Page 1

Operator’s Manual

125C 125L

Please read the operator’s manual carefully and make sure you

understand the instructions before using the machine.

EEEEnnnngggglllliiiisssshh

hh

Page 2

CONTENTS

Contents

CONTENTS

Contents 2........................

Note the following before starting 2....

KEY TO SYMBOLS

Symbols 3.........................

SAFETY INSTRUCTIONS

Personal protective equipment 4......

Machine’s safety equipment 4........

Cutting equipment 5.................

Checking, maintaining and servicing

the machine’s safety equipment 5.....

General safety precautions 8.........

Starting safety 8....................

Fuel safety 8.......................

Transporting and storage 9...........

General working instructions 9........

Basic safety rules 9.................

Basic working techniques 9..........

KNOW YOUR TRIMMER

Know your trimmer 11................

ASSEMBLY

Fitting the loop handle 12.............

Fitting the trimmer guard and

trimmer head 12.....................

FUEL HANDLING

Fuel 13............................

Fueling 13..........................

STARTING AND STOPPING

Check before starting 14..............

Starting and stopping 14..............

MAINTENANCE

Carburetor 16.......................

Muffler 16..........................

Spark plug 17.......................

Air filter 17..........................

Bevel gear 17.......................

Maintenance schedule 18.............

TECHNICAL DATA

Technical data 20....................

YOUR WARRANTY RIGHTS AND

OBLIGATIONS 21...................

EMISSION CONTROL

WARRANTY STATEMENT 22.........

Note the following before

starting:

Husqvarna AB has a policy of continuous

product development and therefore

reserves the right to modify the design and

appearance of products without prior

notice. Long--term exposure to noise can

result in permanent hearing impairment.

Always use approved hearing protec tion.

Maintenance, replacement, or repair of the

emission control devices and system may

be performed by any nonroad engine repair establishment or individual.

WARNING! The engine exhaust

from this product contains chemicals

known to the State of California to

cause cancer, birth defects or other

reproductive harm.

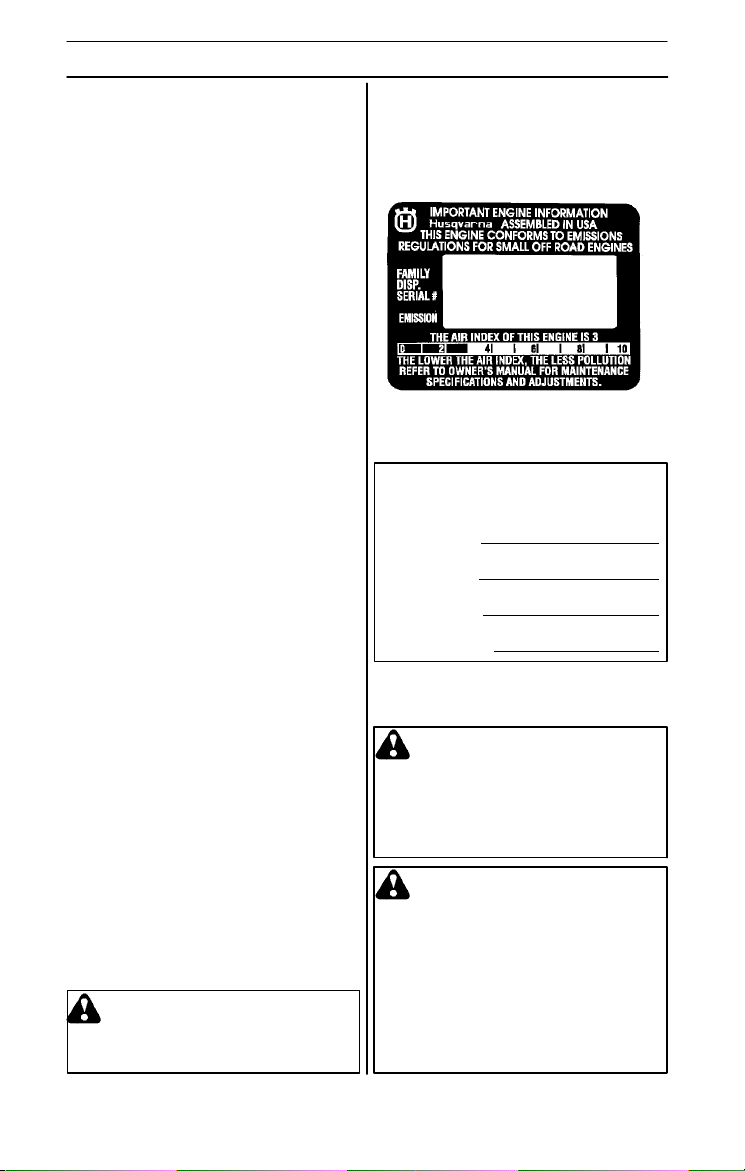

The Emissions Compliance Period referred

to on the Emissions Compliance label indicates the number of operating hours for

which the engine has been shown to meet

Federal emissions requirements.

Category C = 50 hours, B= 125 hours, and

A = 300 hours.

For reference, please fill out the following

information that will be needed for future

servicing of your trimmer:

Model Number:

Serial Number:

Purchase Date:

Purchased From:

WARNING! A clearing saw,

brushcutter or trimmer can be

dangerous if used incorrectly or

carelessly, and can cause serious

or fatal injury to the operator or

others. It is extremely important

that you read and understand the

contents of this operator’s manual.

WARNING! Under no circum-

stances may the design of the

machine be modified without the

permission of the manufacturer.

Always use genuine accessories.

Non--authorized modifications

and/or accessories can result

in serious personal injury or the

death of the operator or others.

Your warranty may not cover

damage or liability caused by the

use of non --authorized accessories or replacement parts.

2

Page 3

KEY TO SYMBOLS

Symbols

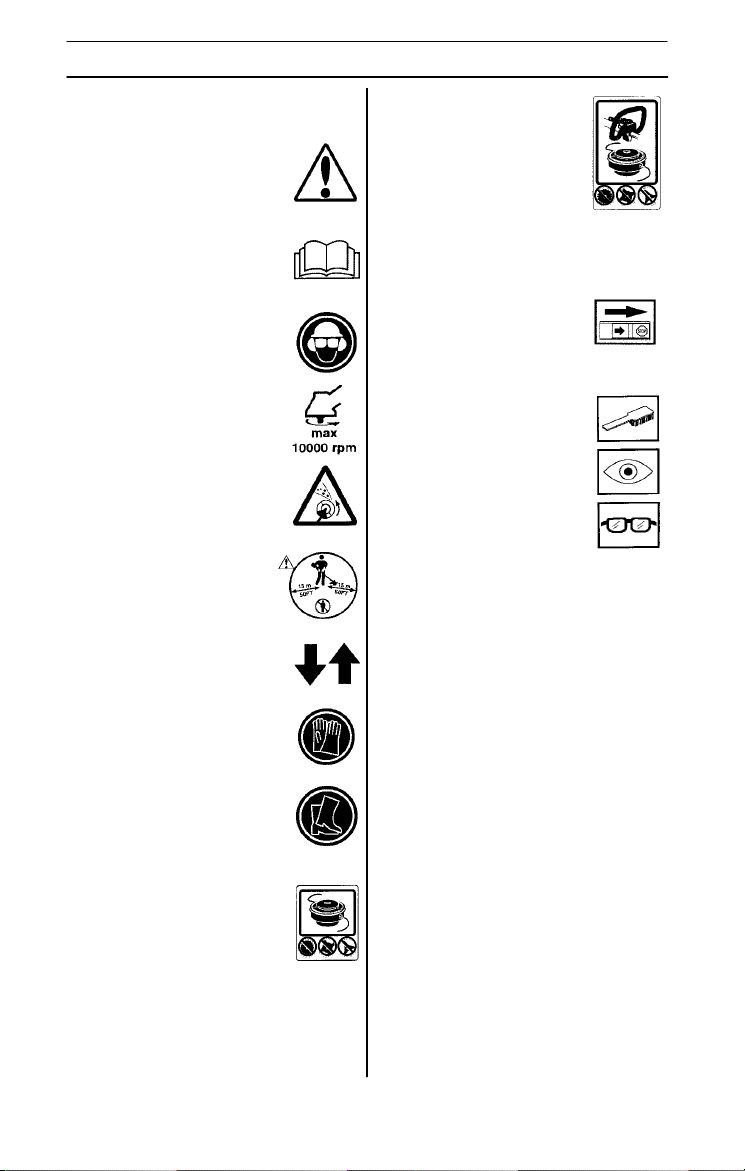

WARNING!

brushcutters and trimmers can be

dangerous! Careless or incorrect

use can result in serious or fatal

injury to the operator or others.

Please read the operator’s manual

carefully and make sure you

understand the instructions

before using the machine.

Always wear:

S A protective helmet where there

is a risk of falling objects

S Hearing protection

S Approved eye protection

Max. speed of output shaft, rpm

Watch out for thrown objects and

ricochets.

The operator of the machine

must ensure, while working,

that no persons or animals

come closer than 50 feet

(15 meters).

Arrows which show limits for

handle positioning.

Clearing saws,

Only intended for trimmer heads.

Other symbols/decals on the machine

refer to special certification requirements

for certain markets.

Stop the engine by pushing

and holding the stop switch

in the STOP position until the

engine stops before carrying

out any checks or maintenance.

Regular cleaning is required.

Visual check.

Approved eye protection must

always be used.

Always wear approved protective

gloves.

Wear sturdy, non--slip boots.

Only use non--metallic, flexible

cutting attachments, i.e. trimmer

heads with trimmer line.

3

Page 4

SAFETY INSTRUCTIONS

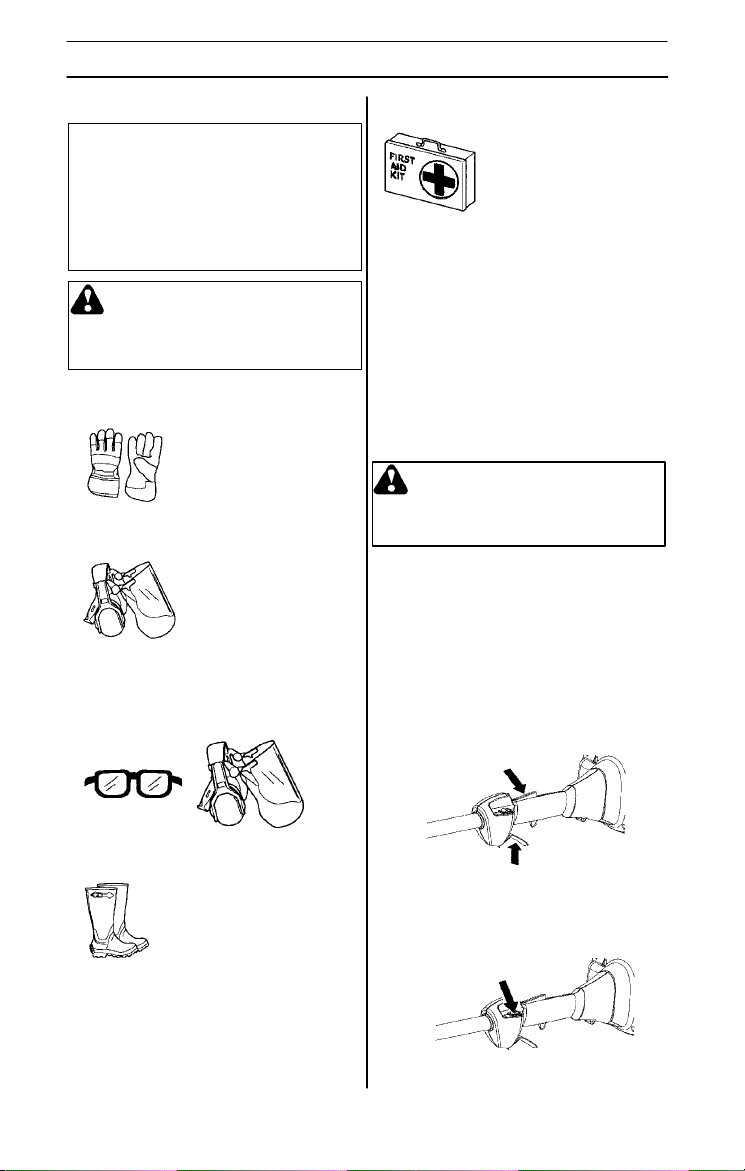

Personal protective equipment

IMPORTANT! Whenever you use a clear-

ing saw, brushcutter or trimmer you must

wear personal protective equipment that is

approved by the authorities. Personal

protective equipment does not eliminate

the risk of accidents, but it can reduce the

effects of an injury in the event of an accident. Ask your dealer for help when

choosing protective equipment.

WARNING! Listen out for warn-

ing signals or shouts when you are

wearing hearing protection. Always

remove your hearing protection as

soon as the engine stops.

GLOVES

Gloves should be worn when necessary,

e.g., when fitting cutting attachments.

HEARING PROTECTION

Wear hearing protection that provides

adequate noise reduction.

EYE PROTECTION

Always wear approved eye protection. If

you use a v isor then you must also wear

approved protective goggles. Approved

protective goggles must comply with

standard ANSI Z87.1.

FIRST AID KIT

Always have a first aid kit nearby.

Machine’s safety equipment

This section describes the machine’s safety equipment, its purpose, and how checks

and maintenance should be carried out to

ensure that it operates correctly. See the

“Know your trimmer ” section to locate

where this equipment is positioned on your

machine.

The life span of the machine can be reduced

and the risk of accidents can increase if

machine maintenance is not carried out

correctly and if service and/or repairs are not

carried out professionally. If you need further

information please contact your nearest servicing dealer.

WARNING! Never use a machine

that has faulty safety equipment!

Carry out the inspection, maintenance and service routines listed in

this section.

Throttle lock

The throttle lock is designed to prevent accidental operation of the throttle control.

When you press the lock (A) (i.e. when you

grasp the handle) it releases the throttle

control (B). When you release the handle

the throttle control and the throttle lock both

move back to their original positions. This

movement is controlled by two independent

return springs. This arrangement means

that the throttle control is automatically

locked at the idle setting.

A

BOOTS

Wear sturdy, non--slip boots.

CLOTHING

Wear clothes made of a strong fabric and

avoid loose clothing that can catch on

twigs and branches. Always wear heavy,

long pants. Do not wear jewelry, shorts

sandals or go barefoot. Secure hair so it is

above shoulder level.

B

Stop switch

Make sure the engine stops when you push

and hold the stop switch.

4

Page 5

SAFETY INSTRUCTIONS

Cutting attachment guard

This guard is intended to prevent loose objects from being thrown towards the operator. The guard also protects the operator

from accidental contact with the cutting attachment.

WARNING! Never use a cutting

attachment without an approved

guard. See the section on “Tec hnical

data”. If an incorrect or faulty guard

is fitted this can cause serious

personal injury.

Use of incorrectly wound trimmer line or an

incorrect cutting attachment increases the

level of vibration.

WARNING! Overexposure to

vibration can lead to circulatory

damage or nerve damage in people

who have impaired circulation.

Contact your doctor if you experience symptoms of overexposure to

vibration. Such symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength,

changes in skin color or condition.

These symptoms normally appear

in the fingers, hands or wrists. The

risk increases at low temperatures.

WARNING! Mufflers fitted with

catalytic converters get very hot

duringuseandremainsoforsome

time after stopping. This also ap plies at idle speed. Contact can result in burns to the skin. Remember

theriskoffire!

WARNING! The inside of the

muffler contain chemicals that may

be carcinogenic. Avoid contact with

these elements in the event of a

damaged muffler.

WARNING! Be ar in mind that:

Engine exhaust fumes contain car bon monoxide, which can cause

carbon monoxide poisoning. For

this reason you should not start or

run the machine indoors, or anywhere that is poorly ventilated.

The exhaust fumes from the engine

are hot and may contain sparks

which can start a fire. Never start

the machine indoors or near combustible material!

Cutting equipment

A trimmer head is intended for trimming

grass.

Muffler

The muffler is designed to reduce the noise

level and to direct the exhaust gases away

from the operator.

CAUTION! Muffler is fitted with a catalytic

converter designed to reduce harmful exhaust gases.

For mufflers, it is very important that you follow the instructions on checking, maintaining, and servicing your machine.

See Checking, maintaining and servicing the

machine’s s afety equipment section.

Checking, maintaining and

servicing the machine’s

safety equipment

IMPORTANT!

All servicing and repair work on the machine

requires special training. This is especially

true of the machine’s safety equipment. If

your machine fails any of the checks described below you must contact your service

agent. When you buy any of our products we

guarantee the availability of professional repairs and service. If the retailer who sells

your machine is not a servicing dealer, ask

him for the address of your nearest service

agent.

5

Page 6

SAFETY INSTRUCTIONS

Throttle lock

S Make sure the throttle control is locked

at the idle setting when the throttle lock

is released.

S Press the throttle lock and make sure it

returns to its original position when you

release it.

S Check that the throttle control and

throttle lock move freely and that the

return springs work properly.

Stop switch

S Start the engine and make sure the engine

stops when you push and hold the stop

switch.

Cutting attachment guard

S Ensure that the guard is undamaged and

is not cracked.

S Replace the guard if it has been exposed

to impact or is cracked.

S Always use the recommended guard for

the cutting attachment you are using. See

section on “Technical data”.

Muffler

S See instructions under the section

“Start”. Start the machine and apply full

throttle. Release the throttle and check

that the cutting attachment stops and remains at a standstill. If the cutting attachment rotates with the throttle in the idle

position then the carburetor idle setting

must be checked. See instructions under

the section “Maintenance”.

S Never use a machine that has a faulty

muffler.

S Regularly check that the muffler is securely

attached to the machine.

S The muffler on this unit is equipped with a

special spark arrestor mesh. The mesh

should be checked and, if necessary.

cleaned by a servicing dealer. A blocked

mesh will cause the machine to overheat,

which can lead to serious damage. Never

use a muffler with a defective spark arrestor mesh. See the Maintenance section.

6

Page 7

SAFETY INSTRUCTIONS

Cutting equipment

This section describes how to c hoose and

maintain your cutting equipment in order to:

S Obtain maximum cutting performance.

S Extend the life of c utting equipment.

General rules

Trimmer head

S Only use the recommended cutting at-

tachments. See the section on “Technical

data”.

1. Only use cutting attachments with the

guards we recommend! See the s ection

on “Technical Data”.

2. Check the cutting attachment for damage

or cracks. A damaged cutting attachment

should always be replaced.

WARNING! Never use a machine

with faulty safety equipment. The

machine’s safety equipment must be

checked and maintained as

described in this section.

If your machine fails any of these

checks contact your service agent to

get it repaired.

IMPORTANT!

This section describes how to choose and

maintain your cutting equipment in order to:

Obtain maximum cutting performance.

Extend the life of cutting equipment.

Only use cutting attachments with the guards

we recommend! See the section on

“T echnical data”.

Refer to the instructions for the cutting attachment to check the correct way to load the

trimmer line and the correct line diameter.

S Smaller machines generally require small

trimmer heads and vice versa. This is because when clearing using trimmer line

the engine must throw out the trimmer

line radially from the trimmer head and

overcome the resistance of the grass

being cleared.

S The length of the trimmer line is also im-

portant. A longer trimmer line requires

greater engine power than a shorter

trimmer line of the same diameter.

S Make sure that the cutter on the trimmer

guard is intact. This is used to cut the

trimmer line to the correct length.

S To increase the life of the trimmer line it

can be soaked in water for a couple of

days. This will make the line tougher so

that it lasts longer.

IMPORTANT!

Always ensure the trimmer line is wound

tightly and evenly around the drum, otherwise the machine will generate harmful

vibration.

WARNING! Always stop the en-

gine before doing any work on the

cutting attachment. This continues

to rotate even after the throttle has

been released. Ensure that the

cutting attachment has stopped

completely and disconnect the HT

lead from the spark plug before

you start to work on it.

7

Page 8

SAFETY INSTRUCTIONS

e

General safety precautions

IMPORTANT!

S The machine is only designed for trimming

grass.

S The only accessories you can operate

with this engine unit are the cutting attachments we recommend in the “T echnical data” section.

S Never use wire, rope, string, etc.

S Never use the machine if you are tired, if

you have drunk alcohol, or if you are taking medication that could affect your vision, your judgment or your coordination.

S Never use the machine in extreme weath-

er conditions such as severe cold, very hot

and/or humid climates.

S Never use a machine that has been modi-

fied in any way from its original specification.

S Wear personal protective equipment. See

instructions in the “Personal protective

equipment” section.

S Never use a machine that is faulty. Carry

out the checks, maintenance and service

instructions described in this manual.

Some maintenance and service measures

must be carried out by trained and qualified specialists. See instructions in the

“Maintenance” section.

S All covers and guards must be fitted before

starting. Make sure the spark plug cap and

HT lead are not damaged. Otherwise you

could get an electric shock.

S The machine operator must ensure that no

people or animals come closer than 15

meters while working.

S Stay clear of spinning line.

S Secure or remove loose clothing or cloth-

ing with loosely hanging ties, straps, tassels, etc. They can be caught in moving

parts.

S Being fully covered also helps protect you

from debris and pieces of toxic plants

thrown by spinning line.

S Keep handles free of oil and fuel.

S Always k eep the engine on the right hand

side of your body.

S Hold the unit firmly with both hands.

S Keep trimmer head below waist level and

away from all parts of your body. Do not

raise engine above your waist.

S Keep all parts of your body away from

muffler and spinning line. Keep engine below waist level. A hot muffler can cause

serious burns.

S Keep firm footing and balance. Do not

overreach or use from unstable surfaces

such as ladders, trees, steep slopes, rooftops, etc.

S Use only in day light or good artificial light.

S Use only for jobs explained in this manual.

WARNING! A faulty cutting at-

tachment may increase the risk of

accidents.

Starting

WARNING! Whentheengineis

started with the choke in either the

choke or start throttle positions the

cutting attachment will start to

rotate immediately.

S Ensure that all of the engine covers and

housings are properly fitted before the

trimmer is started.

S Never start or attempt to run the unit with

the clutch, clutch drum, clutch cover, or

driveshaft removed.

S Never start the machine indoors. Exhaust

fumes can be dangerous if inhaled.

S Observe your surroundings and make sur

that there is no risk of people or animals

coming into contact with the cutting equipment.

S See the “Starting and Stopping” section for

complete instructions.

Fuel safety

S Always use a fuel container with an anti--

spill valve.

S Never refuel the machine while the engine

is running.

S Always stop the engine and let it cool for a

few minutes before refueling.

S Make sure there is plenty of ventilation

when refueling or mixing fuel (gasoline and

2--stroke oil).

S Move the machine at least 10 feet (3 me-

ters) from the refueling point before starting it.

Min. 10 ft.

(3 m)

S Never start the machine:

S If you have spilled fuel on it. Wipe off

the spillage and allow remaining fuel to

evaporate.

S If you have spilled fuel on yourself or

your clothes, change your clothes. Wash

any part of y our body that has come in

contact with fuel. Use soap and water.

8

Page 9

SAFETY INSTRUCTIONS

v

S If the machine is leaking fuel. Check

regularly for leaks from the fuel cap

and fuel lines.

S Avoid all skin contact with fuel. Fuel is

a skin irritant and may even cause

skin changes.

Transporting and storage

S Store and transport the machine and fuel

so that there is no risk of any leakage or

fumes coming into contact with sparks or

naked flames, for example, from electrical machinery, electric motors, electrical

relays/switches or boilers.

S When storing and transporting fuel al-

ways use approved containers intended

for this purpose.

S When storing the machine for long peri-

ods the fuel tank must be emptied. Contact your local gas station to find out

where to dispose of excess fuel.

WARNING! Take care when han-

dling fuel. Bear in mind the risk of

fire, explosion and inhaling fumes.

General working instructions

IMPORTANT!

This section describes the basic safety precautions for working with trimmers. If you

encounter a situation where you are uncertain how to proceed you should ask an ex pert. Contact your servicing dealer.

Avoid all usage which you consider to be

beyond your capability.

You must understand the difference between

forestry clearing, grass clearing and grass

trimming before use.

3. Make sure you can mo

Check the area around y ou for possible obstacles (roots, rocks, branches, ditches, etc.)

in case y ou have to move suddenly. T ake

great care when working on sloping ground.

4. Switch off the engine before moving to

another area.

5. Never put the machine down with the engine

running.

Basic working techniques

S Always slow the engine to idle speed after

each working operation. Long periods at

full throttle without any load on the engine

can lead to serious engine damage.

WARNING! Sometimes branches

or grass get caught between the

guard and cutting attachment.

Always stop the engine before

cleaning.

e and stand safely.

Grass trimming using a trimmer

head

Trimming

Basic safety rules

1. Look around you:

S To ensure that people, animals or other

things cannot affect your control of the

machine.

S To ensure that people, animals, etc.,

do not come into contact with the cutting attachment or loos e objects that

are thrown out by the cutting attachment.

S CAU TION! Do not use the machine

unless you are able to call for help in

the event of an accident.

2. Do not use the machine in bad weather,

such as dense fog, heavy rain, strong

wind, intense cold, etc. Working in bad

weather is tiring and often brings added

risks, such as icy ground, unpredictable

felling direction, etc.

S Hold the trimmer head just above the

ground at an angle. It is the end of the trimmer line that does the work. Let the trimmer line work at its own pace. Never press

the trimmer line into the area to be cut.

S The trimmer line can easily remove grass

and weeds up against walls, fences, trees

and borders, however it can also damage

sensitive bark on trees and bushes, and

damage fence posts.

S Reduce the risk of damaging plants by short-

ening the trimmer line to 4- -4 1/2 inches

(10- -12 cm) and reducing the engine speed.

S When trimming you should use less than

full throttle so that the trimmer line lasts

longer and to reduce the wear on the

trimmer head.

9

Page 10

Clearing

SAFETY INSTRUCTIONS

Sweeping

S The clearing technique removes all un-

wanted vegetation. Keep the trimmer

head just abov e the ground and tilt it. Let

the end of the trimmer line strike the

ground around trees, posts, statues and

the like. CAUTION! This technique

increases the wear on the trimmer line.

S The trimmer line wears quicker and must

be fed forward more often when working

against stones, brick, concrete, metal

fences, etc., than when coming into contact with trees and wooden fences.

Cutting

S The trimmer is ideal for cutting grass that

is difficult to reach using a normal lawn

mower. Keep the trimmer line parallel to

the ground when cutting. Avoid pres sing

the trimmer head against the ground as

this can ruin the lawn and damage the

tool.

S Do not allow the trimmer head to con--

stantly come into contact with the ground

during normal cutting. Constant contact

of this type can cause damage and wear

to the trimmer head.

S The fan effect of the rotating line can be

used for quick and easy clearing up.

Hold the trimmer line parallel to and

above the area to be swept and move

the tool to and fro.

S When cutting and sweeping you should

use full throttle to obtain the best results.

WARNING! Neither the operator

of the machine nor anyone else may

attempt to remove the cut material

while the engine is running or the

trimmer line is rotating, as this can

result in serious injury. Stop the

engine and trimmer head before you

remove material that has wound

around the drive shaft as otherwise

there is a risk of injury. The bevel

gear can get hot during use and may

remain so for a while afterwards. You

could get burned if you touch it.

WARNING! Watch out for thrown

objects. Always wear eye protection.

Never lean over the cutting attach ment guard. Stones, rubbish, etc.

can be thrown up into the eyes

causing blindness or serious injury.

Keep unauthorized persons at a dis tance. Children, animals, onlookers

and helpers should be kept outside

the safety zone of 50 feet (15 meters).

Stop the machine immediately if

anyone approaches.

10

Page 11

KNOW YOUR TRIMMER

2

1

3

6

125L

4

1

1

5

16

125C

4

17

KNOW YOUR TRIMMER

1. Trimmer head 11. Starter handle

2. Grease filler cap 12. Fuel tank

3. Bevel gear 13. Choke control

4. Cutting attachment guard 14. Air purge

5. Shaft 15. Air filter cover

6. Loop handle 16. Handle adjustment

7. Throttle control 17. Drive disc

8. Stop switch 18. 2--stroke engine oil

9. Throttle lock 19. Operator’s manual (EPA)

10.Cylinder cover

8

7

15

13

14

10

9

18

11

12

19

11

Page 12

ASSEMBLY

Make sure unit is assembled

correctly as shown in this

manual.

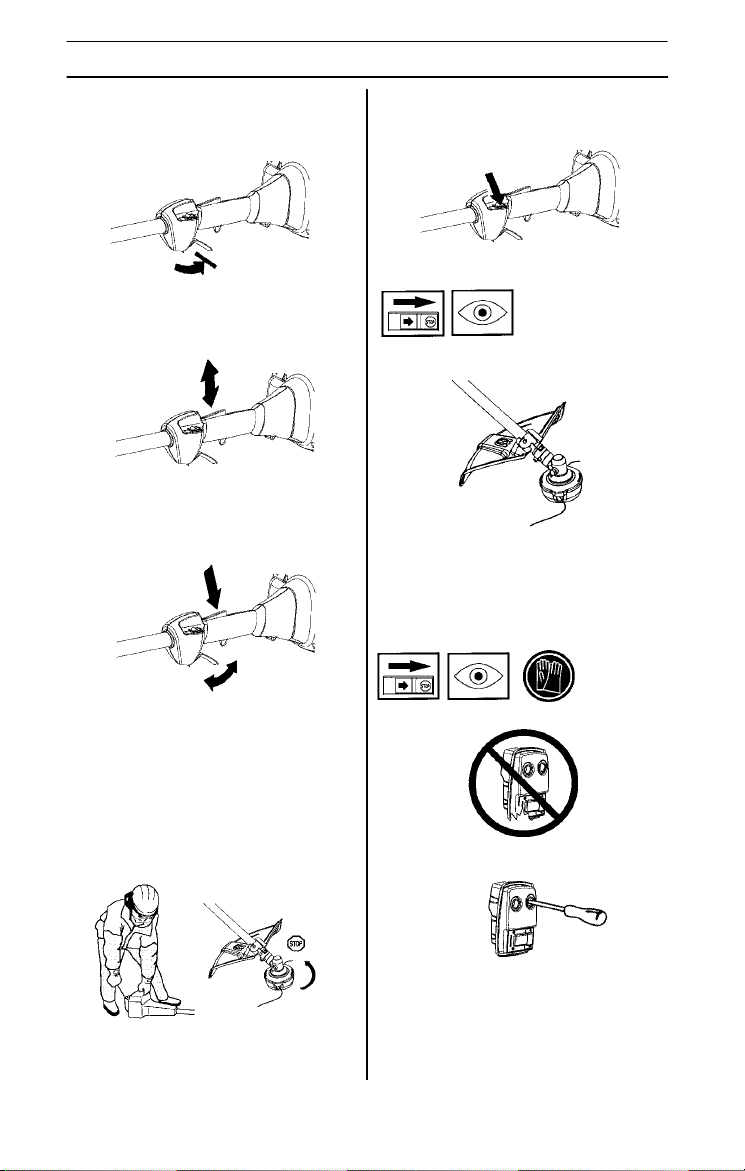

Fitting the loop handle

S Position the handle on the shaft. Note

that the handle must be mounted between the two arrows on the shaft.

S Fit the screw, securing plate and wing

nut as shown in the diagram.

S Tighten the wing nut.

Fitting the trimmer guard and

trimmer head (Model 125L)

S Fit the correct trimmer guard (A) for use

with the trimmer head. Hook the trimmer

guard/combination guard onto the fitting

on the shaft and secure with the bolt (D).

D

Fitting the trimmer guard and

trimmer head (Model 125C)

S Fit the correct trimmer guard (A) for use

with the trimmer head. Hook the trimmer

guard/combination guard onto the fitting on

the shaft and secure with the wing nut (B).

A

C

S Fit the dust cup (C) on the shaft. The nut

must be completely covered by the dust

cup.

S Hold the dust cup with a wrench to pre-

vent the shaft from rotating.

S Screw the trimmer head (D) onto the

shaft.

B

C

B

D

A

S Fit the drive disc (B) on the output s haft.

S Turn the shaft until one of the holes in the

drive disc aligns with the corresponding

hole in the gear housing.

S Insert hex wrench (C) in the hole to lock

the shaft.

S Screw on the trimmer head (H) in the op-

posite direction to the direction of rotation.

H

S To dismantle, follow the instructions in

the reverse order.

A

S To dismantle, follow the instructions in

the reverse order.

12

Page 13

FUEL HANDLING

A

f

Fuel

CAUTION! The machine is equipped with

a two--stroke engine and must always be

run using a mixture of gasoline and two-stroke engine oil. It is important to accurately measure the amount of oil to be

mixed to ensure that the correct mixture is

obtained. When mixing small amounts of

fuel, even small inaccuracies can drastically affect the ratio of the mixture.

WARNING! Always ensure

there is adequate ventilation when

handling fuel.

Gasoline

CAUTION! Always use high quality

unleaded gasoline.

S This engine is certified to operate on

unleaded gasoline.

S The lowest recommended octane rating

is 87. If you run the engine on lower octane rating than 87, “knocking” can occur. This leads to an increased engine

temperature, which can result in a serious engine breakdown.

S When working at continuous high revs a

higher octane rating is recommended.

Two - -st roke o i l

S For great results and performance use

HUSQVARNA two--stroke oil, which is

specially formulated for our two--stroke

engines. Mixture 1:50 (2%).

S To maximize the life of your trimmer, you

may choose to use a high quality synthetic oil formulated for two-- stroke

engines. Mixture 1:50 (2%).

S Never use two-- stroke oil intended for

water-- cooled outboard engines,

sometimes referred to as outboard oil.

S Never use oil intended for four-- stroke

engines.

Gasoline

U.S. gallon U.S. fl. oz.

121/2

2 1/2 6 1/2

5127/8

Mixing

S Always mix the gasoline and oil in a

clean container intended for fuel.

Two -- s tro ke oi l

2% (1:50)

S

S Mix (shake) the fuel mixture thoroughly

S Do not mix more than one month’s sup-

S If the machine is not used for some time,

Fueling

13

lways start byflling halfthe amount o

the gasoline to be used. Then add the

entire amount of oil. Mix (shake) the

fuel mixture. Add the remaining amount

of gasoline.

before filling the machine’s fuel tank.

ply of fuel at a time.

the fuel tank should be emptied and

cleaned.

WARNING! The catalytic con-

verter muffler gets very hot during

and after use. This also applies

during idling. Be aware of the fire

hazard, especially when working

near flammable substances and/or

vapors.

WARNING! Taking the following

precautions, will lessen the risk of

fire:

Do not smoke or place hot objects

near fuel.

Always shut off the engine before

refueling.

Always stop the engine and let it

cool for a few minutes before refuelling.

When refueling, open the fuel cap

slowly so that any excess pressure

is released gently.

Tighten the fuel cap carefully after

refueling.

Always move the machine away

from the refueling area before

starting.

Min. 10 ft.

(3 m)

Page 14

STARTING AND STOPPING

S Clean the area around thefuel cap. Con-

tamination in the tank can cause operating problems.

S Ensure that the fuel is well mixed by

shaking the container before filling the

tank.

Check before starting

S Inspect the unit before each use. Re-

place damaged parts. Check for fuel

leaks. Make sure all fasteners are in

place and secure. Make sure the cutting

attachment is properly installed and securely fastened. Use only flexible, nonmetallic line recommended by the

manufacturer. Never use, for example,

wire or wire rope, which can break off

and become a dangerous projectile.

S Chec k that the trimmer head and trimmer

guard are not damaged or cracked.

Replace the trimmer head or trimmer

guard if they have been exposed to

impact or are cracked.

S Never use the machine without a guard

nor with a defective guard.

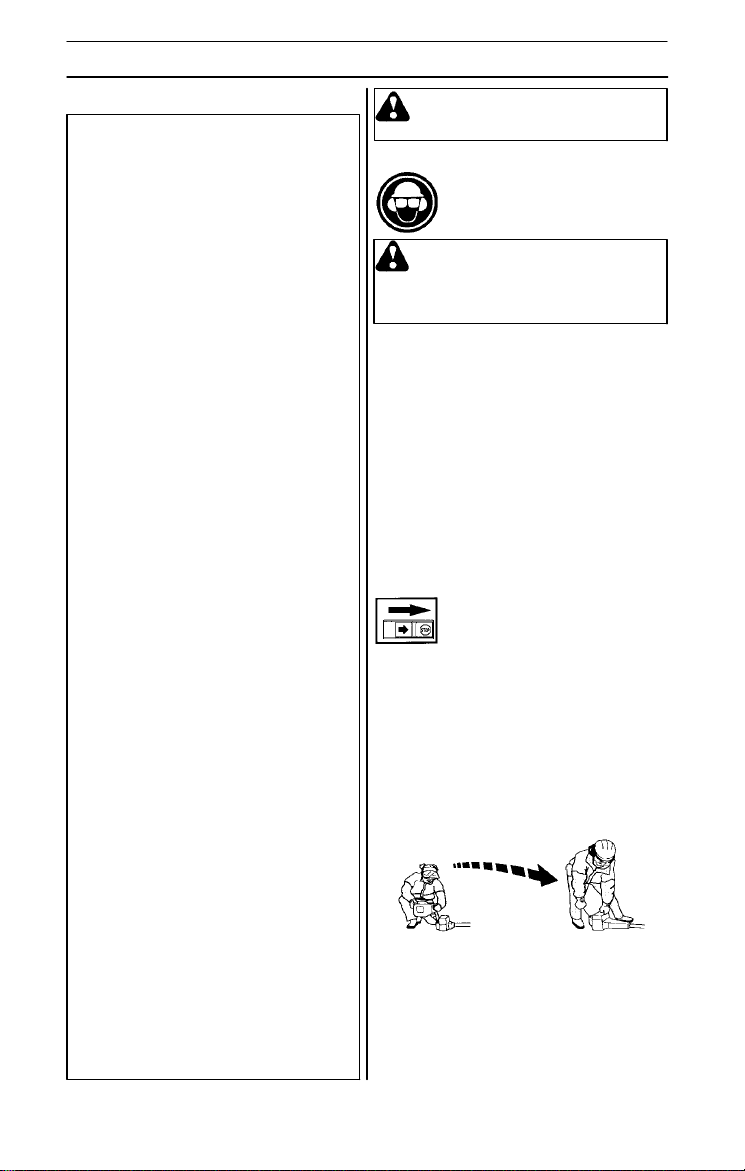

Starting and stopping

WARNING! The complete clutch,

clutch cover, and shaft must be

fitted before the machine is started,

otherwise parts could come loose

and cause personal injury.

Always move the machine away

from the refueling area before

starting. Place the machine on a

flat surface. Ensure the cutting attachment cannot come into contact

with any object.

Make sure no unauthorized persons

are in the working area, otherwise

there is a risk of serious personal

injury. The safety distance is 50 feet

(15 meters).

Cold engine

Air purge: Press the air purge diaphragm

6 -- 10 times until fuel begins to fill the diaphragm. The diaphragm need not be completely filled.

Choke: Move the blue engine choke lever

over to the closed position.

Starting

Hold the body of the machine on the

ground using your left hand (CAUTION!

Not with your foot!).

Grip the starter handle. Slowly pull out the

cord with your right hand until you feel

some resistance (the starter pawls grip);

then quickly and powerfully pull the cord.

Never wrap the starter cord around

your hand.

Repeat pulling the cord until the engine

attempts to start. Squeeze throttle trigger

to release the choke and pull starter rope

until engine runs.

NOTE: If engine dies, return blue engine

choke lever to the closed position and

repeat starting steps.

CAUTION! Do not pull the starter cord all

the way out and do not let go of the starter

handle when the cord is fully extended.

This can damage the machine.

14

Page 15

STARTING AND STOPPING

Warm engine

With a warm engine, squeeze and hold the

throttle trigger. Pull starter rope sharply

while squeezing throttle trigger until engine

runs.

Stopping

Stop the engine by pushing and holding

the stop switch in the STOP position until

the engine stops.

WARNING! Whentheengineis

started with the choke in the closed

position the cutting attachment will

start to rotate immediately.

15

Page 16

MAINTENANCE

f

The owner is responsible

mance of all required maintenance as

defined in the operator’s manual.

Carburetor

Your Husqvarna product has been designed

and manufactured to specifications that reduce harmful emissions. After the engine

has used 8-- 10 tanks of fuel, the engine will

be run--in. To ensure that it continues to run

at peak performance and to minimize harmful exhaust emissions after the run--in period, ask your servicing dealer to adjust your

carburetor.

WARNING! The complete clutch,

clutch cover, and shaft must be

fitted before the machine is started,

otherwise parts could come loose

and cause personal injury.

or the perfor-

Function

S The carburetor governs the engine’s

speed via the throttle control. Air and fuel

are mixed in the carburetor.

S The T--screw regulates the throttle setting

at idle speed. If the T--screw is turned

clockwise this gives a higher idle speed;

turning it counterclockwise gives a lower

idle speed.

Basic setting

S The basic carburetor settings are ad-

justed during testing at the factory. Fine

adjustment should be carried out by a

skilled technician.

CAUTION! If the cutting attachment rotates

when the engine is idling the idle adjustment

screw T should be turned counterclockwise

until the cutting attachment stops.

Rec. idle speed:

See “Technical data” section.

Recommended max. speed:

See “Technical data” section.

WARNING! Iftheidlespeed

cannot be adjusted so that the cut ting attachment stops, contact your

dealer/service workshop. Do not use

the machine until it has been correctly adjusted or repaired.

Fine adjustment of the idle

speed--T

Adjust the idle speed using the idle adjustment screw--T if it is necessary to readjust.

First, turn the idle adjustment screw--T

clockwise until the cutting attachment starts

to rotate. Then, turn the screw counterclockwise until the cutting attachment stops.

The idle speed is correctly adjusted when

the engine will run smoothly in every position. The idle speed should also be well

below the speed at which the cutting attachment starts to rotate.

Idle Speed

Screw-- T

WARNING! If the idle speed can -

not be adjusted so that the cutting

attachment stops, contact your ser vicing dealer. Do not use the ma chine until it has been correctly adjusted or repaired.

Unit/Maintenance Safety

Disconnect the spark plug before performing maintenance, except carburetor adjustments.

Muffler

CAUTION! Muffler is fitted with a catalytic

converter designed to reduce harmful exhaust gases.

The muffler is designed to reduce the noise

level and to direct the exhaust gases away

from the operator. The exhaust gases are

hot and can contain sparks, which may

cause fire if directed against dry and combustible material.

Mufflers are equipped with a special spark

arrestor mesh. The mesh should be

checked and, if necessary. cleaned by a

servicing dealer. If the mesh is damaged,

it should be replaced. Ifthemeshisfrequently blocked, this can be a sign that the

performance of the catalytic converter is

impaired. Contact your servicing dealer to

inspect the muffler. A blocked mesh will

cause the machine to overheat and result

in damage to the cylinder and piston.

16

Page 17

MAINTENANCE

Muffler bolts

CAUTION! Never use a machine that has

a faulty or loose muffler. Ensure the muffler

bolts are tight.

WARNING! Mufflers fitted with

catalytic converters get very hot

during use and remain so for some

time after stopping. This also ap plies at idle speed. Contact can result in burns to the skin. Remember

theriskoffire!

WARNING! The inside of the

muffler contain chemicals that may

be carcinogenic. Avoid contact with

these elements in the event of a

damaged muffler.

WARNING! Bear in mind that:

Engine exhaust fumes contain car bon monoxide, which can cause

carbon monoxide poisoning. For

this reason you should not start or

run the machine indoors, or anywhere that is poorly ventilated.

The exhaust fumes from the engine

are hot and may contain sparks

which can start a fire. Never start

the machine indoors or near com bustible material!

Spark plug

The spark plug condition is influenced by:

S Incorrect carburetor adjustment.

S An incorrect fuel mixture (too much or in-

correct type of oil).

S A dirty air filter.

These factors cause deposits on the spark

plug electrodes, which may result in operating problems and starting difficulties.

If the machine is low on power, difficult to

start or runs poorly at idle speed: always

check the spark plug first before taking

any further action. If the spark plug is dirty,

clean it and check that the electrode gap is

0.024″ (0.6 mm). The spark plug should be

replaced after about a month in operation or

earlier if necessary.

0.024″ (0.6 mm)

Air filter

The air filter must be regularly cleaned to

remove dust and dirt in order to avoid:

S Carburetor malfunctions

S Starting problems

S Loss of engine power

S Unnecessary wear to engine parts

S Excessive fuel consumption

Clean the filter every 25 hours, or more

regularly if conditions are exceptionally

dusty.

Cleaning the air filter

Remove the air filter cover and take out the

filter. Wash it clean in warm, soapy water.

Rinse thoroughly. Ensure that the filter is dry

before refitting it.

An air filter that has been in use for a long

time cannot be cleaned completely. The

filter must therefore be replaced with a new

one at regular intervals. A damaged air

filter must always be replaced.

Bevel gear

(125L)

The bevel gear is filled with the right quantity of grease at the factory. However, before using the machine you should check

that the bevel gear is filled three--quarters

full with grease. Use HUSQVARNA special

grease.

CAUTION! Always use the recommended

spark plug type! Use of the wrong spark

plug can damage the piston/cylinder.

17

Page 18

MAINTENANCE

The grease in the bevel gear does not normally need to be changed except if repairs

are carried out.

Maintenance schedule

Below you will find some general maintenance instructions.

Daily maintenance

S Check throttle trigger and throttle trigger

lockout function.

S Checkthatthestopswitchworks

correctly.

S Check that there are no fuel leaks from

the engine, tank or fuel lines.

S Check that the cutter does not rotate

when the engine is idling.

S Clean the outside of the machine.

S Check that the harness is not damaged.

S Check that the blade guard is not dam-

aged or cracked.

S Replace the blade guard if it is exposed to

impact or is cracked.

S A non--balanced trimmer head induces

heavy vibrations that may damage the

machine.

S Check that nuts and screws are tight.

S Check that the screws that hold the bevel

gear are tight.

S Check that the trimmer head is tight.

Weekly maintenance

S Chec k the starter and starter cord.

S Clean the carburetor area.

S Clean the outside of the spark plug. Re-

move it and check the electrode gap. Adjust the gap to 0.024″ (0.6 mm), or

replace the spark plug. Use resistor spark

plug Champion RCJ-- 6Y or equivalent.

S Clean the cooling fins on the cylinder and

check that the air intake near the starter

is not blocked.

S Chec k that the bevel gear is filled with

grease up to 3/4 full. Use special grease.

S Clean the air filter.

Monthly maintenance

S Clean the fuel tank.

S Clean the outside of the carburetor and

the space around it.

S Clean the fan and the area around it.

S Chec k fuel lines for cracks or other dam-

age. Change if necessary.

S Change the fuel filter in fuel tank.

S Chec k the clutch, clutch springs and the

clutch drum for wear. Replace if necessary.

S Chec k electrical wires and connections.

S Replac e the spark plug. Use resistor

spark plug Champion RCJ--6Y or equivalent.

S Change the air filter.

18

Page 19

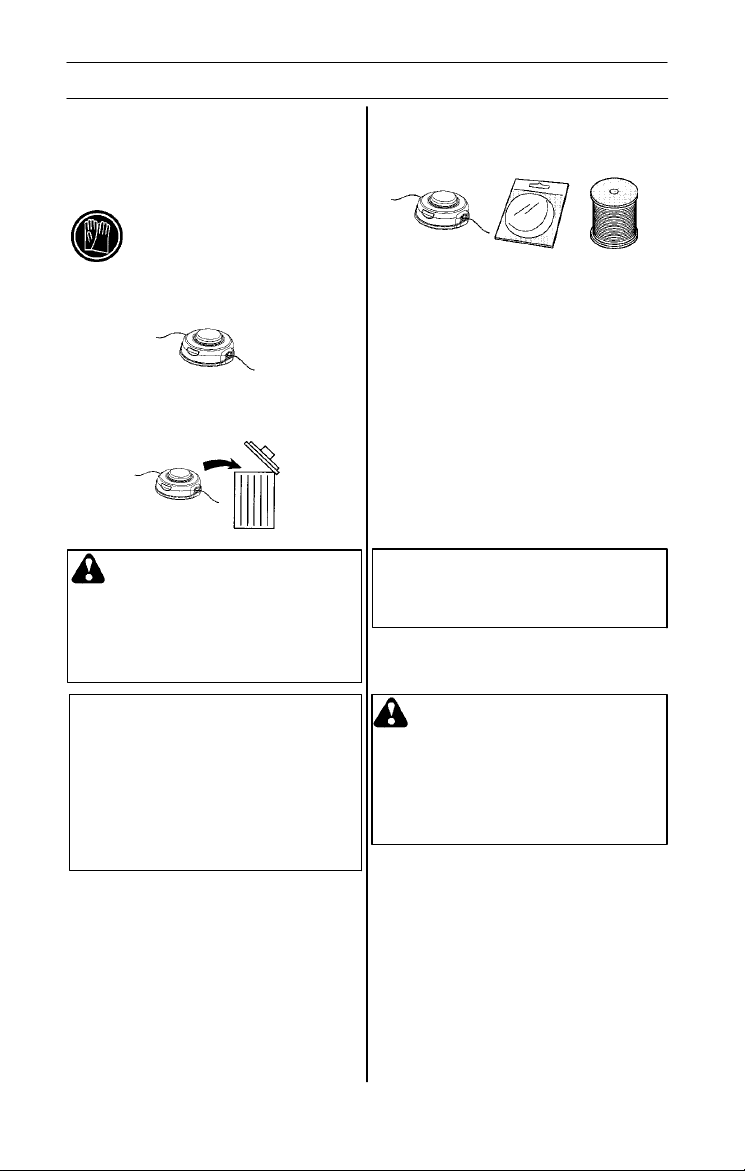

Trimmer Head Line Loading Instructions

6m

20i

3m

10i

19

Page 20

TECHNICAL DATA

Technical data

Engine

Cylinder volume, cu.in./cm

Cylinder bore, inch/mm 1.4/35 1.4/35

Stroke, inch/mm 1.130/28.7 1.130/28.7

Idle speed, rpm 2,800--3,200 2,800--3,200

Recommended max. speed, rpm 10,000 11,000

Speed of output shaft, rpm 8,000 8,000

Max. engine output, acc. to ISO 8893, hp/kW 1.1/0.8 1.1/0.8

Catalytic converter muffler Yes Yes

Speed--regulated ignition system No No

Ignition system

Manufacturer/type of ignition system Walbro/CD Walbro/CD

Spark plug Champion Champion

Electrode gap, inch/mm 0.024/0.6 0.024/0.6

Fuel and lubrication system

Manufacturer/type of carburetor Zama Zam a

Fuel tank capacity, US pint/liter 0.85/0.4 0.85/0.4

Weight

Weight without fuel, cutting attachment and guard, lbs/kg 10/4.4 11/4.8

Sound levels

(see note 1)

Equivalent sound pressure level at the user’s ear,

measured according to ANSI B175.3--1997, dB(A),

min/max: 94/97 94/97

Vibration levels

Vibration levels at handles, measured according to ANSI

B175.3-- 1997, m/s

At idle, left/right handles: 3/5 3/5

At max. speed, left/right handles: 9/8 9/8

Note 1: Equivalent noise pressure level is calculated as the time--weighted energy total for

noise pressure levels under various working conditions with the following time distribution:

1/2 idle and 1/2 max. speed.

NOTE! Noise pressure at the user’s ear and vibration on the handles are measured with all

the machine’s approved cutting equipment fitted. The table indicates the highest and lowest

values.

3

2

125C 125L

1.7/28 1.7/28

RCJ--6Y RCJ--6Y

Model 125C (3/8 RH arbor shaft thread)

Approved accessories Type Cutting attachment guard, part. no.

Trimmer head T25 537 33 83--03

Model 125L (M10 LH arbor shaft thread)

Approved accessories Type Cutting attachment guard, part. no.

Trimmer head T25 537 33 83--02

Plastic blades Tricut 300 mm 531 00 38--24

J- -Handle kit (to equip

unit for brush blade) 503 78 17- -01

*Brush blade 537 14 95--01

*For safety reasons, use ONLY when the trimmer has been fitted with the J--handle kit!

20

Page 21

WARRANTY STATEMENT

Y

X

SECTION 1: LIMITED WARRANT

Husqvarna Forest & Garden Company

(“Husqvarna”) warrants Husqvarna product

to the original purchaser to be free from defects in material and workmanship from the

date of purchase for the “Warranty Period” of

the products as set forth below:

Lifetime Warranty: Trimmer shafts, ignition

coils and modules.

2 Year NON--COMMERCIAL Warranty:

Trimmers for non-- commercial, non- -professional, non--institutional or non- -income producing use, except as herein stated.

Emission control sy stem components necessary to comply with CARB--TIER II and EPA

regulations.

1 Year Warranty: All trimmers used for

commercial, institutional, professional, or income producing purposes or use.

SECTION 2: HUSQVARN A ’S OBLIGATIONS UNDER THE WARRANTY

Husqvarna will repair or replace defective

components without charge for parts or labor

if a component fails because of a defect in

material or workmanship during the warranty

period.

SECTION 3: ITEMS NOT COVERED

BY THIS WARRANTY

The following items are not covered by this

warranty:

(1) Normal customer maintenance items

which become worn through normal regular use, including, but not limited to, filters,

lubricants, rewind springs, spark plugs,

and starter ropes.

(2) Natural discoloration of material due to

ultraviolet light.

SECTION 4: EXCEPTIONS AND

LIMITATIONS

This warranty shall be inapplicable to defects resulting from the following:

(1) Accident, abuse, misuse, negligence and

neglect, including stale fuel, dirt, abra sives, moisture, rust, corrosion, or any

adverse reaction due to incorrect storage

or use habits.

(2) Failure to operate or maintain the unit in

accordance with the operator’s manual or

instruction sheet furnished by Husqvarna.

(3) Alterations or modifications that change

the intended use of the product or affects

the product’s performance, operation,

safety, or durability, or causes the product

to fail to comply with any applicable laws.

(4) Additional damage to parts or c ompo-

nents due to continued use occurring after any of the above.

REPAIR OR REPLACEMENT AS PROVIDED UNDER THIS WARRANTY IS THE

EXCLUSIVE REMEDY OF THE PURCHASER. HUSQVARNA SHALL NOT BE LIABLE

FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR BREACH OF ANY

EXPRESS OR IMPLIED WARRANTY ON

THESE PRODUCTS E

TENT PROHIBITED BY APPLICABLE LAW.

ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ON THESE PRODUCTS IS LIMITED IN DURATION TO THE

WARRANTY PERIOD AS DEFINED IN THE

LIMITE D WARRANTY STATEMENT. HUSQVARNA RESERVES THE RIGHT TO

CHANGE OR IMPROVE THE DESIGN OF

THE PRODUCT WITHOUT NOTICE, AND

DOES NOT ASSUME OBLIGATION TO UPDATE PREVIOUSLY MANUFACTURED

PRODUCTS.

Some states do not allow the exclusion of incidental or consequential damages, or limitations on how long an implied warranty lasts,

so the above limitations or exclusions may not

apply to you. This warranty gives you specific

legal rights, and you may also have other

rights which vary from state to state.

CEPT TO THE EX-

SECTION 5: CUSTOMER RESPONSIBILITIES

The product must exhibit reasonable care,

maintenance, operation, storage and general upkeep as written in the maintenance

section of the operator’s manual. Should an

operational problem or failure occur, the

product should not be us ed, but delivered

as is to an authorized Husqvarna dealer for

evaluation. Proof of purchase, as explained

in Section 6, rests solely with the customer.

SECTION 6: PROCEDURE TO OBTAIN WARRANTY CONSIDERATION

It is the Owner’s and Dealer’s responsibility to

make certain that the Warranty Registration

Card is properly filled out and mailed to Husqvarna Forest & Garden Company. This card

should be mailed within ten (10) days from the

date of purchase in order to confirm the warranty and to facilitate post-- sale service.Proof

of purchase must be presented to the authorized Husqvarna dealer in order to obtain warranty service. This proof must include date

purchased, model number, serial number, and

complete name and address of the selling

dealer.To obtain the benefit of this warranty,

the product believed to be defective must be

delivered to an authorized Husqvarna dealer

in a timely manner, no later than thirty (30)

days from date of the operational problem or

failure. The product must be delivered at the

owner’s expense. Pick-- up and delivery

charges are not covered by this warranty. An

authorized Husqvarna dealer can be normally

located through the “Yellow Pages” of the local telephone directory or by calling

1--800--HUSKY62 for a dealer in your area.

7349 Statesville Road

CHARLOTTE, NC 28269

21

Page 22

U.S. EPA / CALIFORNIA / ENVIRONMENT CANADA

Y

EMISSION CONTROL WARRANTY STATEMENT

OUR WARRANTYRIGHTSAND

OBLIGATIONS:

The U.S. Environmental Protection Agency,

California Air Resources Board, Environment

Canada and HUSQVARNA are pleased to

explain the emissions control system warranty

on your year 2005 and later small off--road

engine. In California, all small off--road engines must be designed, built, and equipped

to meet the State’s stringent anti--smog standards. HUSQVARNA must warrant the emission control system on your small off- -road

engine for the periods of time listed below provided there has been no abuse, neglect, or

improper maintenance of your small off-- road

engine. Your emission control system includes

parts such as the carburetor and the ignition

system. Where a warrantable condition exists,

HUSQVARNA will repair your small off--road

engine at no cost to you. Expenses covered

under warranty include diagnosis, parts and

labor.

MANUFACTURER’S WARRANTY

COVERAGE:

If any emissions related part on your engine

(as listed under Emissions Control Warranty Parts List) is defective or a defect in the

materials or workmanship of the engine

causes the failure of such an emission related part, the part will be repaired or replaced by HUSQVARNA.

OWNER’S WARRANTY RESPONSIBILITIES:

As the small off--road engine owner, you are

responsible for the performance of the required maintenance listed in your operator’s

manual. HUSQVARNA recommends that

you retain all receipts covering maintenance

on your small off--road engine, but HUSQVARNA cannot deny warranty solely for the

lack of receipts or for your failure to ensure

the performance of all scheduled maintenance. As the small off--road engine owner,

you should be aware that HUSQVARNA

may deny you warranty coverage if your

small off--road engine or a part of it has

failed due to abuse, neglect, improper maintenance, unapproved modifications, or the

use of parts not made or approved by the

original equipment manufacturer. Y ou are

responsible for presenting your small off-road engine to a HUSQVARNA authorized

repair center as soon as a problem exists.

Warranty repairs should be completed in a

reasonable amount of time, not to exceed

30 days. If you have any questions regarding your warranty rights and responsibilities,

you should contact your nearest authorized

service center or call HUSQVARNA at

1--800--487-- 5963.

WARRANTYCOMMENCEMENT

DATE:

The warranty period begins on the date the

small off--road engine is purchased.

LENGTH OF COVERAGE:

This warranty shall be for a period of two

years from the initial date of purchase.

WHAT IS COVERED: REPAIR OR

REPLACEMENT OF PARTS.

Repair or replacement of any warranted

part will be performed at no charge to the

owner at an approved HUSQVARNA servicing center. If you have any questions regarding your warranty rights and responsibilities, you should contact your nearest authorized service center or call HUSQVARNA at 1--800-- 487-- 5963.

WARRANTY PERIOD:

Any warranted part which is not scheduled

for replacement as required maintenance,

or which is scheduled only for regular inspection to the effect of “repair or replace

as necessary” shall be warranted for 2

years. Any warranted part which is scheduled for replacement as required maintenance shall be warranted for the period of

time up to the first scheduled replacement

point for that part.

DIAGNOSIS:

The owner shall not be charged for diagnostic labor which leads to the determination that a warranted part is defective if the

diagnostic work is performed at an approved HUSQVARNA servicing center.

CONSEQUENTIAL DAMAGES:

HUSQVARNA may be liable for damages to

other engine components caused by the failure of a warranted part still under warranty.

WHAT IS NOT COVERED:

All failures caused by abuse, neglect, or

improper maintenance are not covered.

ADD-- ON OR MODIFIED PARTS:

The use of add--on or modified parts can be

grounds for disallowing a warranty claim.

HUSQVARNA is not liable to cover failures

of warranted parts caused by the use of

add--on or modified parts.

HOW TO FILE A CLAIM:

If you have any questions regarding your

warranty rights and responsibilities, you

should contact your nearest authorized service center or call HUSQVARNA at

1--800--487-- 5963.

WHERE TO GET WARRANTY SERVICE:

Warranty services or repairs shall be provided at all HUSQVARNA service centers.

Call 1 --800-- 487-- 5963.

22

Page 23

U.S. EPA / CALIFORNIA / ENVIRONMENT CANADA

EMISSION CONTROL WARRANTY STATEMENT

MAINTENANCE, REPLACEMENT

AND REPAIR OF EMISSION RELATED PARTS:

Any HUSQVARNA approved replacement

part used in the performance of any warranty maintenance or repair on emission related parts will be provided without charge

to the owner if the part is under warranty.

This engine is certified to be emissions compliant for the following use:

Moderate (50 hours)

Intermediate (125 hours)

Extended (300 hours)

EMISSION CONTR OL WARRANTY

PARTS LIST:

Carburetor, Ignition System: Spark Plug

(covered up to maintenance schedule), Ignition Module.

MAINTENANCE STATEMENT:

The owner is responsible for the performance of all required maintenance as defined in the operator’s manual.

23

Page 24

Loading...

Loading...