334T 338XPT

336 339XP

English

CONTENTS

Introduction .................................................... 3

Safety instructions ......................................... 4

Symbol explanation ....................................... 5

Technical Data ................................................6

Tools ................................................................ 8

Trouble shooting .......................................... 10

Service data 334T/338XPT ........................... 12

Service data 336/339XP ............................... 14

Safety equipment ......................................... 16

Starter............................................................ 23

Ignition system ............................................. 25

Centrifugal clutch ......................................... 27

Carburettor ................................................... 29

Tank unit ....................................................... 41

AV-System ..................................................... 46

Crankshaft, Piston and Cylinder................. 47

Bar bolt.......................................................... 51

Oil pump........................................................ 52

2 – English

INTRODUCTION

General

This Workshop Manual provides a comprehensive description

of how to trouble shoot, repair and test the chain saw. A

description of different safety measures that should be taken

during repair work is also given.

Safety

NOTE!

The section dealing with safety must be read and understood by all those carrying out repair work or service on

the chain saw.

Warning symbols can be found in this Workshop Manual and on

the chain saw. See the chapter "Symbol explanation". A new

decal must be applied as soon as possible if a warning symbol

on the chain saw has been damaged or is missing so that the

greatest possible safety can be obtained when using the chain

saw.

Target group

When producing this Workshop Manual the assumption has

been made that personnel who use it have general knowledge

in the repair and service of small engines.

The Workshop Manual must be read and understood by

personnel who will carry out repair work and service on the

chain saw. The Manual is also suitable for use when training

new employees.

Modifications

Modifications will be successively introduced on the chain saw

during production. When these modifications affect the service

and/or spare parts, separate service information will be sent out

on each occasion. This means that in time this Workshop

manual will become out of date. In order to prevent this, the

Manual should be read together with all service information

concerning the chain saw in question.

Tools

Special tools must be used during specific steps. All service

tools are listed in the Workshop Manual. Usage is evident from

respective sections.

Always use Husqvarna’s original:

• Spare parts

• Service tools

• Accessories

Layout

This Workshop Manual can be used in two different ways:

• For the repair of a particular system on the chain saw.

• For dismantling and assembly of the entire chain saw.

Repair of a particular system

When a particular system on the chain saw is to be repaired,

proceed as follows:

1. Look up the page for the system in question.

2. Carry out the sections:

• Dismantling

• Cleaning and Inspection

• Assembly

Dismantling and assembly of the

entire chain saw

Proceed as follows when the entire chain saw is to be dismantled and assembled:

1. Look up the chapter "Starter" which deals with the Starter

and carry out the instructions set out under Dismantling.

2. Work forward in the Manual and carry out Dismantling in

the order set out in the sections.

3. Go back to the chapter "Starter" and carry out the instructions under Cleaning and Inspection.

4. Work forward in the Manual and carry out Cleaning and

Inspection in the order set out in the sections.

5. Order or take out all requisite spare parts from the stores.

6. Look up the chapter "Oil pump" which deals with the Oil

pump and carry out the instructions set out under Assembly.

7. Work back towards the beginning of the Manual and carry

out Assembly in the order set out in the sections.

Some sections include a Description of the actual unit in order

to increase the basic understanding.

Numbering

Position references to components inside the figures are

designated A, B, etc.

The position references restart in each new section.

English – 3

SAFETY REGULATIONS

General instructions

The workshop where chain saw repairs are to be done must be

equipped with safety equipment as set out in local provisions.

No one may repair the chain saw unless they have read and

understood the content of this Workshop Manual.

This Workshop Manual contains the following boxes in relevant

places. Warning boxes are positioned before the procedures

they refer to.

WARNING!

The warning box warns of the risk of personal

injury if the instructions are not followed.

NOTE!

This box warns of material damage if the instructions are

not followed.

Special instructions

The fuel used in the chain saw has the following hazardous

properties:

• The fluid and its vapour are poisonous.

• Can cause skin irritation.

• Is highly inflammable.

The bar, chain and clutch cover (chain brake) must be fitted

before the saw is started otherwise the clutch can work loose

and cause personal injury.

Wear ear-muffs when test running.

Do not use the saw until it has been adjusted so that the chain

remains still when idling.

After test running, do not touch the muffler until it has cooled.

Risk for burns.

Insufficient chain lubrication can result in chain breakage, which

can cause serious, even life-threatening injury.

Ensure that the spring in the starter does not fly out and cause

personal injury.

If the spring tension is activated on the starter pulley when it is

to be taken up, the spring can fly out and cause personal injury.

Check that the brake is applied when removing the pressure

spring on the chain brake. Otherwise the pressure spring can fly

out and cause personal injury.

Do not direct the compressed air jet towards the body when

using compressed air. Air can penetrate in to the blood circulation, which means mortal danger.

