Page 1

HP 9000 rp3410 and HP 9000 rp3440 User Service Guide

HP Part Number: A7137-96008-ed6

Published: February 2010

Edition: 6

Page 2

Legal Notices

Copyright © 2003, 2010 Hewlett-Packard Development Company, L.P. The information contained herein is subject to change without notice. The

only warranties for HP productsand services are set forth in theexpress warranty statements accompanyingsuch products and services.Nothing

herein should be construed as constituting an additional warranty. HP shall not be liable for technical or editorial errors or omissions contained

herein. Intel, Pentium, Intel Inside, and the Intel Inside logo are trademarks or registered trademarks of Intel Corporation or its subsidiaries in

the United States and other countries.

Warranty

To obtain a copy of the warranty for this product, see the warranty information website:

BCS Global Limited Warranty and Technical Support

Page 3

Table of Contents

About This Document.......................................................................................................15

Intended Audience................................................................................................................................15

New and Changed Information in This Edition...................................................................................15

Publishing History................................................................................................................................15

Document Organization.......................................................................................................................15

Typographic Conventions.....................................................................................................................16

HP-UX Release Name and Release Identifier.......................................................................................16

Related Documents...............................................................................................................................17

Contacting HP.......................................................................................................................................17

Before You Contact HP....................................................................................................................17

HP Contact Information..................................................................................................................18

Subscription Service........................................................................................................................18

Documentation Feedback................................................................................................................18

1 Overview.......................................................................................................................19

HP 9000 rp3410 and rp3440 Server Views............................................................................................19

Detailed Server Description..................................................................................................................20

Processor..........................................................................................................................................20

Memory...........................................................................................................................................20

PCI Riser..........................................................................................................................................21

Internal Core I/O..............................................................................................................................21

External Core I/O.............................................................................................................................21

Power Supply Unit..........................................................................................................................21

System Board Manageability...........................................................................................................22

Enhanced Server Manageability Using the iLO MP........................................................................22

Hard Disk Drives.............................................................................................................................22

Internal RAID..................................................................................................................................22

Firmware..........................................................................................................................................22

Event IDs for Errors and Events.................................................................................................23

Dimensions and Values...................................................................................................................23

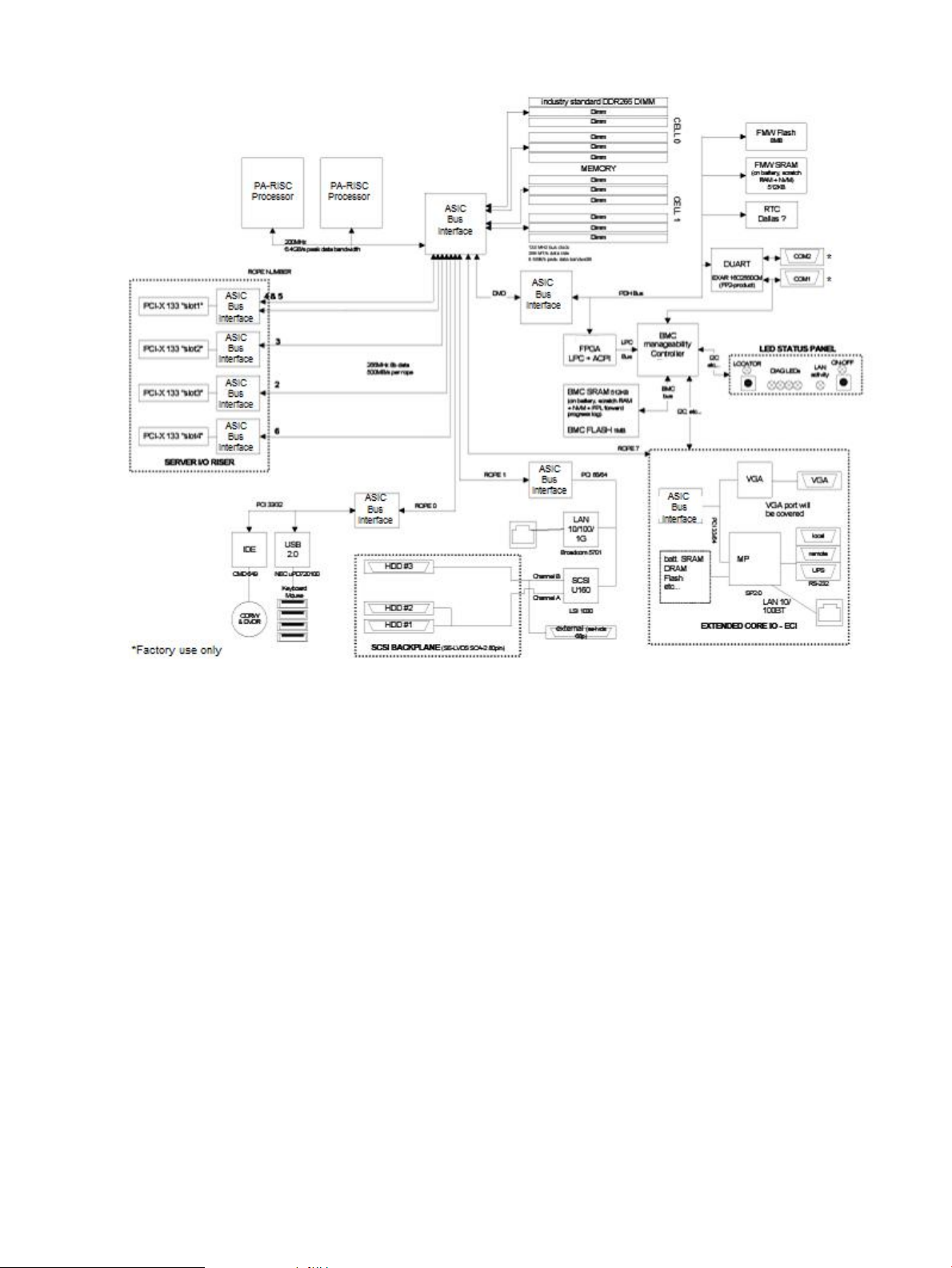

System Board...................................................................................................................................23

System Board Components........................................................................................................24

PA RISC Processor......................................................................................................................24

Processor Bus..............................................................................................................................25

ZX1 I/O and Memory Controller................................................................................................25

Memory......................................................................................................................................25

Memory Architecture............................................................................................................26

Chip Spare Functionality......................................................................................................27

Serial Presence Detect...........................................................................................................27

I/O Bus Interface.........................................................................................................................27

Processor Dependent Hardware Controller..............................................................................27

Field Programmable Gate Array................................................................................................28

BMC............................................................................................................................................28

SCSI Controller...........................................................................................................................28

IDE Interface...............................................................................................................................29

1 GB System LAN.......................................................................................................................29

USB Connectors..........................................................................................................................29

Disk and I/O Path Logging.........................................................................................................29

Controls, Ports, and LEDs.....................................................................................................................31

Control Panel...................................................................................................................................31

Table of Contents 3

Page 4

Additional Controls and Indicators................................................................................................33

Hot-Pluggable Disk Drive Indicators.........................................................................................33

Optional Removable Media Drive.............................................................................................33

Rear Panel........................................................................................................................................34

10/100/1000 Base-T Ethernet LAN Connector............................................................................35

USB Ports....................................................................................................................................35

SCSI Port, Ultra 3, 68-Pin............................................................................................................36

iLO MP Card LAN LEDs...........................................................................................................37

Powering the Server On and Off...........................................................................................................38

Power States.....................................................................................................................................38

Powering On the Server...................................................................................................................39

Powering On the Server Using the iLO MP...............................................................................39

Powering On the Server Manually.............................................................................................39

Powering Off the Server..................................................................................................................39

Powering Off the Server Using the iLO MP...............................................................................39

Powering Off the Server Manually............................................................................................40

2 System Specifications...................................................................................................41

System Configuration...........................................................................................................................41

Dimensions and Values.........................................................................................................................41

Grounding.............................................................................................................................................42

Electrical Specifications.........................................................................................................................42

AC Power Cables.............................................................................................................................42

Circuit Breaker.................................................................................................................................42

System Power Specifications...........................................................................................................43

Power and Cooling..........................................................................................................................43

Environmental Specifications...............................................................................................................44

Operating Environment...................................................................................................................44

Environmental Temperature Sensor................................................................................................45

Nonoperating Environment............................................................................................................45

Cooling.............................................................................................................................................45

CPU and Memory Cooling.........................................................................................................45

Bulk Power Supply Cooling.......................................................................................................45

PCI and Mass Storage Section Cooling......................................................................................45

Acoustic Noise Specification...........................................................................................................46

Physical and Environmental Specifications..........................................................................................46

3 Installing the System.....................................................................................................47

Introduction..........................................................................................................................................47

Server Views....................................................................................................................................47

Detailed Server Description.............................................................................................................48

Features......................................................................................................................................48

Firmware....................................................................................................................................49

Event IDs for Errors and Events...........................................................................................49

Dimensions and Values..............................................................................................................49

Safety Information...........................................................................................................................50

Installation Sequence and Checklist................................................................................................50

Unpacking and Inspecting the Server...................................................................................................51

Verifying Site Preparation...............................................................................................................51

Inspecting the Shipping Containers for Damage............................................................................51

Unpacking the Server......................................................................................................................51

Checking the Inventory...................................................................................................................51

Returning Damaged Equipment.....................................................................................................52

4 Table of Contents

Page 5

Unloading the Server with a Lifter..................................................................................................52

Installing Additional Components.......................................................................................................52

Removing and Replacing Server Covers and Bezels.......................................................................52

Rack-Mounted Server.................................................................................................................52

Accessing a Rack-Mounted Server.......................................................................................52

Extend the Server From the Rack..........................................................................................53

Removing and Replacing the Top Cover on a Rack-Mounted Server..................................53

Removing and Replacing the Front Bezel on a Rack-Mounted Server................................55

Accessing a Pedestal-Mounted Server.......................................................................................57

Removing the Side Cover on a Pedestal-Mounted Server....................................................57

Removing the Top Cover on Pedestal-Mounted Server.......................................................57

Replacing the Top Cover on a Pedestal-Mounted Server.....................................................58

Replacing the Side Cover on a Pedestal-Mounted Server....................................................59

Removing and Replacing the Front Bezel on a Pedestal-Mounted Server...........................60

Installing Internal Hard Disk Drives...............................................................................................61

Installing a DVD Drive....................................................................................................................64

Installing the DVD Drive...........................................................................................................64

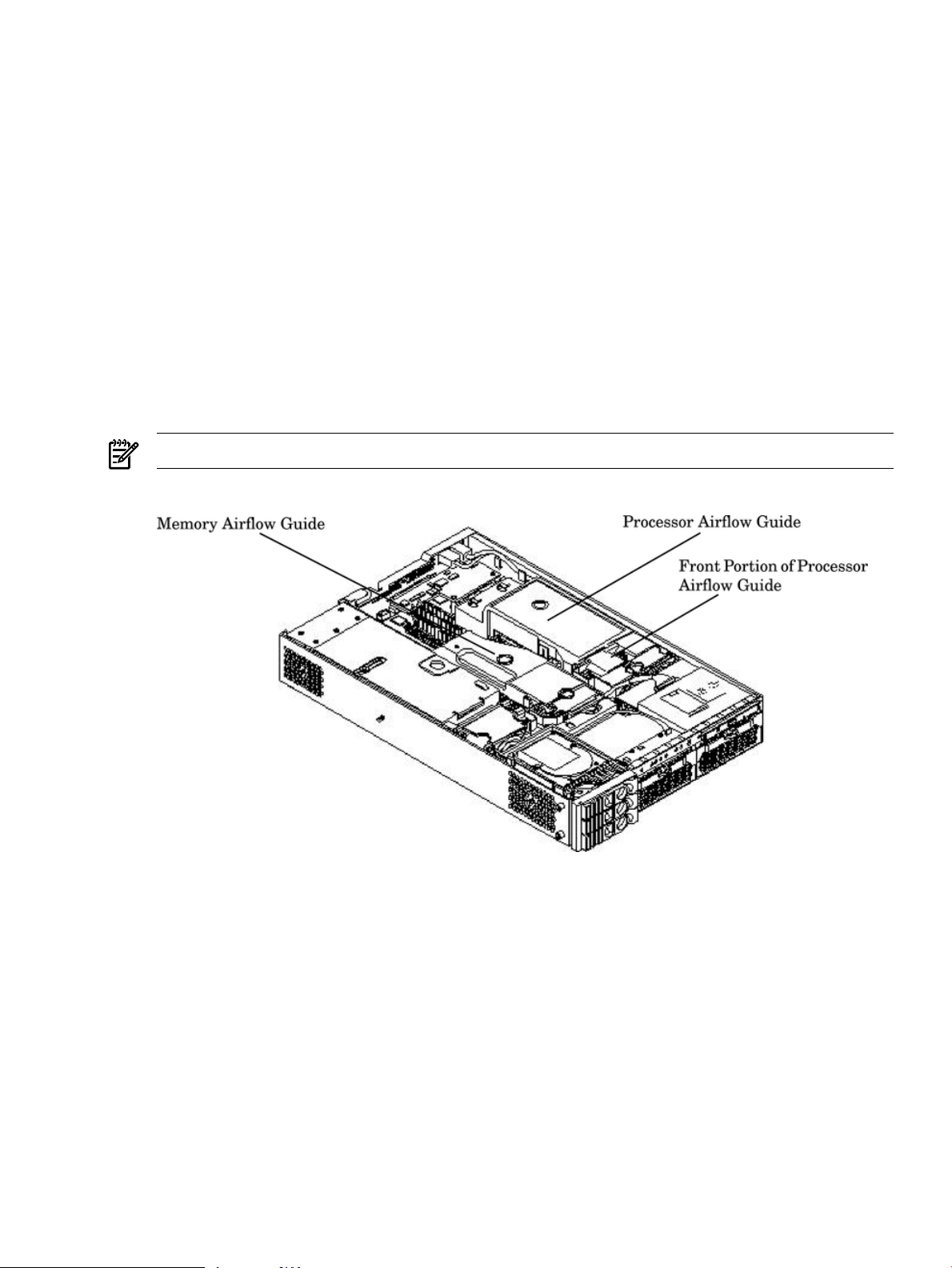

Removing and Replacing Airflow Guides......................................................................................65

Removing and Replacing the Memory Airflow Guide..............................................................65

Removing the Memory Airflow Guide.................................................................................65

Replacing the Memory Airflow Guide.................................................................................66

Removing and Replacing the Processor Airflow Guide............................................................66

Removing the Processor Airflow Guide...............................................................................66

Replacing the Processor Airflow Guide...............................................................................69

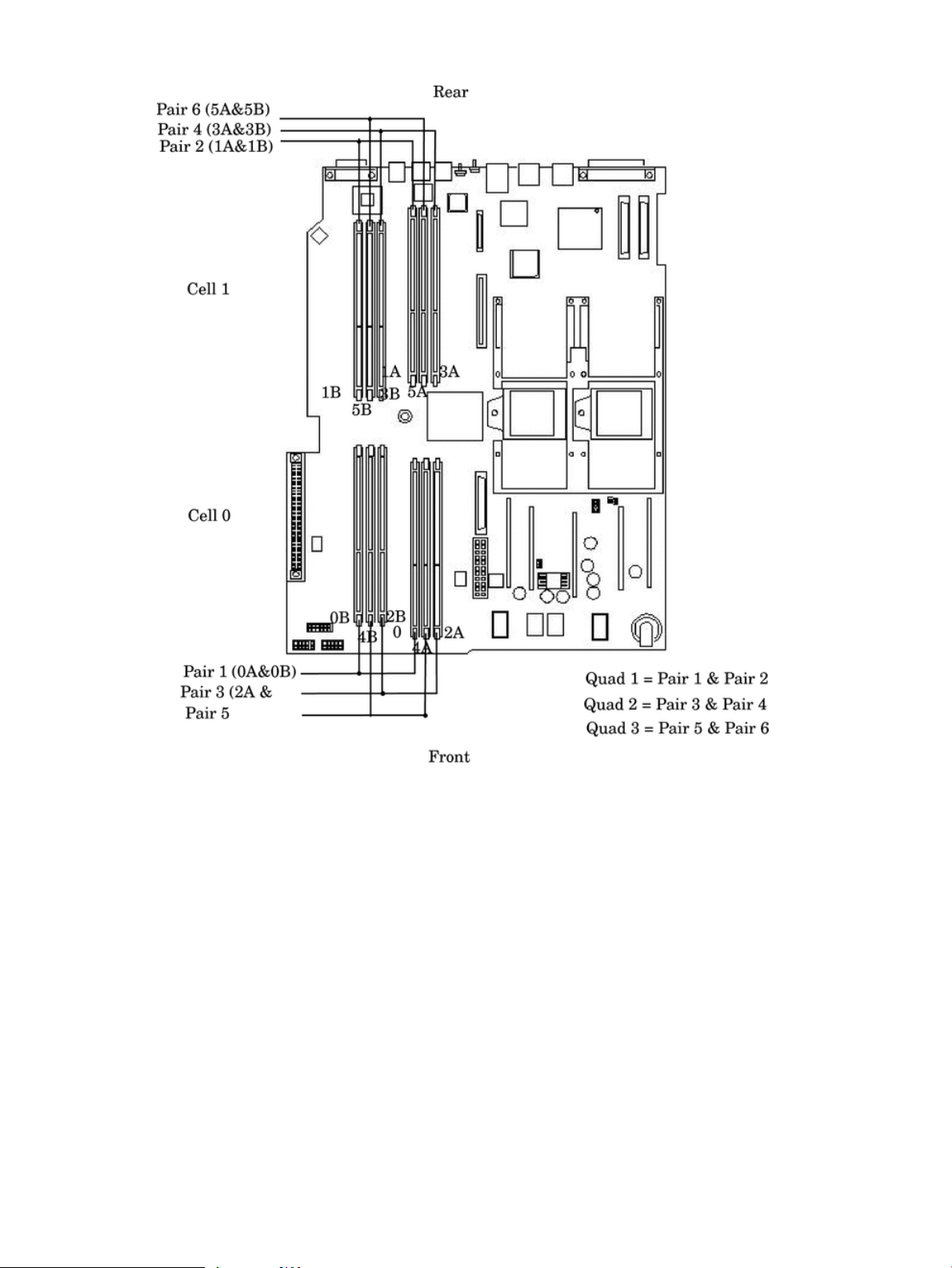

Installing Additional System Memory............................................................................................70

Supported DIMM Sizes..............................................................................................................70

Installing System Memory.........................................................................................................71

rp3410 Memory Configuration.............................................................................................71

Memory Loading Rules and Performance Guidelines.........................................................72

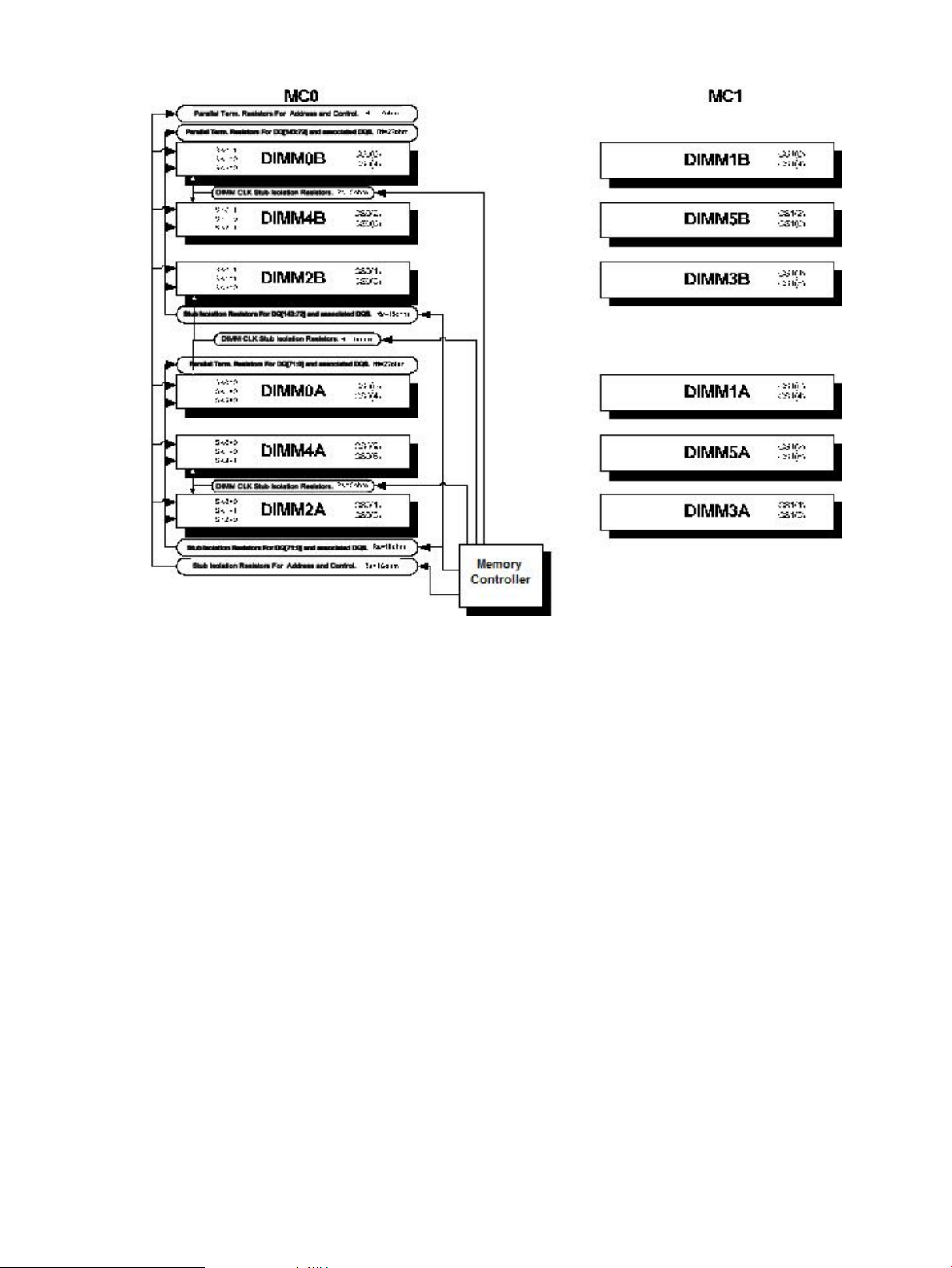

rp3440 Memory Configuration.............................................................................................72

Memory Loading Rules and Performance Guidelines.........................................................72

System Firmware Requirements...........................................................................................72

Installation Procedure...........................................................................................................73

Removing and Replacing the PCI Card Cage.................................................................................74

Removing the PCI Card Cage....................................................................................................74

Replacing the PCI Card Cage.....................................................................................................75

Installing PCI Cards.........................................................................................................................75

Installing a PCI Card..................................................................................................................76

Installing an Additional Power Supply...........................................................................................76

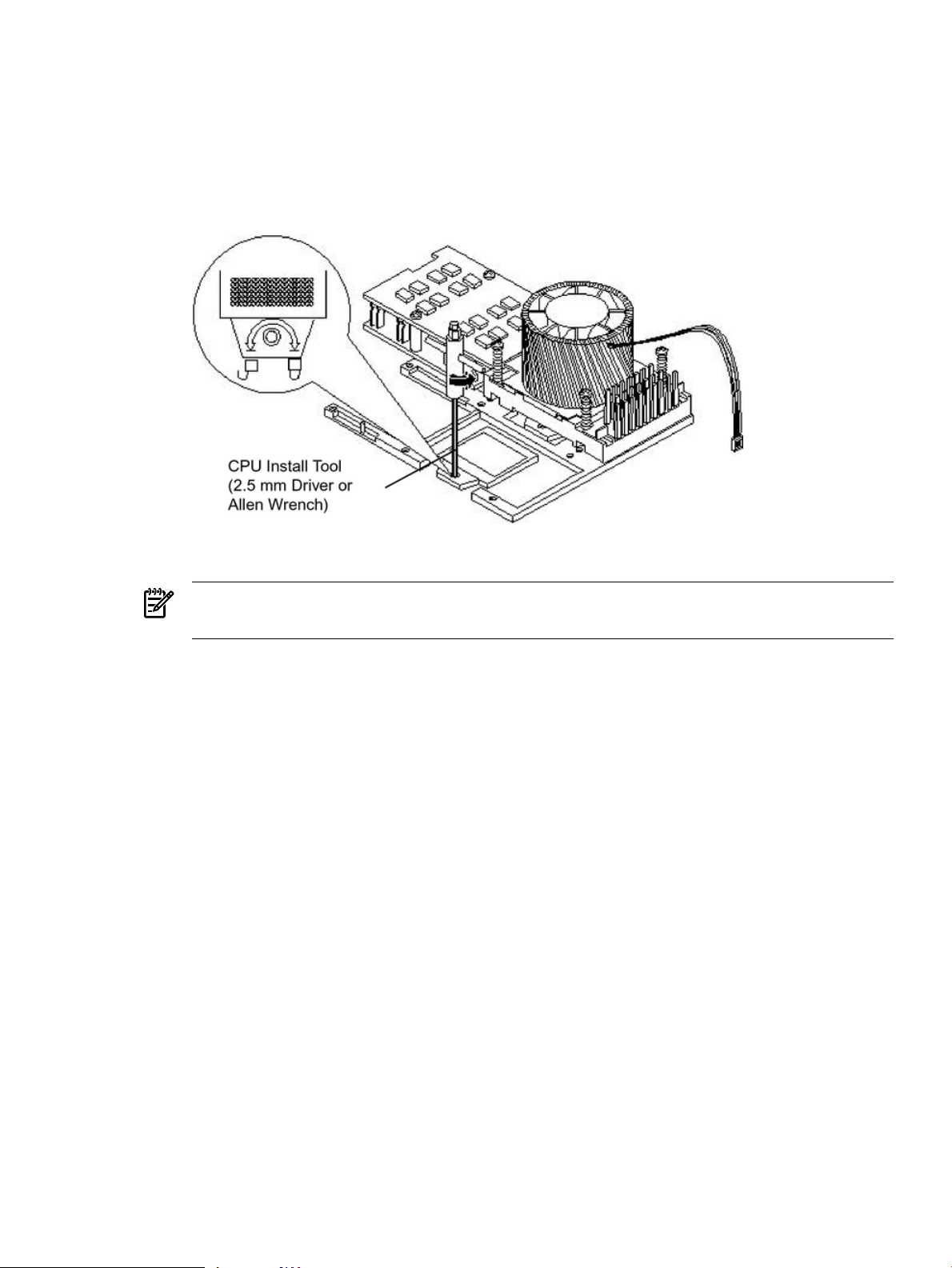

Installing an Additional Processor Module....................................................................................78

Replacing the System Battery..........................................................................................................85

Battery Notice.............................................................................................................................85

Replacing the System Battery.....................................................................................................85

Installing the Server Into a Rack, Non-HP Rack, or Pedestal...............................................................86

HP Rack...........................................................................................................................................87

Non-HP Rack...................................................................................................................................87

Pedestal Mount................................................................................................................................87

Connecting the Cables..........................................................................................................................87

AC Input Power...............................................................................................................................87

Core I/O Connections......................................................................................................................87

Applying Standby Power To the Server..........................................................................................88

Connecting To the LAN...................................................................................................................88

Console Setup.......................................................................................................................................89

Setup Checklist................................................................................................................................89

Setup Flowchart...............................................................................................................................90

Table of Contents 5

Page 6

Preparation......................................................................................................................................91

Determining the Physical iLO MP Access Method....................................................................91

Determining the iLO MP LAN Configuration Method.............................................................92

Configuring the iLO MP LAN Using DHCP and DNS...................................................................92

Configuring the iLO MP LAN Using ARP Ping.............................................................................93

Configuring the iLO MP LAN Using the RS-232 Serial Port..........................................................94

Logging In to the iLO MP................................................................................................................95

Additional Setup..............................................................................................................................96

Modifying User Accounts and Default Password.....................................................................96

Setting Up Security.....................................................................................................................97

Security Access Settings........................................................................................................97

Accessing the Host Console..................................................................................................................97

Accessing the Host Console With the TUI - CO Command............................................................97

Interacting With the iLO MP Using the Web GUI...........................................................................98

Accessing the Graphic Console Using VGA...................................................................................99

Enabling VGA Graphics Capability...........................................................................................99

Installing Your A6150B Graphics Card....................................................................................100

Connecting a Monitor Using the VGA Port.............................................................................100

Powering the Server ON and OFF......................................................................................................100

Power States...................................................................................................................................100

Powering On the Server.................................................................................................................101

Powering On the Server Using the iLO MP PC Command.....................................................101

Powering On the Server Manually...........................................................................................101

Powering Off the Server.................................................................................................................101

Powering Off the Server Using the iLO MP PC Command.....................................................102

Powering Off the Server Manually...........................................................................................102

Booting the Operating System............................................................................................................102

Supported Operating System........................................................................................................102

Booting and Shutting Down HP-UX.............................................................................................102

Standard HP-UX Booting Using the Boot Console Handler....................................................102

Booting HP-UX in Single-User Mode.......................................................................................103

Booting HP-UX in LVM Maintenance Mode............................................................................103

Shutting Down HP-UX.............................................................................................................103

Verifying the Server Configuration Using Boot Console Handler................................................104

Troubleshooting..................................................................................................................................104

Troubleshooting Methodology......................................................................................................104

Troubleshooting Using the Server Power Button..........................................................................104

Server Does Not Power On............................................................................................................105

Operating System Does Not Boot..................................................................................................105

Operating System Boots with Problems........................................................................................106

Intermittent Server Problems.........................................................................................................106

DVD Problems...............................................................................................................................106

Hard Drive Problems.....................................................................................................................106

Console Problems..........................................................................................................................106

Downloading and Installing the Latest Version of the Firmware.................................................106

Downloading the Latest Version of the Firmware...................................................................107

Installing the Latest Version of the Firmware..........................................................................107

Troubleshooting Using LED Indicators.........................................................................................107

Front Control Panel LEDs........................................................................................................107

Information to Collect Before You Contact Support......................................................................108

4 Booting the Operating System.................................................................................109

Supported Operating System..............................................................................................................109

Booting and Shutting Down HP-UX...................................................................................................109

6 Table of Contents

Page 7

Standard HP-UX Booting Using the Boot Console Handler.........................................................109

Booting HP-UX in Single-User Mode............................................................................................110

Booting HP-UX in LVM Maintenance Mode.................................................................................110

Shutting Down HP-UX..................................................................................................................110

Verifying the Server Configuration Using Boot Console Handler.....................................................111

5 Troubleshooting..........................................................................................................113

Troubleshooting Methodology...........................................................................................................113

Troubleshooting System Power..........................................................................................................113

Using the Front Panel Power Button.............................................................................................113

Operating System Does Boot.........................................................................................................114

Operating System Does Not Boot..................................................................................................114

Troubleshooting Using Online Support Tools....................................................................................114

Support Tools Manager.................................................................................................................114

Event Monitoring Service..............................................................................................................114

iLO MP...........................................................................................................................................115

Accessing the iLO MP Interface and System Logs...................................................................115

SEL.......................................................................................................................................115

Troubleshooting Using Offline Support Tools....................................................................................116

Offline Diagnostic Environment....................................................................................................116

Identifying and Diagnosing Hardware Problems..............................................................................117

Troubleshooting Using LEDs..............................................................................................................117

Power and System LEDs................................................................................................................118

LAN LEDs......................................................................................................................................118

System Board LEDs.......................................................................................................................119

Cleaning Procedures...........................................................................................................................120

6 Removing and Replacing Components...................................................................123

Safety Information...............................................................................................................................123

Required Service Tools........................................................................................................................123

Location of Internal Components and Connectors.............................................................................123

Removing and Replacing Server Covers and Bezel............................................................................126

Accessing a Rack-Mount Server....................................................................................................126

Extending the Server From the Rack........................................................................................126

Inserting the Server Into the Rack............................................................................................127

Removing and Replacing the Top Cover on a Rack-Mounted Server.....................................127

Removing the Top Cover on a Rack-Mounted Server........................................................127

Replacing the Top Cover on a Rack-Mounted Server.........................................................128

Removing and Replacing the Front Bezel on a Rack-Mounted Server....................................129

Removing the Front Bezel...................................................................................................129

Replacing the Front Bezel...................................................................................................129

Accessing a Pedestal-Mount Server...............................................................................................130

Removing the Side Covers on a Pedestal-Mounted Server......................................................130

Replacing the Top and Side Covers on a Pedestal-Mounted Server...................................132

Removing and Replacing the Front Bezel on a Pedestal-Mounted Server.........................134

Removing and Replacing System Fans...............................................................................................136

Removing a System Fan.................................................................................................................136

Replacing a System Fan.................................................................................................................138

Removing and Replacing the Power Supply......................................................................................138

Removing the Power Supply.........................................................................................................138

Replacing the Power Supply..........................................................................................................139

Removing and Replacing an Internal Hard Disk Drive.....................................................................140

Removing a Hard Disk Drive........................................................................................................140

Table of Contents 7

Page 8

Replacing a Hard Disk Drive.........................................................................................................142

Removing and Replacing Airflow Guides..........................................................................................144

Removing and Replacing the Memory Airflow Guide.................................................................144

Removing the Memory Airflow Guide....................................................................................144

Replacing the Memory Airflow Guide.....................................................................................145

Removing and Replacing the Processor Airflow Guide................................................................145

Removing the Processor Airflow Guide..................................................................................145

Replacing the Processor Airflow Guide...................................................................................148

Removing and Replacing System Memory........................................................................................149

Supported DIMM Sizes.................................................................................................................149

rp3410 Memory Configuration......................................................................................................150

Memory Loading Rules............................................................................................................151

rp3440 Memory Configuration......................................................................................................151

Memory Loading Rules............................................................................................................151

System Firmware Requirements....................................................................................................151

Replacing Deallocated Memory Ranks..........................................................................................151

Removing System Memory...........................................................................................................152

Installing System Memory.............................................................................................................152

Removing and Replacing a Dual Processor Module..........................................................................155

Removing a Dual Processor Module.............................................................................................155

Installing a Dual Processor Module..............................................................................................160

Removing and Replacing the System Battery.....................................................................................165

Battery Notice................................................................................................................................165

Removing the System Battery........................................................................................................165

Replacing the System Battery........................................................................................................166

Removing and Replacing the PCI Card Cage.....................................................................................167

Removing the PCI Card Cage........................................................................................................167

Replacing the PCI Card Cage........................................................................................................168

Removing and Replacing PCI Cards..................................................................................................169

Removing a PCI or Graphics Card................................................................................................169

Replacing a PCI or Graphics Card.................................................................................................170

Removing and Replacing the PCI Backplane.....................................................................................171

Removing the PCI Backplane........................................................................................................171

Replacing the PCI Backplane.........................................................................................................171

Removing and Replacing a Removable Media Drive.........................................................................172

Removing a Removable Media Drive............................................................................................172

Replacing a Removable Media Drive............................................................................................173

Removing and Replacing the iLO MP Card.......................................................................................173

Removing the iLO MP Card..........................................................................................................173

Replacing the iLO MP Card...........................................................................................................174

Removing and Replacing the iLO MP Card Battery...........................................................................175

Battery Notice................................................................................................................................175

Removing the iLO MP Card Battery.............................................................................................175

Replacing the iLO MP Card Battery..............................................................................................176

Removing and Replacing the LED Status Panel.................................................................................176

Removing the LED Status Panel....................................................................................................176

Replacing the LED Status Panel.....................................................................................................177

Removing and Replacing the System Board.......................................................................................177

Removing the System Board..........................................................................................................177

Replacing the System Board..........................................................................................................180

Replacing the Resident System Board with a Replacement System Board........................................184

Replacing a System Board.............................................................................................................185

Removing and Replacing the Power Supply Interface Module.........................................................186

Removing the Power Supply Interface Module............................................................................186

Replacing the Power Supply Interface Module.............................................................................187

8 Table of Contents

Page 9

Removing and Replacing the Hard Disk Drive (SCSI) Backplane.....................................................189

Removing the Hard Drive Disk SCSI Backplane...........................................................................189

Replacing the Hard Disk Drive SCSI Backplane...........................................................................191

A Replacement Parts.....................................................................................................193

Parts Illustrations................................................................................................................................193

Customer Self Repair..........................................................................................................................194

Replaceable Parts List..........................................................................................................................195

B Utilities.........................................................................................................................199

Boot Console Handler.........................................................................................................................199

BCH Commands............................................................................................................................199

BCH Main Menu Commands and Submenus..........................................................................200

Boot Command...................................................................................................................200

Path Command...................................................................................................................200

Search Command................................................................................................................201

Configuration Menu.................................................................................................................201

Information Menu....................................................................................................................202

Service Menu............................................................................................................................203

Display Command...................................................................................................................203

SCSI Command........................................................................................................................203

ProductNum Command...........................................................................................................203

iLO MP................................................................................................................................................203

C Physical and Environmental Specifications.............................................................205

Index...............................................................................................................................207

Table of Contents 9

Page 10

List of Figures

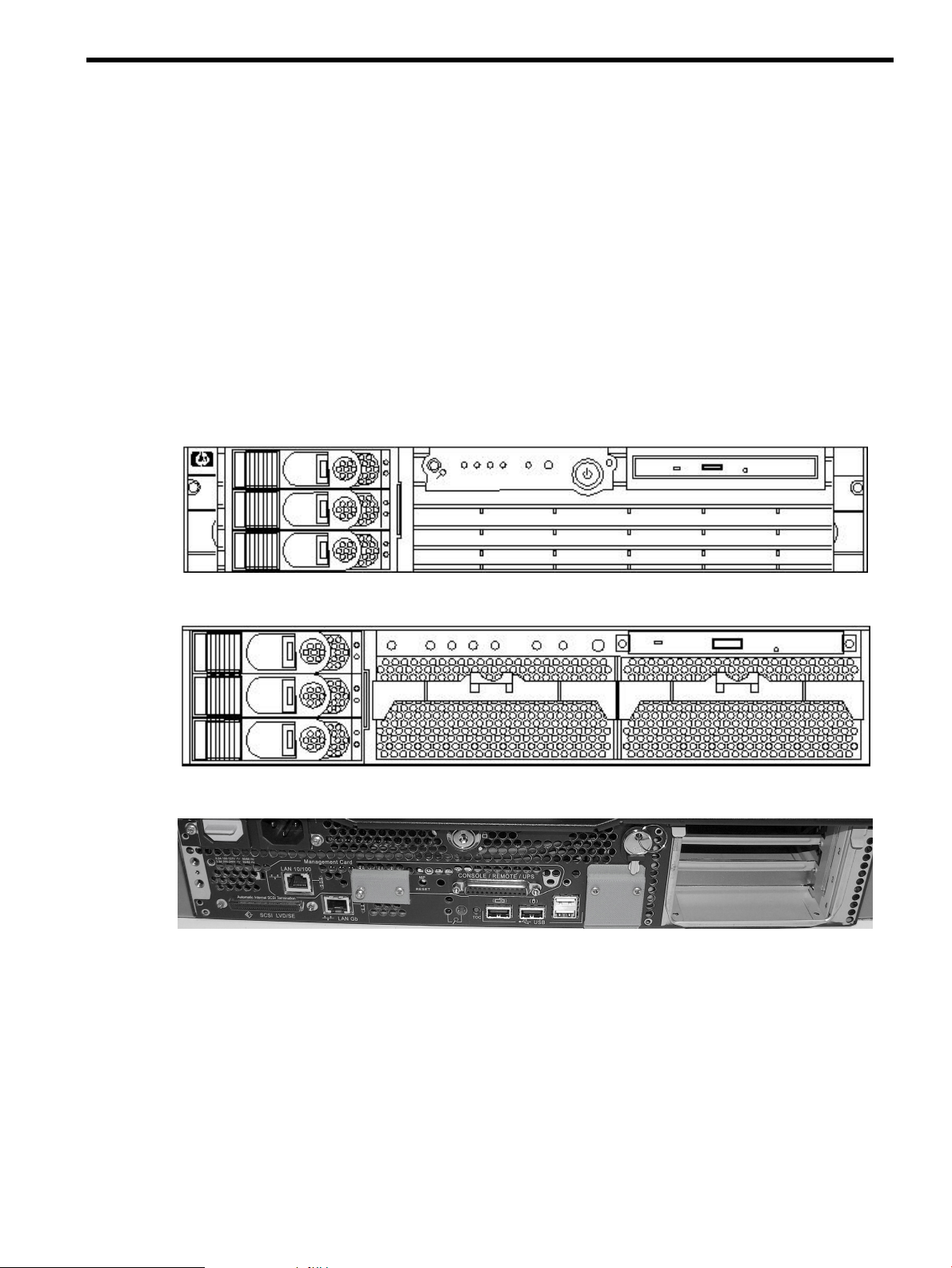

1-1 HP 9000 rp3410 and rp3440 Servers - Front View.........................................................................19

1-2 HP 9000 rp3410 and rp3440 Servers - Front View with Bezel Removed......................................19

1-3 HP 9000 rp3410 and rp3440 Servers - Rear View..........................................................................19

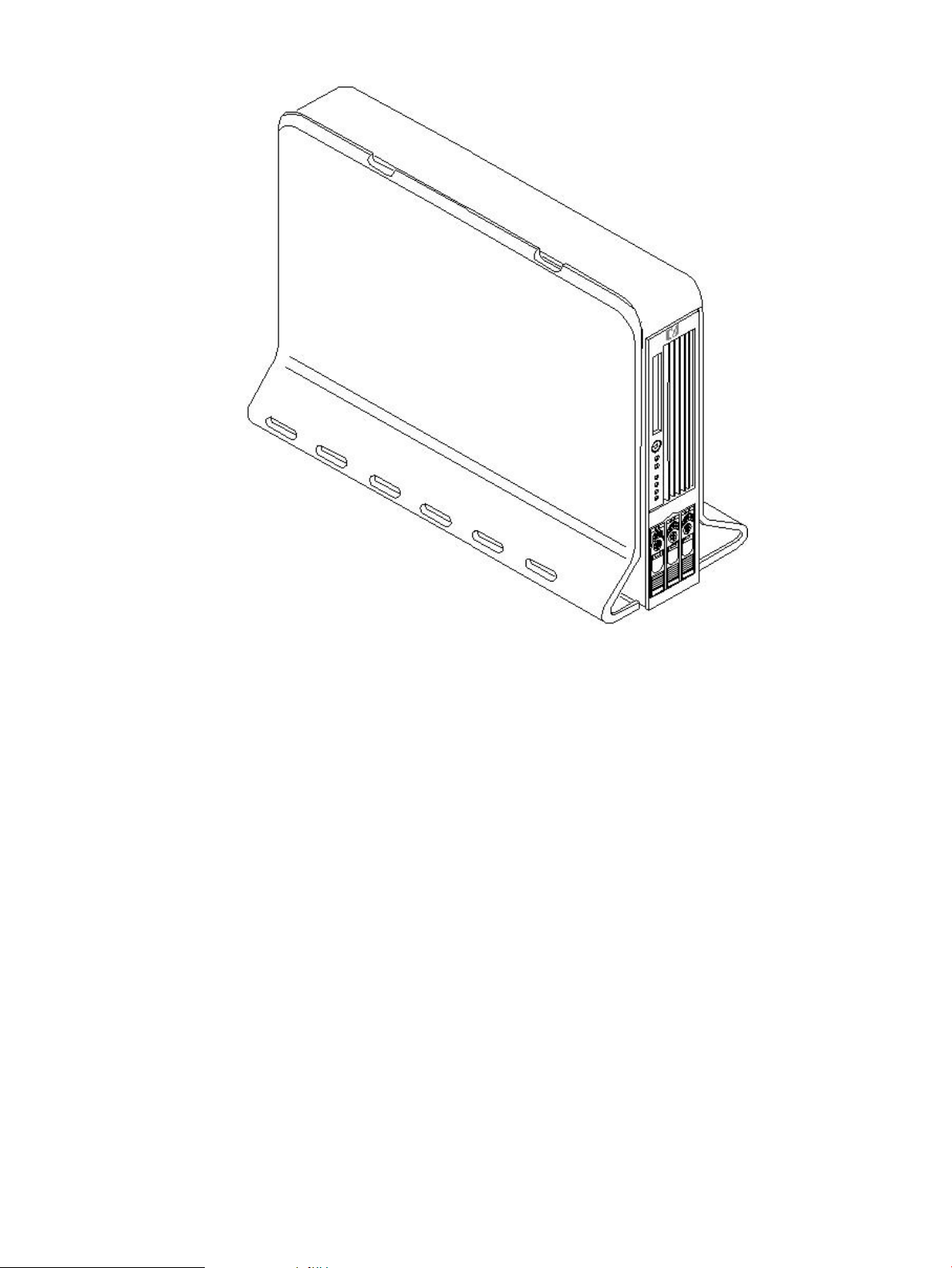

1-4 HP 9000 rp3410 and rp3440 Servers - Pedestal Mount..................................................................20

1-5 System Board Block Diagram........................................................................................................24

1-6 Memory Block Diagram................................................................................................................26

1-7 Front View.....................................................................................................................................31

1-8 Control Panel LEDs and Buttons...................................................................................................32

1-9 Hot-Pluggable Disk Drive LED Indicators....................................................................................33

1-10 DVD Drive.....................................................................................................................................33

1-11 Rear View......................................................................................................................................34

1-12 10/100/1000 Base-T Ethernet LAN Connector LEDs.....................................................................35

1-13 Dual USB Port Connector..............................................................................................................36

1-14 Single USB Port..............................................................................................................................36

1-15 SCSI Port, Ultra 3, 68-Pin...............................................................................................................36

1-16 iLO MP Card LAN LEDs...............................................................................................................38

3-1 HP 9000 rp3410/rp3440 Server - Front View.................................................................................47

3-2 HP 9000 rp3410/rp3440 Server - Front View with Bezel Removed...............................................47

3-3 HP 9000 rp3410/rp3440 Server - Rear View...................................................................................47

3-4 HP 9000 rp3410/rp3440 Server - Pedestal Mount..........................................................................48

3-5 Release the Rack Latches...............................................................................................................53

3-6 Removing and Replacing the Top Cover on a Rack-Mounted Server..........................................54

3-7 Aligning the Top Cover.................................................................................................................55

3-8 Closing the Top Cover...................................................................................................................55

3-9 Front Bezel Retaining Clip............................................................................................................56

3-10 Replacing the Front Bezel..............................................................................................................56

3-11 Removing the Side Cover on a Pedestal-Mounted Server............................................................57

3-12 Removing the Top Cover on a Pedestal-Mounted Server.............................................................58

3-13 Top Cover Alignment Mark..........................................................................................................58

3-14 Replacing the Top Cover on a Pedestal-Mounted Server..............................................................59

3-15 Replacing the Side Cover on a Pedestal-Mounted Server.............................................................59

3-16 Removing the Front Bezel on a Pedestal-Mounted Server............................................................60

3-17 Aligning the Pedestal Front Bezel.................................................................................................61

3-18 Front View of the HP 9000 rp3410/rp3440 Server.........................................................................61

3-19 Filler Removal from Slot 1.............................................................................................................62

3-20 Disk Drive Installation in Slot 3.....................................................................................................62

3-21 Hard Drive Lock............................................................................................................................63

3-22 DVD Drive Installation..................................................................................................................64

3-23 Airflow Guides Locations.............................................................................................................65

3-24 Removing the Memory Airflow Guide.........................................................................................66

3-25 Removing the Processor Airflow Guide.......................................................................................67

3-26 Removing Fans 1A and 1B............................................................................................................67

3-27 Opening the Release Clip..............................................................................................................68

3-28 Removing the Front Portion of the Processor Airflow Guide.......................................................68

3-29 Routing the Turbofan Power Cables Through Heatsink Posts.....................................................69

3-30 DIMM Slot Identification..............................................................................................................71

3-31 Inserting the DIMM Into the Connector.......................................................................................73

3-32 Removing the PCI Card Cage.......................................................................................................74

3-33 Removing the PCI Card Cage Cover.............................................................................................75

3-34 Installing a PCI Card.....................................................................................................................76

3-35 Removing the Power Supply Filler Panel......................................................................................77

3-36 Replacing the Power Supply.........................................................................................................77

10 List of Figures

Page 11

3-37 Unlocking the Dual Processor Module Locking Mechanism.......................................................79

3-38 Aligning the Processor Module.....................................................................................................80

3-39 Locking the Dual Processor Module in Place................................................................................80

3-40 Sliding the Sequencing Retainer Plate...........................................................................................81

3-41 Securing the Captive Screws.........................................................................................................81

3-42 Power Module Shims....................................................................................................................82

3-43 Aligning the Processor Module Power Pod..................................................................................82

3-44 Installing the Processor Module Power Pod Mounting Screws....................................................83

3-45 Connecting the Power Pod Cable..................................................................................................84

3-46 Routing the Turbofan Power Cables through Heatsink Posts......................................................84

3-47 Replacing the System Battery........................................................................................................86

3-48 LAN Ports on the Server Rear.......................................................................................................89

3-49 iLO MP Setup Flowchart...............................................................................................................91

3-50 Web GUI Login Page.....................................................................................................................98

3-51 Status Summary Page....................................................................................................................99

3-52 Control Panel LEDs and Buttons.................................................................................................107

5-1 Control Panel LEDs.....................................................................................................................118

5-2 Location of the STBY and BMC LEDs.........................................................................................120

6-1 Internal Physical Layout..............................................................................................................124

6-2 System Board Connectors and Slots............................................................................................125

6-3 Release the Rack Latches.............................................................................................................127

6-4 Removing the Top Cover on a Rack-Mounted Server.................................................................128

6-5 Aligning the Top Cover on a Rack-Mounted Server...................................................................128

6-6 Closing the Top Cover on a Rack-Mounted Server.....................................................................129

6-7 Front Bezel Retaining Clip...........................................................................................................129

6-8 Replacing the Front Bezel on a Rack-Mounted Server................................................................130

6-9 Removing the Side Cover on a Pedestal-Mounted Server..........................................................131

6-10 Removing the Top Cover on a Pedestal-Mounted Server...........................................................132

6-11 Top Cover Alignment Mark........................................................................................................133

6-12 Replacing the Top Cover on a Pedestal-Mounted Server............................................................133

6-13 Replacing the Side Cover on a Pedestal-Mounted Server...........................................................134

6-14 Removing the Front Bezel on a Pedestal-Mounted Server..........................................................135

6-15 Aligning the Pedestal Front Bezel...............................................................................................135

6-16 Removing Fan 1A or Fan 1B........................................................................................................137

6-17 Removing Fan 2...........................................................................................................................137

6-18 Removing Fan 3...........................................................................................................................137

6-19 Releasing the Power Supply Retaining Clip................................................................................139

6-20 Removing the Power Supply.......................................................................................................139

6-21 Replacing the Power Supply.......................................................................................................140

6-22 Unlocking the Disk Drive............................................................................................................141

6-23 Releasing the Disk Drive.............................................................................................................141

6-24 Removing the Disk Drive............................................................................................................142

6-25 Removing the Disk Drive Slot Filler............................................................................................143

6-26 Installing the Hard Disk Drive....................................................................................................143

6-27 Airflow Guides Locations............................................................................................................144

6-28 Removing the Memory Airflow Guide.......................................................................................145

6-29 Removing the Processor Airflow Guide......................................................................................146

6-30 Opening the Release Clip............................................................................................................147

6-31 Removing the Front Portion of the Processor Airflow Guide ....................................................147

6-32 Routing Power Cables Through Heatsink Posts.........................................................................149

6-33 DIMM Slot Identification.............................................................................................................150

6-34 Inserting the DIMM Into the Connector Socket..........................................................................154

6-35 Disconnecting the Power Pod Cable............................................................................................155

6-36 Removing the Power Pod Mounting Screws...............................................................................156

6-37 Disconnecting the Power Pod From the Dual Processor Module...............................................156

11

Page 12

6-38 Removing the Power Pod............................................................................................................157

6-39 Disconnecting the Turbo Fan Cable.............................................................................................157

6-40 Releasing the Heatsink Captive Screws......................................................................................158

6-41 Unlocking the Dual Processor Module Locking Mechanism......................................................158

6-42 Removing the Dual Processor Module........................................................................................159

6-43 Dual Processor Module Location on System Board....................................................................159

6-44 Unlocking the Dual Processor Module Locking Mechanism......................................................160

6-45 Aligning the Dual Processor Module..........................................................................................161

6-46 Locking the Dual Processor Module in Place..............................................................................161

6-47 Securing the Captive Screws.......................................................................................................162

6-48 Power Module Shims...................................................................................................................162

6-49 Aligning the Processor Module Power Pod................................................................................163

6-50 Installing the Processor Module Power Pod Mounting Screws..................................................164

6-51 Routing the Turbofan Power Cables Through the Heatsink Posts..............................................164

6-52 Connecting the Power Pod Cable................................................................................................165

6-53 Removing the System Battery.....................................................................................................166

6-54 Removing the PCI Card Cage......................................................................................................168

6-55 Removing the PCI Card Cage Cover...........................................................................................168

6-56 Installing a PCI Slot Cover...........................................................................................................170

6-57 Installing a PCI Card...................................................................................................................170

6-58 Removing the PCI Backplane......................................................................................................171

6-59 Replacing the PCI Backplane.......................................................................................................172

6-60 Removing the Removable Media Drive......................................................................................173

6-61 Removing the iLO MP card.........................................................................................................174

6-62 Removing the iLO MP Card Battery...........................................................................................176

6-63 Removing the LED Status Panel..................................................................................................177

6-64 Removing the Mechanical Covers...............................................................................................178

6-65 Removing the Backplane System Board Mounting Screws........................................................178

6-66 Removing the System Board Mounting Screw...........................................................................179

6-67 Removing the System Board.......................................................................................................180

6-68 Aligning the System Board PCI Connector.................................................................................181

6-69 Sliding the System Board in the Chassis.....................................................................................181

6-70 Installing the Rear Panel Mounting Screws................................................................................182

6-71 Replacing Mechanical Covers......................................................................................................182

6-72 Reinstalling the Power Connectors.............................................................................................182

6-73 System Product Number, System Serial Number, Key Certificate.............................................185

6-74 Power Cables and Holding Clips................................................................................................186

6-75 Removing the Mounting Screw...................................................................................................187

6-76 Removing the PSI Interface Module............................................................................................187

6-77 Replacing the Power Supply Interface Module...........................................................................188

6-78 Securing the Power Supply Interface Module and Cables..........................................................188

6-79 Opening the Fan Power Bridge...................................................................................................189

6-80 Disconnecting the SCSI Cables....................................................................................................190

6-81 Removing the Mounting Screws.................................................................................................190

6-82 Removing the SCSI Backplane....................................................................................................191

6-83 Removing the SCSI Backplane From the Chassis........................................................................191

A-1 Parts Identification.......................................................................................................................193

A-2 Pedestal and Rack Parts...............................................................................................................194

12 List of Figures

Page 13

List of Tables

1 Publishing History Details............................................................................................................15

2 HP-UX 11i Releases.......................................................................................................................17

1-1 Server Dimensions and Values......................................................................................................23

1-2 Memory Array Capacities.............................................................................................................27

1-3 Internal Disk and DVD Paths........................................................................................................29

1-4 Extended Core I/O Paths...............................................................................................................29

1-5 PCI I/O Paths.................................................................................................................................30

1-6 PCI I/O Hardware Paths................................................................................................................30

1-7 Control Panel LEDs and Switches.................................................................................................32

1-8 Hot-Pluggable Disk Drive LED Definitions..................................................................................33

1-9 DVD Drive LED Definitions..........................................................................................................33

1-10 Rear Panel Connectors and Switches............................................................................................34

1-11 10/100/1000 Base-T Ethernet LAN Connector LEDs.....................................................................35

1-12 10/100/1000 Base-T Ethernet LAN Connector Pinouts..................................................................35

1-13 USB Pinouts...................................................................................................................................36

1-14 SCSI Port Pinouts...........................................................................................................................36

1-15 iLO MP Card LAN LEDs...............................................................................................................38

1-16 iLO MP Card LAN Connector Pinouts.........................................................................................38

1-17 Power States...................................................................................................................................39

2-1 Minimum and Maximum System Configurations........................................................................41

2-2 Server Dimensions and Values......................................................................................................41

2-3 Power Cables.................................................................................................................................42

2-4 System Power Specifications.........................................................................................................43

2-5 Additional Component Power Consumption...............................................................................44

2-6 Environmental Specifications........................................................................................................44

2-7 Physical and Environmental Specifications..................................................................................46

3-1 HP 9000 rp3410 and rp3440 Server Features.................................................................................48

3-2 Server Dimensions and Values......................................................................................................49

3-3 Installation Sequence Checklist.....................................................................................................50

3-4 Setup Checklist..............................................................................................................................89

3-5 Console Connection Matrix...........................................................................................................92

3-6 MP LAN Configuration Methods.................................................................................................92

3-7 ARP Ping Commands....................................................................................................................94

3-8 Power States.................................................................................................................................101

3-9 Server Power Button Functions When Server is On and at BCH................................................104

3-10 Server Power Button Functions When Server is On and OS is Running....................................105

3-11 Server Power Button Functions When Server is Off...................................................................105

3-12 Front Control Panel LED Definitions..........................................................................................107

5-1 Power Button Functions..............................................................................................................113

5-2 ODE Commands..........................................................................................................................117

5-3 System LED States.......................................................................................................................118

5-4 10/100/1000 Base-T Ethernet LAN Connector LEDs...................................................................119

5-5 iLO MP Card LAN LEDs.............................................................................................................119

5-6 System Board LEDs.....................................................................................................................120

5-7 Cleaning.......................................................................................................................................121

6-1 Component Locations..................................................................................................................124

6-2 Connector Locations....................................................................................................................125

A-1 Customer Self Repair Information..............................................................................................195

A-2 Replaceable Parts List..................................................................................................................195

B-1 BCH Main Menu, Submenus, and Commands...........................................................................199

B-2 Boot Paths....................................................................................................................................200

C-1 Physical and Environmental Specifications................................................................................205

13

Page 14

14

Page 15

About This Document

This document provides information and instructions on how to service and troubleshoot the

HP 9000 rp3410 and rp3440 servers.

The document publication date and part number indicate the document’s current edition. The

document part number will change when extensive changes are made.

Document updatesmay be issued between editions to correct errors or document product changes.

To ensure that you receive the updated or new editions, you should subscribe to the appropriate

product support service. See your HP sales representative for details.

The latest version of this document can be found online at http://www.hp.com/go/

HP9000_Servers-docs.

Intended Audience

This document is intended to provide technical product and support information for authorized

service providers, system administrators, and HP support personnel.

New and Changed Information in This Edition

This document was updated to comply with HP publishing standards.

Publishing History

Table 1 lists the publishing history details for this document.

Table 1 Publishing History Details

A7137-96003

Document Organization

This guide is divided into the following chapters:

Chapter 1 Overview: Provides views and descriptions of the server.

Chapter 2 System Specifications: Server details such as system configuration, physical

specifications, and requirements.

Chapter 3 Installing the System: Unpacking, installation, and preparation for booting the

operating system.

Chapter 4 Booting and Shutting Down the Operating System: Provides procedures to boot

and shut down the operating system.

Chapter 5 Troubleshooting: Provides diagnostics and basic troubleshooting methodology.

Chapter 6 Removing and Replacing Components: Provides instructions and procedures on

how to remove and replace server components.

Appendix A Replacement Parts: Provides a list of available customer self-repair parts.

Publication DateDocument Manufacturing Part Number

July 2003N/A

April 2005A7137-96002

April 2007A7137-96008

September 2008A7137-96008-ed5

February 2010A7137-96008-ed6

Intended Audience 15

Page 16

Appendix B Utilities: Provides information on the utilities on the server such as Boot Console

Handler (BCH) and the iLO MP.

Appendix C Physical and Environmental Specifications: Provides temperature and airflow

information for minimum, typical, and maximum configurations for the server.

Also lists the server and rack weights and dimensions.

Typographic Conventions

This document uses the following conventions.

%, $, or #

Command

Computer output

Ctrl+x A key sequence. A sequence such as Ctrl+x indicates that you

ENVIRONMENT VARIABLE The name of an environment variable, for example, PATH.

[ERROR NAME]

Key The name of a keyboard key. Return and Enter both refer to the

Term The defined use of an important word or phrase.

User input

Variable

[] The contents are optional in syntax. If the contents are a list