Page 1

HP 3PAR StoreServ 7000 Storage

nl

Installation Guide

Abstract

This guide is designed to instruct qualified technicians who are authorized to install the HP 3PAR StoreServ 7000 Storage

system and associated hardware components.

HP Part Number: QR482-96436

Published: August 2013

Edition: 1

Page 2

© Copyright 2013 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP shall

not be liable for technical or editorial errors or omissions contained herein.

Acknowledgments

Microsoft® and Windows® are U.S. registered trademarks of Microsoft Corporation.

Apple® and Mac OS® are trademarks of Apple Incorporated.

Mozilla® and Firefox® are trademarks of Mozilla Incorporated.

Warranty

To obtain a copy of the warranty for this product, see the warranty information website:

http://www.hp.com/go/storagewarranty

Printed in the US.

Page 3

Contents

1 Getting Started..........................................................................................6

Tools.......................................................................................................................................6

Precautions..............................................................................................................................6

Preventing Electrostatic Discharge...........................................................................................6

Racks.................................................................................................................................7

Inspecting the Packaging...........................................................................................................7

Redeeming and Registering HP 3PAR Licenses..............................................................................8

Storage System Installation.........................................................................................................8

Storage System Hardware Installation Checklist............................................................................8

2 Identifying Storage System Components........................................................9

Understanding Component Numbering.......................................................................................9

Disk Drive Numbering..........................................................................................................9

Controller Nodes...............................................................................................................10

Controller Node PCIe Slots and Ports ..............................................................................11

I/O Modules ....................................................................................................................12

Power Cooling Modules......................................................................................................12

Service Processor...............................................................................................................13

Power Distribution Units......................................................................................................14

3 Setting Up a Factory-Integrated Storage System............................................15

Unpacking the Cabinet............................................................................................................15

Positioning the Cabinet............................................................................................................15

Verify the Cabling..................................................................................................................15

Installing and Removing the Cable Restraint Shipping Brackets ....................................................16

4 Installing Storage System Components into a Rack........................................19

Unpacking Disk Drive and Controller Node Enclosures ...............................................................19

Installing the Rail Kit................................................................................................................19

Installing PCIe Adapters in the Controller Nodes.........................................................................22

Installing Enclosures ...............................................................................................................22

Guidelines for Installing Disk Drives in Disk Enclosures.................................................................24

Installing a Disk Drive.........................................................................................................25

Installing the Service Processor in the Storage System..................................................................27

5 Cabling the Storage System.......................................................................34

Cabling Controller Nodes........................................................................................................34

Host/Ethernet Cables.........................................................................................................34

Cabling the Service Processor..................................................................................................35

Cabling Power to the Storage System........................................................................................35

Cabling the Power Distribution Unit......................................................................................36

Cabling the Power Strips.....................................................................................................36

6 Verifying Setup and Powering On the Storage System....................................37

Verifying Setup.......................................................................................................................37

Verifying Power Connections...............................................................................................37

Repositioning the Storage System.........................................................................................37

Acclimating the Storage System...........................................................................................38

Powering On the Storage System..............................................................................................38

Verifying LED Status................................................................................................................39

Node Interconnect Ports......................................................................................................42

Drive Enclosure LEDs..........................................................................................................43

Identifying Service Processor LEDs........................................................................................44

Contents 3

Page 4

7 Initializing the Service Processor.................................................................46

Connecting to a Virtual Service Processor..................................................................................46

Establishing the Virtual Service Processor IP Address...............................................................47

Connecting to a Physical Service Processor................................................................................48

Configuring the Physical Service Processor IP Address.............................................................48

8 Setting Up the Service Processor and Storage System....................................51

Storage System Software Installation Checklist............................................................................51

Launching HP 3PAR SmartStart.................................................................................................53

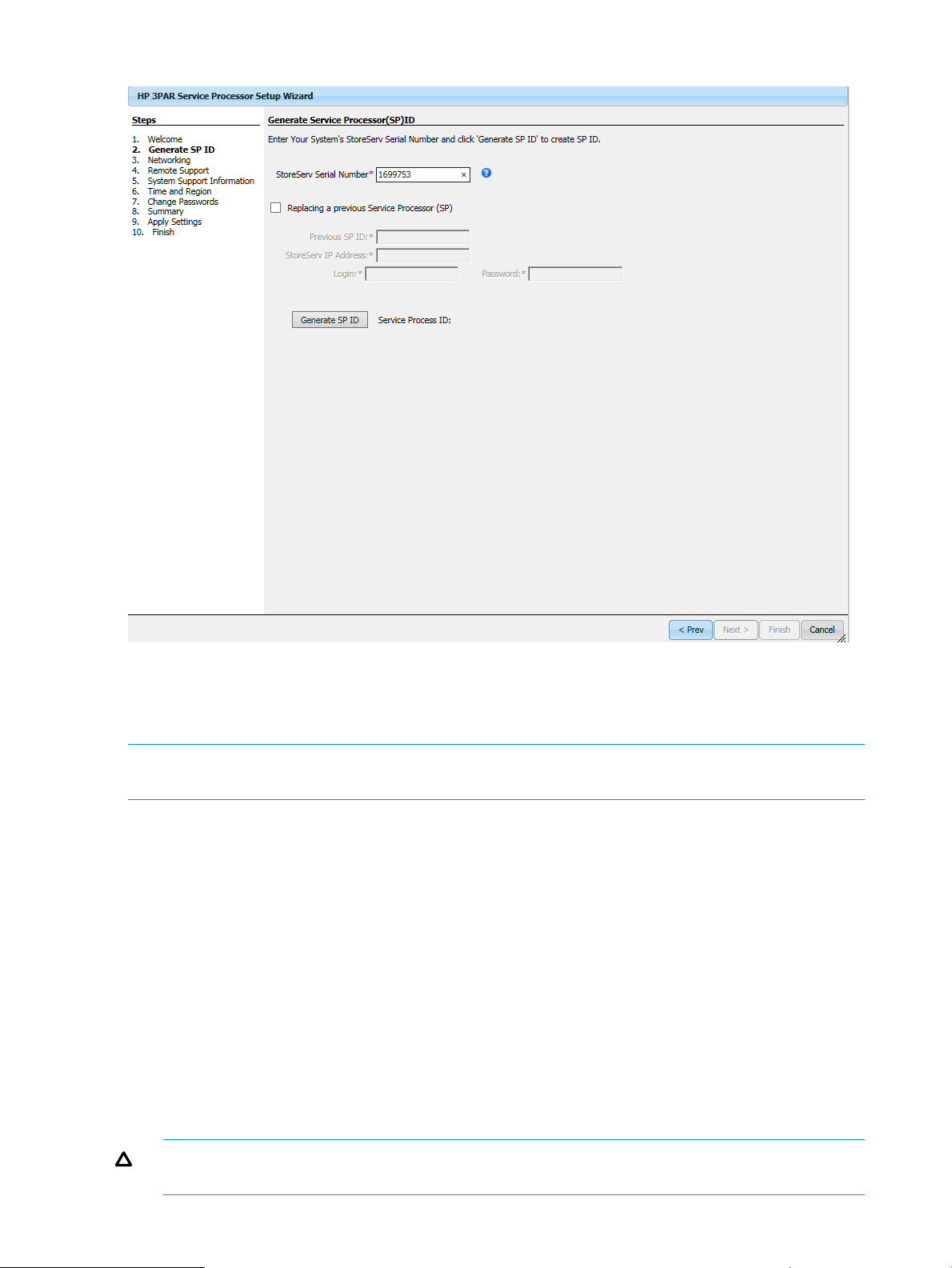

Launching the HP 3PAR Service Processor Setup Wizard..............................................................53

Welcome Page..................................................................................................................54

Generate Service Processor ID.............................................................................................55

Configure SP Networking....................................................................................................56

Remote Support.................................................................................................................57

System Support Information.................................................................................................59

Time and Region................................................................................................................60

Change Passwords.............................................................................................................61

Summary..........................................................................................................................63

Applying Settings...............................................................................................................63

Finish...............................................................................................................................64

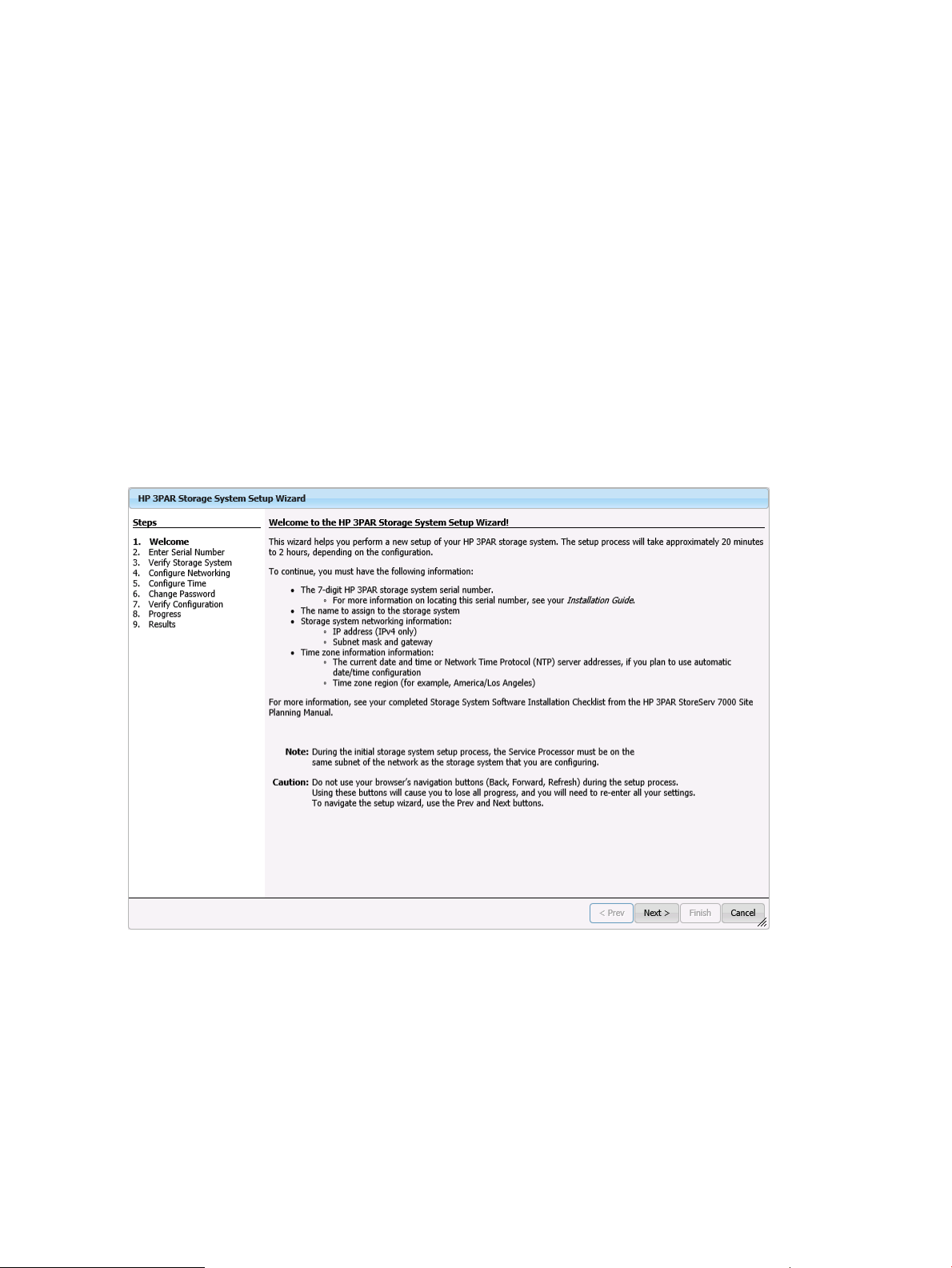

Launching the HP 3PAR Storage System Setup Wizard.................................................................65

Welcome..........................................................................................................................66

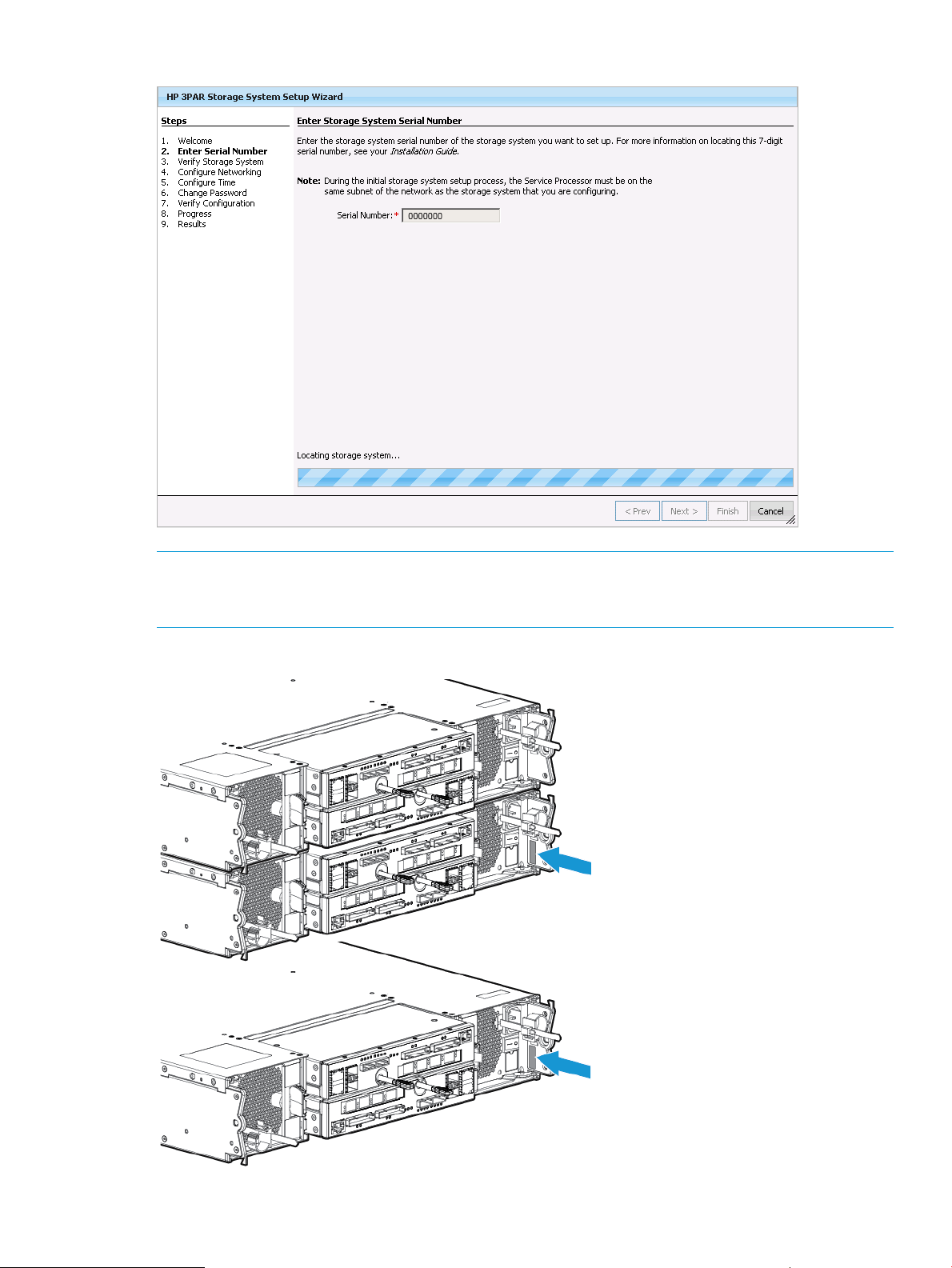

Enter Serial Number...........................................................................................................66

Verify Storage System.........................................................................................................68

Configure Networking........................................................................................................68

Configuring Time...............................................................................................................69

Change Password..............................................................................................................70

Verify Configuration...........................................................................................................71

Progress............................................................................................................................71

Results..............................................................................................................................72

Post-Installation System Tasks....................................................................................................73

9 Support and Other Resources.....................................................................74

Contacting HP........................................................................................................................74

HP 3PAR documentation..........................................................................................................74

Typographic conventions.........................................................................................................77

HP 3PAR branding information.................................................................................................77

10 Documentation feedback.........................................................................78

A HP 3PAR StoreServ 7000 (Controller and Storage) and M6700 Series (Storage)

Contents List ...............................................................................................79

HP 3PAR StoreServ 7000 and M6700 Components....................................................................79

Accessory Kits........................................................................................................................83

Service Processor Field Replaceable Unit (FRU)...........................................................................83

Rail Kits.................................................................................................................................83

B Enhancing Security with Data Encryption.....................................................86

C Adding Disk Drives and Expansion Drive Enclosures.....................................87

Adding Disk Drives ................................................................................................................89

Checking Initial Status........................................................................................................89

Inserting Disk Drives...........................................................................................................89

Checking Status.................................................................................................................89

Checking Progress.............................................................................................................90

Completing the Upgrade....................................................................................................91

Adding Expansion Drive Enclosures..........................................................................................91

4 Contents

Page 5

D Installing HP 3PAR Storage Software When HP 3PAR SmartStart is

Unavailable................................................................................................92

Launching the SP Setup Wizard................................................................................................92

Launching the Storage System Setup Wizard..............................................................................92

Installing the Management Console When HP 3PAR SmartStart is Unavailable...............................92

E Validating Remote Support.........................................................................93

F Troubleshooting........................................................................................95

Troubleshooting Duplicate IP Address Issues...............................................................................95

Contents 5

Page 6

1 Getting Started

Before you begin, read the following guidelines to help you complete the installation successfully.

If you need assistance with the installation, contact HP Support or visit http://www.hp.com/support.

Tools

The following tools are not required but can be useful, especially when unpacking or installing the

storage system.

CAUTION: Always wear an electrostatic discharge (ESD) wrist-grounding strap when installing

a storage system hardware part.

• ESD wrist-grounding strap

• ESD mat

• #1 and #2 Phillips screwdrivers

• T-25 Torx toolbit

• 1/8 inch (3 mm) slotted screwdriver

• 3/16 inch (5 mm) slotted screwdriver

• Adjustable wrench

• Diagonal cutting pliers

Precautions

To avoid injury, data loss, and damage, observe these general precautions when installing or

servicing the storage system:

• Using improper tools can result in damage to the storage system.

• Prepare an ESD work surface by placing an antistatic mat on the floor or on a table near the

storage system. Attach the ground lead of the mat to an unpainted surface of the rack.

• Always use the wrist-grounding strap provided with the storage system. Attach the grounding

strap clip directly to an unpainted surface of the rack.

• Avoid contact between electronic components and clothing, which can carry an electrostatic

charge.

