Page 1

Humminbird®CHIRP Radar

Humminbird®CHIRP Radar

Installation Manual

Installation Manual

Page 2

Thank You!

Thank you for choosing Humminbird®, the #1 name in marine electronics. Humminbird has built its reputation

by designing and manufacturing top-quality, thoroughly reliable marine equipment. Your Humminbird is

designed for trouble-free use in even the harshest marine environment. We encourage you to read this

installation manual completely in order to get the full benefit from all the features and applications of your

Humminbird product.

Important Information

Review the following important information before proceeding with the installation.

Certified Installation

WARNING! Humminbird recommends certified installation by a Humminbird approved installer. Contact

your Humminbird dealer for further details, and refer to the warranty information included at the end of this

manual.

WARNING! This product must be installed and operated in accordance with the instructions provided.

Failure to do so could result in personal injury, damage to your vessel and/or poor product performance.

CAUTION! Installation and radar tuning should only be performed by a qualified radar service technician.

Potential Ignition Source

WARNING! This product is NOT approved for use in hazardous and/or flammable atmospheres. Do NOT

install in a hazardous and/or flammable atmosphere (such as in an engine room or near fuel tanks).

High Voltages

HIGH VOLTAGE WARNING! Dangerously high voltages are present within the scanner unit. There

are no internal connections or adjustments necessary for installation. Do NOT remove any covers or

otherwise attempt to access internal components, unless specifically instructed in the documentation

provided. The cover should be removed only by a qualified radar service technician. Technicians must

exercise extreme care when working inside the unit.

WARNING! Connecting this product to a voltage supply greater than the specified maximum rating may

cause permanent damage to the unit. Refer to the Specifications section for voltage rating.

i

Page 3

Radio Frequency and Microwave Radiation

DANGER: Microwave Radiation Hazard! The microwave energy radiated by a radar antenna is harmful

to humans, especially to one’s eyes. Do NOT look at the scanner from close range. Never look directly into an

open waveguide or into the path of radiation from an enclosed antenna. Make sure personnel are clear of

the scanner when it is powered on. Turn off the radar whenever it is necessary to work on the antenna unit

or on other equipment in the beam of the radar.

DANGER! Radar and other radio frequency radiation can upset cardiac pacemakers. If someone with a

cardiac pacemaker suspects abnormal operation, immediately turn off the equipment and move the person

away from the antenna.

CAUTION! For safety reasons, the radar must be installed above head height and out of range of personnel.

Positive Ground Systems

WARNING! Do not connect this unit to a system that has positive grounding.

Service and Maintenance

WARNING! Disassembly and repair of this electronic unit should only be performed by authorized service

personnel. Any modification of the serial number or attempt to repair the original equipment or accessories

by unauthorized individuals will void the warranty.

CAUTION! This product contains no user serviceable components. Please refer all maintenance and

repair to authorized Humminbird dealers. Unauthorized repair may affect your warranty.

Compass Safe Distance

WARNING! To prevent potential interference with the vessel's magnetic compasses, ensure an adequate

distance is maintained from the product.

NOTE: When choosing a suitable location for the product you should aim to maintain the maximum

possible distance from any compasses. Typically this distance should be at least 3 feet (1 m) in all directions.

However, for some smaller vessels it may not be possible to locate the product this far away from a compass.

In this situation, when choosing the installation location for your product, ensure that the compass is not

affected by the product when it is in a powered state.

Additional Warnings and Notes

WARNING! This device should not be used as a navigational aid to prevent collision, grounding, boat

damage, or personal injury. When the boat is moving, water depth may change too quickly to allow time for you

to react. Always operate the boat at very slow speeds if you suspect shallow water or submerged objects.

WARNING! The electronic chart in your Humminbird unit is an aid to navigation designed to facilitate the

use of authorized government charts, not to replace them. Only official government charts and notices to

mariners contain all of the current information needed for the safety of navigation, and the captain is

responsible for their prudent use and the safety of the vessel and its passengers.

NOTE: This product is specifically designed to be installed on boats and other means of maritime transport. If

your country forms part of the EU, please contact your dealer for advice before attempting to install elsewhere.

ii

Page 4

NOTE: Some features discussed in this manual require a separate purchase, and some features are

only available on certain models. Every effort has been made to clearly identify those features. Please

read the manual carefully in order to understand the full capabilities of your model.

NOTE: The procedures and features described in this manual are subject to change without notice. This

manual was written in English and may have been translated to another language. Humminbird is not

responsible for incorrect translations or discrepancies between documents.

NOTE: Humminbird does not warrant that this product is error-free or that it is compatible with products

manufactured by any person or entity other than Humminbird.

NOTE: Humminbird is not responsible for damages or injuries caused by your use or inability to use the

product, by the interaction of the product with products manufactured by others, or by errors in information

utilized by the product supplied by third parties.

NOTE: Although the waterproof rating capacity of this product meets the stated IPX standard (refer to the

Specifications section), water intrusion and subsequent equipment failure may occur if the product is

subjected to commercial high-pressure washing. Humminbird will not warrant products subjected to highpressure washing.

NOTE: This product is protected by patents, design patents, patents pending, or design patents pending.

ATTENTION INTERNATIONAL CUSTOMERS: Products sold in the U.S. are not intended for use in

the international market. Humminbird international units provide international features and are designed to meet

country and regional regulations. Languages, maps, time zones, units of measurement, and warranty are examples of

features that are customized for Humminbird international units purchased through our authorized international

distributors.

iii

Page 5

Compliance Statements

IEEE STATEMENT: This product complies with the IEEE C95.1 – 2005 – Standard for Safety Levels with respect

to Human Exposure to Radio Frequency Electromagnetic Fields, 3 kHz to 300 GHz.

ICNIRP GUIDELINES: When properly installed and operated, the use of this Radar conforms to: ICNIRP

Guidelines 1998 - International Commission on Non-Ionising Radiation Protection: Guidelines for limiting exposure to

time-varying electric, magnetic and electro-magnetic fields (up to 300 GHz) 1998.

DECLARATION OF CONFORMITY: Johnson Outdoors Marine Electronics, Inc. declares that this product

is compliant with the essential requirements of R&TTE directive 1999/5/EC.

IMO AND SOLAS: The equipment described within this document is intended for use on leisure marine boats

and workboats NOT covered by International Maritime Organization (IMO) and Safety of Life at Sea (SOLAS) Carriage

Regulations.

RADAR LICENSING: Installation and operation of this radar may be subject to individual licensing of the

equipment, operator or vessel. You are strongly advised to check with the requirements of the licensing authority of

your national administration. In case of any difficulties, contact your local Humminbird dealer.

FCC NOTICE – RADAR: Changes or modifications to this equipment not expressly approved in writing by

Johnson Outdoors Marine Electronics, Inc. could violate compliance with FCC rules and void the operator’s authority

to operate the equipment.

ENVIRONMENTAL COMPLIANCE STATEMENT: It is the intention of Johnson Outdoors Marine

Electronics, Inc. to be a responsible corporate citizen, operating in compliance with known and applicable

environmental regulations, and a good neighbor in the communities where we make or sell our products.

WEEE DIRECTIVE: EU Directive 2002/96/EC “Waste of Electrical and Electronic Equipment Directive (WEEE)”

impacts most distributors, sellers, and manufacturers of consumer electronics in the European Union. The WEEE

Directive requires the producer of consumer electronics to take responsibility for the management of waste from

their products to achieve environmentally responsible disposal during the product life cycle. WEEE compliance may

not be required in your location for electrical & electronic equipment (EEE), nor may it be required for EEE designed

and intended as fixed or temporary installation in transportation vehicles such as automobiles, aircraft, and boats. In

some European Union member states, these vehicles are considered outside of the scope of the Directive, and EEE

for those applications can be considered excluded from the WEEE Directive requirement.

This symbol (WEEE wheelie bin) on product indicates the product must not be disposed of with other

household refuse. It must be disposed of and collected for recycling and recovery of waste EEE. Johnson

Outdoors Marine Electronics, Inc. will mark all EEE products in accordance with the WEEE Directive. It is our

goal to comply in the collection, treatment, recovery, and environmentally sound disposal of those products;

however, these requirements do vary within European Union member states. For more information about where you

should dispose of your waste equipment for recycling and recovery and/or your European Union member state

requirements, please contact your dealer or distributor from which your product was purchased.

ROHS STATEMENT: Product designed and intended as a fixed installation or part of a system in a vessel may

be considered beyond the scope of Directive 2002/95/EC of the European Parliament and of the Council of 27

January 2003 on the restriction of the use of certain hazardous substances in electrical and electronic equipment.

iv

Page 6

EMC Installation Guidelines

Humminbird equipment and accessories conform to the appropriate Electromagnetic Compatibility (EMC)

regulations, to minimize electromagnetic interference between equipment and minimize the effect such

interference could have on the performance of your system.

Correct installation is required to ensure that EMC performance is not compromised.

NOTE: In areas of extreme EMC interference, some slight interference may be noticed on the product.

Where this occurs the product and the source of the interference should be separated by a greater distance.

For optimum EMC performance, we recommend that wherever possible:

• Humminbird equipment and cables connected to it are:

– At least 3 feet (1 m) from any equipment transmitting or cables carrying radio signals (e.g. VHF

radios, cables and antennas). In the case of SSB radios, the distance should be increased to 7 feet

(2 m).

– More than 7 feet (2 m) from the path of a radar beam. A radar beam can normally be assumed

to spread 20 degrees above and below the radiating element.

• The product is supplied from a separate battery from that used for engine start. This is important to

prevent erratic behavior and data loss which can occur if the engine start does not have a separate

battery.

• Humminbird specified cables are used.

• Cables are not cut or extended, unless doing so is detailed in the installation manual.

NOTE: Where constraints on the installation prevent any of the above recommendations, always ensure

the maximum possible separation between different items of electrical equipment, to provide the best

conditions for EMC performance throughout the installation.

HELIX®, Humminbird®, ONIX®, and SOLIX® are registered trademarks of Johnson Outdoors Marine Electronics, Inc.

Adobe, Acrobat, Adobe PDF, and Reader are either registered trademarks or trademarks of Adobe Systems Incorporated in the United

States and/or other countries.

© 2017 Johnson Outdoors Marine Electronics, Inc. All rights reserved.

v

Page 7

Table of Contents

Thank You i

Important Information i

Introduction 1

1. Installation Preparation 2

1. Review the Box Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Determine the Cable Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Create a Schematic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. Clear the Mounting Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. Choose the Mounting Location 5

3. Test Route the Cables 11

4. Install the Scanner 12

1. Prepare the Mounting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2. Connect the Power and Data Cables to the Radar Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3. Install the Radar Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5. Route the Cables 17

1. Route the Power and Data Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6. Connect to Power and Ethernet 18

1. Determine Your Fuse and Thermal Breaker Requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2. Connect to Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3. Connect to the Control Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7. Test the Installation 22

Mechanical Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Power On the Control Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Two Year Limited Warranty & Service Policy 23

Maintenance 26

Troubleshooting 27

Specifications 28

Contact Humminbird 34

vi

Page 8

Page 9

Introduction

The Humminbird Radar scanner is a compact, solid-state radar that utilizes CHIRP pulse compression for

improved range resolution. Connect the Radar scanner to your Humminbird control head to view a map-like

representation of the area surrounding your vessel, enabling you to identify other vessels, buoys, and land

features such as coastlines and hills.

The Humminbird Radar scanner includes the following features:

• Solid-state technology (no magnetron) for improved efficiency and quick start-up.

• Range performance up to 24 nm (dependent on installation location).

• CHIRP pulse compression for improved target range resolution and reduced background noise.

• Radar image display and control via compatible Humminbird control head.

• 24 RPM scanner rotation.

• Low power consumption.

Installation Overview

This manual will guide you through the following installation requirements for the Humminbird Radar

scanner:

• Preparing for Installation

• Selecting the Mounting Location

• Installing the Radar Scanner

• Connecting to Power and Ethernet

Multiple Radar Installation: Only one radar scanner can be used at any one time, per networked system.

If you have more than one radar scanner installed on your boat and want to use them at the same time, the

control heads to which the scanners are connected must NOT be networked together.

CAUTION! Installation and radar tuning should only be performed by a qualified radar service technician.

1

Overview

Page 10

1. Installation Preparation

Following are instructions for the installation of this accessory. Before you start installation, we encourage

you to read these instructions carefully in order to get the full benefit from your Humminbird accessory.

Supplies: In addition to the hardware included in this box, you will need a separate 12 or 24 VDC power

supply from that used for engine start, adhesive tape, a powered hand drill and various drill bits, various

hand tools, safety glasses, and a dust mask.

NOTE: It is important that you have read and understood the warnings and cautions provided in the

Important Information section of this manual before proceeding with the installation.

NOTE: A separate 12/24 VDC power supply is required for the Radar scanner installation to prevent erratic

behavior and data loss, which can occur if the engine start does not have a separate power supply.

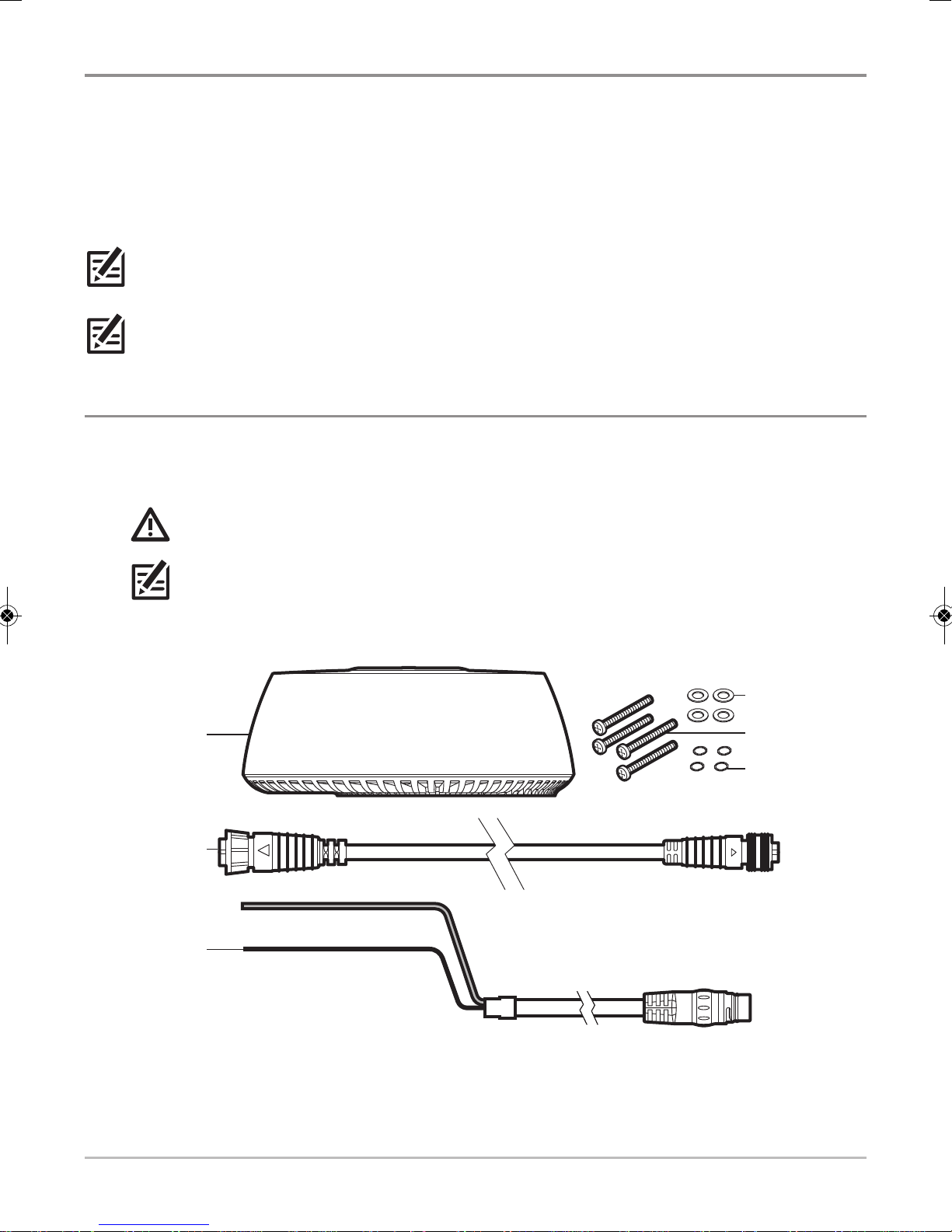

1. Review the Box Contents

Also, see the Specifications section for additional product information.

1. Unpack the box and confirm the contents with the illustration shown below.

CAUTION! Do not remove the cover from the unit. There are no connections or adjustments inside

the unit that are needed for installation or operation.

NOTE: Product supplies and features are subject to change without notice.

(1) Radar scanner

(1) AS EC M12

to RM data cable

(32.8 ft [10 m])

(1) power cable

(32.8 ft [10 m])

Parts Supplied

(4) flat washers

(4) M8 mounting bolts

(4) spring washers

Installation Preparation

2

Page 11

2. Determine the Cable Requirements

Depending on your Humminbird model and network configuration, you may need to purchase additional

accessories to connect your Radar scanner to your control head or Ethernet network. Before starting the

installation, determine whether you will need to purchase Ethernet Adapter Cables or extension cables.

Also, see Connect to Power and Ethernet for more information.

Hardware Cable Requirement to Connect to Radar Scanner Voltage Requirements

ONIX/SOLIX No additional cables required. 12 VDC

HELIX

Separate purchase AS EC QDE Ethernet Adapter

Cable is required.

12 VDC

Ethernet Switch No additional cables required. 12 or 24 VDC

3. Create a Schematic Diagram

A schematic diagram is an essential part of planning any installation. It is also useful for any future additions

or maintenance of the system. The diagram should include the following:

• Location of all components

• Cable types, routes, and lengths.

NOTE: Confirm that you have read and understood the warnings and cautions provided in the Important

Information section before proceeding with the installation.

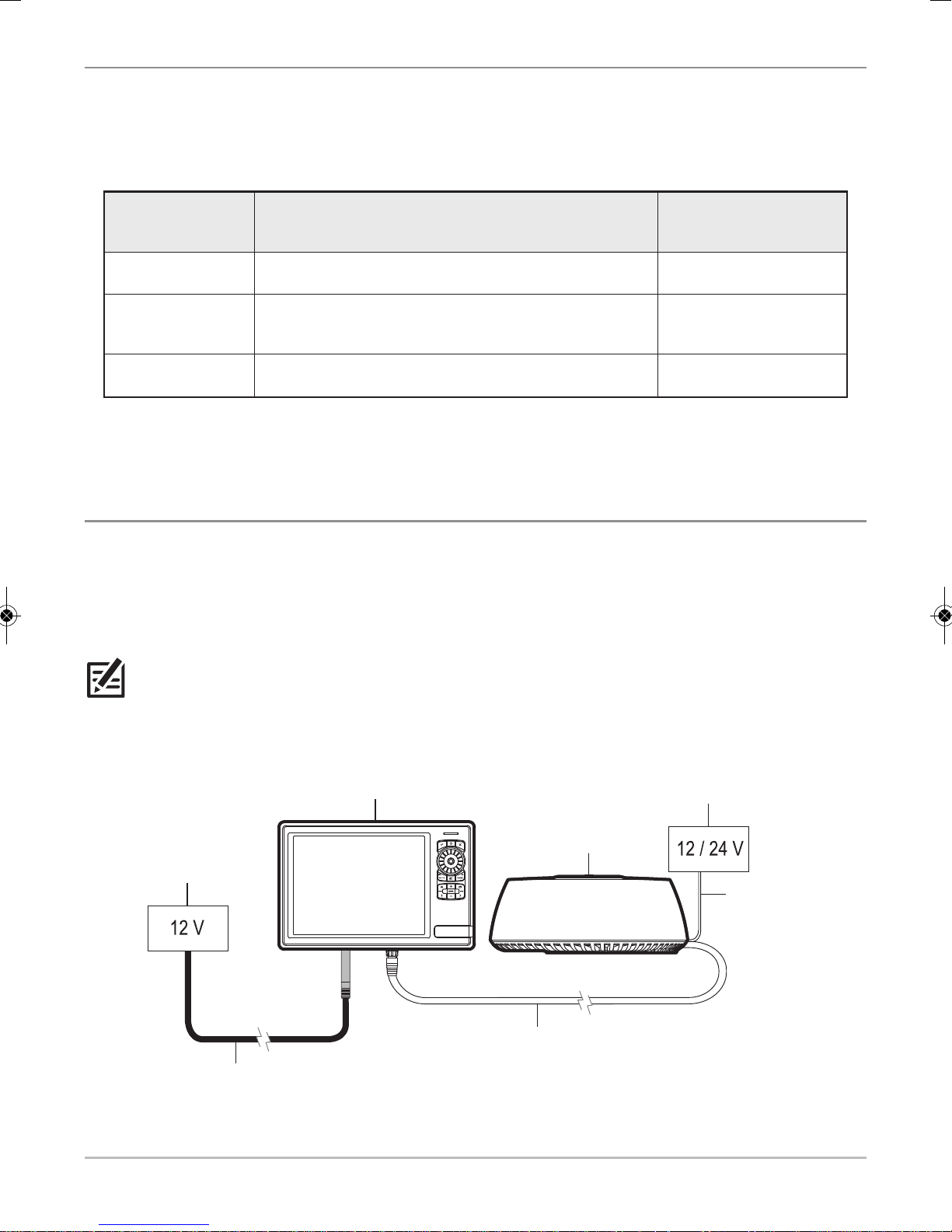

Example of a Schematic Diagram with a Direct Connection to the Control Head

control head

power supply

control head power cable

(6 ft [2 m])

