Page 1

MA7200 PLUS INVERTER

SERIES

FAN Quick Start Manual

1 to 2 HP

Models- MA7200 -2001/2-N1 (230V)

&

MA7200-4001/2-N1 (460V)

Rev. 1.2 – April 14th 2008

Page 2

MA7200 PLUS Inverter 1 to 2 HP Fan Quick Start Manual

_______________________________________________________________

Quick Start Guide for Fan Applications

This guide is to simplify the start up of the MA7200 PLUS Inverter series, 1 to 2 HP, for fan

applications. It is not intended to replace the MA7200 PLUS Installation and Operation Manual, and

the user is urged review this manual. There are three methods of control or combinations thereof that

that may be selected; Keypad, Analog Signal (external terminal), or Serial Communication. Only

Keypad and analog signal control will be covered as Serial Communication is beyond the scope of

this manual. For serial communication control or special external control, the user is referred to the

MA7200 PLUS Installation and Operating Manual.

SAFETY FIRST!

Step 1 - Before Starting the Inverter

• Referring to the MA7200 PLUS Instruction Manual, please review and verify that the correct

inverter size for the associated motor was received free of damage. To ensure personnel safety

and to avoid equipment damage, follow the precautions and the installation procedures for

mounting, wiring, and operating environment.

CAUTION - To avoid damage to the inverter when removing the inverter cover

and/or LCD Operator, refer to Appendix B for the proper procedure.

• In accordance with applicable codes, make electrical connections to the motor and input power

terminals. (Refer to the block diagram, Fig. 4). No other external connections should be made at

this time, as the initial control will be from the keypad.