• If applicable, ensure all cables are properly labeled and easily identifiable before you remove

a component.

• Observe local occupational safety requirements and guidelines for heavy equipment handling.

• Do not attempt to move a fully loaded equipment rack. Remove equipment from the rack before

moving it.

• Use at least two people to safely unload the rack from the pallet.

Preventing Electrostatic Discharge

ESD can damage electrostatic-sensitive devices and microcircuitry. Proper packaging and grounding

techniques are important precautions to prevent damage. To prevent electrostatic damage, observe

the following precautions:

• Transport products in electrostatic-safe containers, such as conductive tubes, bags, or boxes.

• Keep static-sensitive parts in their containers until they arrive at static-free workstations.

6 Getting Started

Page 7

Racks

• Cover workstations with approved static-dissipating material. Use a wrist strap connected to

the work surface, and properly grounded (earthed) tools and equipment.

• Keep the work area free of nonconductive materials, such as ordinary plastic assembly aids

and foam packing.

• Ensure that you are always properly grounded (earthed) when touching a static-sensitive

component or assembly.

• Avoid touching pins, leads, and circuitry.

• Always place drives with the printed circuit board assembly-side down.

• Use conductive field service tools.

Ensure that precautions have been taken to ensure rack stability and safety. Observe all cautions

and warnings included in the installation instructions.

WARNING! To reduce the risk of personal injury or damage to the equipment:

• Observe local occupational safety requirements and guidelines for heavy equipment handling.

• Obtain assistance to lift and stabilize the product during installation or removal. Use at least

two people to safely unload the rack from the pallet.

• Extend the leveling jacks to the floor.

• Rest the full weight of the rack on the leveling jacks.

• Attach stabilizing feet to the rack if it is a single-rack installation.

• Ensure the racks are coupled in a multiple-rack installation.

• Fully extend the bottom stabilizers on the equipment. Ensure that the equipment is properly

supported and braced when installing options and boards.

• Be careful when sliding rack components with slide rails into the rack. The slide rails can pinch

your fingertips.

• Ensure the rack is adequately stabilized before extending a rack component with slide rails

outside the rack. Extend only one rack component at a time. A rack can become unstable if

more than one component is extended.

• Verify the AC power supply branch circuit that provides power to the rack is not overloaded.

Overloading AC power to the rack power supply branch circuit increases the risk of personal

injury, fire, and damage to the equipment. The total rack load should not exceed 80% of the

branch circuit rating. Consult the electrical authority with jurisdiction over your facility wiring

and safety electrical requirements before performing the installation.

• Remove all pluggable power supplies and modules to reduce the weight of the product.

• Always load the heaviest item first, from the bottom of the rack and up. This makes the rack

bottom-heavy and more stable.

• Do not attempt to move a fully loaded equipment rack. Remove equipment from the rack before

moving the rack.

Inspecting the Packaging

Before unpacking any boxes, inspect the packaging for crushes, cuts, water damage, or any other

evidence of mishandling during transit. If there is any damage, photograph the packaging for

future reference.

Inspecting the Packaging 7

Page 8

Redeeming and Registering HP 3PAR Licenses

HP 3PAR StoreServ 7000 products include 3PAR licensing, which enables all system functionality.

Failure to register the license key may limit access and restrict system upgrades.

The Summary Entitlement Certificate is enclosed in a blue envelope in the accessories kit shipped

with the system. The certificate must be redeemed through the HP Licensing for Software portal

before you begin installing the hardware and software components.

To redeem the Summary Entitlement Certificate, visit www.hp.com/software/licensing and register

all applicable HP software licenses. Use your HP Passport credentials or create a new HP Passport

profile.

For assistance with registering the HP software licenses, visit the HP Support website: http://

www.hp.com/support.

Storage System Installation

You can install the storage system in one of two ways, depending on your configuration. Both

methods connect to the network in the same way.

• Setting up an HP integrated rack installed with system components and delivered to the

customer. See “Setting Up a Factory-Integrated Storage System” (page 15).

• Installing system components in an existing rack. System components are shipped to the

customer in separate packaging, and are installed by the customer in a third-party rack or HP

rack. See “Installing Storage System Components into a Rack” (page 19).

See the HP 3PAR StoreServ 7000 Storage Site Planning Manual for configuration specifications

and installation requirements.

For information about supported hardware and software platforms, visit the Single Point of

Connectivity Knowledge for HP Storage Products (SPOCK) website at http://www.hp.com/storage/

spock.

Storage System Hardware Installation Checklist

Before you begin installing the storage system hardware components, verify the environmental,

rack access, and electrical requirements (as documented in the HP 3PAR StoreServ 7000 Storage

Site Planning Manual) have been met and that you have the following:

• Standard AC power

• Host computer with access to software, BIOS, drives, and HP 3PAR OS

• Fibre Channel (FC) HBA, FC host cable, and power cord

• Network access

• Service Processor (SP) connectivity

• Tools

• Rail kits

• Storage system and its components

8 Getting Started

Page 9

2 Identifying Storage System Components

NOTE: The illustrations in this chapter are examples only and may not accurately represent your

storage system configuration.

Understanding Component Numbering

Due to the large number of prospective configurations, component placement and internal cabling

is standardized to simplify installation and maintenance. System components are placed in the

rack according to the principles outlined in this chapter, and are numbered according to their

order and location in the cabinet.

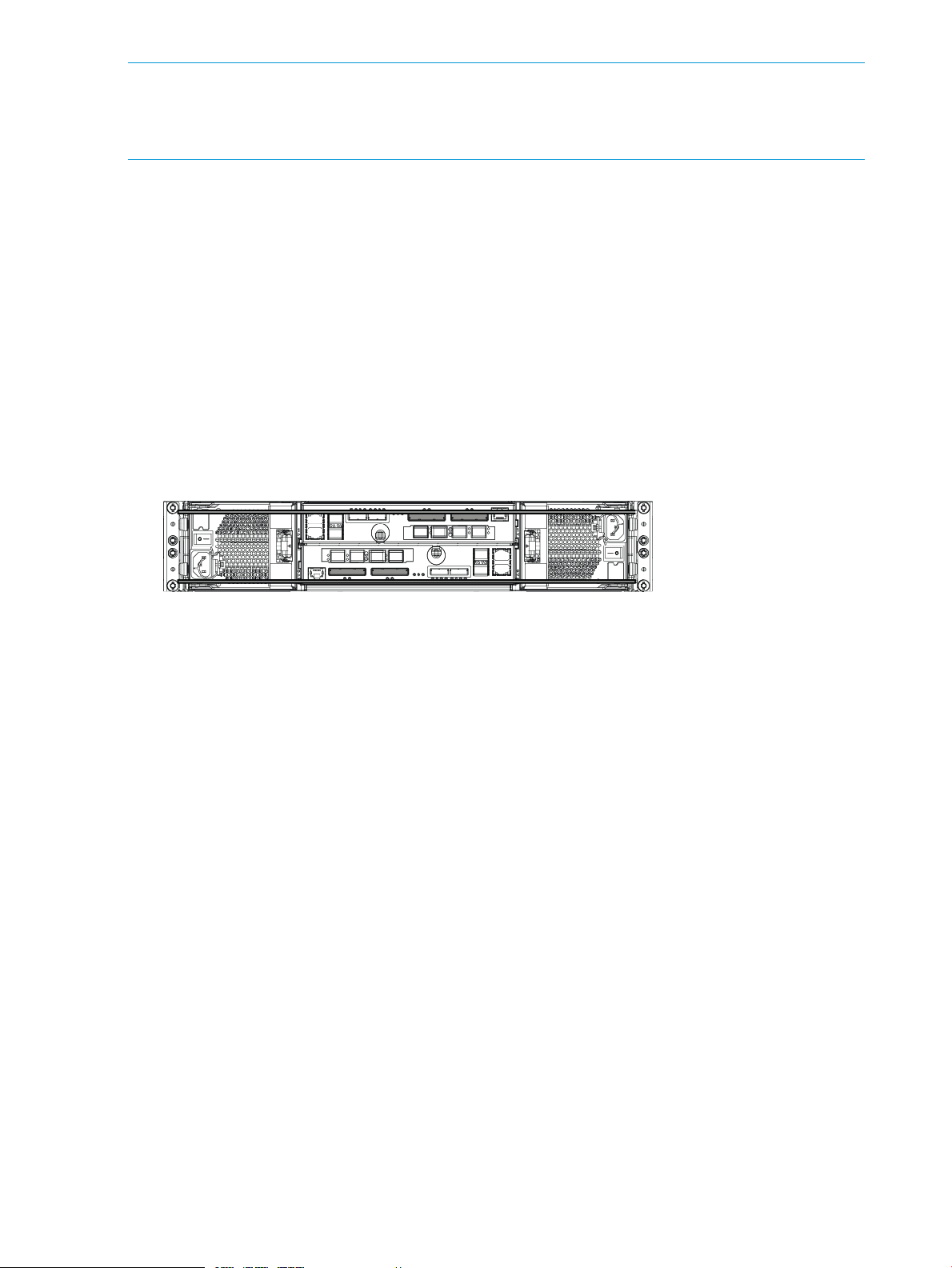

The storage system can include the following types of drive and node enclosures:

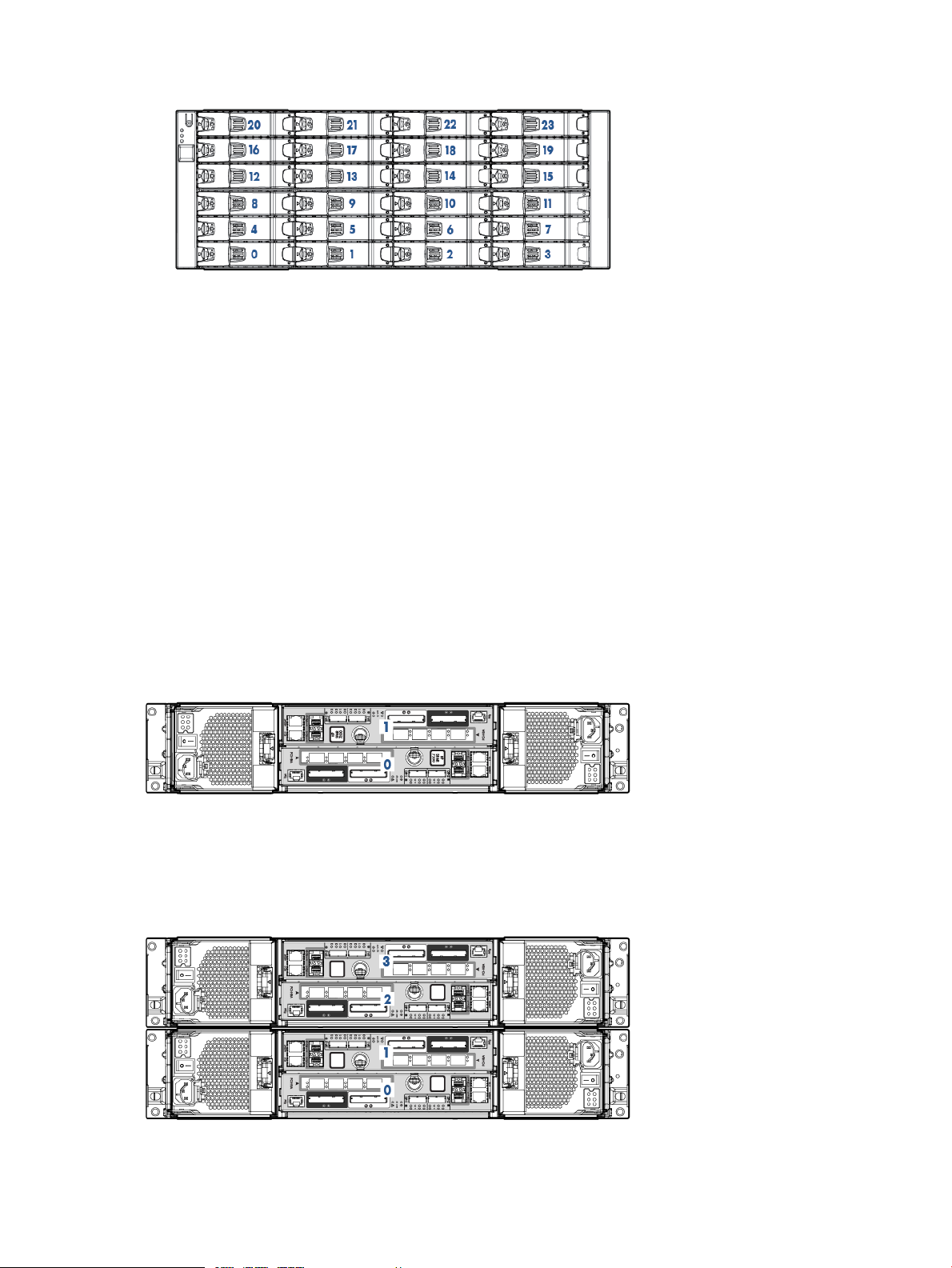

• The HP M6710 Drive Enclosure (2U24) holds up to 24, 2.5 inch small form factor (SFF) Serial

Attached SCSI (SAS) disk drives, arranged vertically in a single row at the front of the enclosure

(numbered 0 to 23). The back of the enclosure contains two 580 W power cooling modules

(PCMs) and two I/O modules. Figure 1 (page 9) shows the 2U24 drive enclosure, and also

applies to the StoreServ 7200 and 7400.

• The HP M6720 Drive Enclosure (4U24) holds up to 24, 3.5 inch large form factor (LFF) SAS

disk drives, arranged horizontally with four columns of six disk drives at the front of the

enclosure (numbered 0 to 23). The back of the enclosure contains two 580 W PCMs and two

I/O modules. Figure 2 (page 10) shows and applies only to the 4U24 drive enclosure.

• The HP 3PAR StoreServ 7200 and 7400 controller enclosures hold up to 24, 2.5 inch SFF

SAS disk drives arranged, vertically in a single row at the front of the enclosure (numbered 0

to 23). The back of the enclosure contains two 764 W PCMs and two controller nodes.

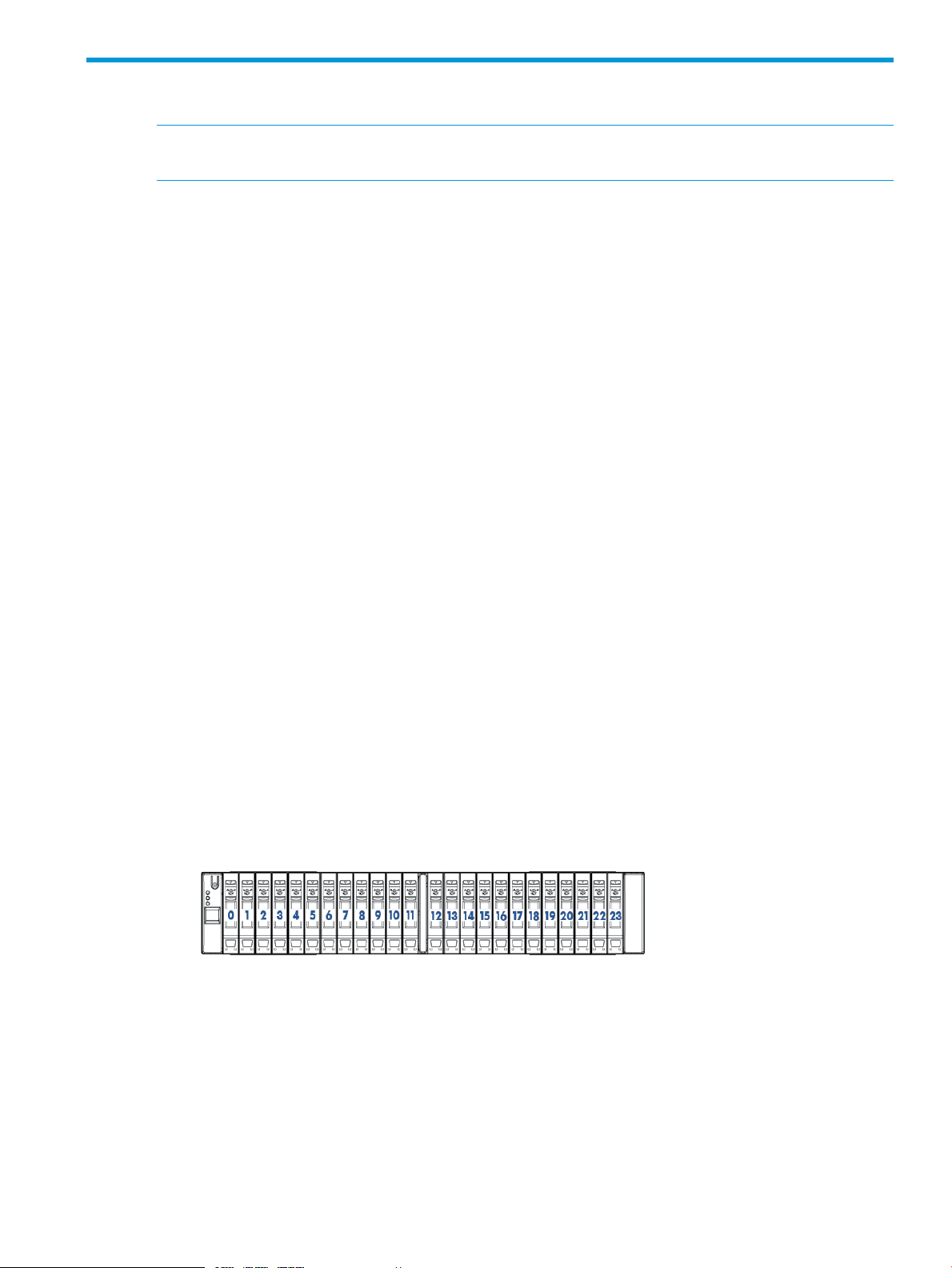

Disk Drive Numbering

There are two types of drive enclosures. The maximum number of supported drive enclosures varies

based on the model and the number of nodes.

Disk drives are mounted on a drive carrier or magazine and are located the front of the enclosures.

