Page 1

Workshop manual

340 345 346XP

350 351 353

English

Page 2

Workshop manual

Husqvarna 340/345/346XP/350/351/353

Contents

Introduction ........................................................... 2

Safety regulations ................................................. 3

General instructions ........................................... 3

Special instructions ............................................ 3

Special tools .......................................................... 4

Technical data ....................................................... 6

Construction and function ................................... 8

Carburettor ......................................................... 8

Troubleshooting .................................................. 10

Repair instructions ............................................. 12

Chain brake ...................................................... 12

Silencer ............................................................ 14

Chain catcher ................................................... 14

Stop switch ....................................................... 15

Stop switch – resistance measurement ........... 15

Choke control ................................................... 16

Throttle trigger .................................................. 17

Hand grip heater .............................................. 18

Starter assembly .............................................. 21

Starter cord ...................................................... 21

Recoil spring .................................................... 22

Ignition module – testing .................................. 23

Ignition module and flywheel ............................ 23

Generator ......................................................... 24

Centrifugal clutch ............................................. 26

Oil pump ........................................................... 27

Carburettor ....................................................... 30

Carburettor – pressure testing ......................... 33

Carburettor heater ............................................ 34

Air intake system .............................................. 35

Carburettor – adjustment ................................. 37

Fuel tank .......................................................... 38

Fuel filter .......................................................... 39

Fuel hose ......................................................... 39

Piston and cylinder ........................................... 41

Decompression valve – pressure testing ......... 42

Cylinder – pressure testing .............................. 44

Crankcase and crankshaft ............................... 45

Crankshaft bearings ......................................... 46

Repairing damaged threads ............................. 49

Thread insert .................................................... 49

Guide bar bolts ................................................. 49

Appendix A, Carburettor – EPA models ........... 50

English – 1

Page 3

Introduction

Arrangement of the manual

This workshop manual can be used in two different

ways.

• To repair a specific sub-assembly on a chainsaw.

• To dismantle and reassemble a complete

chainsaw.

Repairing a specific sub-assembly

If a specific sub-assembly on the chainsaw needs

to be repaired:

1. Look up the page referring to the relevant subassembly.

2. Follow the instructions under the headings:

Removal/Dismantling

Cleaning and inspection

Refitting/Reassembly

Dismantling and reassembling the entire

chainsaw

If the entire chainsaw is to be dismantled, follow

the instructions under the heading “Removal/

Dismantling”.

Work through the manual and follow the instructions given in each section under the heading

“Removal/Dismantling”.

Troubleshooting

These pages describe the most common faults that

affect a chainsaw. They are divided into four

different groups with the most likely faults described first.

Repair instructions

The section that describes how to repair the

chainsaw consists of detailed, step-by-step instructions. It explains in detail the special tools, lubricants and bolt torques that are needed when

working on each component.

This workshop manual covers the following

chainsaw models:

340

345

346XP

350

351

353

Then follow all the “Cleaning and inspection”

instructions in each section.

Working from the back of the manual, follow all the

instructions under the headings “Refitting/

Reassembly” in reverse order.

Each of the sections covering removal/dismantling

and refitting/reassembly include the relevant

lubrication instructions and bolt torques for each

stage of repair.

Construction and function

This chapter gives a simple description of the

chainsaw carburettor and its various parts.

2 – English

Page 4

Safety regulations

General instructions

This workshop manual gives detailed instructions

on how to troubleshoot, repair and test a chainsaw.

This section also describes the various safety

precautions that should be taken when carrying out

repairs.

The workshop manual has been written for personnel who are assumed to have general experience

of repairing and servicing chainsaws.

Workshops where chainsaws are repaired must be

equipped with safety equipment that meets local

regulations.

No-one should carry out repairs on a chainsaw

until they have read and understood the contents

of this workshop manual.

Chainsaws are type-approved to meet the relevant

safety legislation, but this only applies when the

saw is fitted with the cutting equipment specified in

the user’s manual. The fitting of any other equipment, or of accessories or parts that are not

approved by Jonsered, could mean that the saw no

longer meets these safety requirements and the

person who carried out the work may be held

responsible for its non-conformance.

Special instructions

The fuel that is used in a chainsaw poses the

following hazards:

• The fuel and its fumes are toxic.

• May cause irritation to skin or eyes.

• May cause breathing difficulties.

• Highly flammable.

When using compressed air the air jet should

never be pointed at the body. Air can be forced into

the bloodstream and cause fatal injury.

Wear ear protection when testing saws.

After testing a saw do not touch the silencer until it

has cooled down. The silencer gets very hot and

you may burn yourself. Wear protective gloves

when working on the silencer.

The guide bar, chain and clutch cover (chain brake)

must be fitted before the saw is started. If not, the

clutch may come loose and cause injury.

Poor chain lubrication can result in failure of the

chain, which could cause serious or fatal injury.

In this workshop manual the following boxes

indicate where caution should be taken.

WARNING!

The warning text warns of the risk

of personal injury if the instructions are not followed.

NOTE!

The warning text warns of the risk of

material damage if the instructions are

not followed.

Take care to ensure that the spring inside the

starter assembly does not fly out and cause injury.

Wear eye protection. If the spring is under compression when the pulley is removed it could fly out

and cause injury.

Before removing the tensioning spring from the

chain brake, ensure that the brake is in the on

position, otherwise the spring may fly out and

cause injury.

After completing the repair the chain brake must be

tested, see “Chain brake – reassembly \ Operating

test”.

Always consider the fire risk. A chainsaw can

produce sparks that could start a fire.

Inspect the chain catcher and replace it if it is

damaged.

English – 3

Page 5

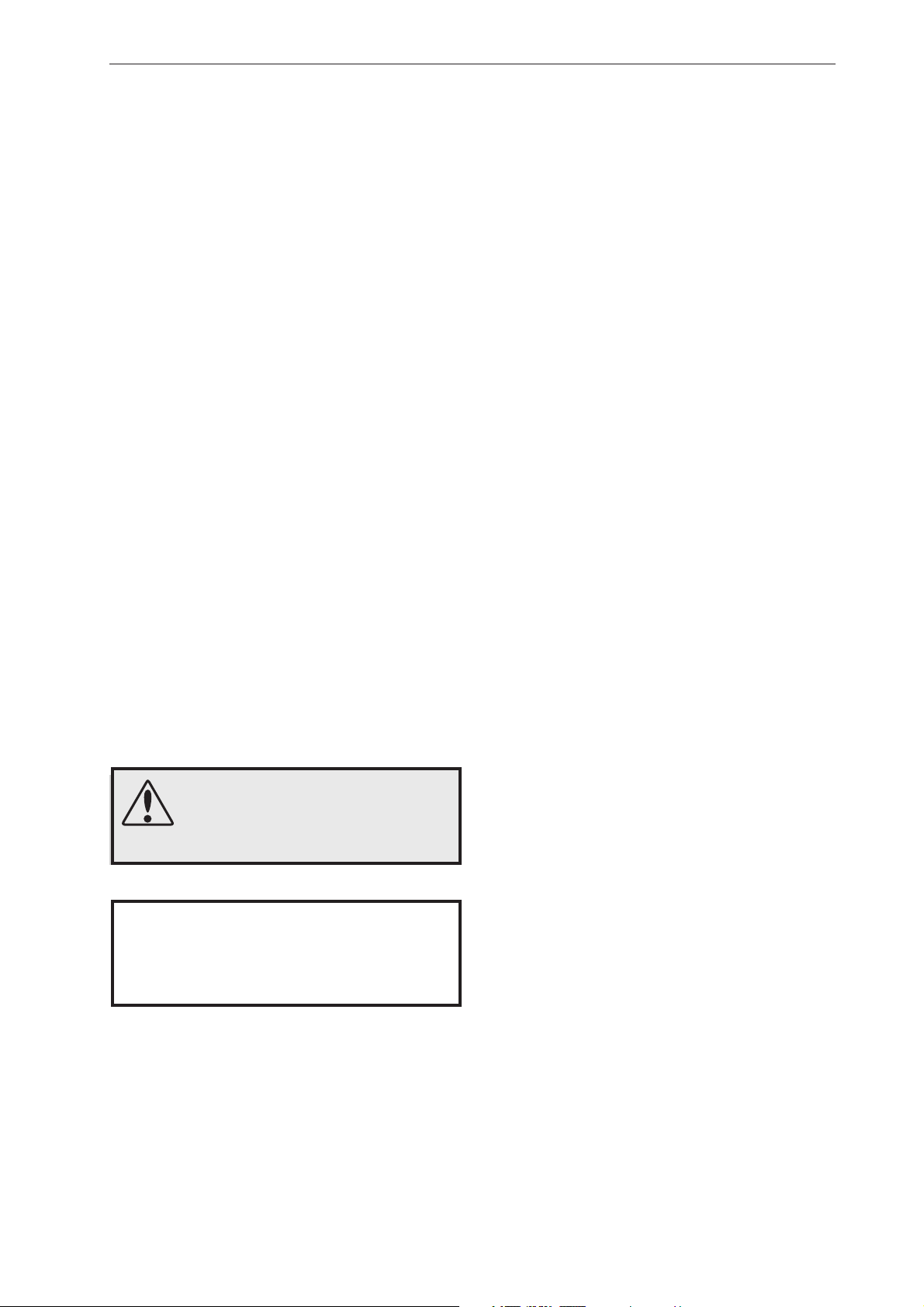

Special tools

1

4

2

5

8

97

3

6

10

13

11

14

12

4 – English

Page 6

15 16

Special tools

17

18

Item Description Used for Order no.