4 – English

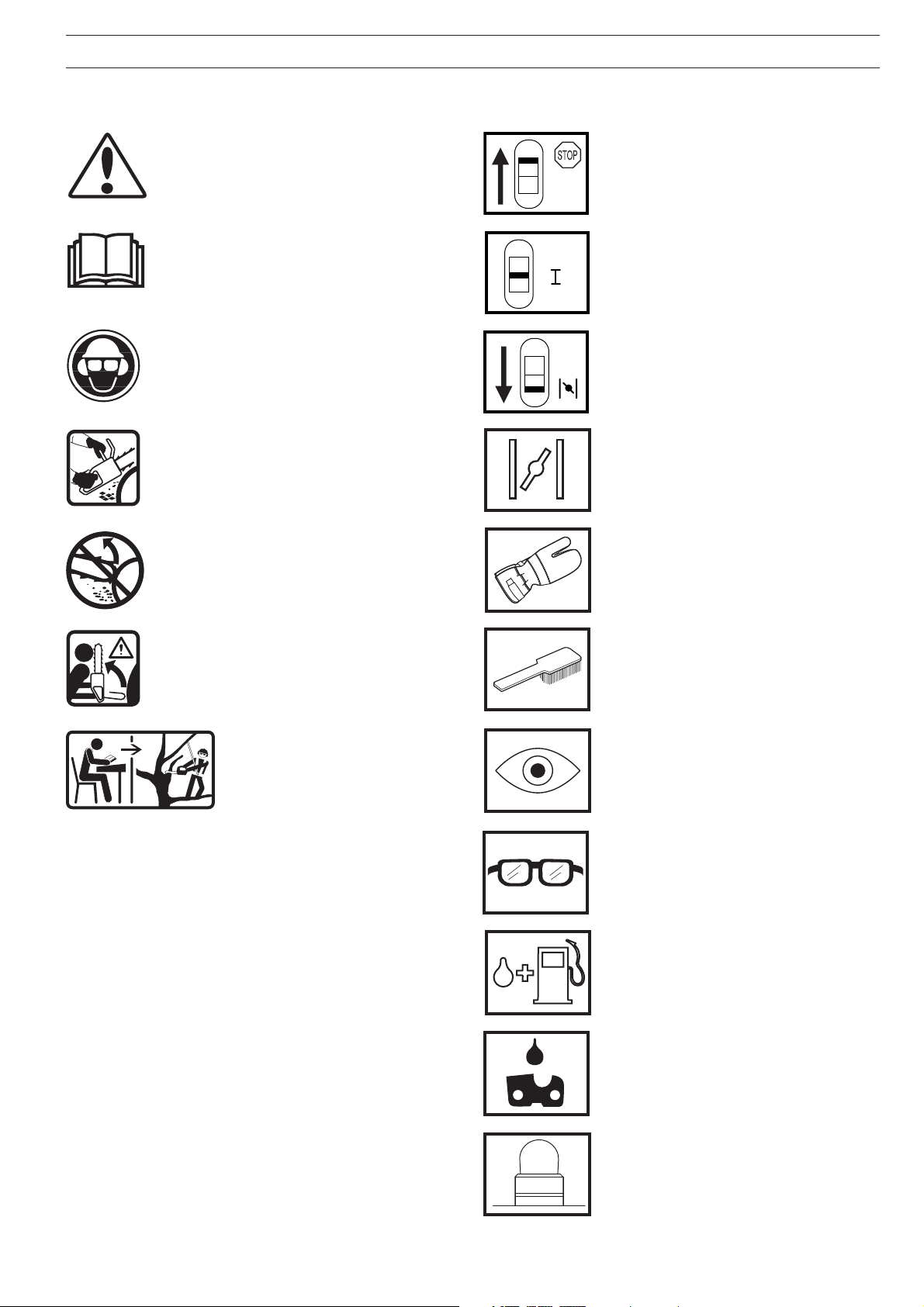

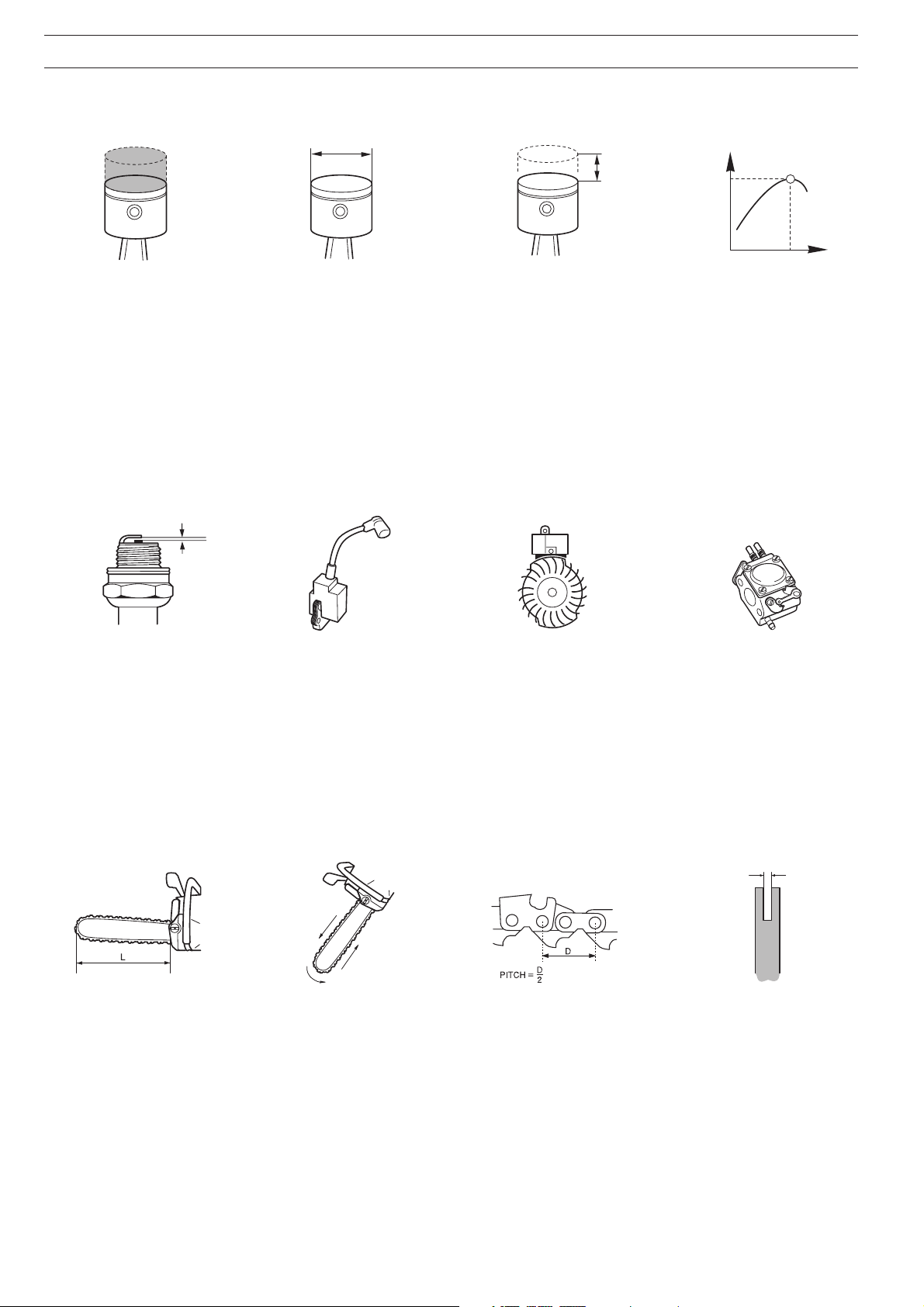

Symbols

SYMBOL EXPLANATION

WARNING! Chain saws can be dangerous!

Careless or incorrect usage can result in

serious injury even death to operator or

others.

Read through the Operator Guide carefully

and understand the content before using the

chain saw.

Always use:

• An approved safety helmet

• Approved ear-muffs

• Protective glasses or a visor

Always use both hands whenever possible

with all chain saw work.

Avoid contact between the tip of the bar and

objects.

Inspection and/or maintenance should be

carried out with the engine switched off,

and with the stop switch in the "STOP"

position.

Operating mode

Choke, 334T, 338XPT

Choke, 336, 339XP

Always wear approved protective gloves.

Contact with the tip of the bar can result in the

bar being suddenly thrown upwards and

backwards, which can result in serious injury.

This saw is only intended for

persons especially trained in tree

conservation. See the Operator

Guide!

Regular cleaning is required.

Visual inspection.

Protective glasses or visor must be worn.

Fuel refilling.

Oil refilling and adjustment of the oil flow.

Air purge

English – 5

TECHNICAL DATA

Stroke volume Cylinder diameter Stroke length Max. output/speed

3

/cubic inch Ø mm/Ø inch mm/inch kW/hp/r/min

cm

336: 35,2/2,1 38/1,5 31/1,22 1,5/2,0/9 600

334T: 35,2/2,1 38/1,5 31/1,22 1,5/2,0/9 600

338XPT: 39,0/2,4 40/1,6 31/1,22 1,7/2,3/9 600

339XP: 39,0/2,4 40/1,6 31/1,22 1,7/2,3/9 600

Electrode gap Ignition system Air gap Carburettor type

mm/inch mm/inch

336: 0,7/0,028 SEM/CD 0,3/0,01 ZAMA C1Q

334T: 0,7/0,028 SEM/CD 0,3/0,01 ZAMA C1Q

338XPT: 0,7/0,028 SEM/CD 0,3/0,01 ZAMA C1Q

339XP: 0,7/0,028 SEM/CD 0,3/0,01 ZAMA C1Q

Bar length Chain speed at Chain pitch Drive link

cm/inch m/s inch mm/inch

336: 33-46/13-18 18,3 3/8/0,0325 1,3/0,050

334T: 29-36/12-14 18,3 3/8 1,3/0,050

338XPT: 29-41/12-16 18,3 3/8 1,3/0,050

339XP: 33-46/13-18 18,3 0,0325 1,3/0,050

max output

6 – English

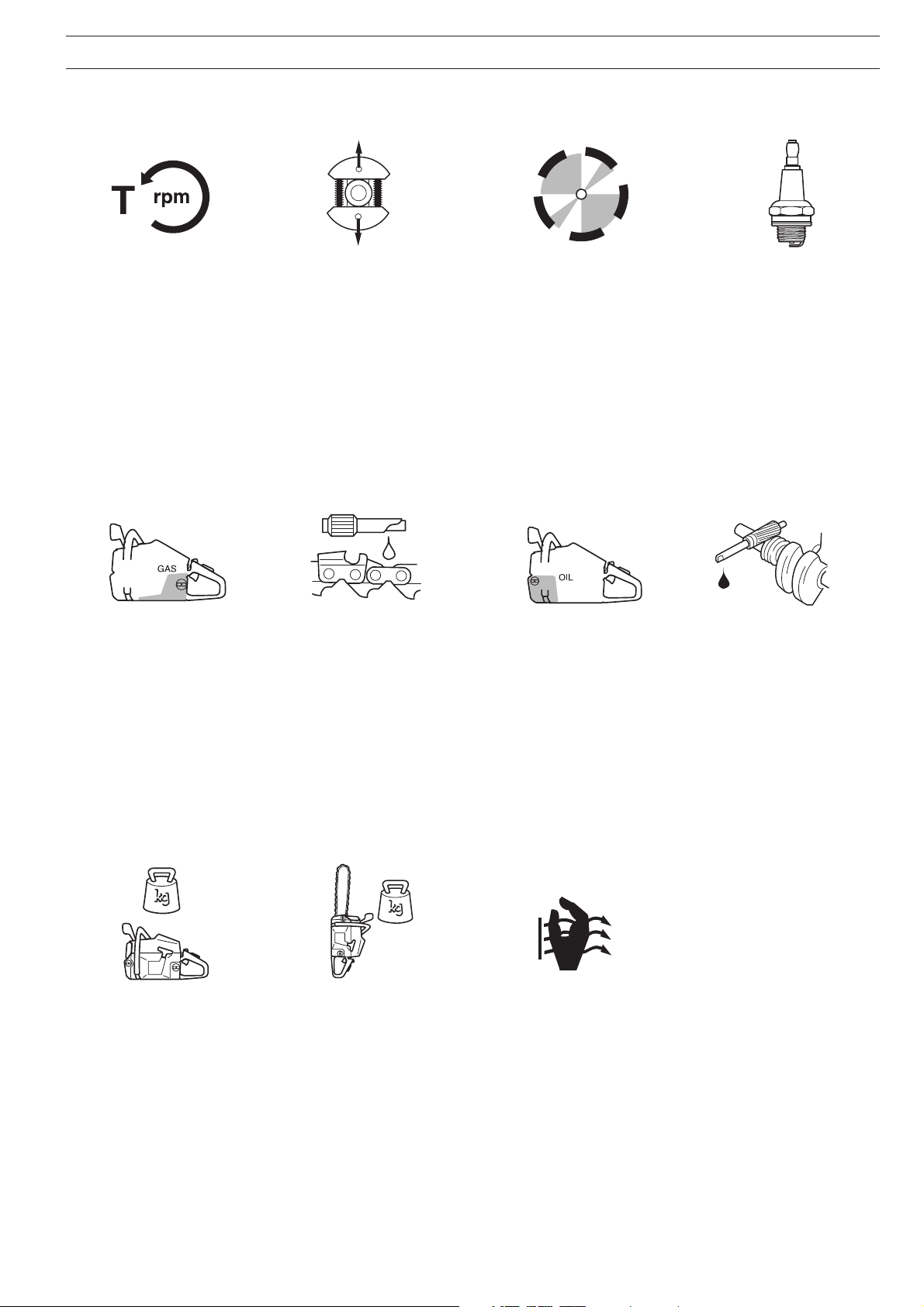

TECHNICAL DATA

Idling speed Engage speed Max. speed Spark plug

r/min r/min r/min

336: 2 800 4 100 13 800 Champion RCJ7Y

334T: 2 800 4 100 13 800 Champion RCJ7Y

338XPT: 2 800 4 100 13 800 Champion RCJ7Y

339XP: 2 800 4 100 13 800 Champion RCJ7Y

Volume fuel tank Capacity oil pump Volume oil tank Automatic oil pump

Litre/US pint cm

336: 0,36/0,76 3-7 0,20/0,42 Yes

334T: 0,3/0,63 3-7 0,16/0,34 Yes

338XPT: 0,3/0,63 3-7 0,16/0,34 Yes

339XP: 0,36/0,76 3-7 0,20/0,42 Yes

3

/min Litre/US pint

NGK BPMR 7A

NGK BPMR 7A

NGK BPMR 7A

NGK BPMR 7A

Weight without chain and bar Weight with chain and bar Handle heater

kg/lbs kg/lbs Watt/ r/min

336: 3,8/8,4 4,5/9,8 - / 334T: 3,4/7,5 4,0/8,8 - / 338XPT: 3,4/7,5 4,0/8,8 - / 339XP: 3,8/8,4 3,8/8,4 - / -

English – 7

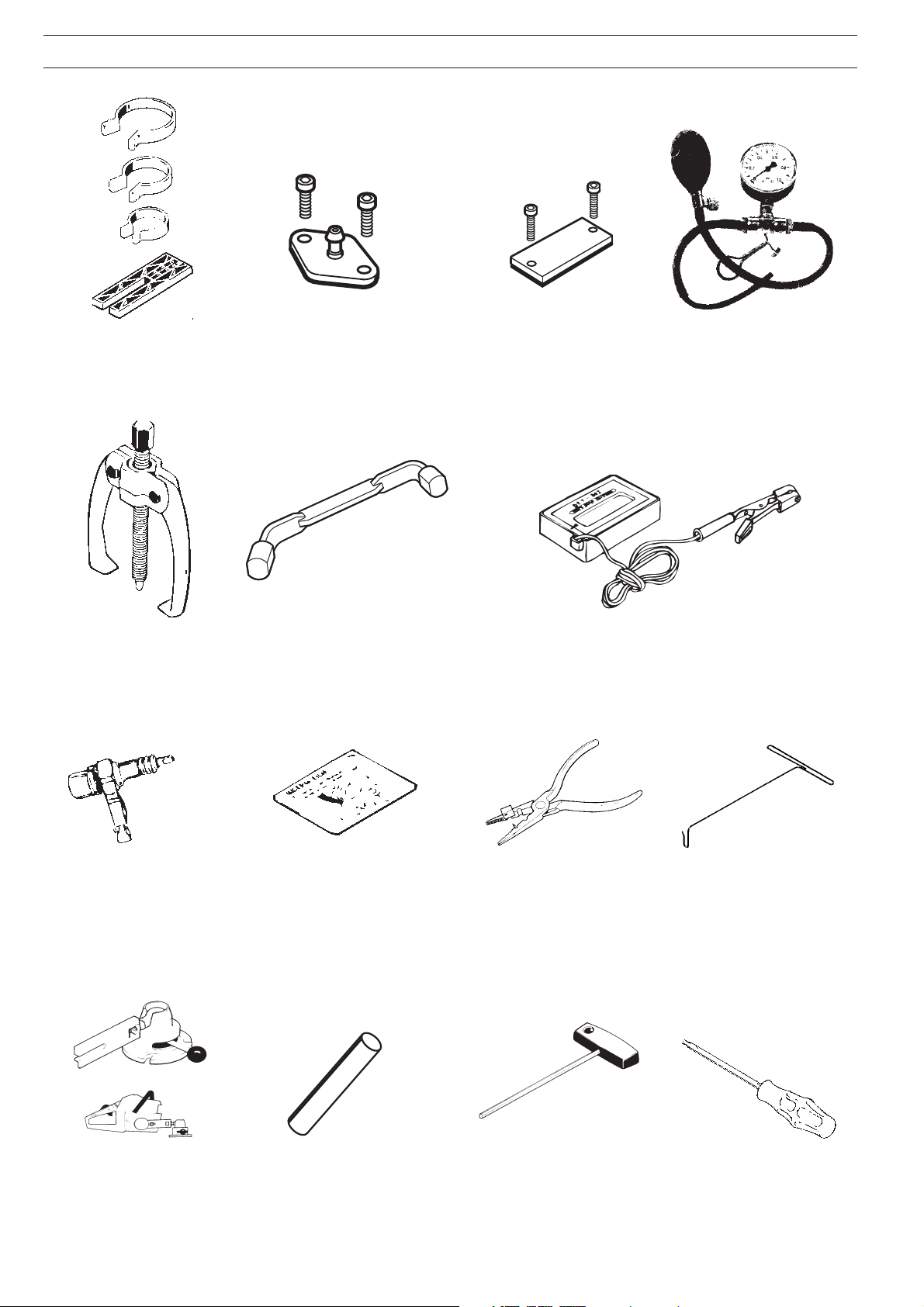

TOOLS

12 34

56 7

8 9 10 11

8 – English

12 13 14 15

TOOLS

The tools listed here are service tools intended for use on the

chain saw in question. In addition to these tools, a standard set

of hand tools is required.

Pos Description Used for Order No.

1 Piston assembly set Assembling the piston 502 50 70-01

2 Cover plate, inlet Sealing the inlet manifold 502 52 01-01

3 Cover plate exhaust Sealing the exhaust port 502 52 31-01

4 Pressure tester Produce pressure when leakage testing 502 50 38-01

5 Puller Removing bearings from the crankshaft 504 90 90-01

6 Piston stop Locking the crankshaft 502 54 15-01

7 Tachometer Adjusting the carburettor 502 71 14-01

8 Test spark plug Checking the ignition module 502 71 13-01

9 Feeler gauges, air gap Adjustment of the ignition module 502 51 34-02

10 Assembly bar Assembly of the spark plug guard 502 50 06-01

11 Hook for fuel filter Lifting out the fuel filter 502 50 83-01

12 Assembly fixture Assembling the chain saw 502 51 02-01

13 Punch Dismantling the flywheel 502 51 94-01

14 Allen key, 3 mm For M4 bolts 502 50 19-01

14 Allen key, 4 mm For M5 bolts 502 50 18-01

15 Hexagonal screwdriver, 3 mm For M4 bolts 502 50 86-01

15 Hexagonal screwdriver, 4 mm For M5 bolts 502 50 87-01

English – 9

TROUBLE SHOOTING

Trouble shooting chart

The different faults that can occur on the chain saw are divided

into four groups as follows. Within each group possible

operating faults are listed to the left while the probable fault

alternatives are listed to the right. The most likely fault is listed

first, etc.

Starting

Difficult to start

Carburettor leaks

fuel

Floods when the

engine is not running

Adjust the L-screw

Air filter blocked

Choke does not work

Worn choke axle

Worn choke valve

Blocked fuel filter

Blocked fuel line

Piston ring seized

Blocked impulse channel

Loose or faulty fuel pipe

Hole in diaphragm

Worn needle/needle tip

Control system sticking

Control system set too high

Leaking control system (air or fuel)

Cover on the carburettor’s pump side

is loose

Worn needle/needle tip

Control system set too high

Control system sticking

Idling (low speed) (continued)

Idling with closed L

screw

Uneven idling

L-screw needs

constant adjustment