• 2.5-inch SFF disk drive numbering

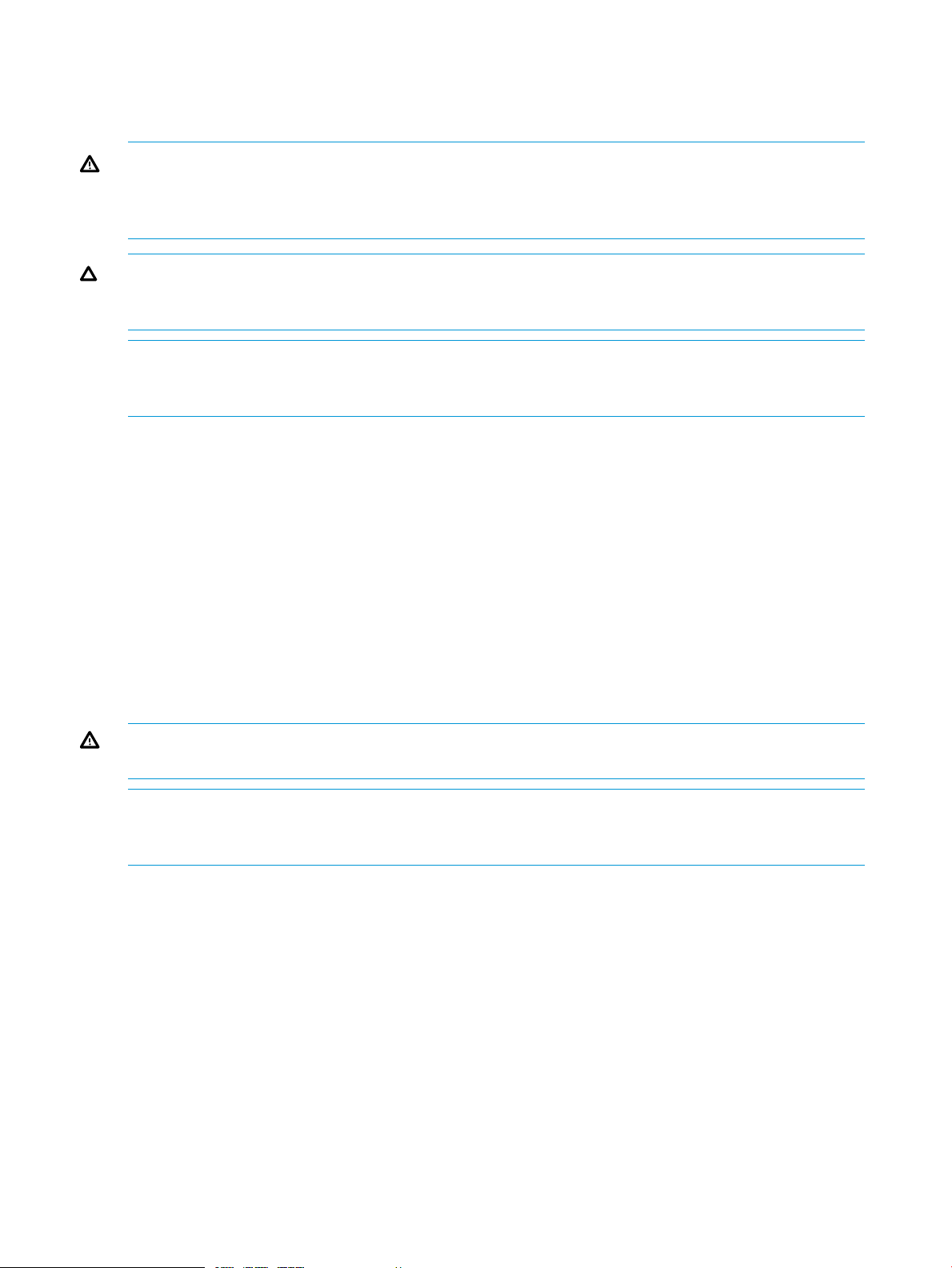

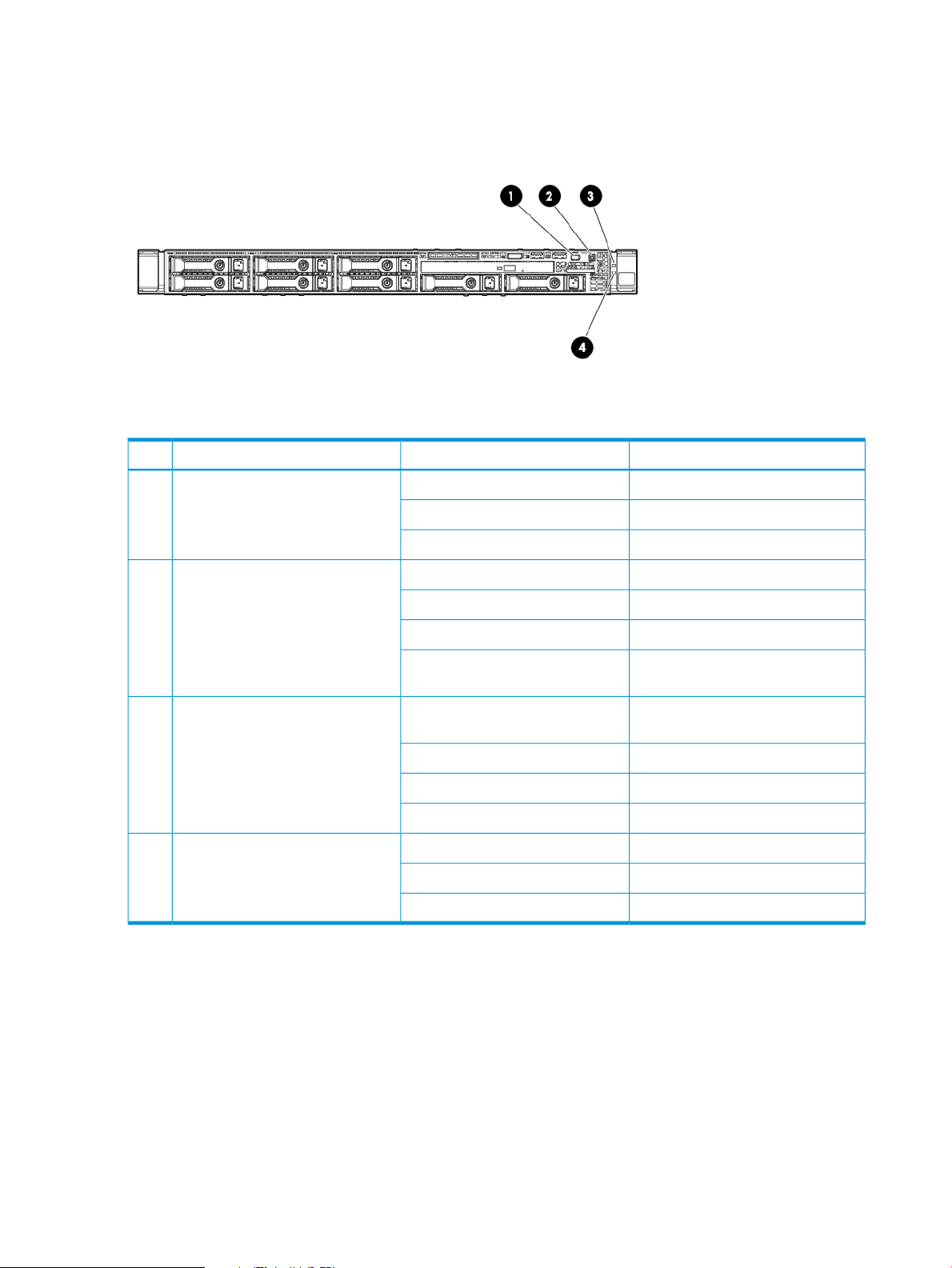

Figure 1 HP M6710 Drive Enclosure (2U24) 2.5-inch SFF

• 3.5-inch LFF disk drive numbering

Understanding Component Numbering 9

Page 10

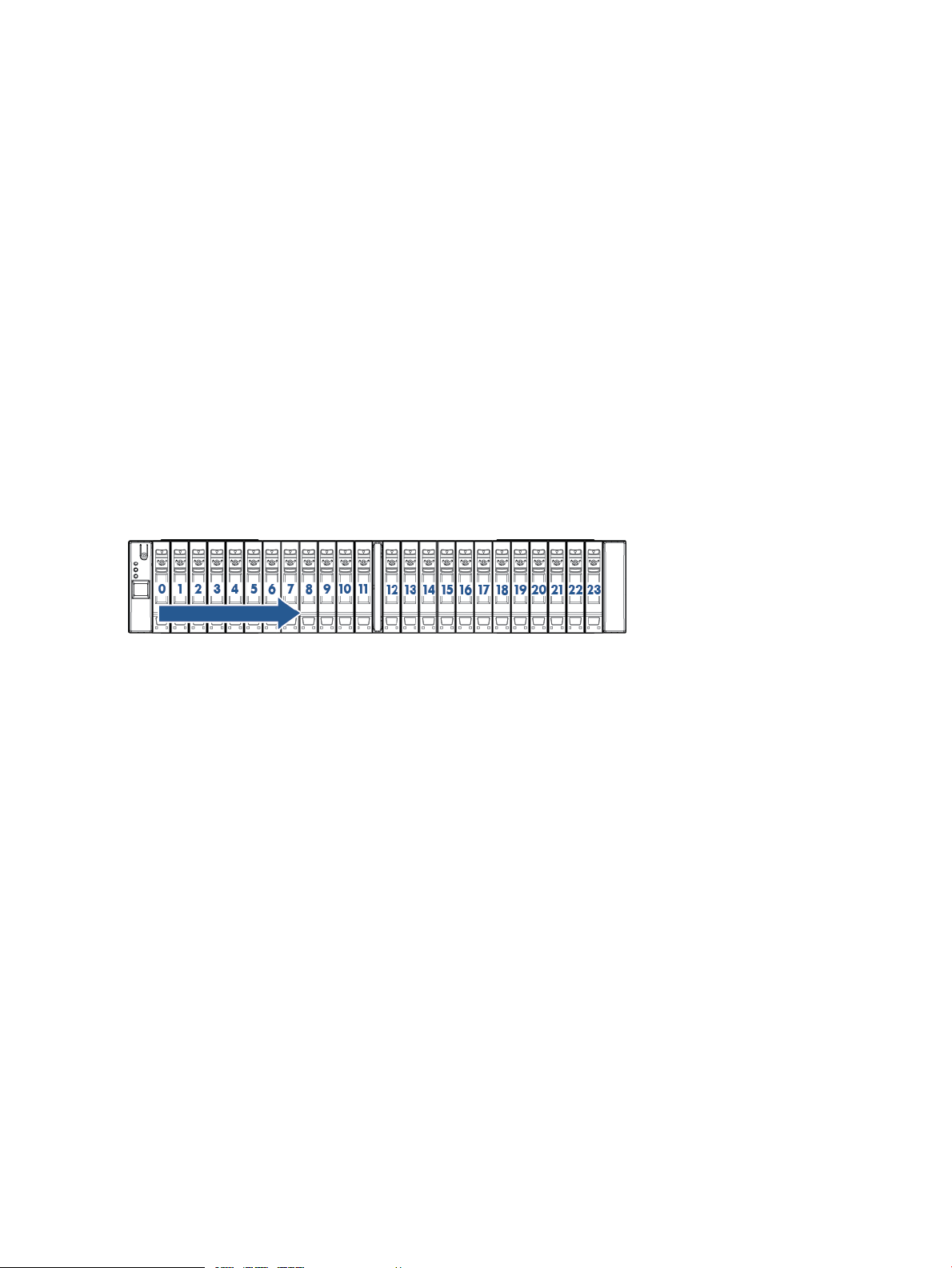

Figure 2 HP M6720 Drive Enclosure (4U24) 3.5-inch LFF

In the HP 3PAR Management Console or CLI, the enclosures are displayed as follows: DCS2 for

the 2U24 (M6710), DCS1 for the 4U24 enclosure (M6720), and DCN1 for the 7200 or 7400

controller node enclosure.

Controller Nodes

The controller node is a storage system component that caches and manages data in a system and

provides hosts with a coherent, virtualized view of the system. Controller nodes are located in the

rear of the node enclosure.

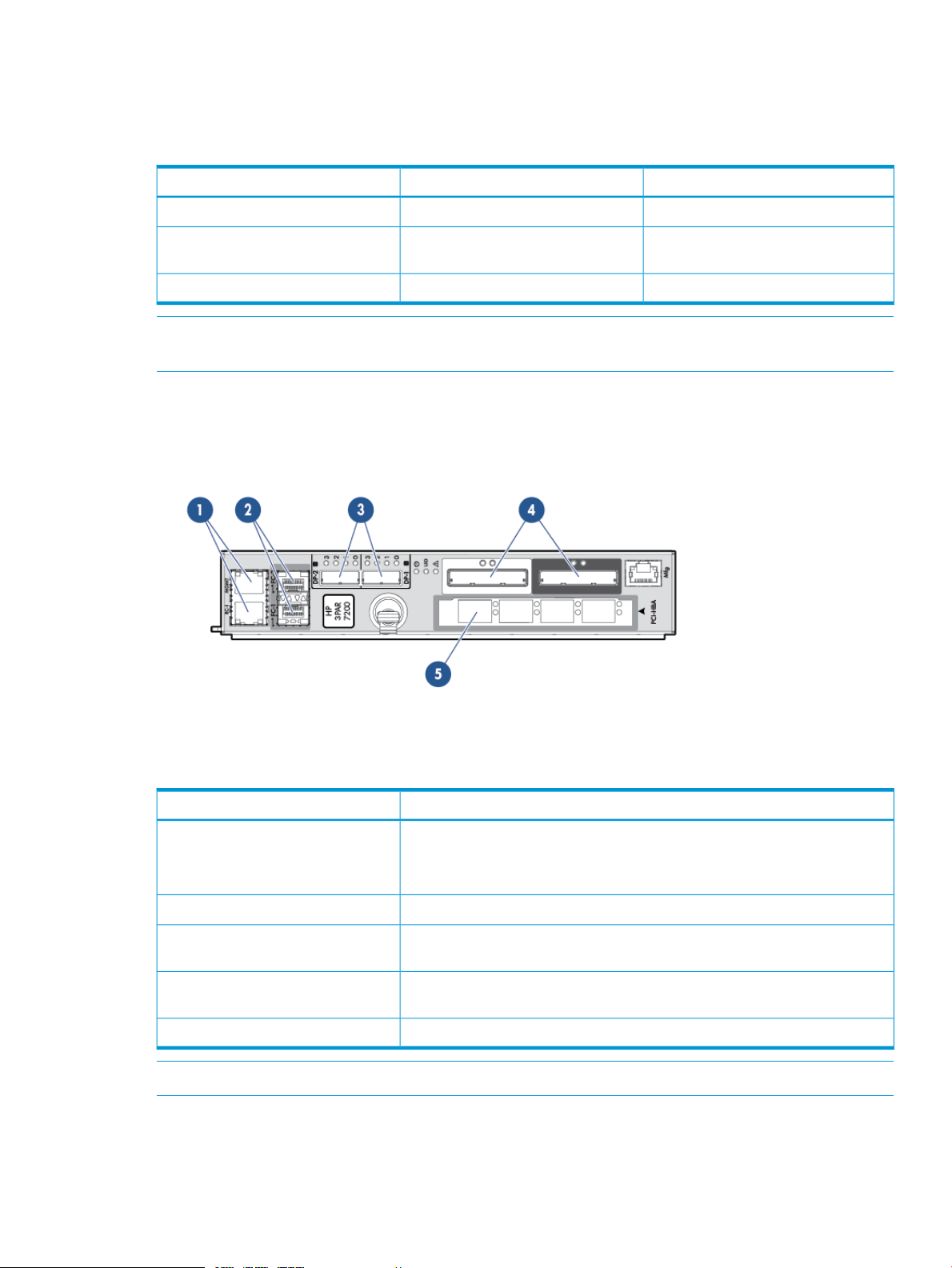

The HP 3PAR StoreServ 7200 Storage system contains two nodes: node 0 and node 1. The HP

3PAR StoreServ 7400 Storage system can contain two nodes or four nodes: node 0 and node 1

in the lower controller enclosure, and node 2 and node 3 in the upper controller enclosure in a

system with four nodes.

Figure 3 HP 3PAR StoreServ 7200 Controller Nodes

Figure 4 HP 3PAR StoreServ 7400 Controller Nodes

10 Identifying Storage System Components

Page 11

Controller Node PCIe Slots and Ports

Table 1 (page 11) describes default configurations for the HP 3PAR StoreServ 7000 Storage

system:

Table 1 Storage System Expansion Cards

adapter (CNA) only

NOTE: If you are upgrading from a two-node to a four-node configuration, you can have CNAs

installed in node 0 and node 1, and FC HBAs installed in node 2 and node 3.

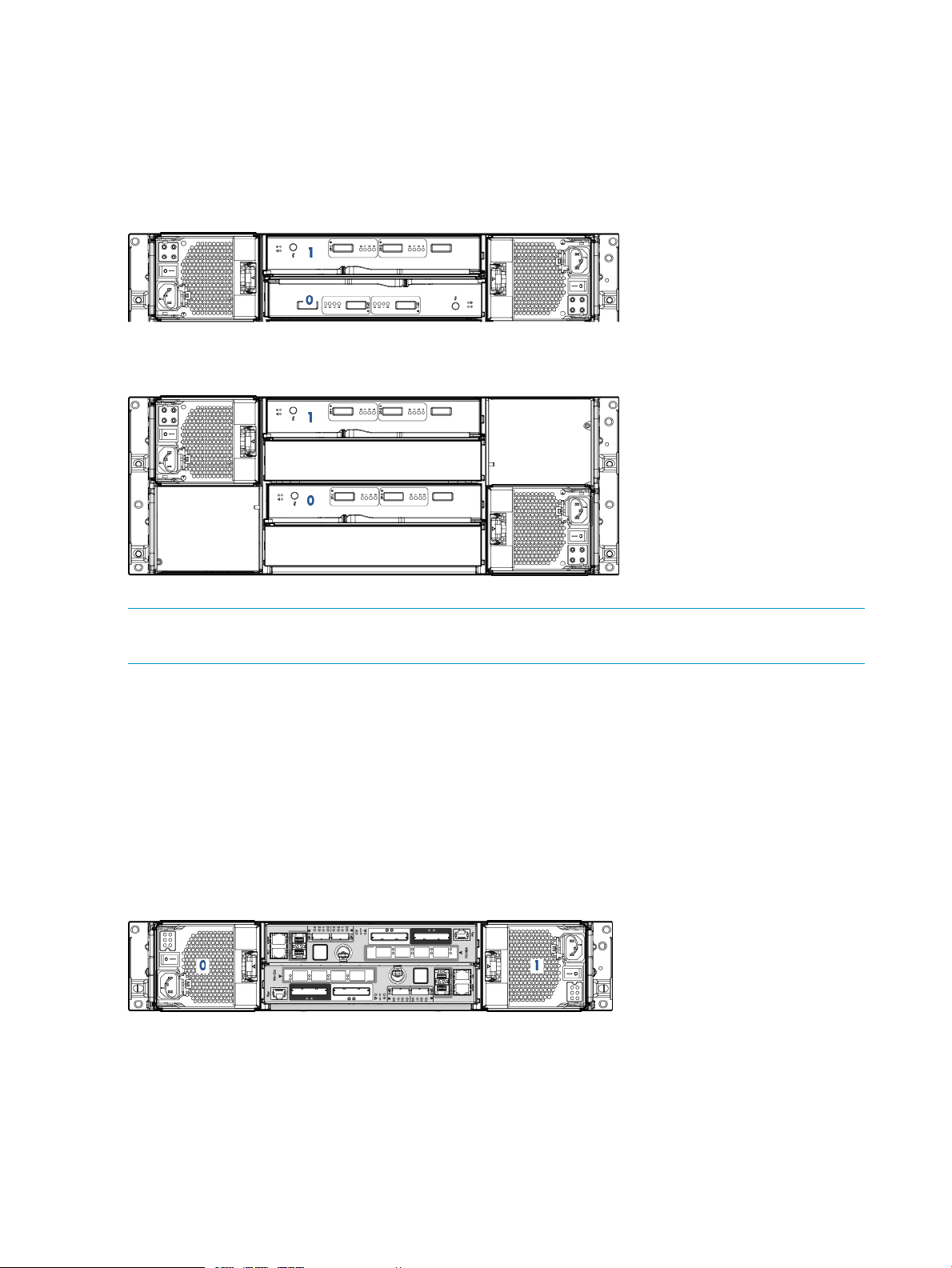

Figure 5 (page 11) shows the ports on a controller node.

Figure 5 Location of Controller Node Ports

Nodes 2 and 3Nodes 0 and 1Expansion cards

No expansion card1 FC HBA each2 FC HBAs only

No expansion card1 10 Gb/s CNA each2 10 Gb/s converged network

1 10 Gb/s CNA each1 FC HBA each2 FC HBAs + 2 10 Gb/s CNAs

Table 2 Controller Node Ports

PortItem

1

3

4

2 Ethernet

MGMT--Used to connect to the storage array management interfaces

RC--Used to connect to Remote Copy

Fibre Channel (FC-1 and FC-2)--used to connect to host systems2

SAS (DP-2 and DP-1)--used with SAS cables to connect to the drive enclosures

and I/O modules

Node Interconnect--Used with 4 directional interconnect cables that connect

the controller nodes (4-node 7400 only)

PCI-e slot for optional 4-port 8 Gb/s FC HBA or 2-port 10 Gb/s CNA5

NOTE: The MFG port is not used.

Understanding Component Numbering 11

Page 12

I/O Modules

The I/O modules connect the controller nodes to the hard drives using a SAS cable, enabling the

transfer of data between the nodes, hard drives, PCMs, and enclosures. The I/O modules are

located at the rear of the drive enclosure. There are two I/O modules per enclosure, numbered 0

and 1 from bottom to top (see Figure 6 (page 12) and Figure 7 (page 12)).

Figure 6 M6710 I/O Module

Figure 7 M6720 I/O Module

NOTE: The I/O modules are located in slots 0 and 1 of the HP M6710 and HP M6720 Drive

Enclosure.

Power Cooling Modules

The power cooling module (PCM) is an integrated power supply, battery, and cooling fan. There

are two types of PCMs:

• The 580 W is used in the drive enclosures and does not include a battery.

• The 764 W is used in the node enclosures and includes a replaceable battery.

The PCMs are located at the rear of the storage system, and on the sides of the enclosure. There

are two PCMs per enclosure. The PCMs are numbered 0 and 1 from left to right.

Figure 8 PCM Numbering for HP 3PAR 7200 (2U) Controller Node Enclosure

12 Identifying Storage System Components

Page 13

Figure 9 PCM Numbering for HP 3PAR 7400 (4U) Controller Node Enclosure

In the HP 3PAR M6720 Drive Enclosure, the two PCMs are located diagonally from one another.

The remaining PCM slots are filled with blank panels (see Figure 10 (page 13) and Figure 11 (page

13)).

Figure 10 PCM Numbering for HP M6710

Figure 11 PCM Numbering for HP M6720

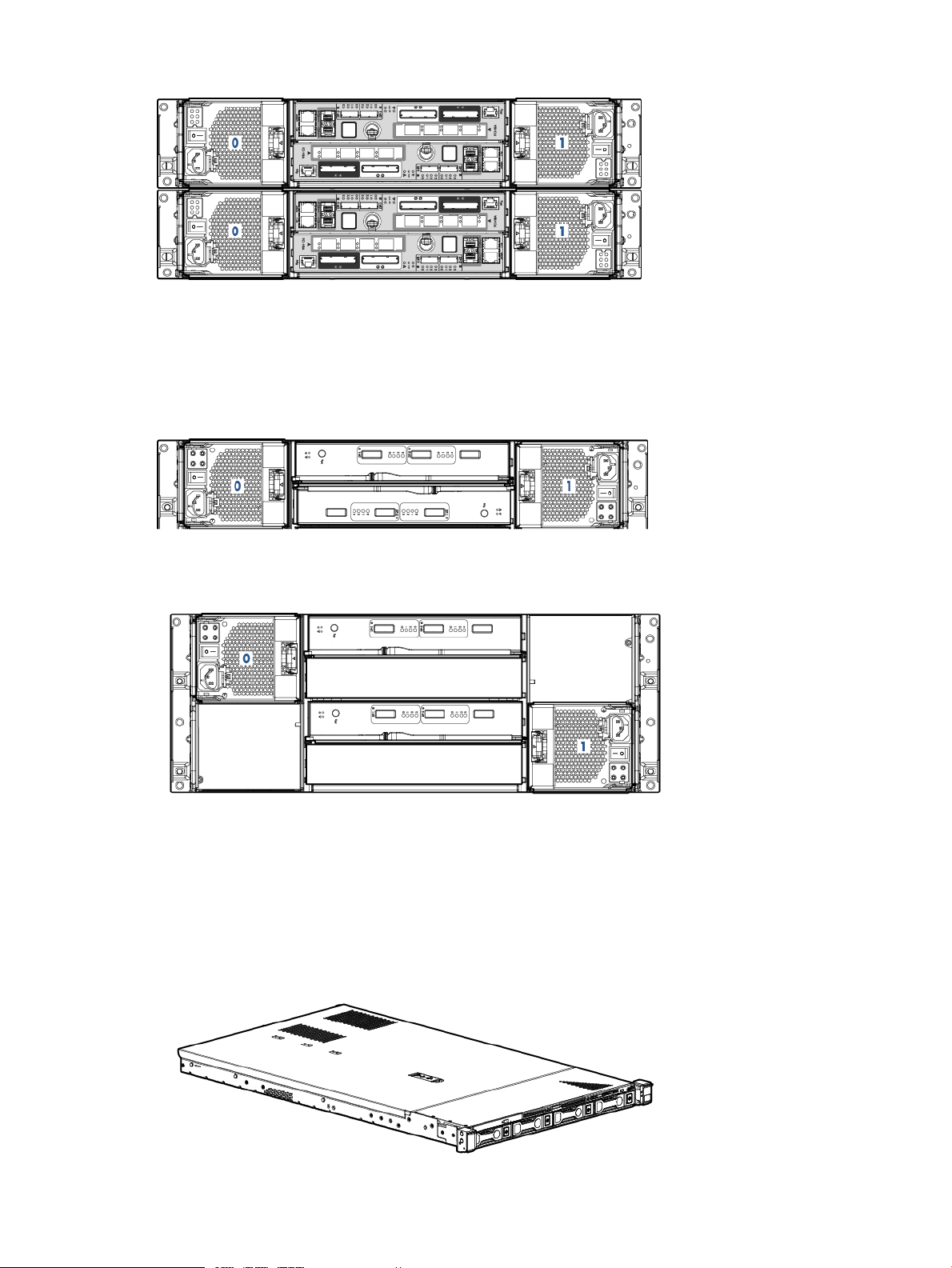

Service Processor

The HP 3PAR StoreServ 7000 Storage system can include an HP 3PAR Service Processor (SP) or

a Virtual Service Processor (VSP). If your configuration includes an SP, it is located at the bottom

of the rack under the enclosures and above the PDUs.

Figure 12 HP 3PAR Service Processor DL 320e

Understanding Component Numbering 13

Page 14

For more information, see “Connecting to a Physical Service Processor” (page 48).

Power Distribution Units

In each HP G3 rack, two PDUs are mounted horizontally at the bottom of the rack, numbered 0–1

from bottom to top. The default configuration for the HP Intelligent Series Racks is two PDUs mounted

vertically at the bottom of the rack so to provide a front-mounting unit space.

Make sure there is enough clearance for service. For example, the PDUs mounted vertically at the

back of a rack must have enough clearance to remove node and drive chassis power supples.

NOTE: Depending on the configuration, PDUs can be mounted vertically.

14 Identifying Storage System Components

Page 15

3 Setting Up a Factory-Integrated Storage System

This chapter describes the procedures for setting up a storage system that is delivered in a

factory-integrated HP cabinet with all of the components installed. Before you set up a storage

system, ensure all requirements documented in the HP 3PAR StoreServ 7000 Storage Site Planning

Manual have been met.

WARNING! Do not use this procedure if you are installing storage system components into an

existing or partially populated rack. To install storage system components into an existing rack,

see “Installing Storage System Components into a Rack” (page 19).

Unpacking the Cabinet

When unpacking the rack, refer to the unpacking diagrams on the outside of the cardboard

shipping container.

CAUTION: To avoid tipping the cabinet, one person must guide the cabinet down the ramp, with

the other person pushing from behind.

To unpack the rack:

1. Locate the front of the shipping container and unlatch the four rotary latches securing the front

panel. To unlatch the rotary latches, raise the levers and turn them counterclockwise one

half-turn.

2. Lower the front panel of the shipping container to form a ramp.

3. Remove the packing foam from the front of the storage system.

4. Remove the rack from the container.

5. Carefully guide the rack down the ramp.

6. Remove the plastic packing materials and place them into the shipping container for reuse.

Positioning the Cabinet

CAUTION: To prevent potential damage to system equipment, do not adjust the position of the

cabinet when the power is on.

Position the cabinet in the operating location. If the operating location has raised floor tiles with

cutouts to facilitate cable routing, position the cabinet over the cutouts in the tiles. See the HP 3PAR

StoreServ 7000 Storage Site Planning Manual for more information on the structural considerations

for using raised flooring.

After positioning the storage system, use the four leveling feet to stabilize the cabinet and prevent

movement during operation:

1. Using an adjustable wrench, turn each leveling foot clockwise until the weight of the rack rests

on the leveling feet instead of the casters.

2. Using the wrench, lock the leveling feet in place by turning the locking nut on each foot

counterclockwise until tight.

3. Verify the rack is stationary.

For more information on final positioning, see “Repositioning the Storage System” (page 37).

Verify the Cabling

The cabling for a factory-integrated storage system is complete. You must plug in the power cords

and install the host and Ethernet cables.

Unpacking the Cabinet 15

Page 16

NOTE: In a four-node 7400 system, two cable management brackets have Velcro straps to hold

the cables. You can remove and discard these brackets, but HP recommends saving them for future

use. To remove the cable management brackets, loosen the Torx screws and unlatch the Velcro

straps to free the cabling.

Installing and Removing the Cable Restraint Shipping Brackets

The cable restraint shipping brackets support the connected data cables and connectors during

transport. HP recommends installing the brackets before transporting the system to another location

to prevent damage to the connectors. The brackets are not required if the system is in a stationary

position. Retain and store the brackets if they are not being used.

Installing the Brackets

1. Connect the data cables to the enclosure.

2. Attach the hook and loop straps to the brackets.

3. Align the brackets so they parallel to the edges of the enclosure link connectors (see

Figure 13 (page 16)). Adjust the brackets to the height of the screw holes located on the side

rails.

Figure 13 Aligning the Brackets

16 Setting Up a Factory-Integrated Storage System

Page 17

4. Attach the brackets to the side rails.

Figure 14 Attaching the Brackets to the Side Rails

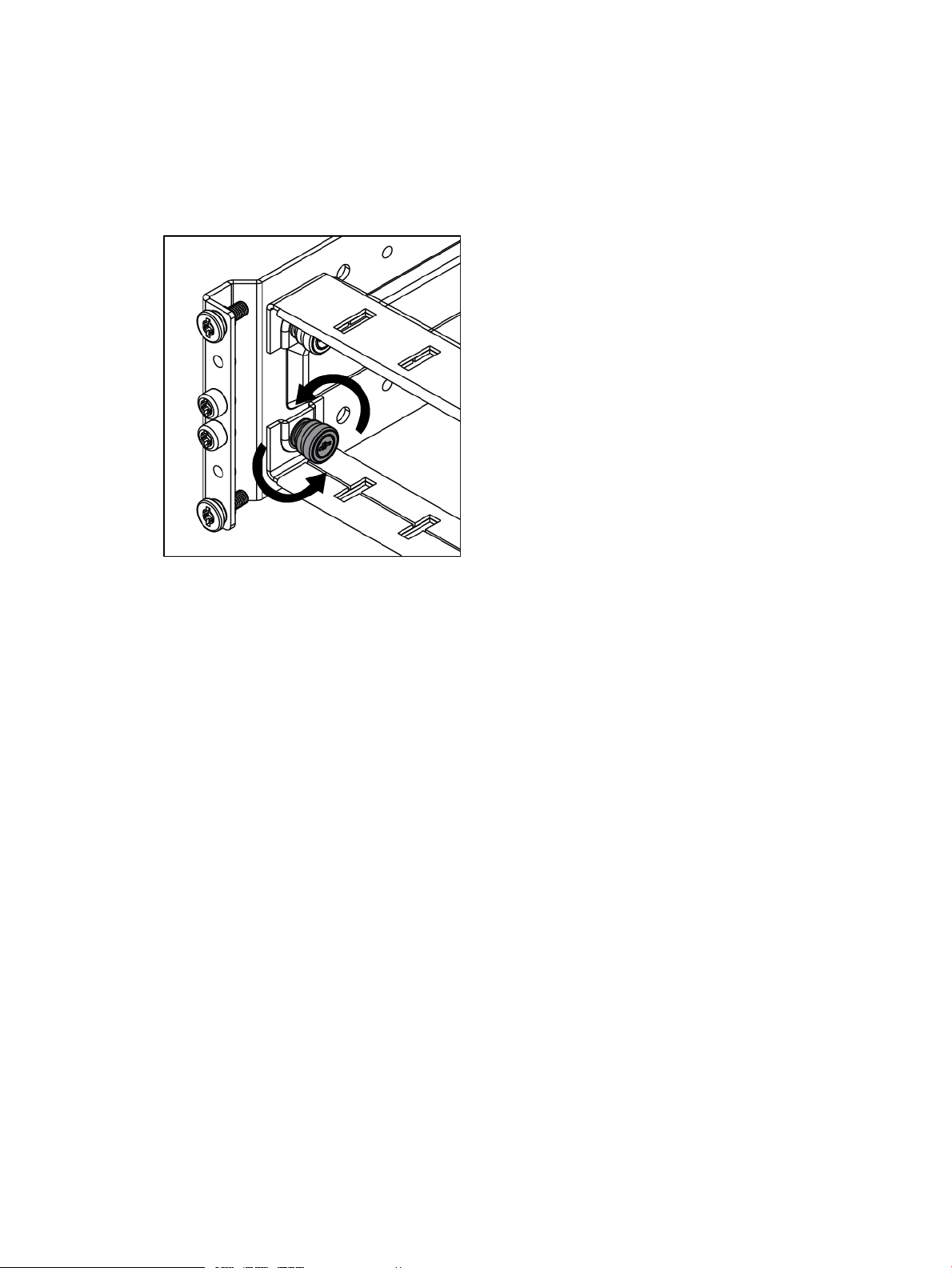

5. Tighten the captive screws (see Figure 15 (page 17)).

NOTE: Make sure the brackets are aligned and leveled with the link connectors before

tightening the captive screws. HP recommends tightening the screws to 19 in-lbs.

Figure 15 Tightening the Captive Screws

Installing and Removing the Cable Restraint Shipping Brackets 17

Page 18

Removing the Brackets

Remove the cable restraint shipping brackets only when the cabinet is in its final location.

Procedure 1

1. Remove the data cables from the hook and loop straps.

2. Loosen the captive screws (see Figure 16 (page 18)).

Figure 16 Loosening the Captive Screws

3. Remove the brackets. Be careful not to damage the attached data cables.

Now continue on to“Verifying Setup and Powering On the Storage System” (page 37) and verify

setup before powering on the storage system and initializing the SP and storage system software.

18 Setting Up a Factory-Integrated Storage System

Page 19

4 Installing Storage System Components into a Rack

This chapter describes the procedures for installing storage system components in an existing rack.

Before you set up a storage system, ensure that all requirements documented in the HP 3PAR

StoreServ 7000 Storage Site Planning Manual have been met.

Follow these procedures if you are installing any of the following storage system components in

an existing or partially populated rack:

• PCIe adapters

• Disk Drive enclosures

• Controller node enclosures

• Cables

• Disk drives

To set up a storage system delivered in a fully loaded HP cabinet, see “Setting Up a

Factory-Integrated Storage System” (page 15).

Unpacking Disk Drive and Controller Node Enclosures

The enclosure includes nodes, I/O modules, and PCMs.

CAUTION: The enclosure is heavy. Lifting, moving, or installing it requires two people.

To unpack the enclosure:

1. Cut open the cardboard box and remove the top.

2. Remove the rail kit.

3. Remove the packing foam around the enclosure.

4. Remove the enclosure from the box.

Installing the Rail Kit

Before you install the enclosure in the rack, you must mount the two rail shelves to the rack.

To mount a one unit (1U) rail shelf (used for installing a SP) to the rack, follow the installation

instructions included with the rail kit.

Table 3 (page 19) lists the rail kit part numbers for each type of installation.

