Page 1

SERIES 70 AND 1800

CONSUMER ELECTRIC PUMPS

INSTALLATION/OPERATION/PARTS

MANUAL

035219

REV. 0259

INSTALLERS - IMPORTANT

In addition to installation information, this manual contains warnings, safeguards

and procedures on the use and care of the Series 70 and 1800 pumps. Please leave

this manual with the pump owner after the installation is complete.

Copyright 1999 by Gasboy International, Inc. All rights reserved.

The information in this document is confidential and proprietary. No further disclosure shall be made without

permission from Gasboy International, Inc. Gasboy International, Inc. believes that the information in this document

is accurate and reliable. However, we assume no responsibility for its use, nor for any infringements of patents or

other rights of third parties resulting from its use. We reserve the right to make changes at any time without notice.

GASBOY INTERNATIONAL, INC. A TOKHEIM SUBSIDIARY LANSDALE, PA

Page 2

IMPORTANT WARNINGS AND SAFEGUARDS

Gasoline and petroleum products are flammable. To avoid injury or death to persons or damage to equipment or

property, follow these listed warnings and other warnings and precautions outlined in this manual when installing, using,

or working around this equipment. Check with GASBOY Technical Services for compatibility of liquids with pump

materials.

TURN OFF AND LOCK OUT ALL POWER TO PUMP BEFORE PERFORMING SERVICE, MAINTENANCE OR IN THE EVENT

OF A FUEL SPILL.

All products must be installed by a

qualified installer and used in

conformance with all building, fire, and

environmental codes and other safety

requirements applicable to its

installation and use, including, but not

limited to, NFPA 30, NFPA 30A, NFPA

395 & NFPA 70. A qualified installer is

familiar with fuel systems installations

under the above stated building, fire,

and environmental codes and other

safety requirements for the particular

type of installation.

This product is only part of a fuel

dispensing system and additional

equipment and accessories, such as,

but not limited to, breakaway

connectors, shear valves, pressure

regulators, flow limiters, and other

safety devices may be necessary to

meet the applicable codes.

For maximum safety, we recommend

that all employees be trained as to the

location and procedure for turning off

power to the entire system. Instructions

regarding proper operation of the

equipment along with the appropriate

safety warnings should be posted in

plain view at the fuel island.

Before performing service or

maintenance (including changing of fuel

filters or strainers) or in the event of a

fuel spill, turn off and lock out all power

to the system. In battery-powered

pumps, disconnect power source. In

submersible pump applications, turn off

and lock out power at the master panel

and close any impact valves to the

submersible pump and any other

dispensers which use that submersible

pump. AC power can feed back into a

shut-off dispenser when dispensers

share a common submersible pump or

starter relay. Also block islands so no

vehicles can pull up to the dispenser

when the dispenser is being worked on.

Federal DOT regulations prohibit

dispensing flammables, such as

gasoline, from portable tanks.

DO NOT

threads in the product.

DO NOT

pumping fuel or additives into aircraft.

DO NOT

direct fueling of aircraft without filters

and separators necessary to ensure

product purity.

DO NOT

required (for food products for human

consumption) or with water-based

liquids.

DO NOT

using the pump.

DO NOT

electrical equipment which may ignite

fumes.

DO NOT

gasoline or other petroleum products

into a vehicle with its motor running.

DO NOT

gasoline or other petroleum products

into unapproved containers or into

approved containers in or on vehicles

including trucks. All containers must be

filled on the ground to prevent static

discharge. Always use Approved and

Listed hoses and nozzles with electric

pumps and dispensers.

DO NOT

manner. Nozzles shall conform to UL

and NFPA code requirements for

attended or unattended service.

DO

with proper filters based on the product

being dispensed and its intended use.

DO

clothes when dispensing any liquid

which may be potentially harmful or

hazardous.

DO

clothing clear of belts, pulleys, and other

exposed moving parts at all times.

use Teflon tape for any pipe

use consumer pumps for

use commercial pumps for

use where sanitary design is

smoke near the pump or when

use near open flame or

permit the dispensing of

permit the dispensing of

block open the nozzle in any

ensure that the pump is equipped

wear safety goggles and protective

keep all parts of body and loose

DO

require washing and changing of

clothes if fuel is spilled on a person or

his/her clothing. Keep away from open

flames, sparks, or people smoking.

DO

provide a receptacle for catching

product from pump/meter when

servicing.

DO

clean up product spills on the

driveway. Turn off and lock out all

power prior to cleanup.

DO

insure pump is properly grounded.

DO

insure hose is compatible with fluid

being dispensed.

DO

inspect hose, nozzle, and pump on

a regular basis for wear, damage, or

other conditions which may create a

safety or environmental hazard.

DO

make sure all pipe threads are

properly cut and the inside reamed to

remove burrs. Use UL classified

gasoline-resisting compound on all

joints of gasoline handling piping.

Sealing compound must also be

resistant to Gasohol (Ethanol and

Methanol). Use gasoline-resistant pipe

compound on male threads only; pipe

compound used on female threads can

be squeezed into the supply line where

it can enter the product stream and

become lodged in the pump or meter.

DO

ensure that junction box covers are

in place and properly tightened. Mating

surfaces between the box and cover

must be free of dirt, nicks, and

scratches. All unused entries into the

junction box must be properly plugged.

035282 Rev. 0215

GASBOY INTERNATIONAL, INC.

A TOKHEIM SUBSIDIARY

707 North Valley Forge Rd. Lansdale, PA, 19446

(215) 855-4631

●

FAX: (215) 855-0341

●

Page 3

CONTENTS

IMPORTANT WARNINGS AND SAFEGUARDS FOR CONSUMER PUMPS

Section 1: INTRODUCTION

Purpose..................................................................................................... 1-1

Specifications* .......................................................................................... 1-1

Section 2: INSTALLATION

Installation Precautions............................................................................. 2-1

Supply Line - Underground Tanks............................................................ 2-2

Pump Dimensions - Series 70, Model 1820 ............................................. 2-3

Pump Dimensions - Series 1820R............................................................ 2-3

Installation Instructions ............................................................................. 2-4

Cabinet Removal for Installation or Service (Series

1820 only - Rounded Cabinet).......................................................... 2-4

Cabinet Removal for Installation or Service (Series

1820 only - Squared Cabinet)........................................................... 2-4

Installing Hose and Nozzle.................................................................. 2-4

Direct Mount on Underground Tank .................................................... 2-5

Direct Mount on Aboveground Tank.................................................... 2-6

Pedestal Mount Pump ......................................................................... 2-7

Wall Mount........................................................................................... 2-8

Vacuum Breaker.................................................................................. 2-9

Section 3: WIRING

Wiring Precautions.................................................................................... 3-1

Circuit Breakers ........................................................................................ 3-1

Grounding................................................................................................. 3-2

The Pump Motor....................................................................................... 3-2

Wire Size .................................................................................................. 3-2

Pulser Wiring ............................................................................................ 3-3

Conduit...................................................................................................... 3-3

Pump Wiring Diagrams............................................................................. 3-4

Section 4: STARTUP AND OPERATION

Pre-Startup Checklist................................................................................ 4-1

Startup ...................................................................................................... 4-1

Post Startup Tests .................................................................................... 4-2

Voltage................................................................................................. 4-2

Tightness............................................................................................. 4-2

Meter Calibration ................................................................................. 4-2

Strainer Cleaning................................................................................. 4-3

Daily Operation......................................................................................... 4-3

Section 5: MAINTENANCE AND TROUBLESHOOTING

Maintaining Trouble-Free Operation......................................................... 5-1

When Your Pump Needs Service............................................................. 5-2

0144 Contents-1

Page 4

GASBOY Series 70 & 1800

Troubleshooting........................................................................................ 5-3

Disassembly of Pump............................................................................... 5-5

Meter-Register Disassembly..................................................................... 5-5

1860 3-Wheel Register Service and Maintenance ................................... 5-6

4860 4-Wheel Register Service................................................................ 5-7

Section 6: PARTS

Series 70 Assembly.................................................................................. 6-2

Optional Accessories........................................................................... 6-3

Series 1800 Assembly.............................................................................. 6-4

Optional Accessories........................................................................... 6-5

Direct Drive Motor-Pump Assembly.......................................................... 6-6

Installation Parts ....................................................................................... 6-8

1860 and 4860 Meter-Register................................................................. 6-9

Register Assemblies................................................................................. 6-9

1860 3-Wheel Meter Register (Model 1820) ............................................ 6-10

4860 4-Wheel Register (Model 72S and Series 1820R) .......................... 6-12

Model 1820 Register Setback and Switch Linkage Assembly.................. 6-14

Optional Kits for Series 70 and 1800 Pumps............................................ 6-15

Series 1820R Parts List............................................................................ 6-16

1820R Pulser and Junction Box Assemblies............................................ 6-18

Warranty

Contents-2 0144

Page 5

Section 1

INTRODUCTION

PURPOSE

The GASBOY

provided to assist the installer in installing and operating the unit. Faulty installations are the

major cause of unit malfunc tions. This manual should be supplied to the electr ician prior to the

installation of conduit and wiring. The Series 70 or 1820 pum ps

as described in this manual. This manual also c ontains warnings, saf eguards and proc edures on

the use and care of the pump. Be sure to leave this manual with the pump owner after the

installation is complete.

Customers and installers having any questions pertaining to the installation should

☎☎☎☎

contact their GASBOY distributor.

Series 70 and 1820 Consumer Electric Pumps Installation/Operation Manual

must

be installed and operated

is

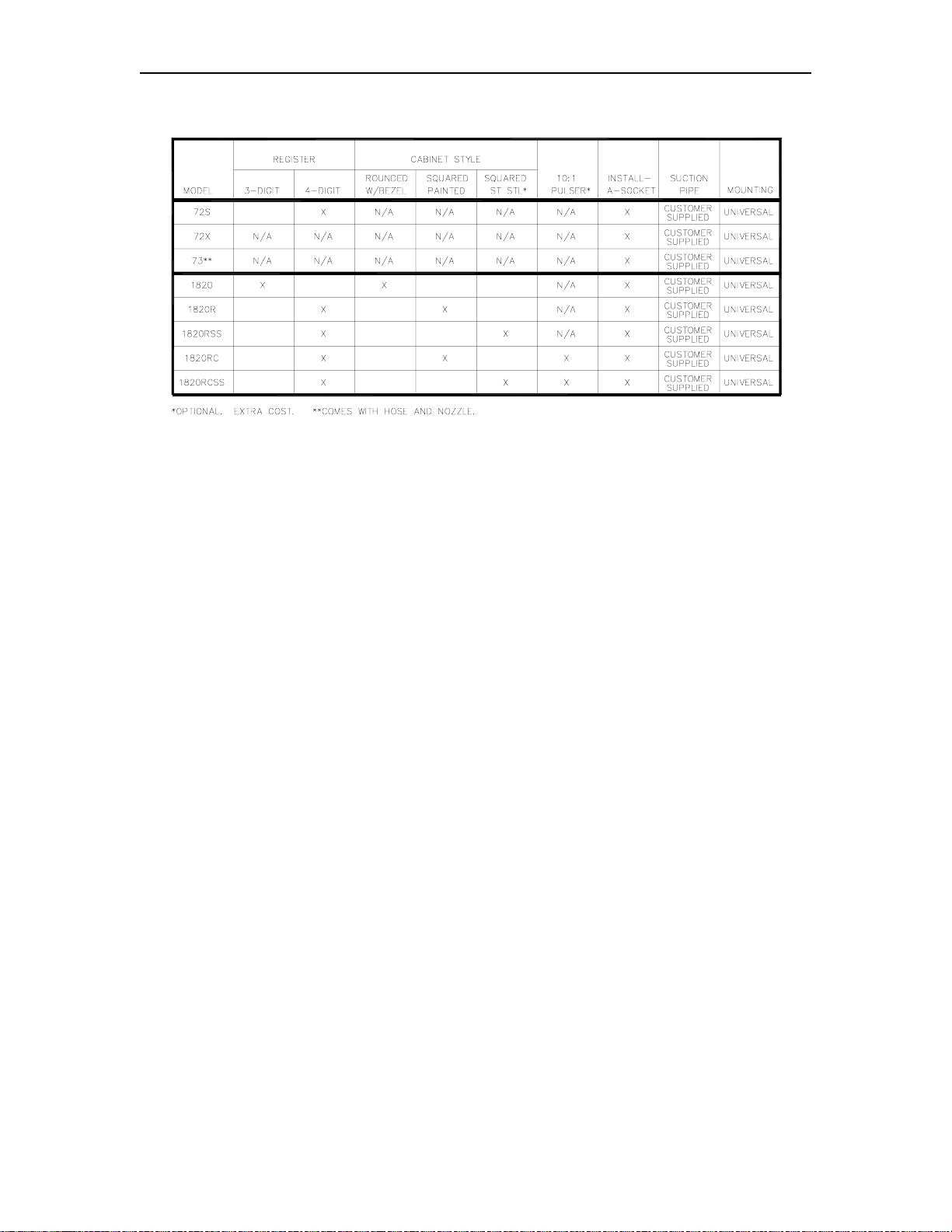

SPECIFICATIONS

Series 70 and Series 1820 pumps are m ade specifically for private use on vented tank s. W hile

their outward appearance differs, they basically offer the sam e features. These pum ps can be

mounted on aboveground skid tank s, directly mounted above underground tank s, or mounted on

pedestals for remote underground installations. Table 1-1 summarizes the features for each

model.

