Page 1

ENGLISH

1

Page 2

PRESENTATION

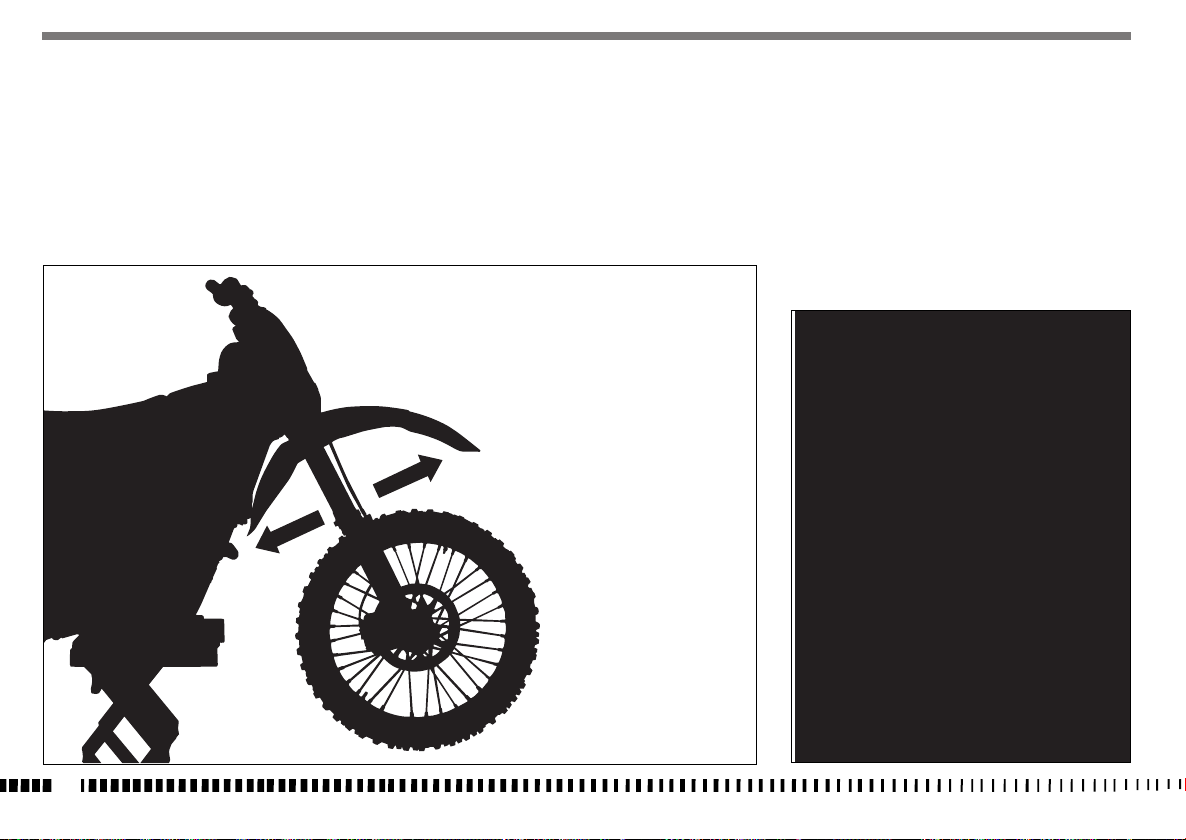

Welcome to the Husqvarna motorcycling Family!

Your new Husqvarna motorcycle is designed and manufactured to be the finest in its field.

The instructions in this book have been prepared to provide a

simple and understandable guide for your motorcycle’s operation and care.

Follow the instructions carefully to obtain maximum performance and your personal motorcycling pleasure. Your owner’s

manual contains instructions for owner care and maintenance.

Information covering repair of major units such as engine,

transmission, etc. is provided in the Husqvarna Service Manual.

The information concerning details or main work of repair or

maintenance are described in the Husqvarna Service Manual.

This manual is available upon request by stating the code

number set on pages 95, 96, 97, 98. Work of this kind requires

the attention of a skilled mechanic and the use of special tools

and equipment.

Your Husqvarna dealer has the facilities, experience and original

parts necessary to properly render this valuable service.

This “Owner’s Manual” and the “Purchase

Registration Booklet” are parts and parcels

of the motorcycle, hence, they have to remain with the motorcycle even when sold to

another user.This “Owner’s Manual” and

the “Purchase Registration Booklet” are

parts and parcels of the motorcycle, hence,

they have to remain with the motorcycle

even when sold to another user.

This motorcycle uses components designed thanks to systems

and state of the art technologies which are thereafter tested in

competition.

In competition motorcycles, every detail is verified after each race

in order to always guarantee better performance. For correct functioning of the vehicle, it is necessary to follow the maintenance

and control table found on Appendix A.

IMPORTANT NOTICES

1) The TC and TXC models are guaranteed COMPETITION motorcycles exempt from functional defects, the suggested maintenance table for competition use is shown on Appendix A.

2) TE and SMR are STREET LEGAL

motorcycles (with LIMITED POWER ENGINE); they are guaranteed exempt

from functional defects and covered

with legal guarantee, if the STANDARD CONFIGURATION is maintained

and the suggested maintenance table,

shown on Appendix A (page A8) is observed.

If TE and SMR are transformed in

COMPETITION MOTORCYCLES (with

FULL POWER ENGINE), the suggested

maintenance table for competition use

is shown on Appendix A.

TC-TXC

TE

SMR

MOTOCROSS

ENDURO

SUPERMOTARD

2

Page 3

IMPORTANT

The reference for recognition of the guarantee will be the MOTORCYCLE CONFIGURATION, as shown below:

A) STANDARD MOTORCYCLE, STREET LEGAL: with LIMITED

POWER ENGINE

B) COMPETITION MOTORCYCLE, RACING USE: with FULL POWER ENGINE

This motorcycles was not designed for long

trips with the engine always at maximum

rpm as can occur whilst travelling on roads

or highways. Long trips at full throttle can

cause severe damage to the engine.

This motorcycles is setup for competition

use and therefore guarantees maximum

performance with the rider alone. It is

thereby not recommended to use the vehicle on circuits or off-road with a passenger.

ing parts and for the labour necessary in

order to respect the maintenance plan, is

charged to the client.

NOTE: the guarantee is EXTINGUISHED in the

case where the motorcycle is rented.

Important Notice

Read this manual carefully and pay special attention to statements preceeded by the following words:

Warning*: Indicates a possibility of severe

personal injury or loss of life if instructions

are not followed.

Caution*: Indicates a possibility of personal injury or equipment damage if instructions are not followed.

Note*: Gives helpful information.

Warning*: After an upset, inspect the motorcycle carefully. Make sure that the

throttle, brake, clutch and all other systems are undamaged. Riding with a damaged motorcycle can lead to a serious

crash.

Warning*: Never attempt to start or operate your motorcycle unless you are

wearing appropriate protective clothing.

Always wear a motorcycle helmet, motorcycle boots, gloves, goggles and other appropriate protective clothing.

Warning*: This motorcycle is a state of

the art competition bike. Do not attempt

to start or ride this motorcycle until you

have received expert instruction and are

in excellent physical condition.

EN

ALWAYS keep in mind that these motorcycles have been designed strictly for competition use, that is, for conditions of

usage very different from those presented on the road.

ALWAYS keep in mind that these motorcycles have been designed strictly for competition use, that is, for conditions of usage

very different from those presented on the

road.

In order to maintain the vehicle’s

“Guarantee of Functionality”, the client

must follow the maintenance program indicated in the user’s manual by carrying

out maintenance checks at authorized

HUSQVARNA dealers. The cost for substitut-

When parts replacement is required, use only Husqvarna

Parts Replacement

ORIGINAL parts.

.

PRECAUTIONS FOR CHILDREN WARNING

G Park the vehicle where it is unlikely to be bumped into

or damaged. Even slight or involuntary bumps can cause

the vehicle to topple over, with subsequent risk of serious harm to people or children.

G To prevent the vehicle from tipping over, never park it

on soft or uneven ground, nor on asphalt strongly heated by the sun.

G Engine and exhaust pipes become very hot during ri-

ding. Always park your motorcycle where people or children can not easily reach these parts, in order to avoid

serious burns.