ONIX control head

Radar scanner

AS EC M12 to RM data cable (included)

(32.8 ft [10 m])

3

separate 12/24 V

power supply

Radar scanner

power cable

(32.8 ft [10 m])

Installation Preparation

Page 12

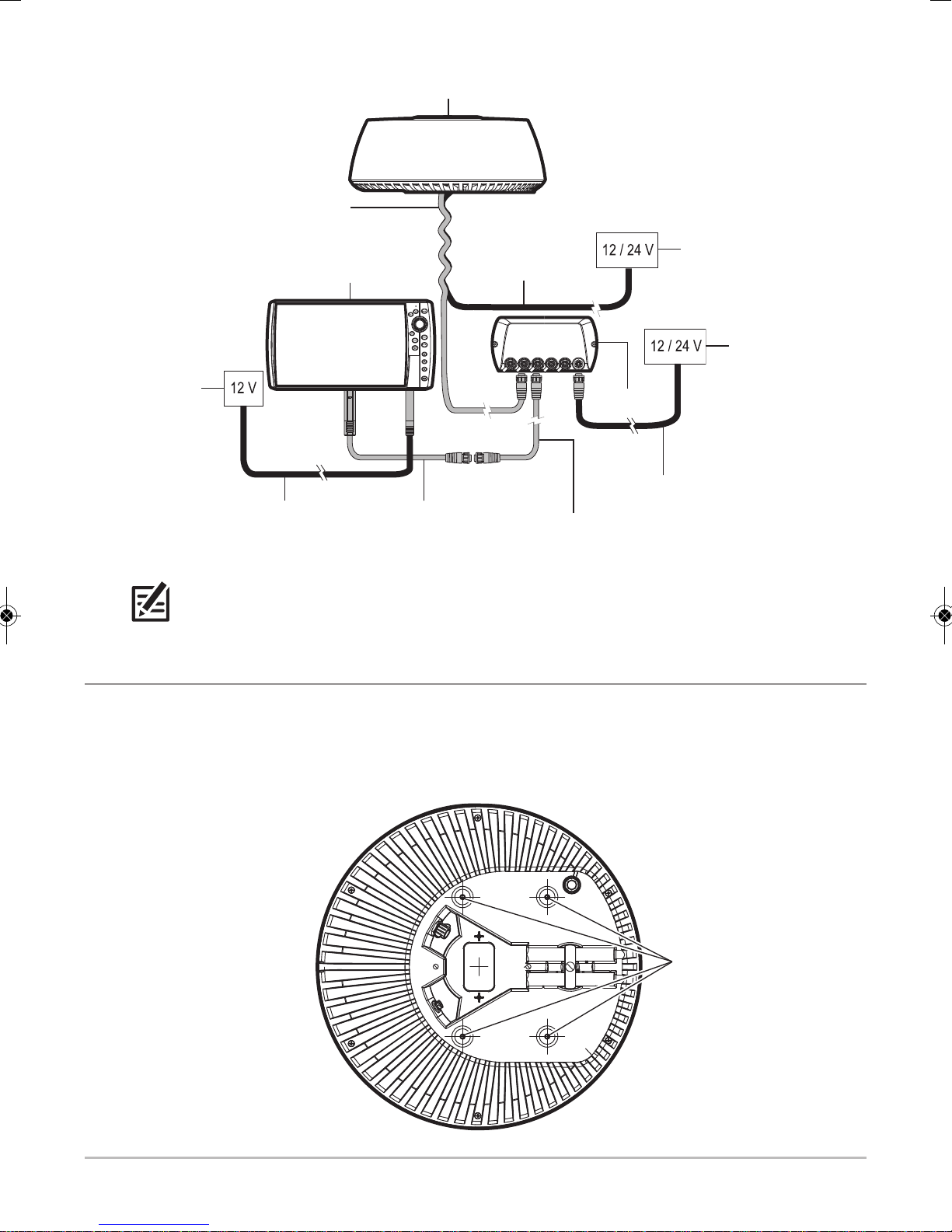

control head

power supply

Example of a Schematic Diagram with an Ethernet Switch Connection

Radar scanner

AS EC M12 to RM data cable

(32.8 ft [10 m])

Radar scanner power

HELIX control head

control head power cable

(lengths vary per model)

AS EC QDE adapter cable

(12 in [304.8 mm])

(separate purchase required)

cable (32.8 ft [10 m])

Ethernet Switch

Ethernet Switch

power cable

Ethernet cable

(separate purchase required)

separate 12/24 V

power supply

Ethernet Switch

power supply

NOTE: Cable lengths and power voltage requirements vary per model. Refer to the installation guides

included with your products for additional information.

4. Clear the Mounting Holes

1. Invert the scanner.

2. Confirm the four mounting holes are clear so they can accept the bolts.

Clearing the Mounting Holes

(4) mounting holes

Installation Preparation

4

Page 13

2. Choose the Mounting Location

It is important to consider the following information when installing the Radar scanner on the vessel. The

Radar scanner must be mounted where it is:

• Near the vessel's centerline

• Above head height

• Clear of large objects such as the flybridge, large engine stacks, searchlights, horns, masts, etc.

• At least 3 feet (1 m) from a magnetic compass or other scanners

• Away from heat and fumes

• On a stable platform that is capable of securely supporting the scanner under seagoing conditions

• Easily accessible

Determining the Mounting Location

rear view side view side view rear view

WARNING! Do NOT install the radar in a location that exposes passengers and

crew to the radar beam. Do NOT mount the radar where it could radiate on any person.

CAUTION! Working at higher elevations may become necessary while installing

the scanner unit. Observe safety measures and take sufficient precautions to avoid

personal injury or damage to the equipment.

5

Installation Preparation

Page 14

Centerline

The scanner unit should be mounted on the centerline of your boat in a location that has an unobstructed

view forward and is as clear as possible the rest of the way around the unit.

Locating the Vessel’s Centerline

centerline

of boat

Height

Choose a location as high as practical to improve maximum range, but not so high as to be adversely affected

by the vessel’s pitching and rolling. Also, keep in mind that minimum range objects may be overlooked if

mounted too high.

Unobstructed View

Position the Radar scanner forward of large structures and exhaust stacks. Contamination from engine

exhaust on the scanner housing reduces radar performance.

• Antennas for GPS, radio communication, or other equipment should not be located in the radar

beam.

• Use non-metallic extension poles to move the active area of antennas above the radar beam.

Blind Spots, Shadow Areas, and False Echoes: Large structures or stacks may cause blind spots and/or

false echoes.

• Wet sails may also cause shadow areas, so Radar performance may be reduced in the rain.

• If you mount the Radar scanner on a mast, echoes from other targets may be reflected from the mast.

• It is particularly important to avoid shadow areas near the bow.

• In shadow areas beyond the obstruction, there will be a reduction of the beam intensity. There may

be a blind sector if the beam intensity is not sufficient to obtain an echo from an object. This may

occur even at close range. For this reason, the angular width and relative bearing of any shadow area

must be determined at installation.

• Identifying shadow areas and/or false echoes on the control head: For example, adjust the

settings on your control head to view sea clutter. Dark sectors on the Radar display indicate possible

shadowed areas. See your control head operations manual for more information.

Installation Preparation

6

Page 15

Potential Interference

For optimum EMC performance, we recommend that wherever possible:

• Humminbird equipment and cables connected to it are:

– At least 3 feet (1 m) from any equipment transmitting or cables carrying radio signals (e.g. VHF

radios, cables and antennas). In the case of SSB radios, the distance should be increased to 7 feet

(2 m).

– More than 7 feet (2 m) from the path of a radar beam. A radar beam can normally be assumed

to spread 20° above and below the radiating element.

• The Radar scanner must be supplied from a separate power source from that used for engine start.

This is important to prevent erratic behavior and data loss which can occur if the engine start does

not have a separate battery or fuse panel.

Mounting Surface

The mounting surface must be flat, stable, and approximately parallel with the boat’s waterline.

• Surface Thickness: If the mounting surface is thin, a doubler should be added. If the mounting

surface is thick, longer bolts must be purchased separately.

• Surface Angle: The Radar beam from the Radar scanner is approximately 20° wide in the vertical

direction to give good target detection even when your vessel pitches and rolls.

Planing hull vessels, and some displacement hull vessels, adopt a higher bow angle when the vessel

is at cruising speed. This may raise the Radar’s main radiation angle, and can cause poor detection

of nearby targets. It may be necessary to compensate for the bow rise to ensure optimum target

detection. This can be achieved by fitting a wedge or washers between the mounting platform and

the base of the Radar scanner, so that the Radar beam remains parallel to the water line when the

vessel's bow rises at cruising speed.

7

Installation Preparation

Page 16

Compensating for Bow Rise

wedge or washers

Mounting Base

The Radar scanner can be installed directly to a roof or other flat surface. The mounting location must be

secure enough to support the Radar scanner under seagoing conditions. You can also use a mounting

bracket (separate purchase required). Be certain to keep the water drain tube clear, which is located at the

bottom of the scanner unit.

NOTE: If the mounting bracket or surface has a curvature of more than 5/64" (2 mm), use spacers with the

mounting bolts to prevent stress on the scanner housing.

Correct Mounting Base

mounting surface is clear and doesn’t trap water Do not mount on a surface with an edge that might trap water.

Incorrect Mounting Base

Access

Access to the under side is required for installation of the mounting bolts.

Installation Preparation

8

Page 17

Sailing Vessels

Additional considerations apply when installing the Radar scanner on a sailing vessel. A separate purchase

mast mounting bracket is highly recommended.

Review the following important mounting requirements:

• When mounting the Radar scanner onto the mast, check that the unit is not fouled by the sails,

especially when tacking.

• Depending on the type of sailing vessel and the design of the sailplan, a Radar scanner guard

(separate purchase required) should be attached to the mast if the sails or rigging contact either the

Radar scanner unit or the mounting bracket (separate purchase required). See the illustration

Example of a Radar Guard Installation.

WARNING! Without a proper Radar guard, serious damage can result to the Radar mounting

bracket and the Radar scanner itself. In extreme cases, such damage could result in the Radar scanner

unit being pulled off the mast. Therefore, it is recommended that a Radar scanner guard should be

mounted additionally and separately to the Radar scanner mounting bracket.

• To prevent the risk of the Radar scanner falling after it has been damaged, the security lanyard

supplied with the mast bracket (separate purchase required) must be secured properly to the mast

and to the Radar scanner, according to the instructions provided with the bracket.

If a safety lanyard is not supplied with the mounting bracket, contact your local dealer for appropriate

parts. Do NOT attach other equipment to either the Radar scanner or the bracket.

• Maintenance: Humminbird strongly recommends that you check the condition and security of the

bracket mounting feet, the security lanyard(s), the Radar scanner guard, and the Radar scanner

itself, on a yearly basis (or more frequently depending on environmental applications). Any fittings

should be replaced as appropriate.

Example of a Radar Guard Installation

mast

safety lanyard

attachment

Radar scanner guard

(separate purchase required)

NOTE: The Radar guard shown in the illustration above is provided as an example only. The design and

positioning of the Radar guard depends on your vessel type, sailplan, and installation environment. Contact

your local dealer or qualified marine installer for assistance.

9

Installation Preparation

Page 18

Example of a Mast Platform Mount with a Safety Lanyard

mast

safety lanyard

attachment point

to mast

mounting

platform

safety lanyard attachment

point to M8 bolt

Multiple Radar Installation

It is important to note that multiple radars cannot be connected to the same network. If you are installing

more than one radar on the same vessel, review the following important location requirements:

• Scanners should be mounted above each other, and vertically separated by at least 1.6 ft (0.5 m).

This applies to all installation locations on the vessel.

• Multiple scanners should be mounted in a way that minimizes interference between the vertical

beamwidths of the 2 scanners.

• To minimize any potential interference, mount the scanners with as much physical separation as

possible.

Installation Preparation

10

Page 19

3. Test Route the Cables

Using the information in this section, test route the cables from the planned mounting location to the control

head or Ethernet Switch location and the power source. Cables must be routed correctly to maximize

performance and prolong cable life. See Connect to Power and Ethernet for more information.

CIRCUIT ISOLATION WARNING! Proper circuit isolation is required for installations using both

AC and DC current. If you are installing a 3rd party product that utilizes AC current, contact a qualified

marine installer for assistance.

CAUTION! Do NOT mount the cables where the connectors could be submerged in water or flooded. If

cables are installed in a splash-prone area, it may be helpful to apply dielectric grease to the inside of the

connectors to prevent corrosion. Dielectric grease can be purchased separately from a general hardware or

automotive store.

Avoid Cable Bending

Do NOT bend cables excessively. Wherever possible, ensure a minimum

Avoiding Cable Bending

bend radius of 4" (100 mm).

4" (100 mm)

Strain Relief

Ensure adequate strain relief is provided. Protect connectors from strain and ensure they will not pull out

under extreme sea conditions.

Cable Protection

Protect all cables from physical damage and exposure to heat. Use trunking or conduit where possible.

• Do NOT run cables through bilges or doorways, or close to moving or hot objects.

• Do NOT run cables near to engines or fluorescent lights.

• Where a cable passes through an exposed bulkhead or deckhead, use a suitable watertight feedthrough.

• Route data cables away from other equipment and cables, high current carrying AC and DC power

lines, and antennae.

• Secure cables in place using cable ties or lacing twine. Coil any extra cable and tie it out of the way.

• Cable Shielding: Ensure that all data cables are properly shielded and that the cable shielding is

intact (e.g. hasn’t been scraped off by being squeezed through a tight area).

11

Installation Preparation

Page 20

4. Install the Scanner

Confirm that you have read and understood the warnings and cautions provided in the Important

Information section before proceeding with the installation.

WARNING! Confirm the vessel’s power supply is switched OFF before starting the installation. Do NOT

connect or disconnect equipment with the power switched on.

NOTE: Before proceeding with the installation, check the template to confirm that the dimensions match

the unit. Reproduction and moisture can affect the size of the template. See the Specifications section for

product dimensions.

1. Prepare the Mounting Location

1. Confirm that the mounting location meets the requirements described in the section Choose the

Mounting Location.

2. Clean and dry the mounting surface.

3. Align the included template squarely with the center line of the boat (or chosen mounting location), with

the arrow pointing forward (towards the bow of the vessel).

4. Tape the template to the chosen mounting location.

5. Mark the four mounting holes.

6. Drill four 1/8" (3 mm) pilot holes as indicated on the template.

7. Proceed to drill four 23/64" (9 mm) diameter holes through the mounting surface.

NOTE: For a close fit installation, drill 21/64" (8.5 mm) diameter holes. Do not exceed a mounting hole

diameter of 25/64" (10 mm).

Drilling the Mounting Holes

mounting surface

template

centerline

Installation

12

Page 21

8. Test the hardware: Check that each bolt (with spring washer and flat washer) protrudes through the

mounting surface at least 5/8" (16 mm) but less than 7/8" (22 mm).

CAUTION! The Radar scanner may be damaged if bolts protrude through the mounting surface

more than 7/8" (22 mm).

2. Connect the Power and Data Cables to the Radar Scanner

Before securing the scanner to the mounting surface, connect the power cable and data cable to the Radar

scanner. See Test Route the Cables for additional information.

1. Confirm the vessel’s power supply is switched off.

2. On the underside of the Radar scanner, turn the cable latch to the open position. See the illustration

Locating the Cable Ports.

3. Locate the cable ports.

4. Turn the power port locking collar counterclockwise to unlock it.

Locating the Cable Ports

power port

cable latch in closed

position (turn to open)

data port

5. Connect the power cable connector to the power port on the Radar scanner, making sure that the notch

lines up with the guide in the port.

6. Turn the power port locking collar clockwise (approximately 90 degrees) until you hear two clicks to secure

the cable connection. Confirm the cable is securely connected.

7. Connect the data cable connector to the data port on the Radar scanner. Hand-tighten the screw nut on

the cable connector to secure the connection.

8. Route the power cable and data cable through the base of the Radar scanner as needed for your

installation mount. See the illustrations on the following page for cable routing examples.

9. Turn the cable latch to the closed position to secure the cables in place.

13

Installation

Page 22

Cable Routing Examples

data port

data cable

cable latch in

closed position

strain relief

data port

data cable

power port

power cable

power port

power cable

data port

data cable

cable latch in

closed position

Installation

power port

power cable

14

Page 23

3. Install the Radar Scanner

Use the following instructions to install the Radar scanner on your vessel. Confirm you have read the

mounting requirements in the section Choose the Mounting Location.

1. Place the Radar scanner on the mounting surface.

2. Level Mounting Surface: Confirm the Radar scanner is flush against the mounting surface.

Angled Mounting Surface: If you are installing the Radar on a planing vessel (or other angled surface),

place a wedge (shim) under the rear of the Radar scanner so that the beam points slightly down in the

forward direction when the boat is at rest. This will compensate for the bow rising at cruising speed.

Mounting on a Level Surface

The radar scanner should be flush

against the mounting surface.

level mounting surface

Mounting on an Angled Surface (or Planing Vessel)

with planing angle

bolts and washers

install a wedge

or riser block

bolts and washersmounting surface

3. Install one spring washer and one flat washer on each bolt as indicated in the illustration Mounting the

Scanner Unit.

4. Insert each bolt through the drilled bolt holes in the mounting surface and into each threaded bolt hole

on the Radar scanner. Hand-tighten only.

5. Confirm the bolts have a minimum insertion in the Radar scanner base of 5/8" (16 mm) and a maximum

of 7/8" (22 mm) (allowing for washers).

CAUTION! The Radar scanner may be damaged if bolts protrude through the mounting surface

more than 7/8" (22 mm).

15

Installation

Page 24

NOTE: If you need to limit the length of the bolts entering the Radar scanner base, use appropriate

risers (shims) or additional washers.

Mounting the Scanner Unit

mounting surface

(partial view)

6. Hand-tighten the bolts to a torque of 11 ft·lbf (15 Nm).

CAUTION! Do not use a high speed driver on this combination of fasteners. Hand-tighten only.

flat washer

spring washer

bolt

Installation

16

Page 25

5. Route the Cables

After connecting the power cable and data cable to the Radar scanner unit, you must route the cables to

the control head and power source. Cable routing depends on whether you mount the scanner on a platform

or pole.

CAUTION! Confirm that the vessel’s power supply is switched off before proceeding.

CAUTION! Do NOT mount the cables where the connectors could be submerged in water or flooded. If

cables are installed in a splash-prone area, it may be helpful to apply dielectric grease to the inside of the

connectors to prevent corrosion. Dielectric grease can be purchased separately from a general hardware or

automotive store.

1. Route the Power and Data Cables

Route the power cable to the power source and the data cable to the control head or Ethernet Switch location.

You will connect the cables in a later procedure.

1. Confirm the vessel’s power supply is switched off.

2. Route the power cable to the fuse panel or battery.

3. Route the data cable to the control head or Ethernet Switch.

4. Secure the cables near the scanner to support the weight of the cables and prevent strain on the watertight

cable seals.

If the cable is to pass through tubing or a bulkhead, protect the unfinished end.

Make a drip loop and apply sealant at the entry point of an exterior bulkhead.

5. Proceed to Connect to Power and Ethernet.

CAUTION! Do not use the unfinished wires or fabric braid to pull the cable.

17

Route the Cables

Page 26

6. Connect to Power and Ethernet

The power cable must be connected to a separate 12 VDC or 24 VDC power source other than that used for

engine start. Use the instructions in this section to connect the power cable to a battery or fuse panel, and

the data cable to the Humminbird control head or Ethernet Switch.

WARNING: GROUNDING NOT REQUIRED! The Radar scanner power cable is fully insulated and

does not require separate grounding.

WARNING! Humminbird is not responsible for over-voltage or over-current failures. The Radar scanner

must have adequate protection through the proper selection and installation of circuit protection (i.e. fuse,

thermal breaker, etc.).

CAUTION! Only use the power cable supplied with your product. Do not use a power cable designed for,

or supplied with, a different product.

1. Determine Your Fuse and Thermal Breaker Requirement

Ideally, all equipment should be wired to individual suitably-rated thermal breakers or fuses to provide

appropriate circuit protection. Where this is not possible and more than one (1) product shares a breaker,

use individual in-line fuses for each power circuit to provide the necessary protection.

The following in-line fuse and thermal breaker ratings apply to your product:

• In-line fuse rating: 5 Amp

• Thermal breaker rating: 3 Amp (if only connecting one device)

NOTE: The suitable fuse rating for the thermal breaker is dependent on the number of devices you are

connecting.

Connect to Power and Ethernet

18

Page 27

2. Connect to Power

The power cable can be connected to a fuse panel (usually located near the console) or to a battery. The

power cable for each unit in your system should be run as a separate, single length of 2-wire cable from

the unit to the vessel’s battery or fuse panel. Review the following information before connecting the

included power cable to the power supply:

• You may shorten or lengthen the power cable using a minimum wire gauge of 14 AWG (2.08 mm²).

You must also ensure there is a continuous suitable operating voltage at the product’s power

connector.

• The following power density levels do NOT occur at any point: 10 W/m2, 100 W/m2

NOTE: The power cable can also be connected to a factory-fitted power distribution point. The distribution

point should be fed from the vessel’s primary power source by a minimum 8 AWG (8.36 mm²) cable.

1. Route the power cable to the fuse panel or battery (12 VDC or 24 VDC

required). Make sure that the data cable connector can reach the

control head or Ethernet Switch location.

Fuse Terminal Connection

2a. Use crimp-on type electrical connectors (not included) that match

the terminal on the fuse panel. Attach the black wire to ground (–),

and the red wire to positive (+) 12 VDC or 24 VDC power. Install a 5

Amp fuse (not included) for protection of the unit.

OR

Battery Switch Connection

2b. Install the battery switch (not included) using the instructions

provided with it. You will also need to install an inline fuse holder

and a 5 Amp fuse (not included) for protection of the unit. Attach the

black wire to (–) ground, and the red wire to (+) 12 VDC or 24 VDC

power.

NOTE: The in-line fuse rating for the power cable is 5 Amp. The

thermal breaker rating is 3 Amp (if only connecting one device).

The suitable fuse rating for the thermal breaker is dependent on

the number of devices you connect.

Fuse Terminal Connection

Battery Switch Connection

NOTE: Humminbird recommends that best practice is observed in all vessel electrical installations,

as detailed in the following standards:

• BMEA Code of Practice for Electrical and Electronic Installations in Boats

• NMEA 0400 Installation Standard

• ABYC E-11 AC & DC Electrical Systems on Boats

• ABYC A-31 Battery chargers and Inverters

• ABYC TE-4 Lightning Protection

19

Connect to Power and Ethernet

Page 28

Radar Scanner Power Cable

red cable (positive)

black cable (negative)

cable connector

3. Connect to the Control Head

Refer to your control head installation guide for additional information and instructions about connecting

cables.

Connect to ONIX/SOLIX

1. Insert the data cable connector into the Ethernet port on the control head.

2. Hand-tighten the screw nut on the cable to secure the connection.

3. Confirm there is enough cable slack to allow for the control head to pivot through its full tilt range and for

connecting or disconnecting the cables

.

Connect to HELIX

To connect the Radar scanner to a HELIX control head, a separate purchase AS EC QDE Ethernet Adapter

Cable is required.

1. Connect the data cable connector to the AS EC QDE adapter cable connector. Hand-tighten the screw nut

on the cable to secure the connection.

2. Insert the AS EC QDE adapter cable connector into the Ethernet port on the control head.

3. Confirm there is enough cable slack to allow for the control head to pivot through its full tilt range and for

connecting or disconnecting the cables.

Connect to Power and Ethernet

20

Page 29

Connect to an Ethernet Switch

Use the following instructions to connect the data cable to an Ethernet Switch. See the Ethernet Switch

installation guide for information about connecting cables.

1. Connect the data cable connector to an available port on the Ethernet Switch. Hand-tighten the screw

nut on the cable to secure the connection.

2. Connect an Ethernet cable to an available port on the Ethernet Switch.

3. ONIX/SOLIX: Insert the Ethernet cable connector into the Ethernet port on the control head.

HELIX: Connect the Ethernet cable connector to one end of an AS EC QDE adapter cable connector

and insert the other end into the Ethernet port on the control head.

4. If the cable connector has a screw nut, hand-tighten the screw nut to secure the connection.

5. Confirm there is enough cable slack to allow for the control head to pivot through its full tilt range and

for connecting or disconnecting the cables.

21

Connect to Power and Ethernet

Page 30

7. Test the Installation

Perform the following tasks before using the product on the water:

• Mechanical checks

• Power on and initial setup

Mechanical Checks

Before powering on the product, perform the following mechanical checks:

1. Confirm that all securing bolts are fully tightened and the appropriate mechanical locking washers are in

place.

2. Confirm all connections are secure.

3. Confirm all connecting cables and wires are secured and protected as necessary.

Power On the Control Head

See your Humminbird operations manual to configure the radar and start transmission.

Test the Installation

22

Page 31

Two Year Limited Warranty & Service Policy

Registering Your Product

As you build your Humminbird network, it is important to register your control heads and accessories and

keep the software up to date.

• Go to humminbird and select My Humminbird to sign in or set up a new account.

• Software Updates: Under each registered product, click Downloads. Review the instructions in

your control head operations guide before proceeding with the update.

Humminbird 2 Year Limited Warranty

We warrant the original retail purchaser that products made by Humminbird have been manufactured free

from defects in materials and workmanship. This warranty is effective for two years from the date of original

retail purchase. Humminbird products found to be defective and covered by this warranty will be repaired

or replaced free of charge at Humminbird’s option and returned to the customer freight prepaid.

Humminbird’s sole responsibility under this warranty is limited to the repair or replacement of a product that

has been deemed defective by Humminbird. Humminbird is not responsible for charges connected with

the removal of such product or reinstallation of replaced or repaired parts.

This warranty does not apply to a product that has been:

• Improperly installed;

• Used in an installation other than that recom mended in the product installation and operation

instructions;

• Damaged or has failed because of an accident or abnormal operation;

• Repaired or modified by entities other than Humminbird.

Please retain your original receipt as a proof of the purchase date. This will be required for in-warranty

service.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY OTHER WARRANTIES, OBLIGATIONS OR LIABILITIES

ON THE PART OF HUMMINBIRD AND WILL BE THE CUSTOMER’S EXCLUSIVE REMEDY, EXCEPT FOR

ANY APPLICABLE IMPLIED WARRANTIES UNDER STATE LAW WHICH ARE HEREBY LIMITED IN

DURATION TO TWO YEARS FROM THE DATE OF ORIGINAL PURCHASE. IN NO EVENT WILL

HUMMINBIRD BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR BREACH OF

ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE PRODUCTS.

Some states do not allow limitations on an implied warranty, or the exclusion of incidental or consequential

damages, so the above exclusions may not apply to you. You may also have other rights, which vary from

state to state

23

Warranty & Service Policy

Page 32

Humminbird Service Policy

Even though you’ll probably never need to take advantage of our incredible service policy, it’s good to know

that we back our products this confidently. We do it because you deserve the best. We will make every

effort to repair your unit within three business days from the receipt of your unit at our factory. This does

not include shipping time to and from our factory. Units received on Friday are typically shipped by the

following Wednesday, units received Monday are typically shipped by Thursday, etc.

All repair work is performed by factory-trained technicians to meet exacting factory specifications. Factoryserviced units go through the same rigorous testing and quality control inspections as new production

units.

Warranty & Service Policy

24

Page 33

Returning your Unit for Service

Before sending your unit in for repair, please contact the factory, either by phone or by e-mail, to obtain a

Repair Authorization Number for your unit.

NOTE: Please do not return your Humminbird to the store for service.

Please have your product model name and serial number available before calling the factory. If you contact

the factory by e-mail, please include your product model name and serial number in the e-mail, and use

Request for Repair Authorization Number for your e-mail subject header. You should include your Repair

Authorization Number in all subsequent communications about your unit.

For IN-WARRANTY service, complete the following steps:

• Obtain a Repair Authorization Number from Humminbird Customer Service.

• Tag product with your name, street address, phone number, and your assigned Repair

Authorization Number.

• Include a brief written description of the problem.

• Include a copy of your receipt (to show proof and date of purchase).

• Return product freight prepaid to Humminbird, using an insured carrier with delivery confirmation.

For OUT-OF-WARRANTY service, complete the following steps:

• Obtain a Repair Authorization Number from Humminbird Customer Service.

• Include payment in the form of credit card number and expiration date, or a money order. Please

do not send cash.

• Tag product with your name, street address, phone number, and your assigned Repair

Authorization Number.

• Include a brief written description of the problem.

• Return product freight prepaid to Humminbird, using an insured carrier with delivery confirmation.

25

Warranty & Service Policy

Page 34

Maintenance

Use the following procedures to ensure your Humminbird product continues to deliver top performance.

HIGH VOLTAGES WARNING! This product may contain high voltages. Do NOT remove any covers

or otherwise attempt to access internal components.

Recommended Yearly Maintenance Tasks

Clean the Hardware

1. Power off the Radar scanner.

2. Remove one of the bolts and associated washers.

3. Clean the bolt and washers.

4. Replace the bolt and washers.

5. Repeat steps 2 through 4 for all bolts.

6. Tighten all antenna-securing bolts to a torque of 11 ft·lbf (15 Nm).

Check the Cable Connections

1. Power off the Radar scanner.

2. Check that all connected cables are in good condition and securely attached.

3. Examine all cables for signs of chafing, cuts or other damage.

Check the Radar Scanner

1. Power off the Radar scanner.

2. Ensure the Radar scanner is firmly attached to the mounting surface.

Cleaning the Radar Scanner

The Radar scanner does not require regular cleaning. However, if you find it necessary to clean the unit,

please follow the steps below:

1. Power off the Radar scanner.

2. Wipe the unit clean with a damp cloth.

3. If necessary, use a mild detergent solution to remove grease marks.

Storage Requirements

Store upright, making sure you do not block the vents on the underside of the Radar scanner.

Maintenance

26

Page 35

Troubleshooting

Before contacting Humminbird Customer Service, please read the following section. Taking the time to

review these troubleshooting guidelines may allow you to solve a performance problem yourself, and

therefore avoid sending your unit back for repair.

No Connection to the Radar Scanner

• Check the cable connections. Confirm the adapter cable (if used) is connected at both ends and is

in good condition.

• Ensure the power supply thermal breaker has not tripped or fuse has not blown. If necessary, reset

breaker

Humminbird authorized dealer for assistance.

• Ensure power supply maintains the correct voltage when the system is switched on.

• If the Radar scanner is connected to the control head via an Ethernet Switch, ensure that:

or replace fuse (one time only). If breaker keeps tripping or fuse keeps blowing, contact a

• All relevant equipment is correctly connected to the Ethernet Switch.

• The Ethernet Switch power supply is satisfactory.

• The Ethernet Switch is in good condition.

• Ethernet cables are securely connected and in good condition.

• Entire System Restart: Power off the control head and all connected equipment. Wait 10 seconds,

and then power on all equipment.

Displayed Bearing is Different to the True Bearing

Refer to the bearing alignment procedure detailed in your control head operations manual.

Noise

If you are experiencing noise or other interference, contact a NMEA approved technician for assistance.

27

Troubleshooting

Page 36

Specifications

Approvals

USA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47CFR FCC Part 2 & Part 80 Certificate of Approval

Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RSS238 Iss. 1 Technical Acceptance Certificate

European Union & EFTA . . . . . . . . . . . . . . . . . . . . . . . R & TTE Directive 1999/05/EC Certificate of Opinion

Australia & New Zealand . . . . . . . . . . . . . . . . . . . . . ACMA Declaration of Conformity Compliance level 3

General

Voltage Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 or 24 VDC (minimum: 10.8 VDC, maximum: 31.2 VDC)

Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Transmit Mode (maximum): 17 W

Standby Mode: 7 W

Operating Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 to 131° F (-10 to + 55° C)

Storage Temperature Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -13 to 158° F (-25 to + 70° C)

Wind Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . up to 95% at 95° F (35° C) 100 Knots

Range Scales . . . . . . . . . . . . 1/16, 1/8, 1/4, 3/8, 1/2, 3/4, 1, 1.5, 2, 3, 4, 6, 8, 12, 16, and 24 nautical miles

Water Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IPX6 (IEC 529)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12.3 pounds (5.6 kg)

Power Cable Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32.8 feet (10 m)

Transmitter

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . X-band solid-state transmitter with pulse compression technology

Transmit Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9354 to 9446 MHz

Peak Power Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 W

Duplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Circulator

Pulse Widths (3 dB) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 ns to 14.7

CHIRP Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400 ns to 22 μs

μ

s

Pulse Repetition Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2083 Hz to 4167 Hz

CHIRP Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Up to 32 MHz

Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Scanner rotation - OFF

Specifications

Scanner transmission - OFF

28

Page 37

Receiver

IF Bandwidth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 MHz

Noise Figure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.0 dB or less

Antenna

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Patch Array

Peak Power Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 W

Transmit Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9354 to 9446 MHz

Beamwidth (nominal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Horizontal: 4.9°

Vertical: 20°

Polarization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Horizontal

Rotation Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 rpm nominal

NOTE: Product specifications and features are subject to change without notice.

29

Specifications

Page 38

Radar Scanner Dimensions

Radar Scanner Dimensions - Side View

A

B

Dimension Description Measurement

A

B

Distance from the centerline of the Radar scanner to the front

of the mounting base.

Distance from the rear of the mounting base to the front of the

mounting base.

Radar Scanner Dimensions - Rear View

4.57 in (116 mm)

13.95 in (355 mm)

C

D

E

Dimension Description Measurement

C Height of Radar scanner. 8.25 in (209.5 mm)

D Mounting base width (rear of unit). 12.58 in (319.5 mm)

E Width of Radar scanner. 21.30 in (541 mm)

Specifications

30

Page 39

Radar Scanner Dimensions - Underside View

H

I

F

G

Dimension Description Measurement

F Distance from the centerline to the rear mounting hole. 4.59 in (116.5 mm)

G Distance between mounting holes. 9.17 in (233 mm)

H Distance from the centerline to the front mounting hole. 1.08 in (27.5 mm)

I

Distance between front and rear mounting holes. 5.57 in (141.5 mm)

31

Specifications

Page 40

Radar Scanner Dimensions

8.25 in

(209.5 mm)

4.57 in

(116 mm)

13.98 in (355 mm)

12.58 in (319.5 mm)

21.3 in (541 mm)

4.59 in

(116.5 mm)

9.17 in

(233 mm)

1.08 in

(27.5 mm)

5.57 in

(141.5 mm)

Shop the largest selection of reliable marine electronics and navigation in our online store.

Specifications

32

Loading...

Loading...