Pumping Unit: Self-priming, direct-drive rotary vane; 23 PSI (1.6 bars) stainless steel bypass; check

valve with pressure relief valve.

Motor: 1/3 HP, 1725 RPM motor with thermal overload protection and auxiliary AC line.

Standard 115 VAC, 60 Hz; optional 230 VAC, 50 Hz. AC junction box included.

Register: 70: 4-wheel push-button reset, 7-digit master totalizer

1820: 3-wheel, volume only; lever-type reset with interlock; 6-digit master totalizer

(Optional, except for 1820R: 4-wheel push-button)

Registers show delivery in US gallons, Imperial gallons, or liters and change gears are

available to convert registers for unit of measure.

Meter: Nutating disk phenolic measuring chamber in aluminum die-cast housing; adjustable

calibration +.5% at full flow

Hose & Nozzle: 12' (3.66 m) UL-Listed hose assembly with integral static discharge wire; manual self-

closing nozzle.

Connections: 2" (5.08 cm) NPT for tank opening; 1" (2.54 cm) suction; 3/4" (1.91 cm) NPT discharge

Strainer: 100-mesh nylon

Delivery Rate: 18 GPM, at 115V, 60 Hz.; 60 LPM at 60 Hz.; 68 LPM at 50 Hz.

Finish: High-gloss red urethane or color of choice. 1820 only: Stainless steel extra cost option.

Approvals: UL, CSA

Additional extra cost options include: vapor rec overy, vacuum breaker return line, longer hoses,

hose breakaways, automatic nozzles, external filters, wall m ounting kits, and for Ser ies 1820 only,

10:1 pulser or rear- or side-mount filter kits.

9312 1-1

Page 6

GASBOY Series 70 & 1820

Table 1-1. Series 70 and 1820 Features

Stripped-down versions of Series 70 pumps, which mount on customer-supplied piping and

fittings, are available. Model 72X has no attachments or register, Model 73 has a hose and

nozzle, but no meter or register.

1-2 9312

Page 7

Section 2

INSTALLATION

INSTALLATION PRECAUTIONS

All tanks and installations m ust conform with all building/fire c odes, all Federal, State, and Local

codes, National Electrical Code, (NFPA 70), NFPA 30, Automotive and Marine Service Station

Code (NFPA 30A) and NFPA 395 codes and regulations.

Plan your installation carefully. Dispensing troubles, which seem to be pump-related, are

frequently traced to faulty installation. Review the following list of installation

to avoid potential problems:

DO's

and

DON'T's

DO

1.

2.

3.

4.

5.

6.

7.

8.

9.

read the

It contains important information regarding the safe use of your pumps.

DO

install an emergency power cutoff, if the pump is used for other than pers onal use. In

addition to circuit breaker requirements of NFPA 70 and NFPA 30A, a single c ontrol which

simultaneously removes AC power from all site dispensing equipment is recommended.

This control must be readily accessible, clearly labeled, and in accordance with all local

codes. In order to provide the highest level of saf ety, we recommend that all em ployees be

trained as to the location and procedure for turning off power to the dispensing equipment.

DO

use breakaway couplings on discharge hose. W hile not required for tanks under 1100

gallons, use is recommended for safety reasons.

DO

have the pump installed by a competent installer/electrician.

DO NOT

DO NOT

DO NOT

nipples, never close nipples).

DO NOT

DO NOT

crushed rock, or pea gravel).

WARNINGS

experiment with a pump if you are not sure the installation is correct.

overload sub- or main breaker panels.

install any underground piping without proper swing joints. (Always use shoulder

cover any lines until they have been both air- and liquid-tested.

back-fill the tank or supply line with cinders or ashes. (Back -fill with clean sand,

page at the front of this manual, preceding the Table of Contents .

DO NOT

10.

galvanized or fiberglass* pipe and fittings). *Install all fiberglass pipe and fittings acc or ding to

manufacturer's specifications and requirements.

DO NOT

11.

diagram or wire chart provided in Section 3).

DO NOT

12.

DO NOT

13.

DO NOT

14.

storage tank.

9312 2-1

use black iron pipe or fittings for underground installations. (Use only new

use power line wiring of inadequate capacity. (Use gauge specified by the wiring

use a circuit breaker of improper size. (See Section 3).

install fill pipe to tank where it can be submerged with standing water.

use the GASBOY fuel dispensing equipment to remove water ballast from the

Page 8

GASBOY Series 70 & 1820

DO NOT

15.

found around wires at all junction box entrances is a requirement of the National Elec trical

Code and should not be disturbed. Tighten junction box covers before replacing panels.

DO NOT

16.

wires should be run in threaded, rigid, metal conduit. All threaded connections must be

drawn up tight with five (5) threads minimum engagement. Only one opening in the AC

junction box is provided. At completion of the installation, it is the installer's res ponsibility to

ensure that any unused openings are plugged.

use gaskets on covers of explosion-proof type boxes. The sealing compound

use knock-out boxes or flexible conduit for installing this unit. All power and lighting

SUPPLY LINE - UNDERGROUND TANKS

If you are using an underground tank, pitch the tank away from s uction end. Horizontal runs of

suction line should slope down from the pump toward the tank. Do not exceed an equivalent lift of

12' for gasoline or 14' for diesel to the center line of the pumping unit, including f riction res istance

in the suction pipe.

The end of the suction pipe must be at least three inches from bottom of tank.

The tank or piping should not be located under traffic ar eas. Swing joints (two ells) will prevent

damage to piping due to frost heave or ground settlement.

Use nonhardening, gasoline-resistant pipe compound on male thr eads of all pipe joints for liquid

handling piping.