Table 3 Part Numbers

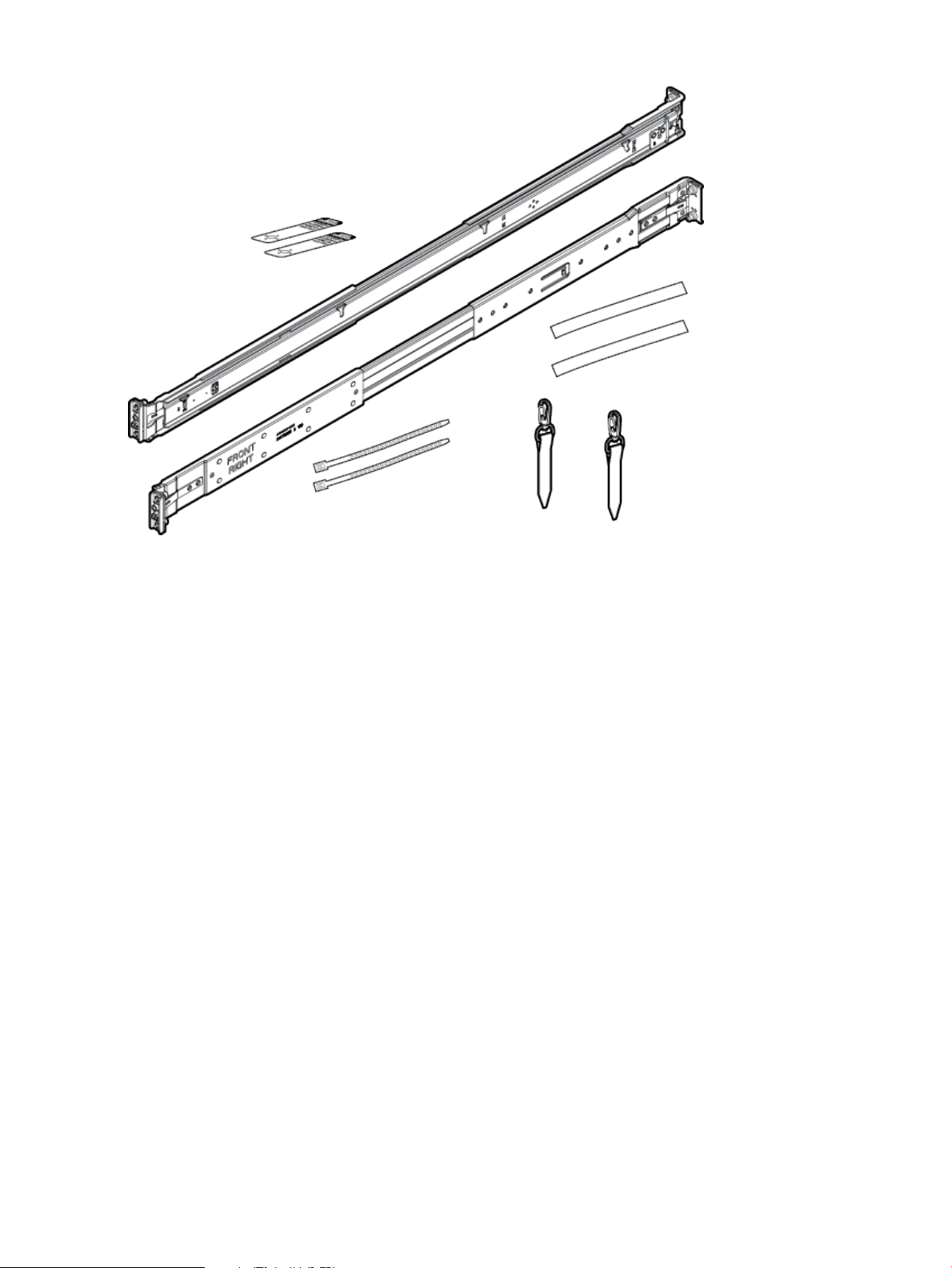

NOTE: For more information about the rail kit assembly, see “Rail Kits” (page 83).

The rail kit contains two rails, two middle support brackets, and T-25 Torx screws. The rail channels

are mounted to the inside of the rack using two shoulder screws at each end of the rack (four

screws per rail), and a middle support bracket for mounting between the adjustable rails. Installing

the middle support bracket applies only to the 2U and 4U enclosures. The following text is imprinted

on both ends of the rails: FRONT-R and FRONT-L.

4U Enclosure2U Enclosure

Rail Kit Assembly 692982-001Rail Kit Assembly 692981-001

NOTE: The middle support bracket is only used in an HP rack with posts that extend to a depth

of 29-inches. Install the middle support bracket when transporting the system to another location.

Retain and store the middle support brackets if they are not being used.

Unpacking Disk Drive and Controller Node Enclosures 19

Page 20

Mounting a 2U rail shelf onto the rack

1. Determine the location of the directional-specific rail matches with the side of a rack post.

The following text is imprinted on both ends of the rails: FRONT-R and FRONT-L.

2. Align one end of the rail channel with the holes of the rack post, and then push to seat the

locating pins in the rack.

3. Expand the rail to connect to the other end of rack post.

4. Secure the front and rear of the rail assembly to the rack post using four T25 Torx shoulder

screws (two in front, two in back) in the top and bottom holes. Tighten the shoulder screws

with a torque of 19 in-lbs.

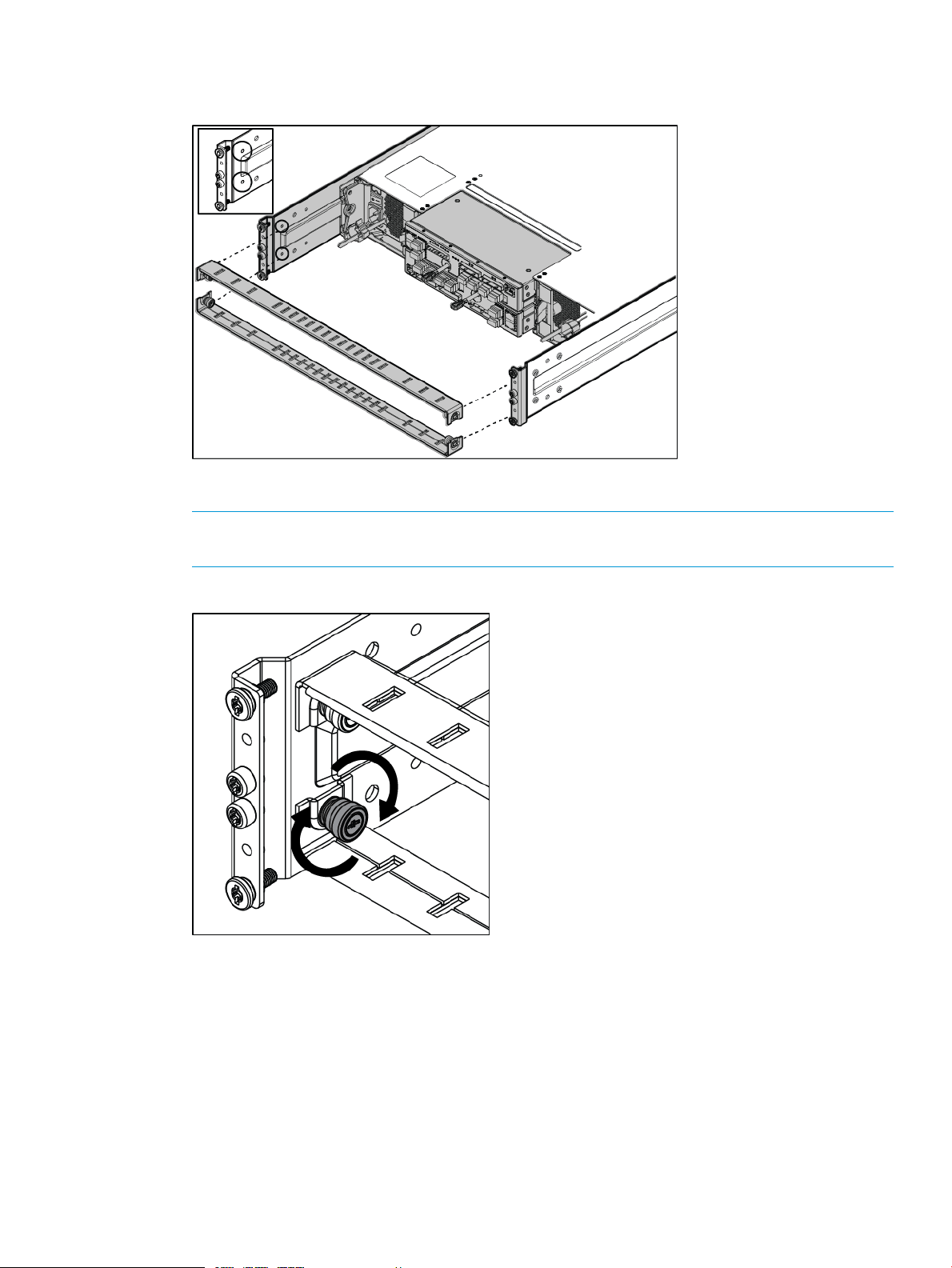

Figure 17 Mounting the 2U Rail Shelf

5. Repeat steps 1 through 4 for the other rail.

6. Check both sides at the front and back of the rack to ensure all screws are installed properly.

Mounting a 4U rail shelf onto the rack

1. Verify each directional-specific rail matches with the side of a rack post.

The following text is imprinted on both ends of the rails: FRONT-R and FRONT-L.

2. Align one end of the rail channel with the holes of the rack post, and then push to seat the

locating pins in the rack.

3. Expand the rail to connect to the other end of rack post.

4. Secure the front and rear of the rail assembly to the rack post using four T25 Torx shoulder

screws (two in front, two in back) in the top and bottom holes. Tighten the shoulder screws

with a torque of 19 in-lbs.

20 Installing Storage System Components into a Rack

Page 21

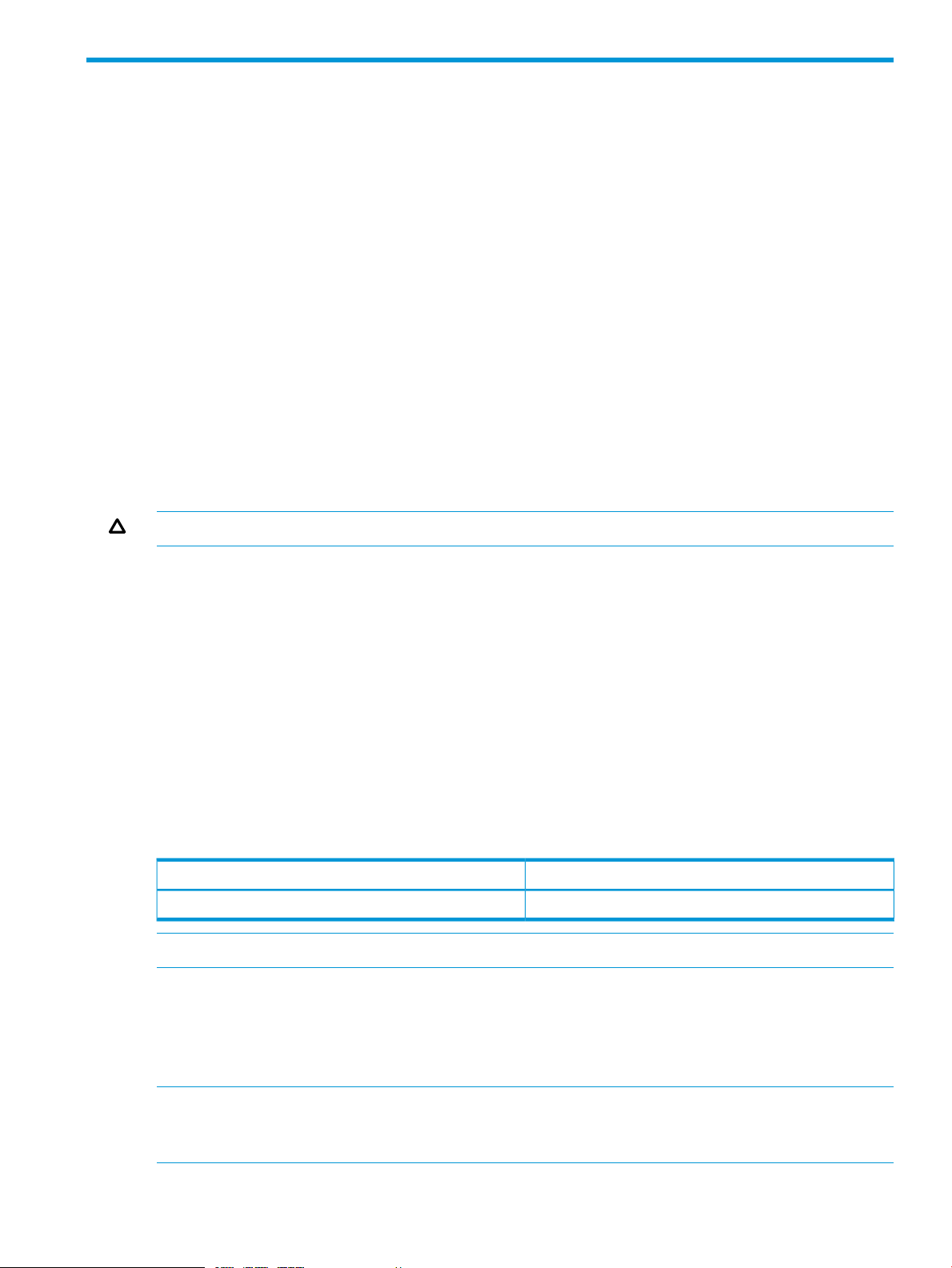

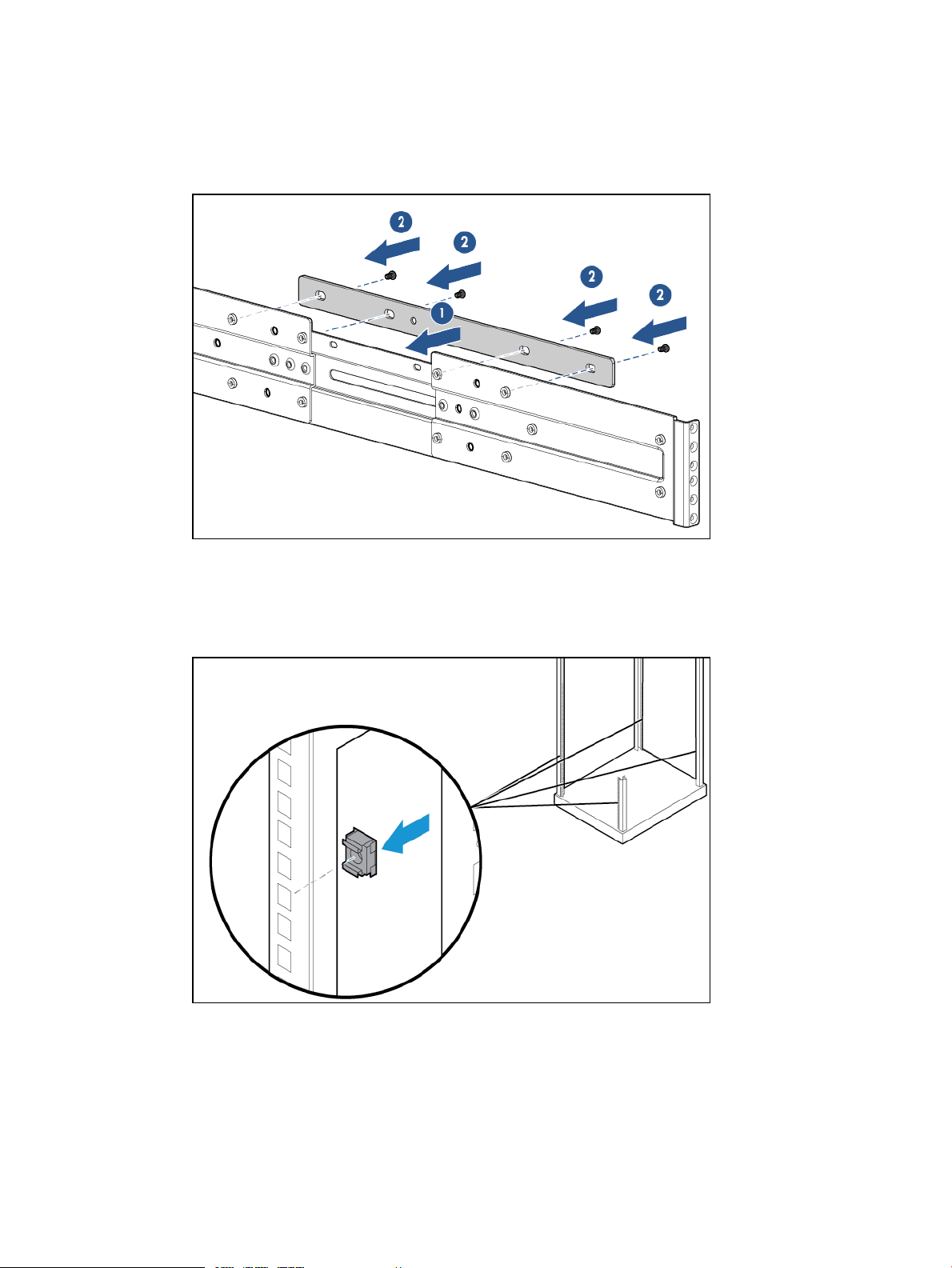

5. Install the middle support bracket before transporting:

a. Align the middle support bracket holes with the top holes of the rail(s). The orientation of

the middle support bracket is neutral.

b. Insert and tighten screws.

Figure 18 Installing the Middle Support Bracket

6. Repeat steps 1 through 5 for the other rail.

7. Snap one cage nut into the rack hole two positions above the rail on both sides.

Figure 19 Installing the Cage Nut

8. Check both sides at the front and back of the rack to ensure all screws are installed properly.

Installing the Rail Kit 21

Page 22

Installing PCIe Adapters in the Controller Nodes

PCIe adapters connect the controller nodes to host computers and disk drives. Installing or upgrading

PCle adapters involves adding additional supported types of adapters or replacing existing adapters.

WARNING! Fibre Channel HBA and iSCSI CNA upgrades on the HP 3PAR StoreServ 7400

Storage system must be serviced by authorized service personnel and cannot be done by a customer.

Contact your local service provider for assistance. Upgrades on the HP 3PAR StoreServ 7200

Storage systems may be performed by the customer.

CAUTION: To avoid possible data loss, only one node at a time should be removed from the

storage system. To prevent overheating, node replacement requires a maximum service time of 30

minutes.

NOTE: When installing the first two HBAs or CNAs in a controller node, install the HBAs in node

0 and node 1. If two FC HBAs and two CNA HBAs are added to a controller node, install the FC

HBAs in node 0 and node 1, and then install the CNA HBAs in node 2 and node 3.

1. Remove the controller node and then the cover.

2. If a PCIe Adapter Assembly is already installed, do the following steps:

a. Remove the PCIe Adapter Assembly, and disconnect the PCIe Adapter from the riser card.

b. Install the new PCIe Adapter onto the riser card, and insert the assembly into the node.

3. If a PCIe Adapter is not installed, do the following steps:

a. Remove the PCIe Adapter riser card.

b. Install the new PCIe Adapter onto the riser card, and insert the assembly into the node.

4. Replace the node cover and the node.

Installing Enclosures

The storage system can contain the following types of drive and controller node enclosures: 2U

and 4U enclosures.

WARNING! The enclosure is heavy. Lifting, moving, or installing the enclosure requires two

people.

NOTE: When installing a 7400 (two-node) enclosure, two units of space must be reserved above

the enclosure for an upgrade to a four-node system. Labels are provided to secure on two filler

panels to reserve this space.

To install an enclosure on the rack:

22 Installing Storage System Components into a Rack

Page 23

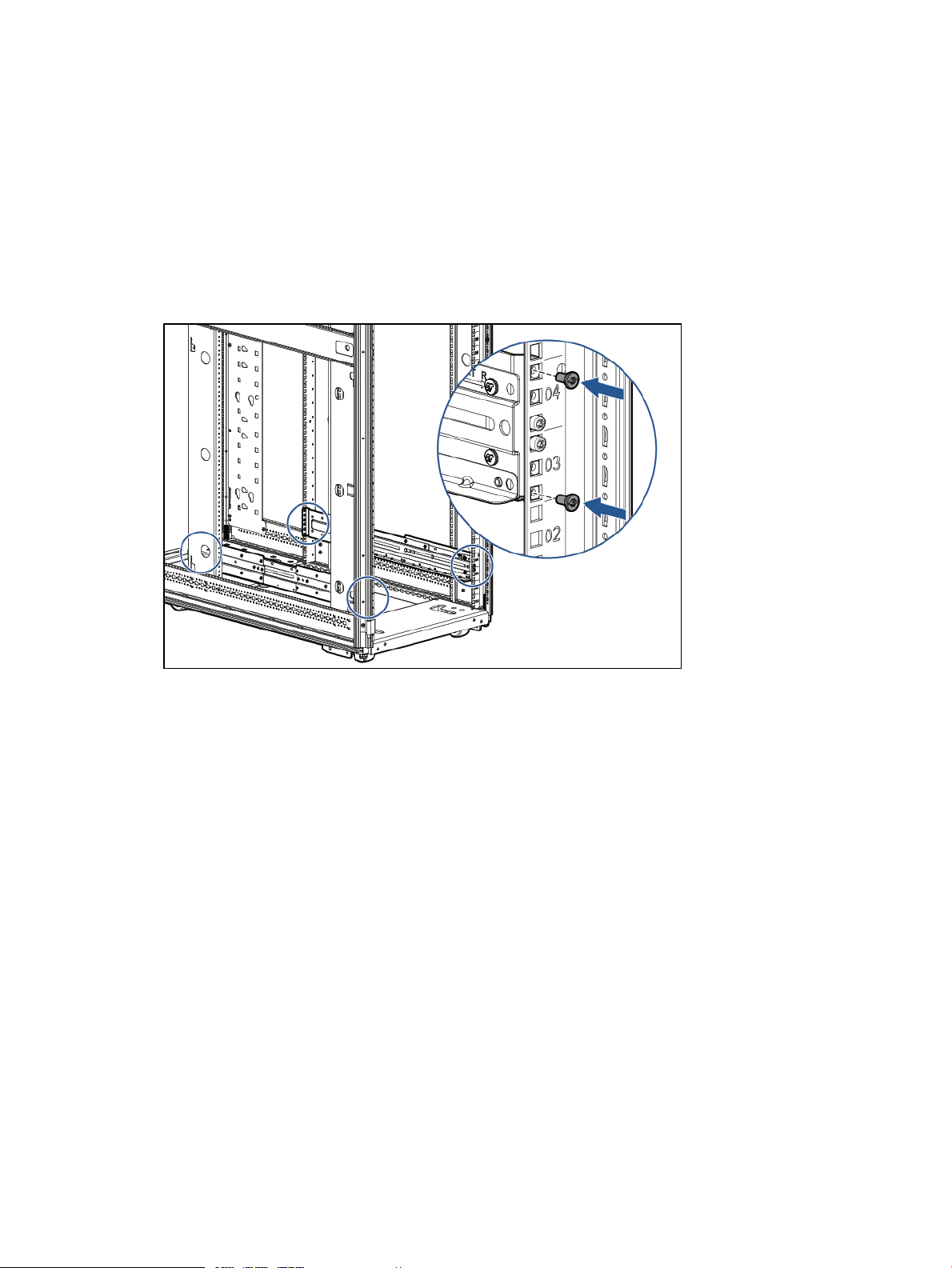

1. Determine that the enclosure is oriented correctly by looking at the rear of the enclosure. Verify

the node numbering by reviewing the controller node label on both edges of the enclosure

slot.

Figure 20 Verify Controller Node Numbering

2. At the front of the enclosure, remove the yellow bezels on each side of the enclosure to expose

the mounting holes.

3. Slide the enclosure onto the rail shelves. Use both hands to handle the enclosure.

4. At the front of the enclosure, do one of the following steps:

• For 2U enclosures, insert one Torx M5 (long) screw into the mounting hole on each side

to secure the enclosure to the rack. Tighten the screws to a torque level of 13 in-lbs.

• For 4U enclosures, insert two Torx M5 (long) screws into the mounting holes on each side

to secure the enclosure to the rack (on each side, one screw goes into the rail and the

other to the cage nut). Tighten the screws to a torque level of 13 in-lbs.

5. At the rear of the enclosure, tighten the two M5 Torx (short) screws on the sides of the enclosure.

Tighten the screws to a torque level of 13 in-lbs. See Figure 21 (page 23).

Figure 21 Tightening the Hold-Down Screw

NOTE: Due to limited access, use a short length or right angle torx bit screwdriver to tighten

the hold-down screws.

6. Reinsert the yellow bezels on each side of the enclosure.

7. Connect power and data cables.

CAUTION: Do not power on without completing the remainder of the physical installation

or upgrade.

Installing Enclosures 23

Page 24

8. Remove the blank filler panels before Installing disk drives into the slots.

9. To ensure proper thermal control, install blank filler panels into any empty slots.

Guidelines for Installing Disk Drives in Disk Enclosures

This section provides information about the requirements and installation order for disk drives in

SFF and LFF drive enclosures.

Only 2.5 inch drives can be installed in HP M6710 (2U) and M6720 (4U) controller node and

drive enclosures. The 3.5 inch drives can be installed only in 4U M6720 drive enclosures.

For all drive enclosures, the slots should be balanced. For example, if two drives are added to

DP-1, two drives should be added to a drive enclosure attached to DP-2. Drives should be added

so that all enclosures are balanced with an even number of drives in each enclosure.

For all drive enclosures, the proper system temperature must be maintained. To ensure proper

thermal control, blank filler panels must be installed in any slots without drives.

Guidelines for Allocating and Loading Order (2.5 inch SFF disk drive)

For a node or M6710 Drive Enclosure, drives must be added in identical pairs, starting from slot

0 on the left and filling to the right, leaving no empty slots between drives. The best practice when

upgrading or building a system is to add the same number of identical drives to every drive

enclosure in the system, with a minimum of three disk drive pairs in each drive enclosure.

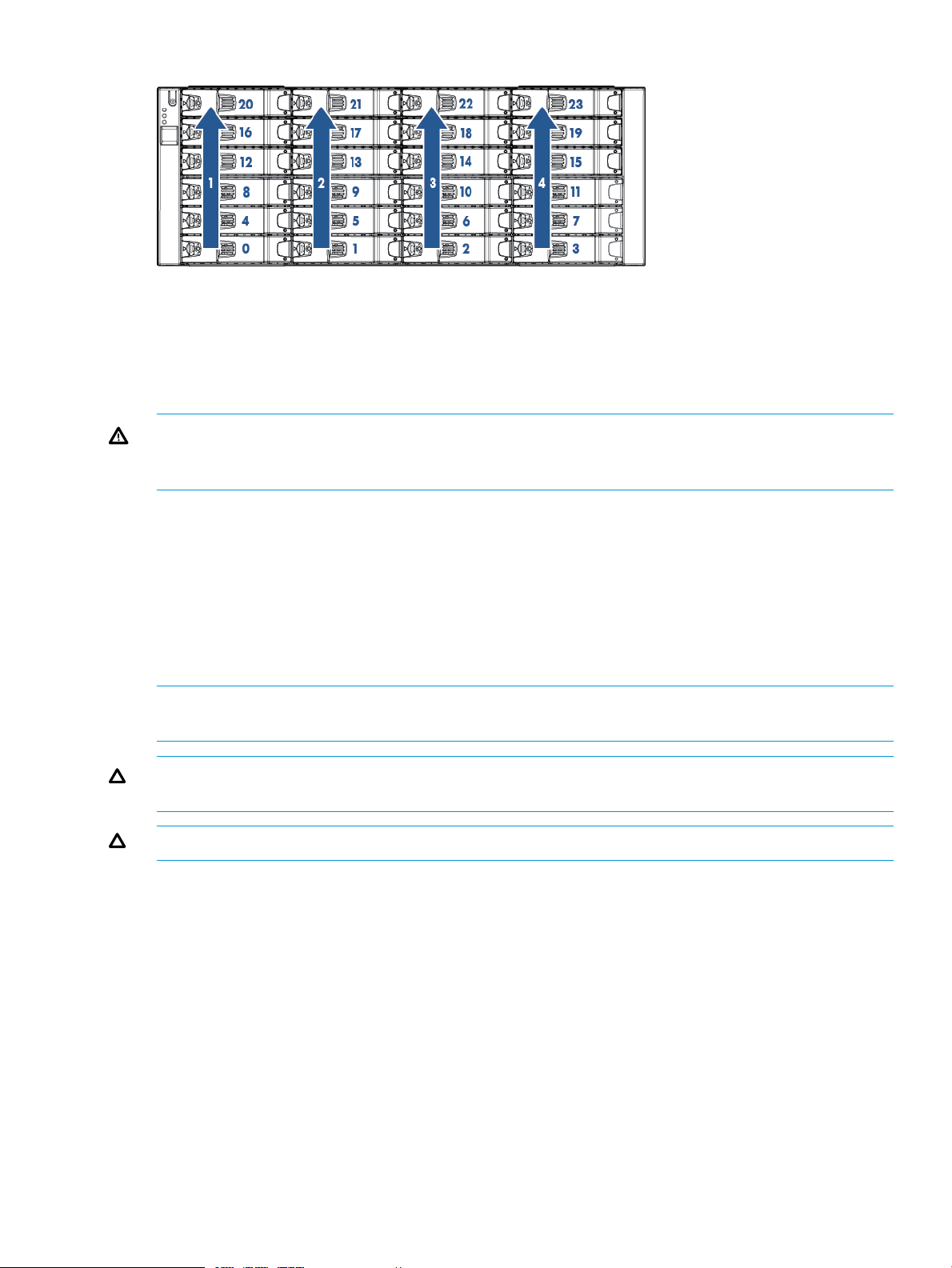

Figure 22 HP M6710 Drive Enclosure (2U24) Disk Drive Placement Order

Guidelines for Allocating and Loading Order (3.5 inch Large Form Factor

(LFF) disk drive)

Columns of drives in an HP M6720 Drive Enclosure must be of the same device type (NL or SSD).

NL disk drives and SSDs must not be mixed in the same column. For an HP M6720 Drive Enclosure,

drives must be installed in identical pairs, starting from the slot at the bottom of the left column and

filling up with drives of the same type, leaving no empty slots between drives in the column. Populate

drives in the columns from bottom to top and from left to right.

The best practice when upgrading or building a system is to add the same number of identical

drives to every HP M6720 Drive Enclosure in the system, with a minimum of two drives added to

each LFF chassis. The minimum supported upgrade for a 7400 with one or more expansion HP

M6720 Drive Enclosures is two identical drives added to adjacent slots in the same column of the

same chassis. If there are more than one expansion enclosure in the system, add the drives in pairs

so they are balanced across the device ports, and then added to enclosures on the same port.

The LFF drives added to the HP M6720 Drive Enclosure on each node pair should be balanced

across node pairs, then across device ports on each node pair, and finally by enclosures on the

same port.

24 Installing Storage System Components into a Rack

Page 25

Figure 23 M6720 Drive Enclosure (4U24) Disk Drive Placement Order

Guidelines for Allocating and Loading Order (Mixed SFF and LFF disk drives)

In a storage system with mixed HP M6710 and M6720 Drive Enclosures there is a minimum of

three pairs of drives for each drive enclosure. Additional upgrades can include all SFF, LFF or a

mixture of SFF and LFF drives but, they must be in pairs of the same drive type. Follow the loading

order as in the sections above for SFF and LFF drives.

WARNING! If the StoreServ is enabled with the Data-at-Rest (DAR) encryption feature, only use

the self-encrypting drives (SED). Using a non-self-encrypting drive may cause errors during the

upgrade process.

For information about encrypting the hard drives with an enhanced security feature known as

Data-At-Rest (DAR) encryption, see “Enhancing Security with Data Encryption” (page 86).

For information about adding drive enclosures, see “Adding Disk Drives and Expansion Drive

Enclosures” (page 87).

Installing a Disk Drive

Before beginning this procedure, review how to load the drives based on drive type, speed, and

capacity. See “Guidelines for Installing Disk Drives in Disk Enclosures” (page 24).

NOTE: To avoid any cabling errors, all drive enclosures must have at least one or more hard

drives installed before powering on the enclosure.

CAUTION: Blank disk drive filler panels are provided and must be used if all slots in the enclosure

are not filled with disk drives.

CAUTION: To avoid potential damage to equipment and loss of data, handle disk drives carefully.

Each disk drive includes a green and amber LED on the front to indicate disk drive status.

Installing a 2.5 inch Disk Drive (SFF)

1. Press the handle latch to open the handle.

2. Insert the disk drive into the enclosure with the handle opened from the top in the vertical

position.

3. Slide the disk drive into the enclosure until it engages. Push firmly until it clicks.

Guidelines for Installing Disk Drives in Disk Enclosures 25

Page 26

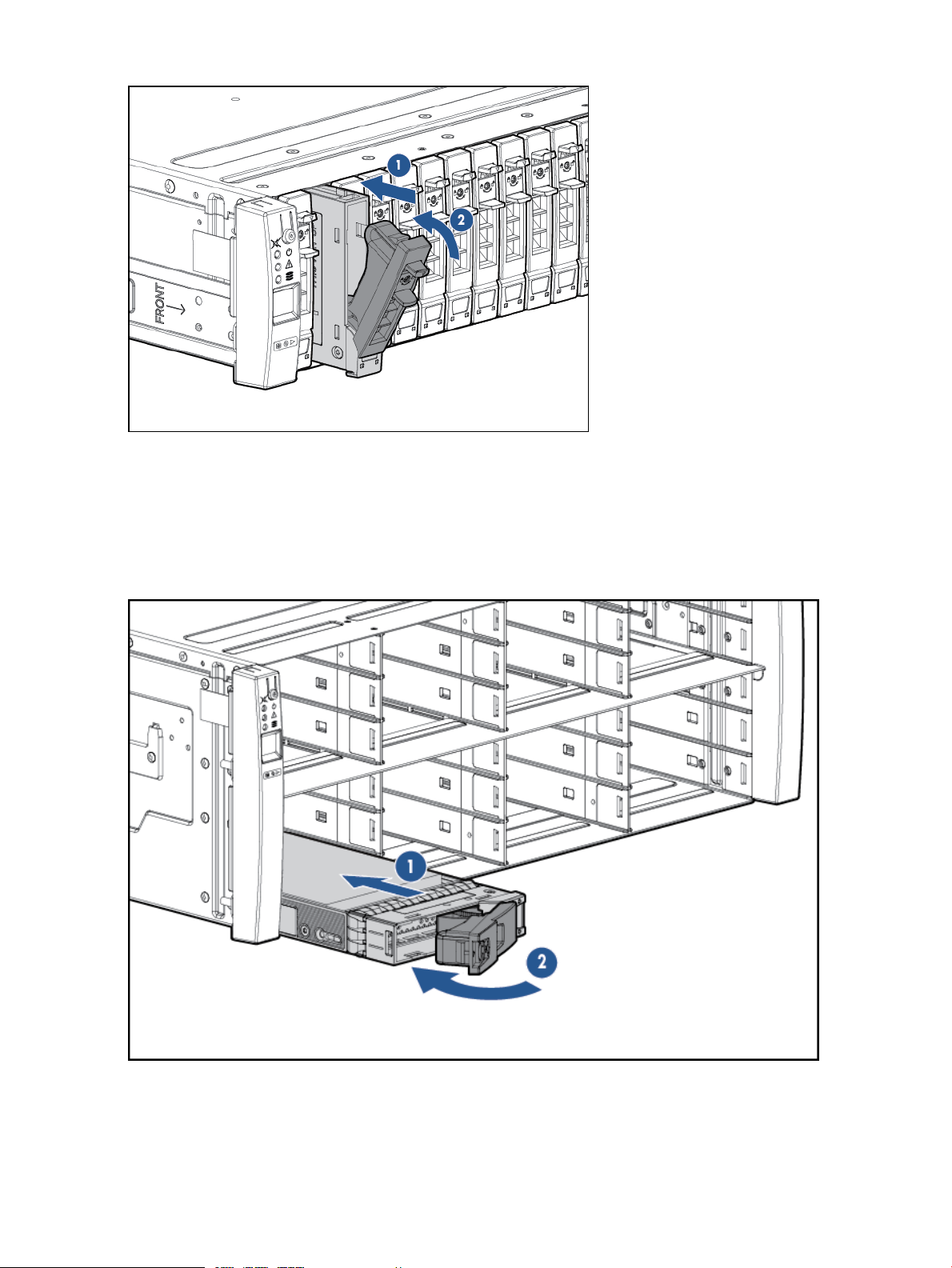

Figure 24 Installing a 2.5 inch Disk Drive

Installing a 3.5 inch Disk Drive (LFF)

1. Press the handle latch to open the handle.

2. Position the disk drive so the handle opens from the left, and slide it into the enclosure.

3. Push firmly until the handle fully engages and clicks.

Figure 25 Installing a 3.5 inch disk drive

26 Installing Storage System Components into a Rack

Page 27

Installing the Service Processor in the Storage System

The HP 3PAR Service Processor consists of the following:

• A standard HP Server

• A 1U Rail Kit for that specific server

NOTE: The SP ID is the HP 7-digit serial number of the array located on the top front of the server

and in a pull-out placard in the front of the server. The serial number is preceded by SP000. For

example, if the 3PAR serial number is 1614983, enter SP0001614983.

Use these procedures when installing an HP 3PAR Service Processor in an existing rack. Before

you begin, verify that you have the proper service processor 1U Mounting Kit (PN 683811-001).

The service processor rail kit supports a variety of products in round, square, or threaded-hole

racks. The following table identifies any tools required for each type of rack.

