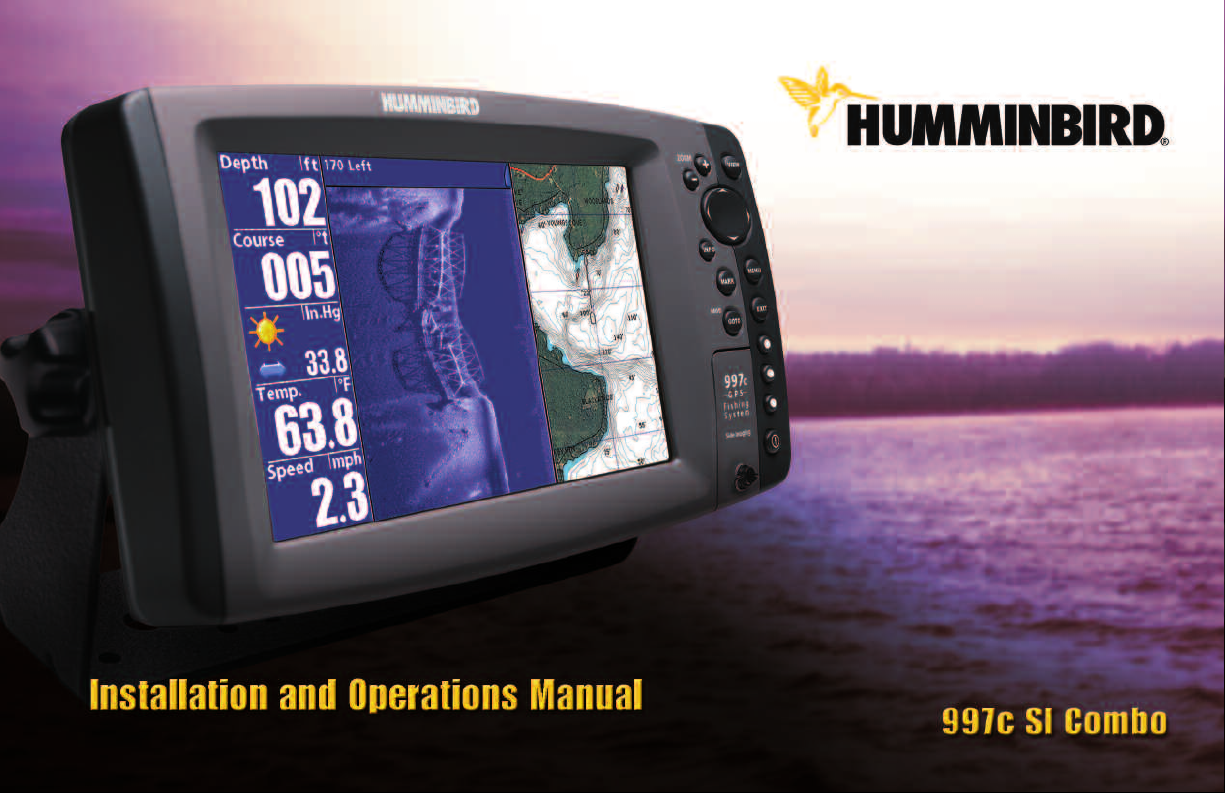

Humminbird 997c SI Combo Installation And Operation Manual

Thank You!

Thank you for choosing Humminbird®, America's #1 name in fishfinders. Humminbird® has built its reputation by designing and manufacturing top-quality,

thoroughly reliable marine equipment. Your Humminbird® is designed for trouble-free use in even the harshest marine environment. In the unlikely event that

your Humminbird® does require repairs, we offer an exclusive Service Policy - free of charge during the first year after purchase, and available at a reasonable

rate after the one-year period. For complete details, see the Warranty section in this manual. We encourage you to read this installation and operations manual

carefully in order to get full benefit from all the features and applications of your Humminbird® product.

Contact our Customer Resource Center at either 1-800-633-1468 or visit our website at www.humminbird.com.

WARNING! This device should not be used as a navigational aid to prevent collision, grounding, boat damage, or personal injury. When the boat is moving, water depth may change too quickly to allow time for you to react. Always operate the boat at very slow speeds if you suspect shallow water or submerged objects.

WARNING! Disassembly and repair of this electronic unit should only be performed by authorized service personnel. Any modification of the serial number or attempt to repair

the original equipment or accessories by unauthorized individuals will void the warranty.

WARNING! This product contains chemicals known to the State of California to cause cancer and/or reproductive harm.

NOTE: Some features discussed in this manual require a separate purchase, and some features are only available on international models. Every effort has been made to clearly

identify those features. Please read the manual carefully in order to understand the full capabilities of your model.

900 Series™, Cannon™, CannonLink™, DualBeam PLUS™, Fish ID+™, HumminbirdPC™, Humminbird®, InterLink™, One-Touch® Zoom, QuadraBeam PLUS™, RTS® Window, SmartCast®, Structure ID®, Total Screen

Update®, TrueArch®, WeatherSense®, WhiteLine®, WideSide®, X-Press™, and X-Press™ Menu are trademarked by or registered trademarks of Humminbird®.

© 2008 Humminbird®, Eufaula AL, USA. All rights reserved.

i

Table of Contents

900 Series™ Introduction 1

How the 900 Series™ Works ................................................................................................ 1

High Definition Side Imaging Sonar ...................................................................................... 2

DualBeam PLUS™ Sonar ...................................................................................................... 3

QuadraBeam PLUS™ Sonar

Universal Sonar 2 .................................................................................................................... 4

How GPS and Cartography Work .......................................................................................... 4

Multi-Media Card (MMC)/SD Slot ........................................................................................ 5

Software Updates .................................................................................................................... 5

Accessory Bus.......................................................................................................................... 6

(optional-purchase QuadraBeam PLUS™ transducer only)

.......... 3

Installation Overview 6

Control Head Installation 7

Gimbal Mounting the Control Head ...................................................................................... 7

Connecting the Control Head Power Cable to the Boat .................................................... 12

Transducer Installation 13

Transom Transducer Installation .......................................................................................... 14

Trolling Motor Transducer Installation ................................................................................ 19

Trolling Motor Transducer Options ...................................................................................... 19

Test and Finish the Transducer Installation ........................................................................ 20

GPS Receiver Installation 21

Stem Mounting with an Existing 1" - 14 Thread Stem ...................................................... 21

Access Under Mounting Location........................................................................................ 22

No Access Under Mounting Location.................................................................................. 23

Finish Routing the Cable and Check GPS Receiver Operation .......................................... 23

Testing the System Installation 24

Getting Started - Using Your 900 Series™ 25

Powering Up the Control Head ............................................................................................ 25

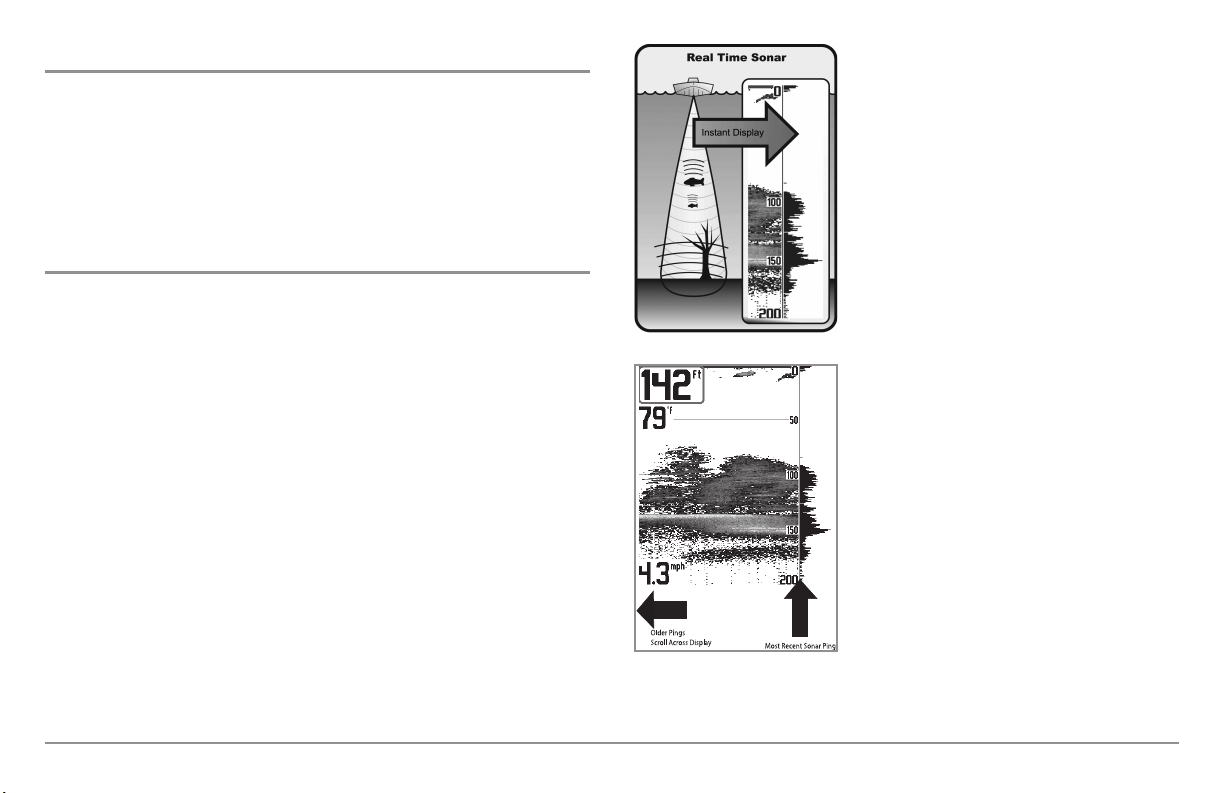

What’s on the Sonar Display .............................................................................................. 26

Understanding Sonar History .............................................................................................. 27

Real Time Sonar (RTS®) Window.......................................................................................... 27

Sonar Bottom Presentation .................................................................................................. 28

Understanding Side Imaging 29

What’s on the Side Imaging Display.................................................................................... 30

Side Imaging Technology: How It Works ............................................................................ 31

Side Imaging: On the Water Interpretation ........................................................................ 31

Key Functions 34

POWER/LIGHT Key ................................................................................................................ 34

VIEW Key................................................................................................................................ 35

MENU Key .............................................................................................................................. 35

4-WAY Cursor Control Key .................................................................................................... 36

View Preset Keys.................................................................................................................... 36

EXIT Key.................................................................................................................................. 36

INFO Key ................................................................................................................................ 37

MARK Key .............................................................................................................................. 37

GOTO Key................................................................................................................................ 37

ZOOM (+/-) Keys.................................................................................................................... 38

ii

531559-1_F

Table of Contents

Views 38

Views and Readouts.............................................................................................................. 39

Side Imaging View ................................................................................................................ 39

Sonar View ............................................................................................................................ 40

Sonar Zoom View .................................................................................................................. 41

Split Sonar View .................................................................................................................... 42

Side/Sonar Combo View ...................................................................................................... 43

Snapshot and Recording View ............................................................................................ 43

Side Beam View

Bird’s Eye View ...................................................................................................................... 50

Chart/Bird’s Eye Combo View .............................................................................................. 51

Chart/Chart Combo View ...................................................................................................... 52

Chart View.............................................................................................................................. 53

Chart/Sonar Combo View...................................................................................................... 54

Chart/Side Combo View........................................................................................................ 55

Chart Orientation .................................................................................................................. 56

(with optional-purchase QuadraBeam PLUS™ transducer only)

................ 48

Viewing Cartography 56

Navigation 57

Waypoints, Routes and Tracks.............................................................................................. 58

Save, Edit, or Delete a Waypoint.......................................................................................... 59

Navigate to a Waypoint or Position .................................................................................... 60

Add a Waypoint Target or Trolling Grid................................................................................ 60

Save, Edit or Delete a Route ................................................................................................ 61

Save or Clear a Current Track .............................................................................................. 62

Edit, Delete or Hide Saved Tracks ........................................................................................ 62

Man Overboard (MOB) Navigation ...................................................................................... 63

The Menu System 64

Start-Up Options Menu 65

Normal Operation .................................................................................................................. 66

Simulator .............................................................................................................................. 66

System Status ...................................................................................................................... 66

Self Test.................................................................................................................................. 67

Accessory Test........................................................................................................................ 67

GPS Diagnostic View ............................................................................................................ 68

Sonar X-Press™ Menu 69

Active Side.............................................................................................................................. 69

Split Position .......................................................................................................................... 70

Sensitivity .............................................................................................................................. 70

Upper Range

Lower Range.......................................................................................................................... 71

Chart Speed............................................................................................................................ 72

Quad Layout

(with optional-purchase QuadraBeam PLUS™ Transducer, Side Beam View only)

Bottom Lock

Bottom Range

Sonar Colors .......................................................................................................................... 73

Cancel Navigation

(Advanced: Sonar, Split Sonar and Active Sonar Side Views only)

(Sonar Zoom View only)

(Sonar Zoom View only, when Bottom Lock is on)

(only when navigating)

.................................................................................. 73

...................................... 73

.......................................................................... 73

................ 71

.......... 72

iii

Table of Contents

Side Imaging X-Press™ Menu 74

Active Side.............................................................................................................................. 74

Split Position .......................................................................................................................... 74

SI Side .................................................................................................................................... 75

SI Sensitivity .......................................................................................................................... 75

SI Range ................................................................................................................................ 75

Chart Speed............................................................................................................................ 75

SI Colors.................................................................................................................................. 76

Navigation X-Press™ Menu 76

Active Side.............................................................................................................................. 77

Split Position .......................................................................................................................... 77

Waypoint [Name]

Cursor to Waypoint

Save Current Track ................................................................................................................ 78

Clear Current Track................................................................................................................ 78

Save Current Route

Skip Next Waypoint

Cancel Navigation

Cancel MOB Navigation

Remove Target

Remove Grid

Waypoint Name

(only with an active cursor on a waypoint)

(Chart or Combo view only)

(only when navigating)

(only when navigating)

(only when navigating)

(only when MOB Navigation is activated)

(only if a Target is active)

(only if a Grid is active)

(most recently-created waypoint)

.......................................................................... 79

........................................................................ 79

............................................................................ 79

.............................................................................. 80

...................................................................................... 80

.............................................. 77

.................................................................. 78

.................................... 79

.............................................................. 80

Snapshot and Recording X-Press™ Menu

(Snapshot and Recording View only) 81

Start Recording

(optional-purchase MMC/SD Card, Snapshot and Recording View only) ..........................

