Husqvarna 130BT User Manual

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

Operator’s manual

130BT

WARNING

Before using our products, please read this manual

carefully to understand the proper use of your unit.

APPLICABLE SERIAL NUMBERS: 70100101 and up

170BT

170BF

English

115 0325-95

English

FEDERAL EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND

OBLIGATIONS

The EPA (The US Environmental Protection Agency), CARB

(California Air Resources Board), Environment Canada and

Husqvarna Forest & Garden are pleased to explain the

emissions control system warranty on your 2007 and later small

nonroad engine. In U.S. and Canada, new small nonroad

engines must be designed, built and equipped to meet the

federal stringent anti-smog standards. Husqvarna Forest &

Garden must warrant the emission control system on your small

nonroad engine for the period of time listed below provided there

has been no abuse, neglect or improper maintenance of your

unit. Your emission control system includes Parts such as the

carburetor, fuel tank and the ignition system. Where a

warrantable condition exists, Husqvarna Forest & Garden will

repair your small nonroad engine at no cost to you. Expenses

covered under warranty include diagnosis, parts and labor.

MANUFACTURER’S WARRANTY

COVERAGE

The 2007 and later small nonroad engines are warranted for two

years. If any emission related part on you engine (as listed

above) is defective, the part will be repaired or replaced by

Husqvarna Forest & Garden.

OWNER’S WARRANTY RESPONSIBILITIES

As the small nonroad engine owner, you are responsible for the

performance of the required maintenance listed in your

Operator’s Manual. Husqvarna Forest & Garden recommends

that you retain all receipts covering maintenance on your small

nonroad engine, but Husqvarna Forest & Garden cannot deny

warranty solely for the lack of receipts or for your failure to

ensure the performance of all scheduled maintenance. As the

small nonroad engine owner, you should, however, be aware

that Husqvarna Forest & Garden may deny you warranty

coverage if your small nonroad engine or a part of it has failed

due to abuse, neglect, improper maintenance, unapproved

modifications or the use of parts not made or approved by the

original equipment manufacturer. You are responsible for

presenting your small nonroad engine to a Husqvarna Forest &

Garden authorized servicing dealer as soon as a problem exists.

The warranty repairs should be completed in a reasonable

amount of time, not to exceed 30 days. If you have any

questions regarding your warranty rights and responsibilities,

you should contact your nearest authorized servicing dealer or

call Husqvarna Forest & Garden at 1-800-487-5963.

WARRANTY COMMENCEMENT

DATE

The warranty period begins on the date small nonroad engine is

delivered.

LENGTH OF COVERAGE

Husqvarna Forest & Garden warrants to the initial owner and

each subsequent purchaser that the engine is free from defects

in materials and workmanship which cause the failure of a

warranted part for a period of two years.

WHAT IS COVERED

REPAIR OR REPLACEMENT OF PARTS Repair or

replacement of any warranted part will be performed at no

charge to the owner at an approved Husqvarna Forest & Garden

servicing dealer. If you have any questions regarding your

warranty rights and responsibilities, you should contact your

nearest authorized servicing dealer or call Husqvarna Forest &

Garden at 1-800-487-5963.

WARRANTY PERIOD Any warranted part which is not

scheduled for replacement as required maintenance, or which is

scheduled only for regular inspection to the effect of “repair or

replace as necessary” shall be warranted for 2 years. Any

warranted part which is scheduled for replacement as required

maintenance shall be warranted for the period of time up to the

first scheduled replacement point for that part.

DIAGNOSIS The owner shall not be charged for diagnostic

labor which leads to the determination that a warranted part is

defective, if the diagnostic work is performed at an approved

Husqvarna Forest & Garden servicing dealer.

CONSEQUENTIAL DAMAGES Husqvarna Forest & Garden

may be liable for damages to other engine components caused

by the failure of a warranted part still under warranty.

WHAT IS NOT COVERED

All failures caused by abuse, neglect or improper maintenance

are not covered.

ADD -ON OR MODIFIED PARTS

The use of add-on or modified parts can be grounds for

disallowing a warranty claim. Husqvarna Forest & Garden is not

liable to cover failures of warranted parts caused by the use of

add-on or modified parts.

HOW TO FILE A CLAIM

If you have any questions regarding your warranty rights and

responsibilities, you should contact your nearest authorized

servicing dealer or call Husqvarna Forest & Garden at 1-800487-5963.

WHERE TO GET WARRANTY SERVICE

Warranty services or repairs shall be provided at all Husqvarna

Forest & Garden authorized servicing dealers.