1 Clutch tool Centrifugal clutch 502 54 16-01

2 Piston stop Locking crankshaft 502 54 15-01

3 Stop plate Locating intake gaiter 502 54 17-01

4 Fuel filter hook Withdrawing the fuel filter 502 50 83-01

5 Allen key For M5 bolts 502 50 18-01

6 Puller Frame bearing 504 90 90-02

7 Removal tool Remove seal from clutch side 502 50 55-01

8 Mandrel, sealing ring Removing crankshaft 502 54 21-01

9 Cover plate Sealing during pressure testing 502 54 11-02

10 Pressure tester Connection to cylinder 503 84 40-02

11 Feeler gauge Adjusting ignition module 502 51 34-02

12 Clamp stand Clamping the saw 502 51 02-01

13 Pressure gauge Pressurisation during testing 502 50 38-01

14 Piston fitting kit Fitting piston 502 50 70-01

15 Test plug Checking ignition module 502 71 13-01

16 Rev counter Adjusting carburettor 502 71 14-01

17 Removal tool Removing crankshaft 502 51 61-01

18 Vacuum gauge Vacuum test 502 50 37-01

19 Assembly pliers Fitting spark plug guard 502 50 06-01

20a Sleeve Fitting crankshaft 502 50 30-18

20b Shaft extension Flywheel side 502 50 30-18

20c Shaft extension Clutch side 502 50 30-18

21 Stop plate Removing crankshaft 502 54 18-01

22 Assembly tool Assembling spring, chain brake 502 50 67-01

23 Crankshaft tool Fitting crankshaft seal 502 50 30-16

19

20 b

20 c

20 a

21

22

23

English – 5

Page 7

Technical data

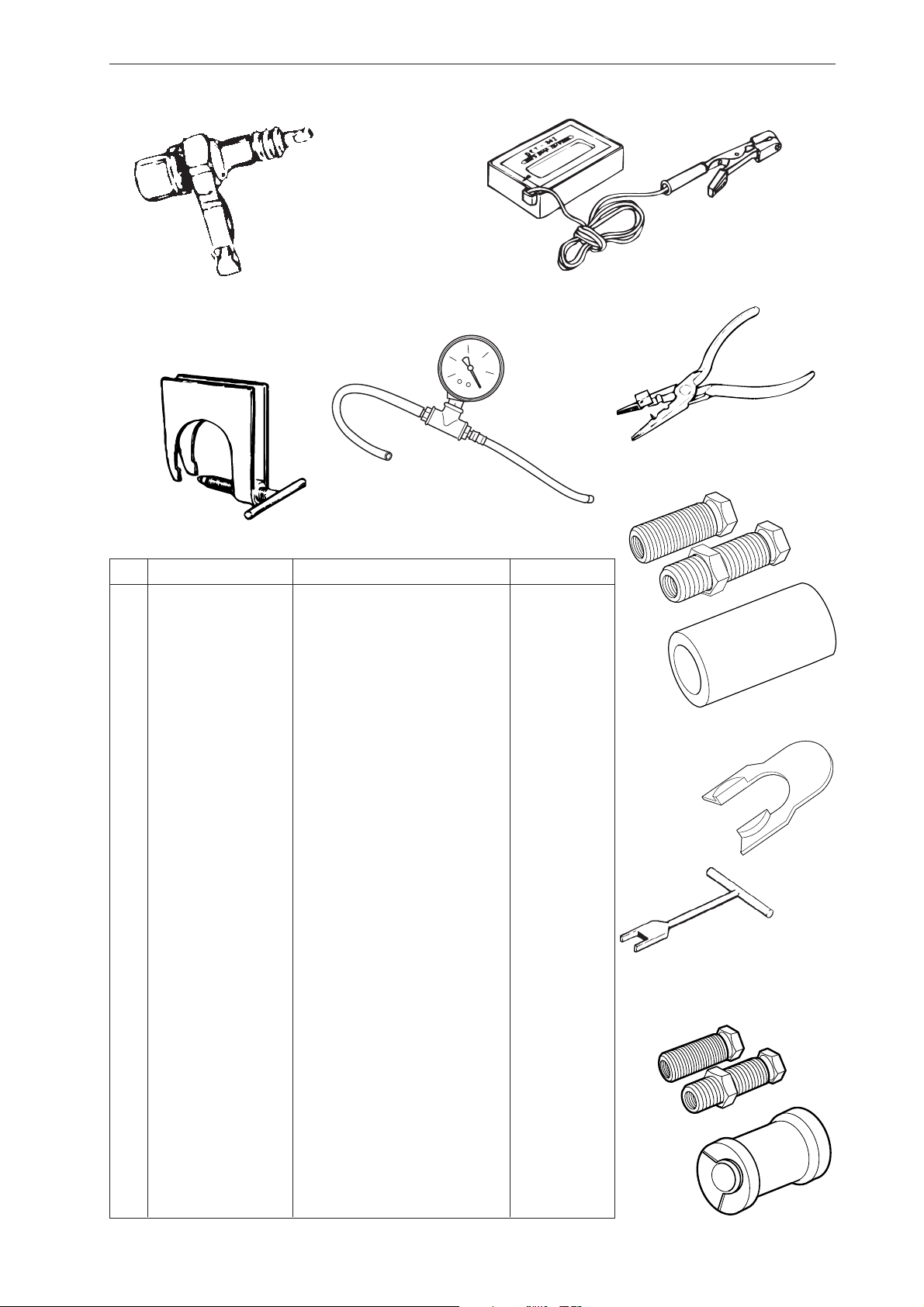

Displacement Cylinder bore Stroke Max power/speed

cm3/cubic inches Ø mm/Ø inches mm/inches kW/hp/rpm

340: 40,8 / 2,44 40 / 1,57" 32 / 1,28" 2,0 / 2,7 / 9 000

345: 45,0 / 2,75 42 / 1,65" 32 / 1,28" 2,2 / 3,0 / 9 000

346XP/G: 45,0 / 2,75 42 / 1,65" 32 / 1,28" 2,5 / 3,4 / 9 600

350: 49,4 / 3,01 44 / 1,73" 32 / 1,28" 2,3 / 3,1 / 9 000

350 EPA: 51,7 / 3,15 45 / 1,77" 32 / 1,28" 2,3 / 3,1 / 9 000

351/G: 49,4 / 3,01 44 / 1,73" 32 / 1,28" 2,3 / 3,1 / 9 000

353/G: 51,7 / 3,15 45 / 1,77" 32 / 1,28" 2,4 / 3,3 / 9 000

Spark plug gap Ignition system Air gap Carburettor type

mm/inches mm/inches

340: 0,5 / 0,02" SEM CD 0,3 / 0,012" Walbro HDA 195

345: 0,5 / 0,02" SEM CD 0,3 / 0,012" Walbro HDA 195

346XP/G: 0,5 / 0,02" SEM CD 0,3 / 0,012" Zama C3-EL17

350: 0,5 / 0,02" SEM CD 0,3 / 0,012" Walbro HDA 195

350 EPA: 0,5 / 0,02" SEM CD 0,3 / 0,012" Zama C3-EL18

351/G: 0,5 / 0,02" SEM CD 0,3 / 0,012" Zama C3-EL17

353/G: 0,5 / 0,02" SEM CD 0,3 / 0,012" Zama C3-EL17

Effective cutting length Chain speed at Chain pitch Drive link

cm/inches max power – revs mm/inches mm/inches

m/s – rpm

340: 30-48 / 12"-19" 17,3 / 9 000 8,25 / 0,325" 1,3 / 0,050" - 1,5 / 0,058"

345: 30-48 / 12"-19" 17,3 / 9 000 8,25 / 0,325" 1,3 / 0,050" - 1,5 / 0,058"

346XP/G: 30-48 / 12"-19" 18,5 / 9 600 8,25 / 0,325" 1,3 / 0,050" - 1,5 / 0,058"

350: 30-48 / 12"-19" 17,3 / 9 000 8,25 / 0,325" 1,3 / 0,050" - 1,5 / 0,058"

350 EPA: 30-48 / 12"-19" 17,3 / 9 000 8,25 / 0,325" 1,3 / 0,050" - 1,5 / 0,058"

351/G: 30-48 / 12"-19" 17,3 / 9 000 8,25 / 0,325" 1,3 / 0,050" - 1,5 / 0,058"

353/G: 30-48 / 12"-19" 17,3 / 9 000 8,25 / 0,325" 1,3 / 0,050" - 1,5 / 0,058"

6 – English

Page 8

Technical data

rpm

Idling speed Engagement speed Max. speed Spark plug

rpm rpm rpm

340: 2 700 3 800 12 500 NGK BPMR 7A, Champion RCJ 7Y

345: 2 700 3 800 12 500 NGK BPMR 7A, Champion RCJ 7Y

346XP/G: 2 700 3 800 14 200 NGK BPMR 7A, Champion RCJ 7Y

350: 2 700 3 800 13 000 NGK BPMR 7A, Champion RCJ 7Y

350 EPA: 2 700 3 800 13 000 NGK BPMR 7A, Champion RCJ 7Y

351/G: 2 700 3 800 13 000 NGK BPMR 7A, Champion RCJ 7Y

353/G: 2 700 3 800 13 000 NGK BPMR 7A, Champion RCJ 7Y

GAS

OIL

Fuel tank capacity Oil pump capacity at Oil tank capacity Automatic oil pump

Litres/US pints 8,500 rpm, Litres/US pints

ml/min

340: 0,5 / 1,05 9 0,25 / 0,53 Yes

345: 0,5 / 1,05 9 0,25 / 0,53 Yes

346XP/G: 0,5 / 1,05 5 - 12 0,28 / 0,59 Yes

350: 0,5 / 1,05 5 - 12 0,26 / 0,55 Yes

350 EPA: 0,5 / 1,05 5 - 12 0,26 / 0,55 Yes

351/G: 0,5 / 1,05 5 - 12 0,28 / 0,59 Yes

353/G: 0,5 / 1,06 5 - 12 0,28 / 0,59 Yes

Weight without bar and chain Weight with bar and chain Heated hand grips

kg / lbs kg / lbs

340: 4,7 / 10,3 5,5 / 12,1 345: 4,7 / 10,3 5,5 / 12,1 346XP: 4,8 / 10,6 5,6 / 12,2 346XPG: 4,9 / 10,8 5,7 / 12,4 Yes

350: 4,8 / 10,6 5,6 / 12,2 350 EPA: 4,8 / 10,6 5,6 / 12,2 351: 4,8 / 10,6 5,6 / 12,2 351G: 4,9 / 10,8 5,7 / 12,4 Yes

