Page 1

iSite BTS3006C

V300R005

Maintenance Manual

Issue

Date

Part Number

01

2007-01-24

31034731

Huawei Technologies Proprietary

Page 2

Huawei Technologies Co., Ltd. provides customers with comprehensive technical support and service. For

any assistance, please contact our local office or company headquarters.

Huawei Technologies Co., Ltd.

Address: Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website: http://www.huawei.com

Email: support@huawei.com

Copyright © Huawei Technologies Co., Ltd. 2007. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior

written consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective

holders.

Notice

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute the warranty of any kind, express or implied.

Huawei Technologies Proprietary

Page 3

iSite BTS3006C

Maintenance Manual Contents

Contents

Safety Precautions.......................................................................................................................1

1 Overview......................................................................................................................................................1

1.1 Guide...................................................................................................................................................1

1.2 Symbols...............................................................................................................................................1

2 Toxic Articles................................................................................................................................................2

2.1 Beryllium Oxide...................................................................................................................................2

2.2 Hydrochloride......................................................................................................................................2

2.3 Hydrofluoride.......................................................................................................................................3

3 Electrical Safety............................................................................................................................................3

3.1 High Voltage........................................................................................................................................3

3.2 Power Cable.........................................................................................................................................4

3.3 Fuse.....................................................................................................................................................4

3.4 Tools....................................................................................................................................................4

3.5 Drilling Holes.......................................................................................................................................4

3.6 Thunderstorm.......................................................................................................................................5

3.7 Static Electricity...................................................................................................................................5

3.8 Labels on Power Supply Cables............................................................................................................6

3.9 Leakage of Current...............................................................................................................................6

3.10 Flammable Air....................................................................................................................................7

4 Microwave and Magnetic Field......................................................................................................................7

4.1 Introduction..........................................................................................................................................7

4.2 Definitions of Environment..................................................................................................................7

4.3 Minimal Distance Formula...................................................................................................................7

4.4 Operation Codes...................................................................................................................................8

5 Laser.............................................................................................................................................................8

6 High Temperature..........................................................................................................................................9

7 Working High above the Ground...................................................................................................................9

7.1 General Operation................................................................................................................................9

7.2 Safety Codes on Ladder Use...............................................................................................................10

8 Other Items.................................................................................................................................................11

8.1 Weight Hoisting..................................................................................................................................11

8.2 Heavy Object Portage.........................................................................................................................12

Issue 01 (2007-01-24) Huawei Technologies Proprietary i

Page 4

Contents

iSite BTS3006C

Maintenance Manual

8.3 Sharp Edge of Objects........................................................................................................................13

8.4 Binding of Signal Wires......................................................................................................................13

8.5 Having Companions in Maintenance and Commissioning...................................................................13

ii Huawei Technologies Proprietary Issue 01 (2007-01-24)

Page 5

iSite BTS3006C

Maintenance Manual Figures

Figures

Figure 1 Wearing an anti-static wrist strap........................................................................................................6

Figure 2 Spread A-shaped ladder...................................................................................................................10

Figure 3 Ladder slant.....................................................................................................................................10

Figure 4 Using the long ladder in a safe way..................................................................................................11

Figure 5 Ladder placement when the ladder is 1 meter higher than the eave....................................................11

Figure 6 Weight hoisting................................................................................................................................12

Figure 7 Laying or erecting a cabinet.............................................................................................................13

Issue 01 (2007-01-24) Huawei Technologies Proprietary iii

Page 6

Page 7

iSite BTS3006C

Maintenance Manual Tables

Tables

Table 1 Typical minimal safety distance...........................................................................................................8

Issue 01 (2007-01-24) Huawei Technologies Proprietary v

Page 8

Page 9

iSite BTS3006C

Maintenance Manual Safety Precautions

Safety Precautions

1 Overview

1.1 Guide

This section describes the safety precautions to be taken while installing and maintaining

Huawei network equipment.

Before any operation, read the operation instructions and precautions carefully to prevent

accidents. The Caution, Warning, and Danger notes in manuals are merely supplements to the

basic safety precautions.

Before installing and maintaining Huawei products:

l

Be familiar with the safety operations

l

Undergo relevant training

l

Get qualified for the related operations.

Abide by the local safety regulations. The safety precautions in this manual only serve as

supplements to these regulations.

Take precautions and follow specific safety instructions to operate Huawei products and

equipment. Huawei is not liable for any damages caused by violating:

l

Universal safety regulations

l

Safety codes on design, production and equipment use

The operation personnel installing and maintaining Huawei products should:

l

Undergo training

l

Master the correct operation methods

l

Keep various safety precautions in mind.

1.2 Symbols

The symbols in this manual, indicate the safety precautions to be taken during the installation

and maintenance.

Safety prompts fall into four categories: Danger, Warning, and Caution.

Issue 01 (2007-01-24) Huawei Technologies Proprietary 1

Page 10

Safety Precautions

iSite BTS3006C

Maintenance Manual

The safety level is to the right of the symbol. The safety instructions are below the symbol.

Indicates a hazard with a high level of risk which, if not avoided, will result in death or

serious injury.

Indicates a hazard with a medium or low level of risk which, if not avoided, could result in

minor or moderate injury.

Indicates a hazard with a medium or low level of risk which, if not avoided, could result in

minor or moderate injury.

2 Toxic Articles

2.1 Beryllium Oxide

Some equipment parts contain toxic beryllium oxide. These parts include the power amplifier

circuit and combiner circuit.

l

If the parts are damaged it may lead to the leakage of beryllium oxide which may cause

injures to the human body. Take necessary precautions.

l

Keep the damaged parts in a safe place to prevent beryllium oxide leakage from

mechanical damages.

l

Do not discard the parts containing beryllium carelessly. Follow the local safety

regulations to perform chemical treatment or special waste treatment on them.

2.2 Hydrochloride

2 Huawei Technologies Proprietary Issue 01 (2007-01-24)

Page 11

iSite BTS3006C

Maintenance Manual Safety Precautions

Some equipment parts contain hydrochloride. If burnt, these parts generate toxic gas.

Prevent the damaged parts from burning.

Do not discard the damaged parts at random. Follow the local safety regulations to perform

chemical treatment or special waste treatment on them.

2.3 Hydrofluoride

Some equipment parts contain hydrofluoride. The burning of these parts generates toxic gas.

Prevent the equipment parts from burning.

Do not discard the equipment parts at random. Follow local regulations to perform chemical

treatment or special waste treatment on them.

3 Electrical Safety

3.1 High Voltage

High voltage power supply provides electricity for equipment operation. Direct contact or

indirect contact of damp objects with high-voltage wires or main power supply can be fatal.

l

Follow the local safety regulations to install AC power supply equipment. The people

engaged in providing the AC power supply must be qualified for high-voltage and AC

operations.

l

Remove electrical conductors such as watches, bracelets, and rings before the operation.

l

If you find that the cabinet is wet, switch off power supply at once.

l

Keep the equipment dry in humid places.

Issue 01 (2007-01-24) Huawei Technologies Proprietary 3

Page 12

Safety Precautions

Improper high-voltage operations may result in fire and electric shocks. Follow the local

safety codes to lay AC cables. Only trained and qualified personnel are allowed to perform

high-voltage operations.

3.2 Power Cable

Never install or remove electrified power cables. The contact of power cable with conductors

may cause electric spark or arc, causing fire or eye injury.

l

Turn off the power before installing and removing power cables.

l

Before connecting the cables, make sure that the cables and the cable tags are correct.

iSite BTS3006C

Maintenance Manual

3.3 Fuse

Never install or remove electrified fuses.

l

Only the technicians qualified for high-voltage operations can install or remove fuses.

l

Switch off the power before replacing AC fuses.

3.4 Tools

High-voltage and AC operations require special tools instead of general-purpose or makeshift

tools.

3.5 Drilling Holes

4 Huawei Technologies Proprietary Issue 01 (2007-01-24)

Page 13

iSite BTS3006C

Maintenance Manual Safety Precautions

Do not drill holes on the cabinet. Improper drilling may damage cables inside the cabinet. The

metal filings resulting from the drilling may fall into the cabinet and cause short-circuits in the

circuit board.

l

Wear insulated gloves and move the cables inside the cabinet.

l

Protect your eyes from the dispersed metal filings.

l

Prevent metal filings from falling into the cabinet.

l

Drill at proper places to avoid affecting the electromagnetic shielding performance of the

cabinet.

l

After drilling, remove all the metal filings immediately.

3.6 Thunderstorm

Never work on high-voltage and AC or work on steel towers and masts in thunderstorms.