2-2 9312

Page 9

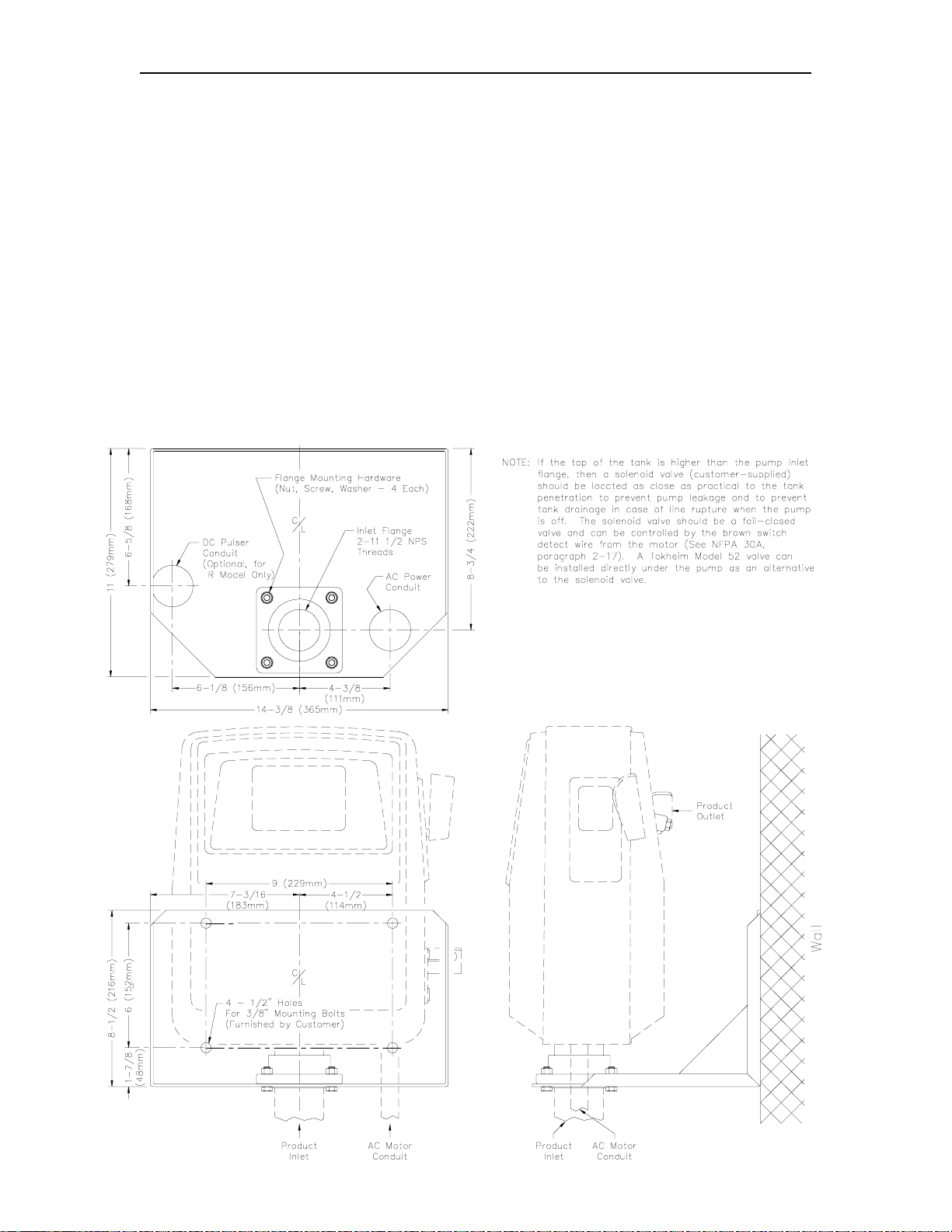

Installation

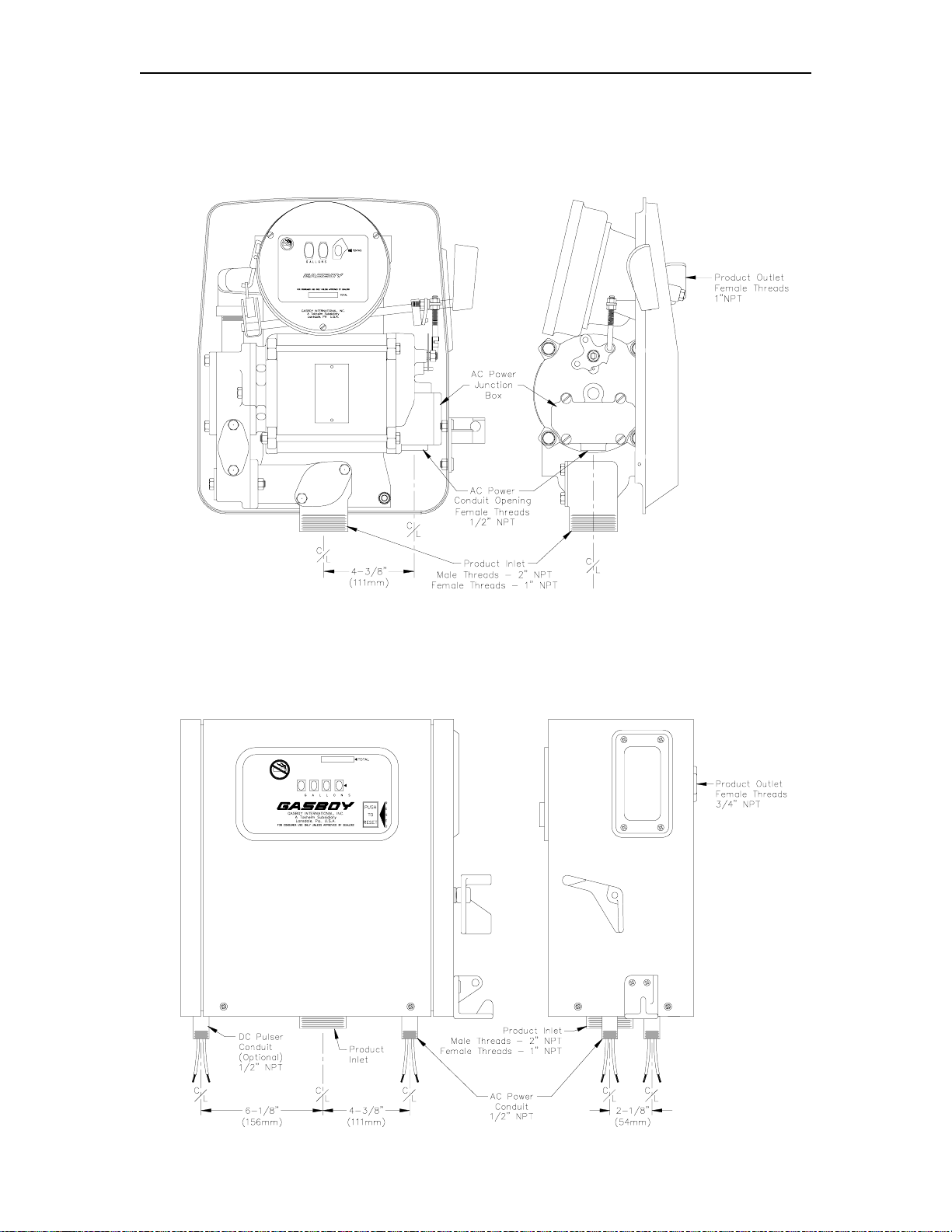

PUMP DIMENSIONS - SERIES 70, MODEL 1820

Pump diagrams shown are for Model 1820. Pump dimensions are the same for all Series 70

pumps.

PUMP DIMENSIONS - MODEL 1820R

Pump diagrams s hown are for Model 1820R. Pump dimensions are the same for these Model

1820 pumps: 1820R, 1820RSS, 1820RC, 1820RCSS.

9312 2-3

Page 10

GASBOY Series 70 & 1820

INSTALLATION INSTRUCTIONS

Cabinet Removal for Installation or Service (Series 1820 Only) - Rounded Cabinet

1. Remove two screws, one on each side of the cabinet.

2. Pull front panel assembly forward at bottom. As it clears the pumping unit, lift up to remove.

3. To replace front panel, engage pins at top in matching holes in rear panel. W ith front panel

assembly tilted back, pins m ay be seen through dial opening. Fr ont panel assembly will now

drop back into position.

4. Reinstall two screws in sides.

Cabinet Removal for Installation or Service (Series 1820R Only) - Squared Cabinet

1. Remove two screws on lower front of cabinet.

2. Remove two screws from upper back of cabinet.

3. Push in and hold the reset button and pivot the cabinet front panel upward until it clears the

button (Be careful not to damage the button). Remove panel.

4. For calibration or service, remove the lef thand side panel by unscrewing the two screws on

the bottom side of the cabinet.

5. To reassemble pum p cabinet, align s ide panel s cr ew holes with holes on base of c abinet and

screw tight. Replace the cabinet top and front panel by positioning the back plate and

pivoting the assembly forward. Be sure to press in the reset button until the front panel

clears it. Then replace the screws in the front and back of cabinet.

Installing Hose and Nozzle

To prevent undue stress and poss ible damage, install hos e and nozzle after installation of pump.

Hose must have static wire which provides electrical continuity between hose couplings to

dissipate static electrical charge.

1. Screw the pipe elbow (provided with the pump) into the product outlet on the back of the

pump. Apply gasoline-resistant pipe compound to male threads.

NOTE: Elbow fitting is not required, however, it provides strain relief for the hose.

2. Screw the hose into the open end of the elbow and tighten. Apply gasoline-resistant pipe

compound to male threads.

3. Screw nozzle onto hose.

NOTE: 1820R models are shipped with a vacuum breaker assembly (P/N 032701)

consisting of a tee, pipe nipple and vacuum breaker. This assembly should be

installed in the pump outlet before connecting the hose.

2-4 9312

Page 11

Installation

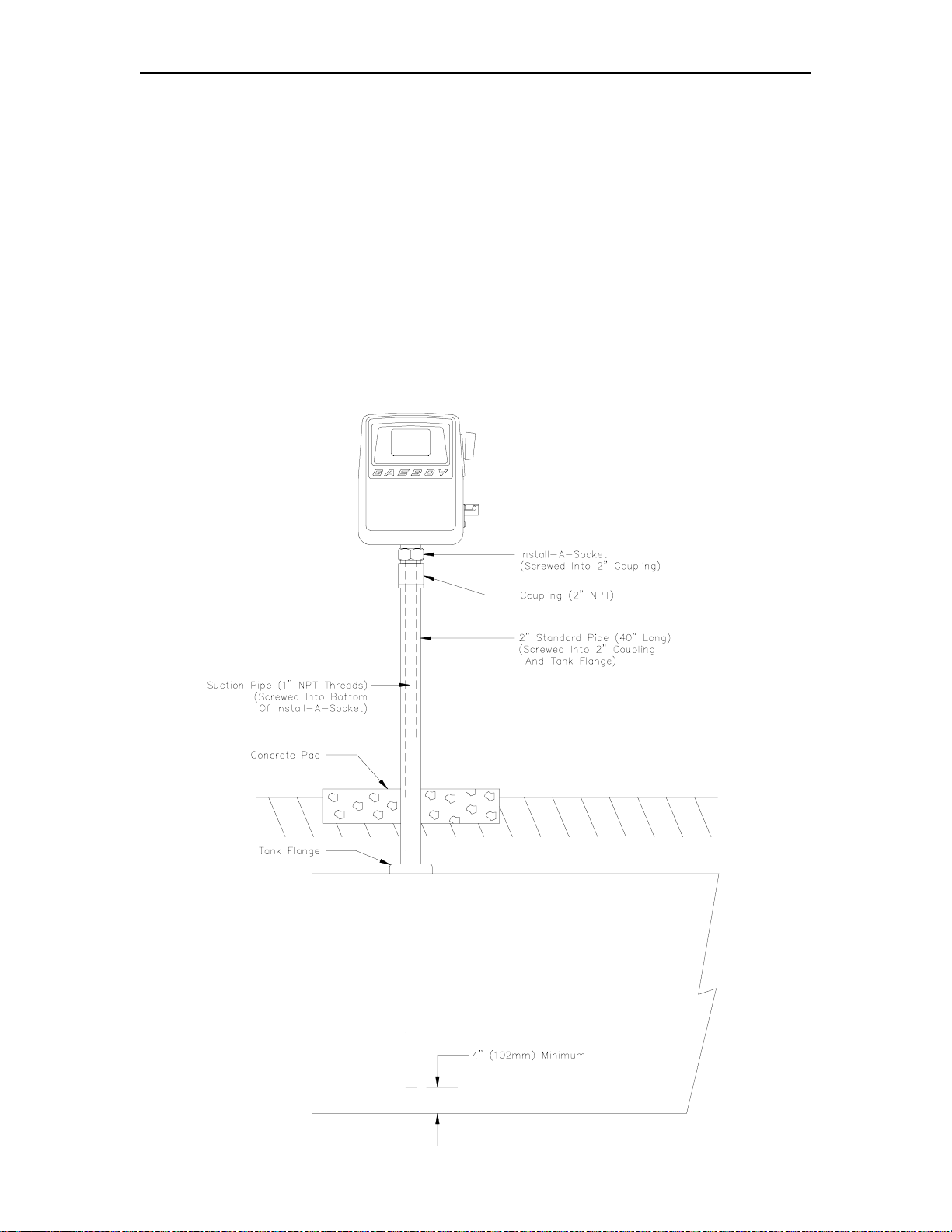

Direct Mount on Underground Tanks

1. Screw 2" coupling onto 2" standard pipe.

2. Screw 2" standard pipe into 2" tank flange. Apply compound to threads at bottom of base to

prevent surface water from entering the tank.

3. Screw 1" suction pipe into install-a-soc ket. Suction pipe should be long enough to allow 3"

clearance from bottom of tank. Apply gasoline-resistant pipe compound to male threads.

4. Lower 1" suction pipe through 2" standard pipe into tank. Tighten install-a-socket into

coupling at top of standard pipe.

5. Screw pump (2" threaded base) into ins tall-a-socket. This is a suction line connection and

must be tight. Apply gasoline-resistant pipe compound to male threads.

See the

Conduit

section for correct installation of electrical conduit.

9312 2-5

Page 12

GASBOY Series 70 & 1820

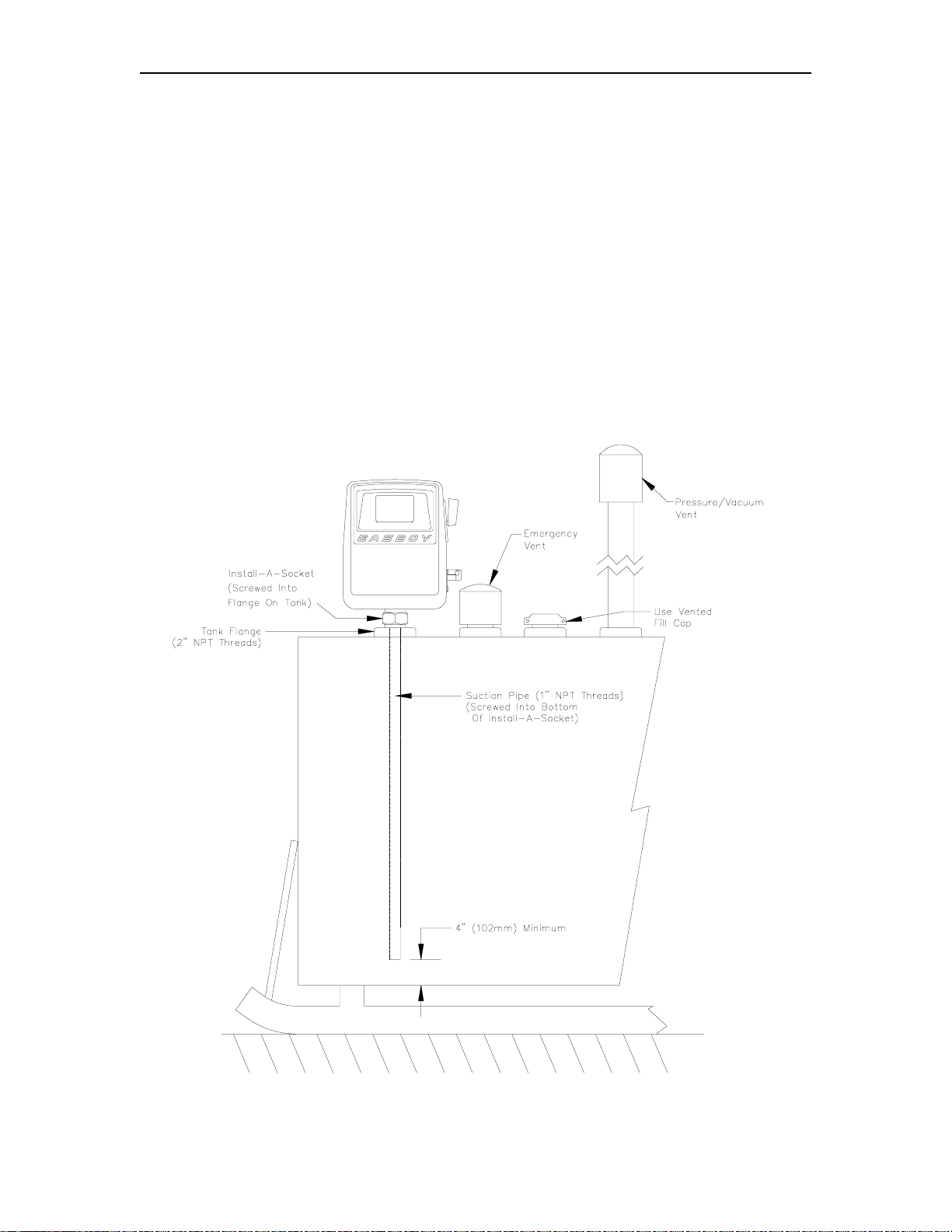

Direct Mount on Aboveground Tank

Aboveground tanks require both a pressure/vacuum vent and an emergency vent. The

pressure/vacuum vent r educes losses due to evaporation and is an air quality control m easure.