3

Page 4

TABLE OF CONTENTS Page

PRESENTATION........................................................................2

IMPORTANT NOTICES...............................................................2

IDENTIFICATION DATA.............................................................5

TECHNICAL DATA...................................................................10

LUBRICATION TABLE, SUPPLIES..............................................12

CONTROLS ............................................................................13

RIDING.................................................................................23

SERVICE LIMITS.....................................................................70

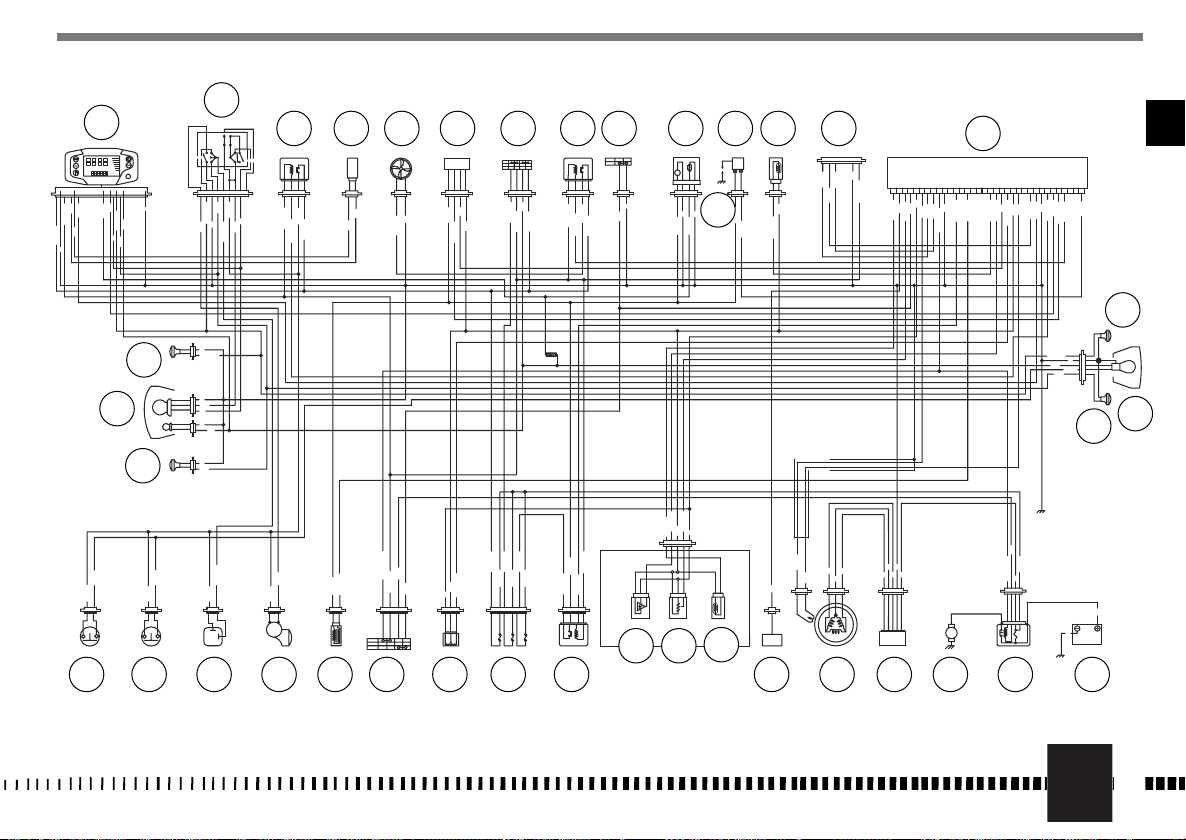

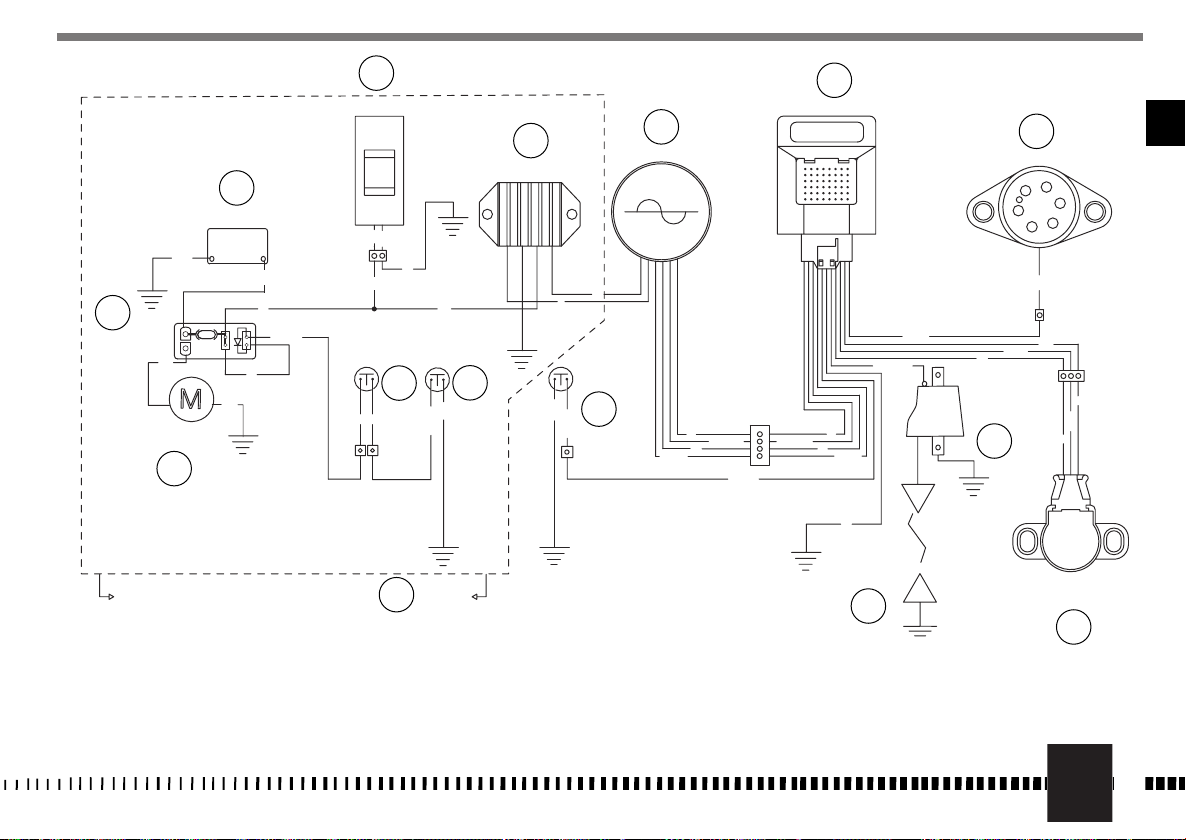

IGNITION SYSTEM/ELETTRICAL SYSTEM.............................79-90

SPECIAL TOOLS .....................................................................91

TIGHTENING TORQUES ..........................................................92

KITS.....................................................................................94

OPTIONAL PARTS LIST ......................................................95-98

APPENDIX.............................................................................99

PRE-DELIVERY INSPECTION...................................................101

NOTE FOR USA/CDN- AUS MODELS........................................102-104

ALPHABETICAL INDEX .........................................................105

PERIODIC MAINTENANCE -ADJUSTMENT.....................Appendix A

G References to the “left” or “right” of the motorcycle are in

Note

the sense of a person facing forwards.

G Z: number of teeth

G A: Austria

AUS: Australia

B: Belgium

BR: Brazil

CDN: Canada

CH: Switzerland

D: Germany

E: Spain

F: France

FIN: Finland

GB: Great Britain

I: Italy

J: Japan

USA: United States of America

G Where not specified, all the data and the instructions are

referred to any and all Countries.

4

Page 5

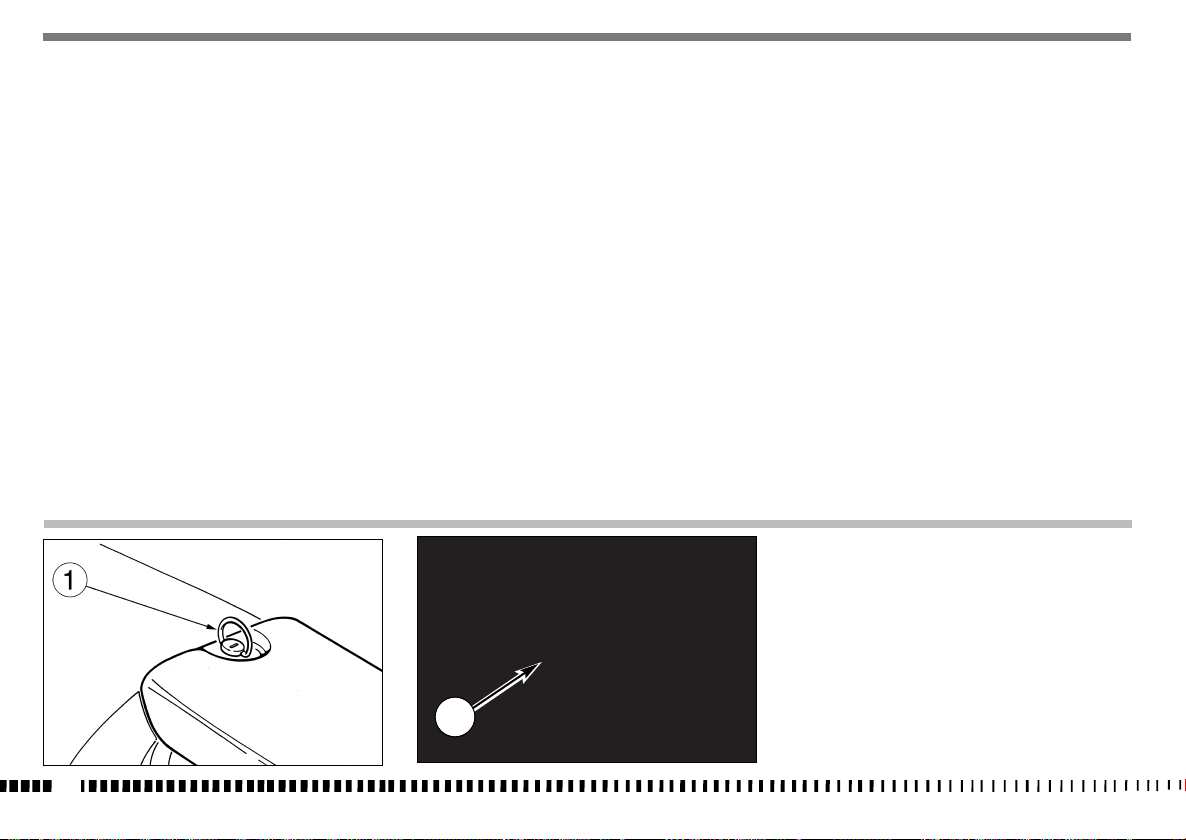

IDENTIFICATION DATA

The engine number is printed on the upper side of the engine

case, whereas the frame number is printed on the steering

tube .

Always state the number stamped on the frame (and write it

on this booklet), when placing orders for spare parts, or when

asking for information on your motorcycle.

FRAME NUMBER

VEHICLE IDENTIFICATION NUMBER (V.I.N.)

The full 17 digit serial, or Vehicle Identification Number, is

stamped on the steering head tube (R.H. side).

EN

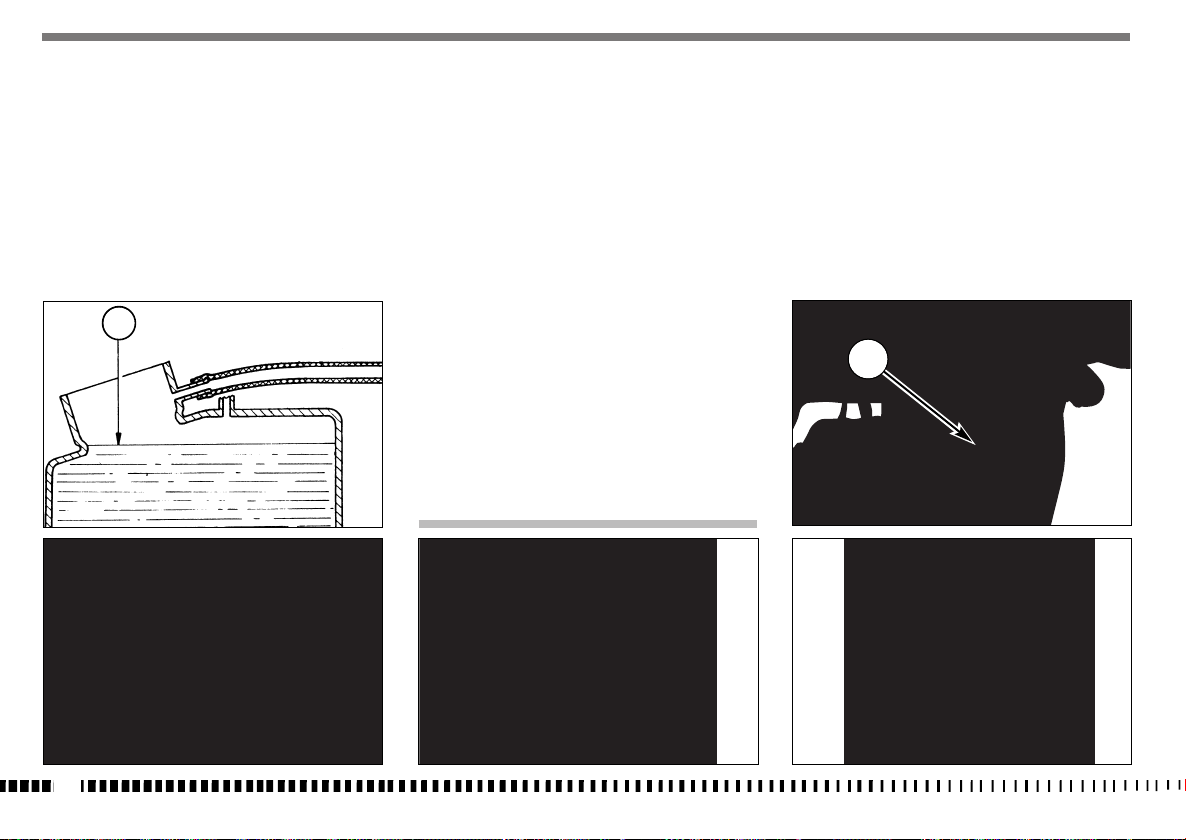

1. Frame serial number

2. Engine serial number

(*): Progressiv nr.

(l): Year of the model

5

Page 6

VEHICLE IDENTIFICATION NUMBER (V.I.N.)

The full 17 digit serial, or Vehicle Identification Number, is

stamped on the steering head tube (R.H. side).

1. Frame serial number

2. Engine serial number

(*): Progressiv nr.

(l): Year of the model

6

Page 7

VEHICLE IDENTIFICATION NUMBER (V.I.N.)

The full 17 digit serial, or Vehicle Identification Number, is

stamped on the steering head tube (R.H. side).

EN

1. Frame serial number

2. Engine serial number

(*): Progressiv nr.

(l): Year of the model

7

Page 8

VEHICLE IDENTIFICATION NUMBER (V.I.N.)

The full 17 digit serial, or Vehicle Identification Number, is

stamped on the steering head tube (R.H. side).

(*): Progressiv nr.

(l): Year of the model

1. Frame serial number

2. Engine serial number

8

Page 9

Control location

1. Front brake lever

2. Throttle grip

3. Rear brake control pedal

4. Choke (L.H. side)

5. Fuel tank filler cap

6. R.H. commutator (engine electric start)

7.Rear shock absorber spring preload adjustment

8. Rear shock absorber compression damper adjustment (low and high damping speeds)

9. Rear shock absorber extension damper adjustment

10. L.H. commutator (TE, SMR)

10. Engine stop button (TC-TXC)

11.Clutch control lever

12. Fuel cock (TC-TXC)

13. Gearbox control pedal

14. Air bleeding screw on front fork leg

15. Compression damper adjustment (front fork leg bottom side)

16. Extension damper adjustment (front fork leg top side)

EN

TC-TXC

TE-SMR

TE-SMR

TC-TXC

TC-TXC

9

Page 10

ENGINE

TECHNICAL DATA

Type.....................................................single cylinder, 4 stroke

Cooling.......................liquid with electric fan on TE-SMR models

Bore (250)....................................................................2.99 in.

Bore (450-510)..............................................................3.81 in.

Stroke (250)..................................................................2.17 in.