Thunderstorms generate powerful electromagnetic fields in air. Ground the equipment

properly to avoid thunder stroke.

3.7 Static Electricity

Static electricity generated in the human body may damage the electrostatic-sensitive parts on

the circuit board, such as large-scale integrated circuit (IC).

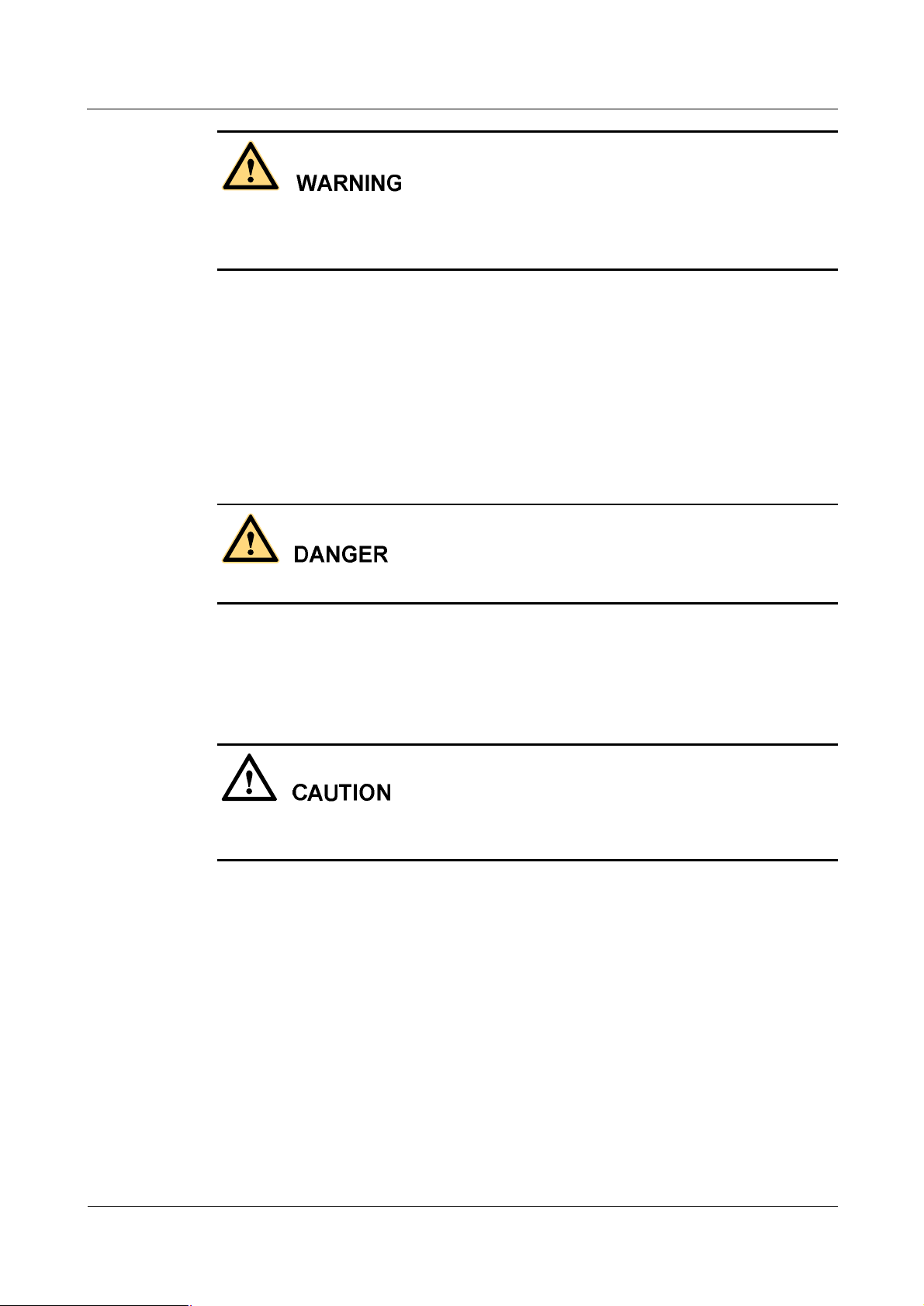

l

In dry climate, the electrostatic charge carried by the human body may go up to 30 kV.

The charge may remain in the human body for a long period. When an operator with

electrostatic charge contacts with an electrostatic-sensitive part, the electric discharge

may damage the part.

l

Before coming into contact with any equipment such as, hand-held plug-in boards,

circuit boards, or IC chips, wear an anti-static wrist strap with one end well grounded to

protect sensitive parts from static electricity on your body.

l

Before touching any board or module, discharge the static electricity in your body by

wearing an anti-static wrist strap.

l

Add a resistance of over 1M between the strap and the grounding point to protect

yourself from electric shock. The resistance over 1M is reliable in terms of electrostatic

voltage discharging. Check the anti-static wrist strap regularly. Never replace the cable

of the anti-static wrist strap with other cables.

Issue 01 (2007-01-24) Huawei Technologies Proprietary 5

Page 14

Safety Precautions

iSite BTS3006C

Maintenance Manual

l

Prevent electrostatic-sensitive boards or modules from touching the object with static

electricity or the object that may easily generate static electricity. For example, when

rubbing on an object of insulating materials such as packing and conveyer, an

electrostatic-sensitive part takes electric charge. When touching a human body or when

connected to the ground, the discharge may damage the part.

l

Electrostatic-sensitive boards or modules should contact only good conductors, such as

anti-static packing bags. Pack the board with an anti-static bag for stock or transport.

l

Before connecting any measurement device to boards or modules, ground it to discharge

its static electricity.

l

Do not place boards or modules near strong DC magnetic field, for example, the cathode

ray tube of a scope. Keep a distance of 10 cm at least.

l

The damage caused by static electricity is accumulative in effect. If the damage is slight,

the part does not fail. However, as the damage occurs repeatedly, the part may suddenly

fail. The damage caused by electrostatic discharge on the part may be explicit or implicit.

The implicit damage is not visible. However, it makes the part vulnerable to over-voltage

and high-temperature.

Figure 1 shows how to wear an anti-static wrist strap.

Figure 1 Wearing an anti-static wrist strap

Plug of anti-static wrist strap

3.8 Labels on Power Supply Cables

Before connecting the cables, check the labels on them.

3.9 Leakage of Current

To avoid large leakage of current, ground the equipment before powering it on.

6 Huawei Technologies Proprietary Issue 01 (2007-01-24)

Page 15

iSite BTS3006C

Maintenance Manual Safety Precautions

Before connecting the AC input power supply, connect the protection-grounding terminal of

the equipment housing to the earth. The purpose is to avoid the electric shock on human body

resulting from leakage of current. The leakage of current is caused by the EMI filter earth

capacitance of the equipment AC power supply input terminal and the Y capacitance of the

primary power supply.

3.10 Flammable Air

Do not place the equipment in an environment with flammable, explosive air or smog. Never

operate any digital equipment in this environment.

It is extremely dangerous to operate any digital equipment in this environment.

4 Microwave and Magnetic Field

4.1 Introduction

Antennas in service generate electromagnetic radiation. Standing too close to the antenna is

against the safety codes.

Only trained professionals can install and maintain antennas.

The radiation design of the equipment should meet the IEEE C95.1-1991 recommendation.

When working near a full-power transmitting antenna, keep the following safety regulations

in mind.

4.2 Definitions of Environment

There are two kinds of environment under electromagnetic radiation.

l

Controlled environment

In such areas, people are aware of the potential danger of the radio frequency radiation.

l

Uncontrolled environment

In such areas, people are unaware of the potential danger of the radio frequency radiation.

They cannot evade the radiation. The area may include living or working places.

4.3 Minimal Distance Formula

This section shows how to calculate the minimal safety distance.

Use the following formula to calculate the minimal safety distance from various antennas.

(G-L)

10

min

N10

=

r

The elements in the formula include:

Issue 01 (2007-01-24) Huawei Technologies Proprietary 7

4 W

OUT

P

Page 16

Safety Precautions

iSite BTS3006C

Maintenance Manual

l

R

is the minimal safety distance. Its unit is meter.

min

l

N is the number of frequency carriers.

l

P

is the output power of the frequency carrier. Its unit is W.

out

l

L is the loss from transmitting party to the receiving party. Its unit is dB.

l

G is the antenna gain. Its unit is dB.

l

W is the greatest field power density permitted. Its unit is W/m2.

In the uncontrolled environment, the greatest field power density permitted is f/150, in which

f is the frequency, and its unit is MHz. Its tested value is the mean value measured when the

testing time is over 30 minutes.