Stop Recording

(optional-purchase MMC/SD Card only) ......................................................

Delete Image

(optional-purchase MMC/SD Card, Snapshot and Recording View only) ..........................

Delete All Images

(optional-purchase MMC/SD Card, Snapshot and Recording View only) ..........................

Delete Recording

(optional-purchase MMC/SD Card, Snapshot and Recording View only) ..........................

Delete All Recordings

(optional-purchase MMC/SD Card, Snapshot and Recording View only) ..........................

Pings Per Second

(optional-purchase MMC/SD Card, Snapshot and Recording View only) ..........................

Playback Speed

(optional-purchase MMC/SD Card, Snapshot and Recording View only) ..........................

Stop Playback

(optional-purchase MMC/SD Card only) ........................................................

Sonar Menu Tab 85

Beam Select .......................................................................................................................... 86

Side View Frequency

(Side Views only)

Fish ID+™ .............................................................................................................................. 87

Fish ID Sensitivity .................................................................................................................. 88

Real Time Sonar (RTS®) Window.......................................................................................... 88

Bottom View .......................................................................................................................... 89

Zoom Width

(Sonar Zoom View only)

83 kHz Sensitivity .................................................................................................................. 89

................................................................................ 86

.................................................................................... 89

82

82

82

83

83

84

84

84

85

iv

Table of Contents

455 kHz Sensitivity

Depth Lines

Surface Clutter

Noise Filter

Max Depth

Water Type

(Advanced, with optional-purchase QuadraBeam PLUS™ transduceronly)

(Advanced)

(Advanced)

(Advanced)

(Advanced)

........................................................................................................ 90

(Advanced)

.................................................................................................... 91

.......................................................................................................... 91

.......................................................................................................... 92

.......................................................................................................... 92

...... 89

Transducer Select .................................................................................................................. 93

Color Bar ................................................................................................................................ 93

Temperature Graph

(Sonar View only, with Temperature input)

.......................................... 93

Navigation Menu Tab 94

Current Track.......................................................................................................................... 94

Saved Tracks .......................................................................................................................... 95

Waypoints .............................................................................................................................. 95

Routes .................................................................................................................................... 96

Chart Orientation .................................................................................................................. 96

North Reference .................................................................................................................... 97

Trolling Grid Rotation ............................................................................................................ 97

Trackpoint Interval ................................................................................................................ 97

Track Min Distance

(Advanced)

Track Color Range.................................................................................................................. 98

Map Datum

(Advanced)

Course Projection Line .......................................................................................................... 99

Export All Nav Data

Delete All Nav Data

(Advanced)

(Advanced)

Continuous Navigation Mode .............................................................................................. 99

............................................................................................ 98

........................................................................................................ 98

............................................................................................ 99

............................................................................................ 99

Chart Menu Tab 100

Chart Detail Level ................................................................................................................ 100

Map Borders ........................................................................................................................ 101

Lat/Lon Grid.......................................................................................................................... 101

Spot Soundings.................................................................................................................... 101

Navaids on Bird's Eye View..................................................................................................102

Shaded Depth...................................................................................................................... 102

Set Simulation Position

Set Map Offset

Clear Map Offset

(Advanced)

(Advanced)

(Advanced)

.................................................................................... 102

.................................................................................................. 103

.............................................................................................. 103

Alarms Menu Tab 104

Depth Alarm ........................................................................................................................ 104

Fish ID Alarm........................................................................................................................ 104

Low Battery Alarm .............................................................................................................. 105

Aux Temp Alarm

(with optional-purchase temp. probe or Temp/Speed only)

.................... 105

Temp Alarm .......................................................................................................................... 106

Off Course Alarm ................................................................................................................ 106

Arrival Alarm ........................................................................................................................ 107

Drift Alarm............................................................................................................................ 107

Alarm Tone .......................................................................................................................... 108

Setup Menu Tab 108

Units - Depth........................................................................................................................ 109

v

Units - Temp

(International only)

Units - Distance

(with Speed input only)

.......................................................................................... 109

............................................................................ 109

Table of Contents

Units - Speed

User Mode............................................................................................................................ 110

Language

Triplog Reset

Restore Defaults .................................................................................................................. 110

Select Readouts

Depth Offset

Aux. Temp. Offset

Temp Offset

Speed Calibration

Local Time Zone

Daylight Saving Time

Position Format

Time Format

Date Format

Digits Format

NMEA Output

Sonar .................................................................................................................................... 116

(with Speed input only)

(International only)

(with Speed input only)

(Advanced)

(Advanced)

(Advanced)

(Advanced, International only)

(Advanced, International only)

(Advanced)

...................................................................................................... 112

(Advanced)

...................................................................................................... 113

(Advanced, with Speed paddlewheel only)

(Advanced)

(Advanced)

(Advanced)

......................................................................................................115

(Advanced)

.................................................................................................. 115

................................................................................ 109

.............................................................................................. 110

.................................................................................. 110

................................................................................................ 111

.............................................................................................. 113

................................................................................................ 113

........................................................................................ 114

................................................................................................ 114

............................................ 113

........................................................................ 114

........................................................................ 114

Views Menu Tab 116

Accessories Menu Tab 118

Using Screen Snapshot ...................................................................................................... 118

Troubleshooting 120

900 Series™ Doesn’t Power Up.......................................................................................... 120

900 Series™ Defaults to Simulator with a Transducer Attached.................................... 120

Display Problems 121

Finding the Cause of Noise 122

1-Year Limited Warranty 123

Humminbird® Service Policy 123

900 Series™ Accessories 125

Specifications 127

Glossary 128

Appendix A - Transducer Mounting Template: XHS 9 HDSI 180 T 138

Contact Humminbird® 143

NOTE: Entries in this Table of Contents which list (International only) are only

available on products sold outside of the US and Canada by our authorized

International Distributors. It is important to note that products sold in the U.S. are

not intended for resale in the international market. To obtain a list of authorized

International Distributors, please visit our website at www.humminbird.com or

contact our Customer Resource Center at 1-800-633-1468 to locate the

distributor nearest you.

NOTE: Entries in this Table of Contents which list (with Speed Input) or (with

Temperature Input) may require the purchase of separate accessories. You can

visit our website at www.humminbird.com to order these accessories online or

contact our Customer Resource Center at 1-800-633-1468.

vi

900 Series™ Introduction

Your 900 Series™ Ultra Wide Screen Fishing System comes in the following

configuration:

• Humminbird® 997c Combo: Ultra Wide Screen Fishing System with

Chartplotter (Maps) and Side Imaging and Dual Frequency

Transducer, GPS Receiver included.

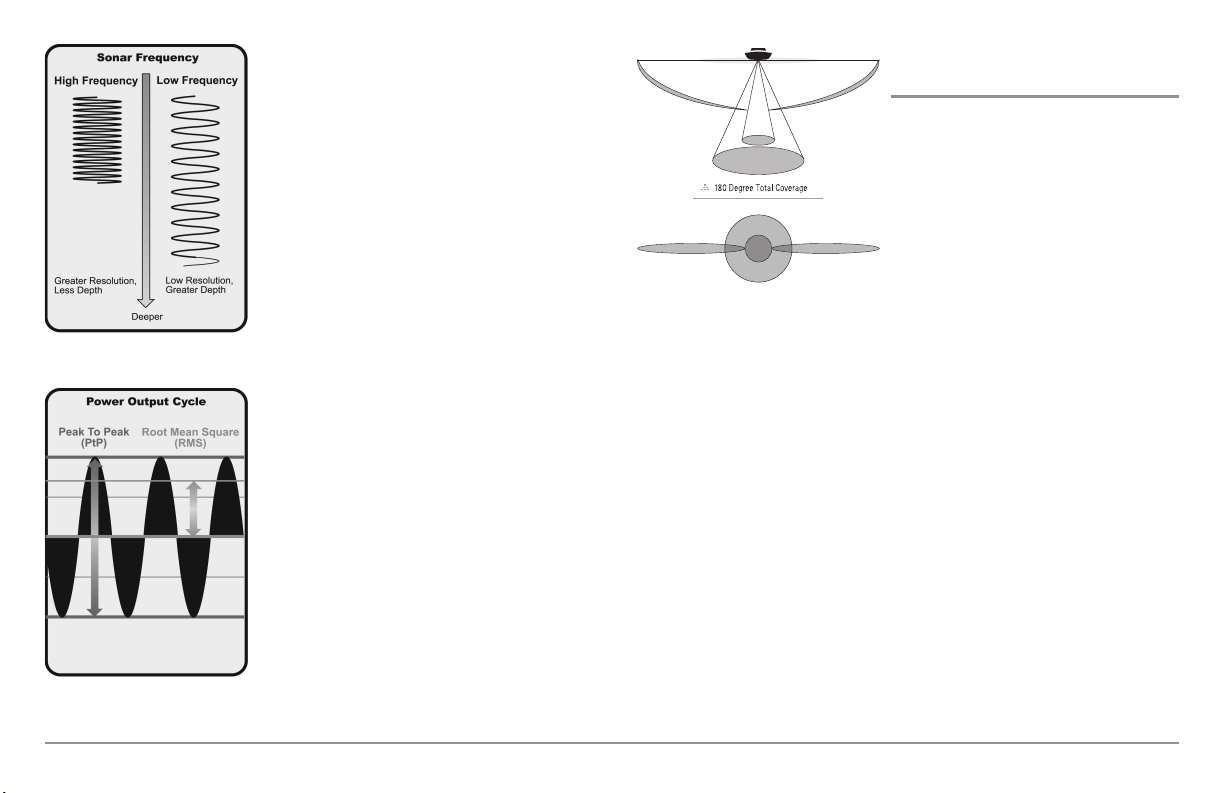

How Sonar Works

Sonar technology is based on sound waves. The 900 Series™ Fishing System

uses sonar to locate and define structure, bottom contour and composition,

as well as depth directly below the transducer.

Your 900 Series™ Fishing System sends a sound wave signal and determines

distance by measuring the time between the transmission of the sound

wave and when the sound wave is reflected off of an object; it then uses the

reflected signal to interpret location, size, and composition of an object.

Sonar is very fast. A sound wave can travel from the surface to a depth of

240 ft (70 m) and back again in less than 1/4 of a second. It is unlikely that

your boat can "outrun" this sonar signal.

SONAR is an acronym for SOund and

NAvigation Ranging. Sonar utilizes precision

sound pulses or "pings" which are emitted into

the water in a teardrop-shaped beam.

The sound pulses "echo" back from objects in

the water such as the bottom, fish and other

submerged objects. The returned echoes are

displayed on the LCD screen. Each time a new

echo is received, the old echoes are moved

across the LCD, creating a scrolling effect.

When all the echoes are viewed side by side,

an easy to interpret "graph" of the bottom, fish

and structure appears.

1

The sound pulses are transmitted at various

60°

8

3kHz

20°

200kHz

86°

4

55kHz

86°

4

55kHz

frequencies depending on the application.

Very high frequencies (455 kHz) are used for

greatest definition but the operating depth is

limited. High frequencies (200 kHz) are

commonly used on consumer sonar and

provide a good balance between depth

performance and resolution. Low frequencies

(83 kHz) are typically used to achieve greater

depth capability.

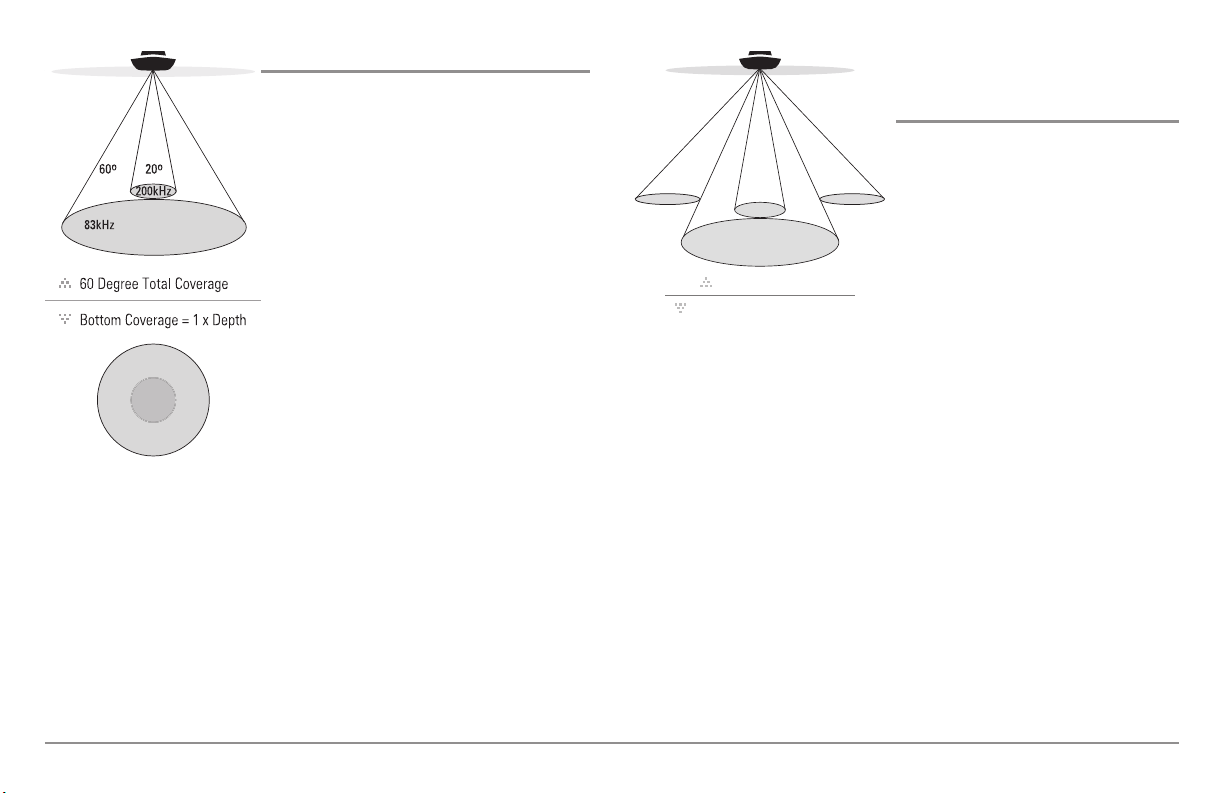

High Definition Side Imaging Sonar

Your 900 Series™ 997c SI Combo uses

Side Imaging sonar to provide a wide yet

precise survey of a large area of water,

including detailed bottom topography

and fish-attracting structure orientation.