MAINTENANCE, REPLACEMENT

AND REPAIR OF EMISSIONRELATED PARTS

Any Husqvarna Forest & Garden approved replacement part

used in the performance of any warranty maintenance or repairs

on emission-related parts, will be provided without charge to the

owner if the part is under warranty.

EMISSION CONTROL WARRANTY

PARTS LIST

1 Carburetor and internal parts

2 Intake pipe, airfilter holder and carburetor bolts.

3 Airfilter and fuelfilter covered up to maintenance schedule.

4 Ignition System

1 Spark Plug, covered up to maintenance schedule

2 Ignition Module

5 Fuel tank with cap and pipe

MAINTENANCE STATEMENT

The owner is responsible for the performance of all required

maintenance, as defined in the operator’s manual.

2

English

Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

SAFETY FIRST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Notes on types of warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warning labels on the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Symbols on the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

WORKING CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

WORKING CIRCUMSTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

AVOID NOISE PROBLEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

WORKING PLAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

FUEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

BEFORE STARTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

USING THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

TRANSPORTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

STORAGE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

What is what? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SWIVEL JOINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

THROTTLE LEVER [130BT/170BT] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

THROTTLE CABLE [130BT/170BT] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

RIGHT HANDLE [170BF] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

HANDLEBAR [OPTION] [130BT/170BT]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

BLOWER TUBES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

HARNESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

WAIST BELT [170BT/170BF] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

FUEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

HOW TO MIX FUEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

FUELING THE UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

CONTROL ARM [170BF] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

STARTING ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

ADJUSTING IDLE SPEED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

STOPPING ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

AIR CLEANER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

FUEL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SPARK PLUG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

MUFFLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SPARK ARRESTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

AIR INLET NET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

IGNITION COIL AIR GAP INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SHOLDER STRAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3

English

T

T

Safety

SAFETY FIRST

Instructions contained in warnings within this manual and

warning seals marked with a symbol on the blower concern

critical points which must be taken into consideration to prevent

possible serious bodily injury, and for this reason you are

requested to read all such instructions carefully and follow them

without fail.

Warning labels on the machine

Symbols

WARNING! The machine can be a dangerous

tool if used incorrectly or carelessly, which can

cause serious or fatal injury to the operator or

others.

Please read the operator’s manual carefully

and make sure you understand the

instructions before using the machine.

Notes on types of warnings

W ARNING

Instructions labeled as shown above, concern critical steps

or procedures which must be followed in order to prevent

accidents which could lead to serious bodily injury or

death.This mark is used to indicate instructions which must

be followed without exception.

IMPORTAN

Instructions labeled as shown above concern steps or

procedures which, if not followed correctly, could lead to

mechanical failure, breakdown, or damage.

NOTE

Used to label supplementary instructions designed to

provide hints or directions useful in the use of the product.

The blower operator must make sure

that no bystanders or animals come

nearer than 50 feet (15 meters).

Whenever several operators are

working in the same work area, they should maintain a safe

distance of at least 50 feet (15 meters) from one another.

A breathing mask should be used when

there is a risk of dust.

Always wear:

• Hearing protection

• Approved eye protection

Always wear protective gloves.

Wear study, non-slip boots

The blower can forcibly throw objects that

can bounce back. This can result in

serious eye injuries if the recommended

safety equipment is not used.

Keep all parts of your body away from hot

surfaces.

Other symbols/decals on the machine refer to special

certification requirements for certain markets.

IMPORTAN

If the warning label peels off or becomes soiled and

impossible to read, you should contact the dealer from

which you purchased the product to order new labels and

affix them in the required location(s).

4

T

Symbols on the machine

English

(c)