The emergency vent provides a relief from the pressur e resulting from heating and boiling of the

tank contents during a fire situation. Both vents must be properly sized for a given tank.

1. Screw 1" suction pipe into install-a-soc ket. Suction pipe should be long enough to allow 3"

clearance from bottom of tank. Apply gasoline-resistant pipe compound to male threads.

2. Screw install-a-socket directly into 2" flange in the aboveground tank.

3. Lift the pump to the height of the tank and tighten it into the install- a-sock et. Apply gasolineresistant pipe compound on male thread.

extended nozzle hanger, you may need to use a 2" coupling and close nipple in between the

pump and the install-a-socket. This will prevent interference of the hanger with the top of the

tank.

NOTE: If using an automatic nozzle with the

See the

Conduit

section for correct installation of electrical conduit.

NOTE: Aboveground tanks, located at commercial, industrial, governmental, or manufacturing

establishments and intended for fueling vehicles used with their busines s, cannot exceed

a capacity of 6000 gallons.

2-6 9312

Page 13

Installation

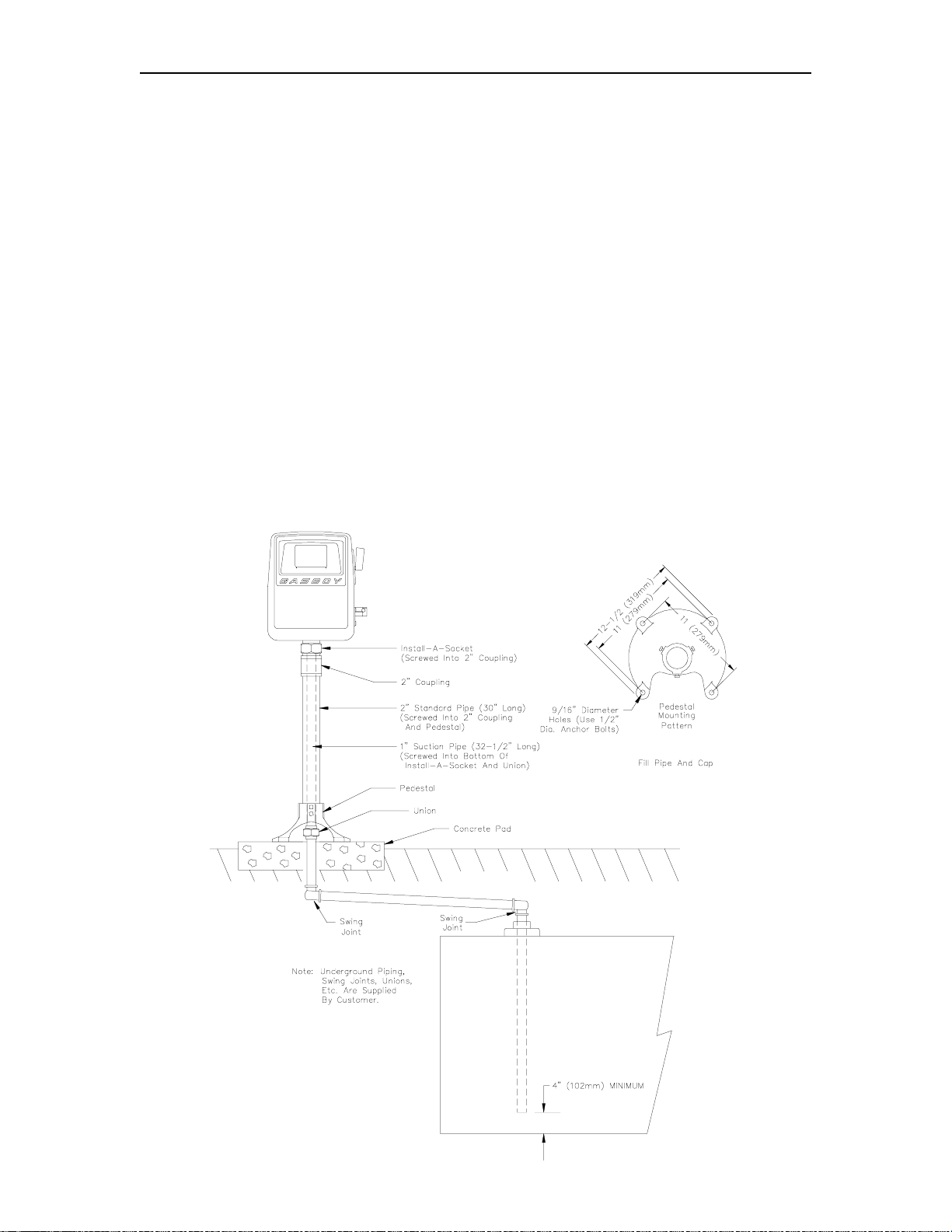

Pedestal Mount Pump

1. Screw 2" coupling onto threaded end of 2" standard pipe.

2. Slide cast iron pedestal base up over the unthreaded end of 2" standard pipe.

3. Screw 1" suction pipe into install-a-soc ket. Suction pipe should be long enough to allow 3"

clearance from bottom of tank. Apply gasoline-resistant pipe compound to male threads.

4. Insert 1" suction pipe into 2" pipe and screw install-a-socket into coupling on end of 2" pipe.

5. Assemble union onto lower end of 1" suction pipe conforming to your site's piping layout.

Note that the GASBOY base is provided with an opening on one side, so that an elbow can

be used and the suction brought out horizontally aboveground if desired, instead of straight

down through the island.

6. Slide base down to proper position at the lower end of the pedestal, tighten six set screws.

7. Screw the 2" male thread on the base of the pum p into the upper end of the install-a-soc ket.

Apply gasoline pipe compound to all male threads.

8. Securely mount pedestal base to concrete. If the pump is not securely fastened to the

foundation, supply line leaks at unions and pipe joints may occur.

See the

and swing joints are supplied by the customer. All metallic piping should be at least

Schedule 40 wrapped/coated black steel pipe with extra-heavy malleable iron screw type

fittings. Protect metallic piping in contact with the ground with a properly designed cathodic

protection system.

Conduit

section for correc t installation of electrical conduit. All under ground piping

9312 2-7

Page 14

GASBOY Series 70 & 1820

Wall Mount

The optional wall mount kit can be used with any Series 70 or 1820 pum p to be located rem ote

from the tank. The wall mount kit consists of a wall mounting bracket, pump mounting flange, and

hardware to attach the flange to the bracket. Hardware to attach the br acket to the wall is not

included.

1. Fasten mounting bracket to wall using appropriate 3/8" fasteners (customer supplied).

2. Screw mounting flange to pum p inlet. The flange with the four holes should be away from

the pump. Pipe thread compound is not required. Tighten flange and align parallel with

pump.

3. Bolt mounting flange to mounting bracket using the hardware supplied.

4. Remove the 1" plastic plug within the 2" pump bas e inlet and install the 1" inlet NPT inlet line

from the tank into the pump. Apply gasoline-resistant pipe compound to male threads.

Follow piping instructions shown on previous page for piping to the tank.

See the

Conduit

section for correct installation of electrical conduit.

2-8 9312

Page 15

Installation

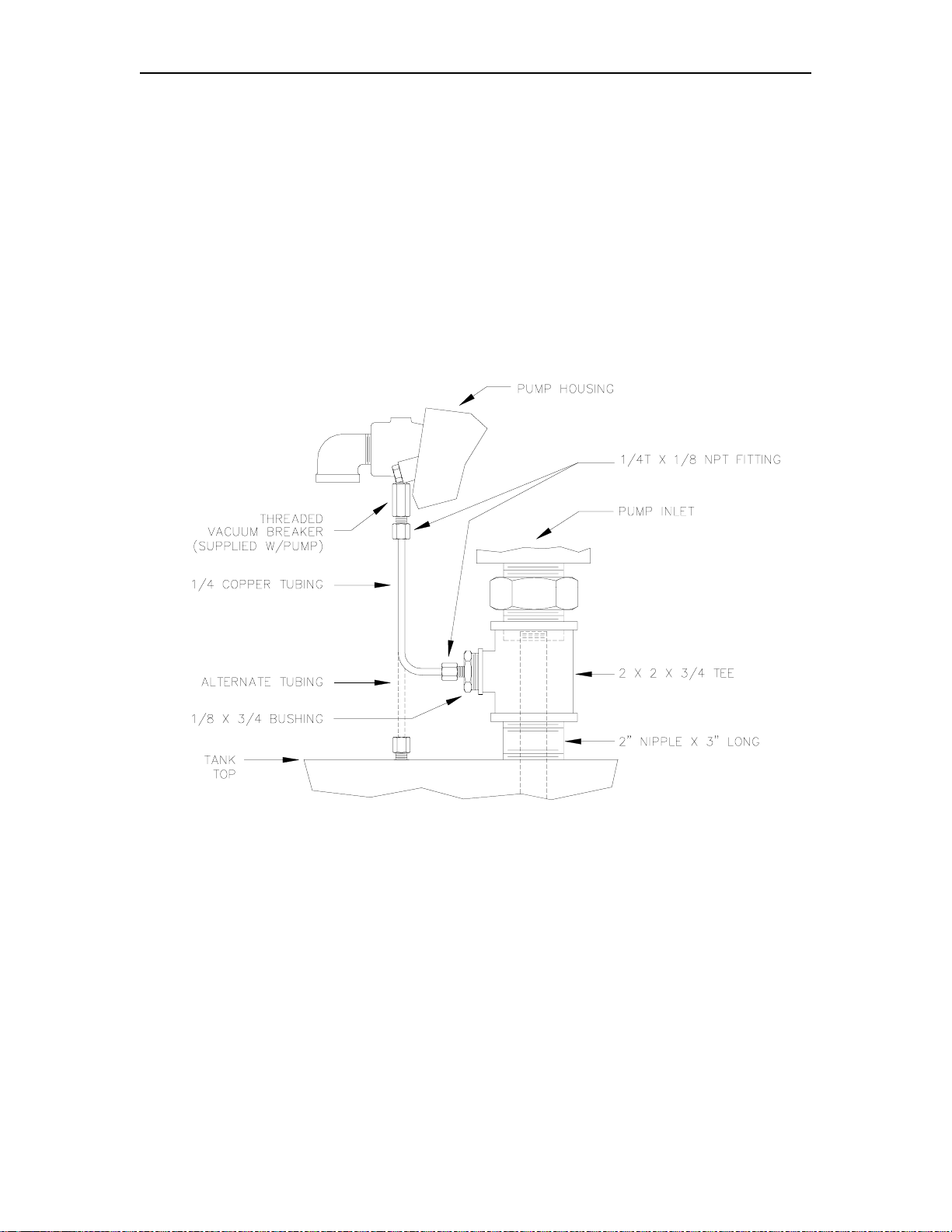

Vacuum Breaker

The vacuum breaker tubing kit can be used with any Series 70 or 1820 pump. The vacuum

breaker is used to break a s iphon s hould the nozzle drop below the fluid level in the tank while the

pump is stuck in the open position. A threaded vacuum break er, P/N 066570 is shipped installed

in the pump. GASBOY recommends that the vacuum breaker be tubed back to the tank.