Table 4 Rack Types

PictureTools RequiredRack Type

NoneRound hole

NoneSquare hole

ScrewdriverThreaded hole

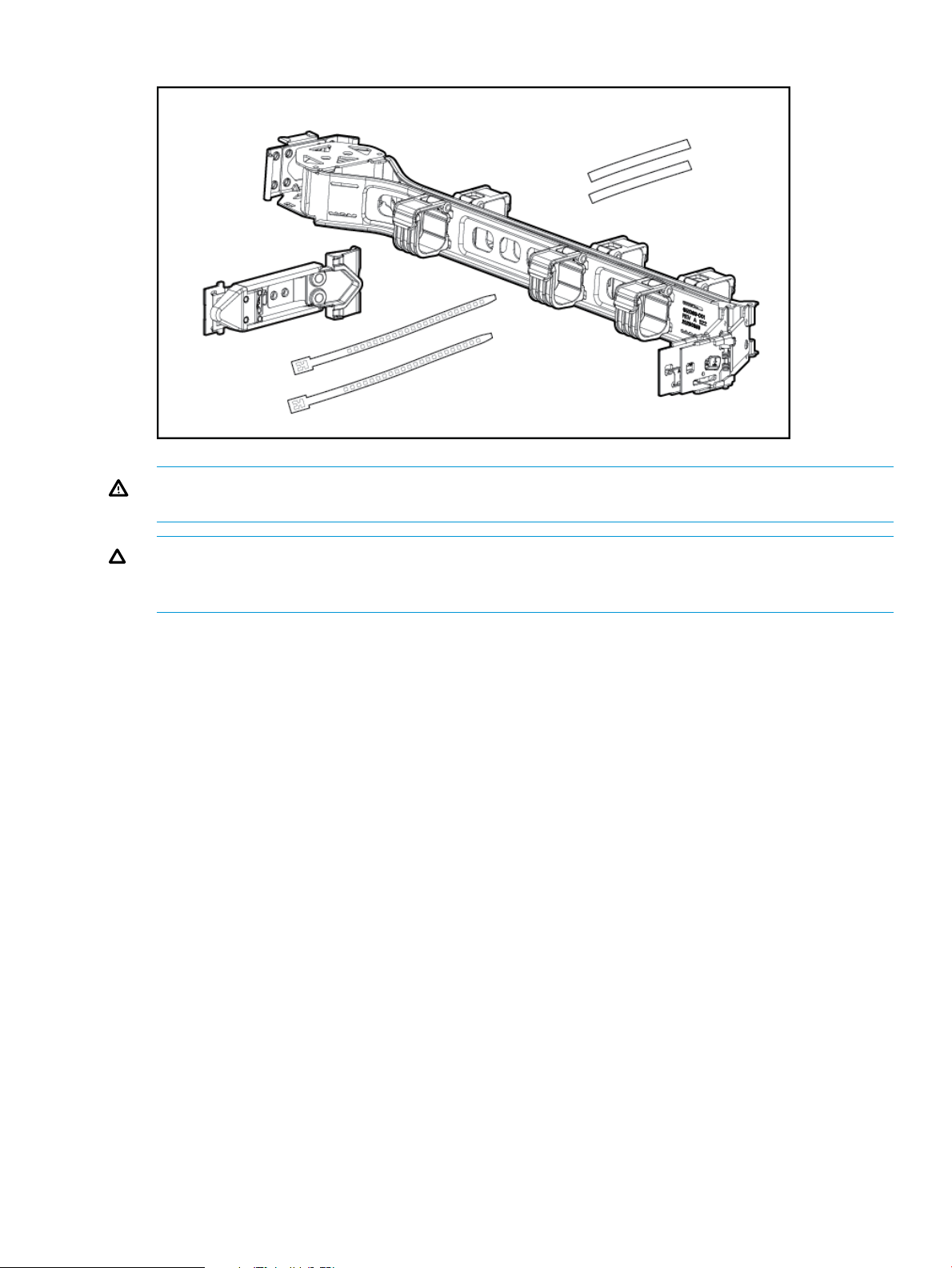

The following components are included in the kit:

• Slide mounting rails

• Screws

• Cage nuts (for the round-hole rack)

• Cable management straps

• Labels

Installing the Service Processor in the Storage System 27

Page 28

Figure 26 Rail Kit Components

In addition to the supplied items, you may also need the following:

• Screws fitting a threaded-hole rack

• Screwdriver

• Optional cable management arm (see Figure 27 (page 29))

28 Installing Storage System Components into a Rack

Page 29

Figure 27 Cable Management Arm

WARNING! To avoid risk of injury or damage to the equipment, do not stack anything on top

of rail-mounted equipment or use it as a work surface when it is extended from the rack.

CAUTION: Always plan the rack layout before installing the equipment. See HP 3PAR StoreServ

7000/7450 Cabling Configuration Guide for the best practices for node and drive enclosure

positioning in specific configurations.

To install the rail kit and service processor:

1. Adjust the length of the mounting rails.

2. Install the threaded-hole cage nuts and rail mounting pins into the rack hole positions where

you want to install the component. Use two cage nuts and two rail mounting pins on the front

of each rail, and two cage nuts and two rail mounting pins on the rear of each rail.

Installing the Service Processor in the Storage System 29

Page 30

Figure 28 Installing Cage Nuts and Rail Mounting Pins

3. Align the mounting rail with the cage nuts, and fasten the mounting rails to the rack with the

proper screws.

30 Installing Storage System Components into a Rack

Page 31

Figure 29 Mounting and Fastening the Mounting Rails

4. Repeat steps 1 through 3 for the other mounting rail.

WARNING! To prevent the risk of injury or equipment damage, inspect the rack to ensure

that it is adequately stabilized before installing the service processor.

Installing the Service Processor in the Storage System 31

Page 32

5. Install the side rails on each side of the service processor by aligning each side rail to the

component, and then snapping it into place.

Figure 30 Installing the Service Processor

6. Slide the service processor onto the mounting rails and into the rack.

Figure 31 Sliding the Service Processor into the Rack

32 Installing Storage System Components into a Rack

Page 33

7. Fasten the service processor to the rack.

8. (Optional) Install the cable management arm. See the instructions provided in the kit.

9. Use the straps provided in the kit to secure all fiber and Ethernet cables. Securing the cables

prevents any improper disconnection or damages during operation.

10. Connect the power cord to the facility power source. Do not power on the SP at this time.

WARNING! To reduce the risk of electric shock or damage to the equipment:

• Do not disable the power cord grounding plug. The grounding plug is an important safety

feature.

• Plug the power cord into a grounded (earthed) electrical outlet where it is accessible at

all times.

• Unplug the power cord from the power supply to disconnect power to the equipment.

• Do not route the power cord through a walkway area or adjacent to other hardware

components that may pinch or damage the cord. Pay close attention to the plug, electrical

outlet, and the point where the cord extends from the component.

Continue on to “Cabling the Storage System” (page 34).

Installing the Service Processor in the Storage System 33

Page 34

5 Cabling the Storage System

For more information about cabling drive enclosures (SAS) before you continue to cable the system,

visit www.hp.com/go/3par. Scroll to Support, and click HP 3PAR StoreServ 7000 Support and

then Manuals. Then scroll to Setup and install — general and select the specific HP 3PAR StoreServ

7000 Storage Cabling Configuration Guide.

Cabling Controller Nodes

Nodes are numbered 0 to 3 from bottom to top. Connections between Nodes 0 and 1 and Nodes

2 and 3 use four large interconnect cables.

These cables are directional and must be installed correctly for the storage system to function

properly. When inserting the cables, you should hear a click to confirm the cable is correctly

installed. If you have to force the connector, the connector is upside down and needs to be inverted.

The direction of the cable connection is indicated by labels on either end of the cable.

In Figure 32 (page 34), see label A for interconnecting node 0 or 1. See label C for interconnecting

node 2 or 3.

Figure 32 Interconnecting the Controller Nodes

Host/Ethernet Cables

Table 5 External Controller Node Connections

Ethernet

Fibre Channel

1

To provide redundancy and to permit online software upgrades, both controller nodes in a node pair (for example,

nodes 0 and 1 or nodes 2 and 3) must maintain connections to each host server.

• Each controller node supports one Ethernet connection to a switch or hub. Separate connections

from the Ethernet switch or hub to at least two controller nodes are required to support

redundancy. With redundancy, one IP address is shared between the two connections, and

Connection from the Ethernet switch

or hub to two controller nodes

Connection from a host computer to

one controller node

NoneMaintenance

Recommended ConfigurationMinimum ConfigurationConnection Type

See the section Supported Network

Topologies in HP 3PAR StoreServ 7000

Storage Site Planning Manual.

Separate connections from host

computers to each node, through a

switch, with connections distributed

evenly across all nodes

Varies according to system and network

configuration

1

34 Cabling the Storage System

Page 35

only one network connection is active at a time. If the active network connection fails, the IP

address is automatically moved to the surviving network connection.

• At a minimum, the storage system requires one Fibre Channel (or iSCSI) connection from a

host computer to a controller node. HP recommends separate connections from each host

computer to each of the controller nodes in the storage system, with connections distributed

evenly across all nodes.

Table 6 (page 35) describes the maximum supported Fibre Channel cable length based on the

cable size and port speed.

Table 6 Cable Limitations for Fibre Channel Host Connectivity

Cabling the Service Processor

Connect a customer-supplied Ethernet cable to the lowest port on the server. Connect the power

cable to PDU, but do not power on at this point.

Cable Length LimitSpeedCable Size

100 meters2 Gbps62.5 micron

70 meters4 Gbps62.5 micron

300 meters2 Gbps50 micron

150 meters4 Gbps50 micron

WARNING! Do not power on the service processor.

The following icon is typical, but it can vary by server.

Figure 33 Connection Icon

Cabling Power to the Storage System

WARNING! Before you begin cabling the power cords, verify your power connections are set

up correctly. See “Verifying Power Connections” (page 37).

When routing PCM power cords, ensure power redundancy is maintained by connecting each

PCM within a shelf to a different PDU. When observed from the rear, the left side cabling (ID #0)

is black, and the right side cabling (ID #1) is gray.

WARNING! The PCM latch can damage any cables that are routed in such a way that when

the PCM latch handle is closed, it will cut into any cable that becomes wedged between the latch

and the rack post. Keep the cables clear from the PCM latch mechanism.

NOTE: When installing cabling, ensure clear access to all storage system components. All power

cords need to be tied and kept behind the rail column in order to access the components during

servicing.

To cable the power cables:

1. Locate the power cord for each PCM.

Cabling the Service Processor 35

Page 36

NOTE: Before inserting the power cords into the PCMs, verify the PCM power switch is set

to 0 (off).

2. Route the main power cords to a power strip or PDU. Ensure the routed cords maintain proper

service clearance.

3. Insert each end of the power cord into the power strip/PDU and PCM. Fasten the PCM power

cord using the restraining clip on each PCM.

NOTE: Do not power on the PCMs at this time.

Cabling the Power Distribution Unit

PDUs can be mounted horizontally below the enclosures at the bottom of the rack. Each PDU AC

cord connects to the appropriate outlet based on the type of cord and power requirements to

supply power to the storage system.

To access the vertically mounted PDUs or servicing area, the PDUs can be lowered out of the rack.

1. Remove the two top mounting screws.

2. Pull down on the PDU to lower.

NOTE: If necessary, loosen the two bottom screws to unhinge the bracket before pulling

down the PDU.

3. Ensure the PDUs are in a fully lowered position before accessing.

Figure 34 Disengaging the PDU Pivot Brackets

Cabling the Power Strips

Power strips can be located on the side of the rack to supply power to the PCMs. Power strips are

connected to PDUs. Do not exceed the capabilities of power strips and PDUs.

Continue on to “Verifying Setup and Powering On the Storage System” (page 37).

36 Cabling the Storage System

Page 37

6 Verifying Setup and Powering On the Storage System

This section describes the verification of procedures for setting up and powering on all components

in the storage system.

NOTE: To avoid any cabling errors, all drive enclosures must have at least one or more hard

drives installed before powering on the enclosure.

Verifying Setup

To complete the installation, you must verify the power connection and final positioning and then

power on the storage system.

Verifying Power Connections

Verify the following before powering on the storage system:

• Redundant Power

• Power cord connections

• AC cord connections

• Main power cords

NOTE: Secure the power cord with the retainer by placing the wire into the circular loop and

cinching it closed. You can slide the retainer by lifting the small tab behind the circular loop.

Redundant Power

The racks use redundant PDUs and power supplies to provide power redundancy throughout the

system. Before powering on the storage system, verify that the system has a valid redundant power

configuration connected to independent electrical power providers. Each of the PDUs must connect

to a power socket with power being separately supplied by an independent electrical power

source.

CAUTION: Ensure the storage system does not exceed the ratings of the power sources and

PDUs, and adheres to the guidelines described in HP 3PAR StoreServ 7000 Storage Site Planning

Manual.

Power Cord Connections

Each storage system arrives with all internal power cords configured and connected. Before

powering on the storage system, verify the following:

• The AC cords are correctly configured and properly connected to the component

• The AC cord locks and cable ties on the PDUs and PCMs are properly connected

• If you have a physical SP, verify it is properly connected to the PDU

Repositioning the Storage System

Install the rear door of the storage system and filler panels that may not have been completed

during installation. If you have not positioned the storage system in a permanent operating location,

as described in “Positioning the Cabinet” (page 15), place the storage system in its final position

before powering on.

Verifying Setup 37

Page 38

Acclimating the Storage System

Before powering on the storage system, the system may require up to 24 hours to acclimatize to

the new operating environment when outside-to-inside conditions vary significantly. If the system

or its components may have experienced environmental changes during the transit, allow enough

time for the system to acclimatize before proceeding with the power-on sequence.

CAUTION: To prevent potential damage to system hardware, do not power on the storage system

until it is fully acclimatized. If condensation is present after the 24-hour acclimatization period,

wait for all condensation to fully evaporate before completing the power-on sequence.

Powering On the Storage System

1. Set the circuit breakers on the PDUs to the ON position.

2. Set the switches on the power strips to the ON position.

NOTE: Some power strips may not have power switches.

3. Power on the service processor.

4. Power on the drive enclosure PCMs.

5. Power on the node enclosure PCMs.

6. After approximately 10 minutes, allowing time for the system to boot and the cache batteries

to charge, verify the status of the LEDs as described in “Verifying LED Status” (page 39).

38 Verifying Setup and Powering On the Storage System

Page 39

Verifying LED Status

1. At the front of the storage system, verify the bezel and disk drive LEDs are illuminating green.

NOTE: If any module fault or disk drive LEDs are not green, do not proceed until the problem

is resolved.

Figure 35 Bezel LEDs

Table 7 Identifying Bezel LEDs

DescriptionItem

Power indicator1

Module fault2

Disk drive status3

Verifying LED Status 39

Page 40

Figure 36 Disk Drive LEDs

Table 8 Identifying Disk Drive LEDs

DescriptionItem

Amber LED indicates a fault.1

Green LED indicates the system is ready.2

40 Verifying Setup and Powering On the Storage System

Page 41

2. At the rear of the storage system, verify the controller node, I/O modules, and PCM LEDs are

lit green. The controller node LEDs should be blinking green once per second. The green LED

of each node will blink together when the storage cluster is properly formed.

Figure 37 Node Enclosure PCM LEDs

Figure 38 Controller Node LEDs

NOTE: The figure shows an HP 3PAR 7200 controller node as an example.

NOTE: The batteries are fully charged during shipment. The batteries may loose some charge

and show a degraded status immediately when power is applied. This is a temporary condition.

Proceed with the system initialization process and software installation. Check the LEDs again

when the installation is complete.

Verifying LED Status 41

Page 42

Node Interconnect Ports

The node interconnect ports are used only with 7400 4-Node systems.

Figure 39 7400 4-Node LEDs

Table 9 Node Interconnect Ports LEDs

DescriptionItem

Green LED1

Amber LED2

Solid (not flashing) green LEDs indicate normal operation. Flashing amber LEDs can be caused by

any of the following:

• Cluster link cabling error

• Controller node in wrong slot

• Serial number mismatch between controller nodes

42 Verifying Setup and Powering On the Storage System

Page 43

Drive Enclosure LEDs

Figure 40 Drive Enclosure PCM LEDs

CAUTION: Do not proceed without first correcting all fault indications (except for PCM batteries).

The cluster is not formed until the storage system software installation has been performed.