353: 5,0 / 11,0 5,8 / 12,6 353G: 5,1 / 11,2 5,9 / 13,0 Yes

English – 7

Page 9

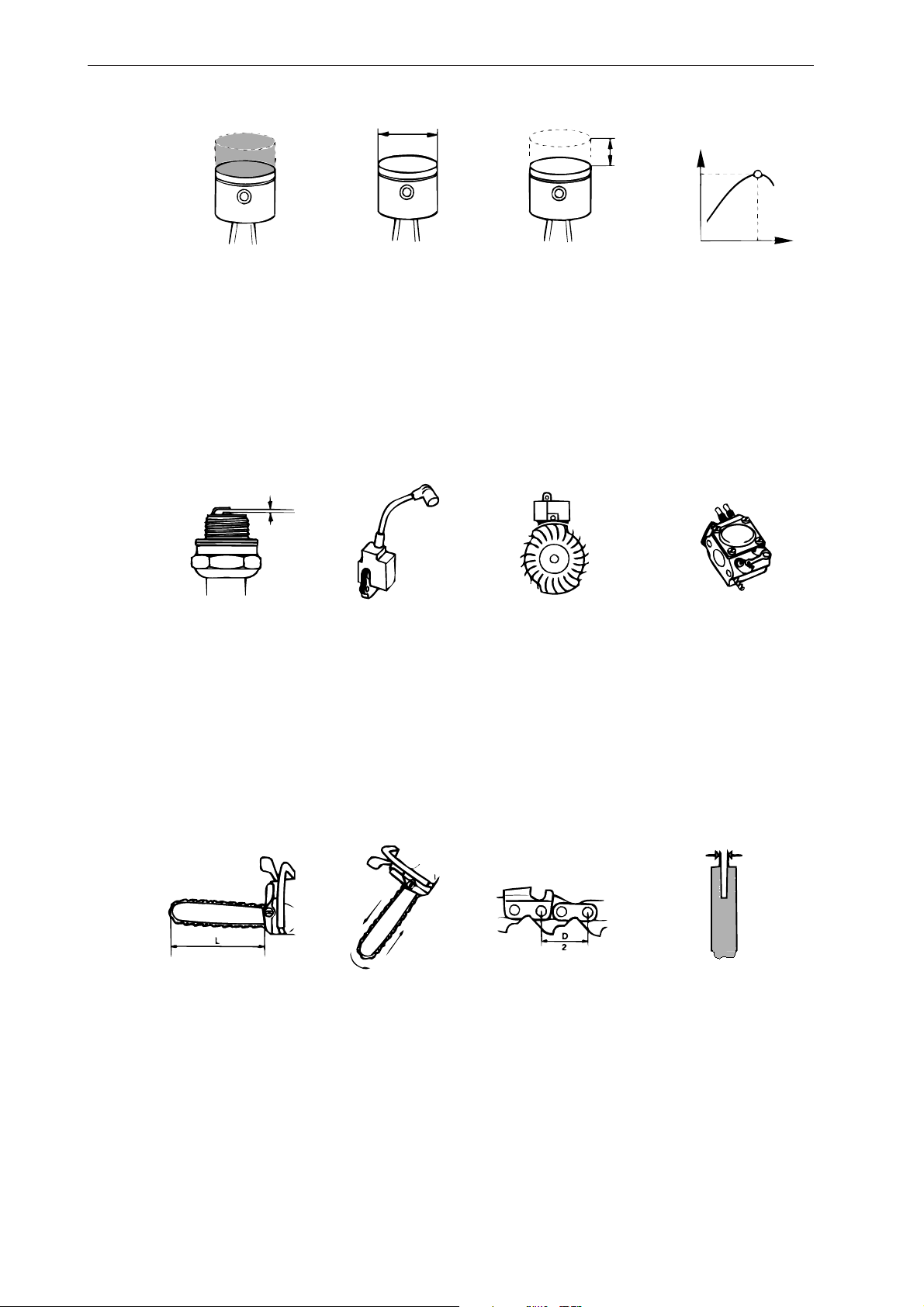

Construction and function

Carburettor

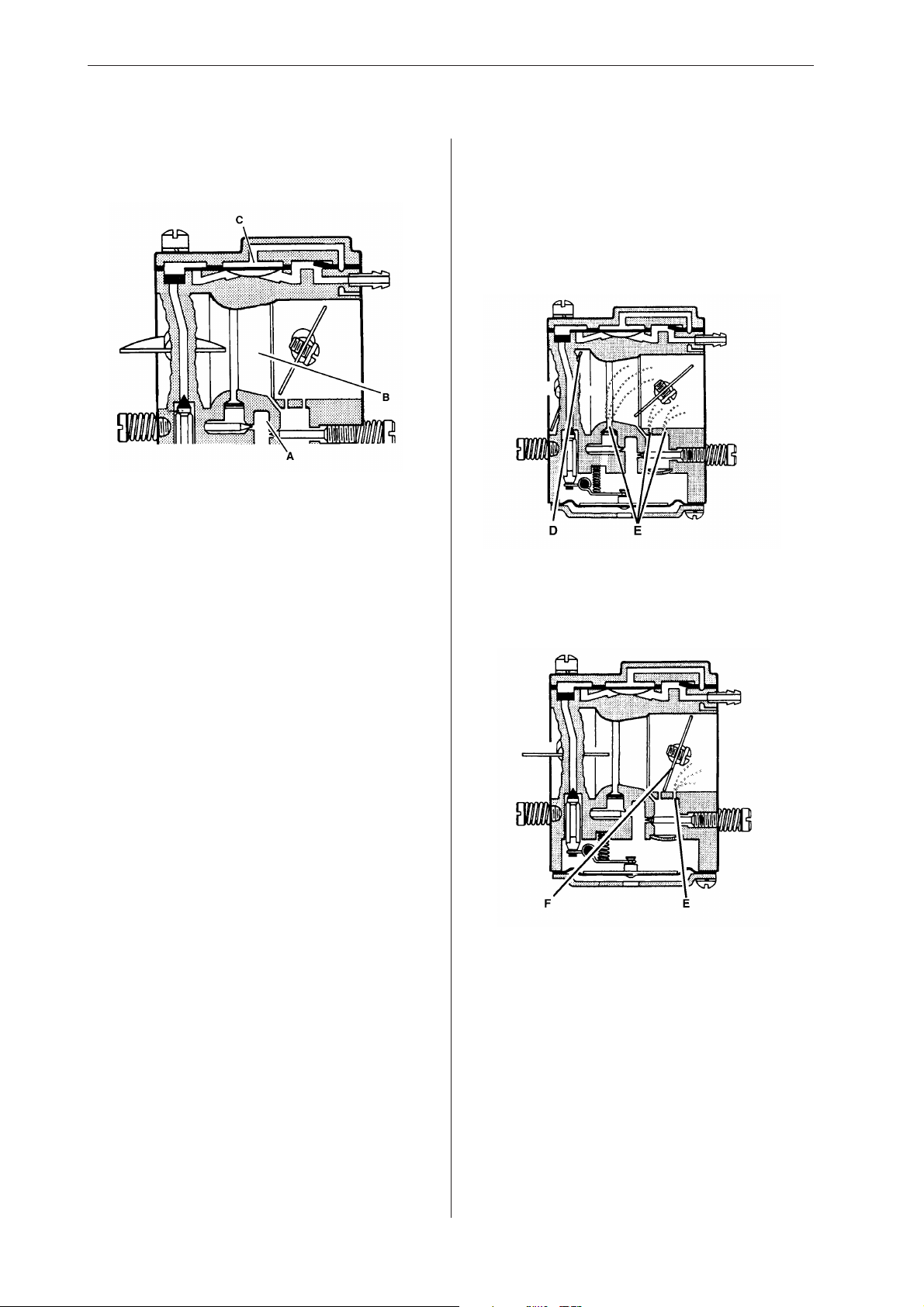

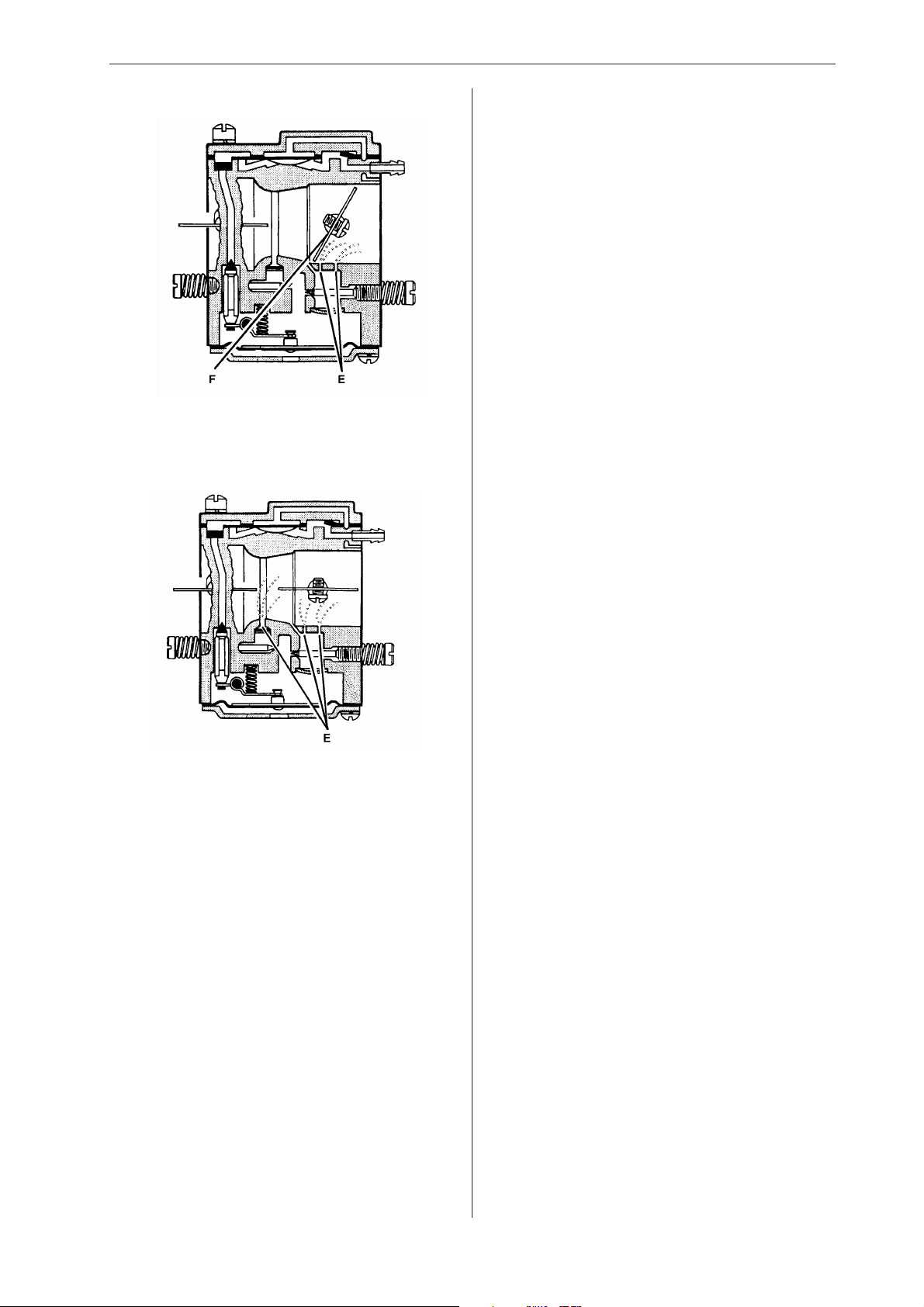

The carburettor consists of three sub-systems:

• The metering unit (A) which contains the jets

and the fuel control mechanism. This measures

out the right amount of fuel to suit the speed of

the saw and the power demand.

• The mixing unit (B) consists of the choke,

diffuser jets and throttle valve. This is where the

air and fuel are mixed to create a flammable

mixture.

The carburettor works in different ways depending

on the setting:

• Cold start mode

• Idling mode

• Part throttle mode

• Full throttle mode

In the cold start mode the choke valve (D) is

completely closed. This increases the vacuum in

the carburettor so that fuel is sucked through the

diffuser jets faster (E).

• The pump unit (C) pumps fuel from the tank to

the metering system inside the carburettor. One

side of the pump diaphragm is connected to the

crankcase and pulses as a result of pressure

changes in the crankcase. The other side of the

diaphragm sucks in the fuel.

In idling mode the throttle valve (F) is closed. Air is

sucked through an aperture in the throttle valve

and a small amount of fuel is supplied through the

diffuser jet (E).

8 – English

Page 10

In part throttle mode the throttle valve (F) is partially open. Fuel is supplied through the diffuser jets

(E).

Construction and function

In full throttle mode both valves are open and fuel

is supplied through all the diffuser jets (E).

English – 9

Page 11

Troubleshooting

The various faults that can affect a chainsaw are divided into four groups. In each group the likely symptoms are given on the left and possible causes are listed on the right. The most likely faults are given first,

and so on.

Starting

Difficulty starting

Carburettor

leaking fuel

Flooding when

engine not

running

Idling (low rpm)

Will not idle

Idling too rich

Adjust L screw

Air filter blocked

Choke not working

Worn choke pivot

Worn choke valve

Fuel filter blocked

Fuel line blocked

Piston ring seized

Blocked impulse channel

Loose or faulty fuel pipe

Hole in diaphragm

Worn needle valve

Needle valve assembly sticking

Needle valve set too high

Leak in metering system (air

or fuel)

Loose cover on carburettor

pump side

Worn needle valve

Needle valve set too high

Needle valve assembly sticking

Adjust L screw

Leaking air intake hose

(rubber)

Loose carburettor mounting

bolts

Loose or faulty fuel hose

Fuel filter blocked

Fuel line blocked

Fuel tank vent blocked

Throttle valve pivot stiff

Throttle pushrod sticking

Defective throttle return spring

Bent throttle stop

Faulty diffuser jet

Adjust L screw

Worn needle valve

Needle valve set too high

Worn needle valve lever

Leaking control diaphragm/

cover plate

Needle valve assembly

sticking

Idling (low rpm) (cont.)

Idles when L

screw closed

Idling uneven

L screw requires

constant

adjustment

Too much fuel at

idling

Worn needle valve

Leaking control diaphragm/

cover plate

Needle valve assembly sticking

Worn needle valve lever

Faulty diffuser jet

Fuel filter blocked

Fuel line blocked

Leaking air intake hose (rubber)

Loose carburettor mounting

bolts

Worn throttle valve pivot

Loose throttle valve screw

Worn throttle valve

Needle valve assembly

sticking

Leak in metering system (air

or fuel)

Metering system centre knob

is worn

Hole in diaphragm

Leaking control diaphragm/

cover plate

Crankcase leaking

Fuel line blocked

Needle valve set too high

Needle valve assembly sticking

Leak in metering system (air

or fuel)

Leaking control diaphragm/

cover plate

Faulty diffuser jets

Crankcase leaking

Needle valve set too high

Needle valve assembly sticking

Metering system damaged

Worn needle valve

Leaking control diaphragm/

cover plate

Metering system incorrectly

assembled

10 – English

Page 12

Troubleshooting

High rpm

Will not run at

full throttle

Low power

Will not “fourstroke”

Adjust H screw

Blocked air filter

Blocked fuel tank vent

Blocked fuel filter

Fuel line blocked

Loose or damaged fuel hose

Impulse channel leaking

Impulse channel blocked

Loose cover on carburettor pump

side

Faulty pump diaphragm

Leaking air intake hose (rubber)

Loose carburettor mounting bolts

Needle valve set too low

Metering system damaged

Metering system incorrectly

assembled

Leaking control diaphragm/cover

plate

Needle valve assembly sticking

Blocked silencer

Adjust H screw

Blocked fuel tank vent

Blocked fuel filter

Impulse channel leaking

Impulse channel blocked

Loose cover on carburettor pump

side

Faulty pump diaphragm

Blocked air filter

Needle valve assembly sticking

Leak in metering system (air or fuel)

Metering system incorrectly

assembled

Loose diaphragm rivet

Hole in diaphragm

Leaking control diaphragm/cover

plate

Blocked fuel tank vent

Blocked fuel filter

Fuel line blocked

Loose or damaged fuel hose

Impulse channel leaking

Impulse channel blocked

Loose cover on carburettor pump

side

Faulty pump diaphragm

Leaking air intake hose (rubber)

Loose carburettor mounting bolts

Needle valve set too low

Leak in metering system (air or fuel)

Metering unit incorrectly assembled

Loose diaphragm rivet

Hole in diaphragm

Leaking control diaphragm/cover

plate

Acceleration and retardation

Does not

accelerate

Engine stalls

when throttle

released

Over rich

acceleration

Adjust L screw

Adjust H screw

Blocked air filter

Blocked fuel tank vent

Blocked fuel filter

Fuel line blocked

Loose or damaged fuel hose

Impulse channel blocked

Loose cover on carburettor pump

side

Faulty pump diaphragm

Leaking air intake hose (rubber)