In the controlled environment, the greatest field power density permitted is f/30, and its tested

value is the mean value measured when the testing time is over 6 minutes.

Table 1 shows the minimal safety distance on the axial line of the antenna field calculated by

the above formula.

Table 1 Typical minimal safety distance

Frequency f (MHz) 1800

Frequency output power P

Loss from the transmitting party to the receiving party L (dBm) 5.5

Antenna gain G (dBm) 18

Number of frequency carriers N 2

Power density/uncontrolled environment W (W/m2) 12

Power density/controlled environment W (W/m2) 60

Uncontrolled environment r

Controlled environment r

4.4 Operation Codes

When operating on the high intensity radio frequency signal equipment, keep in mind that the

high-intensity microwave is harmful to human health.

(W) 40

out

(m) 3.1

min

(m) 1.4

min

5 Laser

8 Huawei Technologies Proprietary Issue 01 (2007-01-24)

Page 17

iSite BTS3006C

Maintenance Manual Safety Precautions

The laser beam inside optical fibers may injure your eyes.

When installing and maintaining optical fibers, keep your eyes away from them and avoid

looking at the optical fiber outlet.

6 High Temperature

The temperature of some equipment parts may be high. Do not touch the surface to avoid

being scalded.

When the equipment is running in the tropical environment, the temperature benchmark of the

parts is 45âC. In that case:

l

The temperature rise is within 30âC or the highest temperature is 75âC when the

equipment is running normally.

l

The temperature rise is within 55âC or the highest temperature is 100âC when a fault

occurs.

The temperature for radiator of the transmitter RF power amplifier and the power supply

radiator can reach the above-mentioned high temperature.

7 Working High above the Ground

7.1 General Operation

Prevent objects from falling, when working from a higher altitude.

Follow the local safety regulations when working from a higher altitude:

l

The workers should be trained.

l

Take care of the machines and tools at hand and prevent them from falling.

l

Put a tool back into the tool bag right after use.

l

Put on a helmet and safety belt.

l

Put on cold-proof clothes in cold areas beforehand.

Issue 01 (2007-01-24) Huawei Technologies Proprietary 9

Page 18

Safety Precautions

l

Check all the hoisting gears beforehand.

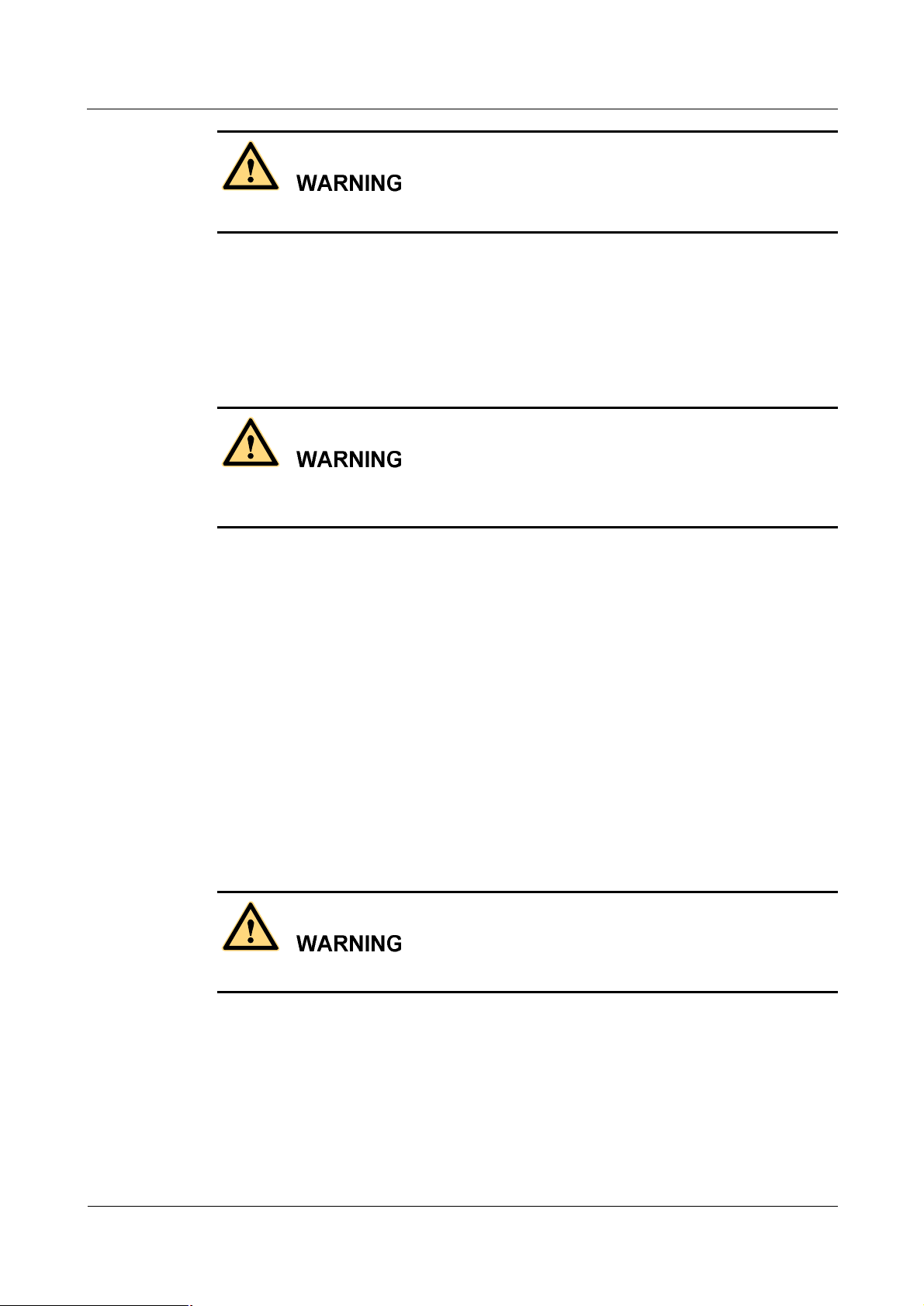

7.2 Safety Codes on Ladder Use

Check the ladder beforehand to make sure that the ladder is safe for use. Overweight on the

ladder is strictly prohibited.

You need to hold or secure the ladder in the following cases:

l

If the ladder slants over 5 m horizontally,

l

If the two legs of the ladder are over 3 m away, or

l

If the environment is dangerous.

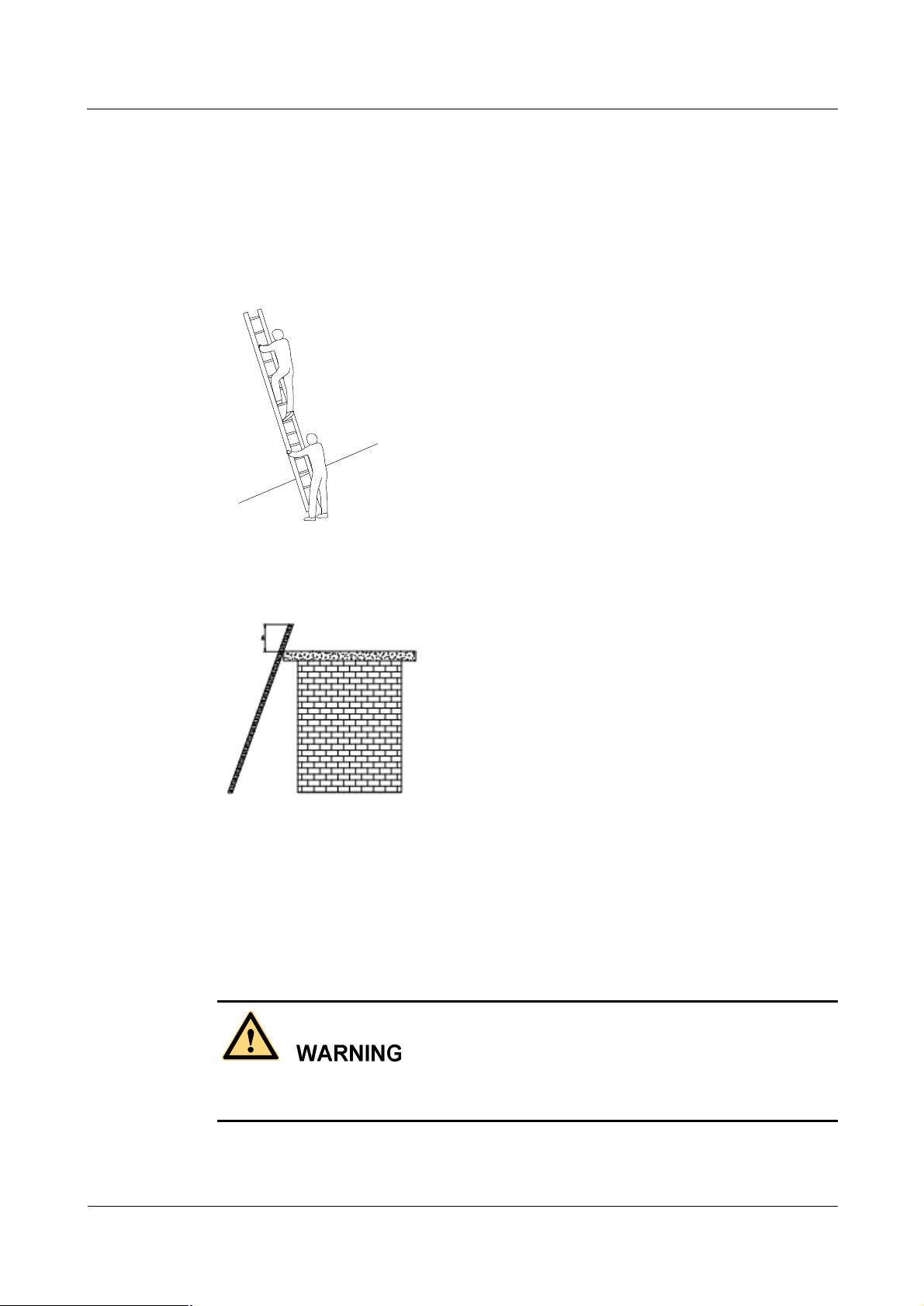

Be sure to spread A-shaped ladders fully, as shown in Figure 2.

Figure 2 Spread A-shaped ladder

iSite BTS3006C

Maintenance Manual

The slant of the ladder is 75â at best.

Measure the slant with the Angle Square or with arms, as shown in Figure 3.

When using the ladder, place the wider end of the ladder against the ground or take protective

measures on the base part of the ladder against skid.

Place the ladder against a stable and level ground. Never place a ladder on slippery objects

such as cartons and stones.

Figure 3 Ladder slant

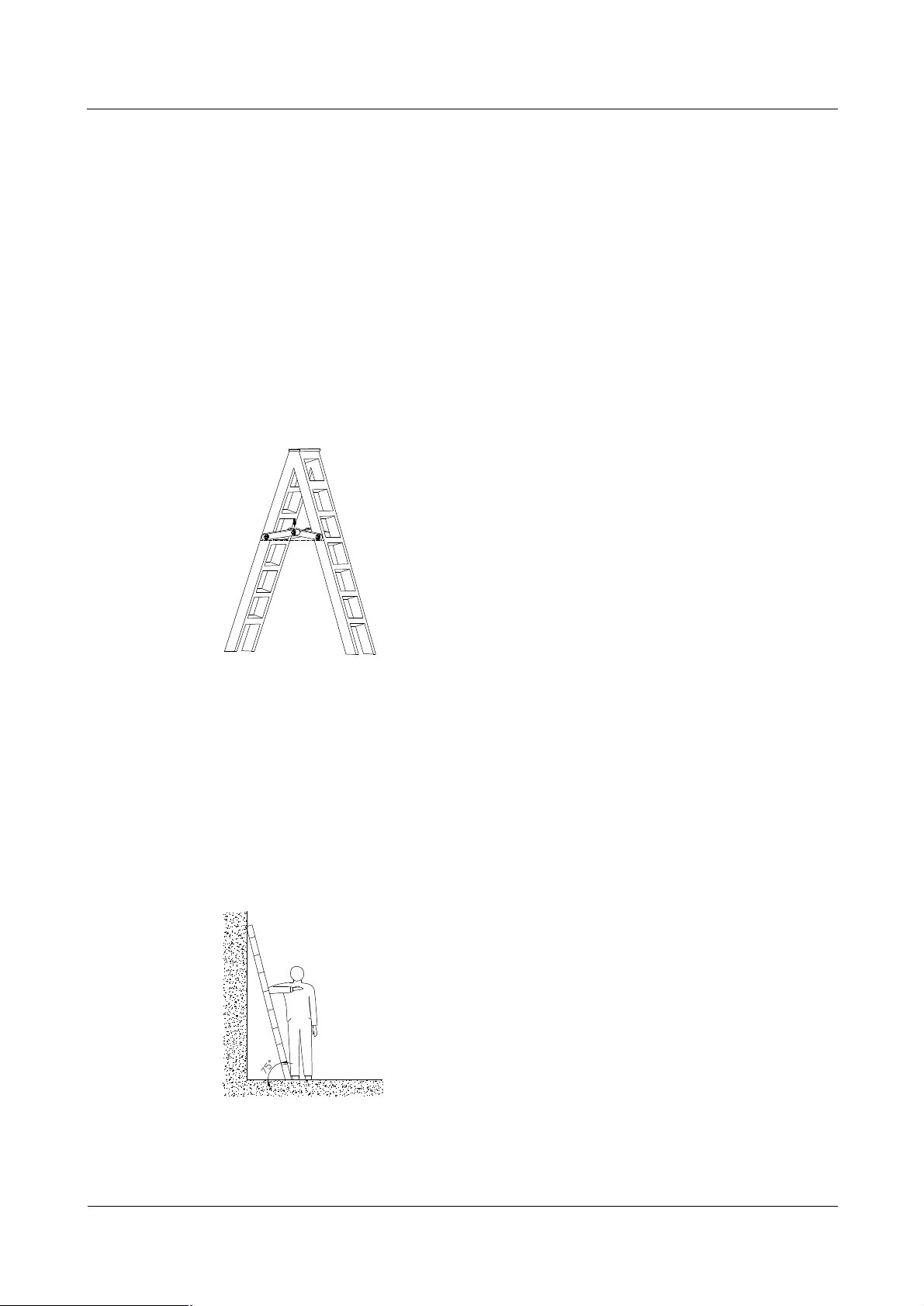

When climbing the ladder,

10 Huawei Technologies Proprietary Issue 01 (2007-01-24)

Page 19

iSite BTS3006C

Maintenance Manual Safety Precautions

l

Make sure that the gravity center of your body is within the ladder range.

l

Keep both feet and at least one hand on the ladder.

l

Do not climb beyond highest fourth step.

To climb to a rooftop, the length of the ladder should be 1 meter higher than the eave, as

shown in Figure 5.

Figure 4 Using the long ladder in a safe way

Figure 5 Ladder placement when the ladder is 1 meter higher than the eave

8 Other Items

8.1 Weight Hoisting

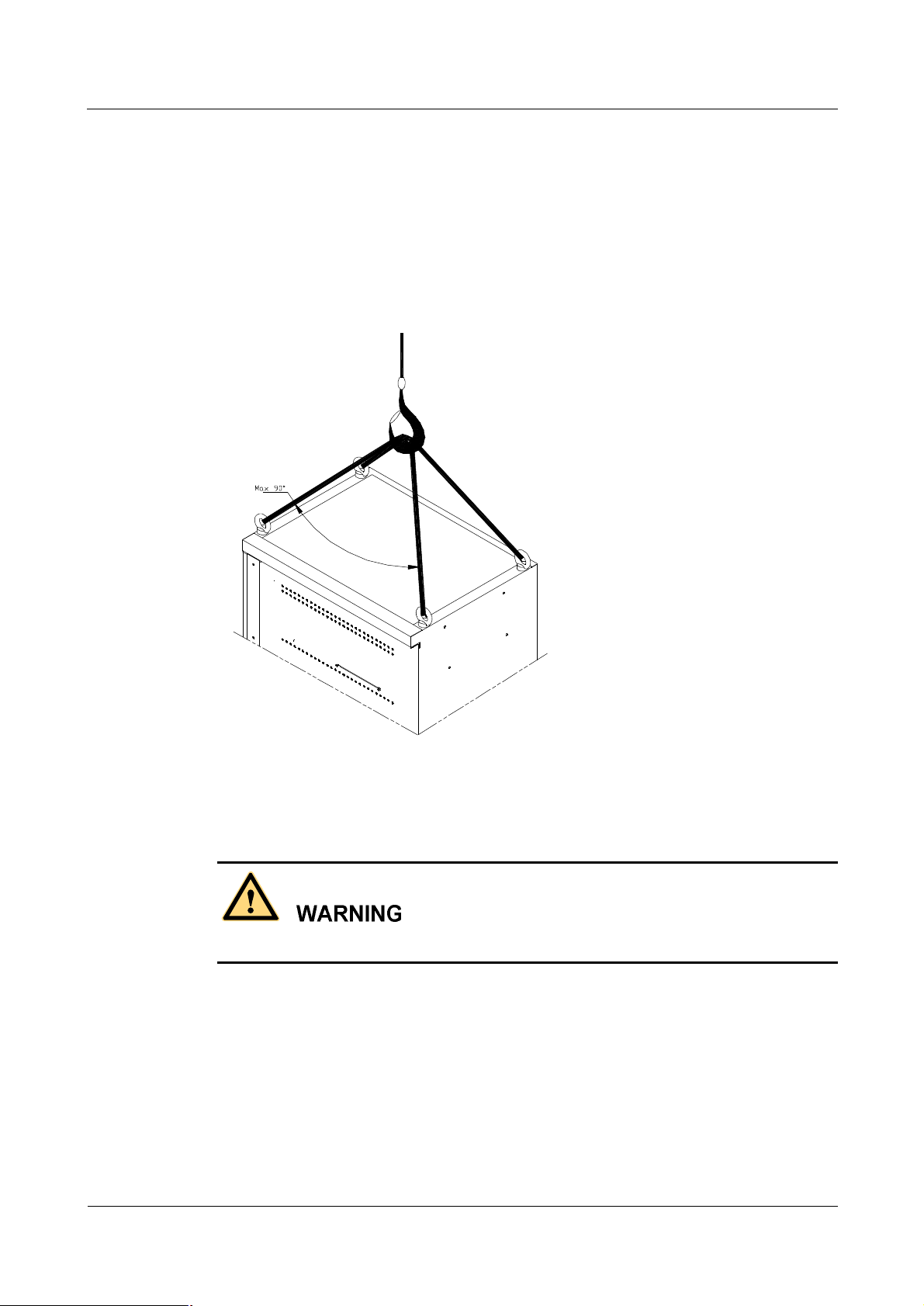

Exclude access to the areas under the gib arm and the goods in suspension during weight

hoisting.

Comply with the following regulations:

Issue 01 (2007-01-24) Huawei Technologies Proprietary 11

Page 20

Safety Precautions

iSite BTS3006C

Maintenance Manual

l

The weight-hoisting workers must be trained and qualified.

l

The weight-hoisting tools must be functional and complete.

l

The weight-hoisting tools must be fixed securely onto a weight-bearing object or wall.

l

Use concise commands to avoid faulty operation.

l

Make sure that the included angle of the cables for hoisting the cabinet is within 90â to

prevent the cable from breaking.

Figure 6 Weight hoisting

8.2 Heavy Object Portage

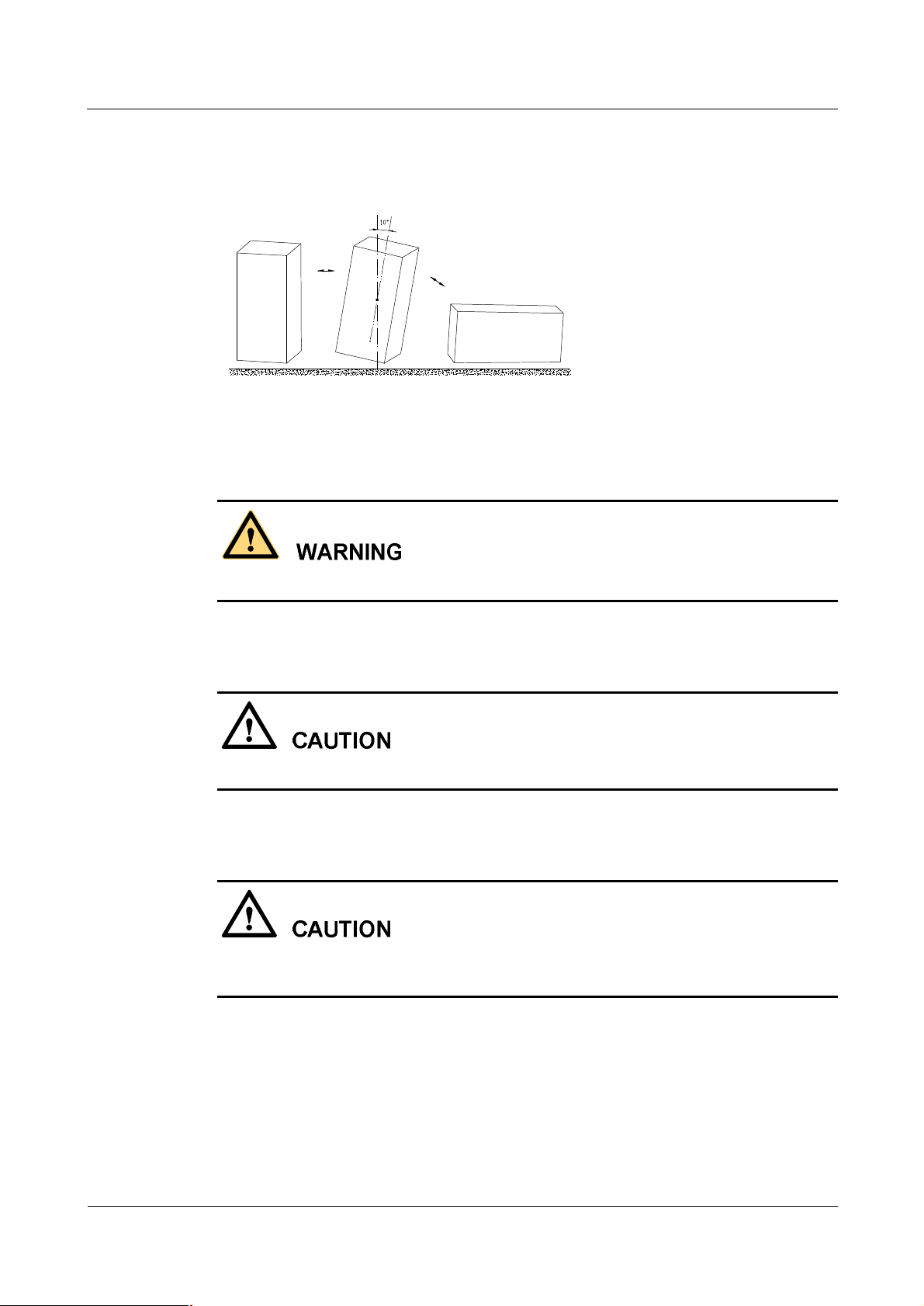

When carrying heavy objects such as the cabinets, be careful not to get bruised by them.

Two or three people are required to perform the following tasks:

l

Installing and maintaining BTS cabinets

l

Slanting, tilting, and erecting the cabinet

When the cabinet center of gravity slants over 10â, the cabinet may be off balance under

gravity.

12 Huawei Technologies Proprietary Issue 01 (2007-01-24)

Page 21

iSite BTS3006C

Maintenance Manual Safety Precautions

Figure 7 shows how to lay or erect a cabinet.

Figure 7 Laying or erecting a cabinet

8.3 Sharp Edge of Objects

When handling equipment, wear gloves for protection against sharp objects.

8.4 Binding of Signal Wires

Bind signal wires separately at least 150 mm from the cables of strong current or high voltage.

8.5 Having Companions in Maintenance and Commissioning

Ensure that there are qualified people for assistance during maintenance and commissioning

of the equipment.

Issue 01 (2007-01-24) Huawei Technologies Proprietary 13

Page 22

iSite BTS3006C

Maintenance Manual Contents

Contents

Safety Precautions.......................................................................................................................1

1 Overview....................................................................................................................................................1

1.1 Guide.................................................................................................................................................1

1.2 Symbols.............................................................................................................................................1

2 Toxic Articles..............................................................................................................................................2

2.1 Beryllium Oxide................................................................................................................................2

2.2 Hydrochloride....................................................................................................................................2

2.3 Hydrofluoride....................................................................................................................................3

3 Electrical Safety..........................................................................................................................................3

3.1 High Voltage......................................................................................................................................3

3.2 Power Cable......................................................................................................................................4

3.3 Fuse...................................................................................................................................................4

3.4 Tools.................................................................................................................................................4

3.5 Drilling Holes....................................................................................................................................4

3.6 Thunderstorm....................................................................................................................................5

3.7 Static Electricity................................................................................................................................5

3.8 Labels on Power Supply Cables.........................................................................................................6

3.9 Leakage of Current............................................................................................................................6

3.10 Flammable Air.................................................................................................................................7

4 Microwave and Magnetic Field....................................................................................................................7

4.1 Introduction.......................................................................................................................................7

4.2 Definitions of Environment................................................................................................................7

4.3 Minimal Distance Formula.................................................................................................................7

4.4 Operation Codes................................................................................................................................8

5 Laser...........................................................................................................................................................8

6 High Temperature........................................................................................................................................9

7 Working High above the Ground..................................................................................................................9

7.1 General Operation..............................................................................................................................9

7.2 Safety Codes on Ladder Use............................................................................................................10

8 Other Items...............................................................................................................................................11

8.1 Weight Hoisting...............................................................................................................................11

8.2 Heavy Object Portage......................................................................................................................12

Issue 01 (2007-01-24)

Huawei Technologies Proprietary

i

Page 23

iSite BTS3006C

Contents

8.3 Sharp Edge of Objects......................................................................................................................13

8.4 Binding of Signal Wires...................................................................................................................13

8.5 Having Companions in Maintenance and Commissioning.................................................................13

Maintenance Manual

About This Document................................................................................................................1

1 Preparations for Maintenance.............................................................................................1-1

1.1 Understanding the BTS Information......................................................................................................1-2

1.2 Preparing Tools and Spare Parts............................................................................................................1-2

2 Routine Maintenance...........................................................................................................2-1

2.1 Routine Maintenance Items...................................................................................................................2-2

2.1.1 Routine Maintenance Items for the Major Equipment..................................................................2-2

2.1.2 Routine Maintenance Items for the Auxiliary Equipment.............................................................2-3

2.1.3 Routine Maintenance Items for the Antenna System....................................................................2-4

2.2 Maintenance Guidelines to the Major Equipment..................................................................................2-4

2.2.1 Querying and Handling the Current Faults and Alarms.................................................................2-4

2.2.2 Call Test.....................................................................................................................................2-6

2.2.3 Short Message Test.....................................................................................................................2-7

2.2.4 Packet Data Service Test.............................................................................................................2-8

2.2.5 Checking the VSWR...................................................................................................................2-9

2.2.6 Cleaning the Fan Box..................................................................................................................2-9

2.2.7 Checking the Trunk Transmission...............................................................................................2-12

2.2.8 Checking the Equipment Wiring.................................................................................................2-12

2.3 Maintenance Guidelines to the Auxiliary Devices.................................................................................2-13

2.3.1 Checking the Alarm Collection Devices......................................................................................2-13

2.3.2 Testing the Grounding Resistance...............................................................................................2-13

2.4 Maintenance Guidelines to the Antenna System....................................................................................2-14

2.4.1 Checking the Tower...................................................................................................................2-14

2.4.2 Checking the Pole......................................................................................................................2-14

2.4.3 Checking the Antenna................................................................................................................2-14

2.4.4 Checking the Feeder...................................................................................................................2-16

2.5 BTS Routine Maintenance Record.......................................................................................................2-17

2.5.1 BTS Weekly Maintenance Record..............................................................................................2-17

2.5.2 BTS Monthly Maintenance Record.............................................................................................2-18

2.5.3 BTS Quarterly Maintenance Record...........................................................................................2-19

2.5.4 BTS Yearly Maintenance Record................................................................................................2-20

2.5.5 BTS Unexpected Fault Handling Record....................................................................................2-21

3 Emergency Maintenance......................................................................................................3-1

3.1 Overview of Emergency Maintenance...................................................................................................3-2

3.1.1 Application Scenarios..................................................................................................................3-2

3.1.2 Basic Principles of Emergency Maintenance................................................................................3-2

3.1.3 Points to Remember....................................................................................................................3-2

ii

Huawei Technologies Proprietary

Issue 01 (2007-01-24)

Page 24

iSite BTS3006C

Maintenance Manual Contents

3.2 Emergency Maintenance Procedures.....................................................................................................3-3

3.2.1 Emergency Maintenance Flowchart.............................................................................................3-3

3.2.2 Checking Services for Faults.......................................................................................................3-3

3.2.3 Locating the Causes....................................................................................................................3-3

3.2.4 Contacting Huawei......................................................................................................................3-4

3.2.5 Recovering Services....................................................................................................................3-5

3.2.6 Observing Recovered Services....................................................................................................3-5

3.2.7 Collecting Data...........................................................................................................................3-6

3.2.8 Performing Emergency Maintenance...........................................................................................3-6

3.3 Handling the Faults in an Individual BTS in Emergency Cases..............................................................3-6

3.3.1 Overview....................................................................................................................................3-6

3.3.2 Abnormal Power Supply.............................................................................................................3-6

3.3.3 Abnormal Transmission...............................................................................................................3-7

3.3.4 Data Mistakenly Modified on the BSC........................................................................................3-8

3.3.5 BSC Hardware Faults..................................................................................................................3-9

3.3.6 BSC Data Configuration Error.....................................................................................................3-9

3.3.7 Abnormal BTS Voltage Control..................................................................................................3-10

3.3.8 Abnormal BSC Clock.................................................................................................................3-11

3.4 Handling the Faults in Associated BTSs in Emergency Cases...............................................................3-11

3.4.1 Overview...................................................................................................................................3-11

3.4.2 Abnormal Power Supply............................................................................................................3-11

3.4.3 Abnormal Transmission..............................................................................................................3-12

3.4.4 Data Mistakenly Modified on the BSC.......................................................................................3-12

3.4.5 Services Interrupted in Associated BTSs.....................................................................................3-13

3.4.6 Optical Connection Error Between Combined Cabinets or Between Cabinet Groups...................3-13

3.4.7 BSC Data Configuration Error....................................................................................................3-14

3.4.8 Abnormal BTS Voltage Control..................................................................................................3-14

3.4.9 Abnormal BSC Clock.................................................................................................................3-14

3.5 Handling Cell Service Disruption in Emergency Cases.........................................................................3-15

3.5.1 Network Access Failure..............................................................................................................3-15

3.5.2 Calling Failure...........................................................................................................................3-15

3.5.3 Called Failure............................................................................................................................3-16

3.5.4 MSC Data Error.........................................................................................................................3-16

3.6 Handling the Alarms of Main Modules in Emergency Cases.................................................................3-17

3.6.1 Overview...................................................................................................................................3-17

3.6.2 Clock Reference Abnormal........................................................................................................3-17

3.6.3 Hardware Critical Alarm............................................................................................................3-18

3.6.4 Internal Power Alarm of the DMCM...........................................................................................3-19

3.6.5 Master Clock Alarm...................................................................................................................3-20

3.6.6 LAPD Alarm..............................................................................................................................3-20

3.6.7 DDRM Communication Alarm...................................................................................................3-21

3.6.8 Clock Critical Alarm..................................................................................................................3-22

Issue 01 (2007-01-24)

Huawei Technologies Proprietary

iii

Page 25

Contents

iSite BTS3006C

Maintenance Manual

3.6.9 Repeat Download of DDRM Version..........................................................................................3-23

3.6.10 Hardware Faults.......................................................................................................................3-23

3.6.11 Abnormal Channel Status.........................................................................................................3-24

3.6.12 VSWR Alarm...........................................................................................................................3-24

3.6.13 LNA Fault................................................................................................................................3-25

3.6.14 Abnormal SFPA/SFPB Sending or Receiving Alarm.................................................................3-25

3.6.15 SFPA or SFPB Local Alarm......................................................................................................3-26

3.6.16 SFPA or SFPB Remote Alarm...................................................................................................3-27

3.7 Data Backup and Restoration...............................................................................................................3-28

3.8 Maintenance Record............................................................................................................................3-28

3.8.1 Emergency Maintenance Note....................................................................................................3-28

3.8.2 Troubleshooting Record Table....................................................................................................3-30

4 Replacing Modules and Parts..............................................................................................4-1

4.1 Overview..............................................................................................................................................4-2

4.1.1 Replacing Parts in Different Situations........................................................................................4-2

4.1.2 Classification of the BTS3006C Modules and Parts.....................................................................4-2

4.2 Replacing Modules...............................................................................................................................4-3

4.2.1 General Procedure.......................................................................................................................4-3

4.2.2 Replacing the DMCM.................................................................................................................4-7

4.2.3 Replacing the DDRM.................................................................................................................4-11

4.2.4 Replacing the DDPM.................................................................................................................4-13

4.2.5 Replacing the DDCM.................................................................................................................4-15

4.2.6 Replacing the DSCM.................................................................................................................4-18

4.2.7 Replacing the DPSM..................................................................................................................4-20

4.2.8 Replacing the DSEM..................................................................................................................4-22

4.2.9 Replacing the DATM.................................................................................................................4-24

4.3 Replacing Parts....................................................................................................................................4-26

4.3.1 Replacing the Fan Box...............................................................................................................4-26

4.3.2 Replacing BTS3006C Antennas..................................................................................................4-29

4.3.3 Replacing the TMA....................................................................................................................4-33

4.4 Replacing Cables.................................................................................................................................4-37

4.4.1 Replacing an E1 Trunk Cable.....................................................................................................4-37

4.4.2 Replacing an SDH External Optical Cables................................................................................4-40

4.4.3 Replacing the AC/DC Power Cables...........................................................................................4-42

4.4.4 Replacing the Power Cable of the TMA......................................................................................4-46

4.4.5 Replacing the RF Interconnection Cable.....................................................................................4-48

4.4.6 Replacing the Combined Optical Cable......................................................................................4-50

4.4.7 Replacing the Alarm Cables.......................................................................................................4-52

4.4.8 Replacing the RF Jumper...........................................................................................................4-54

A Requirements for Antenna Spacing.................................................................................A-1

A.1 Omni-Directional Antenna...................................................................................................................A-2

iv

Huawei Technologies Proprietary

Issue 01 (2007-01-24)

Page 26

iSite BTS3006C

Maintenance Manual Contents

A.2 Directional Antennas............................................................................................................................A-3

B Engineering Labels for Antenna System..........................................................................B-1

B.1 Engineering Labels for Feeders............................................................................................................B-2

B.2 Explanation of the Jumper Engineering Label.......................................................................................B-3

C Glossary................................................................................................................................C-1

D Acronyms and Abbreviations...........................................................................................D-1

Index...........................................................................................................................................i-1

Issue 01 (2007-01-24)

Huawei Technologies Proprietary

v

Page 27

Page 28

iSite BTS3006C

Maintenance Manual Figures

Figures

Figure 1 Wearing an anti-static wrist strap......................................................................................................6

Figure 2 Spread A-shaped ladder..................................................................................................................10

Figure 3 Ladder slant...................................................................................................................................10

Figure 4 Using the long ladder in a safe way................................................................................................11

Figure 5 Ladder placement when the ladder is 1 meter higher than the eave..................................................11

Figure 6 Weight hoisting..............................................................................................................................12

Figure 7 Laying or erecting a cabinet...........................................................................................................13

Figure 2-1 Browse Real Time Alarm window.............................................................................................2-5

Figure 2-2 Module alarm information........................................................................................................2-6

Figure 2-3 Removing the fan box from the cabinet....................................................................................2-10

Figure 2-4 Installing the fan box...............................................................................................................2-11

Figure 3-1 Process of handling emergency maintenance.............................................................................3-3

Figure 3-2 Process of Huawei emergency service handling.........................................................................3-4

Figure 4-1 Replacing the modules..............................................................................................................4-4

Figure 4-2 Querying the board information................................................................................................4-6

Figure 4-3 Replacing the DMCM...............................................................................................................4-9

Figure 4-4 Replacing the DDRM..............................................................................................................4-12

Figure 4-5 Replacing the DDPM...............................................................................................................4-14

Figure 4-6 Replacing the DDCM..............................................................................................................4-16

Figure 4-7 Replacing the DSCM...............................................................................................................4-19

Figure 4-8 Replacing the DPSM...............................................................................................................4-21

Figure 4-9 Replacing the DSEM...............................................................................................................4-23

Figure 4-10 Replacing the DATM.............................................................................................................4-25

Figure 4-11 Replacing the fan box.............................................................................................................4-27

Figure 4-12 Replacing the BTS3006C antenna..........................................................................................4-31

Figure 4-13 Replacing the TMA................................................................................................................4-35

Issue 01 (2007-01-24)

Huawei Technologies Proprietary

vii

Page 29

Figures

iSite BTS3006C

Maintenance Manual

Figure 4-14 Replacing an E1 trunk cable...................................................................................................4-38

Figure 4-15 Replacing an SDH external optical cable................................................................................4-41

Figure 4-16 Replacing the power cable......................................................................................................4-44

Figure 4-17 Replacing the power cable of the TMA...................................................................................4-47

Figure 4-18 Replacing RF interconnection cables......................................................................................4-49

Figure 4-19 Replacing the combined optical cable.....................................................................................4-51

Figure 4-20 Replacing an alarm cable.......................................................................................................4-53

Figure 4-21 Replacing the RF jumper........................................................................................................4-55

Figure B-1 Feeder tag (for the transmit end)...............................................................................................B-2

Figure B-2 Feeder tag (for the receive end)................................................................................................B-3

Figure B-3 Jumper tag (for the transmit & receive end)..............................................................................B-4

viii

Huawei Technologies Proprietary

Issue 01 (2007-01-24)

Page 30

iSite BTS3006C

Maintenance Manual Tables

Tables

Table 1 Typical minimal safety distance.........................................................................................................8

Table 1-1 List of other devices...................................................................................................................1-3

Table 2-1 Routine maintenance items for the major equipment....................................................................2-2

Table 2-2 Routine maintenance items for the auxiliary equipment...............................................................2-3

Table 2-3 Routine maintenance items for the antenna system......................................................................2-4

Table 2-4 BTS Weekly Maintenance Record..............................................................................................2-17

Table 2-5 BTS Monthly Maintenance Record............................................................................................2-18

Table 2-6 BTS Quarterly Maintenance Record...........................................................................................2-19

Table 2-7 BTS Yearly Maintenance Record...............................................................................................2-20

Table 2-8 BTS Unexpected Fault Handling Record....................................................................................2-22

Table 3-1 On-site information record in emergency cases............................................................................3-3

Table 3-2 Modules and related module alarms that affect BTS services......................................................3-17

Table 4-1 Classification of the BTS3006C modules and parts.....................................................................4-2

Table 4-2 List of the modules.....................................................................................................................4-3

Table 4-3 E1 trunk cables..........................................................................................................................4-38

Table 4-4 Trunk cable...............................................................................................................................4-40

Table 4-5 AC/DC power cables.................................................................................................................4-43

Table 4-6 Power cable of the TMA............................................................................................................4-46

Table 4-7 RF interconnection cables between modules...............................................................................4-48

Table 4-8 Combined optical cable.............................................................................................................4-50

Table 4-9 Alarm cables..............................................................................................................................4-52

Table 4-10 RF jumper...............................................................................................................................4-54

Table A-1 Requirements for omni-directional antenna spacing....................................................................A-2

Table A-2 Requirements for directional antenna spacing.............................................................................A-3

Table B-1 Description of the feeder engineering labels...............................................................................B-2

Table B-2 Description of the jumper engineering labels..............................................................................B-3

Issue 01 (2007-01-24)

Huawei Technologies Proprietary

ix

Page 31

Tables

iSite BTS3006C

Maintenance Manual

x

Huawei Technologies Proprietary

Issue 01 (2007-01-24)

Page 32

iSite BTS3006C

Maintenance Manual Contents

Contents

About This Document................................................................................................................1

Issue 01 (2007-01-24)

Huawei Technologies Proprietary

i

Page 33

Page 34

iSite BTS3006C

Maintenance Manual About This Document

About This Document

Purpose

This manual describes the procedures for the BTS3006C maintenance.

Related Versions

The following table lists the versions of the product that is described in this document.

Product Name Version

iSite BTS3006C V300R005

Intended Audience

The manual is intended for BTS operators.

Organization

This document consists of four chapters and two appendixes. It is organized as follows:

Chapter Description

1 Preparations for

Maintenance

2 Routine

Maintenance

This chapter introduces the preparations that have to be made for

routine maintenance.

This chapter describes the BTS3006C routine maintenance items

and maintenance guidelines.

3 Emergency

Maintenance

4 Replacing

Modules and Parts

Issue 01 (2007-01-24)

This chapter describes the methods and procedures for emergency

maintenance on the BTS3006C.

This chapter describes the procedures for replacing modules, parts,

and cables.

Huawei Technologies Proprietary

1

Page 35

About This Document

iSite BTS3006C

Maintenance Manual

Chapter Description

A Requirements for

Antenna Spacing

B Engineering

Labels for Antenna

System

C Glossary Lists the glossary involved in this manual.

D Acronyms and

Abbreviations

Conventions

Symbol Conventions

The symbols that may be found in this document are defined as follows.

Symbol Description

This appendix lists the requirements for the installation spacing of

omni-directional antenna and directional antenna in different

situations.

This appendix lists the engineering labels for the antenna system.

Lists the acronyms and abbreviations involved in this manual.

General Conventions

Convention Description

Times New Roman Normal paragraphs are in Times New Roman.

Boldface

Indicates a hazard with a high level of risk that, if not avoided,

will result in death or serious injury.

Indicates a hazard with a medium or low level of risk which, if

not avoided, could result in minor or moderate injury.

Indicates a potentially hazardous situation that, if not avoided,

could cause equipment damage, data loss, and performance

degradation, or unexpected results.

Indicates a tip that may help you solve a problem or save time.

Provides additional information to emphasize or supplement

important points of the main text.

Names of files, directories, folders, and users are in

boldface. For example, log in as user root.

Italic Book titles are in italics.

Courier New

2

Huawei Technologies Proprietary

Terminal display is in Courier New.

Issue 01 (2007-01-24)

Page 36

iSite BTS3006C

Maintenance Manual About This Document

Command Conventions

Convention Description

Boldface

Italic Command arguments are in italics.

[ ] Items (keywords or arguments) in square brackets [ ] are

{ x | y | ... } Alternative items are grouped in braces and separated by

[ x | y | ... ] Optional alternative items are grouped in square brackets

{ x | y | ... } * Alternative items are grouped in braces and separated by

GUI Conventions

Convention Description

Boldface

The keywords of a command line are in boldface.

optional.

vertical bars. One is selected.

and separated by vertical bars. One or none is selected.

vertical bars. A minimum of one or a maximum of all can

be selected.

Buttons, menus, parameters, tabs, windows, and dialog titles

are in boldface. For example, click OK.

> Multi-level menus are in boldface and separated by the ">"

Keyboard Operation

Format Description

Key

Key 1+Key 2

Key 1, Key 2 Press the keys in turn. For example, pressing Alt, A means

Mouse Operation

Action Description

Click Select and release the primary mouse button without

signs. For example, choose File > Create > Folder.

Press the key. For example, press Enter and press Tab.

Press the keys concurrently. For example, pressing

Ctrl+Alt+A means the three keys should be pressed

concurrently.

the two keys should be pressed in turn.

moving the pointer.

Issue 01 (2007-01-24)

Huawei Technologies Proprietary

3

Page 37

About This Document

Action Description

Double-click Press the primary mouse button twice continuously and

Drag Press and hold the primary mouse button and move the

Update History

Updates between document versions are cumulative. Therefore, the latest document version

contains all updates made to previous versions.

Updates in Issue 01 (2007-01-24)

Initial commercial release.

iSite BTS3006C

Maintenance Manual

quickly without moving the pointer.

pointer to a certain position.

4

Huawei Technologies Proprietary

Issue 01 (2007-01-24)

Page 38

iSite BTS3006C

Maintenance Manual Contents

Contents

1 Preparations for Maintenance.............................................................................................1-1

1.1 Understanding the BTS Information........................................................................................................1-2

1.2 Preparing Tools and Spare Parts..............................................................................................................1-2

2 Routine Maintenance...........................................................................................................2-1

2.1 Routine Maintenance Items....................................................................................................................2-2

2.1.1 Routine Maintenance Items for the Major Equipment.....................................................................2-2

2.1.2 Routine Maintenance Items for the Auxiliary Equipment................................................................2-3

2.1.3 Routine Maintenance Items for the Antenna System.......................................................................2-4

2.2 Maintenance Guidelines to the Major Equipment....................................................................................2-4

2.2.1 Querying and Handling the Current Faults and Alarms...................................................................2-4

2.2.2 Call Test........................................................................................................................................2-6

2.2.3 Short Message Test........................................................................................................................2-7

2.2.4 Packet Data Service Test................................................................................................................2-8

2.2.5 Checking the VSWR......................................................................................................................2-9

2.2.6 Cleaning the Fan Box....................................................................................................................2-9

2.2.7 Checking the Trunk Transmission.................................................................................................2-12

2.2.8 Checking the Equipment Wiring...................................................................................................2-12

2.3 Maintenance Guidelines to the Auxiliary Devices...................................................................................2-13

2.3.1 Checking the Alarm Collection Devices........................................................................................2-13

2.3.2 Testing the Grounding Resistance.................................................................................................2-13

2.4 Maintenance Guidelines to the Antenna System.....................................................................................2-14

2.4.1 Checking the Tower......................................................................................................................2-14

2.4.2 Checking the Pole.........................................................................................................................2-14

2.4.3 Checking the Antenna...................................................................................................................2-14

2.4.4 Checking the Feeder.....................................................................................................................2-16

2.5 BTS Routine Maintenance Record.........................................................................................................2-17

2.5.1 BTS Weekly Maintenance Record.................................................................................................2-17

2.5.2 BTS Monthly Maintenance Record...............................................................................................2-18

2.5.3 BTS Quarterly Maintenance Record..............................................................................................2-19

2.5.4 BTS Yearly Maintenance Record..................................................................................................2-20

2.5.5 BTS Unexpected Fault Handling Record.......................................................................................2-21

Issue 01 (2007-01-24) Huawei Technologies Proprietary i

Page 39

iSite BTS3006C

Contents

Maintenance Manual

3 Emergency Maintenance......................................................................................................3-1

3.1 Overview of Emergency Maintenance.....................................................................................................3-2

3.1.1 Application Scenarios....................................................................................................................3-2

3.1.2 Basic Principles of Emergency Maintenance..................................................................................3-2

3.1.3 Points to Remember.......................................................................................................................3-2

3.2 Emergency Maintenance Procedures.......................................................................................................3-3

3.2.1 Emergency Maintenance Flowchart...............................................................................................3-3

3.2.2 Checking Services for Faults..........................................................................................................3-3

3.2.3 Locating the Causes.......................................................................................................................3-3

3.2.4 Contacting Huawei........................................................................................................................3-4

3.2.5 Recovering Services......................................................................................................................3-5

3.2.6 Observing Recovered Services.......................................................................................................3-5

3.2.7 Collecting Data..............................................................................................................................3-6

3.2.8 Performing Emergency Maintenance..............................................................................................3-6

3.3 Handling the Faults in an Individual BTS in Emergency Cases................................................................3-6

3.3.1 Overview.......................................................................................................................................3-6

3.3.2 Abnormal Power Supply................................................................................................................3-6

3.3.3 Abnormal Transmission.................................................................................................................3-7

3.3.4 Data Mistakenly Modified on the BSC...........................................................................................3-8

3.3.5 BSC Hardware Faults....................................................................................................................3-9

3.3.6 BSC Data Configuration Error.......................................................................................................3-9

3.3.7 Abnormal BTS Voltage Control.....................................................................................................3-10

3.3.8 Abnormal BSC Clock...................................................................................................................3-11

3.4 Handling the Faults in Associated BTSs in Emergency Cases.................................................................3-11

3.4.1 Overview......................................................................................................................................3-11

3.4.2 Abnormal Power Supply...............................................................................................................3-11

3.4.3 Abnormal Transmission................................................................................................................3-12

3.4.4 Data Mistakenly Modified on the BSC..........................................................................................3-12

3.4.5 Services Interrupted in Associated BTSs.......................................................................................3-13

3.4.6 Optical Connection Error Between Combined Cabinets or Between Cabinet Groups......................3-13

3.4.7 BSC Data Configuration Error......................................................................................................3-14

3.4.8 Abnormal BTS Voltage Control.....................................................................................................3-14

3.4.9 Abnormal BSC Clock...................................................................................................................3-14

3.5 Handling Cell Service Disruption in Emergency Cases...........................................................................3-15

3.5.1 Network Access Failure................................................................................................................3-15

3.5.2 Calling Failure..............................................................................................................................3-15

3.5.3 Called Failure...............................................................................................................................3-16

3.5.4 MSC Data Error...........................................................................................................................3-16

3.6 Handling the Alarms of Main Modules in Emergency Cases...................................................................3-17

3.6.1 Overview......................................................................................................................................3-17

3.6.2 Clock Reference Abnormal...........................................................................................................3-17

3.6.3 Hardware Critical Alarm...............................................................................................................3-18

ii Huawei Technologies Proprietary Issue 01 (2007-01-24)

Page 40

iSite BTS3006C

Maintenance Manual Contents

3.6.4 Internal Power Alarm of the DMCM.............................................................................................3-19

3.6.5 Master Clock Alarm......................................................................................................................3-20

3.6.6 LAPD Alarm................................................................................................................................3-20

3.6.7 DDRM Communication Alarm.....................................................................................................3-21

3.6.8 Clock Critical Alarm.....................................................................................................................3-22

3.6.9 Repeat Download of DDRM Version............................................................................................3-23

3.6.10 Hardware Faults.........................................................................................................................3-23

3.6.11 Abnormal Channel Status............................................................................................................3-24