMPROBACIONES PREVIAS A LA OPERACION