Page 1

HP StorageWorks

300 Virtual Lib

rary System user guide

AH138-96002

Part number: AH1 38–96002

irst edition edition: November 2006

F

Page 2

Legal and notice information

© Copyright 2006 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth

in the express warranty statements accompanying such products and services. Nothing herein should be construed as constituting

an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Page 3

Contents

Aboutthisguide .......................... 11

Relateddocumentation.................................... 11

Documentconventionsandsymbols ............................. 12

Rackstability ....................................... 13

HPtechnicalsupport.................................... 13

Subscriptionservice .................................... 14

OtherHPwebsites .................................... 14

HP-authorizedreseller ................................... 14

1Introduction............................ 15

Features ......................................... 15

Benefits ....................................... 15

Systemstatusmonitoring ................................ 16

Redundancy ..................................... 16

Components ....................................... 16

2 Hardware installation ...................... 19

Preparingfortheinstallation................................. 19

PreparetheEVAfortheVLS300............................. 19

Toolsforinstallation .................................. 19

TakingESDprecautions................................. 19

Groundingmethodstopreventelectrostaticdischarge.................... 20

Unpacking ........................................ 20

Removingthepackingmaterials ............................. 20

Rackplanningresources .................................. 20

Rackrequirements..................................... 21

Rackwarnings ...................................... 21

Optimumenvironment ................................... 21

Space and airflowrequirements ............................. 21

Temperaturerequirements................................ 22

Powerrequirements .................................. 22

Electricalgroundingrequirements ............................ 23

Identifyingtheshippingcartoncontents............................ 23

VLS300systemshippingcarton ............................. 23

InstallingtheVLS300nodesintoarack............................ 25

Installrailsintherack ................................. 25

AttachrailstotheVLS300(appliance) .......................... 26

Installapplianceinrack ................................ 27

Installthe100MbEthernetswitch2524intoarack....................... 27

Installthe1GbEthernetswitch2824intoarack........................ 28

Installrailsforswitch2824intherack .......................... 28

Attachrailstothe2824switch.............................. 29

Installswitch2824inrack................................ 30

InstallingVLS300cables .................................. 30

3Multi-nodesetup ........................ 35

Configureprimarynode—node0 .............................. 35

Configurethesecondarynode(s)—nodes1through7...................... 35

HP StorageWorks

3

Page 4

4Storageconfiguration ...................... 37

EstablishingcommunicationbetweentheVLS300andtheEVA.................. 37

Verifyingarrayzoning ................................. 37

PresentingtheLUNs .................................. 37

ManagingVLS300capacity................................. 40

DiscoveringarrayLUNs................................. 40

DeletingarrayLUNs.................................. 41

Configuringstoragepools................................ 42

Destroyingstoragepools ................................ 44

Installingcapacitylicenses ................................. 45

5Operation ........................... 47

PoweringontheVLS300system ............................... 47

Rebootingthesystem.................................... 47

Poweringoffthesystem................................... 48

6Userinterfaces . . ........................ 51

Userinterfacerequirements ................................. 51

CommandViewVLS.................................... 51

Windowregions.................................... 52

OpeningaCommandViewVLSsessionfromawebbrowser................. 53

OpeningaCommandViewVLSsessionfromCommandViewTL ............... 54

Installing the SSL certificateintoyourwebbrowser ..................... 54

RestartingCommandViewVLS ............................. 57

ClosingaCommandViewVLSsession .......................... 58

Secureshellandserialuserinterfaces............................. 58

Openingasecureshellsession ............................. 58

Closingasecureshellsession .............................. 59

Openingaserialsession ................................ 59

Closingaserialsession................................. 59

7Configuration........................... 61

Settingthenetworksettings ................................. 61

SettingthenetworksettingsusingtheVLSdiscoveryutility .................. 61

SettingthenetworksettingsusingtheCLIcommandset ................... 63

SettingthenetworksettingsusingCommandViewVLS ................... 64

Settingtheuserpreferences................................. 65

EditingthedefaultFChostportsettings............................ 66

Enablinganddisablingoversubscription ........................... 67

ManagingvirtualdeviceLUNs................................ 68

DefaultLUNnumbering................................. 69

OperatingsystemLUNrequirementsandrestrictions..................... 69

LUNmasking..................................... 69

LUNmapping..................................... 70

Dualportvirtualdevices ................................ 71

Creatingavirtuallibrary .................................. 72

Creatingtapedrives.................................... 75

Creatingcartridges .................................... 77

Destroyingavirtuallibrary ................................. 80

Destroyingatapedrive................................... 81

Destroyingcartridges.................................... 82

Addingandremovingbarcodetemplates ........................... 84

8Management.......................... 87

Changingtheaccountpasswords .............................. 87

Managinghighavailability................................. 88

Arraydualpathing................................... 88

4

Page 5

Loadbalancing .................................. 88

LUNpathfailover ................................. 89

PrivateLANdualpathing................................ 91

Managingcartridges.................................... 91

Unloadingacartridgefromadrive.............................. 94

Freeingupstoragespace.................................. 94

RestartingVLSdeviceemulations............................... 94

Updating the software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Saving con figurationsettings ................................ 96

9Monitoring........................... 99

Statusinformationinthestatuspane ............................. 99

Statusicons........................................ 99

Devicestatusicon ................................... 99

Navigationtreeicon.................................. 100

Notificationalerts ..................................... 100

CommandViewVLS.................................. 101

E-mail notification ................................... 102

EditingtheE-mailserversettings........................... 102

EdittheE-mailsettings ............................... 103

SNMP notification................................... 104

EditingtheSNMPsettings.............................. 104

Trace log files....................................... 105

Viewing trace log files ................................. 105

Saving a trace log file ................................. 105

Creatingasupportticket ................................ 106

10CLIcommandset........................ 107

Commands........................................ 107

Conventions ..................................... 107

CLI-onlycommands .................................... 107

Connectioncommands................................. 107

Outputcommands................................... 108

VLScommands ...................................... 108

Network settings configurationcommands......................... 108

Configurationcommands................................ 109

Managementcommands................................ 114

Monitoringcommands ................................. 115

11 C o m p o n e n t i d e n t i fication .................... 119

VLS300nodecomponents,LEDs,andbuttons ......................... 119

Frontpanelcomponents ................................ 119

FrontpanelLEDsandbuttons .............................. 119

Rearpanelcomponents................................. 121

Systemboardcomponents ............................... 121

SystemboardLEDs................................... 122

NodeLEDsandinternalhealthLEDcombinations...................... 123

Fanmodulelocations.................................. 125

ProcessorzonefanmoduleLED ............................. 125

Switch2524components.................................. 126

Switch2824components.................................. 126

USBLANadaptercomponents................................ 127

12Componentreplacement..................... 129

Safetyconsiderations.................................... 129

Preventingelectrostaticdischarge............................. 129

Groundingmethodstopreventelectrostaticdamage .................... 129

HP StorageWorks

5

Page 6

Warningsandcautions................................. 129

Preparationprocedures................................... 130

ExtendingaVLS300nodefromtherack ......................... 130

RemovingtheVLS300nodeaccesspanel......................... 131

InstallingtheVLS300nodeaccesspanel ......................... 131

VLS300nodecomponentreplacement ............................ 132

SATAharddrive.................................... 132

CD-ROMdrive .................................... 132

Powersupply ..................................... 133

Powersupplyzonefanmodule.............................. 134

Processorzonefanmodule ............................... 135

DIMM........................................ 136

Processor....................................... 137

Replacingaprimarynode ............................... 139

Replacingasecondarynode .............................. 140

Switch2524replacement.................................. 141

Switch2824replacement.................................. 141

USBLANadapter..................................... 141

13 Disaster recover y . ....................... 143

RecoveringfromanodeRAIDvolumefailure.......................... 143

Restoring the configurationsettings............................ 143

Restoring the virtual library configuration from a configuration file............. 143

Rebuilding the virtual library configuration....................... 144

RecreatingtheVLS300storagepools......................... 145

Re-installingtheVLScapacitylicenses........................... 145

Recoveringfromoperatingsystemfailure ........................... 145

ATroubleshooting......................... 147

Commonissues ...................................... 147

BRegulatorycompliancenotices .................. 151

Regulatory compliance identificationnumbers ......................... 151

Batterystatement ..................................... 151

FederalCommunicationsCommissionnotice.......................... 152

FCCratinglabel.................................... 152

ClassAequipment................................. 152

ClassBequipment................................. 152

Declaration of Conformity for products marked with the FCC logo, United States only . . . . . . 152

Modification ..................................... 153

Cables........................................ 153

Canadiannotice(AvisCanadien) .............................. 153

ClassAequipment................................... 153

ClassBequipment................................... 153

EuropeanUnionnotice................................... 153

Japanesenotices ..................................... 154

Koreannotices ...................................... 154

ClassAequipment................................... 154

ClassBequipment................................... 154

Taiwanesenotices..................................... 155

BSMIClassAnotice.................................. 155

Taiwanbatteryrecyclestatement............................. 155

Lasercompliance ..................................... 155

Dutchlasernotice ................................... 156

Frenchlasernotice................................... 156

Germanlasernotice.................................. 156

Italianlasernotice................................... 157

Japaneselasernotice ................................. 157

6

Page 7

Spanishlasernotice .................................. 157

Recyclingnotices ..................................... 158

Disposal of waste equipment by users in private household in the European Union . . . . . . . . 158