The illustration below shows two methods for installing tubing for the vacuum breaker. In all

instances, the vacuum break er m ust be tubed (us ing 1/4" tubing) to the vapor spac e at the top of

the tank; if the tube is installed below the fluid level of the tank, the ability to break vacuum and

prevent siphoning will be lost. Using the illustrated m ethods, the tube end m ay terminate into the

annular vapor space between the 1" suction pipe and the 2" mounting pipe, or into an opening in

the top of the tank. All components shown are provided when you order the kit, P/N 032700.

NOTE: Tubing can be piped to any available opening on top of tank. Use reducer bushings

as required.

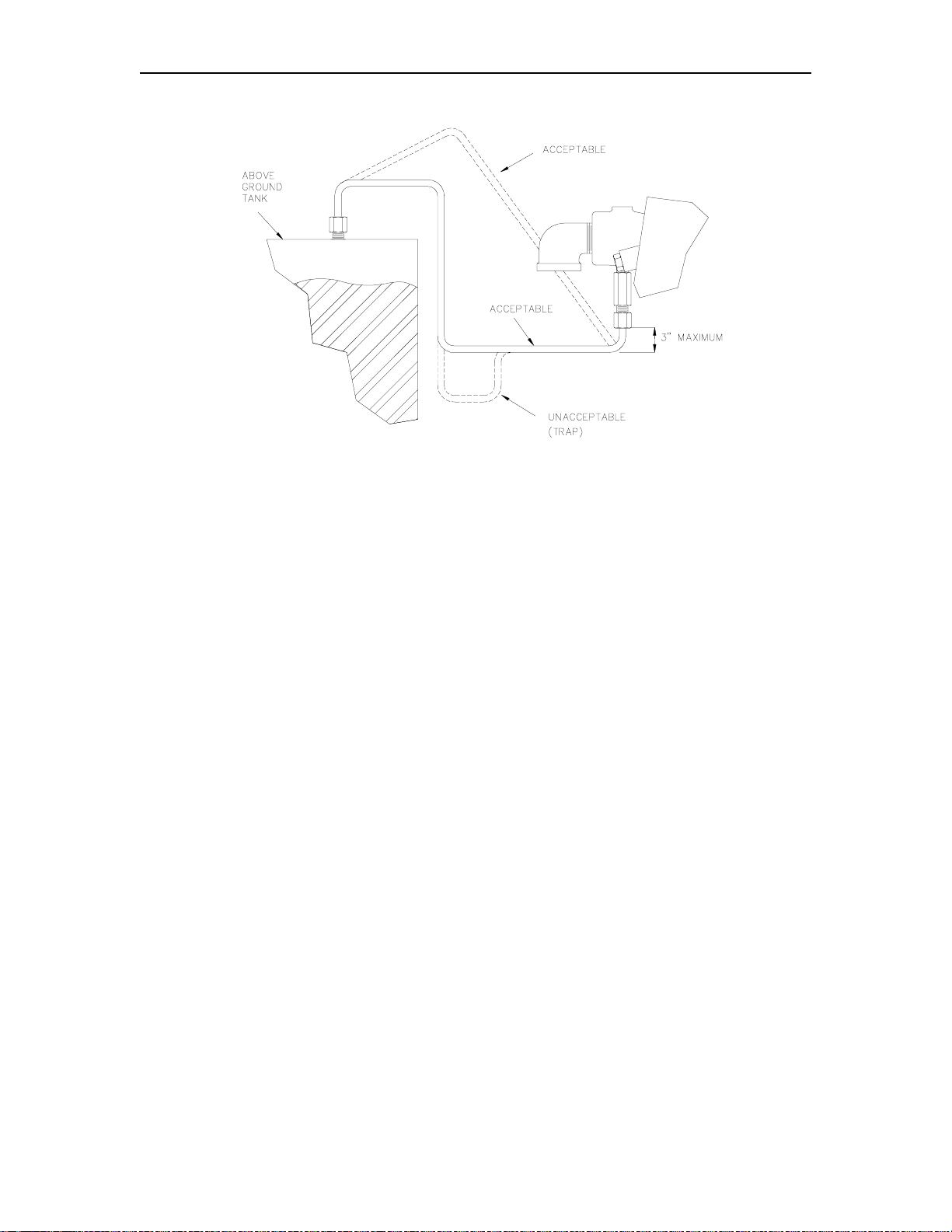

The illustration on the next page shows vacuum breaker tubing for inst allations where the pump is

installed below the fluid level of the tank. For these inst allations, the tubing must run directly to

the tank top. The tubing mus t be horizontal or must slope either toward the pum p or the tank s o

there are no traps or low spots. Traps or low spots can severely affect vacuum breaker

performance. Tubing length should not exceed eight feet.

9312 2-9

Page 16

GASBOY Series 70 & 1820

NOTE: Tubing can be piped to any available opening on top of tank. Use reducer bushings

as required.

Testing the Vacuum Breaker

1. Charge tubing completely with fluid.

2. Turn on pump and run for several minutes to purge any air from the system.

3. Turn off pump.

4. With nozzle at ground level and discharging into a container, open nozzle. A small quantity

of fluid (several cups) should drain and then stop.

2-10 9312

Page 17

Section 3

WIRING

WIRING PRECAUTIONS

The quality of the electrical installation is a m ajor factor in maintaining proper saf ety levels and

providing trouble-free operation of your GASBOY pum p. To assure a quality installation, follow

these rules:

1. Have the pump installed by a competent installer/electrician.

2. All wiring must be installed to conform with all building/fire codes, all Federal, State, and

Local codes, National Electrical Code, (NFPA 70), NFPA 30, Automotive and Marine Service

Station Code (NFPA 30A), and NFPA 395 codes and regulations.

3. Use only threaded, rigid, metal conduit.

4. Use only UL-approved insulated gasoline- and oil-resistant stranded copper wiring of the

proper size.

5. Wire connec tions should be tightly spliced and secured with a wire nut; close off the open

end of the wire nut with electrical tape.

6. The line to the motor should be on a s eparate circuit and installed on a 15 AMP breaker.

This should be sufficient for either 115V, 60 cycle or 230V, 50 cycle operation.

7. The unit must be properly grounded.

8. Install an emergency power cutoff if the pump is used for other than personal use. In

addition to circuit breaker requirements of NFPA 70 and NFPA 30A, a single c ontrol which

simultaneously removes AC power from all site dispensing equipment is recommended.

This control must be readily accessible, clearly labeled, and in accordance with all local

codes. In order to provide the highest level of saf ety, we recommend that all em ployees be

trained as to the location and procedure for turning off power.

9. When DC pulsers are used in the pump, the AC and DC wires must not shar e any conduits,

junction boxes, or troughs.

CIRCUIT BREAKERS

Power to the unit should be supplied from a dedicated 15 AMP circuit breaker. No other

equipment should be powered from this breaker. This motor draws the following current:

115VAC, 60 cycle, 5.1 amps; 230VAC, 50 cycle, 1.95 amps. If two (2) pum ps are supplied from

one breaker, that breaker must be capable of handling the load of both motors . Provisions must

be made to break both legs of any AC circuit.

9312 3-1

Page 18

GASBOY Series 70 & 1820

GROUNDING

To ensure proper operation of the equipm ent and provide the necessary safety factors, this unit

must be grounded. A ground wire (preferably green) m ust be connected between the unit's AC

junction box ground lug and the main electrical service panel. One (1) earth ground c onnection is

required per unit. The ground rod is to be a solid, corrosion-resistant conductor and must be

installed at the main electrical panel in ac cordanc e with the National Electric al Code. It should be

properly tied into the ground bus strip of the panel. W e recomm end the neutral and ground bus

strips be bonded together (unless prohibited by local codes).

THE PUMP MOTOR

Pumps are shipped from the factory with motors wired for either 115VAC, 60 cycle, or 230VAC,

50 cycle.

The pump motor is equipped with therm al overload protection. If overheated, it will shut itself off

without any damage to the windings. Be sure to turn off the pum p power if this occ urs. As the

motor cools, it will start without warning if power is on.

WIRE SIZE

The AC wire size of the AC power lines of a pump depends on the voltage at which the pump will

be operated (115/230) and the distance from the circuit breaker panel to the pump. W hen two

pumps are powered from the same breaker through the same wires, the gauge of the wires

should be increased to handle the added load according to the distance from the breaker panel.

Use the chart below to select the proper wire size for your installation.

Table 3-1. Wire Size

WIRE GAUGE SIZES FOR 1/3 HP MOTOR

DISTANCE

(FEET/METERS)

25’ 7m 14 14

50’ 15m 14 14

100’ 30m 12 12

150’ 46m 10 12

200’ 61m 8 12

250’ 76m 8 12

300’ 91m 8 12

115 VAC

GAUGE

230 VAC

GAUGE

The AC wire size for the reset complete (switch detect) line should be 14 AWG (when it is used).

3-2 9312

Page 19

Wiring

PULSER WIRING

An optional pulser (available on the Series 1820R only) is used when external monitoring of the

dispensing unit operation is desired. The puls er transmits one electrical signal (pulse) for each

predetermined amount of fuel dispensed. Reed 10:1 pulsers operating with DC voltages are

used. Pulser wiring must be 18AW G and ins talled in metal conduit separate from all AC wiring. It

cannot share a common junction box, wiring trough or conduit with any AC wiring.

CONDUIT

All wiring to the GASBOY pump must be installed in 1/2" threaded, rigid, metal conduit.

not use knockout boxes and flexible conduit.

If equipped with a DC pulser, AC power wires must be installed in a separ ate c onduit f r om the DC

pulser and the AC power wires and DC pulser wires must not be run in any sort of common

conduit or trough.

All wiring and conduit runs must also conform with the National Electrical Code (NFPA 70) and the

Automotive and Marine Service Station Code (NFPA 30A). All wiring and conduit runs must

conform to local codes.

The conduit layout drawing on the left is for all Series 70 and 1820 rounded c abinet models. The

drawing on the right is for 1820R models. The junction boxes shown below the 1820R are

supplied with the pump.

Do

9312 3-3

Page 20

GASBOY Series 70 & 1820

PUMP WIRING DIAGRAMS

115VAC Pumps Series 70 and 1820 (left) and Series 1820R (right)

230VAC Pumps Series 70 and 1820 (left) and Series 1820R (right)

NOTE FOR 230V MOTORS: Some motors may contain different wire colors than those shown. In

this case, Hot is Black, Neutral is White and Aux AC Control is Brown.

1. All wiring and conduit runs must conform with all building/fire codes, all Federal, State, and Local

codes, National Electrical Code, (NFPA 70), NFPA 30, Automotive and Marine Service Station Code

(NFPA 30A), and NFPA 395 codes and regulations.

2. For the Series 70 and Series 1820 rounded cabinet models, make the field wire connections in the

motor junction box. The 1820R models with the squared cabinet come with the wires already

extended through the end of a factory-installed conduit. The 1820R models also come with a junction

box which is to be mounted directly beneath the pump. The field wire connections for the 1820R

models should be made in this junction box (not the pump motor junction box). Wire connections

should be tightly spliced and secured with a wire nut. Close off the end of the wire nut with electrical

tape.

3. The Aux AC Control Lead wire is shipped capped from the factory. When used, it connects to a

solenoid valve or fuel management system. Do not connect this wire without first checking the ON

voltage of this line to ascertain compatibility with the equipment being connected.

4. Pulser wiring must be 18AWG and installed in metal conduit separate from all AC wiring. It cannot

share a common junction box, wiring trough or conduit with any AC wiring.

3-4 9312

Page 21

Section 4

STARTUP AND OPERATION

PRE-STARTUP CHECKLIST

The information below should be reviewed to help verif y the proper installation of your GASBOY

pump.

Local codes and requirements, correct the problem before powering on the unit.

1. The unit must be properly secured.

If the installation does not meet criteria listed, as well as any Federal, State, and

2. All plumbing must be c omplete and tight.

leaks

.

3. When DC pulsers are used in the pump, the AC and DC wires must not shar e any conduits,

junction boxes, or troughs.

4. All conduit work must be c omplete. All j unction box covers mus t be s ecured. Conduit seals

should not be sealed until the wiring is verified through proper operation.

5. The unit must be properly grounded.

6. Before any testing begins, remove any water in the tank through a fill opening, using a

suitable pump. Do not use the GASBOY pump to remove water. Serious damage may

occur.

7. A sufficient volume of fuel m ust be put in the tank to insu re that the liquid level is above the

bottom of the suction pipe.

8. Before placing nozzle into service, apply a few drops of light ma chine oil (s uch as 3- in-1) on

the stem. Operate the lever several times so that the oil penetrates the packing. This offsets

the drying action of gasoline and keeps the packing soft and pliable.

All liquid-carrying lines must be checked for

STARTUP

After successf ully verifying the installation against the completion check list, the unit is ready for

startup. Follow the procedure listed below to perform an orderly start-up.

1. Turn on the circuit breaker for the pump.

2. Remove the nozzle from the boot and turn on the pump handle.

3. If your model has an automatic res et, verify that the register resets to zeros. If your model

has a reset button, push it to zero the register.

4. Dispense fuel. Check all plumbing for leaks at this time.

5. Turn the pump handle off . Open the nozzle. No fuel should be dispens ed. The amount

delivered should be displayed on the register. If an optional pulser k it is attached, it will be

supplying pulses which may be recorded by an external monitoring system.

6. Repeat Steps 2 through 5 several times to ensure that the pump is operating satisfactorily.

9312 4-1

Page 22

GASBOY Series 70 & 1820

POST-STARTUP TESTS

Voltage

The incoming voltage to the pump should be checked and any reading not within 10% of rated

voltage should be corrected before tes ting is continued. When dealing with suction pum ps it is

good practice to take voltage readings while the suc tion pump is operating on bypass (turned on

but not dispensing product) and also while making a delivery. Any voltage drop in excess of 10%

during either of these operating states should be considered a low voltage condition. Corrective

action should be taken to insure an adequate power supply to the pump.

Tightness

After determining that the pum p is operating satisfactorily and the system is fully primed, check

the pump and piping to make sure that all connections are tight. W e recommend that the tank

and all piping not be covered until this has been completed.

Meter Calibration

NOTE: This meter was redesigned causing the calibration procedure to be different depending

on the age of your meter. Meters made after May 10,1995 are referred to as new style

meters; meters made before that date are referred to as old style.

All GASBOY pumps are adjusted for acc urate measure for gasoline within + .05 gallons at the

factory. However, since the conditions of the installation can affect pump accuracy, it is the

responsibility of the installer to check the pump for accuracy and make any needed adjustm ents.

Where required

Measures officials for their inspection before the unit is put into service.

, it is the owner's responsibility to report this device to the local Weights and

Choose the flow rate at which the meter will be used most often for the zero calibr ation point. For

example, if the pump is being used with an automatic nozzle, calibrate with the nozzle set on the

middle or top notch position, whichever is used most frequently.

Use a certified five-gallon measure with a sight glass and scale showing cubic inches over or

under an exact five gallons. Fill and drain the test measure to completely wet the interior

surfaces. Reset the register to zero and deliver an exact measured five gallons into the test

measure at the selected flow. Read the level of the liquid in the sight glass on the scale in + cubic

inches.

Follow the instructions in Section 3,

Installation or Service

narrow blade screw driver to turn the adj usting sc rew clock wise

to correct for plus cubic inches or counterclockwise for minus

cubic inches in the test measure.

Count the number of full turns and fr actional turns each tim e f or

reference in judging the num ber and direction of any additional

turns required to calibrate the meter to exact zero.

For new style meters, start with the screw turned all the way in

clockwise. For gasoline calibration, turn the screw

approximately two full turns counter-cloc kwise. For diesel, turn

the screw approximately two full turns counter-clockwise.

Replace the cap screw (old style only). Deliver about 1/2 gallon through the meter before res etting

to zero and retesting. Allow a ten second drain period each tim e the test measure is em ptied to

assure accurate measure. Adjust and retest until register is zeroed at desired flow.

to access the calibration screw. Use a

Cabinet Removal for

Strainer Cleaning

4-2 9312

Page 23

Start-Up and Operation

Clean the strainer immediately after the pump has been installed and tested, and again after a few

hundred gallons have been delivered. Thereafter, once every six m onths, or as required. The

procedure for cleaning the stainer can be found in the

section.

Maintenance and Troubleshooting

DAILY OPERATION

1. To begin fueling, remove the nozzle from the boot and turn on the pump handle.

2. If your model has an automatic reset, the register resets to zeros. If your model has a reset

button, push it to zero the register.

3. Dispense fuel.

4. Turn the pump handle off. The amount delivered is displayed on the register.

9312 4-3

Page 24

Page 25

Section 5

MAINTENANCE AND TROUBLESHOOTING

MAINTAINING TROUBLE-FREE OPERATION

Operating your pump with reasonable care will prolong its life and provide better service.

GASBOY pumps are designed and built to provide years of uninterrupted service; however,

certain parts of a pump ar e bound to wear. To keep your pump running at m aximum efficiency,

GASBOY recommends a periodic inspection at least twice a year.

Remove Water from Tank.

●

accumulate in both underground and aboveground storage tanks due to condensation or

defective fill openings that are not properly protected with watertight covers. Remove any

water with a sump pump to fores tall serious damage to equipm ent. Water, s ediment, and

other foreign matter that acc umulates in the tank can be drawn up into the pump and cause

failures.

Clean the Dial Face.

●

Preserve the Pump's Finish.

●

urethane paint. To preserve this finish, thoroughly clean all painted surfaces at regular

intervals with a high grade automobile polish and protect with a coat of paste wax. Do not

use abrasive cleaners or polish. Do not use high-pressure spraying equipment.

Stainless steel cabinets also requir e regular cleaning, especially in corrosive environments

such as coastal areas. Wash with mild detergent or soap and water followed by a clean

water rinse. Avoid abrasive cleaners which may scratch the f inish. Stubborn s tains, s uch as

oil or grease will require a stronger cleaner.

particles may adhere to the surface and cause corrosion. Always clean in the direction of the

polishing lines in the steel, never across them. In hard water areas, wipe the surface dry with

a soft clean cloth to prevent spotting. Protect the finish with a coat of paste wax.

Check and Change Filter.

●

intervals. A dirty filter in a pump will cause a slower delivery rate.

Clean the Strainer.

●

tested, and again after a few hundred gallons have been delivered. Thereafter, once every

six months, or as requir ed. The symptom s of a dirty or clogged s trainer in a pump are slow

delivery, noisy operation, and pulsation.

Use a soft, clean, damp cloth as needed.

Clean the strainer imm ediately after the pump has been installed and

After every fill-up, check your tanks for water. Water can

GASBOY pump housings are finished with a coating of

DO NOT

If the unit is equipped with a filter, check and change it at r egular

use ordinary steel wool as iron

To clean the strainer, turn off AC power to the pump. Locate the Suction Strainer Cap on the

plumbing unit and unscrew it to access and remove the strainer. Use compressed air to blow

the dirt out of the strainer. Always wear protective safety goggles or glasses when using

compressed air.

Clean the Bypass Assembly.

●

cleaning and should be checked if there is notable loss in system performance. No

adjustment is required. T o remove the valve, turn of f AC power to the unit, rem ove the two

bolts to the bypass cover and lift out the bypass valve assembly.

0144 5-1

The bypass valve assembly should be removed only for

Page 26

GASBOY Series 70 & 1820

WHEN YOUR PUMP NEEDS SERVICE

When your pump needs service, follow these guidelines:

Procedures requiring disassembly of portions of the pump should be performed by

●

competent service personnel. GASBOY has a distributor network which services fuel

dispensing equipment in every part of the country.

Turn off all power to t he pump to reduce the risk of electrical shock w hen servicing

●

(including changing o f fuel filters or st rainers). Also block islands so no v ehicles can

pull up to the pump when it is being worked on.

Replace worn, rusted, or corroded parts immediately with new authorized service parts

●

supplied by GASBOY. Replacing parts with incorrect or substandard subs titutes will result in

unsatisfactory pump operation. Always use new gaskets or seals when servicing or

rebuilding Gasboy equipment; do not re-use old ones. Using authorized parts will insure the

continuity of the Underwriters' Label on your pump.

Section 6 lists parts and service procedures f or the Series 70 and 1820 pumps. Using par t

numbers when ordering will expedite your order and reduce the possiblility of the wrong par ts

being shipped.

The remainder of this section contains troubleshooting information and assembly/disassembly

procedures for various components that may need service.

5-2 0144

Page 27

Service and Troubleshooting

TROUBLESHOOTING

If problems are encounter ed in operation of the pum p, follow the pr ocedures below in an attempt

to isolate the problem. W hen the problem is detected, follow the proc edures for disassem bly of

the pump.

Pump Won't Start

Is the breaker at the panel turned on?

✓✓✓✓

Is the Aux AC Control wire capped or connected to a solenoid valve or fuel management system?

✓✓✓✓

Is there power at pump? Check at junction box. Voltage cannot be below 104 volts on a 115V pump;

✓✓✓✓

204 on a 230V pump.

Is switch rod turning the switch on and off at the motor?

✓✓✓✓

Is motor overheated (thermal switch cutoff)? Be careful, the external motor surface could be hot

✓✓✓✓

enough to be painful or cause injury. Let cool and re-try.

!

Replace motor if above checks do not solve the problem.

Pump hums but won't start.

Is voltage adequate? Check voltage with pump on bypass with nozzle closed. Voltage cannot be

✓✓✓✓

below 104 volts on a 115V pump; 204 on a 230V pump.

Is the Aux AC Control wire is capped or connected to a solenoid valve or fuel management system?

✓✓✓✓

Check rotor, vanes, and bypass valve for free operation. Check motor with rotor and vanes removed;

✓✓✓✓

shaft should turn easily and smoothly by hand. Spin shaft by hand clockwise,

(hand clear of shaft) and observe shaft - shaft should stop clockwise

counterclockwise direction; if it does not, replace motor.

quickly start motor

motion and turn in a

!

Replace motor if above checks do not solve the problem.

Pump runs but won't prime or deliver product.

Is there gas in tank?

✓✓✓✓

Do you have a nozzle with the anti-drain valve removed? (Must be able to blow air through the nozzle

✓✓✓✓

in the direction the fuel flows through it when the nozzle handle is held open.)

038519 for unleaded and 038520 for diesel.

Loosen pump cover and slide aside so you can observe the rotor and vane movement inside the

✓✓✓✓

pump cavity. Rotor should be turning freely in a counter-clockwise motion. If rotor turns

motor is bad.

If register is recording but no product is being dispensed, you may have a supply line air leak.

✓✓✓✓

Check for an air leak on suction side of pump. Is check valve seated properly? Reassemble and

✓✓✓✓

prime pump using liberal quantity of motor oil in pump cavity; if it primes, run pump full

nozzle closed; shut off motor and check for leak on suction side of pump

observed liquid leakage would indicate an air leak when pump is

prevent priming when pump was empty.

Are bypass, strainer, and check valve cover plates flat? They could be bent from excessive pressure

✓✓✓✓

created by a vehicle running over the hose.

Is there an air leak in the suction line below check valve. Make accuracy check using 5 gal Seraphim

✓✓✓✓

test can. Any clock fast error (see

the suction line. The most common source of an air leak in the

for alignment and tightness before checking balance

suction line is blocked or has a severe air

Inaccurate Delivery

of suction line. If pump does not prime using oil,

leak.

) in excess of 2-1/2%

running with nozzle open and would

suction line is the union - check union

Use GASBOY P/N

flow and snap

above check valve. Any

indicates an air leak in

clockwise,

0144 5-3

Page 28

GASBOY Series 70 & 1820

Pump delivers product but won't register.

Is main totalizer recording? If yes, problem is in register assembly. Check to be sure the lever on the

✓✓✓✓

side of the register is returning back to the record position.

If the main totalizer is not working, the problem is a broken or jammed measuring chamber.

✓✓✓✓

Pump delivery is slow.

Check for dirty strainer.

✓✓✓✓

If pump has a filter, change filter.

✓✓✓✓

An automatic nozzle will reduce flow rate about 25%. Check flow rate without nozzle or with standard

✓✓✓✓

nozzle. A farm type automatic nozzle (such as Husky 1GS swivel) provides the

Check for supply line restriction by testing the pump with a vacuum gauge. If vacuum is abnormally

✓✓✓✓

high, there is a restriction.

best flow.

Pump loses prime.

Inspect check valve poppet and seat for clean mating surfaces.

✓✓✓✓

If, after a period of non-use, a pump delivers product initially, followed by air and then full flow, there is

✓✓✓✓

an air leak in the suction line.

Install pressure gauge between hose and nozzle. Operate pump at full flow. Snap nozzle closed and

✓✓✓✓

turn off pump. If pressure falls to zero rapidly, replace check valve and clean

and inspect valve seat.

Inaccurate delivery.

Calibrate the meter (See Section 4).

✓✓✓✓

A clock-fast error (more on the register than is delivered) in excess of 2 1/2% is due to air in

suction line or vaporization of gasoline in the pump. Check pump for loss of prime and

air leak.

A clock-slow condition may result from: any slowing of the register or measuring chamber due to

excessive friction resistance or

Check register for

check for

"hang-up" of number wheels in register or gears not meshing.

zero setback; check reset lever return to top of slot in meter cover after setback;

mechanical failure; inadvertent bypassing of the measuring chamber.

suction line for

Pump delivers product when not turned on.

In aboveground storage tank, if fluid level is higher than pump, positive head pressure may force

✓✓✓✓

product through pump. Install a pressure regulating valve or a solenoid valve in the

pump.

Check for defective vacuum breaker.

✓✓✓✓

supply line to the

Vacuum breaker spits product

Clean and replace. If problem persists, install return line kit.

✓✓✓✓

the

5-4 0144

Page 29

Service and Troubleshooting

DISASSEMBLY OF PUMP

NOTE: Numbers in parentheses corr espond to the numbers shown on the parts illustration

and parts list in Section 6 labeled

When the f ront panel is removed, all the working par ts of the pump are accessible under clearly

marked cover plates. Since pump may contain product, be prepared to catch product in an

appropriate container when removing any cover.

Remove pump cover s crews and rem ove cover plate (1) and square r ing (2). Note orientation of

rotor (4) and of vanes (36) in rotor slots. Remove key (3) and withdraw rotor and vanes from

pump block (12). Since rotor is spring loaded, m ake sure washer (6) and spring (7) r emain on

pump shaft. Insert new rotor and replace vanes so that trailing edge slopes away from direction of

pump rotation (counterclockwise). Reinstall key in shaft slot and rotor keyway. Check pump

cover for scoring (if scored, replace). Replace squar e ring (2) and while holding rotor in against

spring tension, slide cover over opening and tighten screws.

To replace shaft seal, remove rotor and vanes as above. Slide spring (7) and both washers (6) off

shaft. O-ring (8) will act as a br ak e to r es ist r emoval of brass, rotating s eal r ing (9) . T o over c ome

this resistance, lightly grasp brass ring with pliers and pull at the same tim e turning s haf t bac k and

forth with the flat blade of a screwdriver in the keyslot in the end of the shaft. Remove O-ring from

brass ring and spread some gr ease over machined sur face of ring; reinse rt brass ring over shaf t

and press greased surfac e against carbon, floating seal ring (10). The carbon r ing can now be

withdrawn stuck to the brass ring. Do not break up the carbon ring to remove it, since some of the

pieces may get lost in the pump casting and cause the rotor or meas uring cham ber to jam later in

service. Use a bent wire as a button-hook to hook and withdraw O-ring (11) from recess in back

of pump cavity. Install new seal group (5) in reverse order. Make sur e recess in back of pum p

cavity is clean and that O-ring (11) is firmly seated and not twisted in this recess.

Direct Drive Motor-Pump Assembly

.

NOTE It is critical that the seal part mating surfac es r emain c lean and dry . Do not touc h or allow

oil of any type to contaminate the carbon or brass mating surfaces. If the seal

inadvertently becomes contaminated, both mating surfaces must be carefully cleaned with

a lint-free cloth and methyl alcohol.

The bypass valve (29) is preset to provide maximum performanc e without overloading the motor

and can be withdrawn by removing the bypass cover plate (31). When reas sembling, m ake sur e

the holed end of the tube (32) and bullet-shaped nose of the valve (29) are inserted toward the

pump.

The check valve is attached to the c heck valve cover (26) and will come out when the cover is

removed. If you can hear the product in the suction line running back into the storage tank when

this assembly (20) is removed, the chec k valve is holding and keeping the pum p primed. W hen

reassembling, make sure the rubber valve disc is facing down toward the valve seat.

METER-REGISTER DISASSEMBLY

NOTE: Numbers in parentheses corr espond to the numbers shown on the parts illustration

and parts list in Section 6 labeled

The B size measuring chamber ( 5) can be removed for cleaning by taking out four meter body

screws (2), lifting off register assembly (14) and removing three measuring chamber screws (4).

After separating and cleaning top and bottom half , reassemble, making sur e baffle is seated in

grooves in top and bottom halves and through slot in m easuring dis c (7). Do not drop or sharply

strike chamber par ts while handling. Rotate disc to m ak e su re it turns f reely and replace in m eter

body. Do not overtighten screws (4). A torque of 20- 25 ft-lbs is sufficient. W hen reassem bling

register to meter body, use a new O-ring (3).

1860 and 4860 Meter-Register

.

For calibration procedure, see

0144 5-5

Meter Calibration

in Section 4.

Page 30

GASBOY Series 70 & 1820

1860 3-WHEEL REGISTER SERVICE AND MAINTENANCE

NOTE: Numbers in parentheses corr espond to the numbers shown on the parts illustration

and parts list in Section 6 labeled

To service or replace parts in the disc register, remove the self-tapping scr ews and lif t of f the front

panel assembly. W ith the register now exposed, remove three screws with fiber washers (28 &

29). Lift off dial glass (30), and dial mask (32). This permits withdrawal of all parts (8 through 22).

While rem oving parts, observe the position and relationship of the parts to each other to assist

reassembly.

Totalizer assembly (3) can be taken out by removing screw (1). Replace as an assembly.

To gain access to the gear train ( 39, 40, 41 or 44 through 49), the register (1 thr ough 33) can be

removed as an assem bly by taking out 4 screws and lifting it off the m eter body. This is a liquidcarrying section of the meter. Be prepared to c atch any liquid drained from the system at this

point.

The cluster gear (40), contr ols the gear ratio change f or gasoline or dies el fuel in U.S. or Im perial

measure and is removed by taking off the retaining ring (38) and control block (39). For liter

measure, the drive gear (41) controls this ratio, and the drive key (37) must be removed to replace

this gear.

For full liter models , the cluster gear (45) controls the gasoline-diesel ratio change. To replace

this gear, both the retaining ring (38) and drive key (37) must be removed, and gears (44, 49, 47,

and 48) removed in that order.

1860 3-Wheel Meter-Register

.

Replacing Bearing and Seal Assembly (Item 36, Old Style)

To replace bearing and seal assem bly (36), rem ove all gears in gear train (39, 40, 41) or (44, 47,

48, and 49). Do not lose spacer washer (43). Disas semble item s 8-19 and 28-32 from register.

Withdraw gear and shaft (27), bearing and seal assem bly (36) and O-ring (35). Slide new O-ring

(35) over bearing and seal (36) like a ring on a finger. Insert gear and shaft (27) through hous ing

(33) from front to rear and through O-ring seal assembly (35 and 36). Press seal and shaft

together to seat bearing and seal firmly into square cavity in back of housing. Reassemble in

reverse order.

Replacing Bearing and Seal Assembly (Item 36, New Style)

To replace bearing and seal assem bly (52), rem ove all gears in gear train (39, 40, 41) or (44, 47,

48 & 49). Do not lose spacer washer (43). Disassemble items 28-32 and 8-19 from register.

Withdraw gear and shaft (27) . Remove the nylon washer which is part of item 52 and note its

location. Remove both oilite bearings and both O-rings from bore in regis ter housing. Using new

parts, which consist of a new nylon washer, 2 oilite bearings, and 2 O-rings, reass emble parts in

reverse order. Be sure to lubricate both O-rings with an O-ring lubricant before assembling.

When assembling the disc register, observe the following precautions.

1. For full liter models , make sure the spacer washer (43) lies between the control block and

gear (44) and the rear of the housing (33) on the control block post. The f unction of the

remaining plate is to stabilize the shaft (27) and ensure full engagement of gears in the drive

train (44-49).

Reassemble the full liter tr ain in the order 46, 45, 48, 47, 49, and 44. T he gears drive in their

number sequence (i.e. 44 drives 45, 45 drives 46, etc.)

2. A new drive key (37) is L-shaped as shown in drawing. After ins ertion through hole in s haft

(27) and slot in gear (41 or 49) hub, the long leg of L must be bent up to form a U shape and

capture the key and drive the gear train.

5-6 0144

Page 31

Service and Troubleshooting

3. Hook spring (25) over post so that hook lies flat against rear of housing.

4. Make sure lower arm and overthrow stop pawl (19) fits into slot in reset lever.

5. To time the register for zero reset, pry apart the center wheel and (13 and 16) and place 16

on middle post with two red marks pointing toward the other two posts. Line up the red

arrows on the lefthand and righthand wheels with marks on the c enter wheel as shown in

drawing. Make sure pawls 15 and 17 remain in gr ooves of lefthand and center (16) reset

gears (lefthand pawl-red, center pawl-white). Seat count gear (13) over hub of and down

against reset gear (16). Listen to it snap into place.

6. Install righthand overthrow stop (19) on post with lower arm engaged in rec tangular cutout in

reset lever (24). Install center and lefthand overthrow stop (11) on post so that upper arm of

19 fits in the recess in 11 and both stops are driven sim ultaneous ly by reset lever (24) during

reset.

7. If detent spring (21) and retainer (20) bec ome separated, reassem ble on post so that short

leg of spring points toward top of register.

8. If all parts are rem oved from the register, reassemble in the r everse order in the following

sequence: 27-35, 36, 41, 37, 40, 39, 38, 2, 3, 1, 26, 24, 25, 23, 22, 19, 16, 17, 14, 15, 12, 18,

13, 11, 21, 20, 10, 9, 8, 32, 31, 30, 29, 28.

9. Test register for zero reset (one short downward stroke of the reset lever resets register to

zero) and turn control block (39) by hand to record at least one gallon on the register . Mak e

sure O-ring seal on the rear of the housing is clean and the O-ring (34) is free of nicks or cuts

and will lay flat within the seat. Reassemble the meter to the register.

4860 4-WHEEL REGISTER SERVICE

NOTE: Numbers in parentheses corr espond to the numbers shown on the parts illustration

and parts list in Section 6 labeled

To service push button register, remove two (one on each side) screws (2) from bezel (1).

Remove bezel and dial mask (4). Reset button (5) and spring (6) are released when the dial

mask is rem oved. Remove screws (7), res et bearing (8) and sc rews (11) to lif t register as semb ly

(10) out. Drive shaft assembly (12) can be removed by taking out four bearing screws.

Replacing Bearing and Seal Assembly (Item 16, Old Style)

To replace the shaft seal or service the gear train on back of register housing (18), remove

housing from meter body by taking out four screws.

so some means should be available to catch what drains from the case and lines.

gears (22-25), remove three retaining rings (20) and drive k ey (21). W ithdraw the drive shaft and

gear (14), spacer (15), meter stuffing box (16), and O-ring (17). Slide new O-ring over new

bearing seal like you would slide a ring on your finger. Insert shaf t (14) through s pacer (15) and

bearing (16) as shown in the exploded view. Press entire assembled shaft and seal through

housing and seat the square of the bearing firmly into the recess in the register housing (18).

Reassemble the balance of the register in reverse order of disassembly.

4860 4-Wheel Register

NOTE: The meter housing will be full of liquid

.