Stroke (450).................................................................2.39 in.

Stroke (510)..................................................................2.67 in.

Displacement (250) ...............................................15.22 cu. in.

Displacement (450)................................................27.39 cu. in.

Displacement (510) ................................................30.56 cu. in

Compression ratio...........................................................12,9:1

Starting (TC)............. kick start (with automatic decompressor)

Starting (SMR)...............electric (with automatic decompressor)

Starting (TE-TXC) ...............electric and kick start (with automatic

decompressor)

TIMING SYSTEM

Type....................................double overhead camshaft; 4 valve

Valve clearance (with engine cold)

Intake..........................................................0.004 ÷ 0,006 in.

Exhaust........................................................0.006 ÷ 0,008 in.

LUBRICATION

Type.......Dry sump with two oil pump rotor and cartridge filter

IGNITION

Type...........................................C.D.I. electronic, with variable

advance (digital control)

Spark plug type ......................................................NGK CR8EB

Spark plug gap...........................................................0.027 in.

FUEL SYSTEM

Type (TE-SMR)...............................................................Electronic injection feed

Type (TC-TXC 250) ”Keihin” FCR-MX 37 with acceleration pump and

throttle position sensor

Tipo (TC-TXC 450-510) Keihin” FCR-MX 41 with acceleration pump

and throttle position sensor

Venturi diameter (TC-TXC 250) ..................................................1.46 in.

Venturi diameter (TC-TXC 250-450)............................................1.61 in.

High speed jet (TC-TXC 250) ..........................................................175

High speed jet (TC-TXC 450-510) ....................................................180

Low speed jet (TC-TXC 250) ............................................................42

Low speed jet (TC-TXC 450-510)........................................................45

Starting jet (TC-TXC 250)..................................................................72

Starting jet (TC-TXC 450-510) ..........................................................85

Starting air jet. .........................................................................0.16 in.

Main air jet ...................................................................................200

Low air jet .....................................................................................100

Floater ......................................................................................g 11.2

CLUTCH

Type...............................oil bath multiple disc clutch, hydraulic control

TRANSMISSION

Type...............................................................constant mesh gear type

Transmission ratio (TE-SMR-TXC)

1st gear......................................................................2,000 (z 28/14)

2nd gear .....................................................................1,611 (z 29/18)

3rd gear .....................................................................1,333 (z 24/18)

4th gear.....................................................................1,086 (z 25/23)

5 th gear....................................................................0,920 (z 23/25)

6 th gear ....................................................................0,814 (z 22/27)

Transmission ratio (TC)

1st gear......................................................................1,866 (z 28/15)

2nd gear (250)...........................................................1,529 (z 26/17)

2nd gear (450-510) ....................................................1,444 (z 26/18)

3rd gear ....................................................................1,263 (z 24/19)

4th gear.....................................................................1,086 (z 25/23)

5 th gear....................................................................0,954 (z 21/22)

Throttle piston..............................................................................15 M

Metering pin ............................................................................OBDVR

Metering pin slot (TC-TXC 250). ......................................................4th

Metering pin slot (TC-TXC 450-510).................................................5th

Idle mixture adjusting screw (TC-TXC 250)......................rounds 1+1/2

Idle mixture adjusting screw (TC-TXC 450-510)....................... rounds 2

SECONDARY DRIVE

Transmission sprocket- Rear wheel sprocket

(TE-TXC 250).........................................................................Z 13- Z 50

Transmission sprocket- Rear wheel sprocket

(TE -TXC 450-510).................................................................Z 13- Z 47

Transmission sprocket- Rear wheel sprocket

(TC 450)...............................................................................Z 14- Z 50

Transmission sprocket- Rear wheel sprocket

PRIMARY DRIVE

Drive pinion gear- Clutch ring gear (TC 250) .............................Z 20- Z 67

Drive pinion gear- Clutch ring gear (TE-TXC 250)........................Z 24- Z 88

Drive pinion gear- Clutch ring gear (450-510)............................Z 23- Z 63

Transmission ratio (TC 250)..............................................................3,350

Transmission ratio (TE-TXC 250)........................................................3,666

Transmission ratio(450-510).............................................................2,739

(TC 250)...............................................................................Z 12- Z 50

Transmission sprocket- Rear wheel sprocket

(TC 510)...............................................................................Z 14- Z 47

Transmission sprocket- Rear wheel sprocket

(SMR 450-510)....................................................................Z 14- Z 42

Transmission ratio (TE-TXC 250)..................................................3,846

Transmission ratio (TC 250).........................................................4,166

Transmission ratio (TC 450)........................................................3,571

Transmission ratio (TC 510) ....................................................... 3,357

Transmission ratio (SMR 450-510).............................................. 3,000

Transmission ratio (TE-TXC 450-510)........................................... 3,615

10

Page 11

FINAL RATIOS

1st gear (TE-TXC 250) ..............................................28,205

1st gear (TE-TXC 450-510) .............. ..........................19,806

1st gear (TC 250) ....................................................26,055

1st gear (TC 450) .....................................................18,261

1st gear (TC 510) ............... .......................................17,159

1st gear (SMR 450-510)............................................16,435

2nd gear (TE-TXC 250) .............................................22,721

2nd gear (TE-TXC 450-510) .......................................15,955

2nd gear (TC 250) ..................... ..............................21,348

2nd gear (TC 450) ....................................................14,130

2nd gear (TC 510) ....................................................13,283

2nd gear (SMR 450-510)...........................................13,239

3rd gear (TE-TXC 250) ..............................................18,803

3rd gear (TE-TXC 450-510) ........................... ............13,204

3rd gear (TC 250) .....................................................17,631

3rd gear (TC 450) ....................................................12,357

3rd gear (TC 510) ......................................................11,616

3rd gear (SMR 450-510) ...........................................10,956

4th gear (TE-TXC 250) ........................... ...................15,329

4th gear (TE-TXC 450-510) ........................................10,764

4th gear (TC 250) .....................................................15,172

4th gear (TC 450) .......................... ..........................10,633

4th gear (TC 510) ......................................................9,995

4th gear (SMR 450-510) .............................................8,932

5th gear (TE-TXC 250) ...............................................12,974

5th gear (TE-TXC 450-510) ......................... .................9,111

5th gear (TC 250) .......................... ..........................13,324

5th gear (TC 450) ......................................................9,338

5th gear (TC 510) ......................... .............................8,778

5th gear (SMR 450-510) .............................................7,560

6th gear (TE-TXC 250) ...............................................11,491

6th gear (TE-TXC 450-510) ......................... ................8,069

6th gear (SMR 450-510) ............................................6,696

FRAME

Type ........................Steel single tube cradle (roud, rectangular,

ellipsoidal tubes); light alloy rear frame

FRONT SUSPENSION

Type ....“Upside-Down” telescopic hydraulic front fork with advanced

axle (adjustable in compression and rebound stroke); stanchions

tubes .......................................................................................1.97 in.

Legs axis stroke..................(TE, TC, TXC) 11.8 in.; (SMR) 9.84 in.

REAR SUSPENSION

Type...............progressive with hydraulic single shock absorber

Wheel stroke (TC-TXC-TE)................................................11.6 in.

Wheel stroke (SMR).......................................................11.4 in.

FRONT BRAKE

Type...................................fixed disc 10.24 in. dia (TE, TC, TXC)

floating disc 12.6 in. dia (SMR)

with hydraulic control; floating caliper (TE, TC, TXC)

or fixed radial caliper (SMR)

REAR BRAKE

Type.... floating disc, ø 9.45 in. with hydraulic control and

floating caliper

RIMS

Front (TE, TC, TXC) .....TAKASAGO “Excel” in light alloy: 1,6x21”

Front (SMR)..........................SANREMO in light alloy: 3,50x17”

Rear (TE, TXC)..........TAKASAGO “Excel” in light alloy: 2,15x18”

Rear (TC) .......TAKASAGO “Excel” in light alloy: 1,85x19”(250);

2,15x19”(450-510)

Rear (SMR)...........................SANREMO in light alloy: 4,25x17”

TIRES

Front

(TE-TXC) ....................................... Michelin ENDURO COMP. 3 or

Pirelli MT 83 Scorpion or Dunlop 54R-D907;

90/90x21" (TE)

(TC) ............................................................Pirelli 51R-MT 32A;

80/100 x 21”

(SMR) ............................................Pirelli MTR 21 DRAGON-EVO;

120/70-17”

Rear

(TE-TXC)............................. Michelin ENDURO COMP. 3 or Pirelli

MT 83 Scorpion or Dunlop 70R-D907 (TE);

120/90x18” (250); 140/80x18” (450-510)

(TC)..........................Pirelli NHS (62) MT 32; 100/90x19(250);

110/90x19” (450-510)

(SMR)

..........................

Cold tire pressure (front TC)

Cold tire pressure (rear TC)............

(*) Cold tire pressure (front TE-TXC)0,9÷1,0 Kg/cm2(12.8-14.2 psi)

(*) Cold tire pressure (rear TE-TXC).0,8÷0,9 Kg/cm2(11.4-12.8 psi)

(•)Cold tire pressure (front TE-TXC)

(•)Cold tire pressure (rear TE-TXC)

(*) Cold tire pressure (front SMR)

(•)Cold tire pressure (front SMR, rider only)..1,8kg/cm2-25.6 p.s.i.

(•)Cold tire press. (front SMR, rider and passenger) 2,0 kg/cm2--28.4 p.s.i.

(*) Cold tire pressure (rear SMR)

(•)Cold tire pressure (rear SMR, rider only) 2,0 kg/cm2--28.4 p.s.i.

(•)Cold tire pressure

(rear SMR, rider and passenger) ................ 2,2 kg/cm2-31.3 p.s.i.

Pirelli MTR 22 DRAGON-EVO;150/60x17”

............

0,9÷1,0 Kg/cm2(12.8-14.2 psi)

.

0,8÷0,9 Kg/cm2(11.4-12.8 psi)

.................

1,1 Kg/cm2(15.6 psi)

..................

...................

...................

1,0 Kg/cm2(14.2 psi)

1,4 kg/cm2- 20 p.s.i.

1,6 kg/cm2-22.7 p.s.i.

EN

(• ) Road use

(*)

in case of racing use

11

Page 12

DIMENSION, WEIGHT, CAPACITY

Wheelbase (TC-TE-TXC) ................................................58.86 in.

Wheelbase (SMR).............................................................56.89 in.

Overall length (TC)......................................................86.89 in.

Overall length (TE)......................................................89.25 in.

Overall length (SMR) ...............................................................85.94 in.

Overall length (TXC).................................................................86.42 in.

Overall width..............................................................32.28 in.

Overall height (TC-TE-TXC) ...........................................50.59 in.

Overall height (SMR) ........................................................49.21 in.

Saddle height (TC).......................................................38.11 in.

Saddle height (TE-TXC).................................................37.91 in.

Saddle height (SMR) ........................................................36.22 in.

Minimum ground clearance (TC-TXC-TE) ............................11.81 in.

Minimum ground clearance (SMR).....................................9.64 in

Dry weight (TC 250) .................................................. lb 220.5

Dry weight (TC 450) ...................................................lb 230.4

Dry weight (TC 510) ................................................... lb 231.5

Dry weight (TXC 250) ...... .......................................... lb 229.3

Dry weight (TXC 450) ................................................. lb 240.0

Dry weight (TXC 510) ................................................. lb 240.3

Dry weight, “ready to race” (TE 250 I.E.) ....................lb 235.9

Dry weight, “ready to race” (TE 450-510 I.E.) ............. lb 246.9

Dry weight, “ready to race” (SMR 450-510 I.E.) ......... lb 260.1

Fuel tank capacity

............(TE-SMR, 1.5 Imp. Quarts, 1.9 U.S. qt. reserve included)

. .......................................................1.6 imp.gall, 1.9 U.S. gall.