The Side Imaging transducer returns are

processed into an image similar to an

aerial photograph. Typically, the Side

Imaging sonar can search an area that

is 720 feet wide (360 to each side), with

a typical depth performance of 150

The power output is the amount of energy

generated by the sonar transmitter. It is

commonly measured using two methods:

• Root Mean Square (RMS) measures power

output over the entire transmit cycle.

• Peak to Peak measures power output at the

highest points.

The benefits of increased power output are

the ability to detect smaller targets at greater

distances, ability to overcome noise, better

feet when the Side Imaging Sonar

frequency is set for 455kHz. The side

beams can be operated at one of two

frequencies: 455 kHz or 800 kHz.

Selecting 800 kHz produces the sharpest

image but the search area to each side

and the depth capability are limited as

compared to the 455 kHz frequency. See

What’s on the Side Imaging Display

and Understanding Side Imaging for

more information.

high speed performance and enhanced depth

capability.

2

DualBeam PLUS™ Sonar

90° Total Coverage

Bottom Coverage=2 x Depth

35° 60° 20° 35°

455 kHz 455 kHz

83 kHz

200 kHz

Your 900 Series™ Fishing System uses a

200/83 kHz DualBeam PLUS™ sonar system

with a wide (60°) area of coverage.

DualBeam PLUS™ sonar has a narrowly

focused 20° center beam, surrounded by a

second beam of 60°, expanding your

coverage to an area equal to your depth. In

20 feet of water, the wider beam covers an

area 20 feet wide. The 20° center beam is

focused on the bottom, to show you

structure, weeds and cover. The 60° wide

beam is hunting for fish in the wide

coverage area. DualBeam PLUS™ sonar

returns can be blended together, viewed

separately or compared side-by-side.

DualBeam PLUS™ is ideal for a wide range

of conditions - from shallow to very deep

water in both fresh and salt water. Depth

capability is affected by such factors as boat

speed, wave action, bottom hardness, water

conditions and transducer installation.

QuadraBeam PLUS™ Sonar

(optional-purchase QuadraBeam PLUS™

transducer only)

Your 900 Series™ 997c Combo supports

the optional-purchase QuadraBeam

PLUS™ transducer. QuadraBeam

PLUS™ sonar provides an extremely

wide (90°) area of coverage.

QuadraBeam PLUS™ starts with two

fan-shaped 35° 455 kHz Side Structure

locating sonar beams to spot fish, bait

and structure to the left and right of the

boat over an area of the bottom that’s

always equal to twice your depth.

For a detailed view below the boat, QuadraBeam PLUS™ uses DualBeam

PLUS™ technology, with precision 20° and wide 60° beams. QuadraBeam

PLUS™ finds more fish faster, and can even tell you where to put your bait

by showing if fish are to the left, right or directly beneath your boat.

3

Universal Sonar 2

Your 900 Series™ Fishing System supports Universal Sonar 2, a state-of-theart, integrated and protected transducer that is built into the lower unit of

Minnkota trolling motors. With Universal Sonar 2, all wiring is concealed

inside the indestructible composite shaft—out of sight and out of harm’s

way, with no clamps, ties, or exposed wires. Universal Sonar 2 features new

temperature sensing and the performance of DualBeam PLUS™ technology.

An expanded view and greater bottom detail gives you a totally new

perspective of the water below, along with optimal sonar performance to

help you find fish.

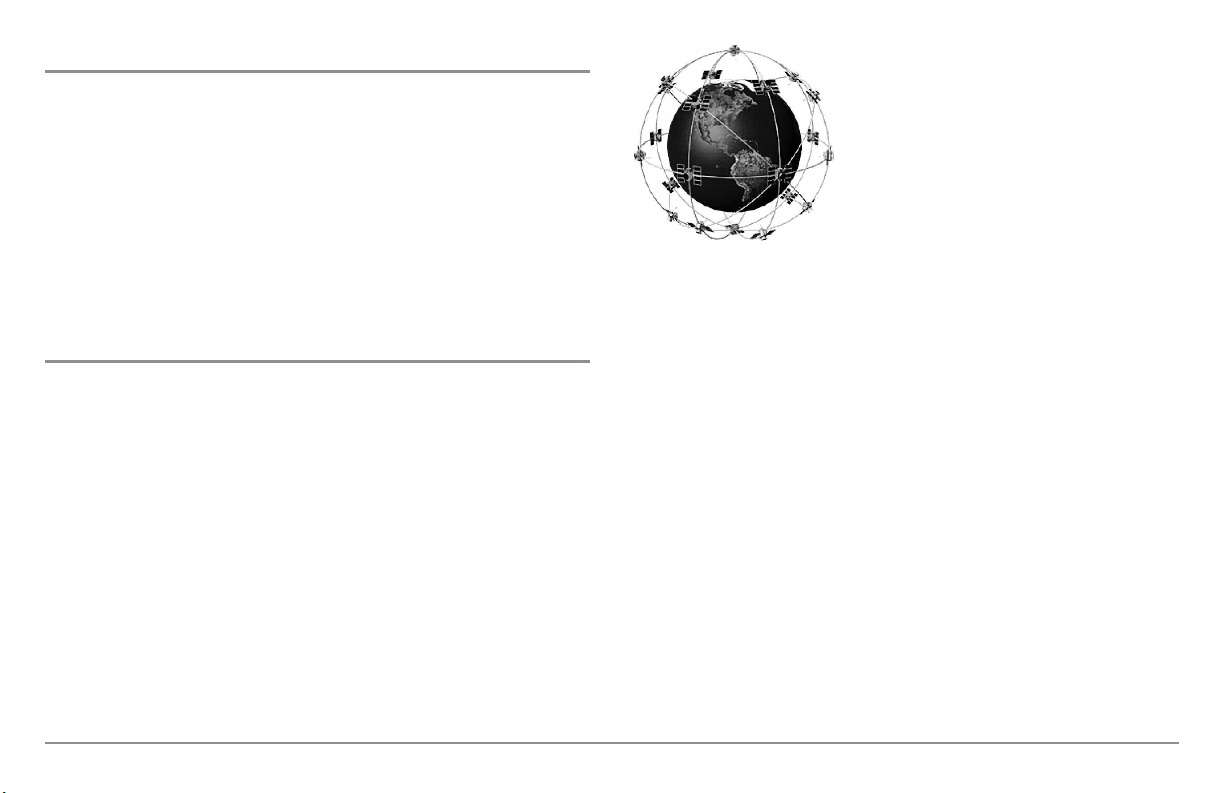

How GPS and Cartography Work

Your 900 Series™ Fishing System also supports GPS and chartplotting, and

uses GPS and sonar to determine your position, display it on a grid, and

provide detailed underwater information. The Global Positioning System

(GPS) is a satellite navigation system designed and maintained by the U.S.

Department of Defense. GPS was originally intended for military use;

however, civilians may also take advantage of its highly accurate position

capabilities, typically within +/- 4.5 meters, depending on conditions. This

means that 95% of the time, the GPS receiver will read a location within 4.5

meters of your actual position. Your GPS Receiver also uses information from

WAAS (the Wide Area Augmentation System), EGNOS (the European

Geostationary Navigation Overlay Service), and MSAS (the MTSAT Satellite

Augmentation System) satellites if they are available in your area.

GPS uses a constellation of over 24 satellites

that continually send radio signals to the earth.

Your present position is determined by

receiving signals from up to 16 satellites and

measuring the distance from the satellites.

All satellites broadcast a uniquely coded signal

once per second at exactly the same time. The

GPS receiver on your boat receives signals from

satellites that are visible to it. Based on time

differences between each received signal, the

GPS receiver determines its distance to each

satellite. With distances known, the GPS receiver

mathematically triangulates its own position.

With once per second updates, the GPS receiver

then calculates its velocity and bearing.

The GPS Receiver included with your 900 Series™ Fishing System allows you

to combine easy-to-use FishingGPS® chartplotter and navigation capabilities

with advanced fishfinding.

4

The following GPS functionality is currently supported by the 900 Series™

Fishing System when it is connected to the included GPS receiver:

Multi-Media Card

(MMC)/SD Slot

• View current position

• View current track (breadcrumb trail)

• View precision speed and heading from your GPS receiver

• Save tracks, waypoints and routes

• Travel a route and navigate from one waypoint to the next.

Your 900 Series™ supports Navionics® Gold, HotMaps™ and HotMaps™

Premium on MMC or SD card media.

NOTE: Your 900 Series™ does not support Navionics® Classic Charts, only

Navionics® Gold, HotMaps™, and HotMaps™ Premium.

Your unit also comes with a built-in UniMap™ with a more detailed map of

North America (Domestic models) or a more detailed map of Europe and

Southeast Asia, including Australia and New Zealand (International models).

Your 900 Series™ uses the GPS Receiver to determine the position of the

boat automatically, and uses the zoom level settings on a particular view to

select the best chart to display. See Viewing Cartography for more

information.

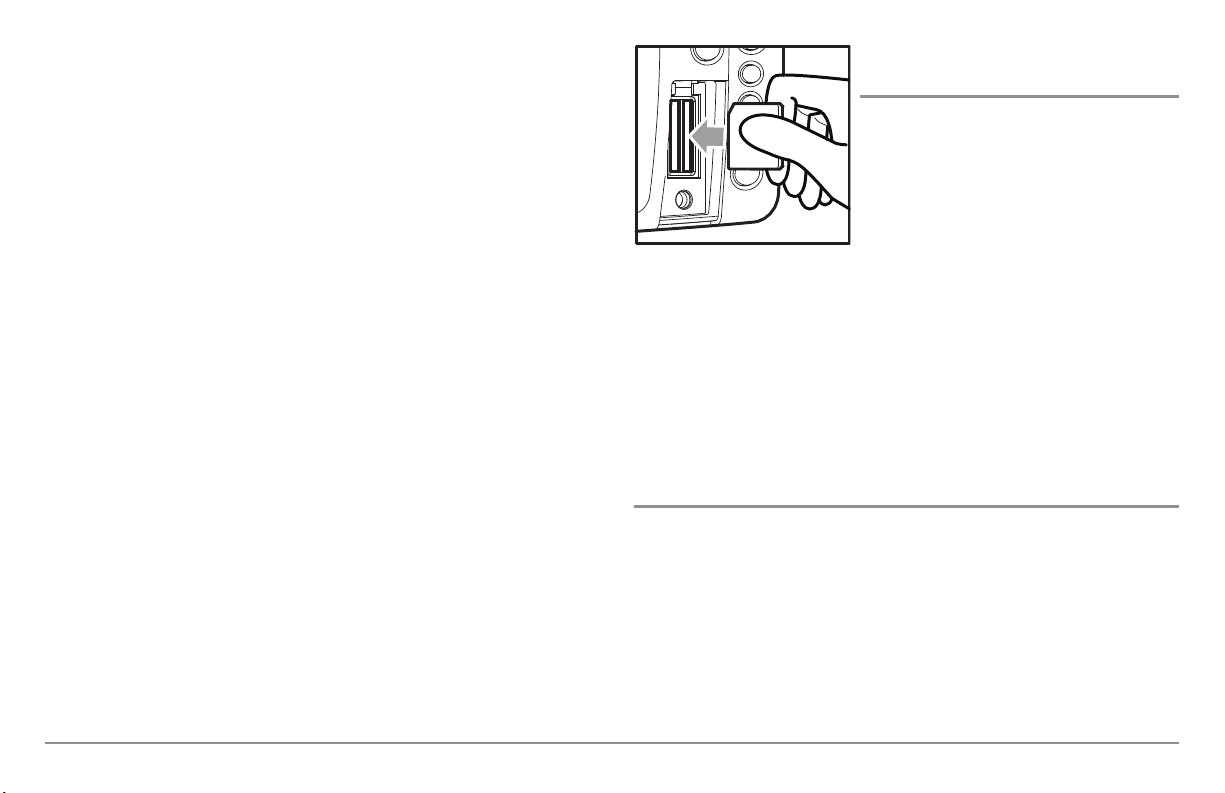

Your 900 Series™ Fishing System also has a

multi-media card (MMC)/SD slot that is used

to insert optional-purchase cards containing

additional detailed maps. If you insert an

MMC/SD that contains a more detailed

chart for a particular location, your 900

Inserting an MMC/SD

into the Card Slot

Series™ Fishing System will retrieve that

chart and display it automatically. Use the

illustration to locate the position of the MMC/SD slot cover, remove the

MMC/SD slot cover, then insert the MMC/SD into the slot. The label on the

MMC/SD should face toward the left side of the unit. Press down on the

card until it clicks into place and replace the slot cover. Then, replace and

tighten snugly - do NOT overtighten, as this will not improve water

resistance, and may damage the cover.

Software Updates

Use the MMC/SD slot to update the software version of your control head.

To update the software in your control head, plug in the appropriate

MMC/SD card that contains a software update file; the unit will recognize it,

will tell you what software version your control head is currently running,

and will ask you if you want to update the software in the unit to match that

on the MMC/SD card. You can obtain software updates from the

www.humminbird.com website.

