Page 1

Operator´s manual

SMB 70

SMB 70 E

Please read these instructions carefully and make sure

you understand them before using the one-man sawmill.

English

Page 2

TABLE OF CONTENTS

Introduction ....................................... 3

Symbols .............................................4

Warning Signs ................................... 4

Safety Regulations............................5

Description ........................................ 7

Installation .......................................16

Fuel Handling .................................. 23

Starting and Stopping..................... 24

Use.................................................... 26

Maintenance .................................... 30

Technical Data ................................. 36

2 – English

Page 3

Introduction

INTRODUCTION

This operator’s manual describes in detail how

the one-man sawmill is used and maintained and

how servicing is to be carried out. It also describes the measures to be taken for maximum

safety and how the safety features are designed

and function, as well as how they are inspected,

maintained, and repaired if necessary.

NOTE! The section dealing with safety must

be read and understood by all those who

install, use, or repair the sawmill.

The operator’s manual comprises installation,

usage, and the different maintenance procedures

that can be performed by the operator. More

comprehensive servicing or troubleshooting

should be performed by the dealer’s service

personnel.

The operator’s manual describes all the requisite

safety features and should be read and understood by the user before the sawmill is assembled.

Symbols and warning signs shown on the next

page can be found in this operator’s manual and

on the one-man sawmill. If a decal on the sawmill

has been damaged or is worn, a new warning

decal must be applied as soon as possible in

order to ensure the greatest possible safety

when using the sawmill.

The one-man sawmill shall only be used to cut

boards and planks from logs.

The one-man sawmill should be used outdoors

and not in enclosed spaces.

English – 3

Page 4

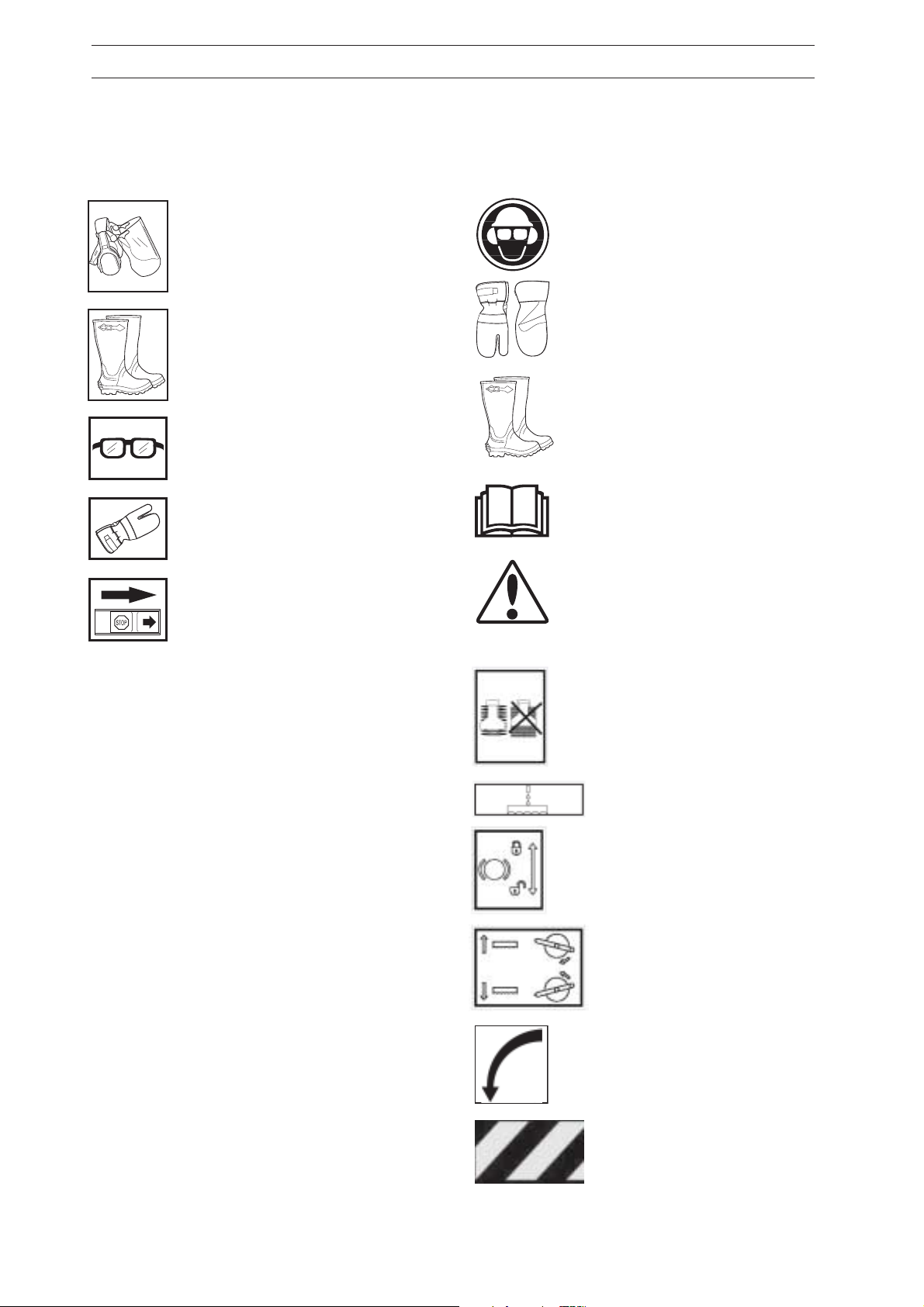

KEY TO SYMBOLS

Symbols

The symbols below are used in this operator’s

manual.

Eye protection and hearing

protection should be used.

Boots or work shoes with

steel toecaps and non-slip

soles should

be worn.

Eye protection should be

used.

Protective gloves should be

worn.

W arning Signs

The decal with the symbols below is found on the

one-man sawmill.

Eye protection and hearing

protection should be used.

Protective gloves should be

worn.

Boots or work shoes with steel

toecaps and non-slip soles

should be worn.

Read this manual carefully

and make sure you understand it before attempting to

use the one-man sawmill.

Switch off the engine by

moving the stop switch to the

STOP position before carrying out any checks or maintenance.

Exercise caution.

Bandsaw blade tension

Bandsaw blade cleaning on

tank

Bandsaw start/stop and

brake

Height setting

4 – English

Arrow for bandsaw blade

direction

Danger

Page 5

SAFETY REGULATIONS

Safety Regulations

WARNING!

A one-man sawmill can be a

!

dangerous tool that can cause

serious or fatal injury if used

incorrectly or carelessly. It is

very important that the person

using the one-man bandsaw

reads and understands the

content of this manual.

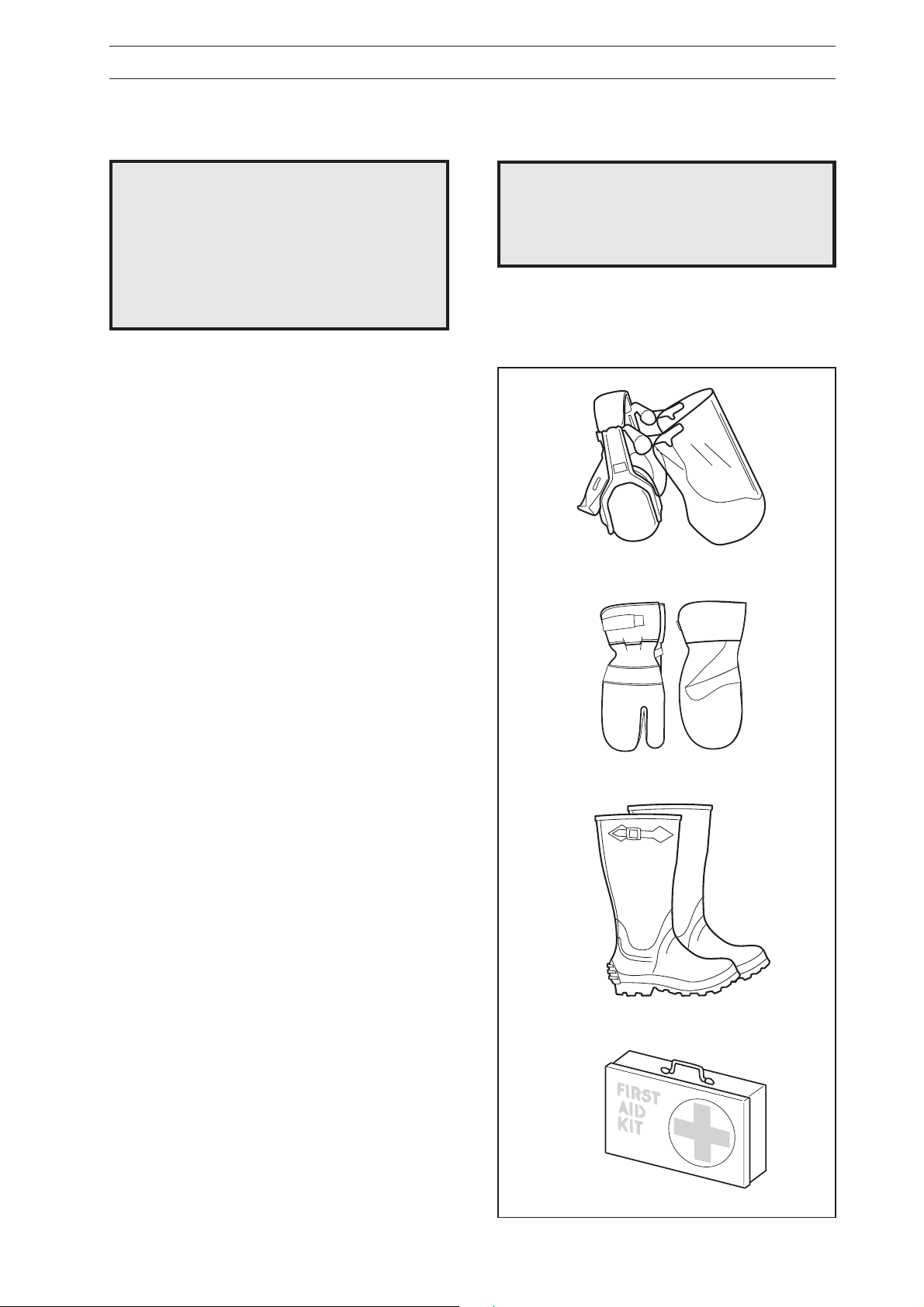

Personal Protective Equipment

The person or persons using the one-man

sawmill or remaining in its close proximity must

be equipped with the personal equipment as set

out below:

1. Hearing protection.

2. Eye protection.

!

WARNING!

Always ensure good ventilation. Exhaust fumes and

sawdust can cause injury or

allergies.

3. Approved protective gloves.

4. Boots or work shoes with steel toecaps and

non-slip soles.

5. First aid kit.

English – 5

Page 6

SAFETY REGULATIONS

The One-man Sawmill Safety

Equipment

WARNING!

!

There are a number of safety devices and

guards in order to prevent accidents when using

the sawmill. These are described in the sawmill’s

general description. See page 15.

The safety devices and guards also require

regular inspection and maintenance. Measures

and intervals are documented in the section

Maintenance. See page 30-35.

The one-man sawmill must

never be used if any of the

safety devices or guards is

damaged or does not work.

Fuel Safety

WARNING!

!

The fuel used in the one-man

sawmill has the following

hazardous properties:

1. The fluid, its vapour, and its

exhaust fumes are poisonous.

2. Can cause skin irritation.

3. Is highly inflammable.

Safety During Use

The safety regulations that apply while using the

one-man sawmill are documented in their respective areas under the section Use on page

26-29.

The operator should observe the following safety

measures before and during use:

1. Check that all safety devices and guards are

fitted and undamaged.

2. Check that no fuel has been spilt on the

outside of the tank or on the ground.

3. Ensure that there are no people or animals

within the one-man sawmill’s risk zone.

