Page 1

Ultra 500/750/1000 Single Cavity Valve Gate 2.0

Service Procedure: 521-0

.

Product Affected Reference

Molds

Revision History

Rev. No. Comments Date

0 Initial release 2006-April-28

©2006 Husky Injection Molding Systems Ltd.

This document is the property of Husky Injection Molding Systems Ltd.

and the information herein is strictly confidential. This document shall

not be reproduced or used without the written permission of Husky

Injection Molding Systems Ltd.

Keeping our customers in the lead

Page 2

Summary: Follow this procedure to:

- perform preventative maintenance

- disassemble the Single Cavity Valve Gate (SCVG) unit

- replace the valve stem

- replace the seals

- reassemble the SCVG unit

Estimated Hours: 2 hours

Special Tools Required:

Reverse taper stem removal tool (HPN: 3512615).

Parts List:

HPN Description Qty

644751

534526 High temperature grease

High temperature anti-seize compound

*

1

1

1. Perform Lockout/Tagout. Refer to Machine Manual

for details.

WARNING!

Complete Lockout/Tagout of all energy

sources in accordance with applicable

local codes before performing

maintenance activities. Failure to do so

can result in injury or death.

*Estimated hours are for planning purposes only and do not include preparation times.

Service Procedure 521-0 2 of 21

Page 3

Weepage

Every 250,000 cycles the SCVG unit should be

disassembled, any weepage in the stem retainer well

should be cleaned out, and all seals replaced (see Seal

Replacement).

