Page 1

HP StorageWorks

2500 Disk System user guide

Part number: 5697-5922

irst edition: November 2006

F

Page 2

Legal and notice information

© Copyright 2006 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth

in the express warranty statements accompanying such products and services. Nothing herein should be construed as constituting

an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained herein.

Page 3

Contents

Aboutthisguide .......................... 9

Intendedaudience...................................... 9

Relateddocumentation.................................... 9

Documentconventionsandsymbols .............................. 9

Rackstability ....................................... 10

HPtechnicalsupport.................................... 10

Customerselfrepair .................................... 11

Subscriptionservice .................................... 11

OtherHPwebsites .................................... 11

Documentation feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1Overview ........................... 13

Generaldescription .................................... 13

Features ......................................... 13

Components ....................................... 14

DS2500frontview................................... 14

DS2500rearview................................... 14

Statusindicators...................................... 15

Systemrequirements.................................... 15

Operatingsystemsoftware ............................... 15

Harddiskdrivefirmware ................................ 16

HBAs ........................................ 16

Diskdrives ...................................... 16

2 Components . . . . . ..................... 17

Listofparts........................................ 17

EMU........................................... 17

EMUfunctions .................................... 17

Controlsanddisplays ................................. 18

I/Omodules ....................................... 19

Powersupplyandblowerassembly ............................. 21

Features ....................................... 21

Powersupplyandblowerstatusindicator......................... 21

FibreChanneldisks .................................... 22

Diskdrivestatusindicators ............................... 22

Driveblanks ..................................... 24

Cablesandcabling .................................... 24

Transceivers........................................ 24

3Installation........................... 25

PreparingtoinstallaDS2500................................ 25

Unpackingtheshippingcarton ............................... 25

InstallingtheDS2500 ................................... 26

Installingthesnap-inrails................................ 26

Convertingtherailsforround-holeracks ....................... 27

Installingtherails ................................. 27

Reducingtheenclosureweight.............................. 29

Removingthedriveblanks ............................. 29

Removingthepowersupply/blowerassemblies .................... 30

2500 Disk System user guide

3

Page 4

RemovingtheEMU ................................ 30

RemovingtheI/Omodules ............................. 31

InstallingtheDS2500intherack ............................ 31

Connectingthecables ................................. 33

SettingtheenclosureID(En)............................... 34

SettingtheenclosureloopID(Li)............................. 35

DiskdriveloopID................................... 36

Verifyingtheinstallation .................................. 36

AddingdrivestoanexistingDS2500............................. 36

Installingmultiplediskdrives .............................. 37

4UsingtheEMU......................... 39

Alphanumericdisplay ................................... 39

Displaygroups ...................................... 39

EncodingtheenclosureID(En) ............................. 39

LoopID(Li)...................................... 40

Audiblealarm(Au) .................................. 41

Enablingtheaudiblealarm............................. 41

Mutingtheaudiblealarm.............................. 41

Firmwarerevision(Fr).................................. 42

Errorconditionreport(Er)................................ 42

5Troubleshooting . . ....................... 45

Eventmonitortools..................................... 45

EMUerrorconditionreport................................. 48

Severitylevels..................................... 48

Errorconditionreports ................................. 48

Statusindicators...................................... 48

Audibleerrorindicators ................................ 50

Visualerrorindicators ................................. 50

I/Omoduleandtransceivers ............................ 50

Diskdrives .................................... 51

Catastrophicerrors..................................... 52

EMUtemperaturewarningandshutdownoperation .................... 53

6Customerselfrepair ....................... 55

Customerselfrepair .................................... 55

Parts-onlywarrantyservice ............................... 55

Bestpracticesforreplacinghardwarecomponents ....................... 56

Verifyingcomponentfailure............................... 56

Procuringthesparepart ................................ 56

Returningthedefectivepart............................... 57

Replacingapowersupply/blowerassembly.......................... 57

Beforeyoubegin ................................... 57

Removingapowersupply ............................... 57

Replacingapowersupply ............................... 58

Removingablower .................................. 58

Replacingablower .................................. 59

Replacingadiskdrive ................................... 60

Beforeyoubegin ................................... 60

Removingadiskdrive ................................. 60

Replacingadiskdrive ................................. 62

ASpecifications . . ....................... 63

Physicalspecifications ................................... 63

Environmentalspecifications................................. 63

Powerspecifications .................................... 64

4

Page 5

B Regulatory notices ........................ 67

FederalCommunicationsCommission(FCC)notice....................... 67

FCCClassAcertification................................ 67

ClassAequipment................................... 67

ClassBequipment................................... 67

Declaration of conformity for products marked with the FCC logo, United States only . . . . . . 68

Modifications..................................... 68

Cables........................................ 68

Laserdevices ....................................... 68

Lasersafetywarnings ................................. 68

CompliancewithCDRHregulations ........................... 68

Certificationandclassificationinformation........................... 69

Canadiannotice(avisCanadien) .............................. 69

ClassAequipment................................... 69

ClassBequipment................................... 69

Europeanunionnotice................................. 69

NoticeforFrance ................................... 69

WEEERecyclingNotices ................................ 70

Englishnotice................................... 70

Dutchnotice ................................... 70

Czechoslovakiannotice............................... 70

Estoniannotice .................................. 70

Finnishnotice................................... 71

Frenchnotice ................................... 71

Germannotice .................................. 71

Greeknotice ................................... 71

Hungariannotice ................................. 72

Italiannotice ................................... 72

Latviannotice................................... 72

Lithuaniannotice ................................. 72

Polishnotice ................................... 73

Portuguesenotice ................................. 73

Slovakiannotice.................................. 73

Sloveniannotice.................................. 73

Spanishnotice .................................. 74

Swedishnotice .................................. 74

Germanynoisedeclaration............................... 74

Japanesenotice.................................... 74

Harmonics conformance (Japan) . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Taiwanesenotice ................................... 75

Japanesepowercordnotice............................... 75

Country-specificcertifications .............................. 75

CEMU-generatederrorconditionreports............... 77

Errorconditionreportformat ................................ 77

Correctingerrorconditions ................................. 78

Diskdriveerrorconditions ............................... 78

Powersupplyerrorconditions.............................. 78

Blowererrorconditions................................. 79

Temperatureerrorconditions .............................. 80

EMUerrorconditions ................................. 81

ResettingtheEMU................................. 82

Transceivererrorconditions............................... 82

Voltagesensorandcurrentsensorerrorconditions ..................... 83

Backplaneerrorconditions ............................... 84

I/Omoduleerrorconditions .............................. 84

Index .............................. 87

2500 Disk System user guide

5

Page 6

Figures

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

..FC-ALloops(directconnect) ........................... 14

..DS2500—frontandrearviews.......................... 15

..EMU control

..Redundantdiskconnections ........................... 19

..I/Omodule.................................. 20

..Powersupplyandblowerassemblycomponents .................. 21

..HP FC disk d

..Diskdrivestatusindicators............................ 23

..Driveblank .................................. 24

..Contentsofsnap-inrail-mountingkit........................ 26

..Convertingtherailsforround-holeracks...................... 27

..Engagingthescissor-typelockinglatches ..................... 28

..Insertingtherailintotherearrackcolumn..................... 28

..Disengagingtheshippingbracket ........................ 29

..Drive bl

..Removingapowersupply/blowerassembly .................... 30

..RemovingtheEMU............................... 31

..RemovinganI/Omodule............................ 31

..Enclos

..Installingadiskdrive.............................. 32

..EMUalphanumericdisplayandcontrols...................... 33

..Enclosureoperationalstatusindicators....................... 33

..FC-ALloops.................................. 34

..Driveblank .................................. 36

..Installingadiskdrive.............................. 37

..LEDsintheoperationalstate........................... 50

..I/OmodulestatusLEDs............................. 51

..Diskdrivestatusindicators............................ 52

..Typicalproductlabel .............................. 57

..Removingapowersupply............................ 58

..Replacingapowersupply............................ 58

..Removingablower............................... 59

..Replacingablower............................... 60

..Removingadiskdrive.............................. 62

..Replacingadiskdrive ............................. 62

..Typicalenclosurecertificationlabel........................ 75

..Transceiverelementnumbers........................... 83

sanddisplays ........................... 18

rive................................ 22

ank .................................. 30

urethumbscrews ............................. 32

6

Page 7

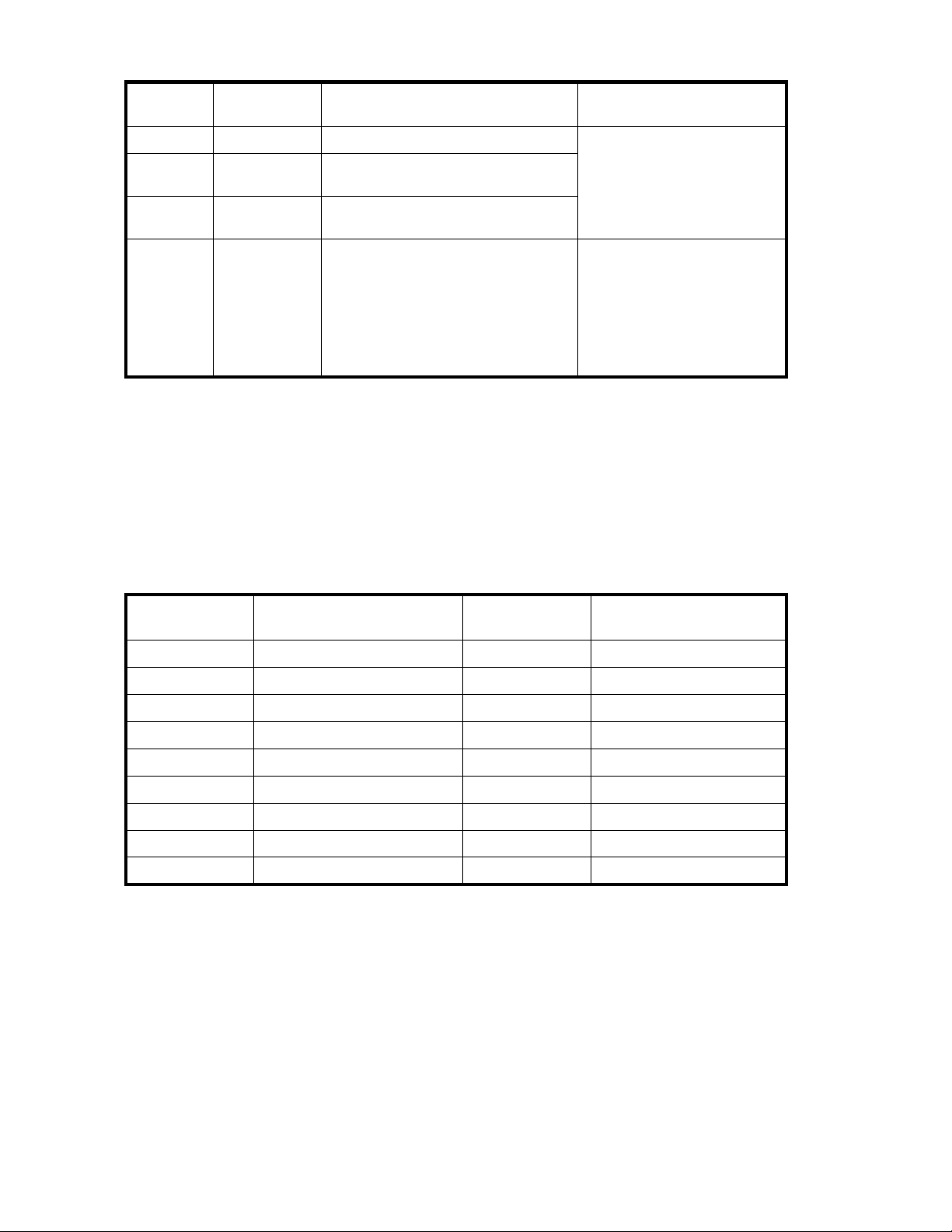

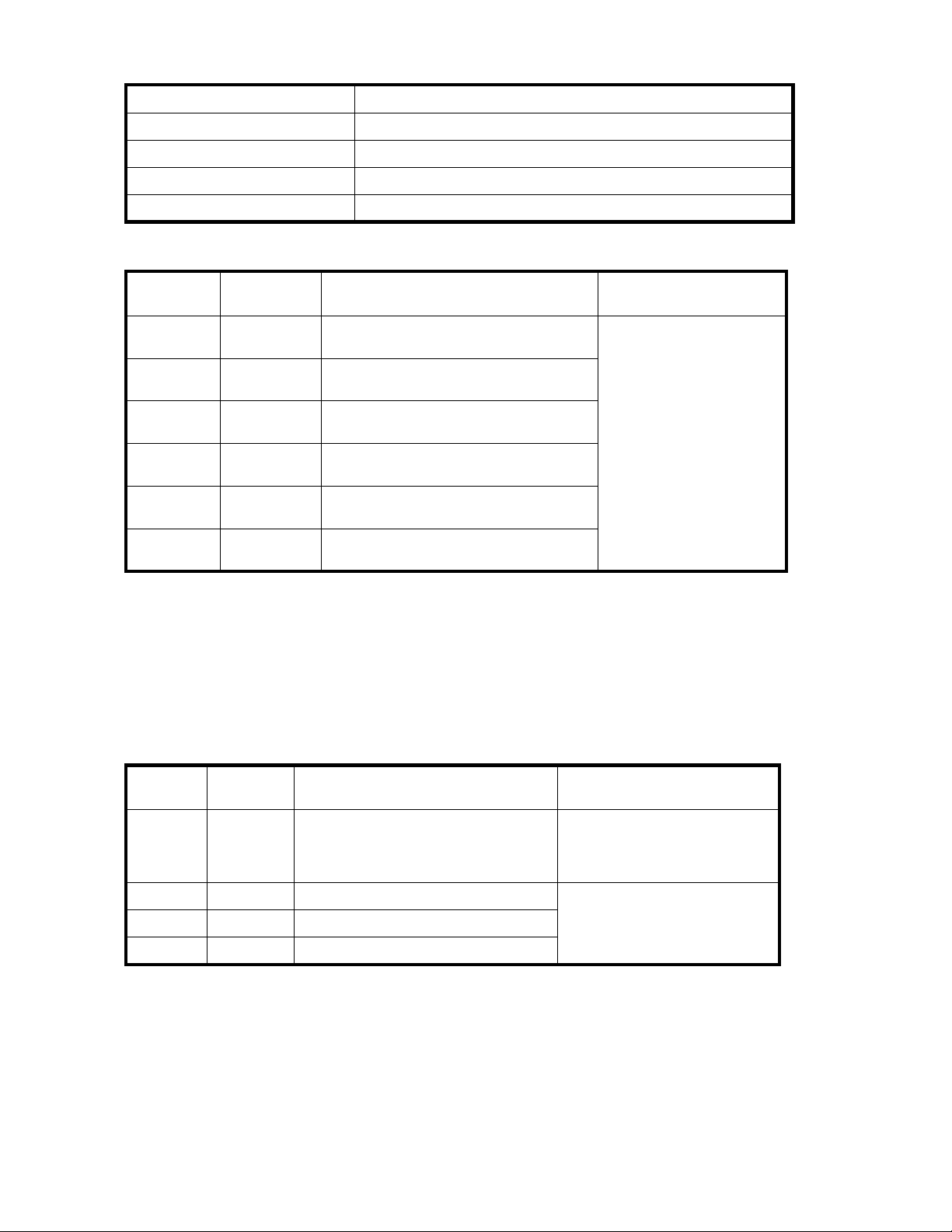

Tables

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

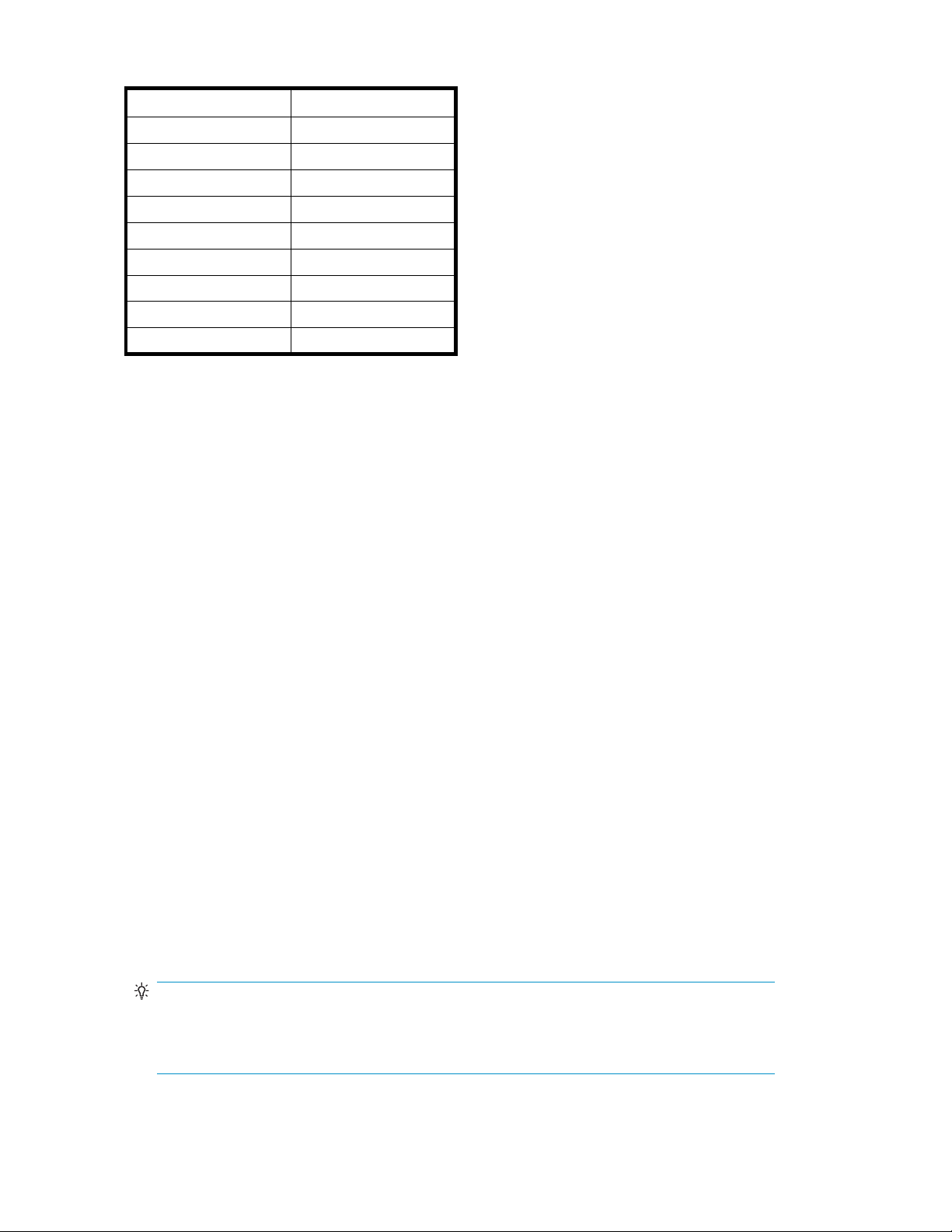

..Documentconventions .............................. 9

..Diskdrivestatusindicatordescriptions....................... 23

..EnclosureIDandcorrespondingloopIDs ..................... 35

..EMUdisplaygroups .............................. 39

..EnclosureIDandcorrespondingloopIDs ..................... 40

..Elementtypes ................................. 43

..Enclosure

..EMUstatusindicators.............................. 49

..Audiblealarmsoundpatterns .......................... 50

..I/OmodulestatusLEDs............................. 51

..Disk dri

..DiskdriveloopIDs............................... 61

..DS2500physicalspecifications.......................... 63

..Environmentaloperatingspecifications....................... 63

..Environmentalshippingorshort-termstoragespecifications.............. 64

..DS2500ACinputlinevoltages.......................... 64

..ACinputcurrentandwattage .......................... 65

..Outputvoltageandcurrentspecifications ..................... 65

..Power s

..Elementtype.................................. 77

..Diskdriveerrorconditions............................ 78

..Powersupplyerrorconditions .......................... 79

..Blowererrorconditions ............................. 80

..Temperaturesensorelementnumbers ....................... 80

..Temperaturethresholderrorconditions....................... 81

..EMUerrorconditions.............................. 82

..Transceivererrorconditions ........................... 83

..Voltageandcurrentsensorlocations ....................... 84

..Voltageandcurrentthresholderrorconditions ................... 84

..Backplaneerrorconditions ........................... 84

Omoduleerrorconditions........................... 85

..I/

statusicondisplays .......................... 49

vestatusindications ........................... 52

pecifications .............................. 65

2500 Disk System user guide

7

Page 8

8

Page 9

About this guide

This guide provides information about:

• Installing an HP StorageWorks 2500 Disk System (DS2500)

• Using the Environmental Monitoring Unit (EMU) to determine the status of DS2500 components

• Troubleshooting problems within the DS2500

• Replacing customer replaceable units (CRUs)

Intended audience

This guide is intended for system administrators with knowledge of:

• Storage area

• Basic HP-UX operating system commands and utilities

Related documentation

The following documents provide related information:

• HP StorageWorks SAN design guide

• HP EMS hardware monitor user guide

networks (SANs)

You can find these documents on the HP web site:

ttp://www.hp.com/support/manuals

h

In the Storage section, click Disk Storage Systems and then select your product.