Dutchnotice ..................................... 158

Czecholslovakiannotice ................................ 158

Estoniannotice .................................... 159

Finnishnotice..................................... 159

Frenchnotice ..................................... 159

Germannotice .................................... 159

Greeknotice ..................................... 160

Hungariannotice ................................... 160

Italiannotice ..................................... 160

Latviannotice..................................... 161

Lithuaniannotice ................................... 161

Polishnotice ..................................... 161

Portuguesenotice ................................... 162

Slovakiannotice.................................... 162

Sloveniannotice.................................... 162

Spanishnotice .................................... 163

Swedishnotice .................................... 163

Batteryreplacementnotices................................. 164

Dutchbatterynotice .................................. 164

Frenchbatterynotice.................................. 164

Germanbatterynotice ................................. 165

Italianbatterynotice.................................. 165

Japanesebatterynotice................................. 166

Spanishbatterynotice ................................. 166

CSpecifications ......................... 167

VLSnode......................................... 167

Switch2824 ....................................... 168

Switch2524 ....................................... 169

Environmental specifications................................. 169

Glossary............................. 171

Index .............................. 177

HP StorageWorks

7

Page 8

Figures

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

..Installrails................................... 26

..Removeslidesfromrails............................. 26

..AttachingrailstotheVLS300node ........................ 27

..Switch2524mountingbrackets.......................... 28

..Switch2824railinstallation,front......................... 29

..Switch2824railinstallation,back ........................ 29

..Attach rai

..Primarynodeports............................... 31

..Secondarynodeports.............................. 32

..Switch2824ports ............................... 33

..Switch2524ports ............................... 34

..Notificationswindow.............................. 35

..AddNodeWizardwindow ........................... 36

..FibreChanneldetailswindow .......................... 37

..Add a Hos

..AddaHostPortwindow............................. 39

..VdiskActiveMemberPropertieswindow...................... 40

..StorageLUNsdetailswindow .......................... 41

..UnpresentHost(s)window............................ 42

..ConfirmDestroyStoragePoolwindow....................... 44

..Identitytabwindow............................... 46

..RestartHeadWizardwindow .......................... 48

..ShutdownHeadWizardwindow......................... 49

..CommandViewVLSloginwindow ........................ 53

..SecurityAlertwindow.............................. 55

..Certificatewindow............................... 56

..Cert

..RestartCommandViewVLSwindow ....................... 58

..VLSdiscoveryutility–mainwindow........................ 62

..VLS discovery utility – Device Con

..Set Network ConfigurationWizardwindow .................... 65

..UserPreferenceswindow ............................ 66

..FCHostPortswindow.............................. 67

..Chassisdetailswindow ............................. 68

..HostLUNMappingModewindow ........................ 70

.. LibraryParameters–MapLUNswindow ..................... 71

..CreateVirtualLibraryWizardwindow(1of12)................... 72

..CreateVirtualLibraryWizardwindow(2of12)................... 73

reateVirtualLibraryWizardwindow(3of12)................... 74

..C

..CreateVirtualLibraryWizardwindow(4of12)................... 74

..CreateVirtualLibraryWizardwindow(5of12)................... 75

..CreateVirtualLibraryWizardwindow(6of12)................... 76

..CreateVirtualLibraryWizardwindow(7of12)................... 77

..CreateVirtualLibraryWizardwindow(8of12)................... 78

lstoswitch2824............................ 30

twindow .............................. 38

ificateImportWizardwindow ........................ 57

figurationwindow................. 63

8

Page 9

45

..CreateVirtualLibraryWizardwindow(9of12)................... 79

46

..CreateVirtualLibraryWizardwindow(10of12) .................. 79

47

..CreateVirtualLibraryWizardwindow(11of12) .................. 80

48

..CreateVirtualLibraryWizardwindow(12of12) .................. 80

49

..Virtuallibrarydetailswindow .......................... 81

50

..Tapedrivedetailswindow............................ 82

51

..Cartridges

52

..Cartridgesparameterswindow.......................... 84

53

..Add/RemoveBarcodeTemplateswindow ..................... 85

54

..EditAccountswindow.............................. 87

55

..StorageLUNswindow ............................. 89

56

..FixPrimaryPathsWizardwindow......................... 90

57

..Notificationswindow.............................. 90

58

..CartridgeDetailswindow ............................ 92

59

..CartridgesParameterswindow.......................... 93

60

..RestartEmulationswindow............................ 95

61

..Software Update window . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

62

..Save Configurationwindow ........................... 97

63

..Devicestatusiconinthestatusbanner....................... 100

detailswindow............................ 83

64 ..Navigationtreeicon .............................. 100

65

..Notificationalertexamples ........................... 100

66

..Notificationswindow.............................. 101

67

..Edit Ma

68

..EditEmailSettingswindow ........................... 103

69

..EditSNMPSettingswindow ........................... 104

70

..LogViewerwindow............................... 105

71

..SupportTicketwindow ............................. 106

72

..Slidingthenodeoutoftherack.......................... 131

73

..Removinganodeharddrive........................... 132

74

..EjectingtheCD-ROMdrive............................ 133

75

..Removinganodepowersupply ......................... 133

76

..InstallinganACpowersupply .......................... 134

77

..Placingthepowercordinthestrainreliefclip.................... 134

78

..Removingthenodepowersupplyzonefanmodule ................. 135

79

..Rem

80

..RemovingthenodeDIMM............................ 136

81

..Liftingtheprocessorretainingcard ........................ 137

82

..Releasingtheprocessorretainingclipsandliftlockinglever.............. 138

83

..Removingtheprotectivecoverfromtheprocessor .................. 138

84

..Aligningtheprocessorpinswiththesocketholes .................. 139

85

..Closingtheprocessorlockingleverandretainingclips................ 139

86

..Railreleasebracket............................... 140

87

..Re

ilServerSettingswindow......................... 102

ovingtheprocessorzonefanmodule ..................... 136

store Configwindow ............................. 144

HP StorageWorks

9

Page 10

Tables

1

2 ..VLS300capacity................................ 17

3

4

5

6

7

8

9

..Documentconventions.............................. 12

..VLS user inte

..CLIconnectioncommands............................ 107

..CLIoutputcommands.............................. 108

..CLI network settings configurationcommands.................... 109

..CLI configurationcommands........................... 110

..CLImanagementcommands........................... 115

..CLImonitoringcommands............................ 116

rfaces ............................... 51

10

Page 11

About this guide

This user guide provides information to help you:

• Become familiar with HP StorageWorks 300 virtual library system (VLS) features, models, and

components

• Install and operate your VLS

• Configure your VLS to meet the data backup needs of your environment

• Manag e your VLS so that it continues to meet the data backup needs of your environment

• Monitor your VLS hardware status

• Replace failed customer-replaceable components

• Perform disaster recovery

• Troubleshoot configuration problems

“About this Guide” topics include:

• Related documentation

• Document conventions and symbols

•Rackstability

• HP technical support

•Subscriptionservice

• Helpful web sites

• the section called “HP-authorized reseller”

Related documentation

HP provid

• HP StorageWorks 300 virtual library system release notes

• HP StorageWorks 300 virtual library system user guide

• HP Stora

See the D

documentation.

es the following documentation to support this product:

geWorks 300 virtual library system solutions guide

ocumentation CD provided with the VLS and our web site (h

ttp://www.hp.com)forrelated

HP StorageWorks

11

Page 12

Document conventions and symbols

Table 1 Document conventions

Convention

Blue text: Table 1

Blue, underlined text: http://

www.hp.com

Bold text

Italic text Text emphasis

Monospace text

Monospace, italic text

Monospace, bold text

WARNI

Indic

NG!

ates that failure to follow directions could result in bodily harm or death.

Element

Cross-referen

Web site addresses

• Keys that are pressed

• Text typed into a GUI element, such as

abox

• GUI elements that are clicked or

selected, such as menu and list items,

buttons, tabs, and check boxes

• File and directory names

• System output

• Code

• Commands, their arguments, and

argument values

• Code variables

• Command variables

Empha

ce links and E-mail addresses

sized monospace text

CAUTION:

Indicates that failure to follow directions could result in damage to equipment or data.

NOTE:

Provides additional information.

The following equipment symbols may be found on hardware to which this guide pertains. They have

the following meanings:

WARNING!

These symbols, which mark an enclosed surface or area of the equipment, indicate the

presence of electrical shock hazards. The enclosed area contains no operator serviceable parts.

WARNING: To reduce the risk of injury from electrical shock hazards, do not open this enclosure.

12

About this guide

Page 13

WARN ING!

These symbols, which mark an RJ-45 receptacle, indicate a network interface connection.

WARNING: To reduce the risk of electrical shock, fire, or damage to the equipment, do not plug

telephone or telecommunications connectors into this receptacle.

WARN ING!

These symbols, which mark a surface or area of the equipment, indicate the presence of a hot

surface or hot component. Contact with this surface could result in injury.

WARNING: To reduce the risk of injury from a hot component, allow the surface to cool before touching.

WARN ING!

Power supplies or systems marked with these symbols indicate the presence of multiple

sources of power.

WARNING: To reduce the risk of personal i njury from electrical shock, remove all power cords to

completely disconnect power from the power supplies and systems.

WARN ING!

Any product or assembly marked with these symbols indicates that the component exceeds the

recommended weight for one individual to handle safely.

WARNING: To reduce the risk of personal injury or damage to the equipment, observe local

occupational health and safety requirements and guidelines for manually handling material.

Rack stability

Rack stability protects personnel and equipment.

WARN ING!

To reduce the

• The leveling jacks are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• In single ra

• In multiple rack installations, the racks are coupled.

• Only one rack component is extended at any time. A rack may become unstable if more than one

rack compo

riskofpersonalinjuryordamagetotheequipment,besurethat:

ck installations, the stabilizing feet are attached to the rack.

nent is extended for any reason.

HP technical support

Telephone numbers for worldwide technical support are listed on the following HP web site:

h

ttp://www.hp.com/support/. From this web site, select the country of origin.

HP StorageWorks

13

Page 14

NOTE:

For continuous quality improvement, calls may b e recorded or monitored.

Be sure to have the following information available before calling:

• Technical support registration number (if applicable)

• Product serial numbers

• Product model names and numbers

• Applicable error messages

• Operating system type and revision level

• Detailed, specificquestions

Subscription service

HP strongly recommends that customers register online using the Subscriber’s choice web site:

1. Access h

2. Click the Subscribe link near the bottom of the screen.

3. Click the Business & IT Professionals link.

4. Click the Driver and Support aler ts link.

5. Click [edit] on the Product ownership task bar to add and delete products.

Subscribing to this service provides you with E-mail updates on the latest product enhancements, newest

driver versions, and firmware documentation updates as well as instant access to numerous other product

resources.

ttp://www.hp.com.

Other HP web sites

For additional information, see the following HP web sites:

•h

ttp://www.hp.com

•http://www.hp.com/go/storage

•http://www.hp.com/service_locator

•http://www.docs.hp.com

HP-authorized reseller

For the name of your nearest HP authorized reseller:

• In the United States, call 1-800-345-1518

• In Canada, call 1-800-263-5868

• Elsewhere, see the HP web site for locations and telephone numbers: h

ttp://www.hp.com.

14

About this guide

Page 15

1Introduction

This section describes the HP StorageWorks 300 virtual library system features and models.

Features

The HP StorageWorks 300 virtual library system (VLS) is a RAID disk-based SAN backup device that

emulates physical tape libraries, allowing you to perform disk-to-virtual tape (disk-to-disk) backups using

your existing backup application(s). The many benefits of performing data backups to a VLS instead of

physical tape are described in Benefits.

The VLS emula

libraries. Y

of tape drives and cartridges included in each tape library to meet the needs of your environment. You

configure the size of the virtual cartridges in your VLS, which provides even more flexibility.

The VLS accommodates mixed IT platform and backup application environments, allowing all your servers

and backup applications to access the virtual media simultaneously. You can specify which servers

are allowed to access each virtual library and tape drive you configure. You can change the default

LUNs assigned to the virtual library and tape drives for each host as needed to accommodate different

operating

tes a variety of physical tape libraries, including the tape drives and cartridges inside the

ou determine the number and t ypes of tape libraries a VLS emulates, and the number and type

system requirements and restrictions.

Benefits

Data stor

using a backup application.

Integrating a VLS into your existing storage and backup infrastructure delivers the following benefits:

• Faster backups

• Faster single file restores

• Lower operating costs

• More efficient use of storage space

• Reduced risk of data loss and aborted backups

ed on a VLS is easily cloned to physical tape for off-site disaster protection or long-term archival

BackupspeedsarelimitedbythenumberoftapedrivesavailabletotheSANhosts. TheVLS

emulates many more tape drives than are available in physical tape libraries, allowing more hosts

to run backups concurrently.

The VLS is optimized for backups and delivers faster performance than a simple disk-to-disk solution.

Asinglefile can be restored much faster from disk than tape.

Fewer physical tape drives and cartridges are required as full backups to tape are eliminated. Also,

fewer cartridges are required as small backups stored on multiple virtual cartridges can be copied to

one physical cartridge.