Verifying LED Status 43

Page 44

Identifying Service Processor LEDs

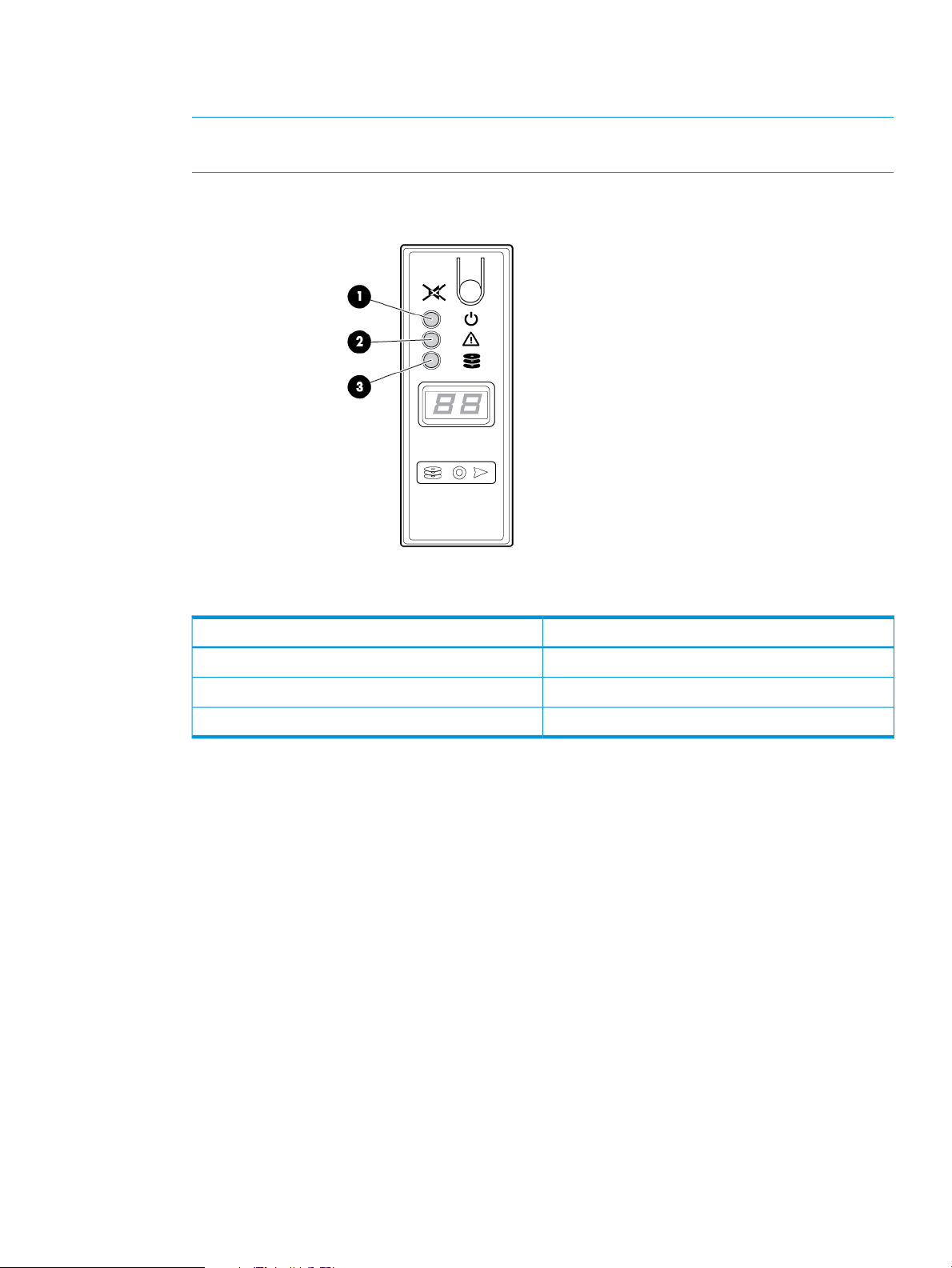

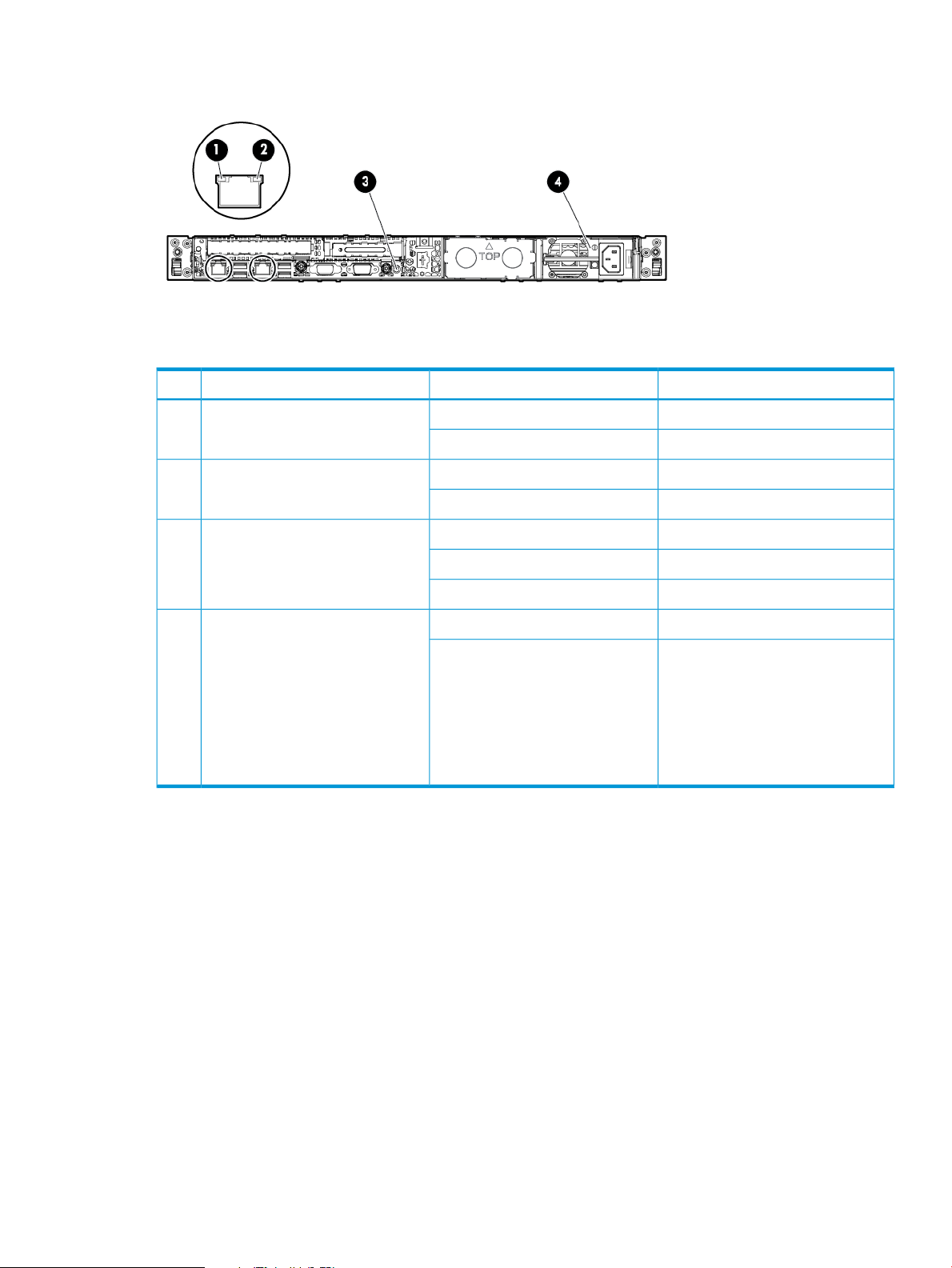

The HP 3PAR SP (Proliant DL320e) LEDs are located at the front and rear of the SP.

Figure 41 Front Panel LEDs

Table 10 Front panel LEDs

DescriptionAppearanceLEDItem

ActiveBlueUID LED/button1

System is being managed remotelyFlashing Blue

2

system power

Off

GreenHealth3

DeactivatedOff

System is onGreenPower On/Standby button and

Waiting for powerFlashing Green

System is on standby, power still onAmber

Power cord is not attached or power

supplied has failed

System is on and system health is

normal

System health is degradedFlashing Amber

System health is criticalFlashing Red

System power is offOff

Linked to networkGreenNIC status4

Network activityFlashing Green

No network linkOff

44 Verifying Setup and Powering On the Storage System

Page 45

Figure 42 Rear Panel LEDs

Table 11 Rear panel LEDs

DescriptionAppearanceLEDItem

LinkGreenNIC link1

No linkOff

ActivityGreen or Flashing GreenNIC status2

No activityOff

ActiveBlueUID LED/button3

System is being managed remotelyFlashing Blue

DeactivatedOff

4

NOTE: May not be applicable to

your system (for hot-plug HP CS

power supplies ONLY)

Off

NormalGreenPower supply

Off = one or more of the following

conditions:

• Power is unavailable

• Power supply has failed

• Power supply is in standby mode

• Power supply error

For more information about LED status, see Understanding LED Indicator Status in the HP 3PAR

StoreServ 7000 Storage Service Guide.

Continue on to “Initializing the Service Processor” (page 46).

Verifying LED Status 45

Page 46

7 Initializing the Service Processor

The SP supports all actions required for maintenance of the storage system. The service processor

provides real-time, automated monitoring and remote access to HP 3PAR Support in order to

diagnose and resolve potential problems. An HP 3PAR StoreServ system can include either a virtual

or physical SP.

Use the following table as guidance for setting up a specific type of service processor.

ActionType of Service Processor

See “Connecting to a Virtual Service Processor” (page 46).Virtual Service Processor (VSP)

Physical Service Processor

Connecting to a Virtual Service Processor

Prerequisites for Using a VSP

Before you connect to a VSP, review and complete the following tasks:

• Ensure the ESXi time and date are properly set, either through the Network Time Protocol

(NTP) server or manually through the ESXi console. Setting the correct date and time ensures

VSP real-time monitoring and access.

• Verify both the VSP and StoreServ system are on the same subnet.

• Verify the VMware vSphere client is available before deploying the VSP OVF file. Access your

ESXi server to download the VMware vSphere client or visit https://my.vmware.com/web/

vmware/downloads.

NOTE: Open Virtualization Format (OVF) is an open standard for packaging and distributing

virtual machines or software.

• Verify the HP 3PAR Virtual Service Processor software DVD is available. If you cannot locate

the DVD, contact HP Support through http://www.hp.com/support, or call your HP Sales

Representative at 1-800-334-5144 and request assistance with the HP 3PAR StoreServ 7000

Storage product.

See “Connecting to a Physical Service Processor” (page

48).

WARNING! Do not install the VSP on the same StoreServ 7000 array because it may lead to

the inability of properly managing the array when connectivity to the storage is unavailable.

Provision the VSP on a VMware server and ensure the VSP boots from the local disk of the assigned

VMware server and not from the StoreServ 7000 LUNs.

CAUTION: VMware vMotion is not a supported application. Do not use vMotion to migrate the

VSP from one physical server to another. Using vMotion may cause communication failure and

interrupt system service.

Deploying the VSP OVF File

NOTE: The virtual service processor supports VMware ESXi versions 4.1 and later. For more

specific VMware environment support, see the VMware compatibility matrix on the VMware

website. The following set of instructions may vary depending on the version of VMware ESXi you

are using.

1. Insert the HP 3PAR Virtual Service Processor software DVD.

46 Initializing the Service Processor

Page 47

2. In the VMware vSphere Client window, select File > Deploy OVF template.

3. On the Source page, click Browse to locate the OVF file on the DVD.

4. Select the OVF file, click Open and then click Next.

5. On the OVF Template Details page, verify the OVF template is selected, and then click Next.

6. On the Name and Location page, create a name for the VSP, and then click Next.

7. On the Storage page, select a storage destination for the virtual machine files, and then click

Next.

8. On the Disk Format page, select Thin Provision, and then click Next.

9. On the Network Mapping page, map the virtual machine to the networks in your inventory,

and then click Next.

10. On the Ready to Complete page, do the following steps:

a. Review the deployment settings.

b. Select the Power on after Deployment checkbox. Selecting this option powers on the VSP

after the installation is complete.

c. Click Finish.

A Deployment Completed Successfully message should appear after a few minutes.

11. Click Close.

12. On the left navigation pane, verify the system is on and the green icon is displaying on the

new VSP. If necessary, expanding navigation tree to find the deployed VSP.

a. Right-click the VSP in the virtual machine list.

b. Select Open Console.

The VSP is now ready to set up. Continue on to “Establishing the Virtual Service Processor IP

Address” (page 47).

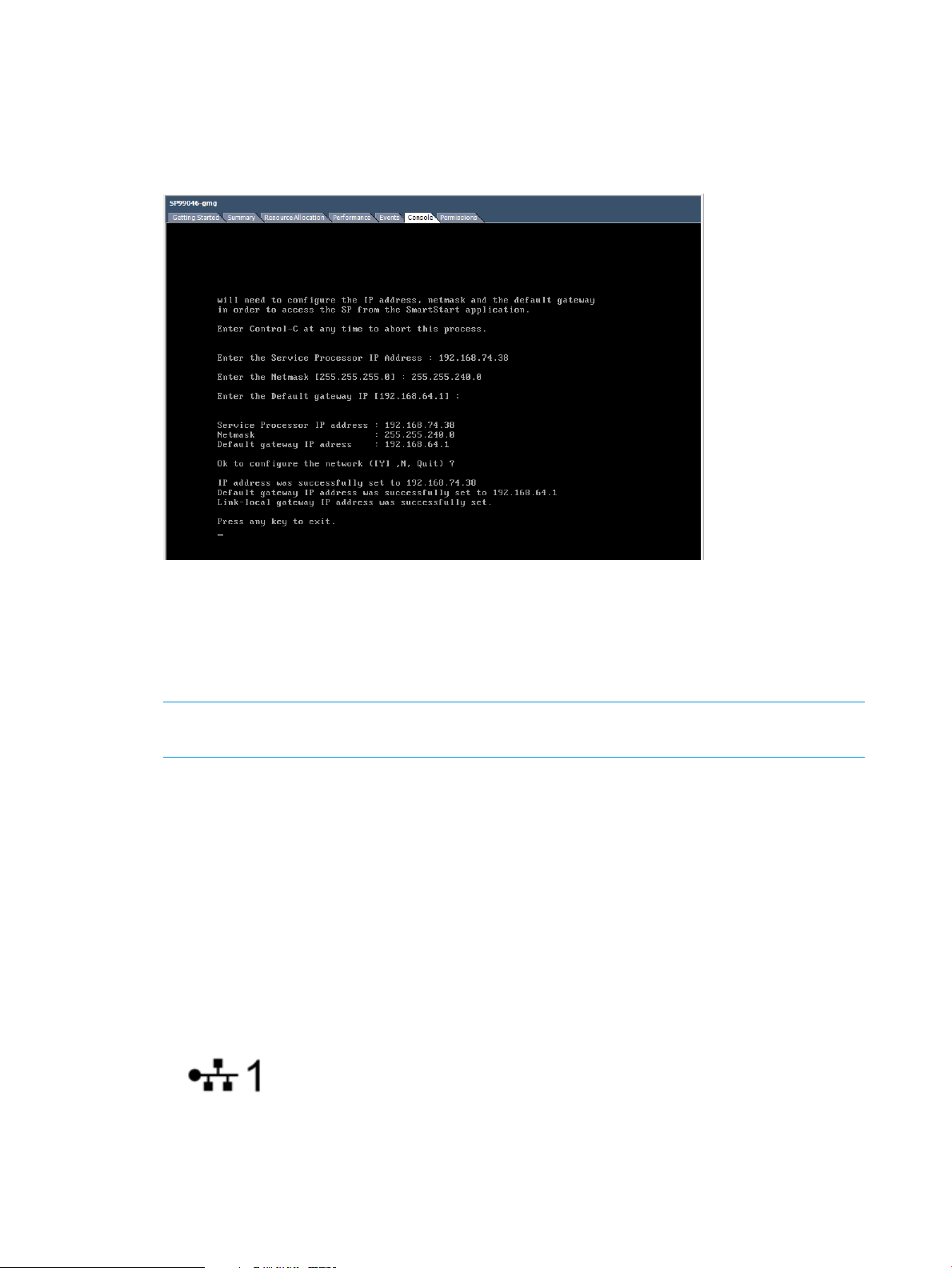

Establishing the Virtual Service Processor IP Address

After verifying the connection to the Virtual Service Processor, you must perform one of the following

options:

• Option A: Determine the temporary IP Address of the VSP in a DHCP environment.

• Option B: Set the IP address of the VSP in a non-DHCP environment.

Option A: DHCP Network Environment

To determine a temporary IP address for the VSP:

1. In the VMware vSphere Client window, select the Summary tab and wait 5-10 minutes for

the IP address to appear (in the General section, IP address field).

2. Make a note of this VSP IP address, and launch HP 3PAR SmartStart.

3. Continue on to “Setting Up the Service Processor and Storage System” (page 51) to set up

the VSP with SmartStart over the public network. If you are not using SmartStart, see “Installing

HP 3PAR Storage Software When HP 3PAR SmartStart is Unavailable” (page 92) to manually

launch the setup wizards.

Option B: Non-DHCP Environment

To set the IP address of the VSP:

1. In the VMware vSphere Client window, select the Console tab, click anywhere on the screen,

and press Enter.

2. Log on as setupusr. Press Enter.

A password is not required to configure the network settings.

3. Enter the service processor IP address and press Enter.

4. Enter the Netmask address and press Enter.

Connecting to a Virtual Service Processor 47

Page 48

5. Enter the default gateway address and press Enter.

6. Enter Y to configure the network and press Enter.

7. Review the configuration confirmation and record the VSP IP address for reference during

subsequent setup procedures with HP 3PAR SmartStart or the SpSetupWizard.

Figure 43 Network Setup Confirmation

8. Press Enter to exit.

9. Press Ctrl-Alt to release the cursor.

10. Continue on to “Setting Up the Service Processor and Storage System” (page 51) to set up

the VSP with SmartStart over the public network. If you are not using SmartStart, see “Installing

HP 3PAR Storage Software When HP 3PAR SmartStart is Unavailable” (page 92).

NOTE: This network configuration is temporary. If the VSP is rebooted, you will need to

repeat this procedure before continuing to the Service Processor configuration.

Connecting to a Physical Service Processor

Use the following instructions to connect to a physical service processor installed in the rack. Do

not continue with the section if you are using a VSP.

Configuring the Physical Service Processor IP Address

The following example uses Microsoft Windows 7™ to configure the SP IP address and the

procedures may vary depending on the type of OS being used.

1. At the rear of the storage system, connect one end of the network cable to the lowest numbered

Ethernet port on the SP, and then connect the other end to the customer LAN. Ethernet port

silk-screening may vary with the server, but port 1 is typically represented by the following:

2. Connect the other end of the cable to the Ethernet port on the laptop.

3. Configure LAN settings on the laptop:

48 Initializing the Service Processor

Page 49

NOTE: The configuration procedures may vary depending on the version of Microsoft

Windows, Apple Mac, or Linux OS in use.

a. Select Control Panel > Network and Internet > Network and Sharing Center, and click

Change adapter settings.

b. Right-click the connection name for the port, and select Properties.

c. In the Properties dialog box, on the Networking tab, double-click Internet Protocol Version

4 (TCP/IPv4) in the list.

d. In the Internet Protocol Version 4 (TCP/IPv4) Properties dialog box, make note of your

current settings.

e. Select Use the following IP address, and enter the following:

• IP address: 192.168.0.2

• Subnet mask: 255.255.255.0

• Default gateway: 192.168.0.1

f. Click OK and Close to confirm and activate your changes.

4. In a browser window, enter https://192.168.0.100/sp/SetIpAddress.html.

5. Log in with the user ID setupusr and no password.

The Service Processor IP Setup wizard is displayed.

NOTE: The Service Processor Setup Wizard may not display correctly when using Microsoft

Internet Explorer 10 with default security settings. If the wizard continues to display incorrectly,

try refreshing the browser page.

6. In the Assign IP Address pane, enter the SP IP address to be used on the customer LAN.

Figure 44 Assign IP Address

While you are entering an IP address, the IP Address field indicates an error. After you have

entered a valid IP address, the Subnet Mask and Gateway fields are automatically populated.

Connecting to a Physical Service Processor 49

Page 50

Figure 45 Subnet Mask and Gateway Fields Populated

You can customize settings for the Subnet Mask and Gateway if required.

7. Select Next, review the Summary screen, and then select Next when you are ready.

The settings are applied.

NOTE: You may see a dialogue box indicating the laptop is unable to connect to the SP.

This dialog box remains displayed until the adapter settings have been changed in the SP

and verified. No action is necessary; the dialogue box closes within three minutes.

8. Select Finish when completed.

9. Repeat Step 3 and reconfigure the original LAN settings on the laptop.

10. Disconnect the network cable from the laptop, and connect the SP to the customer LAN.

11. Continue on to “Setting Up the Service Processor and Storage System” (page 51) and set up

the SP with SmartStart over the public network.

If you are not using SmartStart, see “Installing HP 3PAR Storage Software When HP 3PAR

SmartStart is Unavailable” (page 92).

50 Initializing the Service Processor

Page 51

8 Setting Up the Service Processor and Storage System

Before you begin setting up the storage system, review and complete the following tasks: