Page 1

user’s guide

hp StorageWorks

disk system 2405

Edition E0902

.

Page 2

Notice

Trademark Information

© Hewlett-Packard Company, 2002. All rights

reserved.

A6250-96020

Hewlett-Packard Company makes no warranty of

any kind with regard to this material, including, but

not limited to, the implied warranties of

merchantability and fitness for a particular purpose.

Hewlett-Packard shall not be liable for errors

contained herein or for incidental or consequential

damages in connection with the furnishing,

performance, or use of this material.

This document contains proprietary information,

which is protected by copyright. No part of this

document may be photocopied, reproduced, or

translated into another language without the prior

written consent of Hewlett-Packard. The

information contained in this document is subject to

change without notice.

Format Conventions

WARNING Identifies a hazard that can cause

personal injury

Red Hat is a registered trademark of Red Hat Co.

C.A. UniCenter TNG is a registered trademark of

Computer Associates International, Inc.

Microsoft, Windows NT, and Windows 2000 are

registered trademarks of Microsoft Corporation

HP, HP-UX are registered trademarks of Hewlett-

Packard Company. Command View, Secure

Manager, Business Copy, Auto Path, Smart PlugIns are trademarks of Hewlett-Packard Company

Adobe and Acrobat are trademarks of Adobe

Systems Inc.

Java and Java Virtual Machine are trademarks of

Sun Microsystems Inc.

NetWare is a trademark of Novell, Inc.

AIX is a registered trademark of International

Business Machines, Inc.

Tru64 and OpenVMS are registered trademarks of

Compaq Corporation.