Document conventions and symbols

Table 1 Doc

Convention

Blue text: Table 1

Blue, unde

Bold text

Italic text Text emphasis

Monospace text

Monospace, italic text

Monospace, bold text

ument conventions

rlined text: h

ttp://www.hp.com

Element

Cross-reference links and e-mail addresses

Web site addresses

• Keys that are pressed

• Text typed into a GUI element, such as a box

• GUI elements that are clicked or selected, such as

menu and list items, buttons, tabs, and check boxes

• File and directory names

• System output

• Code

• Commands, their arguments, and argument values

• Code variables

• Command variables

Emphasized monospace text

2500 Disk System user guide

9

Page 10

WARNING!

Indicates that failure to follow directions could result in bodily harm or death.

CAUTION:

Indicates that failure to follow directions could result in damage to equipment or data.

IMPORTANT:

Provides clarif

NOTE:

Provides additional information.

TIP:

Provides helpful hints and shortcuts.

Rack stability

ying information or specific instructions.

Rack stability protects personnel and equipment.

WARNING!

To reduce the risk of personal injury or damage to equipment:

• Extend leveling jacks to the floor.

• Ensure that the full weight of the rack rests on the leveling jacks.

• Install stabilizing feet on the rack.

• In multiple-rack installations, fasten racks together securely.

• Extend only one rack component at a time. Racks can become unstable if more than one

component is extended.

HP technical

Telephone nu

ttp://www.hp.com/support/.

h

Collect the following information before calling:

• Technical s

• Product serial numbers

• Product model names and numbers

• Error messa

• Operating system type and revision level

• Detailed questions

For contin

uous quality improvement, calls may be recorded or monitored.

support

mbers for worldwide technical support are listed on the HP support web site:

upport registration number (if applicable)

ges

10

About this guide

Page 11

Customer self repair

HP customer self repair (CSR) programs allow you to repair your StorageWorks product. If a CSR

part needs repl

Some parts do no

repair can be accomplished by CSR.

For more information about CSR, contact your local service provider. For North America, see the

CSR website: h

acing, HP ships the part directly to you so that you can install it at your convenience.

t qualify for CSR. Your HP-authorized service provider will determine whether a

ttp://www.hp.com/go/selfrepair.

Subscription service

HP strongly recommends that customers register online using the Subscriber's choice web site:

h

ttp://www.hp.com/go/e-updates.

Subscribing to this service provides you with e-mail updates on the latest product enhancements,

newest driver versions, and firmware documentation updates, as well as instant access to numerous

other product resources.

After subscribing, locate your products by selecting Business support, and then Storage under Product

Category.

Other HP web sites

For additional information, see the following HP web sites:

•h

ttp://www

•http://www.hp.com/go/storage

•http://www.hp.com/support/manuals

•http://ww

.hp.com

w.hp.com/support/downloads

Documentation feedback

HP welcomes your feedback.

To make comments and suggestions about product documentation, please send a message to

storagedocs.feedback@hp.com. All submissions become the property of HP.

2500 Disk System user guide

11

Page 12

12

About this guide

Page 13

1Overview

This chapter includes the following topics:

•

General description, page 13

•

Features, page 13

• Components, page 14

• Status indicators, page 15

•Systemrequirements, page 15

General description

The DS2500 i

operating s

disk drives

together to create a storage ring.

Features

The DS2500 disk enclosure provides:

• Redundant power supplies and blowers

• FC disk drives that can be added or replaced with the system on (although the affected file

• Environmental services sensors that monitor the disk enclosure and provide real-time error

• High-availability to minimize unplanned downtime

• Customer-replaceable components

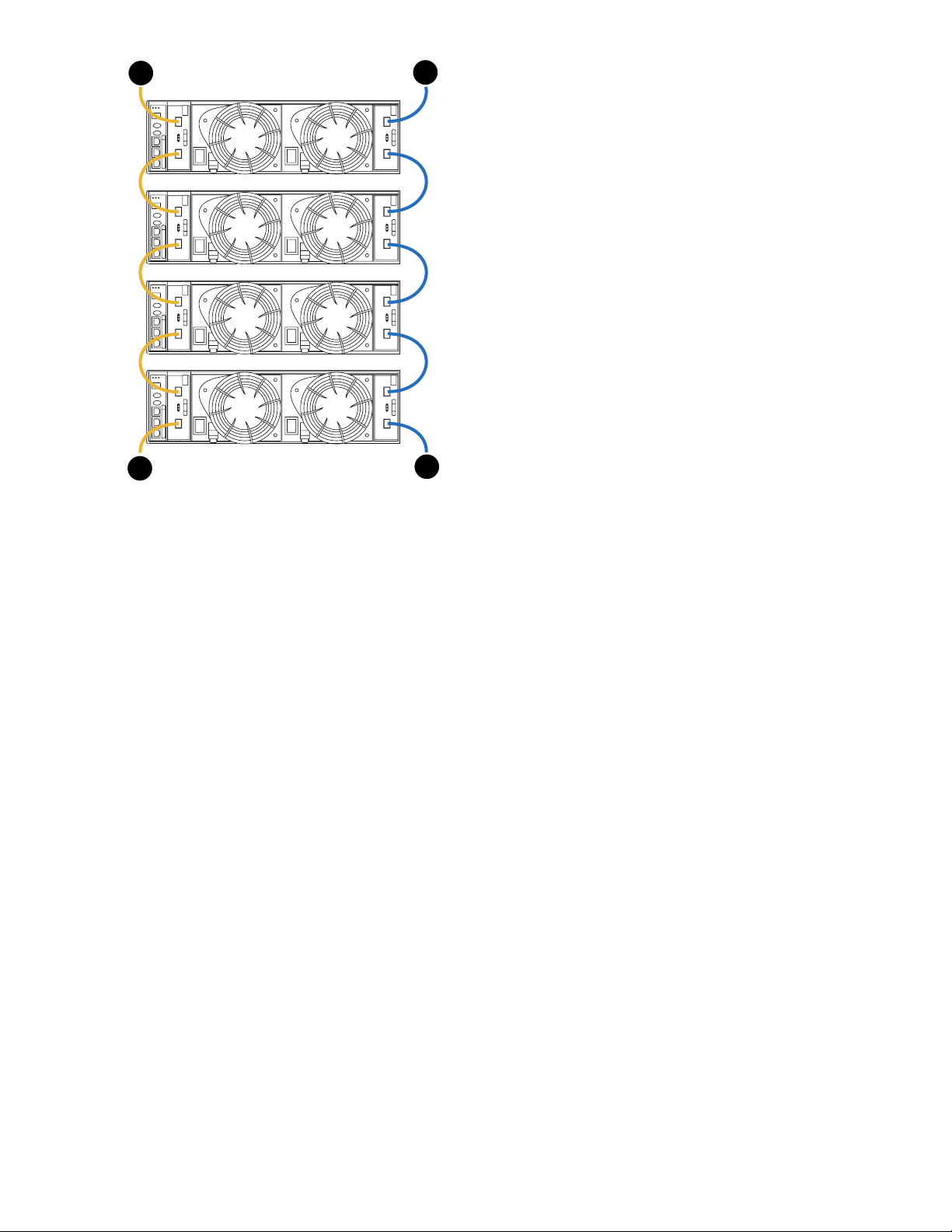

Each DS2500 is connected to Host Bus Adapters (HBAs) through two independent Fibre Channel

Arbitrated Loop (FC-AL) buses, also known as loops, to provide no single point of failure (NSPOF). Each

disk drive connects to loop A through I/O module A, and to loop B through I/O module B. Figure 1

shows the maximum configuration of four DS2500s.

The disk enclosure supports high-availability requirements through the following features:

• Hot-pluggable components

• High-capacity, high-speed disks

• Redundant, customer replaceable power supplies and blowers

• Redundant I/O modules

• Support for mirrored disks in the HP-UX environment

• Online firmware upgrades

• Hardware event monitoring and real-time error reporting

s a dual-redundant Fibre Channel (FC) loop storage system used on systems running HP-UX

ystemsoftware. TheDS2500occupies3EIAunitsinastandard19-inchrack. Upto14

can be mounted in the front of the enclosure. Up to 4 DS2500s can be daisy-chained

Only one operational power supply and one operational blower are required for the DS2500

to function.

systems must be taken offline)

reporting

2500 Disk System user guide

13

Page 14

1

10

3

2

1. Loop B—Connects to an HBA 3. Loop A—Connects to an HBA

2. Loop B—Connects to an HBA 4. Loop A—Connects to an HBA

Figure 1 FC-AL loops (direct connect)

Components

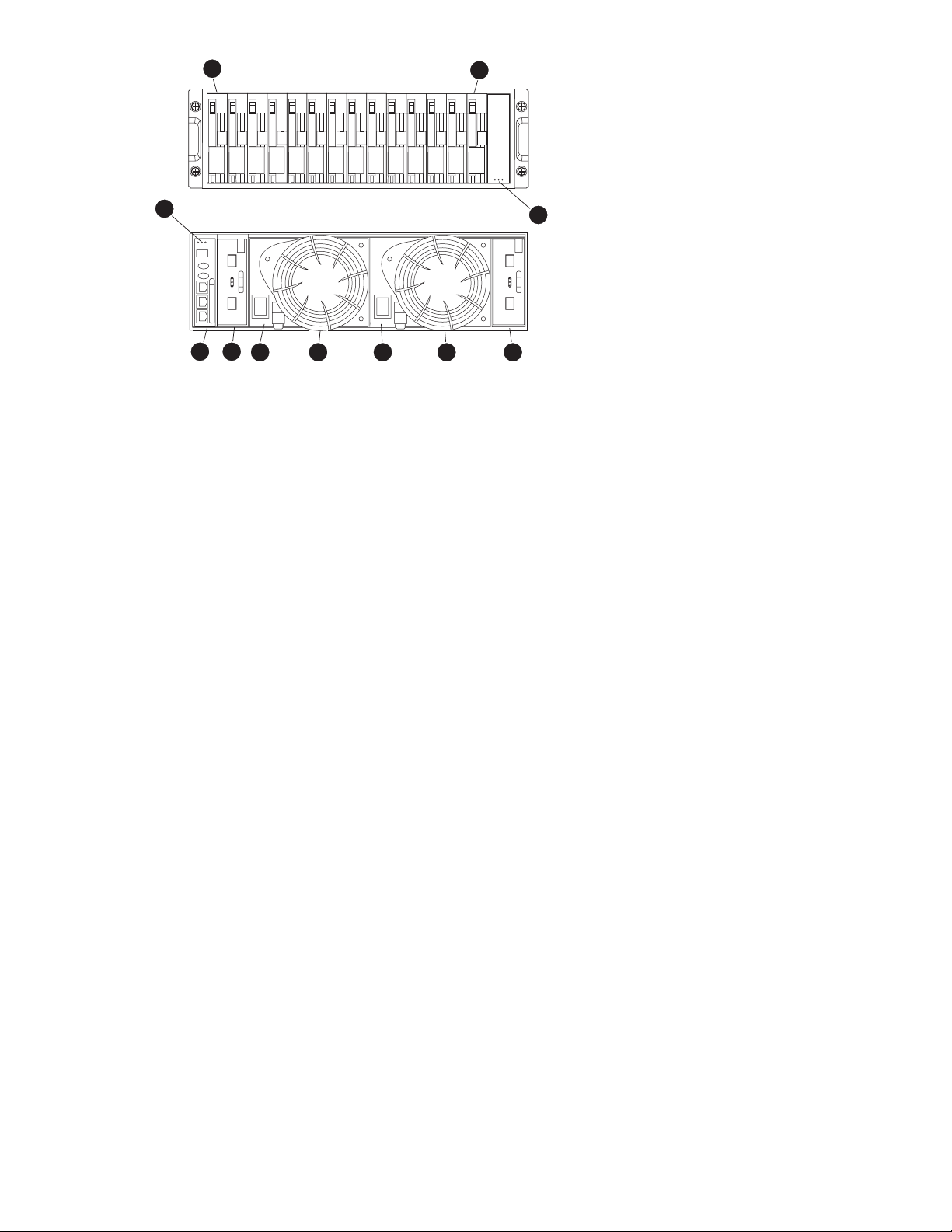

Figure 2 shows the components of the DS2500 from front and rear views.

DS2500 front view

The front of the DS2500 holds the following components:

• Up to 14 FC disk drives mount in bays numbered 1 through 14 sequentially, from left to right. For

simplicity, a drive is referred to by its bay number.

• Enclosure status indicators located in the lower corner to the right of bay 14.

DS2500 rear view

The rear of the DS2500 holds the following components:

• An Env

monit

• Redundant power supply and blower assemblies that provide protection against power overloads,

short circuits, and overheating

• Redu

ironmental Monitoring Unit (EMU) that provides protection against catastrophic failures. It

ors, records and reports disk enclosure status conditions to the operating system software.

ndant I/O modules that provide an interface between the disks and the HBA

4

25176a

14

Overview

Page 15

1

2

10

Figure 2 DS2500—front and rear views

Status i

You can monitor DS2500 performance by observing various status indicators:

• Indicators on the front of each disk drive report individual disk drive status.

• Indicat

• Indicators on the top rear of the EMU report overall DS2500 status (duplicates of the indicators

• A statu

• Status LEDs on each I/O module indicate the detection of transceiver signals and power.

• An audible alarm alerts you to an error condition.

Specif

10

4

3

1. Drive bay 1 6. Blower 1

2. Drive bay 14 7. Power supply 2

3. EMU

4. I/O module B 9. I/O module A

5. Power supply 1 10. Status indicators (EMU heartbeat, enclosure power,

65 87 9

25203a

8. Blower 2

enclosure fault)

ndicators

ors on the front lower corner of the enclosure report overall DS2500 status.

on the front of the enclosure).

s LED on each power supply/blower assembly verifies proper operation of the assembly.

ic LED information is provided in the description of the individual components in Chapter 2.

System requirements

Operating system software

The DS2500 is supported on the following HP-UX systems:

• For PA

• For IPF: HP-UX 11.23

-RISC: HP-UX 11.11 and 11.23

2500 Disk System user guide

15

Page 16

Hard disk drive firmware

You can download the latest hard disk drive (HDD) firmware from the HP support web site:

h

ttp://www.

1. Under maintenance and support,clickdownline drivers and firmware.

2. Under storage,clickDisk Storage Systems.

3. Click 2500 Di

For installation instructions, double-click on the firmware description, and then select the Release

Notes tab.

hp.com/support/downloads

sk System.

HBAs

The DS2500 is supported with 2 Gb and 4 Gb Host Bus Adapters (HBAs). For a list of supported HBAs,

see the DS2500 QuickSpecs on the HP storage web site:

ttp://www.hp.com/support/manuals

h

In the Storage section, click Disk Storage Systems and then select your product.

In the Resources for my selected product section, select See more, and then HP product bulletins

(QuickSpecs).

Disk drive

The DS2500 supports high-speed FC disk drives. For a list of supported disk drives, see the DS2500

QuickSpecs on the HP storage web site:

ttp://www.hp.com/support/manuals

h

In the Stor

In the Res

(QuickSpecs).

s

age section, click Disk Storage Systems and then select your product.

ources for my selected product section, select See more, and then HP product bulletins

16 Overview

Page 17

2Components

This chapter contains information about the components of the DS2500, including:

• List of parts, page 17

•EMU,page17

•

I/O modules, page 19

• Power supplies and blowers, page 21

•FCdisks, page 22

• Cables and cabling, page 24

•Transceivers, page 24

List of parts

The DS2500 consists of:

• ADualloopchassis

• 14 disk bay

• Up to 14 FC disk drives

• Drive blanks

• An EMU

• 2I/Omodules

• 2 power supplies

• 2blowers

• Small Form-factor Pluggable (SFP) transceivers

• Fiber optic cables

s

EMU

TheEMUmonitorsandrecordsdiskenclosurestatusinformation.