Physical tape libraries cannot share storage space with other physical tape libraries, and physical

cartridges cannot share storage space with other physical cartridges. This unused storage space

is wasted.

Storage space is not wasted in a VLS, because VLS storage space is dynamically assigned as it is

used. Storage space is shared by all the libraries and cartridges configured on a VLS.

RAID-basedstorageismorereliablethantapestorage.

Aborted backups caused by tape drive mechanical failures are eliminated.

HP StorageWorks

15

Page 16

Sy stem status monitoring

VLS hardware, e

monitored by th

Anotification alert is generated by the VLS software when a ha rdware or environmental failure is detected

or predicted. VLS notification alerts are displayed on Command View VLS, and can also be sent as mail

to the mail addresses you specify and/or SNMP traps to the m anagement consoles you specify.

For more information about viewing VLS hardware status, and/or receiving VLS notification alerts by

mail or as SNMP

Redundancy

The VLS includes some important redundancy features:

• Redundant fans

Each node includes redundant fans. If a fan fails in a node (head unit), the remaining fans run at

a faster speed, temporarily providing enough cooling.

• Redundant power supply

Each node includes a redundant power supply. With redundant power supplies, if one power

supply fails in a node, the remaining functional power supply provides enough power for the

node to function. HP recommends that the primary power supplies be connected to a separate

powersourceatthesitefromtheredundantpowersupplies.

CAUTION:

Replace a failed fan or power supply as soon as possible to maximize the life expectancy of the

remaining fan(s) or power supply and to maintain redundancy.

nvironmental, and virtual d evice (library, tape drive, cartridge) status is constantly

e VLS software and displayed on the VLS web user interface, Command View VLS.

traps, see Monitoring.

• Redundant system disks

Each VLS node (head unit) contains two system hard drives configured into a RAID 1 (mirrored)

volume. This provides dual boot capability and quick recovery if one of the system hard drives fail.

For more information about VLS features, visit the H P web site: h

Components

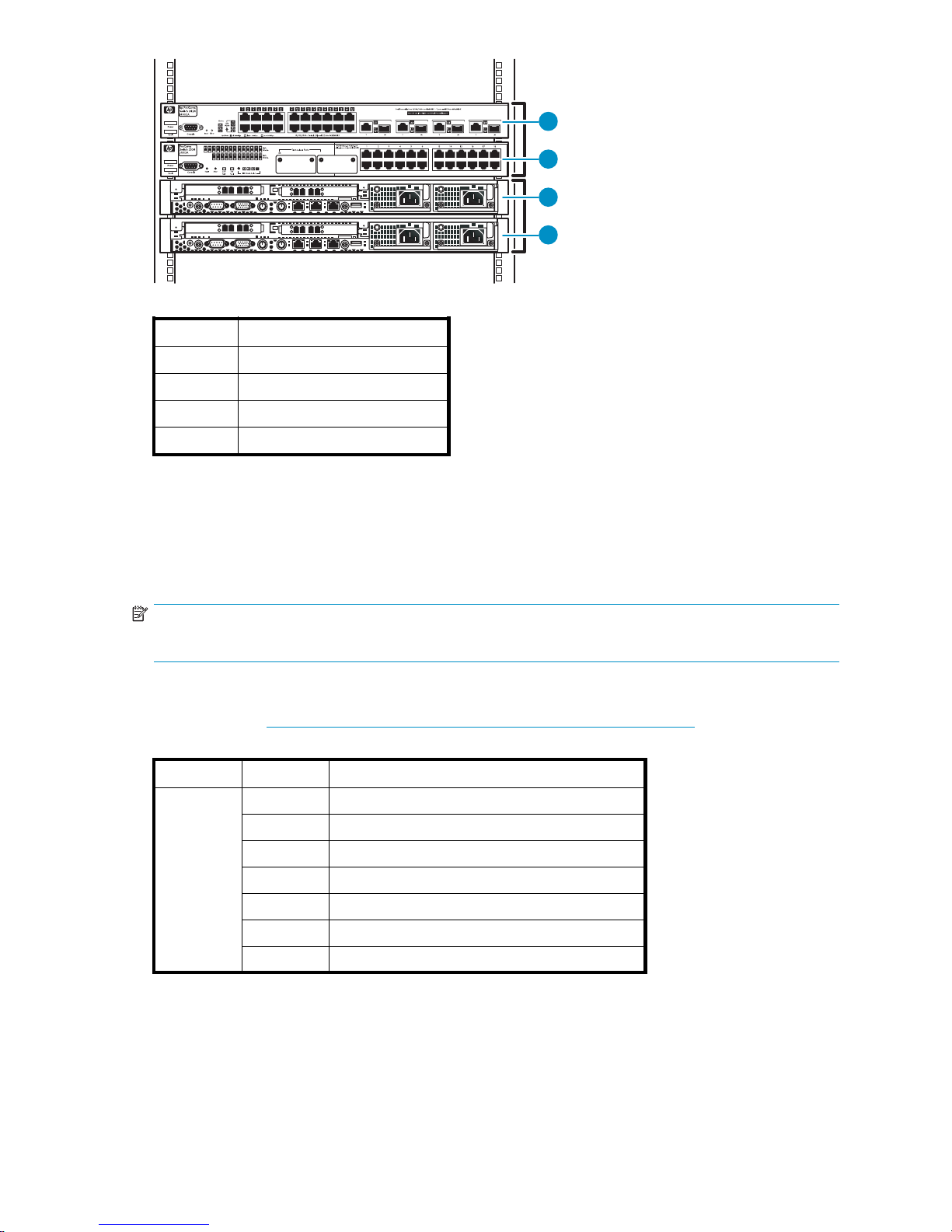

A VLS300 consists of at least two nodes (one primary node and between one and seven secondary

nodes) and dual LAN switches for internal inter-node connections. See the drawing of racked nodes

below. Each node contains dual processors, two dual port FC HBAs, four 512 MB memory modules,

and two 80 Gb hard drives.

No external storage is included with the VLS300; instead, the gateway uses external storage in existing

arrays.

ttp://www.hp.com

16

Introduction

Page 17

1

Item

1

2

3

4

26

Description

Ethernet switch 2824 (1 Gb)

Ethernet switch 2524 (100 Mb)

Node 0, primary node

Node 1, secondary node

2

3

4

11149

The two nodes include a base license to configure up to 25 LUNs—ten LUNs per gateway node plus five

2 TB upgrade licenses—which gives the gateway up to 50 TB capacity.

Up to six nodes can be added to a VLS300 for a total of eight nodes in a single gateway. Each

additional node adds licenses for up to ten more LUNs and increases maximum external capacity by up

to 20 TB. Capacity can also be increased by purchasing capacity bundles, each of which adds licensing

for one additional external array LUN and increases maximum external capacity by up to 2 TB.

NOTE:

Maximum capacity for each LUN on the VLS300 is 2 TB.

Adding nodes and licenses increases the VLS300 storage capacity as shown in Table 2. Adding nodes

also increases the performance. See the HP StorageWorks VLS300 Virtual Library System Quickspec on

the HP web site (h

ttp://h18006.www1.hp.com/products/storageworks/6000vls) for performance data.

Table 2 VLS300 capacity

Model Nodes Maximum capacity without expansion LTUs

VLS300

250TB

370TB

4

5

6130TB

7

8170TB

90 TB

11 0 T B

150 T B

HP StorageWorks

17

Page 18

18

Introduction

Page 19

2 Hardware installation

This section details the steps to install the VLS hardware:

• Preparing for the installation

• Unpacking

• Id entifying the VLS shipping carton contents

• Installing the VLS node(s) into a rack

• Install the 100 Mb Ethernet switch 25 24 into a rack

• Install the 1 Gb Ethernet switch 2824 into a rack

• Installing VLS300 cables

Preparing for the installation

PreparetheEVAfortheVLS300

Arrays that will be connected to the VLS300 must already be setup with the appropriate configuration

as described in the solutions guide, including:

• Command View EVA is installed, at firmware revision 5100 or later, and functioning properly.

• There are either two external FC switches/fabrics or two zones on an external FC switch/fabric so that

there are two (high availability) data pathways from the VLS300 to the EVA.

• All of the required VRaid LUNs required for the VLS have been created on the EVA according to the

design g uidelines (for example, each LUN is roughly the same size—2 TB is preferred. The LUNs can

not be read-only. RAID 5 is recommended. Path failover is balanced across both EVA controllers).

If this has not been done, refer to the solutions guide for instructions.

Tools for installation

• Two p eople

• Phillips screwdriver

• Box cutt

ing knife

Taking ESD precautions

To prevent damaging the system, be aware of the precautions you need to follow when setting up the

system or handling parts. A discharge of static electricity from a finger or other conductor may damage

system boards or other static-sensitive devices. This type of damage may reduce the life expectancy of

the device.

To prevent electrostatic damage:

• Avoid hand contact by transporting and storing products in static-safe containers.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-free workstations.

• Place parts on a grounded surface before removing them from their containers.

• Avoid touching pins, leads, or circuitry.

• Always be properly grounded when touching a static-sensitive component or assembly.

HP StorageWorks

19

Page 20

Grounding metho

ds to prevent electrostatic discharge

Several method

installing electrostatic-sensitive parts:

• Use a wrist strap connected by a ground cord to a grounded workstation or computer chassis.

Wrist straps are flexible straps with a minimum of 1 megaohm ±10 percent resistance in the

ground cords.

• Use heel straps, toe straps, or boot straps at standing workstations.

Wearthestrapsonbothfeetwhenstandingonconductivefloors or dissipating floor mats.

• Use conductive field service tools.

• Use a portabl

If you do not h

install the part.

For more information on static electricity or assistance with product installation, contact your authorized

reseller.

s are used for grounding. Use one or more of the following methods when handling or

To provide proper ground, wear the strap snug against the skin.

e field service kit with a folding static-dissipating work mat.

ave any of the suggested equipment for proper grounding, have an authorized reseller

Unpacking

Place the shipping carton as close to the installation site as possible. Before unpacking the VLS, inspect

the shipping carton for damage that may have occurred during shipment. If you detect any damage,

notify the carrier and HP before unpacking the unit.

Removing the packing materials

To unpack the VLS:

1. Open the t

2. Carefull

3. Place th

NOTE:

Inspect

detected, contact your authorized service representative.

4. Remove the accessory kits and documentation from the shipping cartons. Set them aside for later use.

5. Place shipping materials back into the shipping cartons.

6. Set the shipping cartons aside for later use.

op of the shipping cartons.

y lift the units out of the boxes and remove the packing materials.

eunitsonastableworksurface.

the units for any damage that may have occurred during shipment. If damage is

Rack planning resources

The rack resource kit ships with all HP or Compaq branded 9000, 10000, and H9 series racks. A

summary of the content of each resource follows:

• Custom Builder is a web-based service for configuring one or many racks. Rack configurations

can be created using:

•Asimple,guidedinterface

• Build-it-yourself model

• The Installing Rack Products video provides a visual overview of operations required for

configuring a rack with rack-mountable components. It also provides the following impor tant

configuration steps:

• Planning the site

20

Hardware installation

Page 21

• Installing rack servers and rack options

•Cablingserversinarack

• Coupling multiple racks

• The Rack Products Documentation CD enables you to view, search, and print documentation for

HP and Compaq branded racks and rack options. It also helps you set up and o ptimize a rack

in a manner that best fits your environment.

Rack requirements

HP supports the HP System E racks and the HP 10000 Series racks for use with VLS systems. Other racks

might also be

suitable, but have not been tested with the VLS.

Rack warnings

WARN ING!

To reduce the risk of personal injury or damage to the equipment, be sure that:

• The leveling jacks are extended to the floor.

• The full weight of the rack rests on the leveling jacks.

• The stabilizing feet are attached to the rack if it is a single-rack installation.

• The racks are coupled together in multiple-rack installations.

• Only one component is extended at a time. A rack may become unstable if more than one

component is extended for any reason.

WARN ING!

To reduce the risk of personal injury or equipment damage when unloading a rack:

• At least two people are needed to safely unload a rack from a pallet. An empty 42U rack can weigh

as much as 115 kg (253 lb), can stand more than 2.1 m (7 ft) tall, and may become unstable when

being moved on its casters.

• Never stand in front of a rack when it is rolling down the ramp from the pallet. Always handle a

rack from both sides.

Optimum environment

When installing a VLS in a rack, select a location that meets the environmental standards described

in this section and Environmental specifications.

Space and airflow requirements

To allow for servicing and adequate airflow, observe the following space and airflow requirements

when deciding where to install a rack:

• Leave a

• Leave a minimum clearance of 76.2 cm (30 in) behind the rack.

• Leave a minimum clearance of 122 cm (48 in) from the back of the rack to the back of another

rack w

A VLS draws in cool a ir through the front door and expels warm air through the rear door. Therefore, the

front and rear rack doors must be adequately ventilated to allow ambient room a ir to enter the cabinet,

and the rear door must be adequately ventilated to allow the warm air to escape from the cabinet.

minimum clearance of 122 cm (48 in) in front of the rack.

hen racks are back-to-back.

HP StorageWorks

21

Page 22

CAUTION:

To prevent improper cooling and damage to the equipment, do not block the ventilation openings.

When vertical space in the rack is not filled by a VLS or rack component, the gaps between the

components cause changes in airflow through the rack and across the servers. Cover all gaps with

blanking panels to maintain proper airflow. Using a rack without blanking panels results in improper

cooling that can lead to thermal damage.

The Compaq 10000 Series racks provide proper VLS cooling from flow-through perforations in the front

and rear doors that provide 64 percent open area for ventilation.

CAUTION:

If a third-party rack is used, observe the following additional requirements to ensure adequate airflow

and to prevent damage to the equipment:

• Front and rea

5,350 sq cm (

(equivalent to the required 64 percent open area for ventilation).

• Side—The clearance between the installed rack component and the side panels of the rack must

be a minimum

r doors—If the 42U rack includes closing front and rear doors, you must allow

830 sq in) of holes evenly distributed from top to bottom to permit adequate airflow

of 7 cm (2.75 in).

Temperature requirements

To ensure continued safe and reliable equipment operation, install or position the system in a

well-ventilated, climate-controlled environment.

The maximum recommended ambient operating temperature (TMRA) for the VLS system is 35° C (95° F).

The temperature in the room where the rack is loca ted must not exceed 35° C (95° F).

CAUTION:

To reduce the risk of damage to the equipment when installing third-party options:

• Do not permit optional equipment to impede airflow around the VLS or to increase the internal rack

temperature beyond the maximum allowable limits.

• Do not exceed the TM RA.

Power requirements

Installation of a V LS must comply with local and regional electrical regulations governing the installation

of information technology equipment by licensed electricians. This equipment is designed to operate in

installations covered by NFPA 70, 1999 Edition (National Electric Code) and NFPA-75, 1992 (code for

Protection of Electronic Computer/Data Processing Equipment). For electrical power ratings on options,

see the product rating label or the user documentation supplied with that option.

WARNING!

To reduce the risk of personal injury, fire, or damage to the equipment, do not overload the AC supply

branch circuit that provides power to the rack. Consult the electrical authority having jurisdiction over

wiring and installation requirements of your facility.

22

Hardware installation

Page 23

CAUTION:

Protect the VLS from power fluctuations and temporary interruptions with a regulating uninterruptible

power supply (UPS). This device protects the hardware from damage caused by power surges and

voltage spikes and keeps the system in operation during a power failure.

When installing a VLS connected to more than one disk array, you may need to use additional power

distribution devices to safely provide power to all devices. Observe the following guidelines:

• Balance the device power load between available AC supply branch circuits.

• Do not allow the overall system AC current load to exceed 80 percent of the branch circuit

AC current rating.

• Do not use common power outlet strips for this equipment.

• Provide a separate electrical circuit for each device.

Electrical grounding requirements

The V LS must be grounded properly for proper operation and safety. In the United States, you must install

the equipment in accordance with NFPA 70, 1999 Edition (National Electric Code), Article 250, as well

as any local and regional building codes. In Canada, you must install the equipment in accordance

with Canadian Standards Association, CSA C22.1, Canadian Electrical Code. In all other countries,

you must install the equipment in accordance with any regional or national electrical wiring codes, such

as the International Electrotechnical Commission (IEC) Code 364, parts 1 through 7. Furthermore, you

must be sure that all power distribution devices used in the installation, such as branch wiring and

receptacles, are listed or certified grounding-type devices.

Because of the high ground-leakage currents associated with multiple VLS and servers connected to the

same power source, HP recommends the use of a power distribution unit (PDU) that is either permanently

wired to the building’s branch circuit or includes a non-detachable cord that is wired to an industrial-style

plug. NEMA locking-style plugs or those complying with IEC 60309 are considered suitable for this

purpose. Using c ommon power outlet strips for a VLS is not recommended.

Identifying the shipping carton contents

Unpack the VLS shipping cartons and locate the materials and d ocumentation necessary for installing the

VLS. All the rack mounting ha rdware and documentation necessary for installing a VLS node into a rack

is included in the node shipping carton. All the rack mounting hardware and documentation necessary

for installing a VLS disk array into a rack is included in the disk array shipping carton.

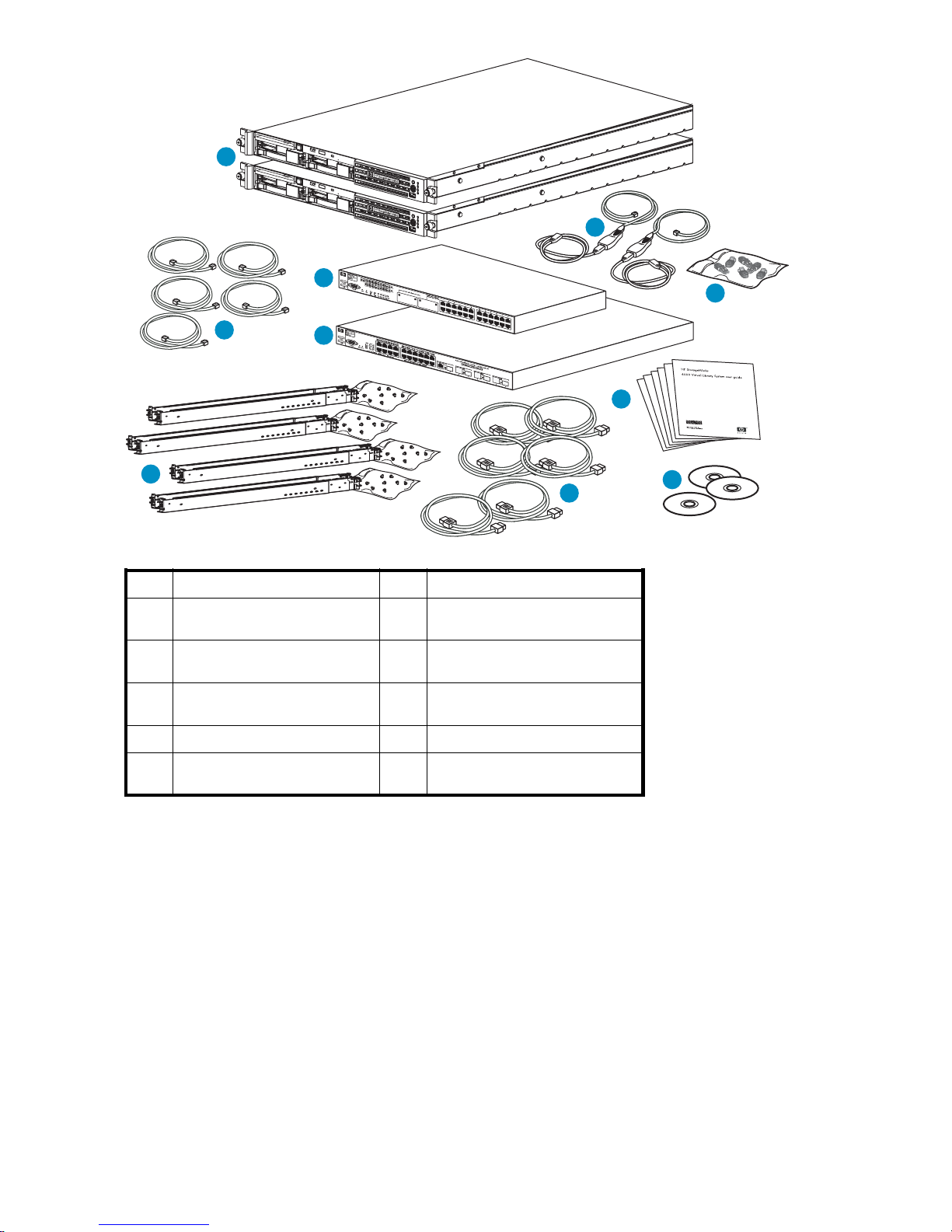

VLS300 system shipping carton

NOTE:

In addition to the contents of the shipping carton(s) and an existing EVA, you will also need a #1 Phillips

screwdriver , a #2 Phillips screwdriver , 1 Ethernet cable to connect to the existing external network, and 4–8 FC

cables to connect from the nodes to the external FC fabri cs/switches. These are not included with the VLS300.

HP StorageWorks

23

Page 24

1

10

5

Item

1

2

3

4

5

2

4

3

Description

VLS300 Gateway primary and

secondary nodes

100 Mb Ethernet switch 2524

(1)

1GbEthernetswitch2824(1)

3ftEthernetcables(5)

1U rack mounting hardware kits

and documentation (3)

Item

6

7

8

9

10

2

6

6

Description

Power co rds (6)

Documentation CD (1) and VLS

Quick Restore CDs (2)

Printed VLS node installation

poster (1)

Loopback plugs

USB LAN adapters (2)

9

8

7

11145

24

Hardware installation

Page 25

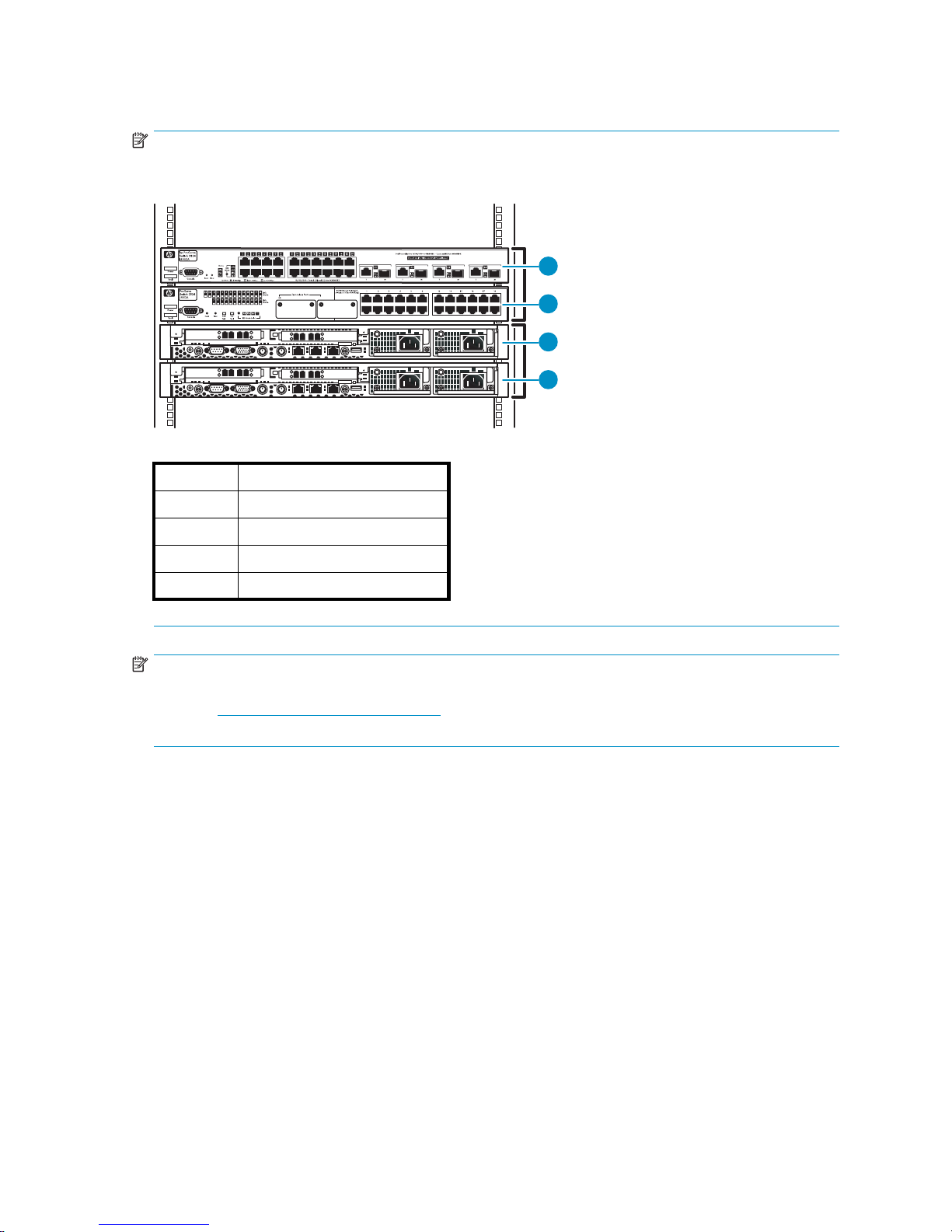

Installing the

NOTE:

The components of the VLS300 are connected with 3 ft. cables. Install the components close enough in

the rack to accommodate the cable lengths. HP recommends the racking configuration:

VLS300 nodes into a rack

1

Item

1

2

3

4

26

Descripti

Ethernet switch 2824 (1 Gb)

Ethernet switch 2524 (100 Mb)

Node 0, primary node

Node 1, secondary node

on

2

3

4

11149

NOTE:

If you are installing the node into a telco rack, order the appropriate option kit at the RackSolutions.com

web site: h

ttp://www.racksolutions.com/hp. Follow the instructions on the web site to install the rack

brackets.

To install a node into the rack involves three main tasks:

• Install rails in the rack

• Attach rails to the VLS (appliance)

• Install appliance in rack

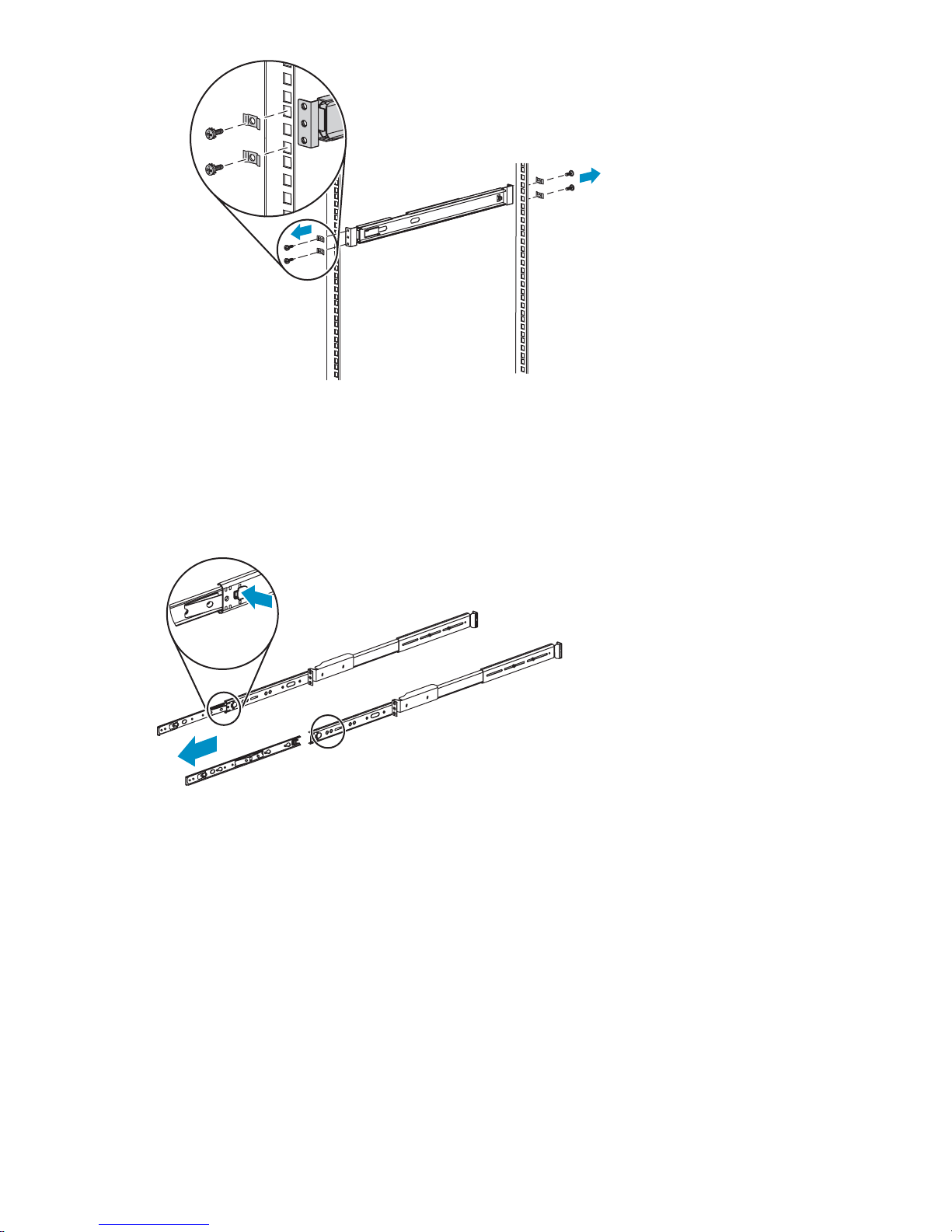

Instal

lrailsintherack

1. Locate the appropriate rail kit—part number 361190-B21.

2. Instal

l the two slide rails to the sides of the rack.

a. Adjust the side rail assemblies to the approximate rack depth.

b. At one side of the rack, align the rail holes with the holes in the rack and secure with the

ded mounting hardware using a #2 Phillips screwdriver.

provi

HP StorageWorks

25

Page 26

5201b

Figure 1 Install rails

c. Repeat these tasks for the rail on the other side of the rack.

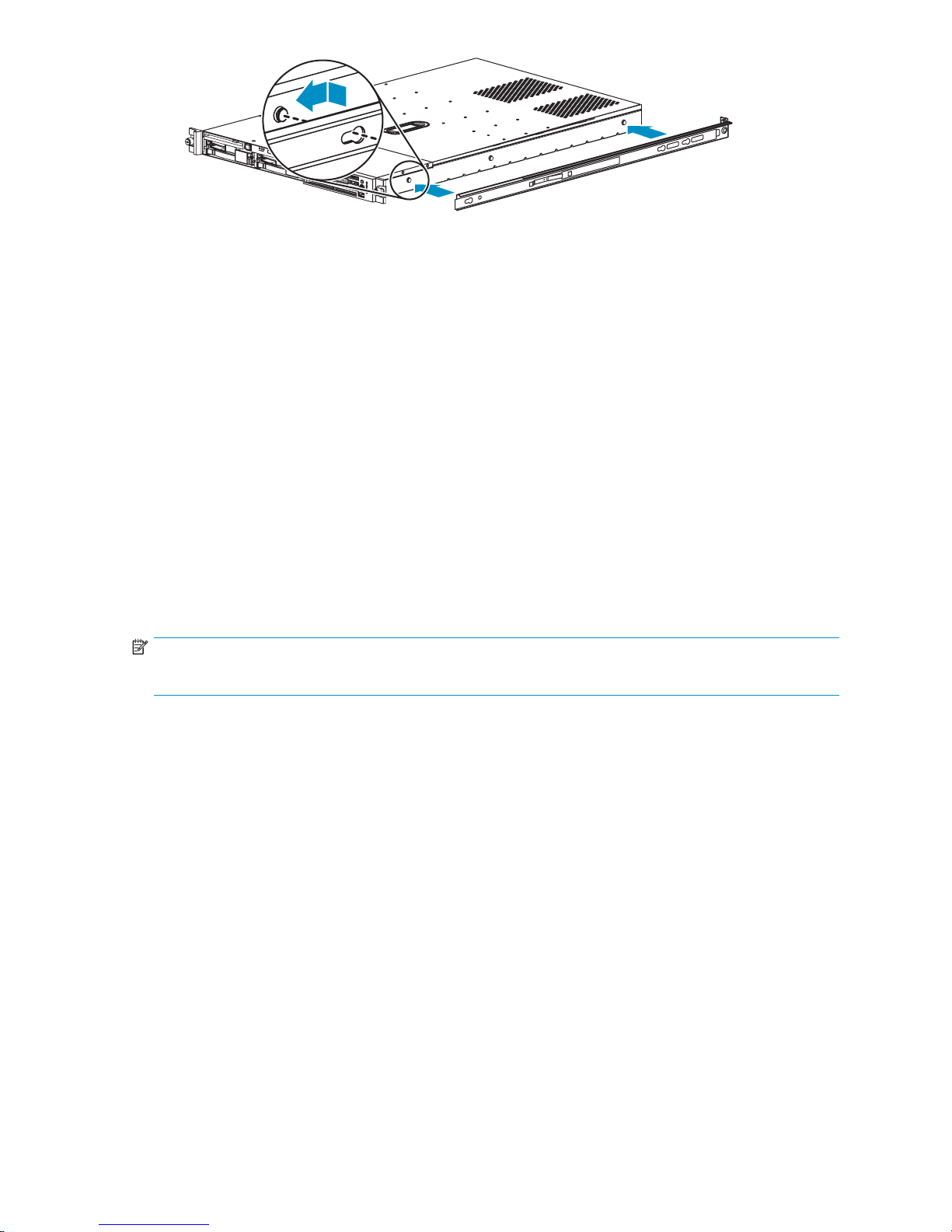

3. Remove the inner slide rails from the outer slide rails. To do so, extend the inner slide rails from the

front of the rack until they lock in place. Then press the inner rail release latch (see Figure 2)and

pull the inner slide rails straight out.

10685A

Figure 2 Remove slides from rails

Attach rails to the VLS300 (appliance)

To attach the rails to the appliance:

1. Align the rail with the node so that the word “FRONT” on the rail is seen right-side-up and at the

front of the node.

26

Hardware installation

Page 27

Figure 3 Attaching rails to the VLS300n ode

2. Align the holes in the rail with the round tabs on the side of the node.

3. Put the rail onto the node with the tabs extending into the holes on the side of the rail, then slide the

railtowardthefrontofthenodeuntilthetabsarelockedintotherail.

4. Perform these steps again to Install the other rail on the other side of the node.

Install appliance in rack

1. Align the rails on the appliance with the rails in the rack.

2. Slidetheappliancefullyintotherack.

The rails

3. With the appliance fully seated in the rack, tighten the thumbscrews just until the node bezel is

secured to the rack.

on the appliance will lock into the rails on the rack.

Install the 100 Mb Ethernet switch 2524 into a rack

To install the 100 Mb Ethernet switch 2524 into the rack:

NOTE:

There are no rails associated with this switch.

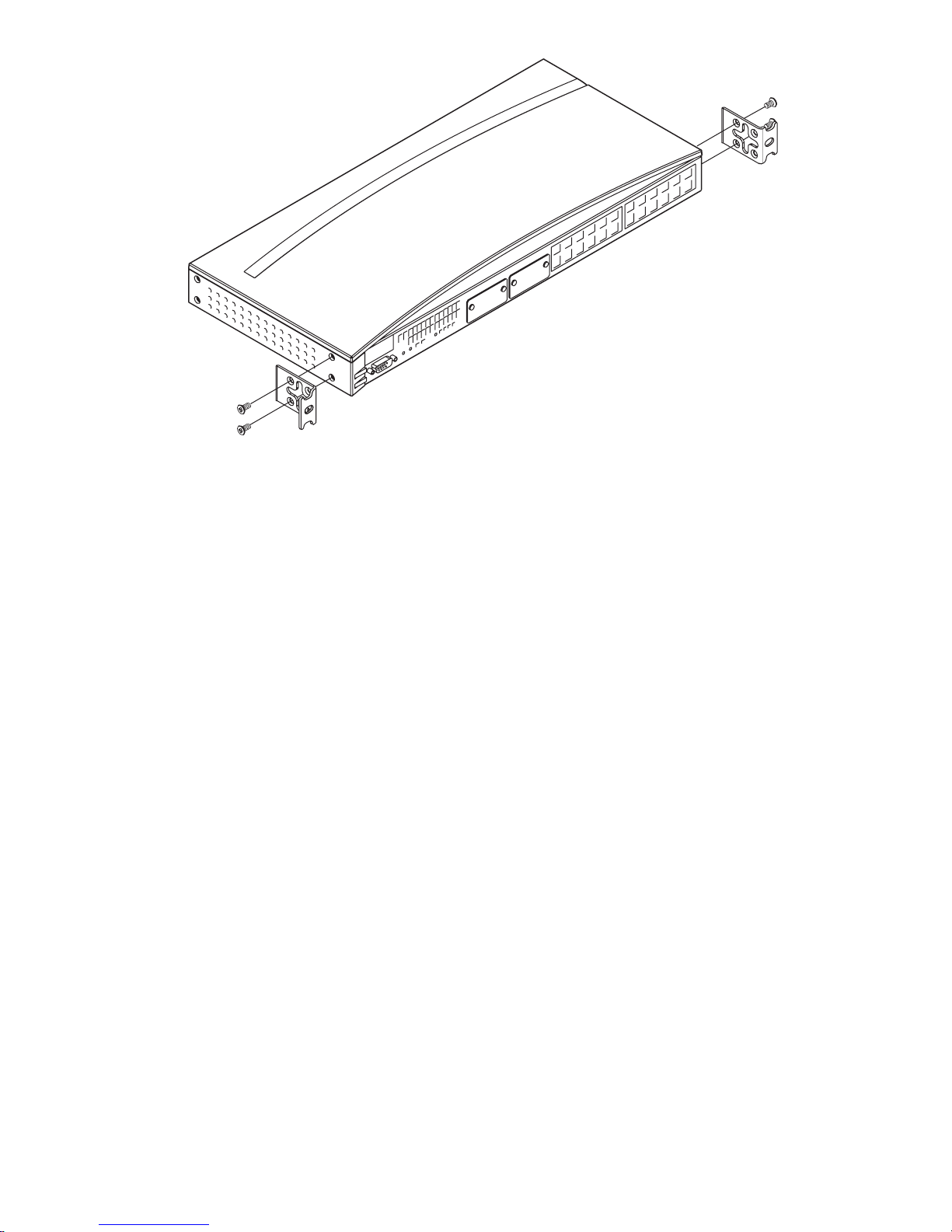

11184

1. If the metal mounting brackets are not attached to the switch, at tach them now.

a. Align the brackets so that the four screw holes are ag ainst the side of the switch and the side

of the bracket with the single screw hole extends from the switch and a ligns with the front of

the bezel. See Figure 4.

HP StorageWorks

27

Page 28

11192

Figure 4 Switch 2524 mounting brackets

b. Adjust alignment so that the holes in the side of the mounting bracket line up with the holes in

the switch.

c. Use a #1 Phillips (cross-head) screwdriver and the four M4 screws (included) to attach the

mounting brackets to the switch.

2. Placetheswitchontopofnode0intherack.

3. Align the holes of the mounting brackets on both sides of the switch’s bezel with the holes in the rack.

4. On each side of the switch, insert a Phillips screw through the holes in the mounting bracket and into

the holes in the rack.

5. Tighten the Phillips screws to secure the switch to the rack.

6. Connect the power cable to the front of the switch, run the cable through the holes in the rack to the

back of the rack but do not connect the cable to a PDU at this time.

Insta

ll the 1 Gb Ethernet switch 2824 into a rack

To install a node into the rack involves three main tasks:

• Install rails for switch 2824 in the rack

•Atta

• Install switch 2824 in rack

ch rails to the 2824 switch

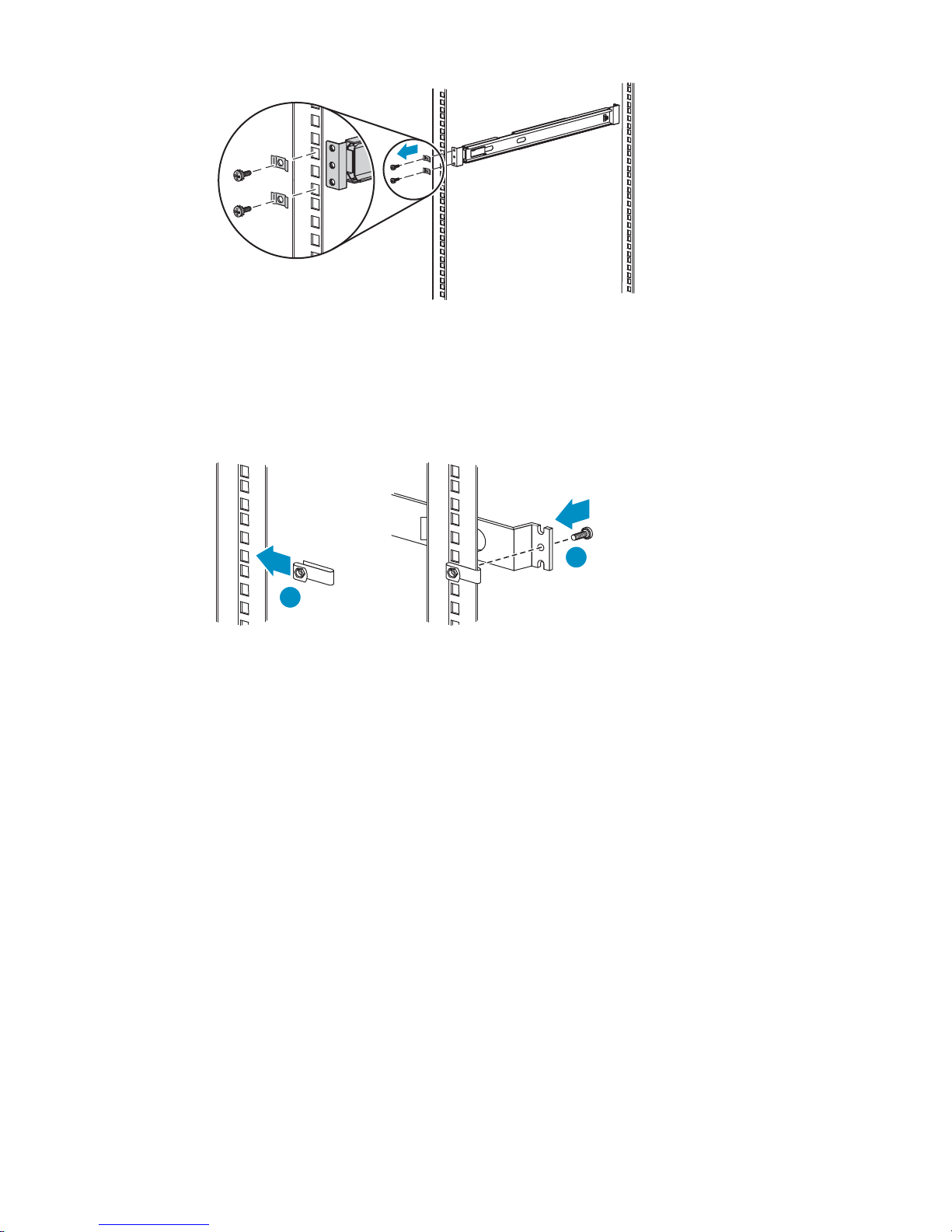

Installrailsforswitch2824intherack

1. Locate the correct rail kit—part number 356578–B21.

2. Install the two slide rails to the sides of the rack.

a. Locate four of the MS screws and insert each one into a square, semi-pierced washer (included).

b. At one side of the rack, align the front rail holes with the holes in the back of the rack Secure by

inserting two of the provided MS screws and semi-pierced washers through the two outermost

holes in th e rail and into the rack (see Figure 5).

28

Hardware installation

Page 29

11194

Figure 5 Switch 2824 rail installation, fron t

c. At the front of the rack, slide the clip onto the rack so that the hexagonal hole i s facing out

and align the holes in the clip with the proper hole in the rack. Then align the rail hole with

these holes.

