Page 1

OPERATOR'S

MANUAL / 2008

WITH PARTS LIST

EDGER/TRIMMER

Model:

LE475 / 966951101

• Specications

• Operating

Instructions

• Maintenance

Information

Page 2

TABLE OF CONTENTS

General Safety Suggestion...................3

Edger-Trimmer Features ......................4

Assembly...............................................5

Attaching the Handle .............................. 5

Installing Throttle Wire ............................5

Fill Engine With Oil ................................. 5

Operating Your Edger-

Trimmer ..................................................6

Correct Engine Operation .......................6

Fuel Specication ................................... 5

Oil Specication ......................................5

Starting The Engine ................................6

Engaging Drive Belt ................................6

Stopping The Engine ..............................6

Correct Edger-Trimmer

Usage .....................................................8

Operation of the

Edger-Trimmer ........................................8

Maintaining Your

Edger-Trimmer ......................................9

Maintenance Check List ......................... 9

Engine ....................................................9

Oil Quality ...............................................9

Oil Level..................................................9

Oil Changes ............................................9

Spark Plug ..............................................9

Blade Maintenance .................................9

Blade Changes .......................................9

Lubrication ..............................................9

Storage Instructions................................13

Maintenance Notes.................................13-15

Parts Illustration ................................... 10

Parts List ............................................... 11

Troubleshooting Chart .........................12

Warranty ................................................Back Cover

CAUTION

TO AVOID INJURY

This symbol marks important instructions relating to your personal safety. To

avoid the possibility of injury, read and follow such instructions carefully.

When the manual refers to the left or right side of the edger-trimmer, it means

your left and right when standing in the operation position.

2

Page 3

GENERAL SAFETY SUGGESTIONS

Recommended by Outdoor Power Equipment Institute

DO NOT MODIFY EDGER-TRIMMER

Unauthorized modication to the edger-trimmer may impair

TRAINING

1. Read the Operating and Maintenance Instruction Manual carefully. Be thoroughly

familiar with the controls and proper use of

the equipment.

2. Never allow children to operate edger-trimmer.

3. Keep area of operation clear of all persons, particularly small children and pets.

4. Thoroughly train anyone using the edgertrimmer. Make sure all edger-trimer operators

know the safety, operating, and maintenance

procedures.

PREPARATION

1. Thouroughly inspect the area where edgertrimmer is to be used, and remove all stones,

sticks, wire, bones, and other foreign objects

which might be picked up and thrown.

2. Do not operate edger-trimmer when barefoot

or wearing open sandals. Always wear substantial foot wear, and pants or slacks that cover your legs when operating edger-trimmer.

3. Check fuel before starting engine. Do not ll

gasoline tank indoors, when engine is run-

ning, or while engine is still hot. Clean o any

spilled gasoline before starting engine.

4. Disengage cutterhead drive before starting

engine.

5. Do not use edger-trimmer unless blade guard,

belt guards, and debris guard are properly in

place.

6. Edge or trim only in daylight or in good articial

light.

7. Never operate equipment in wet grass. Always

be sure of

the handle and walk, never run.

your footing. Keep a rm hold on

OPERATION

1. Start the engine carefully. Keep hands and

feet well away from blade.

2. Do not change engine governor setting or

overspeed engine.

3. Wear safety glasses when operating edger-

trimmer.

4. Keep clear of discharge opening at all times.

Never direct discharge of any material toward

bystanders nor allow anyone near machine

while it is in operation.

5. Stop blade when crossing gravel drive, walks,

or roads.

6. After striking a foreign object, stop the engine

and inspect edger-trimmer for damage. Repair

damage before starting engine.

7. Avoid loss of control or tipping on slopes and

sharp corners by reducing speed.

its function and safety and aect edger-trimmer life.

8. If edger-trimmer should start to vibrate abnormally, stop the engine and check for the cause.

Vibration is generally a warning of trouble.

9. Stop the engine whenever you leave the

edger-trimmer, and when making repairs or

inspections.

10. When repairing or inspecting, make certain

blade and all moving parts have stopped.

Disconnect spark plug wire and keep wire

away from plug to prevent accidental starting.

11. Do not run engine indoors.

12. Shut engine o and wait until blade comes to

a complete stop before removing grass that

may clog blade guard.

13. Watch out for trac when working near

roadways.

14. Stay alert for uneven sidewalks, holes in terrain,

or other hidden hazards when using edger-trimmer. Always push slowly over rough ground.

15. Remember, never operate edger-trimmer

unless blade guard, belt guards, and debris

guard are properly in place.

16. Disengage power to cutterhead and stop

engine before leaving edger-trimmer, before

making repairs, inspections or adjustments,

and when transporting or not in use.

MAINTENANCE AND STORAGE

1. Check blade mounting nut frequently for

proper tightness.

2. Keep all nuts, bolts, and screws tight to be

sure equipment is in safe working condition.

3. Never store edger-trimmer with

in the tank in a building where fumes may

reach an open ame or spark. Be sure engine

has cooled before storing in any enclosure.

4. To reduce re hazard, keep engine free of

grass, leaves, or excessive grease.

5. After operating engine, never touch exhaust muer until it has cooled completely.

6. Keep edger-tirmmer in good operating

condition, and keep safety devices in place

gasoline

CAUTION

TO AVOID INJURY

Read Operator's Manual. Know location

and function of controls. Maintain safety

devices. Remove potential thrown objects.

Never edge or trim near people. Never carry

passengers. Look before backing. Avoid

slippery or steep areas. Stop blade and back

slowly if machine stops. Avoid blade unless

blade and engine are stopped.

3

.

Page 4

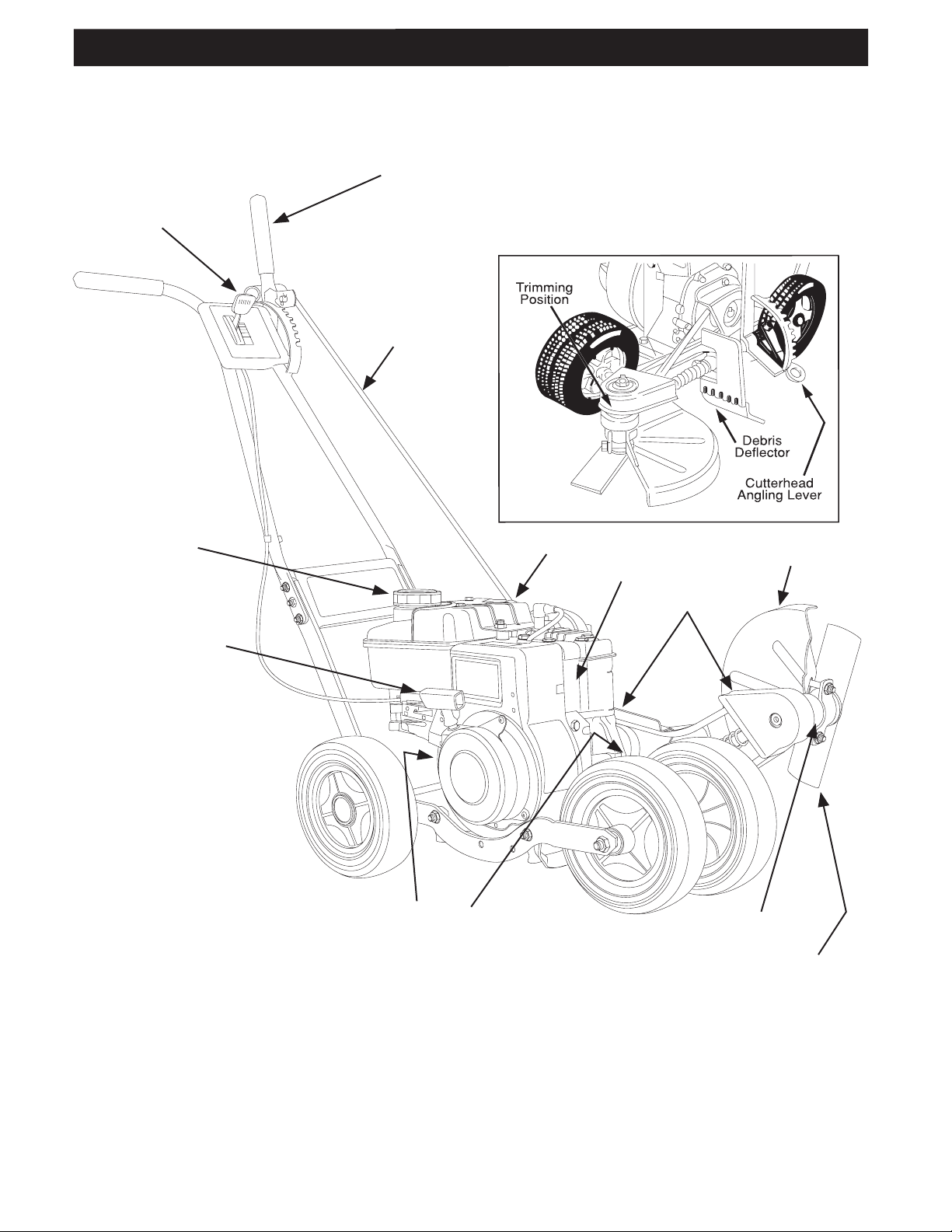

Throttle Lever

EDGER-TRIMMER FEATURES

Clutch & Depth Lever

Control Rod

Gasoline Fill

Recoil Starter

Oil Fill

Front & Back

Air Cleaner

Engine

Blade Guard

Belt Guards

Cutterhead

Blade

4

Page 5

ASSEMBLY

TOOLS REQUIRED: 7/16" Wrench, Pliers,

Screwdriver

NOTE: Reference to Left or Right side of machine

is from the operator's position of the handle,

facing forward.

The lawn edger, except the handle and throttle

control, is fully assembled, packed, and shipped

in one container.

ATTACHING THE HANDLE

1. Remove handle brace, nuts, and bolts. Align

the handle, lower support, and handle brace

holes. Use all six nuts and bolts. Leave bolts

loose until Steps 2 and 3 are completed (See

Fig. 1).

2. Install control rod into upper and lower pivot

holes and secure with cotter pins (See Fig.

1). Oil pivots lightly before installing rod.

3. Move clutch-depth lever into rear notch of

quadrant on handlebards. Move cutterhead

angling lever to top notch of quadrant.

4. Remove spark plug wire from spark plug.

Move throttle to OFF position. Check clutch

operation by pulling recoil starter rope. If

blade turns when depth lever is in top notch,

loosen handle bolts and pull toward operator.

Snug bolts and check clutch operation again.

— IMPORTANT NOTE —

FILL ENGINE WITH OIL

NOTE: There is no oil in engine crankcase.

1. Follow instructions in the engine manual for

correct grade of oil, oil lling, and oil changing.

2. Do not mix oil with gasoline.

INSTALLING THE THROTTLE WIRE

1. If the throttle cable is not attached to the

engine carburetor, follow the instructions in

the engine operating manual. Some throttle

cables cannot be attached before shipping.

Check oil level of engine every time edgertrimmer is used. An improper oil level can cause

extensive internal damage to engine.

FUEL SPECIFICATION

1. Follow fueling instruction in the engine

manual.

CAUTION

Handle fuel with care — it is highly ammable.

Use only approved fuel container. Never add

fuel while engine is running. Fill fuel tank

outdoors, with extreme care. Never ll fuel

tank indoors. Replace gasoline cap securely

and wipe up all spilled fuel.

Make sure blade does not turn when lever is in

top notch (disengaged).

5. Slip on the handle grips.

6. Tighten bolts.

Throttle Cable

Install 6 Bolts Through

Handle Lower Support

& Handle Brace Holes

Throttle

Cable Clip

Control Rod

Always clean area around fuel cap before

removing it to prevent excessive amounts of dirt

from entering fuel system. Also insure that the

fuel storage container you are using is clean and

in good condition.

CORRECT ENGINE OPERATION

CAUTION

Before starting engine, become familiar with

all controls. Read this Operator's Manual

thoroughly. Always check engine oil level

before starting engine.

WARNING

Care should be taken to avoid inhaling exhaust gasses, as they contain carbon monoxide gas, which is colorless and oderless.

Carbon monoxide is a dangerous gas that

can cause unconsciousness and is poten-

tially lethal. Do not run engine in conned

areas such as closed garages.

Fig. 1

5

Page 6

OPERATING YOUR EDGER-TRIMMER

CORRECT ENGINE OPERATION

CAUTION

Always disengage edger-trimmer blade and

shut engine o when leaving the edger-trimmer unattended, even if for just a few minutes. Prevent accidents; don't give children

or unauthorized persons an opportunity to

operate this machine.

CAUTION

Always start edger-trimmer in motion

slowly. Sudden starts can be damaging

to the equipment and could cause loss of

operator control.

CAUTION

Rotating blade can throw dirt or debris.

Wear safety glasses when operating the

edger-trimmer.

ADJUSTING CUTTERHEAD ANGLE

(See Fig. 2)

Before starting engine, adjust cutterhead angle.

The cutterhead angling lever, located on the left

hand side of the frame, enables the operator

to position the blade horizontally for trimming

or choose several vertical positions for edging.

WARNING

Never adjust cutterhead angle when engine

is running.

CLUTCH AND DEPTH LEVER

SETTINGS (See Fig. 3)

Clutch and Depth lever is used to engage and

disengage the drive belt, which operates the

blade. It is also used to regulate the depth of

edging and height of trimming.

Clutch/Depth Controls

Throttle/Choke

Controls

Depth

Settings

Fig. 3

STARTING THE ENGINE

Be sure the clutch lever is in the rear DISENGAGED

position before starting engine.

Manually pull out choke on engine.

Grasp the recoil starting handle and pull quickly.

Return the handle slowly. If the engine fails to

start after three or four pulls, lower the throttle

to the detented full throttle (fast) position.

Once the engine starts, push the choke to the o

position. Use the SLOW position to idle the engine.

Cutterhead Angle Adjustmet

Fig. 2

ENGAGING THE DRIVE BELT

Move clutch and depth lever forward to engage

drive belt and blade. Notches in base of lever

permit adjusting depth of cut for edging and height

for trimming.

TO STOP

Disengage edger-trimmer clutch and depth lever.

Move throttle control to stop position. Make

sure engine is stopped and blade is not

rotating before leaving the operating position.

6

Page 7

OPERATING YOUR EDGER-TRIMMER, CONT.

WHEEL POSITIONING (See Fig. 4)

The wheel adjusting spacer should be centered

between the wheels when edging in the vertical

position. Wheels must be in the dual position

to the right when edging with cutterhead in an

angle position or trimming (horizontal position).

WARNING

Do not change wheel positions when engine

is running.

Wheel Spacer Positioned For Trimming

Remove the spacer from between the wheels

by lifting on spacer with open side down. Slide

the left front wheel on the axle toward the

right wheel, and once again install the spacer

on the axle between the frame and wheel.

CAUTION

Before starting the engine, be sure the wheels

and cutterhead are positioned so the blade

will not strike the wheels.

NOTES

Fig. 4

CURB RIDING POSITION

Remove the spacer from between the front

wheels. Slide the right wheel toward the left wheel

and replace the spacer between the wheel and

right frame. Only vertical edging can be done in

this position.

NOTE: As pictured above, wheels are positioned

to the right for trimming. The wheels are positioned

to the left for curb riding edging.

7

Page 8

CORRECT EDGER-TRIMMER USAGE

CAUTION

Read all manuals provided before operating.

These manuals give a detailed description

of operation and point out other areas of

caution. Familiarize yourself thoroughly

with equipment before attempting to use it.

OPERATION OF THE EDGERTRIMMER

WARNING

Keep all shields in place. Never attempt to clear discharge areas or edgertrimmer blade wihout disengaging the

edger-trimmer and stopping the engine.

Your edger-trimmer is designed to give a

professionally groomed appearance to your

lawn with minimum eort. It will edge lawns at

walks, around ower beds, trim close to poles

and hydrants, and also under fences and other

hard to reach locations. For best appearance

around owers, adjust blade to 20" angle cut.

Too deep a cut will put unnecessary stress

on engine and accelerate blade wear. Cutting

too shallow allows rapid regrowth of roots.

Make sure to re-adjust cutting depth as blade

begins to wear at tips.

Avoid edging or trimming in wet grass, as it may

clog up in the blade guard and cause splattering.

The general appearance will be much better when

grass is dry.

Always push edger-trimmer at moderate walking

speed — at this speed your edger-trimmer is

designed to cut more than 100 ft. per minute.

Four-wheel design of edger-trimmer permits easy

and stable edging, riding securely on sidewalk or

cement surfaces.

Around specially shaped ower beds or

sections, follow these simple steps. It will be

easier to cut around corners when front wheels

are placed together at right side of trimmer-edger.

Before starting engine, remove wheel spacer

clip on front axle, slide wheels to side away from

blade, and replace spacer.

curved

For best results, adjust the cutting depth of the

blade to within 1/2" to 1" deep (with a new blade

usually in the third notch of the adjustment bracket

at handle).

WARNING TO PURCHASERS OF

INTERNAL COMBUSTION ENGINE

EQUIPPED MACHINERY OR DEVICES

This equipment does not include a spark arrestor

muer.

If this equipment is used on any forest-covered

land, brush-covered land, or grass-covered land

in the State of California, the law requires that

a spark arrestor be installed and in eective

working order before using this equipment on

such land. The spark arrestor must be attached to

the exhaust system and comply with Section 4442

of the California Public Resources Code.

If this equipment is used in a state or national

park or campground, a U.S.D.A. Forestry

Department approved spark arrestor muer

must be utilized.

After starting engine, set blade depth and by

slightly lifting rear wheels, guide edger-trimmer

around corners and odd angles.

8

Page 9

MAINTAINING YOUR EDGER-TRIMMER

CAUTION

To minimize the chance of injury, perform all

maintenance and adjustments on your edgertrimmer with engine o, unless instructed

otherwise in this section. Use extreme care

when working near operating machinery.

Do not wear loose tting clothing. Remove

watch and jewelry before beginning work

and observe common safety practices when

using tools.

MAINTENANCE CHECKLIST

1. Refer to the engine manual for engine maintenance instructions.

2. Correct grade of oil and gasoline is included

in the instructions.

Check the oil level of the engine every time the

edger-trimmer is used. An improper oil level can

cause extensive internal damage to engine.

Failure to change engine oil at recommended

intervals can lead to serious damage to engine.

This is especially true when using detergent

oils which are designed to hold impurities in

suspension; when saturation point is reached,

oil may suddenly break down to form a gelatinlike substance which seriously impairs and can

even stop ow of oil. Increase frequency of oil

changes if edger-trimmer is operated under

extremely dusty conditions.

Replace spark plug that is not in

good condition.

Never sand blast, wire brush, scrape, or reinstall

spark plug in poor condition. Best results are

obtained with a new plug.

Always check spark plug gap before installing a

new plug or reinstalling the original plug. Use a

spark plug gap gauge to adjust the electrode air

gap as indicated in the engine manual.

BLADE MAINTENANCE

CAUTION

Sharp edges of edger-trimmer blade can cut

you during blade maintenance or adjustment. Use suitable covering over cutting

edges of blade to prevent bodily harm.

BLADE CHANGE

1. Place a 5/16" Allen wrench on the inside of

cutterhead shaft and a 3/4" wrench on the

blade nut, and turn to loosen nut. Remove

outer washer and old blade.

2. Replace blade with only Husqvarna blade

(available in 3-pack). Place outer washer the

same direction as removed, and tighten nut

as snug as possible.

LUBRICATION (See Fig. 5)

1. The cutterhead body needs occasional greas-

ing. Use #2 multi-purpose grease.

2. The cutterhead mandrel has two precision-

sealed bearings that do not need lubrication.

SPARK PLUG

Engine misre, or generally poor operation, is

often caused by spark plug in poor condition or

with incorrect spark gap setting. Spark plug should

be checked after each fty hours of operation.

Replace a spark plug at one hundred operating

hour intervals, or sooner if inspection reveals

fouling or excessive deterioration.

Always clean area around spark plug before

removing it to prevent dirt from entering engine.

Use a spark wrench to remove and install plug.

Check condition of plug. Good operating

conditions are indicated by a light coating of grey

or tan deposit. A dead white, blistered coating

could indicate an "overrich" fuel mixture caused

by a clogged air cleaner, or improper carburetor

adjustment.

USE #2 MULTI-PURPOSE GREASE

Grease Fitting Location

Fig. 5

Oil all exposed bearings, linkage, and front

wheels. Check all nuts and bolts for tightness.

9

HORIZONTAL

20

°

10

°

VERTICAL

10

°

20

°

BLADE

ANGLE

Page 10

LAWN EDGER AND TRIMMER PARTS ILLUSTRATION

10

Page 11

LAWN EDGER AND TRIMMER PARTS LIST

REF. PART

NO. NO. DESCRIPTION

1 505289901 Handle

2 505289902 Pin, Cotter 1/8 x 3/4 (2 Req.)

3 505289903 Nut Lock Hex 7/16" - 14 (4 Req.)

4 505289904 Spring

6 505289905 Bolt, Hex 7/16 - 14 x 2

7 505289906 Rod, Clutch & Depth

8 505289907 Grip (3 Req.)

9 505289908 Lever, Clutch & Depth

10 505289909 Throttle Control (3 HP Ball Brg)

(40-3/4)

11 505289910 Clip, Throttle Cable

12 505289911 Cross Brace for Handle

13 505289912 Nut 1/4-28 Hex (10 Req.)

14 505289913 Bolt 1/4-28 x 7/8 hex (6 Req.)

15 505289914 Frame, Right Hand 8"

16 505289915 Hub Cap for 7" & 8" Rear Wheels

505289916 8" Rear Wheel Complete w/

Bearings, Wide Tire & Hub Cap

505289917 8" Rear Wheel Outside Bearing

Only

505289918 8" Rear Wheel Inside Bearing

Only. Also for 8" Front Wheel.

(2 needed/front)

16A 505289919 8" Front Wheel Complete

w/Bearing & Wide Tire

505289920 8" Tire Only

505289921 8" Rear Wheel Rim Only

505289922 8" Front Wheel Rim Only

17 --- -- -- -- Engine (Briggs & Stratton Dist.)

18 505289924 Bolt 5/16-24 x 1-1/2 (4 Req.)

19 505289925 Bolt 5/16-24 x 7/8 Hex (5 Req.)

20 505289926 Nut 7/16-14 Hex (3 Req.)

21 505289927 8" Front Axle

22 505289928 8" Front Wheel Spacer (2-13/16"

Use With 7075-7 Wheels)

23 505289929 Nut 5/16-24 Hex (9 Req.)

24 505289930 8" Fram Crossmember

25 505289931 8" Rear Axle (13-5/8") (Use with

7058 wheels)

26 505289932 Bracket, Engine Pulley Guard

27 505289933 Guard, Engine Pulley

28 505289934 Engine Pulley Guard & Bracket

Complete

29 505289935 Screw #110 x x1/2 Sheet Metal

(4 Req.)

30 505289936 8" Fram, Left Hand

31 505289937 Set Screw 5/16-24 x 5/16

33 505289938 Cutterhead Pulley & Shaft Comp.

REF. PART

NO. NO. DESCRIPTION

34 505289939 Screw 1/4-20 x 1/2 Hex

35 505289940 Cutterhead Pulley Guard

36 505289941 Cutterhead Bearing (2 Req.)

36A 505289943 Spring Washer (New 01/87)

37 505289942 Mandrel, Head

40 505289944 Clamp, Blade Guard

41 505289945 Bolt 1/4-28 x 1-1/2 Hex (2 Req.)

42 505289946 Blade Guard Main

505289947 Complete Blade Guard

44 505289948 Washer, Friction (2 Req.)

45 505289949 Nut 1/2-20

46 505289950 Deector, Debris Sweep

47 505289951 U-Clamp

505289952 Complete Debris Guard

49 505289953 Pivot Bolt

50 505289954 Flat Washer 7/16

51 505289955 Spring, Head Recoil

52 505289956 Cup

53 505289957 Body, Cutterhead

54 505289958 Lever, Angle Shifting

55 505289959 Pin 5/16 x 2

56 505289960 Spring

57 505289961 Brace Cutterhead

58 505289962 Drive Belt (4L-300)

59 505289963 Cutting Blade

61 505289964 1-1/4 Pin

62 505289965 U-Clamp Spacer

63 505289966 Grease Fitting

505289967 Handle and Wheel Bearing

505289968 Cutting Head Complete (Inc. No

33,53,51,52,54,55,56,61,37,(2)63,

505289969 LE475 Decal

NOTE: All component dimensions given in U.S. inches

1 inch = 25.4 mm

(2)36)

11

Page 12

TROUBLESHOOTING CHART

ESUAC MELBORP

1. Engine fails to start. A. Check fuel tank for gas.

B. Spark plug lead wire disconnected.

C. Throttle control lever not in starting position.

D. Check spark plug.*

E. Carburetor improperly adjusted. Engine ooded. Re-

F. Old/stale gas. Drain and rell with fresh gas.

2. Hard Starting or loss of power. A. Spark plug wire loose.

B. Carburetor improperly adjusted.*

C. Dirty air cleaner.*

3. Operation erratic. A. Dirt in gas tank. Drain, clean and rell.

B. Dirty air cleaner.*

C. Water in fuel supply. Drain and rell.

D. Vent in gas cap and/or carburetor plugged. Clear vent.

E. Carburetor improperly adjusted.*

4. Hard Starting or loss of power. A. Spark plug fouled, faulty or gap too wide.*

B. Carburetor improperly adjusted.*

C. Dirty air cleaner.*

gulp htiw enigne knarc ,gulp eht yrd ,gulp kraps evom

kraps ecalpeR .noitisop ffo ni elttorht dna ,devomer

.serudecorp gnitrats emuser dna eriw dael dna gulp

5. Idles poorly. A. Carburetor idle speed too slow.*

B. Spark plug gap too close.*

C. Carburetor idle mixture adjustment improperly set.*

6. Hard Starting or loss of power. A. Adjust carburetor.*

B. Remove any obstructions from air passages in shrouds.

C. Clean cooling ns.

D. Fill crankcase to proper oil level.

* NOTE: For repairs beyond the minor adjustments listed above, please contact your local

Lawn Mower Service Shop.

12

Page 13

STORAGE INSTRUCTIONS

Edger-trimmers stored for any length of time should be completely drained of fuel to prevent

gum deposits forming on essential parts such as the carburetor and fuel tank. Such deposits

may aect the operation of the engine when used again. Therefore, it is important that the

following instructions be adhered to before starting engine. 1. Drain fuel tank completely. 2.

Operate the engine until it stops from lack of fuel, to clean all gasoline out of carburetor. 3.

While engine is still warm, drain the crank case. Rell with fresh oil. 4. Remove spark plug, and

pour one ounce of oil into the cylinder. Pull starter rope on the engine to spread the oil. Replace

spark plug. 5. Clean dirt and cha from cylinder and cylinder head ns, blower housing, etc.

MAINTENANCE NOTES

13

Page 14

MAINTENANCE NOTES

14

Page 15

MAINTENANCE NOTES

15

Page 16

TION

CONSIDERA

TIONS

EMENT. HUSQVARNA RESERVES THE RIGHT TO CHANGE OR

AND LIMITA

This warranty shall be inapplicable to defects resulting from the following:

SECTION 4: EXCEPTIONS

starter ropes and tiller tines;

(2) Natural discoloration of material due to ultraviolet light;

(3) Engine and drive systems not manufactured by Husqvarna; these items are covered by the respective manufacturer’s

warranty as provided in writing with the product information supplied at the time of purchase; all claims must be sent to the

appropriate manufacturer;

(4) Lawn and garden attachments are covered by a third party which gives a warranty, all claims for warranty should be sent

to the manufacturer,

(5) Commercial or consumer mowing decks with sand abrasion damage.

(6) Emission Control System components necessary to comply with CARB-TIER II and EPA regulations which are

manufactured by third party engine manufacturer.

(1) Accident, abuse, misuse, negligence and neglect, including stale fuel, dirt, abrasives, moisture, rust, corrosion, or any

adverse reaction due to incorrect storage or use habits;

safety, or durability, or causes the product to fail to comply with any applicable laws; or:

REPAIR OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE EXCLUSIVE REMEDY OF THE

by Husqvarna;

(3) Alterations or modifications that change the intended use of the product or affects the product’s performance, operation,

(2) Failure to operate or maintain the unit in accordance with the Owner’s/Operator’s manual or instruction sheet furnished

(4) Additional damage to parts or components due to continued use occurring after any of the above.

BREACH OF ANY EXPRESS OR IMPLIED WARRANTY ON THESE PRODUCTS EXCEPT TO THE EXTENT

PURCHASER. HUSQVARNA SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR

PROHIBITED BY APPLICABLE LAW. ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PREVIOUSLY MANUFACTURED PRODUCTS.

IMPROVE THE DESIGN OF THE PRODUCT WITHOUT NOTICE, AND DOES NO T ASSUME OBLIGATION TO UPDATE

Some states do not allow the exclusion of incidental or consequential damages, or limitations on how long an implied

PARTICULAR PURPOSE ON THESE PRODUCTS IS LIMITED IN DURATION TO THE WARRANTY PERIOD AS

DEFINED IN THE LIMITED WARRANTY STAT

:

warranty lasts, so the above limitations or exclusions may not apply to you. This warranty gives you specific legal rights, and

The product must exhibit reasonable care, maintenance, operation, storage and general upkeep as written in the

SECTION 5: CUSTOMER RESPONSIBILITIES

you may also have other rights which vary from state to state.

maintenance section of the Owner’s/Operator’s manual. Should an operational problem or failure occur, the product should

ARRANTY

HUSQVARNA

7349 Statesville Road

Charlotte, NC 28269 2008

To obtain the benefit of this warranty, the product believed to be defective must be delivered to an authorized Husqvarna

It is the Owner’s and Retailer’s responsibility to make certain that the Warranty Registration Card is properly filled out and

section 6, rests solely with the customer.

not be used, but delivered as is to an authorized Husqvarna retailer for evaluation. Proof of purchase, as explained in

SECTION 6: PROCEDURE TO OBTAIN W

Proof of purchase must be presented to the authorized Husqvarna retailer in order to obtain warranty service. This proof

in order to confirm the warranty and to facilitate post-sale service.

mailed to Husqvarna Forest & Garden Company. This card should be mailed within ten (10) days from the date of purchase

must include date purchased, model number, serial number, and complete name and address of the selling retailer.

delivered at the owner’s expense. Downtime, pick-up and delivery charges are not covered by this warranty. An authorized

Husqvarna retailer can be normally located through the “Yellow Pages” of the local telephone directory or by calling 1-800-

HUSKY62 for a retailer in your area.

retailer in a timely manner, no later than thirty (30) days from date of the operational problem or failure. The product must be

WARRANTY STATEMENT

ARRANTY

Lifetime Warranty (“PARTS ONLY” after initial warranty expiration): Ignition coils and modules on handheld product.

Husqvarna Forest & Garden Company (“Husqvarna”) warrants Husqvarna product to the original purchaser to be free from

defects in material and workmanship from the date of purchase for the “Warranty Period” of the product as set forth below:

Lifetime Warranty (Parts and Labor): All tiller tines and trimmer shafts against breakage. Proof of purchase required.