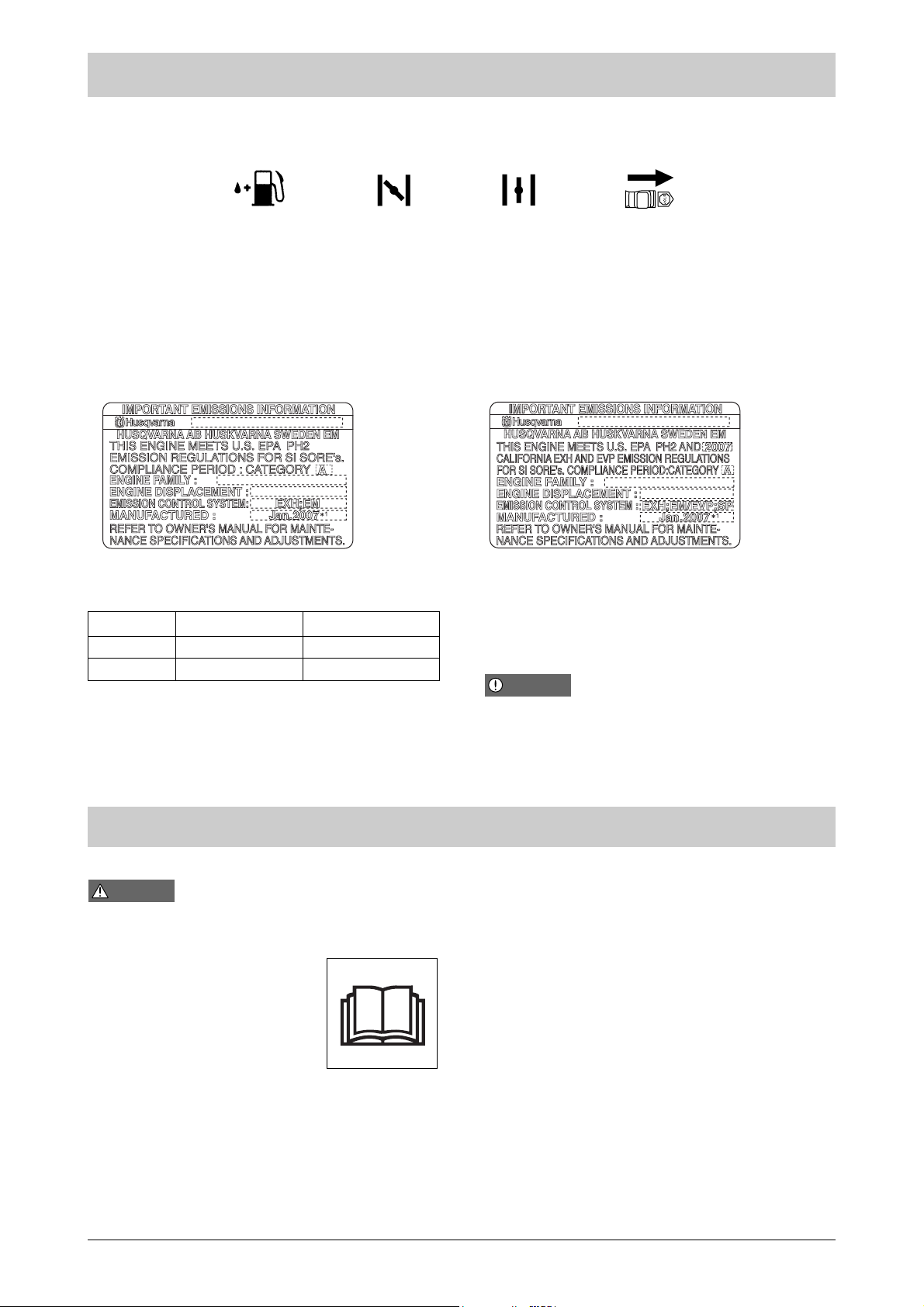

For safe operation and maintenance, symbols are carved in relief on the machine. Using to these indications, please be careful not to

make a mistake.

(a) The port to refuel the "MIX GASOLINE"

Position: FUEL TANK CAP

(b) The direction to close the choke

Position: INTAKE CUP

<FOR EPA ONLY> <FOR EPA & CARB>

A

B

C

∗1 : THE ACTUAL MANUFACTURING MONTH WILL BE

PRINTED.

A : Model B : ENGINE FAMILY C :

∗

130BT

170BT/170BF

∗2 : THE INITIAL NUMBER WILL BE CHANGED EVERY YEAR

OF MANUFACTURING.

This engine label certifies that the product is certified in

accordance with American exhaust emissions requirements

EPA Ph II and CARB Tier III. The Emissions Compliance Period

7KZXS.0294BK

7KZXS.0655BE

2

∗

2

ENGINE DISPLACEMENT

29cc

65cc

(c) The direction to open the choke

Position: INTAKE CUP

(d) The direction to stop the engine

Position: THROTTLE LEVER [130 BT/170 BT only]

referred to on the emissions Compliance label indicates the

number of operating hours for which the engine has been shown

to meet Federal and California emission requirements.

Category C = 50 hours, B = 125 hours, and A = 300 hours.

For customer assistance call: 704-921-7000 or contact us at our

website: www.husqvarna.com

IMPORTAN

Check the emission information label on your product.

In the case of <FOR EPA ONLY>, the product is

unsupported to use in California.

(d)(a) (b)

A

B

C

Safety Precautions

W ARNING

1. Read this Blower Operator Manual carefully. Be sure

you understand how to operate this unit properly before

you use it. Failure to do so could result in serious injury.

2. Be sure to keep this manual handy

so that you may refer to it later

whenever any questions arise. Also

note that you are requested to

contact the dealer from whom you

purchased the product for

assistance the event that you have

any questions which cannot be

answered herein.

3. Always be sure to include this manual when selling,

lending, or otherwise transferring the ownership of this

product.

4. Do not lend or rent your machine without the owner's

manul.

5. Be sure that anyone using your unit understands the

information contained in this manual.

6. Never let a child use the machine.

7.

Long-term exposure to noise can result in permanent

hearing impairment. So always use approved hearing

protection.

8.

Under no circumstances may the design of the machine

be modified without the permission of the manufacturer.

Always use genuine accessories. Non-authorized

modifications and/or accessories can result in serious

personal injury or the death of the operator or others.

9.

A blower is a dangerous tool if used carelessly or

incorrectly and can cause serious, even fatal injuries. It

is extremely important that you read and understand the

contents of this Operator’s manual.

10.

Husqvarna AB has a policy of continuous product

development and therefore reserves the right to modify

the design and appearance of products without prior

notice.

11.

The machine is only designed for blowing lawns,

pathways, asphalt roads and the like.

5

English

Safety Precautions

WORKING CONDITIONS

1. Refrain from operating the blower if you are tired, ill, or upset,

or if you are under the influence of alcohol, drugs or

medication

2. To reduce the risk of hearing loss associated with sound

levels, hearing protection is required.

3. To reduce the risk of injury associated

with thrown objects, always wear eye

protection and foot protection.

Approved protective goggles must

comply with standard ANSI Z87.1 in the

USA or EN 166 in EU countries.

4. To reduce the risk of injury associated

with the inhalation of dust, use a face

filter mask in dusty conditions.

5. Wear rubber-soled shoes or shoes with

some other form of anti-slip protection

to help protect you against falling.

6. To reduce the risk of injury associated

with objects being drawn into rotating

parts, do not wear loose clothing,

scarves, neck chains, hair longer than

shoulder length, or other loose

material.

7. Prolonged use of a blower, exposing the operator to

vibrations and cold, may produce whitefinger disease

(Raynaud’s phenomenon), the symptoms of which include

tingling and burning sensations followed by loss of color and

numbness in the fingers. All factors which contribute to

whitefinger disease are not known, but cold weather,

smoking diseases or physical conditions as well as long

periods of exposure to vibration are mentioned as factors. In

order to reduce the risk of whitefinger disease, the following

precautions are strongly recommended

a) Keep your body warm. Never use the blower during rain.

b) Wear thick anti-vibration gloves.

c) Take more than 5 minutes of break

in a warm place frequently.

d) Maintain a firm grip at all times, but

do not squeeze the handles with

constant, excessive pressure.

e) If you feel discomfort, redness and

swelling of your fingers or any other

part of your body, see a doctor before it gets worse.

AVOID NOISE PROBLEM

NOTE

Check and follow the local regulations as to sound levels

and hours of operations for blower.

1. Operate power equipment only at reasonable hours, not

early in the morning or late at night when people might be

disturbed. Comply with times listed in local ordinances.

2. To reduce sound levels, limit the number of pieces of

equipment used at any one time.

3. Operate power blowers at the lowest possible throttle speed

to do the job.

4. Check your equipment before operation, especially the

muffler, air intakes and air filters.

WORKING PLAN

• To reduce the risk of health damages, avoid excessive use

and take sufficient time to rest .

FUEL

W ARNING

To reduce the risk of fire and burn injury:

a) Handle fuel with care. It is highly

flammable.

b) Do not smoke while handing fuel.

c) Do not refuel a hot engine.

d) Do not refuel a running engine.

e) Avoid spilling fuel or oil. Always wipe

unit dry before using.

f ) Move at least 10 ft. (3 meters) away

from the fueling point before starting the engine.

g) Always store gasoline in a container approved for flammable

liquids.

h) Make sure the unit is properly assembled and in good

operating condition.

i ) Do not use the blower near a fire, as

aiming the blower in the direction of a

flame may cause flammable

substances to ignite.

8. The ignition system of your unit produces an electromagnetic

field of a very low intensity. This field may interfere with some

pacemakers. To reduce the risk of serious or fatal injury,

people with pacemaker should consult their physician and

the pacemaker manufacturer before operating this tool.

WORKING CIRCUMSTANCE

1. To reduce the risk of injury associated

with exhaust fume inhalation, do not

operate in unventilated area. The

exhaust gases contain harmful carbon

monoxide.

2. Avoid using the blower where stable

footing and balance are not assured.

3. Never operate the machine in high

wind, bad weather, when visibility is poor or in very high or

low temperatures.

(Our recommended use environment is below 40 degrees C

(104 degrees F).)

6

Loading...

Loading...