Loose carburettor mounting bolts

Needle valve set too low

Metering system incorrectly

assembled

Needle valve assembly sticking

Faulty diffuser jets

Blocked silencer

Adjust L screw

Adjust H screw

Faulty pump diaphragm

Needle valve set too high

Needle valve assembly sticking

Faulty diffuser jets

Adjust L screw

Adjust H screw

Blocked air filter

Faulty pump diaphragm

Faulty diffuser jets

Troubleshooting methods

In addition to the faults described in the above

table, trouble shooting can be carried out on

specific components or sub-systems of the

chainsaw. The various procedures are described in

the relevant chapters, see the contents page, as

follows:

• Checking the operation of the chain brake

• Measuring the resistance of the stop plate

• Pressure testing the carburettor

• Pressure testing the decompression valve

• Pressure testing the cylinder

English – 11

Page 13

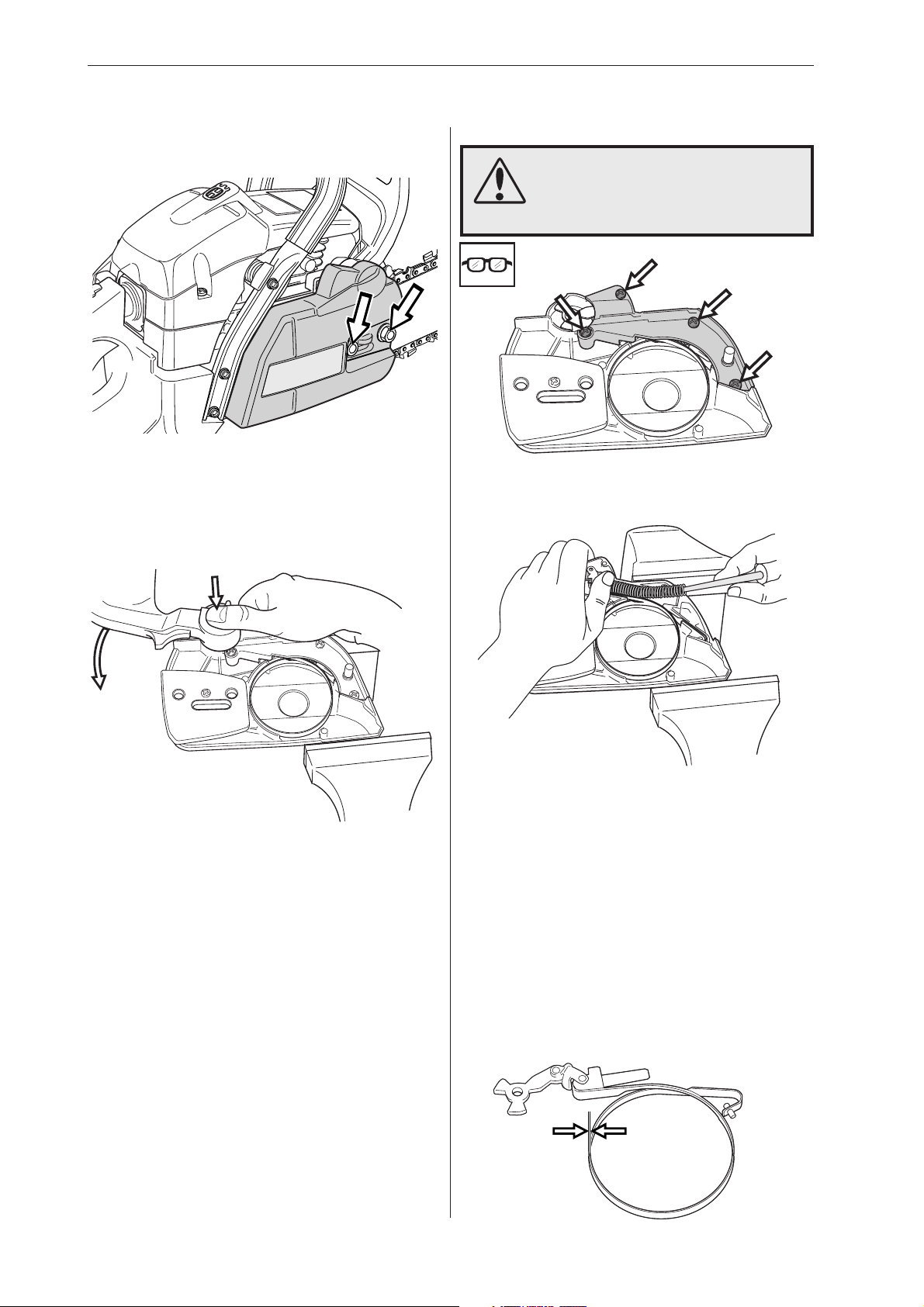

Chain brake – dismantling

Repair instructions

3

1

Disengage the brake by pushing the kickback

guard backwards. Unscrew the guide bar bolts and

remove the clutch cover, chain and guide bar.

2

WARNING!

Make sure the spring does not fly

out and cause injury. Wear eye

protection.

Remove the screws and carefully remove the cover

from the chain brake spring.

4

Grip the clutch cover carefully in a vice. Release

the brake spring by using the kickback guard from

the saw as a tool. Engage it with the brake mechanism and turn anticlockwise to activate the brake.

Place one hand over the spring and insert a small

screwdriver between the bottom end of the spring

and the clutch cover. Carefully prise the spring

upwards so that it slides onto the screwdriver shaft.

Cleaning and inspection

• Clean and inspect all parts carefully. If there are

any cracks or other defects replace the damaged

parts with new ones. Always use original parts.

• Measure the thickness of the chain brake band.

It must be no less than 0.6 mm at any point.

• Lubricate the elbow joint with grease.

min 0,6 mm

12 – English

Page 14

Repair instructions

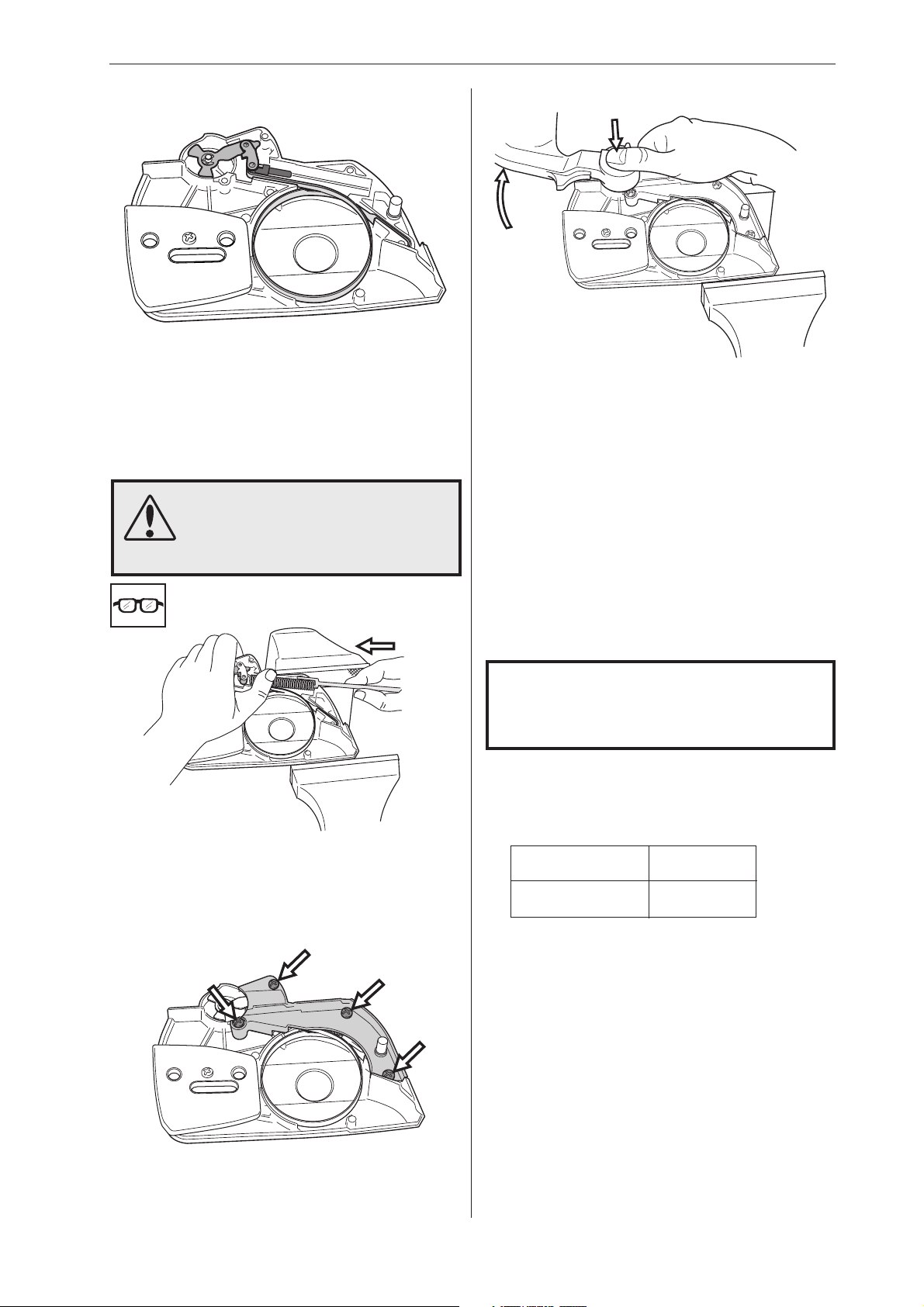

Chain brake – reassembly

1

Bolt the elbow joint to the brake band and tighten

to a torque of 1–1.5 Nm.

Locate the elbow joint and connected brake band

in their recesses in the clutch cover. Lubricate the

recess for the spring with grease.

2

WARNING!

Make sure the spring does not fly

out and cause injury. Wear eye

protection.

4

Tension the brake spring by using the kickback

guard from the saw as a tool. Engage it with the

brake mechanism and turn clockwise to release

the brake.

5

Turn the chain tensioner anticlockwise as far as it

will go.

Refit:

• guide bar

Grip the clutch cover in a vice. Compress the

spring with special tool 502 50 67-01 and push it

down with your thumb.

3

• chain

• clutch cover

NOTE!

After completing the repair the chain

brake must be tested as described below.

Operating test:

The engine must not be running during the test.

Guide bar length Height

38cm/15" 50 cm/20"

• Hold the chainsaw over a firm surface. The

height of the guide bar above the surface is

given in the table above.

• Let go of the front handle and let the chainsaw

fall towards the surface.

• When the guide bar hits the surface the chain

brake must engage.

Fit the cover over the chain brake spring, tightening

the screws to a torque of 1–1.5 Nm.

English – 13

Page 15

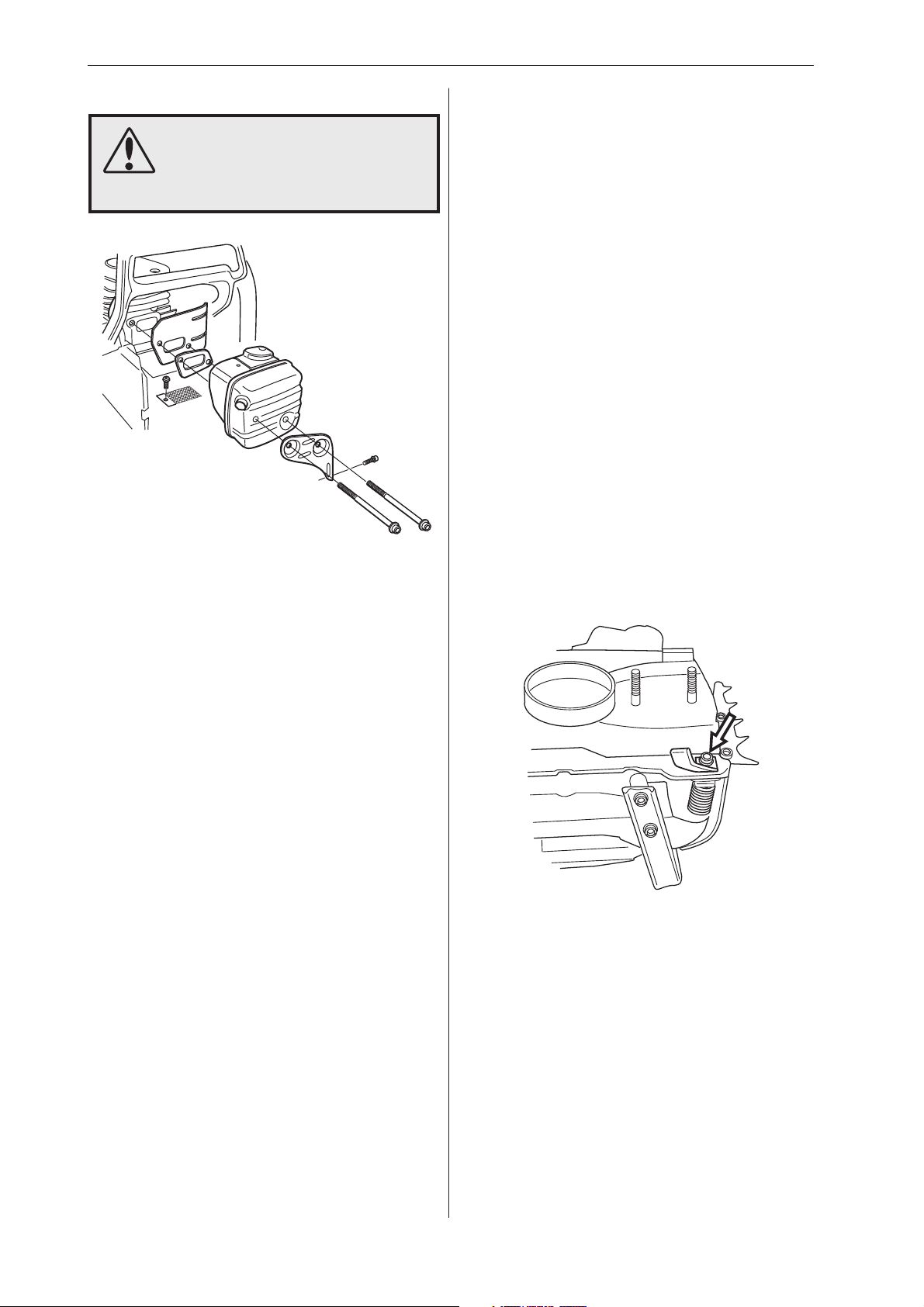

Repair instructions

Silencer – removal

WARNING!

Do not touch the silencer until it

has cooled down, otherwise you

may burn yourself.

1

Silencer – refitting

1

If the saw is equipped with a spark arrestor mesh

this should be fitted first.

2

Refit

• cooling plate

• gasket

• silencer, tighten bolts to a torque of 8–10 Nm.

• silencer support

• cylinder cover

3

Run the saw for at least 1 minute, then retighten

the silencer bolts to 8–10 Nm.

Chain catcher – replacement

If the chain catcher is worn it must be replaced with

a new one.

Remove the cylinder cover, silencer support,

silencer, gasket and cooling plate.

2

If the saw is fitted with a spark arrestor mesh this

must also be removed.

Cleaning and inspection

Clean and inspect all parts carefully. If there are

any cracks or other defects replace the damaged

parts with new ones.

The spark arrestor mesh is best cleaned with a

wire brush. If the mesh is damaged it must be

replaced.

If the mesh is blocked the saw will overheat and

this will cause damage to cylinder and piston.

Never use the saw with a silencer that is in poor

condition. Always use original parts.

1

Release the brake by pushing the kickback guard

backwards. Undo the guide bar bolts and remove

the clutch cover, chain and guide bar.

2

Remove the chain catcher and replace it with a

new one. Check that the vibration damping spring

locates correctly against the crankcase when you

bolt the new chain catcher in position.

A worn (damaged) chain catcher on 340, 345 or

350 can be replaced with the same chain catcher

as 346XP, 351 and 353 (see figure above).

14 – English

3

Turn the chain tensioner anticlockwise as far as it

will go.

Refit:

• guide bar

• chain

• clutch cover

Page 16

Repair instructions

Stop switch – removal

1

Remove the cylinder cover and air filter.

2

Disconnect both leads from the stop plate and stop

switch. Remove the stop plate by carefully sliding it

over the lug on the front mounting.

3

Cleaning and inspection

Clean and inspect all parts carefully. If there are

any cracks or other defects replace the damaged

parts with new ones. Always use original parts.

Stop switch – resistance measurement

Clean the mating surfaces and check the resistance as follows:

Carefully prise the carburettor assembly off the lefthand rubber mounting using a small screwdriver.

4

Measure the resistance by connecting a multimeter

to the ignition coil. NOTE! The switch must be in

the “on” position to give the correct reading.

The resistance must not be higher than 0.2 ohm

when the switch is in the on position.

Carefully prise the stop switch’s upper mounting off

the air filter holder while lifting the switch to release

it from the lower mounting.

English – 15

Page 17

Repair instructions

Stop switch – refitting

1

Carefully press the new stop switch into place.

Check that the switch’s upper mounting clips over

the air filter holder.

2

Choke control – removal

1

Remove the cylinder cover, air filter and stop

switch. Disconnect the fuel hose from the carburettor.

NOTE!

Do not use knurled pliers to disconnect or

reconnect the fuel hose. This could

damage the hose and lead to leakage or

fracture.

A

2

C

B

Refit the stop plate. Engage the stop plate in the

front slot first then lift the rear edge onto the stop

switch. Slide the stop plate in as far as it will go.

3

Refit:

• the leads to the stop plate and stop switch

• air filter

• cylinder

Disconnect the pushrod from the carburettor by first

carefully prising up the spring over the end of the

rod, where it connects to the throttle lever (A). Then

press the throttle lever forwards (B) while pressing

the throttle pushrod backwards (C) and lifting it off

the lever. Withdraw the throttle pushrod from the

tank and lift it upwards without pulling it through the

rubber inlet manifold. Carefully release the carburettor assembly from the right-hand rubber mounting and lift it upwards.

3

16 – English

Compress the clip that holds the choke control to

the carburettor while pulling it out at the same time.

Disconnect the choke control from the air filter

holder.

Page 18

Repair instructions

Choke control – refitting

First reattach the choke control to the air filter, then

press it onto the carburettor so that the clips engage.

Then refit:

• stop switch

• carburettor into its rubber mountings

• throttle pushrod into the fuel tank and connect to

throttle lever.

• lift the spring arm over the throttle pushrod

• fuel hose to the carburettor

• air filter and cylinder cover

Throttle lock, throttle trigger and return

spring – removal

1

B

A

C

Cleaning and inspection

• Clean and inspect all parts carefully. If there are

any cracks or other defects replace the damaged

parts with new ones. Always use original parts.

• Lubricate the throttle lock with oil.

• Check that the spring is not broken and has not

lost its tension.

Throttle lock, throttle trigger and return

spring – refitting

1

A

Refit the return spring to the throttle trigger as

shown. Make sure the spring is correctly positioned

by engaging one end in the slot in the throttle

trigger (A).

Remove the throttle lock by pressing it to the left

(A) and carefully levering it up with a screwdriver

on the clutch side (B) of the saw to disengage the

lugs on either side of the throttle lock from the fuel

tank. When both lugs are clear of the tank, pull the

lock backwards (C).

2

A

B

C

Drive out the steel pin using a 2.5 mm/0.1" diameter drift (A). Push it out from the flywheel side of

the saw. Remove the throttle trigger by first pressing it towards the clutch side of the saw (B) until it

clicks, then towards the flywheel side until it clicks

again. Remove it from the tank and lift out the

return spring.

2

First insert the rear edge of the throttle trigger into

the tank. Then push/clip the front edge into the two

clips on the tank with the aid of a combination tool,

for example. Drive in the steel pin from the clutch

side. Use a 2.5 mm/0.1" diameter drift.

3

Then press down the return spring while pressing

the throttle lock forwards/upwards into the retaining

clip in the fuel tank until you hear a click. Release

the return spring in the throttle lock, then press the

lock down onto the tank.

4

Check the operation of the throttle lock by trying to

press the throttle trigger without pressing down the

throttle lock. Also check that the throttle lock and

throttle trigger return freely to their original positions when released.

English – 17

Page 19

Repair instructions

Hand grip heater on model 346XPG,

351G, 353G – removal

No heating or heating only in front hand grip

• Front hand grip – troubleshooting

1

Remove the three bolts that secure the cover over

the front hand grip. Disconnect the leads from the

switch and generator and measure the resistance of

the hand grip heater, which should be 3–4 ohm.

Replace the front hand grip if the resistance is higher.

2

2

Reconnect the lead and refit the hand grip cover

and cylinder cover.

• Switch – troubleshooting

1

Carefully free the switch and frame from the front

hand grip using a screwdriver.

2

Disconnect the leads from the switch and connect

a multimeter to it. The meter should read over

1000 ohm when the switch is in the “0” position.

The meter should read no higher than 0.1 ohm with

the switch in the “1” position. Replace the meter if

the readings are outside these limits.

Rear hand grip heater not working

• Rear hand grip heater – troubleshooting

1

Remove the cylinder cover, air filter and cover from

the rear hand grip.

2

Disconnect the red lead from the heater and

connect a multimeter between it and the black

earth lead that is bolted to the bottom of the

carburettor on the clutch side of the saw. The

meter should read 0.7–1.2 ohm. If the reading is

higher replace the heater element.

Reconnect the leads and refit the cover.

3

Push the switch back into place and reconnect the

leads.

4

Bolt the cover back onto the hand grip.

• Generator – troubleshooting

1

Remove the cylinder cover and cover from the

front hand grip. Disconnect the black lead from the

generator and connect a multimeter between it and

a clean area on the cylinder. The multimeter should

show a resistance of 0.9–1.3 ohm. If the reading is

higher or lower, replace the generator, see “Replacing the generator”.

3

Remove the air filter, throttle pushrod, rubber

diaphragm and carburettor, see “Carburettor –

removal”.

4

Remove the bolt from the plate at the base of the

carburettor to release the lead for the heater

element.

5

Unscrew the three bolts from the front hand grip

and remove the cover to reveal the leads. Disconnect the red lead.

18 – English

Page 20

Repair instructions

6

Unscrew the two bolts from the right side of the

rear hand grip. Remove the throttle lock and

throttle handle, see “Throttle trigger”. Pull out the

heater element with the leads still connected.

Rear handle heater

Measure the resistance between F and Z. It should

be 1 ± 0.5 ohm.

If not, replace the rear handle heater.

Generator

Measure the resistance between G and H. It

should be between 0.3–1.3 ohm.

If not, replace the generator.

Carburettor heater

Disconnect the lead at X and clean the connectors.

Measure the resistance between X and G.

The reading should be between 3–10 ohms. If not,

disconnect the lead at Y and clean the connectors.

Measure the resistance between X and Y, if the

reading is not between 3–7 ohms – replace the

carburettor heater.

O

O

Z

Z

5

N

N

5

Troubleshooting carburettor heater

(346XPG, 351G, 353G)

Operation

The carburettor temperature is controlled by an

electronic thermostat to eliminate the risk of ice

formation in the carburettor. The thermostat

switches on/off at 12°C/54F. This means that the

saw operator does not need to remember to switch

the carburettor heater on or off.

• Troubleshooting

Front handle heater

Remove the side cover from the handle. Disconnect the leads at F and G (see diagram).

Clean the connectors. Turn the switch ”on”.

Measure the resistance between F and G.

The reading should be 4±1 ohms. If not, disconnect the lead at O and remove the switch.

Measure the resistance between O and F. The

reading should be 4±1 ohms. If the resistance is

incorrect, replace the front handle.

Disconnect the lead at N and G and measure the

resistance between these points. The reading

should be no higher than 0.1 ohm. If it is too high,

replace the lead.

F

F

G

G

K

K

V

V

Y

Y

3

3

X

X

4

4

1

1

H

H

Switch

Measure the resistance between N and O with the

switch turned off. The reading should be 1 000

ohms or higher.

Repeat the measurement with the switch turned

on. The reading should be no higher than 0.1 ohm.

If it is too high, replace the switch.

English – 19

Page 21

Repair instructions

Heater element and rear hand grip –

removal

1

Remove the cylinder cover, hand grip cover, hand

grip and right-hand stop.

Then remove:

• throttle lock, throttle trigger and recoil spring,

see “Throttle trigger”.

• fuel hose and throttle pushrod from the carburettor

Unbolt the rear tank mounting from the crankcase,

i.e. the rear vibration damping spring, and both

stops. Lower the tank as far as it will go to allow

access to the heater lead where it is connected to

the tank.

Refit:

• fuel tank with both stops and the rear vibration

damping spring

• throttle lock, throttle trigger and recoil spring,

see “Throttle trigger”.

• fuel hose and throttle pushrod to the carburettor

(check that the hose is not trapped between the

tank and crankcase, measurement 43 mm/1.69

inches)

• hand grip cover, air filter and cylinder cover

Hand grip heater on model 346XPG,

351G, 353G – refitting

1

Feed the leads into the rear hand grip and insert

the heater element in the hand grip. Screw in the

two bolts through the right side of the hand grip to

secure the heater.

2

Press the black lead into the base of the carburettor and connect it with the bolt.

Tighten to a torque of 3–4 Nm.

3

Run the red lead to the front hand grip and connect

it.

4

Press the throttle trigger and throttle lock into

position and check that they work correctly, see

“Throttle trigger”.

Heater element and rear hand grip –

removal

1

Screw the heater element into place using the two

screws and feed the leads through the rear hand

grip. Secure the red lead in the clip on the tank and

connect it. Feed the black lead through crankcase

and secure/earth it to the base of the carburettor

using the bolt at the front on the clutch side of the

saw. Tighten to a torque of 3–4 Nm.

2

Refit:

• fuel tank with both stops and the rear vibration

damping spring

• throttle lock, throttle trigger and recoil spring,

see “Throttle trigger”.

• fuel hose and throttle pushrod to the carburettor

(check that the hose is not trapped between the

tank and crankcase, measurement 43 mm/1.69

inches)

• hand grip cover, air filter and cylinder cover

5

Bolt the vibration damping springs that hold the

tank unit back in place and refit the cover over the

front hand grip.

20 – English

Page 22

Repair instructions

Starter assembly – removal

1

Undo the four bolts that fasten the starter assembly

to the crankcase and lift off the starter assembly.

2

Pull out about 30 cm of the cord and fasten it in the

notch in the pulley rim. Release the tension in the

return spring by letting the pulley wind backwards

slowly.

Replacing a broken or worn starter cord

1

Before replacing a worn starter cord the tension in the

recoil spring must be released. Pull the starter cord out

through the notch in the pulley rim and wind the pulley

anti-clockwise to release the tension in the spring.

2

Remove the bolt from the centre of the pulley and

lift off the pulley.

3

3

WARNING!

If the recoil spring is still under

tension when the pulley is removed it can fly out and cause injury. Wear eye protection.

Remove the bolt from the centre of the pulley and

lift off the pulley.

Cleaning and inspection

Clean the parts and check the following:

• The starter cord.

• The teeth on the pulley, lubricate with oil.

• That the pawls on the flywheel are undamaged,

i.e. that they spring back towards the centre and

move freely.

Fit a new cord through the hole in the pulley and tie

a knot to secure it. Feed the other end of the cord

through the hole in the starter housing and through

the starter handle, then tie a double knot in the

end. Wind about 3 turns of the starter cord onto the

pulley. Fit the bolt through the centre of the pulley

and tighten to a torque of 2–3 Nm.

• Lubricate the return spring with light oil.

English – 21

Page 23

Repair instructions

Cleaning and inspection:

• Clean and inspect all parts carefully. If there are

any cracks or other defects replace the damaged parts with new ones. Lubricate the return

spring with light oil.

Replacing a worn recoil spring

WARNING!

Make sure the recoil spring does

not fly out and cause injury. Wear

eye protection.

1

Remove the bolt from the centre of the pulley and

lift off the pulley and spring.

2

Remove the broken recoil spring.

3

Fit the bolt through the centre of the pulley and

tighten to a torque of 2–3 Nm.

Tension the recoil spring, see “Tensioning the recoil

spring”.

Tensioning the recoil spring

1

Fasten the starter cord in the notch in the pulley

rim and wind the pulley about 2 turns clockwise.

Check that the pulley is free to rotate at least

another half turn when the starter cord is fully

extended.

Starter assembly – refitting

1

Position the starter assembly on the crankcase and

tighten the bolts to a torque of 2.5–3.5 Nm.

22 – English

Page 24

Repair instructions

Ignition module – testing

If there is a fault in the ignition system the ignition

module must be tested before the ignition system

is removed.

Test the ignition module as follows:

• Connect a test spark plug 502 71 13-01 to the

ignition lead and clip the test spark plug onto the

cylinder.

• Turn the engine over using the starter cord.

2

If replacing the ignition module, disconnect its leads

and unscrew it. The ignition module can be left in

place if you are simply removing the flywheel.

3

• If the test spark plug produces a spark the

ignition module is OK.

Ignition module/flywheel – removal

1

Remove the cylinder cover. Disconnect the HT lead,

remove the spark plug and fit piston stop 502 54 1501 in its place. Take off the starter assembly, release

the leads from the cable guide and remove it.

Model 346XP, 351, 353:

Remove the cover from the hand grip.

Loosen the flywheel nut using a suitable socket and

unscrew it until it is flush with the end of the shaft.

4

Position puller 504 90 90-02 over the magnets and

counterweight on the flywheel. Tighten 2–3 turns

and tap the head of the puller with a metal mallet to

release the flywheel. Remove the puller, nut and

washer. Lift off the flywheel.

Cleaning and inspection

• Clean all parts, especially the tapers on the

flywheel and shaft.

• Check that the flywheel is not cracked or damaged in any other way.

English – 23

Page 25

Repair instructions

Replacing the generator, model 346XP,

351, 353

1

Remove the cylinder cover. Disconnect the HT lead,

remove the spark plug and fit piston stop 502 54 1501 in its place. Take off the starter assembly, release

the leads from the cable guide and remove it.

Remove the cover from the hand grip.

2

4

Remove the fuel hose and throttle pushrod from

the carburettor.

Unbolt the rear tank mounting from the crankcase,

i.e. the rear vibration damping spring, and both

stops. Lower the tank as far as it will go to allow

access to the heater lead where it is connected to

the tank.

5

Disconnect the generator lead from the hand grip

and unclip it from the tank. Remove the generator

and lead.

Generator – refitting

1

Feed the generator lead through the holes in the

crankcase and hand grip. Bolt the generator in

position, tightening the bolts to a torque of 5 Nm.

Clip the lead to the tank.

NOTE! The lead connector must be positioned on

the right of the clip, see diagram. Connect the lead

to the connector on the hand grip.

Loosen the flywheel nut using a suitable socket

and unscrew it until it is flush with the end of the

shaft.

Position puller 504 90 90-02 over the magnets and

counterweight on the flywheel. Tighten 2–3 turns

and tap the head of the puller with a metal mallet to

release the flywheel. Remove the puller, nut and

washer. Lift off the flywheel.

3

2

Refit:

• fuel tank with both stops and rear vibration

damping spring

• fuel hose to carburettor, hose length between

tank and crankcase: 43 mm/1.69 inches and

between crankcase and carburettor: 53 mm/2.09

inches

• throttle pushrod to carburettor

• flywheel with nut and washer

• cable guide, leads and starter assembly

Remove the piston stop and reconnect the HT lead

and cylinder cover.

Unscrew the two bolts from the generator but leave

the generator in place.

24 – English

Page 26

Repair instructions

0,3 mm

Ignition module and flywheel – refitting

1

Place the flywheel on the crankshaft. Turn the

flywheel so that the key lines up with the keyway in

the shaft.

Fit the washer and nut on the shaft and tighten to a

torque of 25-30 Nm.

2

3

Then refit:

• cable guide and press the leads into position

• HT lead

• starter assembly, tighten to a torque of 2.5–3.5

Nm

To refit the ignition module proceed as follows:

Turn the flywheel so that the magnets are in line

with the ignition module. Fit the ignition module

with the plastic feeler gauge (502 51 34-01) held in

position at the same time, without tightening the

bolts. Connect the black earth lead to the front

screw on the ignition module. Adjust the gap

between the ignition module and magnet to 0.3 +/-

0.1 mm. The gap must be measured at either of

the two lowest pegs on the ignition module.

Tighten the bolts to 4.5–6 Nm. Connect the blue

lead to the ignition module.

• cylinder cover

English – 25

Page 27

Repair instructions

Min 65mm

Centrifugal clutch – removal

1

Remove the cylinder cover. Disengage the chain

brake by pushing the kickback guard backwards.

Undo the guide bar bolts and remove the clutch

cover, chain and guide bar.

2

Disconnect the HT lead. Remove the spark plug

and fit piston stop 502 54 15-01 in its place.

Inspection and cleaning

• Clean and inspect all parts carefully. If there are

any cracks or other defects replace the damaged parts with new ones. Always use original

parts.

• Check the thickness of the clutch shoes by

using vernier callipers to measure the diameter

of the clutch. If the diameter is less than 65 mm

the clutch assembly must be replaced.

3

Unbolt the clutch using tool 502 54 16-01 and a

suitable socket or combination spanner. Turn the

nut clockwise to remove it.

4

NOTE!

Handle the clutch springs carefully. If they

are opened up too much they could

damage the saw.

Centrifugal clutch – refitting

1

NOTE!

Handle the clutch springs carefully. If they

are opened up too much they could

damage the saw.

Insert the clutch springs in the shoes using circlip

pliers.

Carefully prise out the clutch springs with a screwdriver.

26 – English

Page 28

Repair instructions

2

Fit the clutch onto the crankshaft and tighten

anticlockwise as far as it will go. Then tighten to a

torque of at least 20 Nm using tool 502 54 16-01

and a suitable socket or combination spanner.

3

Remove the piston stop. Fit the spark plug, tightening

it to a torque of 15 Nm, then connect the HT lead.

Then refit:

3

D

C

B

A

Unbolt and remove the clutch drum (A), RIM chain

sprocket (B) if fitted, needle bearing (C) and pump

drive wheel (D).

Model 350:

Remove the bolts on the anti-vibration elements on

the same side.

4

• cylinder cover

• guide bar

• chain

• clutch cover

Oil pump – removal 346XP, 350, 351,

353

1

Empty and clean the oil tank.

2

Unbolt the oil pump from the crankcase.

5

A

D

C

B

Remove the cylinder cover. Disengage the chain

brake by pushing the kickback guard backwards.

Undo the guide bar bolts and remove the clutch

cover, chain and guide bar. Disconnect the HT

lead. Remove the spark plug and fit piston stop

502 54 15-01 in its place. Unscrew the clutch

(clockwise) using clutch tool 502 54 16-01 and a

suitable socket spanner or combination spanner.

Remove the oil hose and filter (A).

Model 350:

Push the housing up a little from the fuel tank and

remove the filter (A) from underneath, see the

diagram under “Oil pump – removal 340, 345”.

English – 27

Page 29

Repair instructions

6

Remove the pin (B) from the adjuster screw, using

a small drift to press it out.

7

Press in the pump piston (C) so that the adjuster

screw (D) can be removed. Remove the pump

piston.

Oil pump – removal 340, 345

1-4

See ”Oil pump – removal, models 346XP, 350,

351, 353”, points 1-4.

Remove the bolts on the anti-vibration elements on

the same side.

5

Oil pump –refitting 346XP, 350, 351, 353

1

A

D

Lubricate the pump piston (C) with chain oil and fit

the pump piston and washers.

2

Press down the pump piston (C). Fit the adjuster

screw and spring so that the pin (B) can be

pressed into position.

C

B

Carefully lift out the oil pump from the crankcase.

6

Push the crankcase up a little from the fuel tank

and remove the filter (A) from underneath.

3

Reconnect the oil hose and filter (A).

Model 350:

Push the crankcase up a little from the fuel tank

and screw on the filter (A) from underneath.

WARNING!

Poor chain lubrication can result

in failure of the chain, which could

cause serious or fatal injury.

4

Cleaning and inspection

• Clean and inspect all parts carefully. If there are

any cracks or other defects replace the damaged

parts with new ones. Always use original parts.

• Lubricate all moving parts with chain oil.

28 – English

Bolt the oil pump to the crankcase. The adjustable

oil pump must be bolted to torque of 2–3 Nm.

Page 30

Repair instructions

5

Fit the chain guard plate, tightening the bolts to a

torque of 2–3 Nm.

Model 350:

Fit the bolts on the anti-vibration elements on the

same side.

6

D

C

B

A

Oil pump –refitting 340, 345

1

Lubricate the piston pump (C) with chain oil and fit

the pump piston.

2

Fit the pump. A round pin secures its position.

Lubricate the needle bearing with grease. Fit the

pump drive wheel (D), needle bearing (C), chain

sprocket (B), if fitted, and clutch drum (A).

7

Fit the clutch onto the crankshaft and tighten

anticlockwise as far as it will go. Then tighten to a

torque of at least 20 Nm using tool 502 54 16-01

and a suitable socket spanner or combination

spanner.

8

Remove the piston stop. Fit the spark plug, tightening it to a torque of 15 Nm, then connect the HT

lead. Then refit the cylinder cover, guide bar, chain

and clutch cover.

Push the crankcase up a little from the fuel tank

and screw on the filter (A) from underneath.

3

Fit the chain guide plate (one bolt), tightening

torque 2-3 Nm.

NOTE! Check that the chain tensioner is in position. Fit the bolts on the anti-vibration elements.

Note.

Models 340 and 345 have another type of chain

tensioner, which is adjusted from the side.

4

See ”Oil pump – Refitting, models 346XP, 350,

351, 353” pos. 6-9.

9

Refill the tank with oil. For more information see

the user instructions for this model for the recommended grade of oil.

English – 29

Page 31

Repair instructions

Adjustable oil pump – adjustment

346XP, 350, 351, 353

Use a screwdriver or adjustable spanner to turn the

adjuster screw on the pump. Turning the screw

clockwise decreases the oil flow and turning it anticlockwise increases the oil flow.

+

–

1

2

3

Recommended setting:

13–15" bar Min. setting

15–18" bar Midway setting

18–20" bar Max. setting

2

A

C

B

Disconnect the pushrod from the carburettor by

first carefully prising up the spring over the end of

the rod, where it connects to the throttle lever (A).

Then press the throttle lever forwards (B) while

pressing the throttle pushrod backwards (C) and

lifting it off the lever. Withdraw the throttle pushrod

from the tank and lift it upwards without pulling it

through the rubber inlet manifold. Carefully release

the carburettor assembly from the right-hand

rubber mounting and lift it upwards.

3

Carburettor – removal

1

NOTE!

Do not use knurled pliers to disconnect or

reconnect the fuel hose. This could

damage the hose and lead to leakage or

fracture.

Remove the cylinder and air filter. Disconnect the

leads from the stop switch and the fuel hose from

the carburettor.

Open the spring lock on the rubber bellows.

4

30 – English

Undo and remove the carburettor bolts. Lift off the

carburettor.

Page 32

Repair instructions

On saws with a carburettor heater 346XPG,

351G, 353G

Heating element

Remove the bracket’s two bolts above the carburettor. Disconnect the cable connections to the

carburettor heater and remove the heating element.

O

O

N

N

F

G

F

G

Z

Z

5

5

3

K

V

K

V

3

X

X

4

4

Carburettor – dismantling

The item numbers in the diagram refer to the steps

below (1–7).

1

Remove the cover from the metering unit and

carefully remove the metering diaphragm and

gasket.

2

Undo the screw and take out the needle valve,

together with the lever arm, spindle and spring.

Y

Y

1

1

H

H

When replacing the thermostat: Disconnect the

cable from X and V. Trouble shooting, see page

20.

On saws with carburettor 346XPG, 351G, 353G

Replacing the heating element: Lower the rear

section of the tank by removing the bolt between

the hand grip cover and vibration damping springs.

Remove the starter and then loosen the stop

screws on both sides (one is located under the

starter and this must be removed first). Now

disconnect the cable from X and Y.

Dismantling the carburettor: Loosen the high, low

and idling jet screws.

3

Remove the cover from the pump unit and carefully

remove the gasket and pump diaphragm.

4

Remove the fuel filter.

5

Remove the high, low and idling jet screws. (HDA

159A high and low jet screws are protected by

plastic caps which can be prised off with a screwdriver. Only on EPA, see appendix A.)

6

Remove the plug by first drilling a hole in it and

then prising it out with a screwdriver or the like.

7

If necessary remove the throttle and choke valves,

and remove the spindles together with the lever

arms and springs.

English – 31

Page 33

Repair instructions

Cleaning and inspection

Clean all the carburettor components in petrol. Use

an airline to dry off the petrol from all components.

Blow through all the channels in the carburettor

body and check that they are not blocked.

Check that:

• The gasket, pump diaphragm and metering

diaphragm are undamaged.

• There is no play in the throttle and choke valves.

• The needle valve and its lever arm are not worn.

• The fuel filter is undamaged.

• The tips of the high and low speed jet screws

are not damaged.

• The air intake duct is not cracked.

1

If the throttle and choke butterflies and their

spindles were removed, these must be refitted.

Lubricate the spindle bearings with light oil.

2

Insert the plug in the hole with the convex side

upwards and expand it by pressing downwards

with a drift.

3

Refit the high and low speed jet screws and

springs, plus the idling screw. Fit the plastic caps

over the high and low speed screws.

4

Fit the fuel filter, using the handle of a small screwdriver.

5

Fit the pump diaphragm, gasket and cover to the

pump unit.

6

Carburettor – reassembly

NOTE!

Cleanliness is very important when

reassembling the carburettor. Tiny particles of dirt can cause operating problems.

Fit the needle valve with lever arm, spindle and

spring and tighten the screw.

Use a rule to check that the lever arm is level with

the cover face. If necessary, the lever arm can be

bent slightly.

7

Fit the metering diaphragm with its gasket and refit

the cover to the metering unit.

8

Carry out pressure testing.

The item numbers in the diagram refer to the steps

below (1–8).

32 – English

Page 34

Repair instructions

Carburettor – pressure testing

Pressure testing should be carried out with the

carburettor fully assembled. Testing should always

be carried out after the carburettor has been

repaired, but can also be performed for troubleshooting before dismantling.

Carry out the test as follows:

• Screw in the high and low speed jet screws and

back them off one turn.

• Connect pressure tester 502 50 38-01 to the

carburettor fuel inlet.

Carburettor – refitting

NOTE!

Cleanliness is very important when reassembling the carburettor. Tiny particles of

dirt can cause operating problems.

1

• Lower the carburettor into a beaker of water.

• Pump up the pressure to 50 kPa (0.5 bar) and

clamp the pump tube.

• There should be no leakage. If leakage occurs,

refer to the table below.

Leakage Fault lies in

Diffuser jets Needle valve

In impulse tube Pump diaphragm

Ventilation hole above

metering unit Control diaphragm

Fit stop plate 502 54 17-01 between the carburettor flange and the insulating plate.

On saws with a carburettor heater

346XPG, 351G, 353G

Insert the heating element between the air filter

connection and carburettor as well as above the

carburettor. Route the cable as illustrated above.

Tighten the bracket above the carburettor with the

two bolts.

Connect the cables to the carburettor heater.

English – 33

Page 35

Repair instructions

2

Fit the carburettor. Screw in the carburettor bolts

directly from behind, without lifting the carburettor

assembly. Tighten to a torque of 1–1.5 Nm. It is

important to hold the carburettor flange while

tightening the bolts to prevent the inlet manifold

from moving.

3

5

Connect the leads to the stop switch.

Carburettor heater 346XP, 351, 353 –

Refitting

Heating element

Push the rear carburettor mounting into its rubber

bushing using a small screwdriver. Remove stop

plate 502 54 17-01.

4

Connect the fuel hose to the carburettor. Refit the

throttle pushrod at the same time as the rubber

inlet manifold, press in the throttle pushrod so that

it engages in the carburettor and fit the spring.

1

Fit the heating element between the air filter

connection and the carburettor as well as above

the carburettor.

2

Tighten the bracket above the carburettor using the

two bolts.

3

Connect the leads to the carburettor heater.

Refit:

• carburettor

34 – English

Page 36

Repair instructions

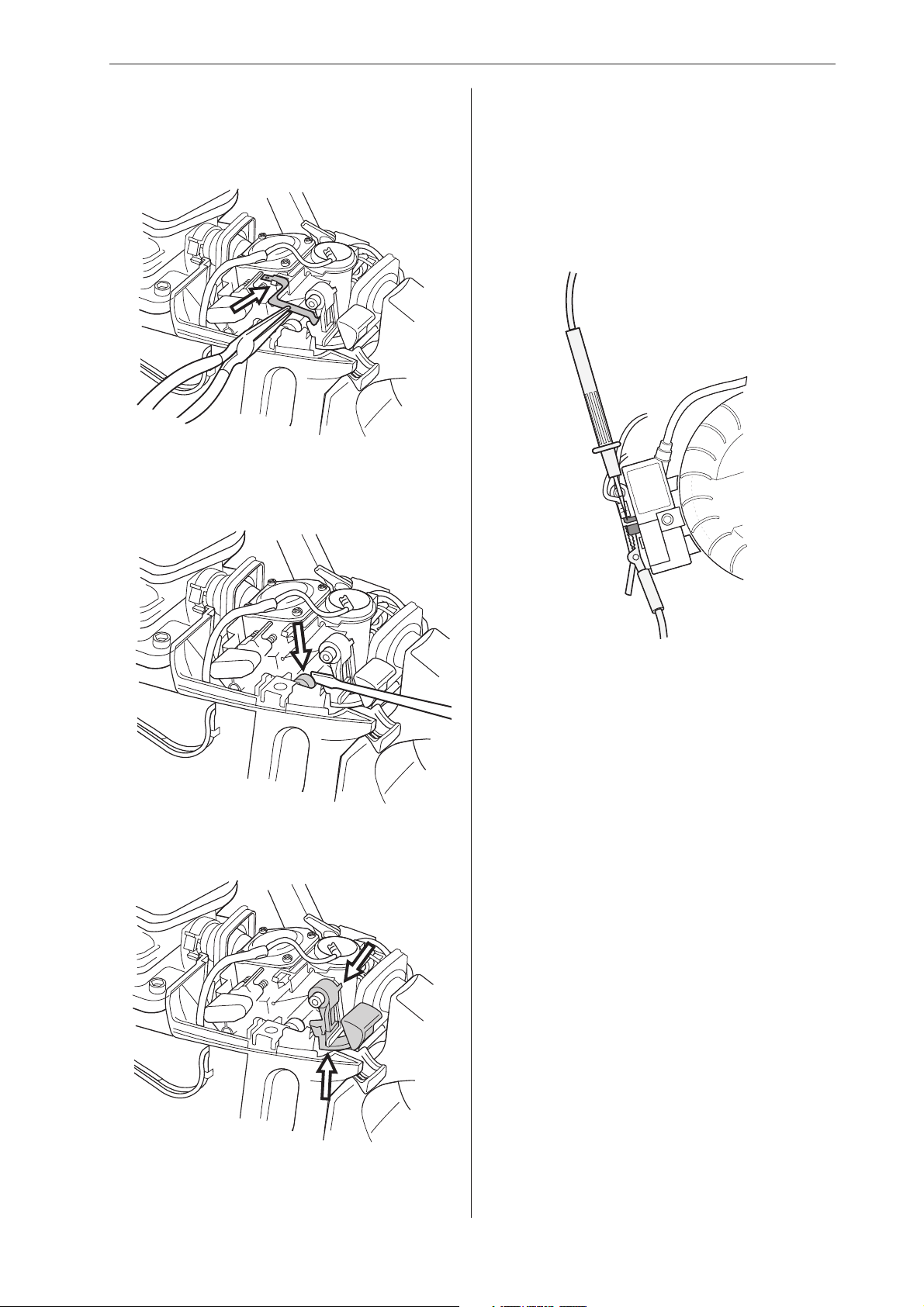

Air intake system – removal

The air intake system comprises:

• inlet manifold

• insulating plate with clip

• carburettor flange

• impulse hose

• support ring

1

Remove:

• cylinder cover

• air filter

• carburettor

• HT lead

• starter assembly (340, 345)

• Fuel tank (340, 345)

4

Unscrew the four cylinder bolts. Lift up the cylinder

so that the intake system insulating plate is free of

the crankcase.

2

Unbolt the vibration damping spring between the

cylinder and hand grip.

3

On models 340 and 345 there are cylinder bolts on

the underside.

5

Free the insulating plate from the cylinder by

releasing the clamp using pliers. Remove the

complete air intake system.

6

Remove:

• support ring

• carburettor flange from the inlet manifold

Unscrew and remove the bolt from the silencer

support.

• insulating plate

Cleaning and inspection

Clean and inspect all parts carefully. If there are

any cracks or other defects replace the damaged

parts with new ones. Always use original parts.

NOTE! When replacing the impulse hose it must

not be lubricated with oil or grease.

English – 35

Page 37

Repair instructions

Air intake system – refitting

1

AB

Fit the inlet manifold (A) through the insulating

plate in the carburettor flange cut-out (B), and

check that the insulating plate’s impulse tube sits

correctly in the inlet manifold. Fit the perforated

brass support ring in the inlet manifold.

2

4

Refit the carburettor. Screw in the carburettor bolts

directly from behind without lifting the carburettor

assembly, tightening to a torque of 1–1.5 Nm. It is

important to hold the carburettor flange securely

when tightening the bolts to prevent the inlet

manifold from moving.

4

Fit the air intake system on the cylinder and snap

the insulating plate into position. Check carefully

that the impulse tube is correctly seated against

the cylinder’s impulse channel.

3

Position tool 502 54 17-01 between the carburettor

flange and the insulating plate.

Push down the rear carburettor mounting into the

rubber bushings using a small screwdriver. Remove tool 502 54 17-01.

5

Refit:

• cylinder, see special instructions

• silencer support (does not apply to 340, 345,

350)

• air filter

• HT lead

• cylinder cover

• after the test run retighten the silencer bolts to a

torque of 8–10 Nm

36 – English

Page 38

Repair instructions

Carburettor – adjustment

For instructions on adjusting the EPA carburettor

see appendix A.

Adjusting the carburettor involves adjusting the

engine to the local conditions e.g. climate, altitude, fuel and type of two-stroke oil.

The carburettor is equipped with three adjustment

options.

L = Low speed jet

H = High speed jet

T = Idling adjustment screw

The L and H jets adjust the fuel flow to match the

airflow that the throttle valve opening allows.

Turning them clockwise makes the fuel/air mixture

weaker (less fuel in relation to the amount of air)

and turning them anti-clockwise makes the fuel/air

mixture richer. A weak mixture increases the

engine speed and a rich mixture decreases the

engine speed.

The T screw controls the throttle position when

idling. Turning the T screw clockwise gives faster

idling; turning it anti-clockwise lowers idling

speed.

WARNING!

The guide bar, chain and clutch

cover must be fitted before the

saw is started, otherwise the

clutch may fly off and cause injury.

Basic settings and running in

During testing at the factory the carburettor is

adjusted to the basic factory settings.

The factory settings are H = 1 turn and L = 1

turn.

To ensure that engine components receive

adequate lubrication (running in) the carburettor should be set to a somewhat richer fuel

mixture for the chainsaw’s first 3-4 running

hours. This is done by adjusting the maximum

speed to 6-700 rpm less than the recommended maximum speed.

If it is not possible to check the maximum speed

with a tachometer then the H jet should not be set

to a weaker mixture than the basic factory setting.

The recommended maximum speed must not be

exceeded.

NOTE!

If the chain turns at idling speed, the T

screw should be turned anti-clockwise

until the chain stops.

Fine adjustment

Once the chainsaw is “run in” the carburettor should

be readjusted. First adjust the L jet screw, then the

idling screw T and finally the H jet screw.

The recommended engine speeds are as follows:

Model Max revs Idle revs

340 12,500 rpm 2,700 rpm

345 12,500 rpm 2,700 rpm

346XP/G 14,200 rpm 2,700 rpm

350 13,000 rpm 2,700 rpm

350 EPA 13,000 rpm 2,700 rpm

351 13,000 rpm 2,700 rpm

353 13,000 rpm 2,700 rpm

Basic requirements

• Before making any adjustments the air filter

should be clean and the cylinder cover should be

in place. If the carburettor is adjusted with a dirty

air filter, the mixture will be too weak next time

the air filter is cleaned. This can cause serious

engine damage.

• Carefully screw in the L and H jets fully, then

back them off 1 turn. The carburettor now has the

settings H = 1 and L = 1.

• Start the chainsaw and allow it to warm up for 10

minutes.

• Place the saw on a flat surface so that the guide

bar is pointing away from you and the guide bar

and chain are not touching the surface.

Low speed jet L

• Find the highest idling speed by slowly screwing

the L screw in and then out again.

• When the highest speed has been found, screw

out the L screw 1/8 - 1/4 turn.

English – 37

Page 39

Repair instructions

Fine adjustment of idling speed T

• The idling speed is adjusted using the screw

marked T.

• If adjustment is necessary, screw in the idling

screw T until the chain starts to turn. Then screw it

out until the chain stops moving.

• The idling speed is correctly set when the engine

runs smoothly in all positions and there is a clear

margin to the speed at which the chain starts to

move.

High speed jet H

• The high speed jet H influences the saw power

output and engine speed. If the H jet is set too

weak the saw will over-rev, which could cause

engine damage.

• Run the saw at full throttle for about 10 seconds.

H=1.

• Then screw out the H screw 1/4 turn. H=1 1/4.

• Run the saw again at full throttle for about 10

seconds and listen to the difference in the engine

note. Repeat this procedure again with the H

screw screwed out another 1/4 turn. H=1 1/2.

• You have now run the saw at settings H ± 0, H =

+1/4 and H = +1/2 from the factory setting. At full

throttle the engine will sound different at each

setting.

• The H screw is correctly adjusted when the saw

“burbles” a little at full throttle without any load.

• If there is a lot of smoke from the silencer and the

saw does not run smoothly then the setting is too

rich.

• Screw in the H screw to the setting that sounds

right.

Fuel tank – removal

WARNING!

The fuel used in chainsaws is

harmful if inhaled, may cause

skin irritation and is highly flammable.

1

Empty the fuel tank.

2

Remove the following:

• cylinder cover

• air filter

• clutch cover

• chain and guide bar

• starter assembly

• cable guide

3

Disconnect the fuel hose from the carburettor.

4

A

C

B

NOTE!

For optimum adjustment, a tachometer

should be used. The recommended maximum speed should not be exceeded.

Carburettor – correct adjustment

• When the carburettor is correctly adjusted the saw

should accelerate without hesitation and the

engine will burble a little at full throttle without any

load.

• The chain must not turn when idling.

• If the L screw is set too weak this can make the

saw difficult to start and cause poor acceleration.

• If the H screw is set too weak the saw will produce

less power, poor acceleration and there is a risk of

engine damage.

• If either the L or H screws are set too rich it will

cause acceleration problems or too low working

speed.

38 – English

Disconnect the pushrod from the carburettor by

first carefully prising up the spring over the end of

the rod, where it connects to the throttle lever (A).

Then press the throttle lever forwards (B) while

pressing the throttle pushrod backwards (C) and

lifting it off the lever. Withdraw the throttle pushrod

from the tank and lift it upwards without pulling it

through the rubber inlet manifold.

Page 40

Repair instructions

5

Cleaning and inspection

Carefully check that:

• there are no leaks from the fuel tank

• there are no leaks from the tank filler cap

• the fuel hose is undamaged and free from wear

• the fuel filter is not clogged

• the tank vent is not blocked or leaking

• the vibration damping springs and stops are not

damaged

Replacing the fuel filter

NOTE!

Do not use knurled pliers to disconnect or

reconnect the fuel hose. This could

damage the hose and lead to leakage or

fracture.

1

First remove the old fuel filter from the tank unit

using special tool 502 50 83-01.

Unscrew both stops and the three vibration damping springs from the flywheel side and clutch side

of the engine.

6

Disconnect and remove the fuel hose from the

crankcase.

2

Pull the fuel hose out of the tank and pull off the

filter.

3

Fit the new fuel filter and feed the fuel hose back

into position.

Replacing the fuel hose

NOTE!

Do not use knurled pliers to disconnect or

reconnect the fuel hose. This could

damage the hose.

1

Before replacing the fuel hose, measure the length

of hose between the crankcase and carburettor

and between the tank and crankcase. The correct

hose length between the tank and crankcase is 43

mm (1.69 inches). The correct hose length between the crankcase and carburettor is 53 mm

(2.09 inches).

2

Remove the fuel hose from the fuel tank using tool

502 50 83-01. Trim off 5 mm (0.20 inches) from the

mitred end of the hose. Fit the fuel filter and

reinsert the hose in the tank.

English – 39

Page 41

Repair instructions

Tank vent – testing

1

Connect pressure gauge 502 50 38-01 to the fuel

hose. Pump the pressure up to 50 kPa (0.5 bar).

The pressure should drop to 20 kPa (0.2 bar)

within 60 seconds.

2

3

Fit the throttle pushrod in the tank and connect it to

the carburettor. Refit the spring.

4

A

C

B

Use gauge 502 50 37-01 to measure vacuum.

Readings should be as follows: the vacuum should

increase from 30 to 15 within 30 seconds. If

readings are outside this range the vyon plugs

must be replaced.

Fuel tank – refitting

1

Insert the fuel hose into the carburettor chamber.

Refit the fuel tank.

2

Bolt the front vibration damping spring into position, followed by both stops and the remaining two

vibration damping springs. Tighten to a torque of

2–3 Nm. Check that both vibration damping

springs and the stops are correctly seated on the

crankcase. Incorrect fitting may result in higher

vibration levels.

Connect the fuel hose to the carburettor. Check

that the hose is not kinked or too long to be

clamped between the crankcase and tank. The

correct hose length between the tank and crankcase is 43 mm (1.69 inches). The correct hose

length between the crankcase and carburettor is

53 mm (2.09 inches) excluding the mitred section.

5

Connect the fuel hose to the carburettor.

6

Then refit:

• cable guide

• starter assembly (2.5–3 Nm)

• chain and guide bar

• clutch cover

• air filter

• cylinder cover

40 – English

Page 42

Repair instructions

Piston and cylinder – removal

1

Remove:

• cylinder cover

• carburettor (see “Carburettor – removal”)

• silencer

• spark plug

• fuel tank (applies to 340, 345)

2

4

Cover the opening in the crankcase.

5

Remove the circlips from the ends of the gudgeon

pin and press it out. Then lift off the piston.

6

Unbolt the vibration damping spring from the hand

grip.

3

Undo the four cylinder bolts and lift the cylinder off

carefully.

Models 340, 345

Remove the bearing from the little end of the

connecting rod.

7

Undo the four cylinder bolts from the underside

and lift the cylinder off carefully.

If replacing the cylinder:

Unscrew the decompression valve. Remove the

intake system, see “Air intake system – removal”.

English – 41

Page 43

Repair instructions

8

When replacing the cylinder 340, 345:

Unscrew the decompression valve. (345)

Remove the intake system, see “Air intake system

– removal”.

Model 350 is fitted with a spacer, which is secured

using four bolts from the underside. The spacer

does not however need to be removed when

removing the cylinder.

• Measure piston ring wear. This should not

exceed 1 mm. Use the piston to push down the

piston ring.

• The needle roller bearing is undamaged.

• The inlet manifold is undamaged.

Cleaning and inspection

Clean all the components, scraping off all traces of

old gasket and carbon from the following places:

• Piston crown

• Top of the cylinder bore

• Cylinder exhaust port

• Decompression valve channel (340, 346XP,

350, 351, 353)

• Pressure test the decompression valve.

• Also refer to Jonsered’s Analysis guide for piston

failures, art. no. 108 07 01-01.

Decompression valve – pressure

testing

1

Connect tool 502 50 38-01 to the decompression

valve.

• Cylinder base and/or crankcase

Check the following:

• The surface coating of the cylinder is not worn

through, especially in the upper part of the

cylinder.

• The cylinder is free from score marks and areas

of wear.

• The piston is free from score marks. Small

scratches can be polished out with fine emery

paper.

• The piston ring is not burnt into its groove.

42 – English

2

Pump up the pressure to 80 kPa (0.8 bar).

3

Wait 30 seconds.

4

The pressure should not be less than 60 kPa

(0.6 bar).

Page 44

Repair instructions

Piston and cylinder – refitting 346XP,

350, 351, 353

1

Lubricate the little end bearing with two-stroke oil

and insert it in the connecting rod.

2

4

Press the insulating plate 503 86 62-01 onto the

cylinder. Check that the impulse tube connected to

the insulating plate is seated correctly in the inlet

manifold and lock the clamp over the manifold.

5

Lubricate the piston ring and piston with two-stroke

oil.

6

Fit the piston with the arrow pointing towards the

exhaust port. Push in the gudgeon pin and fit the