To remove

0144 5-7

Page 32

GASBOY Series 70 & 1820

Replacing Bearing and Seal Assembly (Item 26, New Style)

To replace the bearing and shaft seal assembly (26), or service the gear train on back of register

housing (18), remove housing fr om m eter by taking out four s crews.

will be full of liquid so some means should be available to catch what dr ains from the case and

To remove gears ( 22-25), remove three r etaining rings (20) and drive key (21). W ithdraw

lines.

the drive shaft and gear (14), spacer (15), and all parts of bearing and seal assembly (26).

Remove the nylon washer from item 26 and note its location. Remove both oilite bear ings and

both O-rings from bore in register housing. Using new parts, which consist of a new nylon

washer, 2 oilite bearings, and 2 O-rings, reassem bly parts in reverse order. Be sure to lubricate

both O-rings with an O-ring lubricant before assembling.

Reassemble gear train in following sequenc e: gear (25), k ey (21), cluster gear (24), retaining ring

(20), control block (22), and retaining ring (20).

NOTE: The meter housing

5-8 0144

Page 33

Section 6

PARTS

Using part numbers when ordering will expedite your order and r educe the pos s ibility of the wrong

parts being shipped. W hen ordering replacement par ts, be sure to give the complete nam e and

part number as shown in the appropriate parts lists.

Procedures requiring disassembly of portions of the pump should be performed by competent

service personnel. Do not depend upon the repair service of a general mechanic unless he is

thoroughly familiar with the mechanism. GASBO Y has a distributor network which services fuel

dispensing equipment and management systems in every section of the country.

WARNING:

To reduce the risk of electrical shock when servicing, turn off and lock out all

power to the pump.

9312 6-1

Page 34

GASBOY Series 70 & 1820

SERIES 70 ASSEMBLY

6-2 9312

Page 35

Parts

SERIES 70 ASSEMBLY

Item Part No. Description

1 Pump Assembly

2 044089 3/4" X 6-7/8" Pipe Nipple

3 003597 Flanged Inlet, 72S

024934 Elbow, 72X & 73

4 052000 Screw

5 027055 Gasket

6 003542 3/4" Horiz. Dschg for Vacuum Breaker

003544 1" Horiz. Dschg for Vacuum Breaker

7 052105 Screw

8 Meter Register Assy

9 068020 Washer

10 039085 Hex Nut

11 000325 Nozzle Boot

12 029410 Reset Lever Handle

13 053900 Reset Lever Screw

14 030539 Hose, 5/8 x 12 ft. (Not Shown)

15 038471 Nozzle, 3/4" EBW-unl.(Not Shown)

16 034121 Motor Switch Lever

17 066534 Vacuum Breaker (Not Shown)

(See Direct Drive Motor Parts List)

(See breakdown for your model)

OPTIONAL ACCESSORIES

PART DESCRIPTION

PART DESCRIPTION

032814 Filter Kit (1820/1820R)

(Contains * items shown below)

*017270 Bushing, 3/4" x 1"

*043960 Pipe tube, 3/4" x 2"

*003043 Adapter, Filter 3/4"

*024940 Elbow, street 3/4" x 90

*026005 Filter, Wi x 24006 dsl/gas

030340 Hose-3/4" x 14 ft.

030355 Hose-3/4" x 15 ft.

037461 Motor for 50 cycle, 230V

038471 Nozzle - 3/4" Manual-Unleaded

038475 Nozzle - 3/4" Manual- Leaded

038519 Nozzle-Automatic-Unleaded-Husky

038520 Nozzle-Automatic-Leaded-Husky

038510 Hook Assy., OPW 11A

038511 Hook Assy., EMCO A2000

038503 Hook Assy., OPW 7H

032700 Kit, Vacuum Breaker Tubing and

Fittings

9312 6-3

Page 36

GASBOY Series 70 & 1820

SERIES 1820 ASSEMBLY

6-4 9312

Page 37

Parts

SERIES 1820 ASSEMBLY

Item Part No. Description

1 025393 Dial Face Assembly

2 028850 Dial Glass

3 012265 Bezel

4 040630 Front Panel Assembly

5 029620 Nozzle Hanger

029590 Nozzle Hanger - Automatic

Nozzle

6 038605 Keps Lock Nut

7 003820 Scuff Plate

8 052856 Machine Screw

9 039070 Keps Lock Nut

10 039461 Speed Nut

11 041545 Rear Panel Assembly

12 039815 Nyliner Bearing

13 003717 Control Lever

14 053170 Set Screw

15 038860 1/4-20 Hex Nut

16 068891 1/4 Lock washer

17 063970 Pump and Meter Support

18 051880 Cap Screw

19 013030 Carriage Bolt

20 052105 Machine Screw, Horiz. Dischg

052555 Machine Screw, Flgd Dischg

21 003542 Horiz. Dischg-3/4", for vac

breaker

003544 Horiz. Dischg-1", for vac

breaker

Item Part No. Description

22 027055 Gasket

23 052855 Machine Screw

24 052000 Cap Screw

25 053725 Self-Tapping Screw

26 Meter-Register Assy.

breakdown for your model)

27 054654 Control Shaft Assy.

(See breakdown)

28 Direct Drive Motor Assy

(See

Direct Drive Motor

breakdown)

29 051206 Switch Rod Assembly

(See breakdown)

30 003597 Flanged Inlet, (72S & 1820)

003601 Flanged Inlet, (1820R)

31 044089 3/4" x 6-7/8 Nipple

32 030539 Hose-5/8" x 12 ft., (Not shown)

33 038471 Nozzle-Manual Unl, (Not

Shown)

35 032912 Dial Face Kit (consists of

items 1, 2, & 10)

36 066534 Vacuum Breaker (Not Shown)

(See

parts

OPTIONAL ACCESSORIES

PART DESCRIPTION

032814 Filter Kit (1820/1820R)

(Contains * items shown below)

*017270 Bushing, 3/4" x 1"

*043960 Pipe tube, 3/4" x 2"

*003043 Adapter, Filter 3/4"

*024940 Elbow, street 3/4" x 90

*026005 Filter, Wix 24006 dsl/gas

030340 Hose-3/4" x 14 ft.

030355 Hose-3/4" x 15 ft.

PART DESCRIPTION

037461 Motor for 50 cycle, 230V

038471 Nozzle - 3/4" Manual-Unleaded

038475 Nozzle - 3/4" Manual- Leaded

038519 Nozzle-Automatic-Unleaded-Husky

038520 Nozzle-Automatic-Leaded-Husky

038510 Hook Assy., OPW 11A

038511 Hook Assy., EMCO A2000

038503 Hook Assy., OPW 7H

9312 6-5

Page 38

GASBOY Series 70 & 1820

DIRECT DRIVE MOTOR-PUMP ASSEMBLY

6-6 0259

Page 39

Parts

DIRECT DRIVE MOTOR-PUMP ASSEMBLY

Item Part No. Description

1 003490 Pump Cover

2 049004 Square-Ring

3 031285 Key, 70

4 051475 Rotor

5 054024 Seal Group (Consists of items 6-11)

6 067210 Washer

7 057956 Spring

8 048941 O-Ring

9 049510 Rotating Seal Ring

10 048820 Floating Seal Ring-Carbon

11 048956 O-Ring

12 003210 Pump Block

13 049525 Slinger Ring

14 F37332 Motor, 115V, 60 cycle, 70

F37697 Motor, 115V, 60 cycle, 1800

F37616 Motor, 230V, 50 cycle, 70

F37461 Motor, 230V, 50 cycle, 1800

19 003065 Base

20 066655 Check Valve Assembly (Consists of items 21-25 & 28)

21 029155 Valve Guide

029005 Valve Guide, 1800R

22 068680 Washer

23 038980 Hex Jam Nut

24 068650 Washer

25 024356 Valve Disc

26 022271 Check Valve Cover Assy.

27 042370 Cotter Pin

28 062620 Valve Stem w/Relief Valve

*062365 Relief Valve

29 062335 By-Pass Stem Assy.

30 049001 Square Ring

31 022315 By-Pass Cover

32 065725 Tube

33 049002 Square-Ring

34 063268 Strainer, 100 Mesh, Gasoline

063266 Strainer, 30 mesh, Diesel

35 022900 Strainer Cover

36 067030 Vane

37 049003 Square-Ring

9312 6-7

Page 40

GASBOY Series 70 & 1820

INSTALLATION PARTS

Item Part No. Description

1 003835 Install-a-Socket

2 021970 2" Coupling

3 045010 2" x 40" Pipe (underground)

4 045535 2" x 30" Pipe (pedestal)

5 044380 1" x 32 1/2" Suction Pipe

6 053320 Set Screws

7 066445 1" Union

8 003055 Pedestal Base

6-8 9312

Page 41

Parts

1860 AND 4860 METER-REGISTER

REGISTER ASSEMBLIES

Compatible with new- or old-style adjusting

Item Part No. Description

1 012790 Meter Body

2 051835 Meter Body Screw

3 049075 O-Ring

4 025851 Screw

5 019016 Meas. Chamber Assy.

(sold as assembly only;

includes items 6-9)

019015 Bronze Meas. Chamber

6 Meas. Chamber Top

7 Measuring Disc

8 Baffle

9 Meas. Chamber-bottom

10 053080 Adjusting Screw (Old Style)

11 048865 O-Ring, Buna

048866 O-Ring, Viton

12 052195 Adjusting Screw, Cap

13 048895 O-Ring

14 Register Assembly

(See below for list)

15 053081 Adjusting Screw (New Style;

replaces items 10-12)

9312 6-9

screw design

3-Wheel Disc Register (Shown Above)

(Phenolic Chamber)

035963 US Gallons, Gas

035964 US Gallons, Diesel

036293 Full Liter, Gas

036130 Full Liter, Diesel

048478 1/10 Liter, Gas

036131 1/10 Liter, Diesel

4-Wheel Push-Button Register (Not Shown)

Phenolic Chamber

036400 US Gallons, Gas

036401 US Gallons, Diesel

036404 Liter, Gas

036405 Liter, Diesel

4-Wheel Push-Button Register (Not Shown)

Bronze Chamber

048901 US Gallons, Gas

048900 1820RC, US Gallons, Diesel

Page 42

GASBOY Series 70 & 1820

1860 3-WHEEL METER REGISTER (FOR MODEL 1820)

6-10 9312

Page 43

Parts

1860 3-WHEEL METER REGISTER (FOR MODEL 1820)

035634 US Measure

035640 Liter Measure, 1/10

Item Part No. Description

1 052840 Screw

2 028615 Totalizer Drive Gear

3 065305 Totalizer Assembly (items

8 024280 L H Number disc

9 024310 R H Number disc

10 024220 Center Number disc

11 063220 Overthrow stop center &

12 028225 L H Count Wheel

12A 068994 L H Wheel Assembly

13 027580 Center Count Wheel

13A 068993 Center Wheel Assembly

14 028245 L H Reset Gear

15 042070 L H Reset Pawl

16 027600 Center Reset Gear

17 042040 Center Reset Pawl

18 068995 Wheel and Clutch Assembly

19 042055 Overthrow Stop Pawl

20 048805 Detent Spring Retainer

21 057580 Detent Spring

22 054325 Reset Sector Gear

23 056425 Reset Lever Shoe

24 033822 Reset Lever

25 057895 Reset Lever Spring

26 012085 Reset Lever Bearing

27 054955 Register Drive Gear & Shaft

28 052840 Dial Mask Screw

29 067780 Fiber Washer

30 028780 Dial Glass

32 035394 Dial Mask US Gallons &

035380 Dial Mask, Liter, Tenths

33 022675 Register Housing

34 049075 O-Ring

35 048865 O-Ring

36 014095 Bearing and Seal Assy.

37 031345 Drive Key

38 049390 Retaining Ring

50 012250 Bezel (70 series)

51 053605 Bezel Screw (70 series)

52 036995 Bearing & Seal Assy. (Use only

NOTE: Due to meter redesign, meters

4-7. Not sold separately.)

L H Wheels

(Includes items 12, 14, 15)

(Includes items 13, 16, 17)

Imperial Gallons

(Use only when Rev K is cast

inside of housing #33 If other

Rev., see item 52.)

when Rev P is cast inside of

housing #33 If other Rev.,

see item 36.)