4. The stopping and locking devices required to

fasten the log shall be used in the intended

manner. See pages 26-28.

5. Adjust the bandsaw guide so that it is as

close to the log as possible. See page 27.

6. Adjust the scale and check that the bandsaw

moves freely over the short and long log

supports by the red markings on the scale.

See page 22.

Special safety regulations apply to the fuel used

with the one-man sawmill. These are documented

in the section Fuel Handling on page 23.

Personnel

The following apply to personnel using the oneman sawmill:

1. Shall have read and understood the content

of this operator’s manual.

2. Must not be under the influence of alcohol or

medication, nor suffering from tiredness.

3. Good lighting is required when using the

sawmill outside daylight hours.

4. Shall not be a minor.

5. Earthed circuit breaker recommended.

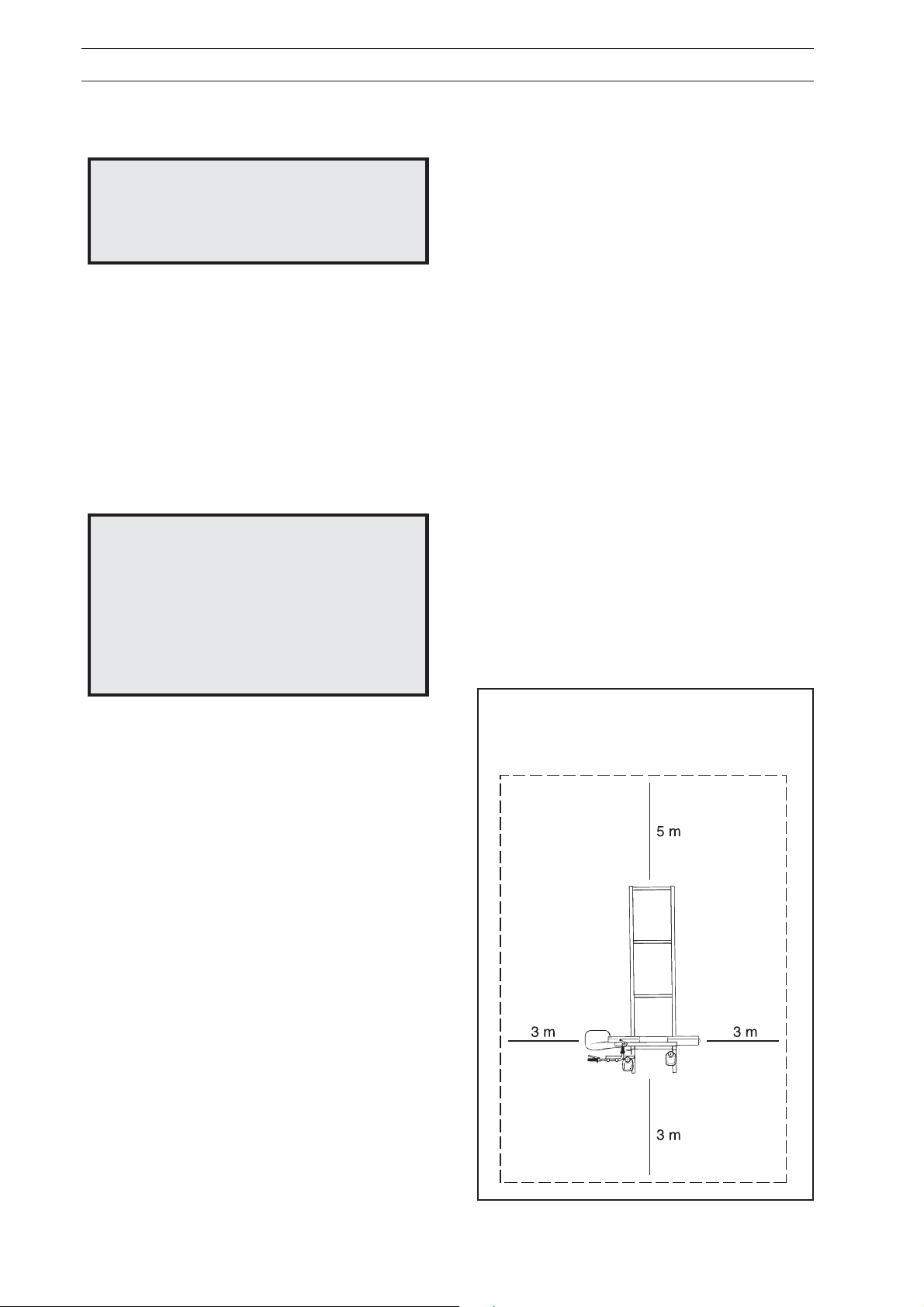

Risk Zone

The risk zone is evident from the picture to the

right.

No unauthorised persons may be present in the

risk zone.

The risk zone should also be kept free of foreign

objects and the ground within the risk zone

should be flat so that the operator avoids stumbling.

FIG. 1

6 – English

Page 7

DESCRIPTION

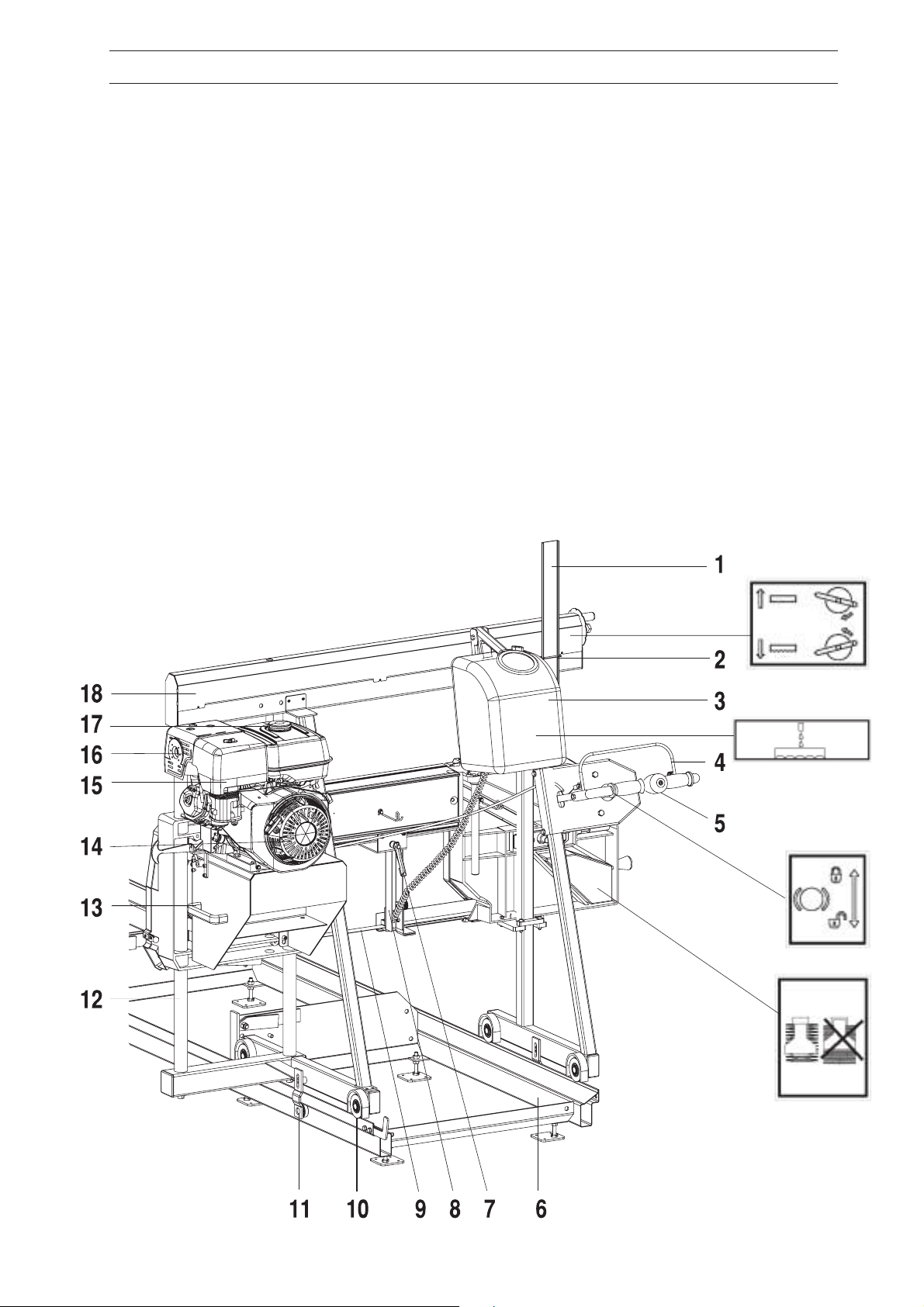

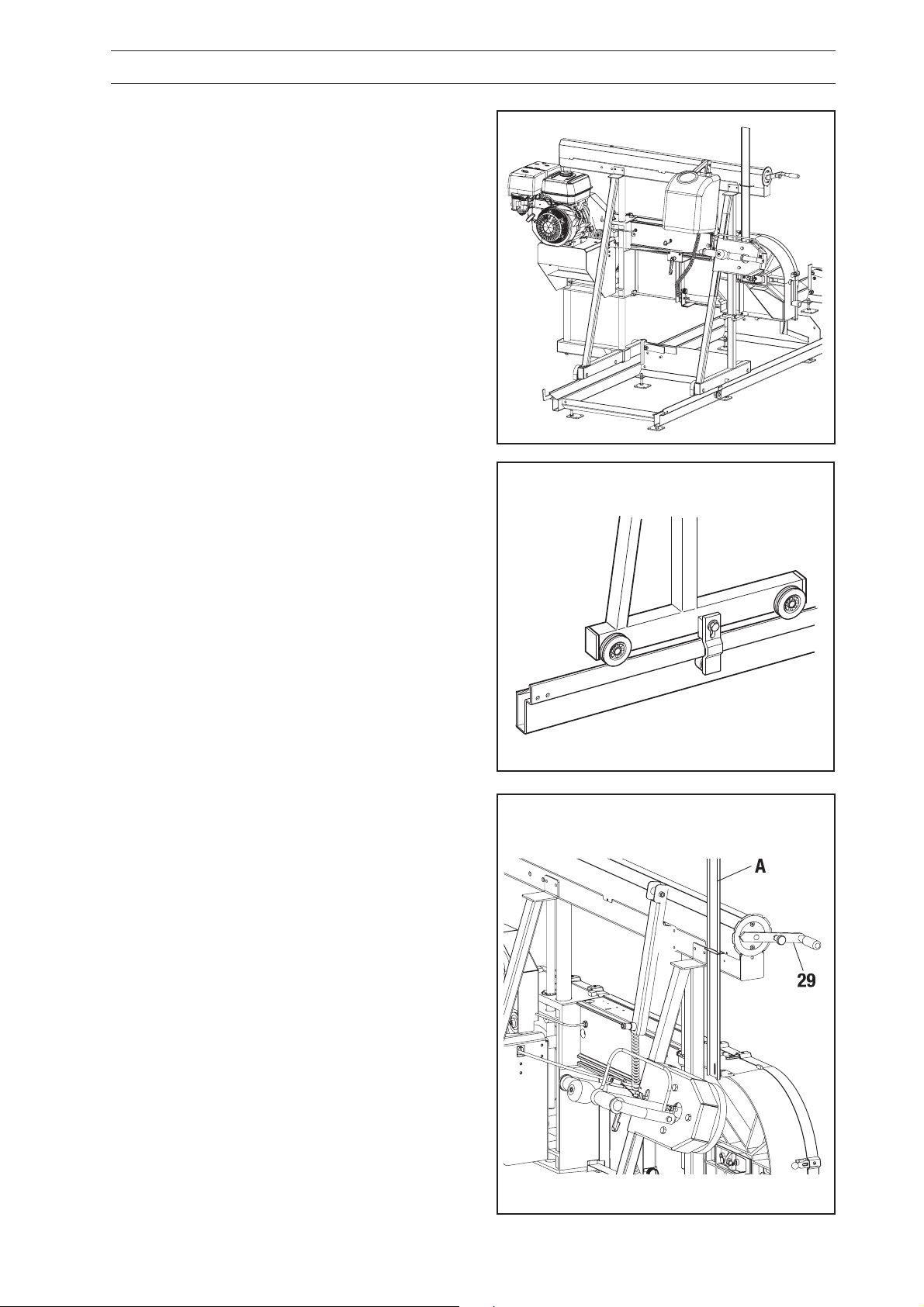

One-man Sawmill Petrol Engine

The one-man sawmill consists of two main parts:

• The carriage with engine and saw

• Rails

The carriage consists of the following:

1. Scale

2. Scale pointer

3. Bandsaw blade cleaning fluid tank

4. Start/stop control

5. Handlebars

6. Rails

7. Adjustable band guide lock

8. Adjustable band guide

9. Bandsaw blade

10. Rail guard

11. Support wheels

12. Runners

13. Lifting handle

14. Stop switch

15. Petrol engine

16. Exhaust system with muffler

17. Fuel tank

18. Chain guard

19. Height setting screw

20. Upper bandsaw blade guard

21. Band wheel guard

22. Safety switch

23. Bandsaw blade guard

24. Scraper

25. Frame

26. Band wheel

27. Band tension crank

28. Band wheel adjuster

29. Height setting crank

30. Index plate

English – 7

Page 8

DESCRIPTION

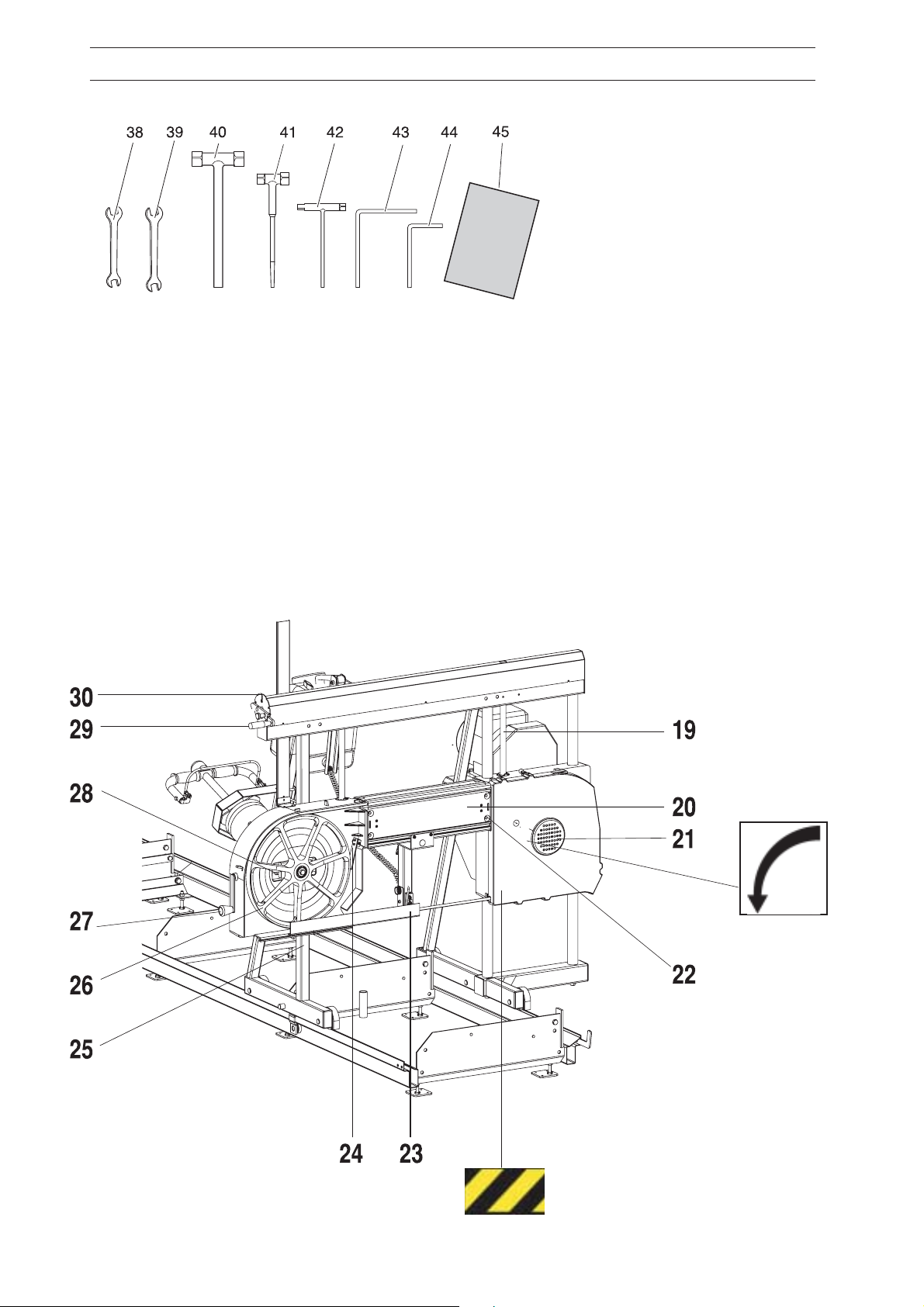

T ools and operator’s manual

38. Open ended spanner 13-15 mm

39. Open ended spanner 17-19 mm

40. Socket spanner

41. Combination spanner 13-19

42. Combination spanner

43. Allen key 4 mm

44. Allen key 5 mm

45. This operator’s manual

8 – English

Page 9

DESCRIPTION

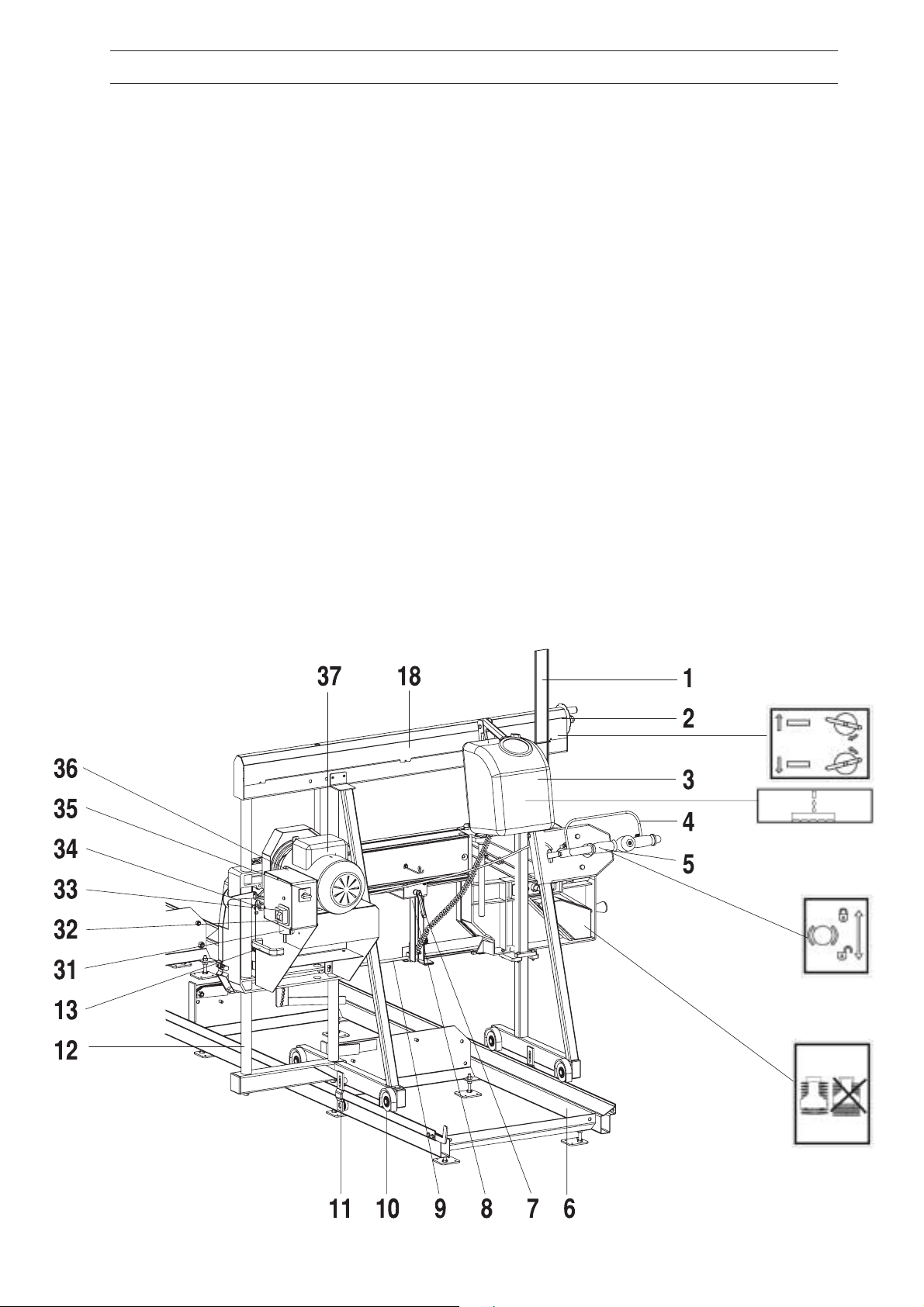

One-man Sawmill Electric Motor

The one-man sawmill consists of two main parts:

• The carriage with motor and saw

• Rails

The carriage consists of the following:

1. Scale

2. Scale pointer

3. Bandsaw blade cleaning fluid tank

4. Start/stop control

5. Handlebars

6. Rails

7. Adjustable band guide lock

8. Adjustable band guide

9. Bandsaw blade

10. Rail guard

11. Support wheels

12. Runners

13. Lifting handle

18. Chain guard

19. Height setting screw

20. Upper bandsaw blade guard

21. Band wheel guard

22. Safety switch

23. Bandsaw blade guard

24. Scraper

25. Frame

26. Band wheel

27. Band tension crank

28. Band wheel adjuster

29. Height setting crank

30. Index plate

31. Connector with polarity reversal

32. Stop switch

33. Start switch

34. Safety switch connector

35. Main switch

36. Distribution box

37. Electric motor

English – 9

Page 10

DESCRIPTION

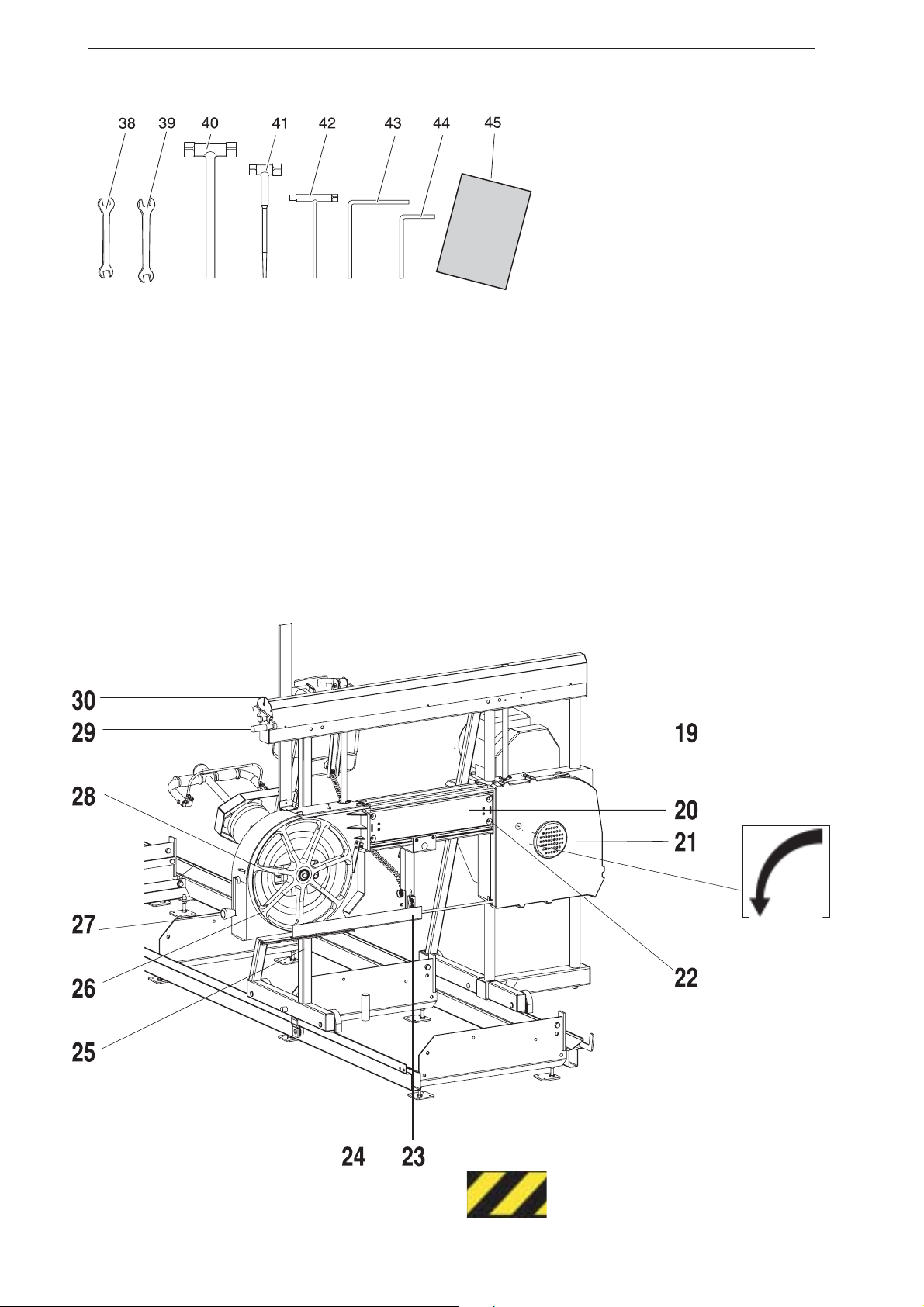

T ools and operator’s manual

38. Open ended spanner 13-15 mm

39. Open ended spanner 17-19 mm

40. Socket spanner

41. Combination spanner 13-19

42. Combination spanner

43. Allen key 4 mm

44. Allen key 5 mm

45. This operator’s manual

10 – English

Page 11

DESCRIPTION

Carriage (FIG 2)

The carriage consists of the following parts:

• Steel structure with runner wheels against

the rails and guides for the saw’s up and

down movement.

• Two screws for the saw’s vertical adjustment.

The screws are connected to a chain and are

operated by a crank, equipped with an index

plate.

• Handle with operating mechanism

• Saw unit with the following parts:

• Engine.

• Adjustable band wheels.

• Bandsaw blade.

• Adjustable support for optimal bandsaw

blade guiding.

• Fuel tank (petrol engine) for petrol. See

the Fuel Handling section.

• Cleaning fluid tank for the bandsaw blade.

• Muffler (petrol engine).

Frame (FIG. 3) and (FIG. 4)

The carriage frame consists of welded square

tubing with requisite corner reinforcement for

stability during cutting.

The frame is equipped with two round runners for

the saw unit's up and down movement. The

guides transfer the saw carriage’s lateral forces

to the frame.

FIG. 2

FIG. 3

On the underside of the frame are four runners,

fitted with bearings, with slots for securing and

smooth running along the rails.

The carriage is equipped with two adjustable

bearings, which run against the underside of the

rails, to prevent it from lifting.

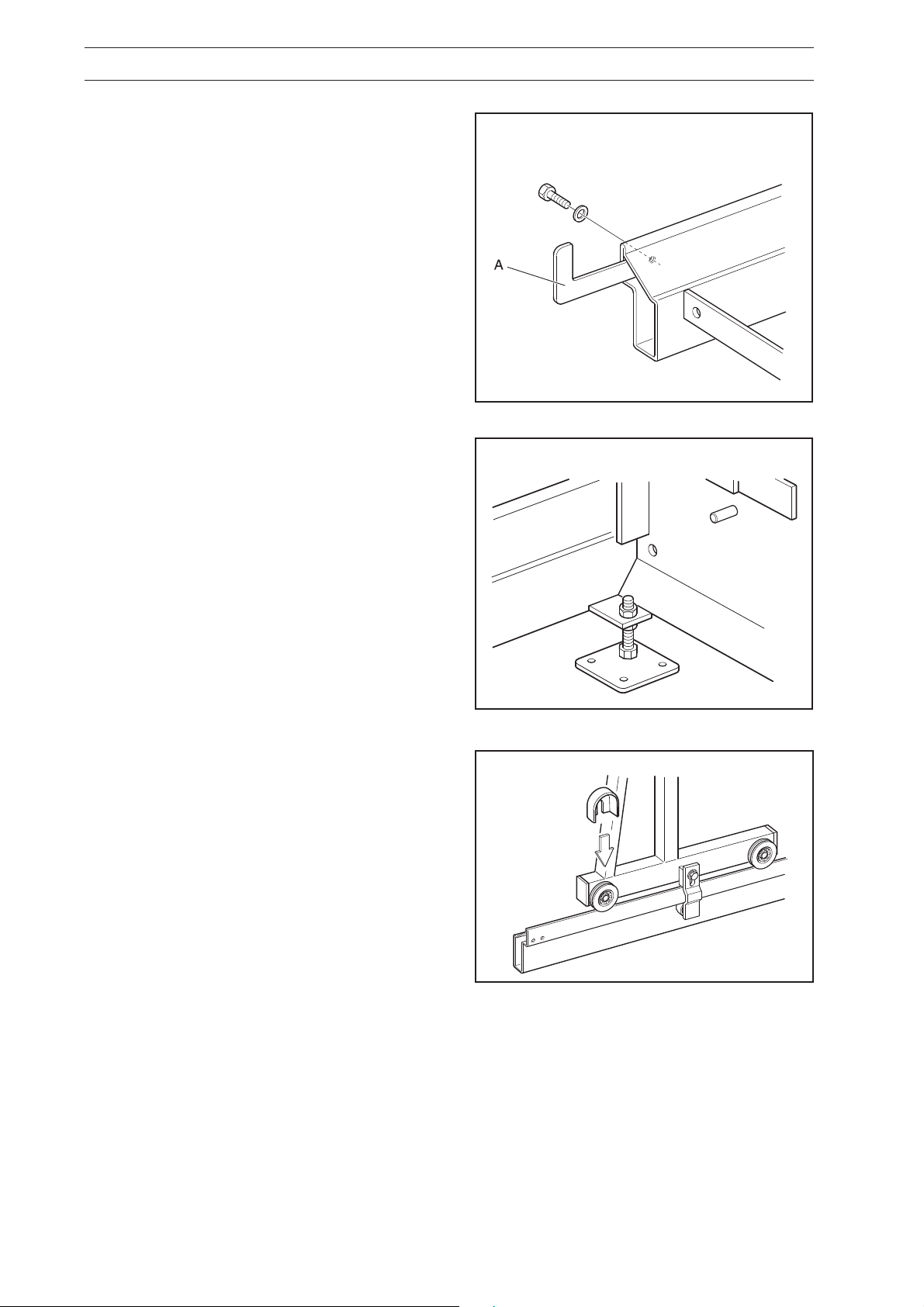

Height Setting (FIG. 4)

The saw unit is secured vertically by two interacting screws. The screws are connected to a chain

for precise and simultaneous movement.

A crank (29) is fitted on the top section of one of

the screws, and is used to set the exact dimension of the timber thickness. One turn of the

crank moves the bandsaw blade 5 mm. The

height of the bandsaw blade above the rails’

cross members is read on the scale (1).

There are two red markings on the scale that

indicate the lowest saw height with the timber

support raised, one red line for the long timber

support and one red line for the short one.

CAUTION! Sawing under the respective markings will damage the bandsaw.

FIG. 4

English – 11

Page 12

DESCRIPTION

Handlebars (FIG. 5)

The saw carriage is operated and moved forward with a vibration-free steering handlebar (5),

located on the carriage’s right hand side. The

handlebar is equipped with start and stop

controls (4) for the bandsaw.

Cleaning T ank (FIG. 5)

The saw carriage is equipped with a cleaning

tank (3). The tank is located beside the handlebars. Cleaning fluid is applied to the blade by

opening the tank valve.

Band Wheels (FIG 6)

The bandsaw blade runs over two band wheels

(26), which are made of cast aluminium and are

balanced to provide smooth operation. The band

wheels are equipped with bearings, and are

adjustable, partly to tension the bandsaw blade

and partly to adjust the correct alignment of the

bandsaw blade.

The band wheels are fitted with scrapers so that

sawdust and the like does not penetrate between

the bandsaw blade and the band wheel.

One of the band wheels is powered by the

engine/motor via an adjustable belt.

FIG 5

FIG 6

Bandsaw and Band Guide (FIG 6)

Two band guides (8) are used to keep the

bandsaw blade (9) in the correct position during

cutting. One of the band guides is placed in front

of the powered band wheel and ensures correct

entry onto the wheel. The other band guide is

adjustable and is positioned above the bandsaw

blade before it runs onto the log. This band guide

absorbs the forces from the log and prevents the

bandsaw blade from shifting.

Propulsion

Petrol Engine (FIG. 7)

The one-man saw is run with an air-cooled fourstroke engine (15). A clutch is located on the

engine’s drive axle that starts, stops, and brakes

the bandsaw blade. The speed of the engine is

regulated with the operating control on the

handlebars. See the enclosed manual for a

description of the engine.

Electric Motor (FIG. 8)

The one-man saw is powered by a 3-phase motor

(37). The motor is started and stopped with the

start and stop buttons on the distribution box,

which has built-in motor protection. There is also

a connection for an electric cable with single

polarity reversal (FIG. 8A), and a main switch

(FIG. 8B.). A clutch is located on the motor’s axle

and starts, stops, and brakes the bandsaw blade.

FIG 7

FIG 8

12 – English

Page 13

DESCRIPTION

Rails

The rails consist of two sections (standard

delivery). Each section is 3 m. The sections are

aligned and bolted together into a track for the

carriage. The rail sections are bolted together

and fastened using M12 bolts with nuts, which

assures stability and ensures that the carriage

runs straight.

The rails also have a number of transverse log

bolsters, designed to provide a stable support for

the log to be cut or the planks to be trimmed.

FIG. 9

The rails’ transverse log bolsters are equipped

with:

• Folding stop for the log

• Log lock

• Height adjustment of one end of the log

The rails are also fitted with stops at both ends

for the saw carriage, as well as adjustable

jointing plates on the section joints.

FIG. 10

Log Bolsters (A)

The rails have a number of transverse log bolsters that provide a stable support for the log to

be cut or the planks to be trimmed.

Height Adjustment (B)

The height adjustment is designed to raise the

small end of the log, so that the core becomes

horizontal.

Folding Stops (C)

There are a number of folding stops for the log on

the left-hand side of the rails. To increase usability, the stops come in two different lengths.

Log Locks (D)

The log locks consist of a cam with handle,

housed in a moveable unit. The locks are used to

secure the log against the folding stops.

English – 13

Page 14

DESCRIPTION

Rail Stop

Rail stops are fitted at the ends of the rails (A).

The stop is mounted using a bolt from the side of

the rail.

Adjustable Support Feet

Adjustable support feet are mounted by each log

bolster. You can fine tune the rails’ adjustment

using the support feet.

FIG. 11

FIG. 12

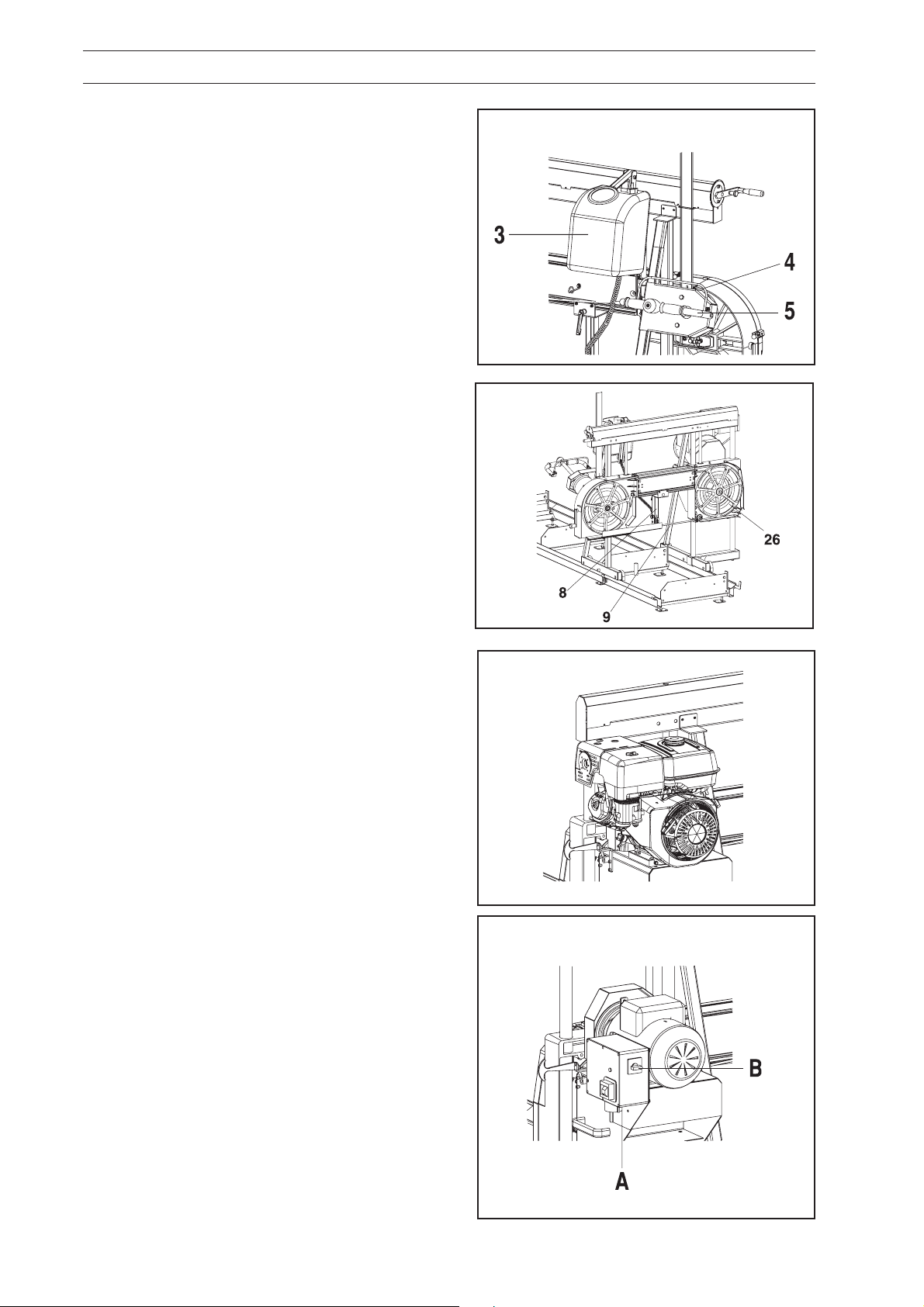

Rail Guard

The saw carriage is equipped with four rail

guards that run above the rails. The rail guards

have the tasks of keeping the rails clean and

preventing crush injuries between the runner

wheels and rails.

FIG. 13

14 – English

Page 15

DESCRIPTION

Safety Devices

The one-man saw is fitted with a number of

safety devices, which are described under the

headings below.

WARNING!

The one-man saw must not be

!

Band Wheel Guard (21)

The band wheels are protected from contact by a

cover on each side. Each cover is equipped with

a safety key that cuts the mains power to the

start switch for units with an electric motor and

short-circuits the petrol engine when the covers

are removed. There are 3 rubber straps on the

guard to allow easy dismantling and assembly

when changing the bandsaw blade. The safety

key activates a safety switch when the covers are

fitted. The rail stop (FIG. 14A) prevents the

bandsaw carriage from rolling off the rails.

started if any of the safety

devices have been removed,

are defective, or are not

working.

FIG 14

FIG 15

Bandsaw Blade Guard (upper)

(20)

The upper section of the bandsaw blade runs in

a slot.

Bandsaw Blade Guard (lower)

(23)

The part of the bandsaw blade that is not in the

log when cutting should be covered by the

adjustable guard.

Bandsaw Blade Brake (FIG. 16)

The bandsaw is equipped with an integrated

brake/clutch (A) that stops the band wheel in

order to quickly stop the band wheel when the

handlebar controls (4) are released.

Starter , Electric Motor (FIG. 17)

The electrically powered saw is equipped with a

main switch (35), safety switch connector with

phase inverter (31), contact for safety switch (A),

and start switch (33). The motor is started with

the green start switch and stopped with the red

stop switch (32). The electric motor stops when

not in use for longer periods or when sawing is

completed. The starter is equipped with a 0-volt

trigger. This means that the sawmill’ s electric

motor must be restarted after a power outage.

FIG 16

FIG 17

Stop Switch, Petrol Engine (14)

On the petrol engine, the stop switch is located

on the engine body and with electric start the

engine is stopped with the key .

English – 15

Page 16

Unpacking

INSTALLATION

Unpack the one-man sawmill and check that the

delivery is complete. Check that no parts are

damaged. If any part is damaged, report this to

the carriers.

The operator’s manual includes detailed instructions about safety , assembly, use, and maintenance of the one-man sawmill.

Installation

Installation Site

The one-man sawmill with petrol engine should

be installed outdoors.

There should be space to lay out timber and

sawn wood.

Rails

Place the rail sections after each other on the

transverse wooden beams, which are placed

under each log bolster, and an extra transverse

wooden beam by the joints between the sections.

Parts that are included are pictured in the Description section on page 7-10 . Component parts

are packed according to the following:

1. Rail sections (quantity according to the order).

2. Split saw carriage with engine/motor.

3. 4 rail guards.

4. Bandsaw blade.

5. Tanks with hoses.

6. Assembly components.

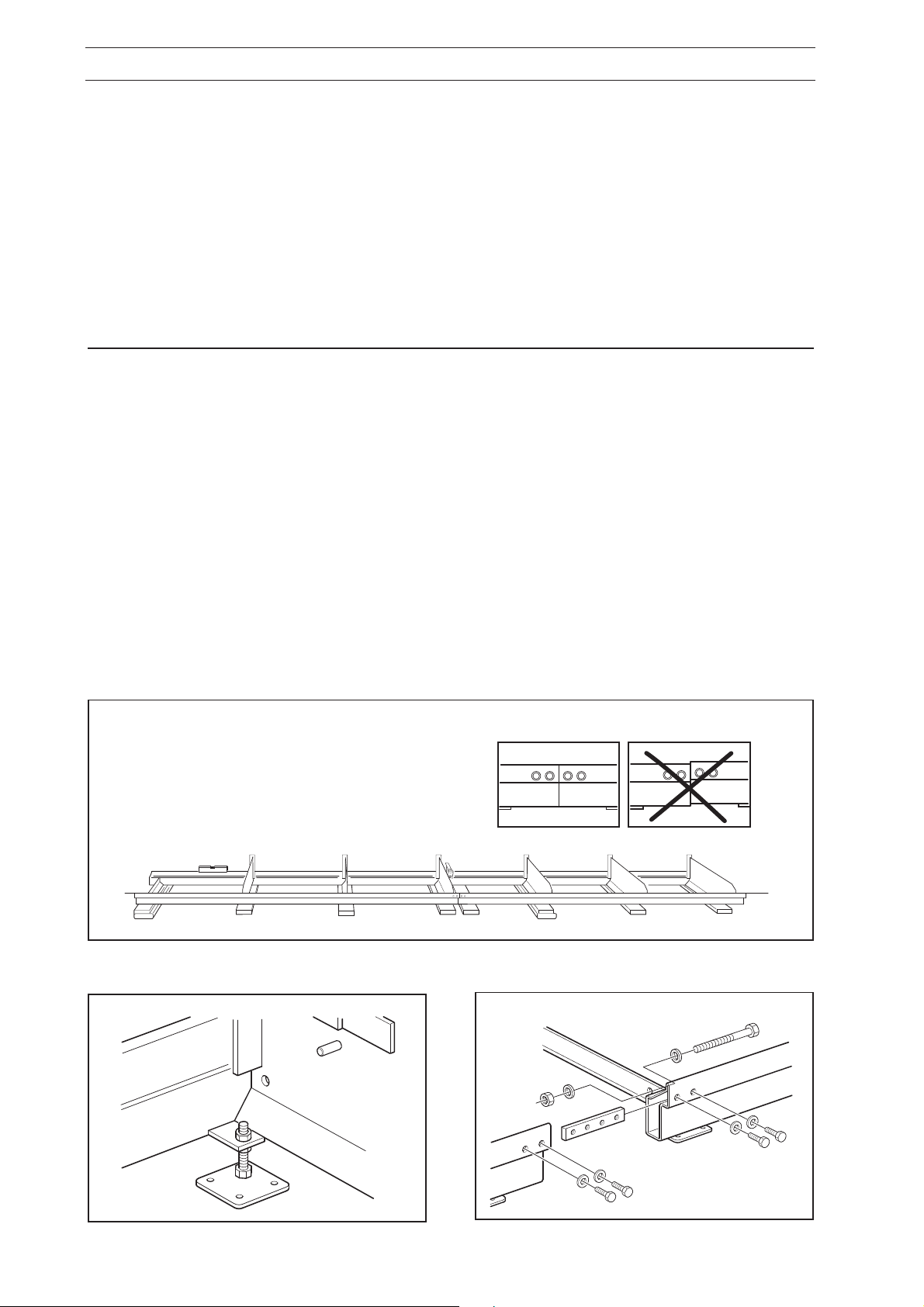

Continue as follows:

1. Assemble the adjustable feet under each of

the 16 log bolsters. Adjust, by using the

adjustable feet and the rails’ bedding, until

the rail sections form a straight line and the

rails sit firmly on each wooden beam. See

FIG. 18.

2. Loosely bolt together the rail sections using

the supplied jointing plates and M12 nuts and

bolts. See FIG. 20.

3. Finely adjust the rails and tighten all the

bolts. Tighten the bolted joints to 5-10 Nm.

See FIG. 18.

4. Fit the stops to the ends of the rails (see page

14, FIG. 11), as well as the folding stops, log

lift, and log lock (see page 13, FIG 10).

5. Load the rails above each wooden beam and

check that the rails do not move.

FIG. 18

Aligning the rails

FIG. 19

FIG. 20

16 –English

Bolted jointAdjustable foot

Page 17

INSTALLATION

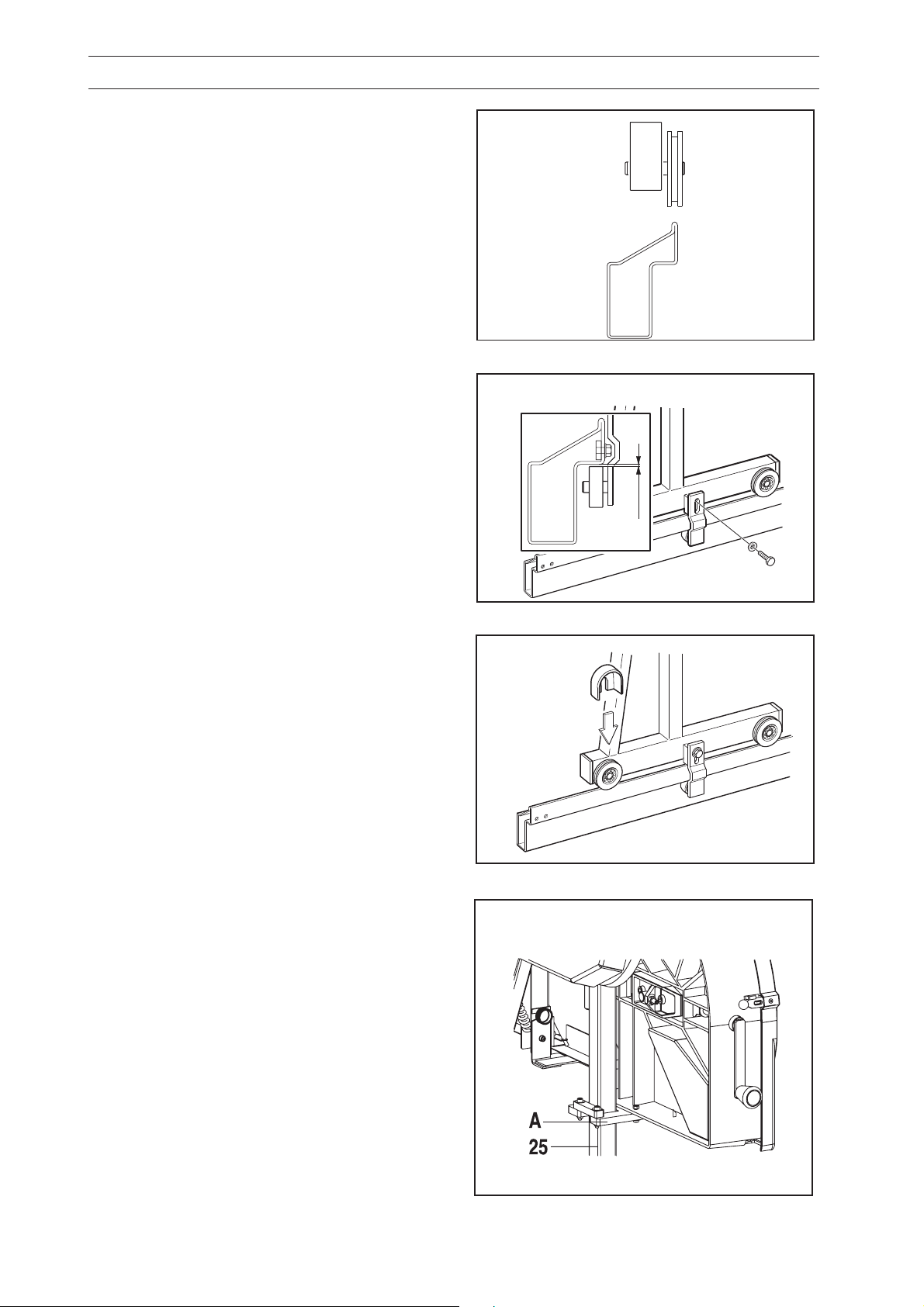

Saw Carriage

Assembling the Saw Carriage

The wheel fixture is assembled in the packaging,

where the sides are disassembled.

1. Crank the height adjustment crank (29) so

that the runner (12) reaches outside the

packaging.

2. Attach the wheel fixture (FIG 21B) to the

runner (12).

3. Attach the stabilising stay (FIG 21A)

4. Loosely attach the frame (25) to its fixture

and guide.

Setting up the Saw Carriage

WARNING!

The saw carriage is heavy. Two

!

persons are required when

setting up. Always wear boots

with steel toecaps.

FIG. 21

CAUTION!

Do not drop the saw carriage onto the

rails or any other hard surface too

heavily . This will result in permanent

damage to the saw carriage’s bearings.

Do not place the saw carriage directly on

the ground so that dirt and unnecessary

contamination can come into contact

with the saw carriage’s wheels.

Place the saw carriage on the rails and make

adjustments as follows:

1. Two persons take hold of the saw carriage,

one on each side. Hold the saw carriage as

follows:

The right-hand side: by the bandsaw blade

tension crank and under the band wheel’s

protective cover.

The left-hand side: by the handle (13) on

the motor/engine console.

2. Lift and place the saw carriage so that the

grooves in its wheels are positioned above

their respective rails. Carefully lower the saw

carriage onto the rails.

3. The one-man sawmill can be fitted with a

wheel kit (FIG. 22) and a handle (Part no. 531

01 95-93) to make handling the saw carriage

easier. The wheel kit is inserted into the steel

structure by the saw carriage’s runner wheels

on the left-hand side. The handle is attached

to the wheel housing on the right-hand side of

the sawmill. When using the wheel kit and

handle, the sawmill can be moved and placed

on the rails by one person.

FIG. 22

English – 17

Page 18

INSTALLATION

Saw Carriage Adjustment

The saw carriage is aligned on the rails by fitting

its lower guide wheels and rail guards. The lower

guide bearings have the task of preventing the

saw carriage from tilting and the rail guards keep

the rails and the saw carriage’s wheels free from

dirt and the like. Assembled on the saw carriage

are:

• Two lower guide wheels

• Four rail guards.

Assembly is done as follows:

1. Fix the guide wheel’s bracket in place with a

screw. Place a 0.2 mm feeler gauge between

the bearing and rail.

2. Press the bearing against the rail and tighten

the bearing bracket screw. Tightening torque:

40-50 Nm. Now remove the feeler gauge.

3. Carry out 1-2 above for the remaining guide

wheels.

4. Position the four rail guards above the wheel.

FIG. 23

FIG. 24

0,2 mm

5. Adjust and screw into place the frame (25)

and guide FIG. 26 A.

FIG. 25

FIG. 26

18 –English

Page 19

INSTALLATION

Handlebars (FIG. 27)

Attach the handlebars with the start lever (5) at a

suitable height on the right-hand frame (25) and

tighten the screws to 10 Nm. Attach the weight

(A) to the rear end of the handlebars.

Band Cleaning T ank (FIG. 28)

The tank (3) is placed on the mounting located

on the right-hand side of the sawmill. The band

cleaning fluid flow is regulated with a continuously variable manual valve on the tank (FIG.

28A).

FIG. 27

FIG. 28

The tank (3) can be easily removed from the

sawmill. The spiral hose is inserted through the

hole in the band guide (8) and is connected in

the hole on the plate mounted on the adjustable

band guide. The fluid can then run down and

clean the bandsaw blade.

English – 19

Page 20

INSTALLATION

Propulsion

1. Place the engine/motor on the engine/motor

console and attach the drive belt.

2. Bolt the engine/motor (petrol or electric) onto

the engine/motor console.

3. Connect the cable to the clutch control arm

(A).

4. Attach the mounting for the drive disc (B), so

that the clutch does not rotate.

5. Tighten the belt with the belt tension device

(FIG. 31 A). A correctly adjusted belt can be

moved 0.5 cm with one finger (FIG. 31 B). If

necessary, adjust the engine/motor console

mounted in the lengthways slot to attain the

correct belt tension.

6. Connect the cable to the start lever (FIG. 30

E), check that the clutch is activated. When

the start lever (FIG 30 F) is activated, the

spring in the control arm on the clutch shall

be lightly compressed.

Wire adjustment

The wire that engages the clutch must be adjusted so that there is no pressure on the clutch

arm that is connected to the clutch. The easiest

way to do this is to adjust the wire so that it is

completely slack when the clutch is not engaged.

Adjustment is by means of the adjuster nipples

on the starter yoke and the engine bracket (FIG

30 G and FIG X A).

It is also important that the attachment to the

clutch is able to swing (FIG X B). The spring in

the fastener prevents excessive leverage being

applied to the clutch arm.

On saw mills with four-stroke engines, the wire

connected to the engine is adjusted using nipple

(FIG X), so that the throttle lever is activated by

the swinging motion (FIG X B) of the wire fastener near the clutch and therefore increases the

engine speed before the clutch is engaged.

FIG 29

FIG 30

FIG X

FIG 31

Petrol Engine

Connect the cable from the covers’ safety switch

(22) to the contact (FIG. 29 D) on the engine.

Electric Motor

Connect the cable from the covers’ safety switch

to the contact on the distribution box (FIG. 32 A).

The contact for the electrical cable for the electric

motor has polarity reversal (31). Make sure that

the main switch (34) is set to 0.

WARNING!

Check that the main switch is

!

20 –English

set to 0, and be sure to invert

the phase if the sawmill runs in

the wrong direction.

FIG 32

Page 21

INSTALLATION

Bandsaw Blade

WARNING!

Wear protective gloves whenever

!

Only bandsaw blades with the part number

531 0194-65 may be used.

Fit the bandsaw blade as follows:

1. Remove the guards over the band wheels.

The guards are attached by three rubber

straps, one upper, one lower, and one in the

middle.

2. Crank the band tension crank (27) anticlockwise so that the distance between the band

wheels is as small as possible.

3. Loosen the crank (FIG. 33A), drop the band

guard (23), and attach the bandsaw blade

with the teeth facing. Make sure that the

bandsaw blade enters the adjustable band

guide (8) and the fixed band support (FIG.

33B).

4. Release the belt tensioner by loosening the

belt idler from the engine/motor. See FIG. 34.

5. Tension the bandsaw blade using the crank

(27) until the spring washers are correctly

compressed. See FIG. 36A. Turn the

bandsaw wheels a few turns by hand, so that

the bandsaw blade centres on the band

wheels. CAUTION! It is important that the

bandsaw blade is not tensioned too much so

that the washers are completely compressed.

See FIG. 36B. The washers should have a

degree of springiness to take up variations in

band tension. Incorrect band tension (too

hard or too loose) means that the bandsaw

blade runs a risk of roaming and coming

loose from the band wheel.

6. Tension the belt FIG. 35 by pulling the handle so that the idler tightens the drive belt.

Lock it. A correctly adjusted belt can be

moved 0.5 cm with one finger.

7. Adjust the band guide’s blocks by loosening

the bolts 1 and 2 (FIG. 33). Adjust the blocks

from both directions so that they lie lightly

against the band.

8. Fold up the band guard (23).

9. Position the guards over the band wheels

and secure them with the rubber straps.

Ensure that the safety keys are in the tracks.

you handle the bandsaw blade!

On delivery a new bandsaw blade

is rolled up and is in a state of

high mechanical tension. Carefully unpack the bandsaw blade

so that it does not fly out and

cause physical injury!

FIG. 33

FIG. 34

FIG. 35

FIG. 36

English – 21

Page 22

INSTALLATION

Scale (FIG 37)

Fit the ruler on the bandsaw blade’s upper guard

as follows:

1. Insert the ruler through the top of the scale

pointer FIG. 37 A. The greatest value on the

ruler shall face downwards.

2. Measure the distance between the underside

of the bandsaw blade and the log bolster’s

upper section FIG. 38 B. NOTE! During this

procedure the bandsaw blade should be

tensioned and adjusted.

3. Set the scale so that the scale pointer has

the same value and can be read on the scale

FIG. 37 C.

4. Bolt the scale to the wheel housing FIG. 37 D.

5. Check that the bandsaw blade moves freely

over the long and short log supports when

the red mark can be read on the scale

pointer. FIG. 37 E

FIG. 37

FIG. 38

22 –English

Page 23

FUEL HANDLING

Fuel

Fuel Safety

WARNING!

!

The following are absolutely forbidden when

fuelling:

• Smoking.

• To have flames or hot objects in close

proximity.

• To have the engine running.

The fuel used in the one-man

sawmill has the following

hazardous properties:

1. The fluid, its vapour, and its

exhaust fumes are poisonous.

2. Can cause skin irritation.

3. Is highly inflammable.

FIG. 39

Petrol

Use leaded or unleaded petrol. The lowest

recommended octane grade is 90. If you run the

engine on a lower octane grade than 90, socalled knocking can occur. This leads to an

increased engine temperature, which can result

in serious engine damage.

Fuelling

1. Clean around the fuel cap.

2. Open the fuel cap slowly so that any excess

pressure is released.

3. Tighten the fuel cap carefully after fuelling.

Clean the fuel tank regularly . The fuel filter should

be changed at least once a year. Contamination

in the fuel tanks causes malfunction.

English – 23

Page 24

STARTING AND ST OPPING

WARNING!

!

Observe the following before

starting the engine:

• The engine must be mounted

in the sawmill before starting.

Otherwise the clutch can come

loose and cause personal

injuries.

• Keep people and animals well

away from the risk zone.

Starting a Cold Petrol Engine

A cold engine is started as follows:

1. Open the fuel tap (A).

2. Set the stop switch to the start position (B).

3. Activate the choke. (C)

CAUTION!

Do not pull out the starter cord fully and

do not release the starter handle from

the fully extended position. This damages the starter.

FIG. 40

4. Slowly pull out the starter handle (D) until you

feel some resistance (the starter pawls grip).

Now pull quickly and firmly.

5. When the engine starts,return the choke

control.

Stopping a Petrol Engine

The engine is stopped by moving the stop switch

(B) to the stop position. Close the fuel tap (A).

Starting a Warm Petrol Engine

A warm engine is started in the same way as a

cold engine, except for the following:

The choke is not used on a warm engine.

Starting instructions can also be found in the

Manual for the engine.

Starting and Stopping the

Bandsaw Blade

The blade is started and stopped using the

control handle (4) on the sawmill’s handlebars

(5). Moving the starter handle towards the

handlebars activates the clutch and the bandsaw

starts. When the control handle is released, the

bandsaw blade is braked and stops.

FIG. 41

24 – English

Page 25

STARTING AND STOPPING

Starting the Electric Sawmill

WARNING!

!

CAUTION!

The first time the sawmill is started or

when it has been moved to another

power outlet:

• Test start the sawmill in accordance

• Check the direction of the bandsaw

The sawmill must not be

started until the appropriate

current and voltage has been

connected. Use suitable personnel trained in the country in

question.

with the starting instructions.

blade. If the bandsaw blade runs in

the wrong direction, there is a phase

inverter on the power connector

(FIG. 42). The phase is inverted with

the aid of a screwdriver, as illustrated in FIG. 42.

Starting the Electric Motor

1. Check that the power cable is connected

correctly.

FIG. 42

FIG. 43

2. Set the main switch (35) to 1.

3. Start the motor with the green start button

(33). The motor starts.

Stopping the Electric Motor

1. The electric motor is stopped with the raised

red button (32).

2. Set the main switch (35) to 0.

Starting and Stopping the

Bandsaw Blade

The blade is started and stopped using the

control handle (4) on the sawmill’s handlebars

(5). Moving the starter handle towards the

handlebars activates the clutch and the bandsaw

starts. When the control handle is released, the

bandsaw blade is braked and stops.

FIG. 44

English – 25

Page 26

Securing the Log

USE

WARNING!

Exercise care during all log

!

1. Fold up the stops (C) on the left-hand side of

the rails.

2. Roll the log up against the stops (C). The log

must not come closer:

• than 300 mm to the end of the rails

• than 500 mm to the start of the rails

This means that when using two rail sections,

the maximum log length is 5200 mm.

3. Raise the log using the height adjuster (B) so

that the log’s core is horizontal.

4. Lock the log in position with the log lock (D).

FIG. 46

handling. Heavy lift! Wear boots

or shoes fitted with steel toecaps.

FIG. 45

26 – English

Page 27

USE

Calculating the Y ield

Measure the log’s top end and determine how

the log should be utilised for the timber in question. Include the thickness of the saw cut in the

calculation.

The saw cut thickness = 2 mm.

Sawing

FIG. 47

WARNING!

!

• Boots or shoes fitted with steel toecaps.

• Hearing protection.

• Eye protection.

• Always have a first aid kit nearby.

Before starting the engine, check that:

• All guards are fitted and undamaged.

• No unauthorised personnel are within

the risk zone.

1. Place the log on the rails facing the folding

log supports (FIG. 46).

2. Set the height of the bandsaw blade using

the crank (29).

3. Clean any sand from the log, if necessary.

This results in less wear.

4. Place the band guide (8) as close as possible

to the log without the log and band guide

touching each other. Lock the band guide

using the lever (7).

Use the following protective

equipment when sawing:

FIG. 48

5. Check the cleaning fluid tank (3) and fill with

cleaning fluid if necessary. Use a cleaning

fluid with lubricating properties, for example,

water and detergent. The mixture should be

made up of 80% water and 20% detergent.

Wintertime: add windscreen washer fluid.

6. Check the fuel tank (17) and fill with fuel if

necessary. See page 23.

English – 27

Page 28

WARNING!

!

!

Check during sawing that the

bandsaw blade does not hit the

folding stops or log lock.

WARNING!

The saw carriage must not be

moved backwards while the

bandsaw blade is in motion.

Otherwise the bandsaw can

jump off and cause personal

injury.

Starting the Petrol Engine

1. Start the engine. See page 24.

Starting the Electric Motor

1. Start the electric motor. See page 25.

USE

Sawing

2. Move the saw carriage forwards and cut off

the sapwood.

3. Remove the sapwood.

4. Loosen the log, turn it 180°, lower the height

adjuster (B), and secure the log.

5. Set the required cutting height using the

height adjustment crank (B). This determines

the width of the board.

6. Set the band guide as close as possible to

the log without the log and band guide

touching each other. Lock the band guide

using its lever.

7. Cut off the sapwood on the other side. See p

2 and 3.

FIG. 49

FIG. 50

28 – English

Page 29

USE

8. Loosen the log and turn it 90°.

9. Adjust the top end of the log using the height

adjuster and secure the log with the flat

surface tightened against the stop.

10. Cut off the upper sapwood.

11. Loosen the log, turn it 180°, lower the height

adjuster, and secure the log.

12. Cut the block according to the previous

instructions. Remember to compensate for

the thickness of the bandsaw blade for each

adjustment of the bandsaw blade’s height.

FIG. 51

FIG. 52

Data for the height adjustment crank:

• 1 turn = 5 mm.

The scale can also be used for varying standard

dimensions.

Edging

Several boards can be edged simultaneously by

clamping them against the stop.

Place a batten between the boards and the stop

in order to keep the boards still during cutting.

The batten should be at least 50 x 100 mm.

FIG. 53

English – 29

Page 30

MAINTENANCE

Bandsaw Blade

WARNING!

!

The bandsaw blade should be set and sharpened

regularly to give optimal performance. During

normal sawing of most species of wood this

should be done at intervals of approx. 2 hours of

effective cutting time. Effective cutting time

refers to only the time that the bandsaw blade

actually works. The bandsaw blade should be

sharpened more frequently when cutting those

species of wood with a high sand content. For

blade sharpening, see the separate instructions

for the Grindlux bandsaw blade grinder.

Dismantling

Dismantle the bandsaw blade as follows:

1. Remove the guards over the band wheels.

See page 21.

2. Loosen the right-hand band wheel by

cranking about 10 turns counter-clockwise.

3. Carefully remove the bandsaw blade.

Cleaning and inspection

Clean sawdust and any coating from the bandsaw

blade. Now check whether there are any cracks

(A) in the gullets. Small cracks can be ground

away when sharpening the bandsaw blade. If the

cracks are so large that they cannot be ground

away , the bandsaw blade should be discarded.

Cracks in the gullets are the most common cause

of bandsaw blade breakage. The bandsaw blade

can be ground to a minimum width of 24 mm. See

FIG. 54. A new bandsaw blade is 32 mm wide.

The bandsaw blade should be discarded once

any part of it reaches the minimum width.

The bandsaw blade is sharp and

can cause cuts. Warning for

personal injury. Wear protective

gloves whenever you handle the

bandsaw blade.

FIG. 54

min. 24 mm

FIG. 55

WARNING!

!

Setting the Saw

The bandsaw blade’s teeth should be set to the

dimensions shown in the adjoining figure. Every

third tooth should remain unset. The teeth

should be set as follows:

B=Set to the right, 0.4-0.5 mm.

C=Set to the left, 0.4-0.5 mm

D=Not set.

The more accurate the set is made, the straighter

and smoother the bandsaw blade runs when

cutting the log. The bandsaw blade should be set,

at a minimum, after every third sharpening.

30 – English

Never use a damaged bandsaw

blade.

Page 31

MAINTENANCE

Saw Setting Pliers

For optimal results the bandsaw blade should be

set using the saw setting pliers as described on

page 30.

The saw setting pliers are adjusted to the correct

setting size.

Place the saw setting pliers over the saw tooth

so that the pliers’ fixing angles rest on the two

closest teeth.

Activate the pliers and the saw tooth will be set

away from the operator.

FIG. 56

English – 31

Page 32

MAINTENANCE

Sharpening

WARNING!

The bandsaw blade is sharp

!

After sharpening, the bandsaw blade should be

set as described in the instructions on the

previous page.

The more accurate the sharpening, the straighter

and smoother the bandsaw blade runs when

cutting the log.

Radii

The radius in the area (A) should be 1-3 mm.

A radius under 1 mm increases the risk of

cracking.

A radius over 3 mm means that the chips are not

broken.

Angles

The clearance angle should be 10-12° and the

cutting angle (F) varies depending on the species of wood as follows:

and can cause cuts. Warning

for personal injury. Wear

protective gloves whenever

you handle the bandsaw blade.

FIG. 57

FIG. 58

FIG. 59

Hardwoods or frozen timber 7°

Medium hardwoods 10°

Softwoods 14°

Before sharpening, the bandsaw blade’s teeth

should be set using the saw setting pliers.

The rake angle should be 90°. See the figure to

the right.

Shape of the Tooth

As the bandsaw blade is sharpened it is

important that the teeth and tooth valleys keep

their original shape.

For optimal results, the bandsaw blade should

be sharpened with the grinder. The procedure is

described on the following pages.

On delivery, the grinder is adjusted for the

correct angles and tooth shape.

FIG. 60

32 – English

Page 33

MAINTENANCE

Band Wheel Adjustment

After the one-man saw has been used for a long

period, the band wheel bearings will start to wear

and change position. Meanwhile, the

foundation’s working geometry will have stabilised. This means the parallelism of the band

wheels may need to be adjusted.

Adjustment is performed as follows:

1. Ensure that the electric power has been

disconnected. Unplug the electrical contact

or short-circuit the petrol engine.

2. Loosen the belt tension by releasing the idler

to the V-belt, so that the band wheel is free

and can be rotated by hand.

3. The bandsaw blade should be fitted and

adjusted.

4. Adjust the right-hand band wheel using the

screw (F). The screw is locked with a lock

nut, which should be loosened during

adjustment.

5. Check the alignment of the bandsaw blade

after adjustment by rotating the band wheel

by hand.

6. See FIG. 61 for the correct position.

7. If the bandsaw blade is not aligned, adjust

the right band wheel with the spacer located

on the outside of the band wheel. The wheel

is dismantled and the spacer is placed on the

innermost part of the wheel axle and the

wheel is then re-mounted. Repeat steps 2 to

5 until the bandsaw blade is aligned.

FIG. 61

FIG. 62

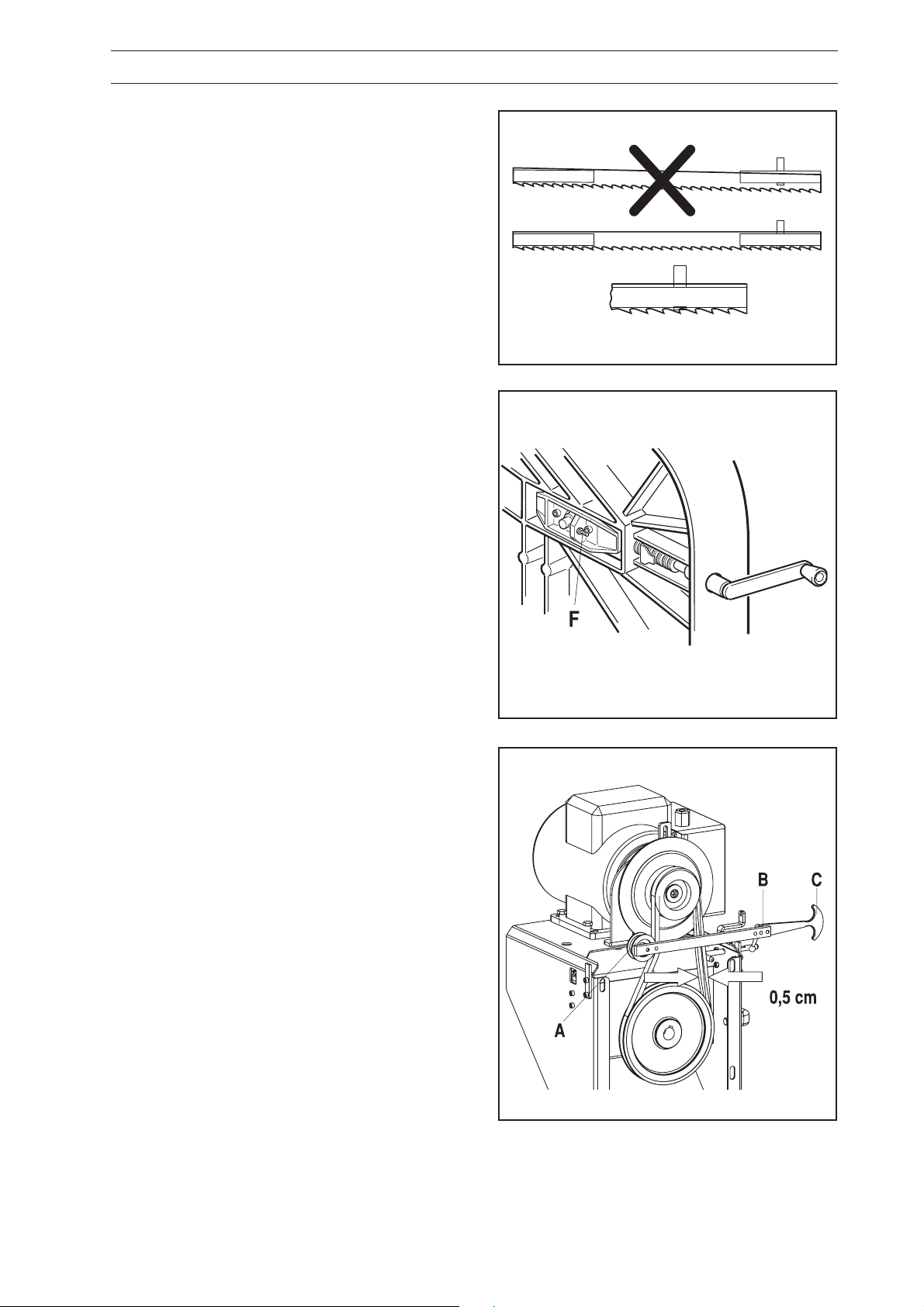

Drive Belt (FIG. 63)

The drive belt wears as the saw is used. The belt

should be replaced after 200 hours of operation

to avoid belt failure during operation. If the drive

slips or the belts need to be frequently adjusted,

this is a sign that the belts need to be replaced.

To replace the belt, proceed as follows:

1. Unplug the electrical contact from the distribution box or short-circuit the petrol engine.

2. Loosen the belt guard.

3. Loosen the idler (A) completely with the

locking lever (B).

4. Change the belt and then tighten the belt by

pulling the handle (C) and tightening the idler

(A) and locking the idler with the locking lever

(B). When the belt is correctly tensioned, it

should be possible to move it about 0.5 cm in

each direction using one finger.

5. Attach the belt guard.

FIG. 63

English – 33

Page 34

MAINTENANCE

Checking the Braking Function

For the one-man saw to meet safety

requirements, the braking function must be

checked at least once per week. Check the

braking function in the following way:

1. Start the sawmill motor/engine.

2. Start the bandsaw blade with the control unit

(4).

3. Release the control unit and the bandsaw

should stop within 5 seconds.

4. If the bandsaw blade does not stop within the

prescribed time, the unit is not to be used

until the braking function clutch is repaired.

Contact your local dealer.

5. Check the Safety Switch Function.

FIG. 64

The Saw Unit’s Height

Adjustment

Maintenance procedures on the components

listed below are necessary in order to assure the

bandsaw blade’s vertical adjustment.

Runners (12)

The guides that locate the saw unit should be

wiped clean and moistened with oil as required.

Screws (19), sprocket (A), and chain (B)

The screws should be wiped clean as required.

The drive chain that links both the height

adjustment screws should be oiled once a year.

To oil the chain proceed as follows: Loosen the

cover on the short side of the chain guard. Crank

back and forth, about 20 turns in each direction,

while spraying oil on the chain. Use a cloth to

wipe up any excess oil.

FIG. 65

34 – English

Page 35

Maintenance

MAINTENANCE

The maintenance described in this section refers

to measures that can be carried out by the user.

If faults are detected that cannot be rectified in

accordance with this operator’s manual, contact

your nearest authorised service representative.

Daily Maintenance

1. Check that nuts and screws are tight.

2. Height adjustment mechanism:

Clean both the screws and the guides. See

page 34.

3. Adjust the bandsaw blade tension. See page

21.

4. Check that the bandsaw blade’s cleaning

system works. If the cleaning fluid is depleted

on an ongoing basis, then the cleaning

system works.

5. Clean any sawdust from the bandsaw blade

guides.

6. Check that all safety devices are undamaged

and work. Check:

• Start/stop devices

• Electrical contacts

• Band wheel guards

• Safety switch for the band guards

• Rail stop

• Rail guards

• Belt guard

• Electrical cables and electrical connections

7. Set and sharpen the bandsaw blade as

required. When cutting timber with a normal

sand content and hardness, these actions

should be carried out after about 1 hour of

sawing (time for adjustments, timber handling, etc are not included). See pages 30-32.

Weekly Maintenance

1. Petrol Engine Maintenance (see the engine

manual).

2. Clean the bandsaw blade scrapers.

3. Clean the height adjustment screws, guides,

and chain. See page 34.

4. Check the belt tension and adjust if required.

See page 33.

5. Clean around the rails. Remove sawdust,

bark, and wood chips to facilitate handling of

the one-man saw.

Monthly Maintenance

1. Checking the Clutch Function. See page 34.

2. Clean the inside of the bandsaw’s cleaning

fluid tank.

3. Check cables and connections.

4. Check that the saw carriage runs easily and

that no binding is felt which can indicate

bearing damage. Replace the wheels if

needed. See page 18.

5. Adjust the play on the bearings that run

against the underside of the rails. See page

18.

6. Check the bolted joints on the rail sections.

See page 16.

7. Check that the rails rest against all contact

points on the wooden beams.

Storage

If the one-man sawmill needs to be stored for a

long period without being used the following

applies:

1. Empty and clean the fuel tank.

2. Empty and clean the bandsaw’s cleaning

fluid tank.

3. Remove the bandsaw blade.

4. Spray preservative oil in the spark plug hole

and carburettor while turning the engine over

with the starter handle.

5. Remove the saw carriage and unbolt the rail

sections.

6. Oil all parts.

7. Store the one-man saw in a dry location.

8. After a period of one year the following

measures apply:

• Spray preservative oil in the spark plug

hole and carburettor while turning the engine

over with the starter handle.

• Oil all parts.

English – 35

Page 36

Petrol Engine

Cylinder displacement, cm3:

Idle speed, rpm:

Max. speed during running in, rpm:

Power, kW/rpm:

Max. torque:

TECHNICAL DATA

389

1 400 + 150

2 800

9.6 / 3 600

2.7 kg-m / 2 500 revs

Fuel:

Volume, fuel tank:

Fuel consumption:

Cooling system

Ignition system:

Axle rotation:

Electric Motor

Power 380-420 delta connection:

Ampere:

Power 220-240 delta connection:

Ampere:

Power 220 delta connection:

Ampere:

Bandsaw Blade Cleaning

Volume, cleaning fluid tank, litres:

Cleaning fluid:

Weights

The saw carriage, petrol engine, kg:

The saw carriage, electric motor, kg:

Two rail sections, kg:

Bandsaw Blade

Bandsaw blade speed, petrol engine, m/s:

Bandsaw blade speed, electric motor, m/s:

Pitch, mm:

Width, mm:

Thickness, mm:

Length, mm:

Part number:

Petrol, 95-98 octane

6.5 litres

230 g/Hpg

Fan cooled

Transistor

Anti-clockwise

50 Hz 5.5 kW, 2855 rpm

10.50

50 Hz 5.5 kW, 2855 rpm

18.20

50 Hz 5.5 kW, 2855 rpm

19.90

16 litres

Detergent and water. In winter, mixed

with windscreen washer fluid

182

184

115

35

35

25

35

1 + set

3 570

531 01 94-85

Sawing

Max. log height, mm:

Max. log width, mm:

Rec. speed when sawing with petrol engine,

rpm:

The log length is determined by the number

of available rail sections.

Height adjustment crank/turns, mm:

Index plate, resolution, mm:

36 – English

700

500

2 800 / 2 900

5

1

Page 37

TECHNICAL DATA

Noise Levels

Equivalent (see note 1) noise intensity at

operator’s ear during sawing, measured according to relevant international

standards, dB(A)

Petrol engine:

Electric motor:

Equivalent (see note 1) noise level

measured according to relevant international standards, dB(A)

Petrol engine:

Electric motor:

Vibration Levels

(See note 2)

Vibration level in the handle, during

sawing, according to international

standards, m/s

Petrol engine:

Electric motor:

2

97.2

95.6

112.8

107.4

2.2

0.7

Note 1: Equivalent noise level is, according to ISO 7182 and ISO 9207, calculated as the time-weighted

energy total for noise levels under various working conditions with the following time distribution: 1/2

idling, 1/2 full load.

Note 2: Equivalent vibration level is, according to ISO 7505, calculated as the time-weighted energy total

for vibration levels under various working conditions with the following time distribution: 1/2 idling, 1/2 full

load.

EC Declaration of Conformity (Only applies to Europe)

Directive 98/37/EC, Annex 2 A.

Lennartsfors Verkstads AB, Lennartsfors 1, SE-672 92 ÅRJÄNG, hereby guarantees that the bandsaws

Husqvarna SMB 70 and SMB 70 E, with serial numbers 02 100001 – 02 5200100, meet the standards

prescribed in the COUNCIL’S DIRECTIVES:

- of June 22, 1998 ”relating to machinery” 98/37/EC, annex IIA.

- of May 3, 1989 ”relating to electromagnetic compatibility” 89/336/EEC, and applicable supplements.

- of February 19, 1973 ”concerning electrical equipment”, 73/23/EEC

For information regarding noise emissions, see the Technical Data chapter.

The following harmonised standards have been applied: EN292-1, EN 1807:1999, 60204:1

Registered body: 0404, SMP Svensk Maskinprovning AB, Fyrisborgsgatan 3, SE-754 50 Uppsala, Sweden,

has carried out EU type approval in accordance with article 8, section 2c. The EU type approval certificate is

numbered 404/02/854.

The supplied bandsaw conforms with the example that underwent EU type approval.

Årjäng February 14, 2002

Lennartsfors Verkstads AB

Örjan Gustafsson, Product Manager

English 37

Page 38

TECHNICAL DATA

Templates for Dressing the Grinding Disc

38 – English

´®z+H66¶6R¨

Page 39

NOTES

English 39

Page 40

114 02 22-26

´®z+H66¶6R¨

2004W12

Loading...

Loading...