SECTION 1: LIMITED W

:

THIS WARRANTY

TIONS UNDER THE WARRANTY

’S OBLIGA

5 year consumer warranty or 1,500 hours of use.

(New warranty applies to units sold after August 1, 2005. Also applies to units factory-equipped with R.O.P.S.

WARRANTY SCHEDULE FOR TURF CARE Equipment - Zero Turn Riders

Proof of purchase required.

iZ, LZ & BZ Zero Turn Riders:

iZ, LZ & BZ Zero Turn Riders: 5 year commercial warranty or 1,500 hours of use.

EZ Zero Turn Riders: 3 year consumer warranty or 600 hours of use (when used solely at the owner’s residence.)

3 Year or 1,500 Hour Commercial Use Warranty: spindles on zero turn riders, hydraulic pumps and wheel motors.

EZ & MZ Zero Turn Riders: 1 year commercial warranty or 600 hours of use.

Warranty Schedule for Turf Care Walk Behind Units - W, WG & WH Zero Turn Riders - 3 year consumer and commercial

2 Year Consumer Warranty: Automatic mower, all Residential Zero Turn Riders, all lawn, yard and garden tractors, all

warranty. New warranty applies to units sold after August 1, 2005. Also applies to units factory-equipped with R.O.P.S.

2 Year COMMERCIAL and CONSUMER Warranty: all Husqvarna ground-engaging commercial equipment.

WARRANTY SCHEDULE FOR CONSUMER TURF CARE EQUIPMENT

noncommercial walk behind mowers, tillers, snow blowers, electrical products and power-assist collection systems for

noncommercial, nonprofessional, noninstitutional or nonincome producing use, except as herein stated. All consumer

2 Year Consumer Warranty: all consumer chain saws, trimmers, brushcutters, clearing saws, handheld blowers, backpack

blowers, hedge trimmers, and electrical products for noncommercial, nonprofessional, noninstitutional or nonincome

producing use, except as herein stated. All consumer product use must have been limited to the owner’s residence.

2 Year or 2,000 Hour Powertrain & 1 Year or 1,000 Hour Body Warranty: Husqvarna Utility Vehicles.

1 Year Warranty: Power cutters, stump grinder, pole pruners and pole saws for non-commercial, non-professional,

noninstitutional, non-municipality or non-income producing use. All 300 series trimmers, brushcutters, clearing saws,

product use must have been limited to the owner’s residence.

WARRANTY SCHEDULE FOR CONSUMER FOREST & GARDEN EQUIPMENT

hovering trimmers, stick edgers, backpack blowers, hand held blowers, hedge trimmers, power-assist collection systems for

Automatic mower, chain saws, 100 series trimmers, power cutters, stump grinders, pole

ear prorated limited warranty with 100% replacement during the first 6 months.

commercial, institutional, professional or income producing purposes or use.

commercial, institutional, professional, municipality or income producing purposes or use except as otherwise provided herein.

90 Day Commercial Warranty:

with a warranty claim form. All care and maintenance instructions must be followed as stated by the manufacturer on the

material and workmanship. Normal wear, tear or abuse is not covered under warranty. Product must be returned to Charlotte

care label. The fit of the protective apparel/boot is not covered under warranty.

Husqvarna Safety Apparel carries a 90-day warranty from the date of the customer’s original purchase for defects in

Rental Warranty: 90 days on all applicable professional equipment reference warranty time period charts

located in the back of the Retailer Warranty Policy & Procedure Manual.

Batteries: 1 y

saws, pole pruners, snow throwers, model series 580 & 600 walk-behind mowers, or any Husqvarna product used for

1 Year Conditional Component Warranty: Chain saw crankshafts for commercial/professional use (parts and labor).Saw

must be operated with Husqvarna XP 2 cycle oil.

warranty with product at time of purchase.

30 Day Warranty: Replacement parts, accessories including bars and chains, tools and display items. Emission control

part of engine systems manufactured by third part engine manufacturers for which the purchaser has received a separate

system components necessary to comply with CARB-TIER II and EPA regulations, except for those components which are

Husqvarna will repair or replace defective components without charge for parts or labor if a component fails because of a

defect in material or workmanship during the warranty period.

SECTION 3: ITEMS NOT COVERED BY

SECTION 2: HUSQVARNA

The following items are not covered by this warranty:

(1) Normal customer maintenance items which become worn through normal regular use, including, but not limited to, belts,

blades, blade adapters, bulbs, clutches, clutch drums, filters, guide bars, lubricants, rewind springs, saw chain, spark plugs,

Loading...

Loading...