Husky 7285, 7356 Owner's Manual

Model #7285 and #7356

Recommended Installation, Maintenance

and Inspection Instructions

Diesel Exhaust Fluid (DEF) Adaptor

Important safety InstructIons - save these InstructIons In a readIly accessIble locatIon.

Designed for use at Diesel Exhaust Fluid (DEF)

WARNING:

dispensing facilities only.

DEF

INSTALLATION INSTRUCTIONS

NOTE: Always adhere to installation / usage instructions and warning. Improper use may result in injury, damage or

hazardous spill.

1. Turn off dispenser and relieve line pressure.

2. Only connect to DEF compatible and 304 stainless steel ttings - see page 2

for applicable seal congurations.

3. Do not use thread sealant (Teon tape, anti-seize or any other kind of sealant).

4. Install at the nozzle.

5. Tighten rmly, approximately 15 - 20 lbf•ft / 20.3 - 27 N•m, but do not

overtighten.

6. Pressurize system and visually check for leaks.

ONLY INSTALL AT NOZZLE. DO NOT OVERTIGHTEN.

IF DRIVE OFF OCCURS

• Turn off dispenser and relieve line pressure.

• Inspect the entire dispensing system for damage.

• Check for leaks.

• Follow all testing and maintenance instructions provided with the nozzle.

• Measure gap at joint - a credit card should not t in the gap (0.03 in /

0.76 mm).

• Check for electrical conductivity.

TESTING / MAINTENANCE / INSPECTION

ADAPTORS

Daily

• Check for leaks / stains

Monthly

• Measure gap at joint - a credit

card should not t in the gap

(0.03 in / 0.76 mm).

Annually

• Check for overall damage.

• Check for electrical

conductivity.

MADE IN THE USA

Husky Corporation • 2325 Husky Way • Pacic, MO 63069 • Phone: (800) 325-3558 • Fax: (636) 825-7300 • www.husky.com

• Always clean / rinse exterior

surfaces of DEF products with

deionized water.

• All drive aways, maintenance and

inspection activities must be logged

using the serial number of the

individual product.

• Apply city, state, or federal testing

regulations as appropriate.

ANY TEST / INSPECTION

FAILURE REQUIRES IMMEDIATE

EQUIPMENT REPLACEMENT OR

REMOVAL FROM SERVICE.

Page 1 009251-3 9/2011

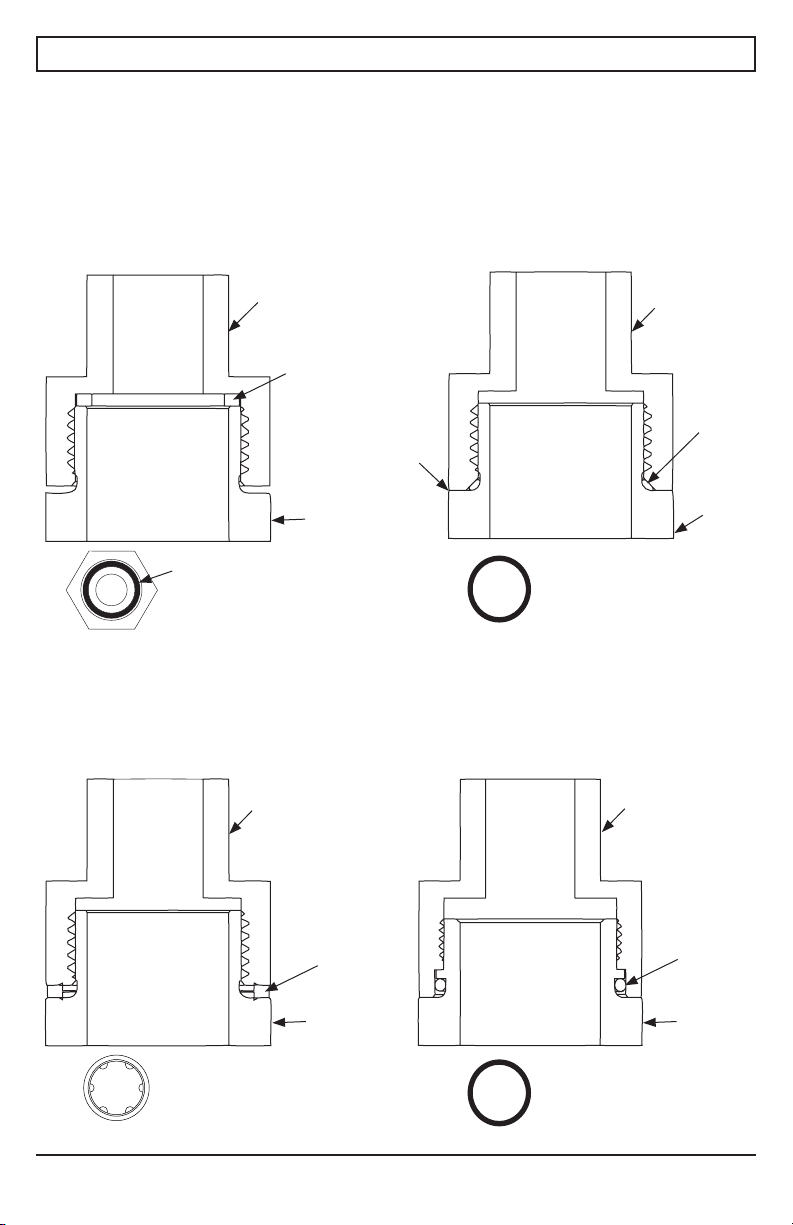

APPLICABLE SEAL CONFIGURATIONS

Model #7356 Adaptor thread type: M34 x 1.5 Male Thread one end; 1 x 11 Male BSPP other end.

Model #7285 Adaptor thread type: 1 x 11 Male BSPP both ends.

Option 1

▪ Seal is in mating device port.

▪ Husky gasket or o-ring seal not

Option 2

▪ Seal formed by Husky o-ring.

▪ Husky gasket not required.

required.

Hose BSPP port

Hose BSPP port

compression seal

(Figure 1.1)

Flange

surfaces

must

mate

Husky BSPP

tting plug

Figure 1.1

Hose BSPP port compression

seal (installed in hose port)

Figure 2.1

Husky o-ring

compression seal

Mating Device

BSPP port

Husky o-ring

compression

seal

(Figure 2.1)

Husky BSPP

tting plug

Option 3

▪ Seal formed by Husky gasket.

▪ Husky o-ring not required.

▪ Thread Husky gasket onto BSPP

tting plug. Do not press on.

Mating Device

BSPP port

Husky gasket

compression seal

(Figure 3.1)

Husky BSPP

tting plug

Figure 3.1

Husky BSPP gasket

compression seal

Husky Corporation • 2325 Husky Way • Pacic, MO 63069 • Phone: (800) 325-3558 • Fax: (636) 825-7300 • www.husky.com

Page 2 009251-3 9/2011

Option 4

▪ Seal formed by M34 o-ring.

▪ Additional Husky gasket or o-ring not

required.

Mating Device

M34 port

Figure 4.1

Husky M34 o-ring

compression seal

Husky M34

o-ring

compression

seal

(Figure 4.1)

Husky M34

tting plug

Loading...

Loading...