Caution Identifies a hazard that can cause

hardware or software damage

Note Identifies significant concepts or

operating instructions

this font - used for all text to be typed

verbatim: all commands, path names, file names,

and directory names also, text displayed on the

screen

<this font> - used for variables used in commands

this font - used for GUI menu options and screen

controls

Page 3

Revision History

First Edition March 2002

Second Edition June 2002

Third Edition Sept 2002

Page 4

Page 5

1 Product Description 13

General Description 13

Features 14

Status Indicators 15

Power/Standby Switch 15

High Availability 15

Upgradability 16

Environmental Services 16

Components 17

Disks and Disk Fillers 17

LCCs 18

Power Supply/Fan Modu le 21

Hardware/Software Requirements 23

Topologies 23

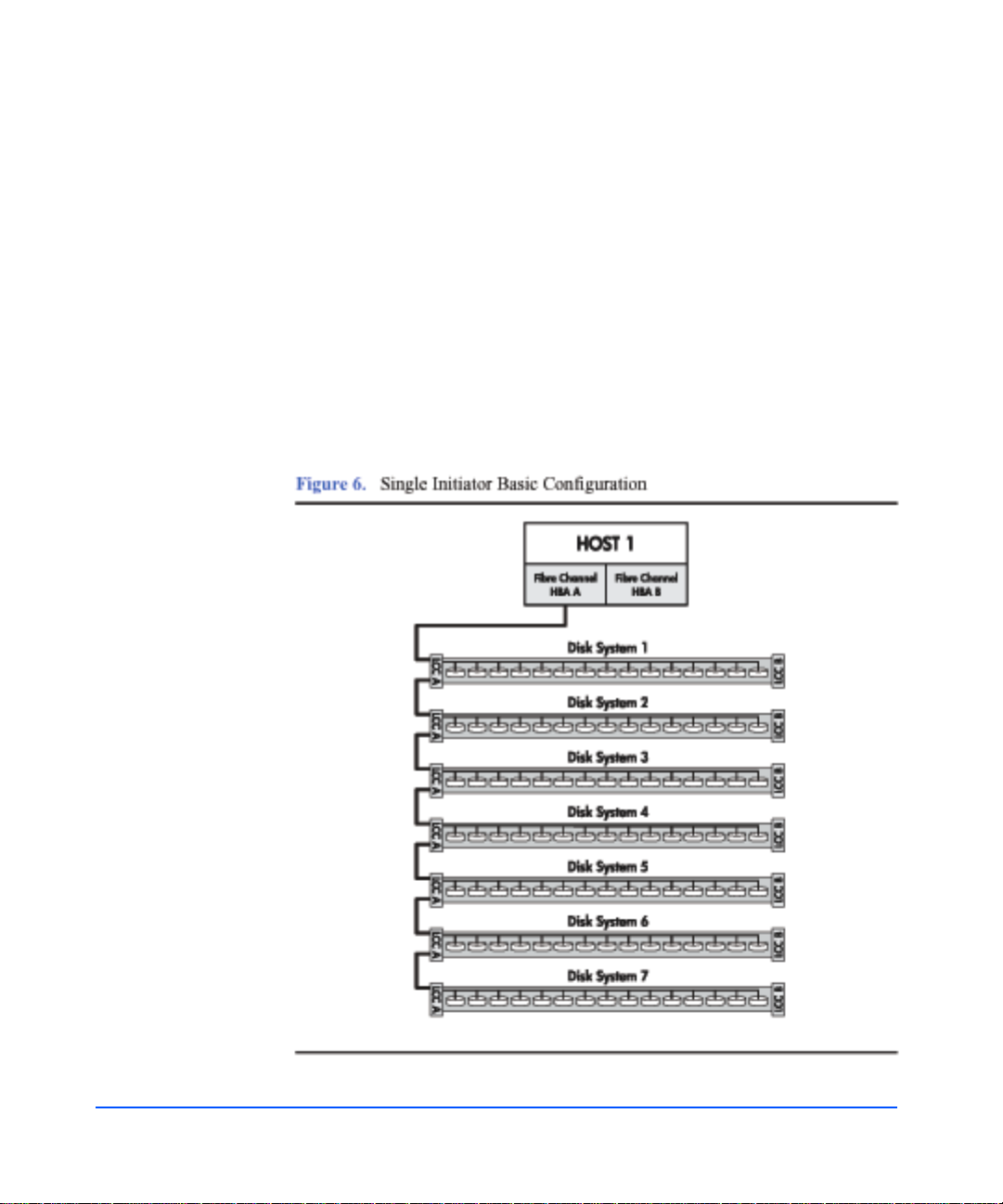

Single Host Basic Configuration 24

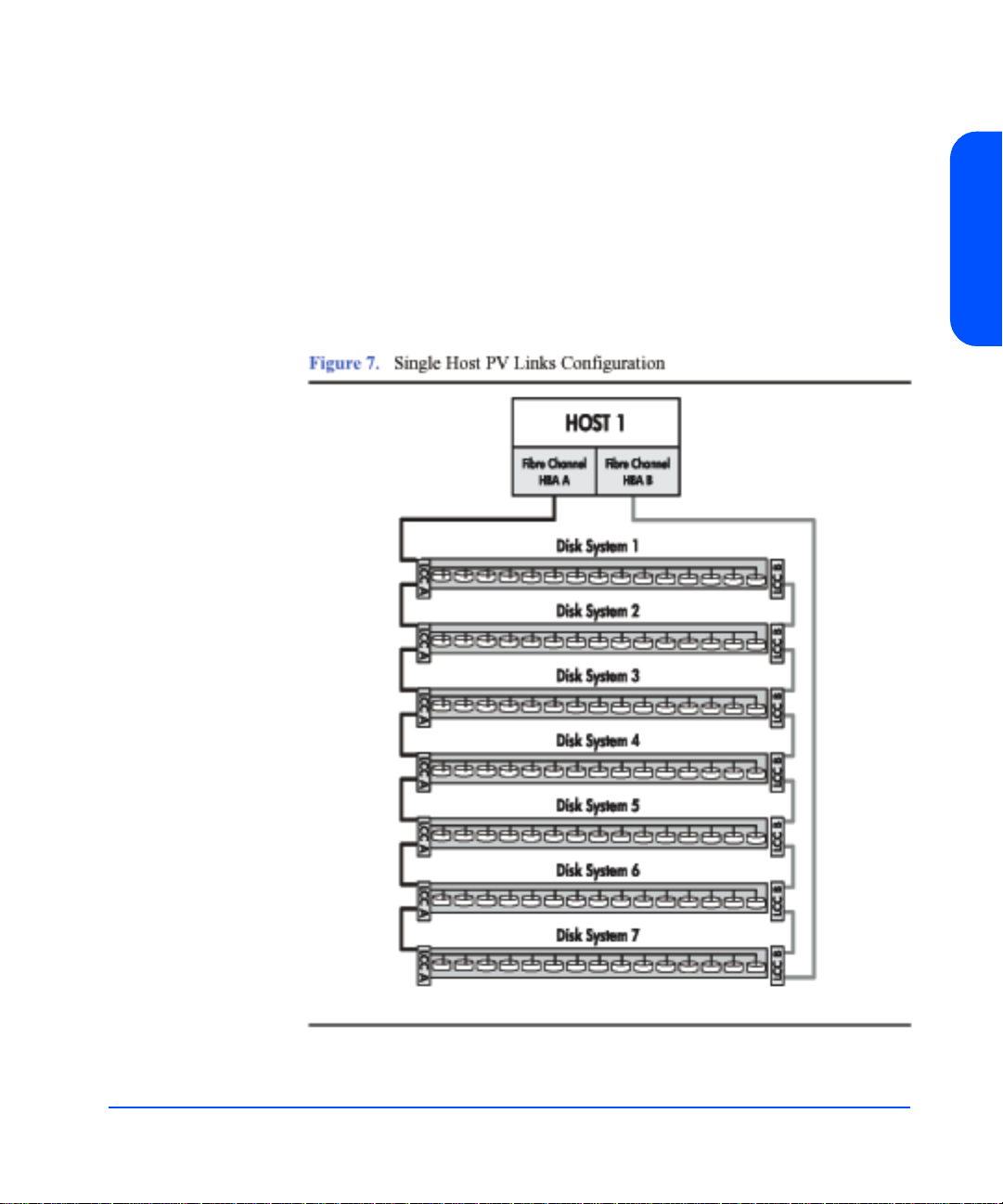

Single Host PV Links Configuration 25

Two Host High Availability Configuration 26

Four Host Hub C onfiguration 2 7

Definitions 28

contents

2 Installation 31

Preparation 31

Electrical Requirements 31

Choosing PDUs 32

Installing PDU/PDRUs 34

Software Requirements 37

Step 1: Gather Tools 38

Step 2: Unpack the Product 38

5

Page 6

Step 3: Install the device 41

Installing the Storage Device into a Rack System/E 41

Installing the storage device into an HP Computer Cabinet 49

Installing the Storage Device into a Rittal-Style Rack 56

Install the Disk System 63

Step 4: Confi gure LCCs 64

Step 5: Set LCC Switches 66

Step 6: Connect FC and Power Cables 72

Step 7: Install Disk Modules 75

Step 8: Turn on the Disk System 76

Step 9: Verify Devices on the Host 78

Sample IOSCAN 78

Where do you go from here? 79

3 Configuration 81

Viewing a Disk System in IOSCAN 81

Sample IOSCAN 81

Interpreting the Hardware Path 83

Loop IDs and Hardware Paths by Enclosure ID 84

Setting Up the Hardware Event Monitor 88

Aliasing Devices (HP-Qualified Only) 88

Using SAM 88

Using STM (HP-Qualified Only) 88

Updating Firmware (HP-Qualified Only) 9 0

4 Troubleshooting 93

Overview 93

Event Notification 93

Status LEDs 96

Online Status Information 98

Viewing Component Status in SAM 98

Viewing the STM Information Log 99

Interpreting Status Values 100

Checking the Fibre Channel Link 102

Isolating Causes 104

6

Page 7

5 Removal and Replacement 109

Disk Module 111

Preparation 111

To Determine If a Volume Group or Physical Volume Group Is

Active 111

To Determine If the Physical Volume Is Attached 112

To Replace Attached Physical Volumes 112

To Replace Unattached Physical Volumes 114

Tools 115

Procedure 115

LCC 117

Tools 117

Procedure 117

Power Supply 120

Tools 120

Procedure 120

Disk System 122

Tools 122

Procedure 122

Top Cover (HP-Qualified Only) 124

Tools 124

Procedure 124

Midplane (HP-Qualified Only) 126

Tools 126

Procedure 126

6 Reference 129

Product Models and Options 129

Upgrade Products 130

PDU/PDRU Products 131

Replaceable Parts 132

Specifications 132

Dimensions 132

Weight 133

AC Power Input 133

DC Power Output 133

7

Page 8

Heat Output 133

Environment 134

Acoustics 134

Safety Certifications 134

EMC Compliance 135

Regulatory Statements 136

A. FCC Statement (For U.S.A. Only) 136

B. IEC Statement (Worldwide) 136

C. Spécification ATI Classe A (France) 137

D. Product Noise Declaration (Germany) 137

E. VCCI Statement (Japan) 138

Harmonics Conformance (Japan) 138

F. BSMI EMC Statement (Taiwan) 138

G. Declaration of Conformity 139

Product Web Site 140

Related Documents 140

8

Page 9

figures

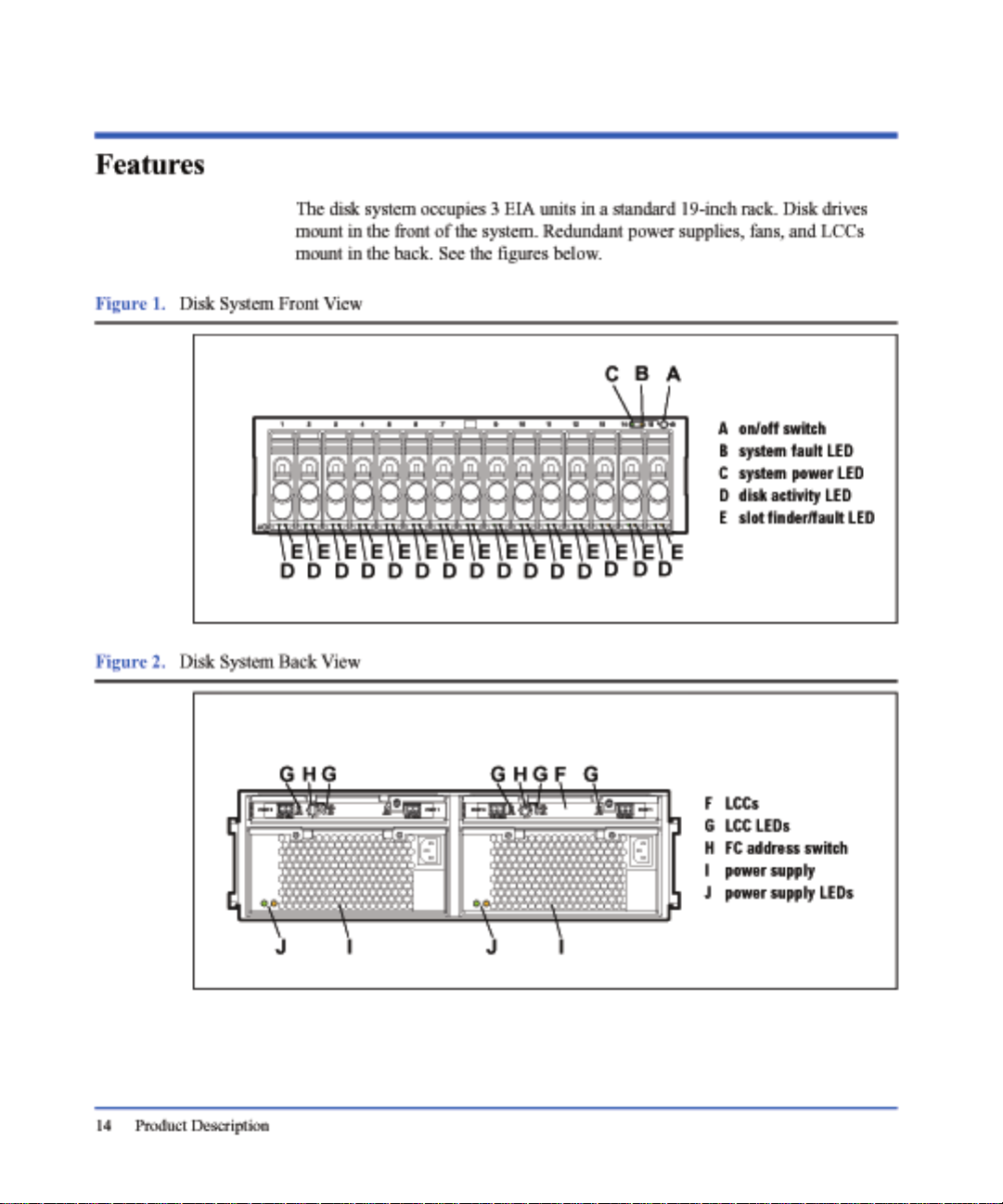

Figure 1 Disk System Front View 14

Figure 2 Disk System Back View 14

Figure 3 Disk Module 18

Figure 4 LCC 19

Figure 5 Power Supply/Fan Module 21

Figure 6 Single Initiator Basic Configuration 24

Figure 7 Single Host PV Links Configuration 25

Figure 8 Two Host High Availability Con figuration 26

Figure 9 Four Host Hub Configuration 27

Figure 10 PDRU Placement in 1.6-Meter Rack 35

Figure 11 PDRU Placement in a 2.0-Meter Rack 36

Figure 12 Disk System Accessories 39

Figure 13 Disk System Contents 40

Figure 14 HP Rack System/E Rail Kit Contents 41

Figure 15 HP Rack System/E Installation Overview 42

Figure 16 Locating the site for the device installation in a System/E

rack 44

Figure 17 Installing clipnuts for an HP Rack System/E 44

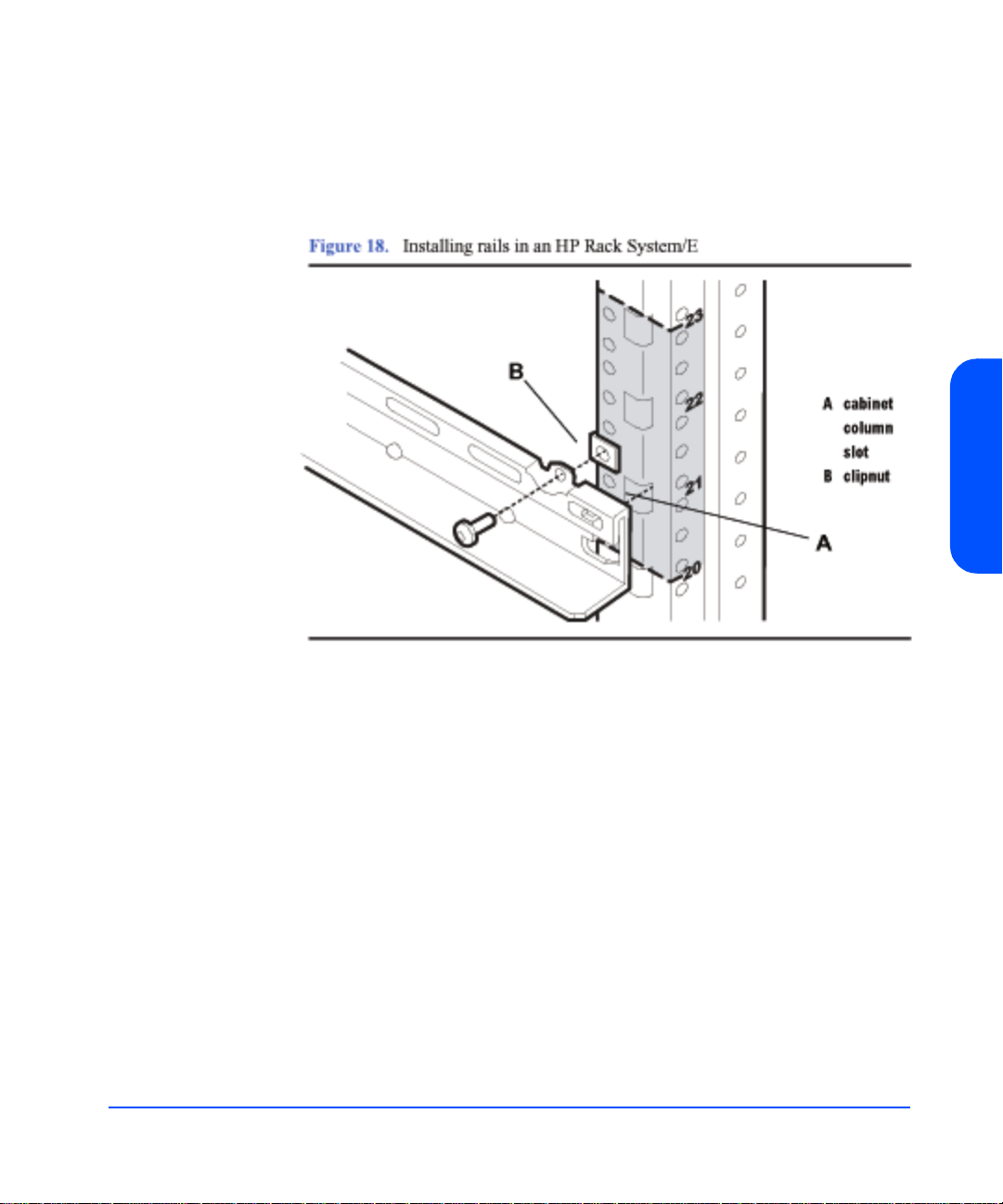

Figure 18 Installing rails in an HP Rack System/E 45

Figure 19 Installing the enclosure clipnut in an HP Rack System/E 46

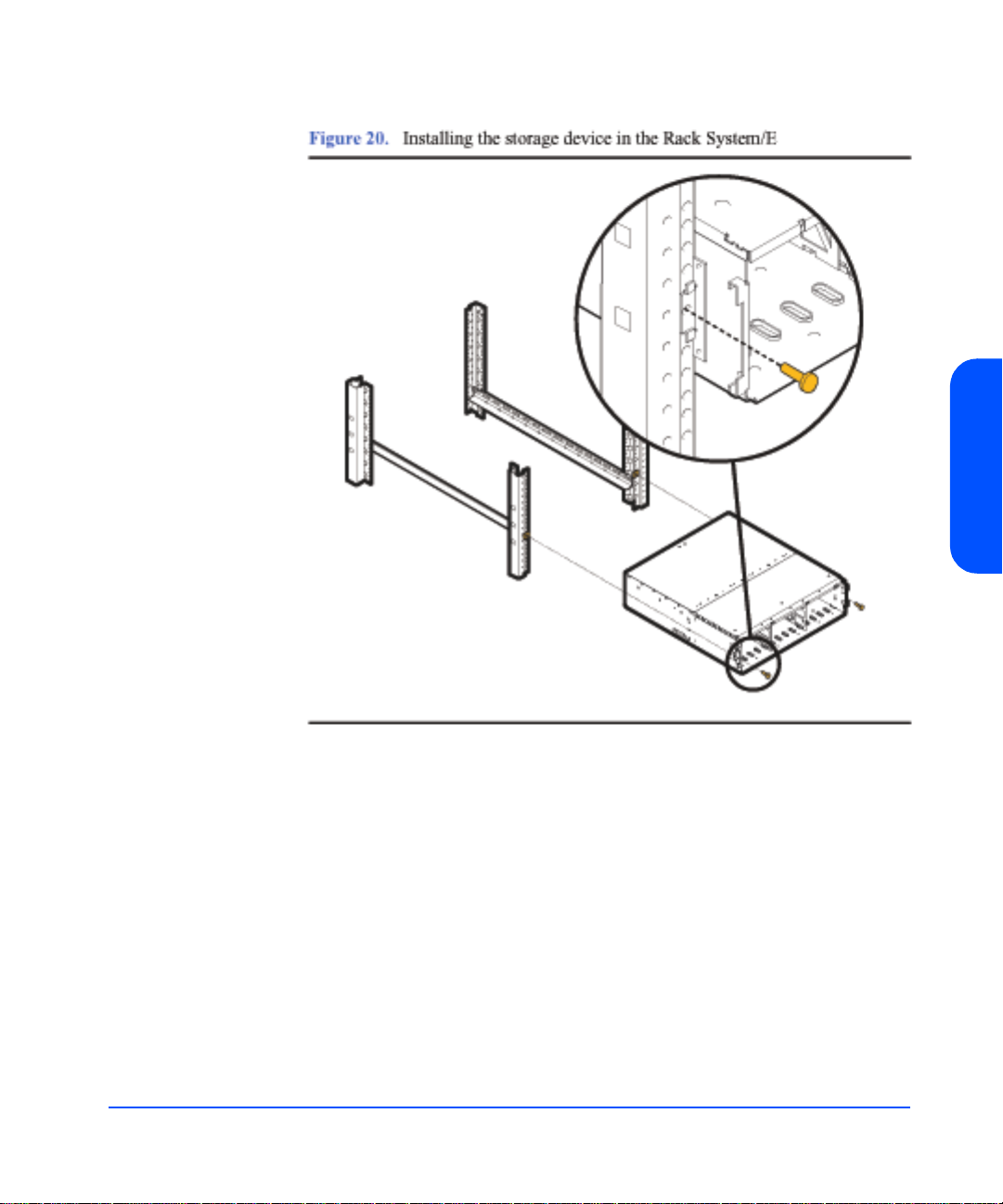

Figure 20 Installing the storage device in the Rack System/E 47

Figure 21 Installing enclosure rail clamps in an HP Rack

System/E 48

Figure 22 HP Computer Cabinet Rail Kit Contents 49

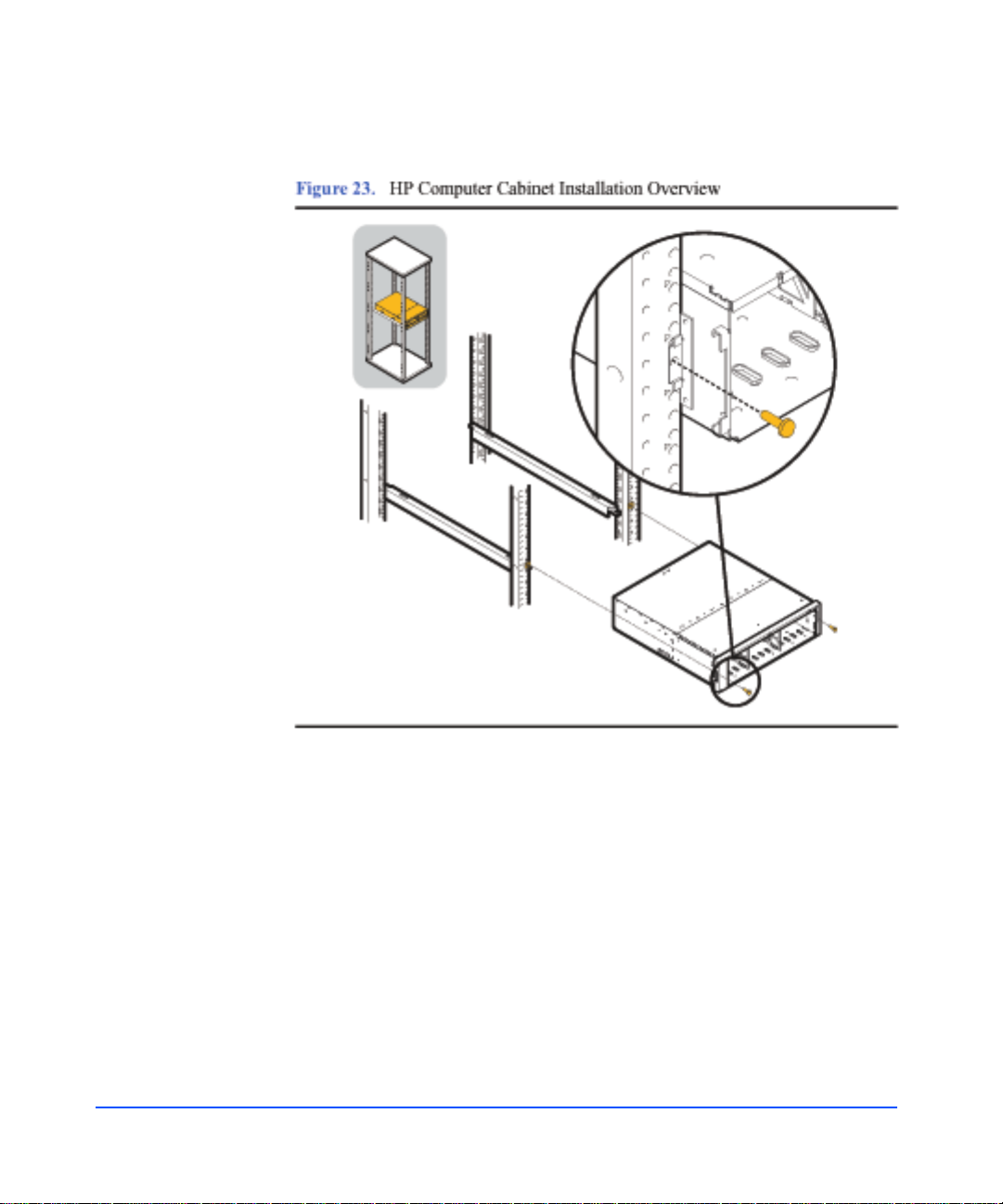

Figure 23 HP Computer Cabinet Installation Overview 50

Figure 24 Locating the site for the device installation in an HP

Computer Cabinet 51

Figure 25 Installing rail clip nuts in the HP Computer Cabinet 51

Figure 26 Installing rails in the HP Computer Cabinet 52

Figure 27 Installing enclosure retention clipnuts in an HP Computer

Cabinet 53

Figure 28 Installing the storage device in an HP Computer

Cabinet 54

9

Page 10

Figure 29 Installing a filler panel in an HP Computer Cabinet 55

Figure 30 Rittal-Style Rail Kit Contents 56

Figure 31 Rail Alignment 57

Figure 32 Front Screw Installation 57

Figure 33 Rear Slide Extension 58

Figure 34 Center Nut Tightening 59

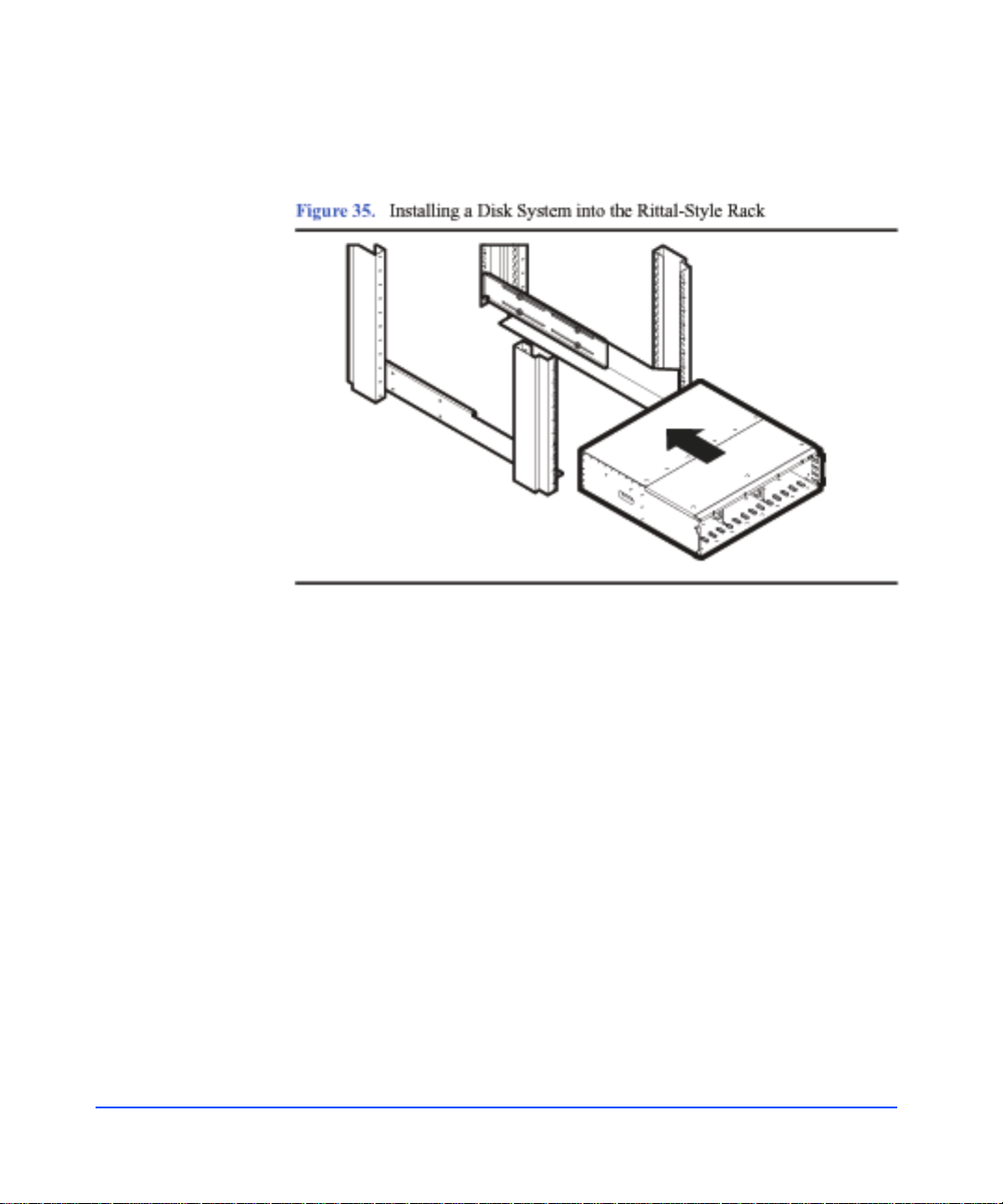

Figure 35 Installing a Disk System into the Rittal-Style Rack 60

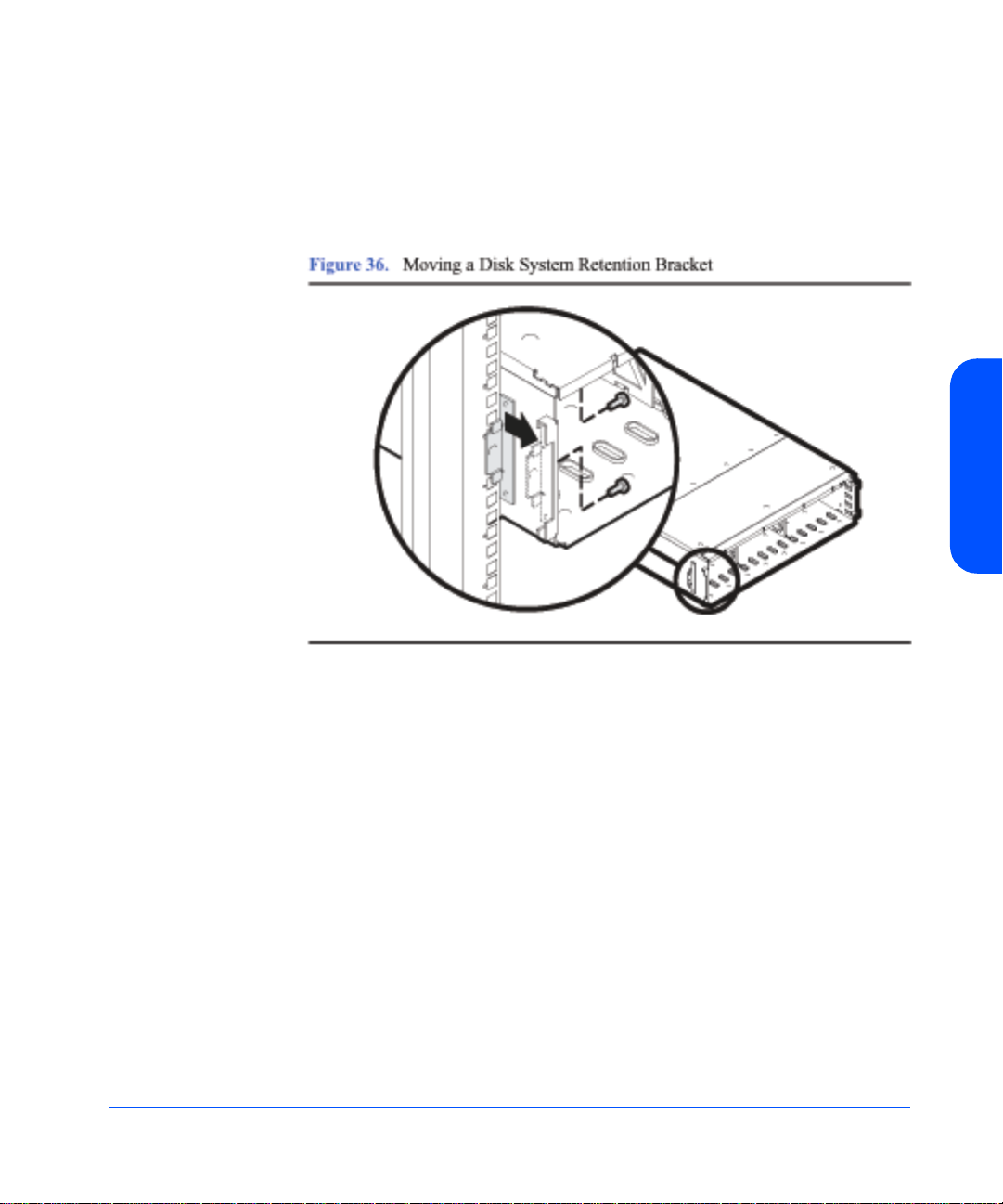

Figure 36 Moving a Disk System Retention Bracket 61

Figure 37 Bolting the Disk System to the Front C olum n o f the

Rack 62

Figure 38 LCC Internal Configuration Switch 64

Figure 39 LCC Installation 65

Figure 40 Fiber Optic Cabling and Address Switch Settings with 1

Disk System 66

Figure 41 Fiber Optic Cabling and Address Switch Settings with 2

Disk Systems 67

Figure 42 Fiber Optic Cabling and Address Switch Settings with 3

Disk Systems 68

Figure 43 Fiber Optic Cabling and Address Switch Settings with 4

Disk Systems 69

Figure 44 Fiber Optic Cabling and Address Switch Settings with 5

Disk Systems 70

Figure 45 Fiber Optic Cabling and Address Switch Settings with 6

Disk Systems 71

Figure 46 Wiring Scheme for 1.6-Meter Rack 73

Figure 47 Wiring Scheme for 2.0-Meter Rack 74

Figure 48 Disk Module Installation 75

Figure 49 Power/Standby Switch and System LEDs 77

Figure 50 Annotate Device Using STM 89

Figure 51 Firmware File Selection Window 90

Figure 52 Firmware Download Confirmation Window 91

Figure 53 Firmware Tool Window 92

Figure 54 Sample Hardware Event Notification 95

Figure 55 LED Status Indicators 96

Figure 56 Disk System Field Replaceable Units (FRUs) 109

Figure 57 Disk Module Removal 116

Figure 58 LCC Removal and Replacement 118

Figure 59 LCC Address Switches and LEDs 119

Figure 60 Power Supply Removal and Replacement 121

Figure 61 Disk System Removal and Replacement 123

Figure 62 Top Cover Assembly 125

Figure 63 Midplane Assembly 128

10

Page 11

tables

Table 1 Inrush (Surge) Current and Duration 31

Table 2 Maximum Operating Current 32

Table 3 Recommended PDU/PDRUs for Multiple Disk Systems in

HP Legacy Racks 33

Table 4 Recommended PDU/PDRUs for Multiple Disk Systems in

HP System/E Racks 33

Table 5 Disk System Accessories 38

Table 6 Dis k System Conte nts 39

Table 7 Rail Positions for Sequential Disk Systems 43

Table 8 Loop IDs and Hardware Paths by Slot Number and

Enclosure ID 0 - 2 84

Table 9 Loop IDs and Hardware Paths by Slot Number and

Enclosure ID 3 - 4 85

Table 10 Loop IDs and Hardware Paths by Slot Number and

Enclosure ID 5- 6 86

Table 11 LED Functions 96

Table 12 Status Indications 100

Table 13 Troubleshooting Table 104

Table 14 Disk System Field Replaceable Units 110

Table 15 Upgrade Products 130

Table 16 PDU/PDRU Pr oducts 131

Table 17 Replacement and Exchange Part Numbers 132

Table 18 Product Weights 133

11

Page 12

12

Page 13

Product Description

General Description

Hewlett-Packard’s StorageWorks Disk System 2405 (referred to in this guide as

the disk system) is a high-availability Fibre Channel (FC) storage product. Dual

optical fiber ports on dual link controllers provide Fibre Channel connections to

the host. Fifteen slots accept high-speed, high-capacity FC disks connected to a

FC midplane. Data throughput is 200 Mbytes/sec. Thirteen disk systems fill a

2-meter System/E rack. Filled with 18-Gbyte disks, the 2-meter Rack System/E

yields 3.51 Terabytes of storage; with 36 -Gbyt e dis ks , 7.0 2 Teraby tes of s t orag e;

and with 73-Gbyte disk, 14.23 Terabytes.

Modular and redundant components are easy to upgrade and maintain. Disks,

power supplies, and link control cards ( LCCs) are replaceable parts that plug into

individual slots in the front and back of the disk system. Redundant power

supply/fan modules and LCCs can be remo ved and replaced without interrupting

storage operations. Disks can be replaced with the system on, and only the

affected file systems taken off -line. Hewlett-Packard technical support is optional

for these procedures.

1

Special electronics and HP-UX software enable remote monitoring and

diagnostics. Sensors on the LCCs monitor the disk system environment,

including temperature, voltage, fan speed, and component status. HewlettPackard’s Command View SDM reports any changes in environmental status to

user-defined locations. Standard HP-UX diagnostic utilities also report

environmental data for enhanced troublesho oti ng.

Product Description 13

Page 14

Page 15

Status Indicators

LEDs on the disk system enable you to detect and replace failed components and

thereby prevent or minimize users’ downtime. For additional information about

LEDs, see chapter 4, Troubleshooting.

On the front of the disk system, a pair of LEDs indicates the status of the disk

system, and an LED for each slot shows disk I/O activity:

■ The system power LED (B in Figure 1) indicates that power is on or off.

■ The system fault LED (C in Figure 1) indi cates whether or not a fault has

■ At the bottom of each disk module, the left LED ( D in Figu re 1) indicates the

■ The right LED, at the bottom of each disk module (E in Figure 1), can be

LEDs (G and J in Figure 2) on the back of the disk system indicate the status of

replaceable components. See chapter 4, Troubleshooting, for specific LED

information.

Power/Standby Switch

Located in the upper right corner of the front of th e disk system, the po wer switch

(A in Figure 1) interrupts power from the power supplies to the LCCs and other

internal components. Power to the power supplies is controlled by the power

cords and the AC source.

Product Description

occurred anywhere in the disk system.

presence of I/O activity on the disk.

flashed to help a customer engineer (CE) locate the disk for physical

inspection or removal.

High Availability

High availability is a general term describing computer systems that are designed

to minimize unplanned downtime. The disk system supports high availability

requirements through the following features:

■ Hot-pluggable, high-capacity, high-speed disks

■ Redundant, hot-pluggable, user-replaceable power supplies and LCCs

■ Support for mirrored disks in the HP-UX environment

■ Online firmware upgrades

■ Hardware event monitoring and real-time error reporting

Product Description 15

Page 16

Upgradability

You can increase disk system storage capacity by:

■ Replacing disk drives with higher-capacity disk drives

■ Adding disks in unused slots

■ Adding another disk system to a FC loop

None of these actions require shutting down the product, but some may require

the use of system utilities to manage file systems.

Disk and LCC firmware is downloadable using the supported tools.

Environmental Services

Environmental services circuitry monitors the following elements:

■ Fan rotation

■ Power supply output

■ Power supply and fan status

■ Disk drive status, including fault conditions

■ LCC status

■ Temperature

■ Self-test results

Each LCC reports the status of all elements in the disk system, even if the LCC

does not have direct access to the element.

16 Product Description

Additionally, the EEPROM on each LCC stores 2 Kbytes of configuration

information and user-defined data, including the manufacturer serial number and

product number.

Page 17

Components

User-replaceable components enable high availability and easy maintenance.

This section describes the following components:

■ Disks and disk fillers

■ LCCs

■ Power supply/fan modules

Disks and Disk Fill ers

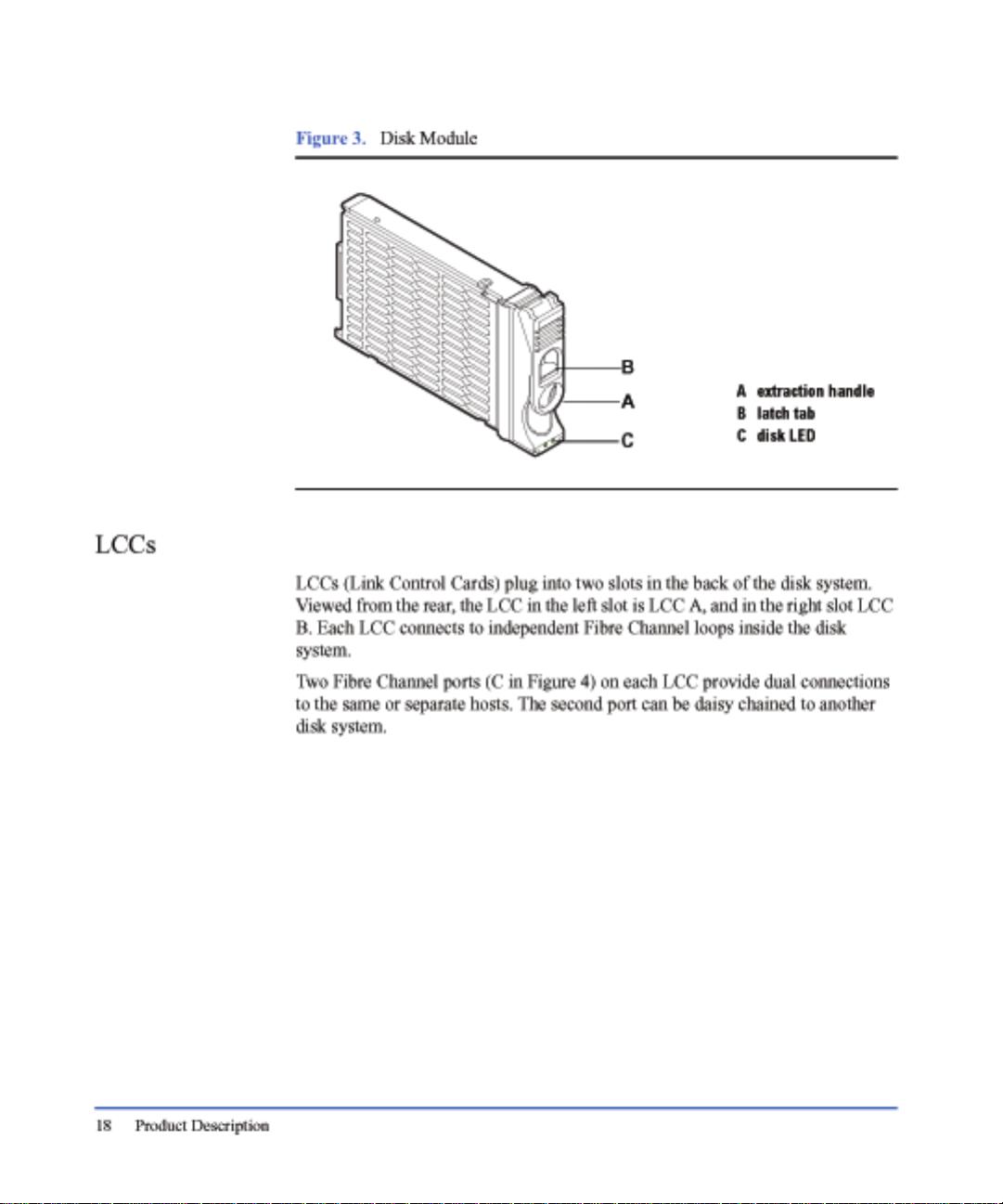

Disks, shown in Figure 3, are 3.5-inch Low Profile disks in open metal carriers.

Disks are Fibre Channel.

The open carrier design requires careful handling to avoid disk damage by

breakage and static electricity. Avoid personal contact with hot surfaces.

WARNING Touching exposed circuits can cause electrical discharge and

The plastic parts of the disk are safe to touch:

■ Extraction handle (A in Figure 3)

■ Latch tab (B in Figure 3)

The initial disk options for this product are 73-Gbyte, 36-GByte and 18-GByte

drives. A label on the disk carrier s hows the stor age capacity and r otational s peed

of the installed disk. Obtain information about the latest disk option s from HP

sales representatives.

Product Description

disable the disk. Disks require careful handling and ESD

precautions.

Disk fillers occupy unused slots to balance the air flow.

Caution Fillers must be installed in unused slots in order to maintain even

cooling around the remaining slots.

Product Description 17

Page 18

Page 19

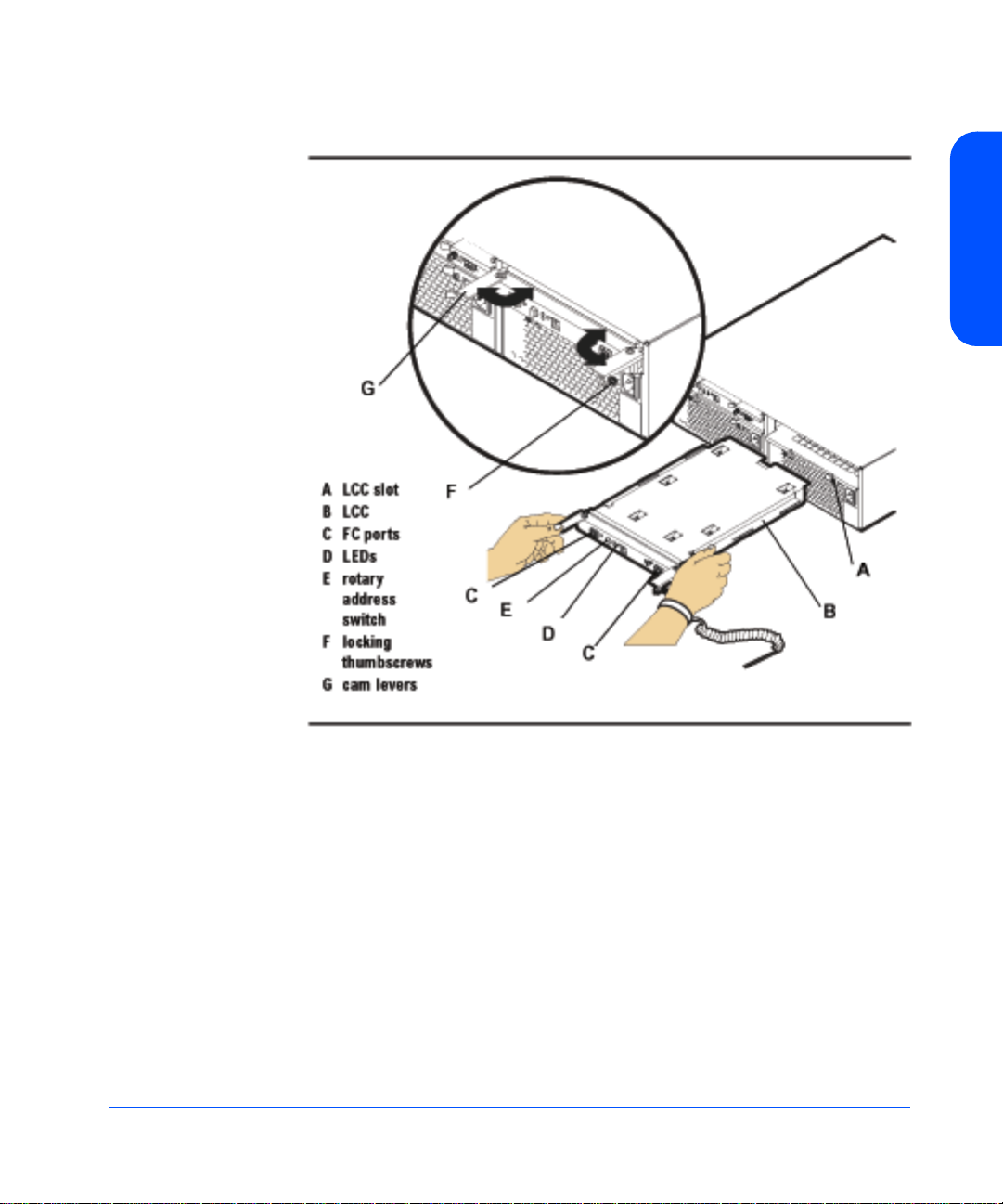

Figure 4. LCC

Product Description

Other features of the LCC are:

■ LEDs (D) indicating LCC status and bus configuration

■ Rotary switch (E)

■ Configuration switch with four settings:

1 Link Speed (1.0625 Gb/s or 2.125 Gb/s)

2 Reserved

3 Reserved

4 Power fail warning (enable/disable)

■ Locking s crews (F)

■ Cam levers (G)

Product Description 19

Page 20

LCC circuitry provides the following functions:

■ System fault detection

■ Disk address generation

Caution If an LCC fails, do not remove it from the disk system until you

are ready to replace it with a new one. The failed LCC should

remain installed to assure proper coo ling for the disk system.

20 Product Description

Page 21

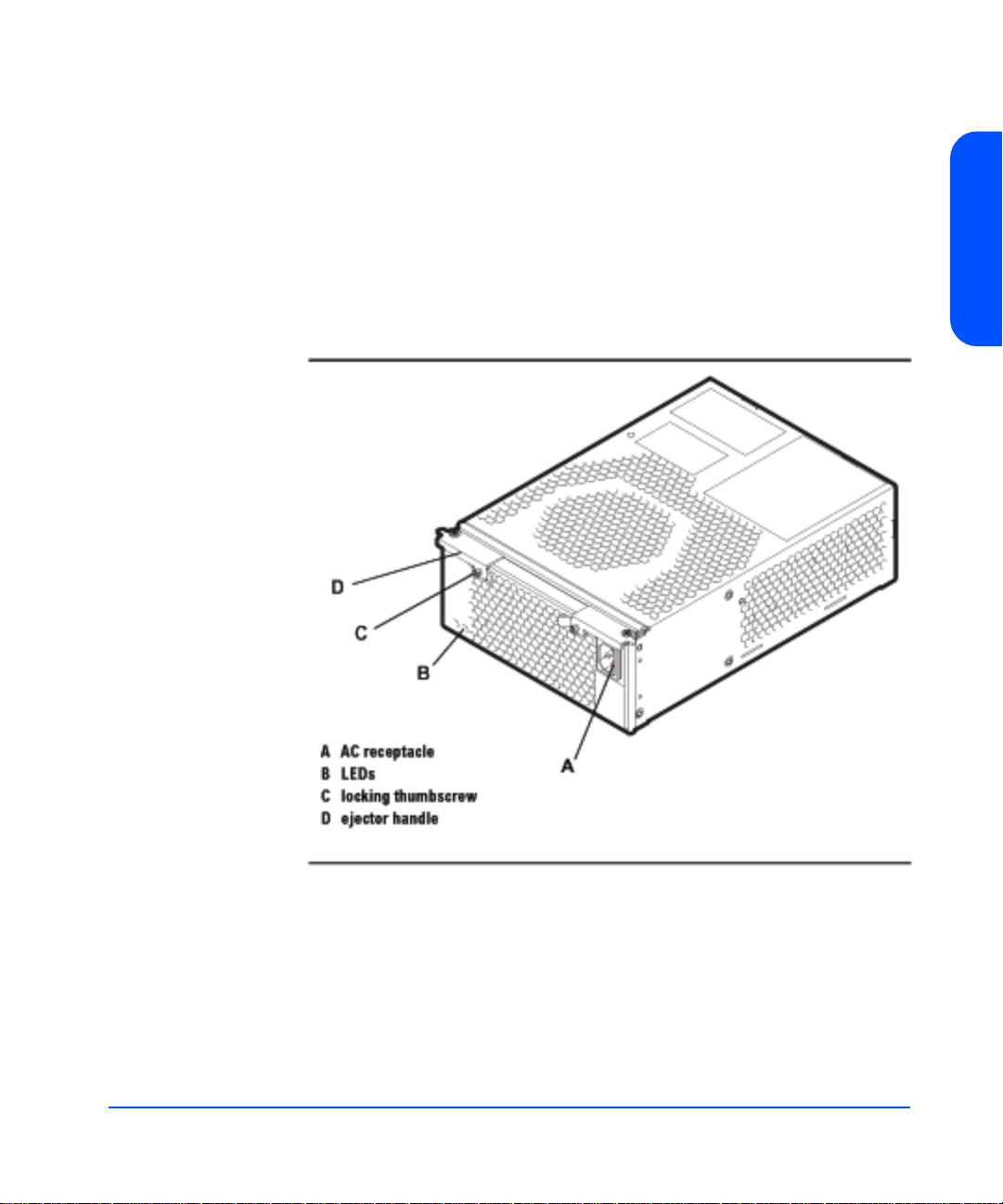

Power Supply/Fan Module

Redundant, hot-pluggable 340-watt power supplies convert wide-ranging AC

voltage from an external main to stable DC output and deliver it to the midplane.

Each power supply has an internal fan, an AC receptacle (A in Figure 5), two

ejector handles (D) with thumbscrews (C), and 2 LEDs (B). Internal control

prevents the rear DC output connector from becoming ener gi zed when the power

supply is removed from the disk system.

Figure 5. Power Su ppl y/F a n Modu le

Product Description

Product Description 21

Page 22

Power supplies share the load reciprocally; that is, each supply automatically

increases its output to compensate for reduced output from the other, and vice

versa. If one power supply fails, the other delivers the entire load.

Internal circuitry triggers a fault when the internal fan or other part fails. At the

same time, the power fault LED (amber) illuminates, and, if enabled, the

hardware event monitor sends an event message. The power supply fan remains

on if other parts fail in order to maintain cooling air flow through the system. If

the fan fails, the power supply shuts down. The fan in the other working power

supply will increase to full speed to compensate for the failed fan. The failed

power supply/fan module must be removed and the replacement power supply/

fan module installed within two minutes. In the event of a failure, if a

replacement fan module/power supply is not available, leave the failed power

supply/fan module installed until you are ready to replace it. This should be done

to maintain proper cooling for the disk system.

Internal circuitry senses fan motion and triggers a fault when the speed of the

power supply’s internal fan falls below a critical level. At the same time, the LED

turns amber, an d, if en abled, the hardware event monitor sends an event message.

22 Product Description

Page 23

Hardware/Software Requirements

The disk system is supported on the following operating systems:

■ HP-UX 11.00 with HWE 0302 or greater

■ HP-UX 11.11 with HWE 0302 or greater

For supported servers, see the latest HP 9000 Configuration and Ordering Guide.

One of the following Fibre Channel HBAs must be installed in the host:

■ A5158A, 1 Gb PCI Fibre Channel HBA

■ A6684A, 1 Gb HSC Fibre Channel HBA

■ A6685A, 1 Gb HSC Fibre Channel HBA

■ A6795A, 2 Gb PCI FIbre Channel HBA

Topologies

The disk system supports high availability through redundan t comp onent s an d

redundant connections to redundant hosts. Each port on a LCC can be connected

to a different host bus adapter in the same or different hosts. Mirroring inside a

disk system is not a high availability solution to the extent that a midplane failure

would necessitate downtime.

Product Description

Basic high availability topologies are described on the following pages. For

information about specific supported topologies, consult an HP sales

representative.

Product Description 23

Page 24

Single Host Basic Configuration

The maximum number of disk systems supported on a Fibre Channel Arbitrated

Loop (FC-AL) is seven. The maximum storage capacity with this configuration

is approximately 7.5 Terabytes (105 disk modules at the 73 Gbyte capacity

point). This configuration does not provide any redundancy to the data path,

however there is some hardware redundancy provided by the enclosures

themselves (power supplies). With the utilization of Mirror/UX software, one or

more mirrors can be created on th e har dware path to p rov ide a basic level of data

protection.

The performance of this co nfigu ration depends on the n umber of d isk sy stems on

the loop. Using the maximum supported number of disk systems reduces the

performance of the loop. To get the maximum performance (200 MB/s or

maximum number of I/Os), the number of disk systems should be limited to four.

24 Product Description

Page 25

Single Host PV Links Configuration

Data path redundancy can be achieved with the configuration shown in Figure .

Using an additional host bus adapter and the LVM software, pvlinks can be

created to provide a redundant path to data. A separate mirror path can be created

for data protection, also. This configuration protects against any single

component failure (cables, HBAs, disks). Like the single host basic

configuration, each loop is capable of 200 MB/s which translates to 40 0 MB/s for

this configuration.

Product Description

Product Description 25

Page 26

Two Host High Availability Configuration

Figure 8 shows a basic high availability configuration. Each disk system can still

be configured using pvlinks and mirroring. High availability software protects

against a disk system failure. A failure in a cable or LCC will result in a loop

failure. Adding FC-AL loops or switches makes this configuration more robust.

26 Product Description

Page 27

Four Host Hub Configuration

The disk system can run at 2 Gb/s speed. For legacy systems a four host

configuration could be used for an advanced high availability environment at 1

Gb/s speed. See Figure 9, below.

The performance of this configur ation i s limit ed to a ma ximum of 20 0MB/s (10 0

MB/s per loop). The performance issues discussed with the single initiator basic

configuration also apply with this configuration .

Product Description

Product Description 27

Page 28

Definitions

The following terms have specific meanings in the context of this guide:

High availability (HA)

HA describes hardware and software systems that are designed to minimize

planned and unplanned downtime. High availability is measured at the system

level and stated as the percentage of time the system is in a state to do useful

work; for example, 99.95% availability translates to four hours of downtime per

year.

Hot-pluggable

Hot-pluggable signifies the ability of a component to be installed or replaced

without interrupting storage operations and within the restrictions of the

operating environment. All customer -replaceable disk s ystem components can be

replaced under power. Adding or replacing disks o r LCCs may requ ir e the u se of

HP-UX commands to manage file systems.

JBOD

Pronounced jay-bod, a JBOD (Just a Bunch Of Disks) is an enclosed group of

disks that are addressed individually by the host.

PDU and PDRU

PDUs (power distribution units) distribute power from a sing le inlet to multiple

outlets. PRUs (power relay units) connect one or more PDU inlets to a single on/

off switch, such as a cabinet power switch. Units that both distribute and switch

power are referred to as PDRUs.

28 Product Description

Short Wave

Lasers or LEDs that emi t light with wavelen gths around 780 nm or 850 nm . Short

wave lasers are used for Fibre Channel links up to approximately 700 m. They

are typically used with multimode fiber. The preferred fiber core size is 50

microns since this fiber has large bandwidth so the distance is limited by fiber

attenuation. A 62.5 micron core size is also supported for compatibility with

existing FDDI installations. Fiber of this type has smaller bandwidth and, in this

case, the distance is limited by fiber bandwidth.

Page 29

Multimode

A type of fiber optic cable that allows more than one mode (rays of light) to be

guided.

Arbitrated Loop (FC-AL)

A Fibre Channel topology that provides a low-cost solution to attach multiple

communicating ports in a loop without hubs and switches.

Arbitrated Loop Physical Address (AL_PA)

A unique one-byte valid value assigned during Loop Initialization to each

NL_Port or FL_Port on a Loop.

Product Description

Product Description 29

Page 30

30 Product Description

Page 31

Installation

Preparation

Before installing the disk system, make sure (1) electrical wiring, breakers, and

PDUs meet power needs, (2) the required support software is installed on the

host, and (3) if you are connecting the disk system to a V-class server, autotermination is enabled on the host bus adapter. This section covers all three of

these topics.

Electrical Requirements

All electrical wiring to the service point (plug) must be sized to carry the

appropriate inrush (20 amps per power supply) and steady state currents. See the

following table for examples.

Table 1. Inrush (Surge) Current and Duration

No. of Disk Systems on Circuit

(2 power supplies per disk

2

Inrush Current and Duration

system)

1 40 amps declining over 100 ms (5 cycles)

2 80 amps declining over 100 ms (5 cycles)

3 120 amps declining over 100 ms (5 cycles)

4 160 amps declining over 100 ms (5 cycles)

Installation 31

Page 32

Table 2. Maximum Operating Current

Incoming Voltage

AC RMS

Maximum RMS Current Drawn

by One Disk System

100 – 120 volts 4.8 amps

200 – 240 volts 2.0 amps

Caution Adding disk systems to 120V circuits rapidly increases amp

requirements. Always make sure that the total current drawn does

not exceed circuit capacity.

Circuit breakers must be adequately rated for inrush and operating currents.

Hewlett-Packard recommends magnetic-type circuit breakers, which are capable

of handling large inrush currents for short durations (10 to 12 cycles) and are

rated adequately for steady state currents.

Choosing PDUs

Peak power requirements and PDU capacity affect the number of disk systems

that can be installed in a rack. For example, to install more than four disk systems

in Hewlett-Packard legacy racks (HP C27 85A, C2786 A, and C2787A), you must

upgrade to 19-inch PDUs.

Besides rack density, the following factors can help you choose PDUs:

■ Redundant power source. To connect redundant power supplies t o separate

PDUs, install redundant PDUs.

32 Installation

■ Number of cords to the AC source. Using 30-amp PDRUs instead of 16-amp

PDUs reduces the number of cords to the wall.

■ Future needs. Installing surplus PDU capacity allows you to add disk system

units later.

■ Inrush margins. For installations that require four or more 16-amp PDUs,

Hewlett-Packard recommends HP 30-amp PDRUs (E7681A, E7682A) for

their inherent inrush protection.

■ On/Off switch capability. Some PDU/PDRU options support the use of a

single-point on/off switch.

The following tables show how many and what kind of PDU/ PDR U s are needed

to install one or more disk systems in an HP rack. Data assumes 220V AC

Page 33

nominal power and redundant PDU/PDRUs. For nonredundant configurations,

divide the number of recommended PDU/PDRUs by 2.

Table 3. Recommended PDU/PDRUs for Multiple Disk Systems in HP Legacy

Racks

No. of Disk

Systems

1 – 5 2 3-foot/16-amp PDUs

or

2 19-inch/16-amp PDUs

6 – 8 NA

2

1.1 meter

(21 U)

1.6 meter

(32 U)

2 5-foot/16-amp PDUs

2.0 meter

(41 U)

1

or

2 19-inch/16-amp PDUs

4 19-inch/16-amp PDRUs

or

4 19-inch/30-amp PDRUs

9 – 10 NA

2

NA

2

4 19-inch/

30-amp PDRUs

1.Supports cabinet on/off switch.

2.Rack height does not allo w additional disk systems.

Table 4. Recommended PDU/PDRUs for Multiple Disk Systems in HP System/

E Racks

No. of Disk

Systems

1.25 meter

(25 U)

1.6 meter

(33 U)

2.0 meter

(41 U)

1 – 4 2 19-inch/16-amp PDUs

or

2 19-inch/30-amp PDRUs

5 – 8 NA

2

1

2 19-inch/30-amp PDRUs

1

4 19-inch/30-amp PDRUs

9 – 11 NA

2

NA

2

4 19-inch/

30-amp PDRUs

12-13 NA

2

NA

2

4 19-inch/

30-amp PDRUs

Installation

1.Supports cabinet on/off switch.

2.Rack height does not allow additional disk systems.

Installation 33

Page 34

Installing PDU/PDRUs

The 19-inch PDUs and PDRUs can be installed vertically or horizontally in the

rack. Choose PDU/PDRU locations with the following guidelines in mind:

■ Place PDU/PDRUs within the reach of disk system cords.

■ Place PDU/PDRUs vertically whenever possible. See sample installations in

Figure 10 and Figure 11. Installing PDU/PDRUs horizontally interferes with

the ability to service disk systems that are behind the PDU/PDRU.

■ Place vertical PDU/PDRUs on each side of the disk system so that the cord

from either power supply does not cross over replaceable components in the

middle of the product.

■ To achieve maximum density in 2-meter racks, install 30-amp PDRUs on

hinged brackets directly behind disk systems. Hinges allow the PDRU (HP

E7681A and E7682A) to swing aside for servicing obscured components.

(See Figure 11.)

34 Installation

Page 35

Page 36

Page 37

Software Requirements

Ensure that the minimum revisions of HP-UX extension software and online

diagnostics are installed. These release packages enable STM and EMS for the

disk system.

1 At the host console, enter swlist | grep XSW and look for the following

extension software according to the installed HP-UX revision:

— HP-UX 11.00 with HWE 0302 (March 2002 Patch bundles)

— HP-UX 11.11 with HWE 0302 (March 2002 Patch bundles)

2 Enter swlist | grep Online and look for the following online

diagnostics according to the installed HP-UX revision:

— OnlineDiags B.11.00.20.09, or greater, on HP-UX 11.00

— OnlineDiags B.11.11.06.09, or greater, on HP-UX 11.11

If swlist does not report the specified releases, install them from the latest

CD-ROM in any of the following products:

— For HP-UX 11.00:

— For HP-UX 11.11:

Installation

o B3920EA HP-UX OE Media for Servers

o B6261AA HP-UX 11.00 Extension Upgrade Media Kit

o B3920EA HP-UX OE Media for Servers

o B6191AA HP 9000 Support Plus Media

o B6821AA HP-UX TCOE Media

o B6845AA HP-UX 11.11 Minimal Technical OE Media

o B7993AA HP-UX Enterprise OE Server Media

o B7994AA HP-UX Mission Critical OE Comm. Media

The external IT Resource Center web site is:

http://us-support3.external.hp.com/

Installation 37

Page 38

Step 1: Gather Tools

Once the electrical, software, and special V-class preparations are complete,

collect the tools you need to install the disk system hardware:

■ Torx T25 screwdriver

■ Torx T15 screwdriver

■ Small flat-blade screwdriver

Step 2: Unpack the Product

1 Lift off the overcarton and verify the contents of the accessories (top) box.

See Table 5 and Figure 12.

Table 5. Disk System Accessories

Figure

Label

A User guide (A6250-96010)

B Quick installation guide (A6490-96003)

C LCCs (A6255-60001)

D Disk Modules and/or Filler Panels

E Fibre Channel cable(s)

– Rail Kits (not shown)

Part (part number)

38 Installation

Page 39

2 Lift off the accessories box and the top of the under box, and verify the

contents shown in Table 6 and Figure 13.

Table 6. Disk System Contents

Installation

Figure

Label

Part (part number)

A T w o power cords (8120-6514)

B FC Cables (Ordered separately)

C Disk system chassis with previously installed disk modules, link

control cards, and power supply/fan modules

Installation 39

Page 40

40 Installation

3 If a part is missing, contact an HP sales representative.

Page 41

Step 3: Install the device

Follow the procedures in this section to install your storage device in one of the

following rack systems:

■ HP Rack System/E

■ HP Computer Cabinet

■ Rittal-Style Rack

Installing the Storage Device into a Rack System/E

Your storage device can be installed into any of these HP Rack System/E

Products:

■ A4900A HP Rack System/E25 (1.25 M; 25U)

■ A4901A HP Rack System/E33 (1.60 M; 33U)

■ A4902A HP Rack System/E41 (2.00 M; 41U)

1 Check the rail kit contents (see Figure 14). If any parts are missing, call your

nearest HP sales office.

Installation

Installation 41

Page 42

2 Study the installation overview (see Figure 15).

42 Installation

The following tools are required for the installation of the storage device:

■ Flat-blade screwdriver

■ T25 nut driver

WARNING To ensure cabinet or rack stability, and avoid possible injury,

always install the storage devices in the rack or cabinet from the

bottom up.

3 Locate a place on the rack columns with the available space required for the

installation of the storage device. The storag e dev i ce and the rail k it requ ire 3

EIA units of space.

Page 43

Use the following table as a guide for placement of the rails in a Rack System/E

where multiple disk systems will be installed. You can rack multiple disk systems

without gaps by installing rails every three EIA units. For example, s tarting at the

bottom of a 2-meter rack, set rails at the following unit/hole locations:

Table 7. Rail Positions for Sequential Disk Systems

Disk Systems Hole from Rack Bottom

One 1

Two 4

Three 7

Four 10

Five 13

Six 16

Seven 19

Eight 22

Nine 25

Ten 28

Installation

Eleven 31

Installation 43

Page 44

Page 45

Note Be sure to use the same tab—upper or lower—on opposing rails.

Also, hole patterns vary at opposite ends of the rails.

5 Insert the rail tabs into the appropriate column holes (see A in Figure 18).

Installation

6 Secure the rail ends with one M5 screw each.

7 Install clipnuts on the front columns of the cabinet (see Figure 19). The se are

used for the retention bracket screws.

Installation 45

Page 46

8 Place the storage device on the rails and slide into the cabinet until the

retention bracket comes into contact with the rack column (see Figure 20).

WARNING An empty disk system weighs appro ximately 54 po unds (2 4.5 kg).

T o avoid personal injury, it is recommended that two people install

the storage device in the rack.

9 Insert and tighten the storage device retention (M5) screws through the

retention bracket (see Figure 20).

46 Installation

Page 47

Installation

Installation 47

Page 48

10 Place a rail clamp on each rail and slide them to each bottom rear corner of

the storage device (see Figure 21).

11 Secure the clamps to the rails. Use one 10-32 screw for each rail clamp.

48 Installation

Page 49

Installing the storage device into an HP Computer Cabinet

Your storage device can be installed into the following Computer Cabinets:

■ C2785A Computer Cabinet (1.10M; 21U)

■ C2786A Computer Cabinet (1.60M; 32U)

■ C2787A Computer Cabinet (1.96M; 41U)

Caution To ensure proper installation, only use the instructions in this

manual for installing the storage device in the HP Computer

Cabinet. Do not use the instructions enclosed in the rail kit box.

1 Check the rail kit contents (see Figure 22). If any parts are missing, call your

nearest HP sales office. The tie-down clamp is not used and may be

discarded.

Installation

Installation 49

Page 50

2 Study the installation overview (see Figure 23).

50 Installation

The following tools are required for the installation of the storage device:

■ Flat-blade screwdriver

■ T25 nut driver

WARNING To ensure cabinet or rack stability and avoid possible injury,

always install the storage devices in the rack or cabinet from the

bottom up.

3 Locate a place on the rack columns with the available space required for the

installation of the storage device. The storag e dev i ce and the rail k it requ ire 4

EIA units of space, three units for the storage device and one unit for the rails

(see Figure 24).

Page 51

Page 52

5 Insert the rail tabs into the appropriate holes on the HP Computer Cabin et

columns (see A in Figure 26).

6 Secure the rail ends with one M5 screw each.

52 Installation

Page 53

7 Install clipnuts on the front columns of the cabinet (see Figure 27). The se are

used for the device retention screws.

8 Place the storage device on the rails and slide it into the cabinet until the

retention bracket comes in contact with the rack column (see Figure 28).

Installation

WARNING An empty disk system weighs appro ximately 54 po unds (2 4.5 kg).

T o avoid personal injury, it is recommended that two people install

the storage device in the rack.

Installation 53

Page 54

9 Tighten the storage device retention (M5) screws through the retention

bracket (see Figure 28).

54 Installation

Page 55

10 Install a filler panel in the space below the storage device.

Installation

Installation 55

Page 56

Installing the Storage Device into a Rittal-Style Rack

Your storage device can be installed into the Rittal-Style Rack by doing the

following steps:

1 Inspect the contents of the rail kit. If any parts are missing, call your nearest

HP sales office (see Figure 30).

56 Installation

2 Align the front of rails to the inside of the front cabinet column.

Carefully observe the alignment of the groups of holes on the columns so the

holes in the rails align properly (see Figure 31).

Page 57

Page 58

4 Extend the adjustable slide to the back column of the cabinet.

5 Insert the mounting screws and finger tighten them through the rear column

of the cabinet (see Figure 33).

58 Installation

Page 59

6 Tighten the center nuts to finger tightness (see Figure 34).

7 Tighten all screws to their final tightness using a driver.

Tighten the screws that hold the rail to the columns first, before tightening the

center slide nuts to their final tightness.

Installation

8 Repeat the procedure above for the other rail.

Installation 59

Page 60

9 Insert the disk system (with disk modules and power supplies removed) onto

the rails (see Figure 35).

60 Installation

Page 61

10 Move the disk system retention brackets to the fron tm ost set o f mo untin g

holes.

This allows the disk system to install further back into the cabinet; and allows

the cabinet doors (if present) to close properly (see Figure 36).

Installation

Installation 61

Page 62

11 Push the disk system back into the rack until the disk system retaining bracket

is flush against the front column of the rack.

12 Bolt the disk system to the front column. Use the fifth hole from the top of the

front of the rail (see Figure 37).

62 Installation

Page 63

Install the Disk System

1 Remove the power supply/fan modules to prepare the disk system for lifting:

a Loosen the screws in the extractor handles of each power supply/fan

module with the chassis still in the box.

b Pull the extractor handles out from the center of the power supply to

disengage it from the midplane. Pull each power supply/fan modu le out of

the chassis. Support the far end of the power supply /fan modul e with your

free hand as it clears the chassis.

c Set the power supply/fan modules aside, on an antistatic pad, to be

reinstalled later.

WARNING An empty disk system weighs appro ximately 54 po unds (2 4.5 kg).

T o avoid personal injury, it is recommended that two people install

the storage device in the rack.

2 Remove the disk modules from the disk system. Place them aside on the pink

antistatic foam pad supplied with your disk syst em.

3 Carry the disk system to the front of the rack and slide the back end onto the

rails (Figure 35) with the help of another person or using a lifting device.

Push the disk system into the rack as far as it will go.

Installation

Installation 63

Page 64

Step 4: Configure LCCs

The disk system comes with two LCCs installed.

If you are connecting this disk system to an HP St orageWorks Virtual Array 7400

or to a 1 Gb/s hub, the link speed switch must be set to 1 Gb/s.

1 Attach your ESD strap to ground.

2 Remove the LCC from the disk system chassis.

Caution Do not touch the pins on the back of the LCC.

3 Set internal configuration dip switch to appropriate link speed.

Be sure to set the internal LCC data t ransmission speed swit ch to 1

Gb/s or 2 Gb/s as appropriate for your configuration. See Figure 2.29

for more detailed information.

64 Installation

Page 65

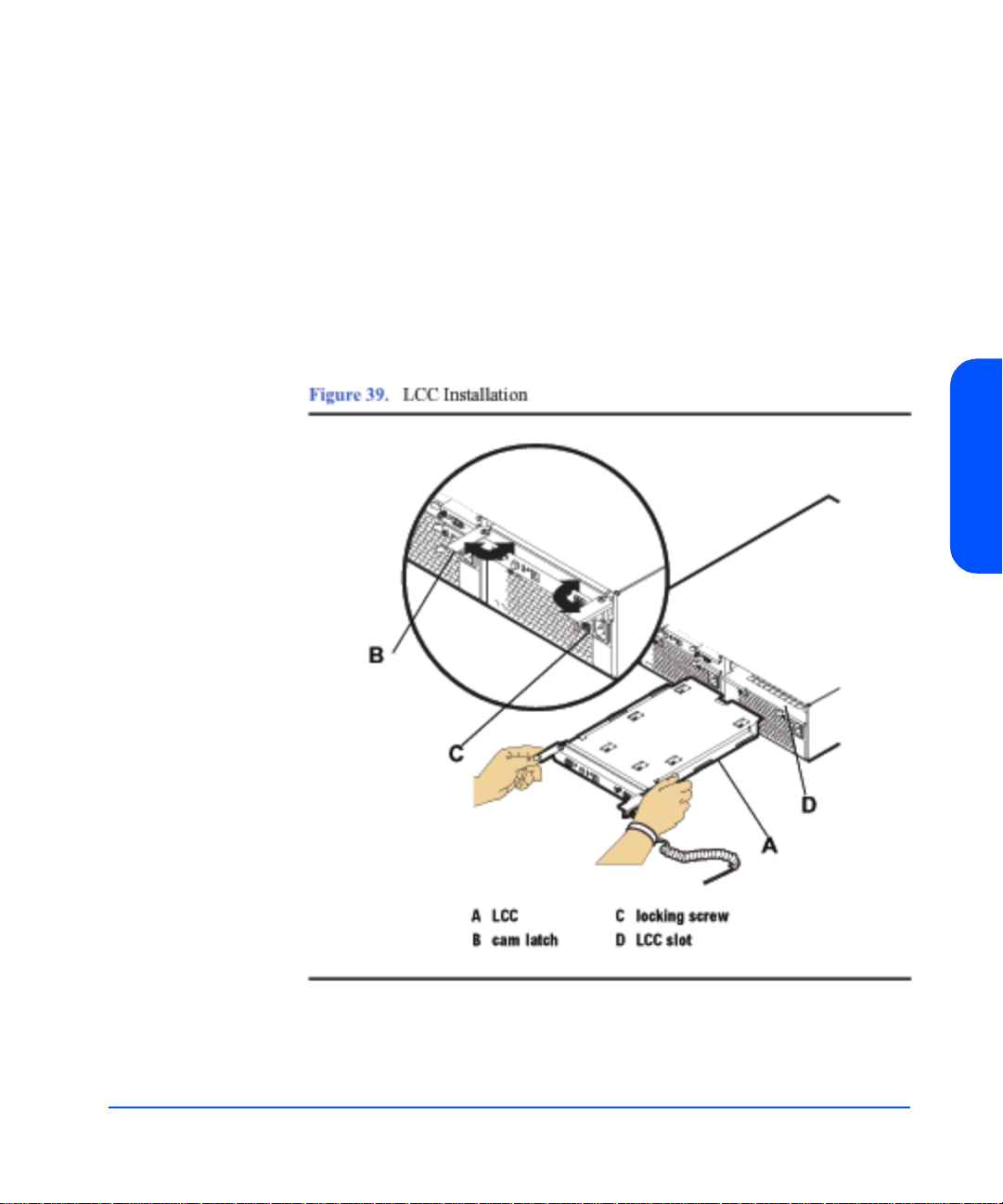

4 Open the LCC cam latches (B in Figure 39) by pulling them away from the

center.

5 Align the LCC with the slot (D in Figure 39), and insert the LCC into the slot

at the back of the disk system. Stop pushing when the LCC meets the

midplane.

6 Press the cam latches inward and flat against the center. The cam action

draws the LCC completely into the slot and seats the connector pins on the

midplane.

7 Tighten the locking thumbscrews (C).

Installation

8 Repeat steps 2 through 7, installing the second LCC in the remaining empty

slot.

Installation 65

Page 66

Page 67

Page 68

Page 69

Page 70

Page 71

Page 72

Step 6: Connect FC and Power Cables

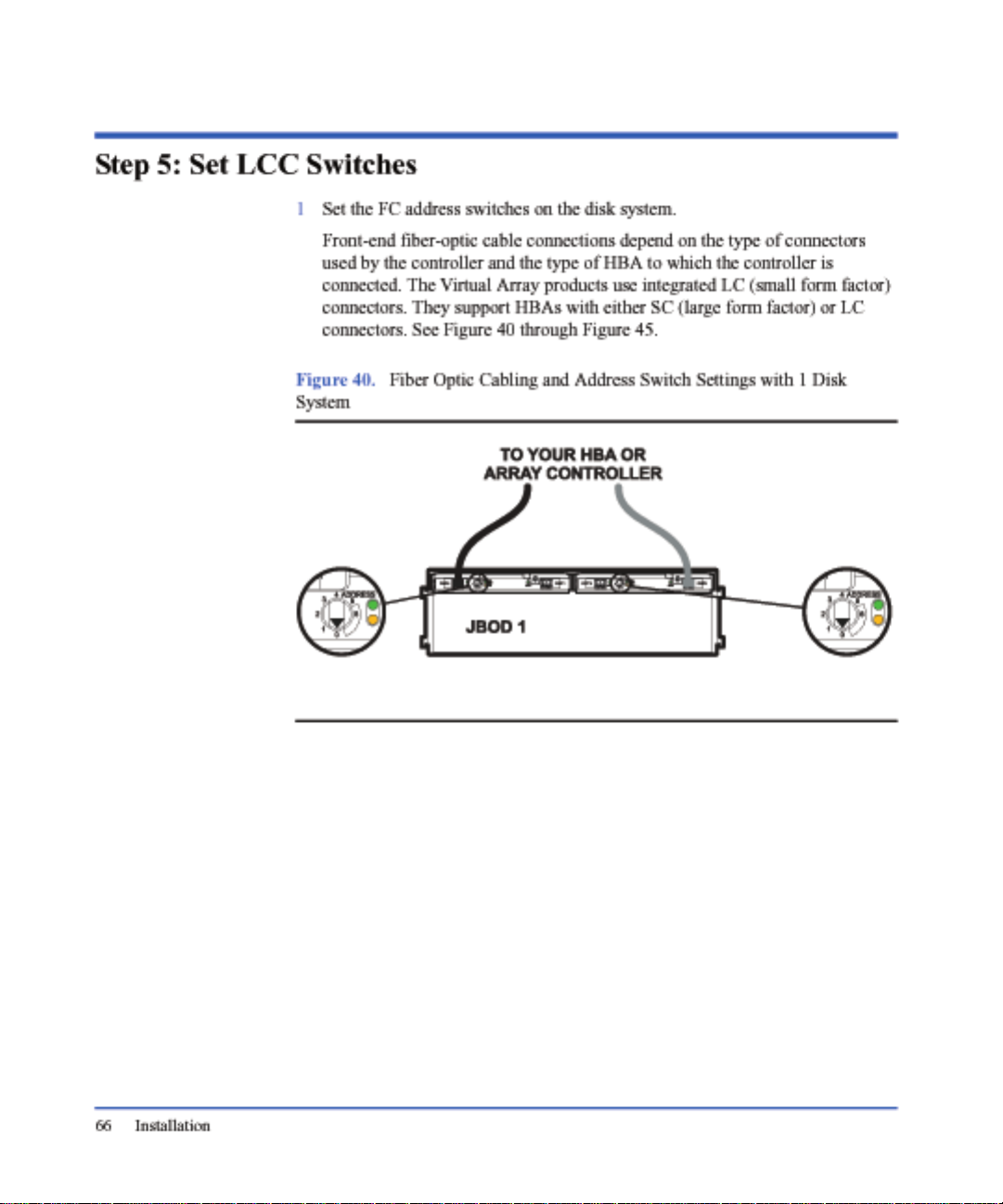

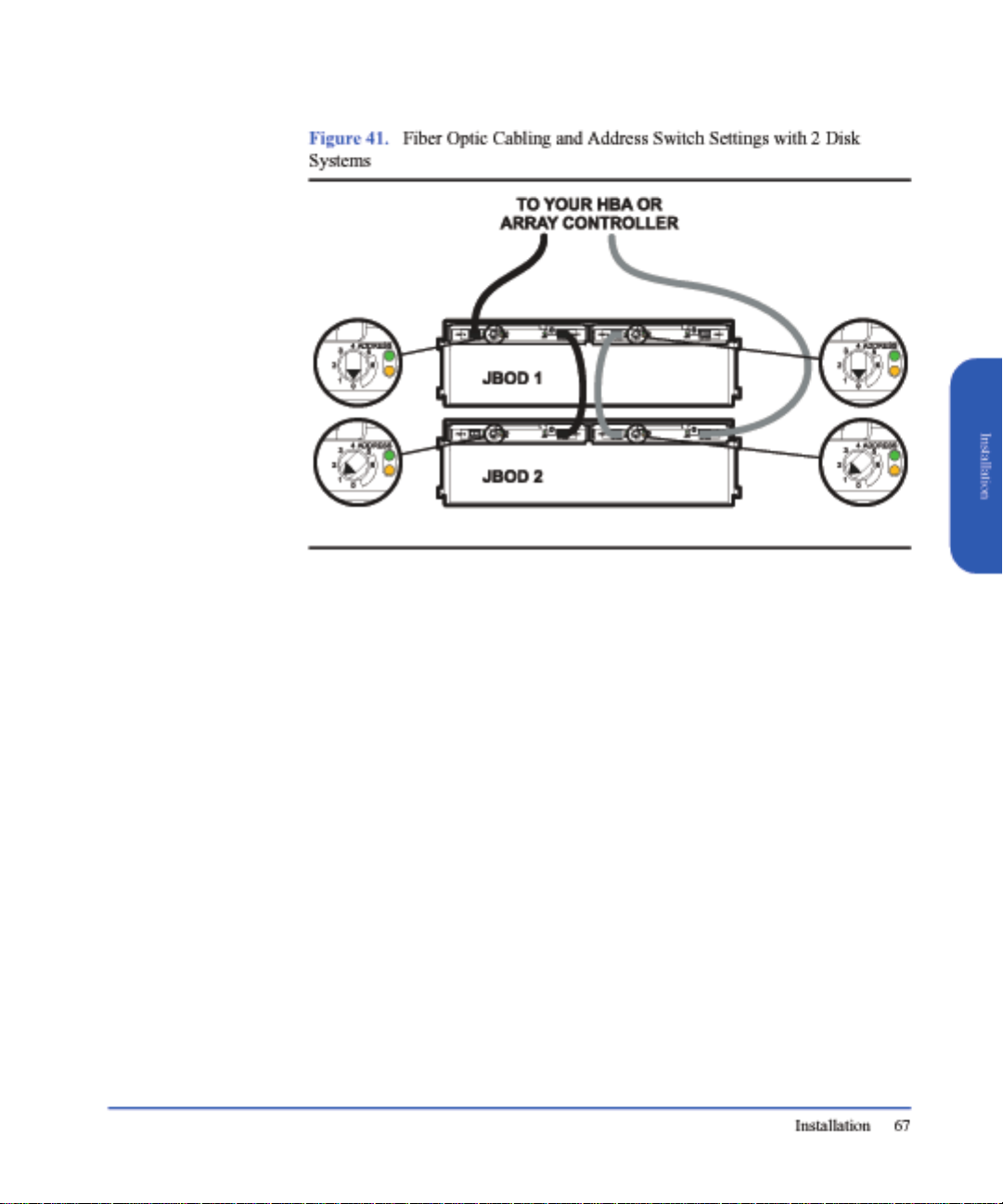

1 Connect the front-end fiber-optic cables.

Front-end fiber-optic cable connections depend on the type of connectors

used by the controller and the type of HBA to which the controller is

connected. The Virtual Array Products use integrated LC (small form factor)

connectors. They support HBAs with either SC (large form factor) or LC

connectors. See Figure 40 through Figure 45.

2 Connect power cords to the power receptacle on the power supply/fan

module(s).

3 Attach the other end of each power cord to a preinstalled PDU/PDRU.

Choose outlets according to the following guidelines:

— Redundancy . To extend the redundancy of the product, attach each cord to

a different PDU. This is represented in Figure 46 and Figure 47.

— Reliability. To avoid cascading faults for a group of disk systems that are

plugged int o the same PDU, distribute redundant power cords to as many

different combinat ions of PDUs as possi ble. See Figu re 46 and Figure 47.

Cascading faults occur when a backup PDU is overloaded with power

surges after the primary PDU fails.

— Serviceability. Choose PDU locations that prevent power cords from

interfering with the removal and replacement of serviceable components.

Also leave a 6-inch service loop to allow for the rotation of PDRUs.

72 Installation

The letters in Fig ures 46 and 47 represent ind e pend ent P DU s or P DU ban ks . Th e

absence of duplicate letters in individual disk systems indicates the products are

using redundant PDUs. The minimal number of duplicate letter pairs indicates

the disk systems are protected against cascading faults.

Page 73

Page 74

Page 75

Step 7: Install Disk Modules

Caution Touching exposed areas on the disk can cause electrical discharge

and disable the disk. Be sure you are grounded and be careful not

to touch exposed circuits.

Disk modules are fragile and ESD sensitive. Dropping one end of the disk just

two inches is enough to cause permanent damage. In addition, static electricity

can destroy the magnetic properties of recording surfaces. Grip disks only by

their handles (A in Figure48) and carriers (C), and follow strict ESD procedures.

Installation

Installation 75

Page 76

1 Determine which slots, 1 through 15, will contain disk modules and which

will contain fillers.

At least two slots must con tain disk modules.

2 Put on the ESD strap and attach the other end of the strap appropriately.

Caution Disk modules are fragile. Handle carefully. Be careful to grasp the

disk module by its handle and avoid touching exposed circuitry.

3 Remove a disk module from the disk pack and its ESD bag.

4 Open the disk module cam latch (C) by pulling the tab toward you.

5 Push the disk module as far as it will go into the selected slot.

6 Close the cam latch by pushing the latch toward the disk until it clicks. The

cam action draws the disk module completely into the slot and seats the

connecting pins on the midplane.

7 Repeat steps 4 through 6 to install add itional disk modules.

8 Install disk fillers in the remaining slots.

Caution Every slot must contain either a disk module or filler.

Step 8: Turn on the Disk System

Caution When starting up the disk system, do not override autom a tic spin-

up of the drives. Doing so could cause an overcurrent fault,

requiring a power cycle to recover.

Press in the power/standby switch with the retracted tip of a pen or pencil to

power-on the disk system (see Figure 49). Allow 2 minutes for the disk drives

and controllers to complete their self-tests.

76 Installation

1 Press the power/stan dby switch (C in Figure 49) to turn on the disk system.

2 Watch the system LEDs for confirmation that the disk system is operational.

The system power LED (A ) sh ould be green, and the faul t LED (B) s hould b e

off.

If the LEDs indicate a problem, refer to chapter 4, Troubleshooting.

Note An amber light that is on briefly when a component turns on is

normal. If this light remains on more than a couple seconds, a fault

has been detected.

Page 77

Page 78

Step 9: Verify Devices on the Host

On the host system ru n IOSCAN (ioscan -f) and veri f y t ha t the d i sks an d LCC (s)

are listed in IOSCAN output. If the displayed “S/W State” is not “claimed,”

begin troubleshooting (see chapte r 4).

Sample IOSCAN

Each LCC (ctl) or disk appears as a separate target in IOSCAN output.

Class I H/W Path Driver S/W State H/W Type Description

==============================================================================================

fc 0 0/4/0/0 fcT1 CLAIMED INTERFACE HP Fibre Channel Mass Storage

Adapter

lan 1 0/4/0/0.5 fcT1_cntl CLAIMED INTERFACE HP Fibre Channel Mass Storage

Cntl

fcp 0 0/4/0/0.8 fcp CLAIMED INTERFACE FCP Protocol Adapter

ba 4 0/5 lba CLAIMED BUS_NEXUS Local PCI Bus Adapter (782)

lan 2 0/5/0/0 btlan5 CLAIMED INTERFACE PCI Ethernet (10110019)

ba 5 0/8 lba CLAIMED BUS_NEXUS Local PCI Bus Adapter (782)

fc 4 0/8/0/0 td CLAIMED INTERFACE HP Tachyon TL/TS Fibre Channel

Mass Storage Adapter

fcp 4 0/8/0/0.8 fcp CLAIMED INTERFACE FCP Protocol Adapter

ext_bus 10 0/8/0/0.8.0.255.0 fcpdev CLAIMED INTERFACE FCP Device Interface

target 5 0/8/0/0.8.0.255.0.0 tgt CLAIMED DEVICE

disk 140 0/8/0/0.8.0.255.0.0.0 sdisk CLAIMED DEVICE HP 18.2GST318451FC

target 6 0/8/0/0.8.0.255.0.1 tgt CLAIMED DEVICE

disk 141 0/8/0/0.8.0.255.0.1.0 sdisk CLAIMED DEVICE HP 18.2GST318451FC

target 7 0/8/0/0.8.0.255.0.2 tgt CLAIMED DEVICE

disk 64 0/8/0/0.8.0.255.0.2.0 sdisk CLAIMED DEVICE HP 18.2GST318451FC

target 8 0/8/0/0.8.0.255.0.3 tgt CLAIMED DEVICE

disk 65 0/8/0/0.8.0.255.0.3.0 sdisk CLAIMED DEVICE HP 18.2GST318451FC

target 9 0/8/0/0.8.0.255.0.4 tgt CLAIMED DEVICE

disk 142 0/8/0/0.8.0.255.0.4.0 sdisk CLAIMED DEVICE HP 36.4GST336704FC

target 10 0/8/0/0.8.0.255.0.5 tgt CLAIMED DEVICE

disk 143 0/8/0/0.8.0.255.0.5.0 sdisk CLAIMED DEVICE HP 36.4GST336704FC

target 11 0/8/0/0.8.0.255.0.6 tgt CLAIMED DEVICE

disk 144 0/8/0/0.8.0.255.0.6.0 sdisk CLAIMED DEVICE HP 36.4GST336704FC

target 12 0/8/0/0.8.0.255.0.7 tgt CLAIMED DEVICE

78 Installation

Page 79

disk 145 0/8/0/0.8.0.255.0.7.0 sdisk CLAIMED DEVICE HP 36.4GST336704FC

target 13 0/8/0/0.8.0.255.0.8 tgt CLAIMED DEVICE

disk 146 0/8/0/0.8.0.255.0.8.0 sdisk CLAIMED DEVICE HP 36.4GST336704FC

The “descriptions” in this example represent some of the valid disk modules.

Valid disk descriptions include:

■ ST336704FC36-Gbyte 10K rpm FC disk module

ST336605FC

■ ST373405FC73-Gbyte 10K rpm FC disk module

■ ST318451FC18-Gbyte 15K rpm FC disk module

ST318452FC

■ ST336752FC36-Gbyte 15K rpm FC disk module

Where do you go from here?

For operating system and application configuration information, refer to the

documentation for your particular server’s operating system.

Installation

Installation 79

Page 80

80 Installation

Page 81

Configuration

3

Viewing a Disk System in IOSCAN

An IOSCAN (example below) shows each LCC (0/8/0/0.8) and disk in the

system.

Sample IOSCAN

Type the command: ioscan -fn

Class I H/W Path Driver S/W State H/W Type Description

===========================================================================================

fcp 4 0/8/0/0.8 fcp CLAIMED INTERFACE FCP Protocol Adapter

ext_bus 10 0/8/0/0.8.0.255.0 fcpdev CLAIMED INTERFACE FCP Device Interface

target 5 0/8/0/0.8.0.255.0.0 tgt CLAIMED DEVICE

disk 140 0/8/0/0.8.0.255.0.0.0 sdisk CLAIMED DEVICE HP 18.2GST318451FC

/dev/dsk/c10t0d0 /dev/rdsk/c10t0d0

target 6 0/8/0/0.8.0.255.0.1 tgt CLAIMED DEVICE

disk 141 0/8/0/0.8.0.255.0.1.0 sdisk CLAIMED DEVICE HP 18.2GST318451FC

/dev/dsk/c10t1d0 /dev/rdsk/c10t1d0

target 7 0/8/0/0.8.0.255.0.2 tgt CLAIMED DEVICE

disk 64 0/8/0/0.8.0.255.0.2.0 sdisk CLAIMED DEVICE HP 18.2GST318451FC

/dev/dsk/c10t2d0 /dev/rdsk/c10t2d0

target 8 0/8/0/0.8.0.255.0.3 tgt CLAIMED DEVICE

disk 65 0/8/0/0.8.0.255.0.3.0 sdisk CLAIMED DEVICE HP 18.2GST318451FC

/dev/dsk/c10t3d0 /dev/rdsk/c10t3d0

target 9 0/8/0/0.8.0.255.0.4 tgt CLAIMED DEVICE

disk 142 0/8/0/0.8.0.255.0.4.0 sdisk CLAIMED DEVICE HP 36.4GST336704FC

/dev/dsk/c10t4d0 /dev/rdsk/c10t4d0

target 10 0/8/0/0.8.0.255.0.5 tgt CLAIMED DEVICE

disk 143 0/8/0/0.8.0.255.0.5.0 sdisk CLAIMED DEVICE HP 36.4GST336704FC

Configuration 81

Page 82

/dev/dsk/c10t5d0 /dev/rdsk/c10t5d0

target 11 0/8/0/0.8.0.255.0.6 tgt CLAIMED DEVICE

disk 144 0/8/0/0.8.0.255.0.6.0 sdisk CLAIMED DEVICE HP 36.4GST336704FC

/dev/dsk/c10t6d0 /dev/rdsk/c10t6d0

target 12 0/8/0/0.8.0.255.0.7 tgt CLAIMED DEVICE

disk 145 0/8/0/0.8.0.255.0.7.0 sdisk CLAIMED DEVICE HP 36.4GST336704FC

/dev/dsk/c10t7d0 /dev/rdsk/c10t7d0

target 13 0/8/0/0.8.0.255.0.8 tgt CLAIMED DEVICE

disk 146 0/8/0/0.8.0.255.0.8.0 sdisk CLAIMED DEVICE HP 36.4GST336704FC

/dev/dsk/c10t8d0 /dev/rdsk/c10t8d0

target 14 0/8/0/0.8.0.255.0.9 tgt CLAIMED DEVICE

disk 147 0/8/0/0.8.0.255.0.9.0 sdisk CLAIMED DEVICE HP 36.4GST336704FC

/dev/dsk/c10t9d0 /dev/rdsk/c10t9d0

target 15 0/8/0/0.8.0.255.0.10 tgt CLAIMED DEVICE

disk 148 0/8/0/0.8.0.255.0.10.0 sdisk CLAIMED DEVICE HP 36.4GST336704FC

/dev/dsk/c10t10d0 /dev/rdsk/c10t10d0

target 16 0/8/0/0.8.0.255.0.11 tgt CLAIMED DEVICE

disk 149 0/8/0/0.8.0.255.0.11.0 sdisk CLAIMED DEVICE HP 36.4GST336704FC

/dev/dsk/c10t11d0 /dev/rdsk/c10t11d0

target 17 0/8/0/0.8.0.255.0.12 tgt CLAIMED DEVICE

disk 150 0/8/0/0.8.0.255.0.12.0 sdisk CLAIMED DEVICE HP 36.4GST336704FC

/dev/dsk/c10t12d0 /dev/rdsk/c10t12d0

target 18 0/8/0/0.8.0.255.0.13 tgt CLAIMED DEVICE

disk 151 0/8/0/0.8.0.255.0.13.0 sdisk CLAIMED DEVICE HP 36.4GST336704FC

/dev/dsk/c10t13d0 /dev/rdsk/c10t13d0

target 19 0/8/0/0.8.0.255.0.14 tgt CLAIMED DEVICE

disk 185 0/8/0/0.8.0.255.0.14.0 sdisk CLAIMED DEVICE HP 36.4GST336704FC

/dev/dsk/c10t14d0 /dev/rdsk/c10t14d0

target 20 0/8/0/0.8.0.255.0.15 tgt CLAIMED DEVICE

ctl 7 0/8/0/0.8.0.255.0.15.0 sctl CLAIMED DEVICE HP A6255A

/dev/rscsi/c10t15d0

82 Configuration

Page 83

The disks shown in the previous sample ioscan -fn are the ST318451FC (used in

the A6191A disk module) and the ST336704FC (used in the A6192A disk

module). The full descriptions of the supported disk modules are:

■ ST336605FC 36 Gbyte 10K rpm disk FC disk module (A6192A)

ST336704FC

■ ST373405FC 73 Gbyte 10K rpm disk FC disk module (A6194A)

■ ST318451FC 18 Gbyte 15K rpm disk FC disk module (A6191A)

ST318452FC

■ ST336752FC 36 Gbyte 15K rpm disk FC disk module (A6193A)

Interpreting the Hardware Path

The elements of the Fibre Channel hardware path are interpreted as follows:

8/12.8.0.255.2.14.0

Port (255 = the target connected directly to the FC)

Area (0 = point-to-point or private loop)

Protocol Type (8 = mass storage)

Adapter

Bus Converter

The loop ID, broken out in upper and lower bits in the example above, is 46. To

derive the loop ID from the Bus and Target values of the hardware path:

1 Convert the Bus and Target fields (the upper and lower bits of th e loop ID) to

binary:

Configuration

LUN (Logical Unit Number of disk)

Target (Lower 4 bits of the loop ID)

Bus (Upper 4 bits of the loop ID)

8/12.8.0.255.2.14.0

1 1 1 0 (Lower 4 bits of the loop ID)

0 0 1 0 (Upper 4 bits of the loop ID)

Configuration 83

Page 84

2 Combine the two binary fields into 8 bits and convert back to decimal:

Upper bit Lower bit

0 0 1 0 1 1 1 0

32 + 8+4+2 = 46

Loop IDs and Hardware Paths by Enclosure ID

The rotary switch on the LCC set the Fibre-Channel Address range for the

enclosure. Both LCCs should be set identically for proper redundancy. Multiple

enclosures need to have unique settings to avoid address conflicts. If devices are

physically present and are not reported as found, suspect address conflicts with

other devices. The following tables helps understand what addressing is being

used:

Table 8. Loop IDs and Hardware Paths by Slot Number and Enclosure ID 0 - 2

Encl.

ID

Disk

Slot #

(dec)

Loop

ID

(dec)

0 1 2

Bus

(dec)

Tgt

(dec)

ALPA

(hex)

Loop

ID

(dec)

Bus

(dec)

Tgt

(dec)

ALPA

(hex)

Loop

(dec)

ID

Bus

(dec)

Tgt

(dec)

ALPA

(hex)

1 000EF1610CD3220B2

2 101 E81711CC3321B1

3 200 E41812CB3422AE

4 303 E21913CA3523AD

5 404 E12014C93624AC

6 505 E02115C73725AB

7 606DC2216 C63826AA

8 707DA2317C53927A9

9 808D92418 C34028A7

10 9 0 9 D6251 9 BC412 9 A6

84 Configuration

Page 85

Table 8. Loop IDs and Hardware Paths by Slot Number and Enclosure ID 0 - 2

Encl.

ID

Disk

Slot #

(dec)

Loop

ID

(dec)

0 1 2

Bus

(dec)

Tgt

(dec)

ALPA

(hex)

Loop

ID

(dec)

Bus

(dec)

Tgt

(dec)

ALPA

(hex)

Loop

(dec)

ID

Bus

(dec)

Tgt

(dec)

ALPA

(hex)

1110010D526110BA42210A5

12 11 0 11 D4 27 1 11 B9 43 2 11 A3

1312012D328112B644 129F

1413013d2 29113B5452139E

1514014D130114B446214B4

SES15015CE31115B363315 73

Table 9. Loop IDs and Hardware Paths by Slot Number and Enclosure ID 3 - 4

Encl.

ID

Disk

Slot #

(dec)

Loop

ID

(dec)

Bus

(dec)

3 4

Tgt

(dec)

ALPA

(hex)

Loop

ID

(dec)

Bus

(dec)

Tgt

(dec)

ALPA

(hex)

Configuration

1 483 0 98 644 0 72

2 493 1 97 654 1 71

3 503 2 90 664 2 6E

4 513 3 8F 674 3 6D

5 523 4 88 684 4 6C

6 533 5 84 694 5 6B

7 543 6 82 704 6 6A

8 553 7 81 714 7 69

Configuration 85

Page 86

Table 9. Loop IDs and Hardware Paths by Slot Number and Enclosure ID 3 - 4

Encl.

ID

Disk

Slot #

(dec)

Loop

ID

(dec)

Bus

(dec)

3 4

Tgt

(dec)

ALPA

(hex)

Loop

ID

(dec)

Bus

(dec)

Tgt

(dec)

ALPA

(hex)

9 563 8 80 804 8 67

10 57 3 9 7C 73 4 9 66

1158310 7A 74410 65

12 59 3 11 79 75 4 11 63

1360312 76 76412 5C

1461313 75 77413 5A

1562314 74 78414 59

SES79415 56 79415 56

Table 10. Loop IDs and Hardware Paths by Slot Number and Enclosure ID 5- 6

Encl.

ID

5 6

Disk

Slot #

(dec)

Loop

ID

(dec)

Bus

(dec)

Tgt

(dec)

ALPA

(hex)

Loop

ID

(dec)

Bus

(dec)

Tgt

(dec)

1 80 5 0 55 96 6 0 3A

2 81 5 1 54 97 6 1 39

3 82 5 2 53 98 6 2 36

4 835 3 52 996 3 35

5 84 5 4 51 100 6 4 34

6 85 5 5 4E 101 6 5 33

86 Configuration

ALPA

(hex)

Page 87

Table 10. Loop IDs and Hardware Paths by Slot Number and Enclosure ID 5- 6

Encl.

ID

Disk

Slot #

(dec)

Loop

ID

(dec)

Bus

(dec)

5 6

Tgt

(dec)

ALPA

(hex)

Loop

ID

(dec)

Bus

(dec)

Tgt

(dec)

ALPA

(hex)

7 86 5 6 4D 102 6 6 32

8 87 5 7 4C 103 6 7 31

9 88 5 8 4B 104 6 8 2E

10 89 5 9 4A 105 6 9 2D

1190510 49 106610 2C

12 91 5 11 47 107 6 11 2B

13 92 5 12 46 108 6 12 2A

14 93 5 13 45 109 6 13 29

15 94 5 14 43 110 6 14 27

SES95515 3C 111615 26

Configuration

In the above tables, columns 0-6 correspond to possible switch settings. Rows 115 indicate the disk slot positions. SES refers the address reserved for the

enclosure controller . The inters ection of a row and a column con tains the loop ID

the device will take. The loop ID is translated to a Fibre Channel address (ALPA) by firmware according to the table in the FC-AL2 standard.

Enclosure IDs (0 through 6) are set with a dial on the LCC. This setting

determines the FC-AL IDs of the disks and LCCs in the disk system. See Table 8

and Table 10 for the FC-AL IDs and corresponding hardware paths for each slot

and LCC bas ed on the Enclosure ID.

Caution The Enclosure IDs on both LCCs in t he sa me dis k sy st em mu st be

identical.

For redundancy , each LCC is connected to a differ ent Fibre Channel loop (that is,

a different host bus adapter).

Configuration 87

Page 88

Setting Up the Hardware Event Monitor

Separate monitors watch over the disks and the disk system. You need to install

and configure the Disk Monitor (disk_em) and the High Availability Storage

System Monitor (dm_ses_enclosure) for complete event notification.

To install and configure the required monitors, refer to the EMS Hardware

Monitors User’s Guide, which is included in Adobe Acrobat format on the IPR

Support Media. You can download a copy of Acrobat Reader without charge

from http://www.adobe.com/prodindex/acrobat/readstep.html.

Aliasing Devices (HP-Qualified Only)

Using host-based software, you can “label” each disk system with any

information that would be useful for the site . You might use this feature to assign

an inventory number or to indicate the location of the product. The maximum

length of the annotation is 256 characters.

Using SAM

To define a text string using SAM, select the desired LCC or disk from the Disk

Devices list; then select Annotate Device from the Actions menu. Type the

comment that you want in the Annotation field and select OK.

You can view the annotation through the Annotate Device option in the Actions

menu or by displaying the Annotation column in the Disk Devices list. To

include the Annotation column in the Disk Devices window, select Columns

from the View menu and choose Annotation.

Using STM (HP-Qualified Only)

Annotating devices is a password-protected function of STM (Support Tools

Manager). Use the System menu License option to install the HP-Only license

before you select the annotate function.

1 Run STM and install the HP-Only license.

2 Select the desired LCC.

3 Select Expert Tool > Run from the Tools menu. An Expert Tool window

opens.

88 Configuration

Page 89

4 Select Write Label from the Info menu. The User Defined Annotation

window, similar to the screen shown below, displays the existing label in an

edit field.

Figure 50. Annotate Device Using STM

5 Type the desired text in the New User Defined Annotation field. Click OK.

The new label will replace the existing label.

To view the annotation of a selected disk system, select Read Label from the

Expert Tool Info menu. The label is displayed in the Expert Tool window.

Configuration

Configuration 89

Page 90

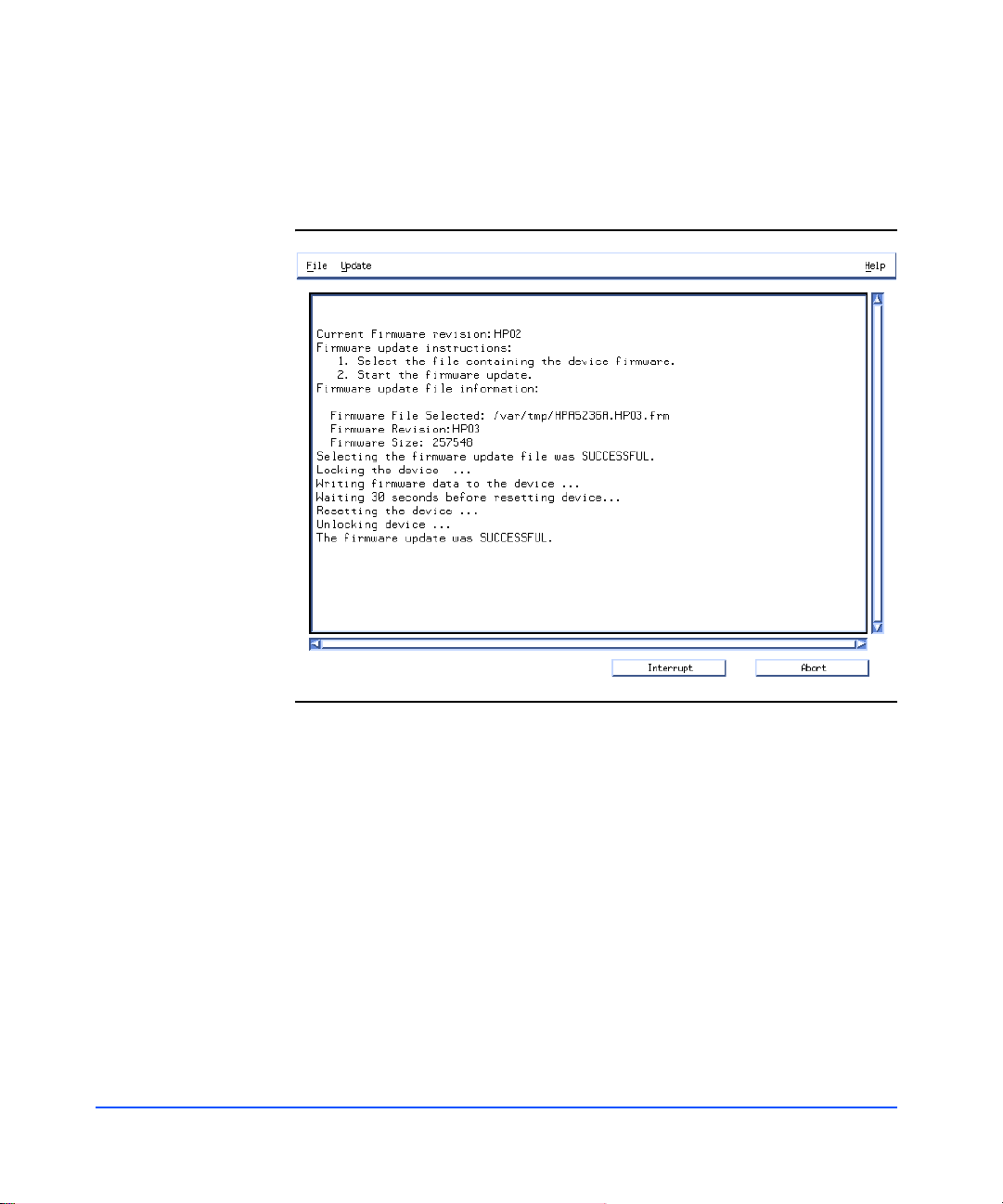

Updating Firmware (HP-Qualified Only)

Obtain the latest disk system firmware release from the support web site before

traveling to the customer site. When you arrive at the site:

1 Save the firmware file on the customer’s system, preferably in the default

firmware directory: /var/tmp

2 If you wan t to run STM in gra phic mode, make sure DISPLAY is exported.

3 Start STM by typing xstm& on the HP-UX command line. This command

starts the graphic version of STM and keeps the X window open when you

quit STM.

4 Select License from the System menu and install the password-protected

HP-Only license.

5 Select Firmware Update > Run from the Tools menu. A tool window opens,

displaying the current firmware version and instructions for upd ating. A

second window lists the available firmware files in the var/tmp directory.

That second window is similar to the one shown below.

Figure 51. Firmware File Selection Window

90 Configuration

If there are no firmware files in the default directory, a pop-up window instructs

you to select an optional path and STM displays a list of directories. Enter the

directory path you used to save the firmware file (in step 1) and click OK.

Page 91

6 Select the firmware file from the list of files displayed in the default or

specified directory. Click OK.

7 Select Start Update... f rom the Updat e menu. STM p rompt s yo u to co nfirm or

cancel the firmware update. A window is similar to the one shown below.

Figure 52. Firmware Download Confirmation Window

Configuration

Configuration 91

Page 92

The results of your action appear in the Tool window. The screen that appears is

similar to the illustration shown below.

Figure 53. Firmware Tool Window

92 Configuration

Page 93

Troubleshooting

Overview

The following steps will help you identify and resolve disk sy stem failures:

8 Gather information from all sources:

— Event notifications (page 93)

— Disk system LED stat us (page 96)

— Online information tools (page 98)

9 Isolate the cause of the problem (page 104).

10 Correct the problem (chapter 5, Removal and Replacement).

11 Verify operational status with IOSCAN or other host utilities.

Event Notification

4

The EMS hardware event monitor polls environmental services on the LCC and

reports any changes in the status of monitored components. Depending on how

the monitor is set up, you can receive messages at the console, in e-mail, in a log

file, or through third-party applications. These messages are likely to be the first

indication of a problem with a disk system.

Events are reported for changes in temperature, voltage, and the status of

replaceable components.

Troubleshooting 93

Page 94

Messages identify five levels of severity:

Critical An event that causes data loss, host system downtime,

or other loss of service. Host system operation will be

affected if the disk system continues to be used w ithou t

correction. Immediate action is required.

Serious An event that may cause data loss, host system

downtime, or other loss of service if left uncorrected.

Host system and hardware operation may be adversely

affected. The problem needs repair as soon as possible.

Major Warning An event that could escalate to a serious condition if

not corrected. Host system operation should not be

affected and normal use of the disk system can

continue. Repair is needed but at a convenient time.

Minor Warning An event that will n ot likely escalate to a severe

condition if left uncorrected. Host system operation

will not be interrupted and normal use of the disk

system can continue. The problem can be repaired

when convenient.

Information An event that is expected as part of the normal

operation of the hardware. No action is required.

Event messages (see Figure 54) contain the following:

94 Troubleshooting

■ Message Data – Date and time the message was sent, the source and

destination of the message, and the severity level

■ Event Data – Date and time of the event, the host, event ID, name of the

monitor, event number, event class, severity level, hardware path, associated

OS error log entry ID

■ Error Description – Narrative information indicating the component that

experienced the event and the nature of the event

■ Probable Cause/Recommended Action – The cause of the event and

suggested steps toward a solution. This information should be the first step in

troubleshooting.

■ Annotation – The user-defined annotation associated with the specific disk

system

Page 95

Figure 54. Sample Hardware Event Notification

Notification Time: Wed Feb 3 11:27:15 1999

yourserver sent Event Monitor notification information:

/storage/events/enclosures/ses_enclosure/8_0_1_0.15.0 is >=1.

Its current value is MAJORWARNING(3)

Event data from monitor:

Event Time: Wed Feb 3 11:27:15 1999

Hostname: yourserver.rose.hp.com IP Address : 15.43.213.13

Event ID: 0x0036b8a313000000002 Monitor : dm_ses_enclosure

Event # : 402 Event Class: I/O

Severity : MAJOR WARNING

Enclosure at hardware path 8/0/1/0.15.0: Hardware failure

Associated OS error log entry id(s): None

Description of Error:

The enclosure services controllers have different versions of

firmware.

Probable Cause / Recommended Action:

The enclosure services controller cards have different versions of

firmware. Update the controllers to the same version of firmware.

User Defined Annotation: Enclosure 37 LCC A.

Troubleshooting 95

Troubleshooting

Page 96

Status LEDs

LEDs indicate the status of the disk system itself and each of its comp onents (see

Table 11). Green and amber system LEDs are visible on the front of the disk

system. They show that power is on (green) and a fault has occurred (amber).

Disk activity (green) LEDs are on the front of the disk drives at the bottom. Other

LEDs are on individual components in the back of the disk system.

Table 11. LED Functions

LED State Indication

System Powe r Green Power is on.

96 Troubleshooting

LED states are described in Table 11:

OFF Power is off.

Page 97

Table 11. LED Functions

LED State Indication

System Fault Ambe r Self-test1 / Problem.

2

OFF Normal operation.

Flashing LCC A & B DIP switch settings do not match.

1

LCC Fault Amber Self-test

/ Fault.

OFF Normal operation.

Flashing Peer LCC DIP switch settings do not match.

Link Active Green Port is in use.

OFF Port is disabl ed (bypassed).

2G ON Disk system is configured for 2.125 Gb/ s operation.

OFF Disk system is configured for 1.0625 Gb/s operation.

1

Power Supply Amber Start-up

/ Fault.

Green Operating.

OFF Power is off.

Disk Activity

3

ON Installed and spinning up. If the LED is still on 3 minutes

after power is engaged, the disk may be faulty.

Flashing There is input/output activity to the disk.

OFF Not installed or not operating.

1.Start-up and self-tests occur briefly when the unit is powered on.

2.A component has fa iled ; te mper atur e or vol tage i s out of n orm al rang e. S ee Iso lat ing Caus es

on page 104.

3.When a disk is installed with power on, its activity LED stays on until the disk has spun up.

When the disk is ready, the LED turns off. Thereafter, it flashes when there is I/O to the disk.

Note An amber light that is on briefly when a component first comes on

is normal. If this light remains on more than a couple of seconds, a

fault has been detected.

Troubleshooting 97

Troubleshooting

Page 98

Online Status Information

Software applications that run on HP-UX hosts display status and descriptive

information about the disk system and its components. SAM is the system

administrator’s interface to specific HP-UX functions. STM is the service

engineer’s tool for information, diagnostics, firmware updates, and more.

Viewing Component Status in SAM

SAM displays the status of disk system components on the host console. Follow

the instructions below to use SAM:

1 Select Disks and File Systems from the main window.

2 Select Disk Devices . SAM displays the hardware paths of all disks, disk

systems, and arrays on the host.

3 Select the path that represents the LCC of the desired disk system. You can

recognize the LCC by the description “HP Disk System 2405 Controller.”

4 Select View More Info from the Actions menu. A window displays header

information and a graphical representation of the front of the disk system.

The header provides the following information:

— LCC Hardware path - the path chosen from the Disk Devices list

— Peer LCC Hardware path - the path to the other LCC in the same unit

— Controller’s ID Switch Setting - Enclosure ID, set by the dial on the LCC

bulkhead

98 Troubleshooting

— Enclosure’s logical ID - the enclosure’s World Wide Name, a unique

identifier in the Fibre Channel network

5 For a view of the back of the selected disk system, click the “Back” tab.

6 To view component information, click the button representing the

component. SAM displays the following information about specific

components:

Button Displays

Disk Disk Slot, hardware path, status

LCC Hardware path, status, firmware revision

Power Supply Name, status

Page 99

Status values are OK, critical error, noncritical, not installed, unknown, and

status not available. See Interpreting Status Values on page 100 for the meanings

of these terms.

Viewing the STM Information Log

STM generates Information and Activity logs for a selected disk system. Execu te

STM in an X window and run the Information tool as follows.

1 At the system prompt, ty pe xstm&.

2 Select the desired disk system (HP A6250A).

3 Select Information from the Tools menu.

4 To generate a current log, select Run.

5 To view log output, select Information from the Tools menu.

6 Select Information Log.

7 Select Done when you have finished viewing the information.

The contents of the STM Information Log are as follows:

Log creation time The date and time the I nfo rmatio n Tool was last

Hardware path The physical path from the host to the reporting

run for the selected disk system.

LCC; for example, 8/12.8.0.255.2.14.0.

Product ID A6250A, the HP product number of the disk

system.

FC Loop ID The FC-AL ID of the reporting LCC, a decimal

value between 0 and 125.

LCC A Status The reported status of LCC A in the selected disk

system. Possible values are OK, critical,

noncritical, not installed, or not available.

LCC B Status The reported status of LCC B in the selected disk

system. Possible values are OK, critical,

noncritical, not installed, or not available.

Reporting LCC LCC A or LCC B, whichever LCC corresponds to

the selected hardware path.

Troubleshooting 99

Troubleshooting

Page 100

Enclosure ID The unique manufacturer number that

distinguishes the reporting LCC from all other

LCCs.

WW Name (node) The World Wide Name assigned to this disk

system. In normal operation, this value is the same

as the Wo rld Wide Name (port) for LCC A.

WW Name (port) The World Wide Name of the reporting LCC.

Firmware Rev. The current firmware version on the reporting

LCC.

Power Supply Status The status of the left (Supply A) and right (Supply

B) power supplies in the selected disk system.

Possible values are OK, critical, not installed, or

not available.

Voltage Sensors

Voltage and Status

Temp Sensors

Temperature and Status

Interpreting Status Values

SAM and STM report status in common terms, which are defined as follows:

Table 12. Status Indications

Reported

Status

OK All replaceable

Applicable

Component

components and

sensors

The voltage detected and status of three voltage

sensors—3.3V, 5.0V, and 12V—on each LCC.

Possible status values are OK, critical, noncritical,

not installed, unknown, and not availabl e.

The temperature detected and status of four

sensors. Possible status values are OK, critical,

noncritical, not installed, unknown, or not

available.

Indication

Component is installed and no error

conditions are known.

100 Troubleshooting

Loading...

Loading...