NOTE: Refer to the section entitled "Disassembly" for

instructions on how to disassemble the SCVG

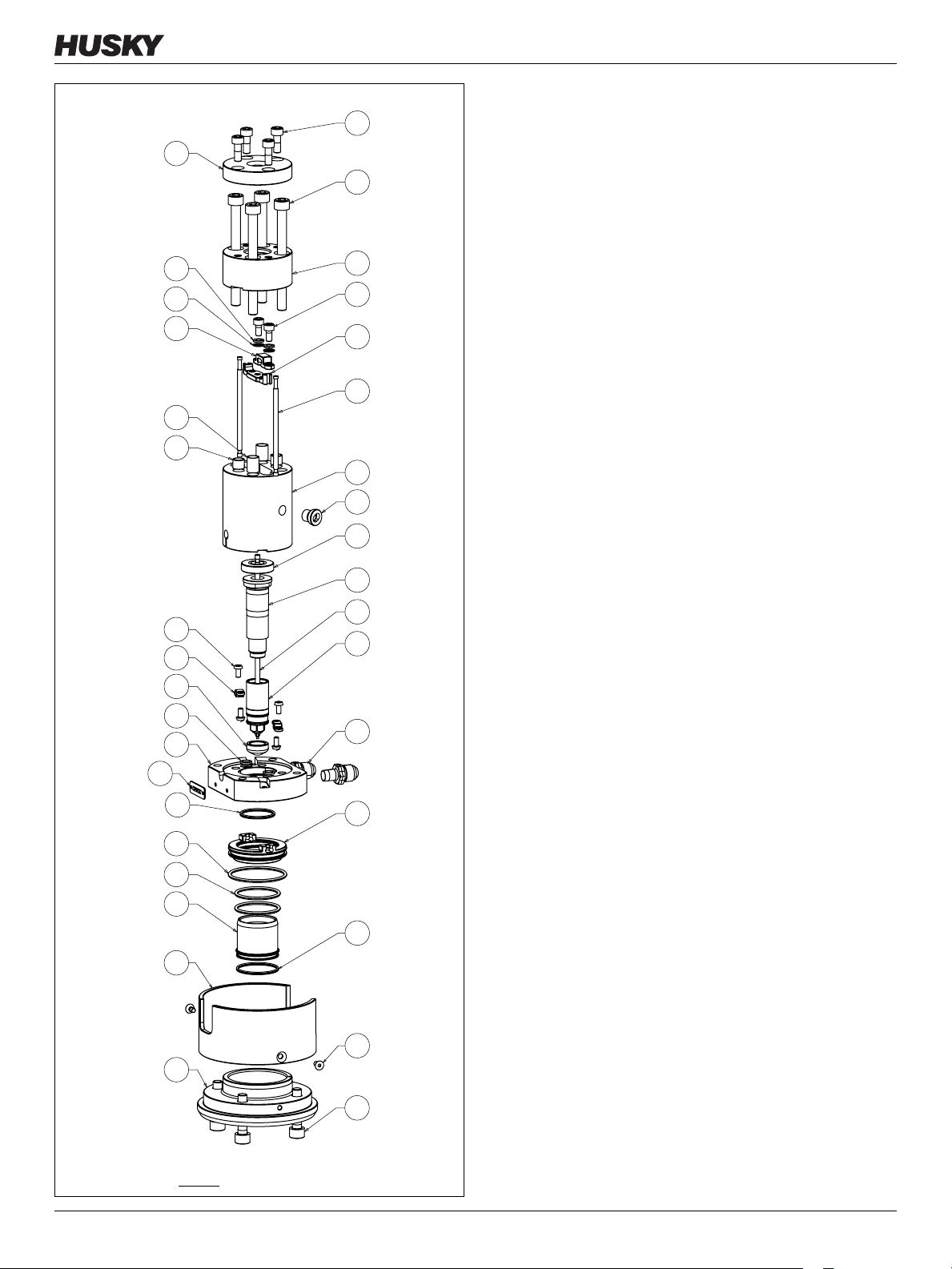

Disassembly

1. Remove the Locating Ring (not shown).

unit.

NOTE: Jacking screws are provided if necessary.

2. Make sure the wires and air lines are free and clear of

the unit.

3. Pull the unit from the mold.

4. Remove the flexible air lines and air fittings

(Figure 1, item 20).

5. Loosen the four SHCS (item 13) securing the sprue

bushing insert (item 32) and remove them from the

extruder pad (item 31).

6. Loosen the four SHCS (item 14) securing the

extruder pad (item 31) and remove them from the

sprue body (item 27).

7. Loosen the two SHCS (item 9) securing the stem to

the stem retainer (item 29).

8. Remove the front ring from the nozzle heater (not

shown).