5

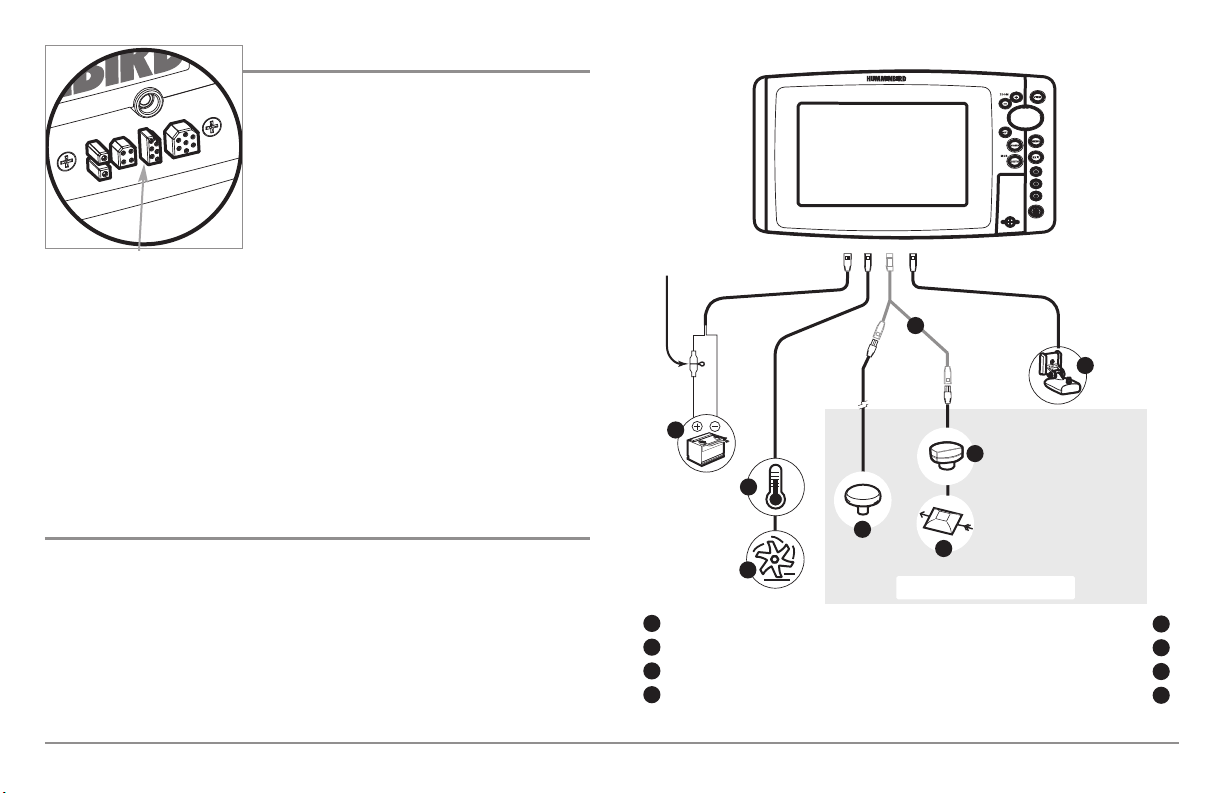

Accessory Bus

Accessory Bus

Use the Accessory Bus to expand the

functionality of your 900 Series™. Accessories

plug directly into the 900 Series™, enabling

Advanced features such as WeatherSense®

and the SmartCast® Wireless Sonar Link.

Additional tabs and menu choices will be

added to the menu system automatically when

an accessory is plugged into the unit. In

addition, multiple accessories can be attached

simultaneously. See Accessories Menu Tab

and 900 Series™ Accessories in this manual,

as well as your accessory Operations Manual

for additional details.

The 900 Series™ has a wide variety of configurations.

2

1

NOTE: Accessories to enable WeatherSense® and the SmartCast® Wireless Sonar Link

require separate purchases. You can visit our website at www.humminbird.com or

contact our Customer Resource Center at 1-800-633-1468 for additional details.

Installation Overview

Please read all instructions that are relevant for your configuration before

beginning the installation process.

NOTE: Installation procedures will depend on product configuration.

3

Sonar Transducer w/Temperature

1

Optional “Y” Cable

2

Power

3

Temperature/Speed

4

5

6

8

4

6

5

7

Accessory Bus

SmartCast® Wireless Sonar Link

Speed through water

GPS Receiver

WeatherSense®

5

6

7

8

Inside the boat there is often a channel or conduit used for other wiring, this

can be used to route cables. Be sure to route the cable as far as practical

from the antenna cable of VHF radios or tachometer cables to reduce the

possibility of interference. The transducer and GPS receiver cables should

not be cut, and care should be used not to damage the cable insulation.

Basic installation tasks that you must perform include:

• Installing the control head (choosing either gimbal or in-dash

mounting, where in-dash mounting requires a separate purchase)

• Installing the transducer (choosing either the transom mount,

inside the hull mount, or trolling motor mounting method)

• Installing the GPS Receiver (if included)

• Testing the complete installation and locking the transducer position.

NOTE: Accessories may require a separate purchase. You can visit our website at

www.humminbird.com to order these accessories online or contact our

Customer Resource Center at 1-800-633-1468.

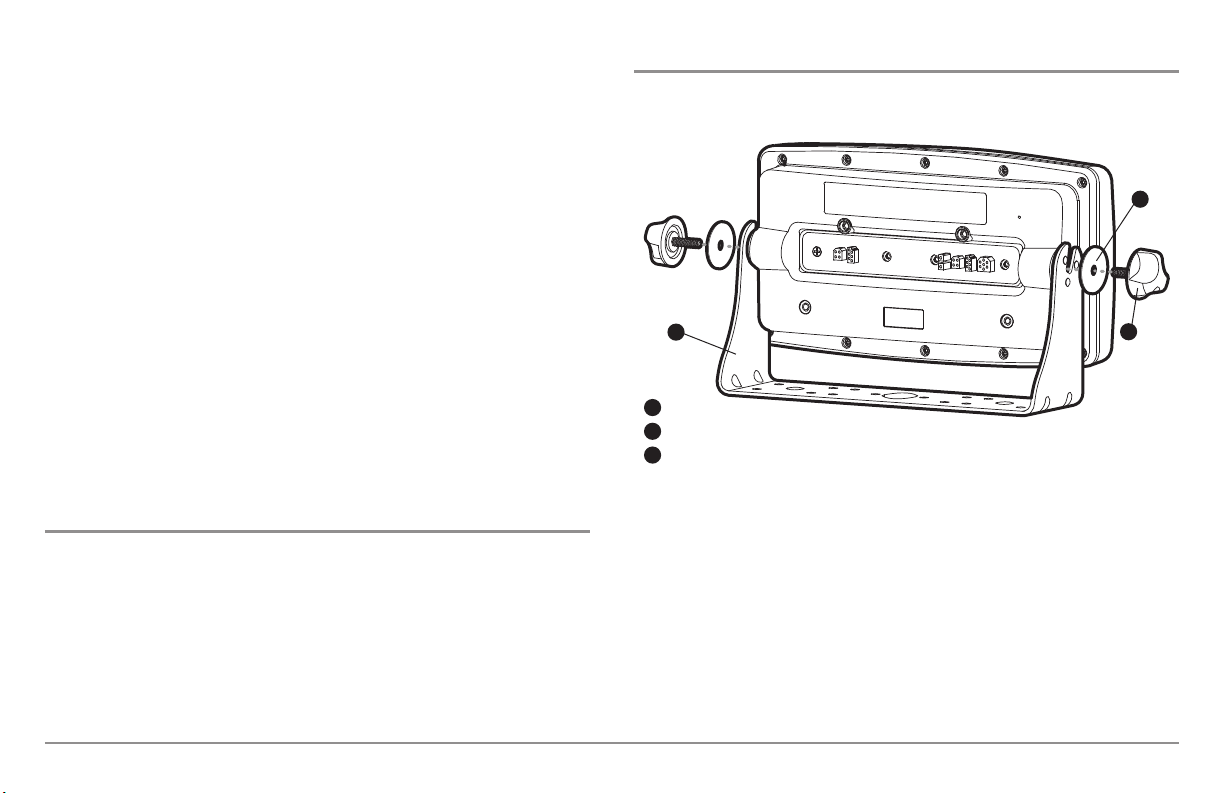

Control Head Installation

You have two choices for mounting your 900 Series™ control head, Gimbal

mounting, where you use a surface on the boat, such as the dash, to mount

the control head so that it can be tilted up or down, or In-dash mounting,

which requires a separate purchase.

Gimbal Mounting the Control Head

If you are gimbal mounting the Humminbird® 900 Series™, you can preassemble the unit in order to plan the best mounting location.

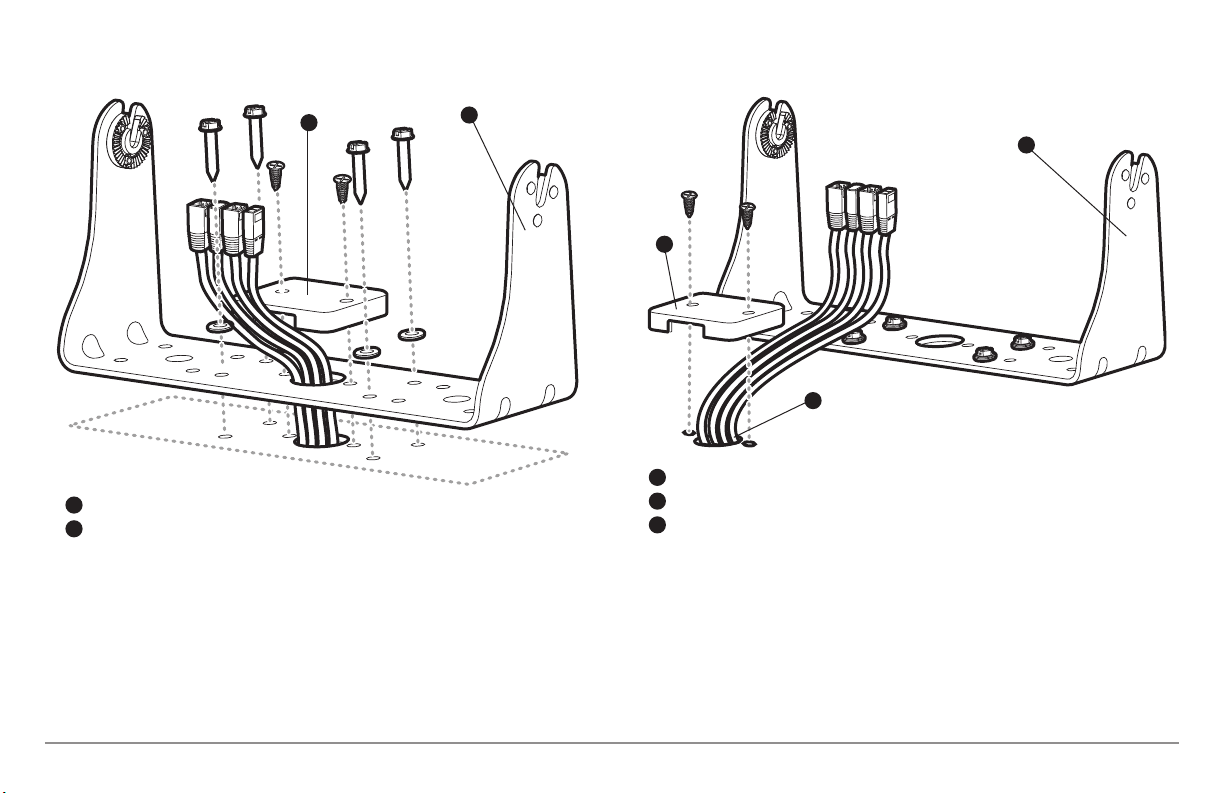

1

3

Washer

1

Gimbal Knob

2

Gimbal Bracket

3

In addition to the hardware supplied with your control head, you will need

a powered hand drill and various drill bits, various hand tools, including a

Phillips head screwdriver, a socket wrench and a flat head screwdriver, a

marker or pencil, safety glasses and dust mask, and marine-grade silicone

sealant.

2

7

1. Place the control head into the gimbal bracket. Make sure that the

straight side of the gimbal arm is against the back side of the control

head.

2. Place a 1" (25 mm) diameter black washer on the gimbal knob and

then thread the knob and washer into the housing. Tighten the

gimbal knob to secure the 900 Series™ control head to the mount.

Repeat step 2 for the other side.

You can now place the control head in various locations to decide which is

best for mounting. Rotating the mounting bracket to the top of the control

head will allow for overhead mounting. The chosen mounting area should

allow for sufficient room so the control head can pivot through the full tilt

range and allow for easy removal and installation.

NOTE: You can drill the cable pass hole underneath the gimbal bracket, allowing

you to thread the cables through the knock-out holes in the mount; however, if

you cannot drill the hole directly under the mounting bracket, then you will need

to drill the cable pass hole behind the bracket, and will need to mount the hole

cover there instead.

NOTE: When drilling holes in fiberglass hulls, it is best to start with a smaller bit

and use progressively larger drill bits to reduce the chance of chipping or flaking

the outer coating. Fill all holes with marine grade silicone sealant.

NOTE: You must have underside access to the mounting location to pass the

cables through to the surface. Also, make sure that the mounting surface is

adequately supported to protect the control head from excessive wave shock and

vibration and provide visibility while in operation.

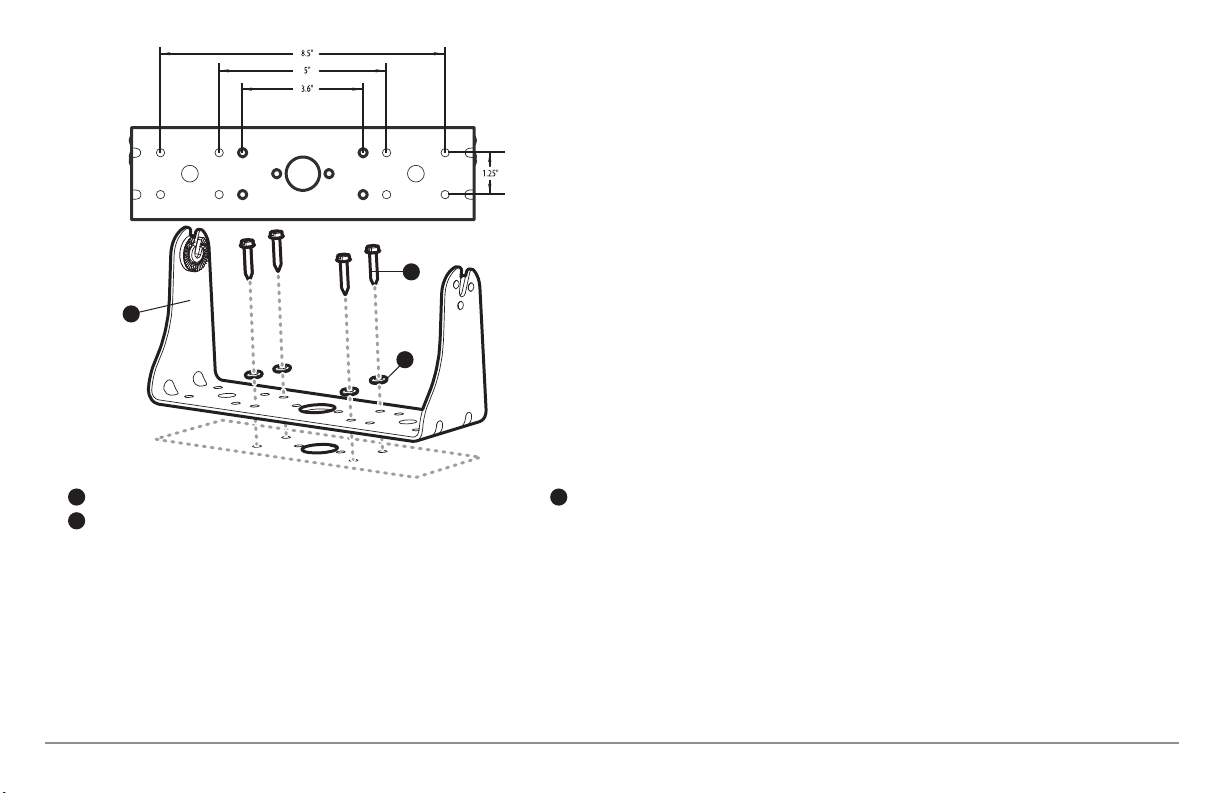

3. After the mounting location has been determined, loosen the gimbal

knobs and remove the control head from the gimbal bracket.

NOTE: Alternate hole patterns are available on the gimbal mounting bracket, and

may match existing holes on the boat. You may choose to use one of these

alternate hole patterns.

4. Place the gimbal bracket in the chosen position on the mounting

surface and mark the four mounting screw locations using a pencil

or center punch.

NOTE: Go to the installation instructions applicable to your transducer, GPS

Receiver and accessories. Make the required installations and then run the

cables to your control head mounting location. Do not cut any cabling (except the

power cable). If your cables are too short, extensions are available from your local

dealer or online from www.humminbird.com.

8

1

3

2

Mounting Screws

1

Washer

2

Gimbal Mounting Bracket

3

5. Set the gimbal bracket aside and drill the four mounting screw holes

using a 5/32" (4.0 mm) drill bit.

6a. If the cables must pass through a hole directly beneath the

mounting bracket, mark and drill an additional 1" (25 mm) hole

centered between the four mounting holes. Route the cables

through the 1" hole. Place the hole cover over the mounting surface

hole, then use it to mark the position of the two mounting screws.

Remove the hole cover, drill the two mounting holes using a 9/64"

bit. Do not install the hole cover at this time.

6b. If the cables cannot be routed directly beneath the mounting

bracket, mark and drill a 1" (25 mm) hole that will allow you to run

the cables close to the bracket. Pass the cables through the 1" (25

mm) hole, routing the cables through the grommet and pressing the

grommet into place. Place the hole cover over the mounting surface

hole, then use it to mark the position of the two mounting screws.

Remove the hole cover, drill the two mounting holes using a 9/64"

(3.5 mm) bit, fill them with marine-grade silicone, then replace the

hole cover and insert the #8 Phillips countersink wood screws.

Hand-tighten only.

7. Place the mounting bracket on the mounting surface aligned with

the drilled holes and fill the mounting holes with marine grade

silicone. Insert the four #10 Slotted-Hex wood screws into the

mounting holes. Hand-tighten only.

8. If the cable pass through hole is beneath the mounting bracket, you

will need to install the hole cover. Place the hole cover over the

mounting bracket cable pass thru hole and align with holes drilled

in step 6a. Insert the #8 Phillips countersink wood screws. Hand

tighten only.

NOTE: Be sure that the cables pass through the slots on the hole cover and that

there is enough cable slack to allow for the control head to pivot through its full tilt

range. Extra cable slack will also help when connecting/disconnecting the cables.

9

Cables Routed Directly Beneath Mounting Bracket

Cables Routed Behind Mounting Bracket

Gimbal Bracket

1

Hole Cover

2

2

1

1

3

2

Gimbal Bracket

1

Grommet

2

Hole Cover

3

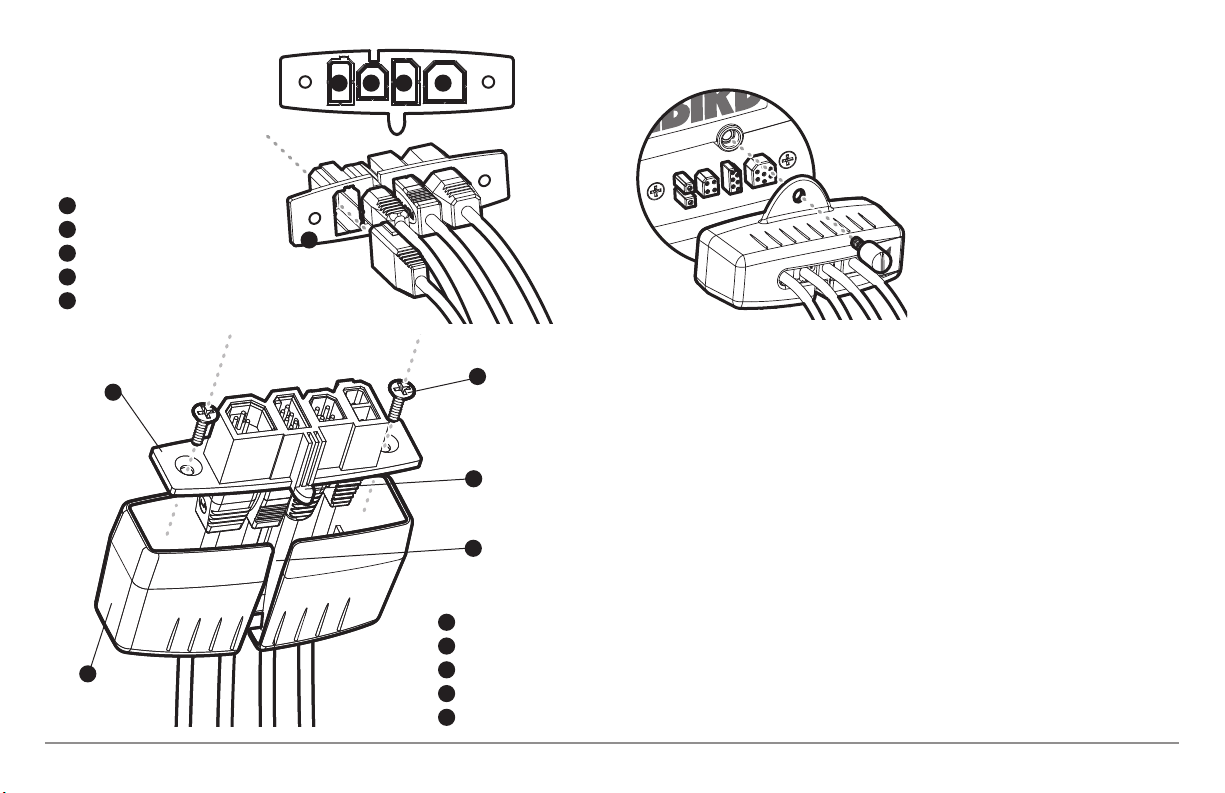

9. Insert cable connectors into the proper recesses on the cable

collector insert. The cable connectors are keyed to prevent reverse

installation, so be careful not to force the connectors into the wrong

slots. If you don’t have a cable for every hole in the insert, install the

blank plugs to protect the control head from the weather.

10

Power

1

Temp/Speed

2

Communications

3

Transducer

4

Cable Collector Insert

5

1

3

1 2

3 4

Plug Cable Connector Assembly to

Back of Control Head

10. While holding cables in place in

the cable collector insert, thread the

cables through the slot in the bottom

of the cable collector cover, line up

the cable collector insert and cover,

then slide the cover into place on the

insert.

5

NOTE: The tab on the Cable Collector

insert goes into the slot on the cover.

11. Attach the cable collector insert to the cable collector cover using

2

the 2 Phillips screws provided.

12. Place the control head back onto the mounting bracket. Plug in the

cable collector assembly to the back of the control head. Cable

connectors and cable sockets are keyed to prevent reverse

4

installation, so be careful not to force the connectors into the wrong

sockets. Once the cable collector and all cables are plugged into the

back of the control head, lock the assembly into place by threading

5

the knurled screw into the threaded insert on the back of the

housing. Adjust the control head to the desired viewing angle and

secure by tightening the gimbal knobs.

Cable Collector Insert

1

Screws

2

Cable Collector Cover

3

Tab on Insert

4

Slot on Cover

5

NOTE: You may wish to dress the cabling with nylon wire ties in order to hold the

cables together and create a cleaner assembly.

The Humminbird® 900 Series™ control head is now ready for operation.

11

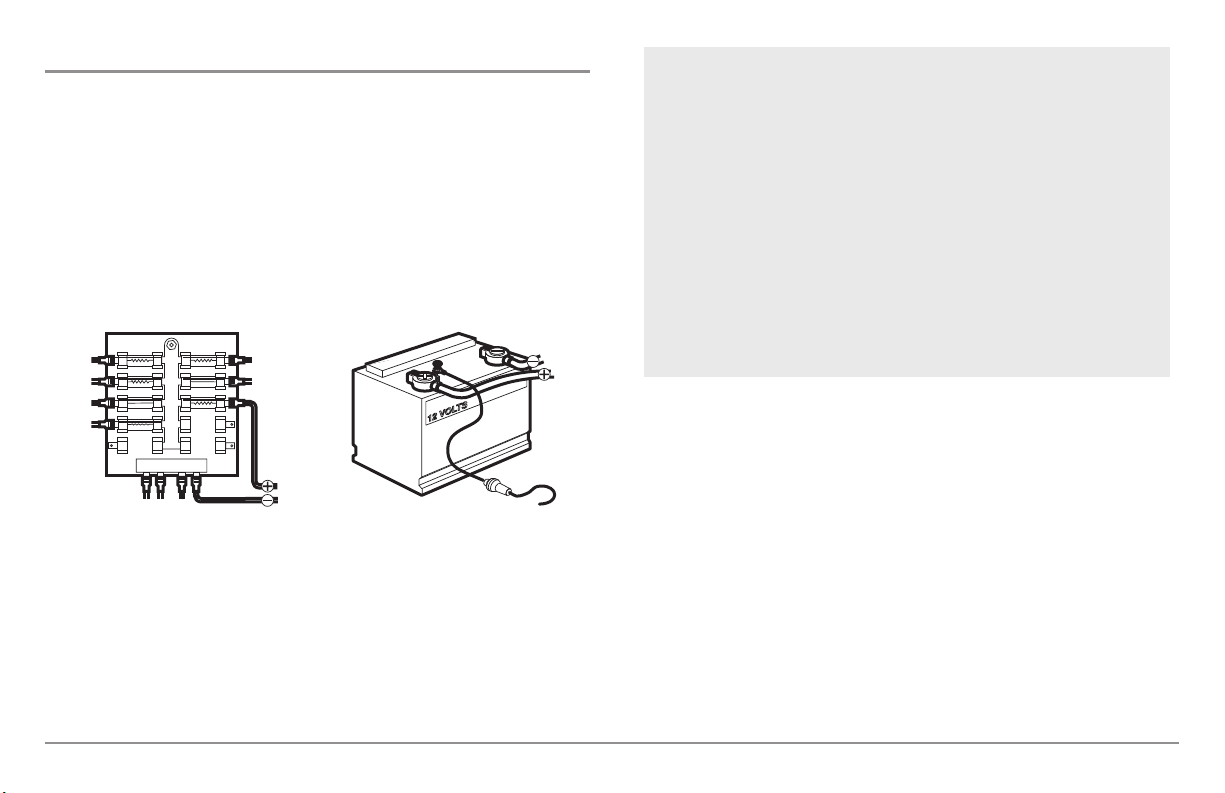

Connecting the Control Head Power Cable to the Boat

GROUNDGROUND

POSITIVEPOSITIVE

A 6' (2 m) long power cable is included to supply power to the control head.

You may shorten or lengthen the cable using 18 gauge multi-stranded

copper wire.

CAUTION: Some boats have 24 or 36 Volt electric systems, but the control head

MUST be connected to a 12 VDC power supply.

The control head power cable can be connected to the electrical system of

the boat at one of two places: a fuse panel usually located near the console,

or directly to the battery.

NOTE: Make sure that the power cable is disconnected from the control head at

the beginning of this procedure.

NOTE: Humminbird® is not responsible for over-voltage or over-current failures.

The control head must have adequate protection through the proper selection

and installation of a 3 amp fuse.

1a. If a fuse terminal is available, use crimp-on type electrical

connectors (not included) that match the terminal on the fuse

panel. Attach the black wire to ground (-), and the red wire to

positive (+) 12 VDC power. Install a 3 amp fuse (not included) for

protection of the unit. Humminbird® is not responsible for overvoltage of over-current failures.

or...

1b. If you need to wire the control head directly to a battery, obtain

and install an inline fuse holder and a 3 amp fuse (not included)

for the protection of the unit. Humminbird® is not responsible for

overvoltage or over-current failures.

NOTE: In order to minimize the potential for interference with other marine

electronics, a separate power source (such as a second battery) may be

necessary.

You are now ready to install the transducer. Find the section that refers to

your specific transducer installation method.

12

Transducer Installation

There are two different installation methods for your transducer:

• Transom Transducer

• Trolling Motor Transducer.

Find the section that describes the method of installation you will be using.

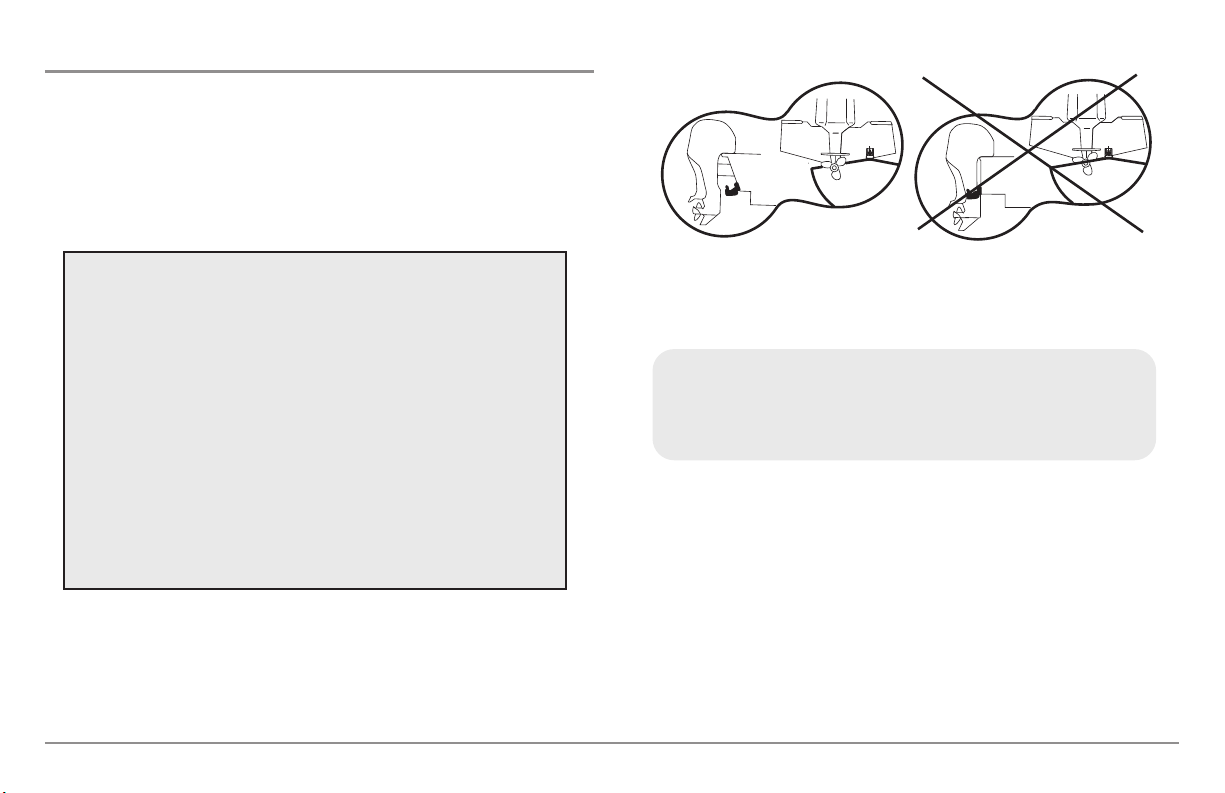

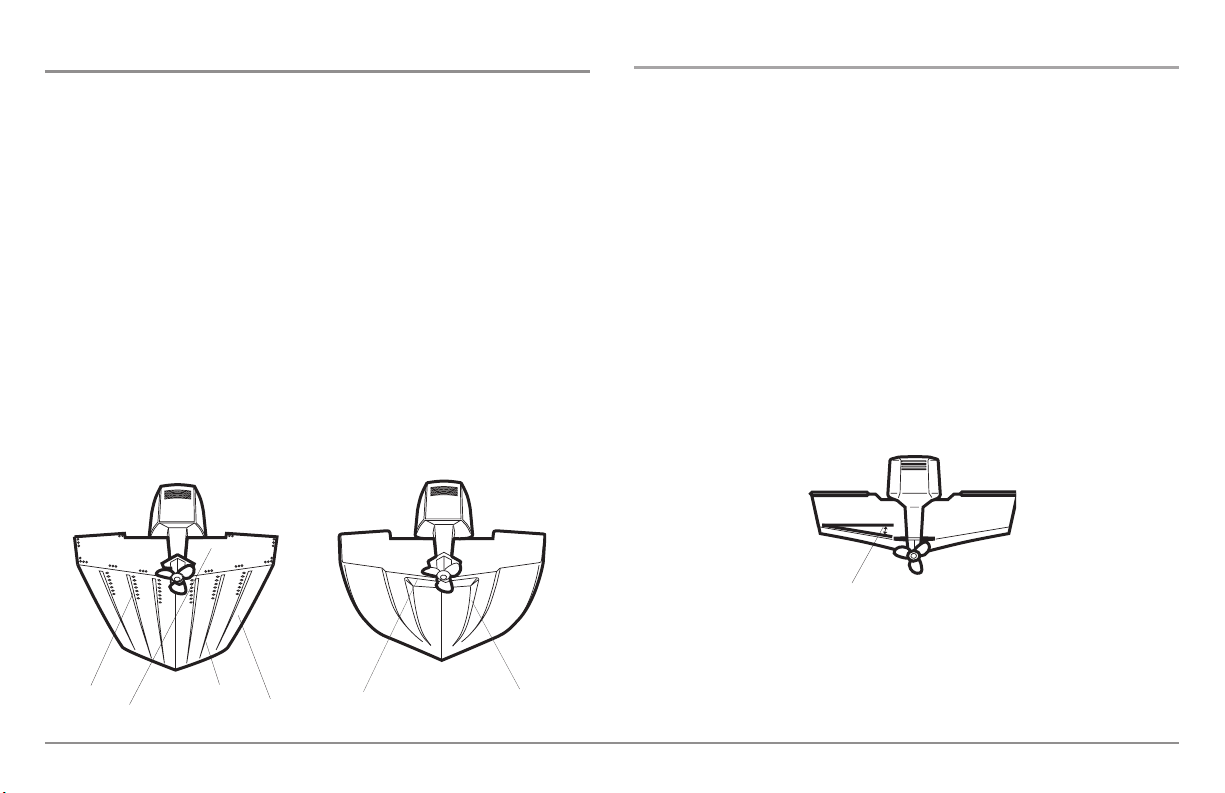

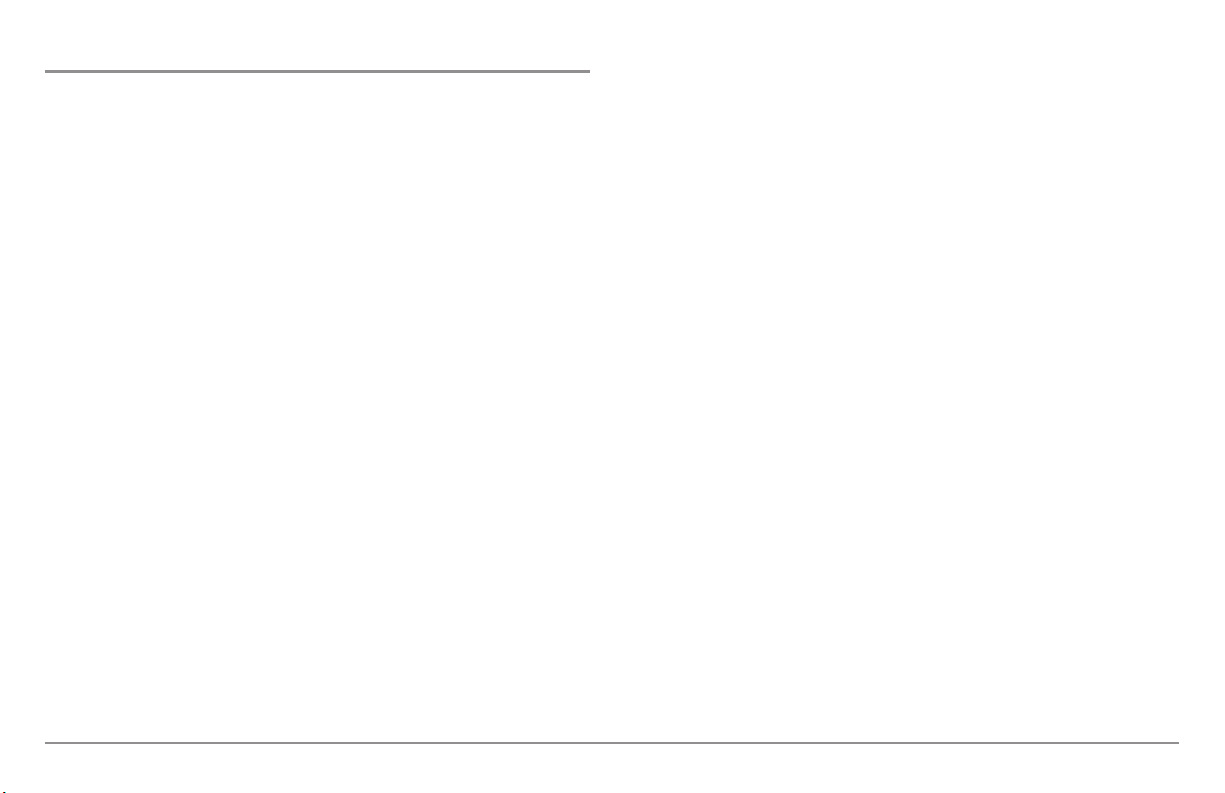

Transducer Mount Position

The Side Imaging transducer has some special requirements

because of its side viewing capabilities:

• The Side Imaging transducer must NOT have anything

obstructing the ‘view’ of the side looking beams, i.e.

nothing can be in the line of sight of these beams (not a

hull, motor, or other transducer, etc).

NOTE: You may need to tilt the motor up and out of the way when

using the side looking beams.

• In order for the side beams to be displayed accurately, the

transducer must be mounted so that it is looking straight

down in the water when the boat is in the water.

Unobstructed View: The jack plate gives

the transducer safe distance from the motor

and turbulence. The side imaging has a

clear view side-to-side.

NOTE: Due to the wide variety of hulls, only general instructions are presented in

this installation guide. Each boat hull represents a unique set of requirements that

should be evaluated prior to installation. It is important to read the instructions

completely and understand the mountingguidelines before beginning installation.

NOTE: If the included transducer will not work for your application, you may exchange it,

NEW and UNASSEMBLED, with mounting hardware included, for a transducer

appropriate for your application - often at very little or no charge depending on the

transducer. Call the Humminbird® Customer Resource Center at 1-800-633-1468 for

details and pricing, or visit www.humminbird.com.

NOTE: In additionto the hardware supplied with your transducer, you will need a powered

hand drill and various drill bits, various hand tools, including a ruler or straightedge, a

marker or pencil, safety glasses and dust mask, and marine-grade silicone sealant.

NOTE: When drilling holes in fiberglass hulls, it is best to start with a smaller bit and use

progressively larger drill bits to reduce the chance of chipping or flaking the outer coating.

13

Obstructed View: The transducer is too

close to motor turbulence, and the side

imaging view is blocked by the motor. The

view cannot extend from side-to-side.

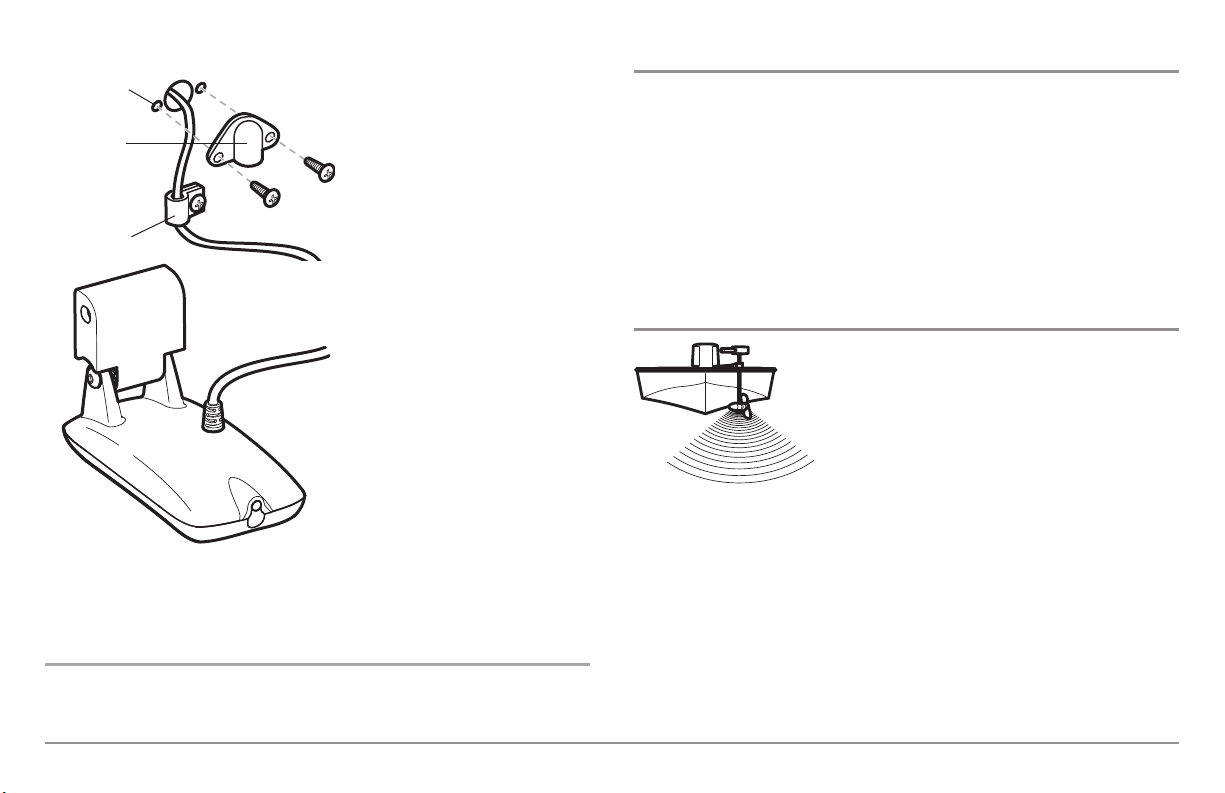

Transom Transducer Installation

If you will be installing a transom mounted transducer, use the procedures

in this section. There are two pieces to the transducer mount assembly: the

pivot, and the bracket. Your transducer comes with a two-piece metal and

plastic bracket assembly. There are several procedures you will have to

perform in order to install a transom-mounted transducer. They are:

To determine transducer mounting location:

NOTE: If transom mounting is not possible because of a stepped hull or

cavitation noise, trolling motor installation may be an option. See Trolling Motor

Transducer Installation for more information.

1. First, determine the best location on the transom to install the

transducer. Consider the following to find the best location:

• Determine transducer mounting location

• Mount the bracket to the boat

• Attach the pivot to the transducer

• Mount the transducer pivot assembly to the bracket

• Adjust the running position of the transducer

• Route the transducer cable

• Perform a final test of the transom transducer installation.

Areas of Possible Turbulence

Rivets Strakes

Transom Hull

Stepped Hull

Step Rib

• It is very important to locatethe transducer in an areawhich is relatively

free of turbulent water. As a boat moves through the water, turbulence

is generatedby the weight of the boat, and the thrust of the propeller(s)

- eitherclockwise or counter-clockwise. Thisturbulent water is normally

confined to areasimmediately aft of ribs,strakes or rowsof rivets on the

bottom of the boat, and in the immediate area of the propeller(s).

Clockwise propellers create more turbulence on the port side. On

outboard or inboard/outboard boats, it is best to locate the transducer

at least 15" (380 mm) to the side of the propeller(s).

Deadrise Angle

• The best way to locate turbulence-free water is to view the transom

while the boat is moving. This method is recommended if maximum

high-speed operation is a high priority. If this is not possible, select a

location on the transom where the hull forward of this location is

smooth, flat and free of protrusions or ribs.

14

• The hydrodynamic shape of your transducer allows it to point straight

down without deadrise adjustment.

• On boats with stepped hulls, it may be possible to mount the transducer on the step. Do not mount the transducer on the transom

behind a step to avoid popping the transducer out of the water at

higher speeds; the transducer must remain in the water for the

control head to maintain the sonar signal.

• If the transom is behind the propeller(s), it may be impossible to find

an area clear from turbulence, and a different mounting technique or

transducer type should be considered (see Trolling Motor

Transducer Installation).

• The Side Imaging transducer must NOT have anything obstructing

the ‘view’ of the side looking beams, i.e. nothing can be in the line

of sight of these beams (not a hull, motor, or other transducer, etc).

To mount the transducer bracket to the boat:

1. Remove the transducer mounting template from this manual. See

Appendix A for the Transducer Mounting Template.

15” (380 mm) from prop(s)

2. Hold the template on the transom of the boat in the location where

the transducer will be installed. Align the template vertically,

matching the lower edge of the transom with the bottom corner of

the template. If your propeller moves clockwise as the boat moves

forward, mount the transducer on the starboard side, and use the

bottom left corner of the template. If your propeller moves counterclockwise as the boat moves forward, mount the transducer on the

port side, and use the bottom right corner of the template.

3. Using a pencil or punch, mark the three mounting holes on the

transom. Do not mark or drill any other holes at this time.

4. Using a 5/32" (4.0 mm) bit, drill the three holes to a depth of

approximately 1" (25 mm). On fiberglass hulls, it is best to use

progressively larger drill bits to reduce the chance of chipping or

flaking the outer coating. Use a marine-grade silicone sealant to fill

the drilled holes.

15

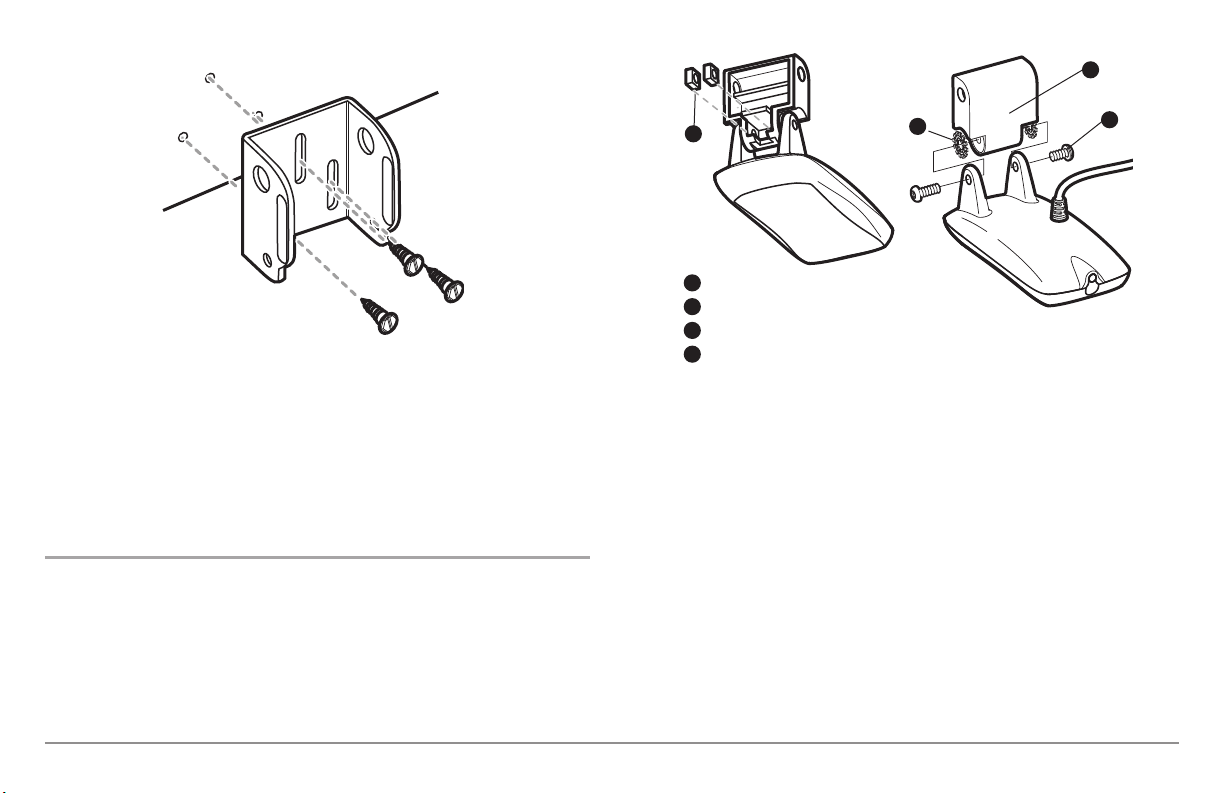

Attaching the Bracket

3

5. Align the metal mounting bracket with the mounting holes. The center

slot should be above the two outer slots. (This bracket and all other

hardware supplied is top quality stainless steel for maximum strength

and corrosionprotection.) Insert the three #10 - 1" long screwsinto the

drilled holes, but do not completely tighten.

To attach the pivot to the transducer:

1. Attach the pivot to the transducer body, using the two 1/4"-20 x 5/8"

(16 mm) machine screws, toothed washers, and square nuts. The

toothed washers must fit on the inside of the transducer ears,

between the pivot and the ears. The square nuts will be prevented

from rotating by the pocket in the back of the pivot. An Allen wrench

is provided which fits all the 1/4"-20 screws, but do not fully tighten

the screws at this time.

1

Insert the square nuts

1

Toothed Washer

2

Pivot

3

Machine Screw

4

2

Attach the Pivot

4

16

To mount the transducer pivot assembly to the bracket:

1. Slide the assembled transducer into the metal bracket from the

bottom, aligning the large hole at the top of the bracket with the

hole in the pivot.

2. Insert the headed pin through the pivot holes in the bracket and

pivot. The headed pin can be inserted from either side of the

bracket.

3. Place the nylon washer over the opposite end of the headed pin.

Place the stainless washer over the 1/4"-20 x 5/8" (16 mm) screw

threads, then insert into the opposite end of the headed pin and

finger tighten only. The screw has a thread locking compound on the

threads to prevent loosening, and should not be fully tightened until

all adjustments are made.

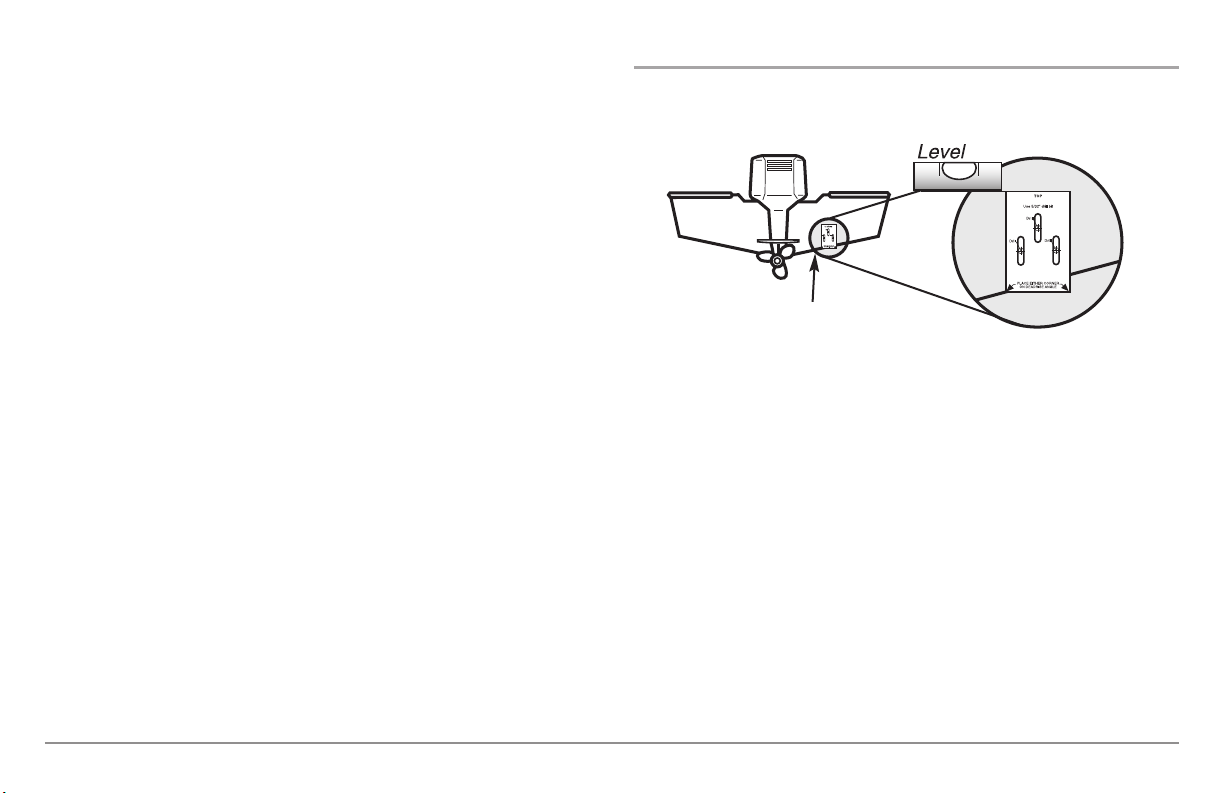

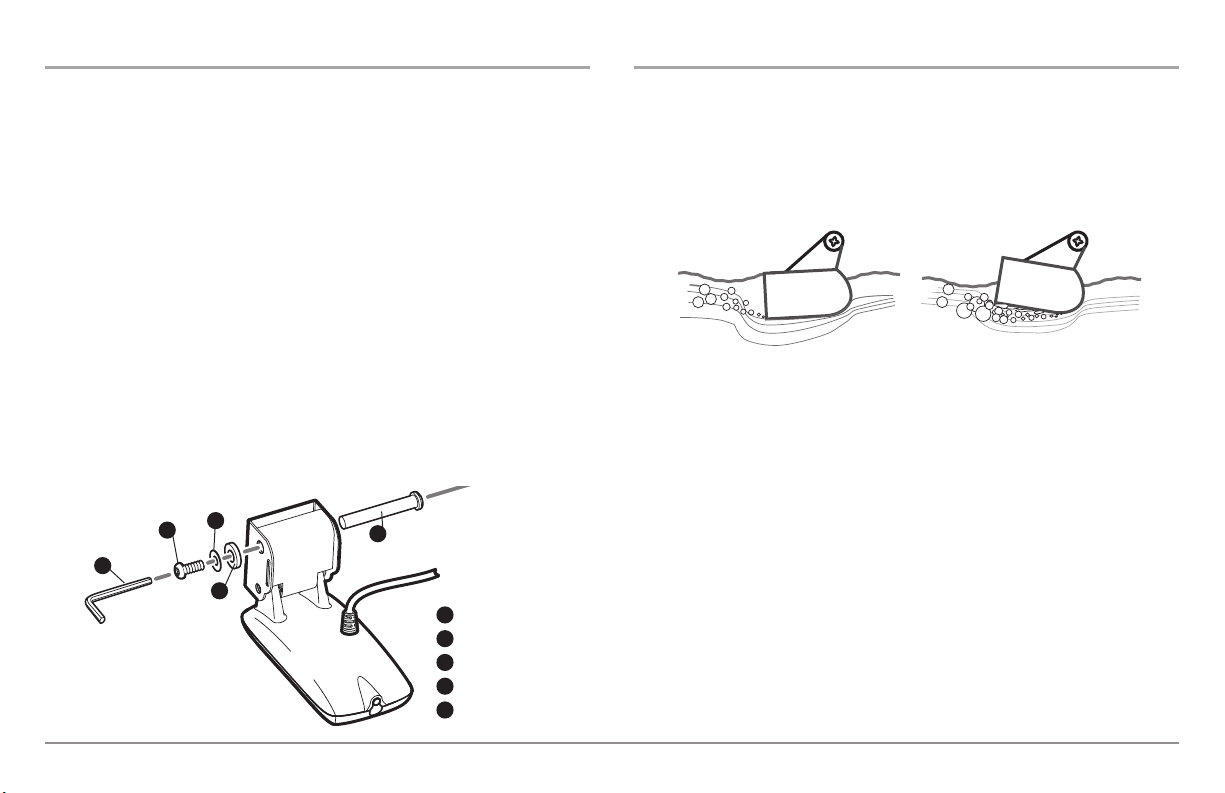

To adjust the running position of the transducer:

The transducer mounting bracket allows height and tilt adjustment, while

the pivot bolt allows angular adjustment. These adjustments will help

reduce cavitation. Initially, adjust the transducer as described in the

following paragraphs. Further adjustment may be necessary to refine the

installation after high-speed testing.

Normal Cavitation Cavitation that will cause

erratic sonar readings

NOTE: The running position of the transducer is now completely adjustable.

Subsequent adjustment may be necessary to tweak the installation after high

speed testing.

5

1

3

4

2

Screw

1

Headed Pin

2

Allen Wrench

3

Nylon Washer

4

Stainless Washer

5

1. First, adjust the pivot angle of the transducer body, so it is parallel

with the length of the hull of the boat.

2. Fully tighten the two pivot screws, using the supplied Allen wrench.

Access to the pivot screws is provided by the lower holes in the side

of the mounting bracket. It may be necessary to re-tighten the pivot

bolt after initial use as the plastic may still be conforming to the

pressure from the lock washers.

17

3. Adjust the height of the assembly so the face of

the transducer is 1/8" (3 mm) to 1/4" (6 mm)

beneath the bottom of the transom, and fully

tighten the three mounting screws.

4. In order to gain access to the mounting screws,

the transducer assembly must be pivoted up in the

Tighten the Mounting

Screws

bracket as shown. Be careful not to alter the

running angle as some force is necessary to pivot

the assembly.

5. If access to the top mounting hole is not possible due to the selected

height of the transducer, fully tighten the two lower screws, then

simply remove the headed pivot pin and the transducer assembly,

and tighten the top screw, then reassemble.

6. Confirm that the pivot angle has not changed and that all mounting

screws are fully tightened.

To route the transom transducer cable:

The transducer cable has a low profile connector that must be routed to the

point where the control head is mounted. There are several ways to route the

transducer cable to the area where the control head will be installed. The

most common procedure routes the cable through the transom into the boat.

1. Unplug the other end of the transducer cable from the control head.

Make sure that the cable is long enough to accommodate the

planned route by running the cable over the transom.

CAUTION! Do not cut or shorten the transducer cable, and try not to damage the

cable insulation. Route the cable as far as possible from any VHF radio antenna

cables or tachometer cables to reduce the possibility of interference. If the cable

is too short, extension cables are available to extend the transducer cable up to

a total of 50' (15 m). For assistance, contact the Customer Resource Center at

www.humminbird.com or call 1-800-633-1468 for more information.

NOTE: Since the transducer may need to pivot up to 90° in the bracket if it strikes

an object, make sure there is sufficient cable slack to accommodate this motion.

It is best to route the cable to the side of the transducer so the cable will not be

damaged by the rotation of the transducer.

2. If you will be routing the cable through a hole in the transom, drill a

5/8" diameter (16 mm) hole above the waterline. Route the cable

through this hole, then fill the hole with marine-grade silicone

sealant and proceed to the next step immediately.

NOTE: Your boat may have a pre-existing wiring channel or conduit that you can

use for the transducer cable.

18

5/8” Hole

Escutcheon

Plate

Cable Clamp

Routing the Cable

3. Place the escutcheon plate over

the cable hole and use it as a guide

to mark the two escutcheon plate

mounting holes. Remove the plate,

drill two 9/64" (3.5 mm) holes, then

fill both holes with marine-grade

silicone sealant. Place the

escutcheon plate over the cable

hole and attach with two #8 x 5/8"

(16 mm) wood screws.

Trolling Motor Transducer Installation

If you want to install the transducer on a trolling motor, use this procedure.

Several styles of the transducer are compatible with trolling motor mounting.

If you have a trolling motor bracket, refer to the separate installation

instructions that are included with the bracket.

NOTE: After trolling motor transducer installation, please perform the final

testing and then finalize the installation (see Test and Finish the Transducer

Installation).

4. Route and secure the cable by

attaching the cable clamp to the

transom; drill one 9/64" dia. (3.5

mm) x 5/8" deep (16 mm) hole,

then fill hole with marine-grade

silicone sealant, then attach the

cable clamp using a #8 x 5/8" (16

mm) screw.

5. Plug the other end of the

transducer cable back into the

control head connection holder.

To perform a final test of the

transom transducer installation:

After transom transducer installation, please perform the final testing and then

finalize the installation (see Test and Finish the Transducer Installation).

Trolling Motor Transducer Options

If you don’t have a trolling motor transducer,

there are several options:

• You may purchase a Trolling Motor Adapter kit

that will allow you to mount the transducer on the

trolling motor.

• You may also exchange your NEW and UNASSEMBLED transducer

(with mounting hardware included) for a trolling motor transducer.

There are also several transducer switches available that support the

following configurations:

• Two control heads with one transducer

• Two transducers with one control head.

NOTE: Call the Humminbird® Customer Resource Center (1-800-633-1468) for

details and pricing, or visit www.humminbird.com for more information.

19

Test and Finish the Transducer Installation

When you have installed both the control head, the transducer, and

accessories and have routed all the cables, you must perform a final test

before locking the transducer in place. Testing should be performed with the

boat in the water, although you can initially confirm basic operation with the

boat out of the water.

1. Press the POWER/LIGHT key once to turn the control head on. There

will be an audible chirp when the key is pressed correctly. If the unit

does not power-up, make sure that the connector holder is fully

seated and that power is available.

2. If all connections are correct and power is available, the control

head will enter Normal operation. If no transducer is detected (or

one is not connected), the unit will go into Simulator mode and will

indicate this by displaying the word Simulator on the control head

display.

NOTE: The transducer must be submerged in water for reliable transducer

detection.

3. If the bottom is visible on-screen with a digital depth readout, the

unit is working properly. Make sure that the boat is in water greater

than 2 ft (.6 m) but less than the depth capability of the unit, and

that the transducer is fully submerged, since the sonar signal

cannot pass through air.

4. If the unit is working properly, gradually increase the boat speed to

test high-speed performance. If the unit functions well at low

speeds but begins to skip or miss the bottom at higher speeds, the

transducer requires adjustment. Angling the rear of the transducer

downward and/or lowering the transducer farther into the water

will help achieve depth readings at high speeds. If the left side of

the fish arch is longer than the right side, then the back of the

transducer is angled too far downward. If the right side of the fish

arch is longer than the left side, then the back of the transducer is

angled too far upwards.

NOTE: It may not always be possible to get symmetrical fish arches and high

speed depth readings at the same time. Due to the wide variety of boat hulls,

however, it is not always possible to obtain high speed depth readings.

NOTE: It is often necessary to make several incremental transducer adjustments

before optimum high speed performance is achieved.

Once you have reached a consistently good sonar signal at the desired

speeds, you are ready to lock down the transducer settings.

5. Mark the transducer bracket location on the transom with a pencil,

then pop up the bracket to reveal the mounting screws. Tighten the

stainless steel mounting bracket screws to secure in place.

Hand-tighten only!

20

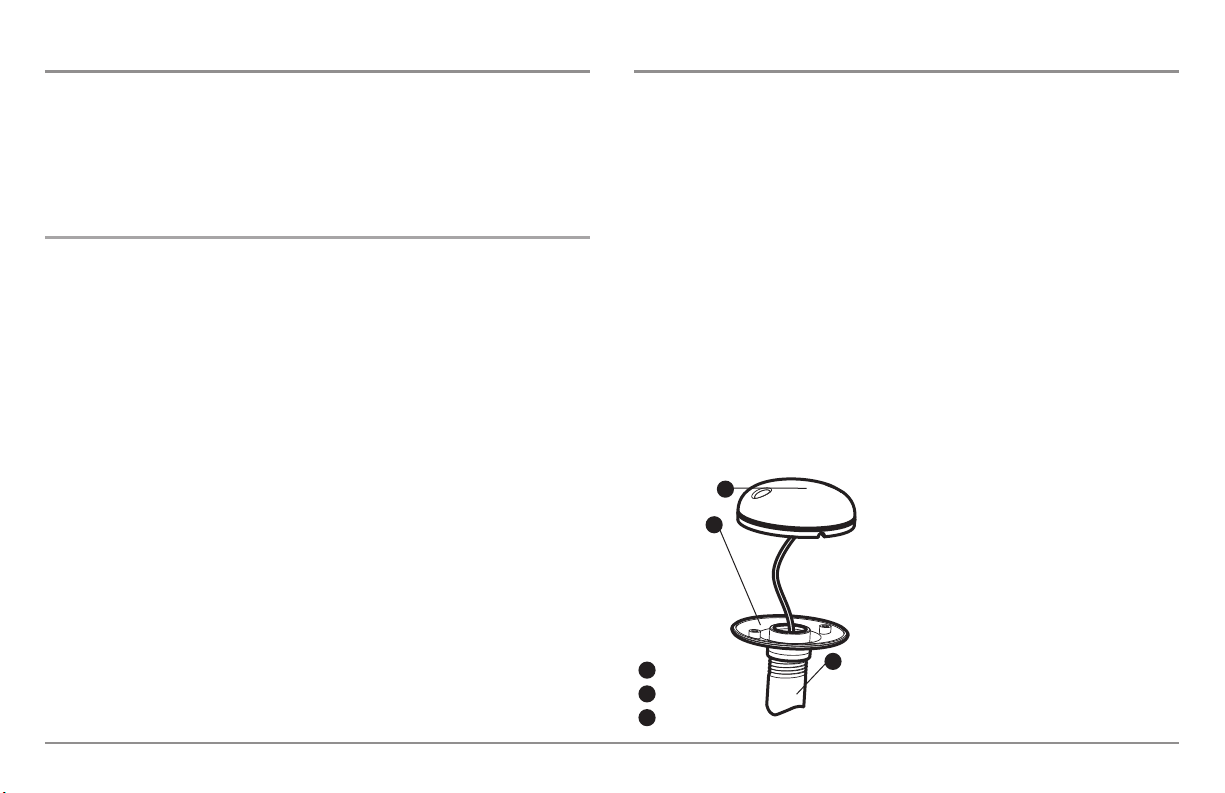

GPS Receiver Installation

Stem Mounting with an Existing 1" - 14 Thread Stem

To optimize performance of the GPS receiver, mount it in an area that has full

exposure to the sky. The effective area of reception is 10° above the horizon.

Different circumstances determine the mounting method appropriate for

your GPS receiver.

If you have… Then use:

An existing antenna stem with

standard 1" – 14 thread stem

Access for cable routing under

the mounting location

No access under the mounting

location

The pinouts of the pigtail cable are as follows:

• Red Wire, +12V (output voltage only)

• Black Wire, Ground

• White Wire, NMEA Out.

CAUTION! Please use caution before connecting the red +12V wire to any other

NMEA device. This is an output voltage provided by the Fishfinder unit and

GPS receiver and should only be connected to those NMEA devices that need a

12 volt input.

Stem Mount with Existing 1” 14 Thread Stem

Access Under Mounting

Location

No Access Under Mounting

Location

Follow these steps to stem mount the GPS receiver:

NOTE: If you have an existing stem for mounting the GPS receiver, proceed

directly to step 2 of the following procedure.

1. Determine the best location to mount your GPS receiver. Preplan

and test the cable routing to your control head before any drilling or

cutting of your boat surfaces. If you have purchased hardware to

stem mount your GPS receiver, follow the instructions included with

that hardware to mount the stem (antenna pole).

NOTE: AS-EC10 10' extension cables are available from Humminbird® if your

planned routing exceeds 20', (6 m). Maximum cable length, including extensions,

should not exceed 50' (16 m).

NOTE: Remember to caulk or seal screw holes and drilled holes as needed to

protect your boat from water damage.

1

2. Screw on the receiver base to the stem

first, making sure that the stem pipe does

2

not protrude from the receiver base. This

adds protection to the cable when pulling it

through the pipe stem. In addition to this,

de-burr the pipe edges to reduce cable

abrasion.

Receiver

1

Receiver Base

2

Stem Pipe

3

3

21

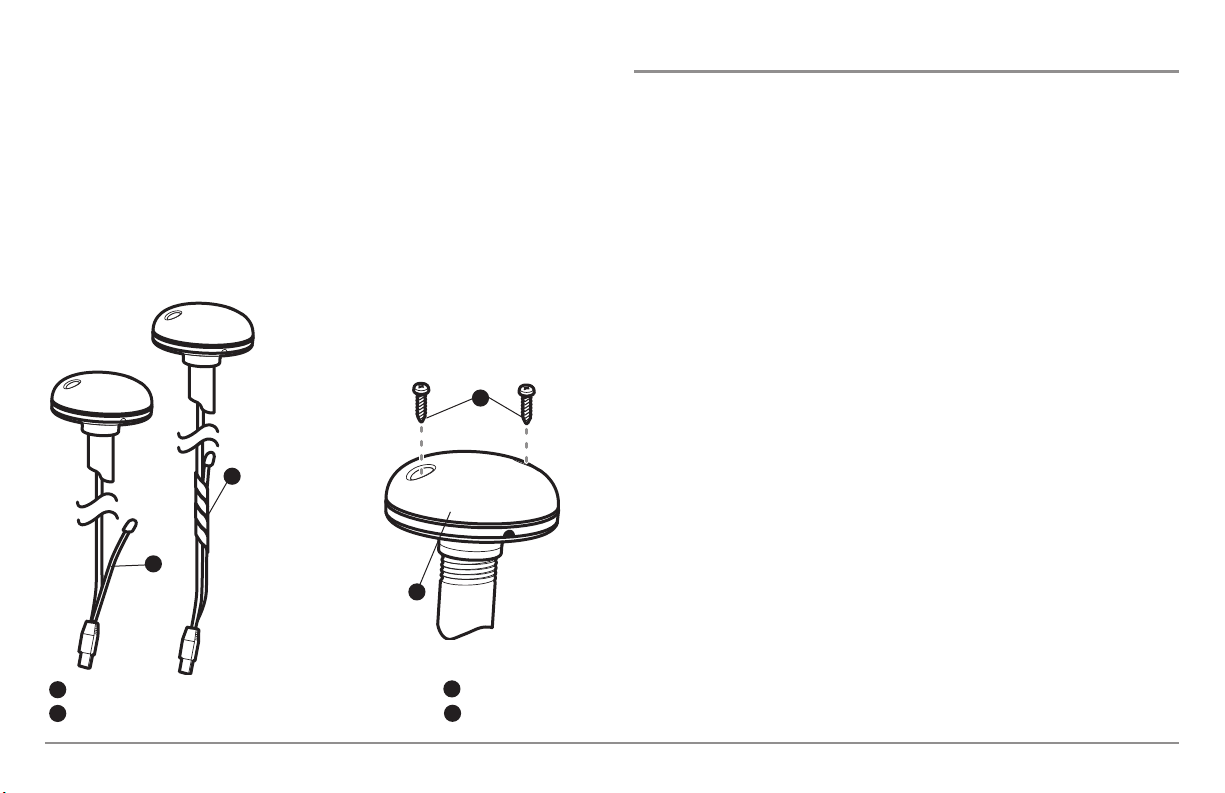

3. Use electrical tape to secure the NMEA pigtail to the cable as

shown.

NOTE: Leave the NMEA pigtail secured to the cable unless needed. This will

make removing the receiver easier.

4. Route the GPS receiver cable through the stem and continue with

the planned route you chose in step 1.

5. Attach the GPS receiver to its base using the included #6 - 7/8"

screws.

3

1

Access Under Mounting Location

Follow these steps to deck mount the GPS receiver when routing the cable

down through the mounting location:

1. Determine the best location, then test route the 20' (6 m) cable from

the mounting location to the control head.

NOTE: Installation details may vary with unit configuration.

2. Mark the mounting location and drill a 3/4" (19 mm) hole for the

cable and cable plug. Route the cable.

3. Cover the cable hole with the receiver. Make sure the receiver is

flush on the surface and mark the two mounting holes with a pencil

or punch.

4. Move the receiver to the side and drill two pilot holes using a 9/64"

(3.5 mm) bit.

NOTE: Remember to caulk or seal screw holes and drilled holes as needed to

protect your boat from water damage.

NMEA Pigtail Taped

1

NMEA Pigtail Cable Out

2

2

4

Mounting Screws

3

Cable Route

4

5. Align the GPS receiver screw holes over the pilot screw holes and

attach with the #8 - 1 1/4" Phillips head screws. Hand tighten only!

NOTE: If the mounting surface is thin and made of a lighter material, a backing

material may be needed below the mounting surface.

22

Loading...

Loading...