EMU functions

The primary functions of the EMU include:

• Display

• Display or change the enclosure loop ID

• Monitor enclosure operation

• Detect

• Implement automatic corrective actions for some conditions

• Provide a means for you to view error condition reports

or change the enclosure ID (En)

, report, record, and display enclosure error status conditions

2500 Disk System user guide

17

Page 18

Whenever the EMU detects a condition that could affect operation, it performs the following operations:

• Generates an audible alarm

• Displays status in visual indicators

• Generates an error condition report

• Reports the condition to the HP-UX application software

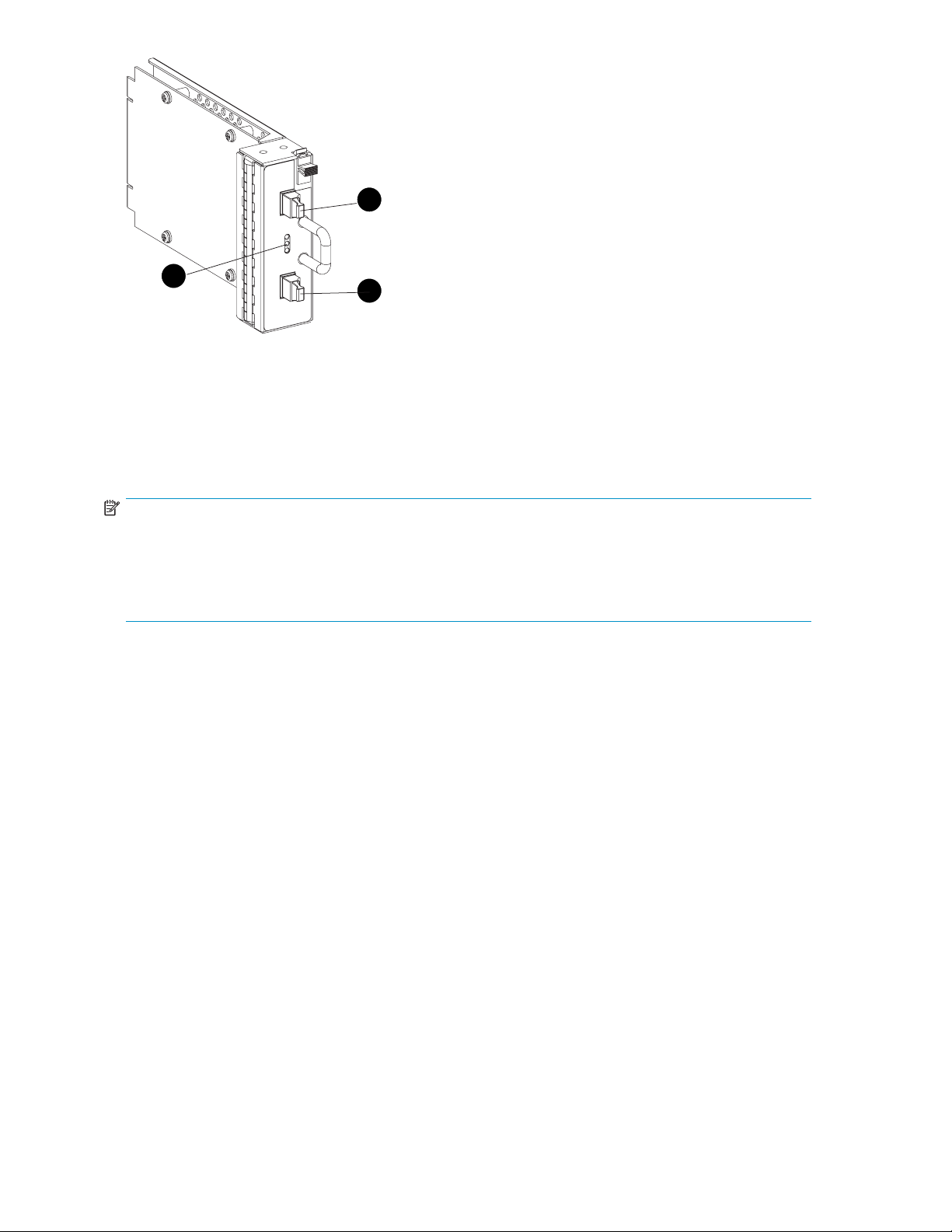

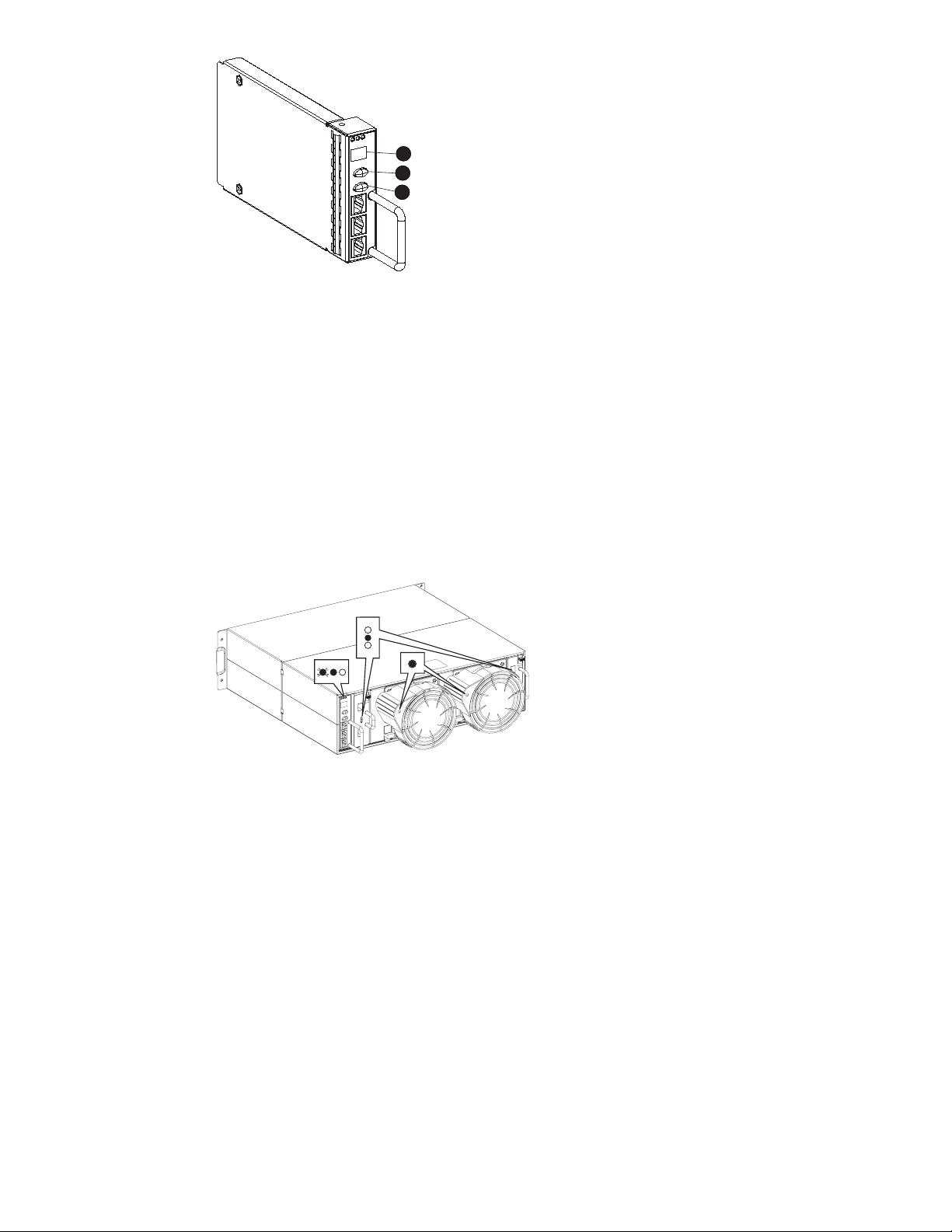

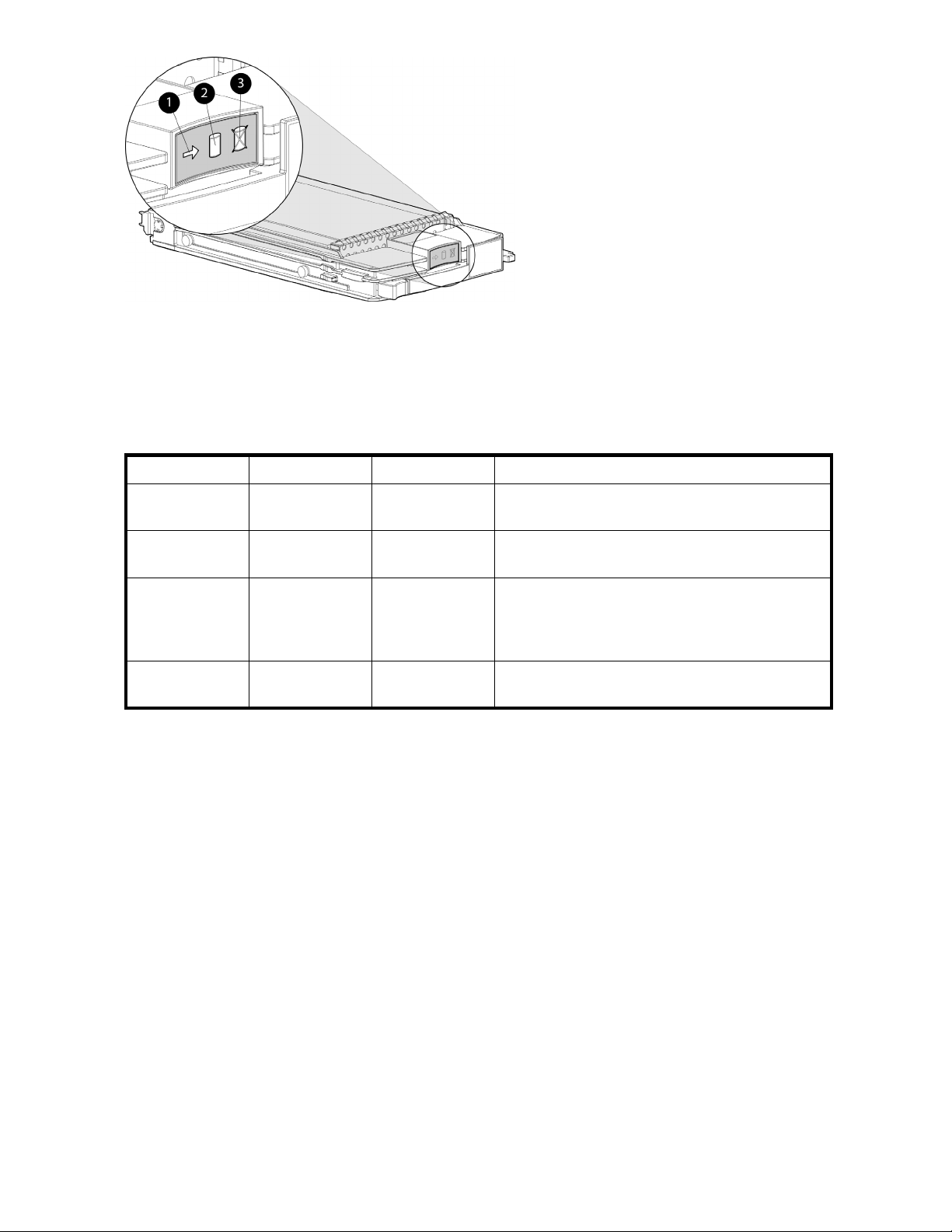

Controls and d

Figure 3 identifies the EMU displays, controls, and connectors.

Figure 3 EMU controls and displays

1. Status indicators:

a. EMU heartbeat—Flashing green signifies an operational EMU

b. DS2500 power—Solid green signifies that the +5 VDC and +12 VDC signals are within

c. DS2500 fault—Solid amber indicates that an enclosure error condition exists (normally off)

2. Alphanumeric display—A two-character display of the enclosure functions and status (typically

displays the enclosure ID).

3. Function select push button and back light—Enables you to specify what information appears

in the alphanumeric display. Pressing and releasing, or tapping the function select button

allows you to sequence through the different sublevels of a display group. The back light is

on when an error condition exists.

4. Display group select push button and back light—Enables you to view display groups and

control the audible alarm. The back light is on when the audible alarm is muted or disabled.

5. Communication ports—Unused in a JBOD environment

isplays

25236a

an acceptable range

18 Components

Page 19

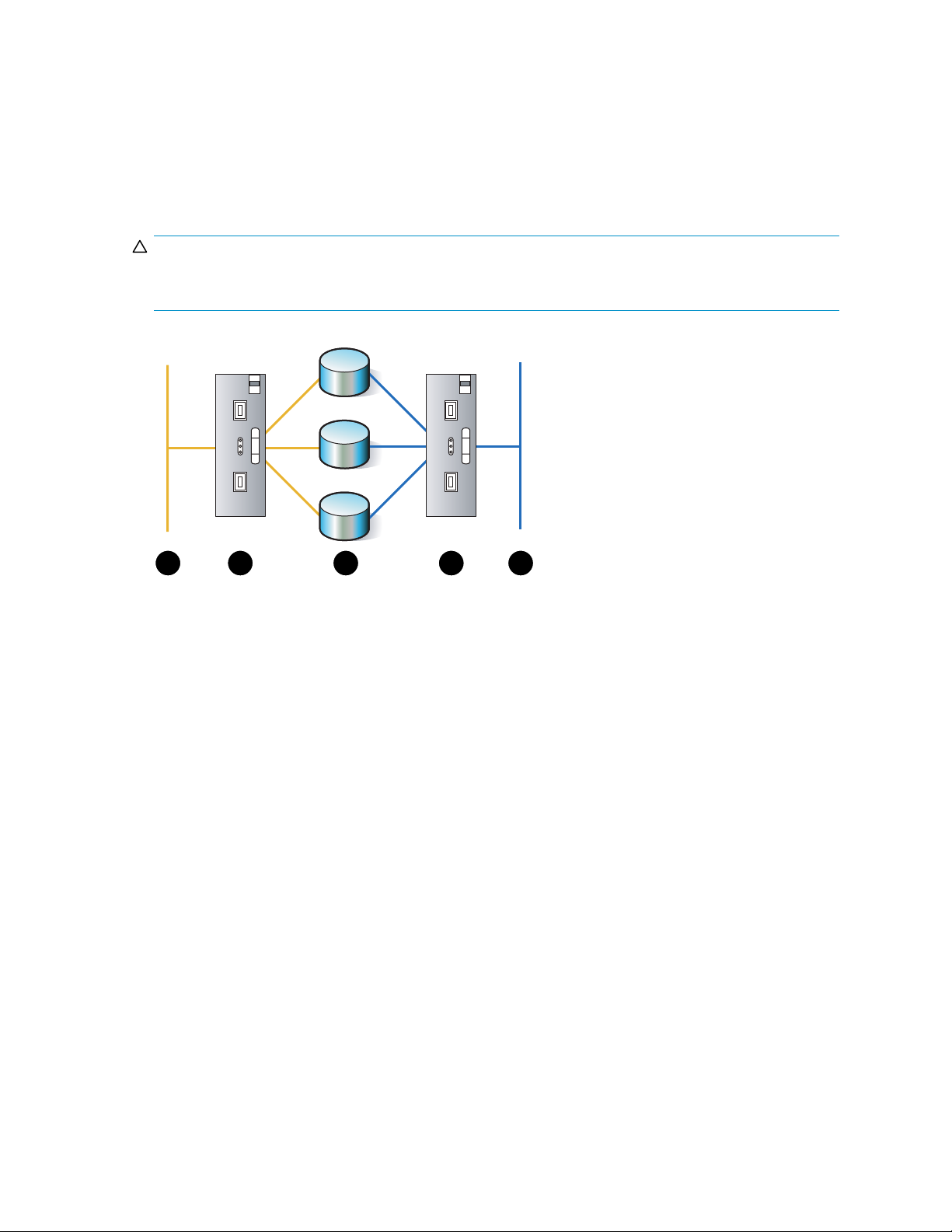

I/O modules

TwoI/Omodulesprovideaninterfacebetweenthedisksandthehostsystem. TheI/Omodulesareused

to route data to and from the disks in a dual-loop configuration to eliminate a single point of failure.

Each disk drive is connected to both I/O module A and I/O module B (Figure 4-3). Each I/O module is

connected to an independent, external FC loop. I/O module A connects to loop A, and I/O module B

connects to

CAUTION:

Keep the loops completely separate to ensure that the failure of a single component (I/O module,

transceiver, or cable) does not stop data transmissions to active drives.

loop B (see Figure 1 on page 14).

1 2 3 4 5

25175a

1. FC loop B

2. I/O module B

3. FC disks (3 are shown, but up to 14 disks are supported in each DS2500)

4. I/O module A

5. FC loop A

Figure 4 Redundant disk connections

The operation and function of both I/O modules are identical. Each I/O module has two ports that

can transmit and receive data for bidirectional operation. Port use and connections are configuration

dependent (see "Cables and cabling" on page 24). Each port is identified with a transceiver element

number,anditsstatusisdisplayedonanLED(Figure 5). Port 1 is the bottom loop port, and port

2isthetoploopport.

• Port 2 LED—On indicates that a signal was detected at the top transceiver.

• Power LED—On indicates that power is present on the I/O module.

• Port 1 LED—On indicates that a signal was detected at the bottom transceiver.

2500 Disk System user guide

19

Page 20

2

1

3

0107a

Figure 5 I/O module

1. Status LEDs

2. Port 2

3. Port 1

NOTE:

Although the I/O modules are similar in appearance, they are not interchangeable. Physical differences

between th

emodulesrequireyoutoinstall:

• I/OmoduleAattherightsideoftheenclosure,behinddrivebay1.

• I/OmoduleBattheleftsideoftheenclosure,nexttotheEMU.

20 Components

Page 21

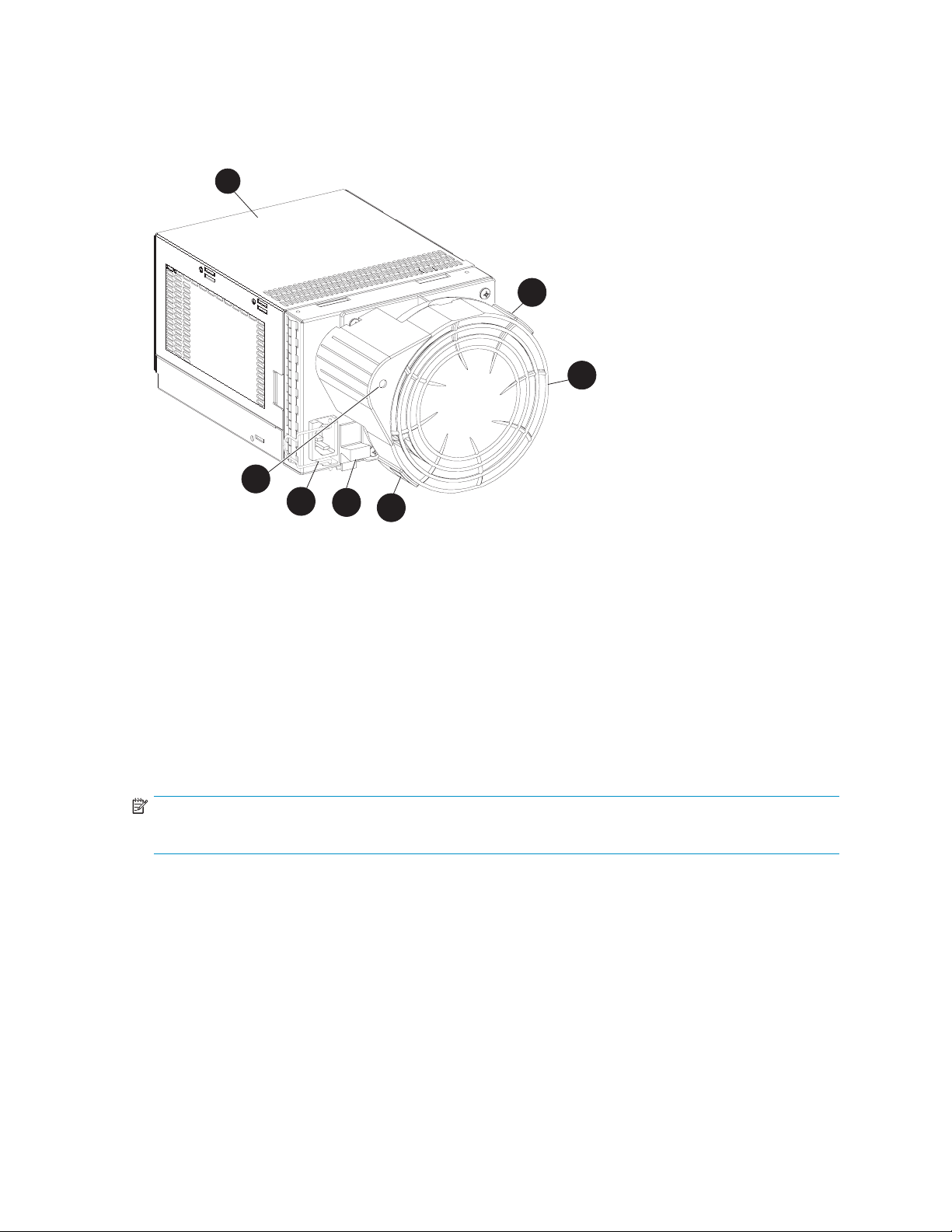

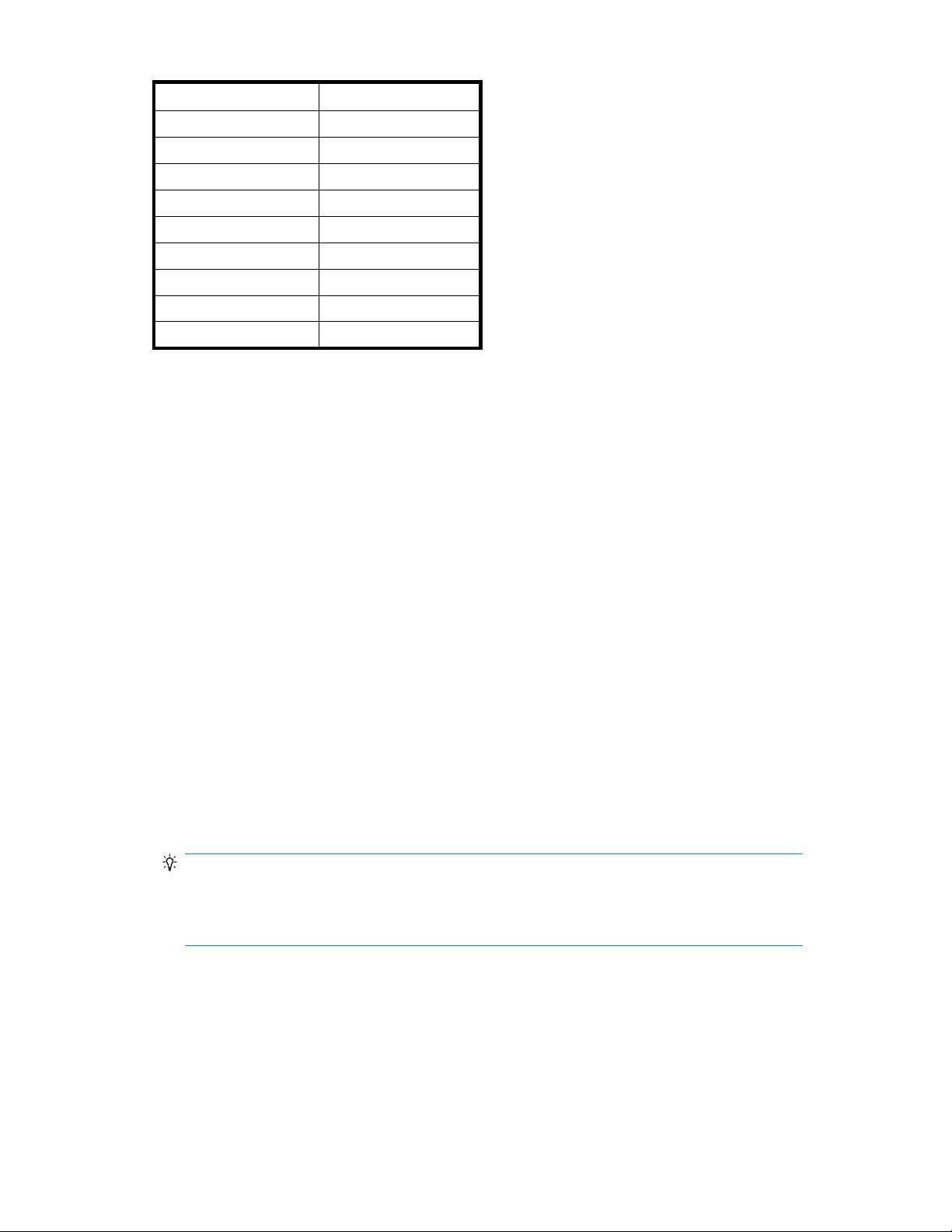

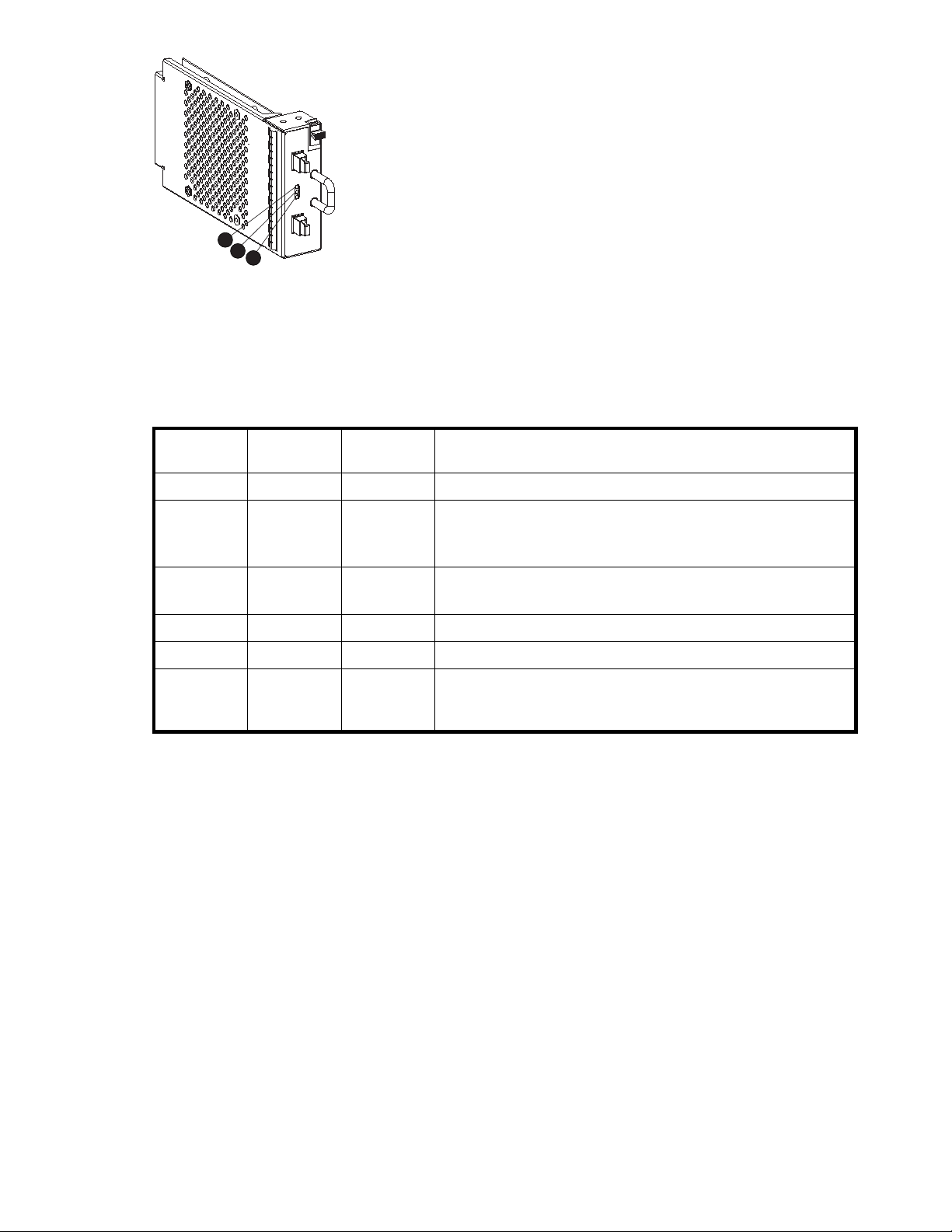

Power supply and blower assembly

Figure 6 shows the power supply and blower assembly components.

1

2

3

4

5

5

6

25206a

Figure 6 Power supply and blower assembly components

1. Power supply assembly 4. Module latch

2. Status LED

3. AC input connector with bail lock 6. Blower

Features

ne operational power supply and one operational blower are required to keep the enclosure fully

Only o

functional. However, in the event of a component failure, HP strongly recommends that a replacement is

installed as soon as possible.

:

NOTE

When a

The power supply circuitry monitors input voltage, current, and temperature. If it detects an unacceptable

level of any of these elements, the status indicator turns off and an error is reported to the EMU.

The EMU uses the temperature sensor signal to adjust the speed of the blowers. If one blower fails or

spins at a reduced speed, the speed of the other blower increases to provide adequate air flow.

power supply fails, the associated blower is disabled.

Power supply and blower status indicator

A green LED on the blower (Figure 6-2) indicates the operational status of the power supply and the

blower. If either component fails, the LED turns off and an error alarm sounds. The failing component

should be replaced as soon as possible.

5. Blower tabs (2)

2500 Disk System user guide

21

Page 22

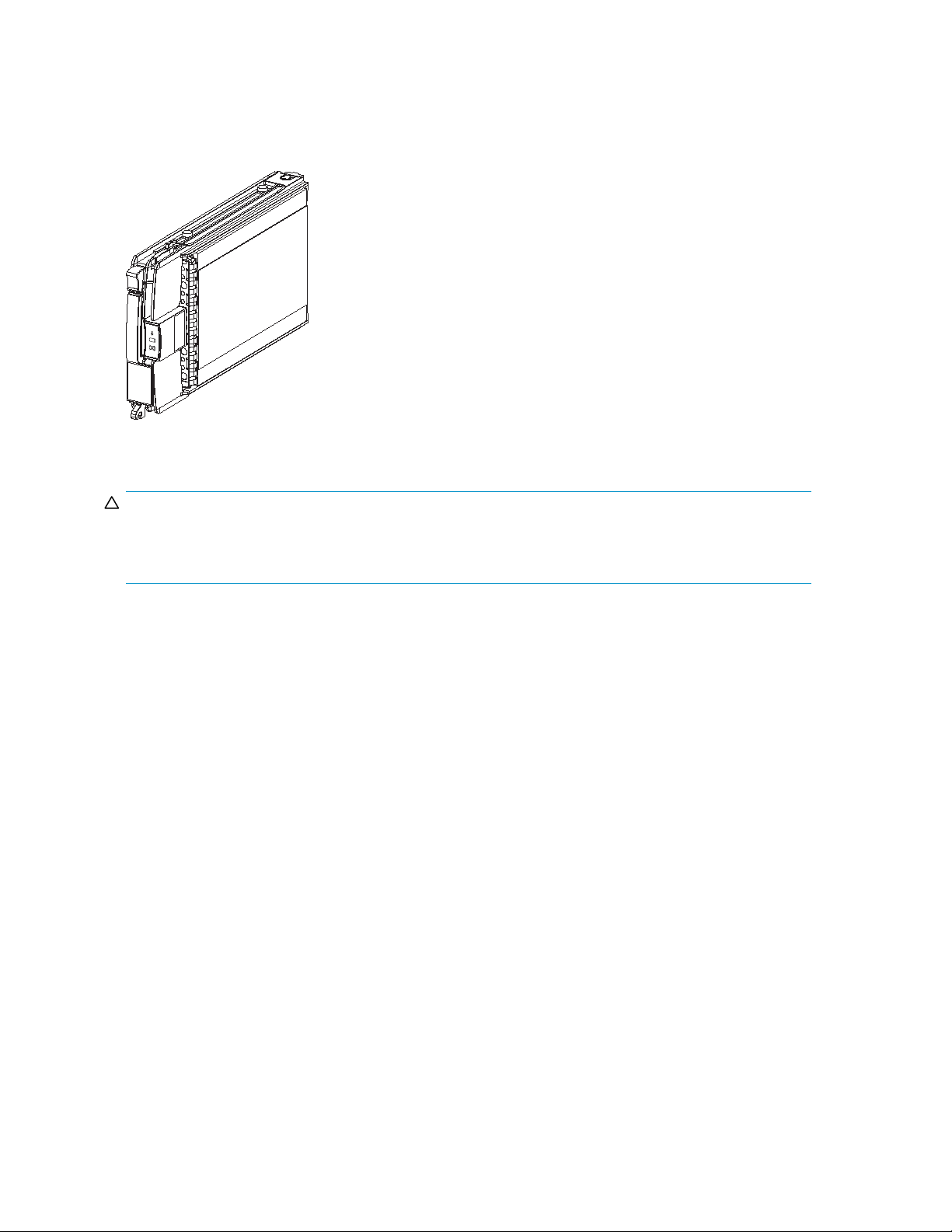

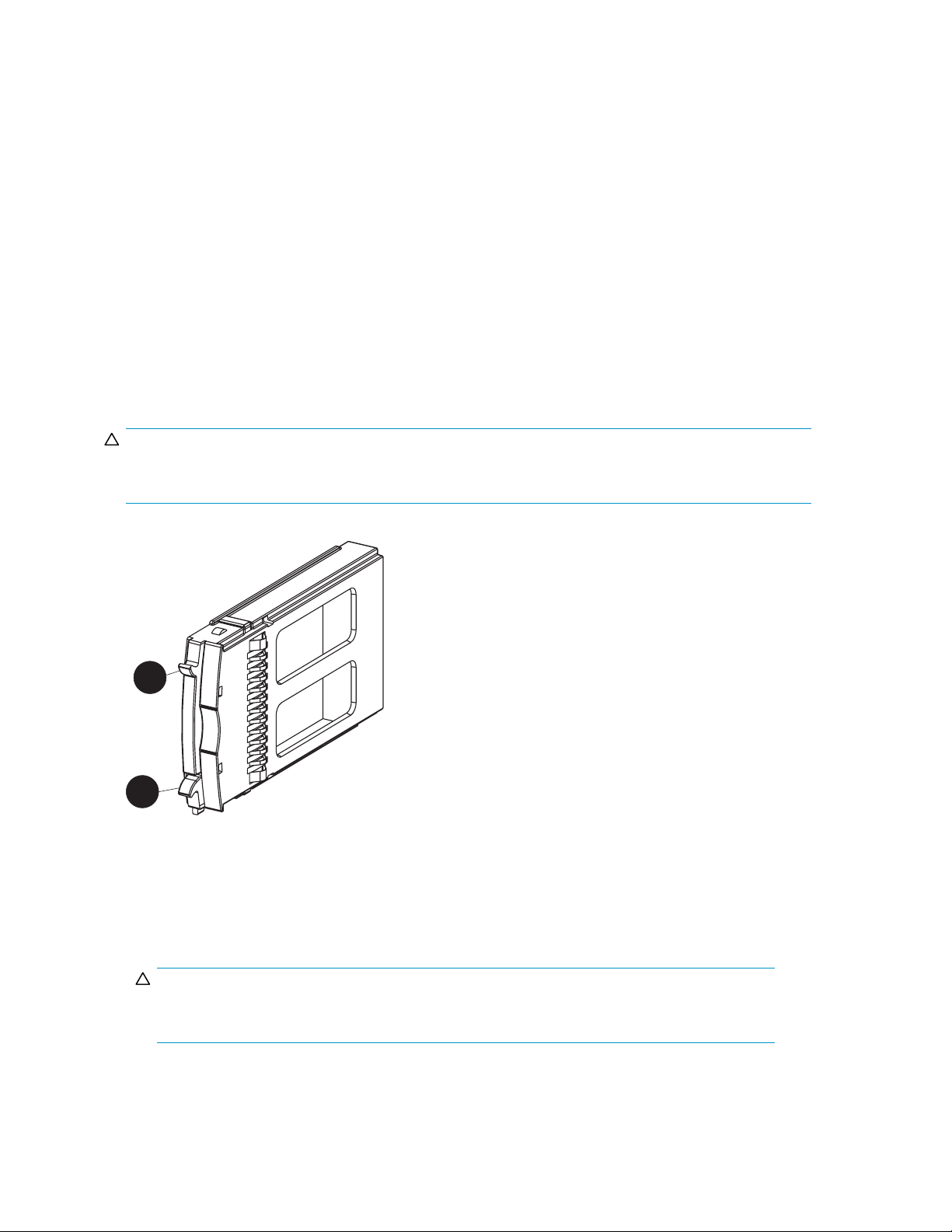

Fibre Channel disks

Up to 14 HP FC disk

supported in a DS2500. Figure 7 shows an FC disk drive.

Figure 7 HP FC disk drive

CAUTION:

To control air flow within the enclosure, you must install a disk drive or a drive blank in each bay.

To avoid overheating, never remove more than one disk or drive blank from an operating enclosure

atthesametime.

drives can be installed in a DS2500. Only HP-supplied FC disk drives are

CXO6695B

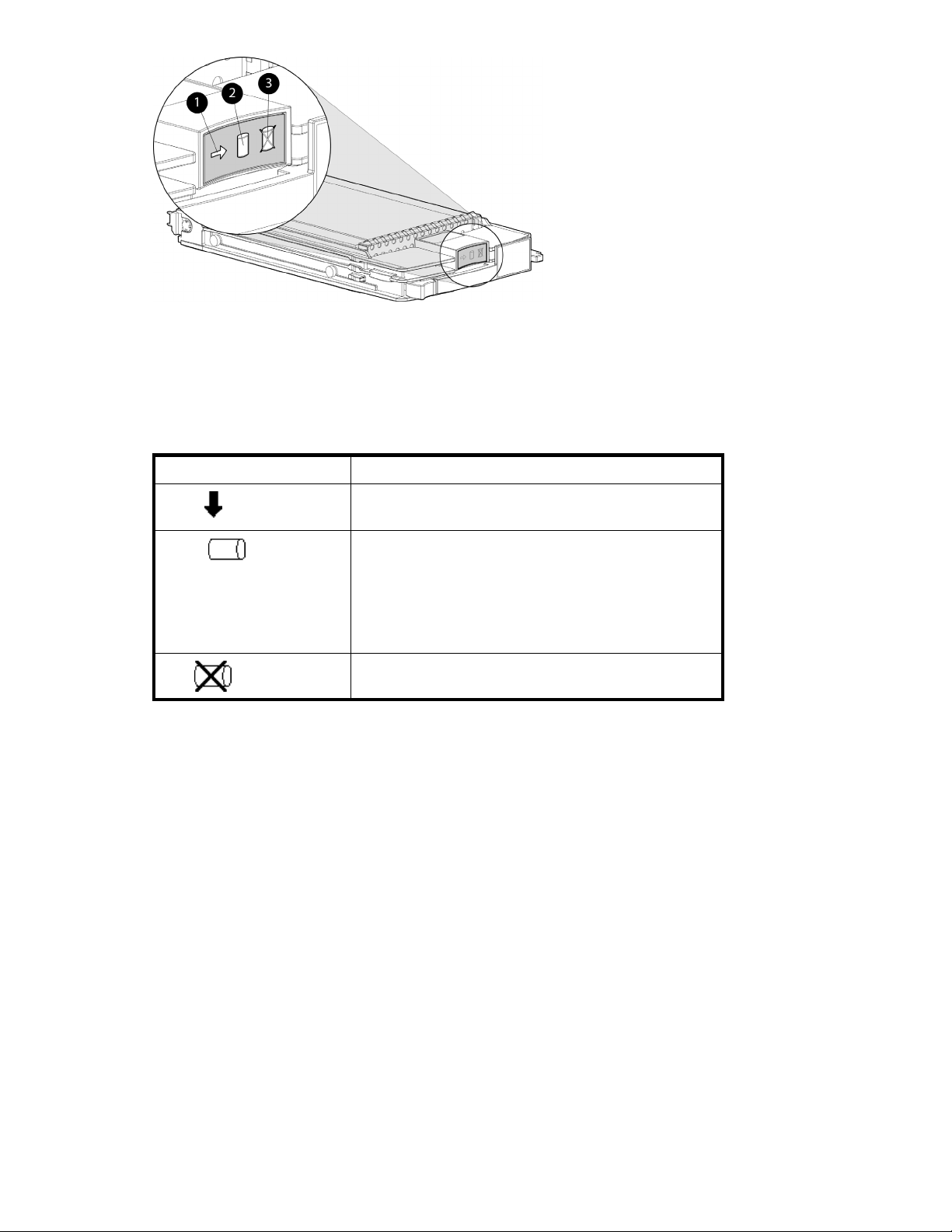

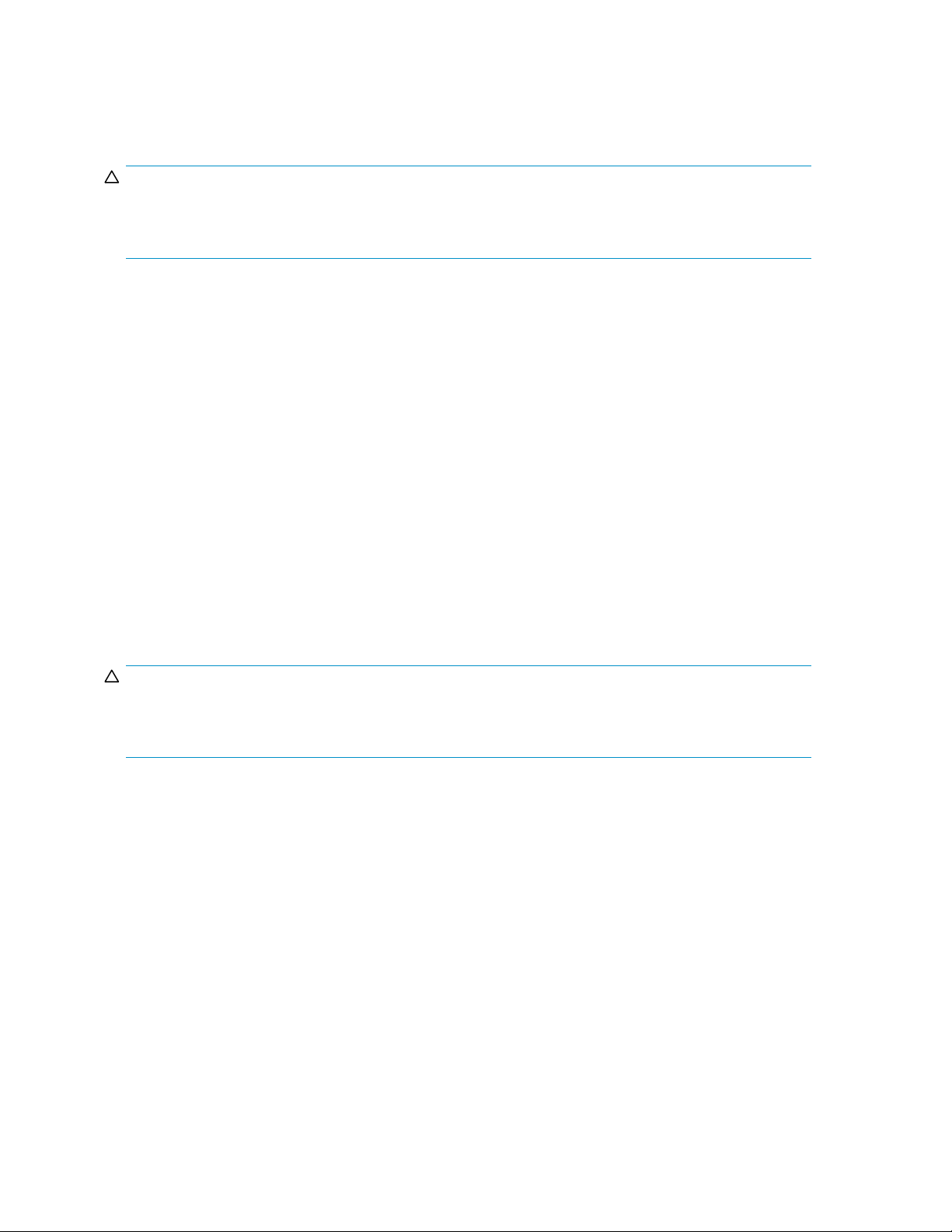

Disk drive status indicators

Three status indicators (Ready, Online, and Fault) show the drive operational status (Figure 8). Table 2

provides a description of each status indicator.

22 Components

Page 23

1. Ready

2. Online

3. Fault

Figure 8 Disk drive status indicators

Table 2 Dis

k drive status indicator descriptions

Status indicator

Ready

Online

Fault

Description

Flashing indicates that the disk drive is being accessed

On indicates that the drive is idle

On indica

normally

Off indic

• This disk

• +5.1 VDC

• The driv

On indicates a disk drive failure

tes that the disk drive is online and operating

ates that there is a problem:

drive is not connected to an HBA

is not detected

e is not properly installed in the enclosure

Additional status codes are described in "Disk drives"onpage51.

2500 Disk System user guide

23

Page 24

Drive blanks

To maintain proper air flow in the enclosure, a drive blank must be present in each bay that does not

contain a disk drive.

CXO6824B

Figure 9 Drive blank

Cables and cabling

TheDS2500uses50micron(m) diameter, multimode fibre cables.

The input port connects to an HBA or the previous enclosure in the loop, and the output port connects to

the next enclosure or an HBA on the loop.

Transceivers

The DS250

that does

0 uses a short-wavelength fiber optic transceiver called a Small Form-factor pluggable (SFP)

not pose a threat to the human eye. SFPs are installed in the I/O module ports.

24

Components

Page 25

3 Installation

This chapter includes the following topics:

•

Preparing to install a DS2500, page 25

•

Unpacking the shipping carton, page 25

•

Installing the DS2500,page26

•

Verifying the installation, page 36

•

Adding drives to an existing DS2500, page 36

Preparing to install a DS2500

Before installing the DS2500:

• Ensure that

• Ensure that the supported HP-UX operating software is installed on the host. See "System

requirements" on page 15 for the minimum version of supported software.

• If you are adding to an existing storage system, ensure that the existing storage system is

operating properly before proceeding.

• Locate a N

HP recommends that you remove the rack side panel for easier access.

electrical wiring and breakers meet the requirements described in Appendix B.

o. 2 Phillips screwdriver.

WARNING!

A DS2500 with all components installed weighs more than 29.5 kg (65 lb.) and requires a minimum of

two people to move. To safely and easily install the DS2500, using antistatic protection remove the

drive blanks, power supply/blower assemblies, EMU, and I/O modules. This reduces the weight of

the DS2500 to approximately 11.0 kg (24 lb). Even though a single person can lift this weight, the

DS2500 is difficult to install because of its physical size. Therefore, HP recommends that a minimum of

two peop

le install an empty DS2500 in a rack.

Unpacking the shipping carton

Inspect the contents of the shipping carton. If anything is missing or appears damaged, contact an

HP sales representative.

The carton contains:

• DS2500 disk enclosure with disk blanks, I/O modules, EMU, and power supply/blower

assemblies

• Two power cords

• FC SFPs

• HP StorageWorks 2500 Disk System read me first document

• Snap-in rail kit

• Eight round-hole conversion pins

• Rack template

2500 Disk System user guide

25

Page 26

Locate the following components, which were ordered separately:

• Disk drives

• FC cables

• FC cable labels

Installing th

This section describes the procedure to install the DS2500:

1.

2.

3.

4.

5.

6.

7.

NOTE:

HP recomme

eDS2500

Installing th

Reducing the enclosure weight, page 29

Installing the DS2500 in the rack,page31

Connecting

Setting the enclosure ID (En), page 34

Setting th

Verifying the installation, page 36

e snap-in rails,page26

the cables, page 33

e enclosure loop ID (Li), page 35

nds that you install the heaviest components low in the rack to ensure rack stability.

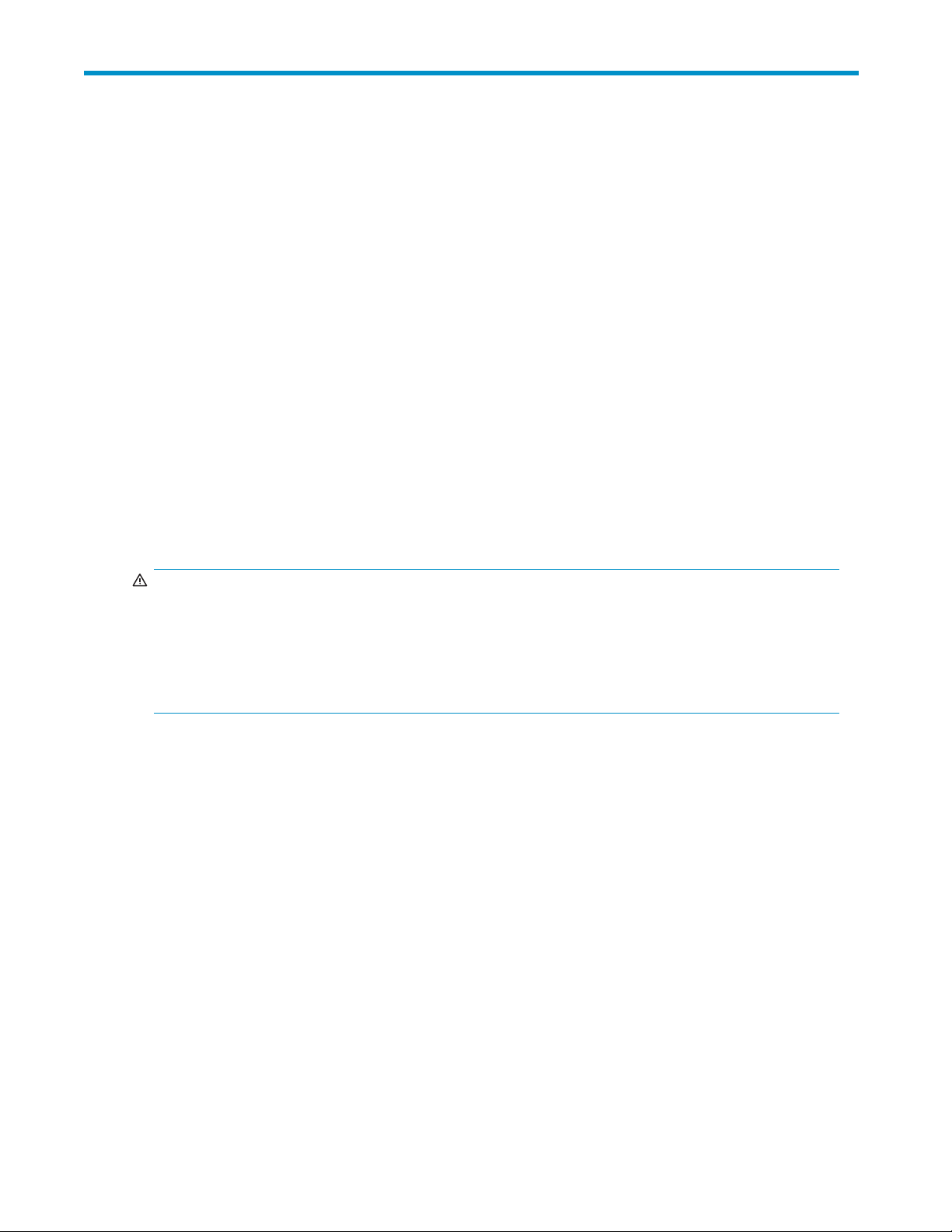

Installing the snap-in rails

1

2

3

1. Left rack rail

2. Right rack rail

3. Pins for round-hole rack conversion (8)

Figure 10 Contents of snap-in rail-mounting kit

You can identify the left and right rack rails by the markings (L) and (R) stamped into the sheet metal.

NOTE:

The rail kit contains adapter brackets that are used when mounting some devices in the rails; however

these brackets are not used when mounting a DS2500.

CXO8193A

26

Installation

Page 27

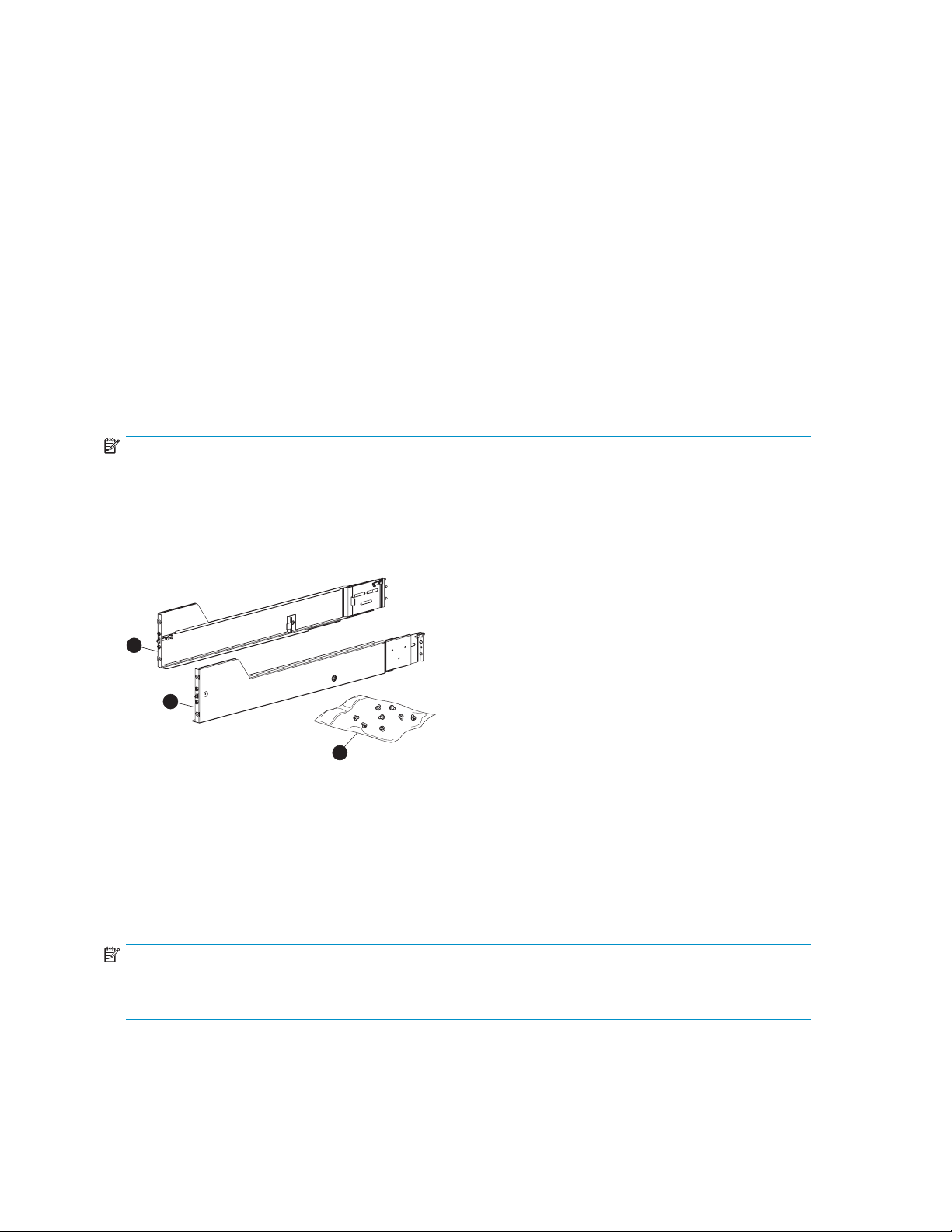

Converting the rails for round-hole racks

By default, the rack rails are configured for square-hole racks with load-bearing pins designed to

fit through the U-holes.

• If you are installing the disk enclosure in a square-hole rack, skip this section and continue with

"Installing the rails"onpage27.Donotremovethepinsfromtheendsoftherails.

• If you are in

stalling the disk enclosure in a round-hole rack, you must convert the rails as follows:

ling the rails

Instal

1. Locate the b

ag of miscellaneous hardware that is shipped with the rack rails.

2. Locate the eight round-hole pins.

3. Use a No. 2 Phillips screwdriver to remove the standard pins from the front and back ends of a rail.

4. Install four round-hole pins into the rail (Figure 11).

5. Repeat st

eps 3 and 4 on the other rail.

CXO8194A

Figure11Convertingtherailsforround-holeracks

For each rail:

1. Determine where the rails will be mounted and use the rack template to mark the U-holes through

the pins will extend.

which

2. Insert the front of the rail into the inside front column of the rack, making sure that the pins extend

through the U-holes marked in the previous step.

CAUTION:

Ensure that the scissor-type locking latches engage when the ends of the rail seat into the

olumns, as shown in Figure 12 inset.Failuretodosocouldresultinanunstablerail.

rack c

2500 Disk System user guide

27

Page 28

CXO8195A

Figure 12 Engaging the scissor-type locking latches

3. Slide the back end of the rack rail into the inside rear column of the rack, making sure that the

pins extend through the U-holes marked in Step 1, and the scissor-type locking latch is fully

engaged (Figure 13).

CXO8196A

Figure 13 Inserting the rail into the rear rack column

4. Locate the shipping bracket on the rail (Figure 14).

5. Use a No

the bac

. 2 Phillips screwdriver to loosen the shipping bracket and slide the bracket toward

koftherack.

6. Install the other rail by repeating Step 1 through Step 5.

28

Installation

Page 29

2

1

Figure 14 Disengaging the shipping bracket

Reducing the enclosure weight

Before you install a DS2500, reduce its weight by removing the drive blanks, power supply/blower

assemblies, EMU, and I/O modules. The removal procedures in this section do not apply to an

operating enclosure, as they assume that there are no cables attached to the components, and no

power is co

WARNING!

A DS2500 with all components installed weighs more than 29.5 kg (65 lb) and requires a minimum of

two people to move. To safely and easily install the DS2500, remove the components as described in

this section. This reduces the DS2500 weight to approximately 11.0 kg (24 lb).

nnected.

CXO8197A

CAUTION:

Parts can be damaged by electrostatic discharge. Use proper antistatic protection as described in the

documentation that shipped with your system.

Removing the drive blanks

To remove

1. Grasp the drive blank by the two tabs (Figure 15).

2. Lift up on the bottom tab and pull the blank out of the enclosure.

a drive blank:

2500 Disk System user guide

29

Page 30

2

1

25205a

Figure 15 Drive blank

Removing the power supply/blower assemblies

To remove a power supply/blower assembly:

1. Lift the mounting latch (Figure 16-2), grasp the blower and pull the power supply/blower assembly

out of the enclosure.

2. Place the power/supply blower assembly on an antistatic work space.

1. Power cord lock

2. Mounting latch

3. Blower

Figure 16 Removing a power supply/blower assembly

Removing the EMU

To remove the EMU:

1. Gras

2. Pla

30

ptheEMUhandleFigure 17-1) and taking care not to tilt it, pull the EMU module straight

ftheenclosure(Figure 17-2).

out o

ce the EMU on an antistatic surface.

Installation

Page 31

Figure 17 Removing the EMU

Removing the I/O modules

To remove an I/O module:

1. Grasp the I/O module handle (Figure 18-1),pressdownonthemodulelatch(Figure 18-2) and

pulltheI/Omodulestraightoutoftheenclosure(Figure 18-3).Takecarenottotiltthemoduleor

bring it in contact with the sides of the rack or other components.

2. PlacetheI/Omoduleonanantistaticsurface.

1

2

Instal

Figure 18 Removing an I/O module

ling the DS2500 in the rack

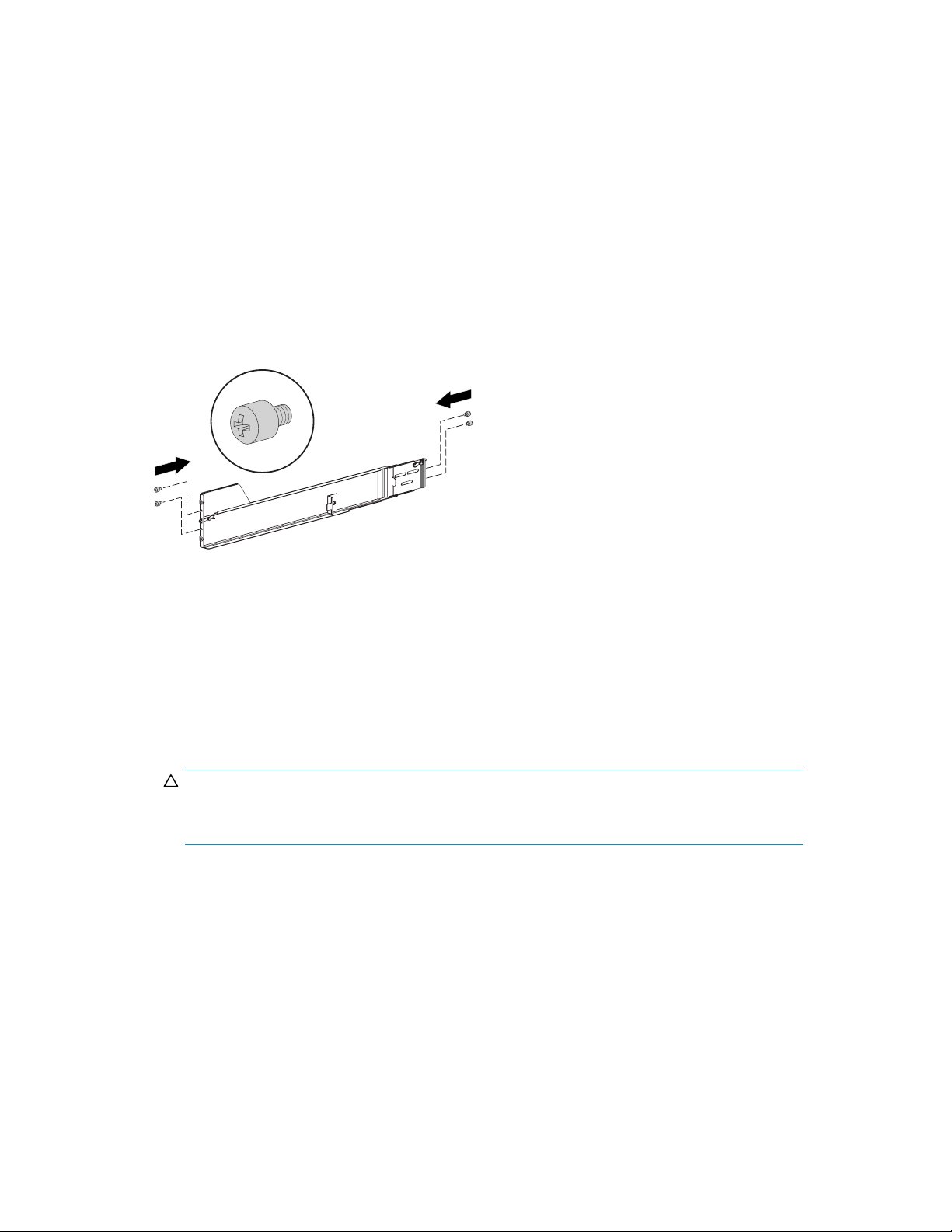

WARNING!

A DS2500 without components installed weighs approximately 11.0 kg (24 lb). Even though a single

person can lift this weight, the DS2500 is difficult to install because of its physical size. Therefore, HP

recommends that a minimum of two people install an empty DS2500 in a rack.

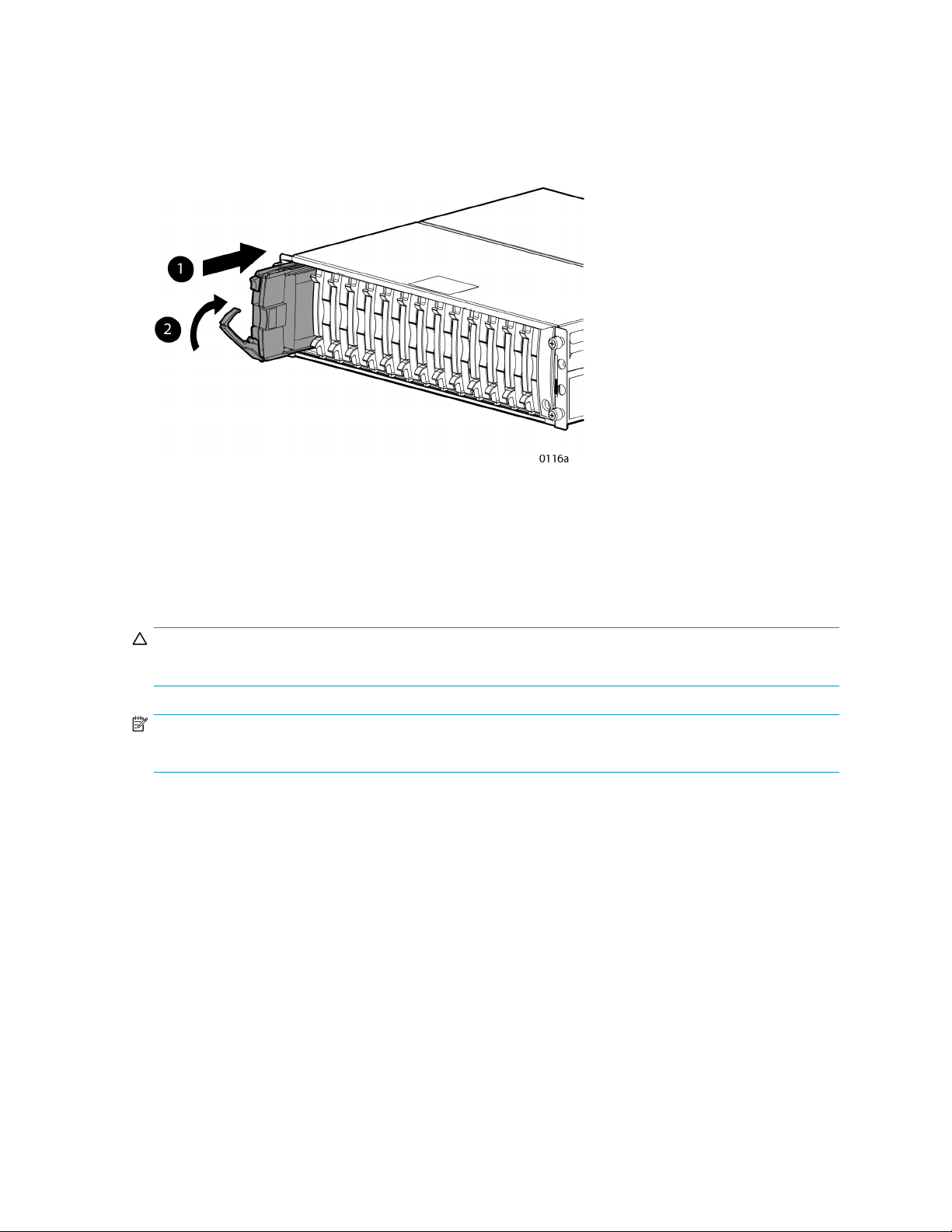

To install a DS2500:

1. From the front of the rack, slide the DS2500 onto the rails.

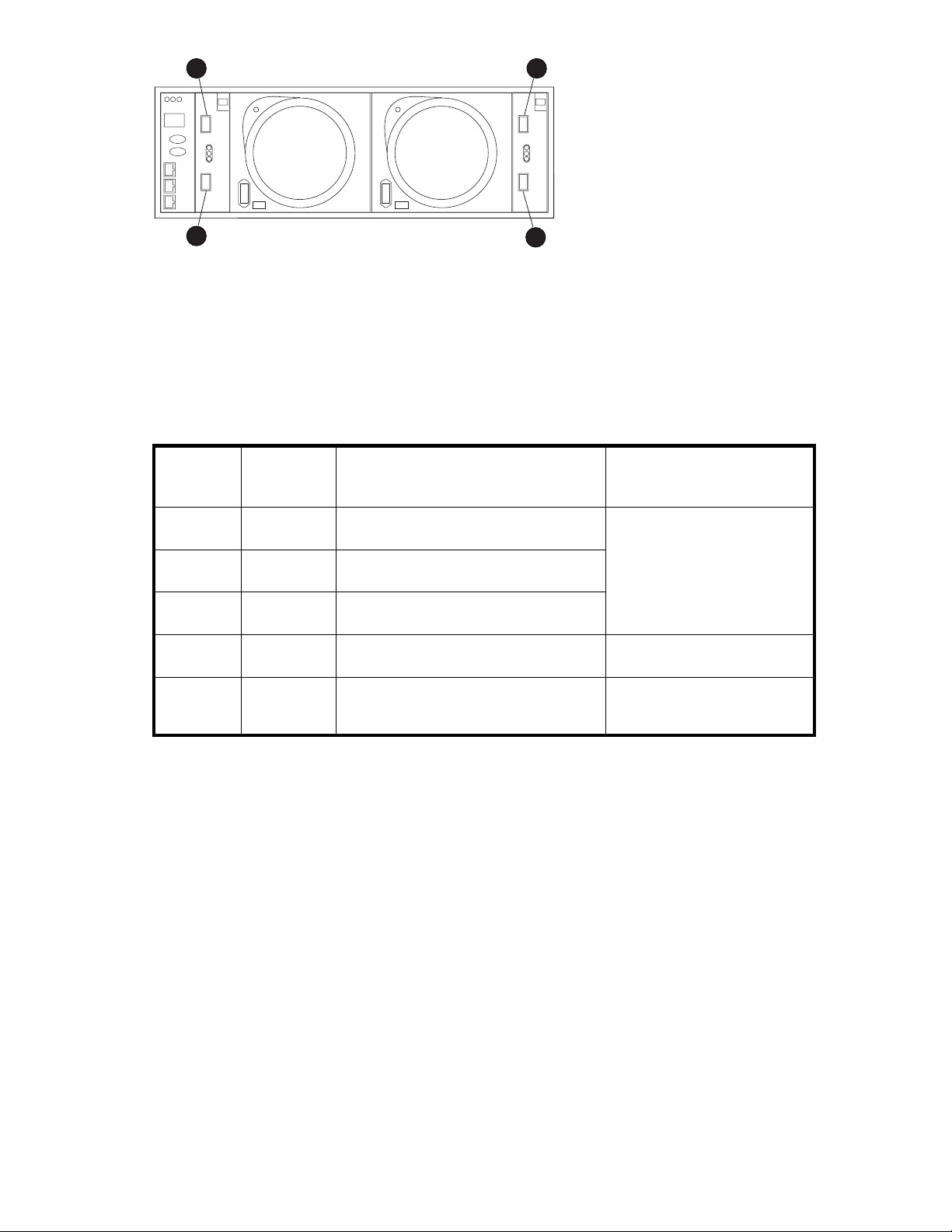

2. Secure the DS2500 to the front of the rack by tightening the four thumbscrews (Figure 19).

2500 Disk System user guide

31

Page 32

25218a

Figure 19 Enclosure thumbscrews

3. Replace the EMU, I/O modules, and power supply/blower assemblies that you removed to lessen

the weight of the enclosure, reversing the procedures that you used to remove them.

4. Install the disk drives:

1. Push in the ejector button on the disk drive and pull the release lever down to the full

open position.

2. Insert the drive into the enclosure as far as it will go (Figure 20-1).

3. Close the release lever until the ejector button engages and the disk drive engages in the

backplane (Figure 20-2).

Figure 20 Installing a disk drive

5. Instal

l disk blanks in all bays that do not contain a disk drive.

6. Connect a power cord to each power supply and engage the cord locks.

7. Plug the power cords into separate AC power receptacles.

TIP:

Using separate power receptacles provides no single point of failure (NSPOF).

8. After the disks spin up, check the following for operational status.

a. The disk drives indicators

b. The EMU alphanumeric display for error status (Figure 21-1).

If Er is displayed, resolve the error before continuing.

32

Installation

Page 33

CXO7373A

1. EMU alphanumeric display

1

2

3

2. Function

3. Display group select

select

Figure 21 EMU alphanumeric display and controls

c. Verify the state of the following status indicators (Figure 22).

• Both power supply status indicators are on.

• The EMU heartbeat is flashing.

• The EMU enclosure power LED is on.

• Both I/O module power status indicators are on.

• All four I/O module port status indicators are off.

25204a

Figure 22 Enclosure operational status indicators

Connec

ting the cables

23 shows a FC-AL configuration with the maximum allowed DS2500s.

Figure

nect fibre optic cables on a direct connect model:

To con

1. Remove the dust covers from the I/O module ports.

2. Insert an SFP in each I/O port.

3. Attac

h one end of an FC cable to I/O module A—port 2 SFP, and the other end of the cable to

either:

• The SFP in port 1 of I/O module A on the preceding enclosure if you are adding the DS2500 to

isting storage system, or

an ex

• The HBA if the DS2500 is the first or only enclosure.

2500 Disk System user guide

33

Page 34

4. Attach one end of an FC cable to the SFP in port 1 on I/O module A and the other end of the

cable to either:

• The SFP in port 2 on I/O module A on the next enclosure, if one exists, or

• The HBA if you are installing the last DS2500 in the loop

5. Coil the excess cable and secure the coiled cable behind the rail with cable ties.

CAUTION:

Avoid coiling the FC cable tighter then the acceptable bend radius of 1.375 inches.

6. Connect the FC cables on the B loop by repeating Step 3 through Step 5.

7. Verify the FC connections by observing that the port status indicators are on and steady.

8. Verify that the EMU heartbeat indicator is flashing.

9. Verify that the disk drives are online by observing their online LEDs.

1

10

2

3

4

25176a

1. Loop B—Connects to HBA 3. Loop A—Connects to HBA

2. Loop B—Connects to HBA 4. Loop A—Connects to HBA

Figure 23 FC-AL loops

Setting the enclosure ID (En)

You must assign a unique enclosure ID and corresponding loop ID to each DS2500 in a loop. See Table

3 for acceptable enclosure IDs and the corresponding loop IDs.

NOTE:

All enclosures must have a hard address in order to function properly with HP-UX software.

34

Installation

Page 35

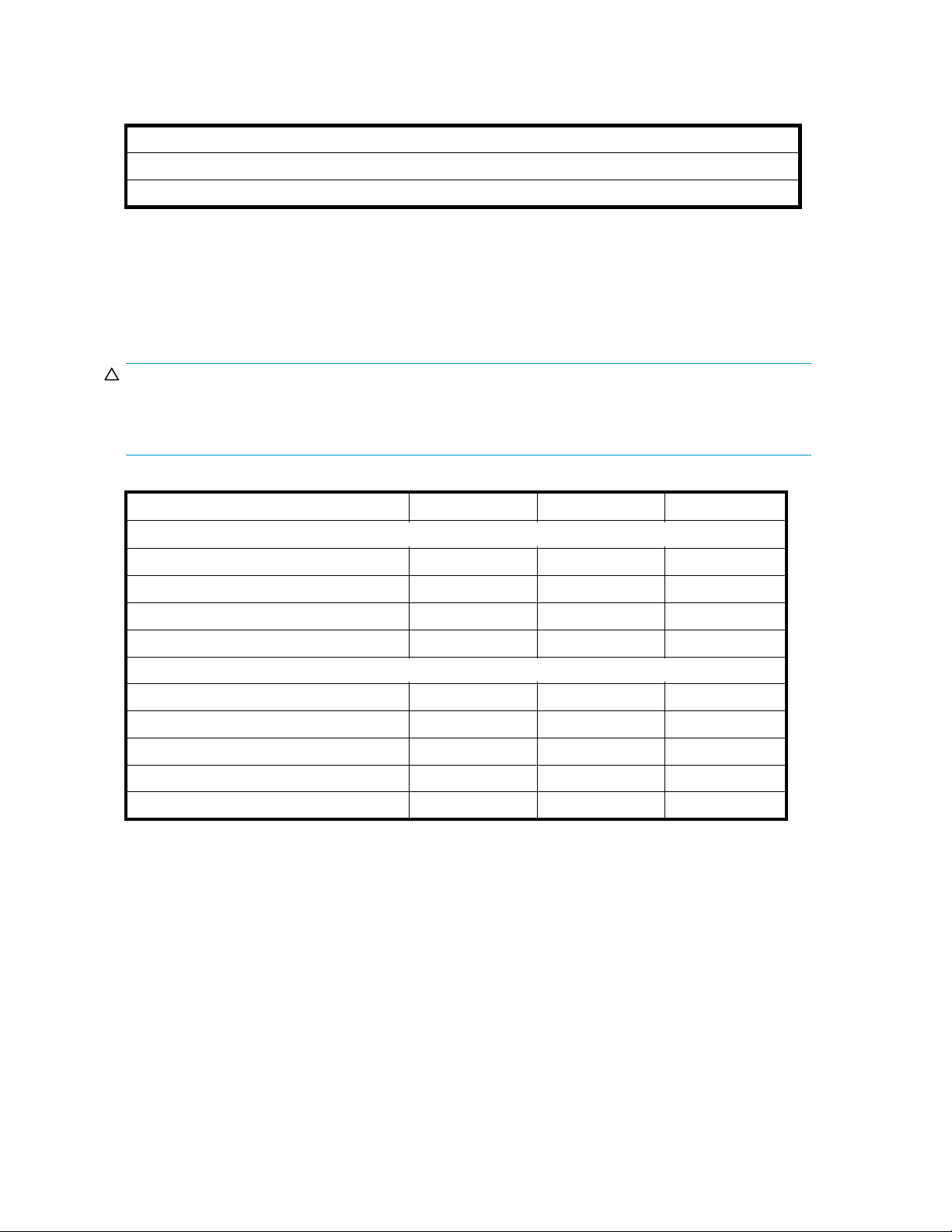

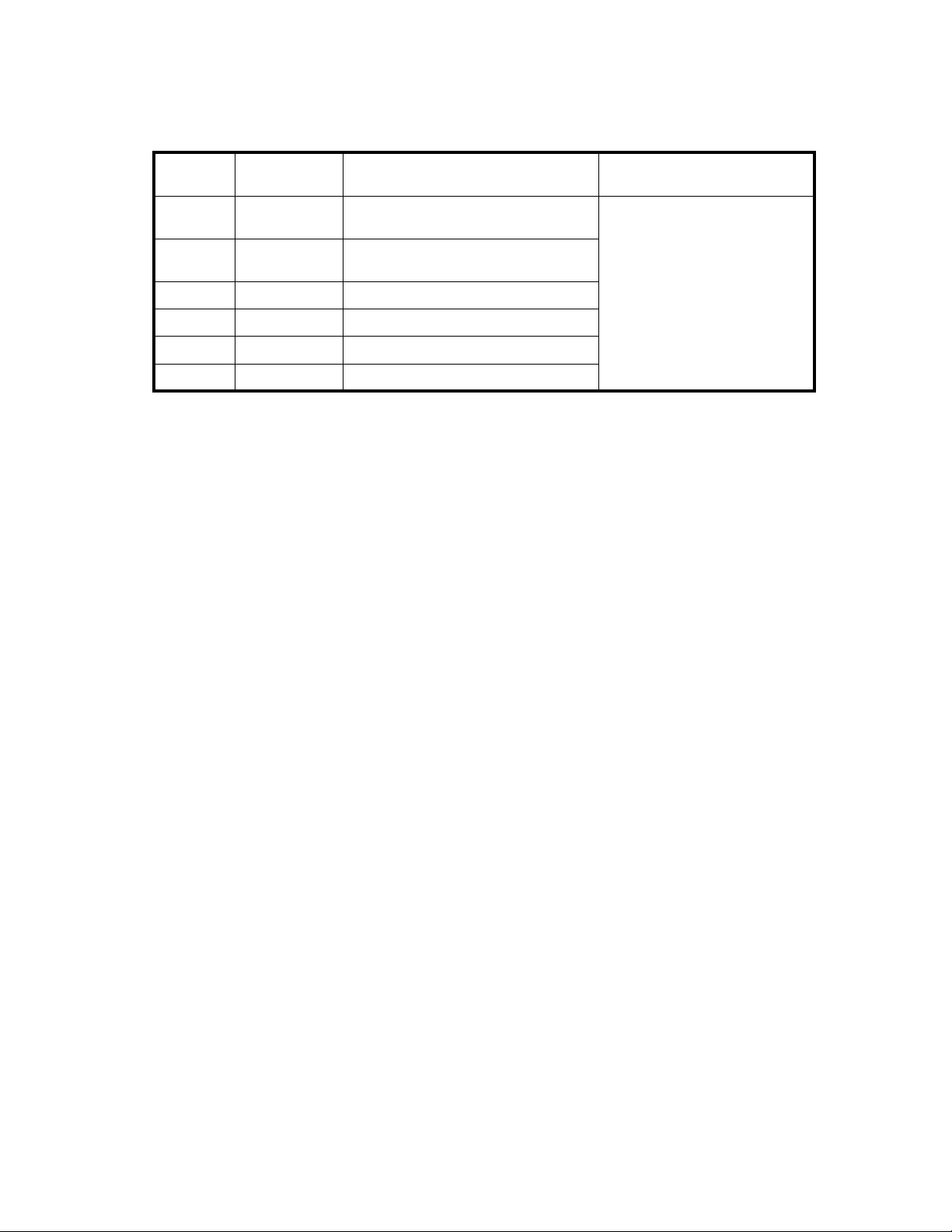

Table 3 Enclosure ID and corresponding loop IDs

Enclosure ID

1

2

3

4

5

61C

15

16 00

17

Loop ID

62

54

46

38

2A

0E

70

To change the enclosure ID:

1. Press and hold the top push button until the alphanumeric display blinks.

2. Tapthetoppu

sh button until the desired enclosure ID is displayed.

3. Press and hold the lower push button until the alphanumeric display is En.

The updated enclosure ID appears in the alphanumeric display upon completion of the enable

procedure.

4. Set the loop ID to correspond with the updated enclosure ID (see Setting the enclosure loop ID (Li)).

Setting the enclosure loop ID (Li)

Set the loop ID to correspond with the enclosure ID. See Table 3 for the enclosure ID and loop ID pairs.

To set the loop ID:

1. Tap the bottom push button until the alphanumeric display is Li.

2. Tapthetoppushbutton.

The loop ID appears in the alphanumeric display.

3. IftheloopIDissettothecorrectvalue(basedontheenclosureID),skiptoStep 6, otherwise

continue with Step 4.

4. Press and hold the top push button until the alphanumeric display blinks.

5. Tap the top push button until the loop ID that corresponds with the enclosure ID is displayed (see

Table 3).

TIP:

You can press and hold the top push button to scan through the numbers quickly. Release

the push button as the desired loop ID approaches, and tap the push button until the

correct loop ID appears.

6. To exit the loop ID display, tap the bottom push button.

The display returns to Li.

7. Tap the bottom push button until the alphanumeric display is En.

8. Tapthetoppushbutton.

The enclosure ID appears in the alphanumeric display.

2500 Disk System user guide

35

Page 36

9. Disengage the power cord locks and remove both AC power cords from the power supplies for

approximately 15 seconds.

10. Reattach the AC power cords to the power supplies and engage the power cord locks.

11. Verify that the server recognizes the DS2500 enclosure with the updated settings.

Disk drive loop ID

The EMU assigns a loop ID to each disk drive based on the enclosure ID and bay in which the disk is

installed. HP-UX stores the loop ID and WWN of each disk, and uses them to authenticate the disk.

Verifying the installation

Use IOSCAN to verify that the S/W state of the disks is CLAIMED.

Adding driv

You can add disk drives to an existing DS2500 without interrupting enclosure operation.

CAUTION:

Parts can be damaged by electrostatic discharge. Use proper antistatic protection as described in the

documentat

2

1

es to an existing DS2500

ion that shipped with your system.

25205a

Figure 24 Drive blank

To remove a drive blank:

1. Grasp the drive blank by the two tabs (Figure 24).

2. Lift the bottom tab and pull the blank out of the enclosure.

CAUTION:

To ensure proper airflow, remove only one drive blank at a time from an operating

enclosure.

To install a disk drive:

1. Push the ejector button on the disk drive and pull the release lever down to the full open position.

36

Installation

Page 37

2. Align the drive in an enclosure bay, and slide the drive into the enclosure as far as it will

go (Figure 25-1).

3. Close the release lever until the ejector button engages, and the disk drive seats in the

backplane (Figure 25-2).

4. Verify the drive status online indicator is on.

Figure 25 I

nstalling a disk drive

Installing multiple disk drives

HP recommends that you install a maximum of four disk drives at one time. If you need to install more

than four drives in an operational system, complete the procedure for each of the four disks (one at a

time), and then repeat it for another set of four until all drives have been added.

CAUTION:

To ensure proper airflow, remove only one drive blank at a time from an operating enclosure.

NOTE:

This procedure applies to the physical installation of disks into DS2500 bays.

1. Insert up to four disk drives into their respective DS2500 bays as described in "Adding drives to

an existi

2. Wait until the ready indicator (the downward arrow) on each drive you inserted has remained

solid green for at least 10 seconds.

a. If after

b. If no dam

c. If the drive continues to fail after two reseats, it may be defective. Try another drive.

3. When all of the drives you inserted in Step 1 have displayed a solid green ready indicator for at

least 10 seconds, you can repeat this procedure with another set of up to four drives.

4. When a

installation" on page 36).

ng DS2500" on page 36.

70 seconds any of the disk drives you inserted has not lit its ready indicator solid

green, remove the drive and check for a damaged connector on the disk drive and the

DS2500 bay.

age is found, reseat the drive and wait for the ready light again.

ll drives have been inserted, verify the addition of the new drives (see "Verifying the

2500 Disk System user guide

37

Page 38

38

Installation

Page 39

4UsingtheEMU

This chapter contains the following topics:

•

Alphanumeric display, page 39

•

Display groups, page 39

Alphanumeric display

The EMU stores information about the status of the DS2500. You can use the EMU alphanumeric display

to view the status information. The push buttons below the display provide a way to select which

data is displ

The alphanumeric display shows multiple levels of information. The top level shows a display group

(see Table 4). Each display group has supporting data in sublevels.

• The bottom p

• The top push button allows you to sequentially view the levels within a display group.

The push buttons double as status indicators:

• The top push

• For a single error, the push button stays lit until the error condition report is viewed.

• For multiple errors, the push button remains lit until the last error condition report is viewed.

• The bottom

ayed and to enter data.

ush button allows you to sequentially view and select the display groups.

button lights when an error condition exists.

push button lights when the audible alarm is muted or disabled.

Display groups

By default, the enclosure ID (En) appears in the alphanumeric display. When you press and release the

bottom push button, the display cycles among the display groups listed in Table 4.

A flashing alphanumeric display indicates that you can edit the contents of a display group.

Table 4 EMU display groups

Display group Display

Encoding

Loop ID Li

Reporting Group rG

Audible alarm

Firmware revision Fr

Error condition

Encoding the enclosure ID (En)

All enclosures must have a hard address to function properly with HP-UX operating software. You must

assign a unique enclosure ID and corresponding loop ID to each DS2500. There are nine allowable

enclosure ID/loop ID pairs. See Table 5 for enclosure IDs and the corresponding loop ID numbers.

En

Au

Er

Description

Used to encode or assign the enclosure ID.

es the enclosure loop ID.

Identifi

Not used in a JBOD environment.

Allows you to control the audible alarm or horn. The sublevel

displays are audible alarm enabled (On) or audible alarm

disabled (OF).

s the EMU firmware version.

Display

Indicates an error condition.

2500 Disk System user guide

39

Page 40

Table 5 Enclosure ID and corresponding loop IDs

Enclosure ID

1

2

3

4

5

61C

15

16 00

17

Loop ID

62

54

46

38

2A

0E

70

By default, the enclosure ID appears in the EMU alphanumeric display.

To display the En when the EMU is in another display mode:

1. Tap the bottom push button until the alphanumeric display changes to En.

2. Tapthetoppushbutton.

The enclosure ID appears in the alphanumeric display.

1. Press and hold the top push button until the alphanumeric display blinks.

2. Tap the top push button until the desired enclosure ID is displayed.

3. Press and hold the lower push button until the alphanumeric display is En.

The updated enclosure ID appears in the alphanumeric display upon completion of the enable

procedure.

4. Set the loop ID to correspond with the updated enclosure ID (see Loop ID (Li)).

Loop ID (Li)

The loop ID is a hexadecimal number that you must set to correspond with the enclosure ID. See Table 5

for the enclosure ID and loop ID pairs.

To set the loop ID:

1. Tap the bottom push button until the alphanumeric display is Li.

2. Tapthetoppushbutton.

3. If the loop ID is set to the correct value (based on the enclosure ID), skip to Step 6, otherwise

4. Press and hold the top button until the alphanumeric display blinks.

5. Tap the top push button until the loop ID that corresponds with the enclosure ID is displayed (see

6. To exit the loop ID display, press and release the bottom push button. The display returns to Li.

The loop ID appears in the alphanumeric display.

continue with Step 4.

Table 5).

TIP:

You can press and hold the top push button to scan through the numbers quickly. Release

the push button as the desired loop ID approaches, and then tap the push button until the

correct loop ID appears.

40

Using the EMU

Page 41

7. Press the bottom push button until alphanumeric display is En.

8. Tapthetoppushbutton.

The enclosure ID appears in the alphanumeric display.

9. Remove both AC power cords from the enclosure for approximately 15 seconds.

10. Reattach the AC power cords.

11. Verify that the server recognizes the DS2500 enclosure with the updated settings.

Audible alarm (Au)

When an error condition exists, the alarm sounds until one of the following events occurs.

• The error is c

• You mute the alarm (if a new error occurs, the alarm sounds).

Using the mute feature keeps you informed of new errors as they occur.

• You disable t

The disable feature prevents any error conditions from sounding the alarm; however, the EMU

alphanumeric display continues to display Er.

When the alar

buttons to mute, enable, or disable the audible alarm.

NOTE:

Er

is displayed in the alphanumeric display when an error condition is present, regardless of the

audible ala

rm status.

orrected.

he alarm.

misenabled(On), the bottom push button status indicator is off. You can use the push

Enabling the audible alarm

To enable or disable the audible alarm:

1. Tap the bottom push button until Au appears in the alphanumeric display.

2. Press and hold the top push button until the alphanumeric display flashes.

3. Tap the top push button until the display shows the state that you want the audible alarm to be in:

On (audible alarm on), or OF (audible alarm off).

4. Press and release the bottom push button to accept the change.

The display shows Au. The bottom push button indicator is off when the audible alarm is enabled,

and on when the alarm is disabled.

Muting the audible alarm

You can mute the alarm if one of the following conditions is present:

• The error does not require immediate corrective action.

• You cannot correct the error at this time.

To mute the audible alarm:

1. Press and hold the bottom push button until the status indicator is on.

A muted alarm remains off until a new error condition occurs.

2. To enable a muted alarm, press and hold the bottom push button until the status indicator is off.

When a new error condition occurs, the alarm sounds.

2500 Disk System user guide

41

Page 42

Firmware revision (Fr)

You can use the f

To view the EMU f

1. Tap the bottom push button until the alphanumeric display shows Fr.

2. Tap the top push button to cycle through four pairs of digits that indicate the firmware revision.

•Thefirstpairo

(for example 0

• The second pair of digits is the minor version number, displayed with the left decimal point off

and the right decimal point on (for example 01.).

• The third pair of digits is the first half of the build number, displayed with the left decimal point

on and the right decimal point off (for example 0.1).

•Thefourthp

points on (f

For example, EMU firmware revision 2.2.68 is displayed as:

02 02. 0.0 6.8.

The display

3. To exit the

The display returns to Fr.

irmware revision (Fr) display group to determine the version of EMU firmware.

irmware revision:

f digits is the major version number, displayed with both decimal points off

1).

air of digits is the second half of the build number, displayed with both decimal

or example 0.1.).

cycle is repeated if the top push button is tapped again.

firmware revision display, press and release the bottom push button.

Error condition report (Er)

You can use the error condition report (Er) display group to determine the source of an error. When

an error occurs, the EMU generates an error condition report. You can use the push buttons view the

six-digit error condition report:

• The first two digits identify the component or element type (et) that is the source of the error,

displayed with both decimal points on (for example, 0.1.).

Table 6 lists the et codes.

• The next two digits identify the specific component or element number (en) that produced the

condition, displayed with the left decimal point off and the right decimal point on (for example,

01.).

• The last two digits is an error code (ec), displayed with both decimal points off (for example, 01).

For example, a left blower failure appears as:

0.3. 01. 03

The display cycle is repeated if the top push button is pressed. You can tell which pair of digits are

displayed by the decimal points.

42

Using the EMU

Page 43

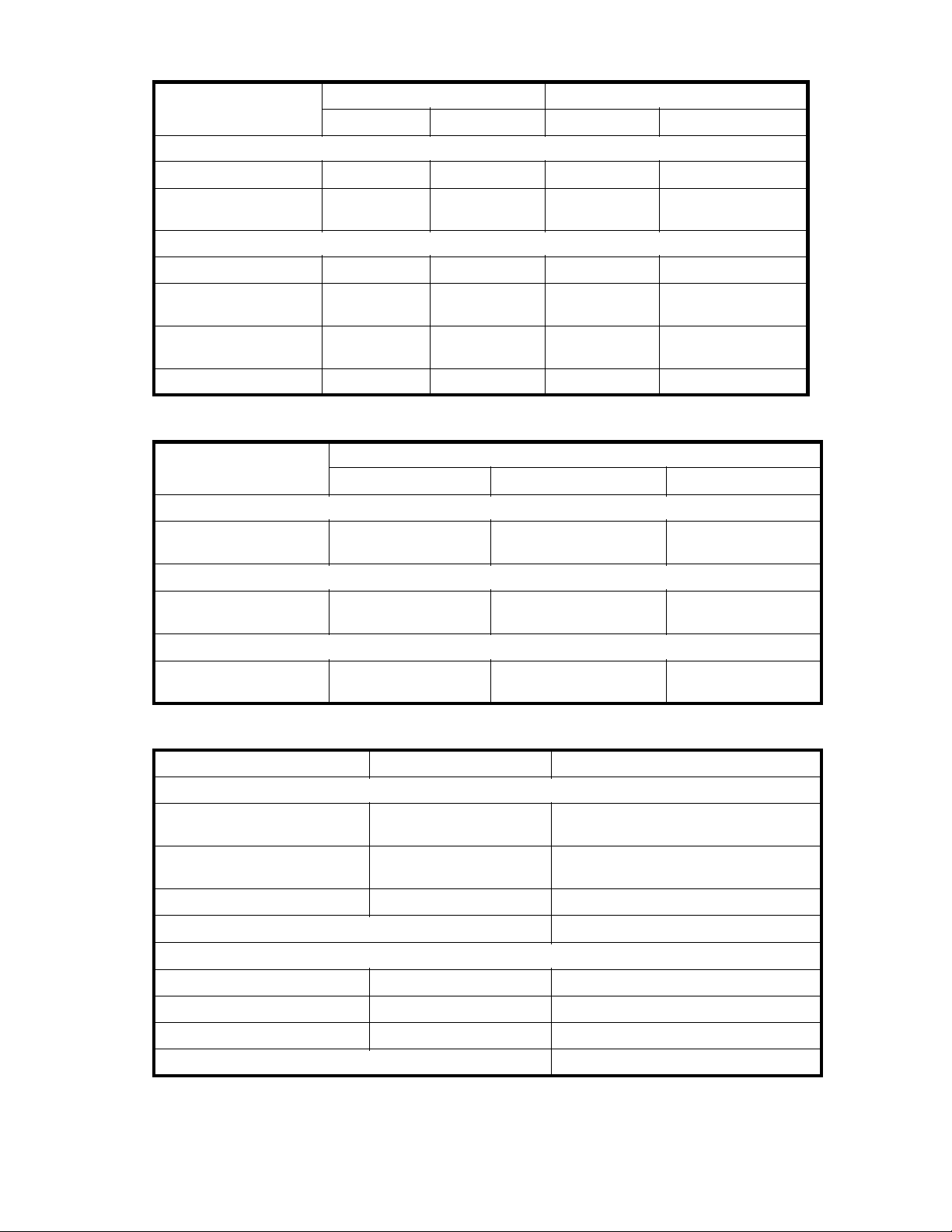

Table 6 Element types

Et Code

0.1.

0.2.

0.3.

0.4.

0.6

0.7.

0.F.

1.0.

1.1.

1.2.

1.3 Current sensor

8.0

8.2.

8.7.

1

Does not generate a condition report. However, for any error, you should record the error code and implement the

recommended corrective action.

Viewing an e

rror condition report

Component

Disk drive

Power supply

Blower

Temperature sensor

Audible alarm

EMU

Transceiver

Language

Communication port

Voltage sensor

DS2500 enclosure

DS2500 back

I/O module

1

s

1

plane

1

1

IMPORTANT:

Always write down the error condition report contents, including the decimal points. You can tell which

digits are displayed by the position of the decimal points.

To view the error condition report:

1. Tap the bottom push button until Er appears in the alphanumeric display, if necessary.

2. Press and hold the top push button until the display changes to the first two digits of the error

condition report. (For example, 0.3.)

3. Tap the top push button to display the next two digits of the error condition report. (For example, 01.)

4. Tap the top push button again to display the last two digits of the error condition report. (For

example, 03)

If you tap the top push button again, the current error condition will cycle through the alphanumeric

display.

5. If the top push button orange LED is lit after viewing the error condition report, another error code is

active in the queue. Repeat Step 2 through Step 4 to view the error condition report.

6. Tap the bottom push button to return to the Er display.

See Appendix C for a description of the EMU-generated error condition reports and corrective actions.

2500 Disk System user guide

43

Page 44

44

Using the EMU

Page 45

5 Troubleshooting

This chapter provides information to help you troubleshoot DS2500 error conditions. Topics include:

•

Event monitor tools, page 45

•

EMU error condition report,page48

•

Status indicators, page 48

•

Catastrophic errors, page 52

Event monitor tools

The EMS Disk

monitor the

Monitors U

Monitor (disk_em) and the HP High Availability Storage System Monitor (ds_ses_enclosure)

disks in the DS2500. For information about these monitoring tools, see HP EMS Hardware

ser’s Guide at the following web site:

h

ttp://ww

The monitoring tools report changes in disk status by sending an e-mail to the root account. These

messages provide early notification of a disk problem. Events reported include media errors, failed read

and write attempts, invalid commands, changed operating parameters, and failed diagnostics. Event are

assigned to one of the following severity levels:

• Critical—An event that causes data loss, host system downtime, or other loss of service. Continued

use the e

• Serious—Aneventthatcancausedataloss,hostsystemdowntime,orotherlossofserviceifleft

uncorrected. Host system and hardware operation may be adversely affected. The problem needs

repair a

• Warning—An event that could escalate to a serious condition if not corrected. Host system operation

should not be affected and normal use of the enclosure can continue. Repair is needed but at a

convenient time.

• Inform

is required.

Example 1 shows an example of a hardware event notification. The notification provides the following

types of information:

• Messa

and th

• Event data—Date and time of the event, the host, event ID, name of the monitor, event number, event

class, severity level, hardware path,and associated OS error log entry ID.

• Desc

and t

• Probable Cause / Recommended Action—The cause of the event and suggested steps toward a

solution. This information should be the first step in troubleshooting.

w.docs.hp.com/en/diag.html

nclosure will negatively impact host system operation. Immediate action is required.

ssoonaspossible.

ation—An event that is expected as part of the normal operation of the hardware. No action

ge data—Date and time the message was sent, the source and destination of the message,

e severity level of the event.

ription of Error—Narrative information indicating the component that experienced the event

he nature of the event.

2500 Disk System user guide

45

Page 46

Example 1. Hardware event notification

>------------ Event Monitoring Service Event Notification ------------<

Notification Time: Thu Aug 17 17:36:29 2006

rxtest1 sent Event Monitor notification information:

/storage/events/enclosures/gazemon/0_3_1_0.8.0.255.5.4.0

is >= 1.

Its current value is INFORMATION(1).

Event data from monitor:

Event Time..........: Thu Aug 17 17:36:29 2006

Severity............: INFORMATION

Monitor.............: gazemon

Event #.............: 112

System..............: rxtest1.india.hp.com

Summary:

Enclosure at hardware path 0/3/1/0.8.0.255.5.4.0 : Hot Plugs Removed /

Inserted

Description of Error:

Disk Drive 2 is missing.

Probable Cause / Recommended Action:

Install Number Disk drive or blank.

Additional Event Data:

System IP Address...: 15.70.197.15

Event Id............: 0x44e45bc500000000

Monitor Version.....: B.01.00

Event Class.........: I/O

46

Troubleshooting

Page 47

Client Configuration File...........:

/var/stm/config/tools/monitor/default_gazemon.clcfg

Client Configuration File Version...: A.01.01

Qualification criteria met.

Number of events..: 1

Associated OS error log entry id(s):

None

Additional System Data:

System Model Number.............: ia64 hp server rx2600

EMS Version.....................: A.04.20

STM Version.....................: C.53.00

Latest information on this event:

http://docs.hp.com/hpux/content/hardware/ems/gazemon.htm#112

v-v-v-v-v-v-v-v-v-v-v-v-v DETAILS v-v-v-v-v-v-v-v-v-v-v-v-v

Component Data:

Firmware Version.......: 3BE6

Serial Number..........: 3ET0WYKT00007316EQTE

Inquiry Product ID.....: BF03654564

Inquiry Vendor ID......: COMPAQ

Product/Device Identification Information:

Logger ID.........: sdisk

Product Identifier: JBOD

Product Qualifier.: M5214 ENCLOSURE

SCSI Target ID....: 0x04

SCSI LUN..........: 0x00

>---------- End Event Monitoring Service Event Notification ----------<

2500 Disk System user guide

47

Page 48

EMU error condit

ion report

The EMU constan

operation. When an error condition is detected, the EMU:

• Displays Er in the alphanumeric display

• Generates an a

• Updates the visual indicators

• Generates a condition report

• Reports the c

Severity levels

DS2500 error conditions are grouped into one of four severity types:

• Unrecoverable—This category is the most severe condition. It occurs when one or more enclosure

components have failed and some enclosure functions are disabled.

HP recommends implementing corrective action immediately for an unrecoverable condition.

• Critical—Occurs when one or more enclosure components have failed or are operating outside

of their specification, and normal operation of at least one component is impossible.

HP recommends prompt corrective action to prevent system degradation.

• Noncritical—Occurs when one or more enclosure components have failed or are operating

outside of their specifications, but normal operation of the enclosure is possible. Additional

errors, however, could affect the ability of the devices to operate correctly.

• Information—Advises you that a condition exists that could become an error and require

corrective action. In effect, an information condition provides an early warning, which enables

you to prepare to implement corrective action before a component fails.

tly monitors enclosure operation and notifies the user of conditions that could affect

udible alarm (if enabled)

ondition to the HP-UX application software

Error condition reports

NOTE:

An error always generates a condition report. However, condition reports may also be generated

forcircumstancesotherthanerrors.

The EMU stores each condition report in an error queue for at least 15 seconds after the error is reported.

This ensures that all errors are displayed in the event of multiple or recurring errors. The complete report

is stored in the error queue. When you correct the error, the condition report is removed from the queue.

You can the use the EMU push buttons to display the condition report in the alphanumeric display.

IMPORTANT:

Always record the 6-digit error code, and call your HP service representative for a plan of action.

See "Error condition report (Er)" on page 42 for information about viewing the error condition reports.

To decode the error condition report, see Appendix C.

Correcting the error removes the condition report from the error queue. An information error doesn't

require repair, and is removed from the queue after a fixed period of time.

Status indicators

LEDs indicating DS2500 status are located on the front and rear of each enclosure.

48

Troubleshooting

Page 49

Enclosure status icons are located on the front, lower right of the enclosure. These same icons can be

seen from the rear of the enclosure on the top of the EMU.

• Table 7 shows the enclosure icons.

• Table 8 describes the status of these icons and recommended action for each.

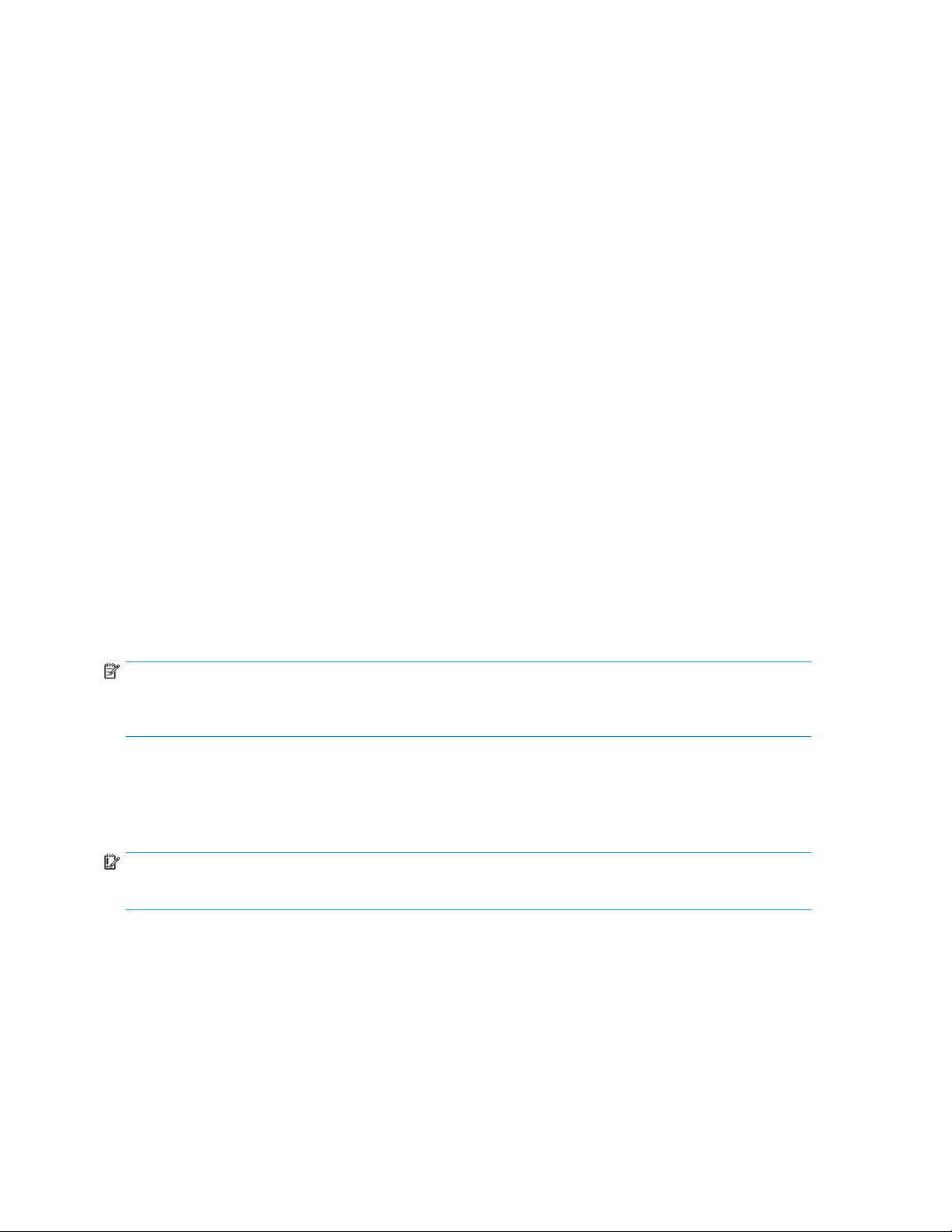

Table 7 Enclosure status icon displays

Icon

EMU heartbeat icon (green LED)

Enclosure power icon (green LED)

Enclosurefaulticon(orangeLED)

Off

Table 8 EMU status indicators

EMU heartbe

at

Power (gree

n)

Fault (ambe

(green)

Flashing Flashing Flashing

Flashing

Flashing

On

On On

Off

On

r)

Status and r

The EMU loca

TheEMUisoperational,theenclosure

power is correct, and there are no

enclosure faults.

The EMU is operational, but there is an

enclosure fault.

Check the alphanumeric display error code

for information about the problem.

ecommended actions

te function is active.

Flashing

Flashing

On On

Off

Off Off Off There is an enclosure fault, most likely, a

Off Off

Off There is an EMU fault, and the enclosure is

On

Off There is an EMU fault, and the enclosure is

The EMU is operational. (This display may

appear when power is initially applied to

the enclosure.)

operational.

operational.

power problem.

2500 Disk System user guide

49

Page 50

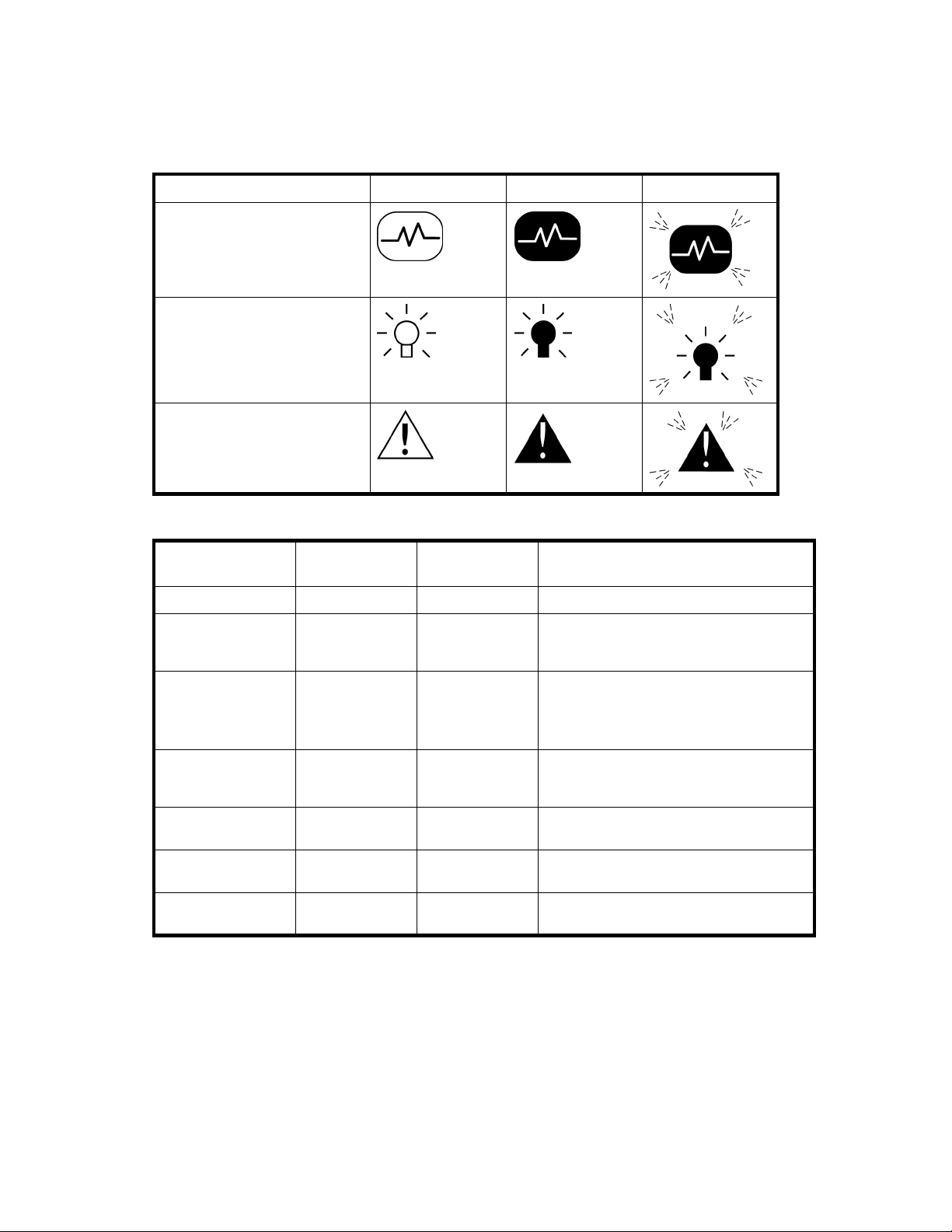

LEDs on the rear of the enclosure indicate the status of the EMU, I/O modules, and power supply/blower

assemblies. Operational states of the LEDs are shown in Figure 26.

Figure 26 LEDs in the operational state

Audible error indicators

If enabled, the audible alarm sounds when the EMU detects an error. The sound pattern identifies the

error sever

for instru

Table 9 Audible alarm sound patterns

ity. Table 9 shows the duration of the different alarms. See "Audible alarm" on page 41

ctions to control the alarm.

CXO7959A

Error sever

Unrecoverable

Critical

Noncritical

Informati

Legend

ity

on

Visual error indicators

I/O module and transceivers

LEDs on the I/O module report the status of transceiver signals and I/O module power. Use Figure 27

and Table 10 to interpret the I/O module errors and determine what action to take.

Cycle 1 Cycle 2

Alarm on

Alarm off

50

Troubleshooting

Page 51

1

2

3

CXO7488A

1. Port 2 status

2. Power stat

3. Port 1 status

us

Figure 27 I/O module status LEDs

Table 10 I/O module status LEDs

Disk drives

Three status indicators show the drive operational status. Use Figure 28 and Table 11 to interpret

disk errors and determine what action to take.

Port 2

status

On On On

On On

Off

Flashing

On On

Off Off Off No I/O module power.

Power Port 1

status

Off

On On

On On

Flashing Port 1 is b

Problem description and recommended action

Normal operational status

No signal is detected on port 1.

Check the t

No signal is detected on port 2.

Check transceiver and fiber cable connections.

Port 2 is being located.

The I/O module is not operational. Check power supplies. If

power supplies are operational, replace I/O module.

ransceiver and fiber cable connections.

eing located.

2500 Disk System user guide

51

Page 52

1. Ready

2. Online

3. Fault

Figure 28 Disk drive status indicators

Table 11 Di

sk drive status indications

Ready Online Fault

On On

Flashing

On On On

On

On

Off

Catastrophic errors

The design of the DS2500 allows it to continue operating in the presence of faulty hardware. However,

a critically-high temperature in the enclosure can cause hardware failure and compromise data integrity.

To prevent catastrophic data loss and further damage to components, the following conditions cause the

DS2500 to shut down:

• A power supply removed from the enclosure

• No operational blowers

• An unacceptable temperature level in the enclosure

If any of these conditions exists, the EMU starts a timer to shut down the enclosure in 7 minutes. If the

condition is corrected before the 7 minute countdown is completed, the EMU aborts the shutdown

and normal operation resumes.

Off

Off

Flashing

Description

Normal operational status.

Drive is idle.

Normal op

Drive is b

Displays on the first disk in the enclosure to indicate

the disk drive is not connected to either I/O module.

Verify the FC cable connections to an HBA.

Indicates disk drive error/not active.

Verify FC loop continuity.

erational status.

eing accessed.

52

Troubleshooting

Page 53

EMU temperat

The EMU uses multiple temperature sensors to monitor enclosure conditions. A sensor is located in:

• Each power supply

• Each disk dr

• The EMU

An algorithm involving data from multiple sensors determines the temperature in the enclosure. The

following occurs when an unacceptable temperature condition exists:

• As the temp

time for corrective action before shutdown occurs.

• If the temperature reaches a critical level, the EMU activates the alarm and starts a timer which

shuts down

ure warning and shutdown operation

ive

erature approches a critical temperature condition, a noncritical alarm sounds to provide

the enclosure in 7 minutes.

2500 Disk System user guide

53

Page 54

54

Troubleshooting

Page 55

6 Customer self repair

This chapter describes the procedures for replacing customer replaceable units (CRUs).

Customer self repair

The DS2500 is designed with three Customer Self Repair (CSR) parts to minimize repair time and allow