9. Remove the nozzle heater snap ring (not shown).

10. Remove the nozzle heater (not shown).

11. Loosen the nozzle tip (item 24).

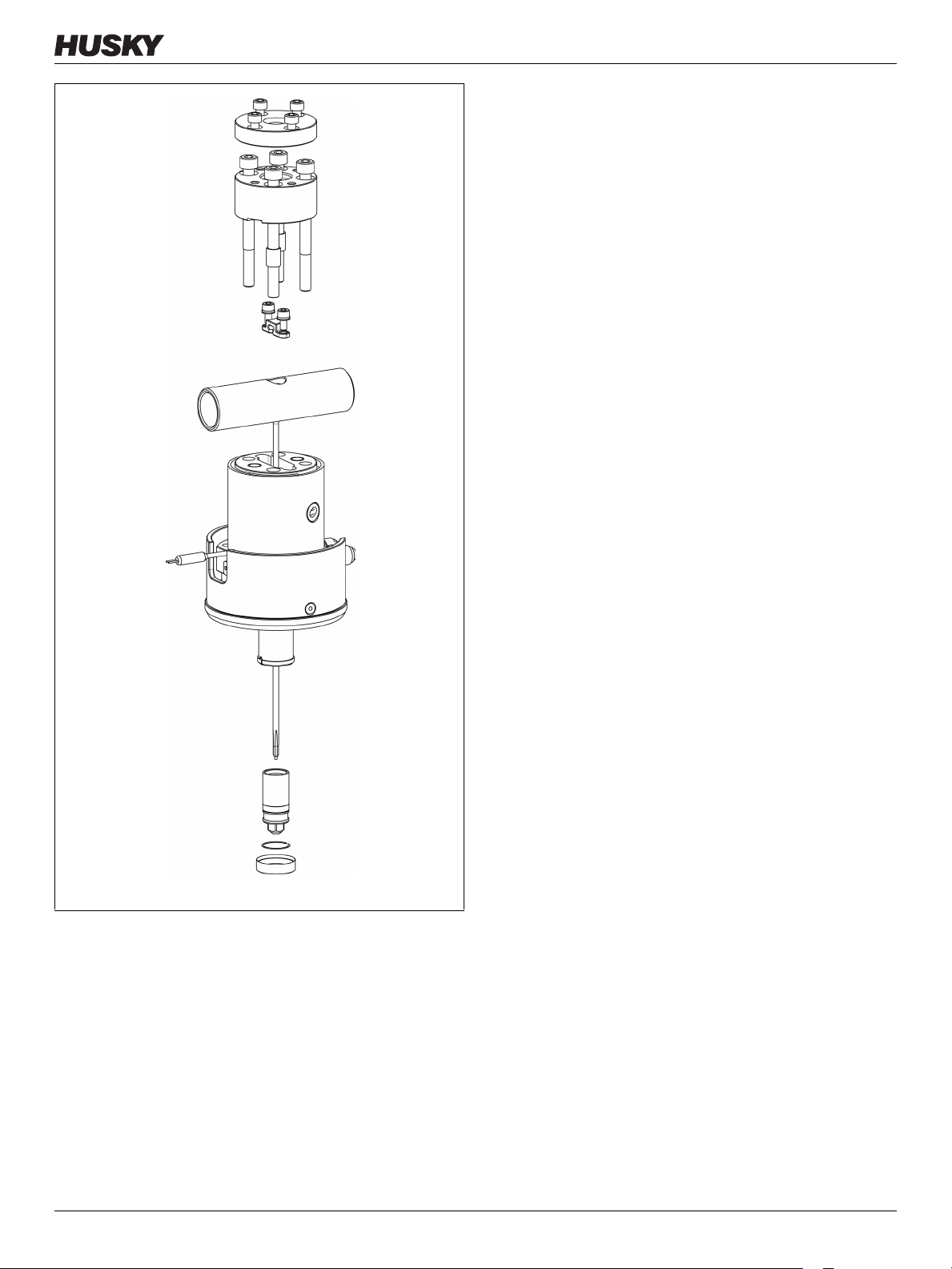

Figure 1 U500 & U750 SCVG assembly (typical)

Service Procedure 521-0 3 of 21

12. Insert the valve stem removal tool (HPN: 3512615)

into the injection side of the sprue body.

13. Gently tap the valve stem removal tool ensuring

contact with the stem (item 45) at all times until the

stem is tapped free from the sprue body.

14. Loosen the two sprue body retainer tab SHCS (item

10) from the air plate (item 39).

15. Loosen the cylinder SHCS (item 11) securing the

cylinder (item 34) to the air plate (item 39).

16. Pull the valve stem slider (item 28) and piston rods

(item 41) out of the sprue body (item 27).

17. Pull off the cylinder insert (item 33) from the air

plate (item 39).

18. Disengage the piston rods (item 41) from the piston

(item 40).

Page 4

19. Pull the Melt Channel (M/C) reducer (item 36) out of

the air plate (item 39).

20. Pull the nozzle (item 23) out of the air plate (item

39).

21. Remove the weep fitting (item 25) from the sprue

body (item 27) to enable removal of the sprue body

heater (not shown).

22. Clean all parts after disassembly. Make sure the

sealing and contact surfaces are free of plastic,

grease, dirt, and dust.

23. Replace the Grafoil seals (item 22), piston seals

(items 18 & 19), cylinder insert seal (item 43), and air

plate seal (item 44) at each disassembly.

Service Procedure 521-0 4 of 21

Page 5

Seal Replacement

All seals should be replaced each time the unit is

disassembled to ensure optimal sealing. Seal life is rated

at 250,000 cycles or 6 months (whichever occurs first).

Husky recommends having a spare Preventative

Maintenance (PM) kit on hand to facilitate easy seal

replacement.

NOTE: The following PM kits are available:

• SCVG 500 PM kit (HPN: 3509935)

• SCVG 750 PM kit (HPN: 3509936)

• SCVG 1000 PM kit (HPN: 3509937)

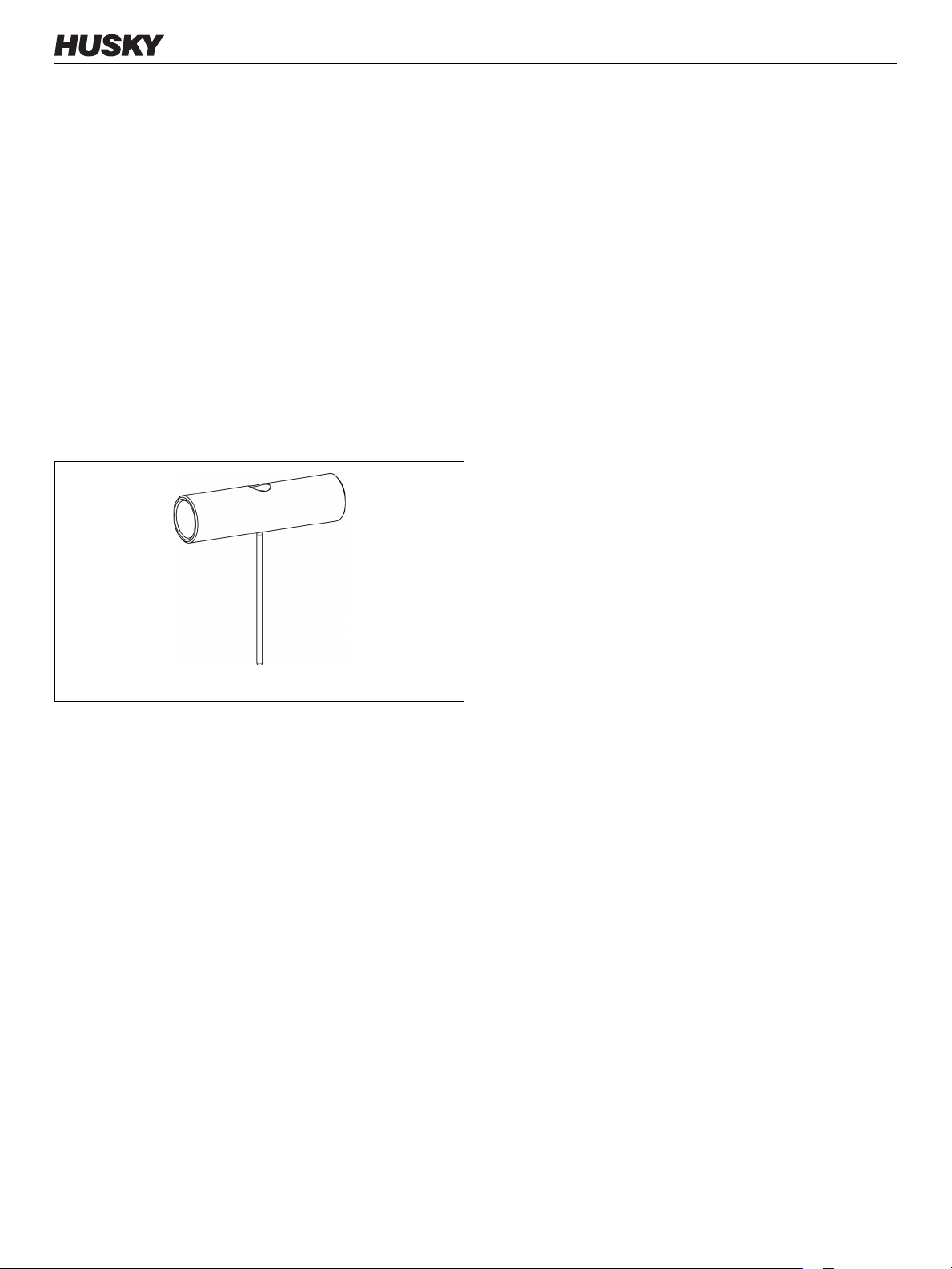

Stem Removal

1. Obtain a stem removal tool (Figure 2, HPN:

3512615).

Figure 2 Stem Removal Tool

Service Procedure 521-0 5 of 21

Page 6

2. Loosen the four SHCS securing the sprue bushing

insert and remove them from the extruder pad.

3. Loosen the four SHCS securing the extruder pad and

remove them from the sprue body.

4. Loosen the two SHCS securing the stem retainer to

the stem slider.

5. Remove the front ring of the nozzle heater.

6. Remove the nozzle heater snap ring.

7. Loosen the nozzle tip.

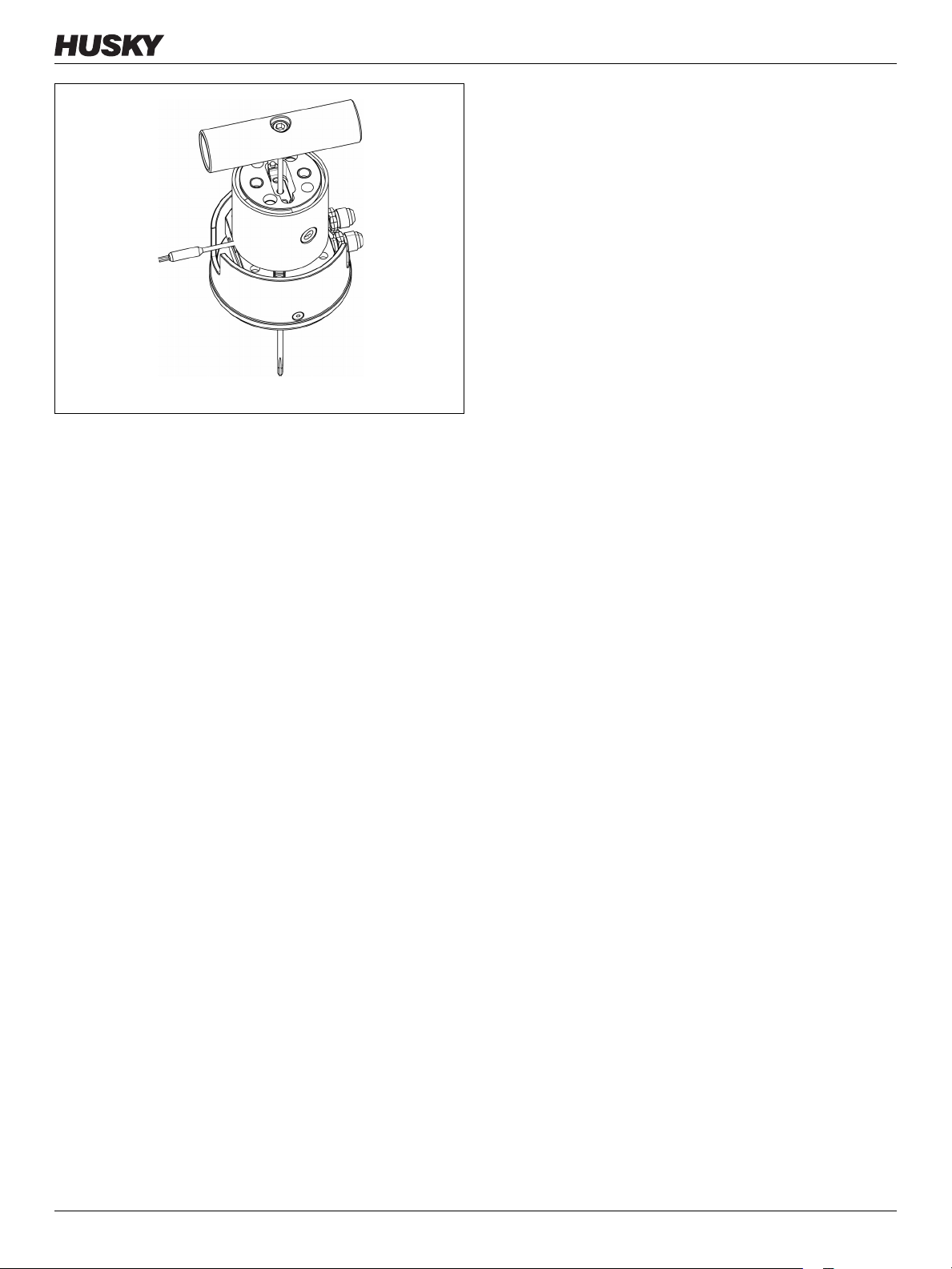

Figure 3 SCVG Assembly

Service Procedure 521-0 6 of 21

Page 7

Figure 4 Inserting the Valve Stem Removal Tool

8. Insert the valve stem removal tool into the injection

side of the sprue body.

9. Gently tap the valve stem removal tool ensuring

contact with the stem at all times, until the stem is

freed from the sprue body.

Service Procedure 521-0 7 of 21

Page 8

Reassembly

1. Unpack and clean all of the components. Compare

the nozzle housing and valve stem to design prints

and BOM. Make sure that the sprue body and nozzle

housing melt channels are clean and free of burrs.

Compare all of the components to the assembly

drawing for proper items and quantity.

2. Attach the name plate to the air plate using the

supplied rivets.

3. Place the air plate in a vise (Figure 5) with the arrow

facing down (i.e. boss down/pocket up).

Figure 5 Air Plate

Figure 6 Air Plate

1. Housing Flats 2. Air Plate Slot

4. Insert the nozzle housing threads down into the

plate (Figure 6).

NOTE: The housing flats will engage the air plate

1

2

2

slot when fully seated.

1

Service Procedure 521-0 8 of 21

Page 9

1

2

Figure 7 Air Plate

1. Grafoil Air Seal 2. Air Plate 3. M/C Reducer

5. Install the Grafoil air seals (Figure 7, item 1) into the

air plate (item 2) and M/C reducer (item 3).

3

6. Install the sprue body retaining tabs (Figure 8, item

1) into the sprue body. Finger tighten into place.

1

1

2

1

Figure 8 Sprue Body

1. Sprue Body Retaining Tabs 2. Older Revisions without

Tab s

NOTE: Older revisions may not have tabs.

Service Procedure 521-0 9 of 21

Page 10

1

3

2

4

Figure 9 Sprue Body and Air Plate

1. Sprue Body 2. Air Plate 3. T/C Hole 4. T/C Groove

1

1

7. Place the sprue body (Figure 9, item 1) onto the air

plate (item 2). Make sure that the Thermocouple (T/

C) hole (item 3) on the sprue body lines up with the

air plate T/C groove (item 4, for the T/C wire leads).

NOTE: The Piston Rods may need to be moved into

alignment with the holes in the insulator to get

the insulator to seat against the sprue body.

8. Install the dowel bushings (Figure 10, item 1) into

the sprue body.

Figure 10 Sprue Body

1. Dowel Bushings

Figure 11 Sprue Body

1. Crush Rings

9. Install the crush rings (Figure 11, item 1) into the

sprue body.

1

Service Procedure 521-0 10 of 21

Page 11

10. Assemble the stem slider (Figure 12, item 1) and

connecting rods (item 2).

1

NOTE: The stem slider is assembled flat side down.

2

Figure 12 Stem Slider and Connecting Rods

1. Stem Slider 2. Connecting Rods

2

11. Tilt the sprue body 45 ° in vise as shown (Figure 13).

Figure 13 Tilting the Sprue Body

Service Procedure 521-0 11 of 21

Page 12

1

2

3

Figure 14 Valve Stem and Sprue Body

1. Nozzle Housing 2. Valve Stem 3. Stem head

4. Pocket

12. Install the valve stem (Figure 14, item 2) into the

nozzle housing (item 1) reverse taper side first, until

the reverse taper bottoms out on the sprue body

and the stem head (item 3) protrudes out of the

pocket (item 4).

4

1

2

Figure 15 Stem Retainer and Stem Head

1. Stem Retainer 2. Stem Head

13. Assemble the stem retainer (Figure 15, item 1) onto

the stem head (item 2) and seat it onto the stem

slider.

Service Procedure 521-0 12 of 21

Page 13

14. Apply anti-seize compound to the stem retainer

screws (Figure 16, item 2) and torque to 7lb-ft (9.49

Nm). Install a lock washer or star washer (item 1).

Make sure the valve stem assembly moves freely.

1

12

Figure 16 Stem Retainer Screws and Valve Stem Assembly

1. Lock Washer 2. Stem Retainer Screws

1

2

Figure 17 Extruder Pad and Sprue Body

1. Extruder Pad 2. Sprue Body

15. Install the extruder pad (Figure 17, item 1) onto the

sprue body (item 2). Make sure the assembly bolt

holes line up correctly.

Service Procedure 521-0 13 of 21

Page 14

1

Figure 18 Rotating the SCVG Assembly

1. Extruder Pad

16. Apply anti-seize compound to the extruder pad

(Figure 18, item 1) and sprue body SHCS. Install and

torque to 32 lb-ft (43.4 Nm).

17. Rotate the SCVG assembly 180 ° in a vise (Housing

up).

18. Install the piston o-rings (Figure 19, item 1) onto the

piston. Lubricate all o-rings with silicon o-ring

lubricant.

Figure 19 Piston O-Rings

1. Piston O-Rings

1

Figure 20 Piston

1. O-Rings 2. Cylinder Insert

1

19. Install the o-rings (Figure 20, item 1) onto the

cylinder insert (item 2). Lubricate all o-rings with

silicon o-ring lubricant.

2

Service Procedure 521-0 14 of 21

Page 15

1

2

Figure 21 Installing the O-Rings onto the Boss Plate

1. Piston O-Rings 2. Air Plate boss

20. Install the o-rings (Figure 21, item 1) onto the air

plate boss (item 2). Lubricate all o-rings with silicon

o-ring lubricant.

21. Install the cylinder insert (Figure 22, item 1) into the

piston. Make sure the cylinder insert does not cover

the inner connecting rod retaining groove.

2

1

Figure 22 Cylinder Insert

1. Cylinder Insert 2. Piston Rod Retaining Slots

1

2

NOTE: The chamfer side of the cylinder insert is

inserted opposite the piston rod retaining

slots (item 2).

22. Assemble the cylinder insert assembly (Figure 23,

item 1) onto the connecting rods (item 2).

2

Figure 23 Installing the Cylinder Insert

1. Cylinder Insert Assembly 2. Connecting Rods

Service Procedure 521-0 15 of 21

Page 16

1

2

3

4

Figure 24 Air Open Line Alignment

1. Cylinder Insert 2. Arrows 3. Air Open Lines 4. Air

Plate

1

1

23. Slide/push the cylinder insert (Figure 24, item 1)

down over the air plate boss o-ring.

24. Lubricate the cylinder inner walls with o-ring

lubricant and assemble onto the air plate (item 4).

Align the air open lines (item 3) by making sure the

arrows (item 2) are pointing to each other.

25. Apply anti-seize compound to the cylinder SHCS

(Figure 25, item 1) and install. Torque to 29 lb-ft (39.3

Nm) in a star pattern.

1

Figure 25 Cylinder SHCS

1. Cylinder SHCS

Figure 26 Air Test Fittings

1

26. Temporarily install the air test fittings (Figure 26)

and cycle the valve stem several times. Apply steady

pressure (110 psi/0.76 MPa) to air open and listen for

audible air leaks. Apply steady pressure (110 psi/

0.76 MPa) to air close and listen for any audible air

leaks.

NOTE: If there are any air leaks check for the

following:

• damaged o-rings

• partially seated components

• improperly torqued components

Service Procedure 521-0 16 of 21

Page 17

Figure 27 Nozzle Tip

1. Nozzle Tip

27. Install the nozzle tip (Figure 27, item 1) and torque

to specification (35-40 lb-ft/47.5-54.2 Nm).

1

28. Rotate the SCVG over 180 ° in a vise (sprue body

facing up).

29. Place/fit the sprue body T/C into the sprue body

(Figure 28, item 1) using small electrical pliers.

Remove the sprue body T/C (item 2) to facilitate

sleeve installation.

1

Figure 28 Sprue Body T/C

1. Sprue Body 2. Sprue Body T/C

2

Service Procedure 521-0 17 of 21

Page 18

30. Install the sleeve with the two M4 FHS (Figure 29,

item 1 - finger tighten).

Figure 29 Air Fittings

1. M4 FHS 2. Air Fittings

1

1

install.

12

31. Apply Teflon tape to the air fittings (item 2) and

32. Install the pre-fitted T/C (Figure 30, item 1) into

sprue body.

1

Figure 30 Sprue Body T/C

1. Pre-fitted T/C

1

Figure 31 Retainer Weep Fitting Hole

1. Weep Fitting Hole

33. Install the sprue body heater onto the sprue body.

Make sure the retainer weep fitting hole in the

heater (Figure 31, item 1) aligns with the sprue body

installation.

Service Procedure 521-0 18 of 21

Page 19

1

Figure 32 Retainer Weep Fitting

1. Heater Retainer/Weep Fitting

34. Install the heater retainer/weep fitting (Figure 32,

item 1) using an M6 Allen key.

35. Install the sprue bushing insert into the sprue body.

Make sure all four counterbores align with the sprue

1

body taps.

36. Apply anti-seize compound to the four M6 SHCS

(Figure 33, item 1) and install onto the sprue

bushing insert. Torque to specification per assembly

drawing.

Figure 33 Sprue Body

1. M6 SHCS

2

1

3

Figure 34 SCVG Assembly

1. Nozzle Heater 2. Snap Ring 3. Wire Leads

37. Rotate the SCVG assembly over 180 ° (nozzle facing

up).

38. Install the nozzle heater (Figure 34, item 1) and snap

ring (item 2). Make sure the wire leads (item 3) are in

the same orientation as the sprue body heater.

Service Procedure 521-0 19 of 21

Page 20

Figure 35 SCVG Assembly

1. Front Ring 2. Nozzle T/C

1

39. Install the nozzle T/C (Figure 35, item 2) and bend

1

the leads to avoid getting pinched between the

cavity plate and the manifold plate.

40. Install the front ring (item 1 - finger tighten).

2

41. Prepare the SCVG for shipment (Figure 36):

• Install the air fitting caps (item 3)

2

• Install the nozzle tip cap (item 2)

• Tie wrap the heater leads as shown (item 1)

3

Figure 36 Completed SCVG Assembly

1. Heater Leads 2. Nozzle Tip Cap 3. Air Fitting Caps

Service Procedure 521-0 20 of 21

Page 21

Table 1 HGT-50 Torque Specifications for SHCS

Sample Torque Chart

Torque

Size

Nm lb ft

M4 3 2.2

M5 6.2 4.6

M6 10 7

M8 25 18

M10 53 40

M12 95 70

M14 130 95

M16 220 160

M18 270 200

M20 390 290

M24 660 490

M30 1300 960

M36 2300 1700

• For a comprehensive listing of torque values for

other fasteners and fittings, refer to the Machine

Manual.

M42 3700 2700

M48 5500 4000

Further Assistance

If you require assistance, please call your Regional Husky

Sales Office or the respective Technical Support Group

listed below:

Bolton

Toll free: 1-800-465-HUSKY (4875)

Direct: (905) 951-4875

Fax: (905) 951-5348

Luxembourg

EC (except Greece): 008000 800 4300

Non-EC: + (352) 52115-4300

Fax: + (352) 523040

Service Procedure 521-0 21 of 21

Loading...

Loading...