Coolant capacity.....................................Imp. Quarts 0.97÷1.14

...............................................................U.S. Quarts 1.16÷1.37

Transmission oil

Oil and oil filter replacement .....Imp. Quarts 1.5U.S. Quarts 1.8

Oil replacement .........................Imp. Quarts 1.3U.S. Quarts 1.6

TABLE FOR LUBRICATION, SUPPLIES

Engine, gearbox and primary drive lubricating oil

AGIP RACING 4T (10W-60)

Engine coolant

AGIP COOL

Brake system fluid

AGIP BRAKE 4 (DOT 4)

Clutch fluid

SAE 10 MINERAL OIL FOR HYDRAULIC SYSTEM

Grease lubrication

AGIP BIKE GREASE

Final drive chain lubrication

AGIP CHAIN LUBE

Front fork oil

AGIP FORK 7,5 (SAE 7,5) (for hard climatic conditions SAE 5)

Oil for rear shock absorber

AGIP FORK 2,5 (SAE 2,5)

Electric contact protection

AGIP CONTACT CLEANER

12

Fillers for radiator

AREXONS TURAFALLE LIQUIDO

Page 13

CONTROLS

FUEL COCK (TC-TXC)

The left-side tap (2) is a screw tap: screw the ring nut (A) to

close the tap, loosen the ring nut to open the tap.

WARNING*: Be careful not to touch the hot

engine while operating the fuel valve.

A fuel filter is incorporated in the fuel valves. Accumulation of

dirt in the filter will restrict the flow of the fuel to the carburetor. Therefore, the fuel filter should be serviced periodically.

1

1 Loosen the input plug (1) on the fuel tank and close the tap;

2 Remove the fuel hose (3) from the carburetor and insert the

hose in a vessel;

3 Open the tap and drain the fuel out of the tank;

4 Remove the fuel valve by removing the screws. Wash the fuel

screen filter in cleaning solvent;

5 Reassemble the fuel valve in the reverse order of removal.

Open the tap and check for leaks.

2

3

FUEL INJECTION ENGINE (TE-SMR)

On vehicles which are fitted with a fuel injection engine, the

fuel pump is built into the fuel tank and there is no tap mounted on the fuel supply system. The quantity of remaining fuel is

indicated on the digital dash-board by the special warning

light (see on page 16).

1. Fuel tank cap

2. Fuel cock

3. Fuel hose

A. Tap ring nut

EN

A

13

Page 14

SIDESTAND

A sidestand (1) is supplied with every motorcycle.

FUEL

Recommended fuel: premium grade unleaded fuel. (R.O.N.

98).

WARNING*: The stand is designed to support the weight of the MOTORCYCLE ONLY.

Do not sit on the motorcycle using the stand

for support as this could cause structural

failure to the stand and could cause serious

bodily injury.

Periodically check the side stand (see “Periodical maintenance

card”); check that the springs are not damaged and that the

side stand freely moves. If the side stand is noisy, lubricate the

fastening pivot (A).

Note*: Do not continue operation if the engine pings or knocks. The engine will be damaged and could seize.

WARNING*: If "knocking" or "pinging" occurs, try a different brand of gasoline or higher octane grade.

WARNING*: Gasoline is extremely flammable and can be explosive under certain conditions. Always stop the engine and do not

smoke or allow flames or sparks in the

area where the motorcycle is refueled or

gasoline is stored.

WARNING*: Do not overfill the tank. After

refueling, make sure the tank cap (1) is closed securely.

2

14

Page 15

CARBURETOR CHOKE (TC-TXC)

The starter knob, located on the left side of the carburetor, is

used to enrich the mixture during the engine start.

Pull out the knob to open the starter, and pull the lever upwards to close it.

The carburetor is equipped with two knobs:

1) BLACK KNOB: COLD start (°)

2) RED KNOB: WARM start (°)

(°) See page 26

2

COLD START (TE-SMR)

For a cold start, the models with a fuel injection engine are fitted with a black knob (3) located on the left of the throttle

body.

Pull the knob outwards to open the starter and push inwards

to close.

EN

1

15

Page 16

*IMPORTANT: Functions of the GREEN warning light (4)

“NEUTRAL” in case of FUEL INJECTION SYSTEM

malfunction (contact your local HUSQVARNA Dealer)

a) With the GEARBOX NOT in NEUTRAL position: the warning

light FLASHES INTERMITTENTLY.

b) With the GEARBOX in NEUTRAL position: the warning light is

initially constantly ON then it FLASHES

TWICE IN RAPID SUCCESSION then returns to being constantly

ON. This cycle repeats itself. After eliminating the malfunction,

the warning light (4) returns to its normal operation.

1- SPEED / ODO (figure 1, page 17)

2- SPEED / H (figure 2, page 17)

3- SPEED / CLOCK (figure 3, page 17)

4- SPEED / TRIP 1 (figure 4, page 18)

5- SPEED / STP 1 (figure 5, page 18)

6- SPEED / AVS 1 (figure 6, page 18)

7- SPEED / SPEED MAX (figure 7, page 19)

8- SPEED / TRIP 2 (figure 8, page 19)

9- SPEED / TRP 2 / CLOCK (figure 9, page 19)

10- SPEED / RPM (engine r.p.m. numerical value) (figure 10, page 19)

.................

NOTE

The RPM function, shown on the vertical LED indicator, is ALWAYS on.

DIGITAL INSTRUMENT, WARNING LIGHTS

(TE-SMR)

The motorcycle is equipped with a digital instrument; on the

instrument are located 5 warning lights too: high beam, lights

(with display lighting), blinkers, neutral and fuel reserve.

1- BLUE warning light “HIGH BEAM”

2- GREEN warning light ”LIGHTS”

3- GREEN warning light “BLINKERS”

4- GREEN warning light “NEUTRAL”

5- ORANGE warning light “Fuel reserve”

(1,8 l - 1.58 Imp. qt - 1.9 U.S. qt)

NOTES

- After the engine starting, for the first 2 seconds, the instrument shows the version of the checking SW; after the check,

the instrument shows the last planned function.

- When the motorcycle engine is OFF, the instrument doesn’t

also show its functions.

- To select the instrument functions and to set to zero the functions, use the SCROLL knob (A).

- The instrument functions are the following, as shown below.

16

2

5

4

1

3

A

Page 17

1- SPEED (kmh or mph) / ODO / RPM (figure 1)

- SPEED: motorcycle speed- maximum value: 299 kmh or 299

mph;

- ODO: odometer- maximum value: 99999 km;

- RPM: engine r.p.m. shown on the vertical LED indicator.

To replace kilometers with miles or miles with kilometers proceed as follows:

1) set to figure 1, stop the engine and push the knob SCROLL

(A);

2) start the engine while pushing for 3 seconds the knob

SCROLL (A).

After the kilometers-miles or miles-kilometers setting operation, for 3 seconds, “SET” and miles/mph or km/kmh will be

on.

NOTE

After the previously described operation,

the ODO setting will be convert and all the

others data will be reseted (the H Counter

is unchanged).

2- SPEED / H / RPM (figure 2)

- SPEED: motorcycle speedmaximum value: 299 kmh or 299 mph;

- H: shows the running hours of the engine (data are saved in

permanent memory every 10 minutes)- Maximum value:

9999:59;

- RPM: engine r.p.m. shown on the vertical LED indicator.

3- SPEED / CLOCK / RPM (figure 3)

- SPEED: motorcycle speedmaximum value: 299 kmh or 299

mph;

- CLOCK: clock- Reading from 0:00 to 23:59:59 (the data will

be lost after battery detachment);

To reset the clock, push the knob SCROLL (A) for more than 3

seconds in order to increase the hours; release the knob and

then, after 3 seconds, it is possible to increase the minutes;

- RPM: engine r.p.m. shown on the vertical LED indicator.

EN

17

Page 18

4- SPEED / TRIP 1 / RPM (figure 4)

- SPEED: motorcycle speedmaximum value: 299 kmh or 299

mph;

- TRIP 1: distance- maximum value: 999.9 km (the data will

be lost after battery detachment).

If the STP 1 will be set to zero, the functions TRIP 1 and AVS

1 will be set to zero too.

The function TRIP 1 is ON unitedly with the

function STP 1 (*).

- RPM: engine r.p.m. shown on the vertical LED indicator.

(*): see figure 5

5- SPEED / STP 1 / RPM (figure 5)

- SPEED: motorcycle speedmaximum value: 299 kmh or 299

mph;

- STP 1: miles/kilometers covered time- Reading from 0:00 to

23:59:59 (the data will be lost after battery detachment).

To activate the function STP 1, push the knob SCROLL (A) for

more than 3 seconds.

- 1st step: function ON;

- 2nd step: stop to the counters;

- 3rd step: STP 1 zero-setting; TRIP 1 and AVS 1 data zero-setting;

- 4th step: function ON;

- 5th step: stop to the counters;

.............................

and so following

NOTE

STP 1 data+TRIP 1 data=AVS 1 (*).

- RPM: engine r.p.m. shown on the vertical LED indicator.

(*): see figure 6

6- SPEED / AVS 1 / RPM (figure 6)

- SPEED: motorcycle speedmaximum value: 299 kmh or 299

mph;

- AVS 1: shows the covered average speed of the motorcycle,

according with a distance (TRIP 1) and a miles/kilometers

covered time (STP 1) (the data will be lost after battery detachment).

NOTE

If the STP 1 will be set to zero, the TRIP 1 and AVS 1 functions

will be set to zero too.

- RPM: engine r.p.m. shown on the vertical LED indicator.

18

Page 19

7- SPEED / V MAX / RPM (figure 7)

- SPEED: motorcycle speedmaximum value: 299 kmh or 299

mph;

- V MAX: shows the motorcycle MAXIMUM speed (reached MAX

speed), kmh or mph. Maximum value: 299 kmh or 299

mph. To set to zero V MAX, push the knob SCROLL (A) for

more than 3 seconds;

- RPM: engine r.p.m. shown on the vertical LED indicator.

A

8- SPEED / TRIP 2 / RPM (figure 8)

- SPEED: motorcycle speedmaximum value: 299 kmh or 299

mph;

- TRIP 2: distance- maximum value: 999, 9 km / miles (the

data will be lost after battery detachment);

To set to zero TRIP 2, push the knob SCROLL (A) for more

than 3 seconds;

- RPM: engine r.p.m. shown on the vertical LED indicator.

9- TRP 2 / CLOCK / RPM (figure 9)

- TRIP 2: distance- Max value: 999.9 km / miles (the data will

belost after battery detachment). To set to zero TRIP 2, push

the knob SCROLL (A) for more than 3 seconds;

- CLOCK: clock- Reading from 0:00 to 23:59:59 (the data will

be lost after battery detachment). To reset the clock, push

the knob SCROLL (A) for more than 3 seconds in order to increase the hours; release the knob then, after 3 seconds, it is

possible to increase the minutes;

- RPM: engine r.p.m. shown on the vertical LED indicator.

10- SPEED /RPM (engine r.p.m. numerical

value) (figure 10)

- SPEED: motorcycle speedmaximum value: 299 kmh or 299

mph;

- RPM: engine r.p.m.; both vertical LED indicator and numerical

value are on.

EN

19

Page 20

THROTTLE CONTROL

The throttle knob (1), is located on the right hand side of the

handlebar. The position of the throttle control can be adjusted

by loosening the two fastenig screws .

CAUTION

Do not forget to tighten the screws (A) after

the adjustment.

FRONT BRAKE CONTROL

The brake control lever (2) is located on the right hand side of

the handlebar. The position of the throttle control can be adjusted by loosening the two fastenig screws .

CAUTION

Do not forget to tighten the screws (B) after

the adjustment.

STEERING LOCK (TE-SMR)

The motorcycle is equipped with a steering lock (1) on the R.H.

side of the steering head tube.

To lock it, procede as follows:

turn the handlebar leftwards, place the key in lock and turn

counterclockwise. Push the key inwards (if necessary, turn to

and from). Turn the key clockwise and remove it from the lock.

To unlock the steering lock, reverse the above procedure.

20

Page 21

21

ENGINE STOP BUTTON (TC-TXC)

On the left side of the handlebar, near the clutch control, is located the engine stop button.

CLUTCH CONTROL

The hydraulic clutch control lever is located on the left-hand

side of the handlebar and is protected against dirt with a rubber guard.

The clutch control position on the handlebar can be adjusted

by loosening the lower fastening screw (A).

CAUTION

Do not forget to tighten the screw after the adjustment.

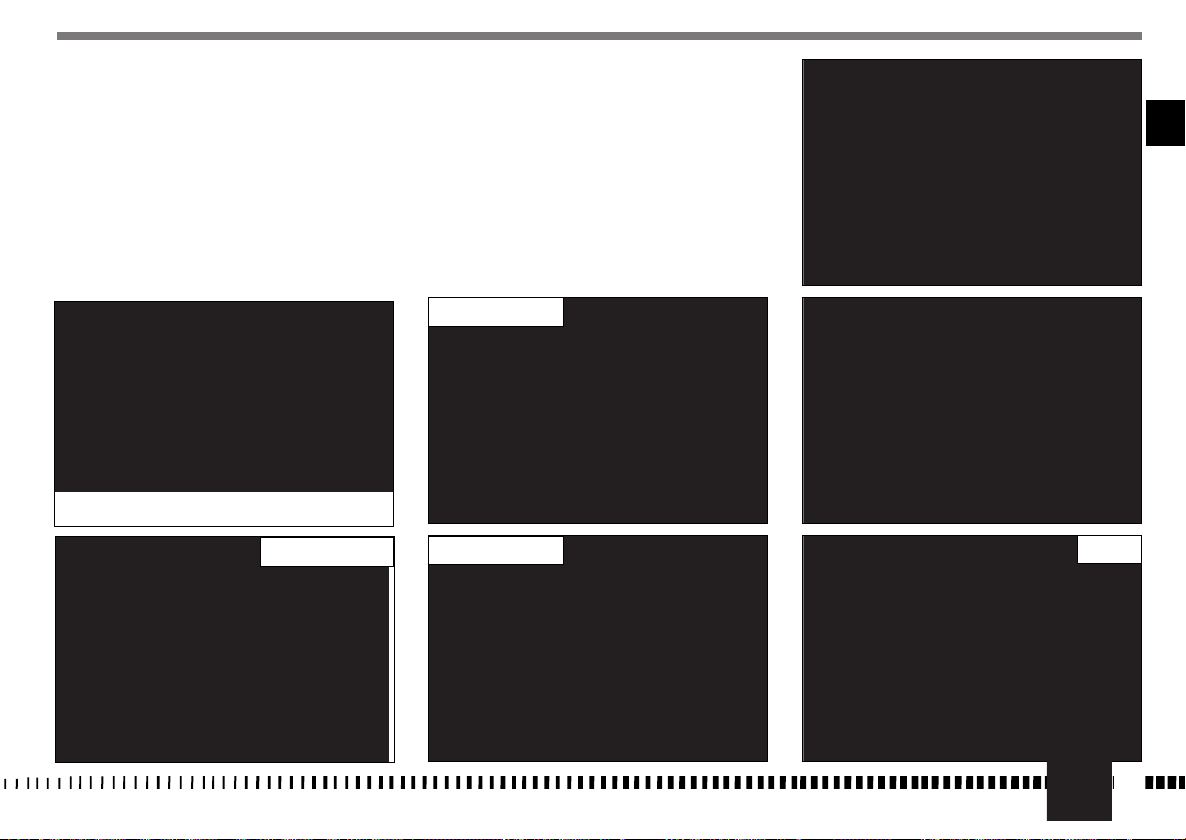

R.H. HANDLEBAR COMMUTATOR (TE-TXC-SMR)

The right commutator has the following controls:

1) Engine start button

3) Engine start - stop switch (TE-SMR)

L.H. HANDLEBAR COMMUTATOR (TE-SMR)

CONTROLS:

1) High beam flash (self cancelling)

2) Selection control High beam

Selection control Low beam

3) Left turn signals (automatic return)

Right turn signals (automatic return)

To deactivate the turn signals, press the control lever after its

returning to center.

4)

Warning horn

TXC

TE-SMR

1

EN

1

TC-TXC

Page 22

REAR BRAKE CONTROL

The rear brake control (1) is placed on the right-hand side of

the motorcycle. On models TE and SMR as stop switch, during

the braking action, causes the rear light to come on.

GEAR SHIFT CONTROL

The lever (1) is placed on the left-hand side of the engine. The

operator must release the lever after each gear change to allow it to return to its central position before another gear

change can be made.

Neutral position (N) is between first (low) and second gears.

First gear is engaged by pushing the lever downwards; all the

other gears are engaged, by pushing the lever upwards.

The position of the gear shift lever on the shaft can be varied

by:

- loosening screw;

- pulling lever out;

- placing lever in new position on the shaft when the operation

is over tighten the screw and then tightening the screw.

CAUTION*: Do not shift gears without disengaging the clutch and closing the throttle.

The engine could be damaged by overspeed

and shock.

WARNING*: Do not downshift when traveling at a speed that would force the engine

to overrev in the next lower gear, or cause

the rear wheel to lose traction.

N: Neutral

N: Neutral

22

TC

1

TE-SMR-TXC

1

Page 23

RIDING

BEFORE EVERY RIDE MAKE FOLLOWING CHECKS

WARNING!

Before each ride, to prevent accidents or failures during ride,

make sure to go through following list.

1. Check all fluids

A. Engine-transmission oil level

B. fuel level

C. coolant level

Make sure all caps are properly adjusted.

WARNING*: Don’t remove radiator cap

when hot!

2. Check all controls

A. Throttle handgrip

B. Clutch lever

Make sure cables are not damaged and turn smoothly.

3. Check brakes

Look for brake fluid leaks and worn hoses. Check for proper functioning.

4. Check suspensions

Compress fork and rear suspensions. Look for oil leaks and

ensure proper functioning.

5. Check wheels

Check spokes and look for worn bearings.

Check rims and tyres.

Check tyre pressure.

6. Check chain rollers and sprockets

Check wear on chain rollers and sprockets

Ensure chain is correctly adjusted and lubricated.

7. Check air filter and intake system

Check that air filter is clean

Check all rubber connections and clamps.

8. Check exhaust system

Check hook up, look for cracks

Check muffler.

9. Check torque

A. Spark plug

B. Cylinder-head nuts

C. General check of torque

10. Check steering action

Check bearing play.

11. Check the electric system (TE- SMR). Start the

engine and check that the front and rear lamps, the stop

light, the turn signals the cluster warning lights and the

horn are working correctly.

WARNING*: Failure to perform these checks

every day before you ride may result in

serous damage or a severe accident.

RUNNIN IN

Before using the motorcycle for sporting activities run in the

engine for two hours at least to increase the life and the performance of the engine.

During the first half-hour of driving we advise keeping a low

speed and avoiding sudden accelerations. Never open the

throttle fully.

Change the oil and carry out all the necessary maintenance operations. After the first half-hour of driving, lightly increase the

rev number, but never run the engine at full throttle. Never

keep low speeds when the high gears are inserted.

Slowly drive the motorcycle for two hours before using it for

sporting activities.

CHECKS WHILE RUNNING IN

- SPOKE TENSION OF WHEELS (see page 78);

- TIGHTENING OF WHEELS (see page 92-93);

- FORK PIN TIGHTENING (see page 92);

- CHAIN ADJUSTMENT (see page 51);

- STEERING BEARING PLAY (see page 40);

- HANDLEBAR TIGHTENING (see page 92);

- ENGINE GRIP TO FRAME (see page 92);

- SUCTION FITTING GRIP (see page 92);

- HEAD AND CYLINDER NUTS GRIP (see page 92);

OFTEN CHECK THE BATTERY CHARGE CONDITION (see page 86).

EN

23

Page 24

ENGINE START (TE-SMR)

With cold engine, as after a prolonged inactivity of the motorcycle or in presence of a low external temperature, proceed as

follows:

1) set ignition key (1) in IGNITION position (the buzz that you

hear when you turn the key to IGNITION is caused by the

fuel pump which puts the feeding system under pressure);

2) pull the starter lever (2);

3) pull the clutch lever (3);

4) shift gear pedal (4) in neutral position then release the

clutch control lever;

5) press the engine start-stop switch (5) then the start button

(6).

Put the start lever (2) in its initial position as soon as the engine is idling. When starting with an already warmed up engine DO NOT USE the starter. When a cold engine has just been

started, do not increase revs, to ensure an

adequate oil warm-up and circulation.

NOTE

A safety switch is set on the clutch lever support. This switch allows you ONLY to start the engine with idle gearbox, or with

the gear engaged and the clutch lever pulled.

IMPORTANT

NEVER START WITH DISCONNECTED BATTERY.

TE-SMR

24

1

3

TE-SMR

5

2

TE-SMR

4

6

Page 25

25

EN

ENGINE START (TXC)

Make sure the fuel tap is in the OPEN position, then shift gear

pedal in neutral position.

Pull the starter knob (BLACK knob (2) for cold starting*, RED

knob (3) for warm starting), pull the clutch control lever,

then press the engine start button (1).

Release the clutch control lever.

*: after a prolonged inactivity of the motorcycle or in presence

of a low external temperature.

STARTING DECOMPRESSOR

Though the engine is provided with an automatic decompressor,

can be necessary, in some cases (carburetor flooding or starting

difficulties due to a battery inadequate charge), to use the manual starting decompressor on the L.H. side of the handlebar. In

these cases, pull the lever (5) whilst simultaneously pressing

the starter button, release the lever (5) keeping the button

pressed and afterwards release the latter as well.

In order to adjust the lever decompressor free play (approximately

3 mm- 0.12 in.), the lever holder is provided with the adjuster (6);

the adjustment can be also effected with the tightener (7) on the

R.H. side of the engine (use this tightener if it is not possible to obtain the correct free play with the adjuster on the handlebar).

2

3

TXC

1

Page 26

ENGINE START (TC-TXC)

Proceed as follows:

1) make sure the fuel tap (A) is in the Open position;

2) shift gear pedal (1) in neutral positio.

3) pull the starter knob (BLACK knob 2 for cold starting*,

RED knob 3 for warm starting)

*: after a prolonged inactivity of the motorcycle or in presence

of a low external temperature.

4) lower the starter pedal (4) until a certain resistance is noticed (piston at T.D.C.);

TC

26

A

2

3

1

TXC

TC-TXC

4

Page 27

5) pull the lever (5) and lower further, by a limited stroke, the

pedal until the abovementioned resistance is overcome

(surpassing of T.D.C.);

6) at this point, release the lever (5) and the pedal (4);

TC-TXC

7) in the case of COLD STARTING, completely rotate the throttle

(6) twice (in the case of warm starting DO NOT carry out

this operation);

EN

TC-TXC

TC-TXC

4

27

Page 28

8) COMPLETELY lower the pedal (4) until the engine starts.

WARM STARTING: BEFORE MOTORCYCLE

STARTING, PRESS RED CHOKE KNOB (3) ON

CARBURETOR TOWARD THE INSIDE IN ORDER

TO DEACTIVATE THE STARTING DEVICE.

In case the engine does not start, repeat this procedure.

IMPORTANT NOTE IN CASE OF COLD STARTS AT

LOW TEMPERATURES

It is recommended to briefly warm-up the engine at idle until,

after having disengaged the starter, there is a normal response from the engine when opening the throttle.

In this way the oil can reach all the surfaces needing lubrication and the coolant will reach the necessary temperature for

correct engine function.

Avoid overheating the engine.

Never accelerate the engine after a cold start.

IMPORTANT

WARNING*: Exhaust contains poisonous carbon monoxide gas. Never run the engine in

a closed garage or in a confined area.

In the case of using a kick-starter, keep in

mind the undermentioned note.

Kick start pedal

WARNING*: This high performance motorcycle can some times «kick back» strongly

when you are starting it.

Do not attempt to start this motorcycle unless you are wearing high top heavy sided

riding boots. You could seriously hurt you

leg if the kickstarter kicked back and your

foot slipped.

TC

28

4

3

Page 29

HOT START (TC-TXC)

If it is a problem to start the engine when hot, or following a

fall, proceed as follows:

1) the transmission (1) should be placed in neutral;

2) pull the RED knob of the starter (2);

3) pull the clutch lever (3);

4) push the kick-starter pedal (5) to start the vehicle.

5) Then release the clutch lever (3).

BEFORE MOVING OFF, DEACTIVATE THE RED

KNOB (2) OF THE STARTER ON THE CARBURETTOR.

EN

TC

2

1

TXC

TC

4

29

Page 30

STOPPING THE MOTORCYCLE AND THE ENGINE

- Close the throttle (1) completely so that the engine will help

slow down the motorcycle.

- For normal braking, gradually apply both front and rear

brakes while down shifting (for maximum deceleration, apply the front and rear brakes firmly).

- When stopped, pull the clutch lever and shift gear lever (2)

in neutral position.

- Press the engine stop RED button (3).

- TC-TXC: close the fuel cock (4).

- TE-SMR: turn towards left the ignition key.

WARNING*: Independent use of the front or

rear brake may be advantageous under

certain conditions. Use caution when using

the front brake, especially on slippery surfaces. Improper use of the brakes can lead

to a serious crash.

WARNING*: In the event of stuck throttle or

other malfunction which causes the engine

to run uncontrollably, immediately depress

the engine stop button and hold it down.

Control the motorcycle by normal use of the

brakes and steering while holding the engine stop button down.

4

TC-TXC

TE-SMR

30

TC-TXC

TE-SMR

Page 31

CHECKING THE OIL LEVEL

Keeping the motorbike level and in a vertical position, check the

oil level through the inspection (1) window on the right

crankcase. Make sure the level is in between the MIN and MAX

notches.

To fill up, remove the filler cap (2).

Note*: Have this operation made with

warmed-up engine.

WARNING*: Be careful not to touch hot engine oil.

ENGINE OIL REPLACEMENT AND BAG FILTERS-FILTER CARTRIDGE CLEANING OR REPLACEMENT

WARNING*: Be careful not to touch hot engine oil.

Drain the oil with WARM ENGINE; proceed as follows:

- remove oil filler cap (1);

- remove the engine guard (A)

- place an oil drain pan under the engine block

- remove the oil drain cap (2)

- drain the used oil completely then clean the magneto on the

cap;

- remove the three filters (4), (5) and (6) on the L.H. side of

the engine, check O-Rings for wear then clean filters with fuel; reassemble using the reverse procedure;

- in order to replace the filter cartridge (3), unscrew the three

fastening screws then the filter cartridge cover;

- after filters replacement, reassemble the drain cap (2), the

engine guard (A) then pour the recommended oil quantity.

EN

1

MAX

A

MIN

2

A

2

3

4

31

Page 32

COOLANT LEVEL CHECK

Check level (1) in right-hand radiator when engine is cold

(place the motorcycle so that it is perpendicular to the ground).

The coolant should be approximately 10 mm above cells and

besides, on TE-TXC and SMR models, it doesn't exceed the middle of the expansion tank (2) located in front of the rear shock

absorber.

The radiator cap is provided of two unlocking positions, the

first being for the previous pressure discharge in the cooling

system.

1

WARNING

Avoid removing radiator cap when engine is

hot, as coolant may spout out and cause

scalding.

WARNING

TE-SMR: Because the cooling fan (A)

can be activated even when the start switch

is in OFF position, always keep at a safe

distance from the fan vanes.

NOTE

Difficulties may arise in eliminating coolant

from varnished surfaces. If this occurs,

wash off with water.

REPLACEMENT OF COOLING FLUID

Place a vessel on the R.H. side of the cylinder, under the

coolant drain screw (1).

FIRST remove the screw (1) then SLOWLY open the R.H. radiator cap; slope the motorcycle on the right side to drain the

coolant easily in the vessel. Reassemble the screw (1).

Pour the necessary quantity of coolant in the radiator then

warm up the engine in order to eliminate any possible air bubble.

1

32

Page 33

Periodically check the connecting hoses (see “Periodical maintenance card”): this will avoid coolant leakages and consequent engine seizure: If hoses (A) show cracks, swelling or

hardenings due to sheats desiccation, their replacement shall

be advisable.

Check the correct tightening of the clamps (B).

THROTTLE CABLE ADJUSTMENT

To check the correct adjustment of the throttle operate as follows:

- remove the upper rubber cap (1);

-

by moving cable (2) back and forth check for 2 mm. clearance;

- should the clearance be incorrect, unblock the counter ringnut (3) and turn the adjusting screw (4) (by unscrewing it,

the clearance is reduced, while by screwing screw (4) it is

increased);

- tighten the counter ring-nut again (3).

WARNING*: Operation with damaged throttle cable could result in an unsafe riding

condition.

NOTE

In case of throttle control cables (1) and (2) replacement it is

necessary to respect, during reassembly, the measure Á

(10mm/0.4 in.), as shown in the picture. Then reassemble

guard cover (B) using screw (3) and adjust throttle control

cables on handlebar as described at side.

To replace throttle control cables, first remove tha fuel tank as

shown on pages 35, 36.

EN

A

B

A

B

WARNING*: Exhaust gas contains poisonous

carbon monoxide gas. Never run the engine

in a closed area or in a confined area.

33

Page 34

ADJUSTING THE CARBURETTOR (TC-TXC)

Adjust the carburettor with warm engine and with the throttle

in closed position.

Work as follows:

- Turn slow running adjusting screw (1) on the left side of the

bike, , until the engine is turning over at fairly high rpm

(turn the screw clockwise to increase the rpm, and anticlockwise to descrease the rpm).

- Turn adjusting screw (2) clockwise until the fully closed position is reached then turn back 1,5 turns (250) 2,0 turns

(450-510)

- progressively loosen adjusting screw (1) to obtain the slow

running required.

ADJUSTING THE IDLE (TC-TXC)

Adjust the carburetor with warm engine and with the throttle

control in closed position. Proceed as follows:

- Turn slow running adjusting screw (1) on the left side of the

bike, near the fuel cock (turn the screw clockwise to increase

the rpm, and anticlockwise to descrease the rpm).

ADJUSTING THE IDLE (TE-SMR)

Adjust the carburetor with warm engine and with the throttle

control in closed position. Proceed as follows:

- turn the idle speed adjustment screw (3) on the throttle

body, located on the right side of the vehicle, until the idle

speed of 1600 RPM is reached (turn clockwise to increase

the speed and anti-clockwise to reduce the speed).

3

34

Page 35

35

SPARK PLUG CHECK

Use NGK CR8EB spark plug; the gap is 0.027 in.

A wider gap may cause difficulties in starting engine and in

overloading coil.

A gap that is too narrow may cause difficulties when accelerating, when idling the engine or when performing at low

speeds.

Clean the dirt away from the base of the spark plug before removing it from the cylinder after removing the cap (1).

It is very useful to examine the state of the spark plug just after

it has been removed from the engine since the deposits on the

plug and the colour of the insulator provide useful indications.

Correct heat rating:

The tip of the insulator should be dry and the colour should be

light brown or grey.

High heat rating:

In this case, the insulator tip is dry and covered with dark deposits.

Low heat rating:

In this case, the spark plug is overheated and insulator tip is vitreous, white or grey in colour.

CAUTION*: Select a spark plug with a colder or

hotter heat range carefully and cautiously. A

spark plug with too hot a heat range may

lead to preignition and possible engine damage. A spark plug with too cold a heat range

may foul as the result of too much carbon

buildup.

Before refitting the plug, thoroughly clean the

electrodes and the insulator using a brass-metal brush.

Apply a little graphite grease to the spark

plug thread; fit and screw the spark plug by

hand then tighten to the torque of 10÷12 Nm-

7.4÷8.9 ft/lb. Loosen the spark plug then

tighten it again to the torque of 10÷12 Nm-

7.4÷8.9 ft/lb.

Spark plugs which have cracked insulators or

corroded electrodes should be replaced.

VOLTAGE REGULATOR (TXC-TE-SMR)

The voltage regulator (3) is fitted to the right side of the chassis, on the front.

2

3

1

EN

Page 36

ADJUSTING THE VALVE PLAY

To check the valve clearance, proceed as follows , WITH COLD

ENGINE:

First turn counterclockwise fastening rear pin (1) then remove

the saddle.

2

HOW TO REMOVE THE TANK (TC-TXC)

Close the fuel tap (2) and loosen the strap (3) on the connecting pipe to the carburettor, pull the pipe out of the carburettor.

Remove the screws (4) and the side panels.

4

A

Remove the locking screw (A) and pull out the tank with its

conveyors.

3

36

Page 37

HOW TO REMOVE THE TANK (TE-SMR)

Remove the screws (1) and the side panels. Remove the locking screw (A) of the tank.

1

Lift the tank, then disconnect the connector of the fuel pump

from the main cabling.

Disconnect the feeding pump (B) from the outlet coupling (C)

on the fuel pump in the lower back section of the tank.

Pull out the tank with its conveyors.

EN

A

TE-SMR

TE-SMR

C

TE-SMR

B

TE-SMR

TE-SMR

37

Page 38

38

Check, by means of a feeler gauge, that the valve clearance is

0,10÷0,15 mm (0.004÷0.006 in.) for INTAKE and 0,15÷0,20

mm (0.006÷0.008 in.) for EXHAUST;

Otherwise, lift the retaining clip (7) using a hook, let the rocker arm slide to one side, extract the pad with a pair of pliers

and check the thickness;

Depending on the result, fit a new pad (as spare parts, pads

are supplied ranging from 1.60 mm to 2.60 mm in steps of

0.05 mm) and return the clip and rocker arm;

Check the valve clearance again and, if it’s correct, reassembly

the removed parts using the reverse procedure.

Remove the spark plug (5), the four cylinder head cover fastening screws (6) and the cylinder head cover.

Engage second gear and, moving the vehicle forwards and

backwards, bring the piston to Top Dead Center (in this condition , the mark on the cylinder head is aligned with the two

marks on the idle gear of the camshafts, as illustrated in the

figure).

Page 39

AIR FILTER CHECK

Turn rear pin (1) counterclockwise, remove the saddle from the

front afstening screw.

Turn forward the housing box complete with the battery (1) (it

is not necessary to remove the battery from its housing box).

To gain access to the air filter, lift a little the electronic power

unit (2).

Remove screw (3) and the filter (4). Separate filter (5) from

frame (6).

AIR FILTER AND CLEANING

Wash the filter with a specific detergent (AGIP” Filter clean

foam air detergent fluid” or similar) then dry it fully (wash

filter with gasoline only in case of necessity).

Plunge the filter in special oil for filters (AGIP "Foam air filter

protection oil" or similar), then wring it to drain superfluous

oil.

CAUTION*: Do not use gasoline or a low

flash-point solvent to clean the element. A

fire or explosion could result.

CAUTION*: Clean the element in a well ventilated area, and do not allow sparks or

flames anywhere near the working area.

ASSEMBLY

To ensure tight fit, slightly (C) grease filter edge on side facing

filter housing.

While re-inserting the filter into its housing, make surs that

piece A is turned upwards and edge B is on the left lower side

of the filter case. Reassemble the parts previously removed

(battery: connect the positive cable first).

CAUTION*: If the element assembly is not

installed correctly, dirt and dust may enter

and the engine resulting in rapid wear of

the piston rings and cylinder.

EN

39

Page 40

STEERING WHEEL BALL PLAY ADJUSTMENT

To ensure maximum safety, the steering wheel should always be

regulated so that the handlebars steering the motorcycle rotate

freely without play. To check steering wheel adjustment, place kick

stand or other support under the engine so that the front wheel is

raised from ground.

Place slight pressure on the tips of the handlebars to rotate steering wheel; the handlebars should also rotate without effort. Stand

in front of the motorcycle and grasp the lower end of the fork rods

sliders moving them in the direction of their axis.

If play is noticed, proceed with adjustment as follows:

lloosen steering sleeve nut (1).

lLoosen four screws that fix steering head to fork rods (3).

Turn the steering ring nut (2) clockwise of the steering sleeve

proper tool, to adjust play properly.

Tighten steering sleeve nut (1) to a torque setting of

57,9÷65,1 Lb/ft; (78,4÷88,3 Nm).

Tighten four screws on the steering head (3) to a torque of

22,5÷26,5 Nm (16.6÷19.5 Lb/ft).

CAUTION*: Do not ride a motorcycle with

damaged steering stem bearings. An unsafe handling condition can result.

40

Page 41

ADJUSTMENT OF THE CONTROL LEVER AND

CHECK OF THE FRONT BRAKE FLUID LEVEL

On the SMR model the lever position can be adjusted (4

adjustments) for any driver hand size. To decrease the lever

distance from the handle grip, turn the adjuster (B)

CLOCKWISE. To increase the lever distance from the handle

grip, turn the adjuster (B) COUNTERCLOCKWISE.

On the TE, TXC and TC models the adjuster (2), located on the

control lever, allows adjusting of the free play (a).

Free play (a) must be at least 3 mm (0.1 in.).

The level of the fluid in pump reservoir must never be below

the minimum value (1), which can be checked from the window

SMR

on the rear side of the pump body (TE, TC). For SMR model,

check the level on the fluid reservoir.

A decrease of the fuel level will let air into the sustem, hence

an extension of the level stroke.

WARNING*: If the brake lever feels mushy

when it is applied, there may be air in the

brake lines or the brake may be defective.

Since it is dangerous to operate the motorcycle under such conditions, have the brake

checked immediately by an authorized

HUSQVARNA dealer.

SMR

CAUTION*: Do not spill brake fluid on to

any painted surface or lenses.

CAUTION*:Do not mix two brands of fluid.

Change the brake fluid in the brake line if

you wish to switch to another fluid brand.

CAUTION*: Brake fluid may cause irritation.

Avoid contact with skin or eyes. In case of

contact, flush thoroughly with water and

call a doctor if your eyes were exposed.

A: to encrease clearance

B: to decrease clearance

EN

TE-TC-TXC

TE-TC-TXC

TE-TC-TXC

+

B

-

2

A

41

Page 42

REAR BRAKE PEDAL POSITION ADJUSTMENT

The position of the rear foot brake pedal as to the footrest may

be adjusted according to the individual needs. For the adjusting proceed as follows:

- loosen the screw (1);

- turn the cam (2) in order to adjust the brake pedal idle

stroke (A);- the operation done, tighten the screw (1).

The adjusting operation carried out, adjust the idle stroke of

the pedal as indicated in page 43.

REAR BRAKE IDLE STROKE ADJUSTMENT

The rear brake foot pedal should have a (B) 5 mm (0.2 in.)

idle stroke before starting the true braking action.

Should this not happen as follows:

- loosen nut (3);

-

operate the pump rod (4) to increase or decrease the idle

stroke;

- tighten nut (3) at the end of the operation.

WARNING

When the idle stroke figures are not met,

the brake pads will be subjected to a fast

wear that may bring to the TOTAL BRAKE INEFFECTIVENESS.

42

Page 43

CHECKING THE FLUID LEVEL

The level (A) must be set between the pump tank notches.

ADJUSTMENT OF THE CONTROL LEVER AND

CHECK OF THE HYDRAULIC CLUTCH FLUID LEVEL

Free play (A) must be at least 3 mm (0.1 in.).

The lever position can be adjusted for any driver hand size.

To decrease the lever distance from the handle grip, rotate the

adjuster (B) CLOCKWISE.

To increase the lever distance from the handle grip, rotate the

adjuster (B) COUNTERCLOCKWISE.

To check the fluid level, proceed as follows:

- remove screws (1), cover (2) and rubber pump diaphragm

on the handlebar clutch control;

- by keeping the master cylinder (3) in horizontal position,

check the fluid level is NOT BELOW 4 mm (0.16 in.) from the

upper surface (D) of the pump body;

- if necessary, add fluid until the correct level is reached see

TABLE FOR LUBRICATION-SUPPLIES for the fluid type page 12.

TC-TXC

CAUTION*: NEVER use brake fluid.

Reassembly the removed parts using the reverse procedure.

Periodically check the connecting hose (see “Periodical maintenance card”): if the hose (C) show is bent or cracked, its replacement is advised.

EN

43

Page 44

HYDRAULIC CLUTCH BLEEDING

Proceed as follows:

- remove screws (1), cap (2) and rubber pump diaphragm;

- remove the bleeding nipple (3);

- mount a syringe in the bleeding nipple hole, then refill with

fresh fluid see LUBRICATION TABLE on page 12.

CAUTION *: NEVER use brake fluid.

- refill until fluid is discharged from the lower hole (B) on the

pump body WITHOUT BUBBLES.

The fluid level MUST NEVER BE below 4 mm from the top (A)

of the clutch pump body (see picture). Reassemble the removed parts.

44

Page 45

ADJUSTING THE SUSPENSIONS ACCORDING TO

PARTICULAR TRACK CONDITIONS

The following information is a useful guide for setting up the

suspensions according to the road conditions.

Always start from the standard calibration before making any

change on the suspensions. Afterwards, increase or decrease

the adjusting clicks one at a time.

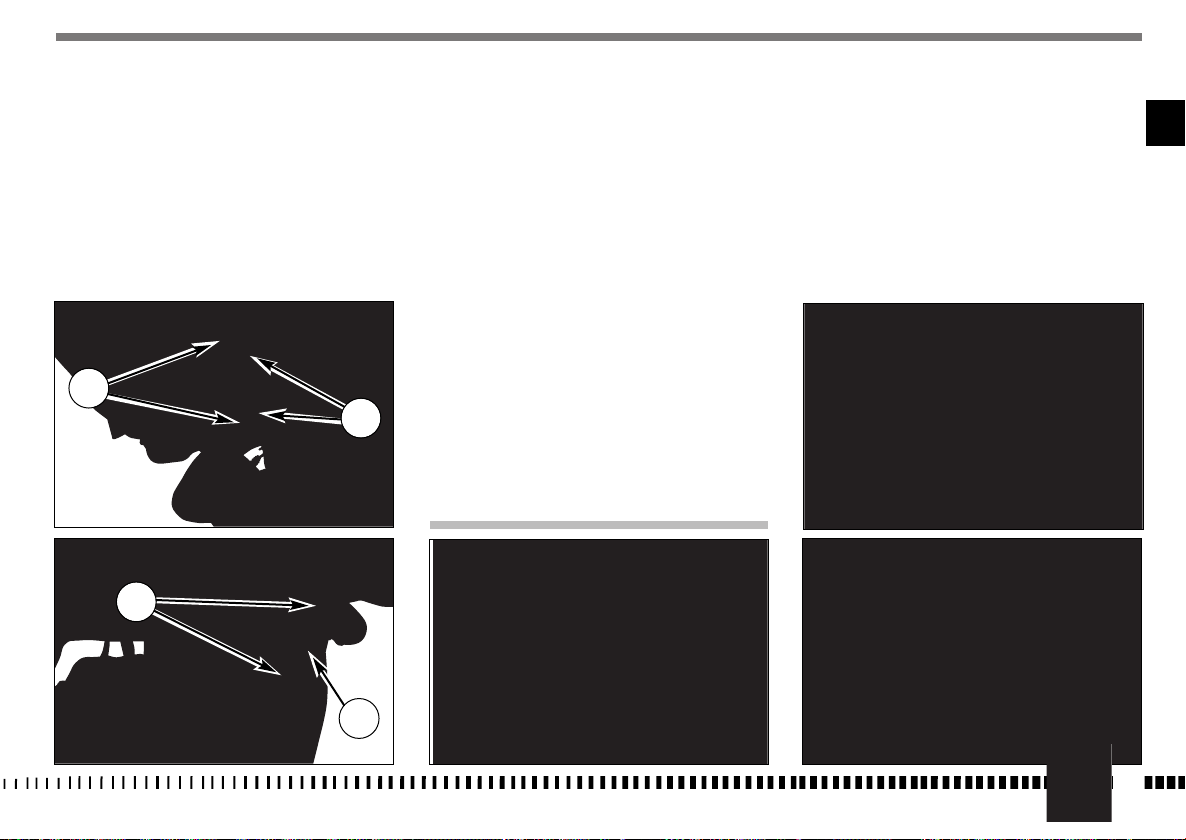

HARD GROUND

Fork: softer compression adjustment.

Shock absorber: softer compression adjustment.

The softer adjustment for the two suspensions is also used

both in compression and in extension when driving at top

speed, in order to have better grip of the tires.

SANDY GROUND

Fork: have a harder compression adjustment, or replace the

standard spring with a harder one, and make a softer compression adjustment and a harder extension adjustment at the

same time.

Shock absorber: have a harder compression, and expecially a

harder extension adjustment. Work on the spring preload to

lower the motorcycle rear side.

MUDDY GROUND

Fork: have a harder compression adjustment, or replace the

standard spring with a harder one.

Shock absorber: have a harder compression and extension adjustments, or replace the standard spring with a harder one.

Work on the spring preload to lift the motorcycle rear side.

We advise replacing the springs of both suspensions to compensate the weight increase due to the piling of the mud.

NOTE:

When the fork results as either too soft or too hard for any adjustment conditions, check the oil level inside the forkrod.

The level can either be too low or too high. Remember that too

much oil inside the fork will involve a more frequent air

drainage. When the suspensions do not react to the changes

of calibration, check that the adjusting units are not blocked.

EN

45

Page 46

The standard calibrations and the adjustment procedures are

shown on the next pages. The springs available upon request,

together with the preload spacers, are shown on pages 95, 96,

97, 98.

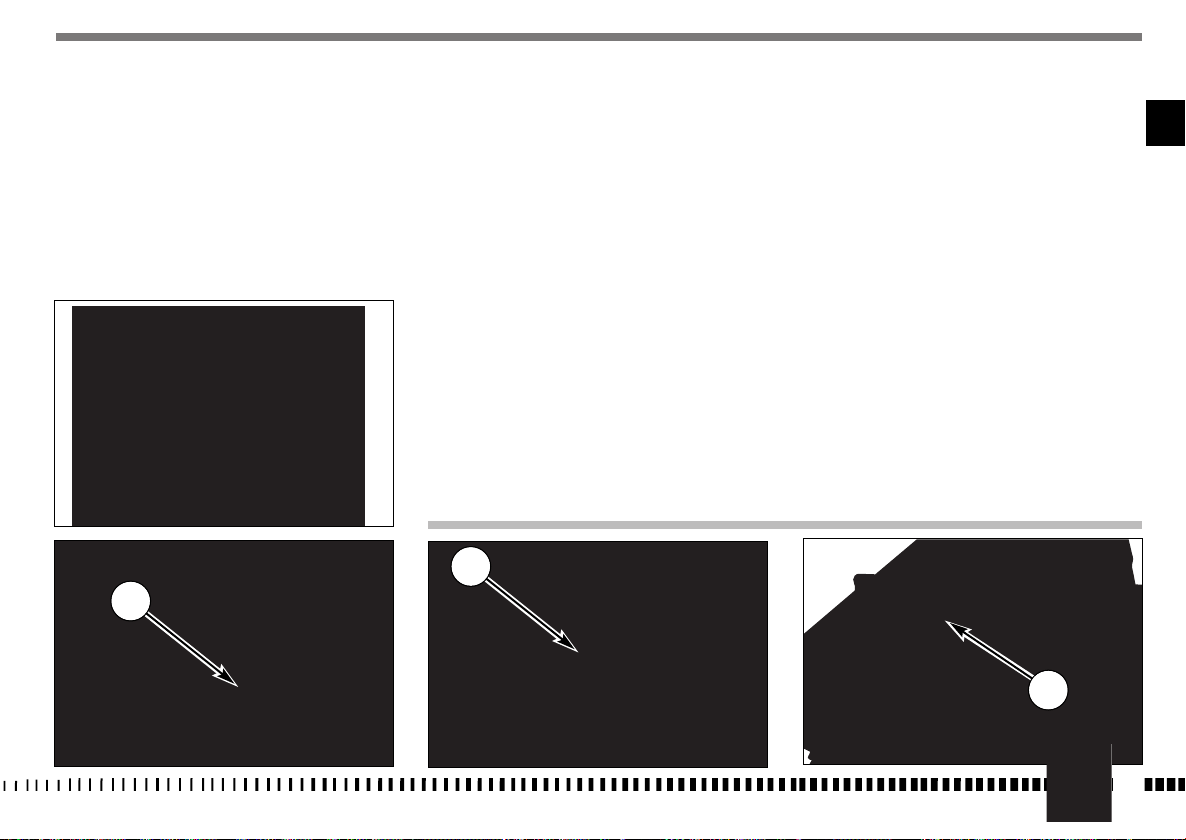

ADJUSTING THE COMPRESSION FORK

a) Compression (Lower register)

Standard calibration: -15 clicks (TC-TXC);

Standard calibration: -12 clicks (TE-SMR).

Remove plug (B) and turn register (A) clockwise until the position of fully closed is reached then, turn back by the mentioned clicks.To obtain a smoother braking action, turn the register anticlockwise. Reverse the operation in order to obtain a

harder action.

b) EXTENSION (upper register)

Standard calibration: - 15 clicks (TC-TXC);

Standard calibration: - 12 clicks (TE-SMR).

To reset standard calibration turn register (C) clockwise to

reach the position of fully closed; then, turn back by the mentioned clicks. To obtain a smoother braking action, turn the

register anticlockwise. Reverse the operation in order to obtain

a harder action.

c) AIR VENT (to carry out after each competition, or monthly).

TE-SMR: set the motorcycle on a central stand and release the

fork fully and loosen the air vent valve (D). Once this operation is over, tighten the valve.

TXC-TC: Place the vehicle on a central stand, pull the fork all

out, then remove the cap (E) and press the valve with a tip. Fit

the cap back in.

WARNING!

NEVER loosen the screw (F).

WARNING: Never force the adjusting screws beyond

the maximum opening and closure positions.

a)

b)

TE-SMR

A

C

B

E

C

TC-TXC

C

TE-SMR

TE-SMR

TC-TXC

D

C

F

46

Page 47

OIL FORK LEVEL

For the regular fork operation, both legs must be provided

with the necessary oil quantity. Remove the forkrods form the

fork to check the oil level inside the forkrods. Work as follows:

- remove the power rod caps;

- remove springs from the stems letting the oil drop into the

latter;

- bring forks to stroke end;

- check that the level is at distance “A” below the upper limit

of rods.

OIL QUANTITY IN EACH FORK LEG

- TC: 310 cm3(18.9 cu. in.)

- TE: 775 cm3(47.3 cu. in.)

- SMR: 740 cm3(45.1 cu. in.)

A=100mm (3.94 in.) - SMR

A=120mm (4.72 in.) - TE

A

NOTE

Besides the serial spring with flexibility index:

K=4,5 N/mm (TE)

K=4,8 N/mm (TC-TXC 250)

K=5 N/mm (TC-TXC 450,510 - SMR)

and relevant preload spacer harder or softer springs, together

with spacers are abailable upon request.

NOTE

Always replace both the spring and the spacers to keep the

preload value unchanged.

47

EN

Page 48

HANDLEBAR POSITION AND HEIGHT CHANGE

The handlebar position (a) and height (b) can be changed for

better suiting Your driving requirements. To effect these operations, remove the upper screw (3), upper clamp (1), lower

screw (4) then lower clamp (2).

a) Handlebar position change

Turn the lower clamp (2) 180° to move forward or backward

(10mm- 0.04in.) the handlebar position with respect to the

original setup.

b) Handlebar height change

Remove the lower spacer (A) then replace the screw (4) with a

new one of L=65 mm (2.56 in.) height.

Once these operations are completed, tighten the screws (3) to

2,75-3,05 kgm (27-30 Nm; 19.9-22 Lb/fts) and the screws (4)

to 2,0-2,2 kgm (19,6-21,6 Nm; 14.5-15.9 Lb/fts).

48

Page 49

ADJUSTING THE SHOCK ABSORBER

The rear shock absorber must be adjusted according to the rider weight and track conditions.

Proceed as follows:

1. With motorcycle on the stand, measure distance (A).

2. Take the normal riding position on the motorcycle with all

your riding apparel.

3. With somebody’s help, take the new distance (A).

B: axis of the panel screw

C: axis of rear wheel pin

4. The difference between these two measurements constitutes

the “SAG” of the motorcycle’s rear end.

Suggested SAG: 4 in. with cold shock absorber. 3.7 in. with

warmed up shock absorber.

5. To get the right SAG according to your weight, adjust the

shock absorber spring preload as described at side.

WARNING*: Never disassemble shock absorber, which contains highly compressed

nitrogen. Contact your Dealer for such major service. Do not incinerate.

ADJUSTING THE SHOCK ABSORBER SPRING

PRELOAD

Proceed as follows:

1. First turn counterclockwise fastening rear pin (1) then remove saddle, screws (2) and R.H. side panel (3).

2

EN

3

49

Page 50

B) EXTENSION - Standard calibration:

- 18 clicks (± 2 clicks)

To reset the standard calibration, turn lower register (5) clockwise until reaching fully closed position. Return then back for

the mentioned clicks. In order to obtain a smooth braking

action, turn the register anticlockwise. Reverse the operation

in order to obtain a harder braking action.

2. Clean ringnut (1) and adjusting nut (2) of the spring (3).

3. Either with a hook wrench or an aluminium punch, loosen

the ringnut .

4. Turn the adjusting nut as required.

5. When the adjusting operation is over (according to your

weight and riding style), tighten the ringnut. (Torque for

both ringnuts: 5 Kgm; 49 Nm; 36.2 ft/lb).

6. Reassemble R.H. side panel and saddle.

WARNING*:Be careful not to touch hot exhaust pipe while adjusting the shock abosrber.

SHOCK ABSORBER DAMPING ADJUSTMENT

Adjustment of the compression stroke is independent from the

rebound stroke.

A) COMPRESSION - Standard calibration:

1) Low damping speed:

- 15 clicks (± 2 clicks)

(register 4)

2) High damping speed:

- 15 clicks (± 2 clicks)

(register 6)

To reset the standard calibration, turn upper registers (4) and

(6) clockwise until reaching fully closed position.

Return then back for the mentioned clicks. In order to obtain a

smooth braking action, turn the registers anticlockwise.

Reverse the operation in order to obtain a harder braking action.

50

1

2

3

6

4

5

Page 51

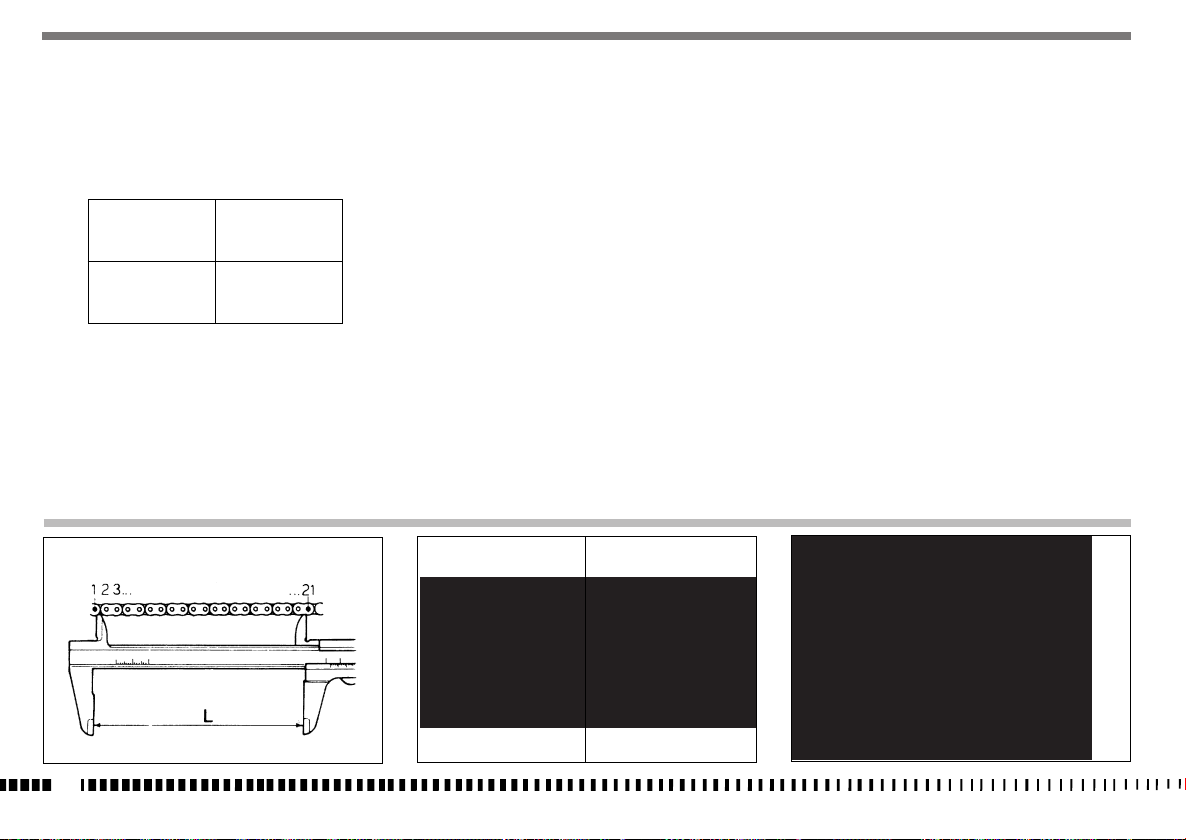

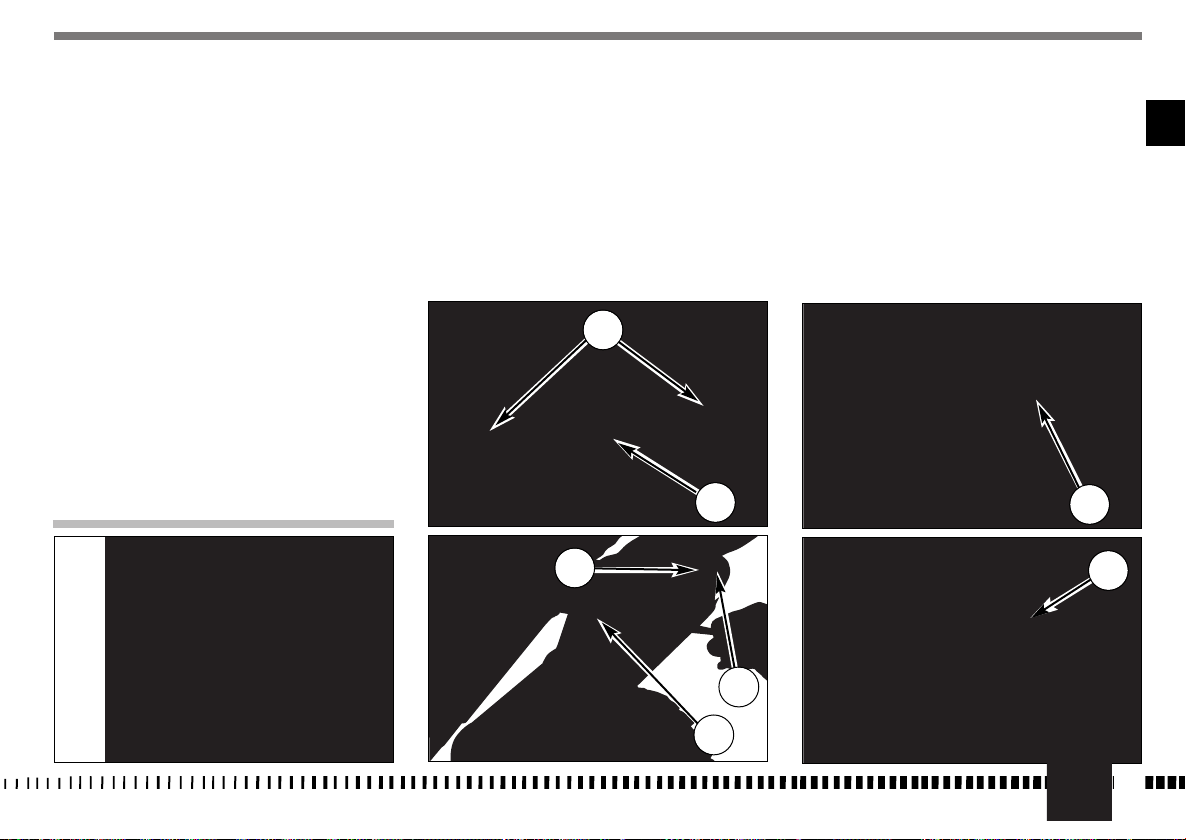

CHAIN ADJUSTMENT

Chain should be checked, adjusted and lubricated as per the

Maintenance Chart to ensure security and prevent excessive

wear. If the chains becomes badly worn or is poorly adjusted

(i.e., if it is too loose or too taught), it could escape from

sprocket or break.

To adjust the rear chain it is necessary to lower the rear part of

motorcycle so to line up the drive sprocket axle, the rear swing

arm axle and the rear wheel axle as shown on drawing. Than

let turn three times the rear wheel. Now the chain should not

be tight. (Fig. A).

Fig. A

Fast adjustment (Fig. B).

In the point shown in the figure, fit a bush (a), 35 mm diameter (or alternatively a shim in the same size) and make sure

the lower branch (C) of the chain is slightly taut.

If it is not, proceed as follows:

- on the right side, with a 27 mm Allen screwdriver, loosen the

locking nut (1) of the wheel pin;

- with a 12 mm screwdriver, loosen the check nuts (2) on both

chain stretchers and work on the screws (3) to achieve the

right tension;

- when the adjustment is over, tighten the check nuts (2) and

the wheel pin nut (1).

When the adjustment is over check the wheel for alignment.

A = 0÷2 mm (0÷0.08 in.)

a

Fig. B

EN

C

1

2

3

Drive sprocket axle

Rear swing arm axle

Rear wheel axle

51

Page 52

CHECKING THE WEAR OF CHAIN, PINION AND