2

1

11195

Figure 6 Switch 2824 rail installation, back

d. Push the screw through the rail, clip, and rack, then into the nut. Tighten the screw to secure

the rail to the rack (see Figure 6).

e. Repeat these tasks for the rail on the other side of the rack.

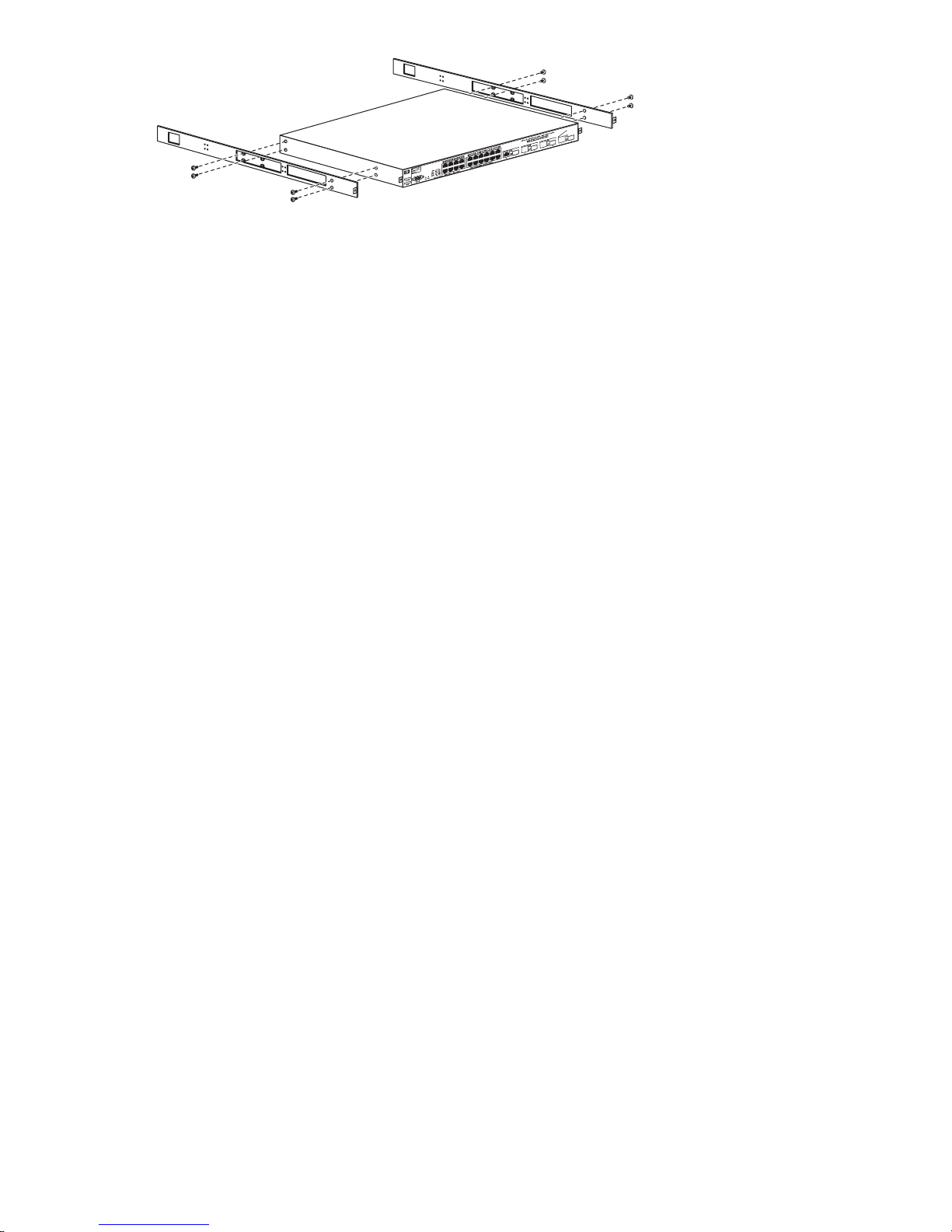

Attach rails to the 2824 switch

To attach the rails to the 2824 switch:

1. Align th

but is p

two hol

e inner rail with the switch so tha t the p erpendicular screw hole faces away from the switch

arallel to the switch bezel (face-plate). The two holes at the front of the rail must align with the

es at the front of the switch (see Figure 7).

HP StorageWorks

29

Page 30

11193

Figure 7 Attach rails to switch 2824

2. Insert two of the pan-head screws through the slide rail and into the switch at the front of the

switch. Tighten the screws.

3. Insert two of the pan-head screws through the appropriate holes in the slide rail and into the switch

at the back of the switch. Tighten the screws.

4. Perform these steps again to Install the other rail on the other side of the node.

Install sw

itch 2824 in rack

1. Align the rails on the appliance with the rails in the rack.

2. Slidetheappliancefullyintotherack.

The rails

3. On each side of the switch, insert an MS screw through the holes in the rail and into the holes

in the rack.

4. Tighten

on the appliance will lock into the rails on the rack.

theMSscrewstosecuretheswitchtotherack.

Installing VLS300 cables

To install VLS300 cables, follow the instructions below.

1. On the primary node of the VLS300:

30

Hardware installation

Page 31

1 2 3 4

10 11

5

1

Dual port FC ca

2

Dual port FC card, host port, port 1

3

Dual port FC card, storage port, port 3

4

Dual port FC card, storage port, port 2

5

Serial port to access CLI

6

Monitor and keyboard

7

NIC1, on pri

8

NIC2, on primary node connects to port 1 of switch 2824

9

USB port, connects to USB/Ethernet adapter, then to port 1 of switch 2524

10

Power supply 2

11

Power supply 1

6789

11148

rd, host port, port 0

mary node only connects to the customer-provided external network (array)

Figure 8 Primary node ports

a. Connect one end of an Ethernet cable (not included) to NIC1. Connect the other end of the

cable to t

b. Connect

he existing external network.

one end of an FC cable (not provided) to host port 0. Connect the other end to an

external FC switch/fabric that connects to your tape backup hosts.

c. If desired, connect one end of an FC cable (not provided) to host port 1. Connect the other end

to an ext

ernal FC switch/fabric that connects to your tape backup hosts. Otherwise, connect a

loopback plug to host port 1.

d. Connect one end of an FC cable (not provided) to device port 3. Connect the other end to an

external FC switch/fabric that connects to your external array.

e. Connec

t one end of an FC cable (not provided) to device port 2. Connect the other end to a

second external FC switch/fabric that connects to your external array.

f. Connecttotheserialport(cableisprovided)toaccessthecommand-lineuserinterfaceatinitial

uration. Also connect to this during debug activities. Disconnect from this port during

config

normal operations.

NOTE:

You must connect to the keyboard and monitor ports when performing Quick Restore

(keyboard and monitor not included).

g. Connect one end of an Ethernet cable to NIC2. Connect the other end of the cable to port

1 of Switch 2824 (see Figure 1 0).

h. Connect one end of a USB cable to the USB port. Connect the other end of the cable to the

USB/Ethernet adapter. Connect an Ethernet cable to the Ethernet end of the adapter, then

connect the Ethernet cable to port 1 of Switch 2524 (see Figure 11).

i. Connect a power cable to each power supply and to a PDU. If possible, connect each power

supply to a separate PDU to provide redundancy.

HP StorageWorks

31

Page 32

j. Begin routing the cables through the cable ties that shipped with the racks.

2. On the secondary node(s) of the VLS300:

NOTE:

Use this procedure to install any secondary node—node 1 which is shipped with the

gateway or upgrade nodes 2–7 which can be ordered separately.

1 2 3 4

5 6

1

2

3

4

5

6

7

8

Dual port FC card, host port, port 0

Dual port FC card, host port, port 1

Dual port FC card, storage port, port 3

Dual port FC card, storage port, port 2

NIC2, on secondary nodes connects to the next available port of switch 2824

USB port, connects to USB/Ethernet adapter

Power supply 2

Power supply 1

78

11153

Figure 9 Secondary node ports

a. Connect one end of an FC cable (not provided) to host port 0. Connect the other end to an

external FC switch/fabric that connects to your tape backup hosts.

b. If desired, connect one end of an FC cable (not provided) to host port 1. Connect the other end

to an external FC switch/fabric that connects to your tape backup hosts. Otherwise, connect a

loopback plug to host port 1.

c. Connect one end of an FC cable (not provided) to device p ort 3. Connect the other end to an

external FC switch/fabric that connects to your external array.

d. Connect one end of an FC cable (not provided) to device port 2. Connect the other end to a

second external FC switch/fabric that connects to your external array.

e. Connect one end of an Ethernet cable to NIC2. Connect the other end of the cable to port

2 of Switch 2824 (see Figure 1 0).

f. Connect one end of a USB cable to the USB por t. Connect the other end of the cable to the

USB/Ethernet adapter. Connect an Ethernet cable to the Ethernet end of the adapter, then

connect the Ethernet cable to port 2 of Switch 2524 (see Figure 11).

g. Connect a power cable to each power supply on the node a nd to a PDU. If possible, connect to

separate PDUs to provide redundancy.

h. Continue routing the cables through the cable ties that shipped with the racks.

32

Hardware installation

Page 33

NOTE:

For each additional node, connect cables from NIC2 and the USB port to the next available

ports on both switches. For example, connect the 3rd node to switch ports 3, connect the

4th node to switch ports 4, etc.

3. On Switch 2824:

1 3 5 7

2 4 6 8 9

1

Ethernet cable from NIC2 of primary node

2

Ethernet cable from NIC2 of 2nd node

3

Ethernet cable from NIC2 of 3rd node (if present)

4

Ethernet cable from NIC2 of 4th node (if present)

5

Ethernet cable from NIC2 of 5th node (if present)

6

Ethernet cable from NIC2 of 6th node (if present)

7

Ethernet cable from NIC2 of 7th node (if present)

8

Ethernet cable from NIC2 of 8th node (if present)

9

Ethernet cable from port 24 of switch 2524

11147

Figure 10 Switch 2824 ports

a. Ensure that the Ethernet cables from the NIC2 ports of each node are firmly set in the

appropriate ports.

b. Connect one end of an Ethernet cable to por t 24 of Switch 2824. Connect the other end of

the Ethernet cable to port 24 of Switch 2524.

c. Connect a power cable to the front of the switch, run the cable through the holes in the rack to

the back of the rack, then connect the cable to a PDU.

d. Continue routing the cables through the cable ties that shipped with the racks.

4. On Switch 2524:

HP StorageWorks

33

Page 34

1 2 3 4 5 6

26

7 8 8

11146

1

2

3

4

5

6

7

8

9

Ethernet cable from USB adapter on primary node

Ethernet cable from USB adapter on 2nd node

Ethernet cable from USB adapter on 3rd node (if present)

Ethernet cable from USB adapter on 4th node (if present)

Ethernet cable from USB adapter on 5th node (if present)

Ethernet cable from USB adapter on 6th node (if present)

Ethernet cable from USB adapter on 7th node (if present)

Ethernet cable from USB adapter on 8th node (if present)

Ethernetcablefromport24ofswitch2824

Figure 11 Switch 2524 ports

a. Ensure that the power cable is connected to the switch, as described in the racking instructions

(see Installing the VLS node(s) into a rack).

b. Ensure that the Ethernet cables from the NIC2 ports of each node are firmly set in the

appropriate ports on the switch.

c. Ensure that the Ethernet cable from port 24 of Switch 2524 is firmly connected to port 24

of Switch 2824.

d. Route the power cable through the holes in the rack to the back of the rack, then connect

the cable to a PDU.

e. Finish routing the cables through the cable ties that shipped with the racks.