Step 2 - Apply Power to the Drive

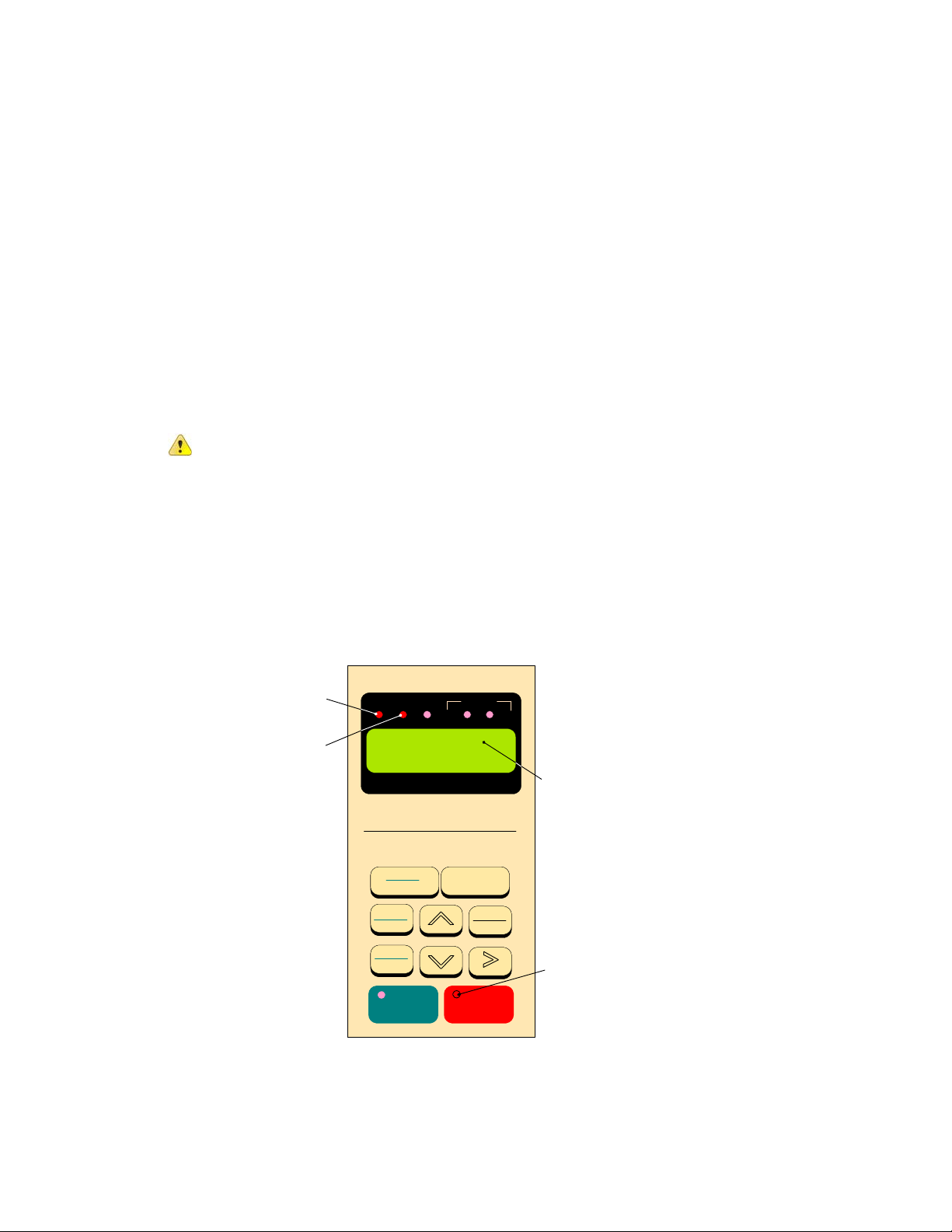

• Apply AC power to the Inverter and observe the LCD Display Line 1; it should read

“Freq. Cmd 000.00Hz”. Line 2 should read “TECO”. The red LED on the STOP key should be on.

The DRIVE and FWD LED’s should be on. (See Fig. 1 below)

LED

ON

DRIVE

FWD

REV

SEQ

REMOTE

REF

LED

ON

Freq. Cmd 000.00Hz

TECO

FLASHING

DIGITAL OPERATOR JNEP-36

PRGM

DRIVE

LOCAL

REMOTE

FWD

REV

RUN STOP

DSPL

EDIT

ENTER

RESET

LED

ON

Fig. 1 MA7200 PLUS Keypad

Step 3 - Set Drive to Run Mode

• If the red DRIVE LED is not on with AC power up, press the PGRM / DRIVE key until the red

Drive LED is on. The Inverter is now in the RUN mode.

______________________________________________________________

TECO – Westinghouse Motor Company

2

Page 3

MA7200 PLUS Inverter 1 to 2 HP Fan Quick Start Manual

_______________________________________________________________

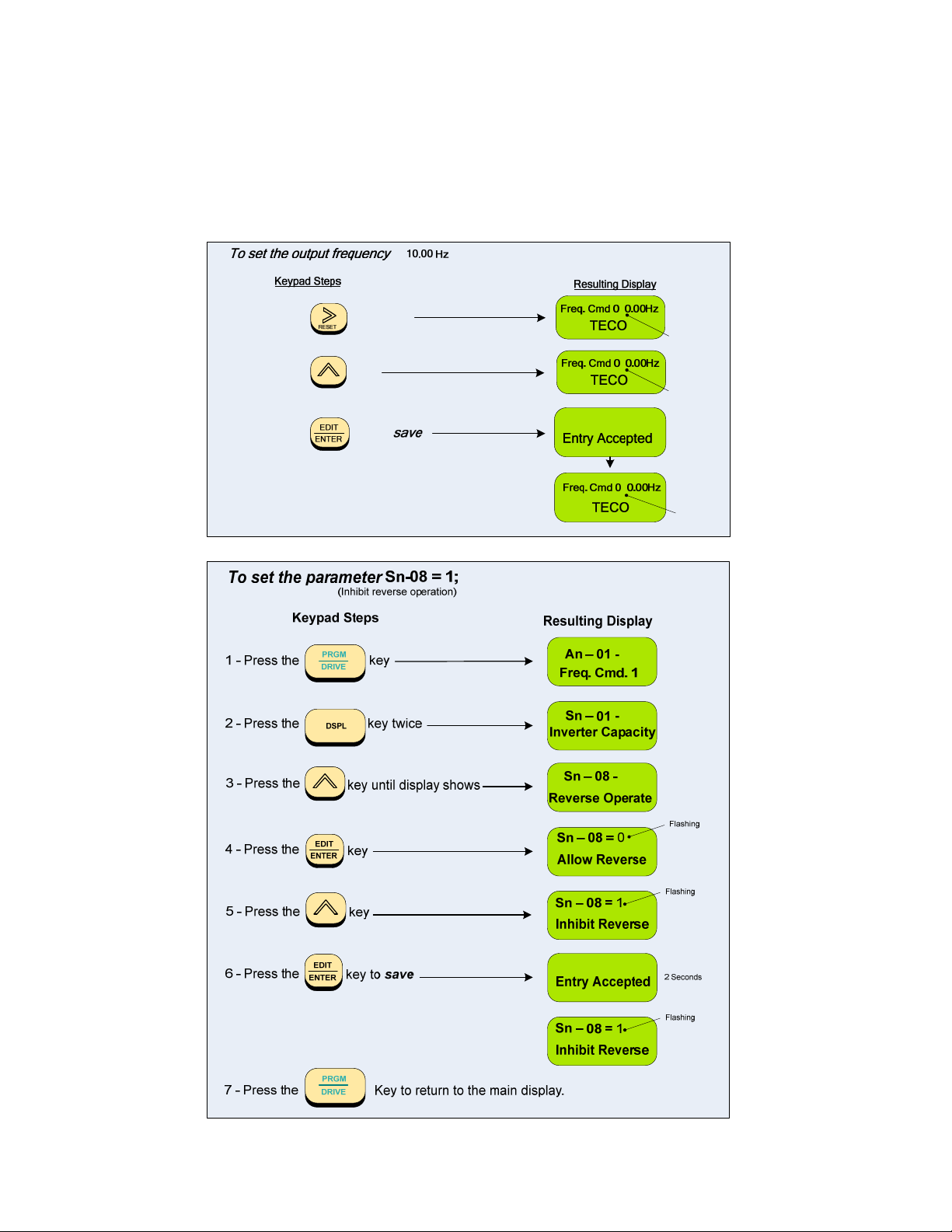

Step 4 - Check Fan Motor Operation

• Enter 10.00Hz for the frequency reference and set parameter Sn-08 = 1 to disable Reverse

Direction operation. Note: The output from the inverter is displayed in Hz as factory default. If

desired, the output may be displayed in per cent (%) of full speed. (see appendix)

to ;

1 - Press the

2 - Press the

3 - Press the

key twice

key

key to .

0

Flashing

1

Flashing

2 Seconds

1

Flashing

______________________________________________________________

TECO – Westinghouse Motor Company

3

Page 4

MA7200 PLUS Inverter 1 to 2 HP Fan Quick Start Manual

_______________________________________________________________

• Press the RUN key, and check the fan direction of rotation. If the direction is not correct, press

the STOP key and wait until the fan has come to a complete STOP. Next, power down the

inverter.

Danger

• Reverse any two of the fan motor connections at the inverter ( U(T1),V(T2), or W(T3) ). Next,

following STEP 2, power-up the inverter; the motor direction should now be correct.

After the power has been turned OFF, wait at least 5 minutes until the charge

indicator extinguishes completely before touching any wiring, circuit boards or

components.

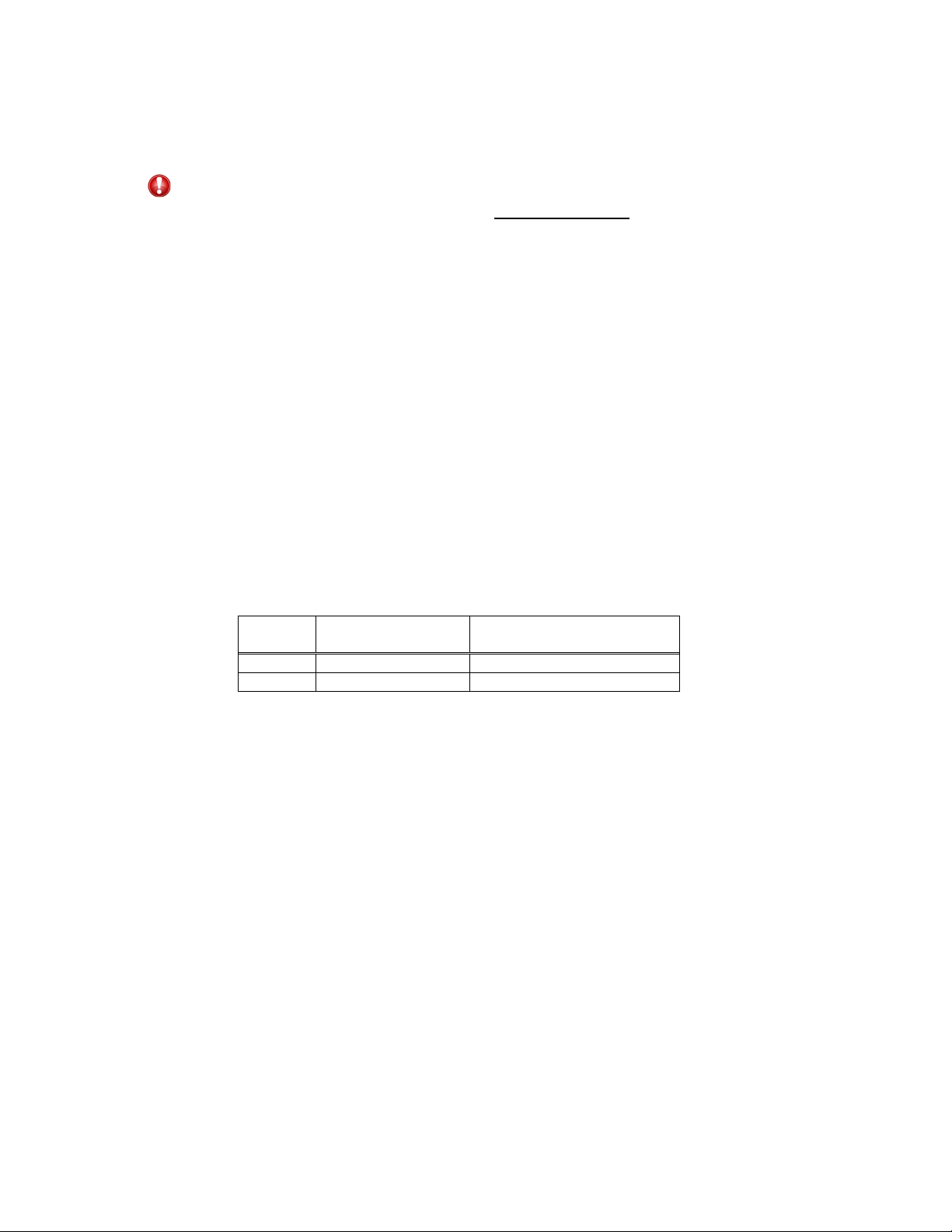

Step 5

• Before selecting the method of control, verify that the inverter is in the STOP mode.

• There are two methods of control or combinations thereof that may be selected; Keypad and

RUN / STOP Command - Can be provided from the keypad or from an external contact

(see Fig. 2a).

Speed Reference – Can be from the keypad or from an external analog signal (0 – 10 VDC or

4 – 20 mA). see Fig’s 3a,3b, and 3c.

• The RUN/STOP method of control is set by parameter Sn – 04 and the Speed Reference is set

– Select Method of Control

Analog Signal.

by parameter Sn – 05. The following table shows the values to be set when selecting.

Value

*0 Keypad Keypad

1 External Contact External Analog

Start / Stop

Sn – 04=

Speed Reference

Sn – 05=

* NOTE

The factory default for Sn – 04 and Sn – 05 is set to 0; Digital Operator (Keypad) No

further parameter changes are necessary if this is the desired method of control. If

External Contact set to Sn – 04 or External Analog set to Sn – 05 is desired then proceed

as follows.

______________________________________________________________

TECO – Westinghouse Motor Company

4

Page 5

MA7200 PLUS Inverter 1 to 2 HP Fan Quick Start Manual

_______________________________________________________________

______________________________________________________________

TECO – Westinghouse Motor Company

5

Page 6

MA7200 PLUS Inverter 1 to 2 HP Fan Quick Start Manual

_______________________________________________________________

• After the method of control has been selected, if external control wiring is required, (e.g. external

analog), power down the inverter before removing any covers or making any connections.

In the following pages are wiring examples for Start / Stop, E-Stop, Restart, and Analog

Connections.

Danger

After the power has been turned OFF, wait at least 5 minutes until the charge

indicator extinguishes completely before touching any wiring, circuit boards, or

components.

______________________________________________________________

TECO – Westinghouse Motor Company

6

Page 7

MA7200 PLUS Inverter 1 to 2 HP Fan Quick Start Manual

_______________________________________________________________

DIGITAL INPUT / OUTPUT terminal connections (1 – 2 HP)

Fig’s 2a, 2b, and 2c below show the control terminal connections for input control functions. The

connections shown are typical and the user is referred to the MA7200 Manual if additional

information is required. Fig. 2d shows an example for the use of the Fault Output Relay.

STOP

RUN

______________________________________________________________

TECO – Westinghouse Motor Company

7

Page 8

MA7200 PLUS Inverter 1 to 2 HP Fan Quick Start Manual

_______________________________________________________________

ANALOG INPUT terminal connections (1 – 2 HP)

Fig’s 3a,3b, and 3c.show the various analog input schemes that can be used to control the

output frequency and thus the speed of the fan motor when External Analog is selected by

Sn-05 in Step 5. Only one method may be used as the input source with Fig. 3a Potentiometer

Input being most common.

______________________________________________________________

TECO – Westinghouse Motor Company

8

Page 9

MA7200 PLUS Inverter 1 to 2 HP Fan Quick Start Manual

_______________________________________________________________

MA7200 PLUS BLOCK DIAGRAM

Fig. 4 is an overall basic electrical connection diagram for MA7200 PLUS inverters rated 1 to 2

HP. It is used in conjunction with the other sections of this guide to give the user the ability to

successfully start up a Fan application. More detailed information is available in the MA7200

PLUS Manual to which the user is referred if further information is required.

______________________________________________________________

TECO – Westinghouse Motor Company

9

Page 10

MA7200 PLUS Inverter 1 to 2 HP Fan Quick Start Manual

_______________________________________________________________

Appendix A-

Changing display to read output speed in percent (%) of full speed.

The display is factory defaulted to show the inverter output frequency in Hz. If desired, the

display can be changed to show the output frequency as a percentage of full speed. To do this

parameter Cn-28 must be changed from (00000) to (00001) as follows:

To set parameter Cn-28 = 1

Keypad Steps

(Display Percent)

Resulting Display

1 - Press the

2 - Press the

3 - Press the

4 - Press the key

5 - Press the

6 - Press the

7 - Press the

PRGM

DRIVE

DSPL

key until display shows

EDIT

ENTER

key

EDIT

key to save

ENTER

PRGM

DRIVE

key

key 3 times

key to return to the main display.

An – 01 -

Freq. Cmd. 1

Cn – 01 Input Voltage

Cn-28-

Operator DSPL Unit

Cn-28 = 00000

Operator DSPL Unit

Cn-28 = 00001

Operator DSPL Unit

Entry Accepted

Cn-28 = 00001

Operator DSPL Unit

Flashing

Flashing

Flashing

2 Seconds

Flashing

______________________________________________________________

TECO – Westinghouse Motor Company

10

Page 11

MA7200 PLUS Inverter 1 to 2 HP Fan Quick Start Manual

_______________________________________________________________

Appendix B Removing the LCD Digital Operator and Inverter Cover(s)

______________________________________________________________

TECO – Westinghouse Motor Company

11

Page 12

Loading...

Loading...