Too much fuel while

idling

Worn needle/needle tip

Leaking diaphragm/cover plate

Control system sticking

Worn lever arm in the control system

Faulty diffuser jet

Blocked fuel filter

Blocked fuel line

Leaking inlet manifold (rubber)

Loose carburettor mounting

Worn throttle valve axle

Loose throttle valve screw

Worn throttle valve

Control system sticking

Leaking control system (air or fuel)

Control system’s centre knob is worn

Hole in diaphragm

Leaking diaphragm/cover plate

Leaking crankcase

Blocked fuel line

Control system set too high

Control system sticking

Leaking control system (air or fuel)

Leaking diaphragm/cover plate

Faulty diffuser jet

Leaking crankcase

Control system set too high

Control system sticking

Damaged control system

Worn needle/needle tip

Leaking diaphragm/cover plate

Incorrectly fitted control system

Idling (low speed)

Does not idle

Too rich idling

10 – English

Adjust the L-screw

Leaking inlet manifold (rubber)

Loose carburettor mounting

Loose or faulty fuel pipe

Blocked fuel filter

Blocked fuel line

Tank ventilator blocked

Throttle valve axle stiff

Throttle sticks

Defective throttle return spring

Bent valve axle stop

Faulty diffuser jet

Adjust the L screw

Worn needle/needle tip

Control system set too high

Worn lever arm in the control system

Leaking diaphragm/cover plate

Control system sticking

TROUBLE SHOOTING

High speed

Will not run at full

throttle

Low power

Adjust H-screw

Blocked air filter

Tank ventilator blocked

Blocked fuel filter

Blocked fuel line

Loose or faulty fuel pipe

Impulse channel leaking

Blocked impulse channel

Cover on the carburettor’s pump side

is loose

Faulty pump diaphragm

Leaking inlet manifold (rubber)

Loose carburettor mounting

Control system set too low

Damaged control system

Incorrectly fitted control system

Leaking diaphragm/cover plate

Control system sticking

Blocked muffler

Adjust H-screw

Tank ventilator blocked

Blocked fuel filter

Impulse channel leaking

Blocked impulse channel

Cover on the carburettor’s pump side

is loose

Faulty pump diaphragm

Blocked air filter

Control system sticking

Leaking control system (air or fuel)

Control system incorrectly assembled

Loose diaphragm

Hole in diaphragm

Leaking diaphragm/cover plate

Acceleration and retardation

Does not accelerate

Engine stalls when

throttle is released

Too rich acceleration

Adjust the L-screw

Adjust H-screw

Blocked air filter

Tank ventilator blocked

Blocked fuel filter

Blocked fuel line

Loose or faulty fuel pipe

Blocked impulse channel

Cover on the carburettor’s pump side

is loose

Faulty pump diaphragm

Leaking inlet manifold (rubber)

Loose carburettor mounting

Control system set too low

Incorrectly fitted control system

Control system sticking

Faulty diffuser jet

Blocked muffler

Adjust the L-screw

Adjust H-screw

Faulty pump diaphragm

Control system set too high

Control system sticking

Faulty diffuser jet

Adjust the L screw

Adjust H-screw

Blocked air filter

Faulty pump diaphragm

Faulty diffuser jet

Trouble shooting methods

Will not "four stroke"

Tank ventilator blocked

Blocked fuel filter

Blocked fuel line

Loose or faulty fuel pipe

Impulse channel leaking

Blocked impulse channel

Cover on the carburettor’s pump side

is loose

Faulty pump diaphragm

Leaking inlet manifold (rubber)

Loose carburettor mounting

Control system set too low

Leaking control system (air or fuel)

Control system incorrectly assembled

Loose diaphragm

Hole in diaphragm

Leaking diaphragm/cover plate

In addition to faults given in the above schematic, trouble

shooting can be carried out on a specific component or specific

chain saw system. The different procedures are described in

respective sections and are as follows:

1. Pressure testing the carburettor. See the chapter

"Carburettor".

2. Pressure testing the crankcase and cylinder. See the

chapter "Crankshaft, Piston and Cylinder".

English – 11

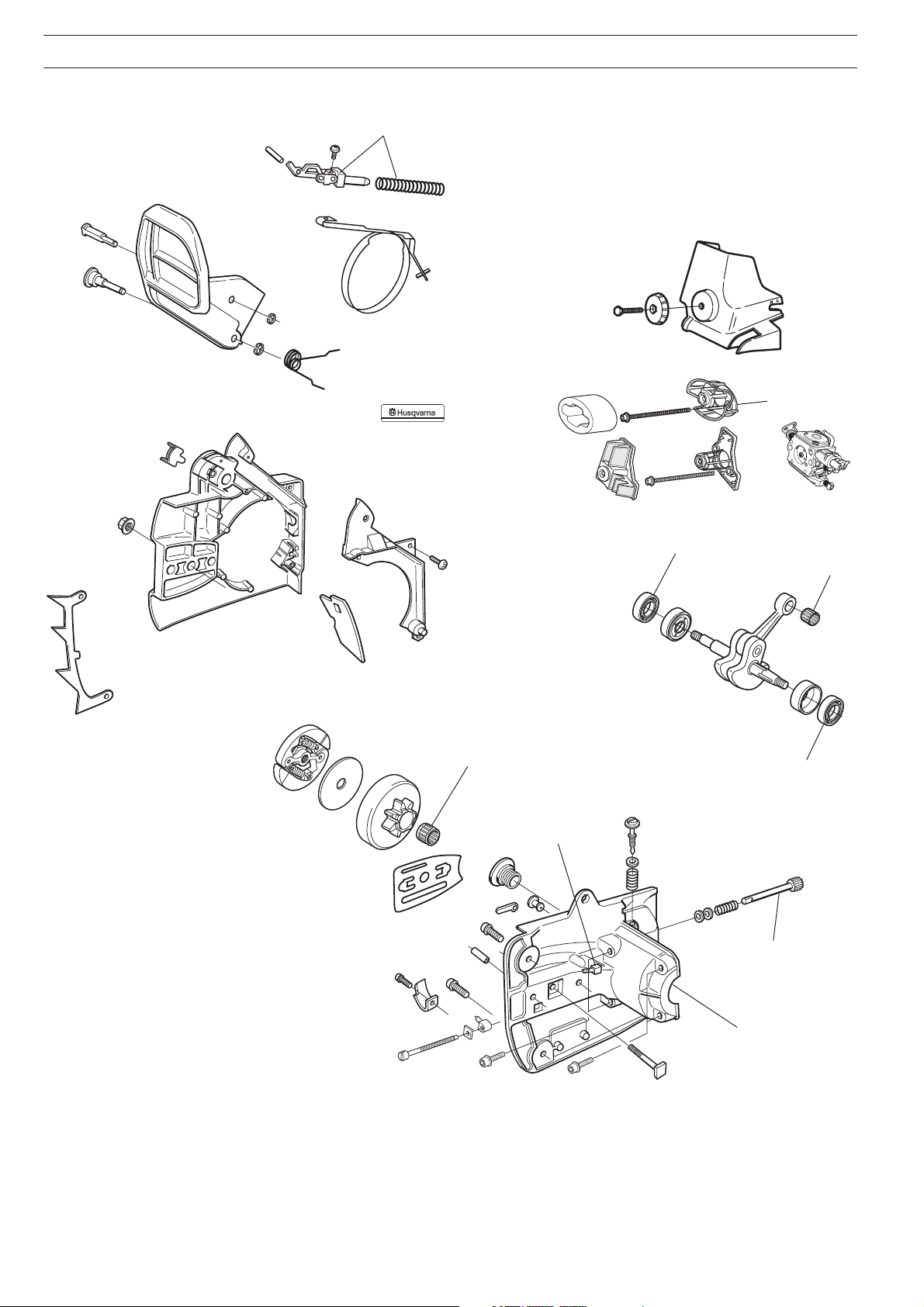

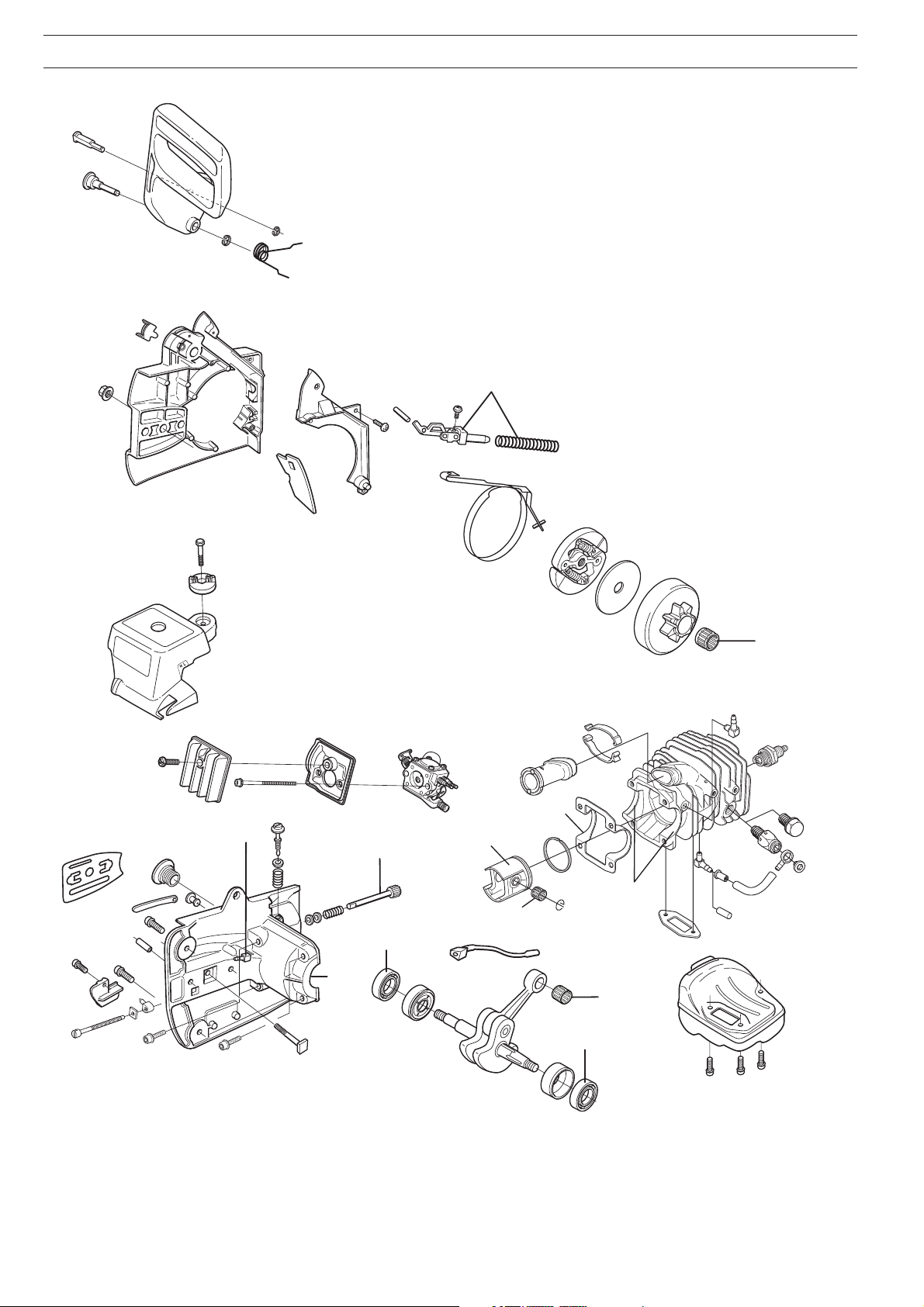

SERVICE DATA 334T/338XPT

15

2-3

20-26

Character key

The numbers by bolted components represent

the tightening torque in Nm.

▲ = Lubricate using two-stroke oil.

■ = Lubricate using engine oil.

● = Lubricate using grease.

❑ = Glued using 2 component adhesive.

❍ = Sealed using silicone.

12 – English

8-10

8-10

SERVICE DATA 334T/338XPT

2,5-4

1-2

2-3

8-10

10-15

*

6-7

2-3

2-3

2,5-4

2,5-4

20-26

English – 13

15

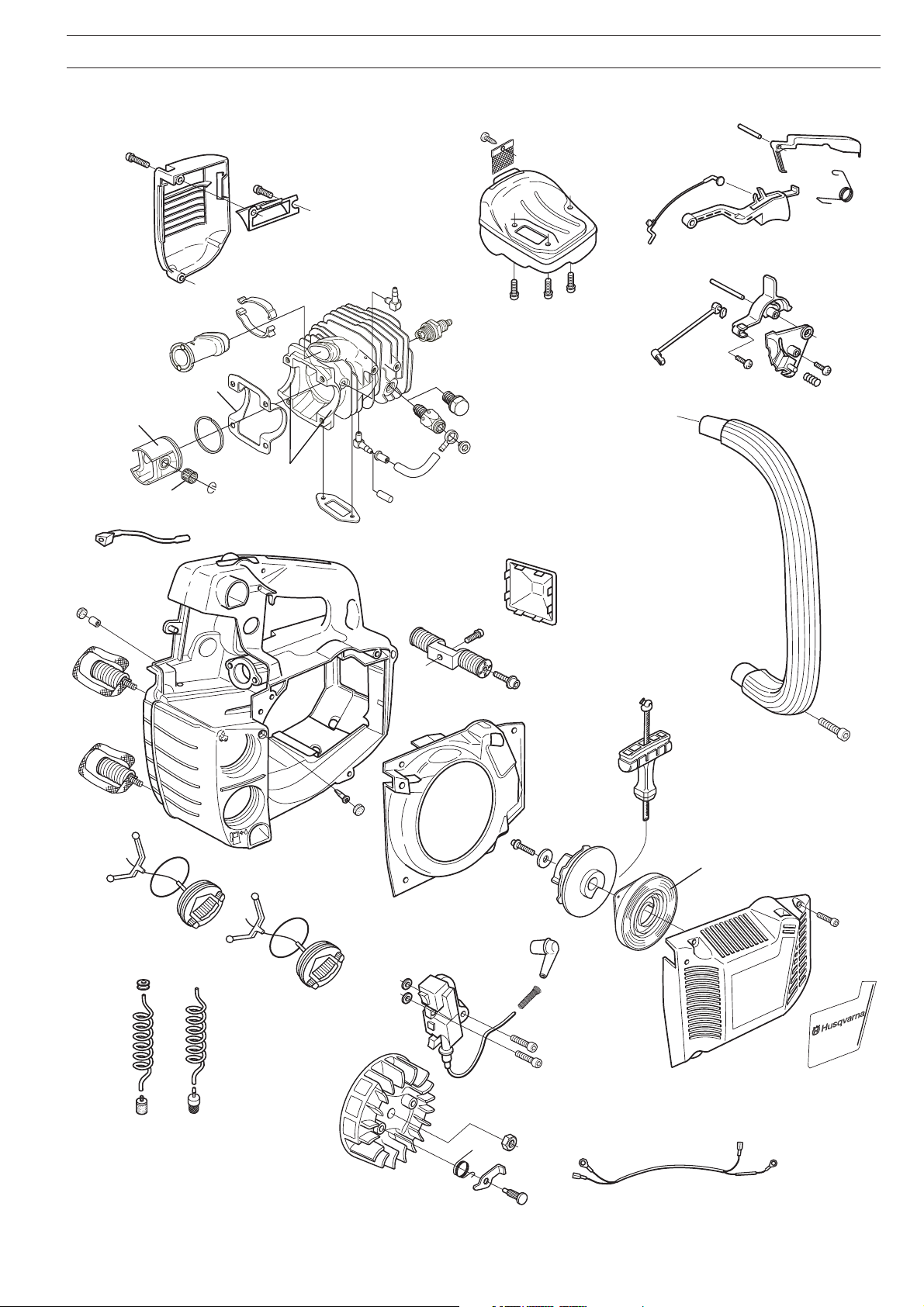

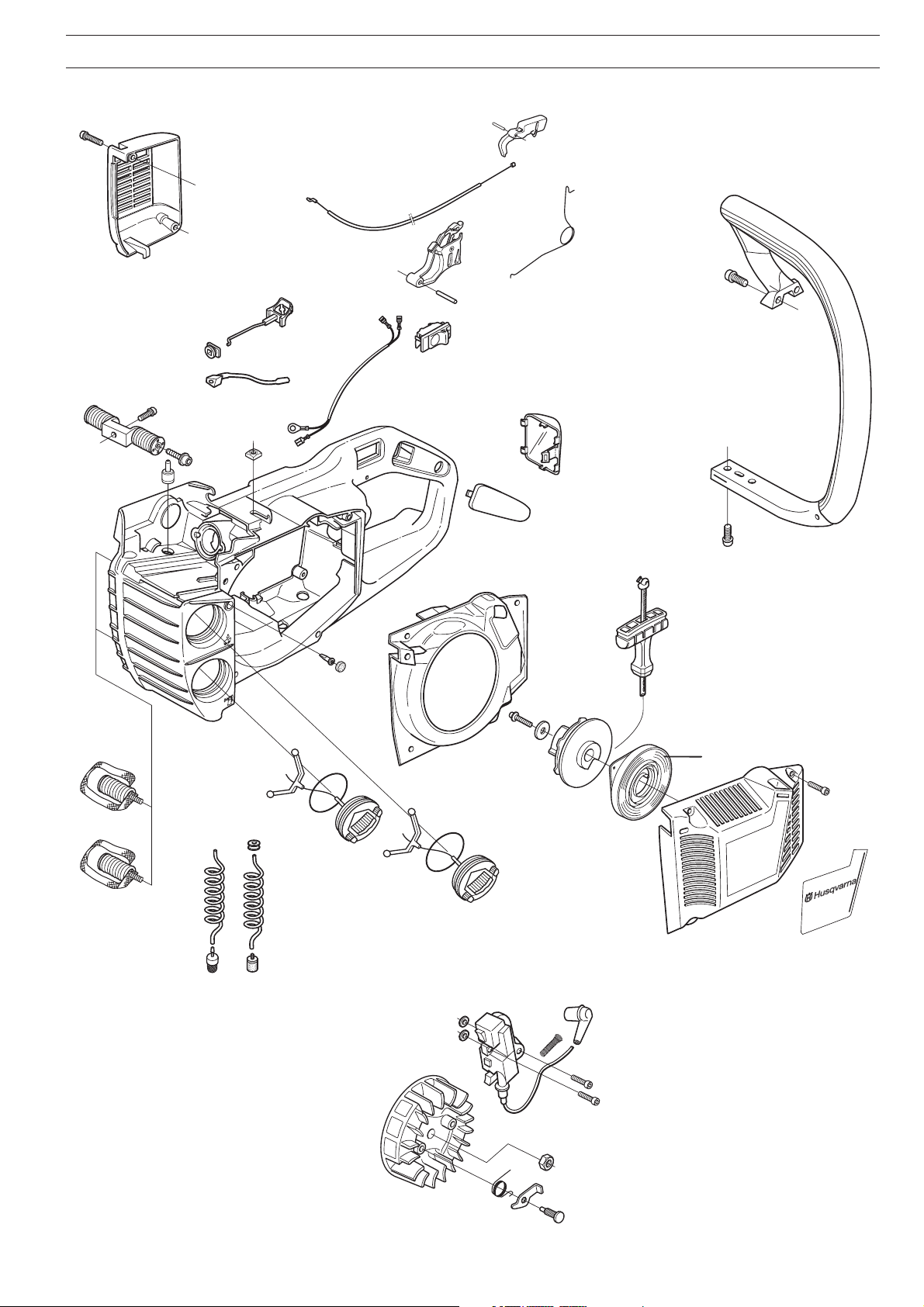

SERVICE DATA 336/339XP

2-3

20-26

10-15

*

8-10

8-10

Character key

The numbers by bolted components represent

the tightening torque in Nm.

▲ = Lubricate using two-stroke oil.

■ = Lubricate using engine oil.

● = Lubricate using grease.

❑ = Glued using 2 component adhesive.

❍ = Sealed using silicone.

14 – English

8-10

2,5-4

6-7

2-3

SERVICE DATA 336/339XP

P

O

T

S

2-3

2,5-4

20-26

2,5-4

English – 15

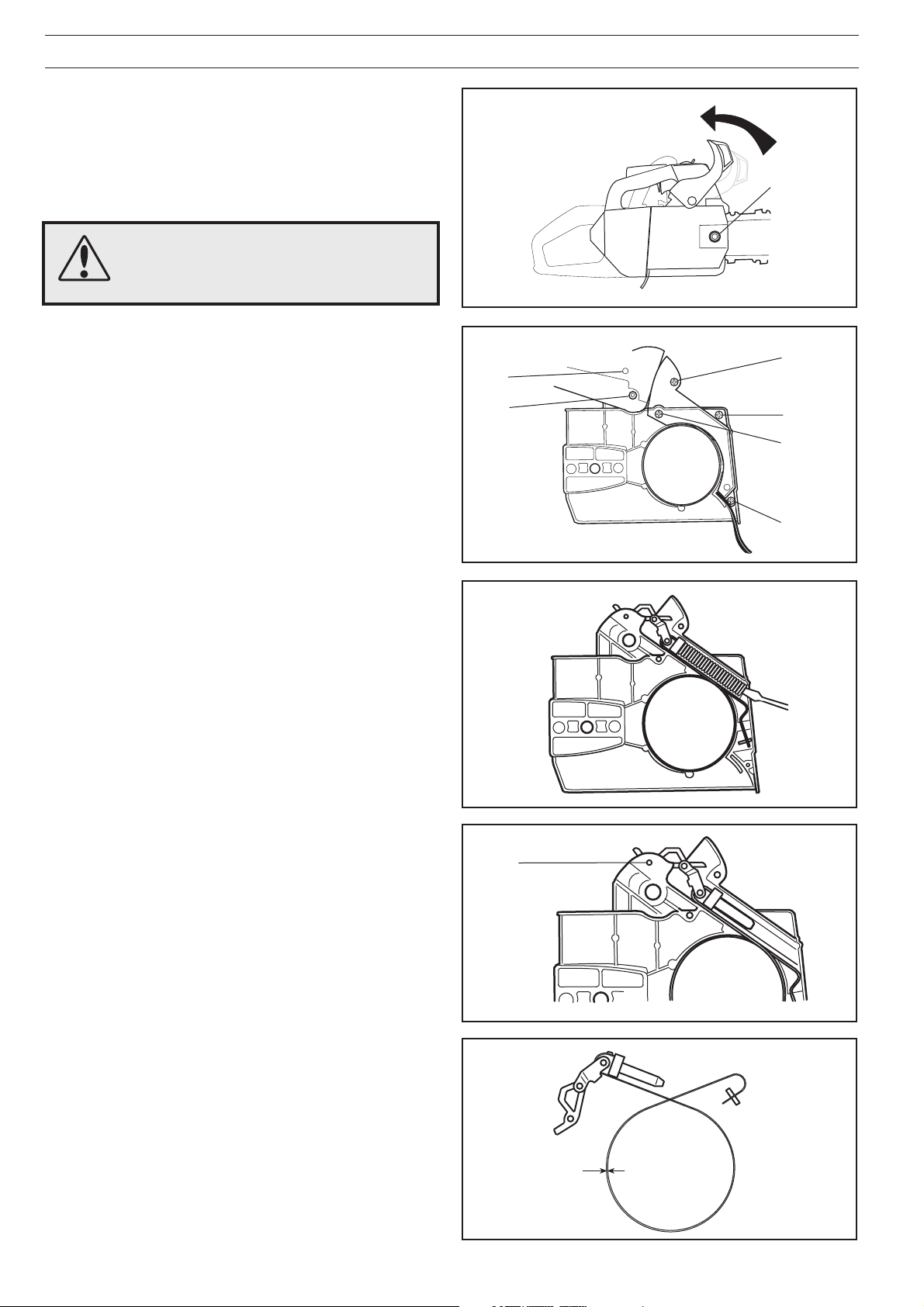

SAFETY EQUIPMENT

Chain brake

Dismantling

1. Check that the chain brake is off and dismantle the bolt (A)

and the clutch cover.

WARNING!

Check that the brake is on. Otherwise the

pressure spring can fly out and cause personal injury.

2. Remove the circlips (B) and (C) then push/knock out the

pins.

3. Remove the handle.

4. Undo the four bolts (D) and remove the cover.

A

D

B

C

D

D

5. Remove the pressure spring by loosening the rear edge

with a screwdriver.

6. Knock out the pin (E) and remove the knee joint with the

attached brake band.

7. Unscrew the brake band from the knee joint.

D

E

Cleaning and inspection

Clean and inspect all parts. The thickness of the brake band

must not be under 0.8 mm at any point.

16 – English

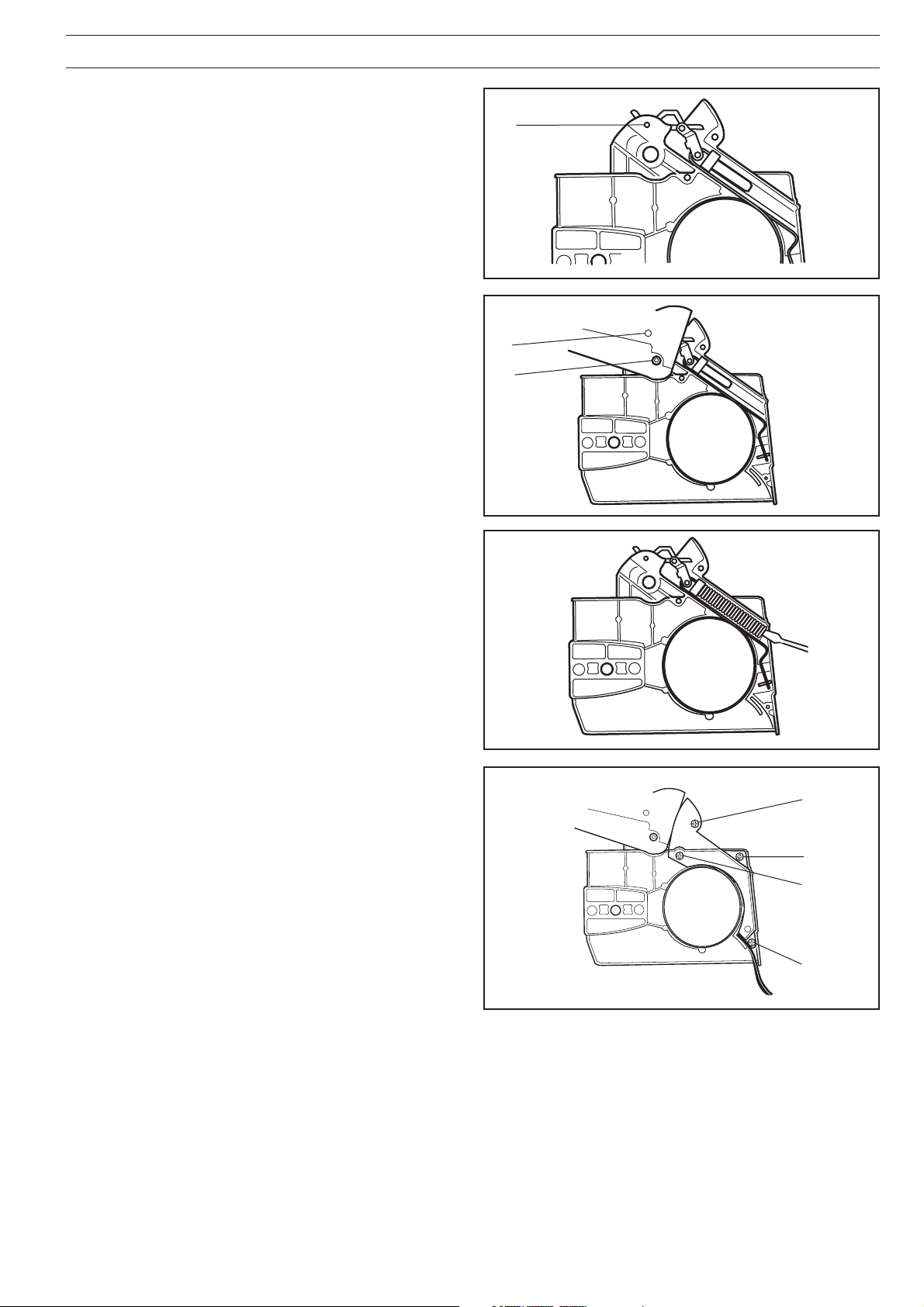

SAFETY EQUIPMENT

Assembly

Assemble the chain brake as follows:

1. Bolt together the knee joint and brake band.

2. Grease the knee joint’s moving parts and assemble the unit

in the cover and knock in the pin (E).

3. Fit the kickback guard, insert the two pins and fit the circlips

(B) and (C).

E

B

C

4. Apply the brake and fit the spring. Use a screwdriver to

press down the rear edge.

5. Fit the cover and tighten the four bolts (D).

6. Release the brake and fit the clutch cover on the chain saw.

Adjust the chain tension, see the Operator Guide. Tighten

the nut to 15 Nm.

D

D

D

D

English – 17

SAFETY EQUIPMENT

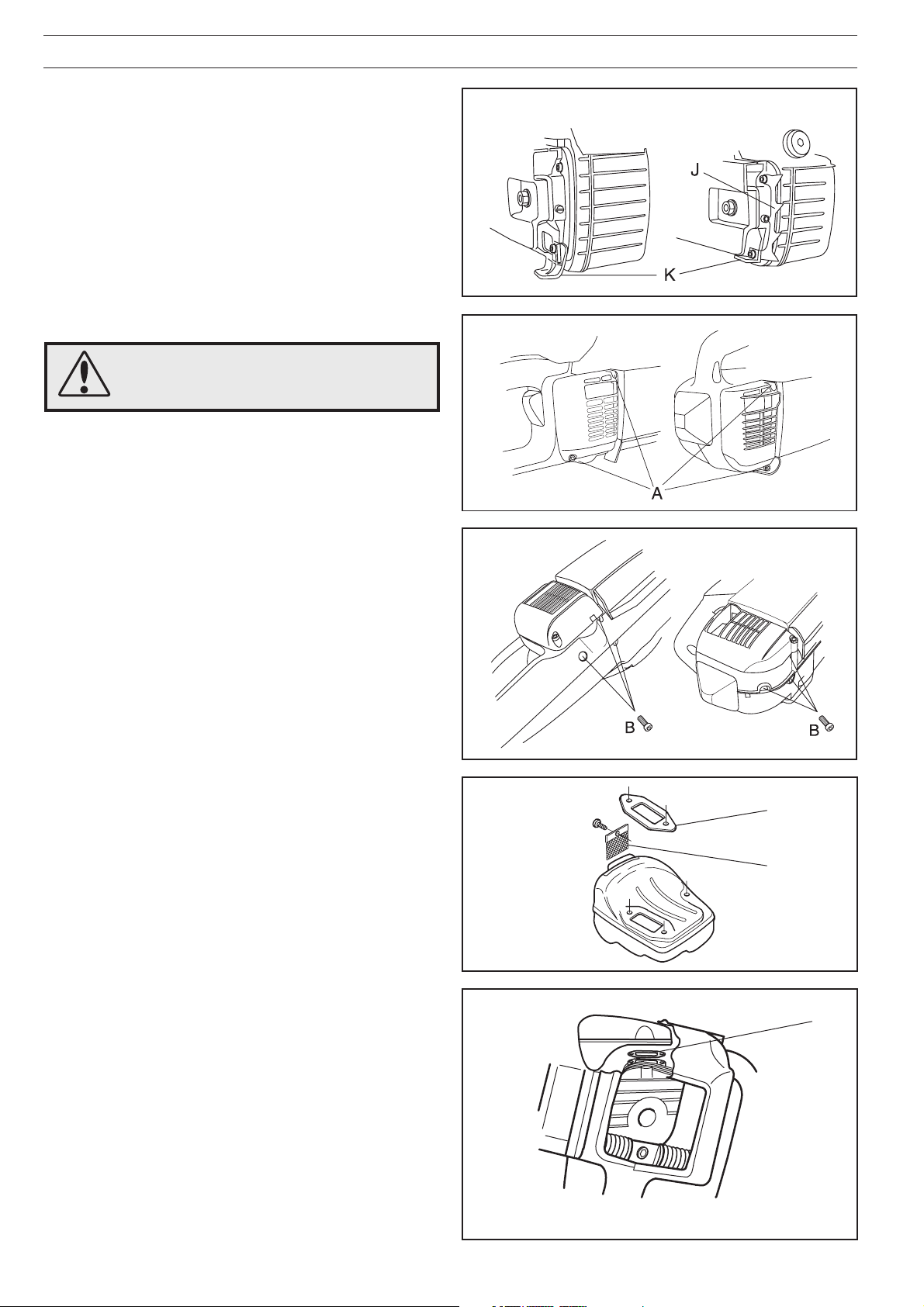

Chain catcher

Dismantle the chain and bar. See the Operator Guide. Check

the spike (J), does not apply to 333, and the chain catcher (K).

Replace any components if damaged. The bolts should be

tightened to 4 Nm.

Assemble the chain and bar. See the Operator Guide.

Muffler

WARNING!

Do not touch the muffler until it has cooled.

Risk for burns.

Dismantling

Dismantle the muffler as follows:

1. Dismantle the muffler guard by removing the two bolts (A).

2. Turn the saw and undo the three bolts (B) holding the

muffler.

3. Lift out the muffler to the side.

4. Remove the gasket.

Cleaning and inspection

Clean all components and check the following:

1. That the spark-arrester (C) is intact.

2. That the muffler and its mountings are not cracked or

having any other defects.

3. That the gasket (D) is undamaged.

D

C

Assembly

1. Place the chain saw in the fixture (see service tools) or in a

vice so that the muffler’s seating on the cylinder is

horizontal.

2. Place the gasket (D) in position on the cylinder.

3. Carefully slide in the muffler without disturbing the gasket.

4. Press the muffler down on the cylinder once the bolt holes

in the muffler, gasket and cylinder are aligned. The gasket

can be adjusted using a small screwdriver.

5. Tighten the muffler bolts to 8-10 Nm.

6. Fit the muffler guard.

18 – English

D

Loading...

Loading...