The VLS300 system hardware installation is complete. Continue installation by configuring the identities

of each node.

34

Hardware installation

Page 35

3 Multi-node setup

After the VLS300 is physically installed, configure the identities of each node:

•Configure primary node--node 0

•Configure the secondary node(s)—nodes1 through 7

Configure primary node—node 0

To configure the primary node:

1. On the primary node, connect to the serial port or use the keyboard and mouse ports to connect to

aconsole.

2. Power on the primary node of the VLS300.

After several minutes, a menu will appear on your monitor asking whether the node is a primary

(master, m) o

3. Enter “m”. The VLS300 will then run cable checks and configuration checks.

4. Afterthechecksarecompletethenodewillrebootautomatically. Waitfortheprimarynodeto

fully boot.

Rebooting

completed

the login prompt on the terminal (Figure 1 2).

r secondary (slave, s) node.

is complete when you receive the “Initializing node#”, then “Initializing for node#

.” messages in the systems notifications (if you have DHCP enabled) or when you see

Figure 12 Notifications window

5. Set the IP a ddress and other public network configurations on the VLS300. Refer to Setting the

network settings for instructions.

Config

ure the secondary node(s)—nodes 1 through 7

figure the secondary nodes (nodes 1 through 7):

To con

1. On the secondary node, connect to the serial port or use the keyboard and mouse ports to connect

to a console.

HP StorageWorks

35

Page 36

2. Power on the primary node and all previously installed secondary nodes of the VLS300.

3. Power on the secondary node being added to the VLS300.

After several minutes, a menu will appear on your monitor asking whether the node is a primary

(master, m) or secondary (slave, s) node.

4. Enter “s”.

5. At the prompt, enter the node number (next sequential node number).

The VLS300 will then run cable checks and configuration checks, then reboot automatically.

6. Once the new secondary node has finished rebooting, log on to Command View VLS.

7. Select the System tab.

8. Select Nodes from the navigation tree.

9. Select Add Node from the task bar in the main window. This will bring up the Add Node Wizard.

10. VerifythatthenodenameintheNode Name field is the next available number that you configured

previously (Figure 1 3). For example, the primary node, previously configuredasNode0,isidentified

as Node 0 in the list of nodes on the navigation tree. The first secondary node added should be

Node 1. The next secondary node added should be Node 2.

Figure13AddNodeWizardwindow

11 . Select Finish to add the node.

12. Repea

t these steps to add nodes until all of the nodes are listed in the navigation tree.

NOTE:

Node numbering must be sequential with no gaps. Gaps in ID numbering will prevent the VLS300 from

recognizing any nodes with an ID after the gap. For example, if node numbering is 0, 1, 2, 4, 5,

the VLS300 will not recognize nodes 4 and 5.

36

Multi-node setup

Page 37

4Storageconfiguration

After all of the nodes have been c on figured, configure the storage:

• Establishing communication between the VLS300 and the EVA

• Managing VLS300 capacity

• Installing capacity licenses

Establishing

communication between the VLS300 and the EVA

Verifying array zoning

Verify that you have configured the zoning between the EVA por ts and all storage ports on all the nodes

of your VLS300. For example, storage ports 2 and 3 on each node should connect to different SAN

zones/fabrics; EVA controllers should also be connected to both zones/fabrics. If you have not done

so, refer to the VLS solutions guide to do so now.

Presenting the LUNs

1. Gather the device WWPNs.

a. From Command View VLS, select the System tab.

b. From the N

The statu

(WWPNs) (Figure 1 4).

s pane displays information about the FC ports including the world wide port names

avigation Tree, select Nodes,thenaspecific node, then Fibre Channel.

Figure 14 Fibre Channel details window

c. Write down the WWPN for each storage port on the node. There is no need to write down the

WWPNs for the host ports.

d. Repeat these steps for each node on the VLS300.

2. Create a host entry for the VLS device using the W WPNs gathered in the previous step:

HP StorageWorks

37

Page 38

a. Access Command View EVA.

b. From the Storage tab navigation tree, select the EVA storage system that will be used for the

VLS300, then Hosts.

c. In the status pane, click on Add Host to display the AddaHostscreen.

d. Enter the Host name (preferably the VLS hostname), enter or select one of the WWPNs (noted

in the previous step) in the Port WW Name box on the VLS300, and select Linux for the Host

OS (Figure 15).

NOTE:

If a WWPN is not in the Port WW Name box, there may be a zoning error. After

creating the host entries, verify that your zoning is correctly configured.

Figure 15 Add a Host window

e. Click on Add H ost.

f. From the Storage tab navigation tree, select the host you just added.

g. Click on the Ports tab in the status pane.

h. Click on Add port ,selectoneoftheVLS300WWPNs(notedinthepreviousstep)fromthe

pull-down list or type one of the appropriate W W PNs, then click Add port (Figure 16).

38

Storage configuration

Page 39

Figure 16 Add a Host Port window

i. Continue to add ports until all of the ports on the VLS300 are added and are listed on the Host

Properties screen in the status pane.

3. Present the LUNs:

CAUTION:

Present only the disks that you wish to use with the VLS300 because existing data will be

destroyed during storage pool configuration.

a. In Command View EVA, in the Storage tab navigation tree, select the EV A for the VLS300 storage

system, Virtual Disks, the disk name that you want to present, then ACTIVE under that disk.

b. Select the Presentation tab.

c. Ensure that Write Protect is set to No.

d. Ensure that the Preferred path/mode is set to either Path A-Failover only or Path B-Failover

only (Figure 17).

NOTE:

Set the Preferred path/mode forhalfofthediskstoPath A-Failover only,andtoPath

B-Failover only for the other half of the disks. This balances the data trafficacross

both A and B controllers. For more information on data traffic balancing, see Array

dual pathing.

HP StorageWorks

39

Page 40

Figure 17 Vdisk Ac tive M ember Properties window

e. Click on Present, then select the VLS300 host (just created) on the Present Vdisk screen on

the status pane.

f. Click on Present Vdisk.

g. The Operation Succeeded message displays on the status pane. Click OK.

h. Repeat these steps for each disk to present to the VLS.

NOTE:

If needed, these disks can be unpresented. See To unpresent a LUN.Ifyouunpresenta

LUN, you must then reconfigure the LUN numbering for all LUNs on the VLS300 that

follow the unpresented LUN in sequential numbering.

Managing VLS300 capacity

There are several ways to manage the capacity of your system:

• Add external LUNs to the VLS300 configuration. See Discovering array LUNs.

• Delete external LUNs from the VLS300 configuration. See Deleting array LUNs.

• Create storage pools. See Configuring storage pools.

• Destroy storage pools. See Deleting array LUNs

• Enable device-side data compression when creating new tape drives. See Creating tape drives

Discovering array LUNs

1. Discover the LUNs, either by rebooting the entire VLS300 or:

a. Open a Command View VLS session and log in as the administrator. See Opening a Command

View VLS session from Command View TL.

b. In the Storage tab n avigation tree, select Storage LUNs.

c. Select Discover Unconfigured Storage from the task bar. This causes the VLS to recognize all

presented LUNs and return the following message: # storage lun(s) discovered. #

storage lun(s) deleted. At this point, the LUNs are still unconfigured.

2. Verify that the LUNs are properly assigned and that there are two data paths for each LUN.

40

Storage configuration

Page 41

a. Open a Command View VLS session and log in as the administrator. See Opening a Command

View VLS session from Command View TL.

b. In the Storage tab navigation tree, select Storage LUNs.

c. Under All, select All Nodes in the Nodes dialog box, then click View to display Storage LUN

Details and Storage LUN Details Per Node (Figure 18).

Figure 18 Storage LUNs details window

d. Ensure that all LUNs are listed under each node, and that each has a preferred and secondary

path.

NOTE:

IfaLUNisnotrecognizedbyeachnode,theLUNisunusable.PresenttheLUNtoany

node that does not yet recognize the LUN.

3. Resolve any errors, if necessary.

If there is a license violation, you can still view all the LUNs. Either install more licenses or remove the

LUNs that do not belong. This will eliminate the violation. See Deleting array LUNs.

Deleting array LUNs

To remove a LUN from the device:

1. Unpresent the LUN to the VLS (see instructions below) or delete the LUN from the external a rray.

2. Restart emulations or reboot the device (see Restarting the VLS device emulations or Rebooting

the system).

3. Discover unconfigured storage (see Discovering array LUNs). This deletes the removed LUNs

from the configuration.

To unpresent a LUN:

1. In Command View EVA, Storage tab navigation tree, select the EVA for the VLS300 storage

system, Virtual Disks, the disk name that you want to present, then ACTIVE under that disk.

2. Select the Presentation tab for the ACTIVE Vdisk.

3. Click on the Unpresent button.

HP StorageWorks

41

Page 42

4. Selectthedisktoremovefromthehost(Figure 19).

Figure 19 Unpresent Host(s) window

5. Click on Unpresent host(s).

6. Click OK from the confirmation dialog box.

7. Click OK under Operation Succeeded in the status pane.

8. If there is a break in numbering of the remaining LUNs, LUN numbers after the break must be

reconfigured. See Multi-node setup for detailed instructions.

CAUTION:

LUN numbering must be sequential with no gaps. Gaps in LUN numbering will prevent the VLS300

from recognizing any nodes with a ny LUNs after the gap. For example, if LUN numbering is 0, 1, 2,

4,5,theVLS300willnotrecognizeLUNs4and5.

Configuring storage pools

VLS auto creates the first storage pool, but you must create any additional pools. To do so:

NOTE:

The VLS300 can have either one storage pool for all LUNs, or one storage pool for each array. Refer to

thesolutionsguidefordetails.

42

Storage configuration

Page 43

1. Create a storage pool(s):

a. Open a Command View VLS session and log in as the administrator. See Opening a Command

View VLS session from Command View TL.

b. In the Storage tab navigation tree, select Storage Pools.

c. From the task bar, select Create Storage Pool.TheCreate Storage Pool Wizard is displayed.

d. Click Finish. CREATE STORAGE POOL COMPLETED is displayed.

e. Click Return.

f. If you a

re creating a separate storage pool for each array, repeat this process for each storage

pool.

2. Add the array LUNs to the storage pool(s).

a. Open a

View V

Command View VLS session and log in as the administrator. See Opening a Command

LS session from Command View TL.

b. In the Storage tab navigation tree, under Storage Pools, select a storage pool.

c. From the task bar, select Add External LUN.TheAdd External LUN Wizard is displayed.

NOTE:

This task does not appear if there are no licenses available.

d. From the list of available unconfigured LUNs, select the LUNs to add to the pool. (By default, all

LUNs are selected.)

NOTE: