Page 1

HP StorageWorks Modular

Smart Array 500 System

User Guide

(formerly Smart Array Cluster Storage System)

March 2005 (Fifth Edition)

Part Number 240333-005

Page 2

© 2001-2003, 2005 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for

HP products and services are set forth in the express warranty statements accompanying such

products and services. Nothing herein should be construed as constituting an additional

warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Microsoft, Windows, and Windows NT are U.S. registered trademarks of Microsoft

Corporation.

Linux is a U.S. registered trademark of Linus Torvalds.

UNIX is a registered trademark of The Open Group.

HP StorageWorks Modular Smart Array 500 System User Guide

March 2005 (Fifth Edition)

Part Number 240333-005

Page 3

Contents

About This Guide

Audience Assumptions..................................................................................................... vii

Important Safety Information ........................................................................................... vii

Symbols on Equipment .................................................................................................... vii

Rack Stability .................................................................................................................... ix

Symbols in Text.................................................................................................................ix

Related Documents..............................................................................................................x

Getting Help ........................................................................................................................x

Technical Support .........................................................................................................x

HP Website ................................................................................................................. xi

Authorized Reseller .................................................................................................... xi

Reader’s Comments .......................................................................................................... xi

Chapter 1

Component Identification

Front Panel Components ................................................................................................. 1-2

Enclosure LEDs............................................................................................................... 1-3

Rear Panel Components .................................................................................................. 1-4

Power Supply/Blower Assembly LEDs .......................................................................... 1-5

Shared Storage Module with Integrated Environmental Monitoring Unit ...................... 1-6

Shared Storage Module Overview ............................................................................ 1-6

2-Port Shared Storage Module Components............................................................. 1-7

2-Port Shared Storage Module LEDs ....................................................................... 1-8

4-Port Shared Storage Module Components............................................................. 1-9

4-Port Shared Storage Module LEDs ..................................................................... 1-10

Controller Components ................................................................................................. 1-11

Controller Display................................................................................................... 1-11

HP StorageWorks Modular Smart Array 500 System User Guide iii

Page 4

Contents

Controller LEDs ......................................................................................................1-12

Battery-Backed Cache Module Overview...............................................................1-14

SCSI IDs ........................................................................................................................1-15

Hot-Plug SCSI Hard Drive LEDs .................................................................................. 1-16

Hot-Plug SCSI Hard Drive LED Combinations ............................................................1-17

Chapter 2

Installation and Operation

Optimum Environment ....................................................................................................2-1

Warnings..........................................................................................................................2-2

Shipping Contents............................................................................................................2-2

Shipping Container Contents.....................................................................................2-3

Rack Mounting Hardware Kit Contents.................................................................... 2-4

Converting the Rack Rails for Round-Hole Racks .......................................................... 2-5

Installing the System into the Rack .................................................................................2-7

Installing Hardware Options.......................................................................................... 2-12

System Cabling .............................................................................................................. 2-12

SCSI Cabling Guidelines.........................................................................................2-13

Power Cords ............................................................................................................2-13

System Power Up...........................................................................................................2-14

Controller Display..........................................................................................................2-15

Types of Messages ..................................................................................................2-15

Using the Interface ..................................................................................................2-16

Chapter 3

Hardware Options Installation

System Power Down........................................................................................................ 3-1

Hot-Plug SCSI Hard Drive Options.................................................................................3-2

Removing Hard Drive Blanks ...................................................................................3-2

Replacing Hot-Plug SCSI Hard Drives ..................................................................... 3-3

Universal Hot-Plug Tape Drive Option ...........................................................................3-5

4-Port Shared Storage Module Option............................................................................. 3-7

HP StorageWorks Modular Smart Array 500 Controller Option.....................................3-9

Cache Upgrade Option...................................................................................................3-11

DC Power Supply Option ..............................................................................................3-13

iv HP StorageWorks Modular Smart Array 500 System User Guide

Page 5

Chapter 4

Configuration and Utilities

Server Utilities................................................................................................................. 4-1

Recovery Server Option .................................................................................................. 4-2

ROM Functions and Utilities........................................................................................... 4-3

Recovery ROM ......................................................................................................... 4-3

Firmware Upgrades................................................................................................... 4-3

Controller Firmware Auto Cloning........................................................................... 4-4

Selective Storage Presentation ........................................................................................ 4-5

SSP Hardware Configurations .................................................................................. 4-5

Firmware Requirements............................................................................................ 4-5

Enabling SSP ............................................................................................................ 4-6

Array Configuration Utility............................................................................................. 4-6

Moving Array Controller Drives and Arrays............................................................ 4-6

Expanding and Extending Capacity.......................................................................... 4-8

Array Diagnostics Utility ................................................................................................ 4-9

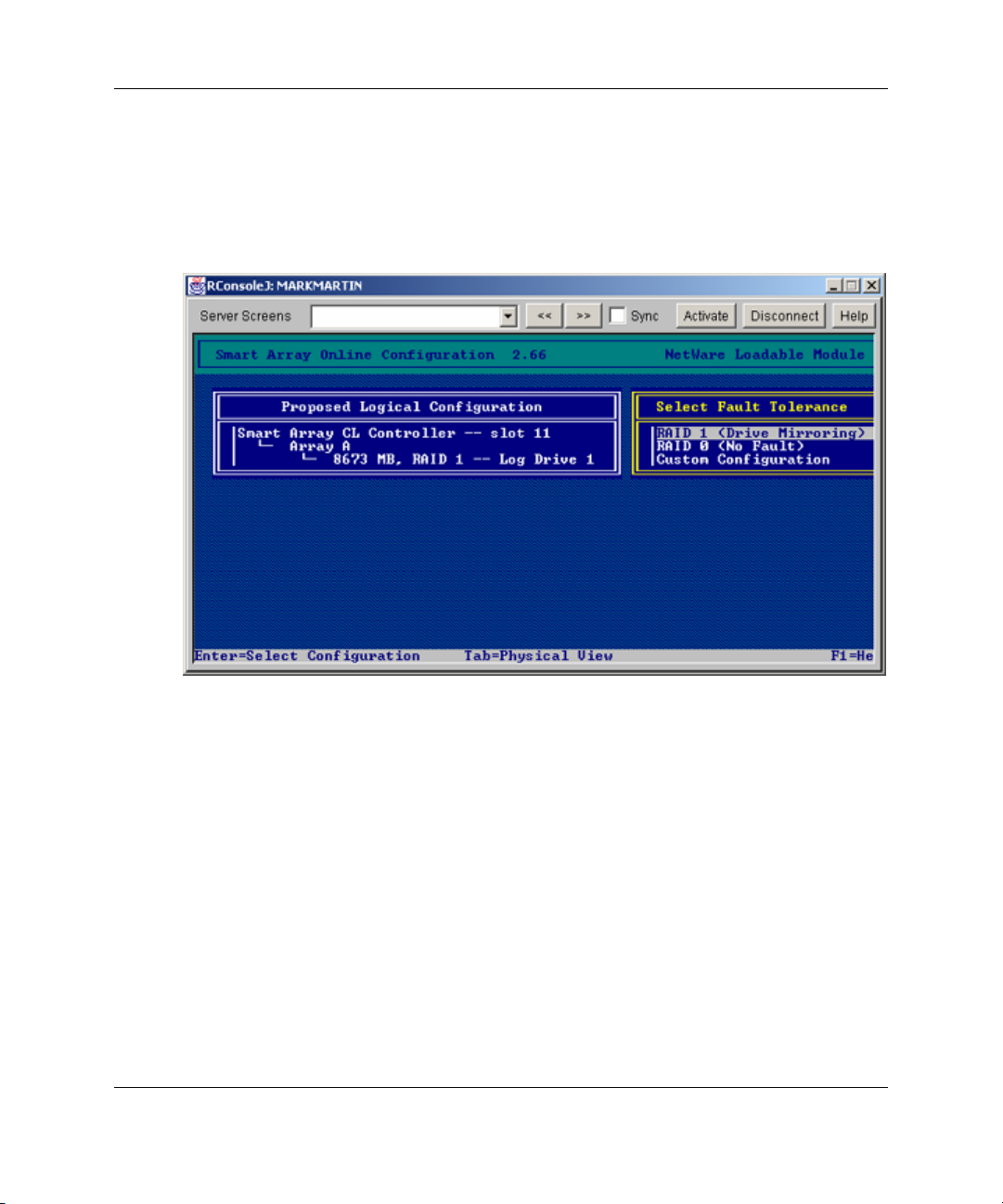

NetWare Online Array Configuration Utility (CPQONLIN).......................................... 4-9

Auto-configuration.................................................................................................. 4-10

Custom Configuration............................................................................................. 4-11

Optimizing Array Controller Performance ............................................................. 4-17

Contents

Chapter 5

Cluster Installation and Configuration

Cluster Hardware Installation.......................................................................................... 5-1

Appendix A

Regulatory Compliance Notices

Regulatory Compliance Identification Numbers............................................................ A-1

Federal Communications Commission Notice............................................................... A-1

Class A Equipment .................................................................................................. A-2

Class B Equipment................................................................................................... A-2

Declaration of Conformity for Products Marked with the FCC Logo,

United States Only.......................................................................................................... A-3

Cables ............................................................................................................................. A-3

Modifications.................................................................................................................. A-4

Canadian Notice (Avis Canadien) .................................................................................. A-4

European Union Notice .................................................................................................. A-4

Japanese Notice .............................................................................................................. A-5

HP StorageWorks Modular Smart Array 500 System User Guide v

Page 6

Contents

BSMI Notice ................................................................................................................... A-6

Laser Compliance ........................................................................................................... A-6

Battery Replacement Notice ...........................................................................................A-7

Taiwan battery recycling notice......................................................................................A-8

Power Cord Statement for Japan..................................................................................... A-8

Appendix B

Electrostatic Discharge

Grounding Methods ........................................................................................................ B-2

Appendix C

Display Messages

Appendix D

Troubleshooting

When the System Does Not Start.................................................................................... D-2

Diagnostic Steps .............................................................................................................D-3

Recovering from Hard Drive Failure.............................................................................. D-6

Hard Drive Failure.................................................................................................... D-6

Replacing a Drive................................................................................................... D-10

Drive Failure in NetWare ....................................................................................... D-11

Appendix E

Specifications

Index

vi HP StorageWorks Modular Smart Array 500 System User Guide

Page 7

This guide provides step-by-step instructions for installation, and reference

information for operation, troubleshooting, and future upgrades.

Audience Assumptions

This guide is for the person who installs, administers, and troubleshoots storage

systems. HP assumes you are qualified in the servicing of computer equipment and

trained in recognizing hazards in products with hazardous energy levels.

Important Safety Information

Before installing this product, read the Important Safety Information document

included with the system.

About This Guide

Symbols on Equipment

The following symbols may be placed on equipment to indicate the presence of

potentially hazardous conditions:

WARNING: This symbol, in conjunction with any of the following symbols,

indicates the presence of a potential hazard. The potential for injury exists if

warnings are not observed. Consult the documentation for specific details.

HP StorageWorks Modular Smart Array 500 System User Guide vii

Page 8

About This Guide

Weight in kg

Weight in lb

This symbol indicates the presence of hazardous energy circuits or electric

shock hazards. Refer all servicing to qualified personnel.

WARNING: To reduce the risk of injury from electric shock hazards, do not

open this enclosure. Refer all maintenance, upgrades, and servicing to

qualified personnel.

This symbol indicates the presence of electric shock hazards. The area

contains no user or field serviceable parts. Do not open for any reason.

WARNING: To reduce the risk of injury from electric shock hazards, do not

open this enclosure.

This symbol on an RJ-45 receptacle indicates a network interface connection.

WARNING: To reduce the risk of electric shock, fire, or damage to the

equipment, do not plug telephone or telecommunications connectors into this

receptacle.

This symbol indicates the presence of a hot surface or hot component. If this

surface is contacted, the potential for injury exists.

WARNING: To reduce the risk of injury from a hot component, allow the

surface to cool before touching.

These symbols, on power supplies or systems, indicate that the

equipment is supplied by multiple sources of power.

WARNING: To reduce the risk of injury from electric shock,

remove all power cords to completely disconnect power from the

system.

This symbol indicates that the component exceeds the recommended

weight for one individual to handle safely.

WARNING: To reduce the risk of personal injury or damage to the

equipment, observe local occupational health and safety requirements

and guidelines for manual material handling.

viii HP StorageWorks Modular Smart Array 500 System User Guide

Page 9

Rack Stability

WARNING: To reduce the risk of personal injury or damage to the equipment,

be sure that:

• The leveling jacks are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time. A rack may become unstable if

more than one component is extended for any reason.

Symbols in Text

These symbols may be found in the text of this guide. They have the following

meanings.

WARNING: Text set off in this manner indicates that failure to follow directions

in the warning could result in bodily harm or loss of life.

About This Guide

CAUTION: Text set off in this manner indicates that failure to follow directions could

result in damage to equipment or loss of information.

IMPORTANT: Text set off in this manner presents essential information to explain a concept

or complete a task.

NOTE: Text set off in this manner presents additional information to emphasize or supplement

important points of the main text.

HP StorageWorks Modular Smart Array 500 System User Guide ix

Page 10

About This Guide

Related Documents

For additional information on the topics covered in this guide, refer to the following

documentation:

• HP StorageWorks Modular Smart Array 500 System Hardware Configuration

and Installation Poster

• HP StorageWorks Modular Smart Array 500 Controller Installation Instructions

• HP DC Power Supply Option Installation Instructions

• HP 4-Port Shared Storage Module Option Installation Instructions

• HP M-Series Rack Rail Option Installation Instructions

• HP Smart Array Multipath Software User Guide

• HP StorageWorks Modular Smart Array 500 System Maintenance and Service

Guide

• Documentation CD

Getting Help

If you have a problem and have exhausted the information in this guide, you can get

further information and other help in the following locations.

Technical Support

In North America, call the HP Technical Support Phone Center at 1-800-652-6672.

This service is available 24 hours a day, 7 days a week. For continuous quality

improvement, calls may be recorded or monitored. Outside North America, call the

nearest HP Technical Support Phone Center. Telephone numbers for worldwide

Technical Support Centers are listed on the HP website,

Be sure to have the following information available before you call HP:

• Technical support registration number (if applicable)

• Product serial number

x HP StorageWorks Modular Smart Array 500 System User Guide

www.hp.com.

Page 11

• Product model name and number

• Applicable error messages

• Add-on boards or hardware

• Third-party hardware or software

• Operating system type and revision level

HP Website

The HP website has information on this product as well as the latest drivers and flash

ROM images. You can access the HP website at

Authorized Reseller

For the name of the nearest authorized reseller:

• In the United States, call 1-800-345-1518.

• In Canada, call 1-800-263-5868.

About This Guide

www.hp.com.

• Elsewhere, see the HP website for locations and telephone numbers.

Reader’s Comments

HP welcomes your comments on this guide. Please send your comments and

suggestions by e-mail to

HP StorageWorks Modular Smart Array 500 System User Guide xi

ServerDocumentation@hp.com.

Page 12

1

Component Identification

The HP StorageWorks Modular Smart Array 500 system is a rack-mountable 4U

SCSI storage system with redundant HP StorageWorks MSA500 controllers and

power supply/blower assemblies. Fault-tolerance support includes RAID 0, 1, 1+0, 5,

and Advanced Data Guarding (ADG), all with battery-backed cache. The Ultra3

SCSI hard drive interface supports Universal Hot-Plug tape drives with AIT and

DDS-4 technology and supports up to 14 (1-inch) universal hot-plug SCSI hard

drives.

HP StorageWorks Modular Smart Array 500 System User Guide 1-1

Page 13

Component Identification

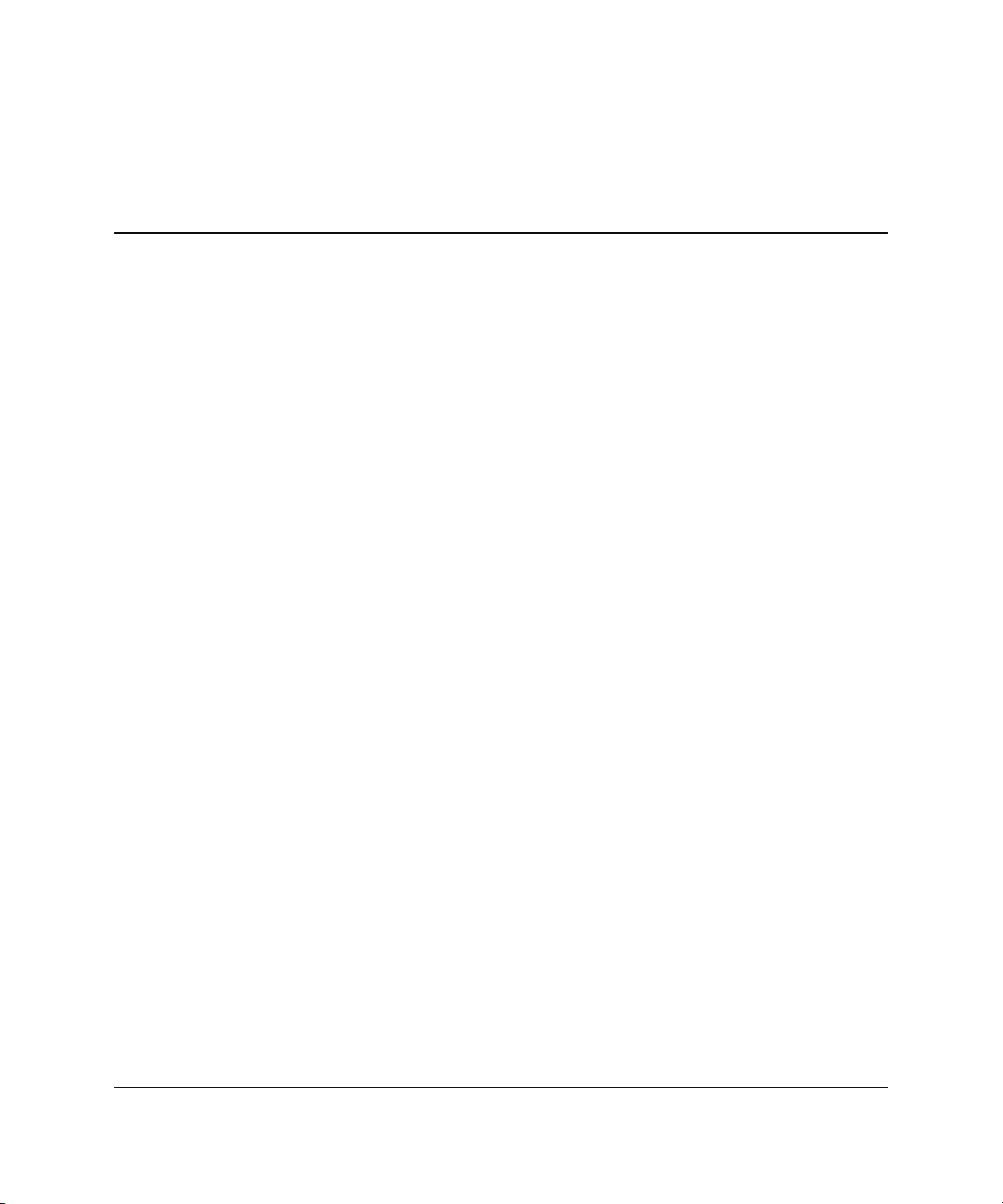

Front Panel Components

1

2

3

4

7

6

Table 1-1: Front Panel Components

Item Description

1 Bezel blank (bay for optional redundant controller)

2 Service port (for HP service technicians only)

3 Hot-plug MSA500 controller

4 Controller display

5 Power On/Standby button

6 Enclosure LEDs (Refer to Table 1-2)

7 Hot-plug SCSI hard drive bays with blanks

5

1-2 HP StorageWorks Modular Smart Array 500 System User Guide

Page 14

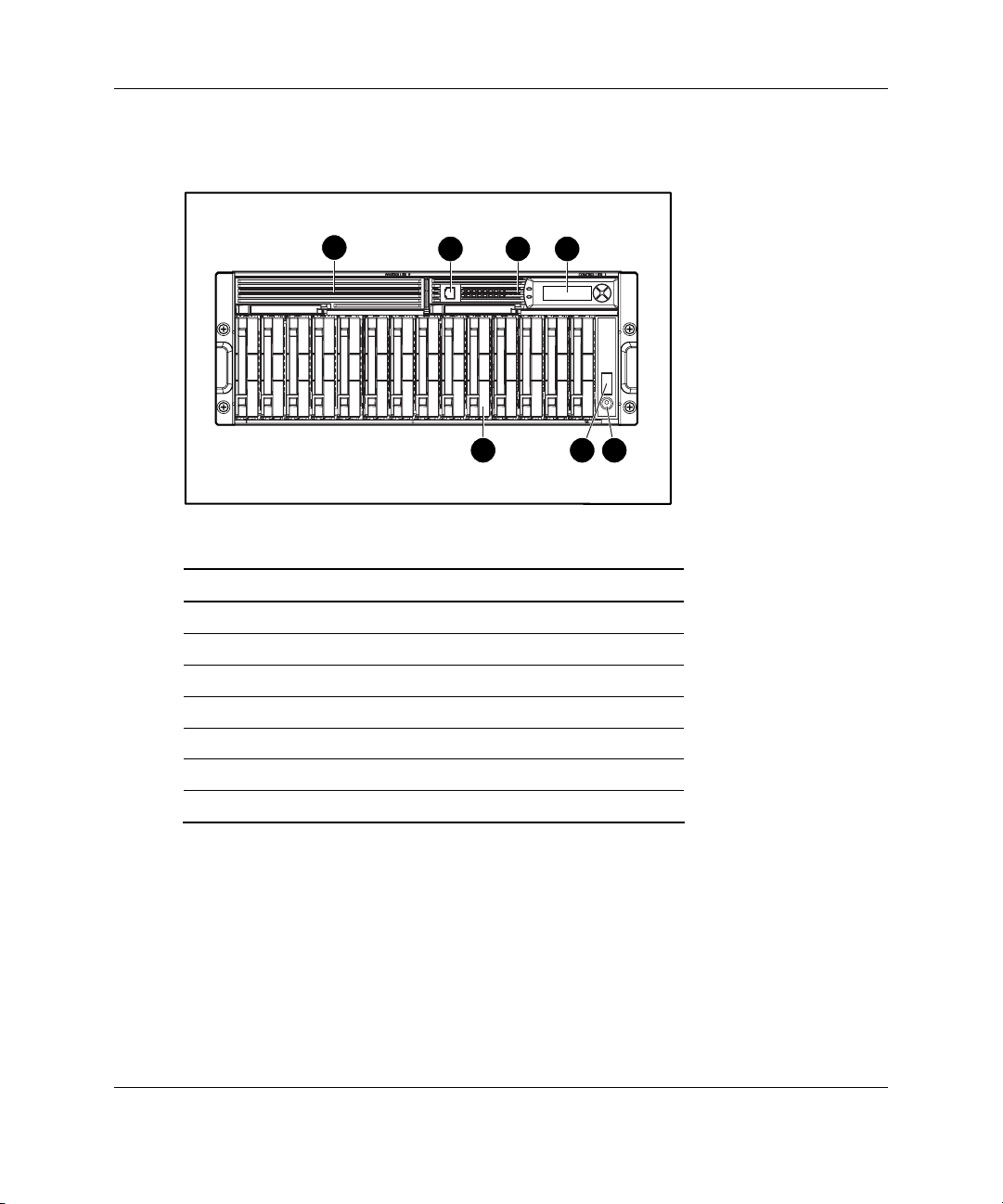

Enclosure LEDs

Component Identification

1

2

3

Table 1-2: Enclosure LEDs

Item LED Description Status

1 Environmental

Monitoring Unit

(EMU) heartbeat

2 System power Green = System power is On.

3 Fault Amber = Fault is detected in a

Green flashing = Shared storage module

is operating normally.

Green/Off = Shared storage module is

not operating normally.

Off = System is in standby mode or

power is removed from the system.

subsystem.

Off = No faults are detected.

IMPORTANT: The Power On/Standby button does not remove all power from the system. The

Standby mode removes power from most of the electronics and the drives, but portions of the

power supply and some internal circuitry remain active. To remove power completely,

disconnect all power cords from the equipment.

HP StorageWorks Modular Smart Array 500 System User Guide 1-3

Page 15

Component Identification

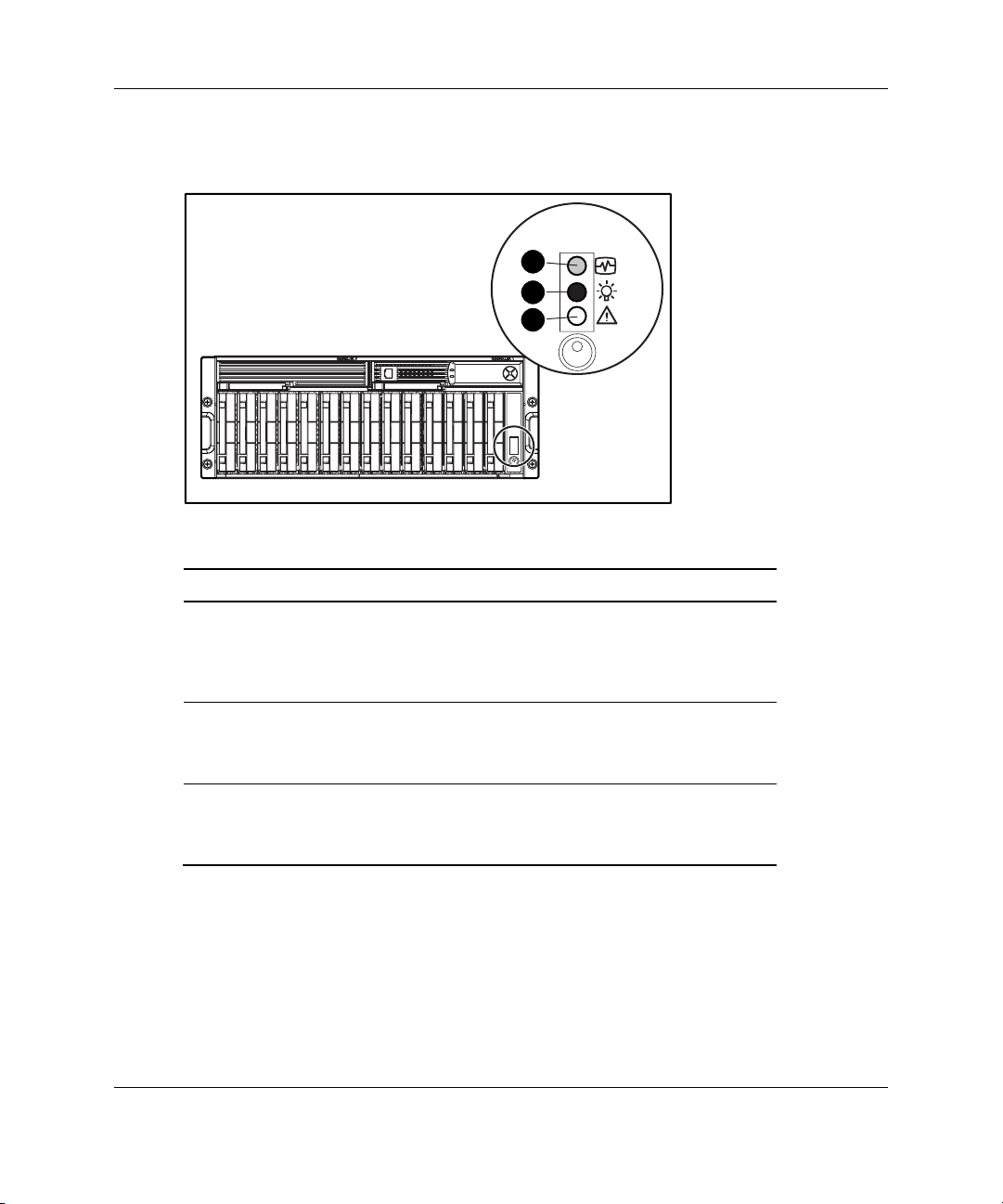

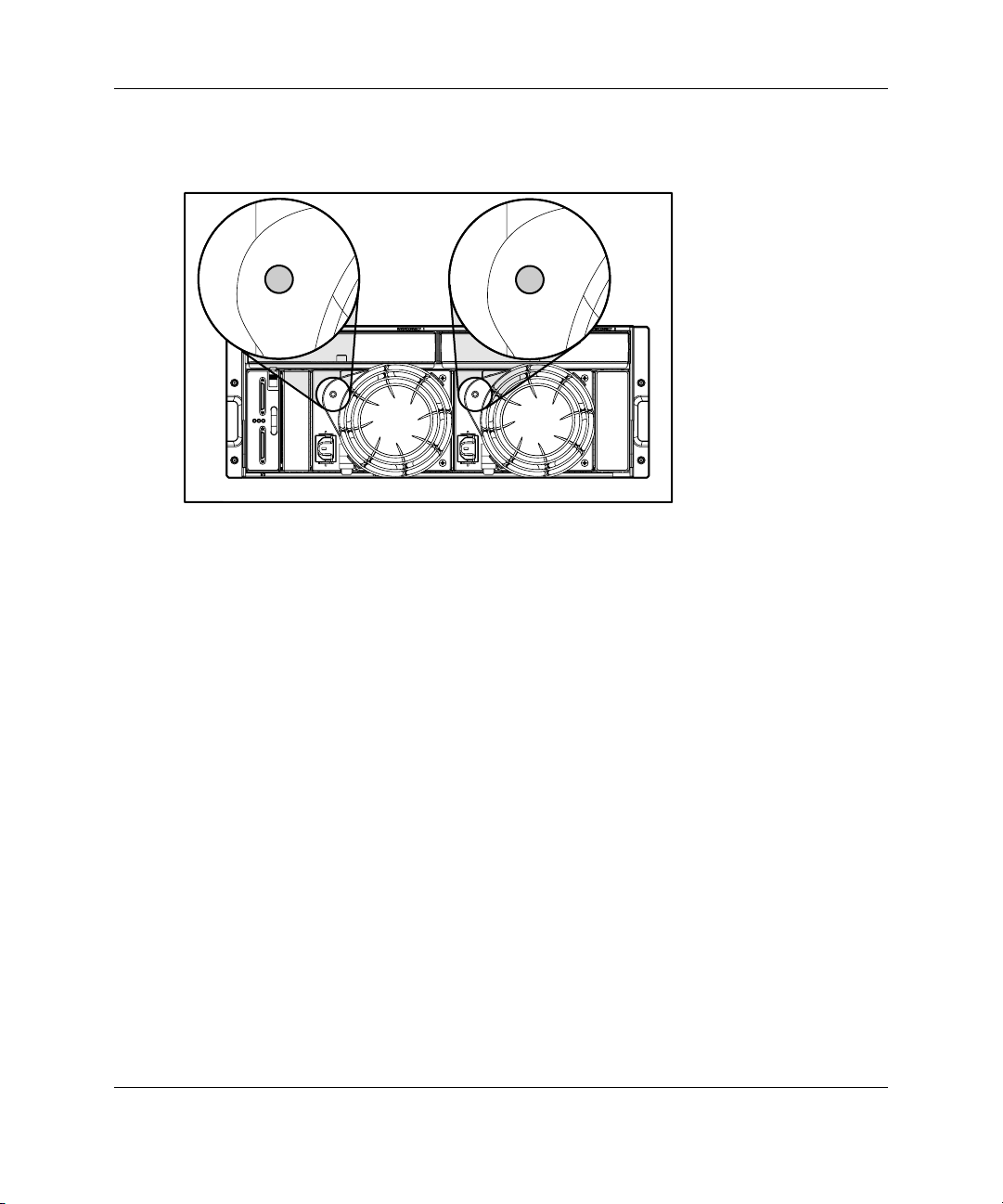

Rear Panel Components

1 2

4 3

Table 1-3: Rear Panel Components

Item Description

1 Interconnect blanks (required for proper airflow)

2 Power supply/blower assemblies

3 AC power connectors

4 2-Port Shared Storage Module

1-4 HP StorageWorks Modular Smart Array 500 System User Guide

Page 16

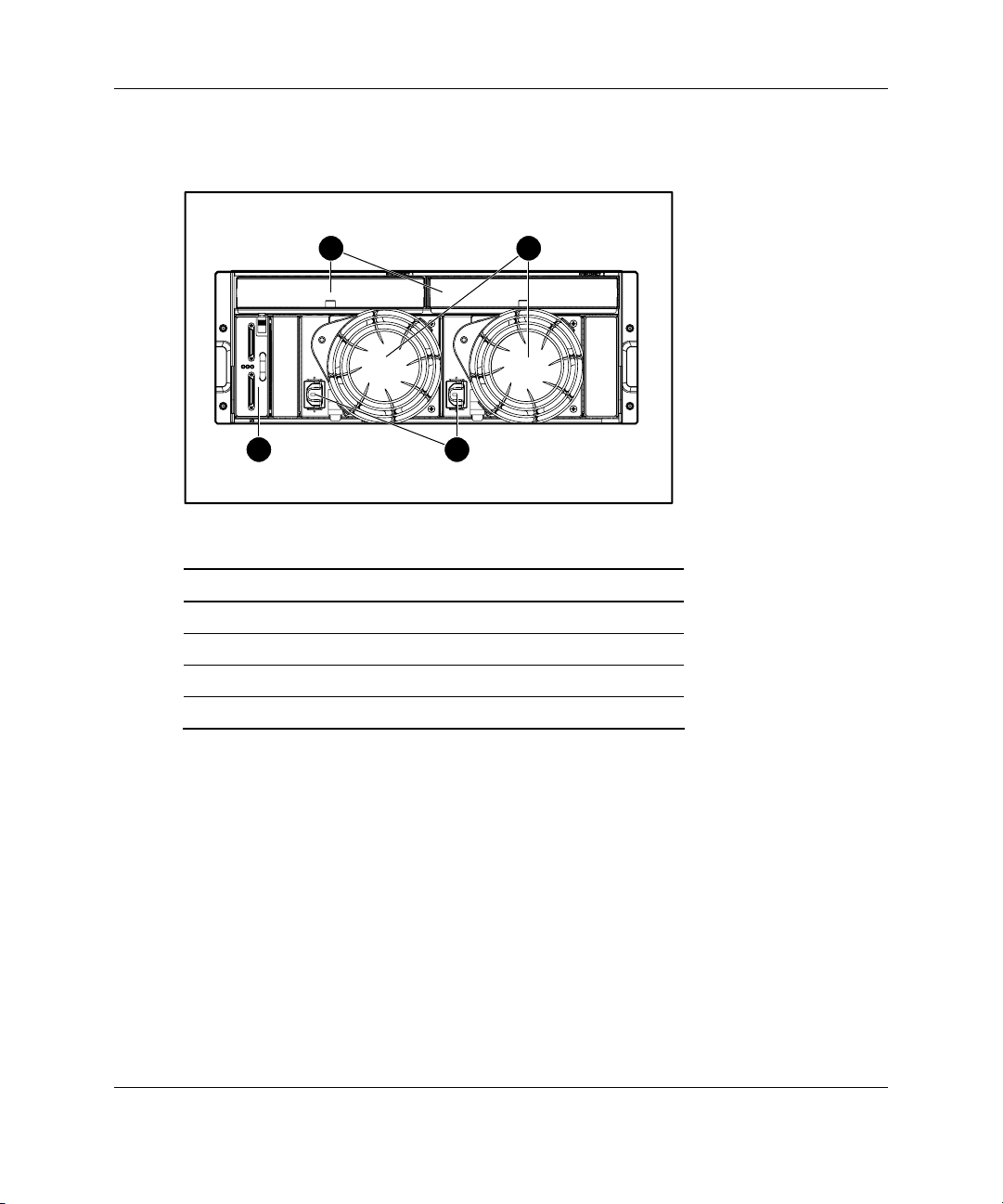

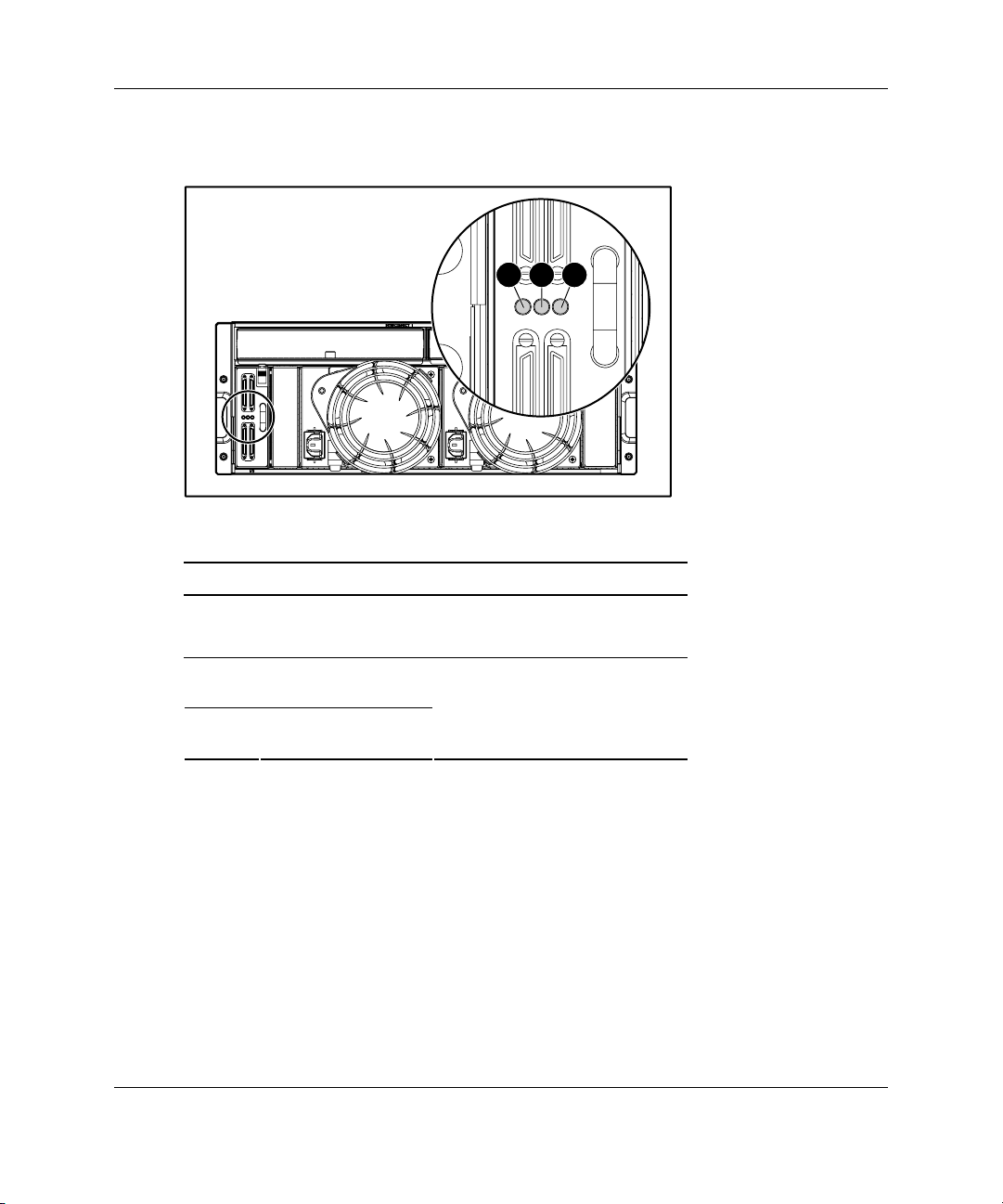

Power Supply/Blower Assembly LEDs

The power supply/blower assembly LEDs have the following functions:

• Green—The power supply is receiving power, and the blower is operating

normally.

Component Identification

• Off—No power is present; the power supply or the blower has failed.

HP StorageWorks Modular Smart Array 500 System User Guide 1-5

Page 17

Component Identification

Shared Storage Module with Integrated Environmental Monitoring Unit

The MSA500 system supports two-node clustering and up to four-node direct

attached storage (DAS) with Ultra3 SCSI I/O hardware. The system ships standard

with the 2-Port Shared Storage Module. A 4-Port Shared Storage Module is available

as an option.

Shared Storage Module Overview

Shared Storage Module functions include:

• Provides the interconnect function to server nodes

• Monitors the enclosure operation for:

— Temperature

— Power supplies

— Blowers

— Drive presence

• Detects and reports component changes in the enclosure (identifies hot-plug

addition and removal)

• Controls drive and enclosure LEDs

1-6 HP StorageWorks Modular Smart Array 500 System User Guide

Page 18

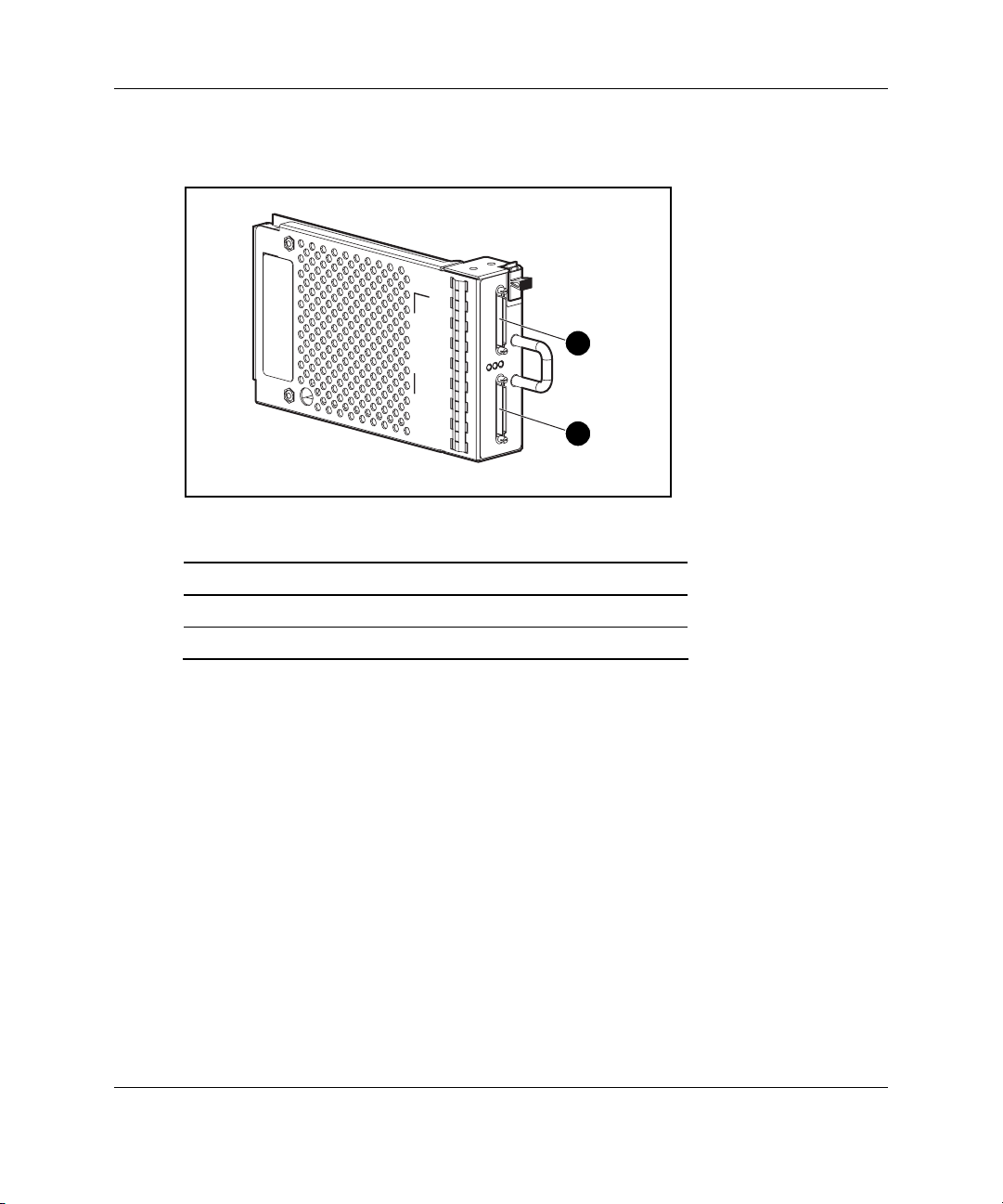

2-Port Shared Storage Module Components

1

2

Component Identification

Table 1-4: 2-Port Shared Storage Module Components

Item Description Bus

1 SCSI port connector A

2 SCSI port connector B

HP StorageWorks Modular Smart Array 500 System User Guide 1-7

Page 19

Component Identification

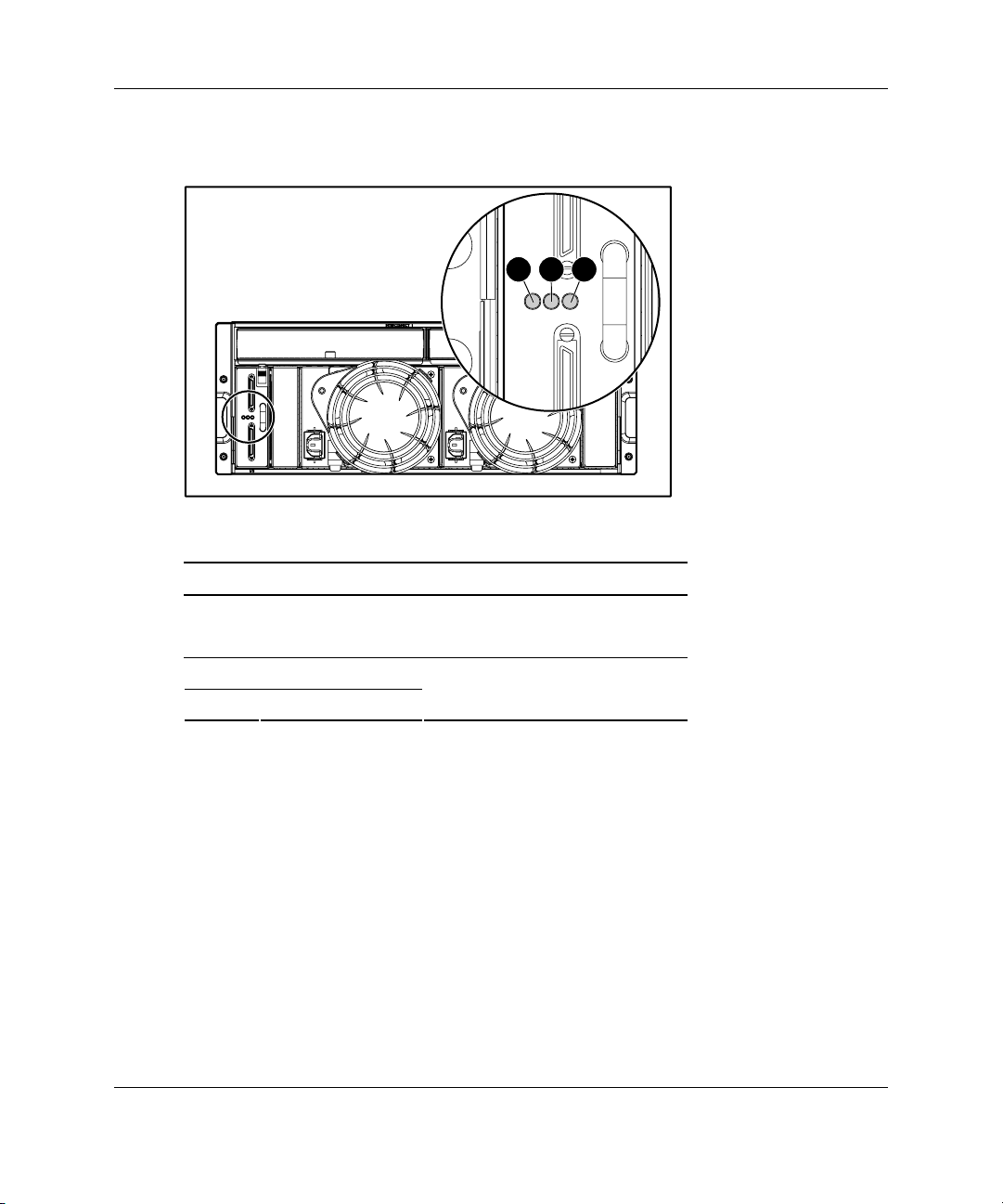

2-Port Shared Storage Module LEDs

1

2

3

Table 1-5: 2-Port Shared Storage Module LEDs

Item LED Description Status

1 Power Green = Power on

Off = Power off

2 SCSI host port A

3 SCSI host port B

Flashing green = On/Activity

Off = Off

1-8 HP StorageWorks Modular Smart Array 500 System User Guide

Page 20

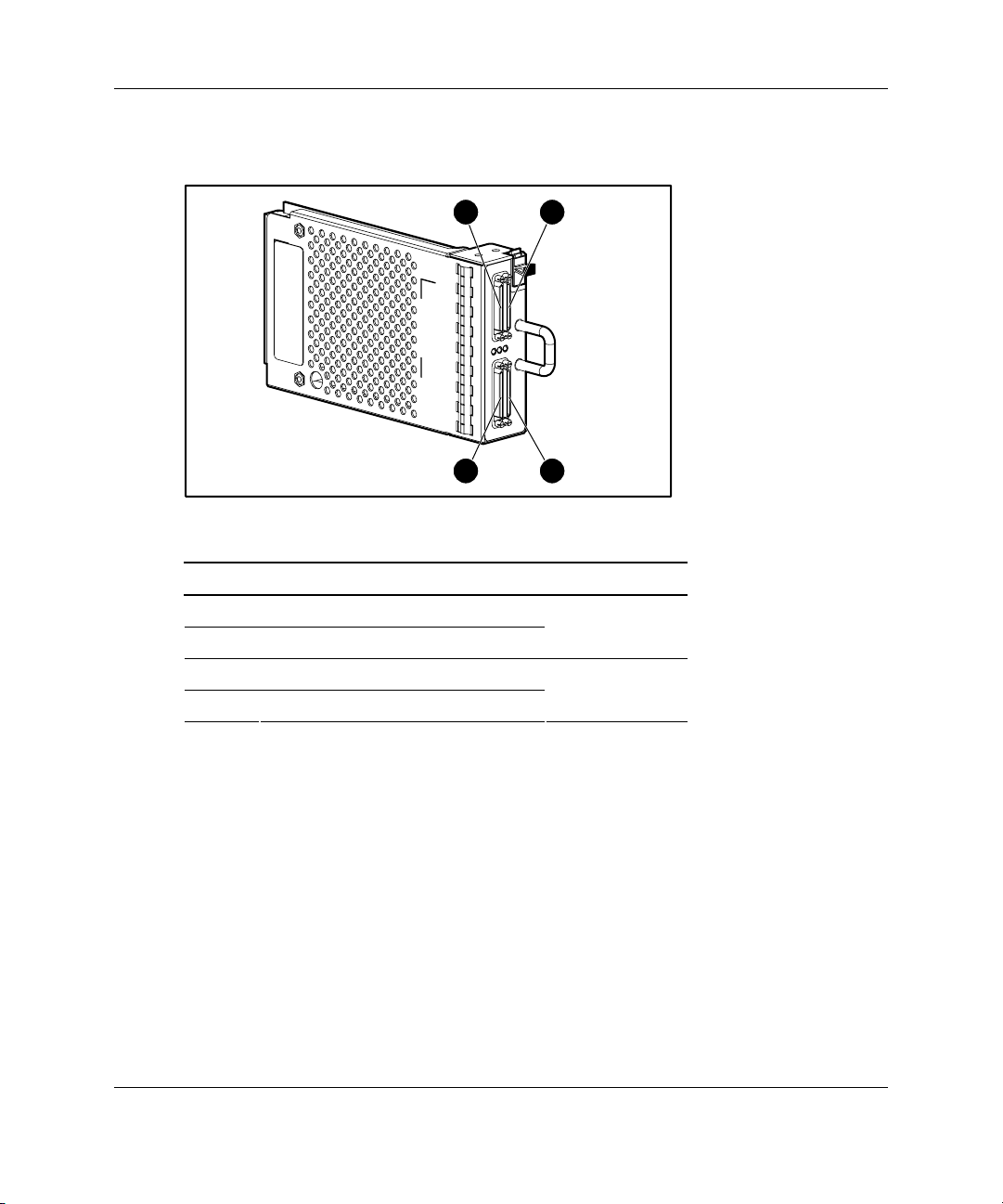

4-Port Shared Storage Module Components

Component Identification

1

3

2

4

Table 1-6: 4-Port Shared Storage Module Components

Item Description Bus

1 SCSI port connector A1

2 SCSI port connector A2

3 SCSI port connector B1

4 SCSI port connector B2

A

B

HP StorageWorks Modular Smart Array 500 System User Guide 1-9

Page 21

Component Identification

4-Port Shared Storage Module LEDs

1

2

3

Table 1-7: 4-Port Shared Storage Module LEDs

Item LED Description Status

1 Power Green = Power on

Off = Power off

2 SCSI host port A

connectors 1 and 2

3 SCSI host port B

connectors 1 and 2

Flashing green = On/Activity

Off = Off

1-10 HP StorageWorks Modular Smart Array 500 System User Guide

Page 22

Controller Components

Controller Display

Each MSA500 controller has an LCD display for informational and error messages.

Component Identification

1

Table 1-8: Controller Display

Item Description

1 Display

2 Left button

3 Up button

4 Right button

5 Down button

2

3

4

5

HP StorageWorks Modular Smart Array 500 System User Guide 1-11

Page 23

Component Identification

Controller LEDs

157146135124113102918 17

0 16

Table 1-9: Controller LEDs

Item LED Descriptions Status

0-2 Busy status Green = Controller is idle.

Off = Controller is operating at full

capacity.

3-5 No function —

6 Host port A

notification

7 Host port B

notification

8 Idle heartbeat Controller is idle and functioning.

9 Active/Standby Green = Controller is active.

10 DMA activity Green = DMA transfers are active.

Green = Notify On Event command active

Off = No Notify On Event command active

Green = Notify On Event command active

Off = No Notify On Event command active

Off = Controller is in standby.

Off = No DMA transfers.

continued

1-12 HP StorageWorks Modular Smart Array 500 System User Guide

Page 24

Table 1-9: Controller LEDs continued

Item LED Descriptions Status

11 Logical I/O activity Green = Currently processing logical

requests from the host adapter.

Off = No processing of logical requests

12 SCSI bus 0 activity

13 SCSI bus 1 activity

14 Cache activity Green = Cache activity

15 Drive failure Green = An array-configured drive has

16 Active redundancy Green = Controllers are operating with

17 Fault Amber = Error message received by

Green = Outstanding requests on the

SCSI bus

Off = No outstanding requests

Off = No cache activity

Flashing green = Cache transfer pending

failed.

Off = No drive failures

redundancy.

Off = No redundancy

controller display.

Off = No error message received or no

error message currently displayed.

Component Identification

HP StorageWorks Modular Smart Array 500 System User Guide 1-13

Page 25

Component Identification

Battery-Backed Cache Module Overview

The battery-backed cache module is a high-performance, 100-MHz SDRAM DIMM

read/write cache that increases performance in database and fault-tolerant

configurations.

Caching Functions

To enable faster data access from disk storage, the cache module performs two types

of caching:

• Posted-write caching—the controller writes user data in the cache memory on the

module rather than directly to the drives. Later, when the system is idle, the

controller writes the data to the drive array.

• Read-ahead caching—the controller detects sequential array access, reads ahead

into the next sequence of data, and stores the data in the read-ahead cache. Then,

if the next read access is for the cached data, the controller immediately loads the

data into system memory, avoiding the latency of a disk access.

Batteries

The cache module has two rechargeable and replaceable NiMH battery packs that

protect cached data during equipment failure or power outage:

• Up to 3 days protection for 256-MB cache DIMMs

• Up to for 4 days protection for 128-MB cache DIMMs

Under normal operating conditions, the battery packs should operate for 3 years

before replacement is necessary. The batteries recharge continuously when the

system is powered on.

NOTE: Temperature, age, and cache size may affect battery life.

The batteries also preserve data when you remove the cache module from the

controller. After you reinstall the cache module, and power is restored, the

initialization process writes the preserved data to the array. This feature is important

for data stored in the posted-write cache, but not yet written to an array.

1-14 HP StorageWorks Modular Smart Array 500 System User Guide

Page 26

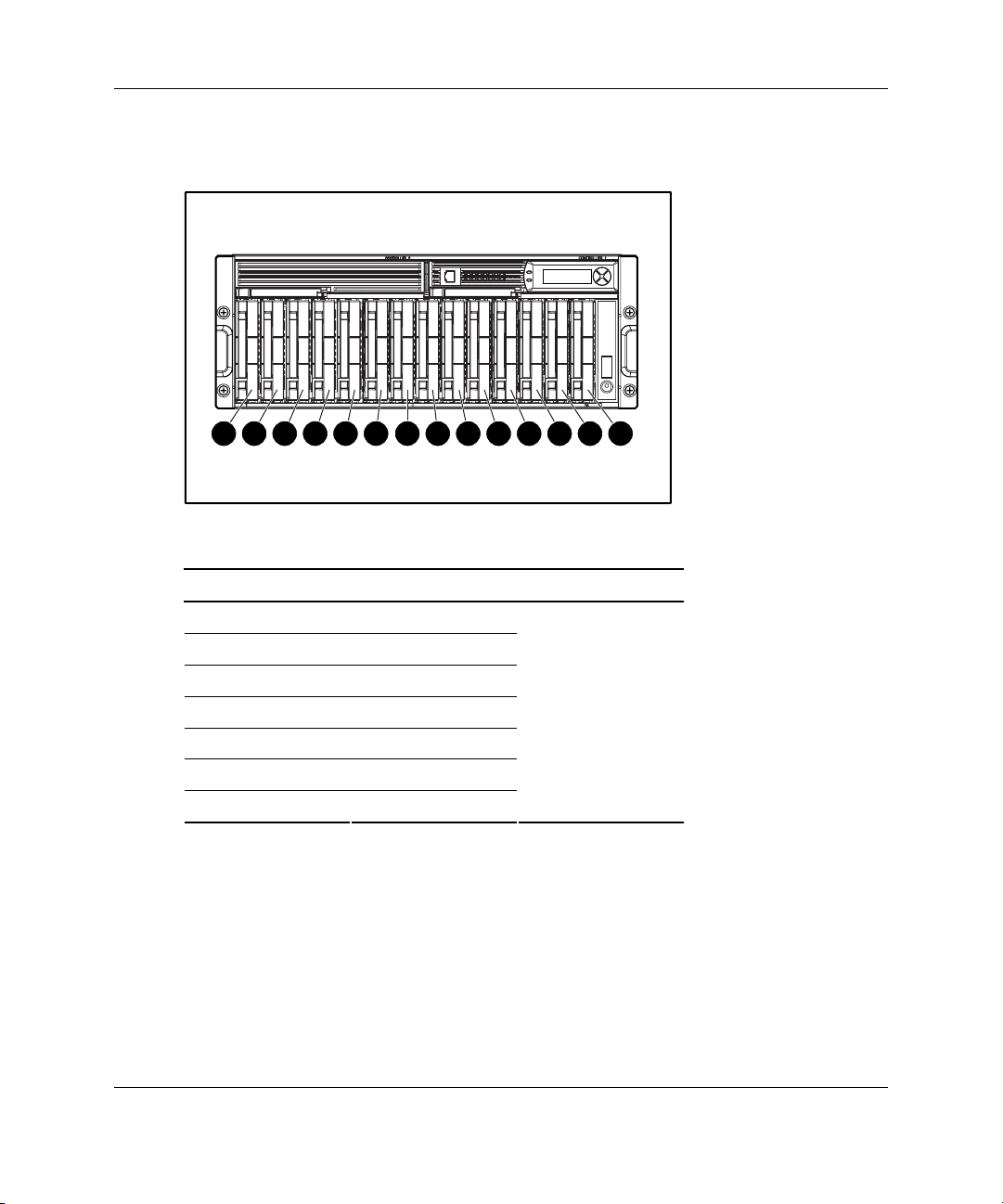

SCSI IDs

Component Identification

1

8

9

10

11

12

7

6

5

4

3

2

Table 1-10: SCSI IDs

Bay SCSI ID Bus Port

1 0

2 1

3 2

4 3

5 4

6 5

7 8

0

13

14

continued

HP StorageWorks Modular Smart Array 500 System User Guide 1-15

Page 27

Component Identification

Table 1-10: SCSI IDs continued

Bay SCSI ID Bus Port

8 0

9 1

10 2

11 3

12 4

13 5

14 8

1

Hot-Plug SCSI Hard Drive LEDs

3

2

1

Table 1-11: Hot-Plug SCSI Hard Drive LEDs

Item LED Description

1 Activity

2 Online

3 Fault

1-16 HP StorageWorks Modular Smart Array 500 System User Guide

Page 28

Component Identification

Hot-Plug SCSI Hard Drive LED Combinations

Table 1-12: Hot-Plug SCSI Hard Drive LED Combinations

Activity

LED

On Flashing Off

Off Off On OK to replace the drive online.

Off, on, or

flashing

Off, on, or

flashing

Online

LED

On Off

On or Off Flashing A predictive failure alert has been received for this drive.

Fault

LED

Status

Do not remove the drive. Removing a drive during this

process can cause data loss in non-fault-tolerant

configurations.

• The drive is a replacement drive and is being rebuilt or

• If all online LEDs in a drive array are flashing, an

expansion is occurring.

The drive has failed and has been placed offline.

Do not remove the drive. Removing a drive during this

process can cause data loss in non-fault-tolerant

configurations.

The drive is online and configured as part of an array.

Replace the drive as soon as possible.

HP StorageWorks Modular Smart Array 500 System User Guide 1-17

Page 29

To install an MSA500 system:

1. Unpack the system. Refer to “Shipping Container Contents” in this chapter.

2. Install the system in a rack. Refer to “Installing the System into the Rack” in

this chapter.

3. Install hardware options, if applicable. Refer to procedures in Chapter 3,

“Hardware Options Installation.”

4. Connect SCSI cables and power cords. Refer to “System Cabling” in this chapter.

5. Power up the system. Refer to “System Power Up” in this chapter.

6. Configure arrays. Refer to Chapter 4, “Configuration and Utilities.”

Optimum Environment

2

Installation and Operation

When installing the MSA500 system in a rack, select a location that meets the

environmental standards described in Appendix E, “Specifications.”

For adequate airflow, use appropriate high-airflow inserts in rack cabinet doors and

observe industry standard practices for adequate spacing between racks or rows

of racks.

HP StorageWorks Modular Smart Array 500 System User Guide 2-1

Page 30

Installation and Operation

Warnings

WARNING: To reduce the risk of personal injury or damage to the equipment,

be sure that:

• The leveling jacks are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time. A rack may become unstable if

more than one component is extended for any reason.

WARNING: To reduce the risk of personal injury or equipment damage when

unloading a rack:

• At least two people are needed to safely unload the rack from the pallet. An

empty 42U rack can weigh as much as 115 kg (253 lb), can stand more than

2.1 m (7 ft) tall, and may become unstable when being moved on its casters.

• Never stand in front of the rack when it is rolling down the ramp from the

pallet. Always handle the rack from both sides.

Shipping Contents

Unpack the system shipping carton and locate the materials and documentation

necessary for installing the system. All the rack mounting hardware necessary for

installing the system into the rack is included with the rack or the system.

2-2 HP StorageWorks Modular Smart Array 500 System User Guide

Page 31

Shipping Container Contents

1

Installation and Operation

2

3

4

5

Table 2-1: Shipping Container Contents

Item Description Quantity

1 MSA500 system 1

2 Power cords 2

3 Ethernet crossover cable 1

4 SCSI VHDCI cables 2

5 4U rack template 1

6 Rack mounting hardware kit* 1

7 Documentation set* 1

*Not shown

In addition to these supplied items, you may need:

• Application software diskettes

• Options to be installed

HP StorageWorks Modular Smart Array 500 System User Guide 2-3

Page 32

Installation and Operation

Rack Mounting Hardware Kit Contents

The rack mounting hardware kit provides the required components for quick

deployment in Compaq branded, HP branded, and most square- and round-hole

third-party racks. The adjustable feature of the rack rails enables installation in racks

with depths of 69.90 to 73.81 cm (27.52 to 29.06 in).

If you are installing the MSA500 system in an M-Series rack, contact an authorized

reseller to obtain an M-Series Rack Rail option kit.

Table 2-2: Rack Mounting Hardware Kit Contents

Item Description Quantity

1 Rack rail (left) 1

2 Rack rail (right) 1

3 Pins for round-hole rack conversion 8

In addition to these supplied items, you may need a No. 2 Phillips screwdriver.

2-4 HP StorageWorks Modular Smart Array 500 System User Guide

Page 33

Installation and Operation

Converting the Rack Rails for Round-Hole Racks

The rack rails ship configured for square-hole racks. To convert the rack rails for use

in a round-hole rack:

1. Locate the bag of miscellaneous hardware that ships with the rack rails.

2. Locate the eight round-hole pins.

3. Use a No. 2 Phillips screwdriver to remove the standard pins from the front and

back ends of the rail.

HP StorageWorks Modular Smart Array 500 System User Guide 2-5

Page 34

Installation and Operation

4. Install four round-hole pins into the rail.

5. Repeat steps 3 and 4 for the second rail.

2-6 HP StorageWorks Modular Smart Array 500 System User Guide

Page 35

Installing the System into the Rack

To install the system in the rack:

1. Use the instructions provided on the rack template to mark the rack for rail

locations.

WARNING: The storage system weight, as assembled for shipping,

22.7 kg

50 lb

exceeds 22.7 kg (50 lb). Install the storage system in the lowest

available position in the rack.

Installation and Operation

HP StorageWorks Modular Smart Array 500 System User Guide 2-7

Page 36

Installation and Operation

IMPORTANT: Unless you are converting the rails for use in round-hole racks, do not

remove the pins from the ends of the rack rails. These load-bearing pins are designed to

fit through the holes without being removed.

NOTE: Identify the left (L) and right (R) rack rails by markings stamped into the sheet

metal.

2. Insert the front end of the left rack rail into the inside front of the rack. Be sure

that the pins extend through the holes marked during the rack template

procedure.

IMPORTANT: Be sure that the scissor-type locking latch engages when the end of the

rail seats into the rack uprights.

2-8 HP StorageWorks Modular Smart Array 500 System User Guide

Page 37

Installation and Operation

3. Slide the back end of the left rack rail into the inside rear of the rack. Be sure that

the pins extend through the holes marked during the rack template procedure.

IMPORTANT: Be sure that the scissor-type locking latch engages when the end of the

rail seats into the rack uprights.

4. Repeat steps 2 and 3 for the right rack rail.

HP StorageWorks Modular Smart Array 500 System User Guide 2-9

Page 38

Installation and Operation

5. Align the system with the rails and slide it into the rack.

22.7 kg

50 lb

WARNING: Always use at least two people to lift a storage system into the

rack. If the system is being loaded into the rack above chest level, a third

person MUST assist with aligning the system with the rails while the other

two people support the weight of the system.

CAUTION: To prevent storage system damage and ease insertion, support the

weight of the storage system and keep it level when sliding the storage system

into the rack.

WARNING: The storage system weight, as assembled for shipping,

exceeds 22.7 kg (50 lb). To reduce the risk of personal injury or

damage to the equipment, at least two people are required to lift the

storage system during removal or installation. Install the storage

system in the lowest available position in the rack.

2-10 HP StorageWorks Modular Smart Array 500 System User Guide

Page 39

6. Secure the system to the rack.

Installation and Operation

2

1

HP StorageWorks Modular Smart Array 500 System User Guide 2-11

Page 40

Installation and Operation

IMPORTANT: Use of the shipping bracket is required only when the rack is shipped with

the MSA500 system installed.

7. Use the shipping bracket to secure the system in the rack for shipping:

a. Loosen the thumbscrew on the shipping bracket.

b. Slide the shipping bracket forward until it engages the storage system

chassis.

1

2

c. Tighten the thumbscrew.

Installing Hardware Options

Install any hardware options before initializing the system. For options installation

information, refer to the option documentation or refer to Chapter 3, “Hardware

Options Installation.”

System Cabling

After installing the system in a rack, connect the SCSI cables and power cords to the

rear panel.

2-12 HP StorageWorks Modular Smart Array 500 System User Guide

Page 41

SCSI Cabling Guidelines

Always be sure that the servers attached to the storage system are powered down and

power cords are disconnected before connecting SCSI cables.

IMPORTANT: Before installing the Smart Array Multipath software on a server with a

Microsoft operating system, connect only one of the SCSI cables from each server to the

MSA500 system. Leave the second SCSI cable for the redundant path disconnected until

after the multipath software is installed.

For SSP cabling configurations, refer to “Selective Storage Presentation” in

Chapter 4.

Power Cords

The power cords should be approved for use in your country. The power cord must

be rated for the product and for the voltage and current marked on the electrical

ratings label for the product. The voltage and current rating of the cord should be

greater than the voltage and current rating marked on the product. In addition, the

diameter of the wire must be a minimum of 1.00 mm² or 18 AWG. If you are using

18 AWG, your maximum length may be up to 12 ft.

WARNING: To reduce the risk of electric shock or damage to the equipment:

• Do not disable the power cord grounding plug. The grounding plug is an

important safety feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily

accessible at all times.

Installation and Operation

• Unplug the power cord from the power supply to disconnect power to the

equipment.

• Do not route the power cord where it can be walked on or pinched by items

placed against it. Pay particular attention to the plug, electrical outlet, and

the point where the cord extends from the system.

To connect AC power cords:

1. Connect the power cords to the power supplies.

2. Connect the power cords to the AC outlet.

HP StorageWorks Modular Smart Array 500 System User Guide 2-13

Page 42

Installation and Operation

For information about connecting DC power cords, refer to “DC Power Supply

Option” in Chapter 3.

System Power Up

Observe the following guidelines before powering up the system:

• Be sure that all components are powered down.

• Always install all components of the storage system and connect components to

the supported interconnect options.

• Install hard drives in the MSA500 system so the controller can identify and

configure them at power up.

CAUTION: You must power up the MSA500 system before powering up the servers.

It may take up to 2 minutes for the system to completely power up. Wait until the

display provides the “Startup Complete” message.

To power up the system:

1. Complete server hardware installation and cabling. Refer to the server

documentation.

2. Connect the SCSI cables and power cords to the MSA500 system. Refer to

“System Cabling” in this chapter.

IMPORTANT: When the power cord is connected to the AC or DC source, the system

automatically enters standby mode and provides power to certain system components.

3. Press the Power On/Standby button on the MSA500 system and observe the

system power LED and controller display. When the system goes from standby

to full power, the system power LED illuminates solid green, and the display

provides a “Startup Complete” message.

4. Power up the servers. Refer to the server documentation.

2-14 HP StorageWorks Modular Smart Array 500 System User Guide

Page 43

Controller Display

Each MSA500 array controller in the MSA500 system contains an integrated LCD

display. This module displays informational and error messages, shows the current

status of the module, and provides an interface for user input. The system combines

traditional POST messages issued by PCI-based array controllers with runtime event

notification messages for this new set of controller display messages. The display

module consists of the following components:

• A two-line, 20-column display text window

• Four buttons

• Two LEDs

Types of Messages

The display module is capable of storing up to 100 messages. When the message log

is full, the system deletes the oldest message to make room for the most recent one.

The types of messages include:

Installation and Operation

• Error Messages—Error messages indicate a problem that may require user

action.

The Fault LED illuminates when you view an error message. It also illuminates

to indicate that an unviewed error message is in the queue and was followed by

other types of messages. When scrolling backwards to view all error messages,

the LED illuminates only when an error message is in the text display window.

• Informational Messages—Informational messages provide feedback on

non-critical changes.

• User Input Messages—User input messages indicate an issue that requires a

choice. The user can choose a selection before the end of a time-out period or

allow the controller to default to a standard choice. User input messages only

occur during system power up.

The Fault LED flashes when a user input message is in the text display window

and requires input. If the user does not provide input within the time-out period,

the message remains, but the LED stops flashing.

HP StorageWorks Modular Smart Array 500 System User Guide 2-15

Page 44

Installation and Operation

For a complete list of messages and their meanings, refer to Appendix C, “Display

Messages.”

Using the Interface

• Scrolling—To view older messages, scroll backwards with the Up button

(indicated by the up arrow). To view newer messages, scroll forwards with the

Down button (indicated by the down arrow).

The arrival of new messages supersedes the display of any previous messages.

When a new message arrives, the display ignores its previous scrolling position

and presents the new message.

• Selecting User Input Options—User input messages present the user with a

choice and define the options in the text display window. Select one of the

options by pushing the left button (indicated by the left arrow) or the right button

(indicated by the right arrow).

• Deleting Messages—To delete a message, scroll to the message, then press the

left and right buttons simultaneously.

For information about controller LEDs, refer to Chapter 1, “Component

Identification.”

2-16 HP StorageWorks Modular Smart Array 500 System User Guide

Page 45

Before installing hardware options, be sure to update the system with the latest

firmware, as needed. For ROM flash software, refer to Chapter 4, “Configuration and

Utilities.” For firmware and software updates, refer to the HP website

www.hp.com/products/serverstorage

System Power Down

For some option installation procedures, you must power down the system.

To power down the system:

1. Power down any attached servers. Refer to the server documentation.

2. Press the Power On/Standby button on the storage system. Wait for the system

power LED to go from green to off.

3

Hardware Options Installation

3. Disconnect the power cords.

HP StorageWorks Modular Smart Array 500 System User Guide 3-1

Page 46

Hardware Options Installation

Hot-Plug SCSI Hard Drive Options

Observe the following guidelines when adding SCSI hard drives:

• If only one SCSI hard drive is used, install it in the bay with the lowest number.

• Hot-plug hard drives must be 1-inch universal SCSI types.

• Drives must be the same capacity to provide the greatest storage space efficiency

when drives are grouped together into the same drive array.

Removing Hard Drive Blanks

CAUTION: Always populate bays with either a component or blank. Proper airflow

can be maintained only when the bays are populated. Operating the system with

unpopulated bays can lead to improper cooling and thermal damage.

To remove a hard drive blank:

1

2

To install a blank, align the blank with the empty bay and push the blank inward until

it locks into place.

3-2 HP StorageWorks Modular Smart Array 500 System User Guide

Page 47

Replacing Hot-Plug SCSI Hard Drives

CAUTION: If you must replace a hot-plug drive, follow the guidelines in this section.

Failure to do so can result in data loss and can void the warranty.

RAID 0 is not a fault-tolerant configuration. Never remove a drive from a RAID 0

array unless it has failed. Drive failure is indicated by an amber drive failure LED. In

a RAID 0 configuration, removal of an operating drive results in data loss. To

remove a drive without losing data, always back up the entire array, replace the drive,

and restore the entire array. Backing up a single drive and replacing it does not

restore the array.

Some instances exist in which you may replace a drive in RAID 1, 5, and ADG

configurations. To determine when drive replacement is possible without data loss,

use the hot-plug SCSI hard drive LEDs combination table in Chapter 1, “Component

Identification.”

Follow these additional guidelines when replacing drives:

• Never remove more than one drive at a time (or two drives if you are using

ADG). When you replace a drive, the controller uses data from the other drives

in the array to reconstruct data on the replacement drive. If you remove more

than one drive, a complete data set is not available to reconstruct data on the

replacement drive(s) and permanent data loss could occur.

Hardware Options Installation

• Never remove a drive while the controller is rebuilding another drive. Each

drive has an online LED that flashes green while the drive is being rebuilt. The

controller requires the data from all other drives to rebuild the replacement drive.

• If the system has an online spare drive, wait for it to complete rebuilding

before replacing the failed drive. When a drive fails, the online spare becomes

active and begins rebuilding as a replacement drive. After the online spare has

completed Automatic Data Recovery (the online LED is continuously lit),

replace the failed drive with a new replacement drive. Do not replace the failed

drive with the online spare. The system automatically rebuilds the replacement

drive and resets the spare drive to an available state.

• If you replace a drive while the system is off, it may be necessary to rebuild

the replaced drive.

HP StorageWorks Modular Smart Array 500 System User Guide 3-3

Page 48

Hardware Options Installation

To replace a drive:

1. Be sure that the online and activity LEDs on the failed drive are both off.

2. Remove the failed drive.

2

1

3. Install the new replacement drive.

3

1

2

CAUTION: Data loss can occur if the drive is not firmly seated.

3-4 HP StorageWorks Modular Smart Array 500 System User Guide

Page 49

4. Be sure that the drive LEDs illuminate one at a time and then turn off together to

indicate that the system has recognized the new drive.

In fault-tolerant configurations, allow the replacement drive to be reconstructed

automatically with data from the other drives. While reconstruction is in

progress, the online LED flashes.

Universal Hot-Plug Tape Drive Option

The MSA500 system supports the Universal Hot-Plug Tape drive (AIT and DDS-4

types) for data storage and backup. The option supports Microsoft and Novell

operating systems in various configurations.

For specific Universal Hot-Plug Tape drive configurations, refer to the HP website

www.hp.com/products/sharedstorage

When installed, the hot-plug tape drive fills two storage system hard drive bays. For

complete information, refer to the documentation that ships with the Universal

Hot-Plug Tape drive.

Hardware Options Installation

To install a tape drive:

1. Remove two adjacent hard drive blanks. Refer to “Removing Hard Drive Blanks”

in this chapter.

CAUTION: Installation of the tape drive height converter is permanent.

Attempting to remove the converter after installation voids the tape drive

warranty.

HP StorageWorks Modular Smart Array 500 System User Guide 3-5

Page 50

Hardware Options Installation

2. Install the tape drive height converter on the tape drive.

NOTE: Hot-plug tape drives have a 1.6-inch form factor. Most hot-plug drive cages have

a 1-inch spacing between drive slots. When placing a 1.6-inch tape drive into a cage that

has 1-inch spacing, you must completely fill two slots in the drive cage to maintain proper

airflow. The drive height converter fills the remaining 0.4-inch.

3-6 HP StorageWorks Modular Smart Array 500 System User Guide

Page 51

3. Install the tape drive.

Hardware Options Installation

CAUTION: Data loss can occur if the drive is not firmly seated.

4-Port Shared Storage Module Option

The MSA500 system ships standard with a 2-Port Shared Storage Module. To

upgrade the unit and enable data transfer through four SCSI ports, install the optional

4-Port Shared Storage Module.

IMPORTANT: Before installing the 4-Port Shared Storage Module option, always upgrade to

the most recent firmware for the server host bus adapters (HBAs) and the MSA500

Controllers. The firmware upgrades ensure that HBAs can negotiate I/O paths with the storage

system controllers. For the most recent firmware, refer to the software CD that ships with the

Smart Array Multipath Software CD or refer to www.hp.com.

To install the module:

1. Power down the system. Refer to “System Power Down” in this chapter.

2. Disconnect the SCSI cabling connected to the 2-Port Shared Storage Module.

HP StorageWorks Modular Smart Array 500 System User Guide 3-7

Page 52

Hardware Options Installation

3. Remove the 2-Port Shared Storage Module.

4. Install the 4-Port Shared Storage Module.

1

2

3-8 HP StorageWorks Modular Smart Array 500 System User Guide

Page 53

Hardware Options Installation

HP StorageWorks Modular Smart Array 500 Controller Option

The system ships with one MSA500 controller. To provide redundancy and

maximize storage system uptime, install a second Smart Array controller.

Observe the following guidelines:

• If a controller has more than one cache DIMM, be sure that both DIMMs have

the same memory capacity.

• Always upgrade the cache in both controllers in a system with redundant

controllers.

• In a system with a redundant controller, be sure that both controllers have the

same number of DIMMs and that all DIMMs have the same memory capacity.

• To configure a MSA500 system for controller redundancy, both controllers must

execute the same version of firmware. If the controllers have different firmware

versions, the system responds as follows:

— In a hot-plug addition of the second controller, the system clones the

firmware version of the active controller onto the second controller. After the

second controller is reset, the controllers become redundant.

— In a non-hot-plug addition of the second controller, the system examines the

firmware versions of both controllers at power up and clones the most recent

version from one controller to the other controller.

For more information about upgrading firmware, refer to Chapter 4, “Configuration

and Utilities.”

HP StorageWorks Modular Smart Array 500 System User Guide 3-9

Page 54

Hardware Options Installation

To install an array controller:

1. Remove the bezel blank.

1

2

2. Open the locking latch on the redundant controller.

3. Install the controller.

3

2

1

4. Verify that the controller is seated properly by observing the controller LEDs.

When seated properly, the LEDs illuminate when the system is powered.

3-10 HP StorageWorks Modular Smart Array 500 System User Guide

Page 55

Cache Upgrade Option

The controller ships with a 128-MB battery-backed cache module. A 256-MB

battery-backed cache module is available as an option. Before installing a cache

upgrade, observe the following guidelines:

• Always power down the system before performing a cache upgrade.

• If a controller has more than one cache DIMM, be sure that both DIMMs have

the same memory capacity.

• Always upgrade the cache in both controllers in a system with redundant

controllers.

• In a system with a redundant controller, be sure that both controllers have the

same number of DIMMs and that all DIMMs have the same memory capacity.

To upgrade the cache:

1. Power down the system. Refer to “System Power Down” in this chapter.

2. Remove the controller.

Hardware Options Installation

3

1

2

HP StorageWorks Modular Smart Array 500 System User Guide 3-11

Page 56

Hardware Options Installation

3. Remove the existing cache module.

2

1

4. Install the new cache module.

3

4

3

2

1

3-12 HP StorageWorks Modular Smart Array 500 System User Guide

Page 57

Hardware Options Installation

5. Install the controller.

1

2

6. Power up the system. Refer to “System Power Up” in Chapter 2, “Installation

and Operation”.

7. Verify that the controller is seated properly by observing the controller LEDs.

When seated properly, the LEDs illuminate when the system is powered.

DC Power Supply Option

The DC power supply procedure provides instructions for converting an existing AC

power supply configuration to a DC power supply configuration.

Observe the required safety guidelines for DC power supply installation.

WARNING: A risk of personal injury from electric shock and hazardous energy

levels exists. The installation of options and routine maintenance and service

of this product must be performed by individuals who are knowledgeable

about the procedures, precautions, and hazards associated with DC

power products.

HP StorageWorks Modular Smart Array 500 System User Guide 3-13

Page 58

Hardware Options Installation

WARNING: To reduce the risk of electric shock, fire, and damage to the

equipment, this product must be installed in accordance with the following

guidelines:

• This power supply is intended only for installation in HP equipment located

in a restricted access location.

• This power supply is not intended for direct connection to the DC supply

branch circuit. It should be connected to a power distribution unit (PDU)

that provides an independent overcurrent-protected output for each DC

power supply. Each output overcurrent-protected device in the PDU must

be suitable for interrupting fault current available from the DC power source

and must be rated no more than 20A.

• This power supply is designed to be connected only to a DC power source

that can be classified as SELV or TNV, in accordance with applicable

national requirements for Information Technology Equipment and

Telecommunications Equipment. Generally, these requirements are based

on the International Standard for Information Technology Equipment, IEC

60950, and/or the European Telecommunication Standard ETC 300 132-2.

The DC source is to have one pole (Neutral/Return) reliably connected to

earth ground in accordance with local/regional electric codes and/or

regulations.

• The green/yellow lead of the power cord assembly must be connected to a

suitable ground/earth terminal located within the rack or cabinet. This

terminal must be connected to a suitable building ground/earth terminal in

accordance with local/regional electric codes/regulations. Do not rely on

the rack or cabinet chassis to provide adequate ground/earth continuity.

WARNING: The blower blades rotate at a high speed and do not stop

immediately when power is removed. Avoid touching the rotating blades when

removing the blower.

CAUTION: Do not operate the storage system with one AC power supply and one

DC power supply installed.

CAUTION: To prevent improper cooling and thermal damage, do not operate the

storage system unless both bays are populated with a power supply.

3-14 HP StorageWorks Modular Smart Array 500 System User Guide

Page 59

Hardware Options Installation

To install a DC power supply:

1. Power down the system. Refer to “System Power Down” in this chapter.

2. Determine the required length of the DC power cord:

WARNING: To reduce the risk of electric shock or damage to the

equipment, do not connect the power cord to the power supply until the

power supply is installed.

a. Place the power supply end of the DC power cord near the power supply bay.

Do not plug the DC power cord into a power supply.

b. Route the power cord to a PDU or other suitable DC power source. Do not

plug the DC power cord into the power source.

c. Trim the DC power cord as required.

3. Connect the free end of the DC power cord to the PDU or other suitable DC

power source.

4. Connect the free end of the green/yellow safety cable to a suitable earth ground.

IMPORTANT: If the power supply fails to operate, the red and black cables may be

connected incorrectly. When connected properly, the black cables should be at a higher

potential (more positive) relative to the red cable. The power supply features reverse

polarity protection so that no damage occurs if the power supply is connected incorrectly.

HP StorageWorks Modular Smart Array 500 System User Guide 3-15

Page 60

Hardware Options Installation

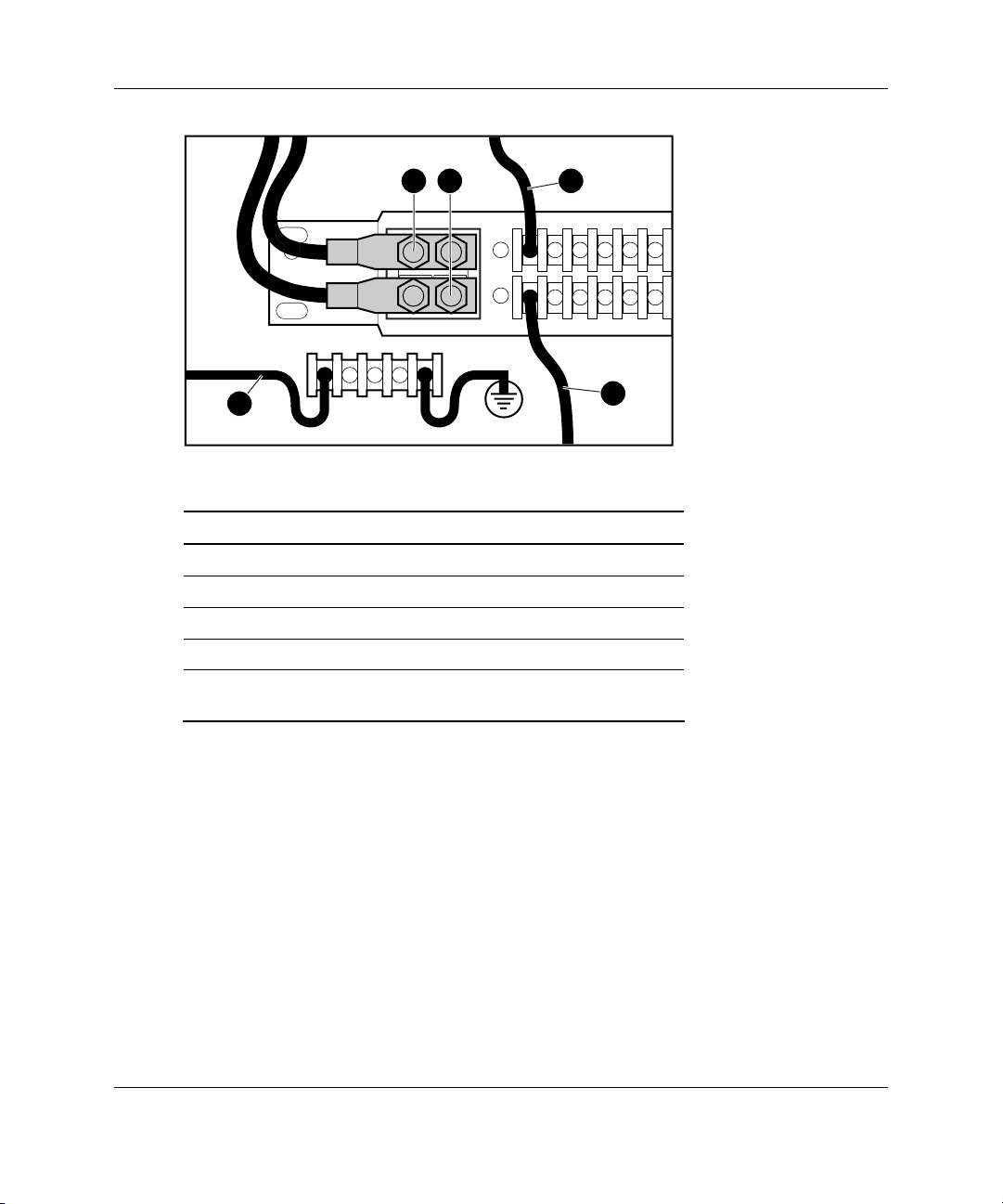

1 2 3

5

4

Table 3-1: DC Cabling Configuration

Item Description

1 -48 VDC cable from facility power source

2 -48 V return cable from facility power source

3 Red cable from power supply

4 Black cable from power supply

5 Green/yellow cable from power supply connecting to

rack chassis terminal block

3-16 HP StorageWorks Modular Smart Array 500 System User Guide

Page 61

5. Remove the existing AC power supply, if installed.

1

6. Remove the blower from the AC power supply.

Hardware Options Installation

2

1

2

1

HP StorageWorks Modular Smart Array 500 System User Guide 3-17

Page 62

Hardware Options Installation

CAUTION: Do not press on the center section of the blower because this action

can damage the blades. Press only on the outer edge of the blower.

7. Install the blower on the DC power supply.

8. Remove the protective cover from the connector pins on the DC power supply.

9. Slide the DC power supply into the bay.

1

2

3-18 HP StorageWorks Modular Smart Array 500 System User Guide

Page 63

Hardware Options Installation

10. Connect the DC power cord to the power supply.

2

1

11. Repeat steps 2 through 10 to install the second DC power supply.

12. Power up the system. Be sure that the power supply/blower assembly LED and

system power LED are green.

HP StorageWorks Modular Smart Array 500 System User Guide 3-19

Page 64

Server Utilities

HP utilities provide reporting functions that enable event-focused management and

diagnostics. To install and run these utilities, refer to the server documentation.

• Diagnostics Utility—This utility tests and verifies proper operation of the system

hardware. If problems are found, the utility isolates failure(s) down to the

replaceable part, whenever possible. When an operating system is installed with

SmartStart Version 5.30 or later, the Diagnostics and utilities are installed on a

partition of the hard drive that contains the operating system. (This hard drive

may or may not be located in the storage system.) Always access these utilities

when a system configuration error is detected during POST.

• INSPECT Utility—This utility provides a report detailing system information.

• Insight Manager 7—This Web-based application enables system administrators

to accomplish normal administrative tasks from any remote location, using a

Web browser. Insight Manager 7 provides device management capabilities that

consolidate and integrate management data from HP and third-party devices.

4

Configuration and Utilities

• Insight Management Agents—These agents enable easy manageability of the

server through Insight Manager 7 software and third-party SNMP management

platforms. Management agents monitor key subsystems that are instrumental in

making health, configuration, and performance data available to the agent

software. The agents act upon that data by initiating alarms in the event of faults.

The agents also provide updated management information, such as network

interface or subsystem performance statistics, to the management systems.

HP StorageWorks Modular Smart Array 500 System User Guide 4-1

Page 65

Configuration and Utilities

• Survey Utility—This utility gathers critical hardware and software information

on servers running Microsoft Windows and Novell NetWare operating systems.

If a significant change occurs between data-gathering intervals, the Survey

Utility marks the previous information and overwrites the Survey text files to

reflect the latest changes in the configuration.

Recovery Server Option

The HP ProLiant Essentials Recovery Server Option (RSO) software kit supports a

standby recovery server configuration. This configuration comprises two identical

(and identically configured) ProLiant servers connected to a common MSA500

system and a common network. One of the servers (the primary) supports network

clients by default. The other server remains in a preboot stage during normal use and

acts as a backup (recovery) server. All hard drive storage is located in the shared

storage system. The storage system also contains a single copy of the operating

system and all the applications, drivers, and data.

When a system fault occurs in either the server or operating system, RSO

automatically takes the primary server offline and initializes the recovery server to

take over operations. While the recovery server is supporting network clients, the

primary server can be repaired at leisure.

For more information about configuring RSO, refer to the HP ProLiant Essentials

Recovery Server Option User Guide that ships with the software.

For installation procedures, refer to the HP ProLiant Essentials Recovery Server

Option Pack Installation Instructions that ships with the software.

4-2 HP StorageWorks Modular Smart Array 500 System User Guide

Page 66

ROM Functions and Utilities

Each MSA500 controller has a ROM that contains the controller firmware.

Recovery ROM

The Recovery ROM feature stores two complete firmware images in the ROM: one

active image and one backup image. When the controller is powering up, it checks

both firmware images to be sure they are valid. If either image is invalid, the system

overwrites the invalid image with the valid image. This process, commonly called

auto-flashing, is performed automatically by the controller and does not require any

user intervention. The controller display provides messages for the status of this

process.

Firmware Upgrades

The ROM flash tool enables system administrators to efficiently upgrade array

controller ROM images. This tool has the following features:

• Supports Microsoft® Windows NT® 4.0, Windows® 2000, Novell NetWare

(offline only), and Linux operating systems

Configuration and Utilities

• Integrates with other software maintenance, deployment, and operating system

tools

• Automatically checks for hardware, firmware, and operating system

dependencies, and installs only the correct ROM upgrades required by each

target controller

For firmware procedures, refer to the SmartStart CD.

HP StorageWorks Modular Smart Array 500 System User Guide 4-3

Page 67

Configuration and Utilities

Controller Firmware Auto Cloning

In a redundant controller configuration, both controllers must execute the same

version of firmware. During power up (or when a redundant controller is installed as

a hot-plug procedure), the system compares the controller firmware versions. If the

versions differ, the controller displays a user input message seeking to initiate

Controller Firmware Auto Cloning. If 60 seconds elapse with no user input, cloning

begins automatically, and the system overwrites one firmware version with the other

version.

When the cloning is complete, the system resets the modified controller. After the

modified controller powers up, the controllers begin operating in redundant mode.

The system clones firmware based on the following criteria:

• Non-Hot-Plug Cloning—If the system powers up with both controllers installed,

the system clones the most recent firmware version from either controller.

• Hot-Plug Cloning—If the system is operating and an optional redundant

controller is installed, the system clones the firmware version from the primary

controller, regardless of which firmware version is more recent. This cloning

method ensures that all host-initiated I/O remains uninterrupted during system

operation.

• Incompatible Version Cloning—If a specific version of firmware is

incompatible with certain hardware revisions of a controller, the system displays

the user input message seeking to initiate Controller Firmware Auto Cloning and

clones the most recent firmware version that is compatible with both controllers.

IMPORTANT: During incompatible version cloning, the system does not reset the

updated controller if the controller is operating and processing I/O. In this case, the system

does not enter redundant mode and provides an informational message on the controller

display. To configure redundancy, cycle the system power. Refer to “System Power

Down” in Chapter 3.

4-4 HP StorageWorks Modular Smart Array 500 System User Guide

Page 68

Selective Storage Presentation

SSP is a controller firmware feature that enables the administrator to control access

from multiple hosts to logical drives on the MSA500 system. The administrator

selects which server host or hosts can access the stored data, restricting access as

needed to assure data integrity and security.

Each logical drive on the controller has an access control list that contains the IDs of

the server host adapters that have access to the drive. If a server attempts to send

commands to a logical drive without access authority, the controller rejects the

command.

The configuration utility maps the IDs of server host adapters to connection names

and sets up access control lists for logical drives based on the adapter IDs.

SSP Hardware Configurations

To configure the hardware for SSP, use SCSI cables to connect each server to the

2-Port or 4-Port Shared Storage Module installed in the storage system. Boot

volumes for individual servers can reside on server drives or storage system drives.

Configuration and Utilities

Firmware Requirements

For Selective Storage Presentation (SSP) support on the MSA500 system, be sure the

following firmware versions are present:

• MSA500 Controller firmware Version 1.66 or later

• Smart Array 532, 5i, or 5i+ Controller firmware Version 2.36 or later

For the most recent firmware, refer to the software CD that ships with the MSA500

system or refer to

www.hp.com

HP StorageWorks Modular Smart Array 500 System User Guide 4-5

Page 69

Configuration and Utilities

Enabling SSP

After choosing the configuration that best suits your needs, enable SSP with

ACU Version 6.0 or later. Locate ACU on the SmartStart CD. For instructions, refer

to the HP Array Configuration Utility User Guide on the Documentation CD.

Array Configuration Utility

ACU Version 6.0 (or later) is a browser-based utility with the following features:

• Supports online array capacity expansion, logical drive capacity extension,

assignment of online spares, and RAID or stripe size migration

• Suggests the optimum configuration for an unconfigured system

• Provides different operating modes, enabling faster configuration or greater

control over the configuration options

• Remains available any time that the server is on

• Displays on-screen tips for individual steps of a configuration procedure

The minimum display settings for optimum performance are 800 × 600 resolution

and 256 colors. The server must have Microsoft Internet Explorer 5.5 (with Service

Pack 1) installed and be running Microsoft Windows 2000, Windows NT 4.0, or

Linux. Refer to the README.TXT file for further information about browser and

Linux support.

For more information about ACU Version 6.0 (or later), refer to the HP Array

Configuration Utility User Guide on the Documentation CD.

Moving Array Controller Drives and Arrays

CAUTION: Back up all data before removing drives or changing configurations.

Failure to do so could result in permanent loss of data. Before moving drives and

arrays, run ACU.

4-6 HP StorageWorks Modular Smart Array 500 System User Guide

Page 70

Configuration and Utilities

Drives can be moved to other ID positions on the same array controller. You can also

move a complete array from one controller to another, even if the controllers are on

different servers or storage devices. Arrays on different controllers can also be moved

to another controller.

Before moving drives, observe the following requirements:

• No drives are failed, missing, or degraded.

• The move does not result in more than 14 physical drives.

• No more than 32 logical volumes are configured for a controller.

• The array must be in its original configuration with no active spare drives.

• Capacity expansion is not running.

• Controller firmware is the latest version (recommended).

• Controller is a Smart Array controller.

Before moving an array from one controller to another, observe these additional

requirements:

• All drives in the array must be moved at the same time.

• Drive positions of the destination controller must match original drive positions.

When all requirements are met:

1. Power down the system. Refer to “System Power Down” in Chapter 3.

2. Move the drives. Refer to “Hot-Plug SCSI Hard Drive Options” in Chapter 3.

3. Power up the system. Refer to “System Power Up” in this chapter.

A #86 controller display message should appear, indicating that drive positions

were changed and the configuration was updated. If a #121 controller display (no

volumes) message is displayed, power down the system immediately to avoid

data loss, and return the drives to their original locations.

For more information about display messages, refer to Appendix C, “Display

Messages.”

4. Check the new drive configuration by running ACU. Refer to the HP Array

Configuration Utility User Guide on the Documentation CD.

HP StorageWorks Modular Smart Array 500 System User Guide 4-7

Page 71

Configuration and Utilities

Expanding and Extending Capacity

CAUTION: Back up all data before removing drives or changing configurations.

Failure to do so could result in permanent loss of data. Before moving drives and

arrays, run ACU.

Array Capacity Expansion is the addition of physical drives to an array that has

already been configured. The capacity of these added physical drives may then

be added to an existing logical drive on the array (capacity extension; refer to the

next paragraph), or it may be configured into a new logical drive.

Logical Drive Capacity Extension is the enlargement of an existing logical

drive after the corresponding array has undergone capacity expansion.

Use ACU to perform capacity expansion and extension. A data backup and

restoration cycle is not required, even in non-fault-tolerant configurations.

With hot-plug drives, you can perform expansion online. Online extension is only

possible with operating system support.

IMPORTANT: When extending a logical drive under Microsoft Windows 2000, upgrade the

disk to DYNAMIC before creating a partition on that disk. If the disk already has a partition

when it is upgraded to DYNAMIC, Windows 2000 may not allow logical drive extension. Refer

to the Windows 2000 documentation for details about DYNAMIC and BASIC disks.

IMPORTANT: Microsoft Windows NT 4.0 only allows four partitions on each logical drive.

Additional drive space created may not be accessible if the four partitions per logical drive limit